MESSAGE FROM DEAN HAHN

MESSAGE FROM NANCY BERGE

PROJECT DESCRIPTIONS

ENGINEERING DEGREE PROGRAMS

ACKNOWLEDGMENTS

THANK YOU TO OUR SPONSORS

THANK YOU, MENTORS & STAFF

DESIGN TEAMS

For the first year ever, students have access to a dedicated design center.

Craig M. Berge Design Day is a story of remarkable student success and the ways engineers improve lives.

We have much to be thankful for this year, including a dedicated Engineering Design Center for students, which bolsters the college’s commitment to experiential learning over all four years. Every engineering student now has 24-7 access to a spacious, well-equipped, safe place to collaborate and build.

Our seniors are thrilled to tell you about their projects. Not only are the designs a testament to their technical agility and creativity, but also the projects show why the college’s graduates are highly sought after in industry and government.

Students worked on ways to make mining and farming more sustainable: 3D-printed construction materials from tailings, an autonomous spider for collecting agricultural data, algae to reduce greenhouse gases, and solar energy covers for canal water evaporation. Teams developed a basketball shooting robot and an interactive model of the Tucson power grid to educate children. They created a haptic imaging device for blind scientists and airplane controls for armless pilots. They designed ways to keep people and animals safer – a drone to monitor wildfires, throw phone for hostage negotiations, and pet and livestock tracker, to name just a few. There are medical devices, robots for space exploration, and wastewater recycling projects, not to mention a BattleBot!

If you miss anything at Design Day, you can still learn about the 99 projects online in the students’ presentation videos, which will be available following the awards ceremony, where $47,000 in prize money will be presented.

Design Day and the Interdisciplinary Capstone Course are part of a lineup of competitions, maker fests, design courses, entrepreneurial and business instruction, and industry and community projects in the Craig M. Berge Engineering Design Program. The program immerses undergraduates at all levels in real-world experiences that integrate design, manufacturing and commercialization.

None of this would be possible without all the hard work behind the scenes. We are grateful to the donors, program mentors, university and industry partners, sponsors, judges, faculty, staff and alumni who help make the program and event a highly successful enterprise.

A special thank you to Nancy Berge and her family for their generosity, and to Larry Head, director of the Craig M. Berge Engineering Design Program, for his dedication to this unparalleled experiential learning and design curriculum in higher education.

Bear Down, and support our Wildcat engineers!

David W. Hahn

David W. Hahn

I love Design Day! It’s the best day ever to see our future. Our future in technology and our future in engineers who will make that technology a reality.”

MARLA PETERSON, alum, judge, Honeywell

The LightBrush

Feeding the Future: Student-led Design at the Nexus of Food, Energy and Water

AIAA Design/Build/Fly Competition

Let’s Boil a Computer Again!

Automated Universal Part Singulator (AUPS)

Throw Phone for UAPD/FBI Crisis Negotiation Team

Optical Scatterometer

Battery Powered Remote Communications via Cost-Effective Satellite Links

Medical Grade Leak-Proof Spigot For Diagnostic Reagents and Waste

Wireless Emergency Lighting System (WELS) Battery Tester

Large Tractor Ladder Latch Design

Cytology Slide Prep and Vial Storage System

Airfoil Cascade Hub Injection II

Mobile Reagent Filling System

Fluid Volume Measurement on a Microscope Slide

Launch Vehicle Ground Support Equipment Frontend

Novel Inspiratory Muscle Strength Training (IMST) Device

Autonomous Mechanical Spider (AMS) Platform for Crop/Turf Management

Autonomous Maintenance Identification Vehicle

Virtual Subject Matter Experts (SME) Training, Critical Asset Control

Telemetry and Data Logging System for the Wildcat Formula Racing Car BattleBots

My Health Navigator

Mechanical Energy Storage System

Automated Oil Dispenser

Pulsed Detonator Ignition System Optimization

Live Silage Analyzer and Mini-Fermenter

Arch Reactivator Brace

Comprehensive Modeling of Beam Propagation in Multimode Fiber and Experimental Validation (Year 2)

Vision-Based Agricultural Implement Awareness

Cyclesafe: An Automobile Proximity Sensing, Warning and Reporting Device for Bicycles

Broadband Tunable Fabry-Perot Spectrometer for Remote Sensing

Rotating Detonation Engine Heat Management System

Spin Balance Mechanism

Directed Energy Deposition (DED) Repair With Integrated Machining

Lightning Protection Garments for Injury Prevention

Smart Medical Drainage Catheter

Design of Remote-Controlled Automation of the Transformer Bioreactor (T-Bioreactor)

Mirror Distortion Measurement

Airplane Controls for Armless Pilots

Pressure Sensing Self-Regaining Retractors

An IoT-Based System for At-Home Behavioral and Physiological Health Interventions

Atto-Grid

SIPhTR: Small Item Photographing Triage Robot

REDIEM 2.0 – Renal Extremity Device to Measure Impedance, Edema and Movement

Sustainable Building Materials Using Mine Tailings

Miniature Animal Health Status Tracker (MAHST)

The Wired Room - Automated Digital Sound, Image and Motion Analysis for Enhanced Medical Diagnostics From a Patient Encounter

Ultra-Low Power RF Communication for Industrial IoT Sensors

Row, Row, Row Your Trike Gently Down the Street

Perio-Dx: Bad Gums = Bad Kidneys + Bad Heart

AQUABOT C3 - Aquatic Drone Coordination, Communication and Control

Snorpheus

Automated PVC Tube Winding

Smart Rocks - A Network of Covert Smart Sensors (Joint UArizona UMass Project)

Basketball Shooting Robot

Mixed Reality (MR) Diagnostic and Treatment System

Lunar Surface Transporter Vehicle (L.V.S.T.) - Team 1

Evaluation of Tensegrity Telescopes for Small Satellites on Asteroid Recon Missions

ElectroDose: Wearable Sensor for Quantitation of Pulsed Electromagnetic Therapy (PEMF)

Supplement Recommending Mobile App with Handheld Measuring Device for Saliva

pH and Calcium Levels

Understanding the Normal Aging Brain So That the Puzzle of Alzheimer’s Can Be Solved

Autonomous Robotic Racecars

PODBot Print on Demand Robots

STAR - Short Term Aerial Recognizance

Desktop Automated Powder Processing Station

Biomedical Sensor Board

Spacecraft Platform at L1 for Future Space Development - Team 1

Lunar Surface Transporter Vehicle - Team 2

Spacecraft Platform at L1 for Future Space Development - Team 2

Tissue Therm: Testbed System for Analyzing Thermal Effects of Pulsed Electromagnetic Therapy on Tissues

Flowing Robotic Surface - Haptic Imaging Device for Blind Scientists

Autonomous Mine Design

Vumbula Resources - Optimizing Geological Exploration in Uganda

SME Metallic Mine Design Competition

Railveyor

Spatial Exploration with Robotic Operators (SpERO)

Support Aerial Incendiary Locator (SAIL)

Irrigation Water Requirements Forecast Tool

Biofuels from Lignocellusoics

AZ Water Competition: Rainbow Water Reclamation Facility

Expansion Project

Liquefied Natural Gas (LNG) Receiving Terminal

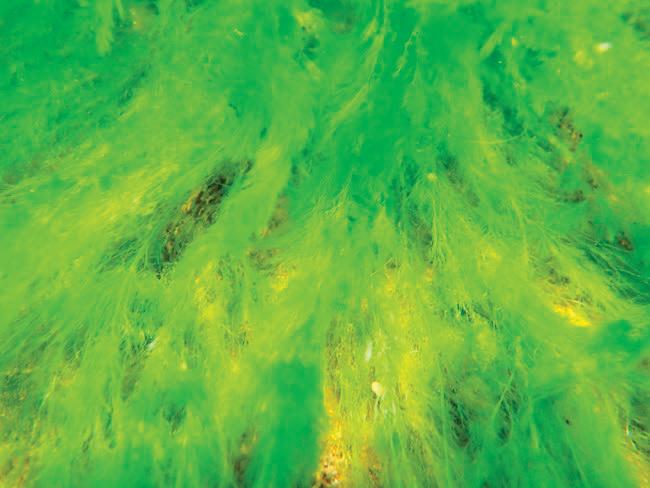

Algae Photobioreactors for Carbon Dioxide Removal

Microbial Electrolysis Cell for Hydrogen Production and Electricity

Generation

Solar Panels Over the Central Arizona Project (CAP)

Bio-Aviation Fuel

Wafer Rinse Chamber Ultrapure Water (UPW) Recycling Stream

Dial-Assist

Perfume Manufacturing Process

Re-injection & Extraction Process for Simulated Crude Oil Plant

In-House Foam Part Production

AZ Water Competition: Rainbow Valley Water Reclamation Facility

Expansion Project

Bioplastic Synthesis Using Organic Waste Material

Dealcoholization of Red Wine Using Osmotic Distillation

It’s our dream, and we’re going to go and make it happen together. It’s going to be very exciting to see.”

YOUSUF CHOUDHARY, member of the BattleBots team

This award recognizes the project that embodies the best attributes of engineering design and the engineering profession. The winning project shall have an outstanding design approach and implementation, excellent system modeling and/or analysis that support the design, comprehensive system testing that verifies system requirements, and a superior presentation of results to Design Day judges. Team members of the winning project shall present themselves professionally and clearly demonstrate engineering knowledge of the design. The winning project shall clearly be the best project at Design Day.

While several designs may meet the judging criteria, this award is given to the design that does so the most effectively. The project that receives this award excels in many ways. The design is well thought out and its implementation is of high quality. It accomplishes all key design requirements and is supported by rigorous analysis and testing. Its poster and presentation are professional and easy to understand.

- $1,000)

This award recognizes the best project related to sustainable, cost-effective and environmentally friendly energy production, distribution or use. Winning projects could focus on developing new energy sources, reducing energy costs, improving efficiency or reducing cost of energy distribution, adapting existing energy distribution methods to better integrate new energy sources, and increasing efficiency of energy use.

Software has become an integral part of the operation, management and control of complex systems comprising mechanical, electrical, and optical elements. This award recognizes the best use of software in a system design to enable task automation, object recognition, system robustness, data collection, or other impressive features that would be difficult to achieve without software. Teams will be judged on the reliability, robustness, maintainability, reusability, originality and testability of software embedded in their designs.

The Systems Engineering perspective is based on systems thinking. When a system is considered as a combination of system elements, systems thinking acknowledges the primacy of the whole (system) and the primacy of the relation of the interrelationships of the system elements to the whole. This award goes to the team that most robustly addresses all aspects of the project from the systems perspective.

The French philosopher Voltaire is credited with the saying “Le mieux est l’ennemi du bien,” which means “the best is the enemy of the good.” Similarly, Leonardo da Vinci is credited with the saying “Simplicity is the ultimate sophistication.” This award recognizes the design team that best emulates these ideals and resists the temptation to overly complicate the design to yield a clean, simple, elegant, lowest-cost design that simply works well.

This award recognizes the most innovative use of optoelectronics and optomechanics in a design and is given to the team that demonstrates the most thorough approach to the design and engineering of its optical system. This award recognizes complete understandings of the optical design, system requirements, tolerance analysis, and optical component usage. Important criteria are integration of optics into the overall system, novel use of optical components, creative use of commercial off-the-shelf items, verification of optical components, meeting system requirements, use of standard optical design software, and manufacturability of optical design and components.

Rincon Research Award for BEST PRESENTATION ($1,500)

This award reflects the quality of the overall verbal and poster presentations. Verbal presentations should be well structured to describe efficiently the overall problem being solved and the specifics of how the team accomplished its design. Answers to questions should be direct and demonstrate mastery of the project. Presenters should speak in a clear and easily audible voice, making good eye contact with the judging pod. The poster board should be visually interesting and graphically well organized to tell a standalone story of the project.

($1,500)

This award recognizes a design solution that goes above and beyond the project design requirements and produces results that may impact and/or be useful for other products and applications. Teams competing for this award must show that they have met all project design requirements and have produced an innovative solution that may lead to other products or applications. Solutions that are sufficiently innovative for a potential patent application and that may form the basis of a new start-up will be given special consideration in the selection process.

($1,500)

Innovation may include the novel use of existing components or the creation of entirely new components to meet customer requirements. The most innovative design will not only be a creative solution to a problem but also an effective solution that is well implemented. This award recognizes the team that has created or made use of components in the most innovative way, or demonstrated excellence in the implementation of innovative design in its project, or both.

($1,250)

This award honors a student team that has improved or enhanced the quality of life for individuals through the outcome of their project. It recognizes the improved standard of health, comfort, environment, community, and happiness experienced by an individual or group. Projects are judged on the ability to promote the well-being of humans through togetherness and the practicality of the implementation. Teams should be able to effectively communicate their design and how it will improve lives.

Steve Larimore Award for PERSEVERANCE & RECOVERY ($1,250)

Issues and roadblocks always occur during the engineering design process. Although they cause panic and distress, they also represent great opportunities to learn and often lead to designs that would otherwise be impossible to conceive. This award recognizes a team’s ability to learn and to overcome issues or roadblocks encountered during the design process. The award is judged based on the ingenuity of solutions to problems caused by issues or roadblocks and the features in the final design that contribute to recovery from them.

Mark Brazier Award

Biomedical engineering is a discipline that advances knowledge in engineering, biology and medicine, and improves human health through cross-disciplinary activities that integrate the engineering sciences with biomedical sciences and clinical practice. This award recognizes the team the has demonstrated excellence and innovation in biomedical engineering design. It recognizes outside-the-box thinking that pushes boundaries and hands-on approaches to creative solutions. Projects are judged on the elegance and creativity of the technical solutions and their implementation. Teams should be able to communicate effectively their design and the processes they use for creativity.

This award goes to the team that best considers the needs of the end user/client. The team should demonstrate that they considered the end user’s needs throughout the design process. The team should have a list of end user concerns and show how they addressed them. Many times, a physical prototype is created to understand and study the fit, form and function of the device or system and usability testing is conducted with a sample group of end users to validate or improve the design. Teams are judged on the appropriateness of the prototyping used, how effectively prototyping is used to improve the design, and how well the needs of end users are considered. Prototypes can be made using rapid fabrication technology, traditional manufacturing, or can be hand built.

Successful implementation of any innovative design requires that all members of the design and production team communicate effectively. Design intent must be communicated from the design activity to the rest of the team using design documentation with a clear map for others to reproduce the design based on documentation only. The mechanical portion of the design is evaluated on the use of drawings with geometric dimensioning and tolerancing, solids models, illustrations and presentations that can be used to manufacture and inspect design hardware. Software and other systems are evaluated on the use of documentation that clearly and fully describes the system and illustrates the approach to testing.

This award recognizes the single-discipline design team that best demonstrates external team collaboration. Like real-world problems, senior design projects require skills from multiple sources and students should learn the value of leveraging the strength of a diverse team as well as seeking out external guidance and support to succeed. These skills are foundational to a successful engineering career.

This award recognizes the team that best executes project design using a flexible and incremental approach. Final project outcome is achieved through several test and evaluation iterations in collaboration with the customer. The project team should continuously review and assess results and quickly adapt to any changes or problems encountered.

IEEE is the world’s largest technical professional organization dedicated to advancing technology for the benefit of humanity. IEEE and its members inspire a global community through its highly cited publications, conferences, technology standards, and professional and educational activities. IEEE is a leading developer of international standards that underpin many of today’s telecommunications, information technology, and power-generation products and services. This award recognizes the team that best shows the standards used in their project and how the use of those standards facilitated or improved their overall design and/or its performance outcome.

The Mensch Prize for Best Use of Embedded Intelligence recognizes the engineering innovation team that best integrates embedded intelligence into a potential commercial product. Specifically, the award will be granted to a student team that has built a smart connected prototype that may have a commercial market. Embedded Intelligence is characterized as the ability of a product to sense, process, communicate, and actuate (SPCA) based upon information gained from an understanding of both itself and others and for the benefit of many. Preference will be given to designs with SPCA capabilities that can demonstrably surpass human abilities to perform the same function.

This award recognizes the interdisciplinary team that creates the best video telling the project story. The video must capture the sponsor’s need, the process the team followed to develop the solutions, the final solution including test and evaluation, and how it meets the sponsor’s needs.

This award recognizes excellence in overall system design in a project that has an aerospace emphasis. Verbal presentations should be well structured to describe effectively the overall system and the specifics of how the team implemented its design project. A key feature of the presentation must be representative data that demonstrate how the system was thoroughly tested. Answers to questions should be direct and demonstrate a high level of team competency about the details of the electronic system for the project. The presentation should demonstrate how all members have contributed to the project to exhibit core values of teamwork and professionalism.

This award recognizes excellence in overall mechanical system design in a project that has an aerospace emphasis. Verbal and written presentations should be well structured to describe effectively the overall system and the specifics of how the team implemented its design project. A key feature of the presentation must be representative data that demonstrate how requirements were analyzed, documented, designed against and tested. Answers to questions during the presentation should be direct and demonstrate a high level of team competency about the details of the mechanical system for the project. The presentation should demonstrate how all members have contributed to the project to exhibit core values of teamwork and professionalism.

Phoenix Analysis & Design Technologies Award for BEST USE OF PROTOTYPING ($750)

This award goes to the team that best uses a physical prototype model to understand and study the fit, form and function of the device or system designed. Teams are judged on the appropriateness of the prototyping technology used, how effectively prototyping is used to improve design, and how effectively the use of prototyping is communicated. Prototypes can be made using rapid fabrication technology, traditional manufacturing, or can be hand built.

The Fish Out of Water award congratulates students for successfully accomplishing a task that was not in their realm of expertise. The projects for senior design require skills from many disciplines, and students must sometimes learn a new subject or skill in an area outside of their major to help the team succeed. A student who not only learns this new subject or skill, but also uses it to effectively help the team thrive, shows dedication and initiative, gains that will continue to help in an engineering career.

This award recognizes the design team that best implements a modern data acquisition and control system. Recognition is given for the use of the system to collect data that characterizes project performance and assists in project optimization and, ideally, uses the same data acquisition system to perform feedback and control operations.

L3Harris

($500)

Some engineering problems are straightforward: optimal solutions are found through the application of engineering best practices. Sometimes, however, the best design choices are not obvious, and only reveal themselves after a thorough analysis of the underlying physical principles. This award recognizes a design that could only have been arrived at after careful study and creative application of physics.

Simpson Family Award for BEST SIMULATION AND

This award recognizes the project that makes the best use of computer-based simulation or modeling. The simulation may be the project itself, or a design tool used to model the performance of the project design. Criteria for this award is based on scope of the simulation, the fidelity of the simulation compared to real-world performance, and the engineering judgement exercised in determining the complexity of the model.

Frank Boyles Award for BEST UAS DESIGN ($500)

This award recognizes the unmanned aircraft systems (UAS) project with the highest quality of design and construction that succeeded in, or made a good attempt to, achieve the sponsor objectives.

Ergo Dave Award for BEST USE OF HUMAN FACTORS ENGINEERING ($500)

This award recognizes the team that makes the best use of HFE (human factors and ergonomics) design principles (understand, design, evaluate) iteratively. The winning team will provide evidence that they collected and understood both tasks and users, and showed significant reduction of fatigue and workload to users.

AZ

This award is given to a team whose system goes beyond sponsor requirements and best considers usability and manufacturing readiness. Teams will be judged on whether they did the following: considered alternative designs and selected the best choice; met or exceeded sponsor requirements; considered producibility, ease of assembly and cost; considered reliability and maintainability in both prototyping and build phases; considered user operation and included operator instructions; and included a complete design technical data package.

This award is given to the team whose design incorporates the most innovative manufacturing method addressing reduced carbon emissions. Projects could include introducing a new technique for manufacturing or an innovative use of an existing technique that reduces the cost and improves the quality of a product while reducing carbon footprint.

This award recognizes students who best exemplify teamwork skills, including the ability to work cooperatively with others to produce high-quality work, to take the initiative, to support and respect the opinions of fellow team members, to give and receive feedback, to demonstrate effective leadership, to keep their team focused, and to elevate the work of their fellow team members. Nominees for this award are selected by their teammates.

Thank you to everyone who has participated in this wonderful event, the Craig M. Berge Design Day which bears our family name. My family and I are delighted to see and learn about your design projects. They are truly outstanding.

Much of my husband’s life and engineering career was all about designing. As a student, he built and designed his dragster. Later in life, as a mechanical engineer, he worked for a company that paid for his education. The company loaned him to the U.S. Navy to design the starter for a jet airplane named the Intruder. That plane is on aircraft carriers to this day. Knowing that the Navy is still using something he created is truly remarkable.

My husband would expect remarkable things from each of you, too. He would be so proud of your creativity and all you have accomplished.

In my husband’s memory, I am honored to support the Craig M. Berge Engineering Design Program and these student experiences that move you toward the next chapters in your lives and careers.

All the Best,

Nancy Berge

It brings me a lot of joy being able to work with students on real-world problems.”

NITIN PATEL, alum and Caterpillar project advisor

“

Improve oral health and surface appearance of the oral cavity using LEDs.

For those who have mental or physical limitations or aversions to traditional toothbrush use, photodynamic therapy can improve overall oral health and decrease plaque bacterial colonization. This project presents a waterless, bristleless alternative to traditional mouth cleaning devices. It allows the user to select a light mode for three individual LED treatments using blue light, red light or a combination of the two.

The LightBrush design uses an Arduino Nano Every microcontroller to power the high-wattage LEDs, which are located on a custom-designed printed circuit board in the head of the brush. Custom code controls the LEDs according to the selected light mode, and it delivers a specific lux dosage amount over a set treatment time. For safety, an accelerometer ensures the user or caregiver is properly holding the LightBrush and automatically shuts off the device when the LEDs are shining upwards, preventing ocular damage. A piezo buzzer notifies the user when the treatment begins and is completed to prevent light exposure outside of the mouth. The lithium polymer battery can be recharged when voltage is low. The team 3D printed a prototype of the LightBrush to verify functionality of the complete system. Further research into potential environmentally sustainable materials for large-scale production of the device was also completed, and instructions for use were developed for customers.

Team 23014

Design an agrivoltaic system to provide power to the Greenery S Freight Farm at Biosphere 2 and create a functional demonstration model.

The project team developed an agrivoltaic system design and established solar production estimates to determine the renewable energy off-set for the Freight Farm located at Biosphere 2. Additional goals included structural design, operational guidelines, design of a secondary freight container to house electronics for the solar components, and a functional model. The design can work in any offgrid system located in arid regions where there is no or limited electrical grid connectivity.

The agrivoltaic system consists of 61 solar panels, a structural support system for the panels and an electrical system that controls the flow and storage of energy. While the team built a functional, smaller-scale prototype, they also created various models and electrical diagrams, worked with structural applications, and performed calculations to verify the full-scale design. The demonstration model incorporates the key components of the Freight Farm-Agrivoltaic System, including a structural assembly, electrical and solar components, and system monitoring.

TEAM MEMBERS

Ismael Ballesteros, Electrical & Computer Engineering

Jazmine Barraza, Engineering Management

Natalie Hall, Biomedical Engineering

Haley Renee Johnson, Biomedical Engineering

Fernando Romero, Industrial Engineering

Sovenna Emily Thorn, Systems Engineering

COLLEGE MENTOR

Mike Nofziger

SPONSOR ADVISORS

Shoshi Almog, Judith Macias-Harris

TEAM MEMBERS

Brooke Elizabeth Bykowski, Engineering Management

Lynn Carroll, Biosystems Engineering

Logan Eaton, Electrical & Computer Engineering

Stephanie Beatrice Orchard, Biosystems Engineering

Alejandro Quijada, Mechanical Engineering

Hailey R Schleining, Biosystems Engineering

COLLEGE MENTOR

Michael Madjerec

SPONSOR ADVISOR

John Adams

TEAM MEMBERS

John Roger Allen, Aerospace Engineering

Charles James Fischer, Aerospace Engineering

Keegan Kelaher, Aerospace Engineering

Kyle Ryan Peabody, Aerospace Engineering

Aidan Petrie, Electrical & Computer Engineering

Will Wong, Aerospace Engineering

COLLEGE MENTOR

Sergey Shkarayev

SPONSOR ADVISOR

Adrien Bouskela

Team 23015

PROJECT GOAL

Create a unique radio control aircraft that will compete in the American Institute of Aeronautics and Astronautics (AIAA) international Design/Build/Fly (DBF) competition.

The annual AIAA DBF competition is an international event, hosted in Tucson and Wichita, Kansas, that invites schools from all over the world to design, build and fly an aircraft according to the design requirements that are set each year. Each team must attempt to maximize their possible points earned via scoring guidelines set by the competition. Flight envelope attributes such as endurance, speed and payload weight must be balanced accordingly to create an aircraft that will obtain the highest score.

This year, the schools were tasked with designing an aircraft that is capable of flying three missions, each with their own stipulations. Based on the scoring and competition guidelines, this design must be able to carry a heavy internal payload, mount a vertical antenna to one wingtip and have an endurance of around eight minutes. In addition, the aircraft must be able to disassemble and fit into a box that is compliant with FAA carry-on regulations, limiting battery size and aircraft dimensions. By employing computational fluid dynamics, advanced composite building techniques and rigorous aerodynamic design processes, the University of Arizona team developed a competitive aircraft to represent the school on the international stage.

Team 23016

TEAM MEMBERS

Jesus Arias, Electrical & Computer Engineering

Chris William Bremser, Electrical & Computer Engineering

Sean Brown, Systems Engineering

Prasanna Raut, Mechanical Engineering

Rusty D Rinehart, Electrical & Computer Engineering

COLLEGE MENTOR

Bob Messenger

SPONSOR ADVISOR

Nicholas Keehn

PROJECT GOAL

Create a two-phase immersion cooling and filtration system with Fluorinert to significantly reduce computer server farm power and water usage.

The rapid growth in smartphone usage has led to a surge in demand for cloud services. Major data centers, which store information for cloud service providers, have replaced traditional local computer storage with large data storage facilities. These facilities require a huge amount of energy to power and drinkable water is used to keep them cool.

To address these issues, the team designed hardware and software to cool the computer servers using FC-72 Fluorinert as an alternative to current swamp cooling forced air systems. Flourinert was selected for its low boiling point of 132.8 degrees Fahrenheit. They also designed a custom filtration system to reduce and mitigate dendritic salt growth, which can lead to electrical shorting. This system eliminates vulcanizers and plasticizers that cause the damaging growth.

The team built a test system for data center applications, which required finding a suitable pump that handles the low boiling point and low viscosity of Fluorinert. Finally, they created an interactive graphical user interface to allow technicians to monitor cooling system efficiency. The team then measured progress toward the goal of reducing power and water consumption.

Team 23017

Design and build a flexible part feeder with a cartesian robot and high-resolution camera for use in automated assembly lines.

With millions of dollars being spent on tooling for automated assembly lines, companies are relying more on reconfigurable part feeding and sorting mechanisms to save costs. This project provides a solution by being easily adaptable to any assembly process without compromising effectiveness or reliability.

The AUPS consists of a cartesian robot, a high resolution camera, a gripping mechanism and a vibrating table. The robot is controlled using the CtrlX Machine Controller developed by Rexroth and an Arduino is used for controlling the sensors and gripper. Parts are fed manually onto the vibrating table, where the camera identifies and locates them, allowing the robot to travel, pick up and sort them correctly. If no parts are detected, the system uses the vibratory table to disperse parts until the camera can locate one. The gripping mechanism is attached to the end of the Z-axis of the robot and is capable of handling parts between 2-10 cm3 with a weight limit of 0.5 kg.

The system can automatically sort parts based on their shape and size. It is designed to operate in an enclosed factory floor environment and is therefore shielded from external interference with a metal frame and acrylic walls.

Team 23018

supported by Craig M. Berge Dean’s Fund

Deliver a rugged, reliable and secure audio-visual communication system for law enforcement to negotiate with hostage-takers and de-escalate situations.

During hostage situations, SWAT teams toss “throw phones” into buildings and encourage hostage-takers to initiate communication with a negotiator at a remote command center. These phones must be rugged, reliable and provide clear communication. However, the current 20-year-old system is hard-wired, cumbersome and intimidating to hostage-takers.

The team has advanced the technology to a more robust, reliable and friendly wireless solution. The solution consists of two major components, the throw phone and the command module. The design utilizes a 4G cellular network to ensure wireless connectivity and full-duplex communication across long distances. Low-light cameras controlled by a multiplexor provide video surveillance of the phone’s surroundings. Audio and video data is wirelessly sent over antennas, processed by a Raspberry Pi microcontroller and recorded onto a micro SD card capable of storing over six hours of audio and video footage. The data can then be quickly uploaded to an external thumb drive. All the components are contained in hard and soft plastic casing that is rugged enough to withstand throwing through windows.

Results of the project have shown the system provides real-time audio and video and a clear line of communication from as far as 300 feet for up to six hours. The device has proven to be nonintimidating to focus groups, which invites users to pick up and handle the phone without worry.

TEAM MEMBERS

Abdullah Albar, Systems Engineering

Kevin Dennis Gilman, Electrical & Computer Engineering

Nafisul Huq Khondaker, Electrical & Computer Engineering

Daniel Mack, Mechanical Engineering

Anthony Phillips, Optical Sciences & Engineering

Esmeralda Pimentel Enriquez, Mechanical Engineering

COLLEGE MENTOR

Pat Caldwell

SPONSOR ADVISOR

Brett Dooley

TEAM MEMBERS

Tanner Birecki, Optical Sciences & Engineering

Reid Clark, Industrial Engineering

John Paul LaRue, Electrical & Computer Engineering, Mechanical Engineering

Thaddeus Propper, Mechanical Engineering

Marcus Tal Wieser, Mechanical Engineering

COLLEGE MENTOR

Jeff Scott Wolske

SPONSOR ADVISOR

Joseph Berriman

TEAM MEMBERS

Nate Thomas Bushong, Systems Engineering

Daulton R Fox, Optical Sciences & Engineering

Ethan Lance Potthoff, Electrical & Computer Engineering

Will Reynolds, Optical Sciences & Engineering

Chase A Toncheff, Optical Sciences & Engineering

Rachel R Turner, Optical Sciences & Engineering

COLLEGE MENTOR

Mike Nofziger

SPONSOR ADVISOR

Benjamin Cromey

Team 23019

PROJECT GOAL

Build an optical scatterometer that measures how light interacts with the surface of a material.

Light scatters differently as it interacts with varying surface properties. Scattered light poses a problem for optical applications as it contributes to undesired stray light reaching the focal plane of a system. Understanding how light scatters helps predict stray light paths and prevents them from compromising system performance. To further this goal, the team designed an inexpensive optical scatterometer to measure the light scattering properties of a material.

The device shines a laser through an optical system which outputs a converging chopped beam onto a test sample and accurately measures the scattered power emitted as a function of angle in the plane of incidence. The focused spot is incident on a high-sensitivity detector, processed through a variable-gain transimpedance amplifier built from scratch, with noise reduction utilizing a lock-in amplifier. Recorded data are then plotted as a bidirectional scattering distribution function (BSDF). The BSDF characterizes the scatter distribution of optical radiation from the test surface, facilitating the analysis and mitigation of stray light in the system.

Team 23020

TEAM MEMBERS

Rahul Chowdhary, Electrical & Computer Engineering

Isabel Mary Dailey, Electrical & Computer Engineering

Carson Hayes, Electrical & Computer Engineering

Benson Hsieh, Engineering Management

Jeffrey T Sillers, Engineering Management

COLLEGE MENTOR

Pat Caldwell

SPONSOR ADVISOR

Randy Montgomery

Study the feasibility and relationships between satellite links and battery powered systems in order to design and optimize a system to control and monitor remote irrigation systems.

Traditional wired irrigation systems come with many challenges, including costly components, such as wiring, installation, maintenance and troubleshooting. With wireless technology, command and control is possible via a low-cost satellite network provided by Swarm Technologies. Battery powered devices allow the system to operate in any environment, regardless of access to external power sources.

The design includes a mobile application capable of connecting with an end device that communicates wirelessly to the irrigation equipment using a hub and spoke model. The mobile application uses various parameters to control and configure a remote irrigation system via the Swarm satellite network. The end device consists of a microprocessor, modem, antenna and power system. Fueled by a solar panel and batteries, it manages and monitors its own power capacity via intelligent wake and sleep cycles. A power model anticipates other energy sources such as hydroelectric. The team developed embedded software to communicate via Swarm satellites back to the hub and control irrigation rotors locally. The system can wirelessly connect to multiple irrigation rotors, where each rotor can be scheduled to turn on and off at specified times.

Team 23021

PROJECT GOAL

Design and prototype a medical-grade spigot to mitigate safety hazards in laboratory settings, ensuring secure and safe dispensing of chemical reagents.

At Roche Tissue Diagnostics, the current method for tissue staining involves dispensing chemicals through a spigot, which regulates the flow of reagents from chemical storage containers known as carboys. This existing system has recently been beset with leaks and issues, which are rooted in a faulty spigot connected to the carboy. The problems arose from a combination of mechanical failure, chemical degradation and incorrect operation.

The team used CAD software, 3D fabrication techniques, chemical compatibility testing, and mechanical and fluid analyses to develop multiple design iterations. Each iteration was tested extensively to ensure that the design is ready for mass production. The improved spigot not only enhances safety by eliminating mechanical failures and chemical degradation, but it also promises better ease of use. Additionally, the modular design approach offers cost efficiency in the manufacturing process.

Team 23022

Develop an easily manufacturable and modular device that will safely charge, discharge and test the batteries that power the Boeing 787 Dreamliner’s Wireless Emergency Lighting System.

In the event of an emergency, the WELS guides passengers to safety with luminescent signs and directions. To power this system, a WELS Battery Unit (WBU) must always be on board, fully charged, and safely operable. Currently, the Combined Ganged Battery Tester is used to verify the functionality of WBUs, but there is an issue with parts obsolescence. To keep up with the growing demand for WBUs, the WELS Battery Tester (WBT) has been designed with safety, reliability and manufacturability in mind.

The project centers around the electrical design which utilizes a custom circuit to interface with the WBU. This allows for charging, discharging, measuring battery temperature, reading internal memory and setting the WBU to a safe charge level for storage and shipping. These tests are implemented in the firmware of the microcontroller, which serves as the link from hardware to software. The packaged software application for the WBT confirms connection with a system, sends commands for which test is to be run and processes the data. The mechanical enclosure is lightweight, easily portable and ensures the WBU can make a secure connection with the device.

TEAM MEMBERS

Mohammed Almousa, Biomedical Engineering

Hector Flores, Biomedical Engineering

Rebecca Ger, Systems Engineering

Alec Jordan Blaauw Mills, Systems Engineering

Daniel Ramos Flores, Mechanical Engineering

Jason Zhang, Materials Science & Engineering

COLLEGE MENTOR

Pat Caldwell

SPONSOR ADVISOR

Ian Aguilar

TEAM MEMBERS

Ellie Griesemer, Mechanical Engineering

Marcel Merrill, Systems Engineering

Ary Nath, Electrical & Computer Engineering

Harrison Jay Pearl, Software Engineering

Ashton Rowe, Electrical & Computer Engineering

Luis Ruiz, Mechanical Engineering

COLLEGE MENTOR

James Sweetman

SPONSOR ADVISOR

Tyler Gleesing

TEAM MEMBERS

Harsh Bansal, Mechanical Engineering

Dom Jelenkovic, Engineering Management

Blake Andrew Rosen, Mechanical Engineering

Albert Isaiah Rubalcava, Mechanical Engineering

Kasey Spradling, Engineering Management

Matthew Villanueva, Mechanical Engineering

COLLEGE MENTOR

Jeff Scott Wolske

SPONSOR ADVISOR

Lloyd Becker

Team 23023

Improve and simplify the mechanical latching mechanism for the safety-boarding ladder on Caterpillar’s large track type tractors, while meeting structural durability and reliability requirements.

The boarding ladder attachment for Caterpillar’s D9 through D11 tractors enables operators to access the cab of the machine safely. However, the current actuator-driven latching mechanism that secures the ladder in the stowed position fails at low operating hours, creating downtime of the machine and loss of production. This project presents a motor-driven redesign of the latching mechanism to improve reliability and ensure backward compatibility for machines already in the field.

In this design, the access ladder swings up from the ground to the side of the tractor and is secured by two pins that firmly hold the ladder to the latching assembly on the machine. These pins are engaged by custom linkages driven by a geared motor and keyed shaft. This motor removes the linear actuator, the key source of failure from the current design. The redesigned linkages consist of a pivot link that interfaces with a shaft and connecting rods that drive the pins. The new system adds holding pads which adjust to the optimum stopping location of the stowed ladder. It also integrates limit switches with the current system of relays to stop actuation of the latching pins. This, in turn, interfaces with the switches, proximity sensor and rotational actuator that controls ladder movement. The new latching mechanism shows higher natural frequencies and reduction of stresses, ultimately improving structural reliability.

Team 23024

TEAM MEMBERS

Paige Bayze, Engineering Management

Collin Garard, Mechanical Engineering

Filiberto Quintero, Biomedical Engineering

Andrew K Tapia, Biomedical Engineering

Jackson Alexander Webb, Mechanical Engineering

Ibrahim Saad Zaky, Biomedical Engineering

COLLEGE MENTOR

Steve Larimore

SPONSOR ADVISORS

Michael Selep, Mansur Olaitan

Design a storage and sensing device for liquid-based cytology sample vials and slides in order to improve ergonomics, stability and usability for cryptotechnicians, reducing the risk of sample damage and human error.

The Slide Prep Utility for Roche (SPUR) is a new system that prepares slides for tissue staining from liquid-based cytology samples instead of tissue. Cytotechnicians manually stack hundreds of the slide and vial samples for processing, which presents the risks of damage and human error. The team developed a tray that allows cytotechnicans to keep the patient samples and slides safe and organized, resulting in a more efficient process.

The design includes a mechanical assembly and an electronic assembly. The mechanical portion consists of 12 holes designed for vial placement and 12 slide holders designed to fit two slides each. The electronic assembly includes an Arduino Nano, a temperature sensor and an E-Ink display, all powered by two 10Ah rechargeable batteries. The device temperature and sample storage age are monitored and presented on the display. If the temperature of the device moves outside a particular range, or if the sample storage exceeds six months, a visual alarm will be displayed, indicating the samples are no longer usable.

Team 23025

Develop a system that mitigates turbo fan engine surges by preventing backflow through compressor rotor gaps.

During critical stages of flight, when turbo fan engines perform at their operating limits, unfavorable atmospheric conditions can cause the direction of airflow through the engine to reverse through gaps between the engine casing and compressor rotor blades. This reverse flow is called a surge, and it can allow high temperature gases in the combustion chamber to back-flow into the compressor. This may cause catastrophic failure of the engine, necessitating an emergency landing.

To address the issue, the team designed a system to prevent backflow and 3D printed a prototype portion of a compressor with rotor blades and engine casing. It was tested by injecting a stream of high-pressure air into the gap. The team used a wind tunnel to measure changes in pressure across the airfoil when controlled by the injected stream of air. The design improves aircraft safety and reduces man-hours and costs required to repair engines after an occurrence of engine surge.

Team 23027

Design a mobile fluid detection system that identifies bulk fluid levels and is compatible with both a human user and an autonomous mobile robot.

The BenchMark ULTRA, an automated tissue staining instrument used in the detection of diseases such as cancer, requires several fluid reagents to perform its analyses. Detecting and maintaining adequate bulk reagent levels currently requires technicians to manually log usage, a process which is burdensome, time consuming and subject to error.

The team developed a cart-mounted, contactless vision system to automatically sense reagent fluid levels. The vision system includes a high-quality camera connected to a Raspberry Pi. An LED strip is used in conjunction with induced light blockers on the custom designed cart to stabilize the environmental conditions and improve measurement accuracy. The Raspberry Pi processes the camera image using gamma correction and performs fluid level estimation using pixel intensity comparisons, resulting in detection of fluid levels within 5% of the true volume. The analysis results are displayed on the system graphical user interface and saved for later use. A rechargeable power supply allows for 30 minutes of uninterrupted use.

TEAM MEMBERS

Becky Burns, Mechanical Engineering

Alhasan Haliru, Mechanical Engineering

Jake David Petersen, Aerospace Engineering

Abishek Sreenivasan, Aerospace Engineering

Avery Stockdale-Stephens, Aerospace Engineering

COLLEGE MENTOR

Doug May

SPONSOR ADVISOR

Nick Nolcheff

TEAM MEMBERS

Adrian Isaiah Alvarado, Biomedical Engineering

Jarod Mate, Mechanical Engineering

Divyansh Harendra Rathod, Biomedical Engineering

Samantha Mata Robles, Biomedical Engineering

Adrian Gildardo Rodriguez, Systems Engineering

Amanda Villegas, Optical Sciences & Engineering

COLLEGE MENTOR

Steve Larimore

SPONSOR ADVISOR

Matt Mette

TEAM MEMBERS

Taron Bashar, Biomedical Engineering

Roman P Golota, Electrical & Computer Engineering

Jacob Jones, Optical Sciences & Engineering

Misa Soto, Biomedical Engineering

Chloe Wetzel, Industrial Engineering

Nathan Yenerich, Biomedical Engineering

COLLEGE MENTOR

Mike Nofziger

SPONSOR ADVISOR

Bryan McKay

Team 23028

Design a system that measures the volume of residual fluid on a microscope slide with minimal user interaction.

Roche’s BenchMark ULTRA staining instrument has a variety of internal conditions, and it controls multiple chemical and physical parameters of the tissue staining process. The residual fluid volume on a microscope slide must be known and controlled. Currently, a technician measures the volume using a Kimwipe and an analytical balance. The team designed an optical approach to measure the volume of residual fluid on the microscope slide with less user interaction than the existing method.

The new system captures side-view images of fluid on a microscope slide and processes the images, measuring the height of the fluid at different points. A Raspberry Pi microcontroller directs the image processing, and a machine learning algorithm is trained to estimate and display the fluid volume onto an LCD screen.

The team designed and manufactured a plastic housing for the camera module that integrates directly onto the slide drawer of the staining instrument. They also manufactured an external housing for the Raspberry Pi and its associated components. Designed for simplicity, this system will greatly reduce the amount of time spent measuring residual fluid volumes.

Team 23029

TEAM MEMBERS

Kyle Ambrose Ambrose, Systems Engineering

Cody Truong Chi, Systems Engineering

Kevin Sean Grady, Electrical & Computer Engineering

Colin Herbert, Electrical & Computer Engineering

Braxton Montgomery Ulmer, Systems Engineering

COLLEGE MENTOR

Michael Madjerec

SPONSOR ADVISOR

Mark Hansen

Transition Northrop Grumman launch vehicle ground support equipment from a Javabased frontend to a web-based one. Apply a systems engineering approach for development of the Human-computer Interface design.

The defense industry typically uses software-based applications to test missiles and other types of flying projectiles. But as technology advances, the software requires numerous updates. By introducing a web-based frontend, the development, testing and release cycles of the system will be faster. The design provides the ability for multiple contributors to automate the integration of code and updates for new software.

By using a systems engineering approach, the team created a user-friendly interface prioritizing safety, performance and user satisfaction. A single client-side application receives data from the launch vehicle sensors and engineers, while simultaneously sending data packets back to the sponsor servers on any occasion of user interaction. With a graphical user interface paired with a backend, data forwarding allows the code to be maintainable and put in a single package. This design is a foundation for the transition to web-based applications for the launch vehicles.

Team 23030

Develop an innovative inspiratory muscle strength training device with enhanced user feedback, improving accessibility and impact for clinical and public applications.

Cardiovascular disease (CVD), the leading cause of death globally, results in over 19 million deaths annually, according to the American Heart Association. High blood pressure is directly linked to increased risk for CVD. While an abbreviated daily IMST regimen has been shown to significantly reduce systolic blood pressure, the exercises are difficult to perform effectively using current devices, which offer limited user feedback.

Our respiratory training system, ReTrain, is comprised of an ergonomic, handheld device containing a one-way breathing valve, pressure transducer and ESP32 microcontroller. It senses and transmits the user’s breathing pressure over a Bluetooth Low Energy interface to a paired smartphone application. The accompanying smartphone application monitors breathing pressure and provides live feedback. The device requires minimal user interaction, and the intuitive framework of the app enhances user experience. For standard training and calibration, a real-time waveform of the user’s pressure and current target level are displayed with an accuracy of 3.5%. Additionally, data from each session is stored on the user’s device and transmitted to a clinical program via Amazon Web Service.

Team 23031

Create a mid-sized autonomous utility robot with a simple, scalable and easily iteratedupon design, able to be adapted to a variety of missions, such as data gathering in industrial agriculture.

The Fourth Industrial Revolution is the idea that efficiency will be revolutionized by mass-data analytics fueling decisions made by AI. Large-area industries, such as agriculture, are racing to design a versatile drone capable of gathering this information. In this effort, ground based, hexapodal platforms have advantages over both flying drones and tracked/wheeled designs. These include the ability to mount heavier and more robust sensor packages, easy modification, longer loitering times, movement below and around foliage, and low impact on soil.

The AMS design uses off-the-shelf electronics, 3D printed parts and open-source software for simplicity, modularity and ease of modification. It includes a Raspberry Pi running the robot operating system, which has an abundant range of packages allowing for the easy integration of additional sensors, missions and parts. This current iteration uses lidar, or Light Detection and Ranging,=4ew31nd supersonic ranging devices, which provide robust obstacle detection and path planning. In addition, a GPS is used to define a roaming area for the robot, so this platform is ready to be adapted to large-area data gathering, especially within the agricultural sector.

TEAM MEMBERS

Tommy M Carder, Systems Engineering

Dylan McGuire, Biomedical Engineering

Collin Alexander Preszler, Biomedical Engineering, Electrical & Computer Engineering

Nicholas Sherwood Quatraro, Biomedical Engineering

Saul Silva, Systems Engineering

COLLEGE MENTOR

Steve Larimore

SPONSOR ADVISORS

Elizabeth F Bailey, Philipp Gutruf

TEAM MEMBERS

Ali Alaqeel, Electrical & Computer Engineering

Eli J Bitzko, Mechanical Engineering

Tam Friedman, Biosystems Engineering

Kaleb Gabriel Lucero, Engineering Management

Shambhavi Singh, Electrical & Computer Engineering

Ismail Abdul-Aziz Zaki, Mechanical Engineering

COLLEGE MENTOR

Pat Caldwell

SPONSOR ADVISORS

Pedro Andrade Sanchez, Brian Little, Mark C Siemens

TEAM MEMBERS

Alan Loreto Cornídez, Electrical & Computer Engineering

Jack T Moffet, Engineering Management

Victor Ferreira Silva, Mechanical Engineering

Nick Tolmasoff, Mechanical Engineering

Viru Vilvanathan, Mechanical Engineering

COLLEGE MENTOR

Bob Messenger

SPONSOR ADVISOR

Joseph Mueller

Team 23034

TEAM MEMBERS

Ahmad Ashraf Eladawy, Electrical & Computer Engineering

Milad Ghaemi, Optical Sciences & Engineering

Salman Mohammed Khashoggi, Industrial Engineering

Wilson Liao, Electrical & Computer Engineering

Rafael Lomeli-Navarro, Optical Sciences & Engineering

COLLEGE MENTOR

Bob Messenger

SPONSOR ADVISOR

Joseph Mueller

PROJECT GOAL

Design a system of sensors that automates the rapid detection of material handling equipment degradation or failure in high-usage warehouse facilities.

The equipment in Amazon fulfillment centers across the globe are susceptible to premature degradation and failure. These issues include bearing overheating and failure, conveyor belt misalignment and debris. To combat these problems, the team developed an autonomous, self-powered maintenance unit that can rapidly identify supply chain issues and streamline maintenance. The design will dramatically reduce the time and cost of critical repairs.

A maintenance worker might need up to eight hours to walk and inspect just one conveyor. But the autonomous robot design can do the task in as little as 15 minutes, while costing less than $600. The system uses a suite of low cost, state-of-the-art commercial sensors and is capable of accurately identifying equipment issues on the conveyor line. The hardware and software quickly detect possible failures and provide near-real-time reporting capabilities to factory maintenance technicians and engineers. The system sends a user-friendly, intuitive report to the local team while being completely customizable and modular, all while adhering to safety protocols required to reduce the hazards to personnel in these industrial settings.

Team 23035

PROJECT GOAL

Provide remote or in-person hands-on training to Amazon SMEs using virtual reality technology.

This project provides a VR training environment that simulates the conveyor belts that are critical to the operations of Amazon fulfillment centers. The system is designed to allow technicians to interact and gain experience with maintenance and repair of these assets. The company needs highly trained technicians because damage to critical assets can cost the company millions of dollars if the issue is not fixed quickly. Training in person is expensive because of travel, instruction costs and lack of experts for each specific asset. This project presents a more cost-effective method of training the technicians.

Through VR development in Unity, the team developed a training platform in which the user can perform functions that are critical to understanding the operation, repair, maintenance and part breakdown of the asset. Technicians can measure distances on an accurate 3D model of the asset. They can also identify part breakdown information of critical components, such as manufacturing, part number, part description and identification, allowing them to quickly procure replacements. The program also provides examples of faulty parts along with customizable procedures that allow technicians easier troubleshooting, repair, replacement and maintenance of the physical asset.

Team 23036

Develop a modular system to sense, transmit and display real-time racecar data.

In motorsports, data is paramount. Having the ability to gather information about the track, environment and car allows a team to better tune a vehicle optimally for a race. Technology that helps gather this data is available, but it is expensive and not compatible with all configurations of vehicles. To tackle these issues, the team created a modular system that is configurable with multiple sensors and usable in a wide variety of scenarios and environments. It provides critical real-time data for the Wildcat Formula Team.

The system has two Raspberry Pi computers that communicate with each other. One of them is onboard the race car for the driver, and the other is at the team’s chosen position, typically the pit lane. The onboard Raspberry Pi is connected to GPS, accelerometers and strain gauges, all gathering information on the car during a race. The remote subsystem has a Grafahan data plotting suite that converts the data into easily read figures. Use of this telemetry system allows setup of the car on race days to improve performance and safeguard against critical issues becoming safety hazards.

Team 23037

Design, build and verify a 250 lb. combat robot with active telemetry sensors capable of competing on the BattleBots TV show.

The BattleBots competition provides a space for builders to forge robots of destruction. As long as robots are under the weight limit and adhere to the BattleBots rules, they can fight. High achieving combat robots deal damage, survive deadly blows and look good while doing it. This project is a leap in the University of Arizona’s robotic community involvement and creates a space for future students to learn and have fun.

The team’s robot design integrates over 400 parts in six major subsystems – drive, weapon, armor, electronics, frame and telemetry sensors. The drive system uses four brushed motors to propel the robot to 20 mph. The weapon spins 45 lb. over 250 mph in eight seconds with a belt system. The stingray exterior is made of ultra high molecular weight plastic and AR400 ballistic steel for defense. The design includes an electronic system with kill switches, safety fuses and critical part protection. Holding it all together, the frame interlaces steel, aluminum and neoprene rubber to absorb impacts. Lastly, the combat robot houses speed, temperature and current sensors to ensure the driver is as informed as the robot is tough.

TEAM MEMBERS

Shayan N Afzal, Biosystems Engineering

Lukas Matthew Baker, Mechanical Engineering

Christian Copic, Electrical & Computer Engineering

Isaac Carlos Gloistein, Mechanical Engineering

Luke Kobran, Mechanical Engineering

Nicholas J Smith, Electrical & Computer Engineering

COLLEGE MENTOR

Doug May

SPONSOR ADVISOR

Michael W Marcellin

TEAM MEMBERS

Yousuf Choudhary, Electrical & Computer Engineering

Al Hurworth, Mechanical Engineering

Knudson Karson, Electrical & Computer Engineering

Mathias Micah Ramirez, Aerospace Engineering

Nick Scott Sivertson, Mechanical Engineering

Alex Tynan Wait, Mechanical Engineering

COLLEGE MENTOR

Steve Larimore

SPONSOR ADVISOR

Michael W Marcellin

TEAM MEMBERS

Dylan Etson, Electrical & Computer Engineering

Jerry Klosterman, Electrical & Computer Engineering

Brandon Kron, Biomedical Engineering

Isabella Martinez, Systems Engineering

Lauren Meloche, Biomedical Engineering

Nathan Owens, Systems Engineering

COLLEGE MENTOR

Elmer Grubbs

SPONSOR ADVISORS

Arun Rao, Lacey Rao

Team 23038

PROJECT GOAL

Develop a mobile phone application to improve outcomes and experience during inpatient hospital stays.

Many hospitals still rely on outdated communication techniques, ultimately leaving patients in the dark. The team designed My Health Navigator to improve the inpatient experience. It consists of two interacting systems, a database and an internet application. The database acts as the central storage of all information passing through the hospital system, while the application is responsible for the major functionality.

The application incorporates three distinct views, for patients, doctors and administration. Patients can see their care team members, schedule and rounding alerts, while physicians control that data using the doctor view. All functionalities are supported by the admin view, where accounts are created and patients are assigned their doctors and care team.

The team began with in-depth stakeholder analysis, operational concept development and requirements engineering. Then they created graphical user interface wireframes along with UML model components to map out the design for future development. The system information and files are securely hosted on a Liquid Web server. Stored HTML and CSS files direct the application front end, while Javascript and routing files dictate all backend functionality.

Team 23039

TEAM MEMBERS

Thomas Carroll, Electrical & Computer Engineering

Jesse Koontz, Electrical & Computer Engineering

Yudong Liang, Mechanical Engineering

Keegan Michael Pierson, Engineering Management

COLLEGE MENTOR

Michael Madjerec

SPONSOR ADVISOR

Michael Hemphill

Design a gravity battery, and characterize the efficiency of such a system for applications in existing vertical mineshafts.

When using renewable energies, storage is essential due to the significant variance in power produced throughout the day. Resolution Copper is evaluating alternatives to battery arrays for on-site power in their facilities. The solution must be cheaper and have less environmental impact, while still being reliable. To answer this need, the team designed a gravity battery that uses Resolution Copper’s existing vertical mine shafts.

The proof of concept is a tower-like structure that uses a brushless motor, a permanent magnet generator and a belt system. It turns electrical energy into potential energy by suspending a mass, which can then be converted back into electrical energy when gravity pulls the mass and drives the generator. Push-button user inputs relay commands to an Arduino microcontroller that interfaces with the motor and braking systems. The design uses proximity sensors to detect the position of the mass and terminate cycles automatically. Additionally, the system uses AC voltage and current sensors to calculate the total energy and efficiency produced by the system.

Team 23040

Design and build an automated oil dispenser to eliminate cross contamination, reduce waste and notify the user of low fluid level for a standard 55-gallon drum.

Machine shops use devices such as computer numerical control (CNC) machines to cut all types of material. These CNC machines can require a variety of lubricant types in different amounts for their operations. They are often filled by the operator manually pumping from a 55-gallon oil drum. This regularly leads to spillage, wasted oil, cross contamination and safety hazards within the workshop.

The team designed the Automated Oil Dispenser to decrease the amount of spillage, time and work required due to manual pumping. This will result in a cleaner, safer and more efficient work environment. The design uses a color-coded categorization system to minimize cross contamination and ensure each machine gets the correct oil. A sink basin filters the oil to eliminate spillage, reduce waste and prevent contamination, while a microcontroller and electric pump fill the oil safe containers. This microcontroller is programmed to detect the amount of oil dispensed and alerts the user when the drum reaches a low level.

Team 23041

Design and optimize a pulsed detonation tube as an igniter for a Rotating Detonation Engine (RDE).

Innovations in propulsion presently are focused on supersonic combustion of propellants to increase the useful energy yield in the cycle of an engine. In contrast, this technology adapts supersonic combustion in an RDE.

Traditional engines and nozzles have subsonic combustion called deflagration, and shock waves travel around a ring-shaped chamber to combust propellants. To successfully start an RDE, a shock wave must propagate within the combustion chamber itself.

This project focused on creating and inserting supersonic combustion waves into an RDE. Geometric and chemical factors dramatically impact the efficiency and reliability of the detonation process. The team designed and fabricated a modular system to conduct an extensive test campaign varying numerous factors, including internal geometry, fuel-oxidizer ratio, pressure, and timing of spark plug ignition.

The result was enhanced supersonic wave velocity measured at the outlet of the system, yielding an optimized design with favorable shock wave generation, reliability and velocity.

TEAM MEMBERS

Harry Chhieu, Mechanical Engineering

Marco Andres Lopez, Mechanical Engineering

Cameron John Frost Meehan, Electrical & Computer Engineering

Tania Mitnasala, Electrical & Computer Engineering

Mandeep Singh, Mechanical Engineering

COLLEGE MENTOR

Michael Madjerec

SPONSOR ADVISOR

David Saucedo

TEAM MEMBERS

Chad Aykroyd, Mechanical Engineering

Ryan Curtis-Sanchez, Aerospace Engineering

Curtis Dodd Goldin, Aerospace Engineering

Weston Cole Meyers, Aerospace Engineering

Jacob Thomas Roschak, Aerospace Engineering

COLLEGE MENTOR

Doug May

SPONSOR ADVISOR

James Villarreal

TEAM MEMBERS

Fahad Mohammad Alrashed, Electrical & Computer Engineering

Martin Calderon, Mechanical Engineering

Canyon Charles Cooke, Mechanical Engineering

Erick F Dzeketey, Biosystems Engineering

Alex J Hillman, Electrical & Computer Engineering

COLLEGE MENTOR

Michael Madjerec

SPONSOR ADVISORS

Duarte Diaz, Brian Little

Team 23042

TEAM MEMBERS

Sebo Diaz, Biomedical Engineering

Vinamra Kumar, Biomedical Engineering

Kenzi Marie McNeil, Biomedical Engineering

Aaron A Ramos, Materials Science & Engineering

Alex Joseph Sciortino, Mechanical Engineering

COLLEGE MENTOR

Justin James Hyatt

SPONSOR ADVISOR

Dan Latt

Build a better research tool for silage analysis.

Silage is a long-storage-life cattle feed created through the fermentation of various agricultural products. The study of silage fermentation and additive processes affects commercial enterprises, such as dairies and feedlots, including the environmental impact of these enterprises. This project redefines silage research.

The current method of silage study wastes large quantities of disposable bags and silage. This team set out to build a research tool to replace the existing wasteful method of analyzing silage as well as simplify the data collection and analysis process.

The team’s design builds on an off-the-shelf pressure cooker modified to collect scientific data. The pressure cooker base is ideal, as it already facilitates successful fermentation with little modification. Students installed several sensors integrated into the lid of the pressure vessel to analyze trends in pH, temperature, humidity, oxygen and volatile organic compound (VOC) content. This information is then processed by an onboard Raspberry Pi before being uploaded to a GitHub repository for ease of access.

Team 23043

Using an energy return mechanism to support normal human gait while maintaining adequate range of motion in the affected foot, design and build a comfortable, wellfitting, brace that corrects Adult Acquired Flat Foot (AAFD).

AAFD is a potentially debilitating condition that affects up to 5 million people in the United States. Left untreated, AAFD can cause limiting pain and arthritis. Mild to moderate AAFD can be addressed using braces and orthotic supports. However, the design of available products to treat AAFD may be impeding their effectiveness.

This team designed a novel brace to address common complaints about available products: high temperatures within the brace, discomfort, poor fit in readily available footwear, inadequate correction of the deformity, and reduced range of foot motion.

Combining previously proven static archplate geometry with an adjustable springpack system, the Arch Reactivator allows a user to step down naturally then get dynamic support via the lifting of a springpack system at the upper portion of the brace. All of this is contained within a sleek, comfortable sleeve that is easy to put on.

Team 23044

Develop a graphical user interface (GUI)-enabled, experimentally verified optical fiber beam propagation software package that accurately models how fiber bending, twisting and ambient temperature impact performance.

Optical fibers are waveguide conduits that transport light. Due to their unique optical confinement mechanisms, optical fibers can only carry a finite number of modes, or electromagnetic (EM) field distributions. Although the physics of straight fibers is well understood, many applications require the waveguides to perform in more complex environments, which significantly alter the behavior of the modes and, therefore, the guided field.

Engineers can compensate for these environmental perturbations, but only with accurate computational modeling. This team based its approach on the software simulation package from last year’s Team 22041, improving the package usability and fiber bending accuracy with verification through a rigorous experimental study.

The simulation can be accessed through a fully functioning GUI that allows the user to propagate Gaussian, flat top, annular and custom EM fields through step index or photonic crystal fibers with arbitrary bending/twisting geometries and ambient temperatures. During the simulation, the GUI displays the fiber layout, propagation loss, and real-time updates of the EM field as it propagates through the fiber, providing the user with enhanced analysis and streamlined fiber-based optical design.

Team 23046

Using various sensors, identify and track the position of any implement attached to an autonomous tractor.

Adding the capabilities of implement recognition and positioning to a tractor dramatically increases the scope of what tasks its autonomous system can perform. This design serves as a cost-saving alternative to adding automation equipment to each of the several implements that a single tractor pulls.

The system, which is completely powered by the tractor itself and can withstand agricultural conditions, sits on top of the tractor cab to visually recognize and track the towed implement. It uses an OAK-D-PoE camera with machine learning models to perform implement detection and identification and a Livox Mid-40 sensor with lidar, or Light Detection and Ranging, and traditional algorithms to accomplish positioning relative to the tractor. All of the visual information is compiled and calculated on an NVIDIA Jetson in conjunction with the OAK-D, with on-board processing capabilities. The Oak-D performs the Neural Network computing on the camera itself, while the NVIDIA Jetson processes the outputs from the neural network and lidar data as well as the overall system code.

The result is a complex network of embedded software and hardware integrated to accurately identify and locate implements, effectively advancing the future of automation in agriculture.

TEAM MEMBERS

Francisco Javier Flowers, Optical Sciences & Engineering

Oscar Hsueh, Electrical & Computer Engineering

Atkin David Hyatt, Optical Sciences & Engineering

Lauren McCaffrey, Optical Sciences & Engineering

Oliver Wu, Optical Sciences & Engineering

COLLEGE MENTOR

Mike Nofziger

SPONSOR ADVISOR

Tao Chen

TEAM MEMBERS

Gavin M Caldwell, Electrical & Computer Engineering

Jessica S Grove, Industrial Engineering

Brett Miller, Biosystems Engineering

Kees Passon, Optical Sciences & Engineering

Everett Schafer, Optical Sciences & Engineering

Howard James Yawit, Electrical & Computer Engineering

COLLEGE MENTOR

James Sweetman

SPONSOR ADVISOR

Darcy Cook

TEAM MEMBERS

Omar Al Hilal, Electrical & Computer Engineering

Young Cho, Mechanical Engineering

Dan S Darnell, Mechanical Engineering

Shane Henry Jordan, Optical Sciences & Engineering

AJ James Sterner, Electrical & Computer Engineering

Jake Timothy Wern, Systems Engineering

COLLEGE MENTOR

Steve Larimore

SPONSOR ADVISOR

Dan Latt

Team 23047

PROJECT GOAL

Design and create an automobile proximity sensor for cyclists to ensure safety on the road and provide potential traffic violation information.

Every year in the United States nearly 1,000 cyclists die, and more than 130,000 cyclists are injured in road accidents. Regulations such as ARS 28-278 guarantee cyclists 3 feet of space on the road, but these laws are often ignored because there isn’t a clear way to determine this traffic violation.

The Cyclesafe, a lightweight device mounted inside the handlebar of a bicycle, employs LEDs to alert drivers of the cyclists’ location and uses a microcontroller and an ultrasonic proximity sensor to detect within milliseconds a driver crossing into the 3-foot boundary of the cyclist.

If an intrusion is detected, the device captures a picture of the offending driver’s license plate as well as the location of the incident using GPS. The photograph and location are stored to an onboard SD card, where the user can later collect the data and report violators to the authorities.

Team 23049

TEAM MEMBERS