WELCOME, AICC 2022–2023 CHAIRWOMAN, JANA HARRIS As AICC looks toward the future, its new board leader is poised to realize opportunity through challenges November/December 2022 Volume 26, No. 6 ALSO INSIDE Growing Forward: A Look Ahead to 2023 Special Section: AICC Annual Report Special Section: AICC Education Catalog Member Profile: Central Packaging & Display A PUBLICATION OF AICC, THE INDEPENDENT PACKAGING ASSOCIATION

BOXSCORE www.AICCbox.org

1

articles

request.

Visit www.AICCboxscore.org for Member News and even more great columns. Scan the QR code

TABLE OF CONTENTS November/December 2022 • Volume 26, No. 6 36 42 46 COLUMNS 3 CHAIRWOMAN’S MESSAGE 4 SCORING BOXES 6 LEGISLATIVE REPORT 10 MEMBERS MEETING 14 ASK RALPH 16 ASK TOM 18 SELLING TODAY 22 ANDRAGOGY 24 LEADERSHIP 30 MEMBER PROFILE 56 THE ASSOCIATE ADVANTAGE 58 WHAT THE TECH? 60 STRENGTH IN NUMBERS 68 THE FINAL SCORE DEPARTMENTS 8 WELCOME, NEW & RETURNING MEMBERS 27 AICC INNOVATION 64 FOUNDATION FOR PACKAGING EDUCATION 66 INTERNATIONAL CORRUGATED PACKAGING FOUNDATION 36 WELCOME, AICC 2022–2023 CHAIRWOMAN, JANA HARRIS As AICC looks toward the future, its new board leader is poised to realize opportunity through challenges 42 GROWING FORWARD Looking ahead to the opportunities and obstacles of 2023 46 SPECIAL SECTION: AICC 2022 ANNUAL REPORT A return to the familiar—and so much more 52 SPECIAL SECTION: AICC EDUCATION CATALOG Essential, free online education now available through Packaging University and AICC NOW

BoxScore is published bimonthly by AICC, e Independent Packaging Association, PO Box 25708, Alexandria, VA 22313, USA. Rates for reprints and permissions of

printed are available upon

e statements and opinions expressed herein are those of the individual authors and do not necessarily represent the views of AICC. e publisher reserves the right to accept or reject any editorial or advertising matter at its discretion. e publisher is not responsible for claims made by advertisers. POSTMASTER: Send change of address to BoxScore, AICC, PO Box 25708, Alexandria, VA 22313, USA. ©2022 AICC. All rights reserved.

to check them out!

OFFICERS

Chairwoman: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas

First Vice Chairman: Matt Davis, Packaging Express, Colorado Springs, Colorado

Vice Chairs: Gary Brewer, Package Crafters, High Point, North Carolina

Finn MacDonald, Independent II, Louisville, Kentucky Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

Immediate Past Chairman: Gene Marino, Akers Packaging Service Group, Chicago, Illinois

Chairman, Past Chairmen’s Council: Jay Carman, StandFast Packaging Group, Carol Stream, Illinois

President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia

Secretary/General Counsel: David Goch, Webster, Chamberlain & Bean, Washington, D.C.

AICC Canada: Lee Gould

DIRECTORS

West: Sahar Mehrabzadeh-Garcia, Bay Cities, Pico Rivera, Califormia

Southwest: Jenise Cox, Harris Packaging/American Carton, Haltom City, Texas

Southeast: Michael Drummond, Packrite, High Point, North Carolina

Midwest: Casey Shaw, Batavia Container Inc., Batavia, Illinois

Great Lakes: Josh Sobel, Jamestown Container Cos. Macedonia, Ohio

Northeast: Stuart Fenkel, McLean Packaging Pennsauken, New Jersey

AICC Canada: TBD

AICC México: Sergio Menchaca, EKO Empaques de Cartón S.A. de C.V., Cortazar, Mexico

OVERSEAS DIRECTOR

Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE

Kevin Ausburn, SMC Packaging Group

Springfield, Missouri

Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma

Guy Ockerlund, OxBox, Addison, Illinois

Mike Schaefer, Tavens Packaging & Display, Bedford Heights, Ohio

Ben DeSollar, Sumter Packaging, Sumter, South Carolina

Jack Fiterman, Liberty Diversifies, Omaha, Nebraska

EMERGING LEADER DELEGATES

Lauren Frisch, Wasatch Container, North Salt Lake, Utah

John McQueary, CST Systems, Atlanta, Georgia

Jordan Dawson, Harris Packaging, Haltom City, Texas

ASSOCIATE MEMBER DIRECTORS

Chairman: Greg Jones, SUN Automation Group Glen Arm, Maryland

Vice Chairman: Tim Connell, A.G. Stacker Inc Weyers Cave, Virginia

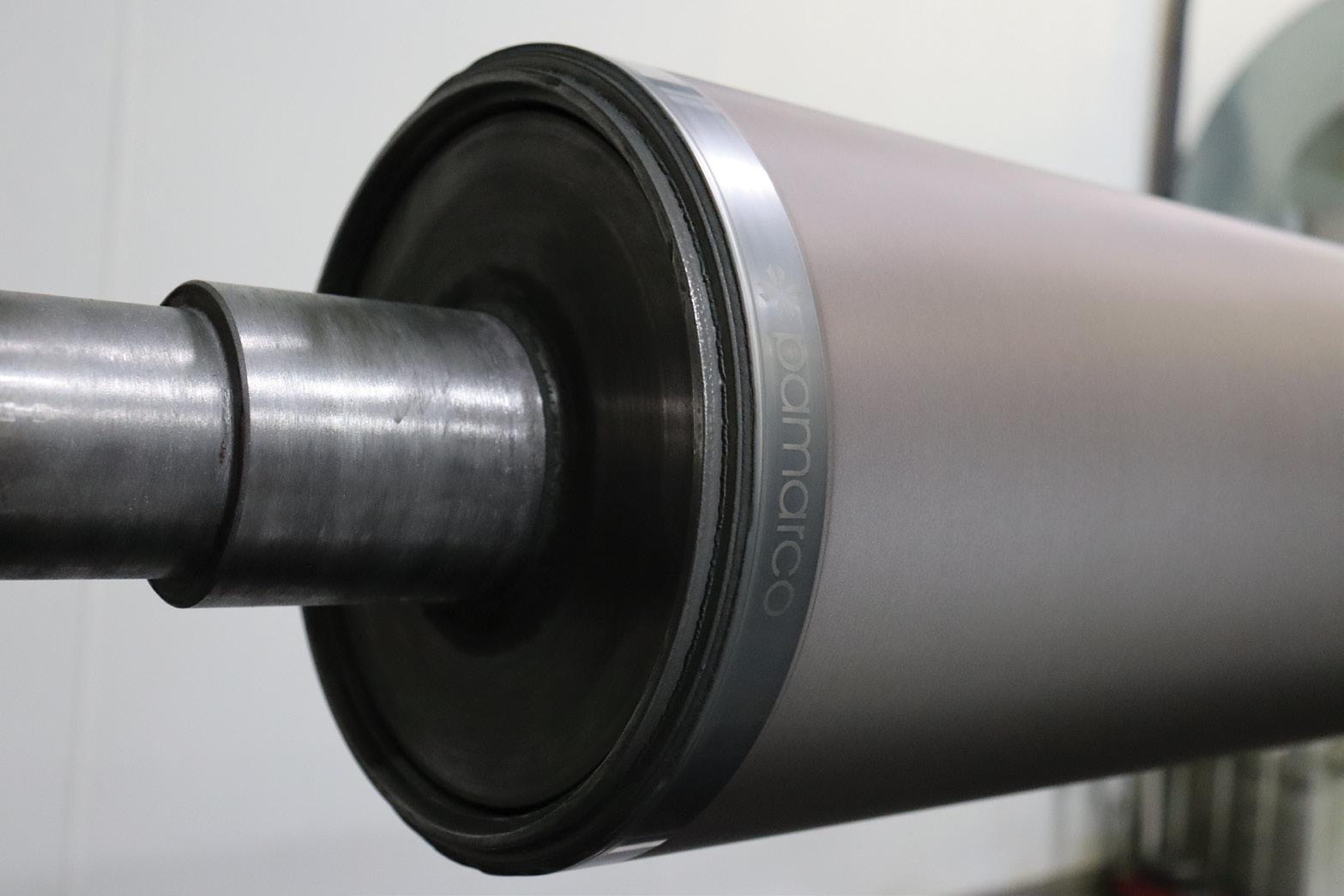

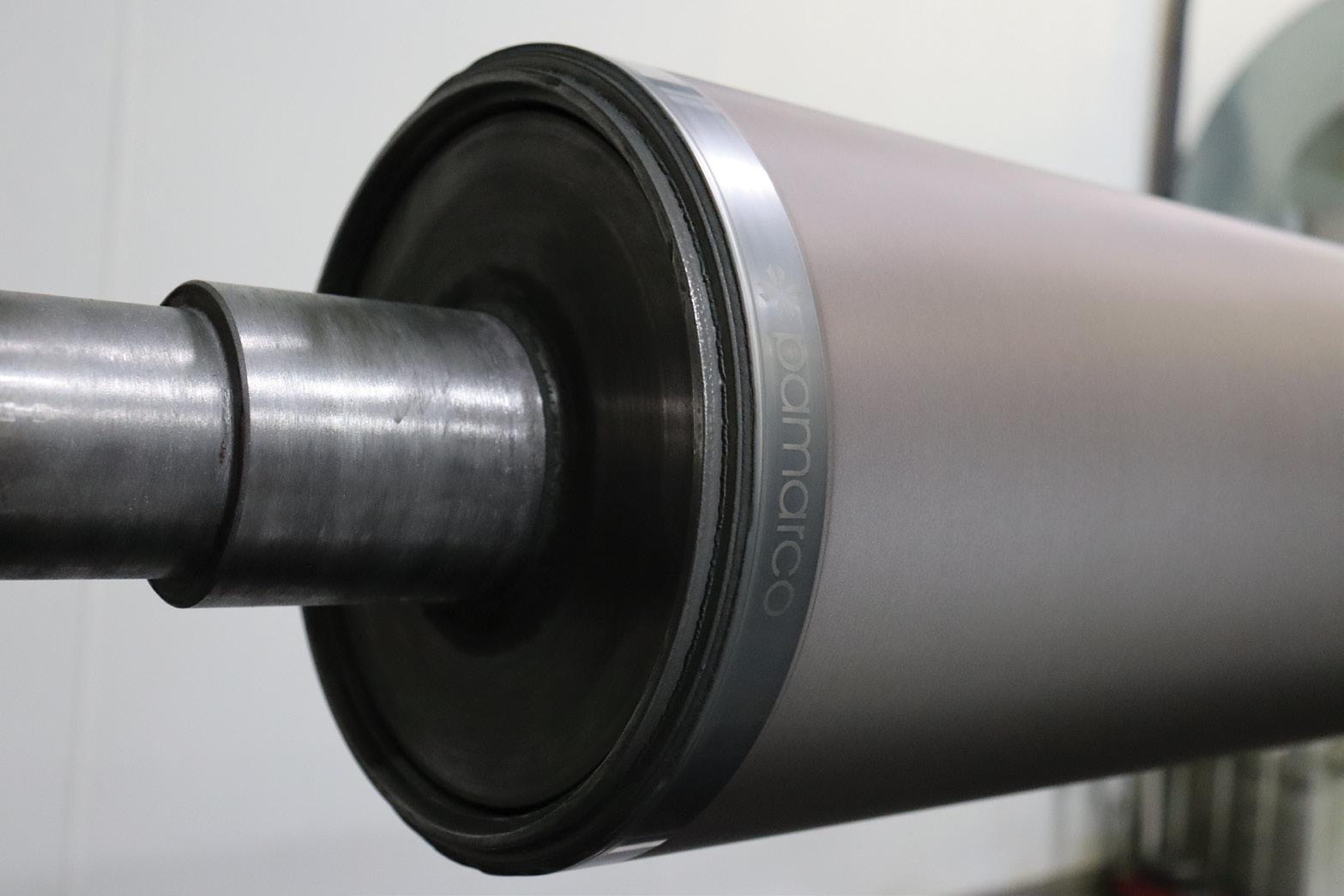

Secretary: John Burgess, Pamarco/Absolute, Roselle Park, New Jersey

Director: Jeff Dietz, Kolbus America Inc., Cleveland, Ohio

Immediate Past Chairman, Associate Members: Joseph Morelli, Huston Patterson Printers/Lewisberg Printing Co., Decatur, Illinois

ADVISORS TO THE CHAIRMAN

Al Hoodwin, Michigan City Paper Box, Michigan City, Indiana

Gene Marino, Akers Packaging Service Group Chicago, Illinois

Greg Jones, SUN Automation, Glen Arm, Maryland

PUBLICATION STAFF

Publisher: Michael D’Angelo, mdangelo@AICCbox.org

Editor: Virginia Humphrey, vhumphrey@AICCbox.org

EDITORIAL/DESIGN SERVICES

The YGS Group • www.theYGSgroup.com

Vice President: Serena L. Spiezio

Content & Copy Director: Craig Lauer

Managing Editor: Therese Umerlik

Senior Editor: Sam Hoffmeister

Copy Editor: Steve Kennedy

Art Director: Alex Straughan

Account Manager: Frankie Singleton

SUBMIT EDITORIAL IDEAS, NEWS, & LETTERS TO: BoxScore@theYGSgroup.com

CONTRIBUTORS

Maria Frustaci, Director of Administration and Director of Latin America

Cindy Huber, Director of Conventions & Meetings

Chelsea May, Education and Training Manager

Laura Mihalick, Senior Meeting Manager

Patrick Moore, Membership Services Manager

Taryn Pyle, Director of Training, Education & Professional Development

Alyce Ryan, Marketing Manager

Steve Young, Ambassador-at-Large

ADVERTISING

Taryn Pyle 703-535-1391 • tpyle@AICCbox.org

Patrick Moore 703-535-1394 • pmoore@AICCbox.org

AICC PO Box 25708 Alexandria, VA 22313 Phone 703-836-2422 Toll-free 877-836-2422 Fax 703-836-2795 www.AICCbox.org

ABOUT AICC

PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974

We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company, and employees at all locations have access to member benefits. AICC o ers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Better Minds, Better Boxes

I’m Jana Harris, CEO and co-owner of Harris Packaging, a sheet plant in Fort Worth, Texas, and American Carton, a folding carton plant in Mansfield, Texas, along with my sister Jenise Cox and our father and founder, Joe Harris. Why have I chosen Better Minds, Better Boxes as my theme? I have a passion for educa tion, especially the education of individuals who could consider a career in our industry.

I became active with our local university, the University of Texas at Arlington (UTA), in 2013 when the International Corrugated Packaging Foundation (ICPF) partnered with UTA’s College of Liberal Arts to introduce packaging design and graph ics into its course offerings. UTA supported this because it gave art students another career avenue—one they probably had never considered.

Some of our employees and I go to UTA every semester and speak about our industry. We judge its sales competitions, which have helped us snag some good sales folks. Harris Packaging sponsors a Joe Harris Scholarship in the College of Liberal Arts in our father’s honor. He’s a UTA graduate—as am I.

Since our involvement at UTA, we have hired 10 students for sales, marketing, and design. It is a great avenue for us to find employees. The benefit to our companies of investing some time with UTA has been tremendous. If you are not doing the same with your local schools, you should consider doing so.

That’s a little background about my passion. In this coming year, I am going to focus on getting the word out about our industry to the next generation of workers. I see three avenues through which we can accomplish this.

First, continued involvement and investment in our industry foundations: ICPF, which works in partnership with colleges and universities, and the Foundation for Packaging Education, which supports training for our industry’s employees. ICPF brings four-year and two-year college and university students to our plant doors. AICC’s Foundation for Packaging Education continues their develop ment inside our doors. Please continue to support or consider supporting both foundations. They are vital to the future of our industry.

Second, I believe we need to tap into the pool of talent in our trade schools and STEM high schools. By collaborating with those within the corrugated, folding carton, and rigid box industries, we can introduce paper-based packaging to an audience that has no idea we exist. I have started a relationship with my local STEM high school. It is very interested in offering packaging education to its students. Based on this recent experience, I hope to have more exciting news to share with you on STEM and how you can connect.

Finally, I don’t want to forget the young people already working in our industries. AICC and TAPPI offer their respective Emerging Leader (EL) and Young Professionals programs. If you have young, promising leaders in your organizations, please help them get involved in our industry associations. Jenise and I currently have three participating in the EL program. I recommend these programs for your upcoming superstars.

Spending time on campuses and around educators has shown me that very few students know about our industry. If they do not know us, how can they consider us? But my experience with the ELs and my 10 UTA hires has shown me that once we get them in, they are hooked and excited to be a part of our industry.

To grow our industry, we need to be in front of our next generation of workers. We have amazing career opportunities for them.

Let’s go spread the news!

Jana Harris CEO and co-owner, Harris Packaging and American Carton Co. AICC Chairwoman

BOXSCORE www.AICCbox.org 3

Chairwoman’s Message

A Conundrum: Ebbing GDP Amid Tight Job Market

BY DICK STORAT

Last year at this time, the U.S. econ omy was on its way to setting a recent annual high growth rate of 5.7%, as consumer spending propelled economic recovery from the recession-causing COVID-19 lockdowns of 2020. This year tells a different story, however.

During the first half of this year, there has been little growth in consumer spending after the adjustment for rising inflation. Since nondurable goods account for some three-quarters of all corrugated packaging made in the U.S., the fact that spending for these fast-mov ing goods has been declining since early this year is of special concern. The chart at right shows this weakness.

Consequently, economic activity as measured by the gross domestic product (GDP) faltered and posted small declines in each of the first two quarters of this year, as indicated in the top chart on p. 5.

Concurrently, though, the labor market remained extremely tight. Jobs were being added at a rate averaging 470,000 jobs per month during the first seven months of this year. This was insufficient to satisfy the demand for workers, which reached 11.2 million in July. One reason for this shortfall is the decrease in the foreign-born working-age population. There is a shortfall of 1.7 million of these workers since before the pandemic. There are still two job openings per every unemployed worker in the U.S. Until this ratio comes down significantly, the central bank will continue to pressure the

demand side of the economy, reducing inflation-adjusted consumer spending and increasing the likelihood of recession. At midyear, the year-over-year wage gains had reached 5.7%. A search of the Indeed job search website for mentions of the hourly rates of $15 per hour and $20 per hour confirmed this trend. Since early this year, the mentions of $15 declined by 76%, while the mentions of $20 rose by 33%.

The conundrum between the lack of GDP growth and a tight labor market can be explained partly by low productivity. Businesses might be hiring actively, but if new workers are not as productive, production will falter. Several activities with their roots in the pandemic could be at work.

Earlier retirements take experienced, productive workers out of the work force. Job switching is at an all-time high. New employees require some training time to become as proficient as their predecessors, just to mention a few factors. Output per hour in the nonfarm business sector fell at an annual rate of 7.3% in the first quarter of 2022, the second-weakest reading since productivity has been reported. If this continues, the GDP decline will seem like more than a passing cloud.

The bottom chart on p. 5 shows the producer price index and the consumer price index (CPI). At the beginning of the third quarter, there was some evi dence that producer prices had peaked. This behavior is primarily the result of

BOXSCORE November/December 20224 Scoring Boxes

Real Consumer Spending

Nondurable Goods Year-Over-Year Percentage Change 19J 20J 21J 22J –10% 5% 0% 10% 5% 15% 20% 25% Source: Bureau of Economic Analysis

on

gasoline and other energy prices declining. However, it remained at an uncomfortably high rate of 10% growth over the previous year. CPI growth shows a similar trend, but at around 8%, it also remains elevated well above the Federal Reserve’s target rate of 2%.

Manufactured foods are intensive consumers of cor rugated packaging. The food component of the CPI rose by 1.1% in July. That brought the year-over-year rise to 10.9%, the largest such gain since May 1979. July was the seventh consecutive month of monthly gains of 0.9% or more.

The food at home index rose 13.1% over the past 12 months, the largest annual increase since the period ending March 1979. The index for cereals and bakery products increased 15% over the year. The remaining major grocery store food groups posted increases ranging from 9.3% (fruits and vegetables) to 14.9% (dairy and related products).

The index for food away from home rose 7.6% over the past year. The index for full-service meals rose 8.9% over the past 12 months, and the index for limited-service meals rose 7.2% over the past year.

At the producer level, food inflation is also quite elevated, suggesting that consumers may still face even higher prices at grocery stores in the weeks ahead. Overall, the producer food index rose by 1% last month, bringing the annual gain to 15%. Components of the pro ducer food index that have suffered the greatest increases include fresh and dried vegetables and eggs. Vegetable prices rose an average of 12.7% in July, while eggs posted an even higher gain of 44.2%.

So, the open question as 2022 comes to a close is whether the central bank’s rapid rise in interest rates will cause enough reduction in consumer spending so businesses will not need to fill all those currently empty positions.

BOXSCORE www.AICCbox.org 5 Scoring

Boxes

Dick Storat is

can

21Q 2 6.7% 2.3% 21Q3 21Q4 22Q1 22Q2 U.S. Real GDP Growth Percent Change Annual Rate –3 –2 –1 0 4 5 6 8 1 2 3 7 Annual 2019: 2.2% 2020: 3.4% 6.9% 1.6% 0.9%

president of Richard Storat & Associates. He

be reached at 610-282-6033 or storatre@aol.com

U.S. Producer Price and Consumer Price Indices Year-Over-Year Percent Change 19 21 22 –2 0 2 6 4 8 10 12 Sources: FRB, BLS Federal Reserve Target: 2% PPI CPI

Sources: BEA, RSA

New Rules on Independent Contractors Published

BY ERIC ELGIN

AICC belongs to the Small Business Legislative Council (SBLC), which actively monitors activity in all of our government branches—legislative, executive, and judiciary. It’s in the executive branch, controlled by the Biden administration, that the Department of Labor (DOL) is proposing new rules for the classification of independent contractors for the purposes of federal wage and hour laws. The DOL published these new rules on October 13, with a public comment period of 45 days.

To understand the DOL’s new proposed rules, it is important to understand the history of the rules over the past couple of years. Before 2021, the DOL used what is known as the economic realities test to determine if a worker can qualify as an independent contractor. The economic realities test looked at five factors:

• The nature and degree of the worker’s control over the work,

• The worker’s opportunity for profit or loss,

• The amount of skill required for the work,

• The degree of permanence of the working relationship, and

• Whether the work is part of an integrated unit of the business.

In the waning days of the Trump administration, the DOL issued a new final rule intended to make it easier for businesses to satisfy the economic realities test and classify workers as contractors. Under the Trump-era independent contractor rule, the DOL focused primarily on the first two factors of the economic realities test. Under

that rule, if a worker qualified as an independent contractor when looking at the factors of control and opportunity for profit and loss, the inquiry would stop there, and the independent contractor classification would be permissible. Only if there was uncertainty or ambiguity would consideration be given to the third, fourth, and fifth factors noted earlier. The rule also allowed businesses to offer certain benefits to independent contractors without undermining their classification.

The new proposed rules would reinstate the economic realities test with each factor receiving equal weight and with the worker’s and employer’s investments into their respective businesses being broken out as its own factor in the test. The pro posed rules also provide additional details on how businesses should assess the issue

of control and determine whether the work is integral to employers’ business.

How this affects you as an AICC member depends on whether you utilize independent contractors in your opera tion. If you use independent sales reps, for example, the independent contractor rules may apply to them. There may be other situations as well, so consult with your accountants and attorneys for the best guidance. Once these new rules are finalized, AICC will supply all members with a summary of their requirements.

Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com

BOXSCORE November/December 20226 Legislative Report

APSTAR

HG2 ROTARY DIE CUTTER

You can’t have quality without precision. The APSTAR HG2 offers print-to-print registration accuracy through as many as seven inline flexo sections. That precision creates less downtime and higher profits.

When you balance speed, print quality, and precision, you get an APSTAR… and that means better boxes.

require precise printing and cutting.

Contact Haire Group to see how the APSTAR's precision can impact your bottom line. hairgroup.com Superior boxes

VANGUARD INKS & COATINGS

DANIEL RAMOS

Sales Professional

2050 Forest Lane, Suite 230 Garland, TX 75042 972-795-3597 www.vanguardic.com

NEWAY PACKAGING CORPORATION

BRADY FACER

Corporate Business Development Manager

1973 E. Via Arado Rancho Dominguez, CA 90220 310-898-3400 www.newaypkg.com

MOVITEC AMERICAS LLC

JOSE A. DIAZ General Manager 111 N. Orange Ave., Suite 800 Orlando, FL 32801 470-846-9736 www.movitec-ws.com

BAKERTITAN ADHESIVES

BILL ZELMAN

Vice President 25 Lake St. Paterson, NJ 07501 973-225-1070 www.bakertitan.com

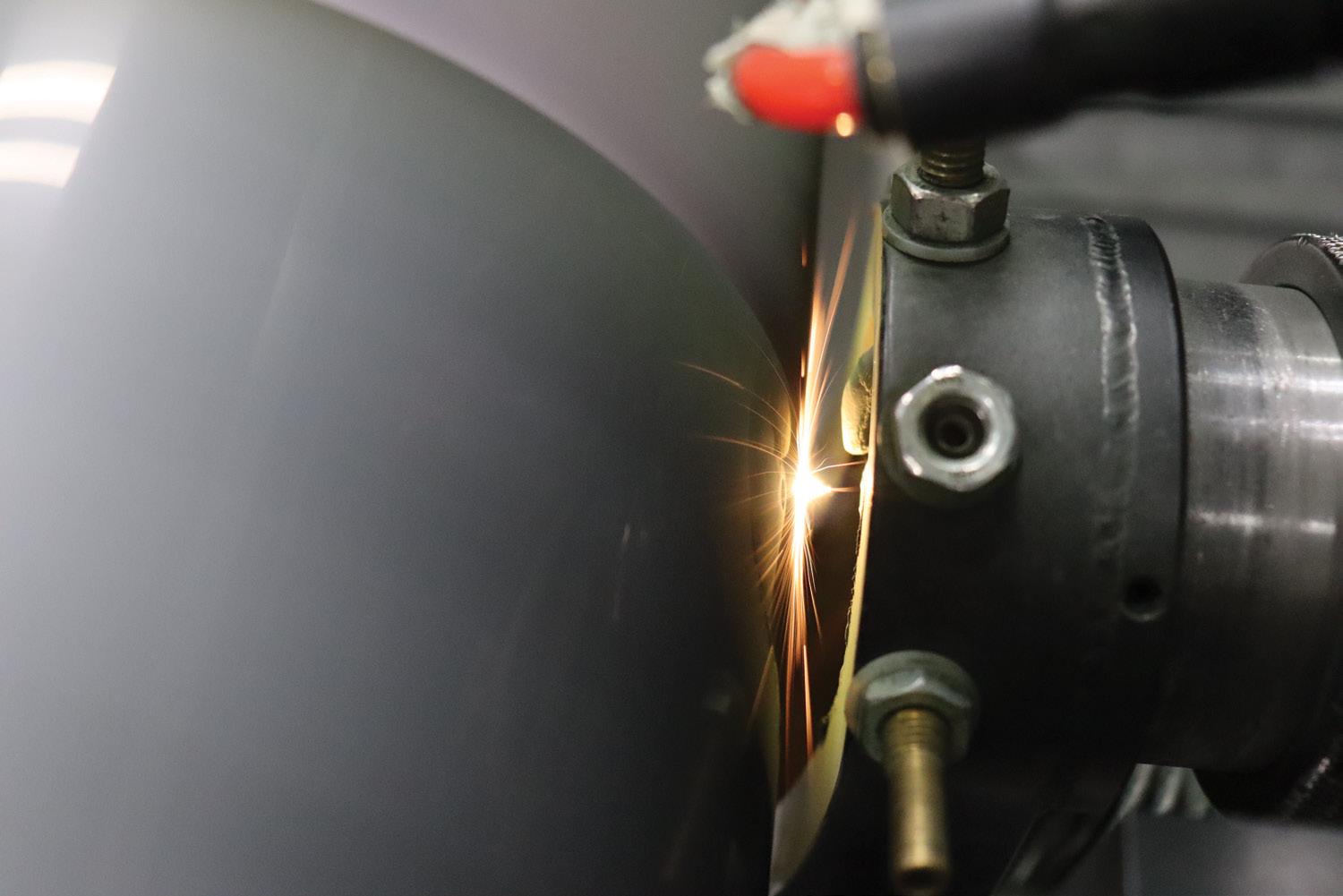

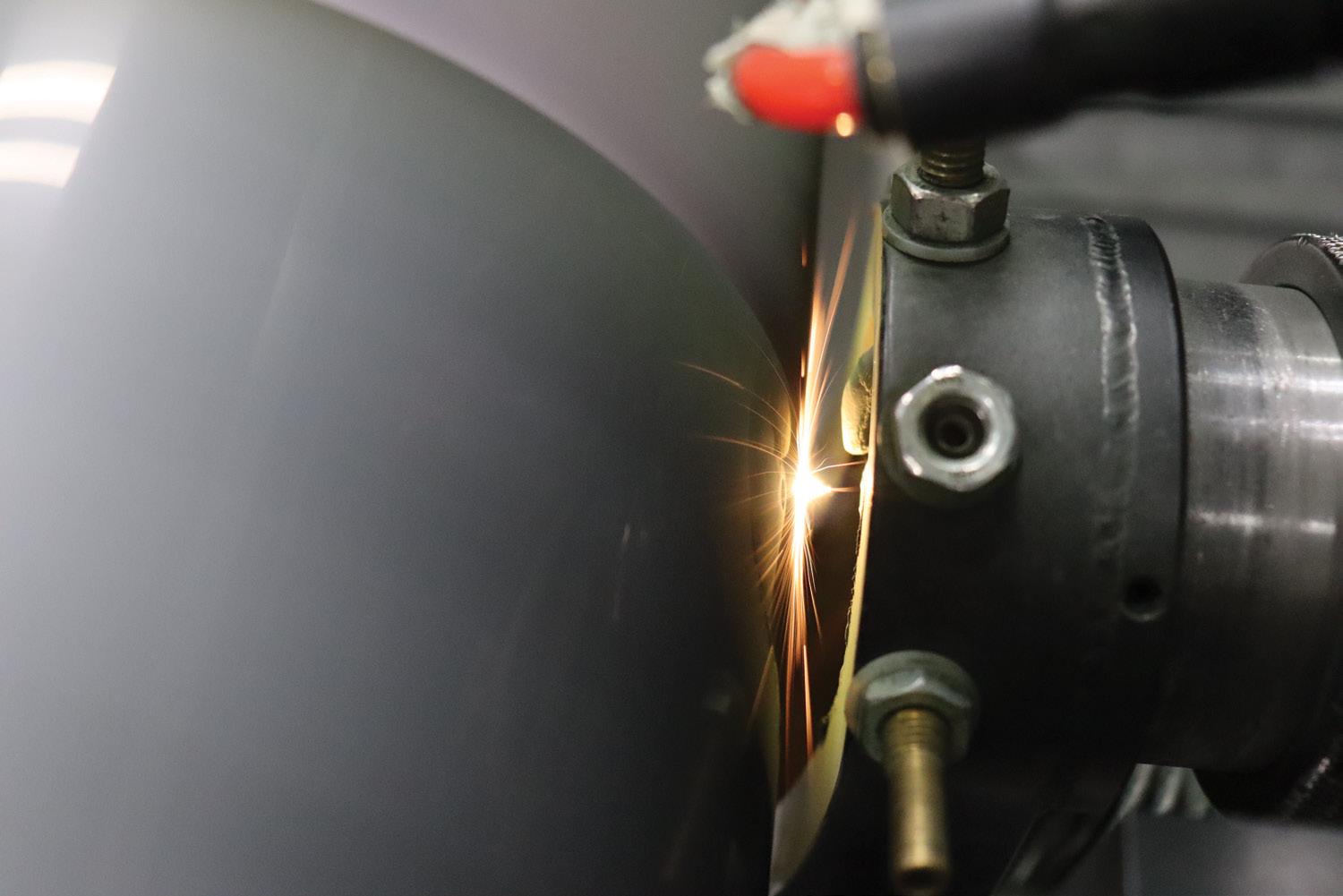

Apex anilox rolls let you printyour best on corrugated.

BOXSCORE November/December 20228

New & Returning Members

AICC’s New Members!

Welcome,

Welcome,

Get on board with Apex apexinternational.com/industry/corrugated Glue it. Print it. Profit. GTTCORR “L”Conventional 250 LPI Anilox Engraving Conventional 360 LPI Anilox Engraving ACHIEVE YOUR FINEST DETAIL GTTCORR anilox (far right) helps you print finer screens, stronger solids, and sharper edges. GTTCORR “L” SOLIDS & SCREENS ON ONE INK STATION Full solid and 65 LPI screen with one print plate on white-coated B-flute using GTTCORR COMBINATION SOLID AND SCREEN PRINTING PROVEN FASTER & EASIER CLEAN-UP PATENTED OPENCHANNEL ENGRAVING NEXT-GEN ANILOX ROLLS The Measure of Quality.

print quality

us

your

quote

CUSTOM OR CONVENTIONAL ENGRAVINGS UPGRADED SOLID, LINE & CMYK PRINTABILITY CORROSION & SCORE RESISTANCE CONVENTIONAL ANILOX ENGRAVINGS AICC BoxScore 3.25x8.25.indd 1 12/3/21 2:24 PM

Don’t let your anilox rolls hold you back from finer screens, stronger solids, & sharper lines. Treat your customers to higher print quality with GTT and UltraCell anilox engravings. Let legendary Apex precision & durability reduce problems & boost your profits. Get on board with higher

&contact

for

next anilox

.

Copyright 2022 HP Development Company, L.P. The information contained herein is subject to change without notice. One press, many possibilities Achieve high-volume production efficiency with a robust, 67” (1.7m) digital web-fed packaging platform for digital single-face lamination, corrugation, and folding carton applications. Find out more: www.hp.com/pagewide-T700i HP PageWide T700i Press

©

Members Meeting

AICC Takes to San Antonio in Big Texas Fashion

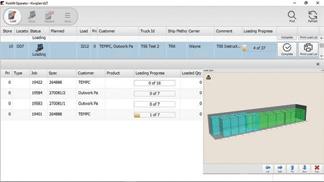

AICC/TAPPI Corrugated Week, September 19–21, in San Antonio, was a resounding success. Nearly 1,500 people walked the exhibit floor, covering 25,000 square feet of the Henry B. González Convention Center, and visited 164 exhibitors.

Attendees heard from the following keynote speakers: Steve York, a noted leader in the corrugated industry for over 46 years, and Michael J. Durant, a former Blackhawk pilot, prisoner of war, author of In the Company of Heroes, and inspiration for the movie Black Hawk Down. York shared insights from his unique career in 1974 with a four-year stint as a summer/hourly employee at U.S. Corrugated in Lincoln, Illinois, to his retirement in 2020 as the senior vice president of engineering and manufactur ing services at WestRock. Durant shared his experiences as a soldier and hostage and their relationship to his commitment to leadership, team building, and growth.

Attendees learned from peers during several workshop sessions, which included panel discussions on digital print,

artificial intelligence/robotics and automation, and employee recruitment and retention.

Several AICC members were also recognized for their excellence, including Gary Brewer of Package Crafters and Greg Jones of SUN Automation Group,

awards for their efforts to recruit and retain AICC members. Buckeye Corrugated Inc. won the AICC and Board Converting News Innovator of the Year award for its roller conveyor platform. Additionally, Elizabeth Collins, a student at Indiana State University, was presented with the J. Richard Troll Scholarship, and

November/December 202210

SAVE THE DATE AICC/TAPPI SuperCorrExpo September 8–12, 2024 Orlando, Florida

Many AICC/TAPPI Corrugated Week attendees got a taste of Texas spirit at the Tejas Rodeo.

Photos courtesy of AICC.

Members Meeting

Ciara Johnson, a Clemson University student, represented her team that won first place in the graphics category of the Student Design Competition.

Gene Marino of Akers Packaging Group also completed his tenure as AICC chair man, and Joe Morelli of Huston Patterson and Lewisburg Printing Co. completed his term as AICC Associate chairman. Several new officers were elected, and Jana Harris of Harris Packaging and American Carton Co. was elected as chairwoman.

Many attendees also enjoyed some Texas hospitality at the Tejas Rodeo.

Major sponsors of Corrugated Week included HP, Mitsubishi Heavy Industries, SUN Automation Group, Geo. M. Martin Co., Arc International, CloudLab, and A.G. Stacker Inc. Please visit www.corrugatedweek.org for a full list of sponsors.

BOXSCORE November/December 202212

Accompanied by his wife, Megan (left), and newly elected AICC Chairwoman Jana Harris of Harris Packaging and American Carton Co., Akers Packaging Service Group’s Gene Marino was honored for his tenure as AICC chairman.

The mechanical bull alongside the exhibit floor proved to be a popular event attraction.

Marino presents Package Crafters’ Gary Brewer (left) with an AICC Champion Award.

Marino presents SUN Automation Group’s Greg Jones (right) with an AICC Champion Award.

Marino presented the following individuals with awards for serving the Association and its members in various roles (from left): Al Hoodwin, Michigan City Paper Box Co. (on behalf of Joseph M. Palmeri, Jamestown Container Cos.); Cassi Malone, Corrugated Supplies Co.; and Joe Morelli, Huston Patterson and Lewisburg Printing Co.

Bibliography Update: Fifth Edition

BY RALPH YOUNG

Since the creation of BoxScore, it was our intention to publish a listing of my articles every two, three, or four years. It has now been two years since the last update.

With the new AICC NOW platform at NOW.AICCbox.org, you have access to all these learning opportunities in one shop. The following list contains articles and resources dating to March 2020:

• “Expected Values for Containerboards Updated” (March 2020): We keep you updated on the strength levels in several grades of linerboard and media. This testing is conducted semiannually through the American Forest and Paper Association. AICC has access to some information, and we share the highlights with you. You will find a wide range of strength values within each substance or basis weight. Some variations can be more than 40%.

• “Updating Educational Resources” (May 2020)

• “Looking Beyond COVID” (July 2020): We focus on current trends impacting your businesses.

• “Times They Are A-Changin’” (September 2020)

• “Plastics: A Primer” (March 2021): Much more details are available in significant research projects such as www.breakfreefromplastic.org and bio-agave.com. And be aware of the impact of what you’re drinking, as Coca-Cola, PepsiCo, and Nestlé were the top three polluters globally. The two largest-polluting countries were China and India.

• “Questions Abound” (May 2021)

• “ESG Programs at the Fore” (July 2021): This is Deutsche Bank’s yearly conference about ever-increasing global

business regulations. You may need to look to suppliers such as International Paper, DS Smith (Mondi), Leipa, SCA, Metsä, and Saica to help develop your responses. You should hear more on these topics going forward. Be aware that the winds of accountability may be changing. “Green infrastructure” will continue to be an ever-evolving subject. Corporate discussions and reports from corporations will relate to:

º Renewable energy

º Emissions and supply chains

º Investors’ perceptions of climate change

º Reduced energy

º Scope 3 or greenhouse gases through the entire supply chain

º Sustainable suppliers

º Reducing waste

º Measuring emissions

º Environmental awareness

• “Expected Values of Domestic Containerboard Grades: Fourth Edition” (September 2021): For a more advanced understanding of this raw material, we point you to the digital brochure Understanding the Key Characteristics of Linerboard and Medium and Their Impact on Combined Corrugated Board

• “Score Cracking Revisited – Again” (November 2021)

• “Microflute and Paperboard – Another Update” (March 2022): These are the highlights of the many seminars, webinars, and articles that Tom Weber, AICC folding carton technical advisor, and others have shared over the past four years. We reintroduced the corner crush and block compression testing methods, most often used for solid fiber

paperboards but useful with E flute and thinner corrugated.

• “Glue Tabs: Failures?” (May 2022): We discovered a study that answered a question about what the strongest glue tab method is—cold-set adhesive, hotmelt adhesive, tape, or stitch/staples. Here is what was reported in pounds per inch per tensile: cold-set adhesive: 127#; hot-melt adhesive: 109#; tape: 53#; and stitch/staples: 26#.

• “ESG: Round Two” (July 2022)

• “Takeaways From Our Most Recent Webinars” (September 2022): Recently, Weber and I collaborated on a six-part webinar series, which is available to you through your AICC membership: º 2022 Fluted vs. Paperboard Workshop Update (three-part series) º Testing Requirements to Guarantee Board Strength

º How to Build a Lab: Material Testing º Physical Attributes of Paperboard/Containerboard

AICC’s Packaging University has nearly 100 modules. Among the resources are a learning segment, Warp: Its Causes and Remedies, and two white papers, Fluted and Paperboard and Score Cracking: Its Causes and Remedies

Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@AICCbox.org

BOXSCORE November/December 202214 Ask Ralph

DualBox

Two-in-one productivity

Revolutionising box production with the EMBA unique solution enabling double production capacity of RSC boxes:

TwinFeed™ + XL Slotter = DualBox™ = 2x Output

TwinFeed™ is an option for the EMBA 245 QS Ultima™, which feeds two identical sheets from 280 mm up to 520 mm in running direction in a single machine cycle.

The extended 4 shaft EMBA Magna XL VSC enables making all slots of both sheets in the slotting unit at speeds up to 30 000 boxes per hour – with no tolerance variations between the boxes. Like having two machines in one.

The DualBox™ innovation combined with the intelligent Ultima™ platform, unique Non-Crush Converting™ and Quick-Set™, makes EMBA 245 QS Ultima™ unbeatable. Converting knowledge into productivity.

To double your output: EMBA 245 QS Ultima™ with DualBox™

TM

www.emba.com Liljedal Communication 2021

Hire an ‘Ever-Blooming Rose’

BY TOM WEBER

Employees and culture are two of the most important assets a company can build upon. Hiring new executives, who are integral to developing both, is never an easy task! How many times have you seen one of these scenarios? A newly hired executive almost immediately makes a positive impact on the company. On the other side of the coin is the new executive who creates more turmoil and upheaval than is good for a company.

Hiring the right people is one of the most strategic, cost-saving, and value-producing practices a company can implement. The goal is to hire that “ever-blooming rose” that rejuvenates themself and others and adds great value as they blossom in their role. The differential is the selection process of these strategic executives. It is not an easy task to fi nd the executive who is a perfect fit for a role. It requires a unique set of skills of those who are fi nding the candidates and of those who are in the hiring progression.

Few companies actually have a complete, defined recruiting process that includes every person involved in the decision. The first requirement is to truly understand the needs of the company, the definition of success in the position, and the appropriate skill sets required for the role. While this sounds simple, this procedure many times is quickly homogenized to get a job brief written and candidates into the pipeline. Next is to have everyone involved in the process agree to the needs to be fulfilled and the skill sets required. Often during an interview process, those interviewing have different viewpoints on the issues and the best skills for creating solutions.

A recruiter must have a strong grasp of the company culture and the requirements for the role. Understanding

culture goes a long way in the ability to transition the correct type of executive into a role. It would be of great value if they had actual experience in retail, the position, and the type of company. They need to understand the grassroots culture that allows the company to be successful. Defi ne the culture on paper, and create questions that identify the characteristics of a candidate who would be a good fit. A strong candidate must know the basic elements such as daily decision-making and, on a higher level, have the talents needed for long-term success in the role. Create a detailed job brief that, through the overview and requirements, immediately defi nes a clear pathway for the proper candidates to be determined. Initially, one has to search out those who have the skills on paper. Once accomplished, prepare a list of questions that lead the dialogue beyond a candidate’s resumé history and into an understanding of their true skill sets, desires, and fit into the culture.

Have discussions with the hiring manager and the team who will be interviewing the candidate. Make sure everyone is concentrating on the same elements when interviewing. Creating a set of leading questions for the interviewers, which again delves beyond the candidate’s resumé, can be of great help. Do allow for independent questions to occur where needed. Don’t make first-impression or gut decisions as to the quality of a candidate. Take your time and control the interview so no one is hawking the company and

candidates do not oversell themselves. Th is is a matching of needs and skills. You need to be looking for the best solution for each party. Consider follow-up interviews with a different set of questions, including a few that have already been asked of the candidate. Confirm that the original decision was the correct one.

Th is is a broad overview of the methodology in a strong hiring process. There are many more detailed elements, but this aff ords you some insight into the opportunities and needs of hiring the correct executives. Create a set of recruiting and interview procedures that bring forward candidates who can be “blooming roses” and deliver strong value to your company and its continual positive cultural growth.

Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@aiccbox.org

BOXSCORE November/December 202216 Ask Tom

AD

Strategies to Increase Website Leads

BY TODD M. ZIELINSKI AND LISA BENSON

It is not a secret that buyers conduct self-directed online research and have short-listed their choice of vendors before ever speaking with a salesperson. This is why it is more important than ever to ensure you have a solid inbound marketing strategy so customers can find you—not only find you but be motivated to contact you. Inbound marketing should be combined with outbound mar keting as part of your overall marketing strategy to see the greatest impact.

Inbound and Outbound Marketing Explained

As you know, when referring to sales and marketing, we are talking about activities and processes that go into converting a sale. Sales and marketing activities can be further broken into inbound and outbound, which have been characterized as pull and push marketing, respectively.

Inbound marketing involves the activities and processes that pull prospects to you, usually through your website. It can be summed up as a process of attracting, nur turing, and converting leads. This is more passive as you are not reaching out directly to a specific person. You are targeting a persona, i.e., a semi-fictional representation of your target customer, with specific strategies to encourage people fitting this persona to contact you. Your inbound mar keting strategy will include search engine optimization (SEO) of your website and content, social media, and tactics that help a prospect who needs corrugated products find your relevant content.

Outbound marketing includes activities and processes that push information to your prospects—phone calls, voicemails, emails, direct mail, etc. These are typically directed at specific individuals. Outbound

marketing can be used in parallel with inbound (i.e., reaching out to individuals or companies that fit your target profile), but it also complements it. Once marketing leads come in through your website, you need outbound activities to convert them to sales-qualified leads and then to a sale. This article will not go into outbound marketing too deeply, other than to iterate the impor tance of following up with inbound leads.

Importance of Inbound Marketing

When done correctly and used as a com ponent of an overall marketing strategy, inbound marketing is an effective method for increasing your lead flow. Inbound marketing reaches audiences interested in the types of products you sell.

There are several stages in a buyer’s journey—awareness, consideration, and decision. As prospects search the internet for solutions (awareness), they are more likely to find you if you have implemented current best-practice inbound marketing strategies. This can be done with content on your site or off-site, for example, through social media. As they acquire more information from several vendors and learn what each offers (consideration), your content that explains your compet itive advantage and addresses their pains can help lead them to a decision. Inbound marketing is used to reach prospects at each stage of the buyer’s journey.

Elements of an Effective Inbound Marketing Strategy

It is important to note that inbound mar keting is not a set-it-and-forget-it method for generating leads. The buyer’s journey is evidence that a strong web presence is vital. However, building a flashy new website and walking away are not enough

to keep a flow of relevant leads coming to your website. The following several ways buyers can land on your site must be considered when developing your strategy:

• A direct search is when they enter your URL directly into the browser.

• A referral is when they arrive at your site from a backlink, which is when another site, like a trade show page, links to your site.

• An organic search is when they use a search engine, type in keywords (such as “cardboard boxes in Wisconsin”), and click on one of your webpages that appear in the results. Remember, people don’t always know the correct terminology, and as painful as it might be, your content should use the terms people use in their searches.

• Other types include social, pay-perclick (paid links), and email links.

Encouraging buyers to come to your site is achieved through SEO. This means optimizing your website and content for search engines, such as Google, to find your content, trust your content, and deliver it as a top result. This doesn’t hap pen overnight and takes continual work.

As a side note, we talk about Google instead of some of the lesser search engines because Google has 83% of the global market, according to Statistica. Google has begun prioritizing content quality related to search queries, so the changes made to your site based on its recommen dations will likely enhance results on other search engines, such as Bing and Yahoo.

Updating Content Is Key

You first need a strong website, which includes being optimized for load speed, URL structure, site hierarchy, images,

BOXSCORE November/December 202218 Selling Today

MagnumInks.com | sales@magnuminks.com | 877.460.8406 ©2022 Magnum Inks & Coatings. All rights reserved.

corrugated

Corr of your printing success. CorrPrint ™ RC Rod Coating Colors

CorrPrint Rod Coating Colors are designed to withstand heat, moisture, and abrasion of

manufacturing. With excellent printability and a glueable coat, Magnum inks deliver consistent performance on rod coaters with very low rod wear and exceptionally smooth coating on the substrate. Our water-based colors are available in standard GCMI, Pantone,® or custom-matched. Responsive and agile, Magnum Inks & Coatings offers excellent technical expertise and outstanding service. Contact us and learn how the right partner can make all the difference in your printing/coating processes. The

mobile use, and other technical factors. After that, the No. 1 element of a good SEO strategy is consistently updating your website content by following best practices for SEO. Updating content lets Google know the page is still relevant and helps it to rank higher on search engine results pages (SERPs).

A good exercise is to put your company name into a search engine and see where your company appears in the results. Then, enter the top four or five products or services you think people would search for when looking for a vendor like you. This will allow you to see how other companies are ranking and allow you to reverse-engineer it.

When a search engine crawls sites looking for information to answer a searcher’s question, such as “corrugated manufacturer near me,” it goes through a hierarchy of steps to fi nd an answer. It will look at the core site and URL structure of that site. If the URL doesn’t have the word “corrugated” in it, Google will stop looking. If it has “corrugated” in the URL, it will look at page headings, content, and pictures to ensure the content on the page is about corrugated.

Website Pages for Product, Services, and Locations Served

As your product or service offerings change (i.e., equipment, certifications, etc.), pages should be updated. Each product or service you want to be found through Google or other search engines should have its own page. Just mentioning it on your homepage is not enough for a search engine to deliver it as a search result. Your pages should contain information that people are looking for. If sustainability is something prospects want, have a page dedicated to sustainability. An excellent way to determine the content and pages for your site is to look at the questions your salespeople get. Does your website answer those questions? Does each question have its own page? An FAQ page is good, but having a page that answers each question is better.

Pages for locations served are also important. When someone searches, Google’s default is to search within their area. We are familiar with this for B2C searches. If you enter the term “steakhouse” into a Google search page, your top results will be steakhouses in your area. The same is true for B2B. Having a Google map on your website of the area you serve helps with search results.

There is no limit to the number of pages a site can have. You don’t have to put them all up at once. At a minimum, your website should have four to six pages that cover core offerings and major areas served. You can then build on those, adding more as you learn what prospects are searching for. Single-page websites are not recommended for successful SEO.

Off-Site Strategies to Drive Traffic

Putting up blog posts around keywords (terms people search for) is a common strategy, but updating your off-site SEO, such as your Google Business Profi le, is just as important. When people conduct a search using “near me” or put in a geographical location, having a listing helps you to be found. Updating social sites, such as LinkedIn, with links to your site can help your page to appear in a SERP and encourages people to click through to your site from the post.

Backlinks also can impact your SEO. In recent years, Google’s algorithm has shifted from emphasizing backlinks to emphasizing relevant and informative content; however, they are still the foundation of Google’s original PageRank algorithm. Th is is because if other sites are linking to your site, it establishes your site’s authority. With this said, it is better to first concentrate on having a good website and content.

Increasing Conversion Rates

If you have ample traffic landing on your site but you are not getting the conversions you need (people contacting you), it is time for conversion rate optimization.

Th is is achieved through the following content enhancements:

• Ensure your site is user-friendly. Can users quickly get the information they need? Do you have appropriate links to other information available? Are links to case studies available that provide testimony that you can do what you say you can do?

• Provide content that reflects what people are searching for and has a high readability level. Readability is how easy it is for someone to read and understand what is written on your website.

• Have a clear call to action. Tell people what you want them to do.

• Minimize form fields. Some people are turned off by having to fill out a long form. You can ask for additional information when you follow up with them.

• Conduct A/B testing. Th is is where you create two versions to compare against each other to see which performs better.

Inbound Marketing Is an Ongoing Process

The most important thing to remember is that your inbound marketing strategy should be an ongoing process. Be consistent and patient with your SEO efforts. It takes time for pages to start ranking in Google searches. As you evaluate your site’s performance data, you may find it necessary to make changes and reoptimize.

Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com

BOXSCORE November/December 202220 Selling Today

It’s time to revolutionize

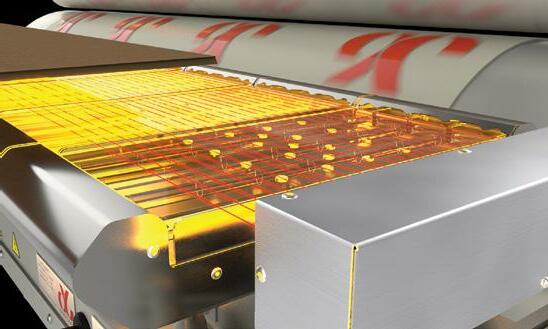

The new ChromaCUT X Pro rotary die-cutter pushes what is possible

The ChromaCUT X Pro is designed for high-performance rotary production of die-cut corrugated products with ultimate flexo post-printing quality. You will achieve paramount performance from the latest embedded technology with a brand new operating concept. It is available with the industry's shortest lead time from our factory to your floor. The ChromaCUT X Pro has a maximum production output of 12,000 boards per hour, including setup while running, integrated remote maintenance for the ultimate uptime, and the easiest machine to operate – the ChromaCUT X Pro will increase your profitability.

Call us to set up a custom demonstration.

Koenig & Bauer

(+1) 502 310-1368

tom.fitzgerald@koenig-bauer.com koenig-bauer.com

Scrolling Your Way to Packaging Success

BY JULIE RICE-SUGGS, PH.D., AND ALLI KEIGLEY

How many of you, after a long day at work, find yourself reaching for the phone to catch up on all your social media feeds? You fix a snack, put your feet up, and start the endless scrolling—or at least as much as you can get to before someone asks when supper is going to be ready.

We sure do! Whether it’s Facebook, Instagram, Twitter, Snapchat, Reddit, or LinkedIn, there’s a lot to choose from for updates on Aunt Carol’s garden, the new job your second cousin once removed just got, or your sports team’s daily stats. So, believe us when we say we understand any resistance to adding yet another app to the mix when there are already too many to keep up with.

However, we do think you need to get one more: TikTok. While TikTok has been around since 2016, it forged a strong presence in 2020 during the COVID-19 pandemic and has yet to slow down, with more than 1 billion users and 200 million downloads in the United States alone. We know that doesn’t mean you need it, but keep reading.

For those new to the TikTok world— we’re just now getting caught up—it’s a social media platform that fi rst made its mark with video content of catchy dance choreography and lip-sync routines. However, the platform has evolved to include other forms of content such as comedy, baking, food, sports, motion graphics, DIY, animals, facial treatments, and many more.

Wanting to move beyond strictly entertainment purposes, TikTok partnered with creators across their platforms to form the #LearnOnTikTok campaign, which highlights the app’s most exciting and unexpected features. Alongside its own creators and organizations, TikTok

collaborates with notable experts in their fields, such as Bill Nye, to bring informative and inspirational content to its billions of users.

Now, we’ve got you up to speed on the ins and outs of the TikTok world, but you’re probably still wondering what this has to do with the packaging world. Interestingly enough, TikTok has taken the marketing and advertising world by storm—completely changing the way brands and organizations share content with their target audiences. Because TikTok is an easily adopted tool, businesses and organizations have begun using it in a variety of ways to interact with their customers in a laid-back, less commercial approach, such as participating in TikTok challenges, posting about their locations with captions and hashtags, and using branded effects (e.g., games, stickers, filters, special effects) to offer a more engaging experience.

Never one to miss out on an exciting marketing opportunity, The Packaging School (TPS) recently jumped on board. We started a TikTok account a few months ago to raise awareness of our online packaging courses and certificate programs. As of now, we have 174 videos on the platform proclaiming the awesomeness of packaging through 15-second video clips. And we’re already seeing some great traction.

To take things a step further, we partnered with Cory Connors, sustainable packaging consultant at Landsberg Orora in Portland, Oregon, to create a superb course introducing packaging professionals to TikTok. Connors has been in the packaging industry for 25 years, and his focus is on helping companies become more sustainable with their packaging. Working in a Weyerhaeuser corrugated production facility helped Connors pay his way through college

while helping him understand the nuances of corrugated in the sustainability sector. He is the host of a sustainable packaging podcast in which he chats with industry leaders about sustainable packaging options, new products, and ways we can each make a difference in packaging sustainability. His TikTok account, @corygated, has more than 75,700 followers, 1.7 million likes, and more than 1,500 videos.

Working as a subject matter expert and instructor with TPS, Connors helped us build an engaging course on the importance of social media in the packaging space— specifically, how TikTok can be used to level up your packaging organization and how to create impactful videos for your audience. The course is about an hour long and is broken up into bite-size lessons that can be engaged with on any device, anywhere, anytime—catering to adult learning styles and their busy schedules. An added bonus—the course sells for only $49, making it light on your wallet, too!

What’s holding you back from joining the TikTok revolution? Take the leap, and if you don’t know where to start, check out this amazing course today at bit. ly/3CLvKCU.

Julie Rice Suggs, Ph.D., is academic director at The Packaging School. She can be reached at 330-774-8542 or julie@ packagingschool.com

Alli Keigley is production coordinator at The Packaging School. She can be reached at alli@ packagingschool.com

BOXSCORE November/December 202222 Andragogy

CCM® OCT THE GAME CHANGER www.engineeredrecycling.com info@engineeredrecycling.com Engineered Recycling Systems takes decades of engineering experience and integration expertise to provide turnkey solutions. We design, service and install world-class recycling and dust control systems. By providing our customers with equipment and system designs that deliver unprecedented levels of quality and craftsmanship, our solutions increase efficiency and cut labor costs. SIGNIFICANT ADVANTAGES OVER CONVENTIONAL DUST FILTRATION TECHNOLOGY • Energy savings due to low pressure loss • No compressed air required • Maximize your productivity due to less downtime of your scrap and dust system • CCM® OCT Filters = SAFE to operate and maintain • No abort gate WE LISTEN TO OUR CUSTOMERS All CCM® OCT-Filters meet NFPA, OSHA and local code requirements.

Bench Strength

BY SCOTT ELLIS, ED.D.

Do you feel like Moses? We are told the pharaoh demanded that his workforce increase production while disrupting their supply of materials, telling them to make more bricks and to gather their own straw supply. If you feel similarly maltreated by staffing challenges, supply chain issues, and the rising cost of goods over the past few years, I have two suggestions.

First, with all due respect, get a grip because all those challenges came during a time of profitability for the packaging industry. Also, most boxmakers are better employers and manufacturers for having overcome those obstacles. The second suggestion is that you make a priority to deepen your company’s bench strength.

Employment numbers indicate that manufacturing will need to continue getting the work done with fewer workers. Our solutions, therefore, need to contain value for the workers we desire to attract and retain, while increasing our ability to meet customer demand with safe, fast, quality service. The solution is crosstraining, but that is the answer you find in the back of the book. The more important part is how to get there, so as my algebra teacher required, I will show my work.

The first step is to take an inventory of the skill sets of the current staff. I will focus on machine centers and give an example below of the application to administrative areas. To get a baseline, gather production management to set your criteria for the levels of capability. Those levels could be labeled “No Training,” “Trainee,” “Assistant Operator,” “Operator,” and “Trainer.” A resource available for this purpose, Cross-Training, can be found on Packaging University. Establish objective criteria for the

knowledge base and demonstration of ability to move from trainee to assistant and so on. Next, set a goal for the number of qualified people on each key machine center. Finally, your team should discuss possible motivations for an individual to be trained on multiple machines.

Production managers have found that many team members are motivated by an unspoken competition. When a training matrix is posted, operators of single machines will see that some co-workers are qualified on multiple processes, and some will find that motivation enough to cross-train. There is not a one-size-fits-all template for how this works in your company culture. Some companies pay for performance, meaning that when team members operate different machine centers, they clock in for pay at that machine’s rate. Other companies pay for knowledge, giving a pay differential as an operator qualifies on multiple processes.

In any case, qualifying as a trainer should receive the highest recognition. It

would not be unusual for a multi-machine operator to question their placement as operator but not trainer. One such interaction was a catalyst for change in a “magician,” which is my term for a skilled operator who does not show their work. The operator scanned the chart and asked why they did not receive the highest rating, saying, “I can train.” The response they received was, “Yes, I am sure you can, but you don’t.” It was a turning point for this skilled operator who had previously thought there was job security in holding onto knowledge.

Once the criteria for the objective ranking of capability is set and the current bench strength is known, you will decide if the best fit for your culture would be publicly posting the information or for private use by super visors for staffing (and human resources if pay is impacted).

For those who would like to take it further, the Training Tracking Tool, also on Packaging University, can be utilized to monitor the training of individuals,

BOXSCORE November/December 202224 Leadership

completion of courses, awareness of procedures, etc. One can also track by procedure, by department, or by company. Th is is an Excel-based resource for companies that do not have their own learning management system to plan and track up to 25 processes across as many as eight departments. It would be well suited for operator certification, as well as providing a training record ISO for state compliance.

The value of cross-training is most visible when production staffi ng is proficient and flexible. There is also a benefit in qualifying and tracking skill levels in maintenance. Consider that a potential customer might be won more easily if various types of sales were ranked and the appropriate expert were to attend certain sales calls. There will be

considerably more comfort in covering for a fellow customer service representative if there is a proactive effort to share specific requirements, contacts, and the status of current orders. It may start with a strategy as simple as allowing a trainee to move through the levels of order complexity (e.g., repeat, repeat with change, new box order, new kit or display order). These tools have led most to create a separate track for preparation of supervisors and managers.

When cross-training is done well, we invest in team members to increase their capability, and their engagement increases accordingly. There is no busload of willing and capable employees being delivered, so we need to be more productive with fewer people. Most who receive a wage that corresponds with

their value to the company, who receive training and encouragement to communicate, who are asked to participate in process improvement, and who are given clear requirements will rise to the occasion.

Scott Ellis, Ed.D., delivers training, coaching, and resources that develop the ability to eliminate obstacles and sustain more eff ective and profi table results. He recently published Dammit: Learning Judgment Th rough Experience . His books and process improvement resources are available at workingwell.bz . AICC members enjoy a 20% discount with code AICC21.

BOXSCORE www.AICCbox.org 25 Leadership

USA MANUFACTURER WITH EXTENSIVE WORLDWIDE SERVICE AND SUPPORT Everthing Corrugated Under SUN Strong Leadership, Strong Partnerships, Strong Solutions Our Team Supports Our Commitment to Industry-Leading Customer Service and Support

Headline

BYLINE

Awards and Recognition So Many Chances to Be Recognized and Rewarded

AICC members have many ways to receive recognition for their achievements. Check out all of the ways your company can shine.

Packaging Design Competitions

The AICC Independent Packaging Design Competition features corrugated, folding carton, and rigid box categories, providing a wider reach into the entire packaging market and a greater diversity of ideas. Every four years, AICC’s Package Design Competition and TAPPI’s CorrPak Competition join forces for the Box Manufacturing Olympics.

Independent Safe Shop

The Independent Safe Shop awards recognize AICC member companies for outstanding performance in plant safety over the past year.

Innovator of the Year

The AICC and Board Converting News Innovator of the Year competition is designed to recognize innovative solutions

created by both AICC box plant and supplier members that enhance the efficiencies, productivity, product quality, and bottom-line profitability of the independent box plant. An Innovator of the Year is awarded every year in the fall in four rotating categories:

• Boxmakers

• Non-Machinery

• Machinery

• Information Technology and Training

AICC Champion Award

AICC created the AICC Champion Award, which will be given annually to recognize AICC members that have made outstanding contributions in furthering the Association’s membership. These efforts can include recruiting new members, retaining members who may need encouragement to maintain their membership, or contributing to helping member companies increase their engagement levels with the Association.

Member Milestone Recognition Program

AICC, through the Member Milestone program, recognizes member companies that, in the current calendar year, are celebrating significant membership anniversaries. Recognition is given each year during the AICC Spring Meeting. Learn more about AICC’s awards and competitions at www.AICCbox.org/ competitions.

BOXSCORE www.AICCbox.org 27

Work-Life Balance

A Leap of Faith

BY REBECCA RENDON

If you could live anywhere in the world, where would you choose? My answer to that question comes with no hesitation: Hawaii. The warm, tropical waters; soft sand; picturesque mountain ranges; and the aloha spirit are unlike anything else. As I’m writing this, I’m sitting on Lanikai Beach in Kailua on the windward side of Oahu. You may be thinking, “What is she doing writing this while she’s on vacation?”

Well, I decided to take a leap of faith and move to Hawaii with my 9-year-old daughter, Kennedy, for one year of adventure. Th is wasn’t a rash decision, rather something that had a great deal of meaning and purpose behind it, which continues to evolve every day.

The fi rst question people ask me when they hear this is “Why?” As a single mother who loves to travel with her daughter and works remotely, the question for me becomes “Why not?”

Obviously, there were plenty of legitimate reasons for not packing up and moving 4,500 miles away to the middle of the Pacific. We already had a comfortable, established life in Carmel, Indiana. We had just moved into a new house, with a big yard for our dog, and Kennedy was enrolled in a top-rated elementary school. Our friends and my mother lived nearby, and that was the place I called home for the past 25 years. What more could we want? Everything was comfortable and stable— except the Indiana weather. So, why not move to a place with daily rainbows and consistently sunny, 80-degree weather?

The decision to move was based off more than just unfavorable Indiana weather. I had this feeling deep in my

heart that there was more to life than settling for comfort and familiarity. I couldn’t help but feel like I was complacently accepting a life based on social norms and familial expectations, rather than a passionate pursuit of adventure and unchartered opportunity. At 33 years old, some people might call this a “pre-midlife crisis.” Call it what you will. I saw this as an opportunity to be brave, pursue a dream, and provide my daughter with some incredible childhood memories. So, why not take this leap of faith?

We had visited Hawaii eight months prior and fallen in love with the beauty of the land and the Hawaiian culture. However, this idea seemed like such a far-fetched dream that it posed a massive challenge. Th ankfully, I love a challenge.

Dreams are just goals without a plan, though, right? During the next month, I’d spend most evenings in deep thought, weighing the amount of effort and sacrifice required to make this happen versus the potential reward. This was also going to require a considerable amount of logistical planning—asking my boss for his support, deciding what to do with my house and car, transferring schools, getting our dog into Hawaii, telling friends and family, and actually making the 4,500-mile move to the middle of the Pacific Ocean.

If it’s meant to be, it will be. But it can never be if you don’t attempt it. Kennedy was excited and 100% on board. We’d move with our dog to the most remote chain of islands in the world, where we don’t know a soul, because why not? Th is would be a year of adventure, personal growth, and the ultimate test of faith and our own limits.

My goal was to provide us with an opportunity to embrace diversity, develop an appreciation for another culture, do good for the planet, and experience things that wouldn’t be possible in the confi nes of Carmel, Indiana.

After my boss at Kolbus gave his blessing, I started laying out a plan of action. I researched everything—best schools, safe areas to live, special Hawaii laws, etc. I felt confident in my plan, knowing that my daughter and I are resilient and could make it work for a year, in hopes of experiencing something wildly exciting and life-changing.

I decided to leave everything behind. We’d move with two suitcases each, bringing what is essential. There’d be no room for excess. We’d be forced to evaluate what was most important to us. I sold my 4-monthold car and moved my mother into my house in Carmel for a year so we could keep our things just as they are in Indiana and return home if needed. As a single mother, I had to be logical and have a backup plan. We visited Oahu for three weeks in May, with the goal of finding a place to live, buying a new car, and enrolling my

BOXSCORE November/December 202228 AICC Innovation

Rendon explores Black Sand Beach in Maui this past July.

Photo courtesy of Rebecca Rendon.

daughter in school. Check. Check. Check. We flew home for two weeks to get our dog, say goodbye to friends, and pack our suitcases.

On July 4, we embarked on this life-changing year. I vividly remember walking out of the Honolulu airport that day, apprehensively thinking to myself, “Oh wow, we’re actually doing this!” Reality was finally hitting me. I loaded up the car, sat there for a few minutes while I cried some anxious tears, and proceeded to drive to our new home in Kailua.

As I write this, we’re in our 11th week as Hawaii residents. We are soaking up the sunshine and aloha every day and have realized how little we actually need in order to be happy.

Life during the weekdays is pretty “nor mal.” Due to the time difference, I wake up early, often at 3 or 4 a.m., for business meetings with colleagues in Germany and the United Kingdom. I take my daughter to school and then wrap up my workday midafternoon. Kennedy is adjusting well and is loving “island life.” She joined the swim team and has quickly developed a love for surfing and all ocean-related activities.

We are assimilating to life in Hawaii and are making the most of every day here. There are still hard days when I miss friends and family, good Mexican food, or the comforts of home. However, those sad feelings are short-lived when I step into the warm, tropical water of Waikiki Beach to surf with my daughter, or when we come across a sea turtle or Hawaiian monk seal basking on the beach.

The biggest lesson I’ve learned so far: Be brave and take that leap of faith because there’s a chance it could turn out better than you could have ever imagined.

Rebecca Rendon is marketing and communica tions manager at Kolbus America Inc. She can be reached at rebecca. rendon@kolbus.com

BOXSCORE www.AICCbox.org 29

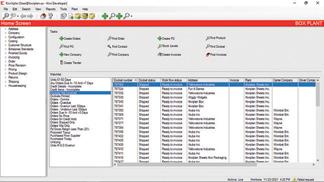

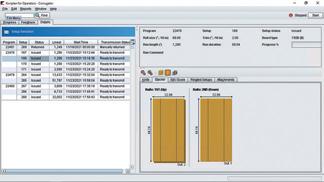

Arvco: The ‘Swiss Army Knife’ of the Corrugated Industry

BY STEVE YOUNG

BY STEVE YOUNG

George B. Arvanigian founded Arvco Container Corp. in Kalamazoo, Michigan, in 1967. But his journey was not a typical entrepreneur’s path into the corrugated box business. “My dad was kind of a unicorn in the industry,” says Greg Arvanigian, president and CEO. “He’s one of the few production guys that started his own business.”

‘He

Wanted His Own Thing’

George’s career path in the production side of the business began in the early 1960s in Worcester, Massachusetts, with Dowd Box. From there, he was recruited by Inland Container to run its Philadelphia plant. He eventually caught the attention of International Paper (IP), which was rapidly expanding its corrugated box operations in the 1960s in the South and Midwest. He was offered the position of production manager at IP’s Howell, Michigan, plant, eventually joining one

of his sheet customers, Grand Rapids Packaging, and its subsidiary Wolverine Packaging in Schoolcraft, Michigan, as vice president and general manager. Like many in the box industry at that time, the elder Arvanigian recognized the growing volume of available corrugated business signaled a great opportunity.

“He was at Wolverine [Packaging] about three years and got tight with a couple of sales guys and met a local banker,” Greg recalls. “He just wanted his own thing; he wanted to make corrugated boxes. That was in 1971.”

The company’s fi rst location in Kalamazoo had two Langston letterpress printer slotters, a slitter, bandsaw, and taper. In 1975, after another move to its current location near downtown Kalamazoo, George acquired a used Hooper-Swift 78" corrugator. He also opened a sheet plant in Warsaw, Indiana, in 1974 and a sheet plant in Northwood,

COMPANY: Arvco Container Corp.

ESTABLISHED : 1967

JOINED AICC : 1974 PHONE : 269-381-0900

WEBSITE : www.arvco.com

HEADQUARTERS : Kalamazoo, Michigan

PRESIDENT AND CEO : Greg Arvanigian

Ohio, near Toledo, in 1978. Following the bankruptcy of Grand Rapids Packaging in 1980, Arvco picked up a number of Grand Rapids Packaging’s salespeople, expanding its market reach north and leading to the opening of a sheet plant in Cadillac, Michigan, in 1982. The following year, Arvco moved its Northwood plant to Delta, Ohio, and added a corrugator, a move that Greg admits was not the best one for the company. “We didn’t invest enough in the plant to keep it economically viable,” he says.

In the meantime, though, Arvco was investing heavily in its Kalamazoo facility, adding a second corrugator—an 87"—and new Hycorr (now Kolbus) rotary die cutters. Then in 1989, George passed away. Greg, at age 28, became president of the company. Reflecting on the transition he had to lead at that time, Greg says, “as As happens with a lot of entrepreneurial guys

BOXSCORE November/December 202230 Member Profile

Photos courtesy of Arvco Container Corp.

Arvco President and CEO Greg Arvanigian and Maintenance Manager Chad Hawkins at the company’s Kalamazoo plant.

Arvanigian standing aside Arvco’s J&L 150" folder gluer.

that start businesses, the business grows and outgrows their ability to run it the way they want to run it.

Greg’s first task, as he described it, was to huddle with the company’s management team. “I called all the managers, and I say, ‘Guys, I’ve got a revelation for you: You’re managers; I expect you to manage. "I can’t do it the way my dad did,’” he says.

Greg taking the reins of the business in 1989 began a period of refocusing Arvco’s mission. The company’s capital equipment was aging, and the customer base—which was at that point largely automotive and consumer appliances—was also shifting. Arvco’s plant in Warsaw, which was built, in part, to serve the Whirlpool parts business in LaPorte, was hobbled by extensive capital equipment needs Greg in his new position could not immediately justify. “The big thing we looked at was our business mix at the Warsaw plant,” he remembers. “We did a lot of folding and gluing down there. Our biggest customer was Whirlpool for their parts boxes, and most of the other business we were running in Kalamazoo anyway. And Warsaw, 73 miles away, is not that far. So, we made the difficult decision to close that plant and put all our money back into the mother ship.”

‘Invert the Bell Curve’

The consolidation of Arvco’s production assets and the reinvestment in capital equipment began in earnest in 1994 with the retirement of its older 78" and 87" corrugating capacity and the acquisition and installation of its 98" Agnati/Fosber corrugator. “I say, ‘We’re going all-in, and we’re going to put in a new corrugator,’” Greg says. “It was the best thing we could have ever done.”

Arvco’s corrugator capacity serves a broad waterfront, with flute profiles A, B, C, E, F, and K in single-face and single-, double-, and triple-wall board. As Greg explains it, Arvco’s business mix at the time was heavyweight-based, with triple-wall applications and heavier containerboard grades. But its

broadening reach into the food and beverage business—Arvco manufactures 265 food packaging items and holds 10 food-related patents—required a machine with flexibility in emerging microflutes like E and F. “We were already in the food business, and so I needed a corrugator that could make triple-wall as well as lighter-weight microflutes,” he says. “The Europeans had a lot of experience with microflutes, so it’s one of the reasons I was steering toward Agnati.”

The company’s converting and fi nishing capabilities have mirrored the flexibility and diversity of the 98" corrugator. Arvco’s Kalamazoo plant maintains an impressive large-box and triple-wall capacity in its jumbo Flexoline 86" x 212", two-color flexo folder gluer, and its J&L 150" specialty folder gluer.

The company also maintains a stable of equipment suitable to the industrial box market, with its Langston Saturn III threecolor mini flexo and its Post 84" specialty folder gluer. In between is a complement of workhorse machines: Ward and Hycorr (Kolbus) rotary die cutters as well as enhanced-graphics rotary die cutters in Arvco’s two Apstar 66" x 110" four-color and its Hycorr 66" x 85" four-color. In Cadillac, a similar machine footprint can be seen in its Langston 50" two-color flexo folder gluer, Ward 66" x 85" two-color die cutter, and Hycorr 66" x 85" three-color rotary die cutters. Rounding out the equipment mix are a Göpfert MAXI boxmaker, a Bahmüller stitcher, and a DPI three-color digital printer.

About Arvco’s broad business mix, Greg says, “We want to sell the stuff that nobody else wants to sell. If you were to look at our mix, take the bell curve of the corrugated industry where ultralightweight is on one end and super heavy triple-wall is on the other end. Invert that bell curve, and you have an Arvco.

“When it comes to doing something with a corrugated box,” he adds, “we do more stuff on-site than anybody else in the world. I don’t know anybody else that

does what we do. And we’re constantly trying to move that along.”

Trying to move that along requires continual investment, and Kyle Baldwin, Arvco’s chief fi nancial officer (CFO), attributes the company’s success at procuring the right equipment to Greg’s gut feel for what will work. Says Baldwin, “He defi nitely has more of that entrepreneurial spirit when it comes to capital expenditures and investments.”

“I make educated guesses,” counters Greg. Greg’s “educated guesses” serve a unique but evolving mix of business. The company’s market has ebbed and flowed through an eclectic mix of government, automotive and industrial, and food and beverage. “We’re very diversified,” he says. “We actually do a fair number of government contract boxes like weather resistant, Class-2 triple-wall, etc. We’ve always done government work.”

Arvco is also a principal player in the pizza box business, a piece of the market brought to the company in the 1970s by Steve France, one of the company’s sales representatives at the time. Today, that business represents 45% of Arvco’s production. “Steve basically focused on selling pizza boxes,” Greg recalls. “He went out and bought cutting dies. We did a couple of marketing pieces, and we trademarked the name, ‘Pizza-tainer.’”

As Greg explains, Arvco’s focus on the food business balanced the highs and lows of industrial and automotive sectors.

“The food business—it’s a hedge,” he says. “When the economy changes, the food business gets good when the industrial business doesn’t. People realize they can feed a family of four for $20 when they order a pizza. Where else can you do that? So, that helps us get through a lot of these downturns.”

Arvco’s specialization in pizza has expanded into other styles of convenience packaging for other kinds of fast-food outlets selling chicken and sandwiches. Giving one specific example, Greg described the on-site packaging space savings they

BOXSCORE November/December 202232

Member Profile

achieved for Subway by transitioning from E flute to F, allowing twice as many packaging units to be held in-store.

People, Family

Like many an independent, Arvco has a family feel to any visitor touring the plant. The company employs around 220 people full time. Citing longtime employees who have been with the company 20, 30, or 40-plus years, Greg says, “We treat people like people. It’s a culture thing. We treat people with respect; we treat people well.”

Arvco has had its share of difficulty finding good employees, just as others in the industry. But the company also takes pride in not laying off employees for economic reasons. “I have never economically laid anyone off in the 30 years I’ve been here,” Greg says. “My job is to make sure they’ve got something to do, so we don’t believe in layoffs. It’s one of the advantages we have.”

To attract and keep the valuable employees it has, Greg is studying a pilot project to pay for an associate degree at a local community college. “I was talking to one of my customer service reps the other day, and she has a son who just graduated from high school,” he says. “He can’t afford to go to college, so he’s going to get a job for a while and try to save money for college. I thought, ‘There must be a lot of kids in that boat. What if we offer to pay for an associate degree at community college if they come to work here?’”

Greg sees this as an answer to the aging of his workforce and the need to attract younger, more motivated workers. Says Greg, “I think the talent level will get better because you’re going to be attracting people who are aspiring to go to college and better themselves.”

Team for the Future

If the workers at Arvco feel like family, imagine how family at Arvco feels like family. As the second generation of Arvco ownership, Greg has followed his father’s model of bringing in his sons to the business.

Nicholas Arvanigian, Greg’s younger son, is a sales representative for the company. Alex Arvanigian is vice president of operations, a position he has held since 2018. Says Greg, “When Alex was a kid, he played competitive hockey at a pretty high level, and I used to tell everyone, ‘Alex is the guy you want on the ice at the end of a 1–0 game.’ He’s cool under pressure; he doesn’t get fazed. Th at’s a really good trait to have in our business.”

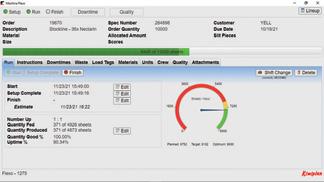

Alex’s view of the business is on the production floor and the issues converters face there each day. “I oversee production between here and Cadillac, shipping, maintenance, all of it,” he says. “The biggest challenge now is fi nding ways to get more out with fewer people—fi nding ways to automate simple processes.”