Lighting programs for broiler chickens continue to evolve

Controlling insects in poultry production

Was it the decade of Asia? The dynamics of global meat and egg production between 2012 and 2022

5 a 2024 Zootecnica International –May 2024 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze

Feeders Gió: the originals without grill

Specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

for the rearing phase (first 30 days of life) for the growing phase (no anti-waste ring)

EDITORIAL

The shift in eating habits observed in recent decades is not solely the result of changing lifestyles and schedules, but rather a phenomenon rooted in undeniable socio-cultural evolution. Meat consumption is decreasing in modern society, and there are several contributing factors to this trend. A few years ago, we noticed this phenomenon reflected in the growing emphasis on “well-being,” the rise of vegetarianism, and health guidelines that promoted its moderate consumption. Today, there is increasing discussion of economic challenges among consumers, affecting not only the disadvantaged classes but also the middle classes. Climate change, military involvement, and the compatibility of production systems, including the meat sector, are frequently discussed. Poultry products belong to a thriving sector that is highly responsive to contemporary dietary needs. Regrettably, when it comes to consumer awareness, we still have a way to go in dispelling certain long-standing misconceptions. In the multimedia landscape, I’ve noticed efforts to address this gap. However, some of these initiatives, while commendable for providing impartial information, are authored by individuals who may not be genuine experts in the particular field. Recently, I read an article that suggested that nearly all poultry products come from a single source, leading to the conclusion that all these products are essentially the same. It’s true that today’s poultry selection often relies on genotype banks largely acquired by a well-known German group, but the quality of a product isn’t solely determined by genetics alone. The communication gap begins precisely with this consideration. Consumers are still largely unaware of the advancements in farming systems and animal welfare that have evolved in recent years.

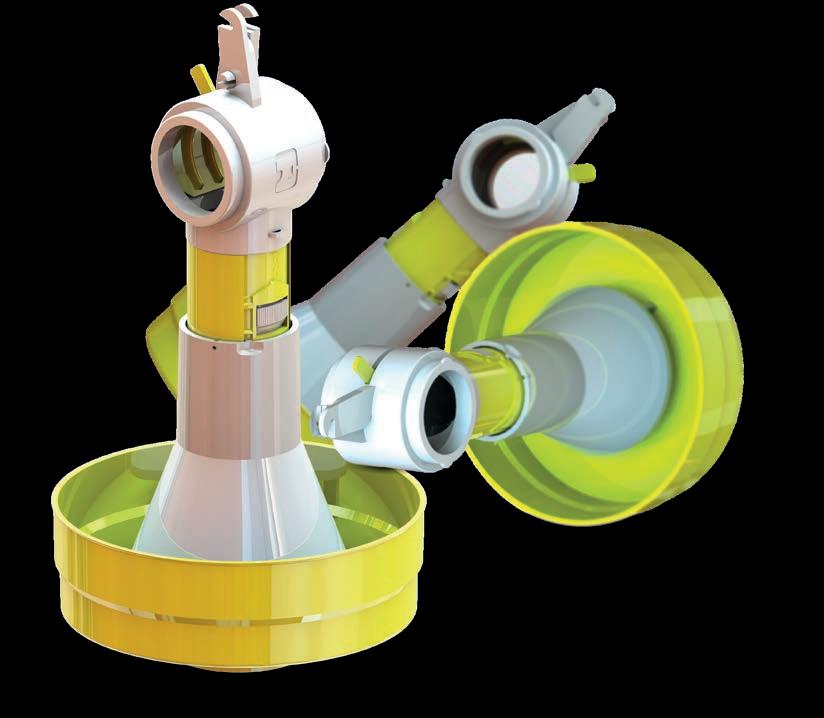

PRATIKA THE INNOVATIVE FEED PAN FOR BROILERS

Automatic feed level adjustment from chick to adult phase with the window opening system.

Low bottom pan from oneday old to slaughtering age.

No chick trapped in the pan.

Bottom pan designed to avoid feed waste.

FULLY AUTOMATIC

ONE SECOND IMMEDIATE OPENING AND CLOSING OF THE BOTTOM PAN FOR COMPLETE AND FAST WASHING.

QUALITY MADE IN ITALY www.azainternational.it I WANT AZA!

SUMMARY WORLDWIDE NEWS ......................................................................... 4 COMPANY NEWS 8 COMPANY FOCUS The poultry industry embraces Nuova-i 10 REPORTAGE Lighting programs for broiler chickens continue to evolve 14 DOSSIER Enrichment of early environments to improve laying hen resilience and welfare 18 FOCUS Controlling insects in poultry production 24 MARKETING Was it the decade of Asia? The dynamics of global meat and egg production between 2012 and 2022 26 TECHNICAL COLUMN Understanding how to preserve the life of hatching eggs 32 MANAGEMENT Hot weather management and nutrition for breeders 36 NUTRITION What is the influence of nutrition and management on egg weight? 40 MARKET GUIDE 44 UPCOMING EVENTS 47 INTERNET GUIDE ............................................................................48 26 14 24

Avian Influenza: One Health surveillance is key to prevent virus evolving

Avian Influenza (AI) virus continues to spread in the EU and beyond, causing high mortality in wild birds, spillover to wild and domestic mammals, and outbreaks in farms. A scientific report by the European Food Safety Authority (EFSA) and the European Centre for Disease Prevention and Control (ECDC) assesses the risk factors for a potential influenza pandemic and related mitigation measures.

Drivers for viral evolution

Experts have identified certain species of farmed fur animals (e.g. mink or foxes), which are highly susceptible to influenza viruses, as possible drivers for spread. Although mammal-to-mammal transmission has not yet been confirmed, wild mammals could act as bridge hosts between wild birds, domestic animals and humans. Companion animals, such as cats, living in households and with access to the outdoors can also be a potential vehicle for transmission. Farming in areas rich in waterfowl with outdoor production and/or poor biosecurity can facilitate introduction of the virus to farms

4 - worldwide newsWORLDWIDE NEWS

and its further spread. Extreme weather events and climate change play an additional role in the evolution of the situation because they can affect the ecology and demography of wild birds and thus influence the way the disease develops over time, experts found.

Risk reduction

Authorities from different fields should work together with a One Health perspective to limit the exposure of mammals, including humans, to AI viruses. Animal and human surveillance should be enhanced, together with genomic analysis and sharing of sequence data. At farms, biosecurity should be strengthened to prevent animals coming into contact with the infection and spreading it.

Next steps

By end of the year, EFSA and ECDC will publish a scien tific opinion assessing how a potential influenza pandem

ic might unfold with guidance to risk managers to reduce the risk to human health.

The full scientific report is available here:

DRINKING FOR TURKEY

EASYLINE 2.0

Consisting of a system with the pendulum as the main element, which ensures a perfect water supply at all times.

• The pendulum is activated every time the animal moves it with its head to drink.

• The new pendulum with two nipples guarantees even grater reliability of the drinker, both in terms of durability and ease manintenance.

• Cleaner litter and the best results in both the rearing and finishing phases at every age of the turkey.

Via Marco Polo, 33 - 35011 - Campodarsego (PD) ITALIA +39 0499202290 - lubingsystem.com - info@lubing.it

WORLDWIDE NEWS

!lanigirO

AVEC Manifesto 2024: together for a sustainable, transparent and innovative poultry sector in Europe

AVEC, the Association of Poultry Processors and Poultry Trade in the EU Countries, stands for resource-efficient poultry production, transparency, innovation, environmental stewardship and climate action, declares its commitment to keeping the European poultry sector sustainable and responsible by continuously improving production in line with the latest scientific developments.

Keeping production in EU

We strongly promote self-sufficiency for the European Union in poultry production to safeguard food security, food safety, animal welfare and the well-being of European citizens.

To achieve this goal, we endorse the following key principles:

• Resilient supply chains. We support investments in building resilient poultry supply chains within the EU to mitigate external disruptions and maintain food security.

• Regional collaboration. We encourage crossborder collaboration and knowledge-sharing among EU member states to optimise resource allocation, improve production efficiency and bolster food security for a well-functioning internal market.

• Reciprocity in trade agreements. We advocate the inclusion of reciprocal measures in all existing and future legislation to ensure fair trade and that imported poultry products meet the same rigorous standards as European poultry products.

Consumer choice

We firmly believe that consumers should have the freedom to make informed choices about the poultry products they purchase.

We stand for:

• Diverse product offerings. Economic accessibility is fundamental and therefore we advocate for a diverse range of poultry products to offer to various market-driven consumer preferences, including different species and conventional, organic and freerange options.

• Clear labelling. We demand clear and accurate labelling of origin for imported poultry products to inform consumers about production methods, the environmental impact and nutritional content, especially in out of home consumption and further processed products.

• Consumer education. We encourage educational programmes and awareness actions to teach consumers about the implications of their choices, empowering them to make decisions aligned with their values.

Resource efficiency and sustainability

We acknowledge the need to optimise poultry production practices to ensure more responsible use of resources and better protection for our environment.

6 - worldwide newsWORLDWIDE NEWS

Top 5 policy priorities

We advocate for:

• Climate action. We pledge to continue reducing greenhouse gas emissions associated with poultry production and support the development of carbonneutral practices within the sector.

• Innovation for efficiency. We promote research and development in poultry supply chains to create sustainable solutions that reduce resource consumption, including water and feed, minimise waste and increase animal welfare. This should be reflected in the next common agricultural policy (CAP) and future policies.

• Dialogue and accountability. We support a constructive dialogue between all stakeholders and encourage more connections with the field by visiting producers who could voice their passion and hard work and open their doors to proudly show how we produce high-quality EU products. Collaboration and strategic dialogue amongst the sector and policymakers are key.

Conclusion

We commit to embracing a sustainable, transparent and innovative poultry sector within the European Union. By upholding the values of resource efficiency, EU production, animal welfare and consumer choice, we aim to strengthen the European poultry sector so that it not only serves the needs of European citizens, but also contributes to a healthier planet and sets a global example for a brighter future for all. We are fully aware that this requires ever greater food safety to reassure consumers in the interest of public health. Together, we are building a European poultry sector that aligns with our shared vision of a sustainable and responsible future.

Source: AVEC

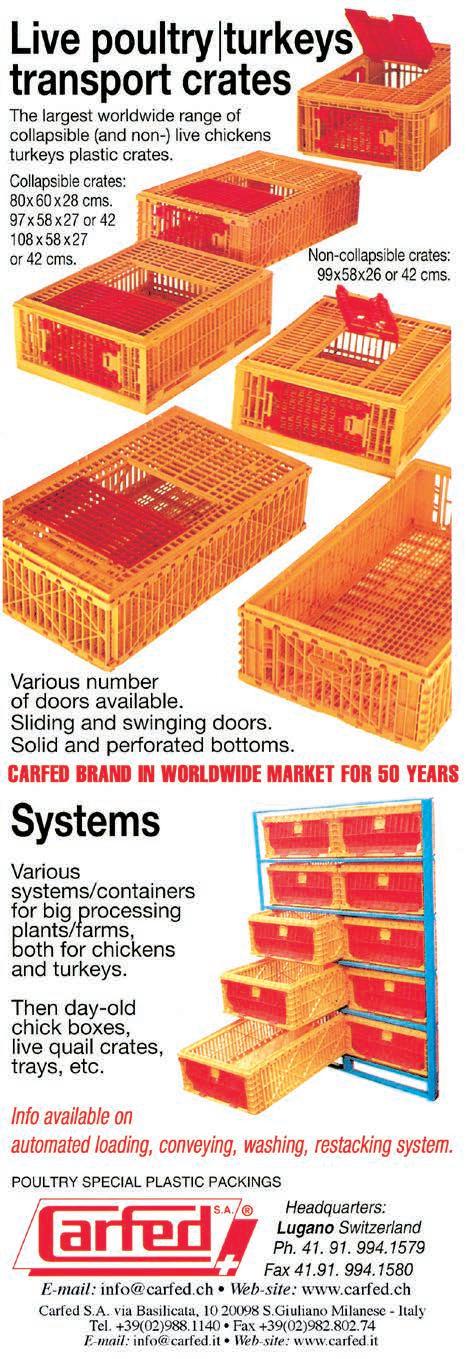

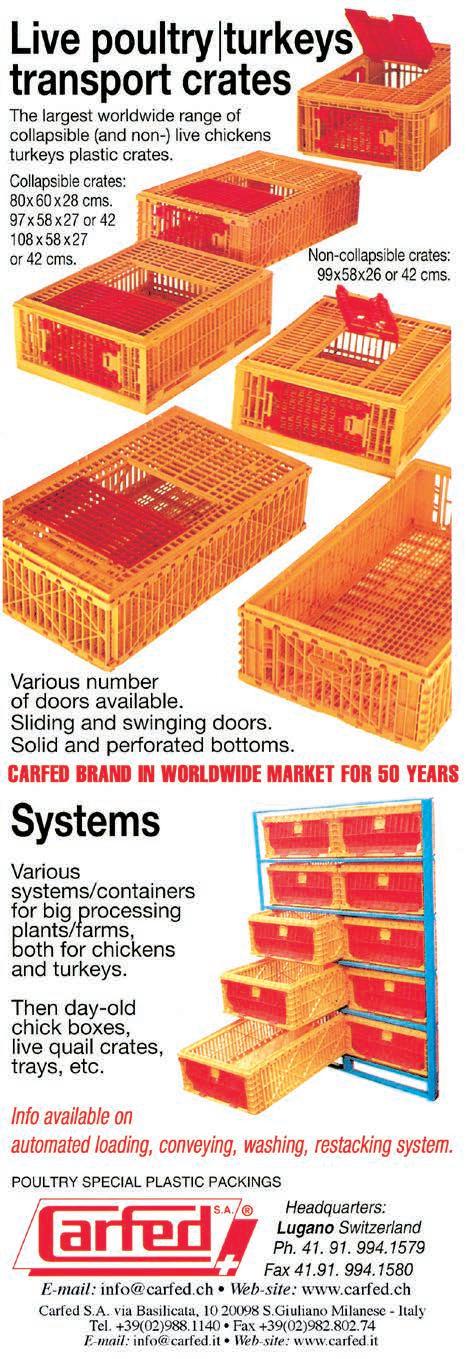

CARFED INTERNATIONAL LTD

Italian headquarters: Piazza Oberdan 3, 20129 Milano (Italy)

Italian warehouse: Via Basilicata 10, 20098 San Giuliano Milanese (Italy)

Ph.: +39 02 9881140 – Fax: +39 02 98280274

Email: carfed@carfed.it – Website: www.carfed.it UK headquarters: 2nd Floor Gadd House, Arcadia Avenue, London, England, N3 2JU, UK Ph.: + 44. 20. 7660.0987 – Email: carfed@carfed.co.uk

- may 2024 - 7 WORLDWIDE NEWS

Clear labelling of origin Financial support/ incentives for poultry farmers More research and development on sustainable practices for the poultry sector

Outcome-based animal welfare key performance indicators

Full

reciprocity with imported products

Royal Pas Reform chosen by Silverlands for new hatchery operation in Tanzania

Tanzania’s Silverlands, a growing integrated farming, processing and poultry business, chose Royal Pas Reform technologies for its new hatchery operation in Arusha, a city in the northeast of the country, known as the safari capital of Tanzania. When fully operational, the facility will have a production capacity of 7.3 million day-old chicks per year.

Already a leading producer of day-old chicks, Silverlands’ hatchery project involved the installation of 6 x SmartSetPro™4 setters and 4 x SmartHatchPro™ hatchers, together with a complete climate control system – with air handling units, air distribution and control, cold-process water chillers, heat pump and heat-recovery system and cold-water buffer tank. The hatchery also features SmartCenterPro™ for process control and data management.

Commenting on the installation, Adriaen Sligcher, Pas Reform’s Sales Director in Southern Africa, says: “We were very grateful for the guidance of Royal Pas Reform’s Stewart Bradnick and his team, which resulted in a firstclass hatchery project. Without doubt, we will see a further extension in the near future.”

Silverlands was established in 2013 to service Tanzania’s growing demand for quality poultry products at a reasonable price. From its headquarters at Makota Farm, Ihemi Village in the Iringa region, the company operates two separate units: a poultry and feed business, and a crop-

ping business. The poultry farm has a feed-mill, hatchery and poultry houses. Silverlands is the only company in Tanzania that produces three different day-old-chick varieties for the commercial market. The Silverlands Broiler and Layer breeder stocks are imported from internationally recognized breeder supply companies to ensure that farmers receive day-old chicks with the latest genetics that will produce maximum results. Silverlands has also secured exclusive rights for the distribution of the SASSO bird in Tanzania, a dual-purpose, slower-maturing chicken.

With the distribution of SASSO day-old chicks, Silverlands provides improved genetics to the small-scale rural farmers, together with technical assistance and training, and offers them access to markets that may not have been possible before. This initiative aims to increase poultry production and productivity, improve rural household income and nutrition, and empower women. Like Royal Pas Reform, Silverlands believes in developing long-term relationships with customers. In 2016 it established the Silverlands Poultry Training Centre at Makota Farm. The objective of the training courses offered is to provide attendees with the knowledge to successfully manage a poultry unit. It has proved to be a highly valued service and today the training centre has an active Facebook community of over 27,000 members.

Adriaen Sligcher says: “We are delighted to have partnered with Silverlands on this important new hatchery. It will help to bring new skills and prosperity to the region and support its commitment to being socially responsible to the communities it operates in. We also look forward to arranging a hatchery managers course with Silverlands in the near future in order to further extend the knowledge of potential hatchery managers in Tanzania.”

8 - company newsCOMPANY NEWS

Till 23 silos in one complete truckload

Till 40 silos in 1x40’ O/T container

Fiberglass silos: the most practical, effective and durable solution to any bulk storage requirement

Agritech s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy

Tel. + 39 030 9968222 r.a. Fax + 39 030 9968444 commerce@agritech.it www.agritech.it

- may 2024 - 9 COMPANY NEWS

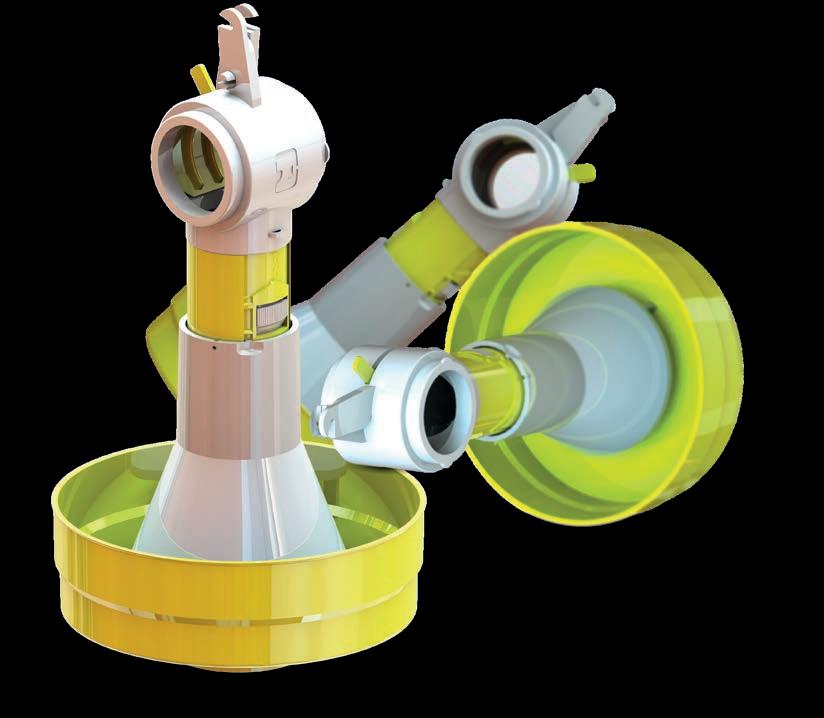

The poultry industry embraces Nuova-i

In the poultry process, evisceration is probably the most delicate operation, requiring consistent performance across all bird weights while effectively handling every single giblet pack. This combination of skills can be challenging, but Marel’s Nuova-i excels in every comparison. Designed to make data-driven decisions, Nuova-i maximizes performance with minimal reliance on human judgments or labor. From Poland to Brazil, each and every processor working with Nuova-i is full of praise and enthusiasm about its performance.

10 - company focusCOMPANY FOCUS

Tackling flock variations

Whether the broiler flock features odd-sized or irregular-shaped products, the Nuova-i adapts effortlessly. The distance adjustment between shoulders can be set, and the shackle guide can be adjusted for long and short feet for optimal performance. Nuova-i is easy to control. When entering a recipe on the touchscreen, all relevant settings will adjust themselves to the flock characteristics, ensuring a seamless and consistent process flow. Once a recipe setting has proven to be successful for certain flock characteristics, Nuova-i can easily recall this flock setting with a single tap on the screen.

A leap forward

“At the moment, it is hard to reach full evisceration performance, because of our exceptionally high flock variations. In addition, 70% of our production follows ‘hard halal’ practices, with no stunning. When birds enter the kill line fully conscious, this impacts the line’s effectiveness. So the 98% performance Nuova-i delivers now is a huge leap forward for us, compared to our previous system” (Lukasz Mielewczyk, co-owner of Mielewczyk, Poland).

“Flock variation has been one of the crucial issues in our production line, and Nuova-i allows adjustments to be made according to needs. This improves the process, with a positive impact on yield and profitability. The ability to adjust to flock variations means an important cost reduction for us, significantly lowering our operational expenses” (Marcel Fogaça, Project Manager of SSA, Brazil).

Hygiene

Nuova-i’s carousel features 24 units and can handle line speeds of up to 15,000 birds per hour, while ensuring the highest levels of efficiency and yield. Technological advancements, such as the robust, long-life spoon, enhance precision and hygiene standards, minimizing the risk of contamination. The spoon design handles positioning and drawing with utmost care, resulting in consistent viscera packs and top-notch downstream processing during giblet harvesting. Nuova-i achieves unparalleled precision in separating the viscera pack

from the carcass and rehanging it to a separate line. All viscera packs are uniform and compact, resulting in higher yield and cleaner carcasses. No unwanted remains are left behind and intestines don’t hang out, so there is a minimum chance of soiling or cross-contamination.

“Improving yield and increasing food safety with reduced contamination are arguments for us to choose the Nuova-i. We aim for the maximum overall contamination rate to go down and yield to increase considerably. With this performance, we can start our seasonal ‘Festa’ pro -

- may 2024 - 11

FOCUS

COMPANY

duction already in August and finish in September. Nuova-i allows us to resume normal production more quickly” (Christian Klauck, Director of Engineering and Automation at Aurora Coop, Brazil).

Perfect product quality

“Products are eviscerated even more precisely than we’ve ever seen before, with their viscera packs in even better condition for the automatic processes which follow. This is important for us, as Cedrob has a significant market for giblets. Nuova-i allows us to harvest livers, gizzards, and hearts precisely and without damage, which is essential if we are to offer top quality to our customers” (Lukasz Olszewski, Maintenance Manager at Cedrob, Poland).

“Looking at the drawing of the pack, Nuova-i does a fantastic job, with

perfect product quality as a result. Individual giblets are not damaged; they look really great. The machine has done well for us. Giblet yield and giblet quality have also improved quite a lot at our facility. The advantages are many” (Lukasz Mielewczyk).

A data-driven approach

What sets the Nuova-i apart is its new data insight, providing processors with unprecedented control of their operations. Integrated SmartBase software enables real-time machine health monitoring. It continuously supervises the crucial parameters, while logging machine settings and historical performance data. In this way, SmartBase can identify potential issues and trends without relying on human intelligence. This proactive data-driven approach prevents unexpected incidents and empowers processors to

make informed decisions, optimize workflows, and enhance operational efficiency.

“We use SmartBase to monitor the Nuova-i. This allows us to check the eviscerator’s status in real-time, while the machine runs. So we have a lot of control over the evisceration process. We had very high expectations for the efficiency of the Nuova-i and it must be said that the performance completely reaches the levels we hoped for” (Lukasz Olszewski).

“With its ability to provide real-time data, Nuova-i enables faster and more accurate decision-making, which aligns with our vision of making our industry a more connected environment, incorporating elements of digital transformation” (Christian Klauck).

For more information: marel.com/nuova-i

12 - company focusCOMPANY FOCUS

and latest technical and scientific advances at zootecnicainternational.com! VISIT OUR WEBSITE zootecnicainternational.com FOR A DEEP INSIGHT INTO THE POULTRY INDUSTRY! NEW PRODUCTS COMPANY NEWS EVENTS FIELD REPORTS INTERVIEWS MARKET TRENDS PROFILES

Tom Tabler, Professor and Extension Specialist, University of Tennessee Yang Zhao, Assistant Professor, University of Tennessee

Tanner Thornton, Graduate Student Department of Animal Science, University of Tennessee

Pramir Maharjan, Assistant Professor and Extension Specialist, Department of Agricultural and Environmental Sciences, Tennessee State University

Jonathan Moon, Extension Instructor, Department of Poultry Science, Mississippi State University

Jessica Drewry, Assistant Extension Professor, Department of Agricultural and Biological Engineering, Mississippi State University

Jessica Wells, Assistant Clinical/Extension Professor, Department of Poultry Science, Mississippi State University

Lighting programs for broiler chickens continue to evolve

Light is a critical environmental factor for broiler chickens, affecting numerous aspects of production such as behavior, health, physiology and welfare. The ability of light to influence production performance, growth and wellbeing of poultry is well documented and has attracted the attention of researchers for over 100 years.

In general, broilers are raised indoors in large flocks where food, water and environment are controlled to provide for their basic physiological needs. However, this is a very different environment than that experienced by their junglefowl ancestors from which modern broiler chickens have evolved. In nature, chickens are exposed to a variety of circumstances and

14 - reportageREPORTAGE

environmental conditions including varying day lengths and light intensities. Lighting is a key management tool in broiler production, however, research to provide detailed characterizations of the internal lighting environment of commercial broiler houses is relatively recent. Use of LED lights have been demonstrated to improve efficiency and production performance, although further adaptation of LED technology may yield additional improvements by providing a more appropriate lighting environment for broilers. Recent reports have suggested that the optimal light environment for broiler production may not be a uniform distribution of light intensity.

Light wavelength and intensity

Light is an important management factor for broiler production that can affect broiler growth, diurnal rhythms, behavior and welfare. The lighting program remains of critical importance because lighting has been intimately associated with not only the establishment of rhythm and synchronous physiology of broiler chickens, but also the secretion of hormones associated with broiler maturation and growth. An appropriate lighting regimen, including proper source of lighting, intensity, duration and wavelength (color) of light, is critical to improve the growth performance and welfare of broilers. Light wavelength also influences fear and stress levels. Broilers raised under blue light had lower fear levels, assessed through tonic immobility, than birds raised under white light. Aldridge et al. (2021) reported that broilers provided a dual light (warm, 2,700 K, and cool, 5,000 K) offering exhibited a clear preferential pattern for warm light during the first and last hour of a 16- hour light period. Impacts on bird behavior may suggest that lighting programs with varying wavelengths and light intensities may be a usable tool to improve welfare and production aspects. However, it is important to understand the origin of the behavioral changes and whether they are related to visual ability or another critical factor.

For example, leg health is one of the most prevalent causes of culling and late mortality in a flock during the grow-out of commercial broilers. Numerous researchers have indicated that increasing locomotor activity in broilers may improve bird welfare. Several studies addressing broiler leg health suggest that the stimulatory effect of bright light on locomotor activity can improve leg condition and thus welfare. Kang et al. (2023) reported

increased volunteer and natural behaviors and physical activity, which may improve footpad condition and leg health, under a variable broiler lighting program.

The effects of light intensity provided by artificial lighting on commercial broilers has been extensively studied in the past. Variable light intensity studies have indicated that when birds have a dual light choice they consumed more feed in the higher-intensity light area (20 lux/1.85 fc) than in the lower intensity area (2 lux/0.19 fc). While there was no significant difference in production parameters (body weight and feed conversion ratio), the results of central welfare indicator studies suggested better central welfare in variable lighting intensity-treated birds. Fewer studies have examined the effect of natural light on performance, welfare, health and behavior. However, de Jong and Gunnink (2019) reported no difference in welfare indicators (lameness, footpad dermatitis, hock burn, cleanliness and injuries) between birds on a commercial farm provided natural light/enrichments and a control with no enrichments or natural light. De Oliveira Sans et al. (2021) reported that broilers preferred a natural light treatment (280 to 900 lux/26 to 84 fc, to an artificial lighting only treatment (22 to 44 lux/2 to 4 fc) after 18 days of age. Bailie et al. (2012) reported that broilers grown in a commercial house and provided natural light (average of 85.2 lux/8 fc) showed increased activity and leg health when compared to broilers grown under artificial lighting only (average of 11.4 lux/1.05 fc). Lower light intensities

- may 2024 - 15 REPORTAGE

have been shown to reduce activity, cannibalism and scratching, whereas higher levels promote increased activity, which may explain some of the differences seen in studies on natural light.

An area receiving increased attention in recent years has been the uncontrolled ingress of natural light through tunnel exhaust fans, sidewall inlets and other house components which increases the temporal and spatial variability of light intensity. Linhoss et al. (2020) reported that light intensity at the fan end of a broiler house reached a peak of 440 lux/41 fc and remained at over 100 lux/9.2 fc for an entire day. Purswell and Olanrewaju (2017) reported significantly higher feed conversion ratio and feed consumption for birds raised in a variable light treatment, designed to mimic the huge variation in light intensity through tunnel fans, when compared to birds raised under a constant prescribed light intensity (2.5 lux/0.2 fc). Linhoss et al. (2022) reported light intensity values as high as 6,000 lux/557 fc in a curtain-sided natural light broiler house compared to a traditional artificial lighting system, over 600 times higher than levels generally accepted by the broiler industry today.

Gradient lighting

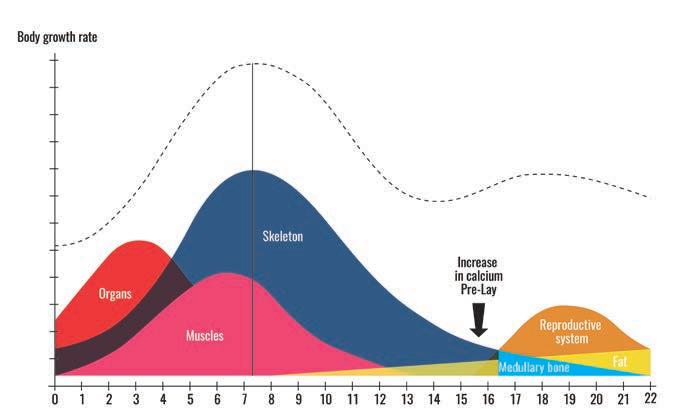

There is increasing evidence that indicates focusing on determining a single uniform light intensity and color (Figure 1) to be applied evenly across time (age) and space (the rearing environment) may have been misguided.

bright light levels near the feed lines and much lower light levels near the walls and allow broilers to “choose” their preferred light level are attracting much greater attention.

Broiler chickens have shown a preference for higher intensity light when they are performing active behaviors (such as eating) but prefer dimmer areas when resting. Light intensity has been shown to affect the activity of birds, but most studies have focused on constant and uniform light intensities to determine their effect on welfare and performance. However, Blatchford et al. (2012) reported a strong effect of contrasting light intensities on the behavior and health of broilers and suggested that high contrast in light intensity was associated with strong daily rhythms of behavior.

With the poultry industry’s increased focus on animal welfare, gradient lighting programs (Figure 2) that provide

Vision is likely the dominant sense in domestic poultry, and the evolution of vision was determined, at least in part, by the natural light available (Prescott et al., 2003), with its gradient combination of direct sunlight and shadows, in the jungles of Southeast Asia where the ancestors of today’s broilers originated. However, broiler chickens in commercial management settings today are typically housed in dim lighting because it is presumed to improve productivity and feed conversion efficiency, as well as reduce overall activity and injurious pecking episodes. If birds perceive different light intensities in different ways, this may influence their behavior. Manser (1996) suggested that light intensities between 5 and 22 lux/0.5 to 2 fc, currently used for broilers and turkeys, may contribute to a decrease of their engaging in exploratory behavior and social interactions and high prevalence of leg ab -

16 - reportageREPORTAGE

Figure 1 – Uniform light levels have been a poultry industry standard for years.

Figure 2 – Gradient lighting for broilers is attracting much attention today.

normalities, mortality, eye abnormalities, breast blisters in growing birds and fearfulness. Therefore, the potential for the enrichment of the perceived environment and, consequently, for improving bird welfare through gradient lighting seems to warrant additional investigation.

Numerous reports indicate that chickens have preferences for specific light intensities. When provided a choice of light intensities of 6, 20, 60 and 200 lux (0.5, 1.85, 5.5 and 19 fc) in a choice system, two-week-old broilers preferred bright light (200 lux/19 fc) for all behaviors. However, by six weeks of age, broiler chickens exhibited active behaviors under 200 lux/19 fc but resting and perching behaviors under 6 lux/0.5 fc.

Raccoursier et al. (2019) reported that broiler chickens given a lighting choice were found disproportionately dispersed with greater numbers in areas at 20 lux/1.85 fc where feed and water were available and to poorly lit (~1 lux/0.1 fc) areas with neither feed nor water compared to areas with feed and water and lit at 5 lux/0.5 fc. Kang et al. (2023) reported that a variable light intensity program increased volunteer natural behaviors and physical activity.

Performance data, including increased daily weight gain and a lowered feed conversion ratio and results of brain welfare indicator gene expression, indicated the beneficial effect of a variable light intensity lighting program on performance and welfare. These studies tend to suggest that a uniform light intensity that the industry has utilized for years may not be the best option for broiler chickens. That message is not being lost on lighting manufacturers, as there are now multiple gradient lighting options available on the market and others in the testing phase.

Summary

Lighting programs in the broiler industry continue to evolve and are far from being an exact science. Responses to shifting consumer demands for alternative rearing programs and improved welfare conditions have resulted in a re-evaluation of lighting programs by the commercial broiler industry in recent years. A variety of lighting programs are currently in use or being studied across the broiler industry. These range from going back to walls and windows that allow use of natural light to the most recent concept of gradient or variable intensity lighting that allows birds to “choose” the level of light they desire throughout the grow-out. This often means higher intensity lighting near the feeders and drinkers where activity levels are high and a much lower light level near the walls for resting where the activity level is lower. Despite our knowledge of the importance of light to broiler chickens, the industry continues to search for the ideal lighting program that can provide the production performance, growth, health and welfare benefits we desire. That search challenges lighting manufacturers to continually develop new state-of-the-art lighting options that can meet the needs of a changing poultry industry.

Continued collaboration between lighting manufacturers and the poultry industry is critical to address lighting challenges and to allow for the continuing improvement of broiler lighting practices.

References are available on request By courtesy of The University of Tennessee Institute of Agriculture and UT Extension

- may 2024 - 17 REPORTAGE

MADE IN ITALY WEB R www.valli-italy.com quality you can depend on Area Baby Area Bellavita Castello Casa Piramide Plus Vita VLV Plus Via Cimatti, 2 47010 GALEATA FC -ITALY ALTERNATIVE SYSTEMS

Enrichment of early environments to improve laying hen resilience and welfare

A collection of studies conducted within Australia and internationally are detailed here to illustrate the positive benefits of environmental enrichment on adaptive capacity of hens when faced with challenges.

Introduction

D.L.M. Campbell1 and I.G. Colditz1

1 Agriculture and Food, CSIRO

Resilience is defined as the ability to successfully cope and thrive when faced with environmental disturbance, adversity, and stress. Across an animal’s lifetime, they will be exposed to many stressors that require the individual to adapt and maintain internal homeostasis against external variability. For a laying hen, these stressors could

include pathogens, vaccinations, extreme temperature variations, transfer from pullet to layer housing, and conspecific aggression as some examples. The challenges hens face could be greater in loose-housed systems such as free-range, where both the likelihood, and magnitude of daily fluctuations are often higher than more controlled indoor-only housing. In the face of these environmental fluctuations, regulation of daily biological rhythms such as feeding, drinking, activity, and resting to maintain the same functional outcomes of growth and egg production would be indicative of a resilient individual. Along the same lines, the ability of an individual to cope with compounded stressors is going to affect susceptibility to and recovery from, disease and infection. Thus, high resilience capacity of the individual birds in a flock is desirable for healthier individuals, optimised welfare, and efficiency of production.

It is well understood across laying hens (and other types of production animals) that there is variation among individuals within a flock. Birds of the same genetic history can vary in their physiological responses to stressors, personality traits (e.g., fear and boldness), and coping styles. There is also a growing body of literature on the impacts of rearing environments on hens’ subsequent physical health, gut microbiome, and behaviour, including propensity to develop undesirable behaviours such as feather pecking and floor egg laying. Early life conditions, including the incubation period, the hatching process, and pullet rearing period can all result in different outcomes depending on what

18

DOSSIER - dossier -

©Pexels

DOSSIER

the bird was exposed to. For example, high decibel noise during incubation can negatively affect neurotransmitter noradrenaline levels and impair spatial behaviour abilities in day-old chicks. Increased environmental complexity during rearing can improve spatial locomotion and navigation abilities of pullets. Commercial hatchery processing conditions versus quieter hatching without transport and delayed vaccination resulted in greater stress reactivity in pullets, increased feather damage, and reduced egg production. It is also well established across many animal species that greater complexity during development will enhance neurological development. Consequently, there is increasing interest in how environmental modifications, particularly in early life, can modulate and improve adaptive capacity and resilience of individual birds. Experiments with environmental enrichment as a means to enhance functional capacity of individuals are providing evidence of the benefits of developmental complexity.

Environmental enrichment to enhance adaptive capacity

Globally, there is a small collection of studies that have been conducted over the past few years investigating the effects of environmental enrichment in enhancing adaptive capacity of hens. More projects around the topic are currently in progress as researchers seek to understand the best strategies for optimising the functioning of individual birds to cope with environmental disturbances which ultimately significantly improves their welfare and production efficiency. Further details of select trials to date are presented here.

The first study to highlight the impact of enrichment on adaptive capacity by Campbell et al. (2021) was conducted in Australia on free-range laying hens within an experimental housing system. This study aimed to understand how varying types of environmental enrichment during the entire pullet rearing period may affect the behaviour, adaptability, and welfare of laying hens at different stages across the production cycle. Hy-Line Brown day-old chicks were housed in an indoor floor-litter based rearing system. Pens with no additional objects served as a ‘control’ treatment. Two enrichment treatment groups were then also provided with either varying novel objects that were regularly changed throughout rearing as a ‘novelty’ treatment, or H-shaped perching structures that were

fixed in place but had both open- frame and opaque sides to increase the complexity of the spatial environment (‘structural’ treatment). Within the larger experiment, different assessments were made on samples of the 1400 birds throughout their life cycle with some tests applied to specifically assess whether the enrichments affected the adaptability of the birds.

As stated earlier, individual chickens can differ in their personalities which dictate how they may react to environmental stimuli. They are also known to vary significantly in individual range use patterns. These ranging preferences may be related to personality differences. In this rearing enrichment experiment, it was predicted that the greater environmental complexity relative to control conditions would modulate personality by reducing fear, as well as increasing adaptive capacity. A sample of birds were individually tested with a series of behavioural tests at 9 to 11 weeks and the same birds again at 20 to 21 weeks. These behavioural assessments included initial responses to a novel arena, adaptation across time to the novel arena with food present, an open field test, novel maze arena training to access food and finally maze completion testing. Additionally, individual range use was measured from 27 to 31 weeks using radio-frequency identification technology that detected movement in and out of pop-holes by individually tagged hens. The results showed that the enrichment treatments reduced the latency to first step in some of the tests which is indicative of reduced fear in a new environment. When 16 correlations were assessed between behavioural test parameters across time, 11 were significant for control birds and only six to seven were significant for the enriched treatments. Furthermore, correlations between test parameters and subsequent range use were significant for only the control birds (Table 1). These study results indicate enrichment during rearing may reduce fear and increase adaptation. Fewer correlations among test parameters including with range use in the enriched hens suggest they developed a more plastic personality type that was flexible to their variable surroundings. A more plastic response strategy could have fitness benefits for hens, particularly free-range birds that encounter drastic environmental change across life stages. The behavioural test parameters were selected to be predictors of range use based on previous studies. These parameters included the latencies (lat) to vocalise in an open field test (OFT), the summed latency for training to reach food in an arena across the first day of training sessions, the latency to

19 - may 2024 -

eat in a maze test, and the latency to leave the holding zone with a novel object present (HZ NO) in the maze test. Table adapted from Campbell et al. (2021) with further details on the behavioural tests in that paper. Significant P-values are indicated in bold.

Within the same rearing enrichment experiment, the adult free-range hens were exposed to a stressor at 44 weeks of age where the range area they had been accessing for several months was reduced by 80% for 11 days. Changes in ranging behaviour and albumen corticosterone concentrations were evaluated. Across all hens, ranging time decreased and the average number of range visits increased when the available area was reduced, but there was a lower increase in visit numbers for the structural treatment hens suggesting they were able to better adapt to the environmental change. The corticosterone concentrations also varied across treatments although the results

were less clear to interpret. Both the control and novelty treatment hens’ eggs showed increases immediately following the range shrinkage which decreased across the range shrinkage period. In contrast, the albumen corticosterone concentration in structural hens’ eggs decreased immediately following the range shrinkage and then increased slightly toward the end of the range shrinkage period. These findings highlight the longer-term impacts of rearing environments and how they can modulate hens’ responses to stressors they encounter across their lifetime.

Expanding our focus internationally, a collection of three studies conducted in Sweden investigated the impacts of rearing complexity on stress responses and adaptability in Bovans Robust white layers. In the first study, similar to the previous research with free-range hens, further support was found for early environmental enrichment improving adaptive plasticity. In a two-factorial

Table 1 – The Spearman’s correlations and P-values for comparisons between four behavioural test parameters conducted at 20-21 weeks of age and the mean daily time spent ranging as well as mean daily range visits as recorded from 27-31 weeks of age for hens from three rearing enrichment treatments (control: n = 29, novelty: n = 23, structural: n = 24).

latencies (sec)

design, small groups of one-dayold chicks were housed in either simple floor litter pens, or complex pens that included perches, a dark brooder, and wooden blocks. They were then also exposed to an acute 6-h cold stress treatment or not at two days of age. Across five days at four weeks of age, the four different treatment groups (enriched/non-enriched + acute stress/no acute stress) were exposed to intermittent and unpredictable stressors. These implemented stressors included, for example, changing the room temperature, changing out the bedding, random noise playback, and lighting schedule modifications. Varying immunological parameters were assessed to measure the birds’ immunocompetence. Results showed the enriched environment was able to mitigate the negative effects of the cold stress treatment. Similarly, the birds from the enriched rearing had improved physiological responses to the intermittent imposed stressors. This improvement may have been facilitated by increased resting behaviour observed in the enriched birds enabling greater recovery. This research contributes further evidence to the beneficial effects of early complexity and the ability to modulate a bird’s phenotypes based on their rearing conditions.

In the second study, the effects of rearing environmental choice were assessed in small bird groups with the prediction that enrichment may have beneficial impacts through the mechanisms of allowing resource choice (i.e., increasing ‘agency’) in the young birds. Treatments were rearing from day one with only a single litter type and a single perch, versus four different litter and perch types. Similar immunocompetence

20

- dossier -

DOSSIER

Parameter Rearing treatment Behavioural

Daily ranging Control Novelty Structural Lat. vocal OFT Mean duration r s = -0.37, P = 0.08 r s = -0.09, P = 0.67 r s = -0.13, P = 0.52 Mean visits r s = -0.53, P = 0.008 r s = 0.06, P = 0.77 r s = -0.10, P = 0.60 Sum lat. train

Mean duration r s = -0.15, P = 0.50 r s = 0.20, P = 0.37 r s = -0.04, P = 0.85 Mean visits r s = -0.20, P = 0.36 r s = 0.19, P = 0.38 r s = -0.04, P = 0.85

Mean duration r s = -0.32, P = 0.13 r s = -0.08, P = 0.72 r s = -0.07, P = 0.74 Mean visits r s = -0.44, P = 0.03 r s = -0.21, P < 0.34 r s = -0.07, P = 0.71 Lat.

Mean duration r s = -0.50, P = 0.01 r s = -0.06, P = 0.77 r s = -0.13, P = 0.51 Mean visits r s = -0.66, P < 0.001 r s = 0.11, P = 0.62 r s = -0.13, P = 0.51

2-5

Lat. eat in maze

leave HZ NO

DOSSIER

High strength and quality materials

Excellent seal, zero water wastage, dry litter

Easy and fix regulation of min and max feed levels

Fast pan filling without any waste of feed

Avoiding the step in by the animals in the pan

Anti-UV and chemical resistance

Use a QR code scanner on your device to access our website.

21

www.cortizootecnici.it

corti_zootecnici

Corti Zootecnici

Corti Zootecnici’s Feeder

tests were performed at three weeks of age as well as behavioural tests of tonic immobility, novelty, and human-reward motivation conflict. Across all the measures, there was evidence that the rearing with environmental choice improved immunological parameters and indicators of fear and adaptability, although not every parameter showed statistical differences. This study again supports that rearing complexity can alter the phenotype of the chick and enhance their coping with what they encounter in their environment.

In a third study by the same research group, Skånberg et al. (2023) built upon the previous findings to assess how both environmental choice, and environmental change affected chick adaptability. Different litter and perch types were provided simultaneously to chicks (static choice) or were swapped around multiple times each week (choice and change), and these treatments were compared with a single choice swapped out multiple times each week (change, no choice), and a no choice static rearing environment deemed to represent standard rearing conditions. When the chicks were four to five weeks old, behavioural tests were conducted including a novel arena test and a social detour test. The test results indicated that greater environmental change had impacts on reducing fear and greater environmental choice, increased exploration, and improved spatial skills. However, combining both change and choice did not have an additive effect on improving the chicks’ behavioural adaptability. This indicated these environmental parameters both have positive impacts, but through different mechanisms.

As a final illustration of enrichment impacts, a study in Canada used small groups of young adult ISA Brown hens in floor pens. Comparisons were made between housing in control littered floor pens or an enriched floor pen environment with a larger area, and more spatial complexity including perches and platforms as well as foraging opportunities. When the birds were assessed in behavioural tests of judgement bias, restraint, and startle reflexes, including physiological measurement of stress-induced hyperthermia, the enriched hens fared better. Housing in a preferred enriched environment reduced both the behavioural and physiological responses to imposed stressors, including a more rapid return to prestress physiological levels which is indicative of improved resilience. These stress test measures did not covary with judgement bias assessments indicating different mechanisms of enrichment impact on affective states.

Discussion and conclusions

The collection of studies detailed here illustrate the effects of early rearing complexity through different environmental enrichment strategies to beneficially modulate the phenotype of the bird. These modulations increase the bird’s resilience and adaptability when faced with environmental stressors and will ultimately improve their welfare. To date, there is some evidence of beneficial rearing effects still being present later in life, and enrichment can also still be beneficial when applied in young adults rather than the early rearing period. However, there is a need for more work to capture how this improved resilience may play out across the entire flock cycle.

The studies described in this paper have reported significant beneficial effects on varying single-point measures that included behavioural as well as physiological assessments. However, not every measure showed significant impacts. This highlights the importance of multiple measurements to assess treatment impacts as the exact mechanism via which these improvements are happening is still under investigation.

While single time point trait assessments are indicative of a modulated phenotype, there is a need for more continuous flock cycle assessments looking at fluctuations across time to wholly capture the longer-term resilience of the bird. For example, body weight variation in an individual bird across time may function as a heritable indicator of the bird’s resilience capacity. Furthermore, egg production traits (weekly deviations of an individual from the average) across a flock cycle may be indicative of individual resilience enabling selective breeding of more adaptive animals. The holistic functioning of an individual organism across its lifetime and the ability to maintain functional performance in the face of environmental disturbances is a resilience individual that will better cope with challenges it may face. Enhancing adaptive capacity through environmental complexity will provide the tools an individual bird needs to better perform throughout its life.

References are available on request

From the Proceedings of the Australian Poultry Science Symposium 2024

22

- dossier -

DOSSIER

MODULA THE SPECIFIC FEED PAN FOR TURKEYS

STURDY AND EASY TO MANAGE

Designed from one day-old chicks to heavy and nervous male turkeys.

Simple washing of any component of the feed pan.

Safe and fast assembly/ disassembly of the antiwaste ring without tools.

Leader in livestock feeding systems

- may 2024DOSSIER

QUALITY MADE IN ITALY www.azainternational.it I WANT AZA!

Controlling insects in poultry production

Pests can cause significant losses to production by reducing productivity and transmitting diseases. Some insects can also cause physical damage including structural damage to the houses. Breeder operations can be impacted by many insect species but the primary issues are caused by flies, beetles, and ants.

Insects are attracted to poultry operations as food, water, and habitats are readily available. Chemical insecticides are not always effective as insects become more resistant to multiple pesticides. Mechanical means of control (traps) are an option and should be part of an insect control program. However, good management practices along with a prevention program are the most effective ways to prevent insect infestations.

and help develop a good pest management program. Once established, good record keeping is a valuable tool to identifying and mitigating pest issues before they become an infestation problem.

Good management and sanitation practices

To prevent an insect infestation, it is crucial to control moisture. Insect eggs and larvae require moisture to hatch and survive, so it is important to keep the house environment dry. Likewise, eliminate potential food sources. Consider the following points:

• If darkling beetles are an issue, leave the litter in the house for at least one day and treat it with an effective insecticide. The beetles will come out in mass once the birds leave the house, so control needs to take place quickly. After removing the litter, cover it to keep the insects out of the litter and to contain others until it can be removed from the farm.

• Ensure that the house drains well and is ventilated correctly to prevent wet litter. Check for and repair any water leaks immediately.

• Ensure that water around the outside of the house drains away and that any drainage systems (ditches, piping) is not blocked with debris or vegetation.

Gracieli Araujo, Specialist in Animal Welfare, Cobb LatCan

Professional pest control companies have experts that can readily evaluate situations

• Ensure that the birds have good quality drinking water. Poor quality water can induce episodes of diarrhea and flushing which will add moisture and manure to the litter.

24

- focus -

FOCUS

©Cobb-Vantress

FOCUS

• Prevent high temperatures in the house which will cause the birds to drink more water.

• Repair any structural damage as these areas can be used as burrows for insects, especially darkling beetles.

• Allow at least 4 weeks of downtime between flocks. This will eliminate the food and water sources and give any applied insecticides time to work.

• Quickly remove and dispose of any mortality.

• Check for feed spills regularly and clean them immediately.

Chemical control

The choice of pesticide should be based on pest target, effectiveness, potential hazards (to humans and birds) as well as local regulations. A professional pest control consultant can provide more information about the right

chemicals for your operation. Here is a bit of information about some common insecticides.

• Carbaryl based products can be used to control multiple insect species. They block the nervous system by inhibiting the enzyme acetylcholineesterase.

• Pyrethrin based products are safe to use while birds are in the house. These chemicals are effective against ants, flies, and beetles. They cause temporary paralysis, but beetles can produce enzymes that detoxify the chemical. Using pyrethrins synergistically with other insecticides can be more effective.

• Insect growth regulators are also available which prevent formation of chitin so that the larvae cannot turn into an adult beetle.

• If any ant trails are seen moving from mounds outside the house to inside the house, insecticides can be sprayed around the house perimeter. Any ant mounds can also be treated with chemical pesticides.

Biological control

Several biological control agents are available for pest control. Be aware that not all these agents are suitable for use in all climates.

• Boric acid can be applied as a pellet or crystal to control beetles and flies, but should only be applied between flocks because it can also injure animals.

• Some fungi are available that infect and kill insect larvae.

• Fly parasitoids are tiny wasps that can kill flies in the pupal stage. If using beneficial insects, be aware that many chemical pesticides can kill the pest and beneficial species.

• Ants primarily prey on other insects. Controlling insect infestations can therefore help prevent ant infestations.

Mechanical control

• There are many types of traps available that include pheromone, sticky tape, and electrical based traps (bug zappers).

• Flies will not move against the wind so fans can be used around doorways to prevent flies from entering.

- may 2024 - 25

Figure 1 – Ensure that water drains away from the house. Standing water around the house can support insect survival and reproduction.

Figure 2 – Mechanical traps can be used to trap flies, a leading pest in poultry production.

Hans-Wilhelm Windhorst

The author is Professor Emeritus of the University of Vechta, Germany

Was it the decade of Asia?

The dynamics of global meat and egg production between 2012 and 2022

The aim of this article is to document the dynamics of global production of meat and eggs, the most important protein suppliers alongside milk, between 2012 and 2022 at continent level as well as for the leading producing countries and to identify the main steering factors.

Although devastating animal diseases severely impaired the development of meat and egg production in numerous countries in the past decade and the Covid-19 pandemic put the global economy into a kind of shock paralysis for almost three years, the production volume

26 MARKETING - marketing -

of meat and eggs increased. However, the dynamics varied considerably depending on the meat type and continent. With the exception of beef, Asia was able to maintain its dominant position but, as will be shown, suffered losses in pork production. While both the US Department of Agriculture (USDA) and the OECD-FAO assumed in their forecasts towards the end of the first decade that the following decade, i.e. the period from 2011 onwards, would be Asia’s decade, the forecasts had to be revised significantly in some cases because outbreaks of African swine fever (ASF), Avian Influenza and the Covid-19 pandemic not only slowed down the economic development, but in some cases even led to a decrease of the gross national product.

Remarkable differences in development at continental level

There were considerable differences in both the absolute and relative increase in production for the three meat types and eggs analysed here (Table 1).

Table 1 – The absolute and relative increase of global meat and egg production between 2012 and 2022 (source: own calculation based on FAO data).

and South America lost shares in chicken meat, Europe and Oceania were able to maintain their positions, Africa and Asia gained shares. Asia’s production volume increased by 12.1 million tonnes or 37.4%, Central and South America followed with 6.2 million tonnes or 27.5%. Africa recorded the highest relative growth rate at 65.2%, however, the low initial value of only 4.7 million tonnes in 2012 must be taken into account.

Table 2 – The contribution of the continents to the global increase of chicken meat, pork, beef and egg production between 2012 and 2022; data in % (source: own calculation based on FAO data)

It is worth noting that the two poultry products showed by far the highest absolute and relative increases. This reflects what I called the red-white shift among consumers from red to white meat (Windhorst 2021) on the one hand and the increased appreciation of eggs as a source of protein on the other, as well as the lack of religious barriers to the consumption of these products. In contrast, pork and beef are banned from consumption in a number of religious communities. Added to this are the higher production costs due to the less favourable feed conversion rate.

A closer look at the four products regarding the development of their shares in global production at continental level between 2012 and 2022 provides interesting insights (Figure 1, Table 2). North America and also Central

*higher than 100.0% because of the decrease in Europe and Oceania

Asia contributed 41.4% to the global increase in chicken meat production in the decade under review, followed by Central and South America with 21.0% and Europe with 16.0%. It is worth noting that the African countries recorded a higher absolute growth than North America. It has to be considered, however, that the USA has dominated global production for decades, domestic consumption is only increasing slowly and the international market is highly competitive.

Although Asia remained the undisputed leader in pork production, the continent only ranked third behind Central and South America and Europe regarding the absolute and relative growth of the production volume. The comparatively lower increase is a result of the outbreaks of African swine fever in China and other countries in East and South Asia.

At first sight, it is surprising that Asia recorded the highest absolute increase in beef production of all continents at 3.4 million tonnes. Central and South America as well as North America fell far behind. The continent contributed 46.9% to the global increase in production, 29% more than North America and 19% more than the countries of Central and South America. Growth in Europe and Oce -

27 - may 2024MARKETING

Product Absolute increase (1,000 t) Relative increase (%) Chicken meat Eggs Pork Beef 29,320 19,981 10,283 7,298 31.1 29.8 9.2 11.9

Pork Beef Eggs Africa Asia Europe North America C.S. America Oceania 10.5 41.4 16.0 9.8 21.0 1.3 6.4 20.5 22.6 19.0 30.7 0.8 11.2 46.918.2 28.24.2 74.1 1.6 5.4 14.5 0.1 World 100.0 100.0 *104.5 100.0

Continent Chicken meat

Chicken meat

Figure 1 – The changing share of the continents in global chicken meat, pork, beef and egg production between 2012 and 2022 (design: A.S. Kauer, based on FAO data).

28 MARKETING - marketing1.3% 23.8% 19.2% 16.3% 34.3% 5.1% Total: 94.3 mill. t 2012 1.3% 23.2% 18.3% 16.4% 35.4% 5.3% Total: 111.7 mill. t 2017 1.3% 23.1% 17.0% 16.3% 36.0% 6,3% Africa Asia Europe N America CS America Oceania Total: 123.6 mill. t 2022

0.4% 6.0% 11.2% 24.3% 56.8% 1.3% Total: 112.3 mill. t 2012 0.4% 6,6% 11.6% 24.5% 55,4% 1.5% 0.5% 8.1% 11.8% 24.1% 53.8% 1.7% Africa Asia Europe N America CS America Oceania Total: 118.8 mill. t 2017 Total: 122.6 mill. t 2022 Pork 4.5% 28.3% 20.9% 16.8% 19.8% 9.7% Total: 62.0 mill. t 2012 4.2% 28.5% 20.5% 16.3% 20.7% 9.8% 3.7% 28.3% 20-6% 14.8% 22.7% 9.9% Africa Asia Europe N America CS America Oceania Total: 69.3 mill. t 2022 Total: 64.3 mill. t 2017 Beef 0.4% 11.2% 9.0% 15.6% 59.1% 4.7% Total: 67.0 mill. t 2012 0.4% 11.9% 8.7% 13.8% 60.9% 4.3% Total: 79.0 mill. t 2017 0.4% 11.9% 8.2% 12.4% 62.5% 4.6% Africa Asia Europe N America CS America Oceania Total: 87.0 mill. t 2022

Eggs

29 - may 2024MARKETING tion in China also rose by 1.5 million tonnes, the country recorded the lowest figure in the country group at just 12.1%. Via Venezia, 30 35010 Campo San Martino (Pd) Italy www.facco.net info@facco.net +39 049 9698111 Contact us Over 65 years of experience as a key turnkey solutions partner in poultry farming!

Chicken meat

Of the 15 leading countries, seven were in Asia, four in America, three in Europe and one in Africa. The seven Asian countries accounted for 23.6% of the global increase, while the four countries of the American double continent accounted for 24.3%. A comparison of the development in the two continents shows that Asia, with a share of 41.4%, ranked well ahead of America with 30.8% (see Table 2).

Global egg production grew by 20 million tonnes in the analysed decade. Of this, the 15 leading countries accounted for 18.1 million tonnes or 90.6%. Figure 2 shows that production volumes increased in all countries except Iran. Of the leading countries, eight were in Asia, five in America and two in Europe. With China, Indonesia and India, three Asian countries ranked in the top positions. Together they shared 13.4 million tonnes or 74.2% in the increase of the country group and 67.2% in the global increase. China was the undisputed leader with 5.7 million tonnes, followed by Indonesia with 4.8 million tonnes and India with 2.9 million tonnes. The increase in production in Brazil (1.3 million tonnes), the USA (0.9 million tonnes) and Mexico (0.8 million tonnes) was significantly lower. The development in Indonesia is remarkable, with a relative growth rate of 421.2%, more than five times higher than India with 79.8%. A comparison of the shares of the two continents in the increase of global egg production shows that Asia, with 74.1%, ranked far ahead of the American double continent with 19.9%.

Global pork production increased by 10.3 million tonnes or 9.2% in the period under review, and by 9.7 million tonnes or 10.3% in the fifteen leading countries. Figure 2 shows that production volumes decreased in six of the fifteen countries. With the exception of Japan, all countries were in Europe. The decline was particularly sharp in Germany at almost 1 million tonnes and in Italy at 0.4 million tonnes. With total production of 55.4 million tonnes in 2022, China continued to play an undisputed leading role, but it was slightly behind Brazil (+2.04 million tonnes) in terms of the increase in production volume (+1.98 million tonnes). Russia, the USA and Spain ranked next, as can be seen in Figure 2. Russia achieved the highest relative growth rate with 77.1%, followed by Brazil with 64.6% and Spain with 46.4%. The highest relative decreases were in Italy with 24.0% and Germany with 17.9%.

In contrast to the two poultry products, Asian countries accounted for a much smaller share in the growth of global pork production in the decade under review, at just

30 MARKETING - marketing -

Brazil USA India Russia China Pakistan Mexico Japan Poland Turkey Peru S. Africa Un. Kingd. Thailand Iran [mill. t] 0.0 0.8 1.5 2.3 3.0 Countries in Asia [mill. t] Decrease Increase Eggs China Indonesia India Brazil USA Mexico Pakistan Argentina Turkey Germany Russia Korea Rep. Colombia Japan Iran -1.5 0.0 1.5 3.0 4.5 6.0 Decrease Increase Countries in Asia [mill. t] [mill. t] Pork Brazil China Russia USA Spain Viet Nam Mexico Netherlands Canada Japan France Poland Denmark Italy Germany [mill. t] -0.3 0.5 1.3 2.0 Decrease Increase [mill. t] Countries in Asia Beef China Brazil USA Turkey Argentina Pakistan Mexico Canada Uzbekistan S. Africa Un. Kingd. Russia France Germany Australia [mill. t] 0.0 0.5 0.9 1.4 1.8 [mill. t] Decrease Increase Countries in Asia

Figure 2 – Changes in the production volume of chicken meat, eggs, pork and beef since 2012 in the 15 leading countries in 2022 (design: A.S. Kauer based on calculations of the author).

20.5%. The American double continent was the undisputed leader with 49.7%, followed by Europe with only 22.6%. The outbreaks of African swine fever in China and other countries in East and Southern Asia explain the low growth rate in production in Asia. Different dynamics were recorded in Europe. While production rose in Russia, Spain and the Netherlands, it fell in Germany and Italy. Changes in per capita consumption and foreign trade were the key drivers.

Of the products analysed here, beef recorded the smallest increase at 13.3 million tonnes. The 15 leading countries contributed 6 million tonnes or 45.0%. Production volumes fell in four of the leading countries between 2012 and 2022, three of which were in Europe. Australia recorded the highest absolute decline at 274,000 tonnes, followed by Germany (-169,000 tonnes) and France (-133,000 tonnes). At first glance, it is surprising that China had the largest absolute increase with 1.6 million tonnes. Brazil, the USA, Turkey and Argentina followed in next places, all countries with extensive natural grasslands. The high growth in China must be seen in the context of the massive decline in pork production. In order to secure the meat supply for the population, domestic production was expanded and, in addition to pork, chicken meat and beef were imported.

A further steering factor was the increase in the per capita consumption of beef in affluent consumer groups in urban centres. The consumption of this comparatively expensive meat type is seen as a status symbol.

Four of the 15 leading producing countries in 2022 were in Asia. They contributed 2.1 million tonnes or 52.5% to the increase in beef production of the country group and 23.6% to the global increase since 2012. If one compares Asia and the American double continent in terms of their share in the global production growth, Asia ranked only slightly ahead of America with 46.9% and 46.4% respectively.

The continuing decline in beef production in some European countries reflects the aftermath of the BSE crisis. BSE first appeared in England in the mid-1980s and then in other European countries, leading to a massive slump in beef consumption that was not compensated for in subsequent years. The higher production costs compared to poultry meat also played a role. This was reflected in the retail price and resulted in a reluctance of the consumers to buy.

Summary and perspectives

The answer to the question posed in the title of this article can be summarised as follows. Asia recorded by far the highest absolute and relative growth rates in the production of chicken meat, eggs and beef. In contrast, only a small increase was achieved in pork because massive animal losses occurred due to outbreaks of African swine fever. However, more recent data from China shows that production rose again quickly and was even higher in 2023 than in 2018. The decade between 2012 and 2022 was largely characterised by Asia in terms of meat and egg production, even if there was a dip in pork production due to the epidemics. In view of the continued rapid population growth and the increasing purchasing power in a number of countries, it can be assumed that Asia will be able to consolidate its leading role.

Data source and additional literature

FAOSTAT: https://www.fao.org/faostat/en

Windhorst, H.-W.: The red-white shift in global meat production. In: Zootecnica International 43 (2021), no. 5, p. 32-37.

Windhorst, H.-W.: A glimpse into the future. Projection of global meat production and consumption until 2030. In: Fleischwirtschaft international 2021a, no. 3, p. 28-31.

Windhorst, H.-W.: Slowing growth projections for pork. A projection for the development of global pig meat production until 2031. In: Fleischwirtschaft international 2023, no. 2, p. 48-51.

Windhorst, H.-W.: A projection for the development of global poultry meat production until 2031. In: Zootecnica International 45 (2023), no. 5, p. 22-26.

Windhorst, H.-W.: Remarkable dynamics of the global poultry industry: Egg production. In: Poultry World 39 (2023), no. 3, p. 28-31.

Windhorst, H.-W.: The remarkable dynamics of the global poultry industry: 50 years in retrospective. Part 2 - Global poultry meat production. In: Zootecnica International 45 (2023), no. 7/8, p. 24-33.

Windhorst, H.-W.: The remarkable dynamics of global pork production. 50 years in retrospect (1970-2020). In: Pig Progress 39 (2023), no. 8, p. 6-9.

31 - may 2024MARKETING

Understanding how to preserve the life of hatching eggs

Hatching eggs require careful management from the moment they are formed to the moment they hatch. Breeder farm conditions, egg handling conditions, incubation conditions… All these factors have an impact on chick embryo physiology and development, and consequently on the health and quality of new-born chicks. In this article, we examine the main factors that need to be considered to preserve the life of hatching eggs.

Mohamed Sobhy

32 - technical columnTECHNICAL COLUMN

Global Incubation Consultant

From breeder farm to hatchery

Incubators provide the optimum conditions for hatching eggs to become high-quality chicks. However, it is important to look further than that. The health and quality of a day-old chick is influenced by the complete ‘history’ of its hatching egg, from breeder farm to hatchery. It is therefore necessary to protect eggs against biosecurity threats, temperature fluctuations and improper handling during egg formation at the farm, storage at the farm, transportation to and handling at the hatchery.

1. Litter and nest management

The typical design of a breeding house involves a centre area filled with floor litter or litter nests. It is very important to keep the litter clean at all times to avoid potential contamination of the hatching eggs. The largest risk for the chick embryo comes from contamination immediately after the egg has been laid. As it cools down, the egg content retracts and suction from the outside to the inside occurs, meaning microorganisms can enter through the eggshell pores. If the environment is dirty, bacteria will gain entry to the egg. Eggs with dirty shells also carry harmful bacteria and are a biosecurity threat.

Any form of contamination will have a big negative impact on hatching results and chick quality:

• Weakened embryos

• Increased early embryonic mortality

• More exploders (‘bangers’)

• More dead in shell

• Increase in culls

• Higher first-week mortality

2. Egg collection and pre-selection

Laid eggs must be regularly collected to reduce the risk of breakage and contamination and all substandard eggs with, for instance, misshapen, cracked or thin shells must be removed.

In addition, an increased frequency of egg collections is important for the eggs’ gradual cooling towards the ‘physiological zero’ (i.e. temperature at which embryonic development is slowed down). If an egg stays in the nest for too long, it increases the risk of a continued cell multiplication (more info under point 5).

“The largest risk for the chick embryo comes from contamination immediately after the egg has been laid. As it cools down, the egg content retracts and suction from the outside to the inside occurs, meaning microorganisms can enter through the eggshell pores”

• customised advice and inhouse production

• high-quality raw materials and strict quality standards

• chicken house equipment from planning to support www.specht-germany.com

33 - may 2024TECHNICAL COLUMN

3. Egg disinfection and on-farm storage

Eggs can either be disinfected at the breeder farm or upon arrival at the hatchery. The purpose of disinfection is to prevent bacterial multiplication. Several practices for egg disinfection can be implemented (depending on the local rules and policies), such as:

• Fumigation

• Spraying

• Fogging

• Washing (mostly used for duck eggs)

After the eggs have been disinfected, they can be stored in an environmentally controlled farm storage room until transport to the hatchery. If the farm has no dedicated egg storage room, eggs must be transported to the hatchery daily.

4. Egg grading

Farm personnel conduct the pre-selection of hatching eggs, whereas hatchery personnel are responsible for the final egg quality control. A careful check of the incoming eggs’ external qualifications prior to incubation is strongly recommended. A good hatching egg should have the following characteristics:

• It is free from any deformities.

• It has a good shell quality.

• It is clean.

• Its colour is uniform within its batch.

5. Egg storage and recommended temperature profile

Hatching eggs are generally stored at the hatchery before they are loaded into the incubators. The total storage time varies, in some cases reaching 10 days or more.

The V-flow diagram below (see Figure 1) visualizes the temperature profile that should be followed: the hatchery’s egg storage room should be the coldest point along the breeder-farm-to-hatchery timeline. If there are uncontrolled temperature fluctuations in the process where specific points are warmer or cooler, then the embryo will be weakened, often resulting in an increased embryonic mortality, especially at the early embryonic stage.

• At oviposition, the egg’s temperature is close to the hen’s body temperature, which is around 40-41 °C (104-106 °F).

• Once the egg is laid, it is important to gradually bring down the egg temperature towards the physiological zero to slow down embryonic development. This cooling process should start within 3 to 5 hours after oviposition. Particularly important are the storage conditions at the hatchery: they are essential to preserve the life of the embryos. The recommended temperature and humidity values depend on the number of days the chicken eggs are stored. It is generally recommended to finetune the absolute humidity in such a way to obtain 0.5% weight loss per week during storage and to maintain the relative humidity at an average of 70%.

• As a next step, the eggs are pre-warmed (pre-heated) before incubation starts (the minimum pre-heating time is 4 hours; the maximum pre-

34 - technical columnTECHNICAL COLUMN

Storage time Storage temperature (constant) Absolute humidity Short term: ≤ 4 days 18 °C (64 °F) 9 g/kg Long term: > 4 days 15 °C (59 °F) 7 g/kg

Figure 1 – V-flow diagram with the recommended temperature ranges, from point of lay to incubator.

heating time is 12 hours). Warming the eggs ensures that all the embryos have the same temperature when the incubation program starts; it also avoids condensation from forming on the egg surface.

Achieve substantial benefits with heat treatment during egg storage

It is well-known that hatch losses increase with each extra day of storage. By applying precise heat treatment in Petersime’s dedicated X-Streamer™ Re-Store incubator, you can regain a substantial part of the hatch that would have otherwise been lost due to storage. The process also takes all embryos to a more advanced developmental stage, improves their robustness and ensures the best possible uniformity at the start of incubation. As sharing know-how within the poultry industry is paramount to Petersime’s mission, further findings and results of new studies will be shared in future articles.

• During incubation, an eggshell temperature of 37.8 °C (100 °F) is optimal.

In summary

There are various factors that influence the health and quality of new-born chicks. Hatching egg management is one of them. It is therefore essential to educate breeder farm and hatchery personnel on the importance of correct hatching egg management.