VLB General Meeting: Positive annual financial statements for 2023 Impact of pasteurization on hoppy ales VLB Research Reports 2024 Certified Brewmaster Course 2025 completed

VLB General Meeting: Positive annual financial statements for 2023 Impact of pasteurization on hoppy ales VLB Research Reports 2024 Certified Brewmaster Course 2025 completed

Both in food safety and food quality – food pro ducers, food designers, processors and consumers have to rely on safe ingredients. As a worldwide leading manufacturer of analytical instrumentation, Shimadzu’s complete product range for food & beverage analysis provides trust in food.

Easy identification and quantification of contaminants such as mycotoxins, dioxins, heavy metals

Cutting-edge analytical systems such as chromatography, mass-spectrometry, spectroscopy, material testing

Regulatory compliance and quality assurance assistance through revolutionary technologies such as comprehensive chromatography and hyphenated techniques

Support with expert knowledge download application handbook free of charge

4 VLB Inside: VLB General Meeting: Positive annual financial statements for 2023 – 2024 on track so far

6 VLB Research: Pasteurization’s impact on the chemical quality of hoppy ales during storage

10 VLB October Convention 2024: VLB presents independent research for the beverage industry

12 Quality Management: 50 years of DLG beer quality testing: 2024 calibration seminar in Weihenstephan

14 Brewing knowledge: Check your brewing expertise!

16 International VLB Conventions: 14th VLB Ibero-American Symposium on Brewing & Filling Technology in Mexico

18 Brewing Conference Bangkok returned to old strength

20 May to October 2024: VLB international activities

VLB ALUMNI

22 Report General Meeting 2024 of ehem. VLBer – Brewers of

On the occasion of the ordinary General Meeting of VLB Berlin as part of the VLB October Convention, VLB's Managing Directors presented a positive financial statement for 2023

The increasing popularity of hoppy beer styles has led to a notable rise in global production. Thereby, dry hopping as a key technique is commonly employed to enhance hop flavors

At the VLB Research Colloquium on 7 October 2024, the VLB research institutes presented the current results of their publicly funded projects and discussed general developments of German research funding

28 June, 2024 25 (from 15 different nations) VLB Certified Brewmasters

The ordinary General Meeting of the Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V. took place on October 7, 2024 as part of the 108th VLB October Convention. The meeting was chaired by VLB President Ulrich Rust. VLB Managing Directors Dr. Josef Fontaine and Gerhard Andreas Schreiber presented a positive financial statement for the 2023 financial year and gave a cautiously optimistic outlook for 2024.

The two Managing Directors of VLB, Dr. Josef Fontaine and Gerhard Andreas Schreiber, explained the report presented on the 2023 financial year, the main points of which were as follows:

• The sales revenue increased by 11% overall in 2023 compared to 2022.

• Following the suspension of research funding in the 2022 federal budget for several months, third-party funded research at the VLB 2023 has been stabilized again.

• The area of donations, contributions and grants remained constant.

• After a deficit in 2022, a positive result was achieved again in 2023. The surplus is transferred to reserves.

VLB President Ulrich Rust thanked the Managing Directors and all VLB employees for their good and committed work. “Despite this positive development, the general business environment for VLB remains volatile,” he warned. However, the ef-

fects of various external influences could be successfully absorbed. This was not least the result of a revised strategy formulated in 2022 and implemented from 2023. It is therefore the Managing Directors' task to continue working with their managers to ensure the future viability of VLB, said Rust.

Managing Director and Administrative Board discharged

The 2023 annual financial statements presented were audited by KWP GmbH & Co. KG Wirtschafts-

On site at the VLB General Meeting on October 7, 2024 in Berlin: Gerhard Andreas Schreiber (VLB), Uwe Ebbighausen (CUE.X Consulting), Dr. Stefan Lustig (Lustig Beverage Consulting), Ulrich Rust (Gerolsteiner Brunnen), Jan Steffes (Gerolsteiner Brunnen), Michael Jakob (Carlsberg Supply Chain Company) and Dr. Josef Fontaine (VLB). Wolfgang Janssen, Dr. Stefan Kreisz and Jens Hoffmann were unable to attend

prüfungsgesellschaft und Steuerberatungsgesellschaft, Berlin, and issued with an unqualified audit opinion on May 23, 2024. The financial statements were approved by the General Meeting. At the request of Thomas Faber, Privatbrauerei ERDINGER Weißbräu, the actions of the Administrative Board and the Managing Directors were unanimously approved.

According to the VLB Managing Directors, the 2024 financial year to date has largely gone according to plan. The analytics, consulting and conferences/seminars business areas have developed positively. The membership area is also stable. In terms of further site development, the plans for the future location of the TU Berlin's Brewing and Beverage Technology department in the VLB building were highlighted in particular.

Overall, the two Managing Directors were cautiously optimistic and held out the prospect of a positive result for the 2024 financial year.

Administrative Board unchanged

There were no changes to the Administrative Board on the agenda

this year. VLB's highest governing body will therefore remain in office in the following composition until the next scheduled election in October 2026:

Chairman

• Ulrich Rust (Gerolsteiner Brunnen GmbH & Co. KG, Gerolstein)

Deputy Chairmen

• Uwe Ebbighausen, Treasurer (CUE.X Consulting, Jameln)

• Dr. Stefan Kreisz (Private brewery ERDINGER Weißbräu Werner Brombach GmbH, Erding)

Other members

• Jens Hoffmann (Haus Cramer Group, Warstein)

• Michael Jakob (Carlsberg Supply Chain Company AG, Ziegelbrücke, Switzerland)

• Wolfgang Janssen (Radeberger Gruppe KG, Frankfurt am Main)

• Dr. Stefan Lustig (Lustig Beverage Consulting, Munich)

• Jan Steffes (Gerolsteiner Brunnen GmbH & Co. KG, Gerolstein)

After around 45 minutes, President Ulrich Rust closed the event. The next ordinary General Meeting of the VLB will take place in Berlin on 6 October 2025.

The Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V. – founded in 1883 – is a registered, non-profit organization. Its purpose is to promote science and vocational training in the fields of brewing, the beverage industry and biotechnology.

Who can become a member?

Voting membership is open to all breweries/ groups of breweries, beverage producers and commercial maltsters. Membership without voting rights ("supporting membership") is open to all natural and legal persons, as well as economic, governmental and scientific bodies.

What are the benefits of VLB membership?

As a member company, you become part of the VLB Berlin network in the national and international brewing and beverage industry. You can participate in our technical-scientific committee, receive regular advice and analyses for the optimization and setup of processes and products. You also support the VLB in maintaining and operating a modern infrastructure for training and research for the benefit of the brewing industry.

Interested in becoming a VLB member?

Contact: Dr. Josef Fontaine mitglieder@vlb-berlin.org

The increasing popularity of hoppy beer styles such as Pale Ales, India Pale Ales (IPAs), session IPAs (SIPAs), and double IPAs (DIPAs) has led to a notable rise in global production. A key technique, dry hopping – where hops are added to fermenting or fully fermented beer – is commonly employed to enhance hop flavors.

During storage, however, these hoppy flavor impressions undergo significant changes, primarily due to ester hydrolysis or aldehyde formation. While terpenoids like linalool and geraniol are regarded as stable and crucial for hop aroma, hop-derived esters such as 2-methylbutyl isobutyrate and isoamyl isobutyrate display variable stability [1,2] Pasteurization, a widely used method to stabilize beer by deactivating microorganisms and enzymes, was also expected to enhance the stability of hoppy beers. However, its impact on hop-derived volatile compounds remains insufficiently studied. This investigation, conducted by the VLB Research Institute for Raw Materials and Beverage Analysis (FIRGA - https://www. vlb-berlin.org/en/firga), examines the chemical effects of pasteurization on key volatile compounds, including terpenes, aldehydes, and esters, in hoppy ales during storage. The study aims to clarify how pasteurization affects flavor development over time under different storage conditions.

VLB Research has demonstrated that the chemical and sensory properties of hoppy ales behave differently when stored at 4 °C compared to 20 °C. At lower temperatures, hoppy characteristics are better preserved, whereas higher temperatures accelerate flavor and aroma changes, highlighting the significant impact

of storage conditions on beer quality over time [1,2] . Initial findings also revealed that hopforward beers exhibited less pronounced changes after pasteurization, particularly showing a smaller reduction in 2-methylbutyl isobutyrate levels, even at 20 °C [2] Based on these observations and the current understanding of chemical changes in heavily hopped beers, FIRGA laboratories decided to investigate this further. Pasteurization is widely used by breweries to enhance beer's microbiological stability. Given that it can be applied to both filtered and unfiltered beers, it made sense to test pasteurization on commercially available hoppy ales, which are generally not filtered or stabilized. Many breweries might be concerned that pasteurization could negatively affect product quality, as shown in Fig. 1. However, over time, the flavor changes might follow a different trend, potentially providing long-term benefits in terms of maintaining beer stability and quality. However, retailers often require a minimum shelf life for product listings, meaning that beers are often pasteurized without fully understanding the long-term effects on quality. This forces breweries to strike a balance between employing gentle production methods and meeting

Fig. 1: Expected relation between stale character in pasteurized and unpasteurized beer during storage [3]

retailers' demands for extended shelf life. Building on insights from lager beers, pasteurization may initially impact the flavor of hoppy ales but could provide long-term advantages. To confirm this, nonpasteurized hoppy beers were subjected to pasteurization and storage tests, as detailed below.

The sample set used in these trials comprised a session IPA (SIPA), two IPAs, and a double IPA (DIPA). At the time of collection, none of the beers were older than 10 days, and all were packaged in 330 mL brown glass bottles (longneck, all nonpasteurized). For the experimental design, half of each beer bottle set

underwent pasteurization at 150 pasteurization units (PU), while the other half remained unpasteurized (Fig. 2). The pasteurization process was conducted using a water bath set to 70 °C, with a holding time of 5.45 minutes. To ensure accurate temperature monitoring, an identically shaped bottle filled with water and equipped with a temperature logger was included in the trial.

Following pasteurization, the beers were stored in the dark at two temperatures: 4 °C and 20 °C. A detailed analytical approach, using methods routinely employed

Parameter

Alcohol content, density, original gravity, apparent/real extract, and degree of fermentation

pH-value

in our labs, was applied to assess the beers at the start of the trial and subsequently at 4, 12, 24, and 52 weeks (equivalent to 1, 3, 6, and 12 months). The analytical methods used during these evaluations are outlined in table 1.

The effects of pasteurization –findings

The current market offers a wide variety of hoppy beers, and previous research has shown that chemical and sensory changes vary uniquely among products [1] IPAs remain one of the most commonly produced styles, with nu -

Bitterness (BU) EBC 9.8

Total polyphenols

Turbidity (25° / 90°)

Metals (Fe, Cu, Mn, Zn)

Fermentation by-products (higher aliphatic alcohols and esters)

Hop aroma compound

Staling aldehydes

Hop related esters

Fatty acid ethyl esters

EBC 9.11

EBC 9.29

ICP-MS (DIN EN ISO 17294-2:2005-02, mod.)

HS-GC-FID (EBC 9.39, mod.)

HS-SPME-GC-MS/MS (VLB Method)

HS-SPME-GC-MS/MS (VLB Method)

HS-SPME-GC-MS (VLB Method)

HS-SPME-GC-MS (VLB Method)

merous freshly brewed local IPAs making them ideal candidates for this study. To minimize variability in beer styles while still capturing product-specific differences, the IPA category was selected. As previously mentioned, the investigation included one session IPA, two IPAs, and one double IPA to analyze changes in various flavorrelated compound classes, such as terpenes, terpenoids, aldehydes, and esters, during storage in both pasteurized and unpasteurized beers. A comprehensive description of these beers and their detailed chemical changes influenced by pasteurization has been published [3] The following section provides a brief summary of the results.

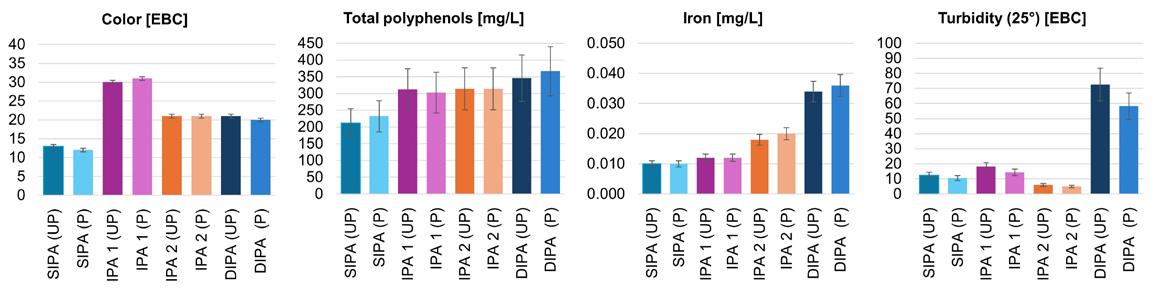

When considering pasteurization beyond its role in microbiological stabilization, the primary question that arises is its direct impact on the products. An examination of standard parameters (e.g., original gravity, alcohol content, and pH) revealed no significant changes in the tested beers. Additionally, parameters such as color, total polyphenols, and metal content (represented here as iron) showed no significant variation immediately after thermal treatment (Fig. 3). However, turbidity (depicted in Fig. 3 as the 25° angle measurement) showed a trend toward lower values after thermal exposure. This could be attributed to the formation of larger particles during pasteurization, which settle more rapidly [4] All these results obtained regarding pasteurization may appear redundant to some readers, as it is known that these parameters change only margin -

Table 1: Analytical approaches applied

ally or only under remarkably high thermal stress. However, it should be reiterated that this knowledge usually pertains to (pale) lager beer styles like Pilsner, thus providing proof for hoppy ales too. In contrast to the previously presented non-volatile results, the flavor-related volatiles showed a different scenario. It was observed that pasteurization led to an increase in aldehyde compounds (such as 2-methylpropanal and furfural) while simultaneously causing a reduction in fatty acid ethyl esters (for instance, ethyl octanoate and ethyl decanoate), which were directly influenced by the thermal effects of pasteurization [3,5] The examined hop aroma components (esters, monoterpenes, sesquiterpenes, and their oxidized forms) appeared to be only minorly influenced directly after pasteurization [3] Since the primary aim of this study was to gain insights into the shelf-life-related flavor changes associated with pasteurization of these products,

the following section will discuss this influence briefly.

It was expected that the thermal input would lead to a slight increase in stale characteristics initially, which was thought to be associated with a rise in staling aldehydes (Fig. 1). The thermal treatment did result in an initial increase in aldehydic compounds, notably 2-methylpropanal, a key compound relevant to ageing in hoppy styles as illustrated by SIPA in Fig. 4 [1] The first and most noteworthy result linked to storage was observed after a few weeks: the levels of these compounds in the pasteurized product (depending on the specific hoppy ale tested) plateaued and did not increase further (Fig. 4). In contrast, the unpasteurized hoppy ales showed a continuous rise in these analytes until the end of the study, even when stored at 4 °C (Fig. 4, for instance: 2-methylpropanal in SIPA). Unlike the aldehydic compounds, the hop related esters exhibited a declining trend during storage.

Fig. 4 demonstrates the reduction of isoamyl isobutyrate as a representative of this substance class in the SIPA example. Nevertheless, the observations suggest that pasteurization positively impacts hop-related esters as well. The untreated beer showed a significant decrease in isoamyl isobutyrate at 4 °C during its shelf life, with an even more pronounced decline when stored at 20 °C. Thus, while thermal treatment could not entirely prevent this negative trend, it clearly mitigated it. Additionally, a noticeable decrease in the class of fatty acid ethyl esters during ageing was also evident. However, pasteurization did not enhance the positive effect, as the pasteurized beers displayed a greater reduction. This may be partially attributed to the increased activation energy imposed by thermal treatment. Furthermore, it is plausible that enzymatic processes in the unpasteurized beers contributed to this effect, thereby lessening the decline of these esters [3]

Other flavor-relevant fermentation by-products that were investigated include the class of higher alcohols. As expected from previous studies, no significant direct effect or observable change during storage was noted for these analytes. Although the compounds discussed represent important aromatic components, hoppy ales are nonetheless characterized by an intense hop aroma [1–3] In addition to the previously mentioned hop-related esters, monoterpenes, sesquiterpenes, and their oxidized forms are also significant aromatic components that are present in larger quantities due to extraction through late or dry hopping. Overall, these hop aroma components exhibited stability and were not significantly influenced (either positively or negatively) by pasteurization or storage conditions. However, certain components, such as myrcene, limonene, and specific sesquiterpenes (e.g., caryophyllene and humulene), demonstrated a decline in concentration during storage, irrespective of treatment or storage temperature [3] Oxidation may particularly impact the sesquiterpenes. The filling process of hoppy ales, often conducted in small-scale breweries, may involve conditions of increased oxygen exposure, and due to the use of topfermenting yeast, these beers lack the natural protection typically provided by SO₂ formation [1] Consequently, even small fluctuations in the concentration of aromatic substances can be significant, especially given the highly sensitive VLB methods employed, which are

capable of detecting changes in the µg/L range. In conclusion, it can be stated that pasteurization has a positive chemical stabilizing effect on the overall hoppy ales. While an increase in aldehyde compounds was noted due to thermal influence, the long-term study (52 weeks) revealed that a stabilizing effect (or no further negative impact) was achieved through the thermal pasteurization treatment.

The publication presented and discussed [3] investigates different IPAs subjected to pasteurization and different storage conditions over a 52-week period. In their fresh state, the ales presented high levels of hop aroma volatiles, including terpenes, terpenoids, and hop-related esters, alongside low concentrations of staling aldehydes, consistent with previous research. The advantages of cold storage were apparent, corroborating past findings [1] Post-pasteurization variations in volatile hop aroma compounds, as well as their concentration trends, aligned with established literature [1,2] For example, linalool levels remained unchanged throughout storage [3] In contrast, the levels of staling aldehydes, specifically 2-methylpropanal and furfural, increased in unpasteurized ales over time, with more pronounced spikes at 20 °C. Over time, the concentration of compounds chemically linked to off-flavor in unpasteurized ales was found to be higher than in the pasteurized samples. This study highlighted the advantages of pasteurization, stressing

the need for strong collaboration between brewers and distributors to maintain the best flavor profiles during transportation, particularly in international and global shipping scenarios.

Contact: VLB Research Institute for Raw Materials and Beverage Analysis (FIRGA) Email: zentrallabor@vlb-berlin.org

References

[1] Schubert, C.; Lafontaine, S.; Dennenlöhr, J.; Thörner, S.; Rettberg, N. The influence of storage conditions on the chemistry and flavor of hoppy ales. Food chemistry 2022, 395, 133616. DOI: 10.1016/j.foodchem.2022.133616.

[2] Rettberg, N.; Schubert, C.; Dennenlöhr, J.; Thörner, S.; Knoke, L.; Maxminer, J. Instability of HopDerived 2-Methylbutyl Isobutyrate during Aging of Commercial Pasteurized and Unpasteurized Ales. Journal of the American Society of Brewing Chemists 2020, 78, 175–184. DOI: 10.1080/03610470.2020.1738742.

[3] Schubert, C.; Lafontaine, S.; Thörner, S.; Rettberg, N. Impact of Pasteurisation on Terpenes, Terpenoids, Aldehydes and Esters in Hoppy Ales on Ageing. Journal of the American Society of Brewing Chemists 2024, 1–16. DOI: 10.1080/03610470.2024.2379636.

[4] Feilner, R.; Jacob, F. F. Improving resistance to aging and increasing haze stability in southern German wheat beer through process optimization. BrewingScience 2015, 68, 58–66.

[5] Schubert, C. Einfluss der Lagerung auf hopfenbetonte, obergärige Biere, Teil 2: Langzeitstabilität erhöhen. Brauwelt 2024, 626–629

The VLB Research Colloquium took place again this year as part of the VLB October Convention. In addition to the general topic “Current Developments in German Research Funding”, the research institutes presented current results from publicly funded projects. The broad interest of the audience in the topics presented once again underlined the importance of the VLB's independent research.

At the opening of this year's Research Colloquium, Gerhard Andreas Schreiber, Managing Director and Research Coordinator of VLB, presented the current status of Germany's innovative strength in a European comparison. Although Germany is strong in terms of cooperation between the private and public sectors and innovative companies are important employers, a downward trend can be observed in innovation itself. A clear decline in the development and introduction of innovations is particularly evident in small and medium-sized enterprises (SMEs). A clear weakness in European competition is the comparatively low level of government support for research and development (R&D).

Schreiber emphasized that funding will continue to be available in the coming years, although the amount of funding available will decrease. For example, funding for the important “Central Innovation Program for SMEs (ZIM)” of the Federal Ministry of Economic Affairs and Climate Action (BMWK) will be reduced by around 109 million euros in 2025. In addition, the “KMU-

innovativ” program of the Federal Ministry of Education and Research (BMBF) will no longer be open to all topics. Both would make access to funding more difficult, especially for innovative SMEs. However, funding for independent industrial research is to be maintained at the current level. In this context, the “Industrial Collective Research (IGF)” program, which has been managed by the DLR Project Management Agency since the beginning of the year, was highlighted. After almost 70 years in the hands of AiF e.V., the transition is still a challenge, and the AiF e.V. will also have to reorient itself as a result of the loss of project funding.

As an easily accessible instrument for innovative companies to promote their R&D activities, Schreiber presented the research tax credit and its novelties through the Equal Opportunities Act. This would allow companies to deduct their R&D costs from their taxes. The research tax credit offers a funding rate of up to 25%, with up to €1 million available retroactively from 2020 to 2023 and up to €2.5 million (€3.5 million for SMEs) per year from 2023. The application process is simple and effective, and the research tax credit can be used by companies of all sizes.

In the transition to the lecture program, Schreiber invited all participants to contact the VLB with problems and research ideas in order to realize projects and create innovations together. He concluded by thanking all the funding agencies and project sponsors for their support.

The first presentation was given by

Michel Werner from the Research Institute for Beer and Beverage Production. Werner presented his findings on “Natural Growth Factor Optimization” (INNO-KOM 49MF210127). He described a new method to increase the zinc concentration in the pitching wort without affecting the free amino nitrogen content. Zinc, an essential growth factor for optimal yeast fermentation performance, is not always sufficiently present in allmalt worts. By using an acid extract from malt rootlets, the zinc content could be increased in compliance with the beer purity law. Werner achieved a doubling of the zinc content in the wort. However, the beer exhibited an off-flavor, which Werner intends to eliminate through further research.

Florian Heukäufer, employee of the Packaging Testing Center, gave a presentation addressing the question, “How high can I stack?”. In the R&D project “Development of an Accelerated Pallet Load Test” (INNO-KOM 49MF220230), Heukäufer and his colleagues investigated

whether the stability testing of bottle crates could be conducted more quickly, in a more space-saving way, and with less material usage. They developed a method in which a quarter load unit and three measurement points within one week would be sufficient to determine the stability of new beverage crates. The new testing method could lead to significant cost savings due to re -

duced resource requirements. The method is now set to be validated for used crates and layer configurations.

Next in the program was the presentation of the results from the project “Process Development for the Analysis of WEAX Gel Formation” (INNO-KOM 49MF190166) by Dulcie Thomson from the Research Institute for Raw Materials and Beverage Analysis. In the project, Thomson and her colleagues developed an UPLC-Q-ToF method for the detection and quantification of various ferulic acid dehydrodimers (di-FA), a component of water-soluble arabinoxylans (WEAX), which may have an impact on WEAX gel formation.

The method, which included enzyme digestion, proved to be robust and was successfully tested on wort samples. Four dehydrodimers were evidenced in digested all barley malt wort samples (8-8c, 8-5nc, 5-5 and 8-O-4 di-FA).

At the end of the event, Marie Ludszuweit from the Research Institute for Biotechnology and Water presented findings from the ongoing

project “Pasteurization of SourFermented Beverages” (INNO-KOM 49VF220041). In this project, Ludszuweit and her colleagues aim to define optimal pasteurization parameters to make innovative fermented beverages safer. It would be essential to preserve the positive product qualities while eliminating harmful organisms. Ludszuweit demonstrated that this is not trivial, as the microorganisms used mean there is no standard blueprint for pasteurization. The team is currently investigating how pasteurization affects the product's characteristics. The next research colloquium will take place during the upcoming VLB October Convention on 7 October 2025.

For almost 50 years, the jury of experts for the DLG (German Agricultural Society) International Quality Test for Beer has been meeting regularly for an calibration seminar, which took place in Weihenstephan this year. This ensures that the highest testing standards are applied, making the DLG quality test one of the most demanding and objective beer competitions.

(BF) The DLG's beer-sensory experts come from the renowned brewing institutes: the Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) and the Weihenstephan Research Centre for Brewing and Food Quality. “The aim of the annual calibration seminar for DLG examiners is to ensure test standards and transparency. And to ensure that the sensory procedures for quality control based on the product-specific DLG-5-Schemata® for beers meet our high standards and that they are applied equally by all parties. This guarantees the reproducibility and objectivity of our test results,” said Thomas Burkhardt, DLG project manager for beverages. From the outset, the aim of the international DLG quality tests for beers and beer-based mixed drinks has been to make tested quality transparent to consumers. This is done with the well-known DLG awards and attractive special prizes. The DLG experts provide participating breweries with advice on how to

optimise quality. They also receive a qualitative assessment of their current position. Over the years, the DLG has continuously developed the criteria for beer evaluation in order to keep pace with the latest trends and developments in the innovative brewing industry. In Weihenstephan in June 2024, the sensory experts from Weihenstephan and Berlin tasted ten beer samples based on the descriptive sensory DLG analysis. These included Pils, Export Hell, wheat beers, beer-based mixed drinks and nonalcoholic beers. The DLG experts examined whether the product was typical of the beer style in terms of its odour and taste. Since sensory tests are always attribute tests, i.e. in addition to recognising sensory deviations or product qualities, a uniform verbal description of the defect is also crucial, the DLG technical vocabulary and sensory descriptors were also checked and trained at the same time. The latter are included in

the DLG 5-Point Inspection Scheme ® and in the publication of the DLG technical vocabulary of sensory analysis.

“The tasting results underscore the high level of professionalism of our testers and thus the high informative value of the DLG test results. Regular reviews of good testing practice in the form of DLG calibration seminars are important to ensure best practice standards and, where appropriate, to develop them further together,” said the two DLG heads of sensory evaluation for beer, Ludmila Linke, VLB Berlin, and Dr. Martin Zarnkow, Weihenstephan. Thomas Burkhardt thanked the sensory experts for their commitment and the Weihenstephan team for preparing and organising the event. Next year, the panels will meet in Berlin.

See dlg.org/en/food/alcoholic-beverages for more information.

How solid is your expert knowledge when it comes to beer brewing? Whether craftsmanship or extensive expertise in the field of microbiology and food chemistry: A brewer needs the knowledge and overview of the entire manufacturing process. In this issue we have collected some questions hat are part of the basic knowledge of a professional brewer.

1. The pH value of the water also has a decisive influence on enzyme activity during mashing. In what range must the pH value of drinking water be (according to the EU Directive on the quality of water intended for human consumption/ Drinking Water Regulation)?

a) pH 2.5 - 4.5

b) pH 4.5 - 6.5

c) pH 6.5 - 9.5

d) pH 9.5 - 11.5

e) pH exactly 7.0

2. Why should cleaning agents have a low surface tension?

a) So that they adhere more easily to the surface to be cleaned.

b) So that they can develop their disinfecting effect on any microorganisms present.

c) So that they can be pumped through pipes more easily.

d) To prevent the cleaning solution from foaming.

e) So that they can penetrate more easily into recesses and crevices in the surfaces to be cleaned.

3. Which cleaning agent should not be used for cleaning aluminum tanks?

a) Hydrochloric acid

b) Caustic soda

c) Sulphuric acid

d) Water

e) Nitric acid

4. Modern sports drinks and many alcohol-free beers are often labeled "isotonic". What does “isotonic” mean in this context? The drink

a) is particularly rich in calories, which an athlete needs.

b) has the same particle concentration as human blood.

c) is always absolutely free of carbohydrates.

d) contains mainly fat-soluble vitamins.

e) is particularly carbonated.

5. The foam of a beer is not only influenced by the raw materials, but also by the production process. Which of the measures listed has a negative influence on the beer foam?

a) The use of malt with a crude protein content

of more than 10.0 %.

b) Very high mashing-in temperatures.

c) A particularly long and intensive wort boiling.

d) Short storage.

e) The use of tannin-free hop extract.

6. Various microorganisms can be present in contaminated beer. Which of these can cause the undesirable formation of diacetyl even in bottled beer?

a) Pseudomonas diacetylus

b) Escherichia coli

c) Lactobacillus brevis

d) Wild yeasts

e) Pediococcus damnosus

7. Which gases may be used to operate a beer dispensing system? (several answers are correct)

a) Carbon dioxide

b) Carbon monoxide

c) Nitrogen

d) Mixtures of carbon dioxide and nitrogen

e) All gases mentioned are permitted

8. Why does the wort need to be aerated before pitching?

a) So that the yeast can start fermentation immediately.

b) The air bubbles ensure that the cold break is formed and precipitated.

c) The oxygen brightens the pitching wort.

d) Yeast requires oxygen for cell proliferation at the beginning of the fermentation process.

e) The oxygen ensures a fine hop bitterness in the finished beer.

9. What is a batch process?

a) A special boiling system for lager beers.

b) A procedural process that is carried out with discrete quantities of materials.

c) A continuous process during fermentation.

d) An automatic cleaning process in the brewery.

10. The technique of "dry hopping" is sometimes used for specialty beers. What does this mean?

a) Only very strongly dried hop cones are added during wort boiling.

b) Only anhydrous hop oils are added to the beer.

c) Adding hop cones or hop pellets in the storage tank and leave to act.

d) The adding of isomerized hop products in the bottle before the beer is filled in it.

1. c) The pH is one of the most important operational water quality parameters. The pH scale ranges from 0 (very acidic) to 14 (very basic/alkaline). The pH of pure water is 7.0, which is considered neutral, which indicates that it is neither acidic or basic. The range of acceptable pH values for drinking water varies from country to country. The EU Drinking Water Directive (DBW) defines a range between 6.5 and 9.5. Natural waters may have a lower pH, for example as a result of acid rain, or a higher pH in limestone areas.

2. e) Water has a relatively high surface tension. This is due to the attractive force between the individual molecules and is expressed, for example, in the formation of water droplets. However, the surface tension also prevents surfaces from being completely wetted or water – and thus also cleaning liquid – from penetrating into very small crevices. By adding surface-active chemicals such as detergents (tensides), the surface tension of an aqueous cleaning solution can be reduced, thus improving the cleaning effect. Such surfactants are usually contained in ready-made cleaning agents.

3. b) Aluminum was commonly used in the brewery for tanks, tuns, and kegs. Aluminum is a relatively inexpensive material, chemically inert, flavor neutral and does not require coating. However, aluminum is not resistant to alkaline agents and is quickly destroyed. The smooth surface of aluminum is quickly attacked and corrosion occurs in an alkaline environment. This increases the risk of contamination, and the vessels become unusable for beer production over time. As a result, aluminum plays little role in today's modern breweries.

4. b) Isotonic means, that two liquids have the same osmotic pressure. This osmotic pressure depends primarily on the concentration of the substances dissolved in the liquids. An isotonic drink has an osmolarity that is similar to that of human blood. This means that the concentration of electrolytes and other particles (e.g., glucose, maltose) corresponds to that of blood. This favours a rapid absorption and regeneration, especially after intensive training sessions or exhausting sports matches. Alcohol-free beer can be isotonic and labeled as such. However, this depends on the concentration of the dissolved carbohydrates and must be confirmed analytically.

5. c) Beer foam consists of CO2 bubbles and a liquid film that is stabilized by foam-positive substances. Proteins with molecular sizes between 10 and 40 kDa play an important role here. With long, intensive wort boiling at high temperatures (e.g. with pressure boiling), many of these proteins are already precipitated in the Whirlpool with the trub and are therefore no longer present in the beer. This can have a negative effect on foam formation and foam stability.

6. e) Diacetyl is formed by yeast during fermentation and then broken down again. This is a normal process. In excessive concentrations, diacetyl

causes off-flavors in beer and is therefore undesirable. However, diacetyl in beer can also result from microbiological contamination by the bacterium Pedicoccus damnosus. In this case, the diacetyl remains in the final beer, in contrast to the diacetyl that is formed by the yeast during fermentation. Pediococcus contamination in the brewery can be very persistent and difficult to remove.

7. a)/c)/d) Beer and many other soft drinks already contain carbon dioxide (CO2). That is why CO2 is the most commonly used gas for beverage dispensing systems. It is colorless, odorless and easily soluble in water. Nitrogen (N2)is also frequently used as a dispensing gas. Air consists of 78% nitrogen. The gas is colorless, odorless and tasteless and has no influence on the appearance and taste of tapped beverages. Nitrogen also has a stabilizing effect on the beer foam in the glass. A carbon dioxide-nitrogen mixture can also be used. Under no circumstances should carbon monoxide be used, as it is a strong respiratory poison in higher concentrations!

8. d) In principle, oxygen is not desired in the entire brewing process, as it has a negative influence on the taste and flavor stability. The only point at which air or oxygen is needed is for yeast propagation. After cooling the hot wort, sterile air is therefore dosed into the wort stream and then the yeast is added to the wort-air mixture. In the presence of this oxygen, the yeast cells can then gain a lot of energy through respiration, which they need for rapid and vigorous cell multiplication. Once this one-time oxygen dose has been consumed, the yeast cells switch their metabolism to alcoholic fermentation.

9. b) In process engineering, a batch process is when a certain quantity of a material is processed simultaneously. This quantity is then transferred in its entirety to the next process step. In contrast, in continuous processes, the processing or conversion takes place during a steady flow. In breweries, mainly batch processes take place, e.g. a certain amount of wort is produced in the brewhouse and then fermented in individual fermentation tanks. There are now also continuously operating brewing systems or fermentation processes on the market. However, these are not (yet) very widespread.

10. c) While the bitter substances of the hops require a certain amount of heat during the isomerization process, the volatile and aromatic hop oils are expelled during boiling. If the brewer wants to brew a particularly hoppy beer, the so-called “dry hopping” is used. In this case, the aroma hops are added only during cold storage. There it can take effect for a longer period of time, so that the hop oils are transferred particularly well into the beer. The alcohol in the stored beer also favors this solution. In principle, hop cones can be used for dry hopping. However, this can easily introduce unwanted microorganisms into the beer, and the leaf residue of the hop cones is difficult to remove without filtration. It is therefore recommended to use hop pellets.

The 14th Ibero-American Symposium of the VLB took place in Mexico City from 2 to 4 September 2024. With 230 participants from 22 countries, this event once again proved its status as one of the most important communication and knowledge platforms for technical managers in the brewing industry in Latin America.

(BF) Since 2008, the Ibero-American Symposium of the VLB Berlin has firmly established itself in the Latin American-speaking world as a high-class specialist event for technical managers in the brewing and beverage industry. This year, the renowned technology forum took place in Mexico for the third time (after 2011 and 2019). With a population of around 128 million and an annual beer produc-

Roasted Malt Beers

Malt Extracts

Beer Concentrate

Brewing Syrups Caramel

Liquid Sugar

ASPERA BRAUEREI RIESE GMBH

45478 Muelheim-Ruhr, Germany

Phone +49 208 58 89 80 / aspera@aspera-riese.de www.aspera.de

tion of an impressive 142 million hectolitres, Mexico is the world's fourth largest beer-producing nation after Brazil and the world's leading beer exporter. The biggest players in the local brewing sector are Grupo Modelo (AB InBev), Heineken México and Constellation Brands. However, a lively craft beer scene has also established. The conference began with a visit to the Heineken brewery in Toluca, about 40 km west of Mexico City. The technical presentations began on the second day. Roberto Biurrun, coordinator for Latin America and Spain at VLB, opened the event and welcomed the participants. This was followed by a tightly packed, technically oriented lecture programme that addressed current aspects and innovations in the areas of brewing raw materials, brewhouse technology, fermentation & yeast management, sustainability and the digitalisation of brewing processes. The presentations were given by experts from VLB, invited speakers from breweries and competent industry representatives. As usual, the symposium was held in English and Spanish with simultaneous translation. The presentations were met with an interested and discussionoriented specialist audience. A dinner on the evening of the second day, sponsored by Ziemann Holvrieka, Constellation Brands and Rovi Ingenieria, rounded off the event. ‘On behalf of VLB and all participants,

we would like to thank our speakers and in particular Heineken México, Constellation Brands, Grupo Modelo and our platinum sponsor Ziemann Holvrieka for supporting this symposium,’ said Roberto Biurrun, lead organiser of the VLB's Ibero-American Symposium since 2015.

The next Ibero-American Symposium of the VLB will take place in Paraná, Brazil, from 10 to 12 November 2025, with the support of Cooperativa Agraria. As a new feature, two workshops on sensor technology and packaging will be offered following the main event.

The VLB Berlin delegation in Mexico City: Dr. Martin Hageböck, Alexander Scharlach, Roberto Biurrun, Dr. Christian Schubert

1) The technical exhibition presented all kinds of innovations and invited participants to touch and be amazed

2) With a fresh beer from the Heineken bar, the lively discussions continued during the breaks

3) Grupo Modelo was also on hand to present its range of renowned beers

4) The event was characterised by many excellent talks, making it a complete success

5) Participants from the breweries of ABInbev's Middle America Zone together with the VLB team

6) Get-together at the legendary Prime Steak Angel de la Independencia at the invitation of Ziemann-Holvrieka, Constellation

More than 280 brewing experts from Southeast Asia, Europe and America attended the 8th Brewing Conference Bangkok, which took place from 9 to 11 June 2024 in Bangkok, Thailand. This year, the programme of visits included the Vattanac Brewery in Phnom Penh, Cambodia. As usual, the event was jointly organised by the Thailand Beer Industry Guild (TBIG) and VLB Berlin.

(oh) Following the successful relaunch of the Brewing Conference Bangkok in 2020, the premium event for the brewing industry in Southeast Asia has returned to its former strength this year: with a total of 280 participants, the conference almost reached the previous all-time high of 300 participants in 2019. The event began on Sunday with an excursion to neighbouring Cambodia. There, Sam Ang Vattanac, Executive Director of Vattanac Brewery Co. and his team welcomed the participants with an elaborate and impressive presentation of their new brewery in Phnom Penh.

Vattanac Brewery – a new player in Cambodia

The brewery belongs to the Vattanac Group, a family-owned group of companies in Cambodia that is active in the real estate and finance sectors, as well as in the luxury goods sector, among others. It has been involved in the brewing sector since 1994, when it was known as Cambodia Brewery Limited (CBL), a joint venture with Heineken-owned Asia Pacific Brewery Limited. In 2014, Heineken took over all CBL shares and continued APB alone. In 2019, Vattanac decid -

ed to re-enter the Cambodian beer market and began planning a completely new brewery supported by Ziemann Holvrieka. The foundation stone was laid in May 2020, and the first brew was tapped in October 2021. Six different types of beer will be produced (mainly Vattanac All Malt, Premium Light and Krud Pilsner), as well as energy drinks and sports drinks. The brewery has room for further expansion, but in the competitive Cambodian beer and beverage market, the focus is currently on optimising ongoing processes, according to Vattanac Chief Technology Officer Dr Maximilian Härtl.

On Monday and Tuesday, the technical-scientific programme of lectures took place at the Bangkok International Trade and Exhibition Center (BITEC). Under the general theme ‘The Art of Brewing Today: Brewing Innovations 2024’, experts from the brewing industry and science presented and discussed their ideas and solutions for effectively meeting the current and future challenges of our industry in 23 lectures.

After the official welcome by Isara Khaola-iead, Boon Rawd Brewery,

and VLB managing director Dr Josef Fontaine, VLB conference coordinator Roberto Biurrun opened the technical-scientific lecture programme. Dr Maximilian Härtl presented the project of the new Vattanac Brewery and its product strategy for the competitive Cambodian beverage market. Prof. Frank Behrendt, TU Berlin, outlined his assessment of the development of future industrial energy supply. Sa -

ran Phuphong, Boon Rawd Brewery, presented the results of extensive research into the formation of fermentation by-products in different tank sizes and tank geometries. His colleague Songsak Hengprathanee, Boon Rawd Brewery, discussed the influence of mashing on the fermentation of raw grain wort. Jan Biering, Dr Martin Hageböck, Ingo Pankoke and Jan Fischer from VLB Berlin presented solutions and new findings in the areas of non-alcoholic beers, packaging technology, yeast, water and bottle inspection. In addition, numerous other lectures were given by experts from the supplier industry, who met with a discussion-friendly audience. The technical part of the conference was rounded off by an extraordinary traditional evening event in the Ancient City in Bangkok on Monday

and the closing party on Tuesday evening.

The organisers of the Bangkok Brewing Conference were once again pleased to have a wide range of supporters. Pentair (platinum sponsor) and the gold sponsors Alfa Laval, Ecolab, KHS, Krones, Pall and Ziemann Holvrieka deserve special mention. VLB would also like to thank the Vattanac Brewery for their hospitality and the Boon Rawd Brewery and other companies for their active support. Last but not least, special thanks go to the entire team of the Thailand Beer Industry Guild for the perfect organisation on site.

The Bangkok Brewing Conference is a joint project of the Thailand Beer Industry Guild (TBIG) and VLB Berlin. First held in 2009 in this constellation, the event has developed over the past 15 years into the meeting

place for the brewing industry in Southeast Asia.

The next Bangkok Brewing Conference is scheduled for June 2026.

v.l.: Kawee Meksongruek, Thai Asia Pacific Brewery, TAP (Heineken), Chonlada Manakul, Pentair/TBIG, Dr Maximilian Härtl, Vattanac Brewery

Anniversary: 15 years of cooperation (2009-2024) Thailand Beer Industry Guild (TBIG) and VLB Berlin

VLB

Visit to the VLB in Berlin in June 2024: Victor Shevtsow

Follow us on our Social Media channels:

www.instagram.com/vlb.berlin/ www.linkedin.com/company/vlb-berlin

www.facebook.com/vlbberlin

The participants of the General Meeting of the “Vereinigung ehem. VLBer –Brewers of Berlin” in the atrium of the VLB Berlin

The 2024 annual General Meeting of the Vereinigung ehem. VLBer e.V. / Brewers of Berlin took place in the run-up to the VLB summer party on 5 July 2024 in Berlin.

The meeting was chaired by Klaus Niemsch and Jan Biering. They reported on the following topics:

Membership development positive: 33 new members joined in the reporting period (July 23 – July 24). On the other hand, there were 4 resignations and 14 expulsions due to multiple delinquent membership fees.

4 International Alumni Gatherings: Bangalore, India (14 Sep 2023) / Bangkok, Thailand (17 Sep 2023) / Las Vegas, USA (22 Apr 2024) / Bangkok, Thailand (8 Jun 2024)

The liquidation of the Berlin Brewers' Guild has not yet been finalised: At the General Meeting 2023, it was decided to take over the members of the Berliner Brauer-Zunft e.V. The process of liquidation of this association was not yet completed. The Zunfthaus was available as usual as a meeting place during the reporting period.

Modification of the membership fees: The Executive Board put up for discussion a modification to the membership fees. Reason: The

administrative effort involved in collecting the annual membership fee of €15 is very high, particularly for international members, and some members remain in arrears for longer periods of time. A new lifetime membership for a one-off membership fee is therefore proposed.

In principle, the members present were in favour of the idea, but there were differing opinions regarding the term and the amount of the contribution. After a lively discussion, the following motion was formulated and put to the vote: “The association of ehem. VLBer – Brewers of Berlin introduces an optional long-term membership for new members in addition to the annual membership. The term of this membership is 10 years. The membership fee for this period is 10 times the regular annual membership fee less a discount of 20 %. At the end of this period, the membership can be extended at the then applicable conditions.” This motion was adopted unanimously.

Vereinigung ehem. VLBer e.V. – Brewers of Berlin

1st Chairman: Klaus Niemsch (Planegg)

2nd Chairman (executive): Jan Biering (Berlin) Contact:

Seestraße 13, 13353 Berlin ehemvlber@vlb-berlin.org www.vlb-berlin.org/ ehemvlber

Information on membership:

Miscellaneous: During the discussion, the question was also raised as to whether the current annual membership fee of €15 should also be increased. As no concrete proposal had been formulated in advance, the Board decided to place this item on the agenda of the next General Meeting. The next General Meeting should again take place before the VLB summer festival (which is scheduled to take place in July 2025 in Berlin).

The full minutes of the meeting are available to all members of the Vereinigung ehem. VLBer / Brewers of Berlin on request. Please contact ehemvlber@vlb-berlin.org

On 28 June, 25 graduates received their certificates, thereby successfully completing the Certified Brewmaster Course 2024. In his speech at the ceremony, VLB Managing Director Dr Josef Fontaine paid tribute to the achievements of the participants. In view of the challenging global situation, such good grades are not a matter of course.

(ew) VLB managing director Dr Josef Fontaine opened the graduation ceremony with an address to the graduates and their families, some of whom had travelled to attend. Fontaine praised the outstanding achievements, which are all the more gratifying in these uncertain times. He congratulated the newly minted brewmasters and presented the coveted certificates to those who had worked very hard over the past six months.

On 8 January, 27 participants began their training to become Certified Brewmasters at the VLB in Berlin. One participant stayed in his home country after the Easter break. Another did not pass the final exams. The others will return to their companies as VLB Certified Brewmasters. “I am convinced that you will all make the most of what you have learned here and

use this knowledge for your future careers,” emphasised Fontaine.

Jana Isabel Krammer from the Hofstetten Brewery in Austria was the top performer of the year. She was followed by Mario Bela, Cidade Imperial, Brazil, and Aidan Strayer from Big Slide Brewery, USA, who both scored the same number of points. All three are cordially invited to attend one of the upcoming international VLB conferences. Burghard Meyer also praised the participants' achievements. “This year, there were many good and hard-working students. The exam preparations were intensive. This is reflected in the grades,” said the course instructor.

This year's excursion, from which the group returned the evening before the award ceremony, was also a success. Breweries, malthouses and suppliers in North

Rhine-Westphalia and Lower Saxony welcomed the newly qualified brewmasters. “The hospitality of the companies was fantastic and the tours were informative and beneficial for everyone,” enthused Burghard Meyer.

As is the case every year, one graduate received a gift on behalf of the class at the end of the course – donated from the personal collection of the course instructor. This time, a pewter mug changed hands and went to Zhadyra Sydykova (Anadolou Efes, Kazakhstan). As Burghard Meyer explained: “Zhadyra showed us all that you can achieve anything with hard work!”

Dr Josef Fontaine thanked everyone involved, both on and off stage, without whom the successful realisation of the VLB-Certiefied Brewmaster Course would once again have been unthinkable.

Course 2025: 6 Jan – 27 Jun 2025

Course 2026: 7 Jan – 26 Jun 2026

"They were particularly hardworking this year" – the participants of the VLB Certified Brewmaster Course 2024 at the official graduation photo in May in front of the legendary guild house

They studied hard for good grades: 24 graduates from 15 different nations received their certificates at the end of June 2024. 1 person did not pass the exams, but remained part of the class until the end. VLB Berlin congratulates all of them on their successful completion of the very demanding Certified Brewmaster Course.

All our trainings take place in our pilot brewery and the highly specialized laboratories

Since its foundation in 1883, VLB has also been a brewing school. VLB supports the regular study programs for brewers at Technische Universität Berlin. Furthermore, it provides continuous training in the field of beer brewing and beverage technology – in German and English. On top, Brewing in a Nutshell is on offer as an on-demand online course.

The VLB’s flagship training course for prospective brewers contains a six-month full-time program providing in-depth understanding of brewing technology with its related major fields of engineering, filling and packaging and quality control. The Certified Brewmaster Course 2025 will be held as a complete classroom event. This means, that the theoretical and practical work will alternate over the six months of the training. The Berlin brewmaster education is focused on a comprehensive, practice-oriented knowledge transfer, on an open dialog with the lecturers and on networking on an international basis.

To receive the VLB Brewmaster Certificate, the graduates have to finish the course and all exams successfully. In addition, they have to prove a minimum of 3 months practical work in a brewery before coming to the VLB. A reasonable group size for practical work guarantees an intensive and individual teaching.

Location: Berlin, Germany

Next date: 6 January – 27 June 2025

More information: www.vlb-berlin.org/en/cbc2025

This is a ten-day full-time training course providing up-to-date knowledge in the field of pub and micro brewing. It covers the basics of beer brewing. The lectures will approach topics such as raw materials (water, malt, hops, and yeast), the brewing process, yeast management, fermentation, hygiene, sensory

evaluation, basics of quality control as well as economic and legal aspects for starting a pub brewery. The course will be held as an on-site class at VLB Berlin.

Location: Berlin, Germany

Next date:

1 – 12 September 2025

More information: www.vlb-berlin.org/en/ craftbrewing2025

The 8-day full-time hands-on course provides up-to-date knowledge in the field of malting. It covers the basics of malting technology in theory and practice. The lectures will approach topics such as malting barley and other relevant cereals (botanics, quality, varieties, enzymes a.o.), malting technology (steeping, germination, kilning, special aspects of small-scale malting, equipment) and practical laboratory work (barley and malt analysis, interpretation and assessment of different quality parameters). In addition, the participants will conduct and accompany a complete malting batch in our pilot malting.

Location: Berlin, Germany

Next date:

Check www.vlb-berlin.org/en/ micromalting for updates

Applied Microbiology is a oneweek full-time training course providing up-to-date knowledge in the field of practical microbiology with relevance for the brewing and beverage industry. It cov -

ers the basics of microbiology, laboratory techniques as well as microbial sampling in theory and practice. The course is conducted in the VLB’s microbiological training laboratory and in our pilot brewery.

Location: Berlin, Germany

Next date:

Check www.vlb-berlin.org/en/ microbiology for updates

This on-demand online course covers the basics of beer brewing. It approaches the general principals of the brewing and malting processes, the raw materials as well as filling and packaging in theory. The participant will receive a Certificate of Attendance.

Location:

Online on-demand

Next date: Anytime throughout the year

More information: www.vlb-berlin.org/en/bianso

VLB Berlin, Seestrasse 13, 13353 Berlin, Germany

+ 49 (30) 450 80-0, brewmaster@vlb-berlin.org , www.vlb-berlin.org

Managing Directors

Dr.-Ing. Josef Fontaine (CEO)

+ 49 (30) 450 80-292

fontaine @ vlb-berlin.org

Gerhard Andreas Schreiber (CFO)

+ 49 (30) 450 80-292

g.schreiber@ vlb-berlin.org

Research Institute for Beer and Beverage Production (FIBGP)

Dipl.-Ing. Jan Biering

+ 49 (30) 450 80-132

biering @ vlb-berlin.org

Research Institute for Management and Beverage Logistics (FIM)

Dipl.-Ing. Norbert Heyer

+ 49 (30) 450 80-139

heyer@ vlb-berlin.org

Dipl.-Ing. Ingo Pankoke

+ 49 (30) 450 80-192

pankoke @ vlb-berlin.org

Event Management

Dipl.-Ing. Alexander Scharlach

+ 49 (30) 450 80-239

scharlach @ vlb-berlin.org

Testing Laboratory for Packaging

M.Eng./Dipl.-Ing. Susan Dobrick

+ 49 (30) 450 80-242

dobrick@vlb-berlin.org

Research Institute for Sustainability, Energy Supply and Optimization and Artificial Intelligence (FINEK)

Prof. Dr. Frank Behrendt

+49 30 314-22756

frank.behrendt@tu-berlin.de

IfGB – Events Spirits & Distilling

Wiebke Künnemann

+ 49 (30) 450 80-270

kuennemann@ vlb-berlin.org

International Sales / Coordination Iberoamerica & Africa

Roberto Biurrun

+ 49 (30) 450 80-185

biurrun@ vlb-berlin.org

PR and Publishing Department / Editorial Office “Brauerei Forum”

Dipl.-Ing. Olaf Hendel

+ 49 (30) 450 80-255

hendel@ vlb-berlin.org

Research Institute for Biotechnology and Water (FIBW)

Dr. Martin Hageböck

+ 49 (30) 450 80-157

m.hageboeck@ vlb-berlin.org

Microbiology and Brewing Biology

Dr. Martin Hageböck

+ 49 (30) 450 80-157

m.hageboeck@ vlb-berlin.org

Water Quality, Management and Technology (WMT)

Dr. Alfons Ahrens

+ 49 (30) 450 80-294

ahrens@ vlb-berlin.org

Research Institute for Raw Materials and Beverage Analysis (FIRGA)

Dr.-Ing. Nils Rettberg

+ 49 (30) 450 80-106

n.rettberg@vlb-berlin.org

Beverage Analysis

Ludmilla Linke

+ 49 (30) 450 80-100

linke@vlb-berlin.org

Special Analysis and Research

Dr. Sarah Thörner

+ 49 (30) 450 80-250

s.thoerner@ vlb-berlin.org

Spirits Analysis

Dr.-Ing. Christian Schubert

+ 49 (30) 450 80-299

c.schubert@ vlb-berlin.org

Sensory

Patrícia Diniz Fischer

+ 49 (30) 450 80-149

diniz.fischer@ vlb-berlin.org

Raw Materials Analysis

Gustav Creydt

+ 49 (30) 450 80-135

creydt@ vlb-berlin.org

Pilot Malting and Customer Services

Markus Wildegans

+ 49 (30) 450 80-285

wildegans@ vlb-berlin.org

VLB LaboTech GmbH

+ 49 (30) 450 80-220

labotech@ vlb-berlin.org

Technical periodical for breweries, malthouses, the beverage industry and their partners

Information service of VLB Berlin www.brauerei-forum.de ISSN 0179–2466

Publisher

Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V. Seestrasse 13, 13353 Berlin, Germany

Editorial Office

Brauerei Forum

Seestrasse 13, 13353 Berlin, Germany

Phone: + 49 (30) 4 50 80-251

Fax: + 49 (30) 4 50 80-210

Email: redaktion@brauerei-forum.de Internet: www.brauerei-forum.de

Editorial Department

Olaf Hendel, Editor-in-Chief (oh) hendel@vlb-berlin.org

Eva Wiesgrill (ew) e.wiesgrill@vlb-berlin.org

Julia Bork (jb), j.bork@vlb-berlin.org

Brauerei Forum Advisory Board

Dr.-Ing. Josef Fontaine, Dr. sc. techn. Hans-J. Manger

Advertising Sales

VLB PR and Publishing Department

Phone +49 (30) 450 80-255 media@brauerei-forum.de

Publication Dates

Appears with 8 editions a year, in German plus 2 issues in English.

Subscriptions

Domestic 95 € incl. VAT

Abroad 95 € (+ shipping)

Cancellation of the subscription in each case at the end of the year Westkreuz Verlag, Berlin

Phone +49 (30) 7 45 20 47

Fax +49 (30) 745 30 66 abo@brauerei-forum.de

Print and Distribution

Westkreuz Verlag GmbH

Töpchiner Weg 198/200 12309 Berlin, Germany

All rights reserved. No part of this publication may be reproduced in any form without the prior written permission of VLB Berlin. We do not accept any liability of unsolicited sended scripts. The editor do not assume any responsibility for contributions marked with a name or signature.

Our next German edition will be released on 20 December 2024

The next international edition will be released in May 2025

Certified Brewmaster Course 2025 6 January to 27 June 2025, Berlin

109 th VLB Brewing & Engineering Conference 2025 25 to 27 March 2025, Kulmbach, Germany

5th VLB Africa Brewing Conference 2025 16 to 18 June 2025, Maputo, Mozambique

VLB Summer Party 2025 4 July 2025, Berlin

General Assembly "ehem. VLBer / Brewers of Berlin" (VLB Alumni) 4 July 2025, Berlin

Workshop "Craft Brewing in Practice" 1 to 12 September 2025, Berlin

VLB October Convention 2025 6/7 October 2025, Berlin

VLB General Assembly 6 October 2025, Berlin

15th Iberoamerican VLB Symposium Brewing & Filling Technology 10 to 12 November 2025, Paraná, Brasil

2nd Ibero-American VLB Craft Brewing Conference 2025 10 to 12 November 2025, Paraná, Brasil

Certified Brewmaster Course 2026 7 January to 26 June 2026, Berlin

VLB will be exhibiting at upcoming international conventions and trade shows in 2025:

Craft Brewers Conference 2025 28 April to 1 May 2025, Indianapolis, USA

drinktec 2025 15 to 19 September 2025, Munich, Germany Check www.vlb-berlin.org/en/events for regular updates

VLB Berlin Hall C3 Booth 122 September 15-19, 2025 Munich, Germany