Biogas Magazine | Edition 24 | 4 CONTENTS 12 16 19 22 31 26 36 In Conversation with Sh. Bijay Kumar Ji After Varanasi, ATEBL plans next compressed biogas plant in Barsana Sustainable Agriculture is here Exploring the Potential of Modern Innovative Biogas Technology Technological intervention boosts Biogas plant profitability HP-RAMP technology Producing biogas from tougher substrates such as lignocellulosic biomass becomes easier Building CBG market in India through Certificates mechanism 16 26 36 19 22 NATIONAL CORNER INTERNATIONAL CORNER

“Dear Reader, Greetings!

We are glad to bring to you the 24th edition of Biogas magazine, where we continue to explore the latest advancements, insights, and trends in the field of biogas production and utilization. This edition includes a diverse range of articles and features highlighting the incredible progress and ongoing research in the biogas industry.

IBA welcomes the latest notification, the PM-PRANAM scheme, from the Ministry of Agriculture, which introduces the Marketing Development Assistance (MDA) of 1500 Rs/Kg for organic manure produced from the CBG plants registered under the GOBARdhan Scheme. Through the scheme, the government emphasizes upon promoting organic manure under the brand names 'Bharat' FOM, LFOM, PROM, etc., and is expected to augment the credibility of organic fertilizer as a product.

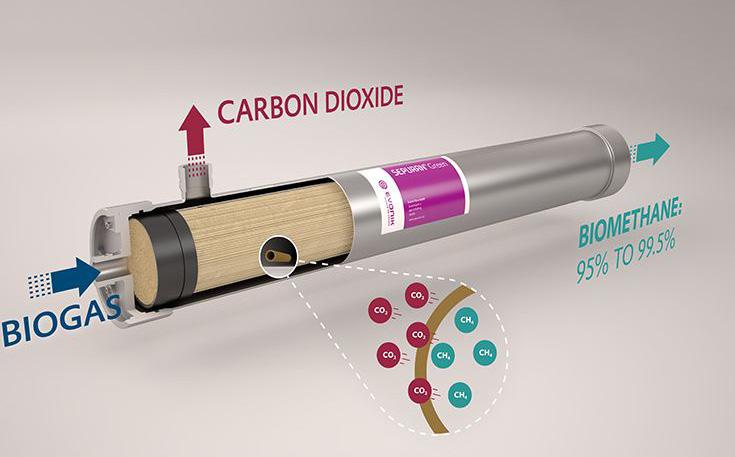

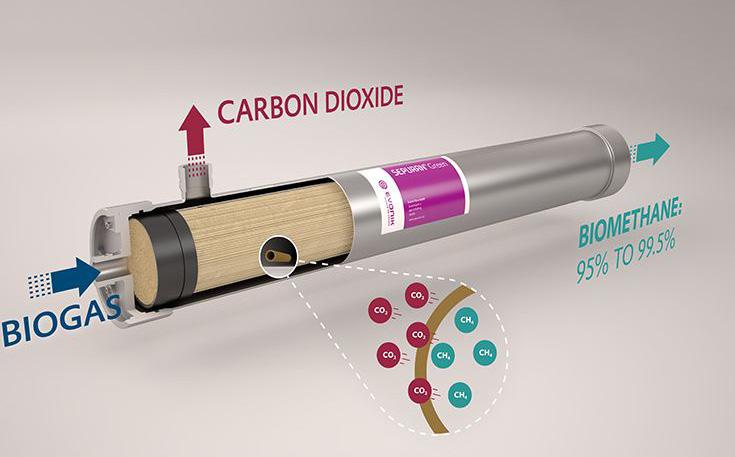

In "Technological intervention boosts Biogas plant profitability," we delve into the exciting realm of biogas degradation through membranes. This novel technique has the potential to improve the efficiency and profitability of biogas facilities, opening the path for a more sustainable and financially viable future.

We are honoured to present an exclusive interview with Mr. Bijay Kumar, a prominent figure in the biogas sector. His perspective on sustainability, government policies, and India's net-zero goals provides valuable insights into the challenges and opportunities that lie ahead for the industry.

Technological advancements are unlocking new avenues for biogas production from tougher substrates, such as lignocellulosic biomass. Our feature article showcases the ground breaking techniques that enable the efficient conversion of these challenging feedstocks into valuable biogas.

Furthermore, we delve into the crucial factors influencing biogas production, including pH, volatile fatty acids, and alkalinity. Understanding and optimizing these parameters is essential for maximizing the yield and quality of biogas, and our article provides valuable insights into this area.

Lastly, we are excited to share the news of Adani's next compressed biogas plant in Barsana. This significant development demonstrates the growing commitment of industry leaders towards sustainable energy solutions marks another milestone in the journey towards a greener future.

We hope that this edition of Biogas magazine inspires and informs you, offering a glimpse into cutting-edge research, technological breakthroughs, and transformative projects shaping the biogas industry. Together, let us continue to champion the cause of sustainable energy and harness the incredible potential of biogas for a cleaner and brighter tomorrow.

Editors

Savita

Boral

Abhijeet

Mukherjee

Designer

Komal Raghav

Administrator

Vishal Kanchan

Production Co-ordinator

Jyoti Malik

About

The “Indian Biogas Association” (IBA) is the first nationwide and professional biogas association for operators, manufacturers and planners of biogas plants, and representatives from public policy, science and research in India.

The association was established in 2011 and revamped in 2015 to promote a greener future through biogas. The motto of the association is “propagating biogas in a sustainable way”.

/biogasindia

/indianBiogasAssociation

/indian-biogas -association

Biogas Magazine | Edition 24 | 5

digesting!

Dr. A. R. Shukla President Indian Biogas Association

Happy

Steverding Agitator Technology

Steverding Agitator Technology is an expert in agitators. High technology is expected today at all levels of power generation. Steverding Agitator Technology can boast more than 20 years of experience in the manufacture of agitators. The continuous optimization and analysis of our products together with constant technical innovation show best results. Today, we are partners and system component suppliers of leading biomass facility manufactures in Germany, France, United Kingdom, Lithuania and many other countries.

This is our current range of agitators from Steverding Agitator Technology:

Impressions:

Hydromixer

Spiralo®

Schwanko

Long shaft agitators

Gerhart-Hauptmann-Str. 41, 48703 Stadtlohn, Germany

+49 2563 - 2088820

Vertical agitators

Plug-flow agitators

info@rt-st.com

www.rt-st.com

Contact person India

Jörg Grondke

Tel.: +49 17664751630

Mail: joerg.grondke@hrgsolutions.de

Steverding Agitator Technology • Gerhart-Hauptmann-Str. 41 • 48703 Stadtlohn • Germany

@

Biogas Magazine | Edition 24 | 7

IBA’s commitment towards leapfrogging the prospect in the biogas/bio-CNG industry

- Period: April- June, 2023

News 1 : IBA at Biofuel Expo

IBA's team actively participated in the Biofuel Expo, which took place from June 4 to 6, 2023, at Pragati Maidan in New Delhi, India. The event was an integral part of the World Environment Expo and Biodegradable Expo, encompassing a wide range of topics such as biomass, biofuel, biogas, and solid waste management.

Representing the IBA team were Ms. Prashansa Gupta, Ms. Jyoti Malik, and Mr. Vishal Kanchan, managed the IBA booth throughout the expo. In addition, Col. Rohit Dev represented IBA

during a conference session. The team's presence was highly notable, as they conducted over 55 meetings and interacted with more than 350 trade visitors during the event.

The team had the opportunity to connect with numerous IBA member companies and other organizations already present in their network. Fruitful meetings were held, fostering valuable relationships and exploring potential collaborations. The Biofuel Expo proved to be an exceptional platform for engaging with stakeholders from the biomass, biofuel, and biodiesel sectors.

The expo was organized at Pragati Maidan, a renowned venue in Delhi, known for hosting large-scale events. More information about the expo can be found on the official website, http://biofuelexpo.com/.

Overall, IBA's team participation in the Biofuel Expo was a resounding success, enabling them to showcase their expertise, expand their network, and explore new business opportunities in the bioenergy sector.

News 2: Formation of Regional Groups

Indian Biogas Association (IBA) is taking a significant

Biogas Magazine | Edition 24 | 8

step towards strengthening its services to members by initiating regional working groups across India. With the aim of aligning the objectives and pursuits of its members, these working groups will enable the identification of local challenges and the formulation of effective mitigating measures to address them. By representing these concerns to the relevant ministries and administrative bodies, IBA seeks to have a sustainable impact on the biogas industry.

To begin with, IBA has proposed the formation of regional working groups focused on the Southern region and Western regions of India. The potential locations for the operation of this Western group are Maharashtra, Gujarat, Rajasthan, and Goa. For the Southern regional group, the locations are Karnataka, Tamil Nadu, Kerala, Andhra Pradesh, and Telangana.

The working group's main goal is to engage in crucial discussions on biogas-related topics, explore mitigation options for identified challenges, devise action plans for their execution, and advocate for feasible solutions at the appropriate administrative levels.

Participation in the regional working group is open to all IBA members, with special

encouragement for members operating within the above-mentioned states to their respective groups. IBA will soon open the voting line for the selection of the regional group members and elections are expected to be declared before mid of July 2023. IBA's initiative to establish regional working groups marks a significant step forward in strengthening the biogas industry's representation and addressing local challenges effectively.

News 3: IBA Participates in MNRE's Women in Renewable Energy Dialogue

Ms. Prashansa Gupta from the Indian Biogas Association (IBA) had the privilege of participating in the "Women in Renewable Energy: A Dialogue on Policy, Technology, Skilling, and Finance" meeting organized by the Ministry of New & Renewable Energy (MNRE). The meeting took place on June 5, 2023, coinciding with World Environment Day.

The objective of the meeting was to highlight the critical role of women in the clean energy transition and discuss policy, technology, skilling, and finance aspects. With the theme of "Vasudhaiva Kutumbakam" or "One Earth · One Family · One Future," which aligns with the mission of LiFE (Lifestyle for Environment), India's G20

Presidency emphasizes the importance of individual and community action to protect the environment.

Recognizing the disproportionate impact of climate change on women and their potential as change-makers at the grassroots level, MNRE aims to bring women to the forefront of the renewable energy sector. The dialogue session aimed to learn from women leaders about the implementation and use of renewable energy technologies, understand the pivotal role of women in the renewable energy value chain and identify challenges and interventions related to finance, technology, and skilling.

IBA’s participation showcased its commitment towards promoting women's participation in the renewable energy sector and contributing to long-term energy security in the country. The meeting provided a platform for sharing experiences, insights, and strategies to advance women-centric policies and sustainable solutions in the renewable energy domain.

News 4: IBA's Expert Insights on Biogas Industry Featured in Print and Digital Media

The Indian Biogas Association (IBA) has been actively sharing insights and recommendations on the biogas in-

Biogas Magazine | Edition 24 | 9

dustry through various print and digital media platforms. The association's representatives have actively participated in discussions addressing important topics related to biogas, bio-fertilizers, organic agriculture, natural farming, and the potential impact of increasing compressed biogas output.

In an article featured on The Times of India's blog, IBA highlighted the need for a comprehensive umbrella scheme like SATAT (Sustainable Alternative Towards Affordable Transportation) for bio-fertilizers. The article emphasized the importance of supporting the biogas industry and its potential to contribute to sustainable agriculture and waste management.

The Hindu Business Line covered IBA's perspective on how biogas is aiding environmental causes and boosting organic agriculture. IBA highlighted the positive impact of biogas in reducing greenhouse gas emissions, providing renewable energy, and promoting organic farming practices. ‘SME Futures’ featured IBA's views on the significance of natural farming in India. The article highlighted the benefits of natural farming techniques and how it aligns with the country's sustainable development goals.

Additionally, Business Standard covered IBA's insights on increasing compressed biogas’ supply and demand. The article highlighted IBA's research, which suggested that boosting compressed biogas production alongwith its consumption through proper policy push could reduce India's annual import bill by $2.5 billion.

IBA's presence in the print and digital media reflects its commitment to promoting and advocating for the biogas industry. By sharing its knowledge and perspectives, IBA aims to create awareness, drive policy discussions, and contribute to the sustainable development of India's renewable energy and agriculture sectors.

News 5: IBA received the support of Advisors

The Indian Biogas Association has been rigorously working towards the advancement and upliftment of the Biogas sector across India. For ensuring its prosperous growth, We feel fortunate to onboard Advisors with us, for embarking the journey of wisdom.

With open hearts, we have welcomed Col. Rohit Dev as an Expert Advisor who is perceived as the thought leader

Abhijeet Mukherjee Program Director Indian Biogas Association

Abhijeet Mukherjee Program Director Indian Biogas Association

in the Biomass-based Bio-Energy Sector in India, with Out-of-the-Box solutions. He has served 24 years of his life in the Indian Army and has detailed insight into the operations, logistics, and supply chain management of a strategic field organization in the Northern, Western, and Central Army Commands. Further, he is an eminent speaker in various Forums in the Bio-Energy Sector and on geopolitical & nation-building related debates on National TV Channels.

We are also delighted to have Mr. Bijay Kumar as Chief Technical Advisor, who has devoted 35 years of his life to the Oil & Gas Sector by serving as General Manager at Indian Oil Corporation Limited. He has also been in charge of Central’s SATAT (Sustainable Alternative Towards Affordable Transportation) Scheme for bio-CNG plants at the Indian Oil Corporation. Their experience and the skills would be a great addition to the IBA team and will help ensure the growth of the sector.

Biogas Magazine | Edition 24 | 10

Biogas Magazine | Edition 24 | 11

In Conversation with Sh. Bijay Kumar

Shri Bijay Kumar, Ex General Manager (Alternate Energy), Indian Oil Corporation Ltd. has over 30 years of experience in the Oil & Gas Industry across Engineering, Vigilance, Alternate Energy and Sustainable Development verticals of Indian Oil. A master’s in business administration from Utkal University, Bhubaneswar, Shri Kumar had completed his Civil engineering from NIT-Jamshedpur, both degrees with 1st class and distinction.

The world is completely aware of the adverse effects of global warming, and everyone is very concerned about environmental pollution as the negative effects of fossil fuels are wreaking havoc on planet Earth. In nature, this situation is irreversible. If we continue to exploit

the earth's resources at the same rate as in the last 70–75 years, the resources available today will be insufficient for the survival of humanity in the coming future. We must follow nature's lead and stop exploiting resources and start using energy sources in a self-sustaining manner that does not harm or impede the earth's natural course. This viewpoint is shared by all nations on the planet, and thus alternate energy/sustainable energy enters the picture.

The paradigm shift to alternate energy/sustainable energy is no longer a choice but a necessity. This is the time's and the world's demand. As a result, the role of the sustainable energy sector should be to create an energy source that does not harm nature or Mother Earth.

A lot of work remains to be done in the biogas sector, and much of the potential of this sector remains untapped. Biogas has enormous

Biogas Magazine | Edition 24 | 12

1. What is your viewpoint of the evolving energy sector from a sustainability perspective, including Biogas/ CBG?

Sh. Bijay Kumar

Ex General Manager Indian Oil Corporation Limited (IOCL)

potential all over the world. Whatever energy source we use, whether coal, fossil fuels, or natural gas, is derived from biomass. We have coal because thousands of years ago, plants and animal remains were buried deep within the earth and then converted to coal due to extreme pressure. In a similar way, crude oil and natural gas are also produced by nature. We are replicating what nature has given us by growing plants, doing vegetation, and putting all organic matter in a biogas digester to produce biogas.

We are not disrupting nature's delicate balance; we are creating fuel without harming the environment or causing pollution. As a result, this is a most advantageous process in which everyone benefits, including nature as well as mankind, mother earth, society, and country. This sector has yet to fully mature, particularly in our country. India is an agrarian economy, with agriculture employing 80% of the population. As a result, the biogas sector has enormous growth potential, particularly using agricultural residue.

As a result, it must be promoted in a way that is consistent with the country's economy. There are currently less than 100 large-scale biogas plants in India. However, based on

current potential, there is room for at least 5,000 plants to be established across the country, depending on feedstock availability. The role of IBA and other oil and gas companies will be critical in propagating biogas.

2. The welcoming news of the CFA revival is bringing fresh motivation to the entire Biogas fraternity, what are your thoughts on that?

The government has taken a very encouraging step by announcing a substantial capital subsidy for the biogas sector. It arrives at a time when the cost of establishing biogas plants has skyrocketed due to the COVID pandemic and also after the funding difficulties the biogas sector is facing, as very few financial agencies have stepped forward to fund the biogas plant.

However, I believe that capital subsidies alone are insufficient to promote the industry; at the very least, some concrete steps should be taken as productivity-linked incentives for the products produced, such as biogas and fertilizer derived from the biogas industry, to make the biogas project funding more attractive.

OMCs have provided a buyback guarantee/assurance/ agreement that they will

purchase it at a certain price, but that price is linked to the CNG price in the market, which is highly volatile in the current scenario, therefore making biogas plants a profitable sector that is highly uncertain. The reason for this is that it is a nascent sector, and the technology is not well established in India; it is far more advanced in the Western nations, but the environment there is different.

Plant equipment such as compressors, balloons, purification systems, and so on are still imported, so they are expensive given that it is not made in the country. Some capital subsidies will help entrepreneurs who are setting up plants with their money, but it must be understood that with interest rates rising to 12% and imported parts such as cascades, balloons, digesters, purification systems, pumps, and so on, the current cost of establishing the plants and the life cycle cost are very high.

With 70% funding from banks and 30% from entrepreneurs, the government should provide some sort of capital subsidy enhancement as well as some productivity-based incentives like INR 10-15 per kg on CBG and INR 2-3 per kg on organic manure to promote the sector. This additional incentive could apply to the first 500 plants

Biogas Magazine | Edition 24 | 13

that are commissioned. If this is done, then it will ensure the stakeholders' seriousness and promote healthy competition among entrepreneurs.This measure will boost the installation of biogas plants. This move should be allowed for a stipulated time limit, perhaps 3-5 years, rather than for an unlimited time. This ensures that anyone who is interested and serious about learning about this industry will benefit. As a result, they will be compensated based on their output and sales. Thus, the MNRE subsidy alone is insufficient, and this is why many plants are not being established. Despite the MNRE subsidy being declared on November 2, 2022, few players have emerged.

3. What specific, big changes need to be made in the renewable energy sector for India to reach its net-zero goals by 2070?

If net zero energy is to be achieved, it must be accomplished entirely through alternative energy sources, of which only solar and biogas make sense. This is because wind energy is highly uncertain, and reliability and maintenance are also some of the concerns. It is debatable whether it can sustain itself. India has an abundance of agricultural residue, and because it is a tropical country,

the sun is available for most of the year.

Piecemeal policies are being developed, but a comprehensive policy should be drawn up in which, in conjunction with agro residues, the plantation of energy crops on barren lands should be taken up. A comprehensive policy must be drafted in order to ascertain from where raw materials will be obtained and how the study will be conducted; a roadmap must be prepared for how this must be accomplished, the availability of solar panels, how they will be made available, and at what cost.

Everything must be clearly specified in the policy draft, including how solar electricity will be generated, how it will be injected into the grid, and at what price it must be injected into the grid. Everywhere, simple declarations are made that are not very helpful. Comprehensive policy development is not taking place.

Similarly, for biogas, how will the equipment be arranged, how many pieces of equipment, compressors, and so on are required, what is the country's current capacity for making cascades, purification systems, or compressors, and how many plants are to be set up? Since the last five years, more and more seminars have been held in place

of real action and concrete measures that are required to be implemented on the ground. Some concrete work on the ground is required.

4. How can we reconcile net zero with the many other sustainability challenges? For example, how do we make circular thinking central to the net zero agenda?

To achieve net zero energy, all aspects of energy must be considered. Carbon accounting must be done because there is currently no concept of carbon accounting in the country: how much we are burning, how much we could save, and how many new avenues must be created. This concept of carbon accounting must become a part of every industry, household, organization, and society.

This concept must be accepted and practiced on every level: as responsible citizens, as responsible industries, and as responsible entrepreneurs, we must account for carbon, what we burn, what we create, how much pollution we cause, and how much we can reduce. We must also educate every student and citizen that wasting our resources, whether food, energy, or water, is a criminal offence. From there, the net zero concept emerges.

Unfortunately, whatever is

Biogas Magazine | Edition 24 | 14

happening is happening intermittently; for example, turn off your car engine at a red light, etc. These are minor things, and even for this, we do not have the right infrastructure: the roads must be designed in such a way that there is no traffic jam if this energy-saving etiquette is followed. It is concerning how much fuel is consumed each day in traffic jams. The sky was clear during the lockdown, and the Himalayan mountains could be seen from Delhi. So, it is quite understandable how much pollution we produce on a daily basis.

5. In 2047, India will celebrate 100 years of independence, so to attain Atmanirbhar Bharat, what are your suggestions or opinions on making the CBG sector more robust?

A comprehensive policy is required for the CBG sector. Starting with feedstock management, the plant's layout, technology, and economics must be worked out or modelled so that any entrepreneur setting up the plant finds them appealing. The following concerns need to be addressed: at what rate funds are available, what incentives are being provided, so that it encompasses everything, including the availability of the cascade, material, compressor, and

purification system in India, how many industries must be established, and so on. What we could do, whether some equipment is imported, whether we can make those in India, whether we can replicate that model— so, starting from feedstock management and policy intervention to technology and product off-take, intervention is required everywhere.

Off-take from oil companies is currently not very appealing, in the sense that a buyback arrangement exists, but demand is dependent on market conditions. Because CBG is essentially replacing CNG, there is no CBG market. The gas grid is not yet operational; it is currently in the process of being built. As a result, there is a need to intervene as a policy matter and as a solution everywhere.

Micromanagement is required at all levels. Not only at the feedstock level but also at the plant setup level. Improvements are required everywhere because the current policy interventions are insufficient. That is the primary reason why even though it is beneficial to society, this industry is not growing despite the large number of interested visitors, including IOCL, HPCL, BPCL, and GAIL. As a result, we must make the sector appealing at

all levels.

We must identify the major problems and find potential solutions in each biogas segment. Every problem must have an implementable solution. Financing is currently a major issue; banks are demanding collateral that entrepreneurs cannot provide. Interest rates are currently so high that it makes no sense to invest in this sector as a plant owner.

These are the primary reasons why this sector is not growing at a faster rate, despite numerous benefits such as job creation, scientific waste management, environmental cleaning, and the achievement of the Swachh Bharat Mission. This is the only government programme that addresses four or five government programmes with a single SATAT programme.

The main idea behind SATAT was that what came from the field should be returned to the field, extracting the energy component and utilizing it more effectively. That is why we proposed collecting feedstock within a 25-kilometer radius of the plant and selling biogas within the same radius.

Biogas Magazine | Edition 24 | 15

After Varanasi, ATEBL plans next Compressed Biogas Plant in Barsana

The initial plan of the company was to set up a BioGas Plant with a capacity of 300 TPD, however soon as the work commenced, there was no stopping back. Unleashing the potential available in the state of Uttar Pradesh, backed by strong parentage from Adani And TotalEnergies, it was decided to roll out a plant of 600 TPD, double the capacity.

The vision is to set up a state of the art Bio Gas Plant, which shall stand as a model plant, best of the equipment, technology, process, and last but not the least, with net zero carbon from day one, with capabilities of Carbon Capture.

The company, with guidance backed by project execution experience and technical expertise in Bio Energy, laid out a blueprint within a much shorter span of time for a plant with such capacity. Now the work of bringing in the right set of partners within the time frame (as time is the essence) to set the blueprint in motion is moving towards the realization of the vision into reality. The process sowing of the right seeds for cultivation was started, and the forage was concluded. Project execution is the key, for which the best of the EPC, technology and design engineering entities were roped in along with the independent engineers who would act as a

The plant is uniquely planned & designed to reach progressively full capacity by inching along with capacity building, with a KAIZEN ideology improving at each stage. We are sure that this process will set the benchmark in the biogas sector and act as a roadmap to drive success towards the vision of GoI. The plant is expected to be completed in a time frame of around 26-29 months at its full capacity of 600 TPD.

The Government of India (GoI) lays strong impetus on bio energy, especially CBG, which is like Natural Gas (essentially methane).

Biogas Magazine | Edition 24 | 16

third eye to team support.

The Ministry of Petroleum & Natural Gas (MoPNG) has an ambitious plan to set up 5,000 CBG plants across the country. MoPNG’s vision is to have 5,000 biogas plants by 2023-24 on a pan-India basis, which would translate to 15 MMT of CBG per year, equivalent to 54 MMSCMD of gas. Biogas being a new sphere, the company decided to appoint a consultant for design, engineering, planning & construction management.

An enquiry was floated to reputed and prominent vendors, out of which five were shortlisted after thorough due-dilligence. It was observed that some were only interested if awarded to work on an endto-end Engineering, Procurement and Construction (EPC) basis. Hence, it was decided to go for Expression of Interest (EoI) and explore the right project methodology.

An EoI was prepared and sent to 26 parties. They were re-

quested to present their plant design along with their capabilities. Two-level committees were formulated to rate and shortlist the submissions. Eleven vendors gave their presentations. A detailed evaluation criterion/matrix was finalized by the internal team in consultation with Total Energies and its technical team, keeping in mind three broad aspects: 1) Technical/ Technological, 2) Experience/ Business /Planning & 3) Financial /Economical.Further filtration of potential bidders was done based on the input and detailed presentation given by each participating bidder.

Four vendors were shortlisted based on parameters like organization profile, capability statement, relevant past experiences, technology offered, testimonials of past experience from other entities, overall vision and suggested scheme for Barsana CBG Plant, etc.

1) Project Risks:

Execution Risk Choosing a capable EPC partner for the job.

A brief functional RFQ, which defined performance parameters on the input and output sides and associated penalties for shortfalls of the same, was kept as part of the commercial conditions. Since the industry is new, freedom of design and engineering was given to the contractor, but an independent engineer was appointed to proof-check the design. Technical specifications were defined, and commercial terms and conditions were designed to ring-fence the contractual liability of the vendor. Two-year O&M was also kept within the scope of the EPC vendor.

As part of the process, SWOT analysis of the shortlisted vendor was carried out for each of the suppliers, and the risk identification and mitigation activities were done. The most important aspect of the project's success is the availability of feedstock and its ring-fencing.The same are as follows:

1) Appointment of Owner’s Engineer and Third-party Inspection agencies for thorough checking of design and engineering and the construction works.

2) Having O&M for 2 years in the scope of the bidder.

Performance of the plant Efficient contracting philosophy. Well-defined KPIs (Key Performance Indicators) in the contract

Sufficient safeguards in the contract has been built.

Biogas Magazine | Edition 24 | 17

Type Of

Mitigation Plan

Risk Risks Identified

2) Operation Risks:

Type Of Risk Risks Identified Mitigation Plan

Availability of Feedstock

Availability of Feedstock –rice straw is available only for one month in a year and press mud is available only 3 -4 months in a year, suitable storage and logistics arrangements to be made

Advocacy from State Govt. shall help in this.

Sustainability aspect

We have chosen technology with lower power and low water consumption

Carbon sequestration is also part of the scope of this project. Carbon negative plant as CO2 is being captured and liquified which is a sellable product generating additional revenue.

Fertilizer Sales Currently, the market for organic fertilizer is growing. Options of blending and enrichment will be explored with respect to market dynamics

Although the contract was finalized for overall delivery progressively. This will not only aid in early revenue realization but also ensure that corrective action is taken in the next phase and the contract is closed after com-

pletion of each phase.

Opportunities to sell value-added items will be explored and if required, a separate facility for the same based on techno-commercial feasibility will be proposed.

The important characteristic of the plant is that all the carbon dioxide generated during operation is captured and liquified via CO2 liquefaction plant. Moreover, the plant

has zero liquid discharge, resulting in no liquid waste.

Overall, the plant will be carbon neutral, emitting no greenhouse gases and so being sustainable and eco-friendly.

The overall decision-making was done keeping in mind the technical and financial capabilities and the input-output financial modelling with ringfenced contractual terms and phasing of the project, with an option to hold back at the completion of any phase.

Biogas Magazine | Edition 24 | 18

Sandip Adani Sr. Vice President & Head (Techno - Commercial) Adani Total Gas Ltd.

Sr NO Number of Phase CBG Production in Tons 1 3 Digestors with 10T CBG capacity 10T 2 3 Digestors with 14 T CBG capacity 14T 3 3 Digestors with 18.5 T CBG capacity 18.6T

SUSTAINABLE AGRICULTURE IS HERE

Nitrogen emissions, in particular ammonia emissions from agricultural waste streams, are negatively impacting the global food supply and future generations. Foremost is the environmental damage caused by ammonia emissions contributing to air pollution and the formation of particulate matter. It harms plants, including crops, by reducing photosynthesis rates, damaging leaves, and inhibiting growth. Consequently, overall agricultural productivity is negatively affected. Further, ammonia deposits increase soil acidity, leading to a decrease in soil pH which has detrimental effects on crop yields and nutrient availability.

These harsh repercussions only scratch the surface. Ammonia emissions contribute to the release of excess ni-

trogen into the environment. While nitrogen is an essential nutrient for plant growth, excessive nitrogen can cause imbalances in ecosystems. It harms aquatic life, reduces biodiversity, impacts the availability of freshwater resources for agricultural purposes, and contributes to the formation of greenhouse gases, such as nitrous oxide, which further exacerbates climate change. More directly, excess ammonia emissions, particularly from concentrated animal feeding operations (CAFOs) and industrial processes, pose health risks to humans. Inhalation of ammonia gas can irritate the respiratory system, leading to respiratory issues, especially in individuals with pre-existing respiratory conditions. Additionally, ammonia can react with other air pollutants to form fine particulate matter, which has been associated with various health problems,

including respiratory and cardiovascular diseases.

Now governments and activists are taking aggressive and often extreme measures to curb nitrogen and ammonia emissions, especially in the context of air pollution and environmental protection, to solve the nitrogen crisis. From complex and invasive regulatory frameworks to unrealistic emissions reduction targets, these approaches are putting family farms out of business, preventing new crops, and driving higher prices for consumers. Pure Green Agriculture believes that innovative technology in conjunction with improved agricultural practices is the sensible and profitable path to solve ammonia emissions issues and create a truly sustainable global food supply that we all will benefit from.

Pure Green is a biotechnology company that developed

Biogas Magazine | Edition 24 | 19

a process to produce fully sustainable, carbon-neutral nitrogen fertilizers that benefit the environment and the global food supply. These fertilizers are produced by extracting nitrogen in the form of ammonia from organic waste streams in a process that is carbon neutral. The products are identical to chemically produced nitrogen fertilizers, but with one critical difference - Pure Green’s products are 100% sustainable. Unlike those that have shown a willingness to curb emissions without consideration for farmers and consumers, Pure Green’s approach is quite novel: solve the nitrogen emissions crisis without crippling the very farmers and producers, we so desperately rely on for our food supply. In fact, Pure Green believes these producers and farmers should increase profitability while making transformative changes to their business, and thus not risk going out of business. According to CEO Phil van Wakeren, “Our proposition is that in order to change agriculture to a fully sustainable regenerative model - one without yield drop, one that maintains or increases production rates, the availability of sustainable nitrogen is essential.” Typically, the chemical nitrogen industry uses two processes to produce nitrogen. The Haber Bosch process produces ammonia using atmospheric gas. The second process is named after its developer.

Wilhelm Ostwald when he

Wilhelm Ostwald when he

patented it in 1902, is a mainstay of the modern chemical industry. The process provides the main raw material for the most common type of fertilizer production. Ostwald turns the ammonia into nitrate. Both Haber Bosch and Ostwald use high levels of energy and therefore emit very large amounts of CO2 into the atmosphere. Additionally, nitrogen from the atmosphere is added to the agricultural cycles disturbing natural nitrogen levels.

Pure Green’s process is vastly different. It extracts nitrogen from organic waste streams that are originally produced on farms such as food, manure, plant residues, and more. When these organic waste streams containing nitrogen (organic bound nitrogen) are decomposed, the nitrogen is made available (released) in the form of ammonia. Pure Green extracts the ammonia very efficiently to form an ammonia feedstock, used in its patented microbial oxidation process called AIR, where nitrification bioreactors facilitate the metabolization of the ammonia into nitrate using microorganisms. The process is entirely unique and completely sustainable. The resulting nitrate is critically important as it is the essential compound for producing fertilizers, in this

case, sustainable fertilizers such as potassium nitrate, calcium nitrate and ammonium nitrate. The end products can be formulated to fit each crop’s feeding specification through blending and concentration. All products allow for drip irrigation and can be used in hydroponics or traditional applications.

Perhaps most unique is the fact that Pure Green has perfected an approach that mitigates harmful emissions at the highest level, eliminates regulatory costs from fines and compliance that many farmers face, reduces operational costs from disposal and tipping that plague the bottom line of many, while creating a new revenue stream from what was otherwise a nitrogen waste product. Further, Pure Green adopts a circular economy model in its approach. By creating a circularity between the conventional agriculture sector and livestock sector, it can be an agent of change by transforming agricultural practices through sustainable food production that reduces by-products and supports environmental initiatives.

Biogas Magazine | Edition 24 | 20

Phil Van Wakeren CEO

Pure Green Agriculture Inc.

Biogas Magazine | Edition 24 | 21 ArmaMixTWIN Theultimateinceiling installation ArmaMixEVO+ Slow-runninglong-shaft agitatorfordrysubstrate contentsofupto15%. ArmaMixEVO Slowspeeds,highcirculation capacityandlongservicelife STIRRING-PUMPING-MOVING-ANDMORE Agriculture,biogas,sewageandwastewater,andindustrialapplications Agricultural,biogas,sewageandwaste waterandindustrialapplications Differentcomponentsforyoursystem ARMATEC-FTS.COM/EN Designed, developed and made in Germany ARMATEC-INDIAPVTLTD G1,Sairesidency, Plotnumber45, srinivasnagarcolony, Nizampet, Hyderabad-500090 VijaykumarLanka Mob:00918919532349 vijayklanka@armatec-fts.de www.armatec-fts.com

Exploring the Potential of Modern Innovative Decentralised Biogas Technology

The history of biogas technology dates back to the 19th century. Research suggests the world's first biogas plant was built in Bombay, India in 1859. However, it wasn't until 1973, when fossil fuel prices started escalating and the government shifted their focus towards renewable energy, that biogas technology gained widespread recognition and attention.

The journey of biogas technology has been marked by continuous development and evolution, leading to the emergence of modern innovative biogas technology.

Modern innovative biogas technology made its debut in the early 2000, with the goal of creating a modular and scalable biogas plant that could address the limitations of the fixed-dome model. The objective was to enable easy installation, expansion, and customization to suit the needs of rural communities.

Although using the same ageold conventional method, modern biogas plants have revolutionized the process of converting waste into renewable natural gas, offering numerous advantages over traditional systems. These plants excel in efficiently generating an optimal amount of energy

for various applications, such as cooking, heating, powering agricultural activities, and generating decentralized electricity. Notably, they also possess several other unique features that sets them apart from their predecessors.

Affordability, Durability and Flexibility

One such key aspect of modern biogas plants is their affordability, durability, and flexibility. Modern innovative biogas plants are designed to be cost-effective and require minimal maintenance, ensuring long-lasting functionality for approximately 15-20 years. Their flexible

Biogas Magazine | Edition 24 | 22

nature allow easy installation, and they don't occupy a fixed space in a farmer's backyard. This mobility enables farmers to adapt their biogas systems to their changing needs and agricultural practices.

User-friendly Nature

Another important advantage of modern biogas plants is their simplicity of operation. Farmers worldwide have adopted these plants due to their user-friendly nature. With minimal training, farmers can easily operate and maintain their biogas plants.

Seamless Supply of Energy

Modern innovative biogas plants also stand out due to their ability to provide a seamless supply of gas directly to the kitchen. By connecting the biogas system to the household kitchen, farmers can conveniently access renewable energy without relying on grid electricity. This feature promotes energy independence and contributes to a sustainable and eco-friendly lifestyle.

Easy Installation

One of the most significant advantages of modern innovative biogas plants is their rapid installation speed. A team of just two trained engineers can install multiple biogas units in a single day. This accelerated installation process enables mass deploy-

ments within a short period, making it feasible to implement large-scale biogas projects efficiently.

Modern innovative biogas plants predominantly exist in rural areas. Smallholder farmers and dairy farmers in particular are the primary beneficiary of this cutting-edge technology. These biogas plants are designed to effectively process animal and farm land waste, both of which are abundantly available in rural networks. The adoption of modern biogas plants bring forth a multitude of benefits, making them a valuable solution for renewable energy generation and effective waste management in rural communities.

Renewable Energy Generation

Modern biogas plants produce biogas, a renewable energy source that can be used for various applications. Biogas is primarily composed of methane, which can be utilized for cooking, heating, electricity generation, and as a replacement for fossil fuels. By harnessing biogas as an energy source, modern biogas plants contribute to reducing reliance on non-renewable energy and lowering greenhouse gas emissions.

Waste Management

Biogas plants play a vital role in addressing the organic

waste management problem. Animal and farm land waste contribute a significant chunk to greenhouse gas emissions. Most of the smallholder farmers have access to cattle; however, the waste generated from them is often left neglected which leads to the generation of poisonous methane gas, a pollutant for the environment. Biogas plants offer an easy remedy to this problem by converting animal waste into a renewable energy source, contributing to a circular economy and sustainable waste management practices.

Improved Air Quality and Health:

A recent study suggested that there are more than 35 million smallholder farmers in India, of which 60% to 70% still rely on firewood for their cooking needs. This leads to indoor air pollution, which is hazardous to health, particularly for women and children who spend significant time indoors. By providing a clean and smoke-free cooking fuel alternative, biogas plants help improve indoor air quality and reduce respiratory illnesses and related health risks.

Rural Employment

The establishment and operation of modern innovative biogas plants leads to the generation of rural employment. Local communities

Biogas Magazine | Edition 24 | 23

can engage in the collection and supply of organic waste feedstock, construction and maintenance of biogas plants, and distribution of biogas and biofertilizer products. These activities contribute to income generation, skill development, and the overall economic growth of rural communities.

Access to Organic Biofertilizer

Biofertilizers support sustainable agricultural practices by reducing the dependence on synthetic chemical fertilizers. Chemical fertilizers can have adverse effects on the environment, including soil degradation, water pollution, and harm to beneficial organ-

isms. Biofertilizers provide essential nutrients to plants, including nitrogen, phosphorus, and potassium, as well as micronutrients. They help improve soil structure and nutrient-holding capacity. By using biofertilizers, farmers can minimize the environmental impact and promote ecological balance in the agricultural ecosystem.

Modern innovative biogas plants play a significant role in mitigating climate change by reducing greenhouse gas emissions. Methane, a potent greenhouse gas, is released during the decomposition of animal and farm land waste. However, instead of allowing methane to escape into the atmosphere, biogas plants capture and utilize it as a renewable energy source in the form of biogas. This helps prevent the release of methane into the environment. Additionally by replacing fossil fuel as a source of energy biogas also helps to reduce carbon dioxide (CO2) emissions.

According to recent statistics, animal and farm waste contribute to approximately 22% of India's annual greenhouse gas emissions. Recognizing the significance of addressing this issue, the Government of

India has implemented various initiatives to promote the adoption of modern innovative biogas technology in rural areas. These initiatives aim to encourage the establishment of biogas plants, particularly in regions where animal and farm land waste is abundant. By promoting the use of biogas technology, the government seeks to mitigate the emissions associated with animal and farm land waste while simultaneously providing renewable energy solutions for rural communities. India's contribution to global greenhouse gas emissions stands at 6%. Embracing modern innovative biogas technology presents a unique opportunity for the government to tackle critical issues such as energy access, waste management, and climate change mitigation. Moreover, by prioritizing the promotion of biogas technology, the government can align its efforts with the ambitious objective of achieving net zero carbon emissions by 2070.

Atul Mittal Director Commercial Sistema.bio

Biogas Magazine | Edition 24 | 24

HP-RAMP technology Producing biogas

from tougher substrates such as lignocellulosic biomass becomes easier

Lignocellulosic biomass is considered a potential substrate for producing bio-methane. Nonetheless, the recalcitrant nature of biomass affects its rapid conversion into biogas. At HPCL Green R&D Centre, Bangalore, a new process called HP-RAMP (Rapid Acidification for Methane Production) has been developed for the efficient conversion of a variety of lignocellulosic biomass (rice straw, napier grass, sugarcane bagasse, mixed biomass, etc.,) into bio-methane. Based on our comprehensive understanding of the structural complexities of biomass, a process was developed to reduce the recalcitrance of biomass, before its anaerobic digestion.

Usually, before subjecting the biomass to any form of microbial conversion, some form of pretreatment is required wherein the lignin sheath of biomass is partially or completely removed through a thermochemical process.

The effectiveness of lignin removal mainly depends upon the severity of the treatment. Although severe process conditions may help in maximum delignification, it is usually accompanied by higher carbohydrate losses and the formation of undesired side products, ultimately affecting the overall process economics. Keeping the cost factor in mind, a pre-conditioning treatment was developed to reduce the recalcitrance of biomass. On treating the

pre-conditioned biomass to anaerobic digestion, a distinctive enhancement in carbohydrate utilization during anaerobic digestion was observed.

In addition, a reduction in crystallinity of the cellulosic components was also noticed during the digestion of pre-conditioned biomass materials. The reduction in crystallinity and increased consumption of cellulosic components possibly resulted in higher biogas formation in a conventional stirred tank reactor.

Environmental impact of the

HP-RAMP process:

The catalysts used during the preconditioning of biomass get neutralized during the

Biogas Magazine | Edition 24 | 26

final stages of the pre-conditioning steps and have no impact on the liquid effluent quality. In fact, with the addition of catalysts during the pre-conditioning step, H2S formation was minimized and was found to be below detection levels. The reduction in H2S content is a direct advantage offered by the HP-RAMP process.

HP-RAMP treatment for different feedstock:

At HPCL R & D, the newly developed process has been successfully tested on several types of biomass varieties such as napier grass, rice straw, wheat straw, sugarcane bagasse, and even garden waste. Compositionally, all these feedstocks vary in their content of lignin, cellulose, and hemicelluloses. They also vary from each other w.r.t their extractives compositions and contents and the presence of additional components such as silica. All the feedstock variations have an impact on the consistency, quality, and quantity of biogas production.

On processing these biomasses with HP-RAMP technology, it was observed that consistent quantities and quality of biogas were obtained although the yields varied marginally from one feedstock to another. Moreover, on comparing the biogas yields

for untreated and HP-RAMPtreated biomass, the biogas production was around 70-80 % higher. In addition, the hydraulic retention time (HRT), a critical decider of reactor productivity was also found to be lower by about 20 % for HP-RAMP-treated feedstock.

The potential of HP-RAMP technology in biogas production:

Several scientific reports published by reputed surveyors and agencies in the last decade have indicated the vast availability of surplus agricultural residues (as high as 230 MT/year) in India. The anaerobic digestion of these residues for biogas production can have a substantial impact on enhancing renewable energy supplies for India.

Since HP-RAMP technology can now solely process lignocellulosic biomass for biogas production, large to very large-scale plants can be built across the country. Previously, agri-residues could be converted into biogas only after combining with some form of organic agri-wastes (cow dung, food waste, chicken litter, etc.) to improve the nutritional content needed for microbial metabolism.

Moreover, these plants had to be set up in a location wherein the availability of organic wastes could be ensured. With the development of HP-RAMP technology, there

is now no need to locate the plant nearer to the source of waste generation. The microbial consortia used in HPRAMP are relatively robust and only occasionally supplement with organic or inorganic nutrients.

The HP-RAMP Process:

Lignocellulosic biomass with moisture content varying from 15 % (wt.) to as high as 70 % has been successfully tested as the feedstock for biogas production with HPRAMP technology (Fig. 1). For low-moisture content-bearing feedstock, a size reduction step using conventional biomass cutting equipment helps to obtain a feed, with the material of ~1-3 cm (at least 80 %). Preventing biomass losses due to dust formation during sizing operations is important. Since bailed biomass usually comes with significant quantities of attached soil, it is necessary to remove soil by conventional techniques.

The pre-processed biomass now undergoes multiple steps of pre-conditioning wherein catalysts are added to the biomass and the mixture is subjected to temperatures below 90 °C for 1-2 hours. Depending upon the nature of biomass, there is a possibility of reducing the number of catalysts used during these process steps. On completion, the biomass slurry is cooled to ambient temperatures and fed into the anaerobic digester.

Biogas Magazine | Edition 24 | 27

To keep the cost lower, anaerobic digestion of the pre-conditioned material was carried out in a standard CSTR and the biogas yields obtained were higher and consistent. There is also a possibility of enhancing gas yields by using specialized reactors.

After a specific HRT, the digestate slurry that comes out of the reactor is subjected to solid-liquid separation, and the liquid effluent is sent back to the reactor. The solid residues were found to be microbially enriched and with simple upgradations have been successfully used as effective bio-fertilizers.

Feedstock processed for biogas production with HPRAMP technology:

Several feedstocks were tested for their potential to produce biogas using HP-RAMP technology. Due to the compositional differences in feed-

stock, the biogas yields varied for each feedstock (Table 1) but were found to be highly consistent for a particular biomass. On the other hand, the composition of biogas for every feedstock was found to be similar (Table 2)

Interestingly, all the HPRAMP-treated biomass vari-

eties, showed extremely low levels of H2S formation and in some cases, these were below even detectable levels.

Biogas Magazine | Edition 24 | 28

S.

Feedstock Moisture

feedstock

of CH4/Ton of biomass 1 Rice straw 10-15 95-89 2 Sugarcane bagasse 20-30 72-63 3 Mixed biomass 10-12 53-55 4 Napier grass 62-70 43-67 5 Mustard biomass 10-15 87-82 6 Rice husk 8-10 46-45 7 Sugarcane Trash 10-15 81-76 8 Wheat straw 10-12 89-87

No.

(%) in the

kg

Table 1: Bio-methane yields from various feedstocks processed by HP-RAMP

The HP-RAMP Process

Using residues as biofertilizers:

The residues exiting the anaerobic digester were characterized and tested for their agricultural suitability (fertilizer potential) under controlled conditions. It was found that residues generated after the anaerobic digestion of each of the biomass types had differing nutritional content. These residues, when used in fields for growing crops showed immense potential as biofertilizers. The produce obtained on residue treatments was always very healthy and less infested with pests, although the yields were lower from chemical fertilizers. To enhance the potential of these residues, it was observed that these had to be blended with external nutrients or specific microorganisms, before applying to crops.

Salient features of HP-RAMP technology:

HP-RAMP technology is a promising technology that can convert a variety of lignocellulosic agri/crop residues

into biogas and could prove to be a milestone development in setting up biogas plants across the country. The new technology is technologically superior due to the following main reasons.

• HP-RAMP is truly, a feedstock agnostic process.

• The carbon footprint of HPRAMP technology is lower.

• The processing of biomass with HP-RAMP avoids the formation of several undesired by-products.

• HP-RAMP is a zero-effluent discharge process and the residues generated can be easily upgraded into bio-fertilizers.

Biogas Magazine | Edition 24 | 29

Dr. Harshad Ravindra Velankar Chief Manager-Bioprocess HP Green R&D Centre

Dr. Chiranjeevi Thulluri Manager-Bioprocess HP Green R&D Centre

Composition Amount (% mol.) CH 4 ~50 CO 2 ~35 N 2 ~4.7 Other gases & Moisture ~10

Table 2: Average composition of biogas produced from different feedstock processed by HPRAMP technology

ICL IS YOUR RIGHT PARTNER ! 80 Years Of Years Years Of Excellence! Excellence! Excellence! Air & Water Cooled Versions "Mini - lubricated" design for lowest oil contamination 275 bar, 2000 Designed in Italy H i g h P r e s s u r e B i o - C N G C o m p r e s s o r s Non - Lubricated Design For 24*7 continuous Process Duty Handles Raw Biogas L o W P r e s s u r e C o m p r e s s o r s Over 1800 Natural Gas/CNG Compressors Working Across India Dedicated Service Network in Every Indian City Serving All major CGD & Biogas Companies I N D I A N C O M P R E S S O R S L T D Sales@Didwania.com | www.Didwania.com Sm3/h BIOGAS COMPRESSORS

Building CBG market in India through certificates mechanism

Introduction

India imports more than 50% of its natural gas requirements and 85% of its crude oil demand. CBG, being an indigenous source of energy, can replace imports and hence has huge potential for saving foreign exchange. To capitalise on the benefits of this indigenous source, GoI in 2018 launched the Sustainable Alternative towards Affordable Transportation (SATAT) scheme, which aimed at setting up 5,000 CBG plants by 2023-24. However, the progress has been relatively slow, and as of March 2023, only 58 CBG plants have been operationalized, though LoI has been issued to 3,694 projects. The creation of transparent markets can fasten the development of CBG ecosystem and production.

According to India's Nationally Determined Contribution (NDC) submitted to the United Nations Framework Convention on Climate Change (UNFCCC), India has commit-

ted to achieving net-zero GHG emissions by the year 2070 and plans to achieve energy independence by 2047. CBG, being a clean and indigenously available source of energy, that can also be integrated into the existing gas infrastructure, provides the easiest route to achieve these goals. Another advantage of biogas systems is that they can be set up and operated locally, thereby enhancing local ecosystem.

To provide fresh impetus to CBG, GoI on February 1 2023 announced its plans to introduce a mandate for all organizations marketing natural gas to use at least 5 per cent CBG in the future. Assuming the GoI mandates a progressive mandate of 1% (starting FY24) to 5% by FY27 on CBG obligation, the country would require CBG starting from 0.40 MMSCMD in FY24 to 5 MMSCMD in FY30 against current production of mere 0.002 MMSCMD.

(refer Table 1 Below)

Also, it is pertinent to mention here is the final report of the “Energy Transition Advisory Committee” constituted by MoPNG has identified certain enablers for CBG Market Development. One of these enablers include providing CBG blending mandates to all CGD entities marketing CNG and PNG, and another important enabler includes trading the green attribute of CBG. An additional source of revenue can be created for biogas producers by monetizing the green attributes of CBG. We can create a certificate from the green attributes that will capture a premium over normal natural gas. This certificate is expected to solve many issues simultaneously.

One, it can overcome barriers of location, technology, and infrastructure. India has ample availability of feedstocks to meet the requirements of CBG; however, the challenge is that each feedstock has its own availability, supply chain, and processing technology. It

Biogas Magazine | Edition 24 | 31

Particulars FY24 FY25 FY27 FY30 India NG demand (MMSCMD) 170 195 245 320 CGD Demand 38 44 70 105 CBG sale mandate (%) 1% 2% 5% 5% CBG sale mandate (MMSCMD) 0.40 0.90 3.50 5.00

Table 1 Estimated CBG demand based on CBG Obligations trajectory

is this variability in terms of feedstock availability, technology, grid infrastructure, and the varied and distributed presence of CBG procurers that creates the diversity in supply and demand in terms of geographical spread, temporal and seasonal spread. Two, CBG certificates can also address the mismatch between the availability of CBG and the requirement of mandated entities to meet their obligations in a costeffective manner and over a longer timescale, say one year, as compared to CBG procurement, which has to be simultaneous and over a comparatively shorter time period. Three, certificate trading also widens the base of buyers and sellers of CBG, obviates inter-state transportation needs, and makes procurement of green energy/ attributes simple and competitive.

Concept of CBG certificates

CBG certificates’ are digital certificates issued against the green attributes of CBG produced/injected in the grid, which represent the “green” value of biogas. The certificate or green value of the CBG may be traded commercially. One of the most important principles of a CBG certificate is that it can be traded independently from the physical molecules of biogas it represents. Also, while CBG certificates can be traded independently from the physical commodity they rep-

resent, CBG certificates can also be bought and sold with the physical commodity it represents. There is currently no mechanism to enable the selling, purchasing, and tracking of CBG and/or green attributes in India. A scheme can be developed to facilitate the same. Also, it may be noted that the ‘Carbon Credits Trading Scheme’ and ‘CBG Certificates Scheme’ shall run independently of each other for the obligated and eligible entities. Further, they can be made fungible over time.

Transaction lifecycle

A CBG producer can sell the gas produced as green gas accompanied by the CBG certificate. Or you can decouple them and sell CBG as normal brown gas in the gas mar-

ket and sell the certificate in the certificate market. There are therefore two markets: a physical gas market for trade in gas and a virtual market for trade in certificates. At the time of CBG production, a certificate would be issued, after which the gas would be traded and transported to users just like normal gas. At that time, CBG would no longer be recognised as CBG because it would mix with natural gas in the pipeline. The "green" attribute would be transformed into a CBG Certificate, which can then be traded separately from the physical gas flow and linked back to the physical gas flow if an end user consumes CBG.

Biogas Magazine | Edition 24 | 32

Figure 2. Schematic representation of certificates and gas market mechanisms

Transaction lifecycle diagram

Scheme design elements

Element

Registry functionality

Certificate attributes

Producer eligibility

Description

Creation, trading, surrender, or cancellation of CCs

Producer, technology, location, feedstocks, time period etc.

Both grid-connected and off-grid plants

Obligated entities As mandated by GoI say CGD licensees or all natural gas consumers etc.

Voluntary entities

Environment conscious corporates/individuals

Certificate denomination 1 certificate = Green attribute relating to 1 MMBTU or equivalent of CBG produced

Certificate validity

Auditing

Certificate price

Initial validity period of 12 months, extendable based on requirement

Regular auditing based on defined reporting period

Benchmark price linked to carbon markets in an advanced economies let’s say EU after adjustments like purchase parity etc.

Formula thus determined can then be used with a discount (let’s say 25%) to start with and gradually tapering it down in 5 years

Biogas Magazine | Edition 24 | 33

Benefits to the ecosystem

Benefits to CBG producers: CBG certificates would provide an additional revenue stream to CBG producers as certificates could be sold as a tradeable instrument independent from the physical CBG commodity. Certificates could also enable CBG producers to gain information on consumer appetite for their product, which could provide market signals for expanding CBG production facilities. Benefits to consumers: Beneficial to consumers as certificates would enable virtual trade instead of physical trade, hence overcoming barriers of location, feedstock availability, technology, infrastructure, and time. Also, certificates would be an attractive proposition for certain industries to meet their green norms.

Benefits to the overall industry: A CBG certificate mechanism shall be able to differentiate CBG from NG in the grid, thus also enabling the trading of green gas through the grid.

Way forward

Developing a CBG certificate scheme can be an important step towards promoting the production and consumption of CBG and supporting the transition to a low-carbon economy. Developing a successful scheme would require a certification mechanism, effective mandates, and compliance, a trading platform,

and effective promotion and communication.

The Ministry of Petroleum and Natural Gas (MoPNG) can serve as the Nodal Ministry for administering such a scheme and providing various policy level directions for promoting CBG and its grid integration. Next the Natural gas retailing entities, specifically CGD entities, would need to be mandated a CBG procurement trajectory yearon-year through the Ministry. The mandate shall also be allowed to be met through CBG certificates. Compliance and monitoring of the scheme can be ensured by enabling regulations. The Petroleum and Natural Gas Regulatory Board (PNGRB) can provide the Regulatory Framework through CBG purchase obligations, CBG trading, and CBG certificate trading regulations.

Also, to ensure proper development of the sector, regulations / modalities need to be modified immediately with respect to CBG. Producers of CBG, if they so desire, should be allowed to unlock higher values for their investment since the sale of CBG is currently limited to only CGD networks as it is considered equivalent to CNG. With marginal investment, CBG can be further processed to match properties essential for various applications of Natural Gas and then be injected into the National Gas Grid. This is in line with international practice.

Biogas Magazine | Edition 24 | 34

Ravi K Singh Lead Strategy Indian Gas Exchange Limited

Rajesh K Mediratta MD & CEO Indian Gas Exchange Limited

Comprehensive Range of Biogas, Biomethane, Offgas & Landfill Gas Analysers

Continuous Online Analyzer

SWG 100 Biogas

TECHMARK OPTIMA Biogas

Up to 10 sites sample gas switching & monitoring on time sharing basis

NDIR sensor for CH4, CO2 and electrochemical for H2S & O2

Integrated Dew Point measurement

Calculated GCV / NCV values

Programmable Auto calibration for data validation

Real Time Monitoring with Remote Access & Data transfer facility.

Actuation of solenoid valve for closure, as per user settable limits

Alarm Generation on deviation from standard composition with message to concerned personnel / control room

Tamper Proof Password protection

Ex Proof Models also available

Handheld Analyzer

Biogas measurement : CH4, CO2, H2S, O2

Gas Leak detection probe for CH4 (LEL)

Light weight : 700gms

Simultaneous measurement of flow rate & biogas

Built-in condensate separator & dust for extra protection

Internal data storage for about 20,000 readings

SD card, Mini-USB & Bluetooth for data transfer to Smartphone, Tablet or PC

Long-life rechargeable battery with standard

USB charger

CONTACT US FOR DEMONSTRATION

TECHMARK ENGINEERS & CONSULTANTS

1020, Ansal Tower, 38 Nehru Place, New Delhi - 110019

Tel 011 46570392 - 94 Mobile : 7011389878

sales@techmark.co.in www.techmark.co.in

German technology with proven performance

Over 2000 anlaysers sold worldwide

Preferred choice of Indian OEMs, Project developers & owners

All India Service & Calibration support by trained team

Experience of over 26 years in handling gas analysers

Technological intervention boosts Biogas plant profitability

India is poised to be a 5-trillion-dollar economy by 2025, and the mobility sector will have a huge role to play in driving this growth. To address the growing energy demands of this sector while at the same time also achieving a reduction in imports and tackling decarbonization in the future energy basket for the transportation sector. Waste-to-biomethanation projects have witnessed renewed interest across the globe – Biogas generated through anaerobic digestion of biodegradable organic feedstocks, i.e. municipal and industrial wastes, animal and agricultural residues, etc., have drawn interests across

the developing and developed economies. Biogas contains a high methane content (40–70%) that can further be upgraded (90–99% methane content), which can be injected into the National gas grid to be used as low-carbon transport fuel amongst other forms of end-usages.

Anaerobic digestion of biodegradable organic wastes provides numerous social and environmental benefits, in addition to energy and manure. Biogas helps to reduce the negative externalities associated with organic wastes, such as pollution of groundwater and soil, emissions of local air pollutants including

dioxins and furans, and methane, a strong greenhouse gas. When compared to untreated animal dung, the mineral nitrogen concentration of the slurry following anaerobic digestion increases, allowing it to be utilised as organic fertiliser.

This assist in partial or complete replacement of the requirement for chemical fertilisers, which have a significant energy demand during manufacturing. Even though the environmental, health, and social benefits of biogas generation are well acknowledged, the CBG sector development still has some grounds to cover in India,

Biogas Magazine | Edition 24 | 36

when compared to the developments on a global scale.

If one considers developments in countries where biomethane production is being embraced on a large scale, two factors have played a major role in its development: strong policy support, and technological innovation. While the Indian Government has given a positive thrust to this market to gain significant interest from investors and entrepreneurs, it is technology innovation that will be crucial for the next phase of growth.

Biogas generation is a well-established technique, but its commercial use is limited due to the necessity for on-site purification prior to shipment or usage. A thorough purification and upgrading procedure that eliminates pollutants is required before biogas can be supplied into the National Gas Grid system or utilised as biofuel. While conventional techniques for biogas purification and upgrading remain in use, worldwide technological developers have also created cutting-edge purification and upgrading innovations, resulting in technology that not only gives high-grade purity of methane but also is sustainable for the environment.

Investing in dependable, high-quality technology will allow us to make the most of the biogas generated by converting it to Bio-CNG. This will

allow investors and Entrepreneurs to get the most out of their CBG plant while lowering the total cost of ownership, considering the chosen biogas production or upgrading method will certainly have an impact on project expenses.

Extensive upgradation and purification treatment that removes contaminants is necessary before biogas can be injected into the national gas grid or employed as a biofuel for the transportation sector. Biogas cleaning is the process of eliminating pollutants from the raw biogas, and biogas purification is the process of enriching methane content to increase the calorific value.

The membrane separation technique is very appealing for biogas purification because of its low energy consumption, excellent selectivity, readily designed modules, and hence lower operational costs. High methane recovery efficiency (>95%) can be achieved, while pure CO2 can be produced as a by-product for various industrial purposes, therefore enhancing the business.

The biogas can be upgraded to the chosen methane concentration depending on grid or user needs. Evonik's Membrane technology, marketed as "SEPURAN® Green," employs highly selective polymer membranes to convert raw biogas into extremely pure

CBG in a simple and economical manner (biomethane). With more than 800 references worldwide, SEPURAN® Green membrane technology has the highest CO2/CH4 selectivity and is, therefore, a superior technology for upgrading biogas. SEPURAN® Green, with its patented 3-step membrane-based gas separation process, significantly increases the recovery of biomethane (>99%), which has a corresponding effect on the profitability of biogas processing plants, hence making the upgrading process as efficient and economical as possible.

Deploying membrane technology also has advantages for CBG project investors in terms of profitability and sustainability. Traditional technologies require comparatively large amounts of energy as well as auxiliary materials and chemicals, resulting in waste and wastewater generation that must be treated and disposed of. Also, methane loss during extraction and upgradation process via Membrane technology is much lower than the methane loss value of several other biogas purification methods. Hence, membrane technology is the ground-breaking method of biogas separation and purification for deploying the benefits of waste-to-biomethanation projects.

The nation has huge promise in the area of biomethana-

Biogas Magazine | Edition 24 | 37

tion projects, considering the country has huge biomass and organic wastes – potential waiting to be unlocked. According to research published in Science Direct, it is envisaged that Biogas will emerge as a promising fuel in the next two decades in India - 310 to 655 billion m³/year in the year 2040, owing to rising waste generation and adequate disposition of relevant infrastructure for waste collection efficiency.

Since 1982, India, among other countries, has promoted ‘Waste-to-Energy' projects. CBG has lately emerged as an important component of India's future green mix, as described in the Government of India's 2018 Sustainable Alternative towards Affordable Transportation (SATAT) programme. The Indian government, under the SATAT scheme, envisages setting up 5,000 CBG plants by 2023-24 with a production target of 15 MMT.

Biogas produced from different waste and biomass sources in the country has several benefits, including reduced natural gas imports, reduced GHG emissions, reduced burning of agricultural residues, remunerative income to farmers, job creation, better waste management, and so on. The SATAT focused on the objectives of the ‘Aatma Nirbhar Bharat', ‘Swachh Bharat Mission,' and the national precedence to boost the MSME sector.

In short, While cost plays a key role in shortlisting technology for biogas purification, it is important to remain cognisant of the long-term implications of using technologies that are not friendly to the environment.

After all, CBG is intended to be a green and sustainable fuel source, which will only be so if the processing that goes into its production remains eco-friendly as well. The newer technologies can be the drivers of change in the patterns of biogas production in India. If India has to succeed in the biomethane journey, the awareness, deployment, and hence investment in newer technologies have to increase. These technologies are advantageous to the CBG Plant owners and work towards achieving the Sustainable Development Goals.

Aashish Maheshwari Associate Business Director Evonik India

Biogas Magazine | Edition 24 | 38

See you soon! BIO-ENERGY PAVILION 2023 By Indian Biogas Association Facts & Figures (2023) KEY FEATURES Networking Business Meetings Pitching with Investment Agencies Conference Sessions Discussion with Industry Experts Social Evening BOOK YOUR SPACE To avail Early Bird Discount! #bioindia2023 India Expo Centre, Greater Noida For more information, please feel free to reach us Mr. Vishal Kanchan, M: +91–7838 447 489, Email: vishal@biogas-india.com 40,000+ Trade Visitors Exhibitors Physical Conferences 700+ 40+ 04 05 06 October ’23

Biogas Magazine | Edition 24 | 40 HARVESTING

Specialization CBG CBG CBG Biogas Engineering India Pv t. Ltd. is a subsidiar y company of Biogas E n g i n e e r i n g I n c . U S A , w h i c h i s a n e n g i n e e r i n g , p ro c u re m e n t a n d c o n s t r u c t i o n ( E P C ) c o m p a n y . W e a r e a n e x p e r t i n u p g r a d i n g Biogas/Land fill gas to Compressed BioGas (CBG), utilize gas for Heat & Power Generation and waste gas for Carbon Capture.

YOUR RENEWABLES

Abhijeet Mukherjee Program Director Indian Biogas Association

Abhijeet Mukherjee Program Director Indian Biogas Association