Designing

Integrated GPUs P44 Solidworks Platform P24 TECHNOLOGY FOR THE PRODUCT LIFECYCLE CALL TO

Zea Parts P42 APRIL / MAY 2024 | DEVELOP3D.COM GREEN CARGO HANDLING APPLE VISION PRO DEVELOPING SMART TOYS

ARMS

for a new era of human/machine collaboration

Industrial workers rely on Ingersoll Rand for powerful, durable impact wrenches. Ingersoll Rand relies on PTC for award-winning CAD performance. To learn more about Creo 11 go to http://www.ptc.com/creo11

ptc.com

EDITORIAL

Editor

Stephen Holmes

stephen@x3dmedia.com

+44 (0)20 3384 5297

Managing Editor

Greg Corke

greg@x3dmedia.com

+44 (0)20 3355 7312

Consulting Editor

Jessica Twentyman jtwentyman@gmail.com

Consulting Editor

Martyn Day martyn@x3dmedia.com

+44 (0)7525 701 542

Staff Writer

Emilie Eisenberg emilie@x3dmedia.com

DESIGN/PRODUCTION

Design/Production

Greg Corke greg@x3dmedia.com

+44 (0)20 3355 7312

ADVERTISING

Group Media Director Tony Baksh tony@x3dmedia.com

+44 (0)20 3355 7313

Deputy Advertising Manager Steve King steve@x3dmedia.com

+44 (0)20 3355 7314

US Sales Director Denise Greaves denise@x3dmedia.com

+1 857 400 7713

SUBSCRIPTIONS

Circulation Manager

Alan Cleveland alan@x3dmedia.com

+44 (0)20 3355 7311

ACCOUNTS

Accounts Manager Charlotte Taibi charlotte@x3dmedia.com

Financial Controller Samantha Todescato-Rutland sam@chalfen.com

ABOUT

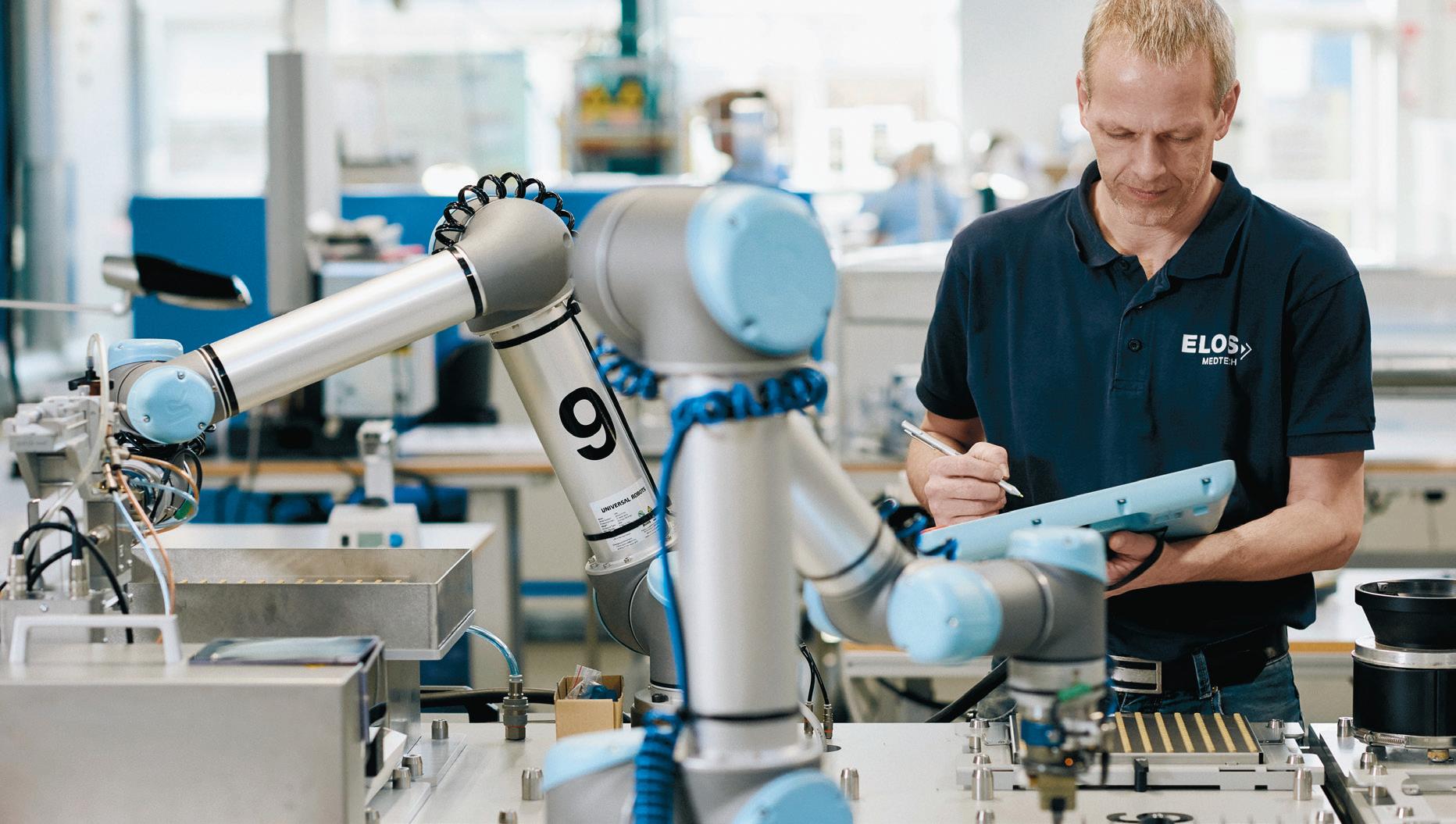

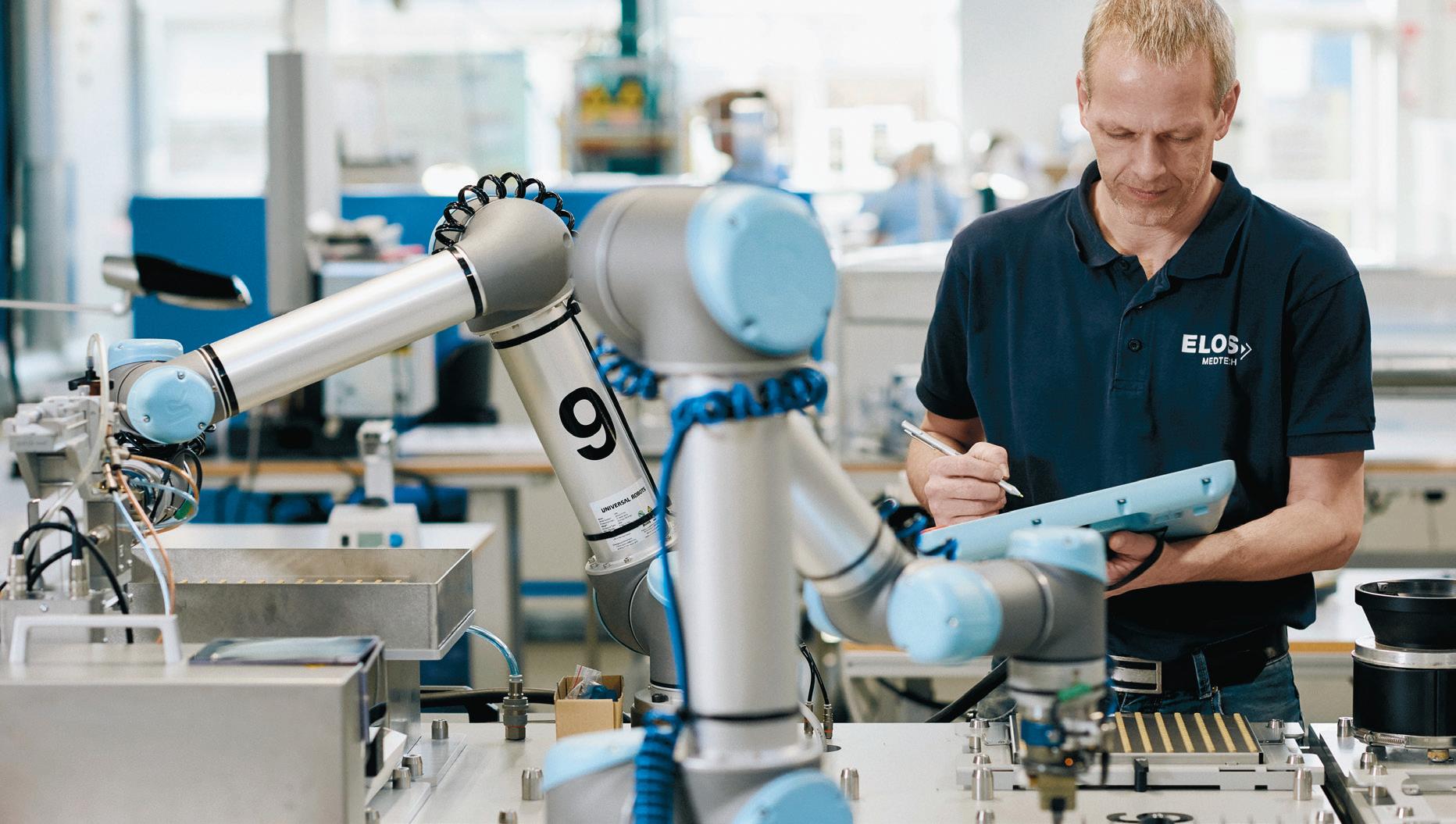

Robots rock, but get in their way, and they’ll likely cleave right through you. Hence the need for smarter, sensorenabled collaborative robots (or ‘cobots’) in the workplace, enabling automation to flourish in peace alongside us vulnerable, fleshy humans.

In this issue, we speak to Universal Robots, possibly the most well-known cobot company in the world, learning a little about what goes into building these incredibly versatile products.

Chances are you’ve seen the company’s pale blue and grey robotic arms in labs and assembly plants, but they’re also spreading fast into kitchens, workshops and even coffee shops, putting the jobs of hipster baristas who can’t spell my name correctly on the critically endangered list.

Cobots can also connect people, as we see in this issue’s uplifting story of how the team at Tatum Robotics is developing a cobot hand that can help DeafBlind people communicate when not in direct contact with another person. We talk a lot in DEVELOP3D about how technology changes lives, but I’ll leave you to read about how empowering this particular technology might be for the people using it.

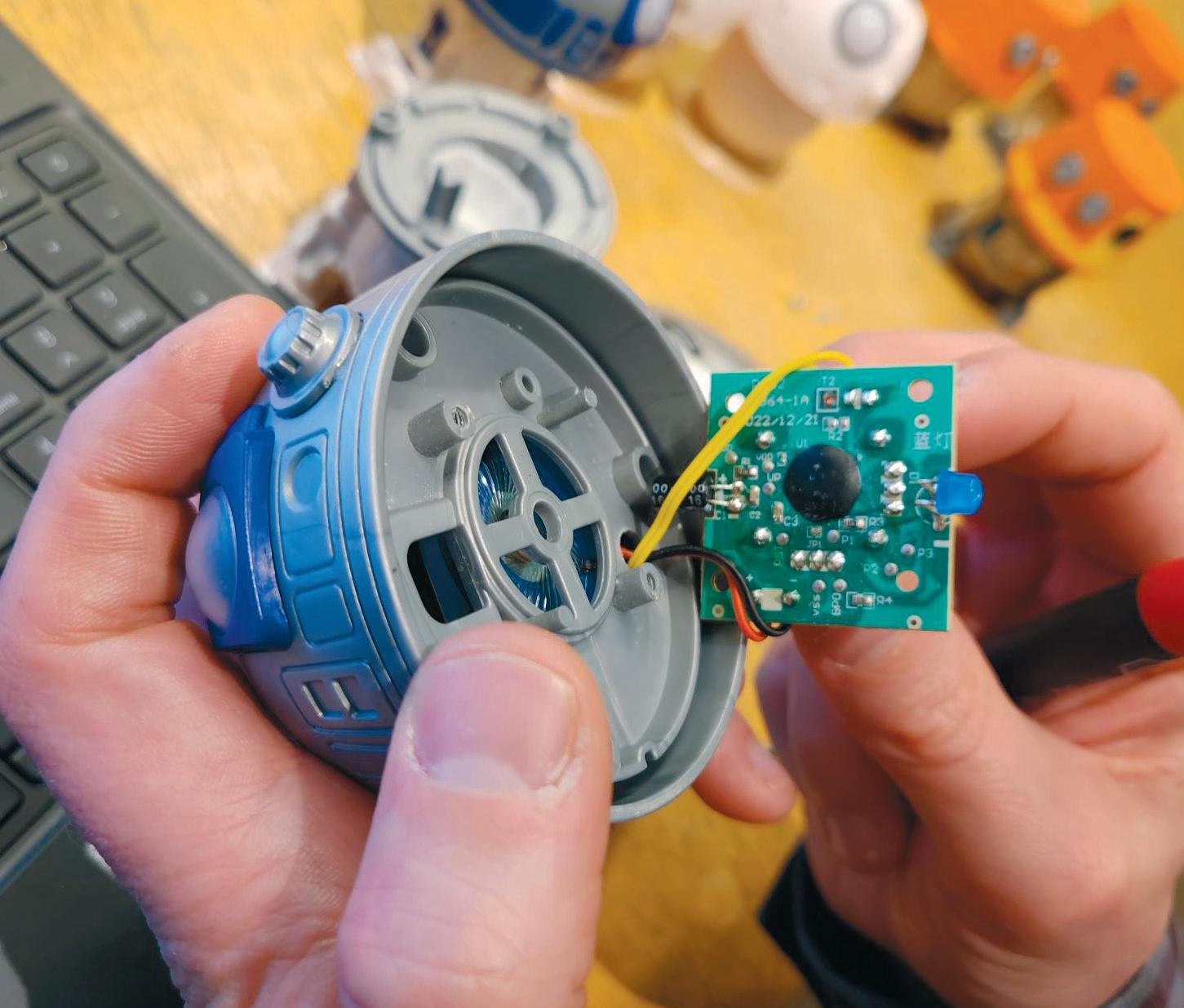

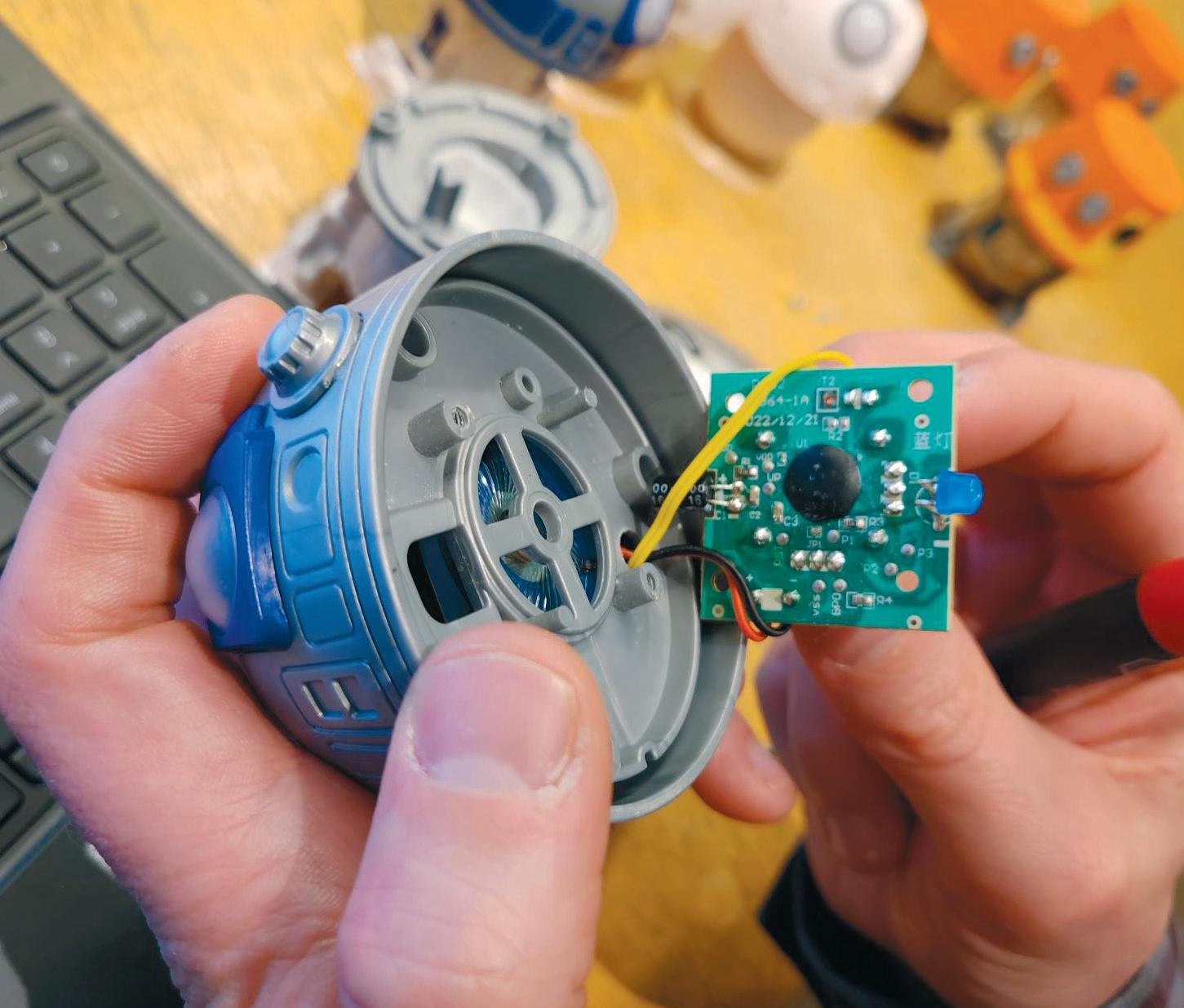

Elsewhere, we get an idea of the design workflow at Hasbro, as we speak to the crack team of R&D fixers who work inside its whirlwind toy and games development process. The volume of new product concepts generated is pretty wild. Only a chosen few will then be developed and brought to market but that task must be achieved very quickly to satisfy market demand.

I’d also like to welcome our new writer Emilie Eisenberg, who makes her DEVELOP3D debut with a round-up of design, visualisation and engineering tools that take advantage of the Apple Vision Pro. One of these tools is Shapr3D, which I take a closer look at through the Vision Pro, as its developer looks to enable greater usability for its CAD and visualisation tools in the concepting and design review stages.

Back on the desktop, Greg has returned from Dassault Systèmes’ 3DExperience World user event in Dallas, from where he has reported on all the hottest developments in Solidworks, as well as a host of other software and hardware companies within the DS ecosystem.

DEVELOP3D is published by X3DMedia 19 Leyden Street London E1 7LE, UK

T. +44 (0)20 3355 7310

F. +44 (0)20 3355 7319

The year is heating up, and there’s activity everywhere when it comes to new software and hardware launches, so expect a full round-up in the next issue, when we’ll be bringing you our annual D3D 30.

DEVELOP3D.COM APRIL / MAY 2024 3

WELCOME DEVELOP3D.com facebook.com/DEVELOP3D @DEVELOP3D groups/DEVELOP3D Join our online community Stephen Holmes Editor, DEVELOP3D Magazine, @swearstoomuch

© 2024 X3DMedia Ltd All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine

19 September 2024

Accelerate your product design & transform your product development

2024 develop3dlive.com Save the date

Warwick Arts Centre, UK

View on-demand 2024 Watch all the presentations from DEVELOP3D LIVE 2023 Register @ www.develop3dlive.com

Creo: Design The Way It Should Be

Creo® helps you build better products faster, by accelerating innovation, reusing the best of your design and replacing assumptions with facts.

Try Creo Today: For Free

Unleash the power of Creo in your organisation. Maximise productivity without sacrificing innovation.

Visit bit.ly/creo-free-trial or scan the QR code to receive your free trial.

0121 506 9720 | sales@concurrent-engineering.co.uk | www.concurrent-engineering.co.uk

NEWS

Nvidia extends Omniverse with Cloud APIs, HP unveils ZBook G11 mobile workstations, Luminary Cloud emerges from stealth mode, and more

FEATURES

Comment: Autodesk’s State of Design and Make report

Visual Design Guide: Aurrigo Auto-Dolly Tug

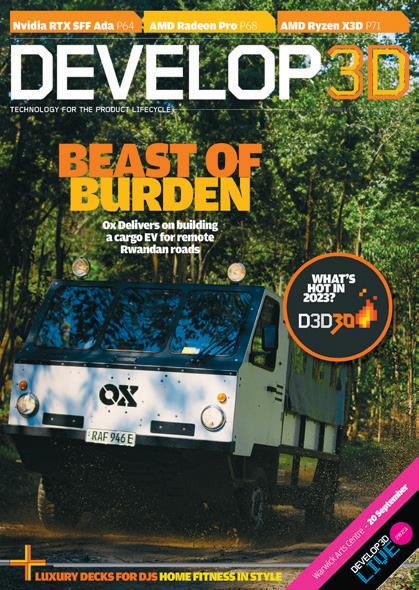

COVER STORY Cobots adopt strong-arm tactics

Solidworks: all roads lead to the platform

Shapr3D’s new perspective on spatial computing

Five 3D design apps for the Apple Vision Pro Child’s play: Smarter toy development at Hasbro

Positive signs: Robotics to assist DeafBlind people

Designing sustainable transit packaging at Loadhog

Taiga Motors stays on track with digital catalogues

Integrated GPUs: Why it’s prime time for CAD

THE LAST WORD

The tale of how carmaker Fisker was sent off course by a negative review of its Ocean model stands as a lesson to all product designers, writes Stephen Holmes

DEVELOP3D.COM APRIL / MAY 2024 7

APRIL/MAY 2024 ISSUE NO. 145 8 13 14 16 24 28 30 34 36 40 42 44 50 The wood used to produce this magazine comes from Forest Stewardship Council certified well-managed forests, controlled sources and/or recycled material CONTENTS 20 September 2023 Warwick Arts Centre, UK 2023 Accelerating product development to manufacture Save the date D3DLIVE returnstowhereitallstarted * *following£25mrenovations Save the date 19 September 2024 develop3dlive.com 2024

NVIDIA ANNOUNCES STRATEGY TO EXPAND ITS OMNIVERSE WITH NEW CLOUD APIS NEWS

» Leading software vendors adopt Omniverse technologies with the aim of helping customers to design, simulate, build and operate physically based digital twins

Nvidia is making its Omniverse Cloud industrial digital twin platform available as a series of five application programming interfaces (APIs), to make it easier for software developers to integrate core Omniverse technologies for OpenUSD and RTX into their existing design and automation software applications.

According to Rev Lebaredian, VP of Omniverse and simulation technology at Nvidia, this gives ISVs all the powers of Omniverse: interoperability across tools, physically based real time rendering, and collaboration across users and devices.

In its simplest form, software developers can embed Omniverse powered viewports into their 3D apps, giving their apps ‘instant’ real-time physically based rendering – which involves pixel streaming from the cloud.

Software developers can also use the API to connect Generative AI tools into their existing apps, as well as a range of workflow tools for OpenUSD data.

The Omniverse Cloud APIs are being adopted by several software developers including Ansys, Cadence, Dassault Systèmes, Hexagon, Microsoft, Rockwell Automation, Siemens, and Trimble to help customers design, simulate, build and operate physically based digital twins.

The five new Omniverse Cloud APIs can be used individually or collectively. USD Render can be used to generate fully ray-traced RTX renders of OpenUSD data; USD Write lets users modify and interact with OpenUSD data; USD Query enables scene queries and interactive scenarios; USD Notify tracks USD changes and provides updates; and Omniverse Channel connects users, tools and worlds to enable collaboration across scenes.

According to Nvidia executives, through the use of Omniverse APIs, workflows such as applying materials, lighting environments and other supporting scenery assets in physically based renderings will be ‘dramatically accelerated using generative AI.

Siemens is adopting Omniverse Cloud APIs within its Siemens Xcelerator Platform. The company is starting with Teamcenter X, to give its cloud-based product lifecycle management (PLM) software the ability to connect design data to Nvidia generative AI APIs, and use Omniverse RTX rendering directly inside the app. It will extend to other Siemens Xcelerator tools, including high-end CAD/ CAM/CAE software, Siemens NX, and Computational Fluid Dynamics (CFD) software STAR-CCM+.

Siemens is also creating a real-time, embedded, photo-real viewport powered

by the USD Render and USD Write APIs, to allow engineers to interactively navigate, edit and iterate on a shared model of their live data.

Meanwhile, Ansys is adopting Omniverse Cloud APIs to enable data interoperability and RTX visualisation in solutions such as Ansys AVxcelerate for autonomous vehicles, Ansys Perceive EM for 6G simulation, and Nvidia accelerated solvers such as Ansys Fluent.

Cadence is adopting Omniverse Cloud APIs into its Cadence Reality Digital Twin Platform so enterprises can design, simulate, and optimise data centres in a digital twin prior to physical build-out.

Hexagon, a specialist in reality technology, will integrate its reality capture sensors and digital reality platforms with the Nvidia Omniverse Cloud APIs through USD interoperability, in order to provide its customers with ‘hyperrealistic simulation and visualisation capabilities’.

Construction and geospatial technology specialist Trimble will use the APIs to provide interactive Nvidia Omniverse RTX viewers with Trimble model data.

Omniverse Cloud APIs will be offered later this year on Microsoft Azure as self-hosted APIs on Nvidia A10 GPUs or as managed services deployed on Nvidia OVX. www.nvidia.com

New possibilities lie ahead for organisations looking to use digital capabilities to manage real-world assets such as ships and harbours

8 APRIL / MAY 2024 DEVELOP3D.COM NEWS

Teams

Built-in PDM - a single source of truth for design data with robust version control.

Real-Time Collaboration - users across the globe can simultaneously view and edit parts, assemblies, and drawings.

Zero IT Overhead - Onshape runs in a browser anytime, anywhere, and on any device. No costly workstation required.

GET:

WITH ONSHAPE YOU

1 2 3 Share Supplier Berlin, DE Designer Boston, US Manager Tokyo, JP

From the founders who created SOLIDWORKS, Onshape is the most widely used cloud-native CAD & PDM system on the market with over 3 million users.

& PDM Free Up To 6 Months! Get started today Onshape.Pro/Develop3D

Engineering

Get Onshape 3D CAD

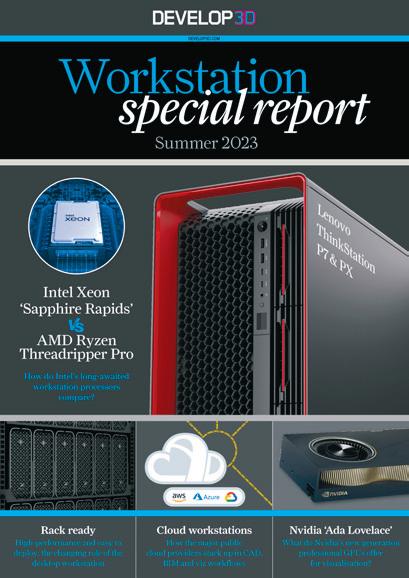

NVIDIA LAUNCHES RTX 2000 ADA GENERATION GPU

Nvidia has added the new Nvidia RTX 2000 Ada Generation (16 GB) to its existing family of workstation GPUs based on the Ada Lovelace architecture.

The $625 add-in board was launched at Dassault Systèmes’ 3D Experience World in Dallas, Texas, a significant location given that product designers and engineers are a key target audience.

The Nvidia RTX 2000 Ada Generation is a low-profile dual-slot board built to fit small form factor and ultra-compact workstations such as the HP Z2 SFF/ Mini and Lenovo ThinkStation P3 Ultra. It comes with half-height and full-height ATX brackets, so can also be used in fullsized towers.

The new board comprises 2,816 CUDA cores delivering 12 TFLOPs of peak

single-precision performance, 88 Tensor (AI) cores delivering 192 TFLOPs of peak performance and 22 RT (ray tracing) cores delivering 28 TFLOPs of peak performance.

The Nvidia RTX 2000 Ada Generation (16 GB) replaces the Ampere-based Nvidia RTX A2000 (12GB) and provide a more price-competitive option than the $1,250 Nvidia RTX 4000 SFF Ada Generation (20 GB). It looks identical to both GPUs and shares many of the same characteristics – four mini DisplayPort 1.4a connectors and a 70W max board power. However, unlike the Nvidia RTX 4000 SFF Ada, it doesn’t support Nvidia Quadro Sync II or 3D stereo.

The Nvidia RTX 2000 Ada is available now through the channel, and will be available from Dell, HP and Lenovo starting in April. www.nvidia.com

HP unveils ZBook G11 mobile workstations

HP has unveiled the G11 editions of its ZBook mobile workstation family. Power, Fury, Studio and Firefly feature a broad range of CPUs including Intel Core Ultra 5, 7 and 9 processors or ‘next-gen’ AMD Ryzen Pro processors with dedicated NPUs.

The HP ZBook Power G11 features a new premium 16-inch design that is slightly deeper than the G10 edition. It’s available with Intel Core Ultra 9 or AMD Ryzen 9 Pro processors and comes with a choice of laptop GPUs.

The HP ZBook Fury G11 is billed as the most powerful ZBook with a choice of ‘desktop class’ Intel Core HX processors, including 13th Gen Intel Core (with vPro) or 14th Gen Intel Core (non vPro).

The HP ZBook Studio G11 is HP’s premium thin and light mobile workstation, starting

at 18.3mm and 1.73kg.

The HP ZBook Firefly G11 is at the budget end of the range and comes in 16-inch and 14-inch form factors. It’s available with Intel Core Ultra 7 or AMD Ryzen 9 Pro 8945HS processors and up to Nvidia RTX A500 Laptop GPU. www.hp.com

Luminary

Cloud

out in the open

Luminary Cloud and its computer-aided engineering (CAE) SaaS platform has emerged from stealth mode, promising high-fidelity simulations 100 times faster than legacy vendors.

The company was incubated by Sutter Hill Ventures from 2019, receiving $115 million in funding. Leveraging the raw speed of GPU- and cloud-based processing, its proprietary simulation platform is powered by parallel Nvidia GPU clusters hosted in the cloud, allowing engineers to iterate and test a variety of scenarios, and optimise product designs.

www.luminarycloud.com

Adobe adds AI to Substance 3D

Adobe has launched the first integration of its Firefly generative AI capabilities to Substance 3D Sampler and Stager, for Text to Texture and Generative Background, in order to accelerate time-consuming and intricate 3D texturing and staging tasks.

Adobe claims these new capabilities will significantly accelerate the creative review process, making workflows using Substance more productive and seamless and saving designers considerable time in their working days. www.adobe.com

Ansys bursts to cloud for speed

AThe HP ZBook Power G11 with its 16-inch screen

nsys has announced its new cloud service to accelerate multiple simulations for design exploration within its Discovery software, offering designers the chance to ‘solve 1,000 design variations in 10 minutes’. According to Ansys executives, Discovery’s new burst-to-cloud service leverages the power of the Ansys Cloud to accelerate parametric studies in Discovery by 100 times or more, thanks to it implementation of Nvidia A10G GPUs with 24 GB GPU memory. The function supports all Discovery Explore physics, including thermal, structural and fluids, and charges for use via Ansys Credits, based on computation time. www.ansys.com

10 APRIL / MAY 2024 DEVELOP3D.COM NEWS

The Nvidia RTX 2000 Ada Generation is a low-profile dualslot board

MELTIO BRINGS DED 3D PRINTING TO SHOP FLOORS WITH M600

The new M600 wire-laser system sees Meltio bring its DED 3D printing technology to the shop floor by utilising Blue Laser technology to deposit welding wire as its feedstock.

A 300 x 400 x 600mm fully inert workspace equipped with smart sensors should allow for large parts to be built using demanding materials, including titanium, copper and aluminium alloys, as well as stainless steels, tool steels, nickel, invar and Inconel.

Designed specifically for machine shops and production environments, the Meltio M600 is capable of 3D printing entire metal parts but also adding features to existing components and repairing damaged surfaces.

This range of capabilities is facilitated by the built-in 3-axis touch probe and support for various workholding solutions, including zero-point clamping.

exceptional properties.

Meltio has developed the system to operate autonomously, meaning that operator interaction is minimal. Common touch points such as manual laser alignment have been removed for increased reliability and programming is sped up thanks to Meltio Horizon, a dedicated slicer for the

ROUND UP

Even smaller workshops are increasingly looking to introduce 3D metals printing

Meltio R&D Director Lukas Hoppe explains that the advantage is multiplied for reflective materials such as copper and aluminium alloys, where the use of near-infrared lasers frequently lead to unsatisfactory results.

Combining this with the fully inert workspace, the Meltio M600 is capable of processing a large range of materials efficiently while producing parts with

According to Hoppe, the vast majority

3D-printed parts require

processing

typically

ambition is to push largescale adoption of metal additive manufacturing, its management has “a very clear vision” that the modern machine shop is the

the next logical step on our continuous journey towards mass adoption of WireLaser DED, the process all Meltio systems are based on,” Hoppe explains.

“We developed every single part of the machine from scratch to take the technology to the next level, based on the learnings of having manufactured and installed over 300 Laser DED machines.” www.meltio3d.com

New zoom-in capabilities for SmartScan kit

The new software-adjustable variable resolution functionality of the SmartScan VR800 3D scanner from Hexagon’s Manufacturing Intelligence division offers ‘zoom’ capabilities for more flexible 3D part inspection.

The VR800 uses four 20 MP cameras in a dual stereo set-up for a wider range of measurement volumes. This is uniquely combined with an optical-zoom digital projection unit, which makes it possible to measure different volumes (three from each camera pair), as well as to vary the resolution within each volume.

Built on a completely reengineered platform, the SmartScan VR800 is said to be the first white light 3D scanner on the market with a motorised zoom lens, which can enable users to adjust data resolution

and measurement volume entirely through software settings.

This, according to the company, allows for more efficient post-scanning alignment processes, including the ability to combine scans of different resolutions within a single project. www.hexagon.com

Renishaw has extended its Agility CMM range to include machines for the measurement lab, featuring 5-axis technology and multi-sensor abilities. These should enable manufacturers to carry out multiple measurements and report results on a single device www.renishaw.com

Stratasys has acquired the technology portfolio of Arevo, which ceased operations in 2023, including patents in carbon fibre printing and Z-strength improvement. The tech is expected to be incorporated into the wider Stratasys FDM 3D printing portfolio www.stratasys.com

Replique has released Material Hub, a database of over 500 industrialgrade polymer materials made for 3D printing. Free to access, the collection contains twice as many materials as was previously available to users, thanks to collaboration with more than 85 specialist polymer providers www.replique.io

EOS has launched the EOS M 290 1kW, intended for serial production of parts using copper and copper alloys. The new laser powder bed fusion (LPBF) printer is based on the EOS M 290, and is compatible with legacy M 290 process parameter sets for laser focus, beam quality etc www.eos.info

Zoom capabilities mean users can focus on the feature-rich areas that matter most in a scanning job

Coreform Cubit 2024.3 builds on existing neutronics workflows to support nuclear engineering calculations directly on CAD geometry or simulation meshes, instead of reconstructing the design in constructive solid geometry (CSG), a notoriously timeconsuming process www.coreform.com

DEVELOP3D.COM APRIL / MAY 2024 11

Armadillo 3D Printer

www.cdg.uk.com CDG: 3D TECHTM Tel: 01420 556755 Stoneware Technical Ceramics Foundry Sand Bio Materials Stone

Powder Binder-Jetting Technology for materials including:-

With 2024 predicted to be the ‘Year of AI’, Autodesk’s State of Design & Make Report finds designers and engineers feeling positive about the technology and confident about harnessing its powers, writes Stephen Hooper

Autodesk’s annual State of Design & Make report has just been released and contains a lot of good news. Increasing adoption and growing trust in artificial intelligence (AI), tied to confidence in resilience and optimism across design and make industries are the top findings.

These are based on surveys and interviews of 5,399 global business leaders, futurists and experts in product design, manufacturing, architecture, engineering and construction, as well as the digital arts. These industries collectively employ almost 300 million people and are projected to have a global value of $30 trillion by 2027.

It’s no surprise that AI is a leading digital transformation tactic across our industries, but what Autodesk’s data reveals is that trust in AI is exceptionally high. Companies are leveraging AI to increase productivity and automate mundane, repetitive tasks. Importantly, they predict it will help with crucial design decisions in the future. It’s changing the way businesses operate, enhancing creativity, promoting novel design solutions and fostering sustainability – and yet, we’re still only seeing the start of its powers.

The report reveals that 79% of respondents believe AI will make their industry more creative, and 78% feel it will enhance their industry. This aligns with another key finding of the report: a surge in confidence among industry leaders about resilience of their companies, with 73% of respondents saying they believe they are more ready to handle unexpected changes.

This confidence is especially pronounced among digitally mature companies – those further along in their digital transformation journeys. While more than half of the companies surveyed state that they are nearing or have achieved their goal of incorporating AI, the report highlights that business leaders recognise we are still far from realising its full potential.

SUSTAINABILITY GOALS

In the realm of sustainability, many companies have integrated AI into their operations to boost productivity and align their businesses with sustainability goals. Changing attitudes are a significant driver of this progress.

Leaders state they recognise that both customers and employees, particularly younger entrants to the workforce, are having a growing impact on the decisions leaders are making. Individuals appear to be make career decisions, as well as buying decisions, based on their understanding of a company’s stance on sustainability.

An impressive 97% of companies say they have taken action to improve sustainability, investing in energy efficiency, materials reduction and other processes.

Companies that fail to make meaningful sustainability commitments risk falling behind competitors whose values resonate better with their employees and customers.

With 87% of industry professionals agreeing that improving sustainability practices is good for long-term business success, the message seems to be that not doing so puts brand loyalty, product sales, as well as talent recruitment and retention, in jeopardy.

TIME TO UPSKILL

Which leads us to another, related topic the report highlights: talent development remains a critical aspect of growth.

About half of industry professionals cite access to skilled talent as a barrier to their company’s growth. Upskilling resources and continuous learning remain essential for businesses of all sizes.

AI shows up in the upskilling category as well, with companies prioritising the ability to work with AI, design using digital tools, and software development/ programming as critical talents in the workforce of today and tomorrow.

The report finds that 79% of respondents believe that AI will make their industry more creative, and 78% feel it will enhance their industry

And while 77% of companies consider upskilling important, there is a worrisome gap in delivery, with only 38% saying their companies possess the necessary skills and resources to design training programmes.

Autodesk’s 2024 State of Design & Make report paints a picture of several interconnected industries that are increasingly confident, forward-looking, and ready to embrace the future.

Technologies like AI that are in the market now, as well as those emerging soon, will increase efficiencies and help address some of these challenges, getting us away from repetitive tasks and analogue processes. Autodesk’s investments in cloud and automation reflect our commitment to leading our customers in their digital transformation journeys.

That said, the challenges of change and improvement, in order to stay competitive, usually go far beyond what the IT department alone can deliver and that shows up throughout the report’s findings. Cultural and philosophical change, getting beyond the “That’s the way we’ve always done it” mindset, or seeing sustainability goals and profitability as complementary, are parts of the alchemy here. I’m elated to see recognition of that coming through in our research.

ABOUT THE AUTHOR: Stephen Hooper is VP of Design and Manufacturing at Autodesk. Over the course of two decades, he has successfully equipped manufacturers with the capabilities they need to thrive and is currently delivering on the company’s promise of a converged design and manufacturing platform. www.autodesk.com

DEVELOP3D.COM APRIL / MAY 2024 13 COMMENT

HEAVY LIFTING

The Auto-Dolly Tug can carry a load of 1.5 tonnes and tow a further 7.5 tonnes behind it

TESTING

The Auto-Dolly Tug is being trialled at Changi Airport, where Singapore’s humid climate and frequent rain storms really put this machine through its paces

FULLY LOADED

The new model combines the utility of a baggage tractor and the carrying capability of an airport dolly

GOOD MOVER

The latest model of Aurrigo’s Auto-Dolly Tug offers new ground handling capabilities. It can rotate its own length and move sideways to slide into tight spaces and park itself

DROP IT LOW

A height-adjustable chassis makes it easier for the vehicle to load heavy freight

14 APRIL / MAY 2024 DEVELOP3D.COM

VISUAL DESIGN GUIDE AURRIGO AUTO-DOLLY TUG

This autonomous electric airport baggage vehicle can move across the tarmac in ways not seen before, getting planes in the air faster

REACH OUT

STAYING IN SHAPE

DEVELOP3D.COM APRIL / MAY 2024

The on-board storage capability can load and unload itself using robotic arms that slide out sideways

The ability to carry a standard ULD cargo container on the vehicle ensures maximum carrying capacity without needing to increase the length of the train

STRONG-ARM

» Working alongside human colleagues to automate repetitive tasks, ‘cobots’ are quickly invading the workplace. Stephen Holmes speaks to Universal Robots, maker of robotic arms that are getting to grips with jobs that vary from maritime welding to making coffee

The distinctive silver and blue colour scheme of a Universal Robots cobot makes it instantly recognisable

TACTICS

COVER STORY

Today, just 2% of applications that could be transformed by robotic collaboration are already automated — but the rise of the collaborative robot, or ‘cobot’, looks set to transform that picture.

Cobots are engineered so that they can work alongside humans without the need for safety barriers and be equipped with different peripherals to perform different tasks. They typically take the form of a robotic arm and demand for them is growing at businesses intrigued by their proven ability to increase productivity.

Today, cobots are performing tasks that range from welding work on ships to serving coffee from kiosks. Barriers of cost, availability and ease of programming are falling, persuading more companies to invest.

At Universal Robots, a leader in collaborative robotic automation, vice-president of strategy and innovation Anders Billeso Beck is confident that we will all soon be accustomed to seeing cobots at work in our daily lives.

“We see more and more cobots where tasks are done repetitively, and where we’re still struggling to find labour to perform them,” he says, speaking from the brand’s headquarters in Odense, Denmark.

Universal Robots is one of the most recognisable brands associated with robot arms, with its products standing out from the crowd with their blue and silver colour schemes, in marked contrast to the block primary colours more typically seen on the heavyweight robotic arms that populate many manufacturing assembly lines.

Beck compares the evolution of the cobot to that of the mobile phone. “People were competing on battery life, and then suddenly, some other people brought along a phone that had really poor battery life and the worst antenna in the world, but it had a touchscreen and could run apps. It really displaced the value proposition!”

Cobots are similar, he explains, in that they may not designed to be as fast, strong, stiff or accurate as industrial

robots, but they change the basic value proposition, because what users prize more highly is ease of use.

“We’re getting to the point where people don’t want to tinker with technology. They want to find a way to get their automation problems solved. And, of course, we offer technology for that – we’ve invested a lot into that, and we have now grown a huge ecosystem around our cobots.”

Over 350 partners have built technologies for the Universal Robot cobot – from gripping tools and vision technologies to simple cable guidance and bumpers.

Some 160 OEM partners, meanwhile have built fully integrated systems of which a Universal Robots cobot forms an integral part.

“It’s safe to be around, it’s easy to programme, and it’s fast to deploy. These are the core things, and that demand has actually not changed a lot,” Beck says.

POWER AND PRECISION

For the first time in its 18-year history, Universal Robots has taken its full product design process in-house, undertaking a full ground-up design on the mechanics, mechatronics infrastructure and all electromechanical parts of its latest models, the UR20 and UR30.

The big challenge is blending the power and precision of the servo motors mounted in each joint of the arm. Beck says that, for the UR20, its biggest produces over 700 newton metres of torque.

“That’s more than a performance model Tesla does on all four wheels, and it does that in a drive that’s the size of a small handball, so there’s an immense amount of torque being generated in a very small, weight-optimised unit,” he explains.

At the same time, he continues, cobots also need to deliver accuracy measured in micro radians. “You have this servo drive, and you attach it to a 1.7-metre-long stick. And then you still need to hit a spot that is within 50 micrometres. So, it has to be ultra-accurate and so powerful at the same time.”

18 APRIL / MAY 2024 DEVELOP3D.COM COVER STORY

● 1 The UR20 and UR30 are the first models to be fully designed in-house at Universal Robots 1

‘‘ It’s safe to be around, it’s easy to programme and it’s fast to deploy

Anders Billeso Beck, Universal Robots

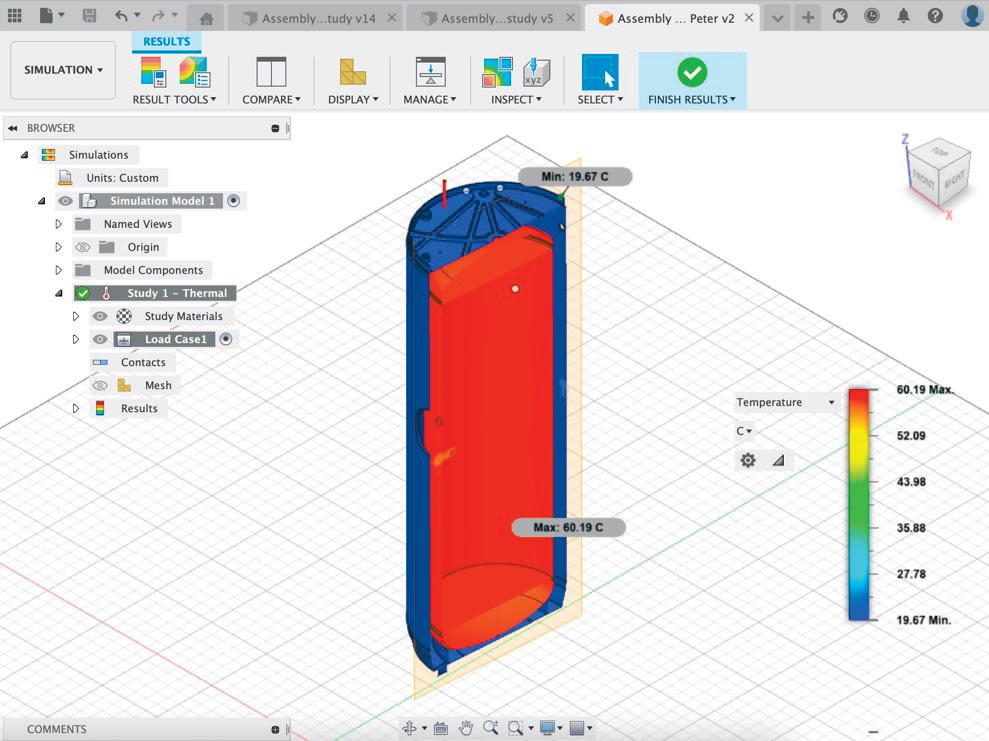

The design process at Universal Robots begins with a 3D model in Dassault Systèmes’ Solidworks. Beck explains that the company is a big user of the Solidworks package, but on top of that, it has added several additional capabilities to help accelerate its design process.

Much of this revolves around simulation and the heavy use of finite element analysis (FEA) modelling.

“One of the key challenges is that we are really pushing every component to just before the breaking point,” Beck emphasises, saying that the engineering team is challenging every material in the robot to optimise it for weight, performance and accuracy.

“Using simulation has increasingly, over the last five years, become a natural development for us,” he says.

For much of this work, Ansys Mechanical has been utilised, with Ansys helping support Universal Robots in setting up the simulation environment and collaborating on the various challenges of trying to simulate so many different use cases.

“It’s actually a really difficult product to do these simulations on, because people will do everything with them,” says Beck.

Not only can the arms and joints be moved in all directions, but there are also different speeds and loads to consider. And then there are use cases that involve vibration stresses from impact wrenches and sanders, or heat from welding. “There are all sorts of things that the robots get exposed to in their natural habitats, and we

need to account for all of those when we’re designing the product. Barely a day goes by where we don’t get a contact from a customer, where they have a brilliant but superchallenging idea about doing something!”

Universal Robots will run a simulation to pre-validate a challenging scenario, like magnetically mounting an arm onto the side of a ship to weld repairs at high temperatures, or handling power tools on building sites that produce juddering vibrations.

In the last five years, the company has built a huge physical testing capability, which allows for functional testing all the way through the development process. For the design team, the goal is to get to a physical product as quickly as possible so that it can start running real-world tests. This speed helps build validation that can be fed back into the simulation analysis.

A farm of nearly 50 robots currently exists to test all the cobot software updates, running through test cycles to make sure that nothing fundamental around the motion or sensors has altered.

Beck adds that, every few weeks, the company has robots run through 16 real-world use cases built by its partners, forming part of a large battery of tests that make sure nothing has changed that would harm a customer application in the outside world and maintaining the harmony between Universal Robots’ in-house hardware and software development teams.

POWER-TO-WEIGHT RATIOS

The key to achieving the perfect design, says Beck, comes down to the power-to-weight ratio that a robotic arm can offer. The less of a moving mass you have, the safer and more productive the robot will be.

The power-to-weight ratio of the UR20 cobot, for example, is astonishing given its size. Weighing in at just 64Kg, it can carry a 20Kg weight within a 1.75 metre reach, using a similar amount of power as a household washing machine and taking up only a 245mm footprint.

Attaining these results forced the team to consider everything that could potentially go wrong. They needed to think not only about combining components in the neatest package, but also how the massive forces generated might deform the intricate parts.

The use of aluminium for Universal Robot’s cobots has its pros and cons, says Beck. It is proven to be the best material in terms of price, weight and performance, but still poses issues for the designers.

“It’s a super-challenging material to use, because it doesn’t have this infinite fatigue life, so you need to be super-careful with that,” he says.

“It’s really poor at dampening vibrations, and vibrations are the enemy of any robot. That’s why all traditional robots are cast iron. They’re perfect for dampening vibrations,” he says.

DEVELOP3D.COM APRIL / MAY 2024 19

’’ 2 3 4 ● 2 ● 3 A complex and powerful servo motor is housed in each joint, supported by an aluminium frame ● 4 The Universal Robots R&D lab at its headquarters in Odense, Denmark

“So, in that way, we were leveraging Ansys very much to get the best out of these materials, so we don’t run into hidden traps we haven’t thought about.”

According to Beck, the ‘nucleus’ of each cobot is the highprecision servo motor in each joint, for which the reuse of components across the family proves a fundamental building block of the design and validation process.

“Our cobots have a very modular design. We build them very modularly in a way where internally we are reusing the joints, so that some joints that are maybe in the wrists of the bigger robots like the UR10 are also the base joint for a small 3kg robot.”

With key components in place, for the UR20 and UR30, the team looked to optimise the designs, removing any ‘kinks’ found in previous models.

That involved taking apart how things were done previously and putting it back together, says Beck, “in a way that’s significantly better than the way we’ve done it before. Because with every design, of course, there are known weaknesses.”

Handling this process entirely in-house meant that any issues around manufacturing or assembly that had caused headaches over the years could be engineered out of the newer models. Additionally, the team looked to make its own production processes as automated as possible, from managing multiple suppliers to making parts that can snap together but still meet high-tolerance requirements.

JOINT EFFORT

By improving the abilities of the new designs, adding strength to joints and increasing ease of assembly, the team encountered another key challenge: maintaining its brand’s visual identity.

‘‘ We are really pushing every component to just before breaking point Anders Billeso Beck, Universal Robots ’’

Universal Robot’s iconic blue lid caps on each joint of the cobot are also an indication of how the joint is assembled from two sides. The housing on previous models formed the exoskeleton of the joint, where all the components are put together inside. “That’s why it has the blue cap, because we are accessing it from both sides,” explains Beck.

“In the new design, we designed something that’s just an independent servo motor, which allows us to put the housing on at the end, and basically sliding in, bolting it on, screwing into the housing. And then we can have this closed design instead.”

The closed design added a lot more stiffness to the arm but took away the iconic logo that stood out wherever it was placed in factories, laboratories and kitchens. The new generation instead features monogrammed joint bumpers in the trademark light blue, which maintain the branding, as well as conforming to the team’s ‘Nordic functional’ design language.

“It’s minimalistic, we think it’s nice and pretty, but it’s also functional. It still feels like it’s a product designed to get work done, not to sit in a showroom,” smiles Beck.

“We’re very, very proud actually about the UR20 design, because we think it captures the company’s DNA, where we came from, but also it looks like a clear evolution.”

With the company dead set on filling those remaining 98% of cobot-friendly processes, expect to see far more flashes of the silver and light blue around you soon, automating all manner of tasks.

www.universal-robots.com

COVER STORY 5 6 ● 5 Cobots from Universal Robots are in multiple industries, from laboratories to pizza restaurants ● 6 A modular design allows a servo motor to be used across different cobot models

For full details and other SOLIDWORKS prices visit

Caught your eye? Our prices certainly will FIND OUT MORE, SCAN ME

www.solidx.co.uk/pricing

3 Real-World Examples of Industry 4.0 Happening Now

The design and manufacturing industry has rapidly evolved throughout the 20th century—from the electrification of factories to the introduction of the assembly line, CNC machine, computers, CAD, automation, and more.Now, Industry 4.0 is here.

Artificial intelligence, advanced robotics, additive manufacturing and sustainability considerations are transforming every aspect of how products

are designed and made. The way we work is also changing—whether it’s a design team in the same office or an engineer collaborating with a factory halfway around the world.

Design and manufacturing businesses need to undergo digital transformation to keep up or they risk falling behind. One of the key tools driving this industry shift is Autodesk’s Fusion Industry Cloud. This comprehensive suite of services offers

advanced capabilities such as Autodesk Platform Services, seamless API integration, robust data management, Fusion extensions and more. By leveraging the Fusion Industry Cloud, companies can enhance collaboration, drive efficiency, and achieve sustainability goals to thrive in the era of Industry 4.0. Many companies are already embracing these shifts in the way they work by leveraging the Fusion Industry Cloud. Let’s take a look at three examples.

Sponsored content

1. Newton | Engineering and Product Development

NASA and ESA are planning an ambitious feat with the Mars Sample Return Mission to bring rocks and soil from Mars safely back to Earth for the first time. Newton | Engineering and Product Development is one of the companies helping to make it happen. They’re developing a lid component that will snap shut to capture rocks that are—quite literally—tossed into space.

Newton used generative design in Autodesk Fusion to design the lid’s hinge. Generative design is a tool that leverages AI to automatically create hundreds of design options based on desired parameters for weight, strength, material, and performance enhancements set by an engineer. Teams can then choose a design to move forward with and optimize it as needed to achieve specific goals. With generative design, Newton reduced the lid’s weight by 30% while maintaining its required stiffness.

“I truly believe that humanity is at the dawn of the AI age and using generative design is absolutely essential for any engineering team to remain competitive in the future,” says Alex Miller, lead mechanical engineer, Newton. “It’s a critical tool in our mission to provide customers with optimal solutions and ensure success.

2. BBi Autosport

BBi Autosport is known for its bespoke motorsports vehicles and custom parts. A few years ago, the company began its own digital transformation while designing Hoonipigasus—a 1,400 HP midengine AWD rally racer conceived from the ground up in partnership with Hoonigan Racing.

The BBi team needed to design concurrently and quickly to meet tight race deadlines. With Fusion, they could bring all their aggregated data into one centralized location. They quickly discovered that they could use its cloud-based CAD, CAM, CAE, and PCB design tools to turn prototypes into production-ready parts.

“With almost the click of a button, Fusion is capable of exporting our 3D models to our CNC machine to manufacture right then and there, ending up with a finished part that is ready to hit the racetrack or ship out the door to our client,” says Betim Berisha, co-founder, BBi Autosport.

3. Termobrasa

Termobrasa designs and manufactures energy-efficient water heaters, heat pumps, and more. For the past 50 years, paper ruled their manufacturing until they underwent a significant digital transformation. The company decided to adopt an entirely new workflow for its production line procedures and management with Autodesk Fusion Operations.

Now its entire assembly line is on tablets that provide the latest production updates and order requirements. Production orders move seamlessly upon completion from one station to the next, and paper has disappeared from the manufacturing floor. They’ve also recently begun to create Fusion 3D models of product designs that were still primarily on paper as well.

In embracing Fusion Industry Cloud, companies are not just preparing for the future; they are shaping it, setting new standards for innovation, efficiency, and collaboration in Industry 4.0.

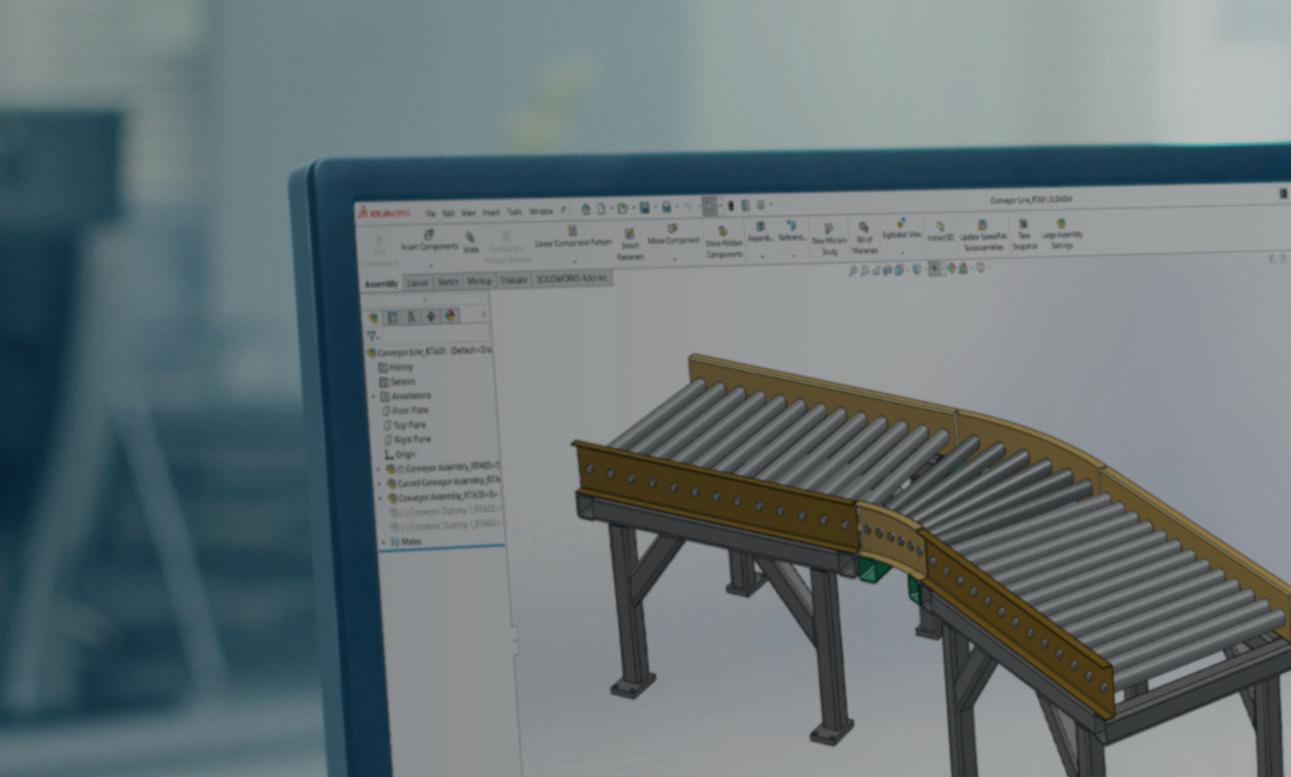

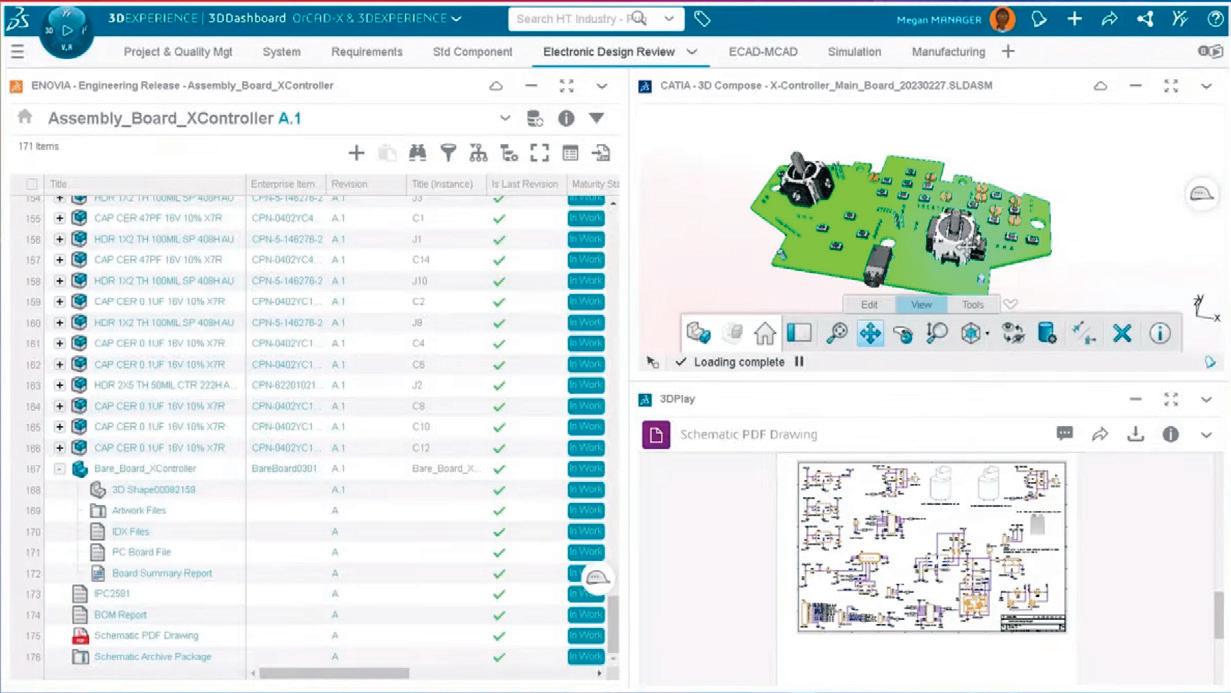

SOLIDWORKS

All roads lead to the platform

Dassault Systèmes is betting big on its 3DExperience Platform. With AI and other new technologies only being developed for the platform, could this mean traditional desktop Solidworks users are about to get left behind? Greg Corke reports

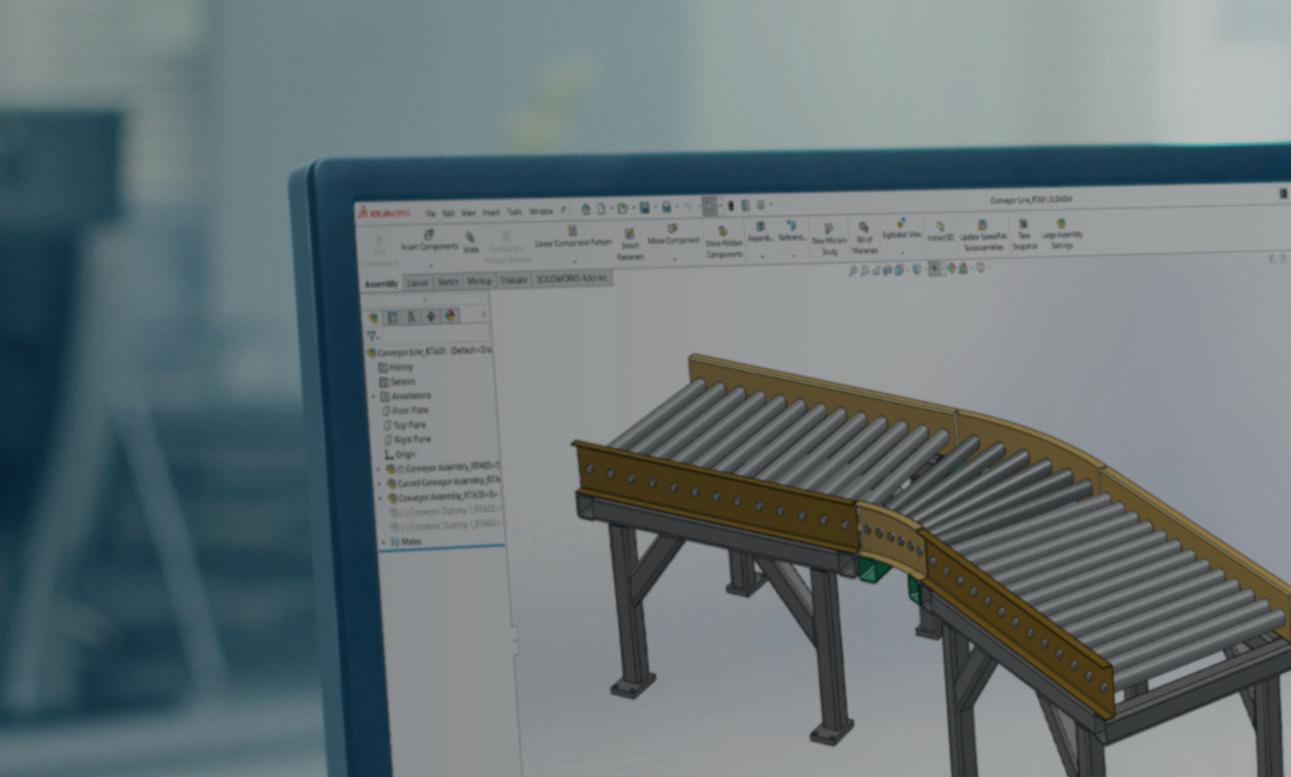

Like many of its competitors, the long-term strategy for Dassault Systèmes Solidworks is to move its customers to the cloud – the multi-app 3DExperience Platform. Launched 12 years ago to provide Dassault users with easy access to a variety of branded applications and services needed for their different workflows, its offering for core Solidworks users has continued to struggle. Browser-based Solidworks xApps have been less than inspirational in enticing users away from their existing, much-loved, desktop software.

However, as Dassault presented at its 3DExperience World user event in February, new AI-enabled features might prove the incentive for designers to move to the cloud.

Over the next few years, if your data isn’t on the 3DExperience Platform you won’t get access to new AI powered capabilities. All of Solidworks’s AI developments will be on the platform, including modelling productivity tools, automated drawings, enhanced data management and design assistants that offer real time feedback on performance (simulation) and manufacturability.

The word ‘data’ is key. Customers will still be able to use Solidworks on the desktop for years to come, but to access new AI-powered capabilities, their data can’t be there too.

As Solidworks CEO Manish Kumar explained during his 3DExperience World keynote, Solidworks now has two flavours: ‘with the platform’, referring to the traditional desktop version with data stored in the cloud, or ‘on the platform’ with the browser-based version.

AI: PAST, PRESENT, AND FUTURE

Dassault Systèmes Solidworks is riding the current wave of excitement around AI, but the company is by no means starting out on its AI journey, having tools that date back several years.

Design Assistant uses AI and machine learning to learn how users work, offering suggestions based on their individual workflows. Tools including ‘Selection Helper’, ‘Mate Helper’, ‘Sketch Helper’ and ‘Smart Mate’ are currently available for the platform-native Solidworks xDesign tool, but will soon make their way into desktop Solidworks, as Kumar told DEVELOP3D.

“We are starting to use the same algorithms that were developed for [xApps] in order to put it back into Solidworks with the platform, so now Mate [Helper] is almost there, Selection [Helper] we’ll do the same, Sketch [Helper] we’ll do the same, but unless your data is on the platform, we can’t do anything.

“Think of it this way: All these AI models that we build, it takes some input in order to learn, or you provide some data in order for it to learn. The output can be given to anyone, whether it’s our xApps, our Solidworks, or even

Catia for that matter,” he said.

During his keynote, Kumar showed an AI ‘self-driving’ mode for both desktop Solidworks and xDesign that predicts which commands a designer may want to use next. “Our intention is to make it irresistible and a very smooth design experience for you,” he said. “You are always in full control, by the way, and you can use your regular commands anytime you like.”

He followed with a new AI driven ‘image to sketch’ capability that can automatically trace a sketch on top of a picture to use as the basis for a new 3D model.

Solidworks is also working on a new tool designed to turn third party data into parametric models. “You give me a model from any system, whether it is a point cloud, whether it is solid geometry coming from some other CAD system or neutral file format, we want to give the parametric feature for that particular model using AI,” Kumar told DEVELOP3D. “Why is it important? Because once it is parametric, you will be able to make modifications there.”

AI is also being used to accelerate more mundane processes. While it’s easy to generate 2D views from 3D models, creating final drawings takes a huge amount of time. As a result, the company is looking to introduce automated drawings to Solidworks by the end of the year.

During his keynote, Kumar showed the technology working on both desktop Solidworks and xApps, via the platform. “Drawings are driven by standards and well understood manufacturing needs,” he said. “Using this open available information, we are working to provide you with AI-driven generative drawings. But of course you can go back to this drawing and make any manual modifications that you may want. It will help you save precious time, but you will still be the final authority.”

All the technologies mentioned above could have a positive impact on the day-to-day productivity of all designers and engineers. However, Kumar admits that Solidworks can sometimes be too focused on design, or drawings, or selection etc. Moving forward, there’s huge potential to harness AI to make simulation and manufacturing a much more integrated part of the design process.

Kumar described a common iterative workflow, where simulation and manufacturing are typically used at the tail end of design and any identified issues often result in a lengthy cycle of design changes.

“It is a no brainer that if a problem is identified at the design time, it’s the cheapest for the manufacturer. If it is identified here, it is also the most environmentally friendly

‘‘ We want to think in a holistic way. And if you want to think in that holistic way, no way anyone will be able to do anything if they are just bound to a desktop kind of environment. Embrace the platform, because we want to go there. Big Data, consolidated, that’s the way to go Solidworks CEO Manish Kumar ’’

24 APRIL / MAY 2024 DEVELOP3D.COM

FEATURE

because you are trying to reduce the waste,” he said. He referenced ‘left shift’, where companies want to capture all the problems as soon as possible. “If you’re trying to shift left, AI is not just about design,” he said. “Rather, when I design something, if it is going to cause a problem in downstream operation, can I also predict that? We can if these sequences of things are happening on the platform.

“We are not just looking at AI from a design centric [point of view] in a confined space. We are looking at it from a holistic point of view that how can we help our clients become more business centric, be more profitable, reduce time to market, be more sustainable for that matter?”

In other words, design becomes less about design-testiterate loops, and more about giving real time feedback on performance and manufacturability from the very early stages.

Of course, Solidworks CAD is just the beginning. Once data is in the platform it can also link into downstream manufacturing processes, as Kumar explained. “You can create manufacturing bill of materials, you can link it to ERP Delmiaworks, where every single step of how this manufacturing BOM was converted into what series of manufacturing steps operations were performed on it.

“If we know all that, we have a lot of data for a given company that when you get something like ‘this’, ‘these’ are the operations you perform. We should be able to tell you that when you come up with something new, maybe there is an alternative design. Or certainly there is an alternative series of processes that you can perform.

“At times it might also happen that it suggests a longer manufacturing process to reduce the overall time to market or to make it more efficient, which a normal human being will not think about.”

According to Kumar, all of this is achievable in the next five years. Longer term, he sees an increased role for virtual twins as part of a broader Dassault Systèmes play where the company helps its clients build virtual twins of real objects covering everything from design and manufacturing all the way to shipping.

“We also want to go in the users’ aspects of it, in the sense if you try to use these things in real life, what is the data being produced and can we use that data in order to improve it further?” he said. “The next step is can these virtual twins live without any context?”

Kumar gave the simple example of a loudspeaker. “It needs to have a context, because how is that speaker going to operate in a room like this, versus outside?” he said.

On a larger scale, he referenced a building, pointing out that a single virtual twin is never enough. You need to put it in the context of a city. What will its relationship be with other buildings in terms of shadows cast and air flow? What impact will it have on transport, on water supply etc.? The answer, he believes, is multiple virtual twins connected through some kind of relationship.

“Then you need to simulate on a much larger scale, in order to come up with solutions that you will never be able to do based on just a study of one virtual twin.

“This is where we want to go, where we want to think in a holistic way. And if you want to think in that holistic way, no way anyone will be able to do anything if they are just bound to a desktop kind of environment. Embrace the platform, because we want to go there. Big Data, consolidated, that’s the way to go.”

PROTECTING IP

With industry wide concerns about the impact of AI on Intellectual Property (IP), Solidworks has been very clear

that customers’ IP will be protected. “We will never give the IP of one company, by extracting the knowledge and know-how, to someone else,” said Kumar.

“We have a very clear barrier between IP and knowledge,” said Gian Paulo Bassi, executive vice president, 3DExperience Works. “We want to create models that represent knowledge in the field of manufacturing, but what is important is the technology behind the creation of those models. But how these models are then built, then populated, so to speak, that is on your own data.”

Bassi sees that AI could present an opportunity for manufacturing firms to share IP, in a similar way to how big pharmaceutical companies are working together. He gave an example in the aerospace industry, “What if Company A has a specific knowledge on a certain type of composites, and they want to expand into another type of composites?” he said. “So, maybe Company B has knowledge on aluminium fabrication, and in exchange they get knowledge and know how on composite fabrication. There is a mutual advantage.”

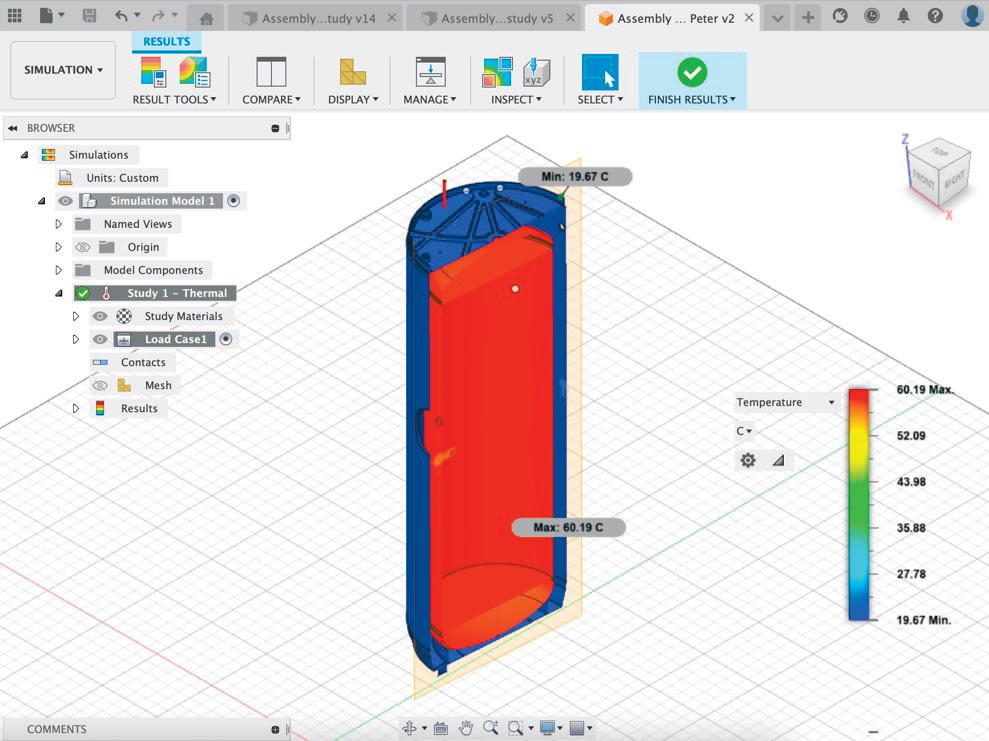

BREAKING DOWN BARRIERS TO SIMULATION

Simulation forms a critical part of many product development processes, but it remains massively underutilised by designers. Kumar said that he wants to bring simulation to every Solidworks user, but there are two major barriers to adoption.

The first is fear, he said, a sense that simulation is something which is only done by analysts. Solidworks Simulation has done a good job of addressing the needs of designers, by putting easy to use tools inside the Solidworks environment, but he admitted that simulation still needs to be taken one level further down. “We want to make it approachable to an extent where even kids should

● 1 Solidworks is looking to introduce automated drawings by the end of the year

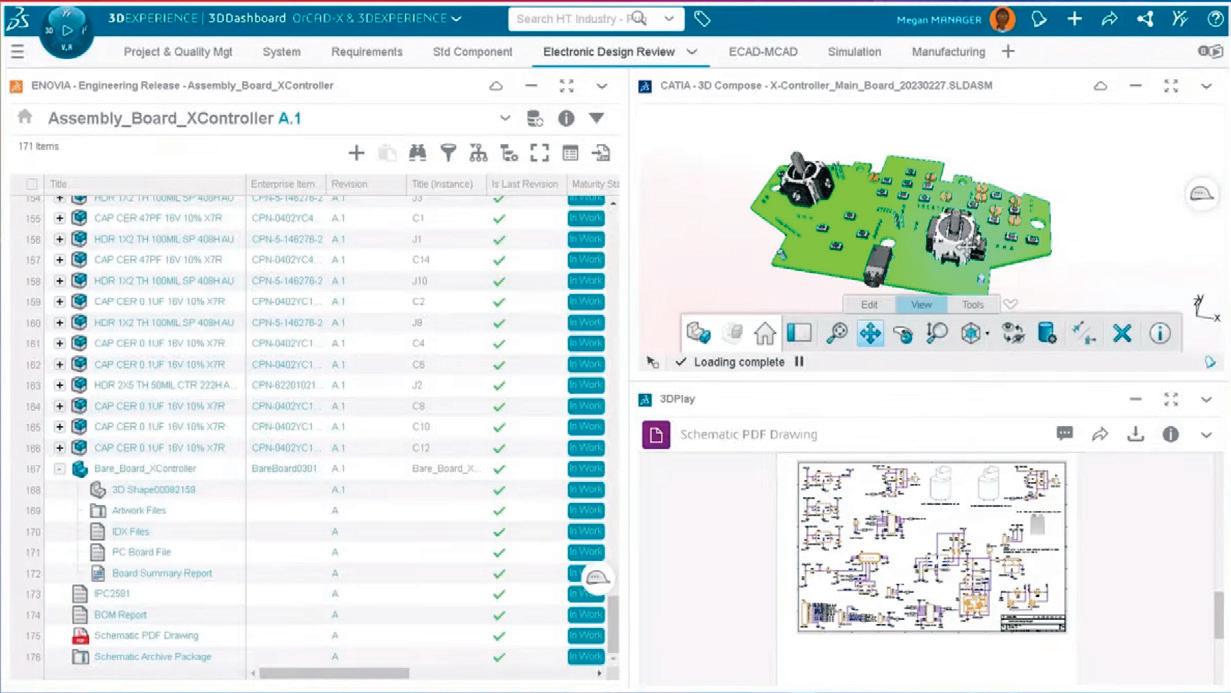

● 2 Dassault Systèmes and Cadence now offer tighter integration between MCAD and ECAD

DEVELOP3D.COM APRIL / MAY 2024 25

1 2

be able to use it, without thinking about it, without getting scared of it,” he said.

According to Kumar, the key to this is making simulation studies much easier to define. “We need to convert simulation speak into something which is a layman speak,” he said.

“Rather than saying ‘how many newtons do you want to apply?’, you change the language to something like ‘are you trying to press it with a thumb, are you trying to press it with a palm, are you trying to stand on it, or is there an elephant standing on it?’. If you try to speak in those terms, anyone can get it. Even a kid will get it.”

The second barrier is a lack of available hardware. Kumar said that while an iPad can be used for design, using xApps, it is not powerful enough to run simulation. Today, you still need a high-end laptop or high-end computer. But that is changing, he said. Kumar described having a simple simulation environment on the iPad, where all the processing is done in the cloud using a credit system. “If it is so cheap [and simple

to use] that anyone can start to leverage it, I think we will break those two barriers.”

MCAD MEETS ECAD

For electromechanical design, mechanical engineers using Solidworks have historically collaborated with electrical engineers by transferring files to tools like Altium Designer, or any other electrical or PCB design software that supports the IDX file format.

In February Dassault Systèmes and Cadence announced a partnership designed to provide a much tighter integration between MCAD (Solidworks) and ECAD (Cadence OrCAD-X or Cadence Allegro-X).

The big difference with this new approach is that it’s a platform-to-platform integration, between the 3DExperience platform and the Cadence Allegro platform. Push a button in Solidworks and all the data gets passed through the 3DExperience Platform, automatically notifying the designer using OrCAD or Allegro. They then get to approve or reject any changes,

and this works bi-directionally.

According to Kumar, this approach provides a single source of truth, with full traceability of what was changed, why it was changed, who changed it and more.

THE CLOUD CARROT

With Solidworks 2024 every new seat purchased comes with cloud services, which is essentially a collection of 3DExperience platform workflows ranging from simple share and markup to full on data management.

Users can dip their toes in as-and-when they are ready. “Nothing’s being thrust on our customers, they can do anything they want with our tools,” emphasised Mark Peterson, senior industry process consultant at Dassault Systèmes.

There are three levels of engagement with cloud services, which Dassault defines as ‘Share and Markup’, ‘Store and Revise’, and ‘Manage and Control’.

Share and Markup allows you to share a file internally or with a manufacturing

TECH FROM THE SHOW FLOOR - 3DEXPERIENCE WORLD

Some of the tech highlights from the show floor at the recent Solidworks conference, 3DExperience World

Driveworks

Driveworks was showing its latest online configurators that can be embedded in a website, so customers can configure and order personalised products. The customer gets an instant quote and essentially does all the work for a process that, when done manually in the traditional way, can be error prone and take hours.

The company highlighted a new configurator aimed at the Australian market, for companies that customise utility vehicles (utes, for short). Customers can choose different canopies, trays, sideboards and more. If a folding ladder is selected, mounting brackets are automatically added.

Customers get real time pricing and a nicely rendered interactive 3D model of their specific configuration. The

system then automatically generates quote documents, and all the manufacturing data.

Designs can also be viewed in AR in any environment using an iPad. The system generates a QR code, which you simply snap with the camera.

Seeing a ‘ute’ in the context of the exhibition show floor might not be the best use of this technology, but picture a conveyor system in a factory or a consumer product in the environment in which it will be used, and you start to imagine the potential.

Driveworks has built a tonne of sample configurators for various products including agricultural trailers, scissor lifts, industrial emergency showers, and folding doors.

The UK firm also offers DriveWorks Pro to build your own Solidworks automation and online 3D product configurator solutions and DirectWorks Solo for part, assembly, and drawing automation inside Solidworks.

Demo of SolidCAM’s iMachining milling technology

Elysium

Elysium, a specialist in 3D data interoperability, showcased two main products: 3DxSuite and CADfeature.

3DxSuite handles data conversion and model-based definition, such as creating technical data packages or derivatives that need Product Manufacturing Information (PMI) within them.

At 3DExperience World the company demonstrated several new features including an HTML Exporter for Technical Data Packages, so TDPs can be created and published in HTML as well as 3D PDF. The company also showed a prototype of a new PMI Checker designed to prevent the publication of incomplete PMI through ‘comprehensive verification’.

CADfeature is a migration platform for companies that are looking to consolidate CAD systems or to move off a legacy system. Elysium told DEVELOP3D that in recent years there has

been an increase in demand for migrating to Solidworks.

Importantly, the software allows firms to preserve the feature history tree, assembly relationships, and associative drawings, as well as nongraphic model properties such as attributes and metadata. Of course, no two CAD system are identical, and Elysium admits that while some CAD models may come over 100% feature-based, others may not, such as those with certain surfaces. In such cases, the company explains that the software has a fallback method where geometry is preserved but some of the features may be supressed.

CADfeature can also be set up for automated batch processing, where jobs can be scheduled to periodically perform a variety of different translation types.

The software supports a wide range of CAD tools including Siemens Solid Edge, Siemens NX, Autodesk Inventor, PTC Creo, and DS Catia - and of

course DS Solidworks and the 3D Experience Platform.

Eagle Point Software

Eagle Point is well known to DEVELOP3D’s sister publication, AEC Magazine, for its architectural, engineering and construction focused learning tools, but we didn’t know that the company also has a focus on product design and manufacturing. Over the last couple of years, the company has been developing a range of Solidworks content for its ‘Pinnacle Series’, focusing on everything from basic modelling to more complex workflows such as simulation (which launched at 3DExperience World).

The Pinnacle Series has both e-learning and learning management system (LMS) components for tracking workforce, identifying skills gaps, collaborating and sharing organisational information.

HCL CAMworks

HCL CAMworks develops a range of Solidworks-integrated CAM software, covering everything from 2D, 2.5-axis, 3-axis and 5-axis to mill turn, wire EDM and others. It includes Solidworks CAM, which comes with a Solidworks subscription, plus a range of CAMworks modules for more advanced features. According to the company, one of the foundations to its software is the Technology Database (TechDB). This provides ‘intelligence’ for ‘knowledge-based’ machining

26 APRIL / MAY 2024 DEVELOP3D.COM PROFILE

FEATURE

Driveworks ‘Ute’ configurator AR demo

partner for markup. From within Solidworks, users click the share button, punch in an email, and the file is then stored in a secure share location on the 3DExperience Platform for the third party to access, view and markup. Once done, feedback is seen directly inside Solidworks through the task pane.

“One of the things I really love about share markup is that you still maintain control of that intellectual property, which is something that has always been challenging for a lot of our clients, because if you email somebody a Solidworks file, they have your data, they have your feature tree, they have your exact dimensions,” said Peterson.

‘Store and revise’ allows customers to store their data on the 3DExperience platform. This can then be accessed from anywhere, on any device, and augmented with simple data management tools like Revision Management.

‘Manage and control’ offers much more comprehensive data management on the platform, although this requires some

handholding. “We have tools that we use to migrate our users from any PDM system to 3DExperience Solidworks or platform,” said Peterson.

THE PLATFORM FUTURE

It appears that Dassault Systèmes Solidworks will be channelling most of its development resources into its 3DExperience platform over the next few years. And if you don’t come along for the ride, you won’t get access to the most advanced new features, potentially optimising everything from modelling and drawings, to simulation, manufacturing, and electromechanical design.

The challenge for the company is how to encourage customers to make the move. One thing seems clear: it’s not going to force them. Desktop Solidworks with local data is going nowhere fast.

Instead, Solidworks looks set to dangle a series of increasingly large carrots - if ‘Share and Markup’ is your snack-sized Chantenay, AI could be your farmer’s

prize-winning goliath.

Of course, it’s still very early days for AI at Solidworks and MCAD in general, and it remains to be seen how new features will appeal to the average Solidworks user. While upfront simulation and manufacturing might not be for everyone, it’s hard to imagine that even the least progressive firms won’t perceive real value in automating drawings.

There’s also the question of cost, in terms of software licensing, cloud storage and cloud processing. Solidworks appears to be taking a similar token-based approach to Autodesk, where Fusion customers pay for computational services including generative design, simulation and rendering.

Perhaps the most interesting point about Solidworks and AI is that all of this could be happening in the next five years. Solidworks is one of the most loved CAD tools out there, but it could be about to experience its biggest change in its quarter-century history. The question is: who will join it on its journey? www.solidworks.com

strategies, allowing companies to ‘automatically generate’ toolpaths. In essence, once a part has been programmed, those algorithms and information can be saved to a company’s TechDB, so they can be used again - a huge time saver.

At 3DExperience World the company launched CAMWorks 2024, and was demonstrating several new features. One of the highlights is Machine Aware Programming which allows users to include a ‘digital twin’ of a CNC machine directly inside Solidworks. According to the company, this ensures the digital model mirrors the physical machine’s capabilities for more precise and dependable programming.

CAMWorks 2024 also includes a new UI enhancement - hover a mouse cursor over a feature in the model, and the operations that are being used to machine that feature will pop up.

The new release also introduces an array of multi-axis toolpaths for both rough milling and finishing. 5-axis machining was supported in previous versions of the software, but the roughing and finishing routines are now more automated.

SolidCAM

SolidCAM offers a huge range of Solidworks-integrated CAM software but the company used 3D Experience World to primarily showcase its advanced mill turn and Swiss turning capabilities. These have been ‘significantly enhanced’ in the last couple of versions with what SolidCAM describes as ‘drag and drop’,

‘plug and play’ functionality, plus improvements to make the software more visual and easier to use.

The company also gave a live demonstration of a tool cutting precipitation hardening stainless steel using its patented iMachining high speed milling technology.

iMachining is designed to create faster and safer CNC programs to machine mechanical parts, while maximising tool life. The amazing thing about the demonstration is that the steel and the tool didn’t even get hot. According to SolidCAM, this is all down to iMachining’s algorithms which help maintain an extremely constant chip size, resulting in a constant load on the part, the tool and the machine. A SolidCAM spokesperson explained that there’s no linear force against the tool, only rotary force, and all the heat comes out with the chip.

Workstation technology

3DExperience World was a natural hotbed for workstation tech, with plenty of standout products for Solidworks users.

HP, Dell and Lenovo had a tonne of mobile workstations on show, but it was the HP ZBook Firefly G10 A and Lenovo ThinkPad P14s mobile workstation that stood out for us. Both pro laptops have a compact 14-inch form factor, so are highly portable and energy efficient, but also deliver plenty of performance for most Solidworks workflows. The interesting thing about these machines is

that, instead of having an Intel processor and separate Nvidia GPU, they are powered by an AMD Ryzen processor with a GPU built in. There’s a whole load of potential benefits. Read our in-depth report on page 44 to find out more.

Nvidia used 3DExperience World to launch the Nvidia RTX 2000 Ada Generation, a low-profile graphics card designed for small form factor desktop workstations, such as the HP Z2 SFF/Mini and Lenovo ThinkStation P3 Ultra.

It’s an important release for Solidworks users as it hits the price / performance sweet spot for those who want to take their design workflows beyond Solidworks and into the realms of visualisation with tools like Solidworks Visualize and Luxion KeyShot. Learn more on page 8 AMD was showcasing its range of AMD Radeon Pro GPUs, along with Dell, HP and Lenovo workstations with AMD Threadripper Pro CPUs with up to 96-cores. Mechanical engineer and product designer Adi Pandzic unveiled his latest creation - a complex motorbike design, modelled in Solidworks and rendered in Solidworks Visualize using an HP Z6 G5 A workstation with AMD Ryzen Threadripper Pro CPU and AMD Radeon Pro W7900 GPU.

Dell gave a soft launch to its new CAD-focused entry-level desktop workstations, the Dell Precision 3280 CFF and Precision 3680 Tower. We refer to this as a soft launch because both machines feature 14th Gen Intel Core processors, which at the

Adi Pandzic Solidworks model on an HP ZBook Firefly G10 A

time had not been announced. Since then Dell and Intel have released full details, which can be found at www.develop3d.com/ workstations. The show floor also brought up some interesting options for remote workstations. Lenovo showed how it can pack up to seven ThinkStation P3 Ultra workstations in a 5U rack (see www.tinyurl.com/Lenovo-cloud), while HP showed off the latest advancements in its HP Anyware remoting software, demonstrating how a powerful desktop workstation can be accessed remotely from a standard laptop.

Sony offered a visual attraction, showcasing its Sony ELF-SR1 Spatial Reality Display which gives the illusion of viewing a model in true 3D without the need for glasses. The device consists of a 15.6” 4K LCD panel which shows independent left- and right-eye images, which are directed to each eye via micro-optical lens. With built in eye tracking, the display adjusts the view as you move your

head, so you can explore the 3D model from any angle. The results are very impressive.

The initial focus for Sony was on DCC and game developers, with SDKs for Unity and Unreal Engine, plug-ins for ZBrush, 3ds Max and Maya, but the company is now turning its attention to CAD.

The idea is that you’d use a 2D display for modelling and the 3D display to get inside your design.

Considering Sony was exhibiting at 3DExperience World, it wouldn’t take a genius to work out that it has something in the pipeline for Solidworks users. Beyond direct support, the monitor should work with any tool that supports openXR. There’s also a file viewer for OBJ, STL and glTF.

Finally, 3DConnexion was showing how its range of 3D mice can be used to improve model navigation in Solidworks, from the portable SpaceMouse Compact to the cable free SpaceMouse Pro Wireless Bluetooth Edition with plenty of configurable buttons.

DEVELOP3D.COM APRIL / MAY 2024 27

A NEW PERSPECTIVE

» The launch of Apple’s new Vision Pro spatial computing headset has got enterprise software vendors excited. Stephen Holmes headed to the Budapest headquarters of Shapr3D to see how the company is bringing its own product design capabilities to the Vision Pro

With the bulk of CAD software programmes locked into PC ecosystems, it’s been interesting to see which companies have been fastest to create tools for the Apple Vision Pro. Swimming somewhat against the tide is Shapr3D, which has been building its CAD and visualisation offering since 2016, when it first appeared on the Apple iPad – and was launched as part of the Apple keynote that year, no less.

Shapr3D quickly switched to the Siemens Parasolid kernel, cementing its desire to be a professional 3D CAD software, and has continued to evolve ever since, moving onto the Mac desktop, spreading onto Microsoft Windows, and adding elements like 2D drawings, a visualisation toolset for rapid rendering, and now parametric historybased modelling.

All of this continues to work in unison across multiple devices – from an iPad sketch concept on the train, to the Windows workstation on your desk, to a design review on a wall-mounted Microsoft Surface Hub power screen. Throughout, the software retains its intuitive nature, preempting tool choices in the menu as you hover over surfaces or edges, whether you are using a mouse or an Apple Pencil.

Its versatility, accessibility and price has made Shapr3D a rising star among teams concepting new product ideas. Its ability to run on Apple devices, buoyed by its longstanding connection to the Californian company since the early iPad days, has put it in prime position to embrace Apple’s latest hardware.

Initially sceptical of the world of head-mounted displays, even Shapr3D CEO István Csanády has been impressed by what his company’s software can achieve in the world of spatial computing.

DESTINATION: BUDAPEST

In March 2024, I visited Shapr3D’s headquarters in Budapest, Hungary, in order to trial the software it has built specifically for Apple’s Vision Pro headset.

Before strapping in, Csanády explained that the product is now an integral part of the Shapr3D ecosystem and workflow. “It is going to enable you to collaborate and design in a way that you have never experienced before,” he said.

“Thanks to the unique capabilities and the incredible power of the Apple Vision Pro, we’ve managed to build a workflow that is unparalleled and going to elevate your design reviews and design workflow to a whole new level.”

Much of this comes down to the seamless pathway between devices – Shapr3D on the Vision Pro needs no tweaking, optimising or rebuilding. This immediately reduces current workloads, by using native CAD and rendering and results in fully editable models that can be updated instantly.

Collaboration and design reviews take full advantage of this technology, where one person hosts the meeting and has control over editing the model and applying materials, while other users can join in and see any updates in real time. For those in the same room, the shared model works over the local network between headsets, without need for expanded WiFi connections.

The emphasis on ease of use is palpable, allowing other stakeholders in the design process – who may not have access to CAD or high-end workstations – to get a better understanding of the product and join in review sessions just as if they were in the same location as the designers.

An easily shared link and an Apple headset is all they need.

THE VISION PRO EXPERIENCE

Given the build-up around the hardware, finally slipping one over your head is a relatively standard XR experience.

Shapr3D’s XR capability takes designs off 2D screens for deeper exploration by designers

28 APRIL / MAY 2024 DEVELOP3D.COM FEATURE

PERSPECTIVE

Apple’s not the only company to have made its goggles lighter, better fitting and easier to adjust. The video passthrough was bright enough, if still a little like looking at the world through a filter.

However, it was the application, not the device itself, that we were here to evaluate: Shapr3D’s CAD and visualisation abilities running in real-time XR.

A car dashboard and centre console was accessed quickly, with Shapr3D’s product manager Mátyás Barsi controlling the session via hand gestures and the standard Apple keyboard and trackpad.

The models didn’t disappoint. Textures such as the leather grain were all distinct, the colours were sharp and the ambient real-world lighting rolled off the curves of the dashboard. Reflective elements like chrome picked up on nearby colours like the green of a nearby plant, further adding to the realism.

The workflow that takes your CAD model or your renders and immediately places them into a detailed 1:1 scale environment via an off-the-shelf product makes

this markedly more impressive than anything else we’ve seen in XR, outside of super high-end set-ups.

With just eight years of development under its belt, Shapr3D is clearly looking to use its nimble, crossplatform abilities to its advantage, wedging itself further into designers’ workflows. Its XR ability is a usable collaboration and review tool, and a brilliant way to take designs off a 2D screen and validate them at your desk.

The company’s move into the virtual realm comes as it prepares for real-world expansion. The new office space in the city overlooking the Danube is soon to be a hive of activity, with new team members from as far afield as the US and Spain relocating to Budapest to join the business.