AMD Ryzen X3D P71 Nvidia RTX SFF Ada P64 TECHNOLOGY FOR THE PRODUCT LIFECYCLE LUXURY DECKS FOR DJS HOME FITNESS IN STYLE AMD Radeon Pro P68 AUGUST / SEPTEMBER 2023 | £6 | € 7 | $10 | DEVELOP3D.COM

BURDEN Ox Delivers on building a cargo EV for remote Rwandan roads WHAT’S HOT IN 2023? 2023 WarwickArtsCentre-20September

BEAST OF

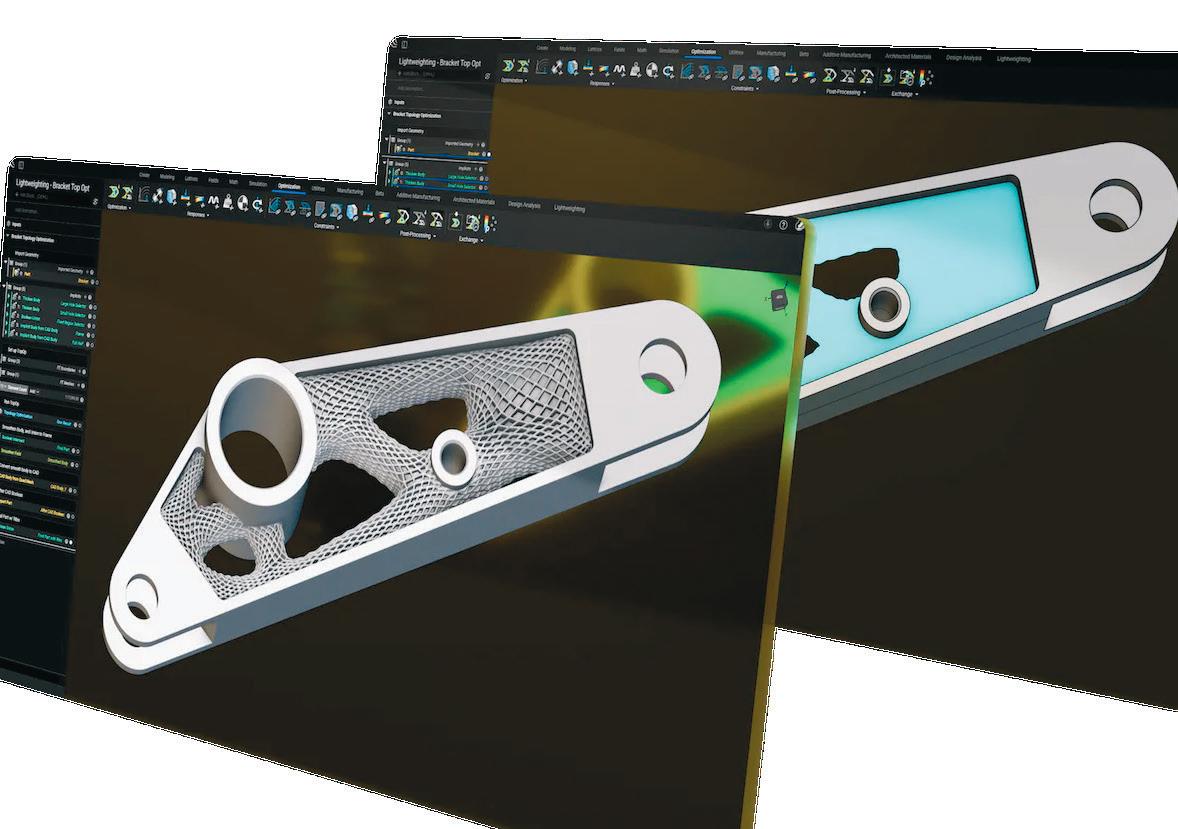

Creo 10 includes numerous enhancements to help you deliver your best designs in less time, with new tools for designing with composites, additive, and subtractive manufacturing. There are also improvements in electrification and ergonomics. Creo also continues to add simulation-driven design capabilities. Creo 10 provides an on-premises solution, while Creo+ delivers a SaaS solution, with cloud-enabled collaboration and license management tools. To learn more about Creo 10 to go www.ptc.com/creo

https://www.ptc.com/hill-helicopters ptc.com

EDITORIAL

Editor Stephen Holmes stephen@x3dmedia.com

+44 (0)20 3384 5297

Managing Editor Greg Corke greg@x3dmedia.com

+44 (0)20 3355 7312

Consulting Editor Jessica Twentyman jtwentyman@gmail.com

Consulting Editor Martyn Day martyn@x3dmedia.com

+44 (0)7525 701 542

DESIGN/PRODUCTION

Design/Production

Greg Corke greg@x3dmedia.com

+44 (0)20 3355 7312

ADVERTISING

Group Media Director

Tony Baksh tony@x3dmedia.com

+44 (0)20 3355 7313

Deputy Advertising Manager Steve King steve@x3dmedia.com

+44 (0)20 3355 7314

US Sales Director Denise Greaves denise@x3dmedia.com

+1 857 400 7713

SUBSCRIPTIONS

Circulation Manager

Alan Cleveland alan@x3dmedia.com

+44 (0)20 3355 7311

ACCOUNTS

Accounts Manager Charlotte Taibi charlotte@x3dmedia.com

Financial Controller Samantha Todescato-Rutland sam@chalfen.com

At times this summer, it’s felt like I’ve been the only person not on holiday, with the constant stream of out-of-office email replies I’ve received. Meanwhile, I’ve been attempting to finish this issue of DEVELOP3D, while simultaneously organising the amazing speaker line-up for our imminent live event, DEVELOP3D LIVE.

The synergy between the two means that these pages and the conference agenda share some wonderful crossover content, hopefully whetting your appetite and helping you to hone your questions for what lies ahead of us in Warwick on 20 September.

The stunning Stilride scooter has swept up almost all the design awards available this year, and still manages to stir the emotions as the star of this issue’s Visual Design Guide. Members of the Stilride team will be among the keynote speakers at DEVELOP3D LIVE, offering more insight not only into the EV design, but the company’s proprietary robotic metal-folding technology.

A more in-depth guide to what to expect at the show will be found in this issue, as we preview some of the big names, brands and technologies that will grace our stages and exhibition space.

Equally exciting is the return of the D3D 30 for 2023. This listing includes 30 of the most recent technologies to catch our eye, the ones that we feel will slip into your workflow and provide you with the boost you need to tackle even your most difficult product design and engineering challenges. From cutting-edge GPUs to AI rendering, and with a pot of print bed adhesive along the way, there’s something on the list to help all workflows.

It’s a sign of how packed this issue is with great content that I’ve somehow got this far without even mentioning our cover feature on Ox Delivers. It’s a terrific story of how a team of engineers are building an EV to provide transport for farm produce across Rwanda, getting goods to market and improving bottom lines for farmers. There are a lot of EV projects in the world today, but it’s nice to find one that looks to solve something other than first-world problems — and that’s without mentioning the specific challenges of designing a truck capable of navigating Rwanda’s famous one thousand hills.

So, here’s hoping we all get a day off soon, fellow grafters. Hopefully, you can grab a day out of the office to join us in person at DEVELOP3D LIVE. After all, you deserve it!

Stephen Holmes Editor, DEVELOP3D Magazine, @swearstoomuch

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 3

ABOUT DEVELOP3D is published by X3DMedia 19 Leyden Street London E1 7LE, UK T. +44 (0)20 3355 7310 F. +44 (0)20 3355 7319 © 2023 X3DMedia Ltd All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine

WELCOME DEVELOP3D.com facebook.com/DEVELOP3D @DEVELOP3D groups/DEVELOP3D Join our online community

DEVELOP3DLIVE returnstowhereitallstarted * *following£25mrenovationofWarwickArtsCentre Accelerate your product design & transform your product development develop3dlive.com

sponsors THREE CONFERENCE STREAMS HANDS-ON TECHNOLOGY EXHIBITION

SILVER SPONSORS Gold sponsors Principal

2023 Warwick Arts Centre, UK 20 September 2023 REGISTER NOW FREE develop3dlive.com

Silver sponsors

Bronze sponsors

Subscribe now FREE Print* or digital Technology for the product lifecycle register.develop3d.com *Free for UK readers ($49 per annum for ROW)

NEWS

Nvidia launches new Ada generation GPUs, UK start-up CloudNC unveils plug-in for Fusion 360, and details of Altair Enlighten Award 2023 winners

FEATURES

Comment: Claas Kuhnen on AI in design education

Comment: SJ on workplace returnees in Wonderland

Visual Design Guide: Stilride 1 electric scooter

COVER STORY Ox Delivers and its fantastic beasts

D3D 30: Our top 30 listing of innovative technologies

DEVELOP3D LIVE: Get ready with our show preview

Rock DJ: A stylish new take on decks from Pioneer

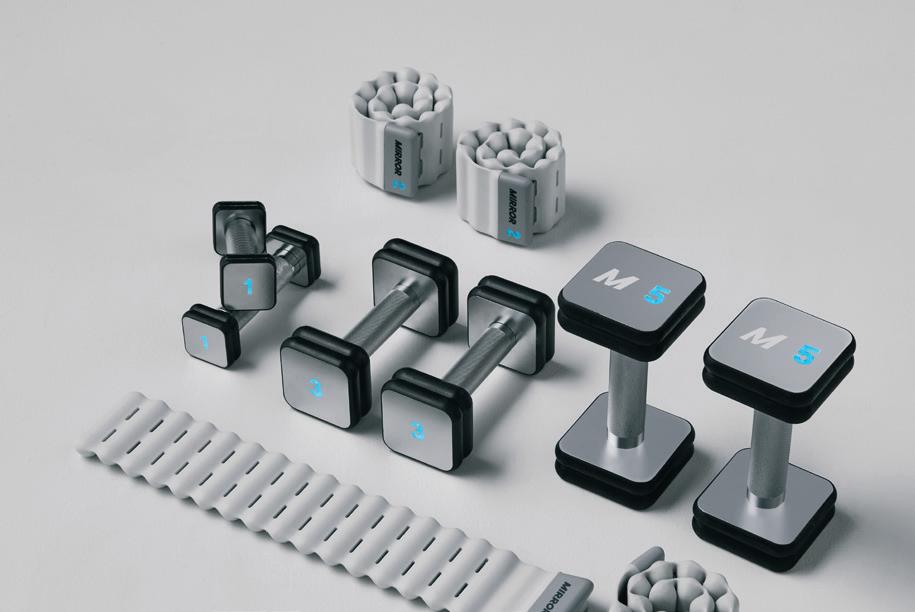

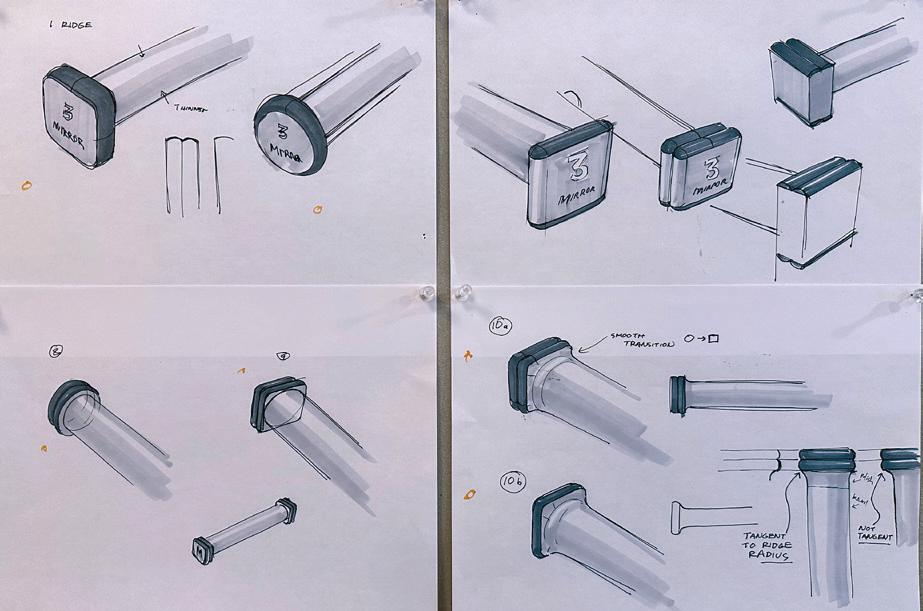

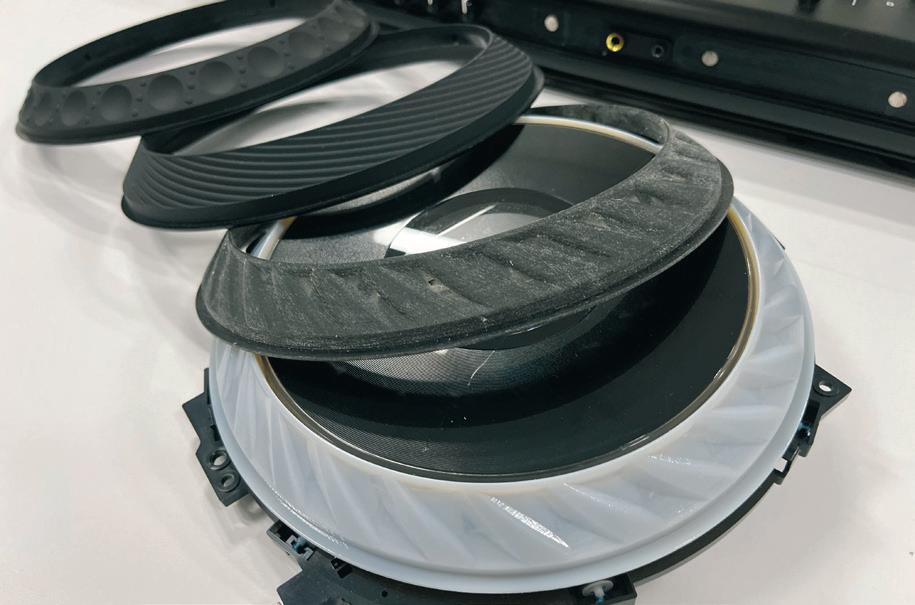

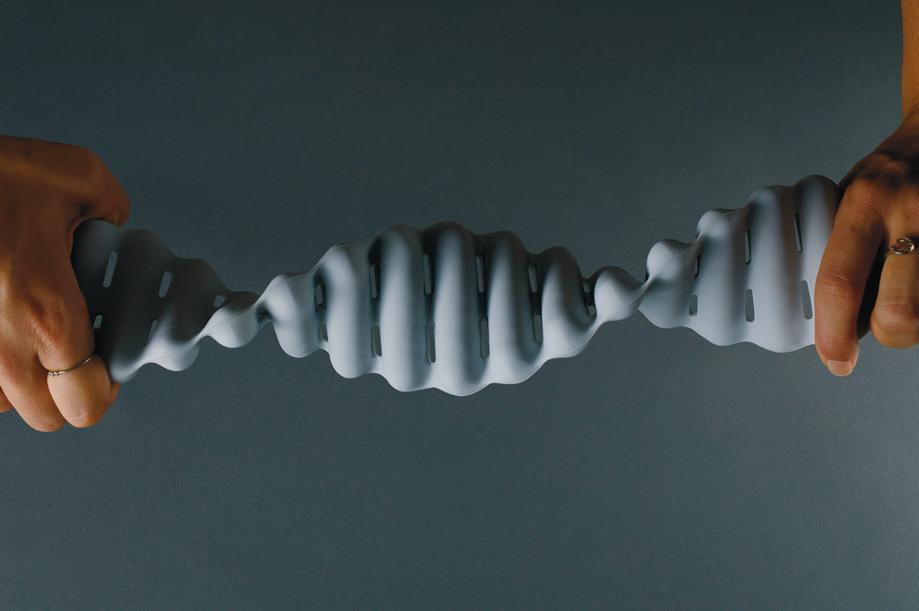

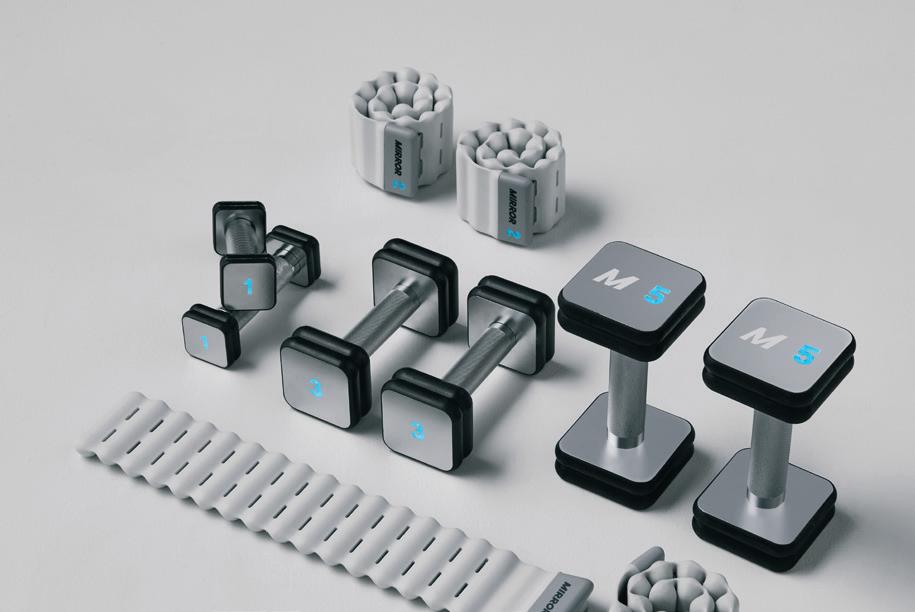

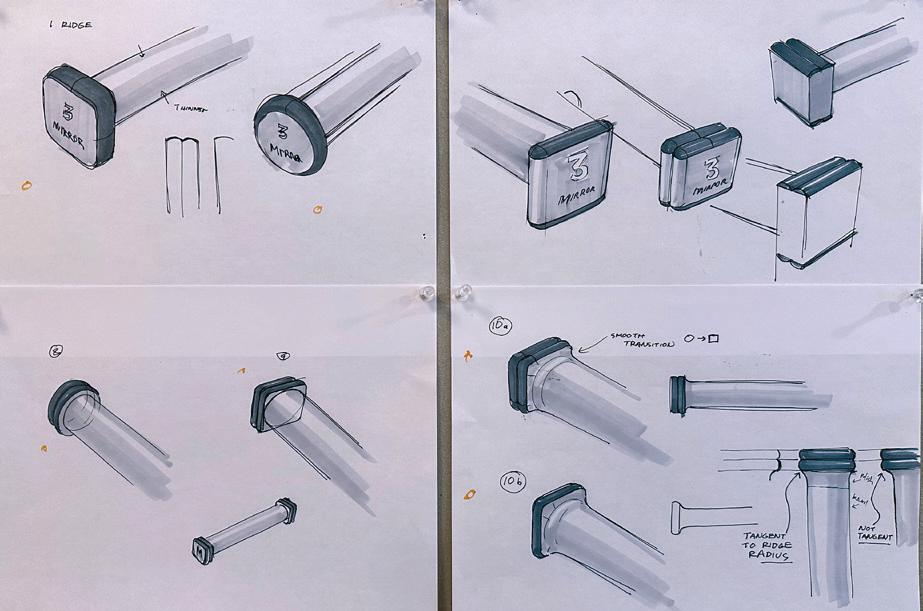

Leadoff Studio’s accessories line for the Lululemon Mirror

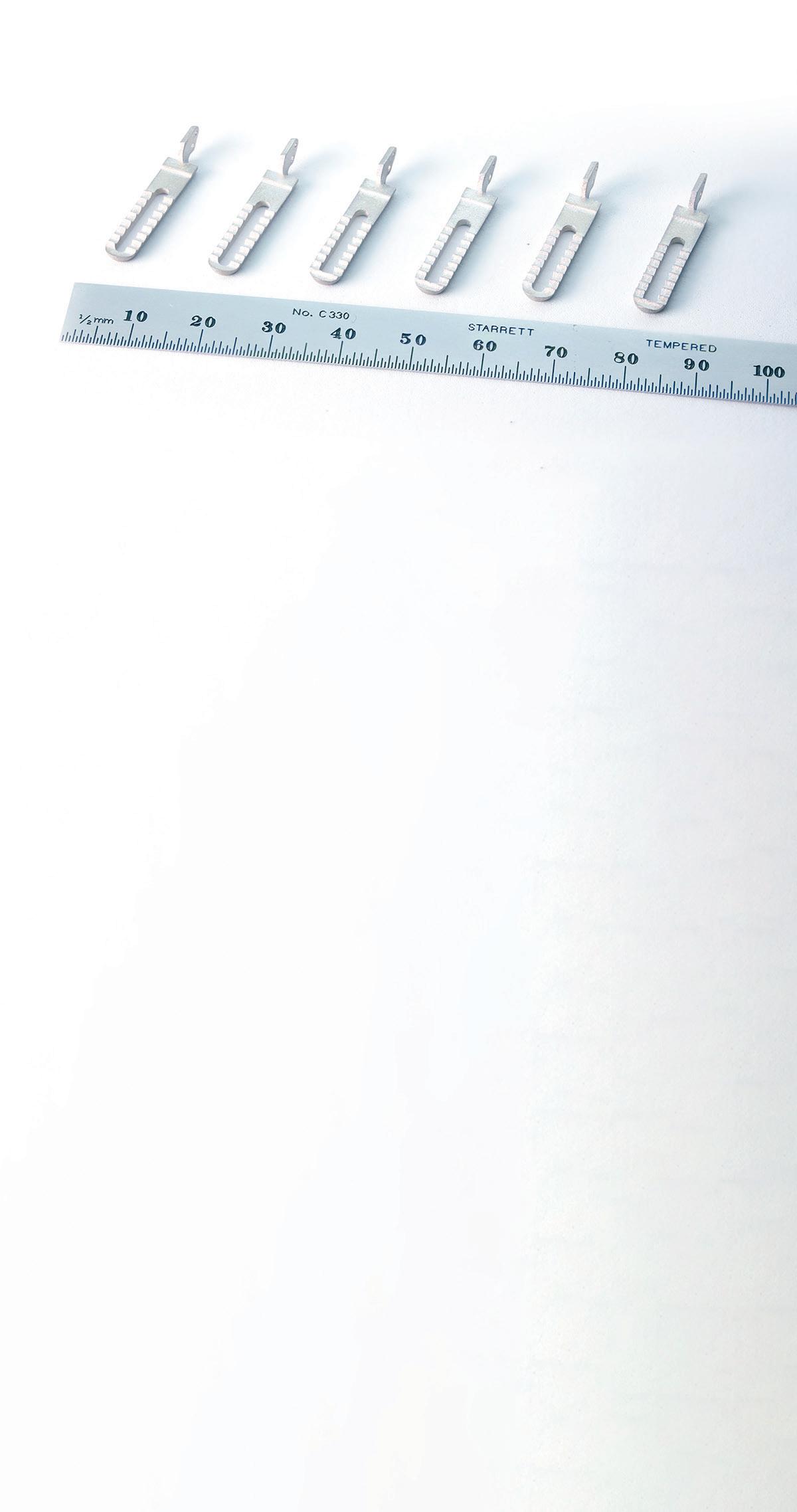

Peak performance: Domin’s designs for hydraulic servos

Opinion: Holo CEO Arian Aghababaie on solving problems

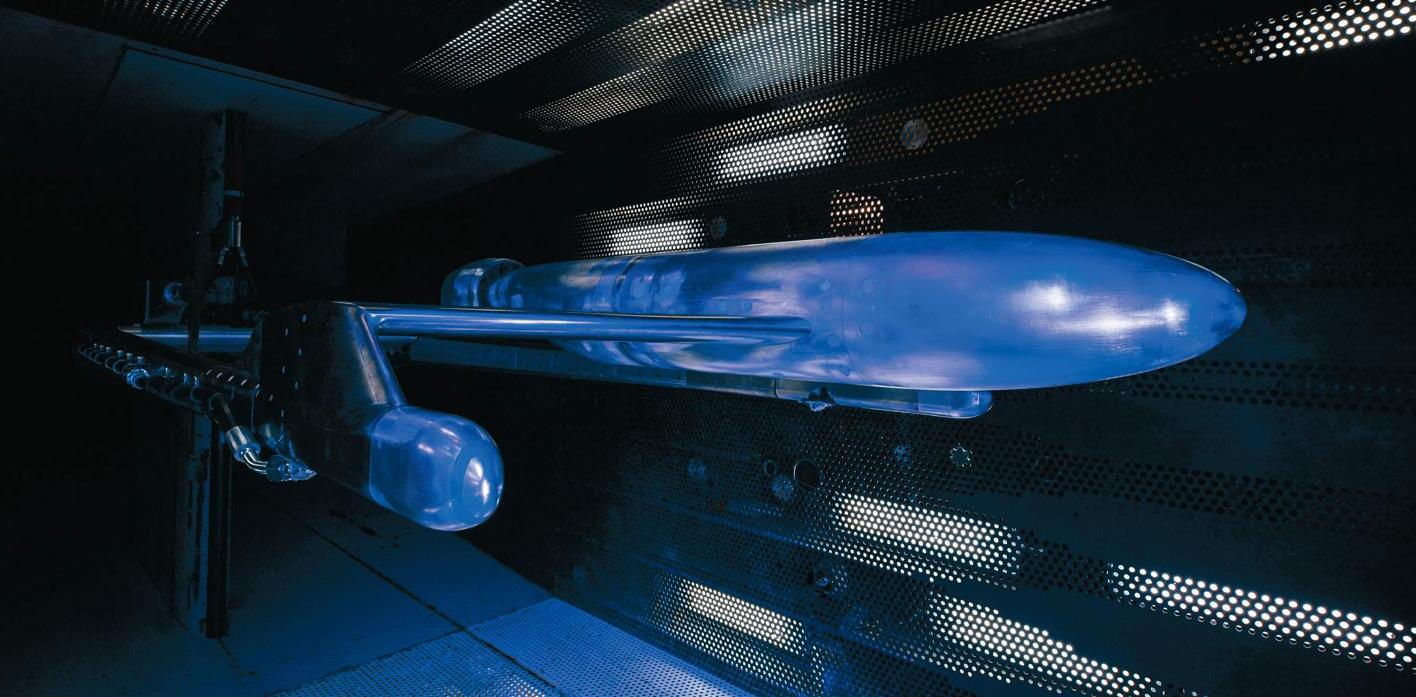

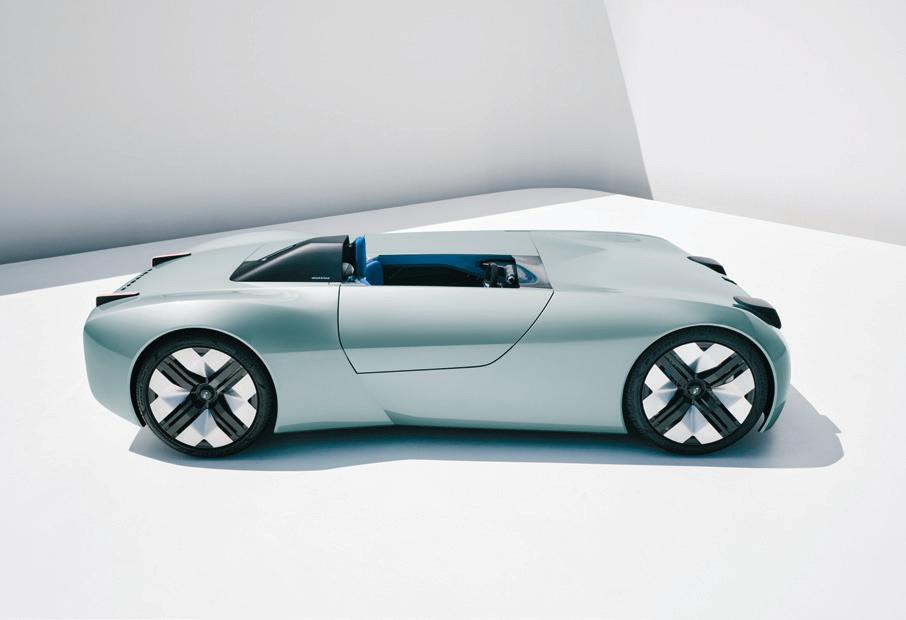

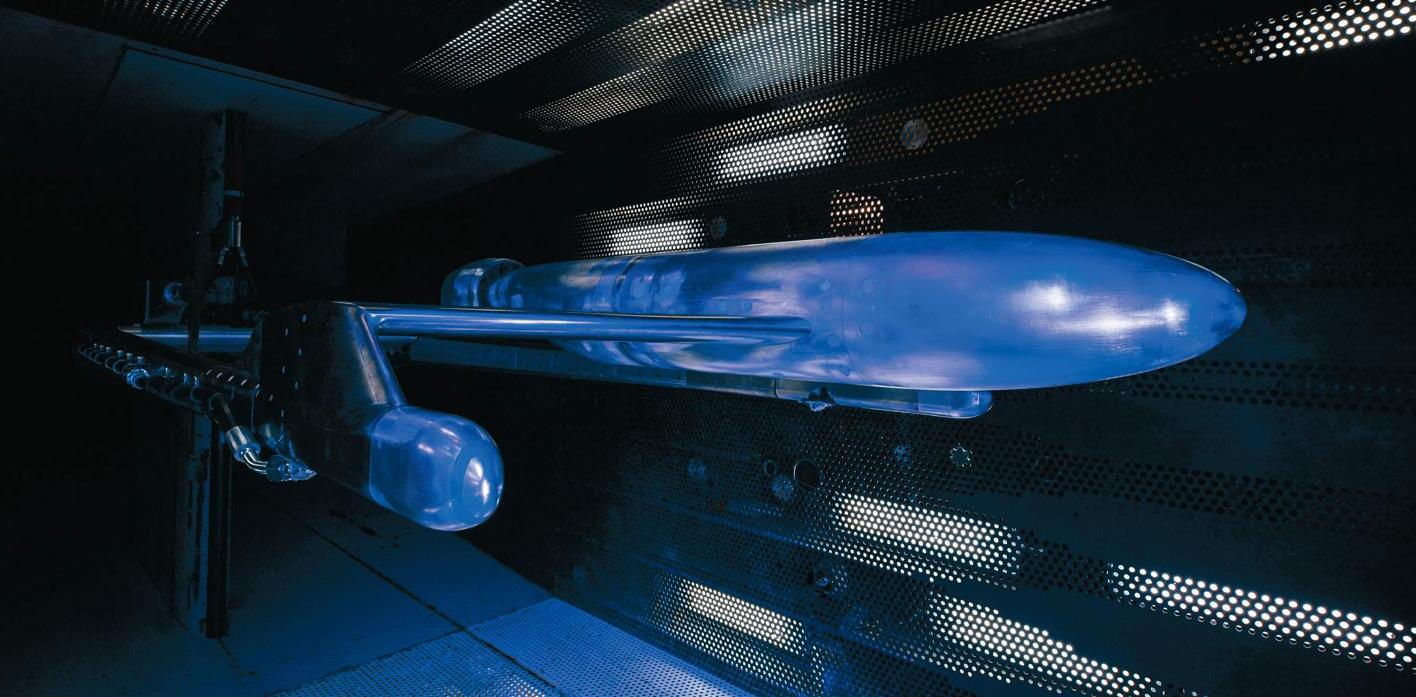

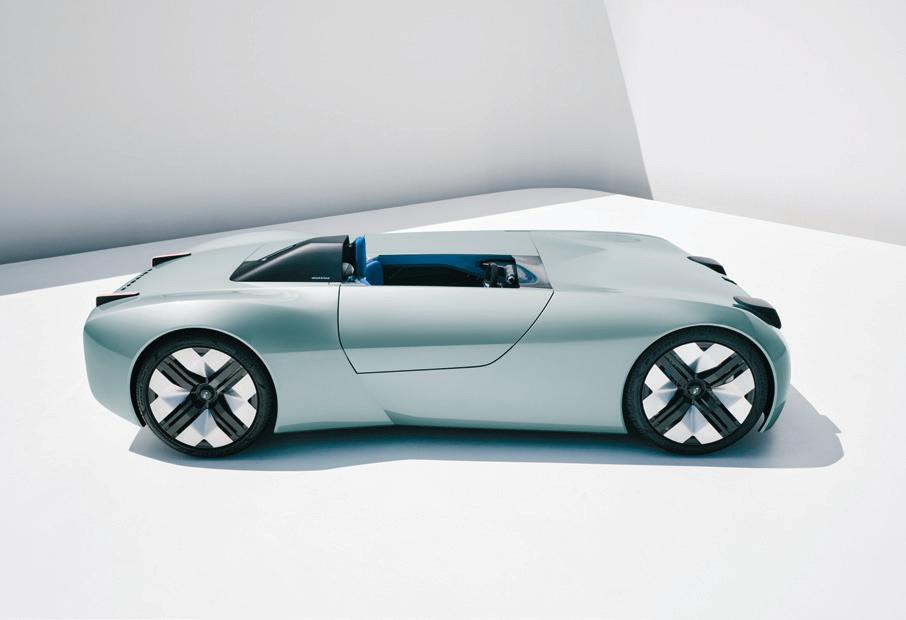

Blue sky thinking: design work on Maeve 01 accelerates

ARA and WAAM3D collaborate on aerospace challenges

Cutting edge: RO-RA Aviation adopts Vericut Force

REVIEWS

Nvidia RTX 4000 SFF Ada Generation GPU

AMD Radeon Pro W7800 / W7900 GPUs

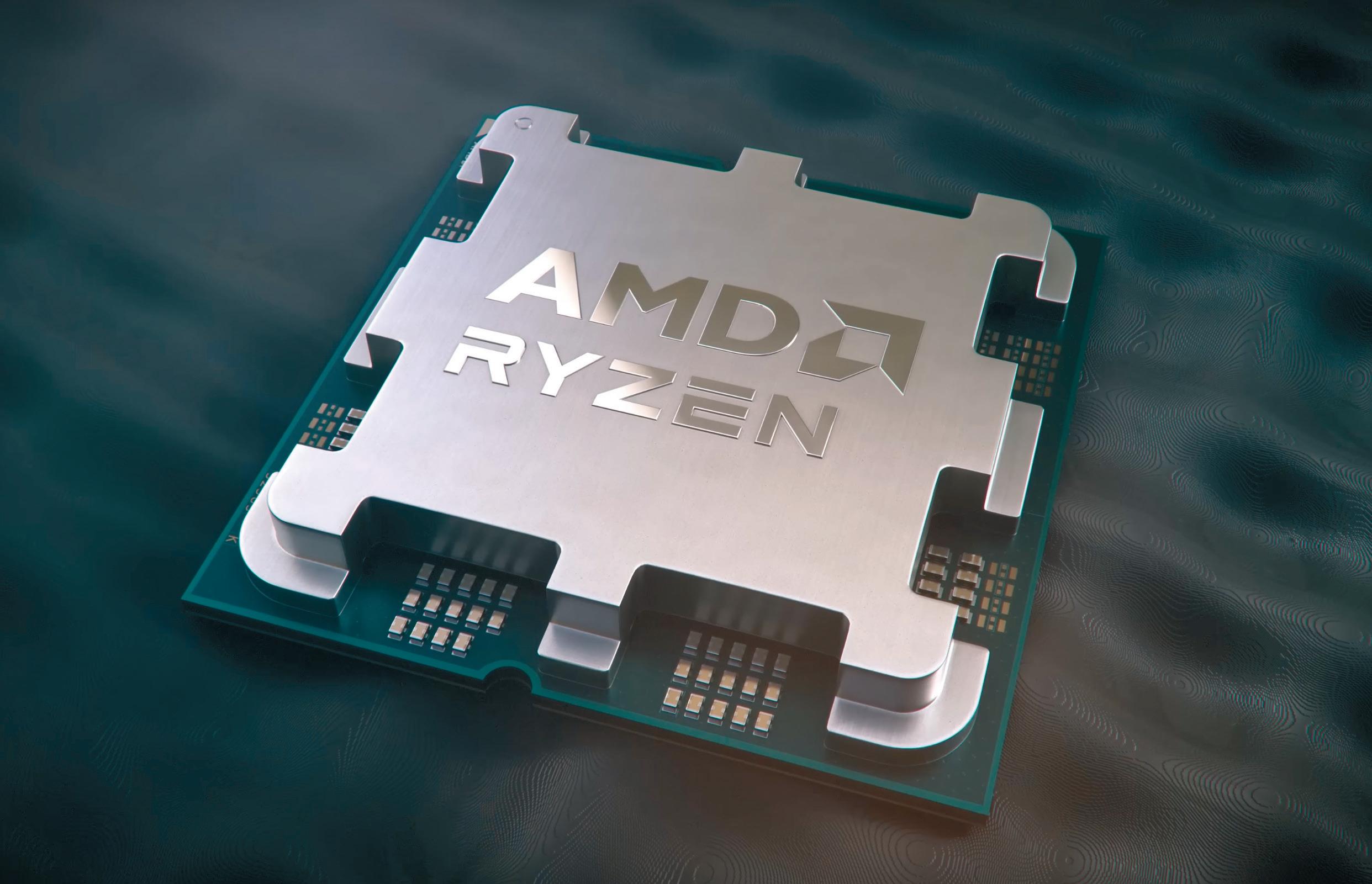

AMD Ryzen 7000 X3D processor

THE LAST WORD

This summer, we’ve all witnessed the rise, fall and bold reimagining of some big-name brands. But what’s in a name, asks Stephen Holmes, and what does branding mean for the products that you and your team design?

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 7

AUGUST / SEPTEMBER 2023 ISSUE NO. 141 8 14 15 16 18 24 34 50 54 57 58 60 61 62 64 68 71 74 The wood used to produce this magazine comes from Forest Stewardship Council certified well-managed forests, controlled sources and/or recycled material CONTENTS 2023 20 September 2023 Warwick Arts Centre, UK www.develop3dlive.com

NVIDIA EXPANDS OPTIONS FOR PRO VIZ WITH NEW ADA GENERATION NVIDIA RTX GPUS

» Nvidia RTX 4000, 4500 and 5000 Ada Generation desktop workstation GPUs start at $1,250 to offer more choice in high-end professional graphics

Nvidia has expanded its pro graphics line-up, adding three Nvidia RTX Ada Generation workstation GPUs to target visualisation, simulation, XR, AI and CAD workloads.

The Nvidia RTX 4000 Ada (20 GB), Nvidia RTX 4500 Ada (24 GB) and Nvidia RTX 5000 Ada (32 GB) fill the middle ground between the Nvidia RTX 4000 SFF Ada (20 GB) and Nvidia RTX 6000 Ada (48 GB) that were launched earlier this year.

The Nvidia RTX 4000 Ada and Nvidia RTX 4000 SFF Ada are identical in their cores specs, and have the same number of cores (CUDA, Tensor and RT) and 20 GB of GDDR6 memory. However, they have different form factors and max power consumption.

The Nvidia RTX 4000 Ada is a full-height, single-slot GPU designed for standard workstation towers. It draws up to 130W via a 6-pin power connector. Meanwhile, the SFF version is a low-profile, dual-slot GPU specifically designed for Small Form Factor and ultra-compact workstations. It draws up to 70W, directly from the PCIe slot.

The Nvidia RTX 4000 Ada is available in September with an ESP of $1,250.

Moving up the range, the Nvidia RTX 4500 (24 GB) is billed as the most balanced GPU for the majority of workloads. The dual-slot card has a max power consumption of 210W and is available in October with an ESP of $2,250.

The Nvidia RTX 5000 Ada has a max power consumption of 250W and needs a 16-pin CEM5 PCIe connector. According

to Bob Pette, VP for professional visualisation at Nvidia, it is for those who need performance closer to Nvidia’s 6000 class GPUs, but don’t necessarily need 48 GB of frame buffer memory. Pette adds that the dual-slot card delivers a huge performance leap over the previous generation Ampere RTX A5000 and A5500.

Compared to the RTX A5000, Nvidia says the RTX 5000 Ada has 1.6 times the graphics performance, twice the rendering performance in commercial renderers and three times the rendering performance in the Omniverse RTX renderer, which takes advantage of Nvidia DLSS 3.

DLSS 3, short for Deep Learning Super

Sampling, boosts performance by using the Tensor cores in Ada Generation GPUs to generate entirely new frames without having to process the graphics pipeline. Meanwhile, for the datacentre, Nvidia has announced the Nvidia L40S Ada GPU, which is effectively a passively cooled version of the Nvidia RTX 6000 Ada but clocked a little higher.

Up to eight Nvidia L40S GPUs can be accommodated in an Nvidia OVX reference server. Compared to the Nvidia A40, Nvidia says the Nvidia L40S Ada is up to 2.4x faster in commercial renderers and up to 4x faster in the Omniverse renderer. www.nvidia.com

HP Z4 Rack G5 remote workstation boosts datacentre density

HP has introduced the HP Z4 Rack G5, a 1U rack workstation designed specifically for server rooms and datacentres to provide 1:1 remote access for workstation users.

The HP Z4 Rack G5 shares many of the same characteristics as the HP Z4 G5 desktop workstation — up to 24 cores with the Intel Xeon W-2400 CPU and up to the Nvidia RTX 6000 Ada Generation GPU — but maxes out at 256 GB of DDR5 memory instead of 512 GB.

It supports one dual-slot GPU, including the Nvidia RTX 5000 or RTX 4500 Ada Generation, or two single slot GPUs, including the

Nvidia RTX 4000 Ada Generation.

With a 1U chassis, the HP Z4 Rack G5 earns is datacentre credentials by being significantly slimmer than its 4U desktop counterpart, delivering four times better density in a standard rack.

It has dual power supplies, where two 675W PSUs can be combined together, or one can be used for redundancy in the event of a failure. In redundancy mode, however,

HP Z4 Rack G5 is 1U delivering four times better density than the HP Z4 Tower G5 in a standard rack

this limits the CPU/GPU options.

The HP Z4 Rack G5 can be configured with the HP Anyware Remote System Controller, a remote out-of-band management solution designed to give IT managers the ability to monitor and manage workstation fleets through a single interface. IT managers can remote in, power workstations on and off remotely, perform bare metal imaging, manage inventory and get hardware alerts and diagnostics info.

The workstation can also be used with HP Anyware remote access and collaboration software so teams can access the power of the Z4 Rack from any device. www.hp.com/ zworkstations

8 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM

The single-slot Nvidia RTX 4000 Ada Generation will be available soon

NEWS

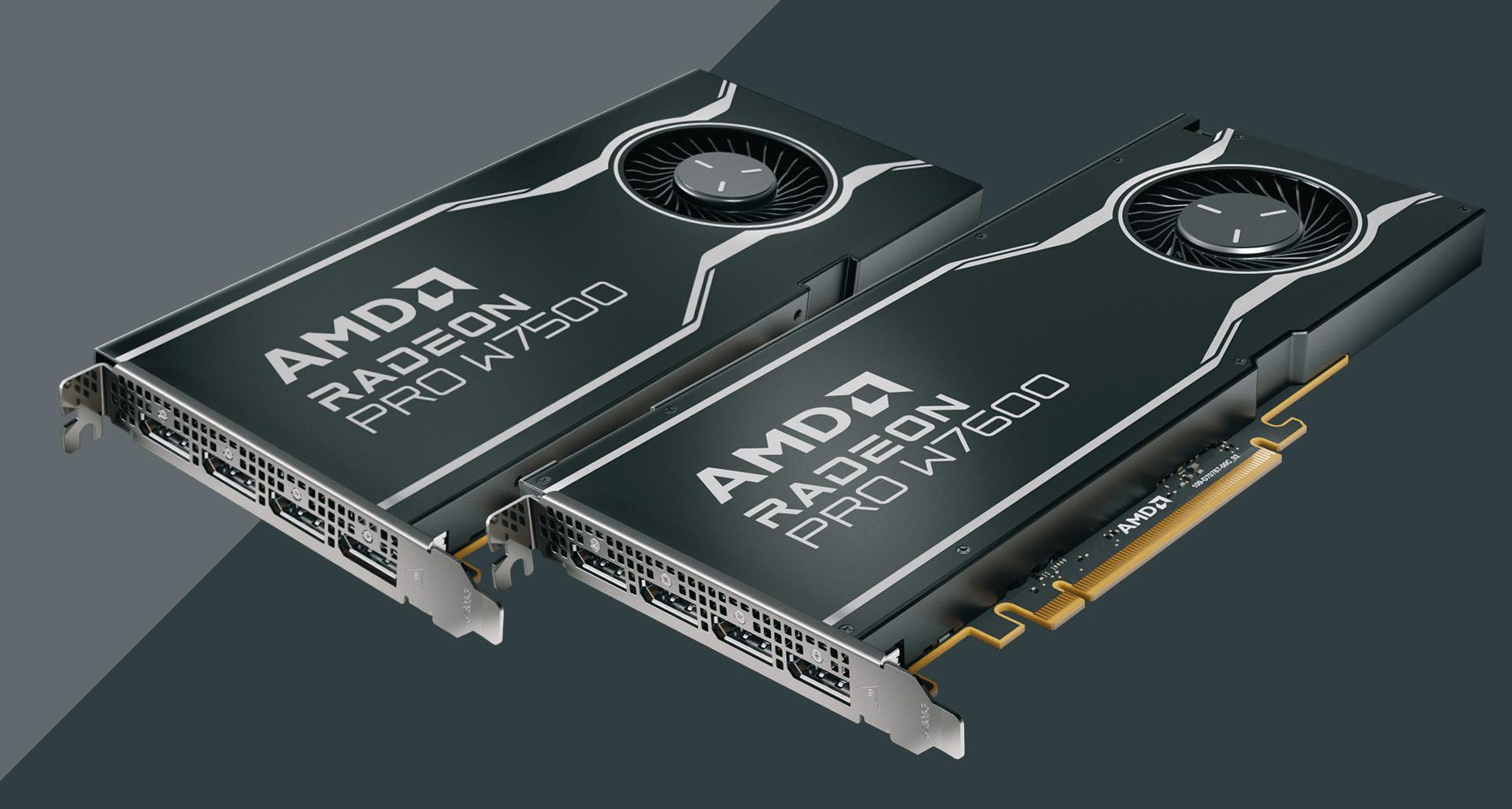

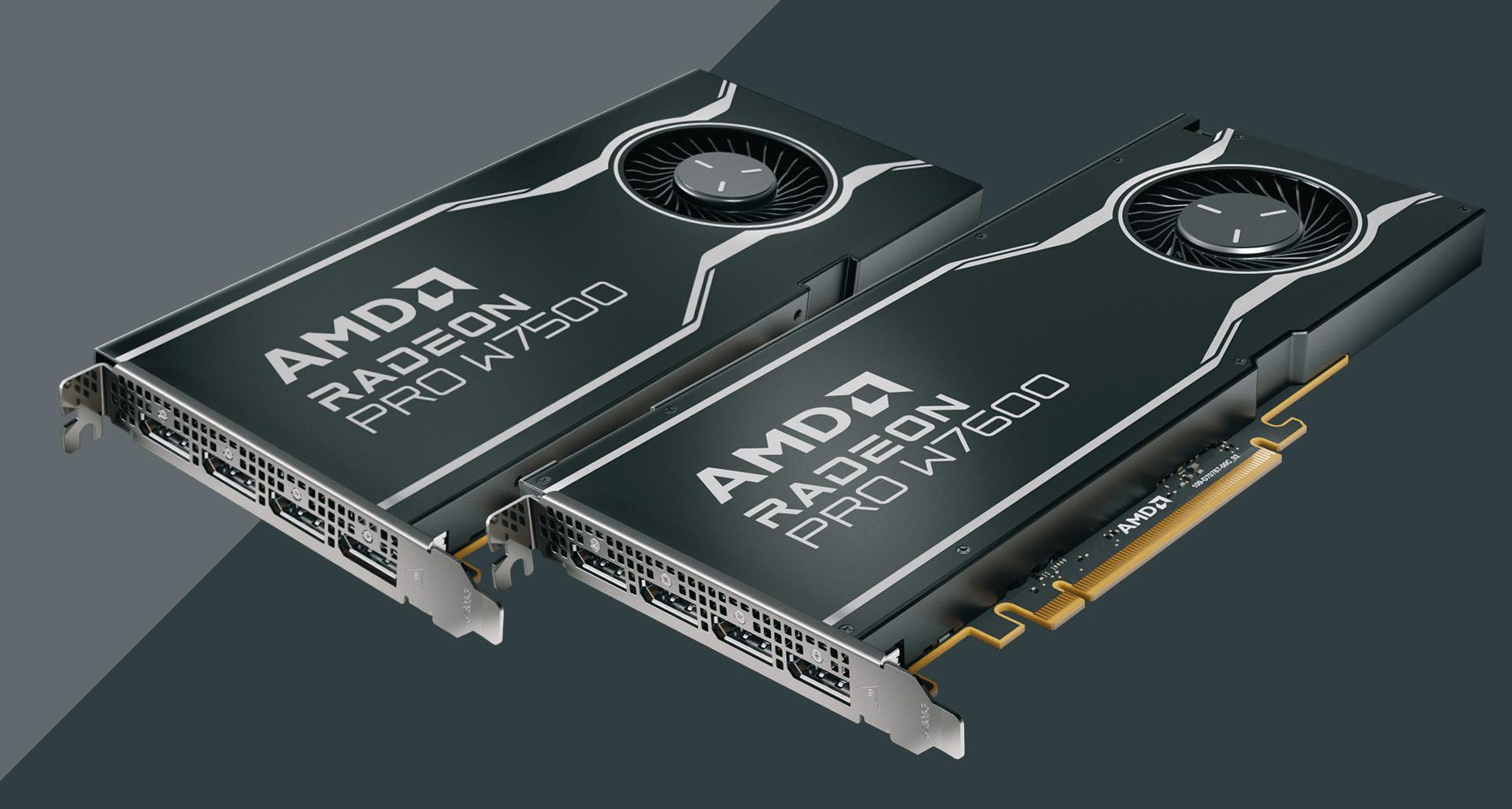

AMD RADEON PRO W7600 AND W7500 PRO WORKSTATION GPUS LAUNCH

» AMD targets volume mid-range workstation segment with new RDNA 3 pro graphics cards, but with no low-profile option, limits the reach to mainstream desktop towers

WHAT DEVELOP3D THINKS

The roll-out of AMD’s new generation RDNA 3-based pro GPUs comes straight out of the workstation graphics

playbook: Start at the high end and then move down the range.

AMD has launched the Radeon Pro W7600 and Radeon Pro W7500, a pair of ‘mid-range’ desktop pro workstation GPUs built on its RDNA 3 architecture.

The new graphics cards are designed to target ‘medium’ workloads for 3D CAD, visualisation, video editing and digital content creation. They follow on from the ‘ultra high-end’ AMD Radeon Pro W7800 and W7900 launched earlier this year

The Radeon Pro W7600 and W7500 are both full-height, single-slot GPUs, so are designed to fit in standard desktop tower workstations and not small form factors (SFFs)/ultra-compacts.

Both GPUs come with 8 GB of GDDR6 memory and four DisplayPort 2.1 Connectors, the latest version of the digital display standard. According to AMD, this means the cards are future-proofed for next gen displays in terms of refresh rate, pixel resolution and colour bit-depth.

The Radeon Pro W7500 offers 12.2 TLOPs of peak single precision performance and has a total board power of 70W, which it draws from the PCIe slot. It costs $429.

The Radeon Pro W7600 offers 19.9 TLOPs of peak single precision performance and

has a total board power of 130W, so needs a 6-pin connector. It costs $599.

Both GPUs comprise multiple unified RDNA 3 compute units (28 on the W7500 and 32 on the W7600). Each compute unit has 64 dual issue stream processors, two AI accelerators and a second gen ray tracing (RT) accelerator. According to AMD, RDNA 3 offers up to 50% more raytracing performance per compute unit than the previous generation.

There is growing software compatibility for AMD RT accelerators. In addition to DirectX Raytracing (DXR) and Vulkan ray tracing, for which there is direct support, AMD’s open-source toolset HIP is helping software developers automatically translate their existing Nvidia CUDA code bases.

In terms of the competition, AMD compares the AMD Radeon Pro W7600 to the similarly priced Nvidia RTX A2000 (12 GB) and the AMD Radeon Pro 7500 to the Nvidia RTX T1000 (8GB). The company claims better performance in CAD applications Solidworks and PTC Creo. Both Nvidia GPUs are available at similar price points, but the Nvidia GPUs are compatible with both standard towers and SFF/ compact workstations.

www.amd.com/radeonpro

The Radeon Pro W7600 and W7500 are both full-height, single-slot GPUs, designed to fit in standard desktop tower workstations rather than small form factors (SFFs)/ ultra-compacts

With the new Radeon Pro W7500 and W7600, AMD is looking to target a specific part of the workstation market – the midrange $350 to $950 dollar segment, which it describes as the largest piece of the pie. In terms of performance profiles and price, the new GPUs seem well positioned. However, it feels like AMD could be limiting their potential reach by not giving at least one of them a lowprofile form factor. Small Form Factor and ultra-compact workstations, such as the HP Z2 Mini and Lenovo ThinkStation P3 Ultra, represent a growing slice of the mainstream workstation market, not just on desktops but also in racks for remote graphics deployments.

AMD could be choosing to focus more on getting these pro GPUs out in the market via specialist system builders, such as Armari and BOXX, which tend to only sell tower workstations.

Alternatively, perhaps AMD feels there'll be less need for a low-profile form factor pro GPU in future. As Jimmy Holbert, director of Radeon Creator & workstation strategy at AMD, pointed out in a recent press briefing, AMD’s APUs (CPUs with integrated GPUs) are now having an impact on the entry-level pro GPU market. With rumours of far beefier models coming next year, could AMD be planning to extend the reach of its APUs into the mid-range?

In addition, by configuring both of the new GPUs with 8 GB of memory, it looks like AMD could be limiting where these cards can be used. While 8 GB is sufficient for most CAD workflows, many real-time visualisation or GPU rendering tools can easily use more memory, especially at higher resolutions. And that’s without considering multi-tasking workflows, where a product designer might continue to model in 3D CAD while rendering in the background.

Lenovo targets power efficiency with AMD Ryzen Pro 7040 APUs

Lenovo has launched new mobile workstations with AMD Ryzen Pro 7040 Series processors with integrated AMD GPUs and Radeon Pro graphics drivers.

The 14-inch ThinkPad P14s Gen 4 and 16-inch ThinkPad P16s Gen 2 target affordability and power efficiency, thanks to the AMD Ryzen Pro 7040U processor. The 16-inch ThinkPad P16v is more

powerful, offering a choice of AMD Ryzen 9 Pro 7040 HS Series processors. It can also be configured with an optional Nvidia RTX 2000 Ada Generation laptop GPU.

www.lenovo.com/thinkpad

DEVELOP3D.COM WORKSTATION NEWS

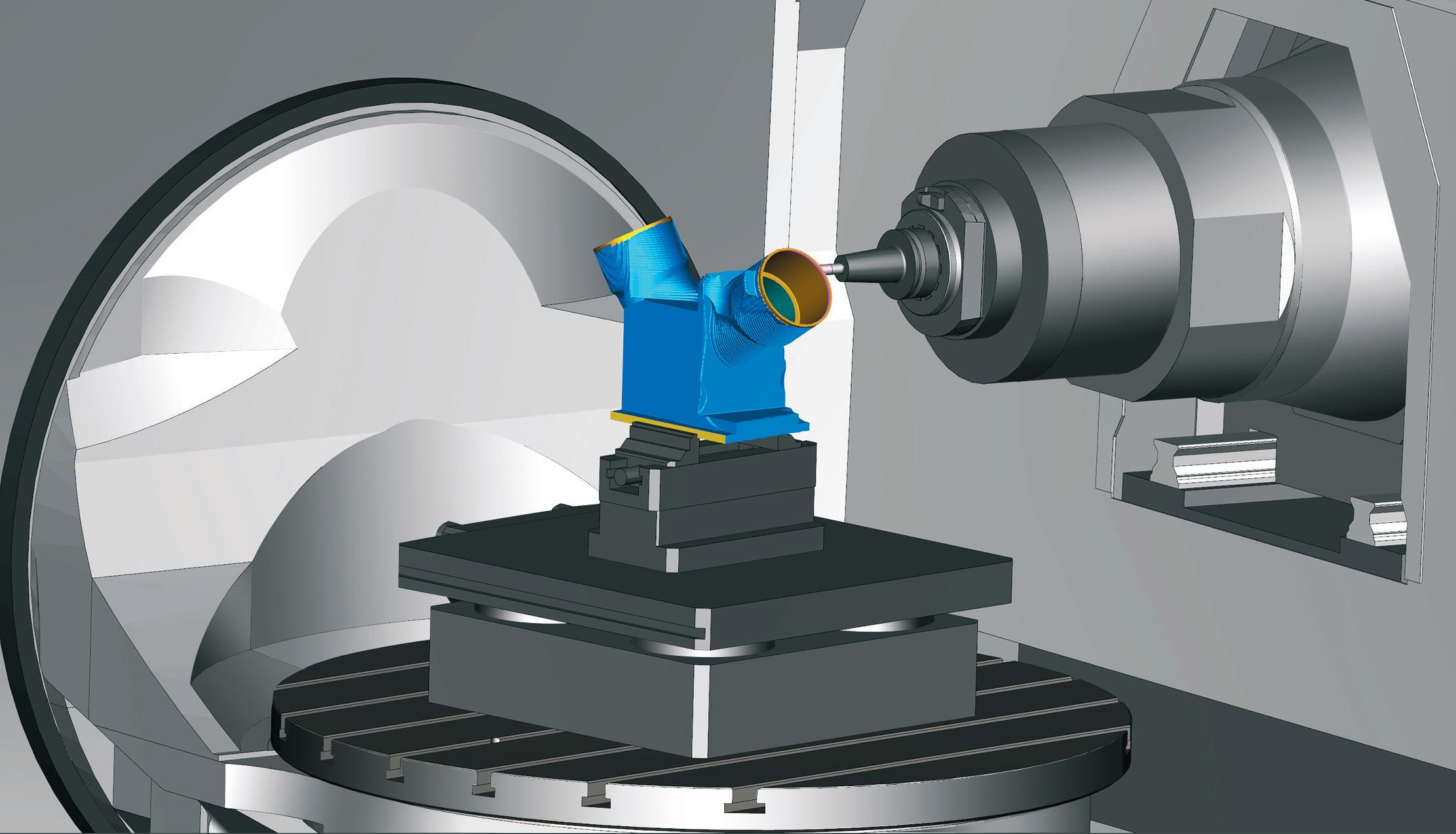

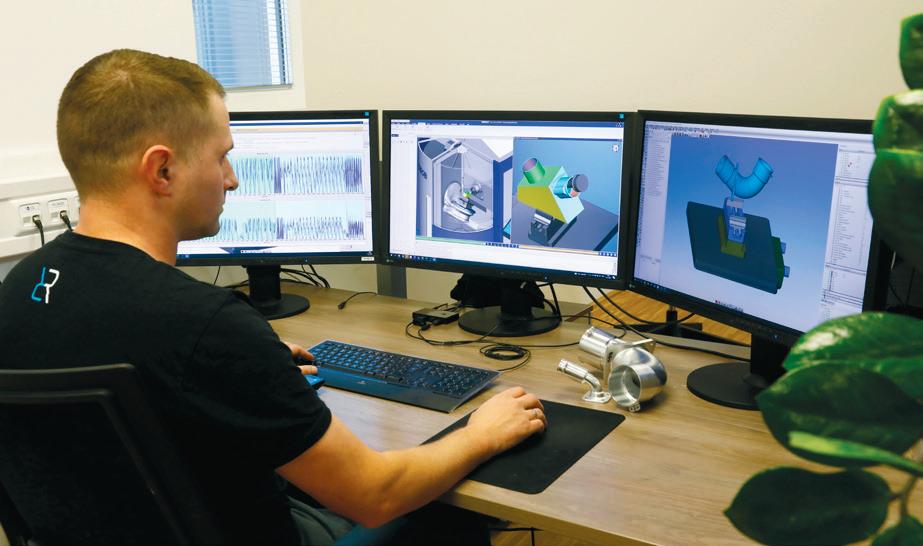

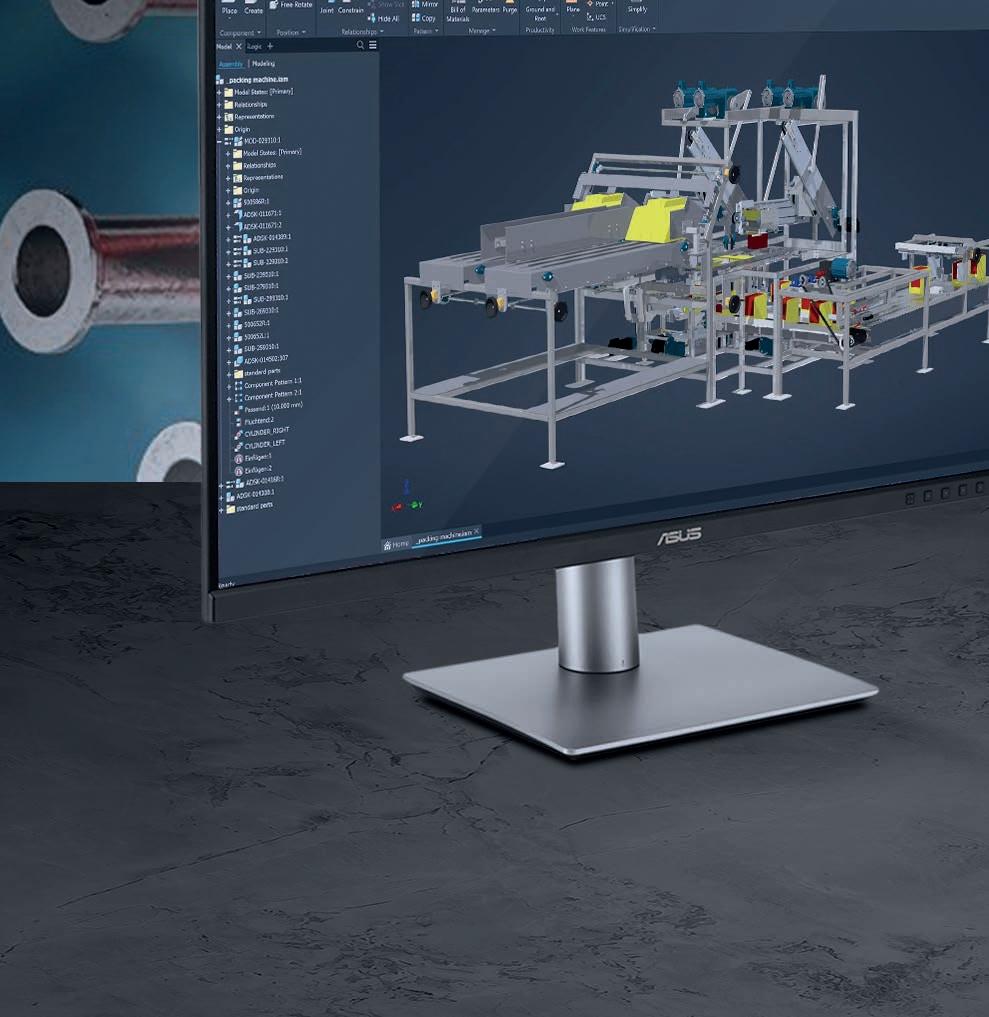

UK START-UP CLOUDNC ANNOUNCES NEW CAM ASSIST PLUG-IN FOR AUTODESK FUSION 360

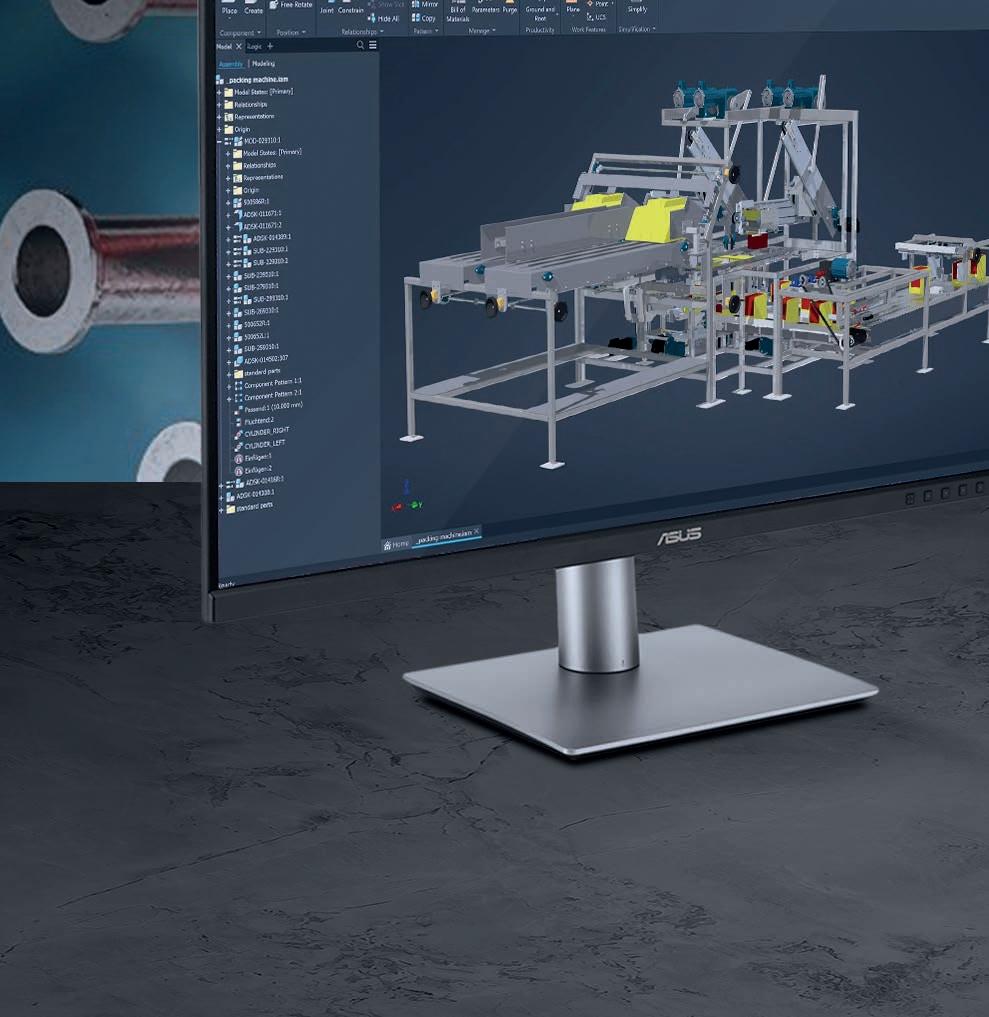

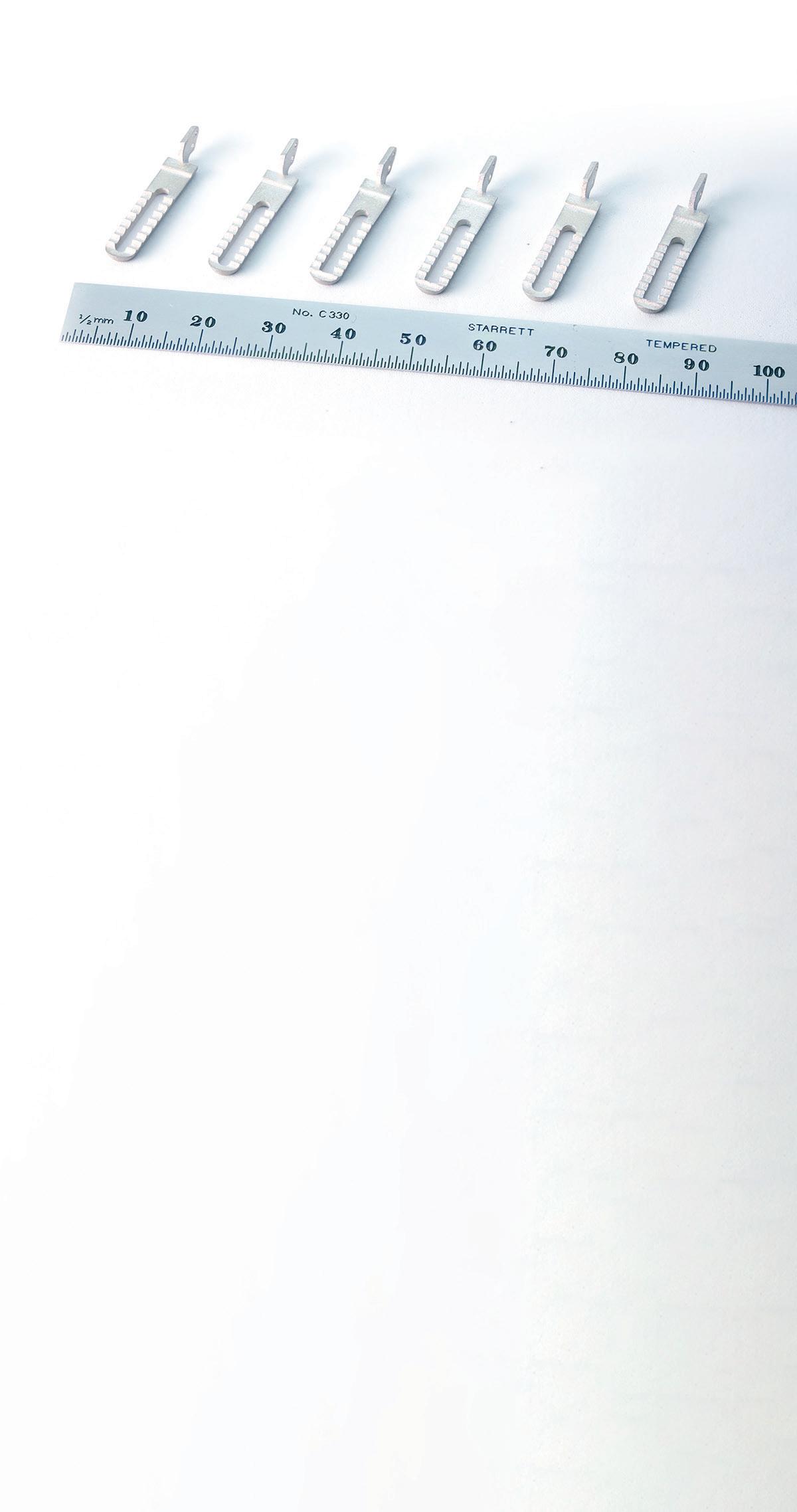

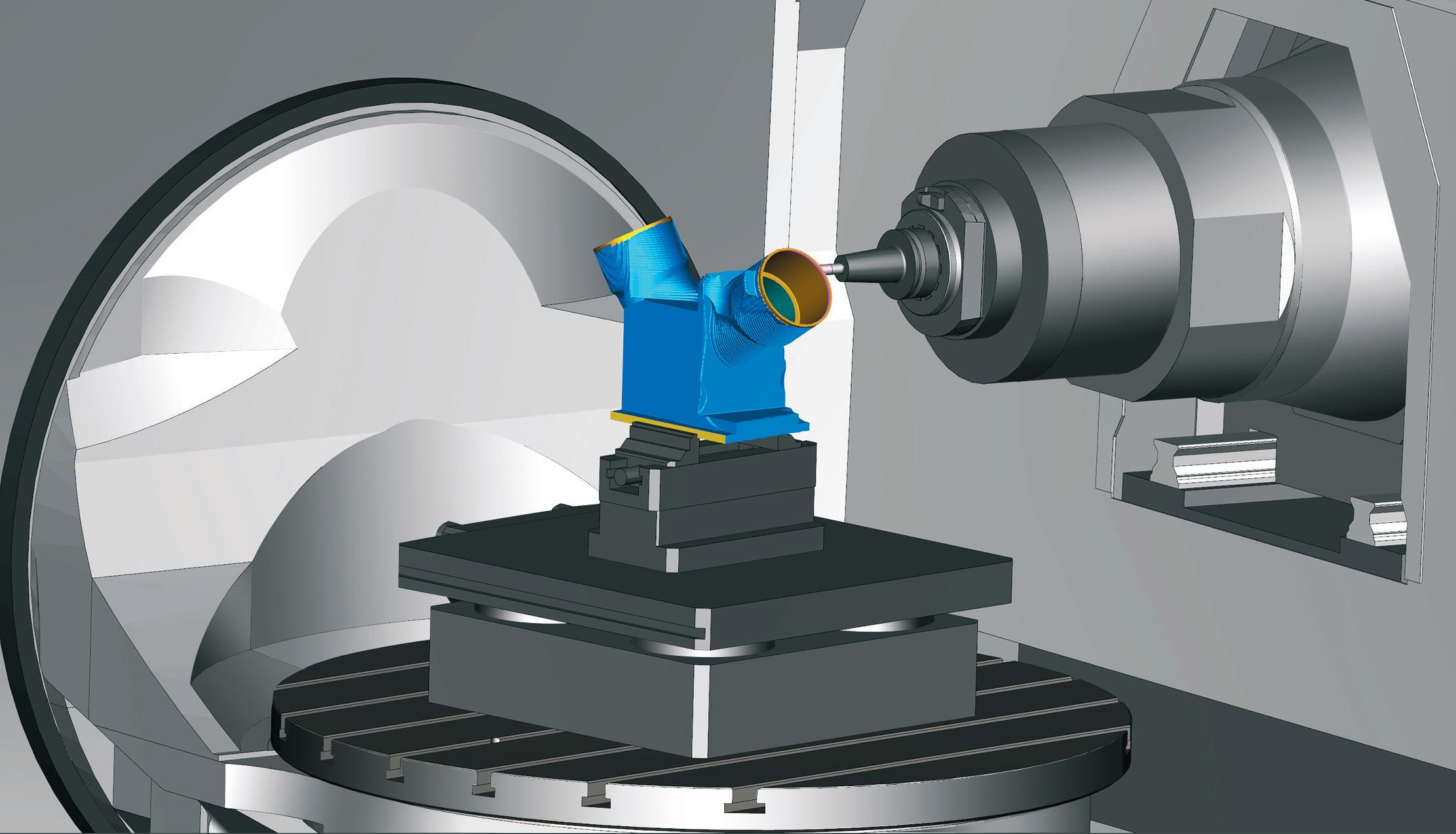

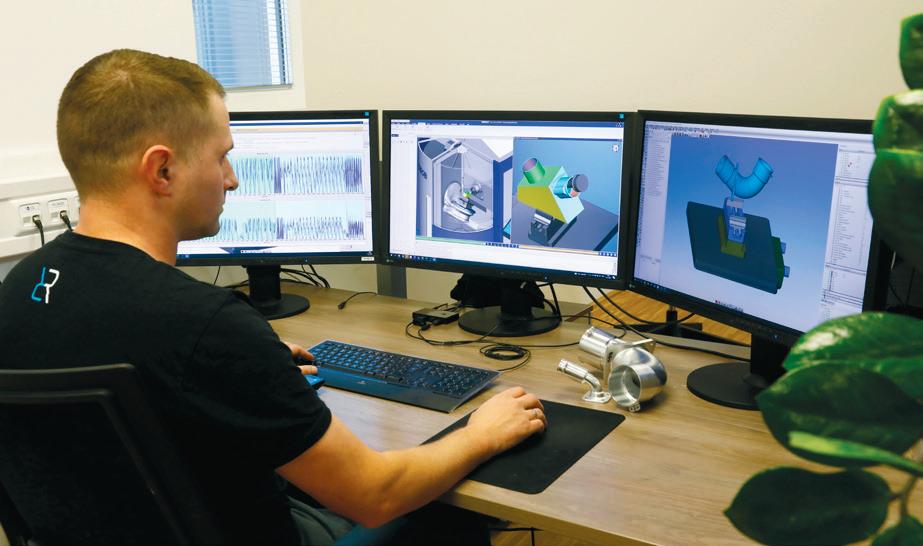

CloudNC has launched CAM Assist, its plug-in for Autodesk Fusion 360, as the UK-based start-up looks to reduce CAM programming times by up to 80%.

The software uses computational optimisation and AI inference to determine the professional strategy and toolset needed to manufacture a part, along with the most appropriate cutting speeds and feeds from the user’s library.

As a plug-in for Autodesk Fusion 360, it’s able to create machining strategies for 3-axis parts in seconds, before working directly with your existing CAM package.

Fusion 360 users can upload a 3D model of a 3-axis component and the cloud-based software will determine the best milling tools needed from those available, how they should be used and the geometric data of the part that you are aiming to machine.

It uses computational techniques to generate the best possible outcome, based on the geometry of the part and your tool library. This can run into the thousands, if not millions, of combinations.

In a matter of seconds, CAM Assist drafts the code required to instruct a CNC machine how to make a part within the user’s existing CAM platform. This code can be edited further by users if required.

CloudNC says it has conducted sideby-side trials of CAM Assist with senior CAM programmers. According to the results, CAM Assist delivers reductions in programming times of up to 80% in comparison to manual programming methods. This saves time for more senior programmers, by completing tasks associated with programme set-up and toolpath creation.

Many machine shop floors find CAM demand inconsistent — they’re either overstaffed or understaffed. CAM Assist aims to shorten lead times and free up experienced programmers for more demanding jobs, while also helping those new to machining get up to speed faster.

It is also hoped that by pre-programming more parts, CNC machines spend less time sitting idle as G-code is entered.

“CAM Assist is the biggest paradigm shift for the precision manufacturing sector in decades,” said CloudNC founder Theo Saville. “By making CAM programmers faster, CAM Assist enables manufacturers to increase machine uptime, slash lead times, improve process stability and upskill staff to become expert machinists more quickly.”

He continued: “These advances will re-energise precision manufacturing companies struggling with rising costs, ageing workforces and competition from

globalisation — shortening supply chains

and keeping costs down.”

The launch of CAM Assist marks the culmination of eight years of testing and refining the technology in the UK startup’s own factory in Chelmsford, Essex, where the company employs around 50 skilled machinists, all well-qualified to offer feedback on the software as it develops, while also generating new ideas for the product.

“By operating our own facility, we have a dedicated space to test, refine and improve our software solutions — live,” explains Saville. “It serves as a real-world testing ground, allowing us to observe and analyse how our software interacts with the complex machinery, materials, and processes involved in precision machining. For example, if we want to really be sure we’ve found the best way to program a CNC machine to drill a hole on a Haas VF2 until the process is absolutely perfect every time, we can.”

With investment from Autodesk, Lockheed Martin and Atomico, CloudNC aims to take autonomous manufacturing to a level that it says will enable customers to make products anywhere in the world at competitive cost, enabling them to more easily onshore supply chains and keep engineering jobs local.

www.cloudnc.com

10 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM NEWS

» CAM Assist is billed by its creators as a 'CAM progamming co-pilot' that uses AI to significantly accelerate professional machining strategies for 3-axis parts

CloudNC CEO Theo Saville says the company is aiming to re-energise precision manufacturing with its AI-based product

©2023 Advanced Micro Devices, Inc. All rights reserved. AMD, the AMD Arrow logo, Radeon, AMD DNA, Ryzen, Threadripper, and combinations thereof are trademarks of Advanced Micro Devices, Inc. Other product names used in this publication are for identification purposes only and may be trademarks of their respective owners. PID#: 232087025 Version: 1 LEARN MORE amd.com/en/graphics/workstations ACCELERATING DESIGN WORKFLOWS TO COMPLETE THE MOST DEMANDING TASKS

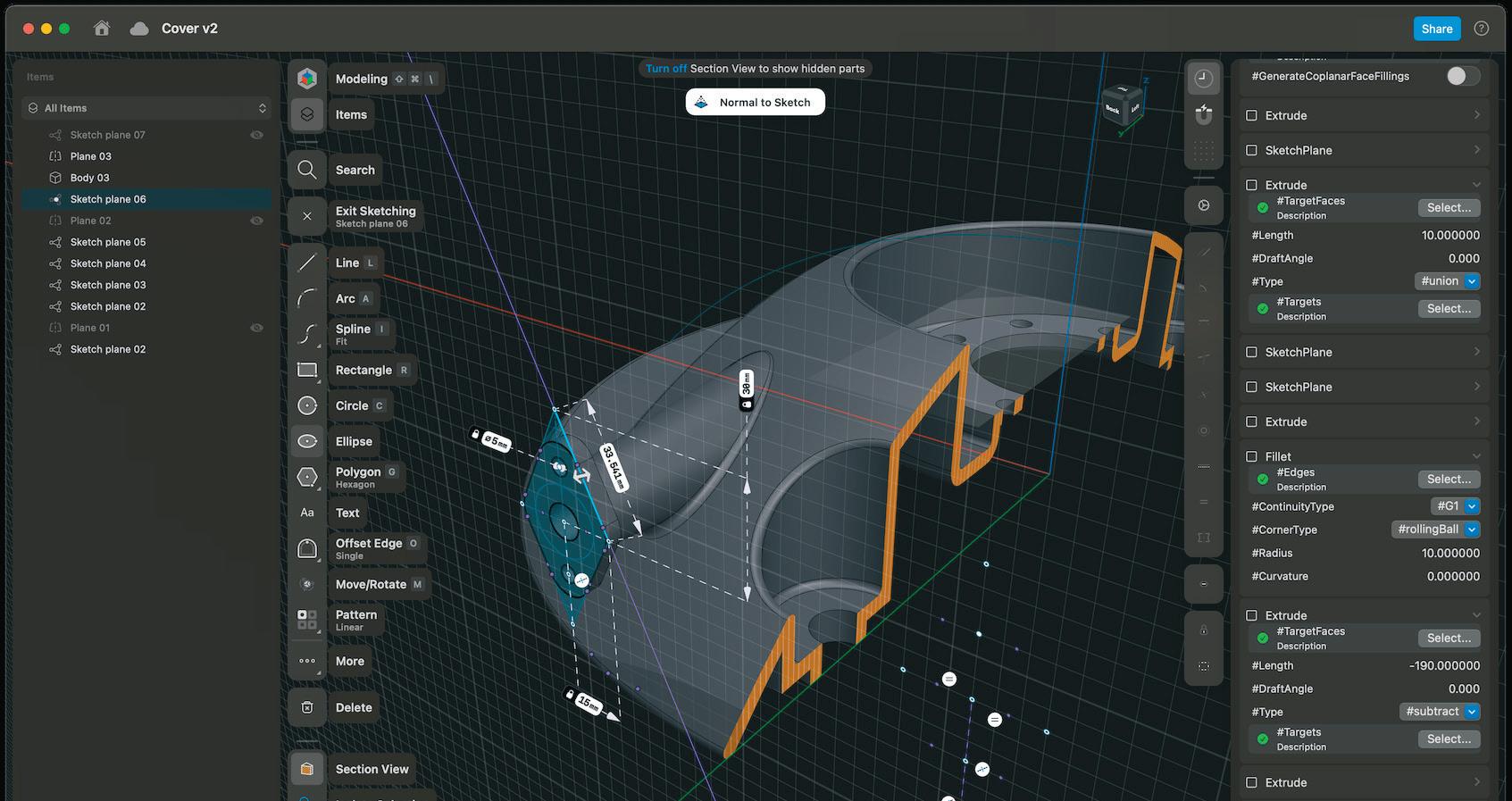

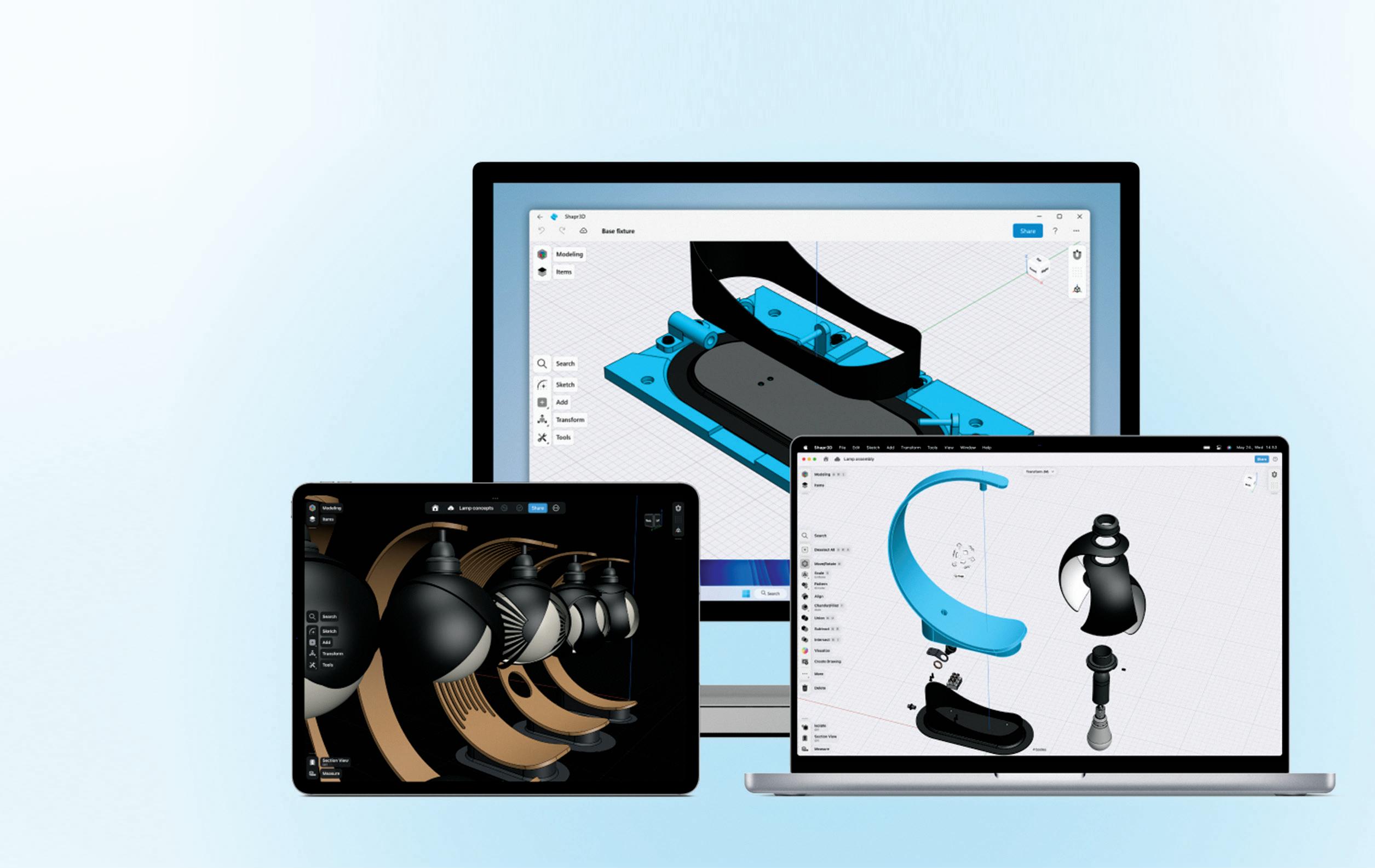

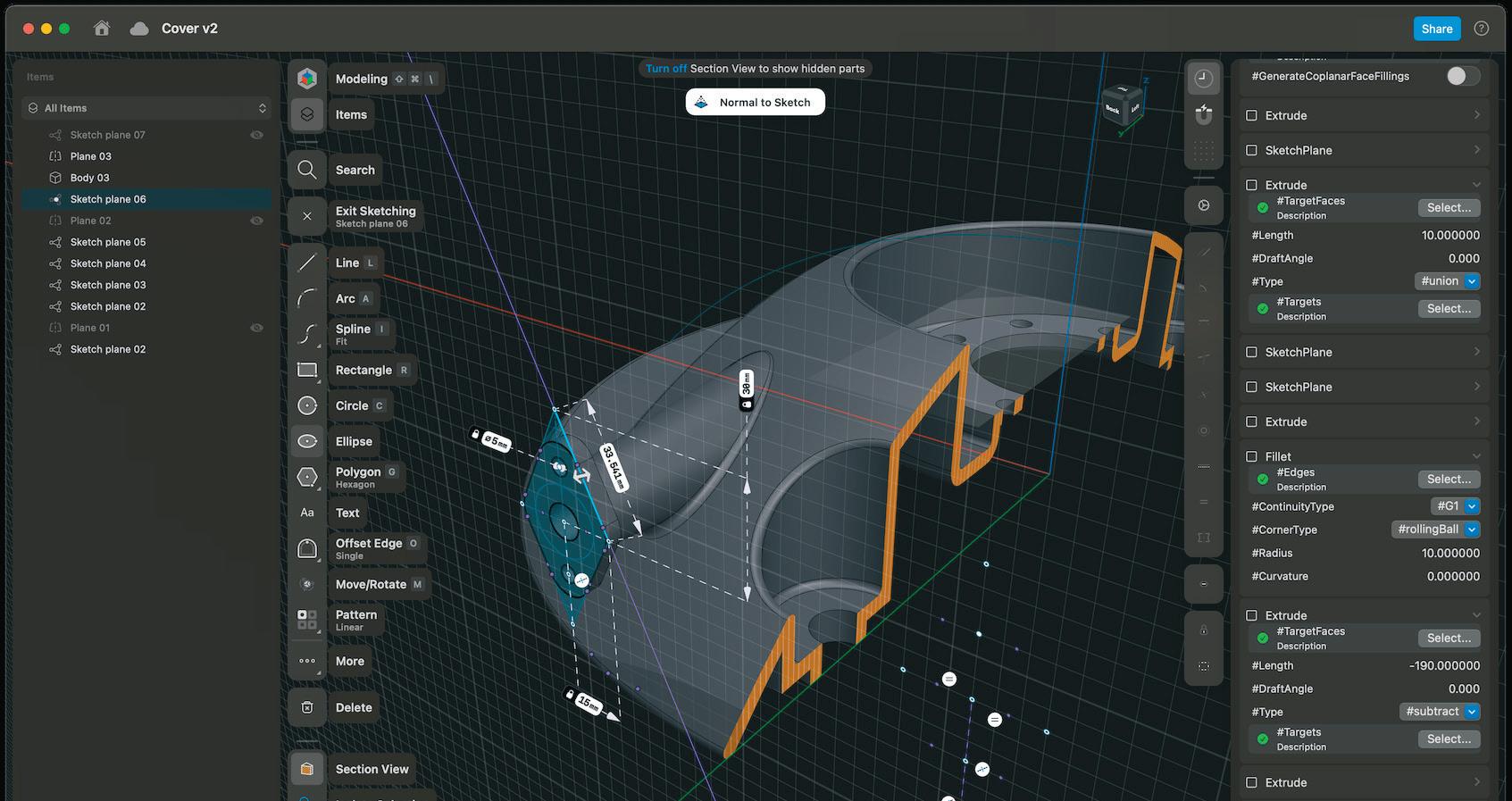

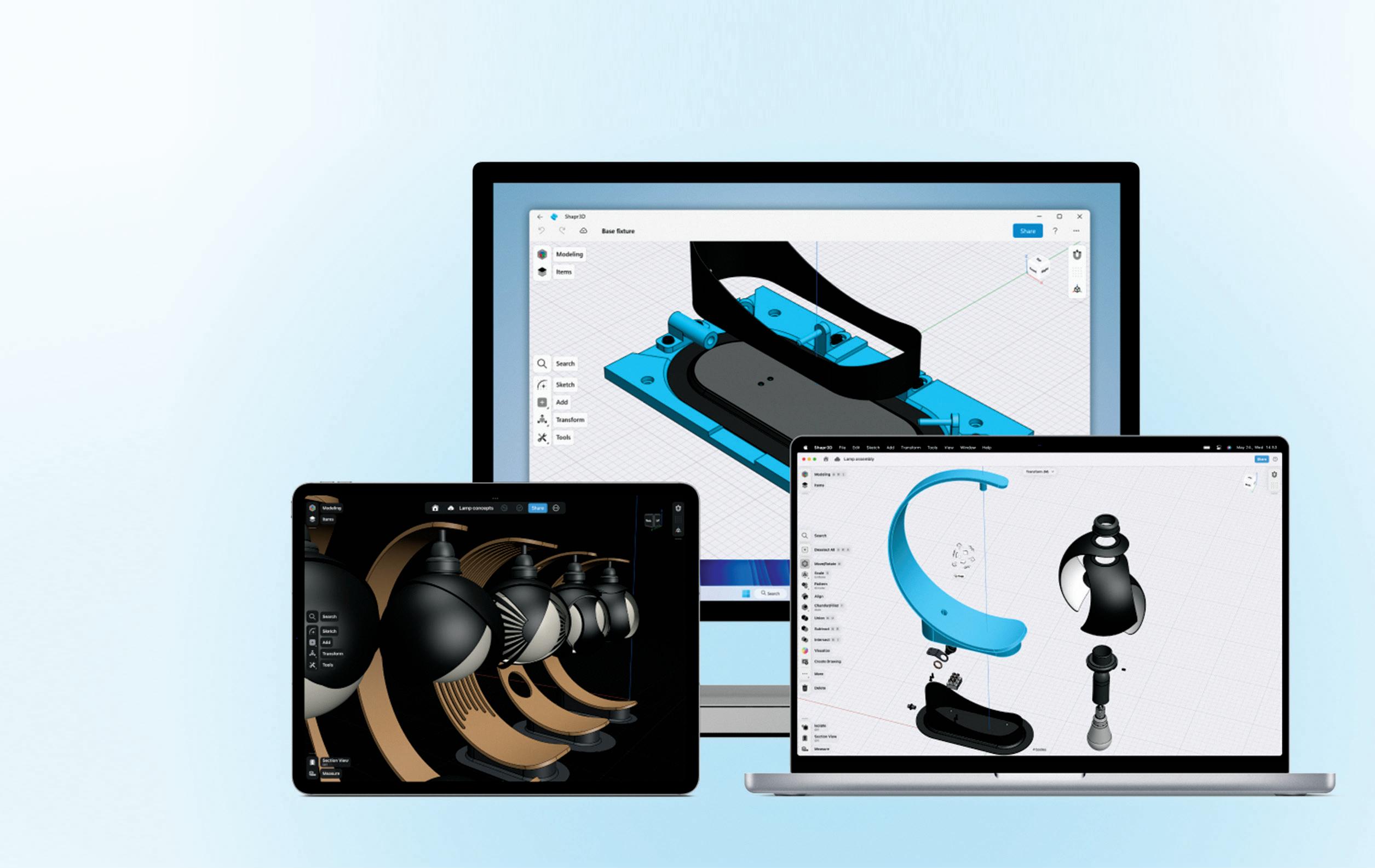

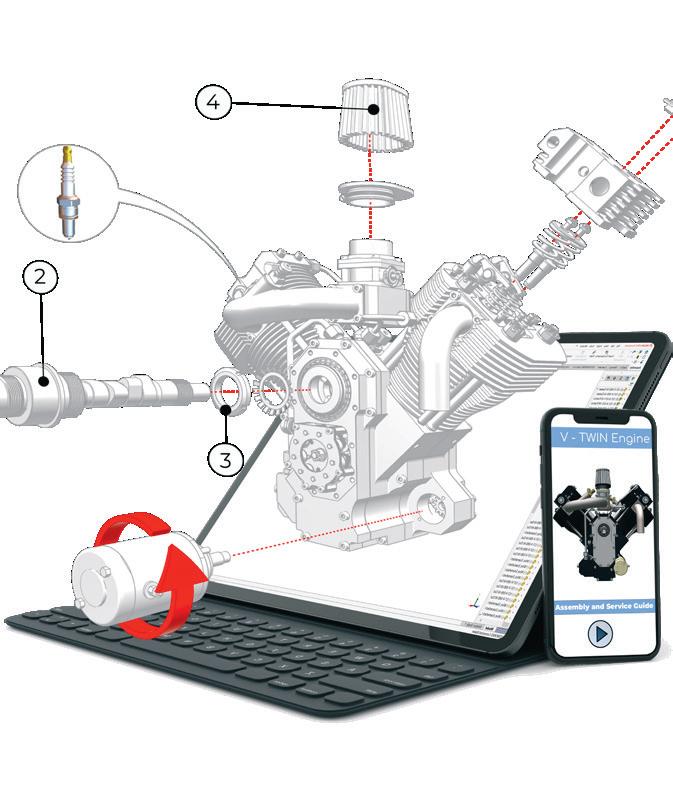

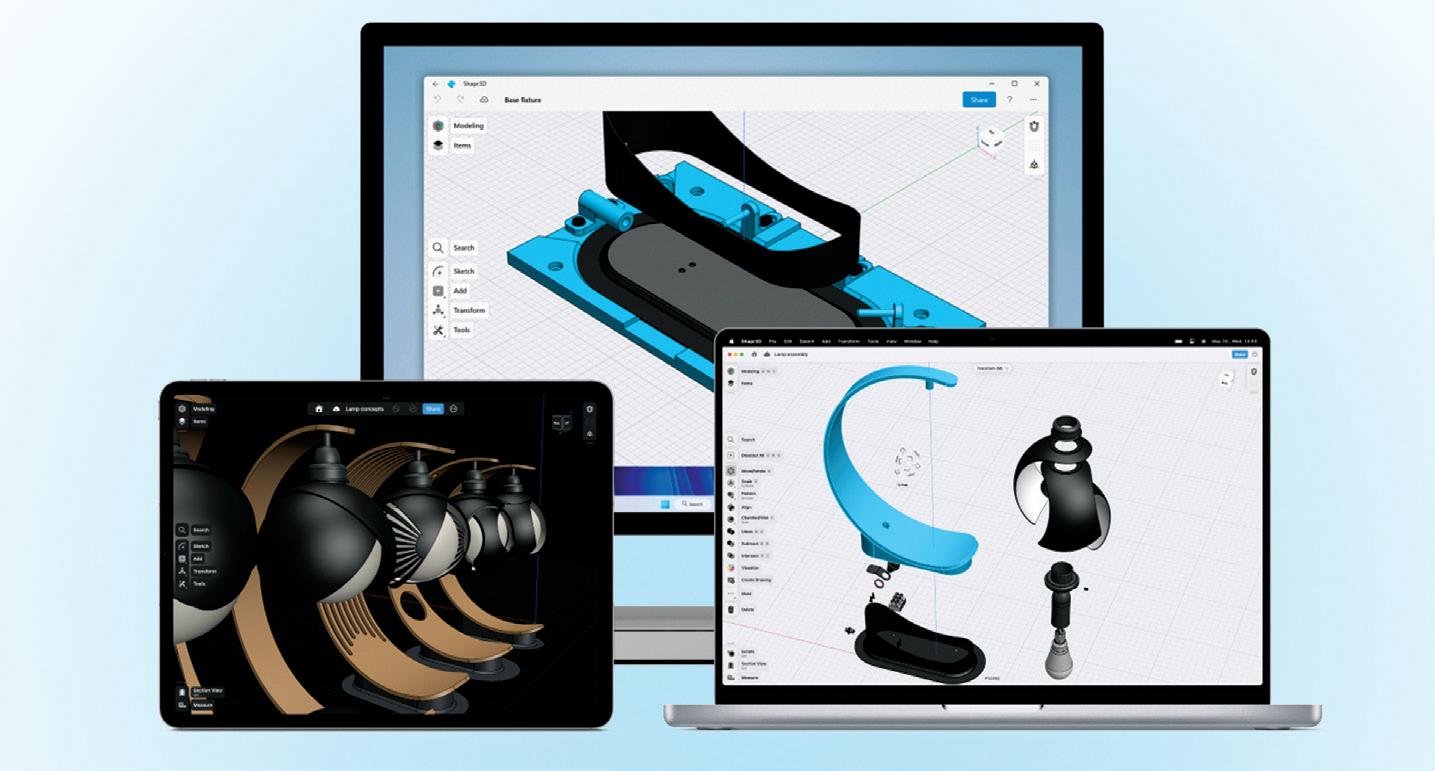

HISTORY-BASED MODELLING COMING TO SHAPR3D IN Q4

Additive Flow gets acquired N

ano Dimension has acquired Additive Flow and its multimaterial AM optimisation software capabilities, led by its consultancy work and FormFlow product.

FormFlow addresses design, production, and quality decisions, optimising for cost, weight, manufacturing productivity and yield. The company behind it has worked with the likes of Saint-Gobain, Royal Haskoning, Tata Steel and Zeiss.

The deal should enable Nano Dimension customers to rapidly and cost-effectively replicate, design and augment AME electronic component layouts.

www.nano-di.com

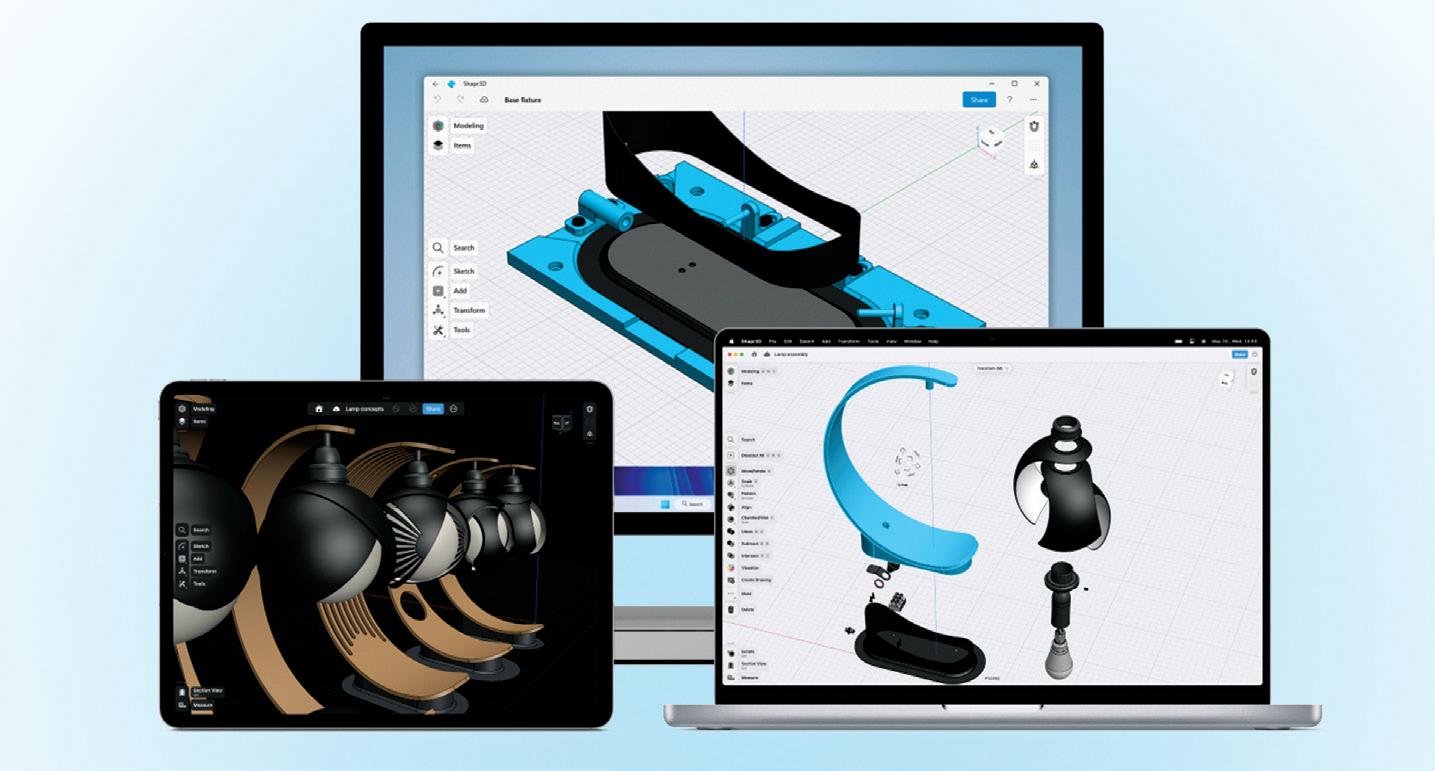

Shapr3D has announced that it will add history-based parametric modelling to its CAD system in Q4 2023, expanding its toolset beyond its current concepting and fast rendering capabilities.

“Last year, we started hearing a common refrain from our customer base, ranging from SMBs to Fortune 500 companies,” explained Shapr3D CEO István Csanády. “They wanted to do even more with Shapr3D, beyond just conceptual design and prototyping.”

More specifically, he continued, what the company heard was that these customers were looking to use Shapr3D in some of their more complex engineering and manufacturing workflows. And for this, the company concluded, they would require history-based parametric modelling.

Shapr3D is also getting a new user interface and folders in which users can store designs and projects.

The new UI continues on Shapr3D’s path to be multi-platform, working equally as well on desktop as on mobile devices. It's capable of making smart assumptions as to what tools a user might need for any given action, such as selecting a part or face, and offers quick on/off buttons for details like measurements.

The folders, meanwhile, aim to provide a more frictionless workflow, by enabling users to share designs with coworkers, clients and stakeholders on the spot, or keep them private.

Folders will be released later this year, while another update, the debut of a search bar for finding projects or folders by title, will follow soon after.

www.shapr3d.com

History-based modelling is being introduced to Shapr3D in direct response to customer requests

Hexagon buys CADS Additive

CADS Additive is the latest company to join the Hexagon additive manufacturing stable, enabling the buyer to further integrate the acquired company's specialised powder-bed fusion build prep software.

The AM Studio software from CADS Additive is already connected to Hexagon’s Nexus digital platform, completing the platform’s Nexusenabled AM workflow, which covers CAD model and build preparation, quality and production intelligence, and the automation of CAM to finish parts.

www.hexagonmi.com

Push to boost D&T education in schools

The Design and Technology Association (D&TA) has announced its latest initiative, 'Inspired by Industry: Transforming Design and Technology Education', in a bid to revitalise D&T education in schools.

This pioneering project offers a comprehensive set of resources and support materials to reshape how D&T is taught to students aged 11 to 14 in England and Wales. Acknowledging the financial challenges many D&T departments face, D&TA is making these resources freely available to all schools.

The initiative will cover a diverse range of subjects, from addressing social and community issues through design thinking to creating inclusive designs for public spaces and building sustainable products.

“D&T education plays a pivotal role in preparing students for future careers,” said D&TA CEO Tony Ryan. “By aligning our projects and activities with industry practice, we ensure students are equipped with the cutting-edge knowledge and competencies employers highly value.”

www.designtechnology.org.uk

Recycled content calculator launch

Makersite has launched an app to help companies calculate and report the amount of recycled content in their products.

The new calculator leverages

Free resources will be made available to school D&T departments in England and Wales

Makersite’s global supply chain data and works within its existing platform, making the compliance process accessible, efficient and accurate for modern global regulations, including the EU Green Deal initiative, the Packaged Product Waste Regulations (PPWR) and the Corporate Sustainability Reporting Directive (CSRD). Makersite claims that this will transform the lengthy data aggregation process associated with complex products based on large numbers of raw materials.

www.makersite.com

12 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM NEWS

ALTAIR ENLIGHTEN AWARD: 2023 WINNERS ANNOUNCED

Toyota, Polestar and Marelli have been named among the winners of this year's Altair Enlighten Award, for products that aim to create a more sustainable, lightweight future.

Presented in association with the Center for Automotive Research (CAR), the 2023 Altair Enlighten Award honours “the greatest sustainability and lightweighting advancements that successfully reduce carbon footprint, mitigate water and energy consumption, and leverage material reuse and recycling efforts.”

The Enlighten Award winners were announced in an awards ceremony at the CAR Management Briefing Seminars on 1 August at the Grand Traverse Resort near Traverse City, Michigan.

Polestar was the winner in the Sustainable Product category, for its Polestar 2 MY24 passenger vehicle, featuring next-generation electric motors, faster charging, greater efficiency and longer range. The runner-up was the Lucid Sedan from Lucid Motors.

Toyota was a winner in two categories. Along with BASF Corp and US Farathane, it won in the Enabling Technology category, for the group's work on a resin frame for an isodynamic vehicle seat. Toyota also won in the Module Lightweighting category, along with Adient and Multimatic, for the group’s work on the same seat.

Marelli, meanwhile, won in the Future of Lightweighting category for its development of a new polyurethane foam that can be applied to all foam-in-place (FIP) applications.

Other category winners included

Volteras in the Responsible AI category, for technology that enables electric vehicle fleet management; and ArcelorMittal in the Sustainable Process category, for shifting its Port-Cartier pellet plant in Canada away from heavy fuel in favour of a biofuel, in the form of pyrolytic oil.

“The Altair Enlighten Award is a special award that showcases how the automotive industry's leading minds from its biggest names to its newest start-ups are applying advanced technologies and responsible AI to create a better, greener industry,” said James Scapa, founder and CEO of Altair.

“Lightweighting, optimisation and sustainability are more important than ever in the automotive industry. Altair is proud to honour the innovations that will drive the future of a sustainable industry.” www.altair.com

Artec 3D unveils Ray II long-range scanner

Artec 3D has released its latest long-range laser 3D scanner the Ray II, capable of combining its precision LiDAR scanning with results from handheld sister product, the Leo.

Developed in collaboration with Leica Geosystems, part of Hexagon, the Artec Ray II has the ability to capture large products and systems ten times faster than the original Artec Ray, with a 36 MP 3-camera system supporting a 3D point accuracy down to 1.9 mm from 10 meters.

Data from Artec Ray II can be combined in Artec Studio software with data from other Artec 3D scanners, such as the wireless handheld Artec Leo, helping to provide comprehensively detailed scans of selected areas of large-object captures.

In addition to its scanning speed, the Artec Ray II boasts an array of features

ROUND UP

OpenUSD has been backed by Pixar, Adobe, Apple, Autodesk and Nvidia, together with the Joint Development Foundation (JDF), an affiliate of the Linux Foundation, in a bid to make Pixar’s Universal Scene Description technology a standardised format for 3D scenes www.openusd.org

Mastercam has partnered with Sandvik Coromant to integrate the latter's CoroPlus Tool Library into its new MasterCam 2024 release software. This will save Mastercam users significant time that might otherwise be spent searching for tools and building 3D tool assemblies www.mastercam.com

Depix Technologies, only recently out of stealth mode, has unveiled its AI-driven software that allows users to create High Dynamic Range (HDR) panoramic images and backplates using text prompts to create what it claims are some of the most vivid, immersive product visualisations possible www.depix.ai

The team at Solidworks Education has launched a new training content that is designed to help users of all ages get up to speed with simulation tools, in the form of its new eBike Modeling and Simulation (MOD-SIM) series. Sessions are free, but users must register www.solidworks.com

designed to provide an easy scanning experience and improve the quality of results. The scanner is equipped with automated targetless field registration, real-time scan alignment and a doublescan feature for the automatic removal of moving objects.

www.artec3d.com

Shining 3D has launched the Einscan H2, a scanner that shares its predecessors’ ergonomics, wide FOV and convenient hybrid light sources, but adds three VCSEL projectors to the handset, so it can scan dark surfaces more efficiently and adapt better to different lighting conditions www.shining3d.com

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 13

Polestar scooped the Altair Enlighten Award for Sustainable Product for its Polestar 2 MY24 electric vehicle

The Artec 3D Ray II (L) can combine data with other Artec products, like the Leo (R)

There’s great anticipation surrounding the current development of AI and its potential impact on our creative world and education.

Naturally, there are valid questions being raised: Is AI a valid tool to use? What are the ethical ramifications? Is using AI considered cheating? What is the impact on students?

While it’s important to address these concerns, it’s equally crucial to embrace the positive aspects of AI and its ability to revolutionise teaching, learning, and established creative workflows.

It’s true that AI technology is continuously improving, but it is still far from being a complete substitute for human creativity and expertise.

A VALUABLE TOOL?

As a design faculty member with a focus on exploring and implementing new technologies to enhance workflows, I view AI as an exciting and valuable tool. It’s essential students learn how to utilise AI and leverage its potential benefits.

Design is a service-oriented field that relies heavily on a thorough process. The ability to produce work efficiently and costeffectively enhances competitiveness.

Design is not merely about making art. As an educator, my role is to equip students with a strong foundation and provide them with tools that make them competitive in a rapidly changing landscape.

Today, with the enhanced accessibility and functionality of 3D modelling and rendering software, designers can simultaneously design and explore various options with unprecedented precision.

Nevertheless, as software capabilities expand, the time saved by using AI may diminish due to increased attention to detail. This is where image-based AI and chatbot engines prove incredibly useful Design, as a service-oriented field, thrives on exploration, discovery and variation, all of which require time. However, students

today face time constraints due to various factors, including rising tuition fees. To address this, I have begun implementing AI as a tool during the concept development phase in my courses.

By leveraging AI, students can prompt the engine to develop interesting material surfaces, engage in conversations with chatbots to explore design considerations for low-cost medical products, and quickly generate visualisations from hand sketches or basic 3D models.

While the results may not always be perfect, AI consistently excels at providing rapid visual ideas and stimulating students’ creativity in surprisingly short timeframes.

One student even highlighted that AI allows them to delegate tedious manual work, freeing up valuable time to focus on the creative aspects of design.

This is a significant breakthrough, because as humans, our brainstorming processes often rely on familiar patterns and recycled ideas. Platforms like Google and Pinterest, which students typically rely on for mood boards and inspiration, are biased and tend to tailor results based on past inquiries.

UNIQUE OUTCOMES

In contrast, AI engines offer unbiased and truly unique outcomes. Also, AI empowers students to bring envisioned visual images to life, liberating them from the constraints of traditional image searches.

Image-based AI engines are also very useful to help beginner students to achieve higher-quality work for presentation purposes. Specifically in foundation courses, this is valuable because it helps build confidence among students while their software proficiency is not strong yet. Excitingly, image AI engines are gradually integrating image editing capabilities. Users can mark areas for refinement and generate new content stylistically aligned with the existing image through text prompts and brush inputs. This represents

a revolutionary improvement over traditional image composition workflows. For fields like interior design and architecture, the ability to expand existing images, previously a painstaking task, can be accomplished in a matter of seconds. Amidst all this excitement surrounding AI, it’s crucial to maintain a realistic perspective. AI will not replace us; rather, it accelerates the pace of design exploration. However, to make the most of AI, a strong design foundation remains essential. Thus, I firmly believe that AI is not an adversary in academia. Instead, it offers an opportunity to create a more modern teaching and learning environment, preparing students for the future. Inevitably, AI will become a ubiquitous tool, so it is essential to educate students on its optimal use, starting now. By embracing AI as an invaluable asset, my students in the upcoming semester will develop persona profiles, mood boards, and quick concept renderings in significantly less time than before. This modernised approach will provide them with a forward-thinking education and equip them with skills that align with the reality of the industry.

(Note: This article was ChatGPT-adjusted by its author.)

ABOUT THE AUTHOR: Claas Kuhnen is an assistant professor for interior and industrial design at Wayne State University, focusing on a modern and interdisciplinary approach to digital 3D design methods and technology. On Twitter, he’s @claaskuhnen

14 AUGUST /SEPTEMBER 2023 DEVELOP3D.COM COMMENT

While industry gets to grips with what AI might offer product designers, the next generation is already embracing these tools, writes Claas Kuhnen. But will AI erode traditional design skillsets or will it enhance them?

While results may not always be perfect, AI consistently excels at providing rapid visual ideas and stimulating students’ creativity in surprisingly short timeframes

I’m late, I’m late, for a very important date!” Like Alice in Wonderland, that’s what I chimed, as I sprinted from the parking lot to the front entrance of my new work building, only taking a moment to pause as I passed through security screening.

Swearing under my breath, even as I struggled to catch it, I slowed my steps for a moment to take it all in. It felt surreal to be returning to a workplace after a year of working from home.

Just like for Alice, coming back to the ‘real world’ felt to me like waking up from a very strange dream. In fact, it feels like waking up in an entirely different reality. Before you lose your own head, here are some tips and tricks, drawn from my own experience, for surviving working life, post-Wonderland.

NAVIGATION TIPS

First, don’t neglect self-care. In Wonderland, one of the first things you’ll notice is that your feet are incredibly uncomfortable.

This might be down to my WFH (working from home) standard uniform of athleisurewear and socks, and hardly ever wearing shoes at all, but my feet are now a completely different shape. Do yourself a favour: Invest in a new and comfortable pair of shoes.

And if it wasn’t enough that your feet feel as though you walked the entire length of Wonderland’s Tulgey Wood, you may also start to notice a searing pain in your eyes.

Readjusting to the jarring luminescent lighting of the standard office cubicle will have you hallucinating the Cheshire Cat’s grin every time you rub your overworked orbitals. My advice: Rest your eyes regularly if you can and invest in light filtering glasses to block out the most harmful rays.

Second, get social. After you’ve physically adjusted to being in your new space, it’s time to start adjusting to your new team.

It can all feel a bit like the Mad Hatter’s tea party, where all of your preconceived notions of social decorum are challenged and you try to keep pace with the banter. But don’t lose yourself trying to solve riddles with no answers.

My recommendation is that you spend your first ten days having one-on-one chats with your new teammates. Anyone that you will interact with — either directly or indirectly — is someone you can learn from.

If you don’t like asking basic questions like, “So what is your role here?” or “How can I be most helpful?”, you might go with my method and ask, “What about your role energises you? Is there anyone on the team that you think could use more support? Can you tell me about what you’re hoping to learn in the coming year?”

I personally found that asking my colleagues about what they loved about the job was a welcome and pleasant icebreaker. And speaking of ice-breakers, when that inevitable moment comes when you need to introduce yourself to a room full of strangers, I highly suggest asking them “What is your most used emoji?” Learning the emojis of my new teammates taught me more about who they were as a person than anything I learned in my one-to-ones.

Third, give yourself time to adjust, especially if, like me, you are moving from the fast-paced, independent self-starter environment of a start-up world to the slow-and-steady vibe of a large corporation.

Often, you’ll find that the assignments are fewer, the decisions take longer and they involve way more people. What may feel like an overwhelming lack of urgency among your colleagues could well produce a niggling feeling in your brain.

There is often a correlation between roles that come with high expectations and low autonomy that can predispose you to madness. I warn you to be wary of it, because if you’re not careful, it can lead you down the slippery slope of burnout.

NO CURE FOR CHANGE

With no magic potion or instant cure for these ailments, my best advice is to open yourself up to a more alternative ways of thinking. (And no, I’m not insinuating that you smoke a little sheesha with a magic caterpillar.)

A new exercise routine, studying a new language, or learning a skill that has nothing to do with your job are all effective ways to unwind from a 9-to-5 routine that is suddenly full of new experiences.

Personally, I’ve taken up the thrill of highspeed downhill longboarding since we’ve moved to a new place where they actually have these things called ‘hills’. (The irony here is that my embrace of this new hobby has shifted the conviction that I’m going mad onto my wife, instead of me.)

With my warnings out of the way, I’d like to conclude by offering this final piece of heartfelt advice to those taking up new roles and going back to the workplace. Whether you love your new role, or totally hate it, always keep in mind that your ‘now’ is not your ‘forever’. It’s just the present. But like they say: “Today is a gift. That’s why they call it the present.”

ABOUT THE AUTHOR: SJ is a metal additive engineer aka THEE Hottie of Metal Printing. SJ’s work involves providing additive manufacturing solutions and 3D printing of metal parts to help create a decarbonised world.

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 15

Starting a new job can be nerve-wracking, but returning to an in-office role for a large corporation after working from home for a start-up can feel like a chapter out of ‘Alice in Wonderland’, as our columnist SJ reports

My recommendation is that you spend your first ten days having one-onone chats with your new teammates. Anyone that you will interact with — directly or indirectly — is someone you can learn from

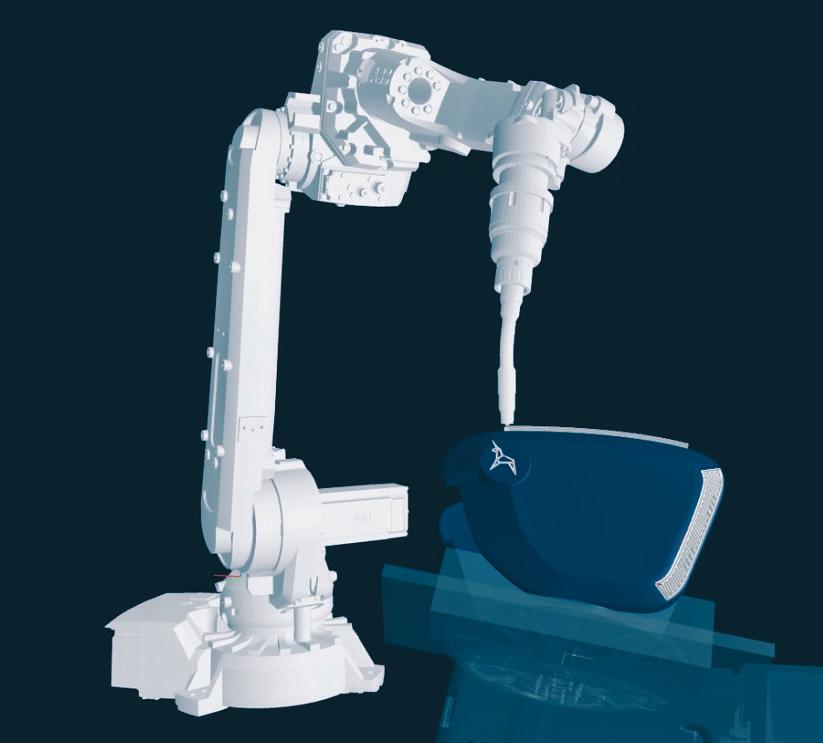

VISUAL DESIGN GUIDE STILRIDE 1 ELECTRIC SCOOTER

Swedish start-up Stilride has designed an innovative electric scooter that boasts a carbon footprint around three times smaller than competing products when it first rolls off the production line

SIT STIL

The saddle boasts a streamlined design, featuring soft padding and independent suspension for ergonomic comfort

GREEN STEEL

Built using recycled Swedish stainless steel from Outokumpu, early life cycle assessment (LCA) analysis of Stilride 1’s carbon footprint, when compared to a market-leading reference scooter from a Chinese manufacturer, puts the Stilride firmly in the lead. Brand new, the Stilride saves 110kg of CO2, and after a full decade, the reference scooter’s footprint is 10% higher. What’s more, an end-of-life Stilride is far more recyclable

DECADES IN DESIGN

Stilride CTO Tue Beijer, pictured way back in 1995 with his first concept bike, comments on the design’s evolution: “Over the years, that silhouette has been an inspiration, to see whether it’s possible to manufacture and replicate it”

16 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM

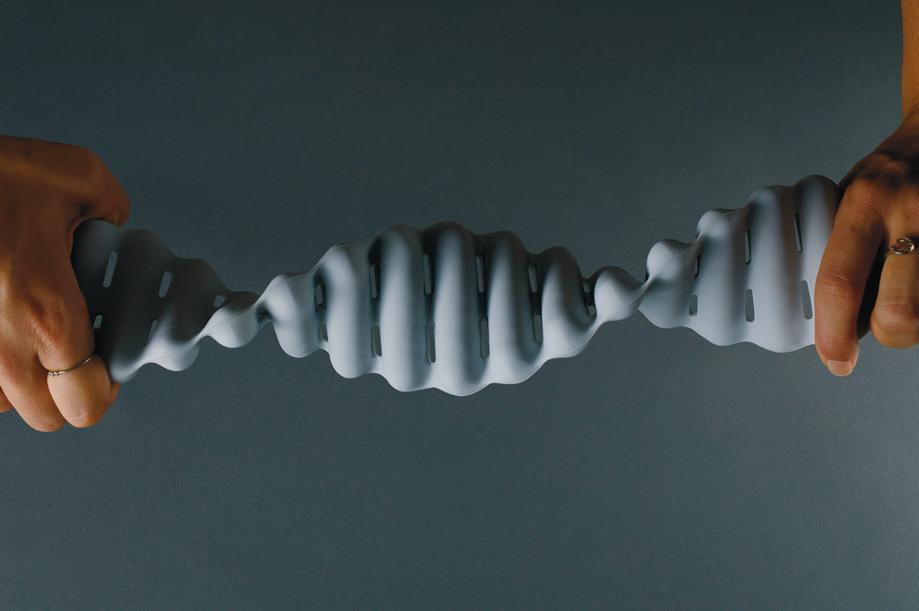

PATENTED FOLDS

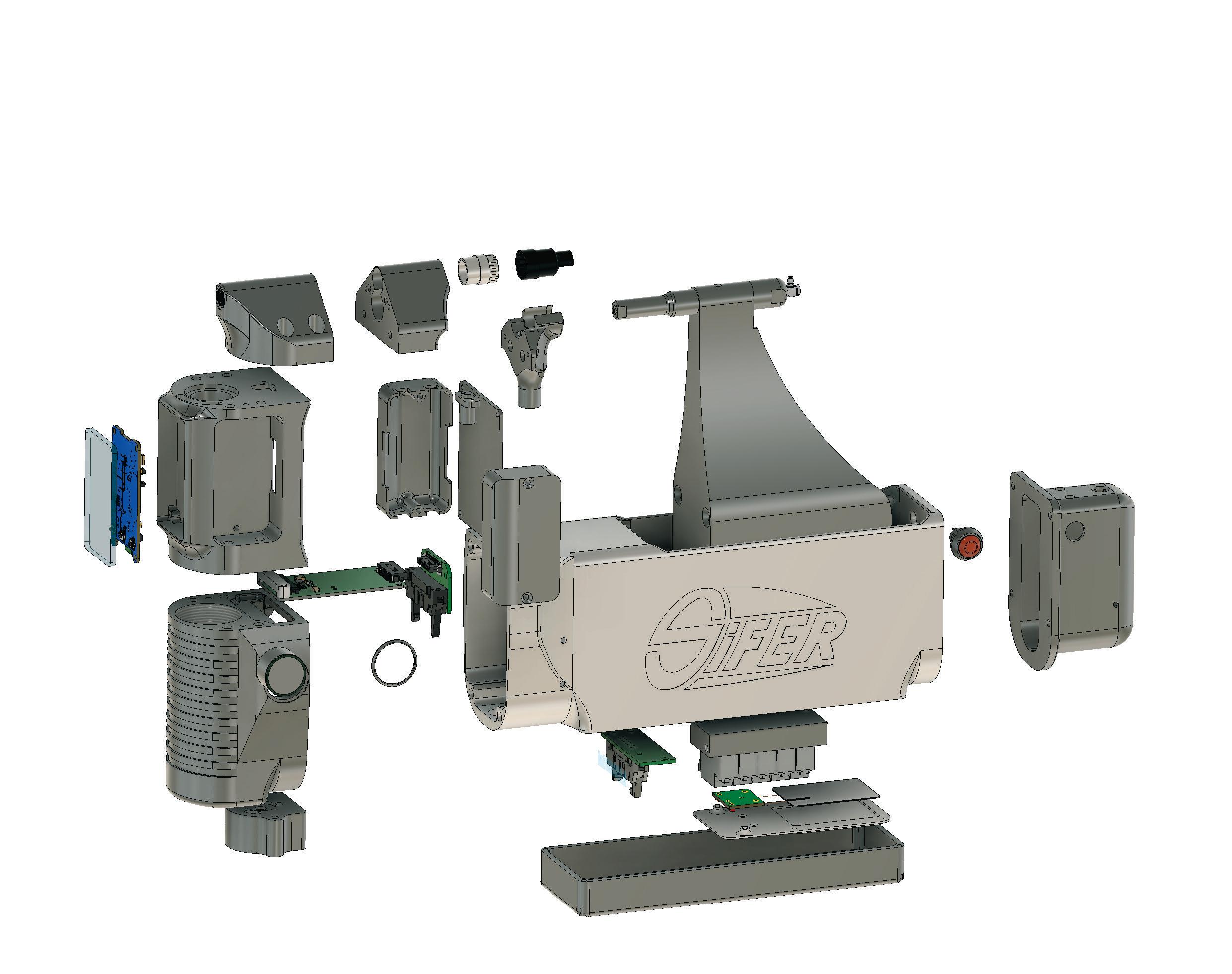

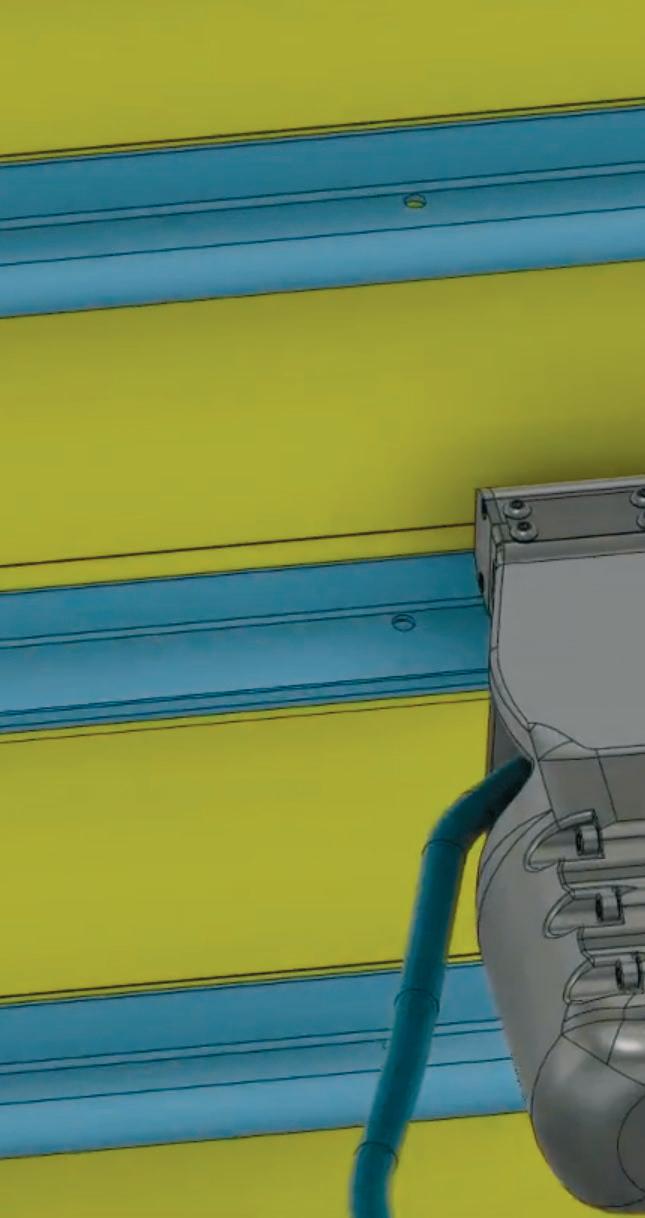

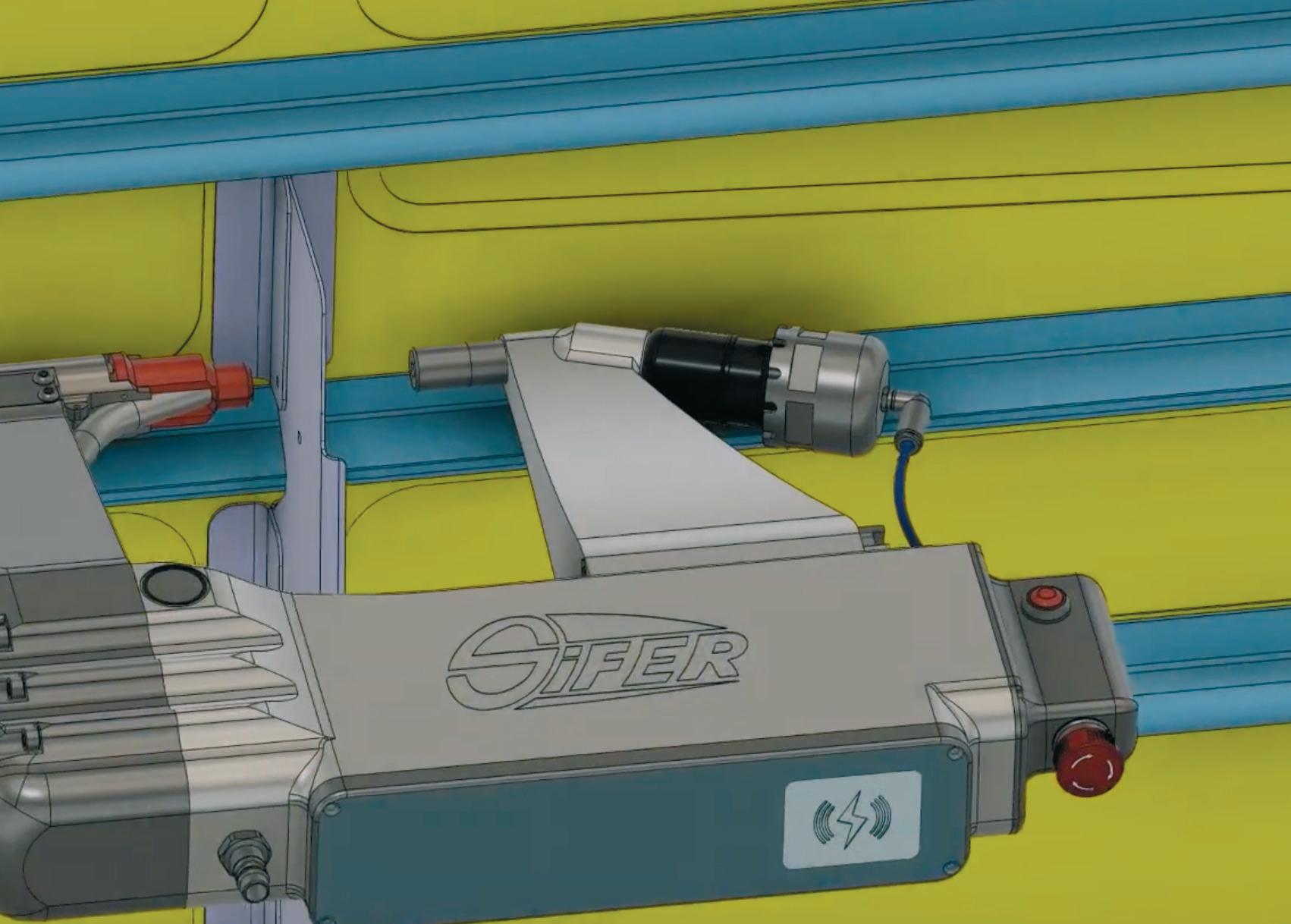

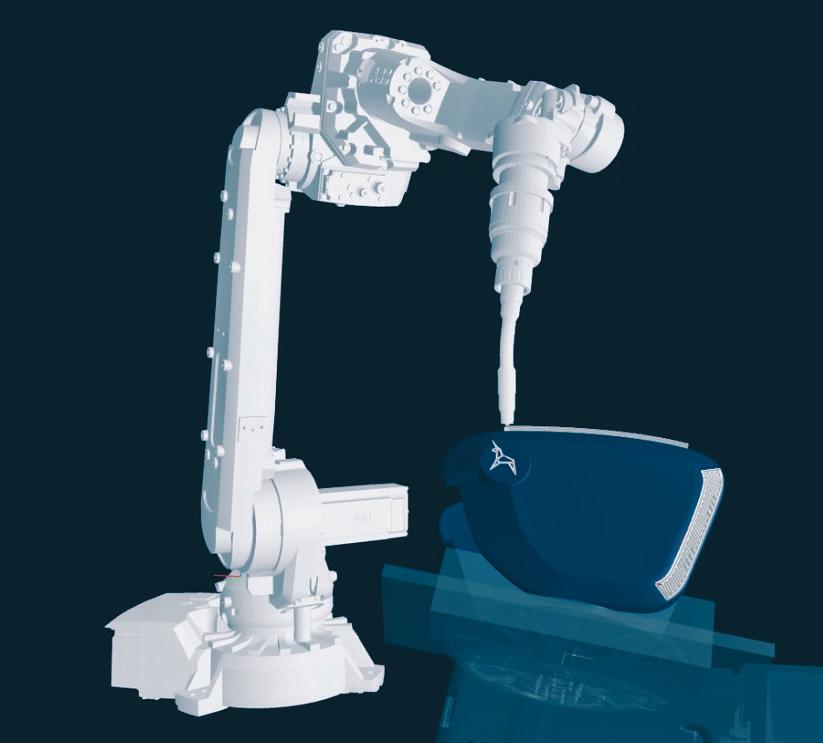

Parent company Stilfold’s patented industrial metal folding origami technology and its proprietary software Stilware are being fine-tuned with the help of robotics expert Adaxis, with the goal of creating localised micro-factories

QUICKER CITY SLICKERS

Zipping around town is a cinch, thanks to the Stilride’s twist-and-go throttle. The scooter has a top speed of 100km/h and a battery range of around 120km

LIGHT ANGLES

The ultralight folded monocoque steel chassis adds structural strength, reducing weight and the number of components associated with a traditional plastic and metal scooter, from around 120 parts to just 20

See Stilride’s Jonas Nyvang present @

2022

20 September Warwick

SAFETY MEASURES

The meticulously designed stopping system was co-developed with motorcycle brake specialist ISR and global tyre manufacturer Continental, in order to bring those 13-inch wheels to a halt in a flash

PRICE & AVAILABILITY

First models are due to roll out of the factory in Spring 2024, costing €15,000 www.stilride.com

STRONG AS

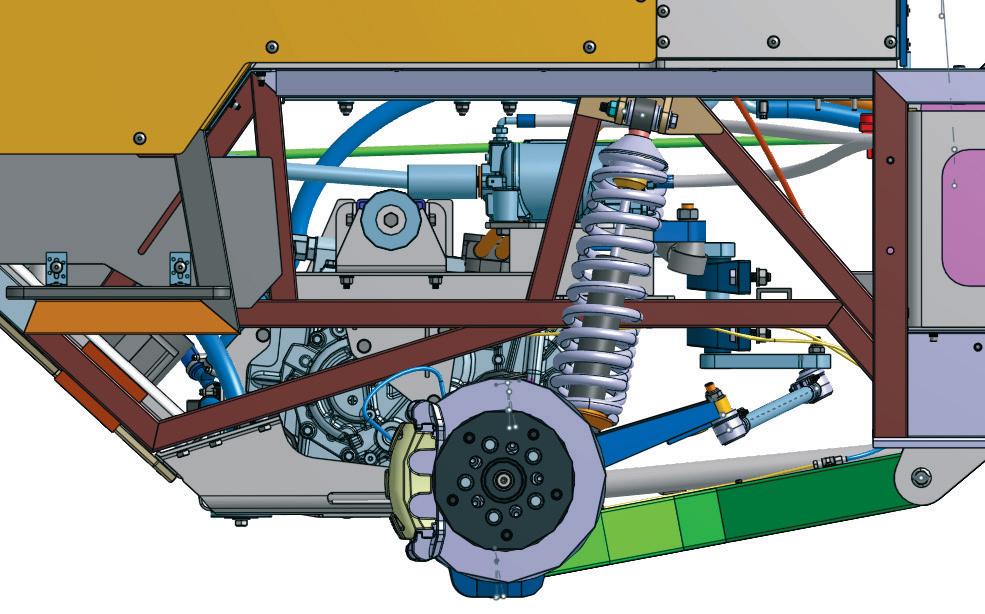

» The engineering team at OX Delivers has hit the bullseye with an electric vehicle designed for use in developing nations. A ‘fail fast’, iterative prototyping approach to design has kept its mission to build the ‘Uber for potatoes’ charging forwards, as Stephen Holmes reports

AS AN OX

In Rwanda, roads to market are rarely as smooth as this, but the OX track can tackle them all

COVER STORY

Getting crops to market in Rwanda can be a real struggle for the nation’s farmers. The terrain may be fertile in this small, landlocked country in the Great Rift Valley of Central Africa, but it’s not known as the ‘land of a thousand hills’ for no reason.

To add to the transportation challenges associated with steep gradients, fewer than 20% of the country’s roads are paved, and severe flooding and landslides during the country’s biannual rainy seasons frequently join the list of obstacles that motorised transport must navigate.

As Kristiana Hamilton, a member of the 14-strong design and engineering team at OX Delivers cheerfully puts it: “The Rwandan roads are considerably worse than I think was originally anticipated!”

The thinking behind OX Delivers dates back to 2013, when philanthropist Sir Torquil Norman and the Global Vehicle Trust (GVT) charity got together to focus on building reliable goods transportation specifically designed for the African continent.

End-of-life trucks from other regions of the world are frequently imported to Africa, but with age-related wear

and the rough terrain they are forced to negotiate, these quickly become too expensive for users in local markets to fuel and maintain. Alternatives include using bicycles, people or animals to move goods – all too slow and restricted in the loads they can manage to build prosperous businesses. And thus the problems of low incomes, inefficient value chains and food waste continue.

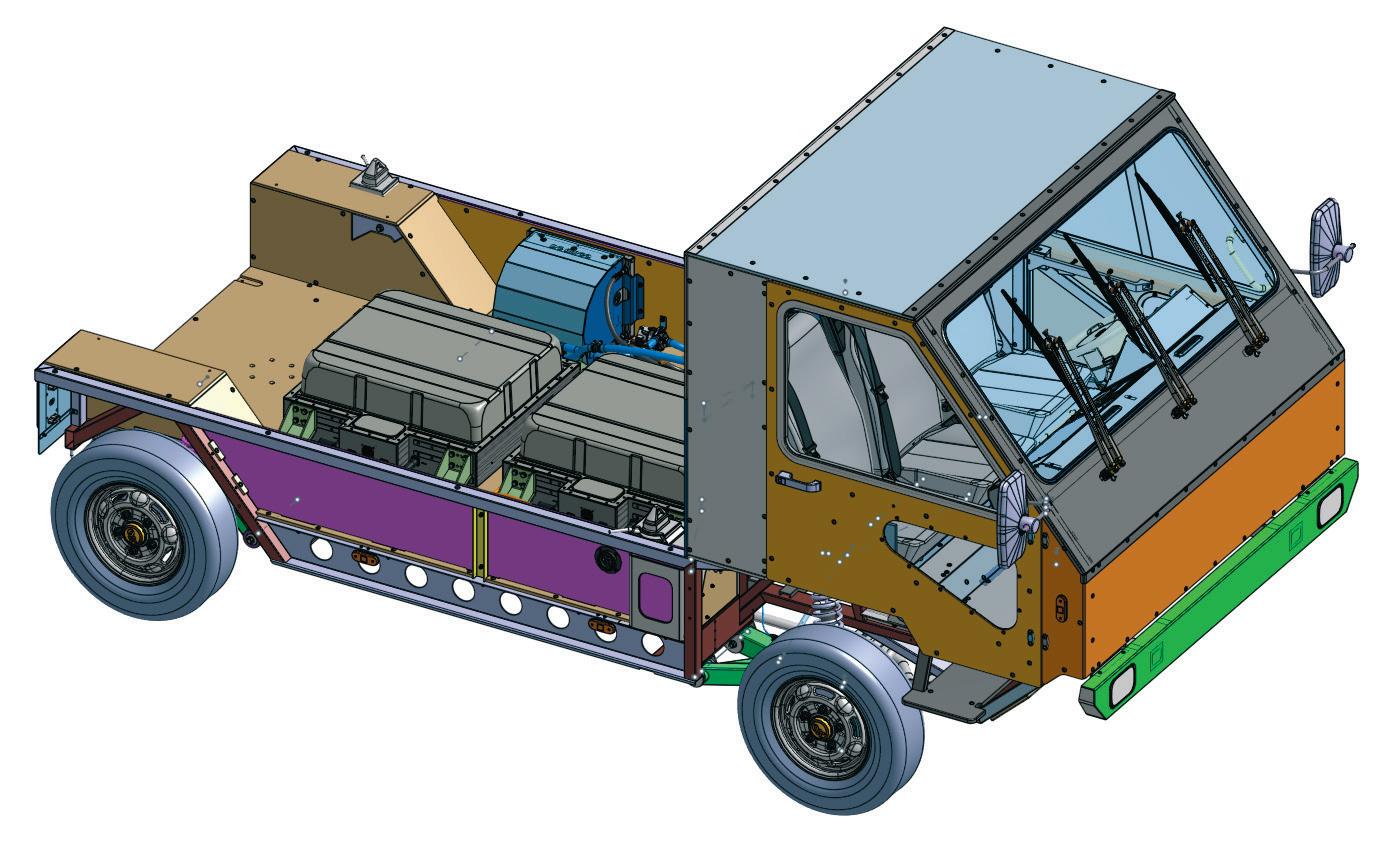

GVT’s response was to commission acclaimed South African-British automotive designer Sir Gordon Murray to create the original OX truck, and four diesel prototypes were built as innovative flat-pack products made of engineered laminated panels bonded to steel frames.

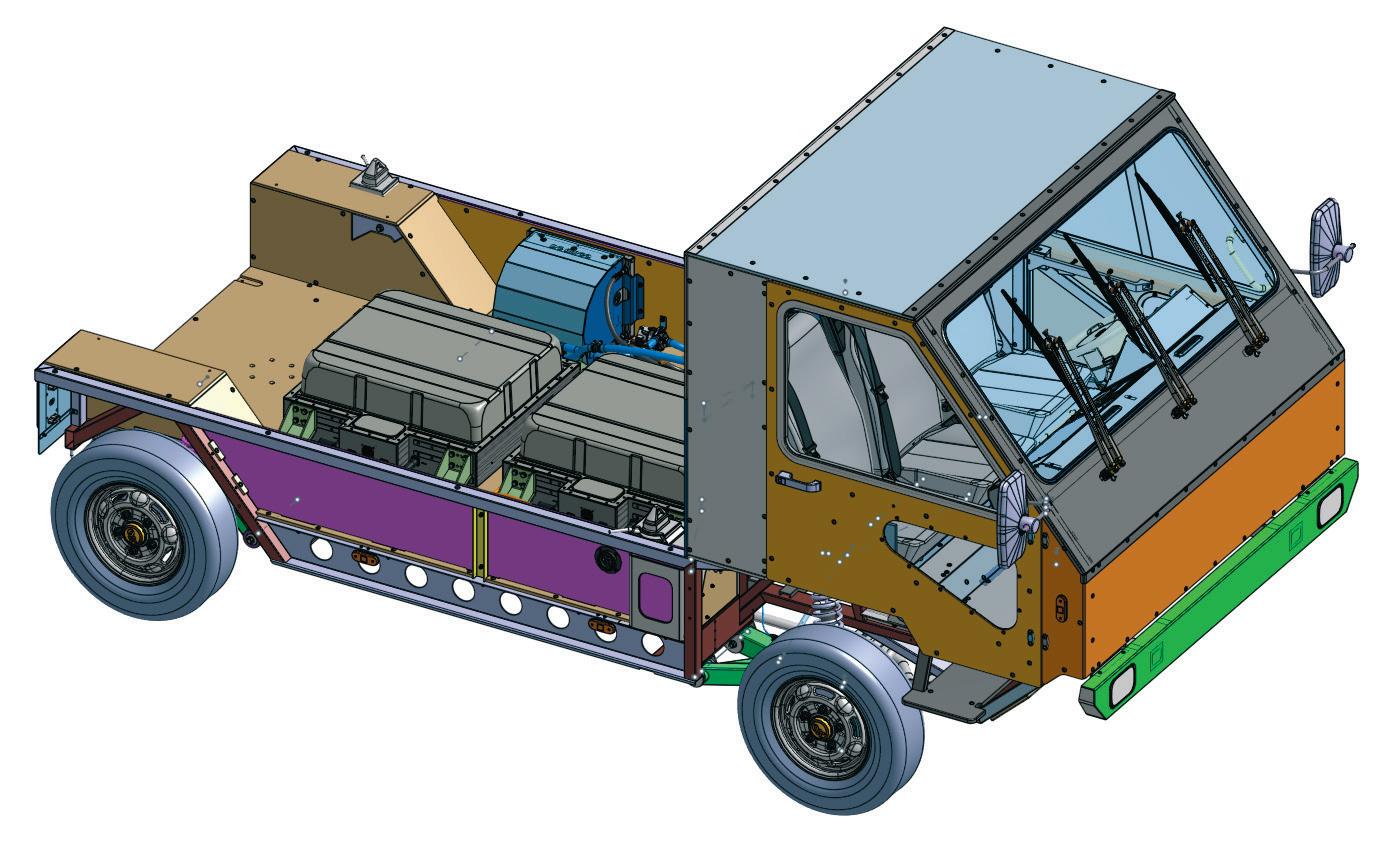

Later, in 2020, OX Delivers was established to create a scalable business model that would support the transition of the OX truck into an electric vehicle (EV) for emerging markets. This design overhaul was backed by funding from US AID, Innovate UK, and the Advanced Propulsion Centre among others.

The idea here is that farmers should be able to rent space on an OX truck to take their goods to market – or as the OX Delivers team like to refer to it: ‘an Uber for potatoes’.

A pilot scheme is now running in Rwanda, chosen for its centrality and its abundance of small businesses, as well its credentials as a forward-thinking country

20 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM COVER STORY

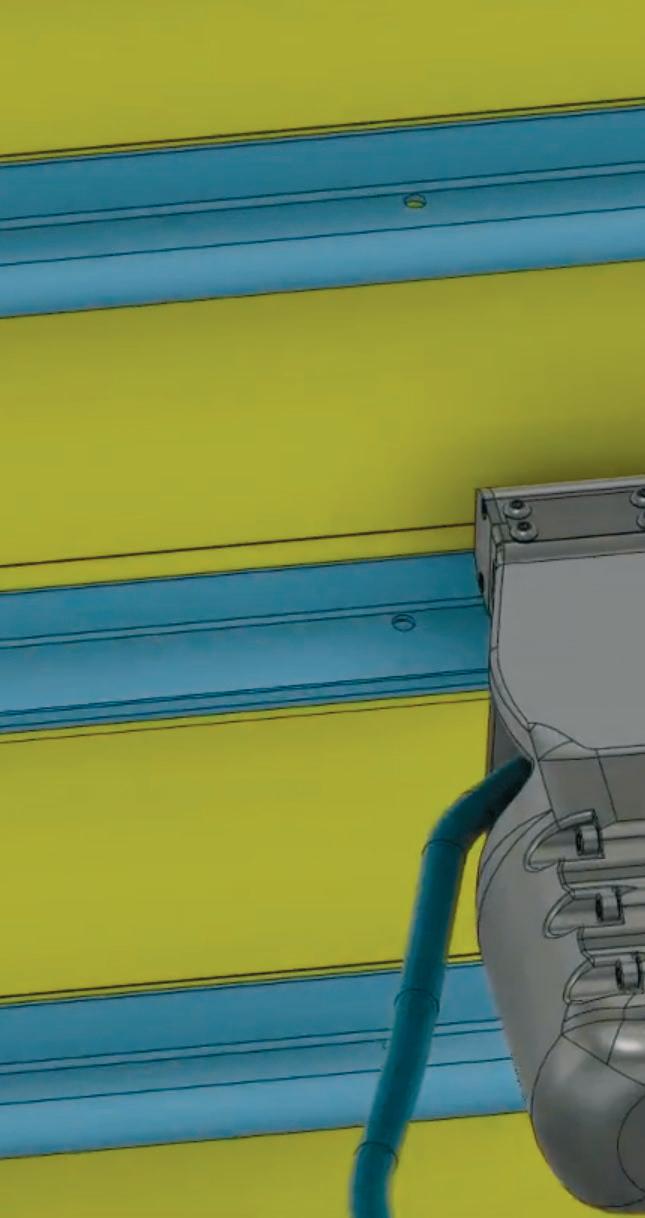

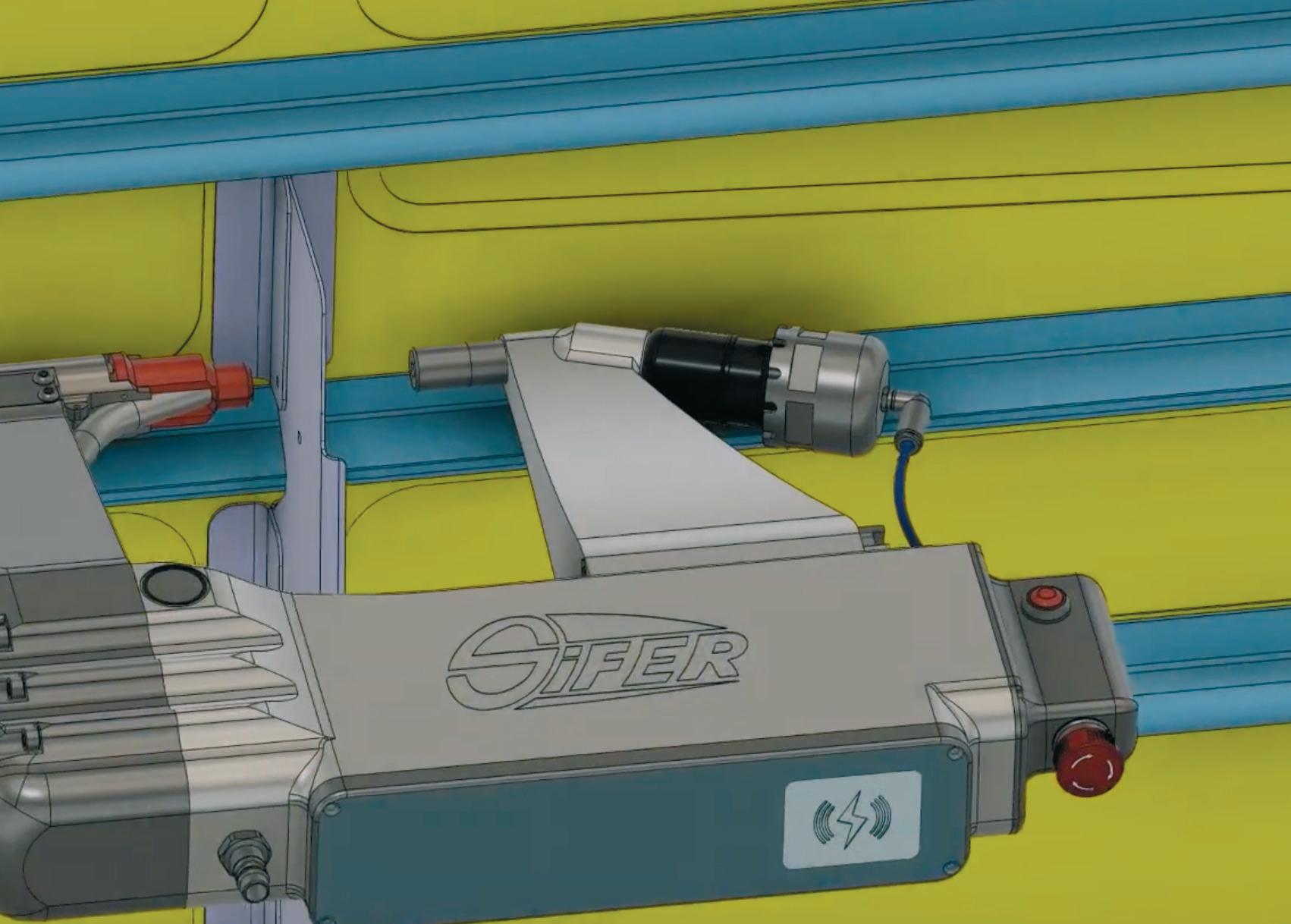

With the OX truck now upgraded to electric drive, Ox Delivers is working closely with key EV OEMs including Dana

that appreciates technology. It also has a relatively good electricity network fed by renewables (mostly hydropower and solar) – a necessity for any EV company.

CHALLENGING TERRAIN

Just as roads to Rwandan farms are seldom paved, the path to market for the OX design hasn’t been the smoothest journey, either.

Far from a straightforward swap-out to an electric powertrain, much of Murray’s original design had to be redeveloped.

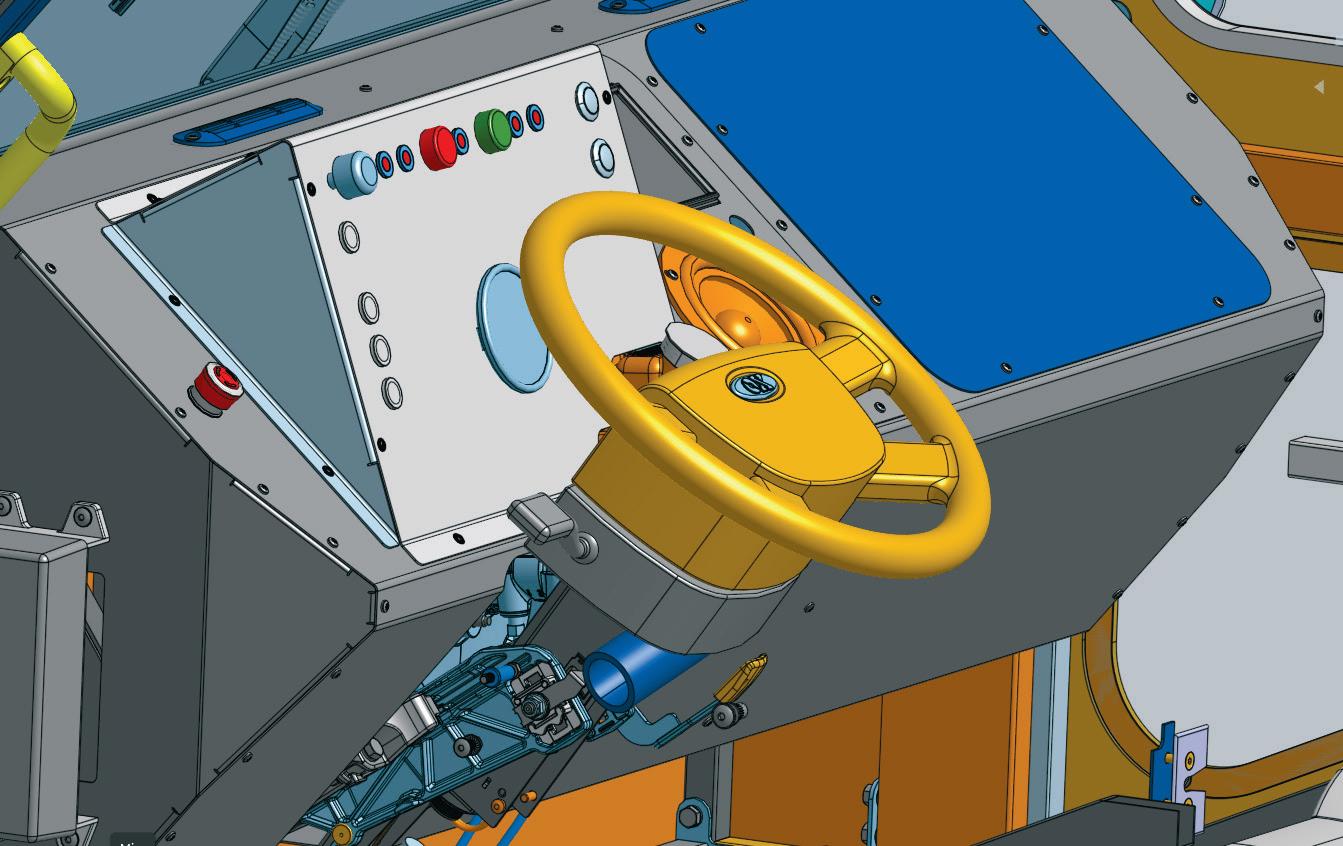

OX 1, a full EV conversion from one of the original diesel trucks, was shipped to Rwanda for in-market testing and feedback, only to find on arrival that the central driving position that Gordon Murray is known for in his supercar designs isn’t permitted on the country’s roads.

“It had to be converted at the port from central drive to left-hand drive, so that we could actually have the vehicle in the market to test,” says Hamilton, running through a list of changes that the team has had to assess, redesign and move forward on.

The original bench seat gave drivers no support on the rough roads, and its lack of adjustment made the ride deeply uncomfortable. “The Rwandan population overall is relatively short in stature, so if you can’t move that forward, you’ve got no support on your back and you’re sitting right at the step. So all of that changed,” she says.

For a vehicle destined to be carrying heavy loads in

challenging conditions, there was a lot to consider when overhauling the original design. Despite this, the transformation has happened quickly, with the OX team set up to ‘fail fast’. In other words, it has worked iteratively, identifying what won’t work, analysing what might work better, and then testing and repeating until the design is perfected.

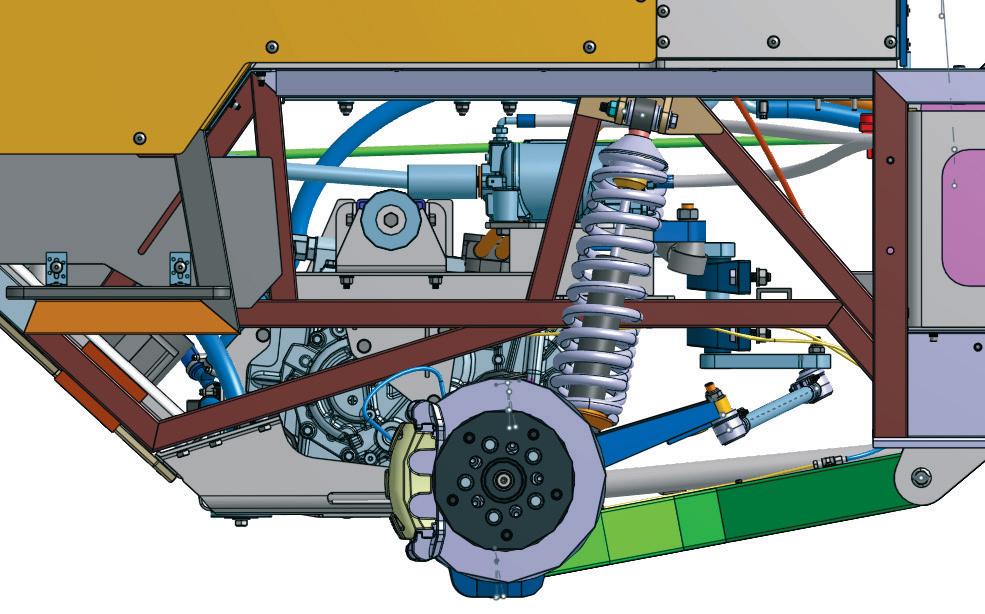

Hamilton explains that at the start of 2022, the team combined to look at the main issues, feedbacks and to define what needed to be core to the OX Truck. “We laid all that out – predominantly stuff like progress on the roads, a decent set of suspension, all these things – and we could filter [the team] out into different sections.”

Having split into pairs of engineers and brainstormed ideas, the team then reunited to plot the best path forward for each section and for the vehicle as a whole.

The original chassis was relatively robust, but after running tests on the ground in Rwanda, the engineering team quickly spotted some issues, particularly with cracks. The chassis, notes Hamilton, was also not made in a way that makes it easy to repair. This has big implications for the OX Delivers business model, since it will be running the trucks itself, rather than selling them to third parties. Truck uptime is critical.

“We’re currently going through an iteration of the chassis and we’re gradually redesigning the whole thing so it fits better for our market and can be easily repaired,” she says. “We know it’s going to be durable and it’s made of materials that are available in this market, which is one of the big issues.”

Meanwhile, the original steel box section design works well – until you need to make repairs in a market where you can only buy bent sheets, which makes it difficult to make a full box section and have it be as strong as it needs to be.

“We work in an agile environment, where we work in two-week sprints. And, if we find something during that sprint, then we can go, ‘Actually, this isn’t going to work out’ and it makes it really easy for us to change direction,” she says. “We try to be as fluid as possible.”

With this design approach being guided by data fed back from the OX team running vehicles in Rwanda, the unloved original cab has been redesigned. An electronic drive unit (EDU) has been developed with EV experts Dana and the vehicle architecture has switched from ineffective front-wheel drive to more powerful rear-wheel drive with the option to adapt to all-wheel drive to deal with the harsh terrain.

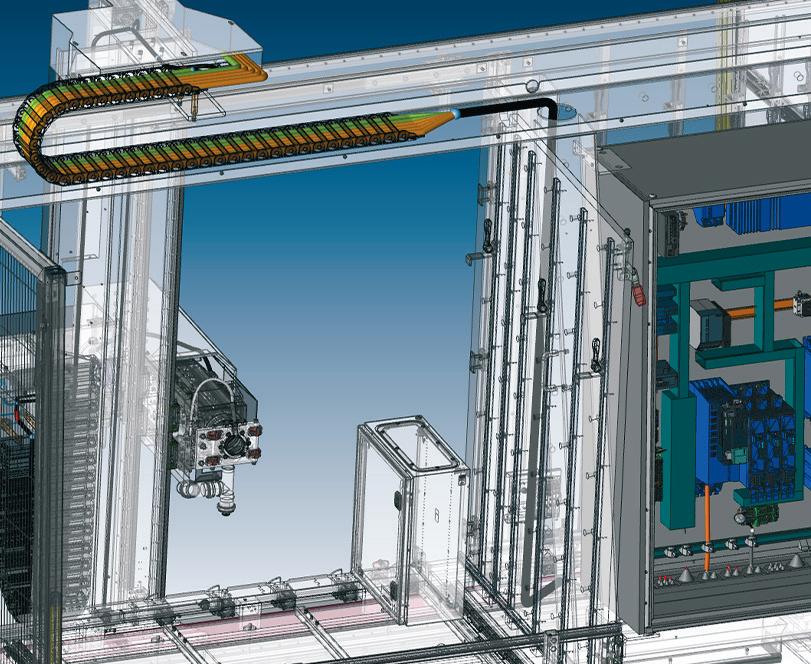

The powertrain team has devised new brackets to hold the revised EDU, quickly working through ideas in Onshape, testing them through Onshape Simulation and iterating them several times before having physical prototypes made.

“We’re trying to move as quickly as possible, and our agile framework allows for that,” says Hamilton.

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 21

1 2 3

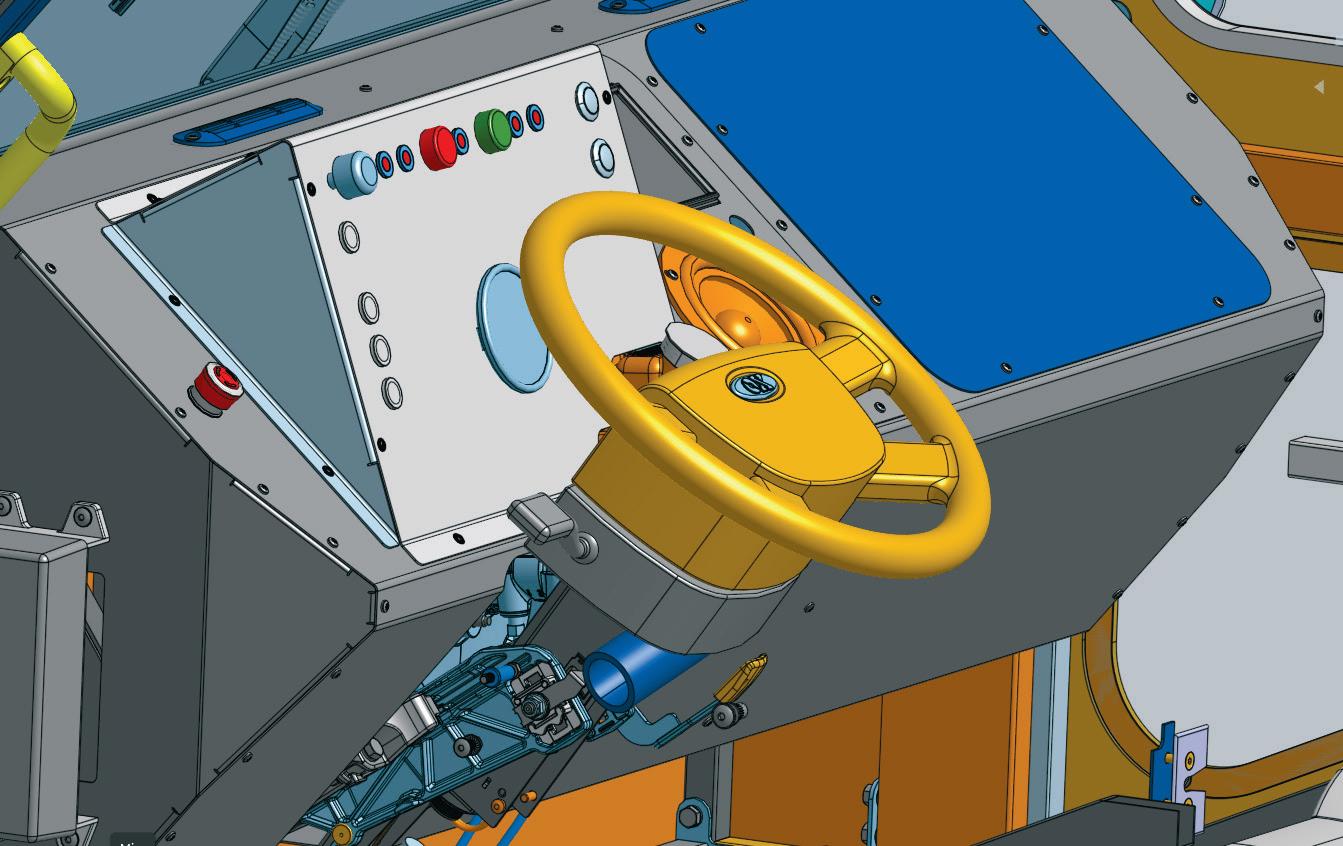

● 1 The 3D CAD design for the Ox Truck was created in cloud-native Onshape

● 2 ● 3

A key priority for testing in Rwanda was switching the original cab design to left-hand drive

‘‘ We know it’s going to be durable and it’s made of materials that are available in the market, which is one of the big issues

Kristiana Hamilton, Engineer ’’

ALWAYS MOVING

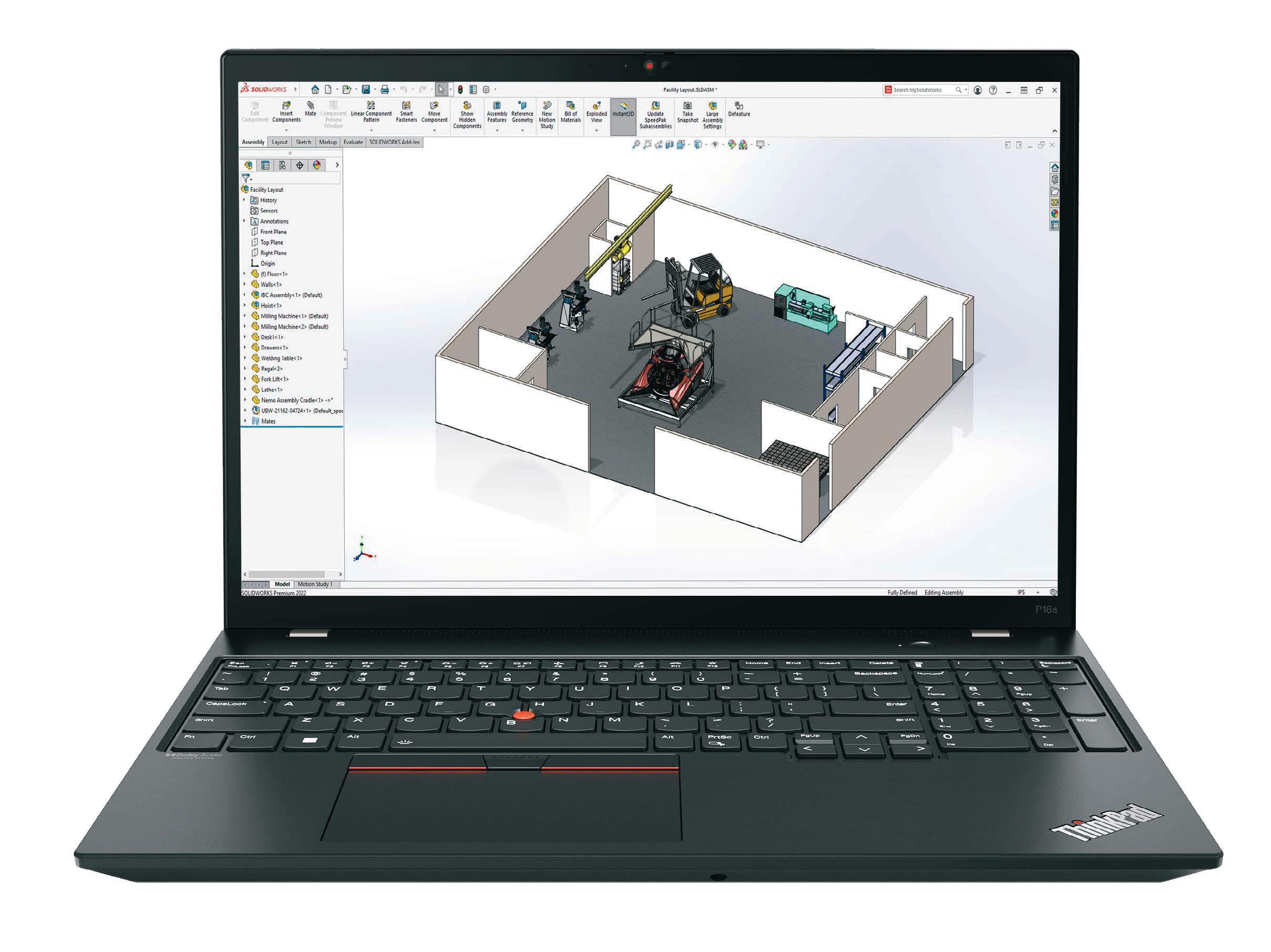

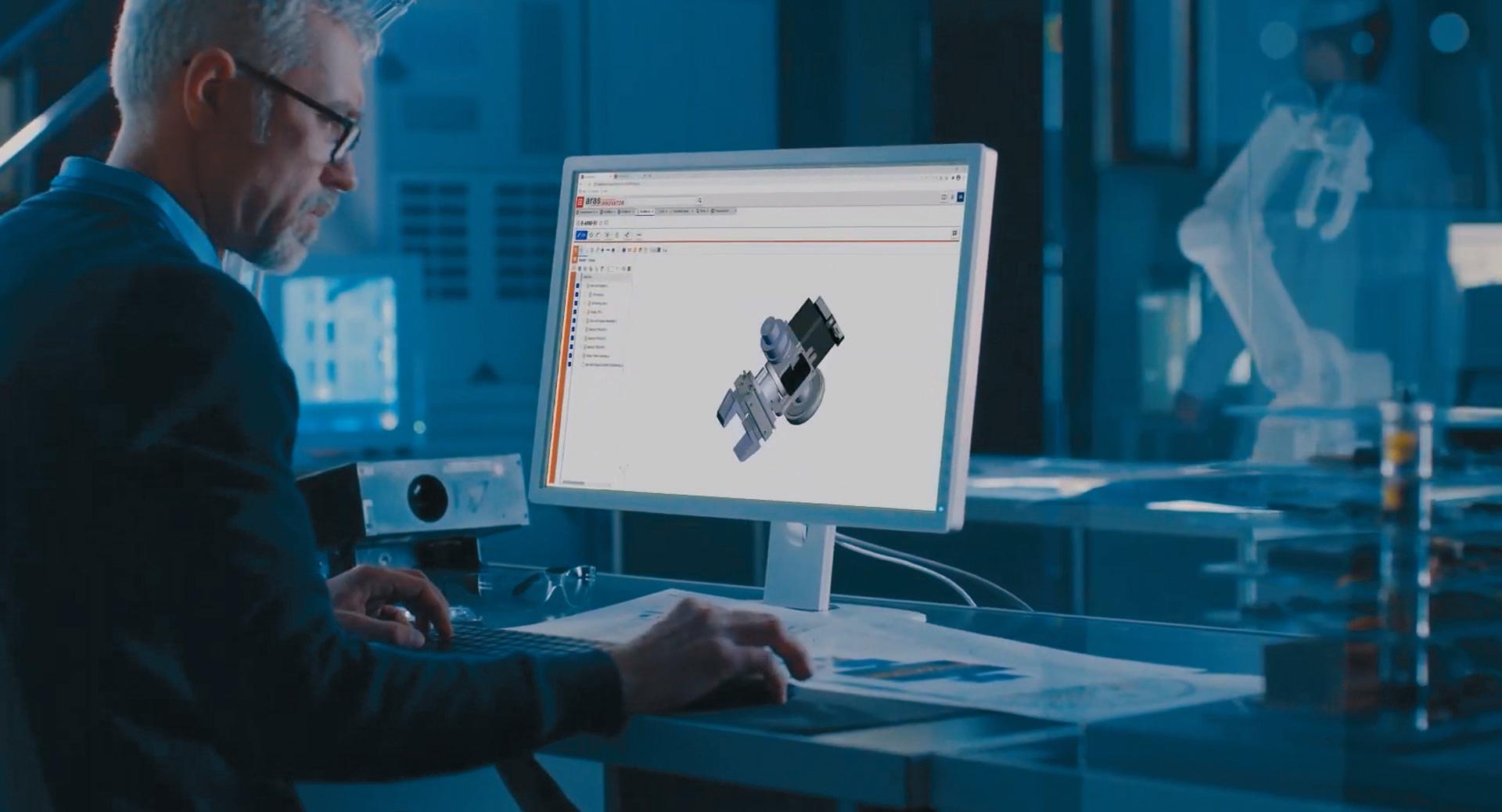

The fluidity of the team within OX Delivers means that the design team is constantly lending its expertise across multiple sections of the truck development. Hamilton explains that she’s recently worked on suspension, steering and chassis, and will be moving into cab improvement at some point in the near future. Since everyone needs access to the latest versions of CAD data, using cloud-based Onshape made perfect sense. “As a start-up, we can’t really afford to have servers that hold all of our data,” says Hamilton, “and Onshape was super easy to access for us.”

She also praises Onshape for its ease of use. “It’s incredibly intuitive and I think that’s been one of the biggest wins for us. We have a variety of engineers, with a variety of different skill sets, but a lot of people are expected to use CAD.”

Take, for example, one team member in particular, a suspension expert who works in kinematics. “He worked out how to do that in Onshape, which was fabulous and it looks great. It really helped us not just with understanding our suspension, but also understanding our packages, how we need to design things. He was never fully confident in CAD, in terms of modelling, but he’s been able [to work in Onshape] because it’s so easy to just pick it up and do it,” says Hamilton.

The customer service offered by Onshape is “incredible”, she adds. “If there’s anything that’s a problem with the software or that we’re struggling to do, they’re really supportive. We have direct contact with them.”

Also proving its worth in Onshape are its custom features. These are created by the wider Onshape community in the native Onshape code, giving the OX team a way to easily find feature scripts and tools to tackle challenges for which the software might not have an immediate answer.

22 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM

‘‘

’’ 4 7

As a startup, we can’t really afford to have servers that hold all of our data, and Onshape was super easy to access for us. It’s incredibly intuitive and that’s been one of the biggest wins

● 4 ● 5 Development models of the truck take shape at Ox Delivers’ headquarters in Warwickshire, UK

● 6 Engineer Kristiana Hamilton behind the wheel of an OX truck

● 7 Loading the cargo bay of an OX truck before it heads off to market

COVER STORY 5 6

● 8 The Ox truck will be produced as a flatpack in the UK before being shipped to Rwanda and assembled there

“We’ve started to use this a lot more recently,” she says. “Even if Onshape doesn’t have the [desired] functionality within the base software, you can find it elsewhere. It’s been really interesting lately, working out how best to utilise that software and the different tools that we can find.”

Ox works closely with partners, including transport OEMs Dana, Penso and Potenza. These organisations help iterate on the truck design with the latest CAD data and even test some prototype units and systems on the physical OX test units.

Both sides want to work with the latest CAD data as much as possible, although the major OEMs tend to work in Catia or NX, for which typically the OX team rely on importing STEP files into Onshape.

Penso has gone a step further: such is the cost and accessibility of Onshape that it has assigned two of its engineers to model files from their native Catia format directly into Onshape. The Penso team is trained not only in Onshape, but also on how OX manages its CAD structure, making it faster to integrate models regardless of complexity.

The existing truck CAD model is split into cab, base and powertrain, leading off into different subsections within that. However, more recently the team has been looking to alter this to cab, front section, middle section and rear, with powertrain in the middle.

“That allows it to be modular and lets us do that individual testing, because it’s not like a traditional vehicle, where the whole chassis is integrated. You have these split sections that all connect to one another and allow you to do these individual tests on specific areas, rather than having to have a full truck design to be able to do that.”

The team outsources some simulation work to partners and specialists in specific scenarios such as crash testing, but by splitting up the design, it allows these trusted third parties to work quickly on the design.

ONLINE DELIVERY

Working using a cloud-based system means that team members in Rwanda can also access and update the latest data, remaining connected to the process

One of the UK team members is now based in Rwanda, where he is gathering a lot of design data from the field, from real-time feedback from testing different duty cycles to information on issues spotted during maintenance. He also has access to the full CAD model.

Another key member of the Rwanda team is a designer focused on the goods storage section at the back of the truck. Here, a lot of work is going into ensuring that the rear canopy is the right size and equipped with the right tools for the job, including scales to ensure customers don’t overload the truck.

Designers and engineers from the UK regularly head out to Rwanda in order to get a first-hand feel for the market, conditions and customers, while mechanics from the Rwandan team travel to the UK to undergo the necessary high voltage training needed to maintain EV systems. This back and forth greatly assists both digital and in-person knowledge-sharing.

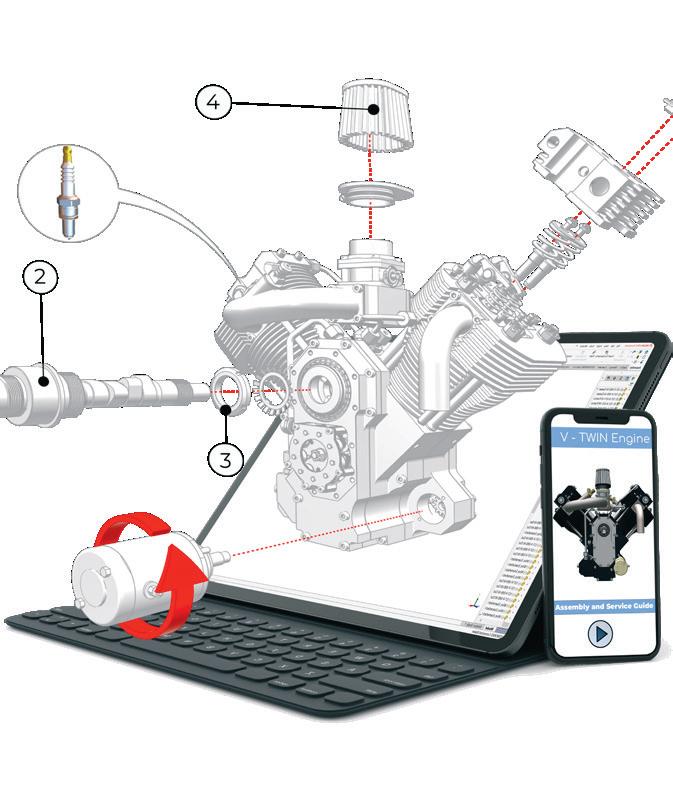

Once the team has the production model ready, the plan is that regular shipments from the UK will form the basis for flat-pack delivery. So the trucks will be built in the UK and then assembled by the OX team in Rwanda, where thought is already going into sharing assembly training guides that leverage the existing CAD data.

Soon, it is hoped, an entire network of OX Trucks will be successfully transporting produce across the hills of Rwanda, before the company expands its reach across borders into neighbouring countries. At the same time, OX will be raising the prosperity of its users through a fit-for-purpose design that puts EV technology at the heart of improving economies. Not even Rwanda’s two rainy seasons can dampen the exciting promise of a better future for its farmers.

www.oxdelivers.com

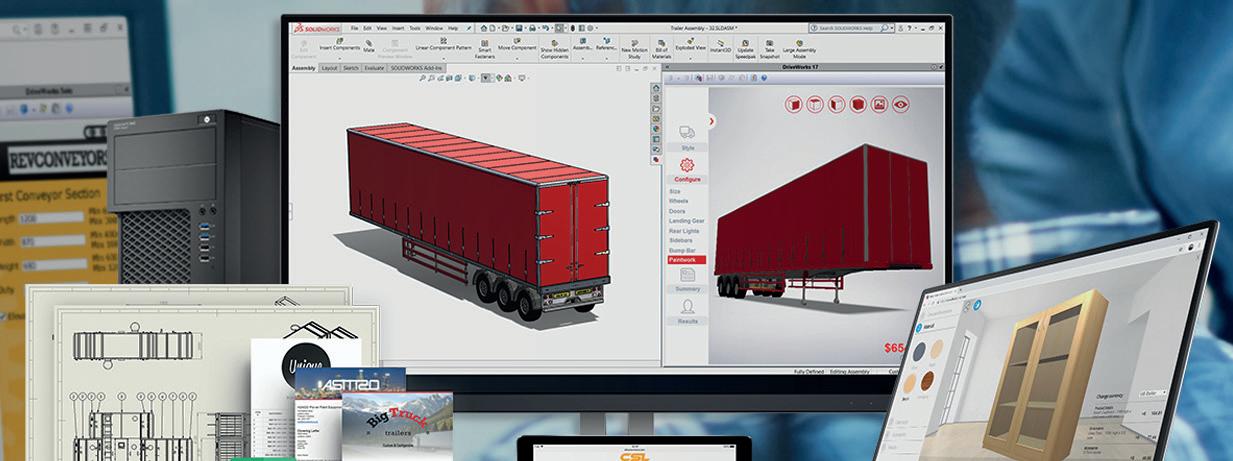

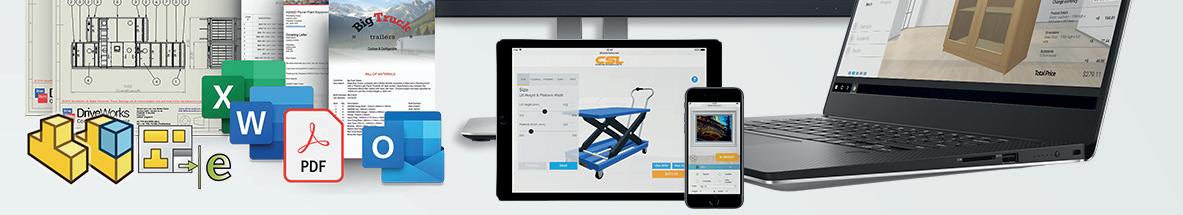

» Welcome to The D3D 30, our round-up of 30 new technologies from around the world that we firmly believe could deliver a major boost to your product development work

THE D3D 30

24 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM

The past 12 months have seen design and engineering teams around the globe working faster and harder than ever before. What better way to keep ahead of unseen challenges and competitive threats than implementing some of the latest technologies on the market?

Selected from companies around the world, the D3D 30 features everything from AI-powered sketching tools to software for manufacturing process observation. Our hope is that you find something here on our list for your own personal toolbox, making you more productive in 2023 and beyond. The products listed, we believe, have the potential to light up your development process, putting you in prime position for taking on even more ambitious projects in the months ahead.

Some of these technologies come from startups that we’re excited to see take their first steps out of stealth mode. Others come from more established companies, working hard to develop

new capabilities within their existing systems or launch brand-new tools to take customers in new and thrilling directions.

We’re delighted to showcase this illustrious group, selected entirely on merit. Our listing includes new takes on modelling, innovative ways to tackle big data challenges, fresh approaches to 3D printing, the very best of AI and more – all with the aim of helping our readers design and build the products and systems of the future.

Previous lists have highlighted new technologies that we’ve watched grow in terms of capability and adoption. Speaking with readers, we know that many of them have since been adopted in your businesses and become vital to your workflows.

We have faith that the Class of 2023 will offer you many more such candidates – and hopefully, you’ll have the chance to get hands-on with many of these products, including at DEVELOP3D LIVE (www.develop3dlive.com) , which returns to the UK on 20 September 2023.

1000 KELVIN AMAIZE Monitoring metals

For 3D printing in volume manufacturing, products like Amaize will be critical in boosting output quality and possible quantities.

Specifically designed for metal 3D-printed parts, Amaize predicts printing errors and defects by analysing material, machine, toolpath and scan strategies, to eliminate distortions and reduce overheating and support structures. AI is at play here, of course, helping to identify problematic regions in builds. It does this in the background, notifying you when it’s ready and offering ready-made optimisation strategies.

In this way, users ensure they have a 3D printing workflow as close as possible to guaranteed before exporting the file to their printer.

www.1000kelvin.com

ALTAIR SIMSOLID CLOUD Simulation without boundaries

Having acquired SimSolid back in 2018, Altair has continued to enhance the product. By enabling it as a cloud-based software, its nextgeneration simulation technology is now available from any web browser, anywhere and at any time.

Altair certainly seems confident in what it’s selling, with CEO James Scapa going as far as to suggest that “anyone using conventional finite element tools will be left behind if they do not embrace this technology soon.”

Being cloud-native, the software looks to eliminate the need for geometry simplification and meshing, the most time-consuming aspects of the process, ramping up the speed for real results and allowing more complex models to be solved in minutes rather than hours.

www.altair.com/simsolid

ARTEC RAY II

Big scan double act

Developed in collaboration with Leica Geosystems, part of Hexagon, the Artec Ray II has the ability to capture large products and systems ten times faster than the original Artec Ray.

Its 36 MP three-camera system supports a 3D point accuracy down to 1.9 mm from 10 metres.

The Ray II’s big onboard touchscreen and clear user interface add to the sense that this is a high-end 3D scanner that anyone can get to grips with. Yet the big trick up the Ray II’s sleeve is its data compatibility in Artec Studio software with data from other Artec 3D scanners, such as the wireless handheld Artec Leo. This lets users provide comprehensively detailed scans of selected areas of bigger objects and scenes being captured.

www.artec3d.com

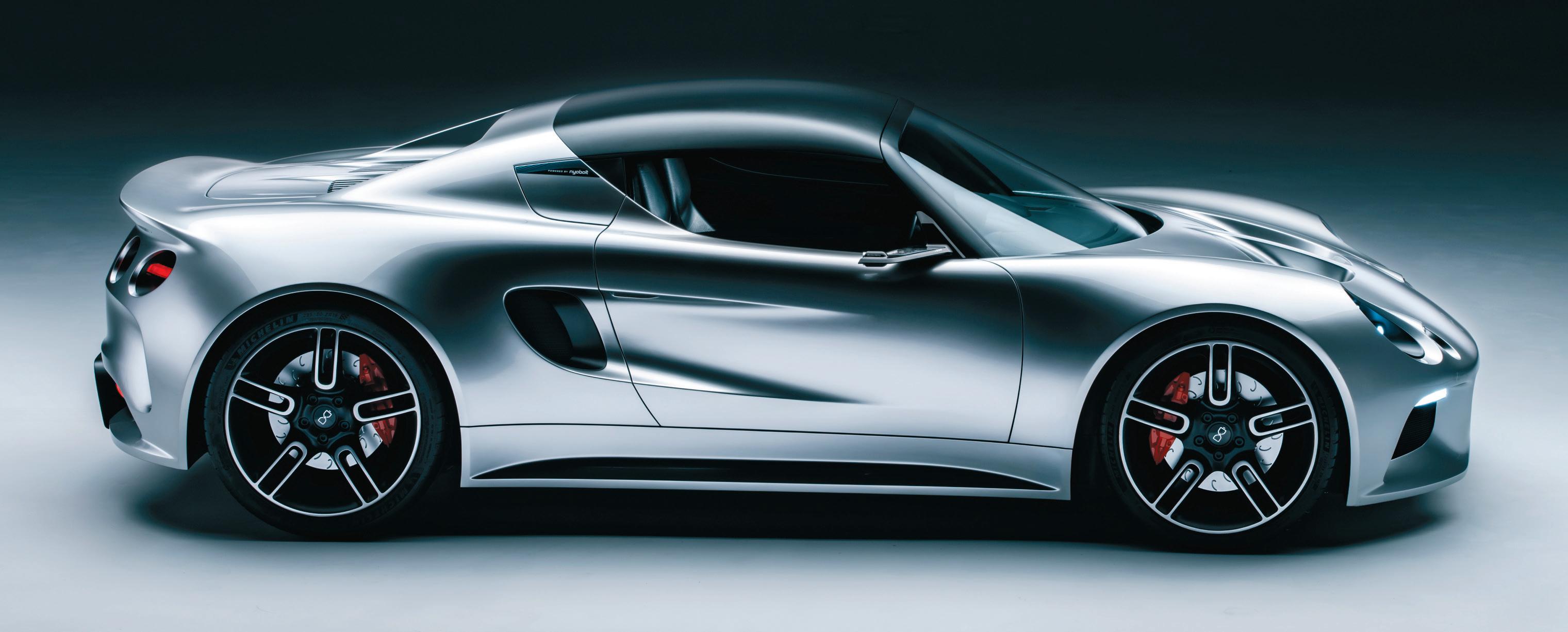

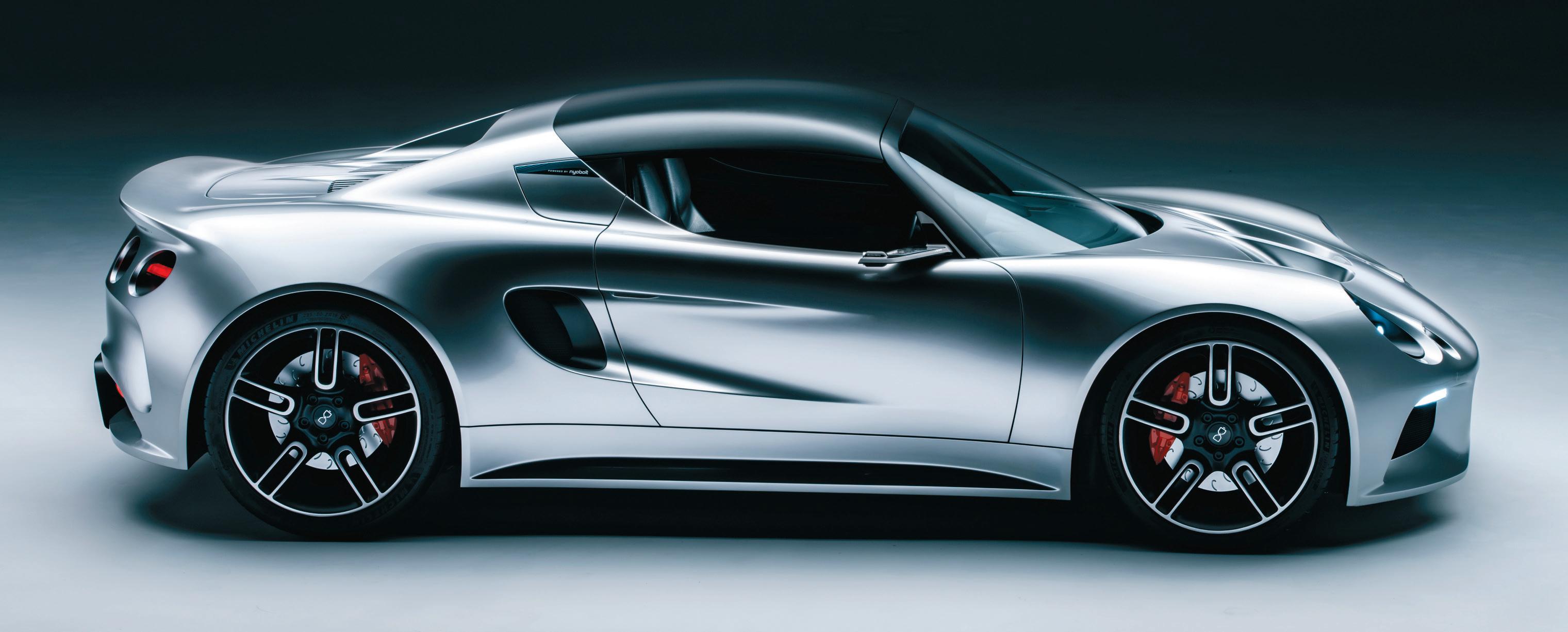

AUTODESK ALIAS X VRED 2024 Smooth automotive

A decade on from its acquisition by Autodesk, VRED really feels part of an automotive design suite capable of taking on all comers.

While v.2024 has seen Alias add more control and time-saving surface modelling tools, it’s the major overhaul of the user experience that users will probably notice most.

VRED has shifted closer to the surfacing tool in both appearance and usability, with similarities including elements such as its icon sets and window management. By sharing a common design language, the aim has been to make transitioning between the two tools more seamless and fluid, and easier to start using for those still holding back from using VRED in preference of other renderers.

www.autodesk.com

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 25

CADMIO CADMIO

The Apple iPad is already a staple among designers, so it was only a matter of time before quick and easy visualisation tools emerged.

Step forward Cadmio, a real-time renderer that quickly imports a .STEP, .STL or .OBJ model and lets you manually tweak and tune colours, materials and lighting. Optimised for a touchscreen interface, it’s as simple as picking up the device and creating some eye-catching variants whenever inspiration strikes.

With a catalogue of over 100 curated material presets and HDR backgrounds for all kinds of products, with new options added frequently based on user requirements, the gesture controls and sliders make for fast scaling and orientation.

www.cadmio.io

BASF FORWARD AM ULTRASIM TESTPAD Learning lattices

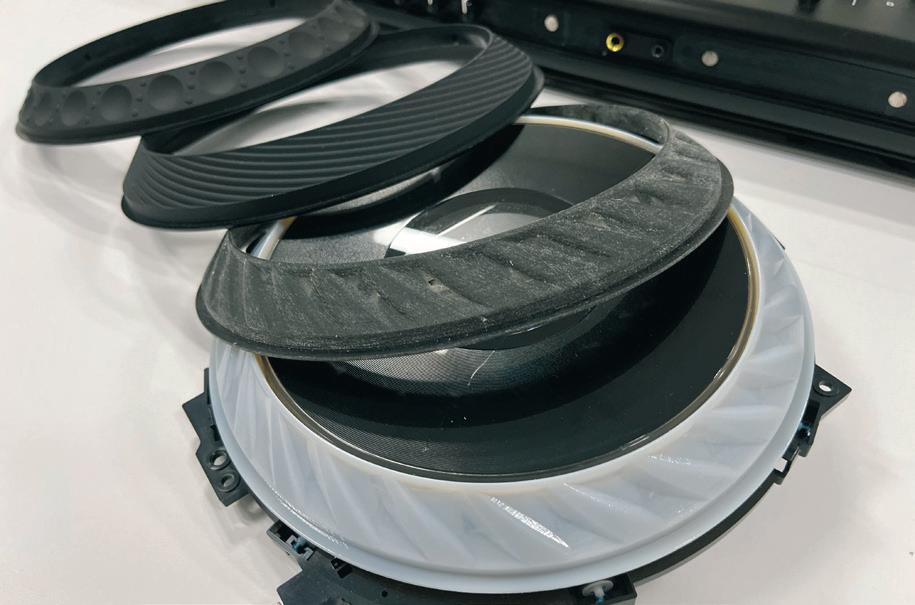

With an enviable reputation in the world of AM materials, BASF Forward AM has moved into promoting the design capabilities of 3D printing, launching its UltraSIM product line to open up the world to lattices.

UltraSIM 3D Lattice Engine, powered by 2022 D3D 30 entrant Hyperganic, enables users to quickly generate validated lattices at an extremely low price point. But if the software isn’t enough to help get your head around the physical properties of a lattice, the UltraSIM 3D Lattice Design Test Pad acts as a touch-and-feel sample chart for lattice parameters, with specific examples for footwear, protection and seating applications. The goal? Helping you find exactly the right lattice for the job.

www.forward-am.com

CLOUDNC CAM ASSIST

A CNC co-pilot

CAM Assist from CloudNC is billed as a CAM programming co-pilot, capable of generating machining strategies in seconds at the click of a button.

Currently available as a plug-in for Autodesk Fusion 360, it’s able to create machining strategies for 3-axis parts in short order, slashing lead times and freeing-up experienced programmers for more demanding jobs.

Using computational optimisation and AI inference to rapidly determine the right strategy and toolset to manufacture a part, along with the most appropriate cutting speeds and feeds from the user’s library, CAM Assist should be on the radar of anyone looking to tackle precision manufacturing while fending off rising costs.

www.cloudnc.com

COGNITIVE DESIGN SYSTEMS COGNITIVE ADDITIVE Generative

for real

Cognitive Design Systems’ (CDS) machine learning tools for 3D modelling have branched out in the direction of 3D printing and toolmaking feasibility. Tools for the former reduce the time needed to perform build prep and part studies through automation.

Designs can be analysed for performance, manufacturability and cost. Risks such as delamination, heat accumulation and surface roughness can be assessed. The most recent update adds a carbon footprint calculator, for a complete view of the cradle-to-gate pathway.

CDS Additive is already integrated with Stratasys’ GrabCAD software, so you might already have these tools at your disposal.

www.cognitive-design-systems.com

DELL PRECISION 5680 Performance meets portability

Dell has done it again with this sleek 16-inch mobile workstation that boasts the smallest footprint on the market. It’s a superb, well-built machine, which also stands out from the crowd with its stunning UHD+ OLED InfinityEdge panel and haptic trackpad.

While it can take up to an Intel Core i9-13900H CPU and Nvidia RTX 5000 Ada GPU, it’s arguably best configured with the CAD and entrylevel viz-focused Nvidia RTX A1000 or RTX 2000 Ada.

Even though EPR technology allows more power to be delivered through USB-C (165W versus 130W), such powerful processors always benefit from more, which is where the 240W Precision 7680 Workstation comes in.

www.dell.com

26 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM THE D3D 30

iPad viz tool

DELTAHUB CARPIO 2.0 All in the wrist

Whipping your mouse around a desktop all day is a sure-fire route to long-term wrist problems, hence our interest in what DeltaHub is doing with its Carpio range.

Keeping the wrist elevated roughly a centimetre from the desk maintains it at as natural an angle as possible, and takes pressure away from the wrist and towards the palm. Most importantly, the entire support glides across a desk mat, letting you move your entire arm and reducing damaging rotational movements.

While the first iteration was built using dozens of prototypes and 3D scans of hand moulds, the second variant has been built on the feedback of some 20,000 users. It’s a slick way to reduce the risk of carpal tunnel syndrome.

www.deltahub.io

FORMLABS FR RESIN Keeping it cool

In the year in which Formlabs launched its automated 3D printer fleet technology and expanded its resins portfolio, it might have been easy to miss the arrival of the company’s new, certified flameretardant material, FR Resin.

FR Resin is UL94 V-0 and FAR 25.853 certified, both key requirements in many hazardous environments. In other words, parts built from it will have the necessary flame, smoke and toxicity (FST) ratings to go straight into operation.

Marry these capabilities with the level of detail that Formlabs printers deliver, and you’ve got a great combo for delivering electrical connectors, high-temp jigs and fixtures, underthe-bonnet automotive components, and interior plane and rail parts.

www.formlabs.com

HEXAGON NEXUS Building a network

While other vendors have focused on building tight-knit, brand-specific platforms, Hexagon has chosen a different approach, opening up its Nexus platform to third parties in its bid to connect data and machines.

With real-time collaboration and feedback between engineering and manufacturing, Hexagon says Nexus for Developers provides the tools necessary to enable anyone to connect equipment, data and processes and get insights in real time, in context and in one place, driving better informed decision-making.

After all, whether it’s data from the latest million-dollar 3D printer that you’re considering splurging on, or from a workshop full of kit you already own, you can only act on the data you can access.

www.hexagon.com

HP Z2 SFF G9 Remote control

This super-compact workstation made its way onto the D3D 30 last year, and while it has since had a significant 13th Gen Intel Core CPU upgrade, that’s not the reason for its reappearance on this year’s listing.

The fact is that this compact workstation is playing an increasingly important role in centralised workstation deployments.

For each HP Z2 Mini in a rack, IT Managers can now plug in the external HP Anyware Remote System Controller USB box to get a similar level of control over their workstation fleet as they already enjoy over their server estate. Combined with HP Anyware remote access and collaboration software, this gives HP a joined-up solution to support the growing shift towards hybrid working.

www.hp.com

INSTRUMENTAL INSTRUMENTAL Spotting errors

Instrumental delivers real-time, traceable manufacturing data for valuable insights across the product lifecycle, using AI to find faults that could cost you dearly in the long run.

Using images and videos from factory production lines, Instrumental’s AI is capable of spotting defects in manufactured products, to the point that you can recognise a design defect before that faulty product ever ships.

Examples show aerial orientations in electronics where, with fractional alterations, product quality and manufacturability could improve. Conversely, there’s the opportunity to reduce waste and the need for shipping replacements — all from faults being spotted on production lines and fed back to design teams. www.instrumental.com

LATTICEROBOT LATTICEROBOT Gyroids on steroids

Lattice infills may be the way to make your products lighter and stronger, and to use less materials, but much of the information on how they can be used best is still siloed away within organisations and research laboratories.

LatticeRobot aims to close the gap, bringing engineers together in a computationally enhanced working space to aggregate their knowledge of lattices, textures, and related mesoscale geometry and applications. In this way, everyone discovers functional lattices and gyroids that could boost their own product development work.

Information from vendor partners highlights referenced products and services, helping users discover new products for their applications.

www.latticerobot.com

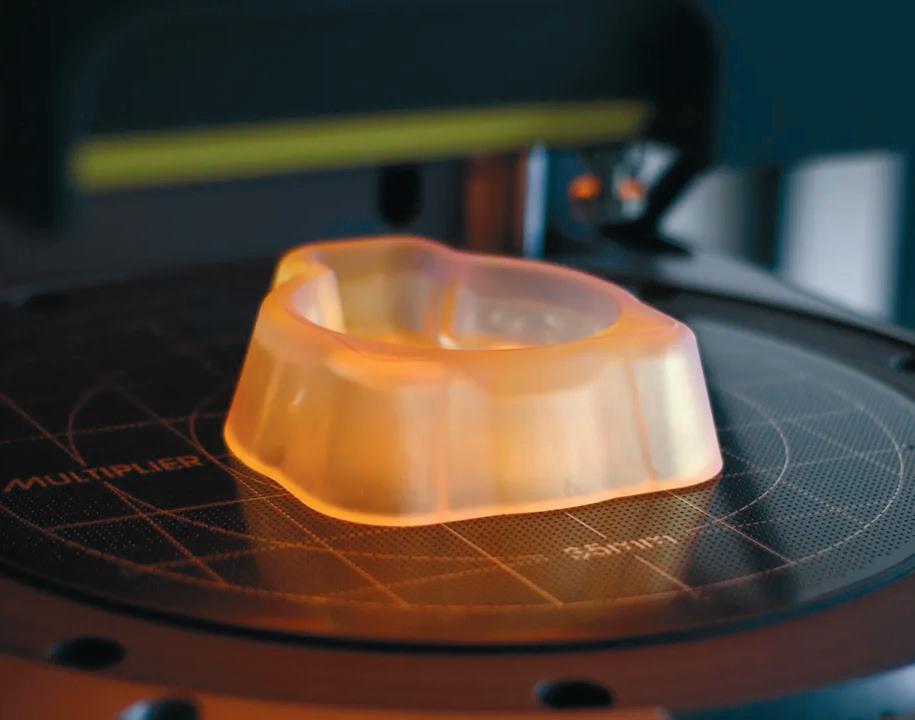

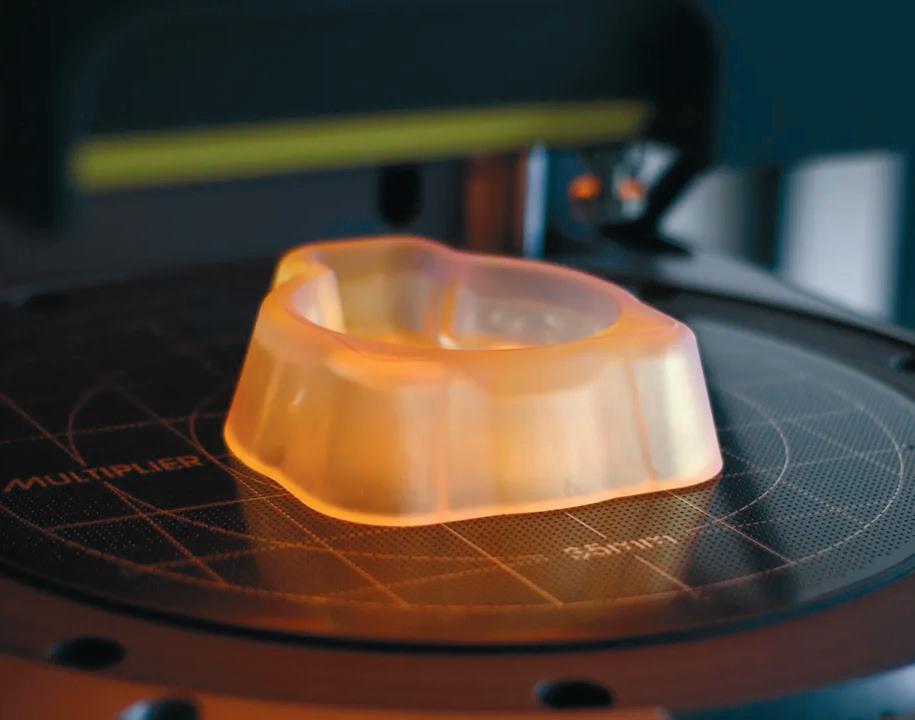

MAYKU ENGINEERING MATERIALS Masterful moulds

Multiplier, Mayku’s peerless pressure former for the desktop, is already the most detailed mouldmaker for low-intensity projects, but with its new range of engineering materials, the company is also delivering some intriguing new options.

The Multiplier can apply four tonnes of pressure to a single material sheet, replicating grooves up to 0.0004mm, and users can now capitalise on the properties of ABS, PMMA (Acrylic), and UHMW materials in their workflows. ABS brings strength and durability; Acrylic is a clear glass alternative, perfect for prototypes; and UHMW is a low-friction choice for moulds.

With more materials in the pipeline, this easy-to-use piece of kit is generating a lot of interest.

www.mayku.com

NAYA CREATE Hands-on work

This customisable, modular keyboard is designed to adjust to your workflow, while remaining ergonomic, no matter what the task.

A touchpad, jog-wheel, threedimensional puck and trackball can all be hot-swapped into the keyboard docks, with each module holding its own battery, allowing Naya Create to support RF and Bluetooth 5 while remaining ultrathin and ultra-portable.

The entire keyboard can be mapped to a user’s preference, giving users the freedom to customise in exacting detail everything, from a double-tap on a key to a three-fingered swipe.

Integration for Autodesk Fusion 360, Adobe Creative Cloud and Blender are already available, with more options promised in future.

www.naya.tech

DEVELOP3D.COM AUGUST / SEPTEMBER 2023 27

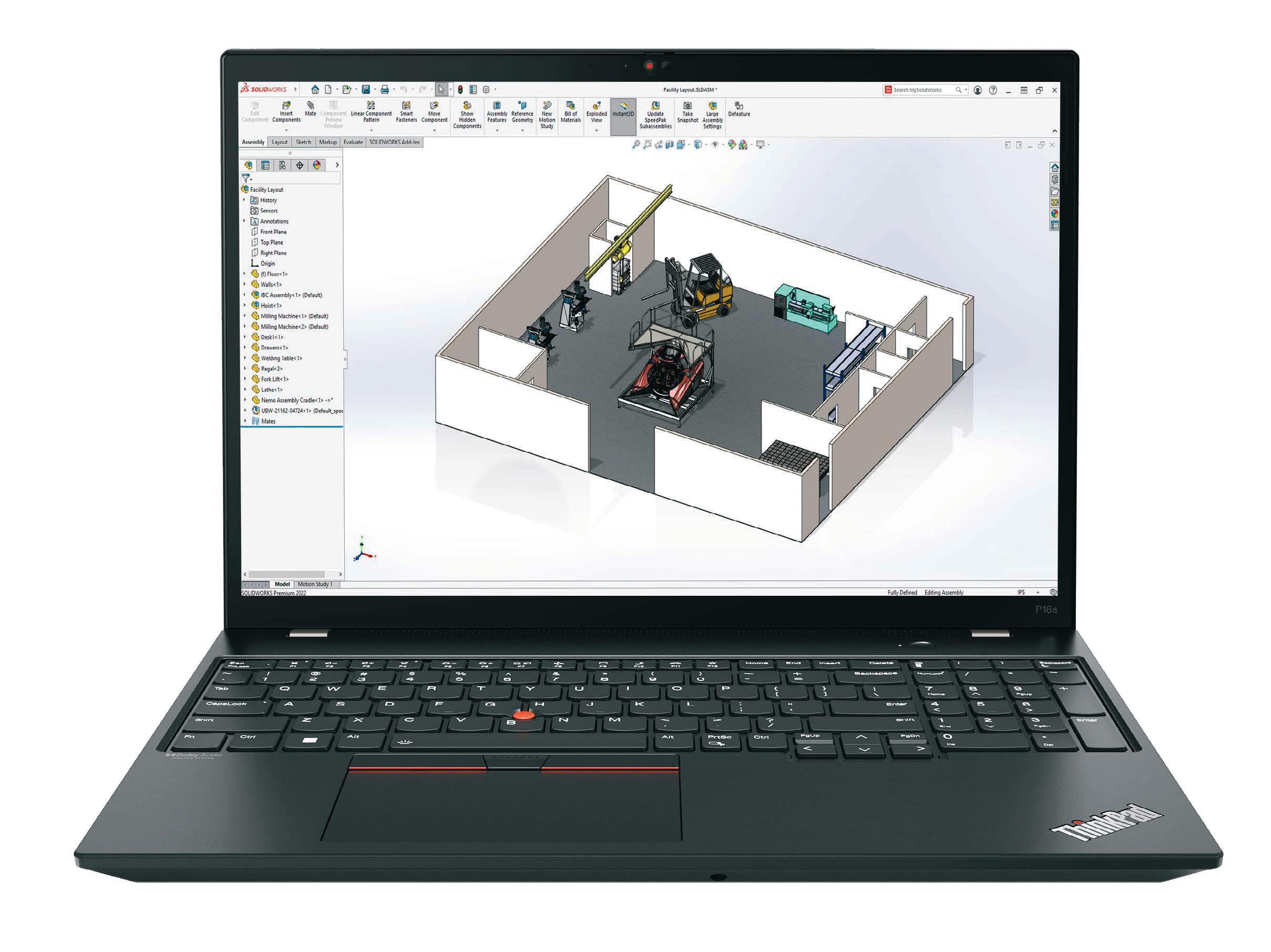

LENOVO THINKPAD P16S GEN 2 Power efficient pro

When it comes to mobile workstations, buyers often place too much emphasis on performance and too little emphasis on other things that also matter, such as power efficiency.

Here, Lenovo’s new 16-inch ThinkPad P16s Gen 2 scores highly, thanks to its AMD processor.

The AMD Ryzen 7 7840U not only packs 8 cores and a substantial 5.1 GHz boost into a 28W package, but it also includes an integrated AMD Radeon 780M GPU. Now, this GPU may not be super powerful, but the upside is that it comes with a pro driver and is perfect for mainstream CAD.

Importantly, there’s no need here for a separate GPU, which brings down costs substantially and also extends battery life. www.lenovo.com

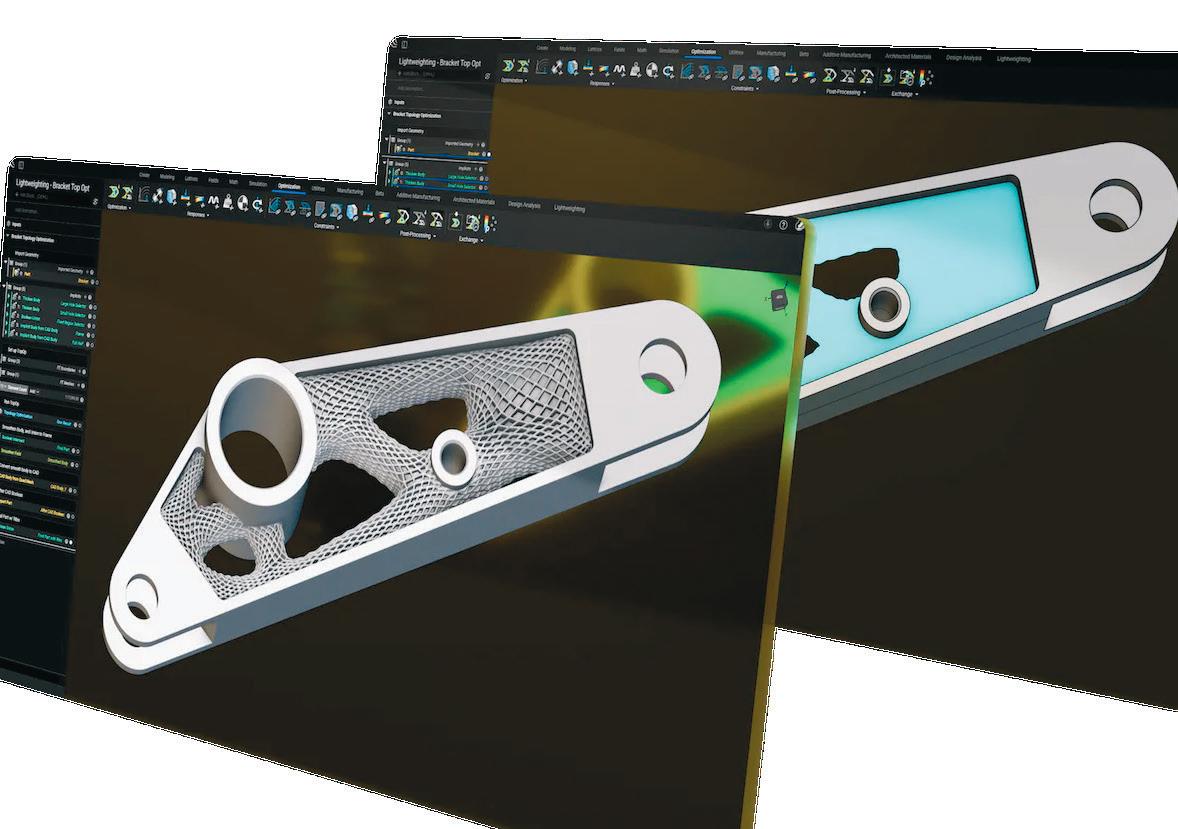

NTOP FIELD OPTIMIZATION

Simplifying the complex

NTop has always been the most intriguing generative design software on the market, but its most recent release, nTop 4, has seen the company behind it go even further to help engineers navigate the overwhelming number of design parameters.

The key benefit of Field Optimization is that the underlying material model used to compute the properties of a structure is now a function of any number of geometric design parameters, rather than a single value such as material density.

This allows engineers to focus on specifying the design intent and requirements of a part, while letting the software automatically determine complex geometric details such as lattice layouts, wall thicknesses, rib patterns and other spatially varying parameters.

www.ntop.com

NVIDIA RTX 4000 SFF ADA GEN Compact powerhouse

Nvidia boldly redefined the lowprofile graphics card back in 2021 with the Nvidia RTX A2000. Its double-slot board design blew other GPUs of the time out of the water, with its bucketloads of power for entry-level viz workflows.

The new Nvidia RTX 4000 SFF Ada Generation takes things to a whole new level, by doubling the performance and putting a whopping 20 GB of memory at the user’s disposal.

From GPU rendering to real-time 3D at 4K resolution, this 70W GPU takes everything in its stride.

In some ways, its arrival marks a true coming of age for the compact workstation, but bear in mind that, as always, stellar performance in a pint-sized package doesn’t come cheap.

www.nvidia.com

PLASTICITY PLASTICITY

Solid modelling

Even as big CAD vendors build out their products as all-singing, alldancing behemoths, we continue to see new solid modelling tools appear on the market, and Plasticity is one of the most exciting of these.

Parasolid NURBS modelling combined with the best workflow innovations from polygonal modelling software forms the basis for the software, for users who have grown up using software like Blender but are now looking to move into more complex solid modelling.

Similar to Blender, a community has already emerged offering YouTube tutorials galore, but Plasticity offers some serious pro-user features, including HOOPS Exchange file translation. All this comes in a slick, easy to navigate UI, all for a pro license fee of $299 for four seats. www. plasticity.xyz

PRINTFOAM 3D PRINTFOAM Forever blowing bubbles

The great advantages of 3D printing when it comes to lightweighting have been expanded by the team at Printfoam 3D. The product incorporates a controlled level of bubbles in 3D printing resin, drastically lightening parts, reducing material costs and improving compressive properties.

More air and less resin mean rapid printing, allowing high-viscosity resins to be used and opening up a whole new world of materials.

Materials filled with ceramic, metal, glass or polymer fibres and particles can be designed to deliver tuned EM/RF, thermal, acoustical and mechanical performance when post-processed, while the lightness means parts can be much larger than traditional 3D printed parts, requiring fewer support materials.

www. printfoam3d.com

28 AUGUST / SEPTEMBER 2023 DEVELOP3D.COM

30

THE D3D

3D scanner is the latest ‘swiss army knife’ handheld unit to be launched by Shining 3D.

Equipped with dual light sources –blue laser and infrared VCSEL – it has been developed for a wide number of applications. And it has the modes to match, including 26 laser lines suitable for large simple parts; 7 parallel laser lines for scanning fine details, and a single laser line option that can obtain 3D data from narrow channels or holes.

The infrared mode, meanwhile, allows the FreeScan Combo to quickly set up and scan without markers.

Compact, ergonomic and weighing a smidge over 600g, the Freescan Combo links to most inspection and design software simply for fast data sharing.

www.shining3d.com