TASK 01

PC10: Understand the whole life carbon implications of procurement methods, materials, components and construction systems.

PC35: Understand the operational and embodied carbon implications of chosen materials, components and systems.

PC45: Understand processes for selecting materials, finishes, fittings, components and systems, based on consideration of quality and performance standards, the impact on Country and the environment, and the whole life carbon impact of the project.

Kamikatz Public House / Hiroshi Nakamura & NAP

Kamikatsu, located in the Tokushima prefecture, is dedicated to achieving a zero waste goal and becoming a sustainable recycling community. The town has successfully reached a recycling rate of 80% through the meticulous sorting of waste into 34 distinct categories. Items that have been used are organized and presented in the recycling center as if they were in a retail store. As society faces challenges with the current model of mass production and consumption, there is a growing global anticipation for the success of such initiatives.

RESTAURANTS & BARS, BREWERY • KAMIKATSU, JAPAN • 2015 STRATEGIES

Embodied Carbon:

- Recycled Materials (Stages A1-A3): The designers utilized a significant amount of recycled materials. For example, the facade features glass windows collected from abandoned houses, and the interior includes wooden materials sourced from dismantled buildings. This approach greatly reduces the embodied carbon typically associated with the production of new construction materials.

- Local Sourcing (Stages A4, A5): Materials were sourced locally to minimize the carbon footprint associated with transportation. This practice not only reduces emissions but also supports the local economy.

Operational Carbon:

- Energy Efficiency (Stage B6): The design incorporates natural ventilation and lighting, which reduces the need for artificial climate control and lighting systems. This significantly lowers the building’s energy consumption and, consequently, its operational carbon emissions.

- Insulation (Stages B1, B4): Effective insulation was used to maintain a stable indoor climate, reducing the demand for heating and cooling systems, which are major contributors to operational carbon emissions.

End-of-Life Carbon:

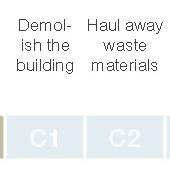

- Design for Disassembly (Stages C1-C4): The building is designed with the end of its life in mind, allowing for easy disassembly and reuse of materials. This ensures that when the building is no longer in use, its components can be recycled or re-purposed rather than ending up in a landfill.

Modular Construction: The use of modular construction techniques facilitates the reuse and recycling of building components, further reducing the end-of-life carbon impact.

Additional Strategies:

- Community Involvement (Stage D): The designers engaged the community in the building process, particularly in sourcing and recycling materials. This involvement fosters a culture of sustainability and awareness, indirectly contributing to reduced carbon emissions.

- Potential for Renewable Energy Integration (Stage B6): Although not explicitly mentioned in the provided article, integrating renewable energy sources such as solar panels would further reduce operational carbon, enhancing the building’s overall sustainability.1

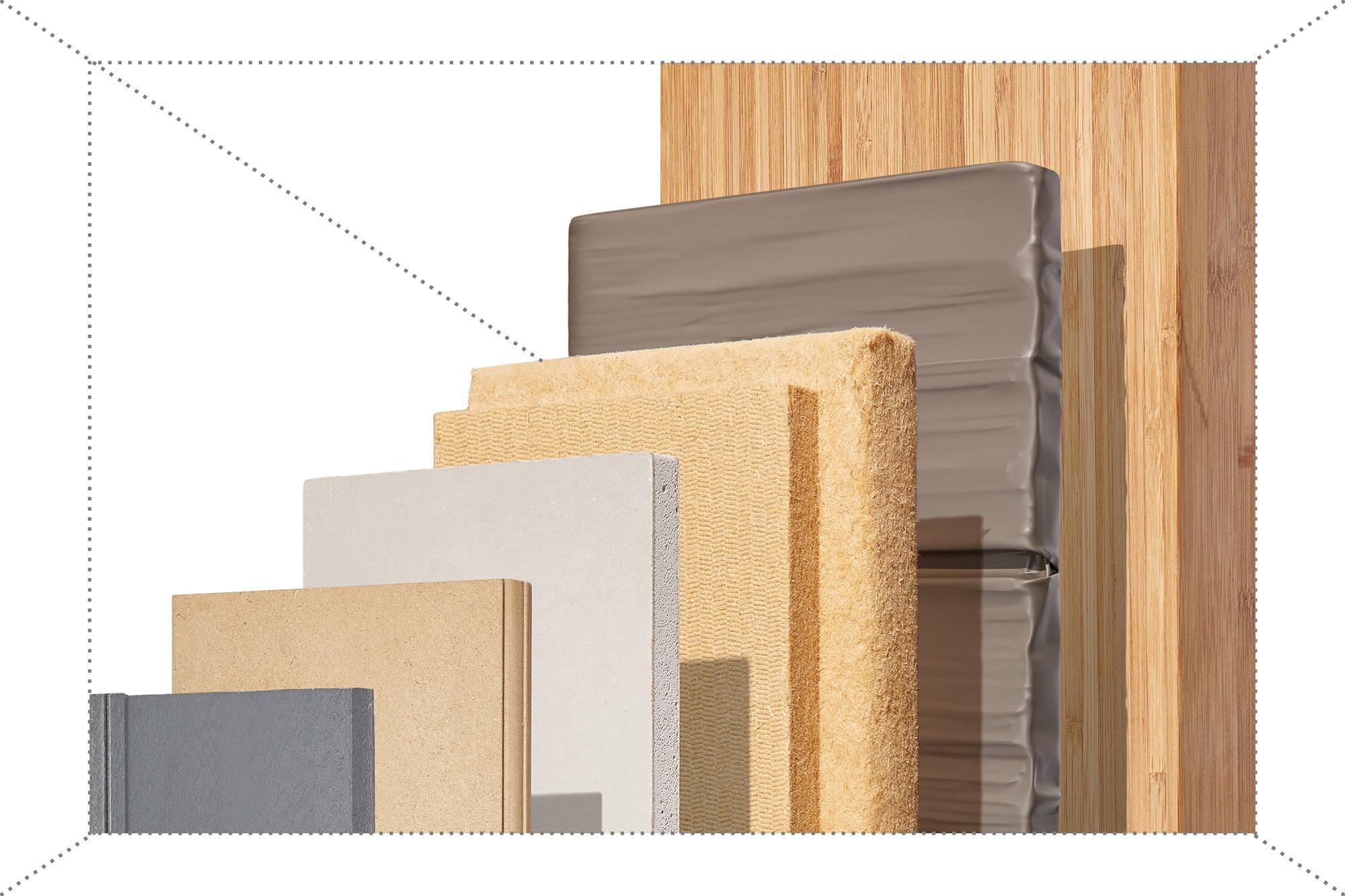

MATERIALS/COMPONENTS

Recycled Materials:

- Glass Windows (Stages A1-A3): Collected from abandoned houses, these recycled windows are used for the building’s facade. This significantly reduces the embodied carbon typically associated with the production of new glass, as the energy-intensive process of manufacturing new glass is avoided.

- Wooden Materials (Stages A1-A3): The interior incorporates wooden materials sourced from dismantled buildings, minimizing the need for new timber and preserving forests, which act as carbon sinks. Reusing wood reduces carbon emissions related to logging, processing, and transportation.

Local Materials:

- Local Timber (Stage A4): Utilizing locally sourced timber for various structural and decorative elements minimizes transportation emissions, further lowering the project’s overall carbon footprint. Local sourcing supports the local economy and reduces environmental impacts associated with long-distance transport.

Innovative and Unconventional Materials:

- Recycled Paper Insulation (Stages A1-A3): This innovative insulation material reduces waste and lowers the carbon impact compared to traditional insulation materials. Recycled paper insulation typically requires less energy to produce, contributing to a lower embodied carbon footprint.

- Sustainable Concrete Alternatives (Stages A1-A3): The project may include low-carbon concrete alternatives, which incorporate industrial by-products like fly ash or slag. These materials reduce the carbon footprint of conventional concrete by lowering the need for cement, a major carbon emitter.

Carbon Implications

- Glass Windows:

Recycled glass significantly reduces the carbon footprint compared to new glass production. This approach avoids the high energy consumption associated with manufacturing new glass and reduces waste. According to Sustainability Victoria, using recycled glass in construction can significantly cut down embodied carbon. They report that incorporating recycled glass fines into construction materials reduces the need for virgin materials and lowers greenhouse gas emissions during production 2

1 "Kamikatz Public House / Hiroshi Nakamura & NAP," ArchDaily, April 19, 2018, accessed June 9, 2024, https:// www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

2 Sustainability Victoria, "Using Recycled Glass Fines in Construction and Product Design," accessed June 9, 2024, https://www.sustainability.vic.gov.au/news/news-articles/using-recycled-glass-fines-in-constructionand-product-design.

Whole-life Carbon

Fig.1 . Life Cycle Stages

Fig.2 . Air Flow

Fig.4 . Recycled Components in Room

Fig.3 . Recycled Windows

Embodied Carbon ⬇Operational Carbon ⬇

Whole-life Carbon

Fig.1 . Life Cycle Stages

Fig.2 . Air Flow

Fig.4 . Recycled Components in Room

Fig.3 . Recycled Windows

Embodied Carbon ⬇Operational Carbon ⬇

- Wooden Materials:

Reused wood minimizes the need for new timber, thereby reducing carbon emissions related to logging, processing, and transportation. Wood also acts as a carbon sink, storing carbon dioxide absorbed during tree growth, which further reduces the carbon footprint. Recycling Bristol indicates that reusing wood can save approximately 2 tons of CO2 per ton of wood reused, contributing to significant carbon savings.3

Local Timber:

- Local sourcing drastically cuts down on transportation emissions, contributing to a lower overall carbon footprint for the project. This practice also reduces the environmental impact associated with long-distance shipping. According to Wade Architecture, local sourcing can reduce transportation emissions by up to 60%, making it a highly effective strategy for carbon reduction.4

Recycled Paper Insulation:

- Recycled paper insulation has a lower embodied carbon compared to traditional insulation materials. Its production process typically requires less energy, and it utilizes waste paper, contributing to a circular economy and reducing overall carbon emissions. Research from First American Roofing and Siding found that recycled paper insulation can reduce embodied carbon by 40% compared to fiberglass insulation.5

Sustainable Concrete Alternatives:

- Incorporating industrial by-products in concrete mixes reduces the carbon emissions associated with traditional concrete production. By using materials like fly ash or slag, the need for cement is lowered, which significantly decreases the embodied carbon of the concrete. A comprehensive review by Shukla et al. highlights that using fly ash can reduce the carbon footprint of concrete by 20-30%, providing a substantial reduction in emissions from one of the most carbon-intensive construction materials.6

CONSTRUCTION SYSTEMS

- Modular Construction (Stages C1-C4): Facilitates easy disassembly and reuse, extending the lifecycle of building components and reducing waste.

- Design for Disassembly (Stage C1-C4): Ensures materials can be repurposed at the end of the building's life, minimizing landfill waste.

- Energy-Efficient Design (Stage B6): Incorporates natural ventilation and insulation to reduce operational energy needs, lowering overall carbon emissions.

PROPOSED CHANGES

Strategies:

- Increase Use of Renewable Energy (Stage B6)): Integrate solar panels or other renewable energy sources to power the building. This change reduces operational carbon and supports sustainability goals. While this may increase initial costs, the long-term energy savings and reduced carbon footprint make it worthwhile.

Materials:

- Use Low-Carbon Concrete (Stages A1-A5): Replace traditional concrete with low-carbon alternatives, such as geopolymer concrete. This reduces the embodied carbon significantly. Geopolymer concrete can maintain structural integrity while lowering carbon emissions associated with cement production. This change could impact the material availability and construction timeline but offers significant environmental benefits.

Construction Methods:

- Prefabrication (Stages A1-A3, A5): Increase the use of prefabricated components to enhance construction efficiency and reduce waste. Prefabrication can lower embodied carbon by optimizing material use and reducing on-site construction emissions. This method can also speed up the construction process and improve quality control, though it may require initial investment in prefabrication facilities.

Reflection on Design Outcome

- Renewable Energy Integration: The design may need to accommodate the space and infrastructure for solar panels, which could alter the roof design and aesthetics. However, the longterm energy efficiency and sustainability benefits are significant.

- Low-Carbon Concrete: Using geopolymer concrete may require adjustments in construction techniques and timelines, but it will significantly reduce the project's carbon footprint without compromising structural performance.

- Prefabrication: Adopting prefabrication might change some design aspects to ensure components are suitable for off-site manufacturing. This approach enhances build quality and reduces construction time, making the project more sustainable and efficient.

3 Recycling Bristol, "6 Benefits of Recycling Wood," accessed June 9, 2024, https://www.recyclingbristol. com/6-benefits-of-recycling-wood/.

4 Wade Architecture, "Using Locally Sourced Construction Materials and Why It Matters," accessed June 9, 2024, https://wadearch.com/using-locally-sourced-construction-materials-and-why-it-matters/.

5 First American Roofing and Siding, "Cellulose vs. Fiberglass Insulation," accessed June 9, 2024, https:// firstamericanroofing.com/cellulose-vs-fiberglass-insulation/.

6 Bishnu Kant Shukla, Aakash Gupta, Sachin Gowda, Yuvraj Srivastav, "Constructing a greener future: A comprehensive review on the sustainable use of fly ash in the construction industry and beyond," Materials Today: Proceedings, Volume 93, Part 3, 2023, Pages 257-264, ISSN 2214-7853, https://doi.org/10.1016/ j.matpr.2023.07.179.

Stomping Ground Brewery / studio Y + PlaceFormSpace

HOSPITALITY ARCHITECTURE, BAR, BREWERY • MOORABBIN, AUSTRALIA • 2021

The Stomping Ground Brewery, designed by Studio Y and Placeformspace, is a vibrant and community-focused brewery located in Melbourne, Australia. This project transforms a former warehouse into a dynamic space that includes a brewery, bar, and event areas. The design emphasizes sustainability and social engagement, incorporating recycled materials and flexible spaces that adapt to various community events. By blending industrial aesthetics with warm, inviting elements, the Stomping Ground Brewery fosters a sense of community and celebrates local craft beer culture.

Embodied Carbon:

- Recycled Materials (Stages A1-A3):

Bricks and Timber: The project utilized recycled bricks and timber from the original warehouse structure. This approach significantly reduces the carbon emissions typically associated with manufacturing and transporting new materials.

Furniture and Fixtures: Many furniture pieces and fixtures are made from re-purposed materials, further lowering the embodied carbon footprint.

Local Sourcing (Stage A4):

- Materials and Suppliers: Materials were sourced from local suppliers to minimize transportation emissions, supporting the local economy and reducing the overall carbon footprint.

Operational Carbon:

- Energy Efficiency (Stage B6):

Natural Ventilation and Lighting: The design incorporates large windows and open spaces to maximize natural light and ventilation, reducing the need for artificial lighting and air conditioning.

Energy-Efficient Systems: The brewery is equipped with energy-efficient brewing systems and appliances to minimize operational energy consumption.

End-of-Life Carbon:

- Design for Disassembly (Stages C1-C4):

Modular Design: The building features modular design elements that can be easily disassembled and reused or recycled at the end of the building’s life, minimizing waste and reducing the end-of-life carbon impact.7

Additional Strategies:

- Community Involvement (Stage D):

Engagement Programs: The brewery actively engages with the local community through sustainability programs and events, fostering a culture of environmental responsibility.

- Renewable Energy Integration (Stage B6):

Solar Panels: The potential integration of solar panels would further reduce operational carbon by harnessing renewable energy sources to power the brewery.8

MATERIALS/COMPONENTS

Recycled Materials:

- Bricks and Timber (Stages A1-A3): The brewery incorporated recycled bricks and timber from the original warehouse structure, significantly reducing the embodied carbon typically associated with manufacturing and transporting new materials.

Local Materials:

- Timber (Stage A4): Locally sourced timber was used for various structural and decorative elements. This approach minimized transportation emissions and supported the local economy.

Innovative and Unconventional Materials:

- Recycled Paper Insulation (Stages A1-A3): The brewery utilized recycled paper insulation, which requires less energy to produce and contributes to a lower embodied carbon footprint compared to traditional insulation materials.

- Sustainable Concrete Alternatives (Stages A1-A3): Low-carbon concrete alternatives incorporating industrial by-products like fly ash or slag were used. These materials reduce the carbon footprint by lowering the need for cement, a major carbon emitter

Impact on the Country

The construction of Stomping Ground Brewery in Moorabbin, managed by MIC Projects, exemplifies a strong commitment to sustainability and local engagement. All materials for the project were sourced from nearby areas, significantly reducing transportation emissions and supporting the local economy. This practice aligns with the recognition of the Bunurong people the traditional owners of the land.9 By using local materials, the project honors the local heritage and promotes environmental responsibility, fostering a sustainable and culturally respectful approach to construction.10

Recycled Materials:

- Bricks and Timber: Recycled from the original warehouse on-site, significantly lowering the carbon footprint by eliminating the need for new materials and transportation emissions.

Local Materials:

- Timber: Sourced from local suppliers within Melbourne or nearby regions, minimizing transportation emissions and bolstering the local economy.

Innovative and Unconventional Materials:

- Recycled Paper Insulation: Likely sourced from local recycling facilities, reducing waste and supporting local recycling industries.

- Sustainable Concrete Alternatives: Fly ash and slag used in the concrete mixes are by-products from local industrial processes, diverting waste from landfills and reducing the environmental impact of these industries.

7 "Stomping Ground Brewery / studio Y + PlaceFormSpace," ArchDaily, January 25, 2022, accessed June 9, 2024, https://www.archdaily.com/975775/stomping-ground-brewery-studio-y-plus-placeformspace.

8 Stomping Ground Brewery, "Sustainability," accessed June 9, 2024, https://www.stompingground.beer/ pages/sustainability.

9 "Map of Formally Recognised Traditional Owners," First Peoples - State Relations, accessed June 9, 2024, https://www.firstpeoplesrelations.vic.gov.au/welcome-country-and-acknowledgement-traditional-owners.

10 "The Stomping Ground," MIC Projects, accessed June 9, 2024, https://micprojects.com.au/project/thestomping-ground/.

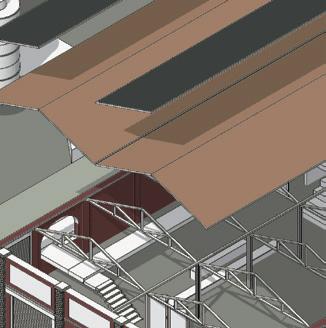

Modular Timber Grid System (Stage A5):

- Structure: The brewery features a modular timber grid structure that supports retractable roofs, translucent roofs, and walls. This system provides flexibility for future modifications and expansions while maintaining structural integrity.

- Sustainability: The timber used in the grid system is sustainably sourced and can be reused at the end of the building’s lifespan, aligning with principles of modular construction and design for disassembly.

Timber Construction (Stage A5):

- Beams and Columns: Exposed timber beams and columns create a warm, inviting atmosphere while showcasing the natural beauty of wood. The use of timber also helps to sequester carbon, contributing to the building’s overall sustainability.

Retractable Roofs and Translucent Walls (Stages B1, B2):

- Flexibility and Efficiency: Retractable roofs and translucent walls allow for natural light and ventilation, reducing the need for artificial lighting and air conditioning. This design element enhances energy efficiency and occupant comfort.

Design for Disassembly (Stages C1-C4):

- Reusability: The modular design allows for easy disassembly and reuse of materials, reducing waste and environmental impact at the end of the building’s life.11

PROPOSED CHANGES

Strategies:

- Increase Use of Renewable Energy (Stage B6): Integrate solar panels or other renewable energy sources to power the building. This change reduces operational carbon and supports sustainability goals. While this may increase initial costs, the long-term energy savings and reduced carbon footprint make it worthwhile.

Materials

- Use Low-Carbon Concrete (Stages A1-A3): Replace traditional concrete with low-carbon alternatives, such as geopolymer concrete. This reduces the embodied carbon significantly. Geopolymer concrete can maintain structural integrity while lowering carbon emissions associated with cement production. This change could impact the material availability and construction timeline but offers significant environmental benefits.

Construction Methods:

- Prefabrication (Stages A1-A3, A5): Increase the use of prefabricated components to enhance construction efficiency and reduce waste. Prefabrication can lower embodied carbon by optimizing material use and reducing on-site construction emissions. This method can also speed up the construction process and improve quality control, though it may require initial investment in prefabrication facilities.

Reflection on Design Outcome

- Renewable Energy Integration: The design may need to accommodate the space and infrastructure for solar panels, which could alter the roof design and aesthetics. However, the longterm energy efficiency and sustainability benefits are significant.

- Low-Carbon Concrete: Using geopolymer concrete may require adjustments in construction techniques and timelines, but it will significantly reduce the project's carbon footprint without compromising structural performance.

- Prefabrication: Adopting prefabrication might change some design aspects to ensure components are suitable for off-site manufacturing. This approach enhances build quality and reduces construction time, making the project more sustainable and efficient. 11 "Stomping Ground Brewery Moorabbin," WoodSolutions, accessed June 9, 2024, https://www. woodsolutions.com.au/case-studies/stomping-ground-brewery-moorabbin.

TASK 02

PC28: Be able to draw on knowledge from building sciences and technology, environmental sciences and behavioural and social sciences as part of preliminary design research and when developing the conceptual design to optimise the performance of the project.

PC33: Be able to investigate, coordinate and integrate sustainable environmental systems – including water, thermal, lighting and acoustics – into the conceptual design.

Building Sciences and Technology

INDOOR ENVIRONMENT QUALITY

The Motivation

Operational Carbon ⬇

Improving indoor air quality is crucial for enhancing the health and well-being of building occupants. Poor indoor air quality can lead to various health issues such as allergies, respiratory problems, and even long-term diseases. Given the increased urbanization and the rise in air pollutants, it is essential to ensure that the indoor environment remains a safe and healthy space. The World Health Organization has emphasized the importance of maintaining good indoor air quality to prevent these adverse health effects12

The Opportunity

Utilizing advanced air purification systems, effective ventilation strategies, and air-purifying plants can significantly enhance indoor air quality. This creates a healthier environment for occupants and aligns with the North Melbourne Brewing Festival’s commitment to sustainability and wellbeing.

The Actions/Strategies

- Air Purification Systems:

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters can capture 99.97% of particles as small as 0.3 microns, including dust, pollen, mold, and bacteria

Activated Carbon Filters: These filters are effective in removing odors, VOCs, and other gaseous pollutants

UV-C Light: Ultraviolet Germicidal Irradiation (UVGI) can kill or inactivate microorganisms, providing an additional layer of purification 13

- Ventilation:

Mechanical Ventilation with Heat Recovery (MVHR): This system improves air quality by continuously supplying fresh air while recovering heat from outgoing air to improve energy efficiency

Natural Ventilation: Designing buildings with operable windows and ventilation shafts can enhance airflow and reduce reliance on mechanical systems.14

- Air Purifying Plants:

Biophilic Design: Integrating indoor plants can help filter indoor air naturally and improve the aesthetic and psychological environment for occupants

Specific Plants: Certain plants such as spider plants, snake plants, and peace lilies are known for their air-purifying capabilities 15

How Does It Work?

Air purification systems work by filtering out pollutants from the air. The process typically involves several stages:

- Pre-Filter: Captures larger particles such as dust and hair.

- HEPA Filter: Traps smaller particles including allergens, smoke, and fine dust.

- Activated Carbon Filter: Adsorbs gases, odors, and VOCs.

- UV-C Light: Sterilizes air by eliminating microorganisms.

Ventilation systems work by ensuring a consistent exchange of indoor and outdoor air, maintaining a flow that dilutes indoor pollutants and supplies fresh air. This can be achieved mechanically or naturally, depending on the design of the building.

The Design Direction

After thorough research, the proposed design will include:

- Installation of Advanced Air Purification Systems: Integration of HEPA filters, activated carbon filters, and UV-C light within the HVAC system to ensure comprehensive air purification.

- Enhanced Ventilation Strategies:

Implementing MVHR systems in all major living and working spaces to ensure continuous fresh air supply without significant energy loss.

- Incorporation of Indoor Plants: Designing indoor spaces to include strategically placed plants known for their air-purifying properties.

12 "Health Impacts of Air Pollution," World Health Organization, accessed June 9, 2024, https://www.who.int/ teams/environment-climate-change-and-health/air-quality-energy-and-health/health-impacts.

13 W. J. Kowalski and W. P. Bahnfleth, "UVGI Design Basics for Air and Surface Disinfection," accessed June 9, 2024, https://pure.psu.edu/en/publications/uvgi-design-basics-for-air-and-surface-disinfection.

14 D. Etheridge , Natural Ventilation of Buildings: Theory, Measurement and Design, Wiley.com (WILEY, 2011), https://www.wiley.com/en-au/Natural+Ventilation+of+Buildings%3A+Theory%2C+Measuremen t+and+Design-p-9781119954378.

15 K. Dijkstra, M. E. Pieterse, and A. Pruyn, "Stress-Reducing Effects of Indoor Plants in the Built Healthcare Environment: The Mediating Role of Perceived Attractiveness," Preventive Medicine 47, no. 3 (2008): 279-283, accessed June 9, 2024, https://www.sciencedirect.com/science/article/abs/pii/S0091743508000042.

Fig.14. Air Purifiers Fig.16. Plants Purifying Fig.15. MVHR systemThe Motivation

As a project located on the fringe of a city's downtown core, improving energy efficiency and reducing reliance on fossil fuels is a priority. While achieving 100% renewable energy usage may be constrained by limited roof area and energy storage capacities, it is crucial to consider how solar panels can offset a significant portion of the building's energy needs.

The Opportunity

To improve energy efficiency, solar panels can be installed on the building's roof to generate clean electricity, reducing reliance on the grid. Excess energy produced can be fed back into the grid or stored in batteries for later use, thereby enhancing energy resilience and reducing overall carbon footprint.

The Actions/Strategies

- Rooftop Solar Panel Array: Install a rooftop solar panel array sized to maximize energy production based on available roof space and building energy consumption.16

- Building Integrated Photovoltaics (BIPV): Incorporate solar cells into the building envelope, such as windows, skylights, or façade elements, to generate electricity while serving architectural functions.17

- Energy Storage: Implement battery storage systems to store excess solar energy for use during peak demand periods or when solar production is low.18

Integrating It into the Design

The solar panel array should be thoughtfully integrated into the building , considering factors such as optimal tilt angle, orientation, and aesthetics.Ideally on west-facing roofs.

How Does It Work?

The solar panels convert sunlight directly into electricity through the photovoltaic effect. The DC power produced is then converted to AC power by an inverter for use in the building 19

How Much to Harvest?

Based on the available roof space, a 200 kW solar array could offset approximately 30% of the building's annual energy consumption, assuming an average of 4.5 sun hours per day 20

The Design Direction

Integrating solar panels into the building's design involves:

- Strategic Placement: Ensuring panels are placed for maximum sunlight exposure.

- Aesthetic Integration: Blending the panels into the architectural design to maintain visual appeal.

- Energy Management: Using smart inverters and energy storage solutions to manage the generated power effectively.

16 National Institute of Building Sciences, "Whole Building Design Guide: Solar Photovoltaic Systems," 2020, accessed June 9, 2024, https://www.wbdg.org/resources/solar-photovoltaic-systems.

17 U.S. Green Building Council, "LEED v4.1 Building Design and Construction: Energy and Atmosphere Credit - Renewable Energy Production," 2021, accessed June 9, 2024, https://www.usgbc.org/credits/newconstruction-core-and-shell-schools-new-construction-retail-new-construction-data-34?return=/credits/newconstruction/v4.1.

18 International Energy Agency, "Renewables 2021: Analysis and Forecast to 2026," 2021, accessed June 9, 2024, https://www.iea.org/reports/renewables-2021.

19 U.S. Department of Energy, "Solar Photovoltaic Technology Basics," 2020, accessed June 9, 2024, https:// www.energy.gov/eere/solar/articles/solar-photovoltaic-technology-basics.

20 "Guide to Installing Solar PV for Business and Industry," Australian Energy Upgrades, accessed June 9, 2024, https://australianenergyupgrades.com.au/wp-content/uploads/2021/05/CEC-Guide-to-installing-solarPV-for-business-and-industry.pdf.

Environmental Sciences

WHOLE-LIFE CARBON IMPLICATIONS

& MODULAR CONSTRUCTION

The Motivation

As a project located on the fringe of a city's urban core, reducing construction waste and improving project efficiency is crucial. Traditional on-site construction methods often lead to significant waste and delays. Pre-fabrication and modular construction techniques can help address these issues by moving a substantial portion of the construction process to a controlled off-site environment. This approach significantly reduces the carbon footprint by optimizing material use and minimizing waste 21

The Opportunity

To reduce construction waste and improve project efficiency, pre-fabrication and modular construction allow for the manufacturing of building components in a factory setting. This minimizes on-site waste and enables more efficient use of materials, reducing embodied carbon. These methods also facilitate better quality control and shorter construction timelines, which further contributes to lower overall carbon emissions 22

The Actions/Strategies

- Off-site Manufacturing: Identify building components that can be pre-fabricated off-site, such as walls, floors, roofs, and bathrooms. Work with manufacturers to design and produce these components to project specifications.

- Modular Construction: Design and construct the building using modular units that are manufactured off-site and assembled on-site. This approach allows for parallel construction of modules, reducing overall project duration and associated carbon emissions.

- Just-in-Time Delivery: Coordinate with manufacturers and logistics providers to ensure prefabricated components and modules are delivered to the site just-in-time for assembly, minimizing on-site storage requirements and potential damage. This reduces emissions from transportation and on-site handling.23

Integrating It into the Design

The building design should be optimized for pre-fabrication and modular construction from the outset. This involves close collaboration between the design team, manufacturers, and construction professionals to create a design that facilitates efficient off-site production and on-site assembly. This integration is critical to maximizing the carbon reduction benefits of these construction methods

How Does It Work?

Pre-fabricated components and modules are manufactured in a controlled factory environment using advanced automation and quality control processes. They are then transported to the construction site and assembled using cranes and other specialized equipment. This method significantly reduces on-site construction waste and shortens the construction timeline, thereby lowering the project's overall carbon footprint 24

How Much to Save?

Studies have shown that pre-fabrication and modular construction can reduce construction waste by up to 90% and improve project schedules by 30-50% compared to traditional on-site construction methods. This reduction in waste and increased efficiency translates directly to lower embodied carbon emissions throughout the construction phase 25

The Design Direction

The design direction will focus on maximizing the benefits of pre-fabrication and modular construction by incorporating these strategies from the initial planning stages.

- Early Collaboration: Engaging with manufacturers and construction professionals early in the design process to ensure that all components are designed for efficient off-site manufacturing and on-site assembly.

- Optimized Design: Creating designs that are conducive to modular construction, such as standardized module sizes and configurations that can be easily transported and assembled.

- Efficiency in Assembly: Planning for just-in-time delivery and efficient assembly processes to minimize disruption and waste on-site.

21 Modular Building Institute, "What is Modular Construction?" 2020, accessed June 9, 2024, https://www. modular.org/HtmlPage.aspx?name=why_modular.

22 National Institute of Building Sciences, "Off-Site Construction Council," 2019, accessed June 9, 2024, https://www.nibs.org/oscc.

23 Alan Mossman, "Just-in-Time Delivery Requires Just-in-Time Production X2 – Synchronising Factory and Site for Successful Prefabrication," Modular and Offsite Construction (MOC) Summit Proceedings (2019): 124132, https://doi.org/10.29173/mocs85.

24 "Permanent Modular Construction: Process, Practice, Performance," Building Design+Construction, accessed June 9, 2024, https://www.bdcnetwork.com/permanent-modular-construction-process-practiceperformance.

25 "Modern Methods of Construction: Summary Final Report," Waste and Resources Action Programme, January 2007, accessed June 9, 2024, https://build360.ie/wp-content/uploads/2023/01/ ModernMethodsofConstruction-Summmary.pdf.

The Motivation

Reducing the environmental impact of construction materials is crucial. The production and disposal of construction materials contribute significantly to greenhouse gas emissions and waste. By using sustainable and reused materials, we can minimize the project's embodied carbon and promote a circular economy 26

The Opportunity

To reduce embodied carbon and construction waste, sustainable materials, such as those with low embodied carbon or made from renewable resources, can help minimize the project's environmental impact. Reusing materials from existing buildings or construction sites can divert waste from landfills and reduce the demand for new materials

The Actions/Strategies

- Low-carbon Materials: Specify materials with low embodied carbon, such as recycled steel, concrete with supplementary cementitious materials (SCMs), and sustainably sourced timber.

- Reused Materials: Identify opportunities to reuse materials from the existing site or nearby demolition projects, such as structural steel, doors, windows, and architectural elements.

- Recyclable Materials: Choose materials that can be easily recycled at the end of the building's life, such as steel, aluminum, and glass. Design connections to facilitate disassembly and recycling.27

- Local Sourcing: Source materials locally to reduce transportation emissions and support the local economy. This can include using regional timber, stone, or other resources.28

How Does It Work?

Sustainable materials reduce environmental impact through lower embodied carbon, renewable resources, or recyclability. Reused materials extend the life of existing resources and prevent waste. These materials are integrated into the construction process in place of conventional materials 29

How Much to Save?

Studies have shown that using sustainable materials and reusing building components can reduce embodied carbon by 30-50% and construction waste by up to 75% compared to traditional practices 30

The Design Direction

The design direction will focus on maximizing the benefits of sustainable and reused materials by incorporating these strategies from the initial planning stages.

- Optimized Material Selection: Choosing materials based on their embodied carbon, recyclability, and ability to be reused.

- Circular Economy Principles: Designing for disassembly and recyclability to ensure that materials can be reused at the end of the building's life.

Reusing Bricks From the stables

26 World Green Building Council, "Bringing Embodied Carbon Upfront," 2019, accessed June 9, 2024, https:// www.worldgbc.org/news-media/bringing-embodied-carbon-upfront.

27 Environmental Protection Agency, "Best Practices for Reducing, Reusing, and Recycling Construction and Demolition Materials," accessed June 9, 2024, https://www.epa.gov/smm/best-practices-reducing-reusing-andrecycling-construction-and-demolition-materials.

28 AMCS Group, "Transporting Building Materials: Reaching Sustainability Goals," accessed June 9, 2024, https://www.amcsgroup.com/blogs/transporting-building-materials-reaching-sustainability-goals/.

29 Ellen MacArthur Foundation, "Completing the Picture: How the Circular Economy Tackles Climate Change," 2019, accessed June 9, 2024, https://www.ellenmacarthurfoundation.org/publications/completing-the-pictureclimate-change.

30 Environmental Protection Agency, "Sustainable Management of Construction and Demolition Materials," 2021, accessed June 9, 2024, https://www.epa.gov/smm/sustainable-management-construction-anddemolition-materials.

Re-creating same format of facade

Behavioral and social sciences

SOCIAL INTERACTION

COMMUNAL SPACES AND COMMUNITY ENGAGEMENT

The Motivation

Operational

Creating spaces that encourage social interaction and community engagement is crucial for projects on the fringe of urban cores. Well-designed communal spaces build a sense of belonging, promote social cohesion, and improve residents' overall well-being 31

The Opportunity

Designing attractive and inclusive communal spaces can encourage residents to interact with one another and participate in community activities. Engaging the community in the design process ensures these spaces meet the residents' needs and preferences 32

The Actions/Strategies

- Diverse Communal Spaces: Create a variety of communal areas catering to different activities and age groups, such as lounges, co-working areas, play zones, and outdoor terraces.

- Inclusive Design: Ensure communal spaces are accessible and welcoming to all, regardless of age, ability, or background. Features like accessible entrances, clear signage, and flexible seating should be included.

- Community Events: Organize regular community events such as workshops, classes, and social gatherings to foster interaction and community spirit.

- Participatory Design: Involve the community in the design process through workshops, surveys, and feedback sessions to ensure the communal spaces reflect their preferences and needs.33

Integrating It into the Design

Integrate communal spaces seamlessly into the overall building layout to ensure a smooth transition between private and shared areas. Consider the location, size, and amenities of these spaces to maximize their use and impact

How Does It Work?

Well-designed communal spaces provide opportunities for residents to meet, interact, and engage in shared activities. By creating various spaces catering to different needs, the project can encourage social interaction among diverse groups 34

How Much to Engage?

Residents in buildings with well-designed communal spaces report higher levels of social interaction, a sense of community, and overall satisfaction compared to those without such spaces 35

The Design Direction

Focus on creating inclusive communal spaces that encourage social interaction and community engagement by:

- Diverse Spaces: Designing areas that cater to various activities and age groups.

- Inclusivity: Ensuring accessibility and welcoming features for all residents.

- Community Events: Planning regular events to foster community spirit.

- Participatory Design: Involving residents in the design process to meet their needs and preferences.

31 N. Hassen and P. Kaufman, "Examining the Role of Urban Street Design in Enhancing Community Engagement: A Literature Review," Health & Place 41 (2016): 119-132, https://doi.org/10.1016/ j.healthplace.2016.08.005.

32 Z. Toker, "Recent Trends in Community Design: The Eminence of Participation," Design Studies 28, no. 3 (2007): 309-323, https://doi.org/10.1016/j.destud.2007.02.008.

33 J. Francis, B. Giles-Corti, L. Wood, and M. Knuiman, "Creating Sense of Community: The Role of Public Space," Journal of Environmental Psychology 32, no. 4 (2012): 401-409, https://doi.org/10.1016/ j.jenvp.2012.07.002.

34 E. Talen, "The Problem with Community in Planning," Journal of Planning Literature 15, no. 2 (2000): 171183, https://doi.org/10.1177/08854120022092971.

35 N. Farida, "Effects of Outdoor Shared Spaces on Social Interaction in a Housing Estate in Algeria," Frontiers of Architectural Research 2, no. 4 (2013): 457-467, https://doi.org/10.1016/j.foar.2013.09.002.

Fig.25. Diverse Communal Spaces Fig.26. Workshop Events Fig.27. Open Social SpaceSustainable environmental systems:

WATER

RAINWATER CAPTURE

The Motivation

Water scarcity is a growing concern globally due to factors like climate change, population growth, and overexploitation of water resources. Exploring alternative water sources is essential for communities facing water shortages. Techniques such as rainwater harvesting, fog collection, and dew collection can augment freshwater supplies sustainably. These methods provide a practical solution to mitigate water scarcity by capturing water from natural sources.

The Opportunity

Implementing water capture systems can reduce reliance on depleted groundwater sources and improve water security, especially in arid and semi-arid regions. Rainwater harvesting and fog/ dew collection can provide an additional source of freshwater for domestic use, agriculture, and maintaining ecosystems. These nature-based solutions are generally low-cost and adaptable to local contexts.

The Actions/Strategies

To expand the adoption of water capture techniques:

- Raise Awareness: Educate communities about the benefits and provide technical guidance on implementing water capture systems.

- Incentives: Offer financial incentives for installing household and community-scale systems.

- Integration: Incorporate water capture into building codes and urban planning to promote widespread adoption.

How Does It Work?

- Rainwater Harvesting: Involves collecting rainfall from rooftops and other surfaces, which is then stored for later use.

- Fog Collectors: Large mesh nets erected perpendicular to fog-bearing winds collect water droplets, which then flow into a storage system.

- Dew Collectors: Passive systems that promote dew formation on surfaces, channeling the collected water into storage vessels 36

Tank Options:

- 5,000L Slimline Steel Water Tank: Suitable for residential rainwater harvesting

- 10,000L Cylindrical Polyethylene Tank: Ideal for larger storage needs

- Other options based on site context and requirements.37

Integrating It into the Design Considerations for incorporating water capture:

- Catchment Area and Storage Capacity: Ensure the system has sufficient capacity to collect and store the water.

- Prevent Contamination: Implement measures to prevent contamination and ensure easy access for maintenance.

- Gravity Flow and Overflow Mechanisms: Use gravity to distribute the collected water and include overflow mechanisms to manage excess water.

- Water Treatment: Treat the collected water to meet quality standards for its intended use

How Much to Harvest?

- Rainwater: Average of 200mm annual rainfall on a 150m² roof can yield approximately 30,000L of water.

- Fog/Dew: A collection surface of 40m² can capture between 5-10L/m²/day, resulting in 73,000146,000L annually 38

The Design Direction

Integrating water capture systems into the project's design involves:

- Early Planning: Including water capture in the initial design stages to ensure adequate space and infrastructure.

- Sustainable Practices: Using eco-friendly materials and construction methods to build the water capture systems.

one brewery tank into water tank

36 Robert S. Schemenauer and Pilar Cereceda, "A Proposed Standard Fog Collector for Use in High-Elevation Regions," Journal of Applied Meteorology (1988-2005) 33, no. 11 (1994): 1313-1322, http://www.jstor.org/ stable/26186654. 37 Tankworld, "Steel Water Tanks," accessed June 9, 2024, https://tankworld.com.au/. 38 Watercache, "Residential Rainwater Harvesting," accessed June 9, 2024, https://www.watercache.com/ rainwater/residential.

Fig.28. Large Irrigation (Pressurized)

Fig.29. Potable Rainwater Harvesting System Schematic

Fig.28. Large Irrigation (Pressurized)

Fig.29. Potable Rainwater Harvesting System Schematic

TASK 03

PC31: Be able to identify, analyse and integrate information relevant to environmental sustainability – such as energy and water consumption, resources depletion, waste, embodied carbon and carbon emissions – over the lifecycle of a project.

PC33: Be able to investigate, coordinate and integrate sustainable environmental systems – including water, thermal, lighting and acoustics – into the conceptual design.

Integrated Environmental Strategy

The Integrated Environmental Strategy for the North Melbourne Brewing Festival focuses on harmonizing sustainability with historical preservation. The strategy encompasses four key areas: Indoor Environmental Quality (IEQ), Water Management, Energy Efficiency, Resources Circle and Material Memory.

- Indoor Environmental Quality (IEQ): Emphasizes thermal comfort, lighting, visual, and acoustic qualities to enhance occupant well-being.

- Water Management: Prioritizes rainwater capture to promote water self-sufficiency.

- Energy Efficiency: Incorporates solar clean energy to reduce operational carbon emissions.

- Resources Circle: Promotes composting and landscape gardening to manage waste sustainably.

- Material Memory: This aspect addresses whole-life carbon implications, ensuring that materials used are sustainable and reflect North Melbourne's historical and cultural heritage. By choosing low-carbon and locally sourced materials, the project honors the past while promoting environmental responsibility.

This strategy not only reduces environmental impact but also aligns with the festival's theme, "MEMORY CONGREGATION," by integrating modern sustainable practices with North Melbourne's rich cultural heritage.

Energy -Solar Panels

(Stage B6)

To reduce operational carbon emissions and promote sustainability, the Integrated Environmental Strategy proposes installing solar panels on the west-facing roofs of the festival site. This placement maximizes solar gain, harnessing sunlight efficiently throughout the day to generate clean energy. The system will significantly reduce reliance on grid electricity, lowering the building’s carbon footprint.

We have learned that installing solar panels on rooftops involves several key components such as mounting systems, inverters, and proper alignment to ensure maximum efficiency and longevity of the system. This knowledge ensures that our implementation is both effective and sustainable.39

Benefits:

- Operational Energy Savings: Solar panels reduce reliance on grid electricity, lowering operational costs and carbon footprint.

- Renewable Energy Generation: Harnessing solar energy contributes to a sustainable energy supply.

Operational Carbon ⬇

(Stage B7)

The Integrated Environmental Strategy incorporates a rainwater capture system to support water sustainability, particularly beneficial for on-site beer brewing at the North Melbourne Brewing Festival. Gutters will collect rainwater from the roof, directing it to storage tanks located next to the living hub. This system not only conserves water but also provides a reliable source for brewing and other non-potable uses, reducing reliance on municipal water supplies.40

System Components:

- Gutters and Downspouts: Efficiently collect and direct rainwater from the roof.

- First Flush Diverter: Ensures initial runoff, which may contain debris, is diverted away from the tank.

- Storage Tanks: Large capacity tanks to store collected rainwater, ensuring a consistent supply.

- Filtration Systems: Filters to ensure the collected water is clean and suitable for brewing and other uses.

Benefits:

- Water Conservation: Reduces dependence on municipal water by utilizing collected rainwater for brewing and other uses.

- Cost Savings: Lowers water bills and operational costs associated with water usage.

- Environmental Impact: Reduces runoff and its associated impacts on stormwater systems.41

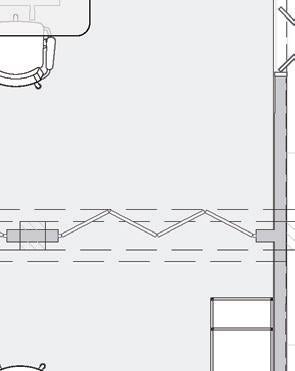

CORRUGATEDROOFSHEETS

200MMMINERALWOOLINSULATION

60MM CLTPANELS

ROOF DETAIL SCALE 1:5

40 "Rainwater Collection Systems," Sunshine Plumbing and Gas, accessed June 8, 2024, https:// www.sunshineplumbingandgas.com/rainwatercollection-systems/.

41 "Residential Rainwater Collection," WaterCache, accessed June 8, 2024, https://www.watercache. com/rainwater/residential.

GUTTER

Material Memory -Whole Life

Carbon

Embodied Carbon ⬇

Operational Carbon ⬇

Project Overview

The project incorporates different material and energy strategies to minimize carbon emissions over a 50-year lifespan. The scenarios analyzed include the use of new materials, recycled materials, and varying numbers of solar panels.

Scenarios:

- All new materials, with 20 solar panels: Higher emissions compared to using recycled materials.

- All recycled materials, with 20 solar panels: Lower emissions due to the use of fewer panels.

- All recycled materials, with 35 solar panels: 636 tonnes CO2-equivalent emissions over a 50-year lifespan.

Building Form Energy

Upfront Carbon:

- Scenario* (All recycled materials, 35 solar panels): The upfront carbon is significantly reduced due to the extensive use of recycled materials, which have lower embodied carbon compared to new materials. Utilizing recycled materials reduces the need for new raw material extraction and processing, thus lowering initial emissions.

Recurrent Carbon:

- Scenario*: The recurrent carbon emissions are managed by using durable materials and efficient maintenance strategies. The use of timber, which is easy to disassemble and recycle, further reduces recurrent carbon as it minimizes the need for frequent material replacements.

Operational Carbon:

- Scenario*: With 35 solar panels, the operational carbon is considerably low. Solar panels provide a renewable energy source that offsets the need for grid electricity, significantly reducing operational emissions. This approach also ensures the building remains energypositive over its lifetime.

Sequestered Carbon:

- Scenario*: The timber structure helps sequester carbon, storing CO2 absorbed during tree growth. This offsets some of the upfront and operational emissions, contributing to the overall carbon reduction strategy.

Wisely use recycled material can help reduce upfront carbon. This timber structure brings more thinking on reduce operational carbon

Utilizing a light timber structure in our project due to its low whole-life carbon footprint and the ease of disassembly for future reuse or recycling

- Energy Demand: Initial Annual Energy Demand: 0.11 kWh/m²/ year - Post Solar Panel Installation: The total annual energy demand decreases significantly with the installation of 35 solar panels, making the building net positive in operation.

Supportive Sustainable Information:

- Solar Harvesting: The inclusion of 35 solar panels significantly lowers operational carbon emissions by generating renewable energy, which offsets the energy used by the building systems.

- Thermal Mass: The thermal mass properties of the building materials are considered to reduce heating and cooling demands. Proper use of thermal mass helps in stabilizing indoor temperatures, thus reducing energy consumption for HVAC systems.

- Insulation and Night Purging: Effective insulation and night purging (ventilation) techniques are employed to maintain indoor comfort and reduce reliance on mechanical heating and cooling. This further lowers the building's operational carbon emissions.

Material Memory -Selection

&Construction

(Stages A1-A5)

Embodied Carbon ⬇

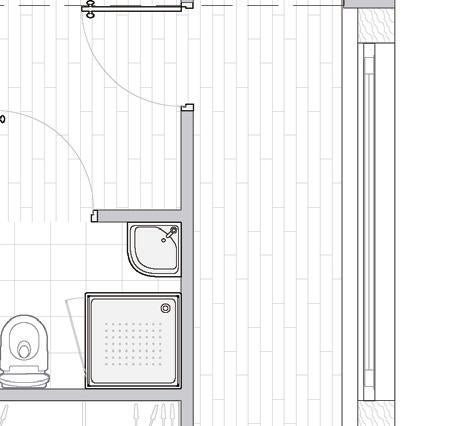

- Pre-fabrication & Modular Construction:

The original steel structure, produced in England and shipped to Melbourne, symbolizes North Melbourne's industrial heritage. By preserving and integrating this structure into the new design, we maintain historical continuity while meeting modern sustainability standards. Pre-fabrication and modular construction techniques will be employed to reduce construction waste and improve efficiency. These methods not only lower upfront carbon emissions but also ensure that the building can be easily disassembled and materials reused in the future.

Sustainable & Reused Materials:

- Use of Masonry:

Reusing bricks in the common bond pattern, characteristic of North Melbourne's historical architecture, helps preserve the area's visual and structural heritage. Using reclaimed bricks significantly reduces the carbon footprint associated with producing new bricks, aligning with whole-life carbon reduction goals.

- Use of Timber:

Timber has a storied history in North Melbourne, with the first wooden house dating back to 1852. Incorporating reclaimed heritage timber from local salvage yards minimizes deforestation and promotes the reuse of valuable materials, contributing to lower carbon emissions throughout the building's lifecycle.

- Reusing Materials:

Sourcing materials from Melbourne’s salvage yards and recycled building materials suppliers emphasizes the importance of reuse. This practice not only reduces waste but also lowers the embodied carbon of the building by avoiding the production of new materials.

Use of Timber

The first house in North Melbourne was a four-roomed wooden one built by a Mr. Adams in Bendigo street in October, 1852.

Existing Structure

The original steel structure was produced in England and shipped to Melbourne to construct

Reusing Materials

40 Melbourne Salvage Yards and Recycled Building Materials Suppliers in Victoria

Use of Masonry

The common bond pattern, a typical choice in the area's historical architecture, rather than the English bond or other styles.

Fig.34. North Melbourne’s Oldest House

Fig.35. Reclaimed heritage architectural and furniture timbers

Fig.36. Common bond

Fig.34. North Melbourne’s Oldest House

Fig.35. Reclaimed heritage architectural and furniture timbers

Fig.36. Common bond

Material Memory

-Selection & Well-being

(Stages A1-A3 &B1)

Embodied Carbon ⬇

Operational Carbon ⬇

Salvaged Wood:

- Description: Utilizing salvaged wood from local sources for various structural and decorative elements.

- Environmental Benefit: Reduces the demand for new timber, minimizes deforestation, and lowers carbon emissions associated with logging and processing.

Metal Weave:

- Description: Incorporating metal weave elements to create a unique, visually appealing design that also pays homage to the industrial past of North Melbourne.

- Environmental Benefit: Reusing metal reduces the need for new metal production, which is energy-intensive and has a high carbon footprint.

Brushed Iron:

- Description: Using brushed iron for fixtures and fittings to add a touch of industrial aesthetics while promoting the reuse of existing materials.

- Environmental Benefit: Repurposing iron reduces the carbon footprint associated with mining and refining new iron ore.

New Oak:

- Description: Incorporating sustainably sourced new oak for specific elements where strength and durability are paramount.

- Environmental Benefit: Sourcing new oak from sustainable forests ensures that the environmental impact is minimized and promotes responsible forestry practices.

Lea Ceramiche -L2:

- Description: Using Lea Ceramiche -L2 tiles for flooring and wall finishes to enhance the aesthetic appeal and durability of the space.

- Environmental Benefit: Lea Ceramiche tiles are known for their sustainability, as they are made with a high percentage of recycled content and produced with environmentally friendly processes.

Summary

The Pub & Brewery area will create a warm, inviting atmosphere by blending North Melbourne's industrial heritage with modern sustainability. Using salvaged wood, metal weave, brushed iron, new oak, and Lea Ceramiche tiles, the space will reflect historical significance and environmental responsibility. Communal spaces designed for social interaction will foster community engagement, making the environment both unique and memorable. This design embodies the theme of "MEMORY CONGREGATION."

Material Memory -Selection

&Well-being

(Stages A1-A3 &B1)

Embodied Carbon ⬇

Operational Carbon ⬇

Steel:

- Description: Utilized for its durability and distinctive rust-like appearance, Corten steel will be a prominent feature in the hub’s exterior and structural elements.

- Environmental Benefit: Its longevity reduces the need for frequent replacements, thereby lowering recurrent carbon emissions.

Rusty Corrugated Metal:

- Description: Incorporating rusty corrugated metal to echo North Melbourne's industrial past while providing a rugged aesthetic.

- Environmental Benefit: Reusing corrugated metal reduces the demand for new production, lowering the carbon footprint associated with mining and processing.

Clay Brick:

- Description: Using clay bricks for construction to maintain the traditional architectural style of the area.

- Environmental Benefit: Selecting locally produced clay bricks minimizes transportation emissions and supports local industry.

Country Oak:

- Description: Integrating sustainably sourced country oak for structural and decorative purposes.

- Environmental Benefit: Sourcing from sustainable forests ensures minimal environmental impact and promotes responsible forestry practices.

Light Wood Flooring:

- Description: Light wood flooring will be used to create a warm and inviting interior atmosphere.

- Environmental Benefit: Using sustainably sourced light wood ensures low embodied carbon and supports sustainable forest management.

Summary

The Workshop & Living Hub area will create a vibrant and engaging atmosphere that blends industrial aesthetics with sustainable design. Using Corten steel, rusty corrugated metal, clay bricks, country oak, and light wood flooring, the space will evoke North Melbourne's heritage while promoting environmental responsibility. Communal spaces designed for social interaction will enhance community engagement, making the hub both functional and inviting.

Resources Circle

- Planting Garden

Air Purifying with the Landscape Garden (Stage B1)

Enhance air quality and contribute to the overall environmental sustainability of the North Melbourne Brewing Festival by incorporating a landscape garden dedicated to growing teas and hops.

Air Quality Improvement:

- Description: The landscape garden will feature tea plants and hops, both known for their ability to absorb CO2 and release oxygen, thus purifying the air.

- Benefits: These plants help improve overall air quality by absorbing carbon dioxide and producing oxygen, contributing to a healthier environment for festival visitors and residents.

Selected Plants:

Tea Plants:

- Description: Tea plants are evergreen shrubs that absorb CO2 and release oxygen, contributing to air purification.

- Environmental Benefit: They are lowmaintenance and can thrive in a variety of soil conditions, making them suitable for sustainable gardening.

Hops:

- Description: Hops are climbing plants that are essential for brewing beer. They grow quickly and densely, which helps absorb CO2 and improve air quality.

- Environmental Benefit: Hops can be grown vertically, maximizing space and enhancing the visual appeal of the garden.

Compost with

Hops

(Stages B4 &B5)

Repurpose hop waste from the brewing process into compost to enrich soil and support sustainable gardening practices.

Benefits:

- Soil Enrichment: Composting hop waste enriches the soil with essential nutrients, improving soil health and plant growth.

- Waste Reduction: Repurposing hop waste reduces the amount of organic waste sent to landfills, lowering greenhouse gas emissions.

Process:

- Collection: After the hops are harvested and used in the brewing process, the remaining hop waste is collected.

- Composting: The hop waste is combined with other organic materials to create compost, which is then used in the garden to support plant growth.

References:

- Texas Real Food: Hops waste can be composted to create nutrient-rich soil amendments that improve plant growth and soil health. Composting hops also reduces landfill waste and greenhouse gas emissions associated with organic waste decomposition 42

- AZ Wood: Repurposing hop waste into compost is an effective way to recycle organic material, enhance soil fertility, and support sustainable gardening practices. The composted hops provide essential nutrients that promote robust plant growth and improve soil structure 43

Air Purification

42 "Compost Conundrum: Hops," Texas Real Food, accessed June 9, 2024, https://discover. texasrealfood.com/compost-conundrum/hops.

43 "Repurpose Hop Waste into Compost," AZ Wood, accessed June 9, 2024, https://azwood.co.nz/ articles/repurpose-hop-waste-into-compost.

Tea Planting

We are proud to feature our very own tea garden as part of the landscape, enhancing the natural beauty and offering a serene environment

Hops Planting

We cultivate our own hop plants on-site, providing a fresh and authentic ingredient for our unique craft beers

Fig.38. Compost with hops

Fig.39. Tea Planting

Fig.40. Hops Farm

Fig.38. Compost with hops

Fig.39. Tea Planting

Fig.40. Hops Farm

Indoor Environmental Quality

(Stages B1 &B2)

Thermal Comfort

- Isolation: Use high-performance 200mm mineral wool insulation to reduce heat loss in winter and heat gain in summer, maintaining a stable indoor temperature.

- Natural Ventilation: Incorporate natural ventilation strategies such as opening windows at night to allow cool air in and warm air out, enhancing airflow and indoor air quality.

- Components: Insulation layers, Corten framed double-glazed windows for effective thermal regulation.

Lighting

- Big Double Glazing: Install large doubleglazed windows to maximize natural light penetration, reducing the need for artificial lighting and enhancing visual comfort.

- Components: Corten framed double-glazed windows.

Acoustic Comfort

- Wood Finishes: Use wood finishes to absorb sound and reduce noise levels, enhancing acoustic comfort.

- Components: Spruce board lining, rough oak flooring.

Visual Comfort

- Natural Materials: Utilize wood and bricks for interior finishes to create a visually appealing and calming environment.

- Components: Spruce board lining, rough oak flooring, salvaged wood glulam posts.

Indoor Environmental Quality (IEQ) Enhancement

- Indoor Plants: Incorporate indoor plants to improve air quality by absorbing pollutants and releasing oxygen, contributing to a healthier indoor environment.

- Benefits: Enhances overall IEQ by improving air quality, providing visual appeal, and creating a calming atmosphere.

LIST OF IMAGES

Fig. 1. "Life Cycle Stages," New Buildings Institute. Accessed June 9, 2024. https://newbuildings.org/code_policy/embodied-carbon/.

Fig. 2. "Air Flow," ArchDaily. Accessed June 9, 2024.

https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 3. "Recycled Windows," ArchDaily. Accessed June 9, 2024.

https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 4. "Recycled Components in Room," ArchDaily. Accessed June 9, 2024.

https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 5. "Timber Structure," ArchDaily. Accessed June 9, 2024. https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 6. "Interior Elevation," ArchDaily. Accessed June 9, 2024.

https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 7. "Re-use Map," ArchDaily. Accessed June 9, 2024. https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 8. "Solar Panel on Roof," ArchDaily. Accessed June 9, 2024. https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

Fig. 9. "Solar Power," Stomping Ground. Accessed June 9, 2024. https://www.stompingground.beer/pages/sustainability.

Fig. 10. "Re-using Old Components," ArchDaily. Accessed June 9, 2024. https://www.archdaily.com/975775/stomping-ground-brewery-studio-y-plus-placeformspace?ad_source=search&ad_medium=projects_tab.

Fig. 11. "Welcome to Country Map," Victorian Aboriginal Heritage Council. Accessed June 9, 2024. https://achris.vic.gov.au/weave/wca.html.

Fig. 12. "Timber Grid Structure," ArchDaily. Accessed June 9, 2024. https://www.archdaily.com/975775/stomping-ground-brewery-studio-y-plus-placeformspace?ad_source=search&ad_medium=projects_tab.

Fig. 13. "Bar Interior," ArchDaily. Accessed June 9, 2024. https://www.archdaily.com/975775/stomping-ground-brewery-studio-y-plus-placeformspace?ad_source=search&ad_medium=projects_tab.

Fig. 14. "Air Purifiers," Bounty Parents. Accessed June 9, 2024. https://www.bountyparents.com.au/expert-advice/best-air-purifiers-for-nursery/.

Fig. 15. "MVHR System," Green Home Technologies. Accessed June 9, 2024. https://www.greenhometechnologies.co.uk/mvhr/.

Fig. 16. "Plants Purifying," Gardening Know How. Accessed June 9, 2024. https://www.gardeningknowhow.com/houseplants/hpgen/plant-windows-for-growing-plants-indoors.htm.

Fig. 17. "Rooftop Solar Panel Array," Apollo Solar Power. Accessed June 9, 2024. https://apollosolarpower.com.au/is-your-roof-suitable-for-installing-solar-panels/.

Fig. 18. "Building Integrated Photovoltaics," UL. Accessed June 9, 2024. https://www.ul.com/services/building-integrated-photovoltaic-bipv-system-testing-and-certification.

Fig. 19. "Energy Storage," Deye. Accessed June 9, 2024. https://deye.com/battery-energy-storage-system-bess/.

Fig. 20. "Off-site Manufacturing," Medium. Accessed June 9, 2024. https://medium.com/blue-future-partners/is-offsite-construction-the-solution-to-a-broken-process-f776ffda59b6.

Fig. 21. "Modular Construction," BigRentz. Accessed June 9, 2024. https://www.bigrentz.com/blog/modular-construction.

Fig. 22. "Just-in-Time Delivery," ResearchGate. Accessed June 9, 2024. https://www.researchgate.net/figure/Prefabrication-and-Just-in-Time-delivery-of-facade-elements-on-the-construction-site_fig1_271019861.

Fig. 23. "Low-carbon Materials," Architect Magazine. Accessed June 9, 2024. https://www.architectmagazine.com/technology/products/sustainable-building-materials-for-low-embodied-carbon_o.

Fig. 24. "Local Sourcing," Built Intelligence. Accessed June 9, 2024. https://www.builtintelligence.com/blogs/home/how-important-is-local-sourcing-for-sustainable-construction-by-darren-evans.

Fig. 25. "Diverse Communal Spaces," Project for Public Spaces. Accessed June 9, 2024. https://www.pps.org/article/diversityinpublicspaces.

Fig. 26. "Workshop Events," Shop Beer & Brewing. Accessed June 9, 2024. https://shop.beerandbrewing.com/products/brewery-workshop-new-brewery-accelerator.

Fig. 27. "Open Social Space," Howard Smith Wharves. Accessed June 9, 2024. https://howardsmithwharves.com/eat-drink/felons-brewing-co/.

Fig. 28. "Large Irrigation (Pressurized)," Watercache. Accessed June 9, 2024. https://www.watercache.com/rainwater/residential.

Fig. 29. "Potable Rainwater Harvesting System Schematic," Watercache. Accessed June 9, 2024. https://www.watercache.com/rainwater/residential.

Fig. 30. "Potable Supply Systems," Watercache. Accessed June 9, 2024. https://www.watercache.com/rainwater/residential.

Fig. 31. "A Rooftop Solar Mounting System," Solar Power World. Accessed June 9, 2024. https://www.solarpowerworldonline.com/2014/03/anatomy-rooftop-solar-mounting-system/.

Fig. 32. "Rainwater Collection System," Sunshine Plumbing and Gas. Accessed June 9, 2024. https://www.sunshineplumbingandgas.com/rainwater-collection-systems/.

Fig. 33. "Irrigation Rainwater Harvesting System Schematic," Watercache. Accessed June 9, 2024. https://www.watercache.com/rainwater/residential.

Fig. 34. "North Melbourne’s Oldest House," Hotham History Project. Accessed June 9, 2024. https://www.hothamhistory.org.au/north-melbournes-oldest-house/.

Fig. 35. "Reclaimed Heritage Architectural and Furniture Timbers," The Junk Map. Accessed June 9, 2024. https://www.thejunkmap.com.au/portfolio/timbersearch/.

Fig. 36. "Common Bond," Buffalo Architecture and History. Accessed June 9, 2024. https://www.buffaloah.com/a/DCTNRY/c/common.html.

Fig. 37. "Plants Purifying," Gardening Know How. Accessed June 9, 2024. https://www.gardeningknowhow.com/special/urban/urban-gardening-in-low-light.htm.

Fig. 38. "Compost with Hops," AZ Wood. Accessed June 9, 2024. https://azwood.co.nz/articles/repurpose-hop-waste-into-compost.

Fig. 39. "Tea Planting," ZME Science. Accessed June 9, 2024. https://www.zmescience.com/science/what-is-matcha-and-what-are-its-real-science-backed-benefits/.

Fig. 40. "Hops Farm," Gardening Know How. Accessed June 9, 2024. https://www.gardeningknowhow.com/edible/vegetables/hops/hops-companion-plants.htm.

BIBLIOGRAPHY

ArchDaily Team. “Kamikatz Public House / Hiroshi Nakamura & NAP.” ArchDaily, April 19, 2018. https://www.archdaily.com/892767/kamikatz-public-house-hiroshi-nakamura-and-nap.

———. “Stomping Ground Brewery / Studio Y + PlaceFormSpace.” ArchDaily, January 25, 2022. https://www.archdaily.com/975775/stomping-ground-brewery-studio-y-plus-placeformspace.

Azwood. “Repurpose Hop Waste into Compost.” Accessed June 9, 2024. https://azwood.co.nz/articles/repurpose-hop-waste-into-compost.

Bishnu Kant Shukla, Aakash Gupta, Sachin Gowda, and Yuvraj Srivastav. “Constructing a Greener Future: A Comprehensive Review on the Sustainable Use of Fly Ash in the Construction Industry and Beyond.” Materials Today: Proceedings, July 1, 2023. https://doi.org/10.1016/j.matpr.2023.07.179.

Building Design + Construction. “Permanent Modular Construction: Process, Practice, Performance,” July 24, 2015. https://www.bdcnetwork.com/permanent-modular-construction-process-practice-performance.

Bushong, Steven. “Anatomy of a Rooftop Solar Mounting System.” Solar Power World, March 19, 2014. https://www.solarpowerworldonline.com/2014/03/anatomy-rooftop-solar-mounting-system/.

Co, Stomping Ground Brewing. “Sustainability.” Stomping Ground Brewing Co., n.d. https://www.stompingground.beer/pages/sustainability.

“Current Practices and Future Potential in Modern Methods of Construction Modern Methods of Construction (MMC) Offer Significant Potential to Minimise Construction Waste. This Report Identifies the Current Use of MMC, the Potential for Further Uptake and the Waste Minimisation Potential.” Accessed June 9, 2024. https://build360.ie/wp-content/uploads/2023/01/ModernMethodsofConstruction-Summmary.pdf.

Dijkstra, K., M.E. Pieterse, and A. Pruyn. “Stress-Reducing Effects of Indoor Plants in the Built Healthcare Environment: The Mediating Role of Perceived Attractiveness.” Preventive Medicine 47, no. 3 (September 2008): 279–83. https://doi.org/10.1016/j.ypmed.2008.01.013.

Discover Real Food in Texas. “Sustainable Waste Management: Composting Hops for Eco-Friendly Practices.” Accessed June 9, 2024. https://discover.texasrealfood.com/compost-conundrum/hops.

Ellenmacarthurfoundation.org. “Completing the Picture: How the Circular Economy Tackles Climate Change,” 2019. https://www.ellenmacarthurfoundation.org/publications/completing-the-picture-climate-change.

Energy.gov. “Solar Photovoltaic Technology Basics,” 2013. https://www.energy.gov/eere/solar/articles/solar-photovoltaic-technology-basics.

EPA. “Sustainable Management of Construction and Demolition Materials | US EPA.” US EPA, August 22, 2018. https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials.

Etheridge , David. Natural Ventilation of Buildings: Theory, Measurement and Design Wiley.com. WILEY, 2011. https://www.wiley.com/en-au/Natural+Ventilation+of+Buildings%3A+Theory%2C+Measurement+and+Design-p-9781119954378.

Farida, Naceur. “Effects of Outdoor Shared Spaces on Social Interaction in a Housing Estate in Algeria.” Frontiers of Architectural Research 2, no. 4 (December 2013): 457–67. https://doi.org/10.1016/j.foar.2013.09.002. firstamericanroofing.com. “Cellulose vs Fiberglass Insulation: Pros and Cons,” February 5, 2024. https://firstamericanroofing.com/cellulose-vs-fiberglass-insulation/.

Francis, Jacinta, Billie Giles-Corti, Lisa Wood, and Matthew Knuiman. “Creating Sense of Community: The Role of Public Space.” Journal of Environmental Psychology 32, no. 4 (December 2012): 401–9. https://doi.org/10.1016/j.jenvp.2012.07.002.

Hassen, Nadha, and Pamela Kaufman. “Examining the Role of Urban Street Design in Enhancing Community Engagement: A Literature Review.” Health & Place 41 (September 2016): 119–32. https://doi.org/10.1016/j.healthplace.2016.08.005.

IEA. “Renewables 2021 – Analysis.” IEA, December 2021. https://www.iea.org/reports/renewables-2021.

Innovative Water Solutions LLC. “Residential Rainwater Collection System Installation in Austin, Hill Country,” n.d. https://www.watercache.com/rainwater/residential.

Kowalski, W. J., and William P. Bahnfleth. “UVGI Design Basics for Air and Surface Disinfection.” HPAC Heating, Piping, Air Conditioning 72, no. 1 (2000): 10. https://pure.psu.edu/en/publications/uvgi-design-basics-for-air-and-surface-disinfection.

MIC Projects. “The Stomping Ground.” Accessed June 9, 2024. https://micprojects.com.au/project/the-stomping-ground/.

Modular.org. “Modular Building Institute,” 2019. https://www.modular.org/HtmlPage.aspx?name=why_modular.

Mossman, Alan. “Just-In-Time Delivery Requires Just-In-Time Production X2 – Sychronising Factory and Site for Successful Prefabrication.” Modular and Offsite Construction (MOC) Summit Proceedings, May 24, 2019, 124–32. https://doi.org/10.29173/mocs85.

Recycling Bristol. “ETM Recycling.” ETM Recycling, April 14, 2020. https://www.recyclingbristol.com/6-benefits-of-recycling-wood/.

Schemenauer, Robert S., and Pilar Cereceda. “A Proposed Standard Fog Collector for Use in High-Elevation Regions.” Journal of Applied Meteorology (1988-2005) 33, no. 11 (1994): 1313–22. http://www.jstor.org/stable/26186654.

Sustainability Victoria. “Using Recycled Glass Fines in Construction and Product Design,” n.d. https://www.sustainability.vic.gov.au/news/news-articles/using-recycled-glass-fines-in-construction-and-product-design.

Talen, Emily. “The Problem with Community in Planning.” Journal of Planning Literature 15, no. 2 (November 2000): 171–83. https://doi.org/10.1177/08854120022092971.

Tankworld. “#1 Rainwater Tanks | Tankworld | Water Tanks for Sale 2024.” Accessed June 9, 2024. https://tankworld.com.au/.

Toker, Zeynep. “Recent Trends in Community Design: The Eminence of Participation.” Design Studies 28, no. 3 (May 2007): 309–23. https://doi.org/10.1016/j.destud.2007.02.008.

US EPA,OLEM. “Best Practices for Reducing, Reusing, and Recycling Construction and Demolition Materials | US EPA.” US EPA, March 10, 2016. https://www.epa.gov/smm/best-practices-reducing-reusing-and-recycling-construction-and-demolition-materials.

“Visit Cleanenergycouncil.org.au GUIDE to INSTALLING SOLAR PV for BUSINESS and INDUSTRY Milner Meats -Alice Solar City.” Accessed June 9, 2024. https://australianenergyupgrades.com.au/wp-content/uploads/2021/05/CEC-Guide-to-installing-solar-PV-for-business-and-industry.pdf.

Wade Architectural Systems. “Using Locally Sourced Construction Materials and Why It Matters,” August 14, 2023. https://wadearch.com/using-locally-sourced-construction-materials-and-why-it-matters/.

WHO. “Health Impacts.” www.who.int, 2024. https://www.who.int/teams/environment-climate-change-and-health/air-quality-energy-and-health/health-impacts.

World Green Building Council. “Bringing Embodied Carbon Upfront,” n.d. https://www.worldgbc.org/news-media/bringing-embodied-carbon-upfront.

www.amcsgroup.com. “Transporting Building Materials: Reaching Sustainability Goals,” n.d. https://www.amcsgroup.com/blogs/transporting-building-materials-reaching-sustainability-goals/. www.firstpeoplesrelations.vic.gov.au. “Welcome to Country and Acknowledgement of Traditional Owners | First Peoples - State Relations,” n.d. https://www.firstpeoplesrelations.vic.gov.au/welcome-country-and-acknowledgement-traditional-owners. www.nibs.org. “Off-Site Construction Council | National Institute of Building Sciences,” n.d. https://www.nibs.org/oscc.

www.sunshineplumbingandgas.com. “Rain Collection Systems | Sunshine Plumbing and Gas,” n.d. https://www.sunshineplumbingandgas.com/rainwater-collection-systems/. www.usgbc.org. “Renewable Energy | U.S. Green Building Council.” Accessed June 9, 2024. https://www.usgbc.org/credits/new-construction-core-and-shell-schools-new-construction-retail-new-construction-data-34?return=/credits/new-construction/v4.1. www.wbdg.org. “Resource Pages | WBDG - Whole Building Design Guide.” Accessed June 9, 2024. https://www.wbdg.org/resources/solar-photovoltaic-systems.

www.woodsolutions.com.au. “Stomping Ground Brewery Moorabbin | WoodSolutions,” n.d. https://www.woodsolutions.com.au/case-studies/stomping-ground-brewery-moorabbin.

MEMORIES MANUAL -BOOKLET