a 11 2022 Zootecnica International –November 2022 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze East Africa poultry consumption trends Understanding egg quality Plant-based antimicrobials against Salmonella in turkey processing

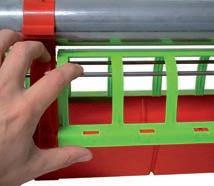

The new feeders

«Gió» range, specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

of the

EDITORIAL

Historically, publishing has conquered a place of primary importance in every social context. Even today, when there is more and more talk of “electronic publishing”, printed paper remains one of the main means of disseminating culture and information.

It has been said that the press represents one of the powers that control our society, and the truth of this statement is demonstrated by the attention paid to the press by all political and economic powers. The telematic and IT revolution obviously also affected publishing, but that fact should not be interpreted as a condemnation of the printed word. Electronic publishing is a new technology that represents a new reality for us to face up to and to use. The speed of telematic information has undoubted advantages, which cannot be ignored, but the effectiveness of the written word - especially in technical-scientific journals - will be irreplaceable.

History teaches us that nothing can oppose the force of new things, if they bring progress. It is therefore necessary for us to adapt, to open up to the new, while at the same time we must acknowledge and not forget that complementarities exists in all disciplines.

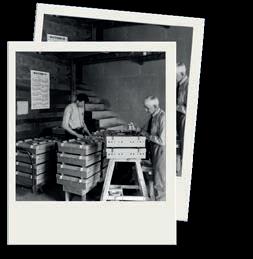

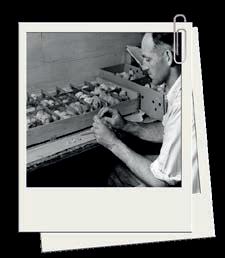

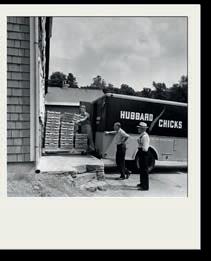

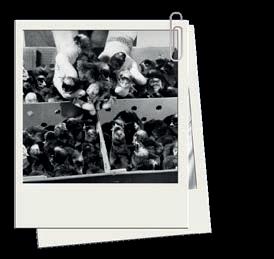

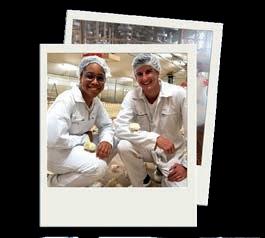

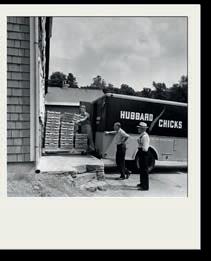

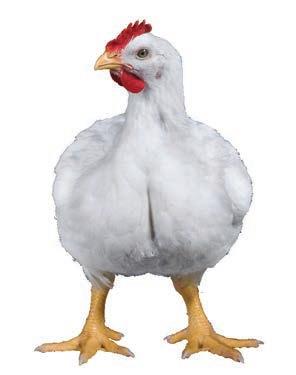

www.hubbardbreeders.com

FIELD CASE

East Africa poultry consumption trends 18

DOSSIER

Understanding egg quality 20

MARKETING

Dynamics and patterns of the poultry industry in the G19 countries between 2010 and 2020. Part 2 – Egg trade 26

TECHNICAL COLUMN

Hatching eggs: the importance of assessing internal egg quality 32

MANAGEMENT

In ovo injection of oregano essential oil at different pH affects hatchability and post-hatching performance in broiler chickens 36 PROCESSING

WORLDWIDE NEWS 4 COMPANY NEWS 14

SUMMARY

MARKET GUIDE................................................................................44 UPCOMING EVENTS ......................................................................47 INTERNET GUIDE 48 40 18 20

Poultry processing ergonomics 38 Plant-based antimicrobials against Salmonella in turkey processing 40

EFSA recommendations to improve animal welfare during transport

Providing more space, lowering maximum temperatures, and keeping journey times to a minimum are all needed to improve the welfare of farmed animals during transport, according to recommendations published by EFSA.

Animal welfare during transport

cluding domestic birds (chickens, laying hens, turkeys etc.) and rabbits. They identify the various welfare consequences that animals may experience during different stages of transportation, the hazards potentially causing them, and the animal-based measures (ABMs) by which they can be assessed. For all species, being fit for transport is of the utmost importance.

“Good animal welfare practices not only reduce unnecessary suffering but also help to make animals healthier. This is a key element for the safety of the food chain considering the close links between animal welfare, animal health and food-borne diseases, in line with the One Health principle that EFSA is committed to”, said Guilhem de Seze, EFSA’s Head of Department for Risk Assessment Production

EFSA has developed quantitative thresholds for the temperatures that should be maintained in a vehicle as well as minimum space allowances for the animals. EFSA also describes the development or progression of various other welfare consequences over time during transport, such as hunger, thirst, and fatigue.

For example, for animals transported in containers (poultry and rabbits), EFSA recommends that the journey duration should be considered as the whole time the animals are kept in the containers. The only way to avoid welfare consequences in day-old chicks is to transport fertilised eggs and hatch them on the farm of destination.

The advice by EFSA is provided to the European Commission in a series of five scientific opinions intended to support its ongoing review of animal welfare legislation in the European Union (EU) – a key element of the EU’s Farm to Fork (F2F) Strategy.

The scientific opinions cover small ruminants (sheep and goats), equids (horses and donkeys), bovines (cattle and calves), pigs, and animals transpor ted in containers, in-

The current EU legislation on the protection of animals during transport entered into force in 2005. Within the framework of the F2F strategy, EFSA’s findings will support the European Commission’s ongoing review of legislation with the aim to align it with the latest scientific evidence, broaden its scope, make it easier to enforce and ultimately ensure a higher level of animal welfare. The Commission’s proposal is expected in the second half of 2023.

Source: European Food Safety Authority

EFSA is the keystone of EU risk assessment regarding food and feed safety. In close collaboration with national authorities a in open consultation with its stakeholders, EFSA provides independent scientific advice and clear communication on existing and emerging risks. Photo credits: Shutterstock.com ISBN 978-92-9499-469-1 doi:10.2805/145091 TM-07-22-938-EN-N Good animal welfare practices not only promote intrinsic animal wellbeing but also help to make animals healthier. This is a key element for the safety of the food chain considering the close links between animal welfare, animal health and food-borne diseases, in line with the One Health principle. ww w.efsa.europa.eu

ANIMALS IN CONTAINERS More space, lower temperatures, journeys up to max 12 hours: these are some of the key recommendations to improve the welfare of animals transported in containers, included in a new scientific opinion by EFSA.

CHICKS The journey duration of animals transported in containers should be considered as the whole time the animals are confined. EFSA recommends journeys up to a maximum of 12 hours, including ‘on farm’ feed withdrawal. Sufficient floor space so all can sit at the same time without overlapping The height of the container should be such that the comb or head does not touch the ceiling when birds sit with their head and neck in a natural posture. The most efficient measure for preventing heat stress is to transport animals in vehicles using effective mechanical ventilation or

EFSA recommends transporting fertilised eggs, instead of day-old chicks, and hatching them on the farm of destination

TIME TEMPERATURE SPACE 12h POULTRY

POULTRY

4 - worldwide newsWORLDWIDE NEWS

EFSA's scientific opinions on RABBITS

air conditioning.

Sufficient floor space to sit in a natural resting posture. The height of the container should be at least 35 cm to ensure rabbits (up to 3 kg) can sit with their ears extended in a comfortable position

RABBITS

max

- november 2022 - 5 WORLDWIDE NEWS

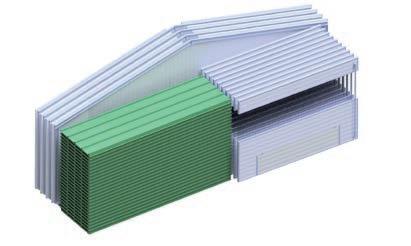

Shed 60 m2 Surface Mobile Poultry Shed. Professional design, made in Italy, suitable for free range poultry breeding. 5 unassembled sheds in one truckload Agritech s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy Tel. + 39 030 9968222 r.a. Fax + 39 030 9968444 commerce@agritech.it www.agritech.it

Mobile Poultry

AVEC General Assembly: energy and feed price surge put the EU poultry meat production at risk

Operators in the poultry meat supply chain are struggling to maintain production levels because of the very high energy and feed prices.

There are huge difficulties to pass the additional costs through the supply chain, so the support of the authorities is urgently needed.

Outgoing AVEC President Paul Lopez asks decision-makers to prioritise food and poultry meat production, to guarantee affordable and continuous supply in the weeks to come. As it happened during the Covid-19 crisis, the poultry meat sector is committed to working with the European Institutions to provide a continuous supply of high-quality and affordable poultry products to the EU citizens. But without intervention from policy makers, this is and will continue to be highly challenging.

The poultry meat producers are affected all along the supply chain,

by unprecedent increase of costs of energy, (especially natural gas, fuel, and electricity), CO2, packaging and external labour which threaten the continuity of the production. Energy and gas supply especially is critical for primary breeding of poultry to maintain the welfare of the birds.

The Russian invasion of Ukraine has also resulted in a substantially raise of the feed prices, which represent 70% of the production cost of poultry. This has led to a situation where farmers may prefer to stop the production in the coming weeks rather than taking the risk of big financial losses.

“ Policy-makers should continue to prioritise the poultry meat sector for access to both energy and feed, similar to Covid crisis where poultry was considered as a crucial sector. However, the simple access to energy and feed material is not sufficient. If affordable and stable prices cannot be guaranteed the survival of the sector is at stake. The Commission must support Member States to intervene to bring energy prices reasonable levels, increase liquidity on energy markets, diversify energy supply, and look for solutions such as placing a cap on prices for energy/feed. Sustainable production is our priority, and we see our sector as part of the solution when it comes to climate change. Therefore, we ask the authorities to strongly support our sector to develop and accelerate the transition towards sustainable sources of energy, to limit the dependence to foreign fossil fuel and feed suppliers, and increase the resilience of the sector ”, concludes outgoing AVEC President Paul Lopez

Source: AVEC

6 - worldwide newsWORLDWIDE NEWS

©congerdesignPixabay

7 Since 1960 Display our complete range of products on our homepage I WANT AZA! THE MOST INNOVATIVE RANGE IN THE POULTRY INDUSTRY We design and manufacture in Italy to guarantee maximum quality at competitive prices Leader in pig & poultry equipment Via Roma 29, 24030 Medolago (BG) Italy - Phone +39 035 901240 - info@azainternational.it www.azainternational.it Old Aza factory BROILERS - TURKEYS - LAYERS - ROOSTERS - BREEDERS Breedaza system Image: Fotolia© Minerva Studio

SPACE 2022: a focus on climate and youth

SPACE took place from Tuesday 13 to Thursday 15 September in a very warm and positive atmosphere, marking its 35th anniversary. Attendance was very high over the three days at the Rennes Exhibition Centre.

The livestock industry provides solutions to face climate challenges, and SPACE was able to demonstrate this. One of the biggest new features of this year’s event was the first Youth Forum, a space for young people organised in collaboration with agricultural teaching networks and opened by the Minister of Agriculture and Food Sovereignty, Mare Fesneau, at the start of the Expo. This new space enabled young people to voice their visions for their future jobs.

SPACE 2022 was extremely successful, with over 90,000 visitors (90,108, of whom 8,406 came from 120 different countries), and close to 1,200 exhibitors (of which 300 were international businesses and 250 were taking part in SPACE for the first time).

The event recovered its full international dimension af ter two years during which travel by visitors from abroad was heavily restricted. Delegations from around the world came to meet exhibitors, visit farms and draw inspiration from our organisational models. Many contacts were established with delegations from West Africa (Senegal, Ivory Coast, Mali, Benin, etc.), Cameroon, Democratic Republic of Congo, Morocco,

Algeria, Vietnam, the Philippines and numerous European countries.

Talks organised for the first time in partnership with Promosalons led to important business exchanges with top buyers from Colombia, Chile, India, Saudi Arabia, Turkey, Morocco and Nigeria.

In a context marked by drought and the soaring price of energy and raw materials, climate was the annual theme developed by the Espace for the Future. Through the numerous debates, conferences, products and equipment presented by exhibitors, SPACE 2022 provided an opportunity to show that agricultural stakeholders are already taking measures aimed at reducing the impact of livestock farming on the climate

SPACE is also unique for its capacity to host around 100 conferences each year, allowing all stakeholders in the agricultural sector to learn about and discuss topical issues such as new technologies, solutions for reducing climate impact, establishing and selling farms, protein self sufficiency, research into new fodder crops, CAP issues, etc.

For its anniversary, SPACE 2022 was the epitome of a professional, international and convivial trade show. Despite a difficult context, these three days have proved that with abundant and constructive dialogue, high at tendance by visitors and exhibitors and the expo’s very positive dynamic, 35 years af ter its first edition SPACE is an exceptional showcase for the livestock industry. A modern, constantly-evolving industry with a bright future and a resolve to feed society and meet its requirements.

Source: Space

8 - worldwide newsWORLDWIDE NEWS

Aviagen Advantage Breeds

The right bird for the right market. Broadest portfolio in the broiler breeding industry. Our unequaled brand diversity will help you meet the needs of your market. Let us show you at aviagen.com.

IFIF and FAO held their 21st annual meeting in Rome

The International Feed Industry Federation (IFIF) and the Food and Agriculture Organization of the United Nations (FAO) held their 21st annual meeting to further strengthen their collaboration on critical issues to ensure safe, nutritious and sustainable feed and food.

The meeting was officially opened by Mrs. Maria Helena Semedo, Deputy Director-General FAO and Mr. Thanawat Tiensin, Director Animal Production and Health at FAO, together with Mr. Ruud Tijssens, IFIF Chairman. They welcomed the IFIF delegates representing over 80% of global compound feed production and reiterated their commitment to this longstanding partnership and agreed to continue to strengthen their work together to tackle the challenges facing the feed and food chain.

Mr. Tiensin reaffirmed the importance of “collaboration between the public and private sector, as well as other stakeholders, to support the evidence-based key role of the livestock sector for achieving United Nations Sustainable Development Goals (SDGs) particularly - zero hunger. Also, for improving nutrition quality and supporting livelihoods worldwide in light of high-level global reflec -

tions on sustainable agri-food systems. We will continue working together with all stakeholders in promoting sustainable, resilient, inclusive, and efficient livestock transformation.”

Mr. Tijssens said “our joint meeting with the FAO once again underlined our strong partnership as IFIF continues to support key FAO initiatives such as the Livestock Environmental Assessment and Performance (LEAP) Partnership, the Global Agenda for Sustainable Livestock and the Multi-stakeholder Partnership for Feed safety.” Mr. Tijssens congratulated “the success of LEAP going into Phase 4 and reaffirmed the support of implementing the LEAP guidelines through the Global Feed LCA Institute (GFLI).

“The publication of the updated FAO and IFIF Manual on Good Practices for the Feed Sector was a key milestone

10 - worldwide newsWORLDWIDE NEWS

as we work together on Capacity Development for feed safety. IFIF continues to contribute to FAO’s work to address antimicrobial resistance including through advancing nutritional innovation to support animal health. IFIF looks forward to the 16th International Feed Regulators Meeting (IFRM) in 2023, which is another great example of IFIF FAO collaboration positively impacting the feed and food chain.”

Mr. Tijssens added that “together with the dedicated colleagues at the FAO we contribute to building a solid science-based approach to support safe and sustainable animal nutrition to bring quality and affordable food to a growing world population, producing more with less and even better under diverse production systems. The high quality of exchanges and cooperation towards the United Nations Sustainable Development Goals (SDGs) continue to build on our achievements and together with all IFIF members I am pleased our relationship with FAO continues to strengthen year to year. In addition, the Global Feed & Food Congress (GFFC), which we will organize

with FAO technical support in Bangkok in March 2024, will be an important opportunity for us to further strengthen collaboration with the Asian feed sector and stakeholders.”

Daniela Battaglia, Livestock Production Officer at the Animal Production and Health Division of the FAO, said “FAO and IFIF have a long standing partnership and this meeting addressed a number of critical issues of common interest, such as the need for capacity development to ensure feed safety and the importance of collaborating to tackle the containment of antimicrobial resistance (AMR). FAO is committed to work with the private sector and the feed operators and believes that they can valuably contribute to make the livestock and food sectors more responsible and sustainable and to achieve important goals such as public health, and animal health and welfare.”

For further information, please visit www.lubingsystem.com Or send an e-mail to info@lubing.it

- november 2022 - 11 WORLDWIDE NEWS

!lanigirO

Source: IFIF

Researchers developing tool to help poultry producers realize full value of solar technology

Michael Popp, professor of agricultural economics and agribusiness, spoke about how producers could utilize the Poultry Solar Assessment tool (PSA). The PSA tool assists producers make decisions about using solar energy on their operations.

professor of agricultural economics and agribusiness for the Arkansas Agricultural Experiment Station, said it could be a pricy endeavor, but one that can help a grower’s balance sheet in the long run.

The Agricultural Experiment Station is the research arm of the U of A System Division of Agriculture. The Center of Excellence for Poultry Science includes both research and extension activities of the division.

“We have analyzed poultry farm installations ranging in installation cost between $250,000 and $600,000,” Popp said. Associated 30-year total profit in today’s dollars ranged from $75,000 to $280,000 for those size installations. “What you are doing is replacing part of your electricity bill with up-front known costs. You know how much electricity you will generate; you know your depreciation, insurance, interest and property tax cost when you install,” he said. “As such, solar panels reduce your exposure to electricity cost volatility.”

Their analysis included tax credits and, to a much lesser extent, grants from REAP, the Rural Energy for America Program.

Decision assistance

Poultry producers considering use of renewable energy in their operations will have a free tool this fall to help them determine whether solar is right for them.

Yi Liang, associate professor of biological and agricultural engineering and a researcher in the Center of Excellence for Poultry Science, conducted solar energy research in 2021 on an Arkansas poultry production operation and found it offered significant savings. The poultry grower saved more than 90 percent off his annual electricity expense, Liang said. He paid only account charges — between $15 and $25 per month — in 11 out of 12 months of utility bills in 2021. The up-front investment of solar technology varies from operation to operation. Michael Popp,

The data inspired Popp and Liang to develop an online decision support software tool to help growers assess whether solar is feasible for their farms. Popp said he wanted to have the Poultry Solar Assessment tool available for download in October. “The Poultry Solar Assessment tool uses farm-specific information to estimate system size as well as appropriate electricity rates on the basis of the last 12 months of electric bill information,” Popp said. “The user can then choose financing terms, as well as how long they think it would take for them to realize income-tax-saving benefits.”

Popp has developed a line of decision support tools that

12 - worldwide newsWORLDWIDE NEWS

Michael Popp, professor of agricultural economics and agribusiness, spoke about how producers could utilize the Poultry Solar Assessment tool (PSA)

help Arkansas farmers easily analyze the advantages and values of choices they must make in every segment of the state’s agricultural industry. They are available for free download at agribusiness.uark.edu/decision-support-software.

Solar outreach

Liang and Walter Bottje, poultry science physiologist, hosted an educational program in July to debut the Poultry Solar Assessment tool and share the benefits of utilizing solar energy in poultry production.

“Adding solar technology is a way to lower the cost of production and displace fossil fuel associated with electricity generation with a renewable resource - sunshine,” Popp said during the event. “Doing this cost effectively, given current government tax benefits, is an added advantage.”

As part of the program, Marvin Childers, president of The Poultry Federation, gave a presentation on net metering and legislation surrounding solar energy in Arkan-

sas. Net metering is a method of billing electric utility customers who use both the power generated by their own renewable energy, such as solar panels, as well as power supplied by an electric company. When a customer produces more electricity than they consume, the excess energy is transmitted to the company’s grid, where it’s used by other customers. The customer is credited for the excess energy they transmitted to the company’s power grid.

“The additional feature of the Arkansas net meter policy includes meter aggregation, meaning the customers can offset all meters under their name using a solar array. This is attractive for agricultural producers since they have meters for different operations and in various locations,” Liang said.

Liang said the Center of Excellence for Poultry Science is planning another solar information event in the fall. It will provide another opportunity to understand the technical and economic aspects of solar technology and ask questions about it.

Source: University of Arkansas

- november 2022 - 13 WORLDWIDE NEWS

IPPE IPPE IPPE IPPE IPPE MEETS YOUR LEARNING GOALS The 2023 IPPE will offer 80+ hours of education programs and TECHTalks. IPPE will meet your learning goals at this powerhouse of a show in January! JAN. 24 - 26, 2023 ATLANTA, GA USA ippexpo.org

SmartVac™: the next generation of in-ovo vaccination and nutrition

Royal Pas Reform has launched its latest innovation in early nutrition and animal welfarefriendly production practices, the SmartVac™ in-ovo vaccination and nutrition system.

A new, patented technology, SmartVac™ allows 100% safe, consistent and accurate in-ovo vaccination and nutrition. It delivers the injectables only into the amniotic fluid, thus preventing possible injury to the growing embryo.

SmartVac™ will enable the poultry industry to apply a wide range of vaccines in-ovo, including Gumboro, Marek, ND and Coccidiosis vaccines. This is optionally performed in combination with nutritional components –for chickens with a healthy gut, favourable microbiota, enhanced immunity, and thus improved field performance.

SmartVac™ is designed to maximise the safety of the injection process, by focusing on the development level and needs of the growing embryo. The Embryo Soft Touch ® sensor on the injector allows automatic and in-

dividual adaptation of the injection depth to each single embryo, regardless of egg and embryo size. EST® also detects when the setter tray has an empty egg position, or contains non-viable eggs (infertiles or early deads) helping to reduce wastage of valuable vaccine. Only eggs containing grown embryos are inoculated with vaccine or nutrition.

For more detailed information visit www.pasreform.com/smartvac

14 - company newsCOMPANY NEWS

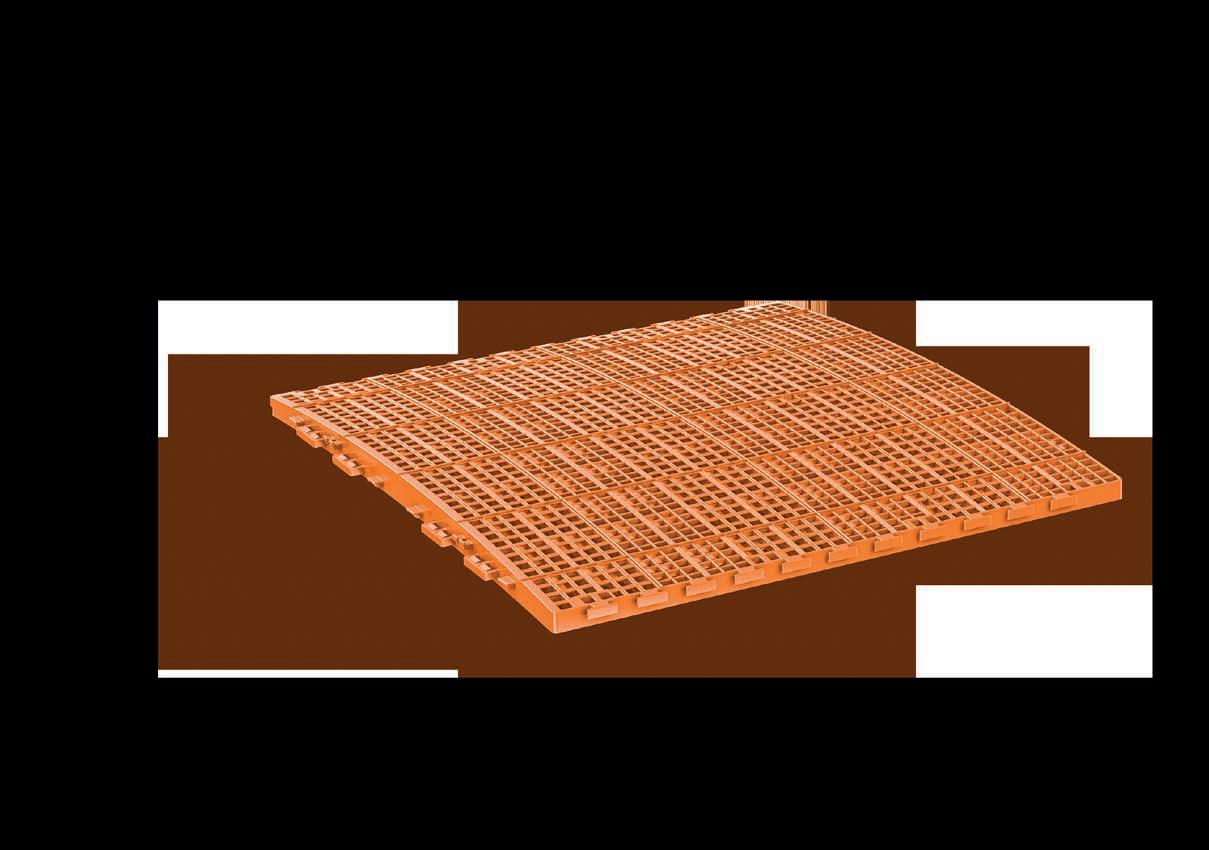

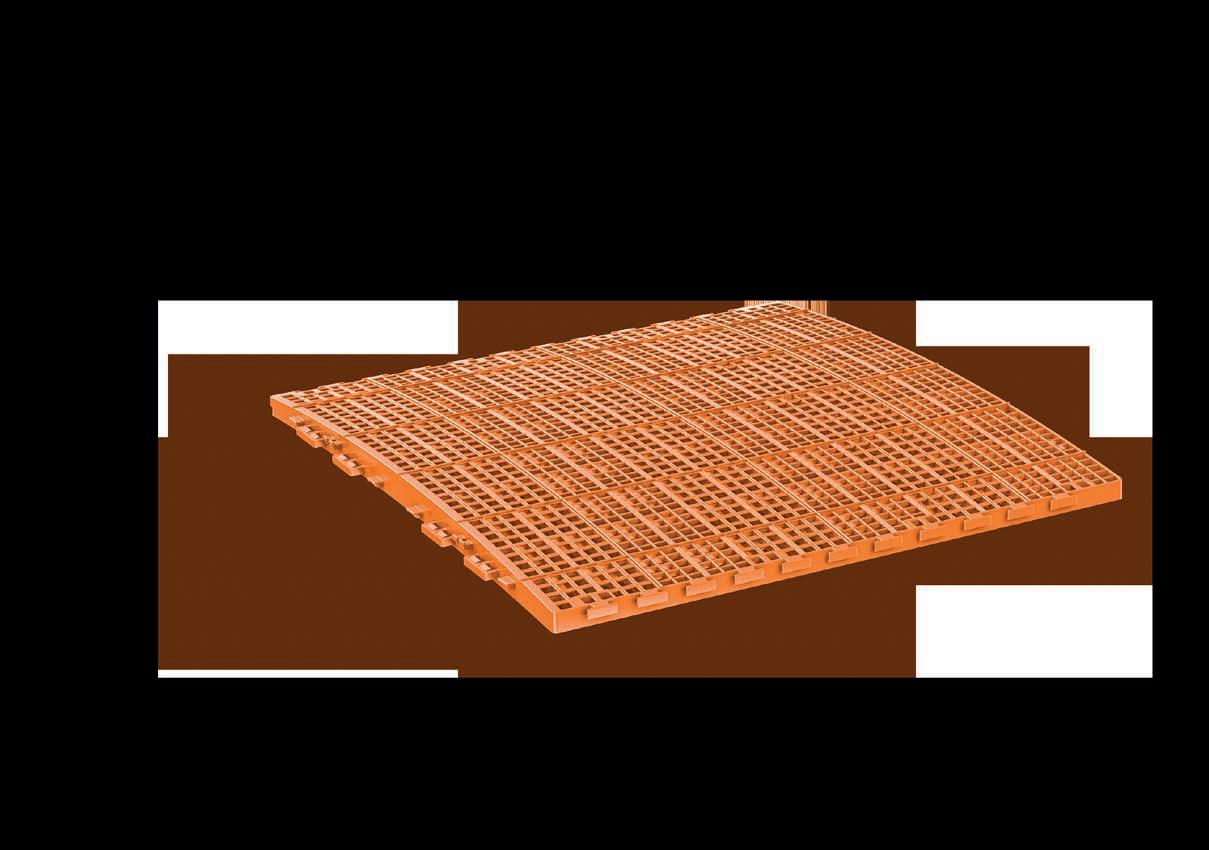

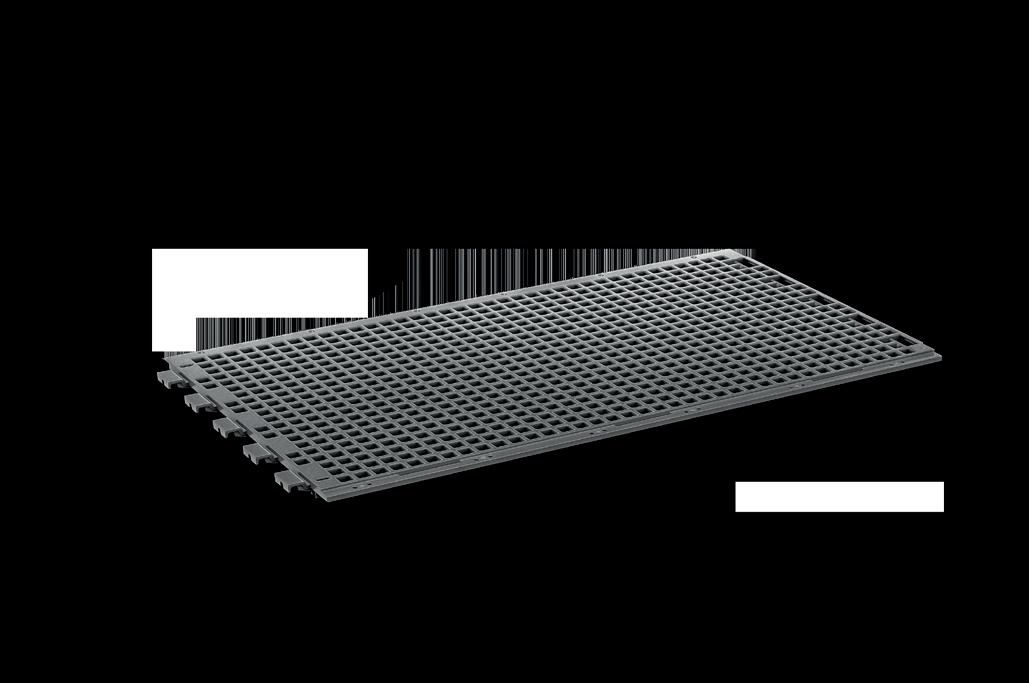

Giordano celebrates 60 years of activity

On 17 September, in their historic headquarters of Caraglio (CN), the Giordano family celebrated its sixtieth year of activity in the poultry sector with a large party together with partners, distributors and customers.

28 countries participated in the celebrations, demonstrating how much Giordano Poultry Plast has grown over the years, starting with distribution aimed at the Italian and French markets, to then expand throughout Europe and then to the rest of the world.

Founded in 1962 by Osvaldo Giordano, the company has been occupying a leading position in the poultry industry for 60 years. Their in-depth direct knowledge of the poultry industry has meant that they have been able to design and manufacture a range of products well suited to meet the technical and practical needs of the various sectors of the world wide poultry industry. Over 200 people from

During the day, a visit to the company premises was organized, during which guests were able to closely observe the production process of the plastic materials and equipment designed for the poultry industry that have made the company famous all over the world. A lunch followed during which Osvaldo, Oscar and Enrico Giordano presented awards to a selection of historical collaborators and new partners from around the world. The celebrations ended with a gala dinner at the Filatoio Rosso di Caraglio, the oldest remaining silk factory in Europe and one of the few in Italy to have been saved and which now serves as a museum.

- november 2022 - 15 COMPANY NEWS

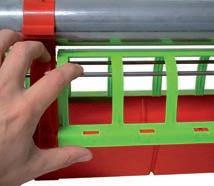

Roxell launches Fortena™ chain feeding system for hens in the production period

Roxell, the leading manufacturer of automatic feeding, drinking, nesting, heating and ventilation systems, launches the Fortena™ chain feeding system for broiler breeders in the production period. Roxell thus completes its total range for feeding, which now contains a solution for every type of poultry farmer. These feeding systems are a component of Roxell’s 360° range for farm equipment with innovative drinking systems, nests, heating, ventilation and controllers.

The Fortena chain feeding system is not just a different version of the current systems on the market. The design of the chain, feed trough and corner wheels has been taken care of by Roxell’s feeding experts. The result is an innovative chain feeding system that improves and speeds up the feed intake of the hens and reduces residual feed. Discover a few of these features below.

Feeding systems for every type of poultry farmer

“It may be surprising that as a notorious pan-feed promoter, Roxell now also has a chain feeding system, but actually it’s a logical step,” says Frank Hartmann, Marketing Manager at Roxell. “We have been working

hard on broadening the range for 10 years. The excellent performance of pan feeding systems is an indisputable advantage. However, those who opt for ease of use and visibility will find an excellent alternative in our chain feeding system. A chain feeding system therefore also belongs in a 360° product range. In short, today Roxell has a solution for every need.”

New chain feeding system, robust and convenient

“The Fortena chain feeding system is not a copy,” so says Inge Van Daele, Product Manager at Roxell. “Our systems are all innovative, durable and performant and this chain system is no different. Specifically, our feeding ex-

16 - company newsCOMPANY NEWS

perts worked on the design of the chain, feed trough and corner wheels. That is why the feed intake improves with Fortena and that is due to the greater ease with which hens eat. The feed remains intact better and the hens get to the feed more easily. Moreover, the new corner wheels require hardly any maintenance. Finally, we use high-quality materials and techniques to guarantee the longevity for which Roxell is known.”

Innovation for better feed intake

• The Fortena chain is a unique design from Roxell with large, open links that take up 25% less space. As a result, there is less friction between the feed and the chain. Because the feed pellets remain intact, the hens also eat them more easily and faster.

• The rounded feed trough promotes access, which limits feed loss. The grill from which the suspension leads is anchored to the feed trough.

• Thanks to an adjustable feed volume (6 positions), different feeding regimes are possible, always with an even and fast feed distribution.

Ease of use with extra durability

• We limit wear on the chain by connecting long sections of feed trough with connections made of polyamide.

• Lubrication of corner wheels is unnecessary due to ball bearings instead of plain bearings.

• We drastically reduce the breakage of chain links by using extra strong connecting links.

Flexibility for great performance

The Fortena chain feeding system offers the poultry farmer flexibility in the way of management:

• you can choose from 2 speeds for the feed distribution;

• the feeding circuit can be winched up, but is also available on legs;

• you can automate and monitor the feeding process with a iQon™ feed computer;

• the feed supply takes place directly (with day bins) or indirectly (via hoppers on the circuit).

You can find more information about the most important features on www.roxell.com/fortena-chain-feeding-system

First choice in agricultural ventilation components

- november 2022 - 17 COMPANY NEWS

tpi-polytechniek.com tpi-polytechniek.com | The Netherlands

East Africa poultry consumption trends

Africa’s population growth is expected to rise from the current 1.24 billion people to 2.4 billion in 2050 if the current annual increase rate of 2.42% is maintained, hence creating a huge demand for the supply of poultry and poultry products for domestic consumption.

A mix of factors such as the change in demographics, growth in urbanization, product pricing and even prevailing cultural beliefs could be some of the drivers shaping the continent’s poultry meat and eggs consumption trends. In fact, a recent joint report by the Organisation for Economic Co-operation and Development (OECD) and Food and Agriculture Organization (FAO) says general meat consumption in Africa is expected to grow by 30% between 2021 and 2030 driven largely by the region’s population growth. “Consumers are attracted to poultry due to lower prices, product consistency and adaptability, and higher protein/ lower fat content,” the report said. Globally, the report estimates consumption of poultry meat could increase to 152 million tonnes

by 2030, accounting for 52% of the additional meat consumed. East Africa, one of the regions in Africa with fast-growing economies, has in recent years reported rapid growth of its poultry industry fueled mostly by the fast-growing urbanization, increase of the middle class population, a rise in the number of quick service restaurants such as American fast food restaurant chain, KFC, especially in key towns. The increasing awareness about the importance of animal protein in addressing Africa’s malnutrition is equally driving up demand for poultry meat and eggs.

Although growth of region’s poultry market is not uniform across all the Eastern Africa countries including Kenya, Tanzania, Rwanda, Burundi, Uganda and Democratic

18 - field reportFIELD REPORT

Shem Oirere

©Albrecht FietzPixabay

©Yeanagro

Republic of Congo (DRC), some of the governments are undertaking major developments that require additional investments such as promoting the rearing of exotic poultry breeds to meet the increasing consumption demand for poultry meat and eggs.

Tanzania is one of the East Africa countries that has come up with a roadmap to increase the additional investment in its poultry sub-sector but also to define the activities to carry out in wooing more Tanzanians and visitors into the country to consume chicken and related poultry products.

Prior to 2016, Tanzania’s Ministry of Agriculture, Livestock and Fisheries says the national average per capita consumption of chicken meat was about 0.7 kg as well as 6.8 kg for eggs. However, Tanzania’s emergent middle class, estimated to be 10% of Tanzania’s 64 million people, the growing mining industry that contributed 5.1% to the national GDP with USD 2.96 billion in 2018, up from the USD 1.9 billion in 2014, are driving up demand for poultry meat and eggs. Moreover, the demand for poultry meat and eggs in the East African country has been positively impacted by the improved performance of the country’s tourism sector that reported a 7.9% surge in earnings for 2019 to USD 2.6 billion compared to 2018 driven by an increase in the number of international visitors from 1,505,702 to 1,527,230. Tanzania, which is anticipating an increase in demand for poultry meat and eggs in the domestic market, is implementing a new plan to ensure adequate supply of poultry products.

The US$4 million plan was initially scheduled to be implemented up to the end this year with a focus on promotion of exotic poultry meat and eggs consumption in Tanzania. “The investment is mainly to raise a large number of broilers and improved family chicken to produce enough to offset the chicken meat and consumption gaps”, a statement by the Ministry of Agriculture, Livestock and Fisheries says. “Furthermore, it is expected that the increase in chicken meat will also contribute to close the all meat production and consumption gap”.

It is estimated that Tanzania has 69 million chicken, out of which 54% are indigenous (backyard chicken) and 46% are commercial poultry made up of broilers (35%) and layers (11%).

The growth of the indigenous chicken population has been estimated at between 2% and 3% and “there is a high preference and demand of this breed by consumers.”

Moreover, egg production in Tanzania has been rising at 1.1% with a previous report by USAID saying there “is a niche market for fertilized local poultry breed eggs as it is perceived to be particularly nutritious and promotes strength in children.” Currently, Tanzania has maintained a ban on the importation of chicken meat and poultry products especially from key markets such as Kenya and Uganda to cushion local poultry farmers from unfair competition, especially that posed by cheap imports of chicken. The ban was announced in 2006 when an outbreak of Avian Influenza was reported in the region.

Elsewhere in East Africa, Kenya remains a key producer and consumer of poultry and poultry products with the market having an estimated 40.4 million birds consisting of indigenous chicken (75%) broilers and layers (22%) breeding stock (1%). The country’s eggs output is estimated at 1.5 billion. Kenya’s poultry meat consumption per capita had reached approximately 1.62 kg by 2019, nearly 37.2% lower than 2018 when uptake was 2.58 kg.

Kenya’s poultry meat and eggs consumption levels are higher than that of Rwanda estimated to be 0.63 kg/person/year far below Africa’s average of 2.5 kg/person/year. Despite the low per capita levels of consumption of poultry meat and eggs in Rwanda, the country’s population is fast rising and could intensify demand for supply of quality animal protein. Rwanda’s population was nearly 13 million in 2021. This is approximately 2.3% rise from 2020.

Elsewhere, in Uganda, where the population is growing at around 3% annually to reach 42 million in 2020, poultry meat is very popular source of animal protein. By 2017, Uganda Bureau of Statistics indicated the poultry meat consumption per capita was on average 1.52 kg and 0.88 kg of eggs.

The consumption of eggs in Uganda has increasingly become popular because of the preference by consumers of Rolex chapatis, which is basically an egg rolled in a form of flatbread with vegetables and is considered “cheap and easy to prepare product.”

As food security turns into a dominant issue both in the public and private discourse in East Africa, governments in the region are seeking for effective and modern ways of ensuring domestic demand for quality poultry and poultry products is met through a combination of critical factors including availability of skilled manpower, deployment of appropriate technology and elevating the role of genetics in poultry production.

19 - november 2022FIELD REPORT

United

Understanding egg quality

Egg quality is multi-faceted, with physical, functional, and microbial aspects contributing to egg quality. Research has shown that many factors impact egg quality including flock age and management, genetics, hen diet, housing design and management, as well as egg handling and storage. As laying egg production around the world shifts to more extensive housing systems, the impact of these housing systems on egg quality is unclear. Furthermore, the handling and storage of eggs have been shown to greatly affect egg quality. Understanding the factors influencing egg quality allows for higher quality eggs reaching consumers.

20

D.R. Jones and R.K. Gast

DOSSIER - dossier -

States Department of Agriculture, Agricultural Research Service, Egg Safety and Quality Research Unit, Athens, Georgia, USA

Introduction

Eggs are an affordable raw agricultural commodity with a high nutrient density. Eggs serve a key role in diets around the world. Maintaining the quality of eggs is a worldwide concern. Generally, there are three types of egg quality: 1) physical, 2) functional, and 3) microbial. During this presentation, all three types of egg quality will be discussed and factors which influence egg quality characteristics will be explained. Understanding the types of egg quality, as well as factors impacting them, is integral to the ultimate goal of safe, high quality eggs reaching consumers.

Physical egg quality is defined by the visible characteristics of the egg. Exterior features such egg shape, shell texture, shell colour, cleanliness, and soundness are the first impression for consumers when selecting eggs for purchase. Interior physical egg quality factors include albumen height and clarity, as well as yolk colour, shape, size, and structure.

Functional egg quality describes the manner which whole egg, albumen, and yolk perform in a variety of food matrices. Eggs perform numerous functional properties in foods. Common functional attributes assessed for egg quality include foaming, coagulation, and emulsification.

Microbial quality of eggs considers both food safety and spoilage organisms. Eggs are a raw agricultural commodity with a shelf life dependent on initial flora present, handling, and storage conditions. Salmonella spp. are the historic foodborne pathogens associated with the consumption of eggs. Other spoilage organisms, including yeasts and molds, can impact the shelf-life of eggs.

Physical egg quality

The shape, texture, color, and soundness of the shell are the first egg quality factors consumers encounter. Shell quality provides aesthetics to the egg. It also serves as the first line of defense for microorganisms entering the eggs via horizontal transmission. A cracked egg is not only a potential loss of revenue due to lack of sale or store return, it is also a food safety risk since organisms can easily move through the crack to the shell membranes. Broken eggs with ruptured shell membranes (leakers) provide microorganisms direct contact with the egg contents and should not be consumed. In the US,

leakers are considered a loss egg. The soundness of the egg also impacts the ability for intact eggs to reach end users. Furthermore, consumers have expectations as to the brightness of white shell eggs, as well as shade and consistency of colour for brown or coloured shells.

Once the egg is broken, the shape, clarity, and appearance of the albumen and yolk define the physical quality of the egg. The Haugh unit is utilised around the world as a quantitative measure for egg grade standards. In the US, Grade AA is defined as a Haugh unit score > 72; Grade A is a score > 60, but less than 72; and Grade B is a score less than 60. The Haugh unit is calculated based on egg weight and thick albumen height. The score has been questioned due to the calculation being weighted for a large size egg (56 g). In such cases, thick albumen height alone is utilised for reporting albumen and egg quality.

Yolk quality is monitored by determining yolk index and vitelline membrane mechanical characteristics. Yolk index is a calculation of yolk height divided by yolk diameter and is an indicator of yolk shape. As an egg ages, water migrates from the albumen into the higher solute yolk. This leads to a flattening of the yolk resulting in a lower yolk index value. Vitelline membrane strength and elasticity are physical properties of the membrane surrounding the yolk. The strength of the vitelline membrane is important not only to ensure the yolk remains intact during cracking and separation of the yolk and albumen fractions for cooking or the manufacturing of egg products, the membrane is also a barrier for microorganisms present in the albumen entering the nutrient rich yolk. The elasticity of the vitelline membrane indicates how much the membrane can deform before rupturing.

Functional egg quality

Eggs are highly functional ingredients in a variety of food matrices including, but not limited to, baked goods, sauces, candies and confections, desserts, snacks, meal replacement bars, and beverages. Functional characteristics can be provided by albumen, yolk, and whole egg. While there are many identified functionalities associated the eggs, three of the overarching categories are: foaming, coagulation, and emulsification.

Primarily, albumen and whole eggs can provide foaming capacity to a food matrix. The proteins in the albumen are

21 - november 2022DOSSIER

“Prompt refrigeration of eggs has been shown to be a key factor in controlling the growth of Salmonella Enteritidis, other Salmonella spp., and many other human pathogens. For this reason, in the US, shell eggs are required to be under refrigeration (7.2 °C) within 36h of lay through distribution and retail. Refrigeration is also key in retaining product physical and functional quality characteristics”

Microbial egg quality

Foodborne pathogens and spoilage organisms contribute to the microbial quality of eggs. Eggs can become contaminated via vertical transmission, as well as horizontal contamination. Salmonella Enteritidis is deposited inside the edible interior of eggs due to infected reproductive organs, although high frequencies of reproductive organ invasion by Salmonella do not always result in correspondingly high frequencies of egg contamination. Both the ovary and oviduct of laying hens can be invaded by S Enteritidis, leading to bacterial deposition in either edible egg fraction.

particularly suitable for unfolding and interacting during whipping to entrap air, forming foams. During heating, the air and any moisture present will expand and provide leavening and lightness to the food product.

Whole egg, yolk, and albumen all assist with coagulation. Coagulation, generally due to heat exposure, is the binding or setting of food components. Coagulation is responsible for the texture created during the scrambling of eggs. Furthermore, coagulation allows for ingredients particles in quiches to be suspended with the dish. Coagulation is also responsible for the thickening achieved during heating of egg-containing puddings or sauces. Coagulation also accounts for the heat setting of foams such as meringues and sponge cakes.

Yolk, whole egg, and to a lesser extent albumen, are emulsifiers bridging the hydrophobic and lipophobic portions of a food matrix to aid in the creation of a stable emulsion. Eggs play a key role in the emulsification of mayonnaise and salad dressings, as well as ice cream bases, Hollandaise, and bearnaise, to name a few applications. Eggs also assist with browning and colour formation during cooking, adhering food coatings, and enhancing mouth- feel. The functional applications of eggs are endless, while also providing nutrient density and clean labels to the foods.

The abundant nutrients in egg yolk can support rapid microbial growth at warm temperatures, whereas albumen of fresh eggs contains antimicrobial compounds that limit iron availability and disrupt bacterial membranes. S Enteritidis is generally deposited inside contaminated eggs in the albumen or on the vitelline (yolk) membrane. Eggs contaminated by S. Heidelberg, a common serovar in laying housing environments, have been implicated in occasional reports of human disease in the US. In Australia, sporadic egg-associated illnesses have been attributed to S. Typhimurium contamination of eggshells. In the US, there were Salmonella Enteritidis egg-associated outbreaks in 2010 and 2018, Salmonella Oranienburg in 2016, Salmonella Braenderup in 2018, and Listeria monocytogenes in hard-cooked eggs in 2019. Other salmonellae, including S. Kentucky in the US, are prevalent in commercial laying flock housing environments but have not been shown to cause egg contamination. Pathogens other than Salmonella are also important for eggs and the egg production environment. Campylobacter spp. and Listeria spp. have frequently been detected in environmental swabs from a variety of hen housing systems. Additional studies have determined the flora present on the shells of nest run eggs is diverse. Spoilage organisms must also be considered when discussing the microbial quality of eggs. Being a raw agricultural commodity, eggs are prone to rotting, especially if the eggs have been mishandled. Organisms which have been associated with the rotting of eggs include Pseudomonas, Acinetobacter, Proteus, Aeromonas, and Serratia. Fungi are also able to grow on the shell surface and between the shell and shell membranes.

22 DOSSIER - dossier -

Egg handling and storage

Around the world, eggs are handled and stored in diverse manners. The controlled washing of shell eggs for human consumption has been a point of debate for over 50 years. In the US, USDA Agricultural Marketing Service standards for the voluntary grading of shell eggs serve as the basis for the washing of shell eggs. Under these standards, eggs must be spray washed in warm water (32 °C or 11 °C warmer than the warmest egg), exposed to a sanitising rinse of 100-200 ppm chlorine or its equivalent, and be blown dry with high velocity, filtered air. Generally, caustic detergents are utilized in the wash water.

The washing of eggs has been a concern due to the potential of disturbing the cuticle of the egg. The cuticle serves as the first line of defense for the movement of water, air, and external microorganisms into and out of an intact egg. With the changes in flock management, hen genetics, as well as hen housing, modern research has produced conflicting results as to the impact of washing on cuticle integrity. Washing of shell eggs removes adhering matter, such as dust, feed, and fecal matter – all of which can harbour both pathogenic and spoilage microorganisms. Washing of consumer eggs enhances egg quality.

Prompt refrigeration of eggs has been shown to be a key factor in controlling the growth of Salmonella Enteritidis, other Salmonella spp., and many other human pathogens. For this reason, in the US, shell eggs are required to be under refrigeration (7.2 °C) within 36h of lay through distribution and retail. Refrigeration is also key in retaining product physical and functional quality characteristics. In a comparison of common egg handling and storage practices utilised around the world, it was determined that refrigeration had the greatest impact on retaining physical egg quality regardless of washing status.

Hen housing systems

Consumers draw conclusions about housing systems in part based on the quality of the eggs from housing systems available in retail. Extensive housing systems often have higher production costs, resulting in more expensive eggs. A consumer has an expectation of enhanced quality with the price premium. Several review articles have been published on the impacts of hen housing on egg quality. In many instances, studies conflict on the

outcomes of egg quality due to housing. Karcher et al. (2015) illustrate the complexity of comparing hen production and egg quality amongst housing systems and the factors which can significantly influence outcomes.

Physical and functional egg quality influence market share and usage, for both consumers and food manufacturers. Many retailers, food service, and food manufacturers in the US and around the world have made pledges to convert to cage-free eggs, but little is known as to the impacts of extensive housing systems on egg quality – in particular egg functionality.

Outcomes of egg quality assessments conducted worldwide regarding hen housing have been inconsistent. Principal component analysis of egg quality and egg production in terms of hen diet composition and environmental temperature across commercial conventional cage, enriched colony cage, and cage-free aviary determined that many factors influence various egg quality parameters and the influence is often dependent on housing system. The effective collection of eggs from extensive systems impacts egg quality. Prompt refrigeration has long-lasting positive influence on all interior egg quality factors. Eggs laid outside of the intended egg collection area (mislaid eggs) may not be effectively collected and could be older when packaged. A comparison of hen genetic strains in cage-free aviaries found strains produced eggs of varying quality and quality declined at different rates during long-term cold storage. Egg grade standards are based on conventional cage eggs. Jones et al. (2014) determined that US federal egg grade standards are equitable for commercial conventional cage, enriched colony cage, and cage-free aviary produced eggs during long-term refrigerated storage.

Research has documented the changes in egg functionality during the extended cold storage of eggs. As egg production shifts to cage-free and food manufacturers are making cage-free commitments, there is limited knowledge on the effect of hen housing on egg functionality. A single study of retail eggs in Italy provided insight and retail egg studies limit the control of egg age and handling, which can impact egg quality. A variety of extensive systems have been developed including enriched colony cages (providing lower stocking densities for larger hen groups plus environmental enhancements such as perches, nesting areas, and scratching pads), cagefree aviaries (allowing birds to move freely among multiple open levels of enriched cage and floor areas within

23 - november 2022DOSSIER

houses), cage-free barn, and freerange housing (offering greater opportunities for freedom of movement via varying degrees of access to outdoor forage or pasture areas). The numerous facility design features and management practices associated with each of these systems influence the environmental and flock persistence and transmission of pathogens such as Salmonella. A considerable body of research has assessed the effects of laying hen housing systems on important food safety parameters, but this work has generated no overall consensus to suggest that any one system is superior to others. Challenge studies have been conducted comparing conventional and enriched colony cages, but there has been limited ability to assess the impact of cagefree housing on infection and trans-

missibility, as well as egg contamination.

A high prevalence of Campylobacter spp. has been detected in both intensive and extensive hen housing systems. Jones et al. (2015, 2016) compared Campylobacter detection in conventional cage, enriched colony cage, and multi-tier cage-free aviary housing and found scratch pads, system wires, and flooring substrate to be environmental reservoirs. Listeria monocytogenes is an important foodborne pathogen, known to proliferate in refrigerated conditions. Listeria has been detected in the shell egg and egg products processing environment but information as to on-farm incidence or impact of housing systems on Listeria prevalence is limited. When hens have outdoor access (such as organic or

free range), the environmental and egg flora are impacted. Mislaid eggs are defined as those which cannot be effectively, efficiently, or hygienically collected. These are often referred to as floor eggs, but may not always occur on the floor of an extensive housing system. Research has found that mislaid eggs have a higher likelihood of microbial contamination. Research has also found that cage-free systems, in particular cage-free aviaries, result in high levels of dust from hens foraging and dust bathing in the substrate. The increase in dust impacts egg safety and worker health.

Conclusions

Maintaining and enhancing shell egg quality requires a holistic approach to egg production, handling, transportation, and distribution. Much is known about conserving egg quality associated with conventional cage production systems. As world egg production shifts to a variety of extensive housing systems for laying hens, as well as changes in dietary formulations and laying hen genetic stocks, controlling egg quality can be challenging. It can be daunting to process the information or lack of information to make informed decisions.

Producers do not have to face these challenges alone. Reach out to the multitude of resources available and in today’s virtual environment, it is even easier to receive assistance from anywhere in the world.

References are available on request

From the Proceedings of the APSS 2022

24 DOSSIER - dossier -

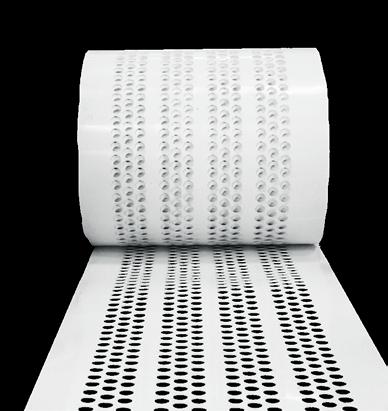

INFINITY 4006 H • 360 degrees opening • Highly strong and durable material • “SOFT” action 4002 H 4626 • Suitable for fattening turkeys • Perfectly dry bedding • Simultaneous watering of 2 and more animals 4901 N Pressure regulator with bypass • Essential design • No chicks in the pan! • Regulation of minimun and maximum feed level • Available in caged broilers version • 360 degrees opening • Highly strong and durable material • “EXTRASOFT” action for breeding ARTICLES ACCESSORIES CORTI ZOOTECNICI • Egg collection • Manure drying system • Manure belt collection • PP woven egg belts • PP hole egg belts PP Belts Corti Zootecnici Srl | Via Volta, 4 21020 Monvalle (VA) Italy| www.cortizootecnici.it |

Dynamics and patterns of the poultry industry in the G19 countries between 2010 and 2020

Part 2 – Egg trade

The G20 (Group of Twenty) was founded in 1999 in Berlin as a forum of 19 individual member countries and the EU1. It substituted the former G8 group. The main goal of the forum is to undertake means, which contributes to the stability of the global financial situation. In this report, 19 instead of 20 countries will be analysed. The EU will be omitted as four member countries are among the G19.

Dynamics and patterns of egg exports by the G19 countries

In contrast to meat, which can be frozen, shell eggs can only be chilled. Because of the comparatively short shelf life, they are in most cases shipped over only short distances. Eggs are mainly produced for domestic consumption. The share of the traded volume in production is very low. In 2020, only 2.4% of the produced eggs reached the global market. Nevertheless, egg exports respectively imports are of considerable economic importance for some countries.

Global egg exports grew by 255,500 t or 14.0%; exports by the G19 countries increased by 84,400 t or 13.2% (Table 1). Their share in the absolute global growth was 33.2%. Obviously, several G19 countries were not only able to intensify their production but also to generate a surplus over demand, which they could export.

The author is Prof. Emeritus of the University of Vechta and visiting Professor at the Hannover Veterinary University, Germany

In 2020, the G19 countries contributed 70.5% to the global laying hen inventory and 74.3% to global egg production. Their share in global egg trade was much lower with 34.9% in the global export and 33.8% in the global import volume. A first paper documented the spatial patterns of egg production at country level (Zootecnica International 10/2022). This paper will deal with the dynamics and patterns of egg trade between 2010 and 2020.

A closer look at the changes in the ranking and the export volumes reveals some remarkable dynamics. Turkey remained the leading exporting country and in 2020 shared 10.5% in the global export volume. Germany was replaced by the USA in second place, China lost one rank and 2.0% of its former share, France 1.5% and Germany 0.6%. In contrast, Turkey gained 3.3% and the USA 3.0%. It is surprising at first glance that Germany with a self-sufficiency

1 Member countries are Argentina, Australia, Brazil, Canada, China, France, Germany, India, Indonesia, Italy, Japan, the Republic of Korea, Mexico, the Russian Federation, Saudi Arabia, South Africa, Turkey, the United Kingdom, the United States and the European Union.

26 MARKETING - marketing -

Hans-Wilhelm Windhorst

of less than 70% exported 118,400 t of shell eggs. This is due to the fact that several Dutch farmers own egg farms in Eastern Germany from which they ship shell eggs to the Netherlands. From there they are either exported or further processed. These eggs are counted as exports from Germany and imports into the Netherlands.

Table 2 lists the G19 countries according to the absolute change of their egg

2.2% 2.5% 2.5% 4.1% 4.6%

Total: 0,726 mill. t G19 Total: 2,081 mill. t World 3.7% 2.1%

Figure 1 – The share of the ten leading G19 countries in global and G19 egg exports in 2020 (design: A.S. Kauer based on FAO data). 193,800 t. China, France, India and Italy reduced their exports considerably. China and India exported less eggs because of the fast increase of the per capita consumption and a rising domestic demand. Declining laying hen inventories in France and Italy explain the re-

27 - november 2022MARKETING

10.0% 16.3% 22.0% 30.0% Turkey USA Germany China France Russia Japan Un. Kingd. India Italy Others 66.2% 0.8% 0.8% 0.9% 0.9% 1.4% 1.6% 3.5% 5.7% 7.7% 10.5%

Barbieri srl Via Garibaldi, 54 • 26040 Scandolara Ravara (CR) Italy Tel. (+39) 0375 / 95135 • Fax (+39) 0375 / 95169 • Manu re re moval belt s • Manu re belt wi th hole s for dr yi ng system s info@barbieri-belts.com www.barbieribelts.com BELTS and ROP ES for AV ICULTURAL USE BE LT S

Table 1 – The development of egg exports by the G19 countries between 2010 and 2020 and their share in the global export volume; data in 1,000 t (source: FAO database).

2010 2020

Country Exports Share (%) Country Exports Share (%)

Turkey Germany China USA France S. Arabia India Italy Brazil Russia Un. Kingdom South Africa Mexico Canada Argentina Japan Korea, Rep. Australia Indonesia

131.6 115.1 100.2 86.1 57.0 41.2 34.9 27.7 13.9 12.9 6.8 5.7 2.8 2.6 1.1 0.9 0.4 < 0.1 < 0.1

7.2 6.3 5.5 4.7 3.1 2.3 1.9 1.5 0.8 0.7 0.4 0.3 0.2 0.1 0.1 < 0.1 < 0.1 < 0.1 < 0.1

Turkey USA Germany China France Russia Japan Un. Kingdom India Italy Brazil South Africa Korea, Rep. S. Arabia Canada Australia Indonesia Argentina Mexico

217.9 159.3 118.4 72.9 33.3 30.0 18.1 18.0 16.1 15.6 12.8 11.0 1.6 0.4 0.2 0.2 < 0.1 0 0

10.5 7.7 5.7 3.5 1.6 1.4 0.9 0.9 0.8 0.8 0.6 0.5 0.1 < 0.1 < 0.1 < 0.1 < 0.1 0 0

G19 640.9 35.1 G19 725.8 35.9 World 1,826.4 100.0 World 2,081.9 100.0

duction of their export volumes. The relative changes fluctuated between 1,911.1% for Japan and -53.9% for India. The growth rates for Turkey reflect the rapid growth of egg production and a high surplus over demand (see Table 5). Figure 1 shows the remarkably high regional concentration in the G19 egg exports. The ten leading countries shared 96.3% in the overall export volume, the leading four 78.3%.

Dynamics and patterns of egg imports by the G19 countries

Egg imports of the G19 countries grew slower than global imports. Global egg imports increased by 468,000 t in the past decade and reached a volume of 2.1 mill. t in

2020, which equals a relative growth of 27.9%. Egg imports of the G19 countries increased by 57,500 t or 8.6%. To the global growth, the G19 countries contributed only 12.3% (Table 3). This indicates that the egg trade of countries, which not belonged to the group of G19, showed a considerably higher dynamics.

A comparison of the ranking of the G19 countries in 2010 and 2020 shows some interesting changes (Table 4). While Germany remained in the top position, despite losing 10.9% of its former share, Russia stepped up three places. Saudi Arabia and Mexico also climbed upward in the ranking while France, Italy, the United Kingdom and the USA fell to lower ranks. In 2020, eight of the G19 countries shared either less than 0.1% in the global import

volume or did not import shell eggs at all. The regional concentration in egg imports was even higher than in exports. Figure 2 shows that the ten leading G19 countries shared 99.7% in the overall import volume, the leading two 63.6%, Germany alone 52.7%.

Table 2 – The G19 countries with the highest increase respectively decrease of egg exports between 2010 and 2020; data in 1,000 t (source: FAO database; own calculations).

Country Exports Change (%)

Turkey USA Japan Russia Un. Kingd. S. Africa Germany Korea, Rep. Brazil Italy India France China

86.3 73.2 17.2 17.1 11.2 5.3 3.3 1.2 - 1.1 - 12.1 - 18.8 - 23.7 - 27.3

65.6 85.0 1,911.1 132.6 164.7 92.9 2.9 300.0 - 7.9 - 43.7 - 53.9 - 41.6 - 27.2

G19 84.4 13.2 World 255.5 14.0

In Table 4, the G19 countries are listed according to their absolute change in egg imports. Ten countries imported more eggs in 2020 than in 2010; eight countries either reduced their imports or did not import eggs.

Only Argentina did not import eggs in 2010 and 2020. The highest import increase showed Russia, followed by Saudi Arabia and Mexico. Germany, the leading egg importing country, reduced its imports by 99,100 t despite a rising per capita consumption. This was possible because of the fast increase in the laying hen inventory by 14 mill.

28 MARKETING - marketing -

Table 3 – The development of egg imports by the G19 countries between 2010 and 2020 and their share in the global import volume; data in 1,000 t (source: FAO database).

2010 2020

Country Imports Share (%) Country Imports Share (%)

food industry due to the massive losses of laying hens during the AI outbreaks in 2015.

Germany France Italy United Kingdom Canada Russia Mexico USA Saudi Arabia Turkey Australia Japan Korea, Rep. China India Brazil Indonesia South Africa Argentina

481.5 54.2 39.9 36.1 24.9 16.7 7.3 3.4 2.0 0.8 0.8 0.8 0.5 0.2 0.1 0.1 < 0.1 < 0.1 < 0.1

28.7 3.2 2.4 2.2 1.5 1.0 0.4 0.2 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1

382.4 79.4 57.4 53.9 44.5 42.2 29.7 27.0 3.7 2.2 1.6 0.7 0.5 0.2 0.2 < 0.1 < 0.1 0 n. d. G19

17.8 3.7 2.7 2.5 2.1 2.0 1.4 1.3 0.2 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 < 0.1 0 n. d.

669.3 39.9 G19 725.6 33.8 World 1,677.2 100.0 World 2,145.2

hens between 2010 and 2020. The Russian Federation, where the per capita consumption grew by more than 50 eggs in the past decade, had to increase their egg imports considerably. The higher imports of Mexico were a result of several AI

outbreaks, which resulted in an egg shortage. The import growth of Saudi Arabia was a result of a fast growing domestic demand. The USA was forced to import eggs because some egg processing companies were not able to fulfill their contracts with the

Only in two of the nine countries with decreasing imports, the reduction reached considerable amounts, the United Kingdom and Germany. In the United Kingdom, the growing production and a more or less stagnant per capita consumption made it possible to reduce the imports. In Germany, egg production increased by 28.9% between 2010 and 2020 due to higher layer inventories. A sharp reduction of the imports was the result.

Egg

trade balances of the G19 countries in 2020

Table 5 lists the egg trade balances of the G19 countries in 2020. Turkey, the USA and China had the highest trade surplus, followed by Japan, India, Brazil and South Africa. The highest trade deficit showed Germany, Saudi Arabia, Russia, Mexico, Canada, Italy and France.

Want to improve bird performance and reduce wet litter? Check impex nl for more information

29 - november 2022MARKETING

Germany Russia France Saudi Arabia Mexico Italy United Kingdom Canada USA Turkey Australia Japan Korea, Rep. Brazil South Africa India Argentina Indonesia China

100.0

The data in Table 5 documents that the regional concentration was very high in positive as well as in nega-

G19 0.3%

Total: 0,722 mill. t 52.7%

2.7% 3.7% 17.8% 0.3% 0.5% 3.7% 4.1% 6.1% 6.1% 7.4% 7.9% 10.9%

Germany Russia France S. Arabia Mexico Italy U.K. Canada USA Turkey Others

Figure 2 – The share of the ten leading G19 countries in global and G19 egg imports in 2020 (design: A.S. Kauer based on FAO data).

Deficit

Surplus

Turkey USA China Japan India France Italy Canada Mexico Russia S. Arabia Germany -264.0 -53.4 -49.4 -44.5 -26.8 -26.6 -24.1 16.0 17.4 72.9 155.6 215.7

-300-225-150 -75 0 75150225300

Deficit

Figure 3 – The egg trade balances of selected G19 countries in 2020; data in 1,000 t (design: A.S. Kauer based on FAO data; own calculations).

tive trade balances. A few countries either had a considerable surplus over demand and only a few countries had remarkably high deficits in their trade with shell eggs (Figure 3).

The data again documents that most countries produce eggs mainly for their domestic demand.

Summary and perspectives

The preceding analysis showed that the share of the G19 countries in global egg trade was much lower with about 33% in exports and in imports in comparison to production.

This reflects the ability of most G19 countries to meet the growing demand by intensifying their domestic egg production. Nevertheless, the trade balances with eggs for

The fast growing demand in parts in Western Asia may result in higher imports. On the other hand, the progress, which several countries of the G19 group made over the past decade by investing in efficient production systems, may enable them to raise their export volumes.

Table 4 – The absolute and relative change of the egg imports by the G19 countries between 2010 and 2020; data in 1,000 t (source: FAO database; own calculations).

Country Imports Change (%) Russia S. Arabia Mexico France Italy Canada S. Africa Turkey Australia USA Un. Kingd. Germany

375.4 2,595.0 409.8 5.9 5.8 8.4 39,900.0 175.0 92.7 8.9 - 17.8 - 20.6 G19 57.5 60.9 World 468.0 67.4

62.7 51.9 37.2 3.2 2.3 2.1 1.6 1.4 0.7 0.3 - 6.4 - 99.1

30 MARKETING - marketing -

Total: 2,145 mill. t World 66.2% 0.1% 0.2% 1.3% 1.4% 2.0% 2.1% 2.5%

single countries differed considerably between a high surplus and the necessity to import large amounts of eggs to meet the growing demand and high export volumes. It can be expected that the share of the G19 countries in global egg trade will further increase because of the remarkable dynamics in several countries, such as India, Indonesia, Brazil and Turkey.

Table 5 – Egg trade balances of the G19 countries in 2020; data in 1,000 t (source: FAO database; own calculations).

Country Balance

Turkey USA China Japan India Brazil S. Africa Korea, R. Argentina Indonesia Australia Un. Kingdom France Italy Canada Mexico Russia S. Arabia Germany

215.7 155.6 72.9 17.4 16.0 12.6 10.8 1.1 0 0 - 1.4 - 11.7 - 24.1 - 26.6 - 26.8 - 44.5 - 49.4 - 53.4 - 264.0

The data in Table 5 document that the regional concentration was very high in positive as well as in negative trade balances. A few countries either had a considerable surplus over demand and only a few countries had remarkably high deficits in their trade with shell eggs.

Data sources, references and suggestions for further reading

FAO database: http://www.fao.org/faostat G20: https://en.wikipedia.org/wiki/G20

Windhorst, H.-W.: Patterns and dynamics of the EU poultry industry: a status report. Part 1: Laying hen husbandry, egg production and egg trade. In: Zootecnica International 43 (2021), no. 12, p. 22-26.

Windhorst, H.-W.: Pat terns and dynamics of global egg trade: the situation in 2020. In: Zootecnica International 44 (2022), no. 5, p. 14-17. Worldbank: https://data.worldbank.org/.

Durability and

feeding expert

Roxell

The new Fortena™ chain feeding system improves and speeds up the feed intake and reduces residual feed. This chain feeding system is part of our 360° portfolio for farm equipment with innovative feeding and drinking systems, nests, heating, ventilation and controllers.

31 - november 2022MARKETING

more at roxell.com

Discover

convenience

from the breeder

for

the

launches Fortena™ chain feeding system

broiler breeders in

production period

Gamie Gundran, Petersime Incubation Consultant

Hatching eggs: the importance of assessing internal egg quality

Hatching egg quality has a significant impact on hatchability and chick quality. By making egg quality control a part of the routine procedures in your hatchery, you will be able to improve your hatch results. Although it is fairly easy to evaluate external egg quality by checking the egg’s exterior, it can be more challenging to perform deeper checks on a regular basis. This article describes the most important interior quality factors to help you assess internal egg quality.

Why perform a deeper check?

A hatching egg is a protected space for the chicken embryo to develop in. Inside the egg are all the essential nutrients and mechanisms to support an optimal development and growth of the embryo. However, while the egg is formed in the reproductive tract of the hen, various events can occur that cause irregularities in eggs. Some of these irregularities affect the internal quality of the egg, which is why it is important to perform both external and internal

32 - technical columnTECHNICAL COLUMN

quality controls. An overview of the most important interior quality factors is given below.

1. Egg fertility

A first parameter is whether the egg has been fertilised or not. Hatching eggs can be analysed before incubation on arrival at the hatchery to distinguish fertile eggs from infertile eggs. This requires a specific technique that needs to be built up by practice. When applied, however, a disadvantage of the technique is the loss of valuable hatching eggs due to the destructive procedure. A fertile egg is characterised by a blastoderm that has a clearly defined ring-shaped appearance (seen as a white symmetrical ring with a clear area in the centre). If for whatever reason the egg is infertile, a blastodisc is visible with a ruffled, irregular shape. A blastodisc is also lighter in colour and smaller in size compared to a blastoderm (Figure 1). It is a well-known fact that the fertility goes down as flock age increases, but a sudden drop in fertility could be an indication of a breeder problem and a reason to perform deeper analysis.

2. Yolk quality

The yolk is an essential part of the hatching egg and constitutes an important food source for the developing embryo. The yolk’s condition can be investigated by performing a fresh egg breakout analysis. The yolk must be clear and not mottled (Figure 2). Mottled yolk is an indicator of stress at the breeder farm. Bad yolk increases the risk of early embryonic mortality during incubation.

Having said that, it is important to ensure a correct handling and storage of hatching eggs, so good-quality embryos can remain in perfect condition. An embryo’s cell division begins from the moment the egg is fertilised. After point of lay, the blastoderm consists of approximately 60,000 cells. Inappropriate handling and storage at the breeder farm, during transportation or at the hatchery will dramatically reduce the chances of producing a healthy day-old chick from that same egg.

2

3. Albumen quality

The albumen (egg white) provides essential proteins for the developing embryo. It also protects the embryo from any bacteria that could get into the egg. The most common test for albumen quality - conducted during a fresh egg breakout analysis - was invented by Raymond Haugh. After weighing, an egg is broken onto a flat surface. A micrometer caliper is used to determine the height of the albumen surrounding the yolk. The height, correlated with the weight, determines the Haugh Unit. The higher the number, the better the albumen quality of the egg (Table 1).

Table 1 – Albumen quality of the egg. Calculated Haugh Unit Egg quality

and below

33 - november 2022TECHNICAL COLUMN

Figure 1 – A fertile egg with blastoderm on the left; an infertile egg with blastodisc on the right.

Figure

– An example of mottled yolk with cloud-like spots underneath the vitelline membrane.

90

80-89 Very

70-79 Fair 69

and above Excellent

good

Poor

4. Vitelline membrane strength

The vitelline membrane encloses the yolk and keeps it separate from the albumen. Keeping this protective membrane intact throughout embryo development in the egg is crucial to its survival. This membrane should not be wrinkled - characterised by small scratches on the membrane surrounding the yolk. If the vitelline membrane is damaged or broken, the yolk can mix with the albumen, ultimately leading to embryonic mortality (Figure 3).

5. Pathogen-free eggs

There are some important groups of pathogens that can be problematic: bacteria, Escherichia coli (E. coli ), Salmonella, Pseudomonas (Figure 4) and Aspergillus (Figure 5). They hinder the development of the embryo and can even destroy the egg during incubation. That is why it is extremely important that hatching eggs are free from pathogens.

Although it is impossible to check an egg for pathogens when it is fresh (unless a laboratory analysis is undertaken), their presence will be clearly revealed after hatch. The contamination level can vary between 0-0.5% for young to middle-aged flocks (25-35 weeks) and between 1-2% for flocks older than 36 weeks (depending on the breeder farm management). By conducting a post-hatch breakout analysis, the level of contamination can be determined.

A sudden increase in contamination characterised by exploders (‘bangers’) can indicate egg management issues either at the farm or at the hatchery. The hatchery breakout data sheet containing the accurate number of contaminated eggs is to be shared with the farm team and hatchery team to take appropriate action. Flocks with contamination records higher than 0.5% should get special attention with regard to egg handling and sanitation procedures.

In conclusion

It is necessary to evaluate internal egg quality on a routine basis. Ensuring that there are procedures in place to evaluate the internal quality of incoming hatching eggs will greatly assist in safeguarding the hatchery from quality issues.

If you want to know more about hatching egg quality, breakout analyses or other best practices for your hatchery, contact training@petersime.com

34 - technical columnTECHNICAL COLUMN

Figure 3 – An egg with a damaged vitelline membrane.

Figure 4 – An egg contaminated with Pseudomonas.

Figure 5 – An egg contaminated with Aspergillus.

The innovative rationing system

FOR BROILER BREEDERS

Linear trough feeder for breeders suitable for 300 meters long systems with one single motor and loading point throughout the circuit. Immediate and homogeneous feed distribution throughout the entire circuit.

Easy cleaning and no residual feed inside the trough. Adjustable anti-cock grid.

FOR LAYERS AND PULLETS

Linear trough feeder for layers and pullets.

Manufactured from sturdy light plastic material for easy winching. The pullets’ version is equipped with a convenient midway drop designed for one day old chicks. Cage version also available.

35 - november 2022TECHNICAL COLUMN Leader in pig & poultry equipment AZA INTERNATIONAL S.r.l. - www.azainternational.it Via Roma 29, 24030 Medolago (BG) Italy - Phone +39 035 901240 - info@azainternational.it • Broilers • Breeders • Cocks • Pullets • Layers • Turkeys • Quails • Ducks THE MOST INNOVATIVE RANGE FOR POULTRY FEEDING :

for

assuring high reliability and quality products at competitive prices. I WANT AZA!

AZA INTERNATIONAL has been working in the zootechnical sector

more than 50 years

BREEDAZA

Pullets’ version QUALITY MADE IN ITALY NEW!

In ovo injection of oregano essential oil at different pH affects hatchability and posthatching performance in broiler chickens

The dynamic complexity of the developing embryo requires the maintenance of differentiated compartments with the capacity to maintain independent environments required to optimise their function. One of the least understood homeostatic mechanisms in embryonic development relates to the pH.