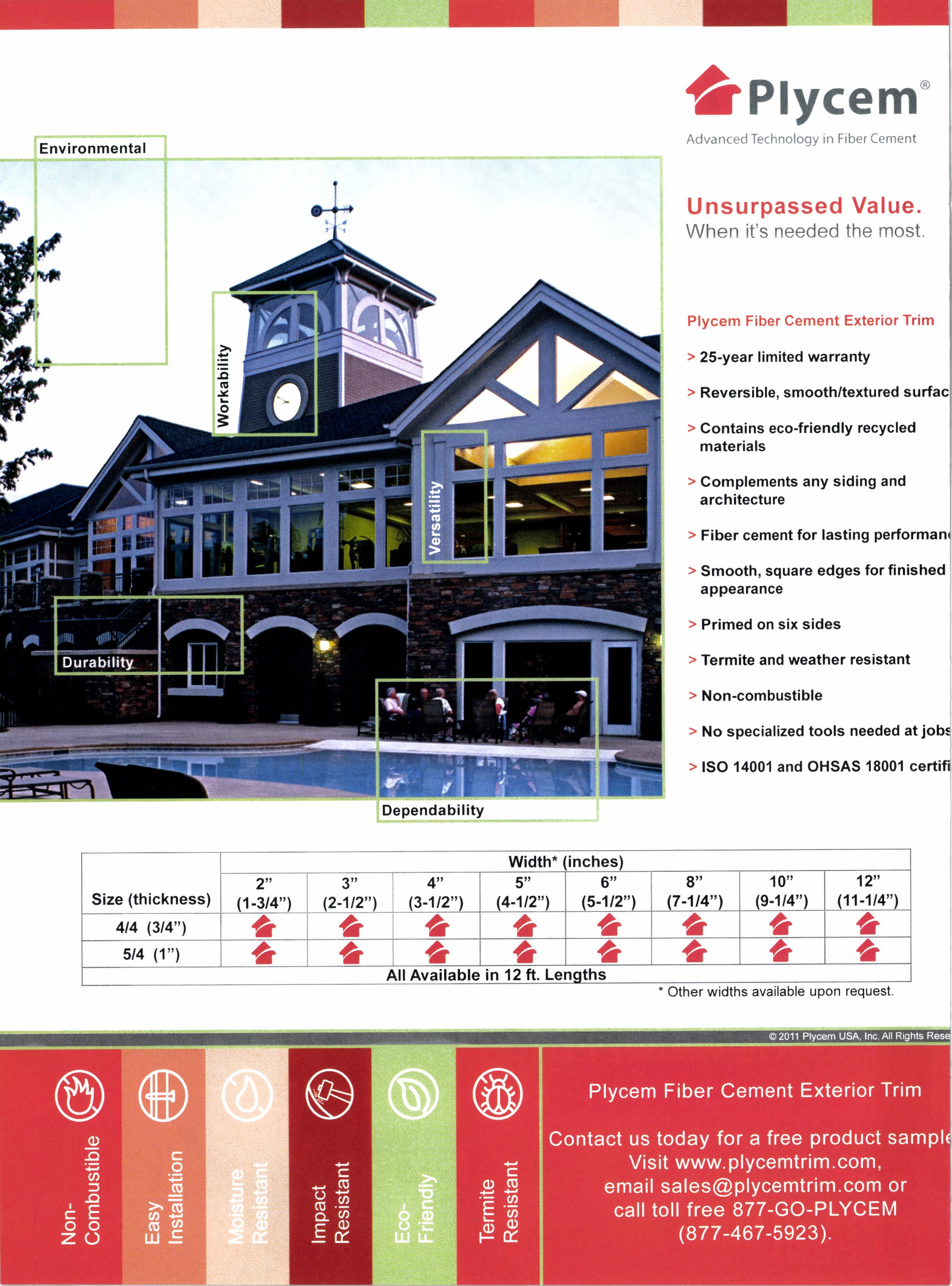

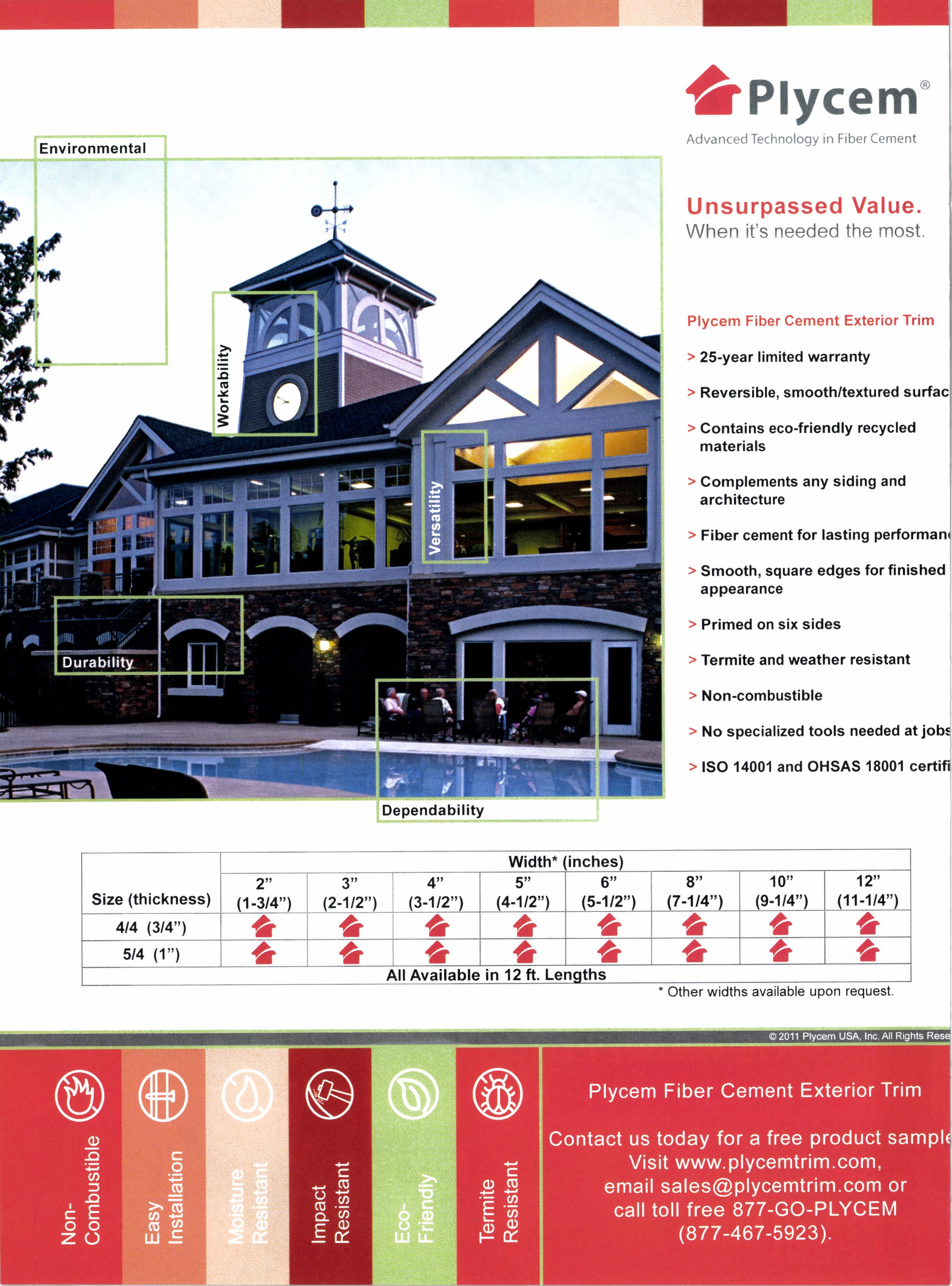

25-y ear I imited wa rranty

Reversible, smooth/textrlred surfac

Contains eco-friendly recycled materials

Complernents any siding and a rc h itectu re

Fiber cement for lasting performanr

Srnooth, sqLrare edges for finished a ppea ran ce

Primed on six sides

ITermite and weather resistant

Non-cornbustible

No specialized tools needed at jobs ISO 14001 and OHSAS 18001 certifi 10" 12" (9-1t4"\ {11-114")

..€ ftil ffiH I il ilI z = (g x E nviron me nta I ffistr

wi w ffi.. ffis' ! @ r-f ";ffir-'.-= *ffi f,E: F ffiWffiM

ffiffifr

2" Size{thickness) 04t4,') 4t4 (3t4") 5/4 (1") Dependability 3" 4" (2-1t2"1 (3-1t2") r@;r Width. (inches) 6" R" (7 -1t4" ) (4-1t2") (5-1t2"1 All Available in 12 ft. Lenqths Other widths avarlable upofr fequest :r,l:irl Y'* /'f.' -u-1...-- ..:': -" ffi K'.1 ru

&DVS$clew

The pioneers of Kiln Dried After fryaffient have partnered with the world's most respec "oor6t cogn€ctor company to bring you the 3 best decking system fo a'f next project. When you buy,.Cox KDAT decking, recei_ mpson Strong-Tie DSV d€cking screws at no extra charg

Scan with your Android phone, iPhone or iPad!

The Orginal Kiln Dried After Treatment (KDAT) Lumber by Cox combines with Simpson Strong-Tie's new DSV Decking Screw to bring you the best decking system for your next project. Contact (8OO) 476-4401 or Click QR codes above to learn more and for purchasinq.

**f M "qeMn wM *weWd M *@ {& M M GffiI M E-ry* ,l&ttt' **-'l.* ,tr;g"'€;-'-i''1 tgS,: "4t, ''l ' rt " :rr I r::ilri l 6[9r''&1' {;: '{ i--* , @:ee&*.ag.'''{1::' l' w*6r46'"t,*'"1; ' Available in hand-drive e :tnd in collated strips ,nr.:''s' for use in the Quik Drive tr''$ '' .,.r., e duto-fegd screw driving I ' sYstem' ,1' {'e t o*tt - e n'u ^'"n' n/ lb,"-'-;; ;"'l:i ; -.::.':"; *:t"tr *";**x *'*,lt!;1 **.'}- -" . "' -': L;] *..1r t furndustr:iesp&;* e.' r f ^fr -/ - Present ,f [@AirD&Kn

cking available in Durapine I Ecolife by Cox g,sglfr,fu

BPD

BuililinA Proilucralligest

Special Features

lHousrnv TnrHos

Freen CrN eNr LEnos rN SrorNc

10

Pnooucr Sporlrcur

Uppen-Cnnor Rrowooo SrorNc

Porseo ron CovrsRcr

1 2 MnNncrmrnr Trps

RuNNrNc ONrrNr CoNrrsrs

'l4 Fmrunr Srony Co-ops Aro rN Socrnr Mrorn

26 SprcrnL Focus SourHenN Fonrsr Pnooucrs UpoRre, ev SFPA nNo SLMA

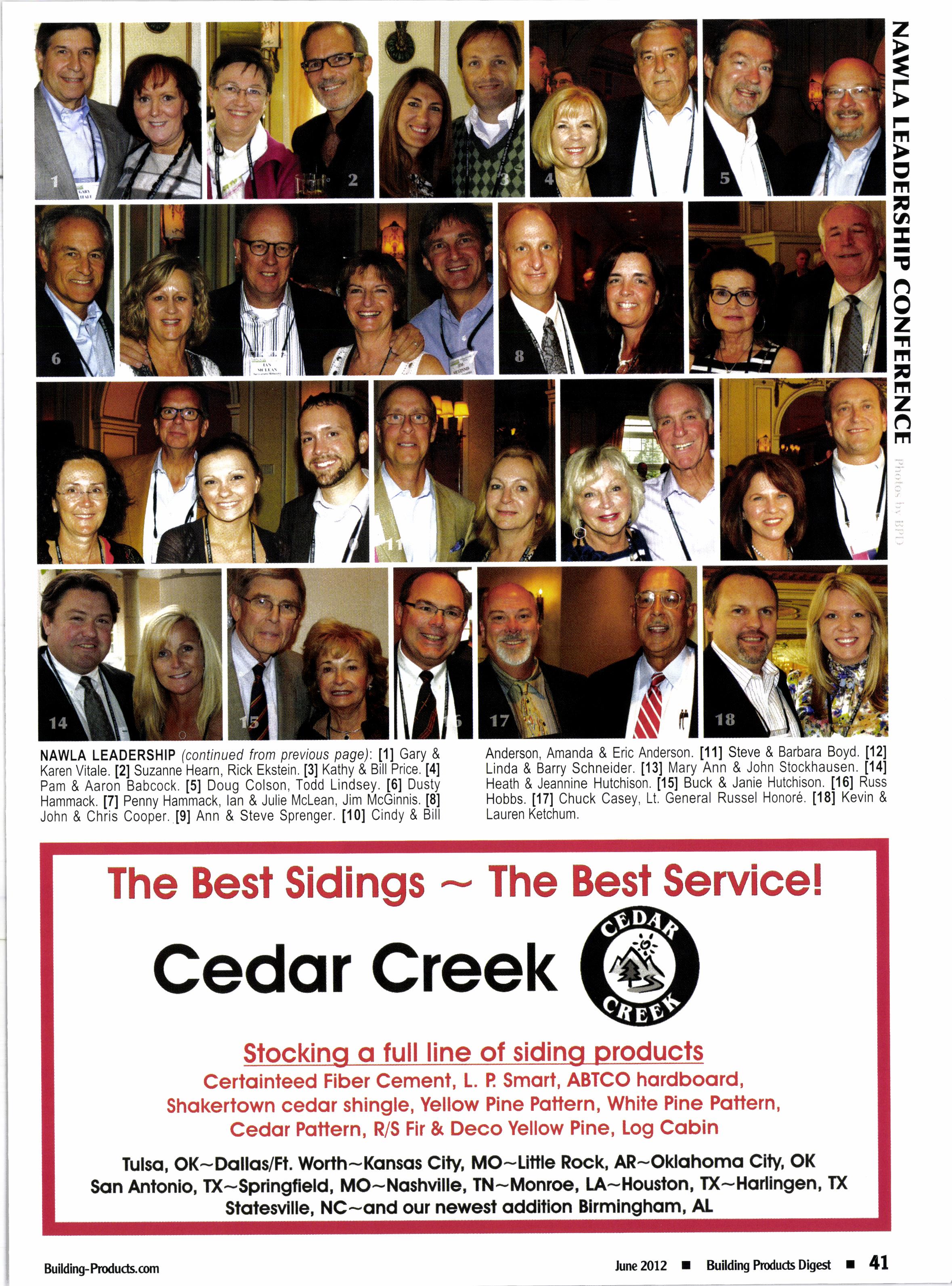

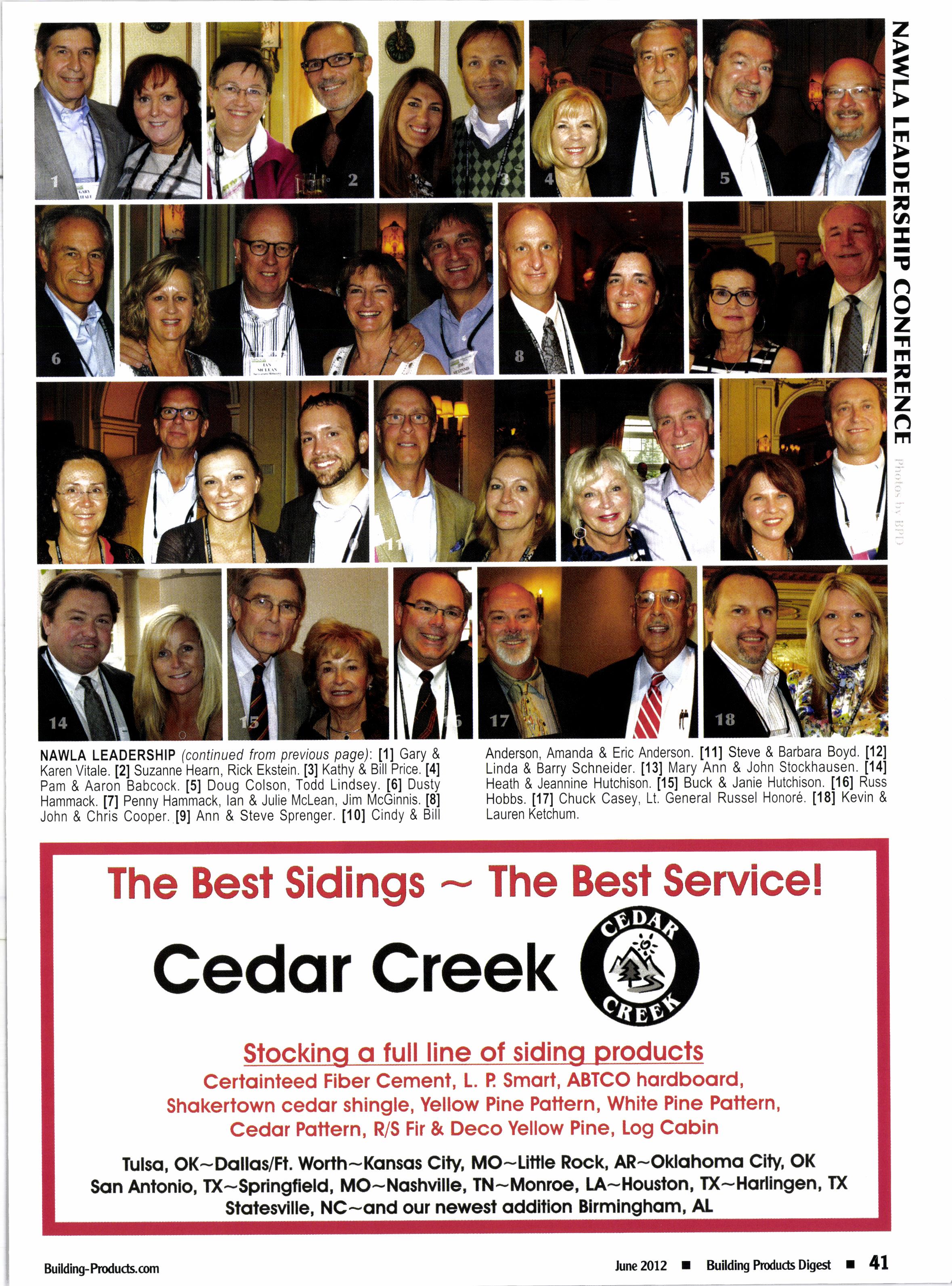

38 Pnoro Rrcnp: NILMA

40 Pnoro Rrcnp: NAWLA

In Every lssue

6 Tornuy Rnroor*

1 6 Cor'aprrrrrvr tNrnlrcENcE

1B OLsrN oN Snles

24 Movrns & Snnxrns

36 Nrw Pnooucrs

42 AssocrnnoN Uponrr

42 lr.r Mrmonrnm

44 Cr-nssrnrro Mnnxrrpmcr

45 DnrE Boor

46 lorn Frlr

46 Aovrnnsrns Inorx Online

BnrnrrNc lNousrny Nrws & Ir,rousrnv PHoro DowHlonos Bu r rot Nc-PnoDUCTS.coM (Forrow LrNr ron PHoros)

BPD: Drcrrnl Vrnsror"

THr Lnrrsr lssur C,qN Now

Be Vreweo Rr

B u rr-or Nc- PRoDUCTS.coM

4 t &riHingPrcdu6Dbest r June20l2 June 20'12 t votume3l r Number4

Bnilding-Roductsom

Pu-Eigi|t.@d Sbal Buildtng S.c R&l Stonga SyabfiE to( B{lldl}g i||b .@!D Adffittd Lumb.r Stong. Syst m Crnttbh. Rsk Palbr Rrh A+nm Rrct ilsrnlM, tos|din! Rrcb, Slrck R.ckr Nrttonally LlceEld Gan.nl c@|nctor

By Alan Oakes

By Alan Oakes

Lifelong learningr ? competitive advantage

f unve JUSr REruRNeo from the first-ever NAWLA Leadership Conference in lColorado Springs. The event emphasized what I had realized over the last few months-that I need to get back to my roots, which I will explain later.

The conference was the first event in my l l years in the industry that was from start to finish full days of management and executive learning programs with top industry and out-of-industry speakers. No time off, just pure session after session and almost l00%o attendance at each session. I learned a lot, as no doubt did the other attendees-a mix of owners, senior managers, and up-and-coming future executives.

First, my congratulations to NAWLA for developing this new program and congratulations to the members for making the investment to attend-and bring along others-in these difficult times. I am sure that, due to initial feedback, next year's program is already being planned, and I urge all current and future NAWLA members to put this event on your calendar for next year. I also recommend taking along other managers and or key employees. The cost vs. return is always a key factor, and I believe that the benefits will far outweigh the expense.

I have spent decades in the educational publishing and conference/seminar training industries (from sales to executive management training to technology, domestic and international, for companies small to Fortune 100). I have spent a good portion of my business life in education and understand the value of lifelong learning. And the more I learn, the more Irealize how much I have left to leam. Today, after we learn something, circumstances change again and different knowledge is needed' At the NAWLA conference, we discussed "Cash is King." I would also argue "Knowledge is Power." We all need constant education, training and reinforcement. Yetlrealize not all companies can afford to offer or are equipped to handle such training.

So, what to do? What was clear to me in the beginning of my current business life was that this industry by nature has been a hands-on training industry, as opposed to sending management and employees for job skills training. What also has become clear to me is that we live in an era where there is a need for more learning opportunities. We have lived through one of the most difficult times in business history. I can imagine many had issues to deal with that they were ill-equipped to handle, in addition to the many day-to-day issues we all face.

Many of our readers-managers, executives, salespeople, and managers-in-training-could benefit from a constant source of education. This should be general education and not just industry training.

Our magazine has over the years featured countless educational articles written by experts, but I have realized over the last six months that we need to do more. So, in the next couple of months, we will launch a new branded educational series aimed at not only executives and owners, but also the future managers in this industry.

It is also clear to me that not all employees see our publications when they arrive at your offices as many subscribers hoard them (normally great news). I ask that our magazines be passed around to those who would benefit. (Or, simply order more subscriptions!) Free digital issues are available on our website, building-products.com. In the near future, each magazine will have a QR code for a direct link to our publications as well. Our publications have always been a source of industry and product news for a combined 120 years, but now I want us to be your resource for executive education as well.

So, look out in the coming issues for our new "Mastering" series-two more good reasons to read and enjoy our publications. As we hit our 90th year in business next month, we want to be your resource for the next 90 years as well.

Alan Oakes, Publisher aioakes@aol.com

BPII Building Producls lligest

www.building-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

Publisher Alan 0akes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial & Production David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@bu ild ing-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes ww. building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One year (12 issues), $24 Two years, $39 Three years, $54 FOREIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico, $49 Other countries, $65 Air rates also avaihbb.

SINGLE COPIES $4 + shipping BACK ]SSUES $5 + shipping

BUILDING PRODUCTS DIGEST is oublished monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buildingproducts.com, by Cutler Publishing, lnc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright@2012 by Cutler Publishing, Inc, Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

r TOTALLY Random

6 r BulHlng hodu6 Dig€d r June 2012

BnildingPrcductscom

I{ave Your Custorners Choose Any Color For Their Siding. Let Us Do The Rest. Cabot Factory Finish'" Fade-Resistant, Nature Inspired Colors . Saves Time and Eliminates Weather Delays . Applied in Factory-Controlled Conditions Available with S-year, 1 S-year or 25-Year Warranty To Learn More, visit CabotFactoryFinish.com or call 1-8OO-US-STAIN Oun PERFORMANcE Is LEGENDARY.*

psffuctural Panels

Srncc l95l s'c'r'c irccn nrrtkitrg tltrrrlitv tirt'c:t uscrl lr)' tlistril''rr f ors, .lcrrlers, [rrril.lers, rertrt rrielcrs,

For or-cr flftl telirs ri'c tlkc carc ttil'trrr; strive ilnrl cusf()mcrs thc u at

har.e tilllou,c,.l rhc s:u'ne Drincinles: trrkc crrre itrr excellencc iurrl ctticicnev in nrnrrrrtirctrrring; rrntl trcrrt irll ttrpplicrs 1't,u lrorrltl like to bc treatcrl.

gffi*' ' "s %" ; 'i": # # sry#

For sales call: 1-800-331"0831

ww\.\'. s rv an s on group inc. c om

:r .i ;.:r rilt:..t::.:1....i:' n. o' " ' "; ':::":i'']::. Uimensionil.:j: " : l'''l]l"'i& ${ -.""{msrc fI:. &r .i :bh,, Ilcrr. , ,:t 'i:1 . r -r:.t 3..'{ ,;,*ttsg S ,'" S t- )'( )l l rsc ffi n t:'iF >\ =-t> \1 \ :> -'--l e il h n n i ,l; ll:.? rS ;f lt.r. .,,:,. ,...i:.,'t:l:t i:: t, .;.ii t fi1.,1r,..:t;r,.,.*nii L ,., tiri;; .r, 1,,.,':i pro.lr r c llll(1 r1( )-

/Jt\ susrnuusir [*$ar FORESTRY ) INITIATIVE ',;; ,',1,;,,1,.',), ,, ,. :APA IE' ENGINTTB'O wooo ^5Joc,Alo0 @,,

Sru

',\ i ."'1 Li i il

Do you like to gamble on your shake and shingle purchases?

We didn't think so.

Educate yourself. Choose Certi-label'" products and enjoy free District Manager technical assistance.

QUALTTY CONTROL REALIilES

FACT: Despite what some product labels say, phone numbers andlot post office box addresses are not 'Third Pafi tnspection Agencies." Legitimate third party inspection agencies hold proper accreditations, have trained, experienced staff and have employees, an address, phone number and business office that are different f rom the manufacturer.

FACT: Statements on product labels that read "lnspected by in house inspectors" are not equivalent to "Third Pafi Inspection Agencies." "ln-house inspectors" just means that the manufacturer's own staff have inspected their own product and declared it fit for sale. Product without third pafi inspection is most often a code violation and can result in a building official requiringthe productto be torn off.

PITCH: "lllle chose not to join the Cedar Shake and Shingle Bureau because our products are actually graded tougher."Alert!The Cedar Shake and Shingle Bureau has never prevented its members from producing AB0VE the grade standard. Members are prohibited, however, from producing BELOW the grade standard. Buyels Tip: When foced with this stotement osk your supplier if the mill uses in house OR o Iegitimote third pafi inspedion ogency. Ask obout their technical seruice. You may be surprised by the onswer you receive.

CAUTION: A product label reads "in accotdance with" as opposed to'tonforms with" the grading rules. Be careful here. Ask your supplier if the products in question actually meet and conform to grading rule standards or if it's a slick way to fool the end user.

PITCH: 'All my stock has got a blue label, therefore all of it is good." The term "Blue Labelu" is actually a registered trademark of the Cedar Shake and Shingle Bureau trade association which has over 250 member companies. Just because a company puts a label in a blue color on its bundles does not mean that it's on grade or third pafi inspected. This confusion may lead to rejection of the load at the job site. Buyels Tip: To specify a Cedar Shoke ond Shingle Bureau member's product and grode, you must write "Certi-lobel'*" brond on the purchose order ond roofing controct. Follow this wording with grade, producttype, length, width ond perhops even the common nome of the produd such as "heovies", "mediums", "R&R" etc. Being specific on your purchase order ond roofing controct gives your supplier no excuse to ship you on undesired product, grode or brond. Specify thot if Certi-lobel'" brond wos ordered, ond the product delivered does not beor the Certi-lobel'", then the lood will be rejected and sent bock. The wrcng brond olso results in worronty denials, thus upsefting your customers.

PITCH: "These products are iust as good as Certi-labelbrand products, but they are cheaper/more readily available/what your roofing contractor prefers to work with." Don't believe these types of misleading statements. You get what you pay for. Certi-label* brand products are readily available, and good roofing contractors prefer to work with quality, on grade materials that conform to building code plus yield less culls and call backs. Buyels Tip: Coll your suppliels bluff when you heor this. lf you need help sourcing materiol or debunking myths then osk one of our District M a n og ers fo r fre e a ssistonce.

PITCH: "This is simply our mill brand... lt comes from the same logs and is manufactured by us in exactly the same way as our regular material." This sounds suspicious. "Mill Crade" product does not conform to building code and is the lowest grade available. Remember, you get what you pay for, so don't be fooled. Buyels Tip: Ask for wriften confirmotion thatthe produd hos legitinote third porty inspection and will be accepted bythe locolbuilding code officiol

for your specific project.

ARGUMENT: "Our firm doesn't belong to the Cedar Shake and Shingle Bureau because of the membership dues. We pass those savings alongto our customers."

Ask your supplier if they've ever used the Cedar Shake and Shingle Bureau's website, referred to our installation manuals, or called a District Manager for assistance with a technical issue. lf yes, then why are they coat tail riding the industry's trade association services and denigrating the association to you?

A simple question: Who would you rather talk to for help - a hungry salesperson looking for their next sales commission OR a knowledgeable, education-focused person who is paid to provide free technical assistance and documentation?

Here atthe Cedar Shake and Shingle Bureau we do get quite a chuckle over the numerous calls from non-members' customers who are frustrated with the lack of technical assistance provided. Some of these customers even tell us that the non-member sent them to us for helpl Buyer's Tip:

Remember, Cedor Shoke and Shingle Bureou District Monagers only provide technicol ossistance for Certi-label'" brond products. A District Monoger would be glod to inform you how much mem bership octu o IIy costs.

Quality Certi-label-" brand products. Cedar Shake & Shingle Bureau members.

SATES MUMBO IUMBO

%4

Manufactured

FACT: Some salespeople will mislead customers into believing certain brands/products are not available, just so that they can move out their current yard inventory. With over 70 member manufacturers in its membership, the Cedar Shake and Shingle Bureau can source the quality cedar shake or shingle product you need. We even have District Managers who will provide free product sourcing and technical assistance on Certi-label*, third pafi inspected shakes and shingles.

PITCH: "Great deals add value to my product lines." Everyone loves a deal, butthere is a difference between a great deal and a misleading deal. No one loves bundles labeled Number One Grade that are 800/o+ flat grain. No one loves bundles or cartons short of coverage. Excessive flat grain and short coverage mean off grade products, job site call backs, code violations and product shortages. You get what you pay Ior. lnstaller's Tip: Poorly groded ond under-pocked, so-colled "BARGAIN" cedor shokes ond shingles will end up costing you more to install when you consider short coverage, coll backs and building code officiol red tagged job site tear offs.

CAUTI0N: Your supplier of non-member shake and shingle products tells you to lie about your product brand just so you can get free Cedu Shake and Shingle Bureau technical assistance. Really? You'd do business with someone who asks you to lie just so they don't have to pay proper membership dues? Come on - Cedar Shake and Shingle Bureau members pay the salaries of District Managers. lt's only fair that our members' customers get the exclusive benefit of District Managertechnical services. Cheap freeloaders are notwelcome, BuyelsTip: Cedor Shoke ond Shingle Bureou representotives ore extremely well networked in the industry. lt doesn't toke long for us to find out if you are reolly using our members' Certilobel" producE. And yes, when you contoct them, District Monogerswill oskyou specific details oboutyour projedto check that it is indeed our members' Certi-lobef' brond moteriol.

AVOID THE OFF GRADE SHg

FACE VIEW

FLAT GRAIN

Flat grain is restricted by grade. No flat grain is permitted in Premium Grade shake or Number One Grade shingle products. Up to 200/o per bundle is allowable in Number One Grade shake products, The officialgrading rules, as referred to in the national building codes, can be reviewed atwwvv.cedarbureau.org

COVERAGE

Some manufacturers cheat by not putting the correct amount of ON GRADE coverage in bundles or cartons. Others make cartons that look full but are actually smaller than standard size. Read the grading rules and compare them with how much the carton holds. Much like serving sizes of food, the calorie count doesn'talways match thefull contents of the container.

MORE SALES MUMBO IUMBO

Good Coverage low Coverage

Edge Grain

THE BOTTOM IINE

Customers want value for their cedar roofing and/or sidewall investment. Their home protects their family possessions and heirlooms, items that shouldn't be risked with roofing or sidewall products of unknown grade or quality.

Make an honest and fair evaluation of your purchasing decision... Ask questions.

Request technical assistance if you need it. The Cedar Shake and Shingle Bureau has been providing technical service to Certi-label'u customersfor almost a hundred years.

The Cedar Shake and Shingle Bureau is making a POSITIVE difference:

y' Free technical services from education-focused (not sales-focused) staff

y' Free literature and grading rule handouts

y' Cedar Quality Auditor and extra inspections as additional layers of quality control

y' Reassurance of legitimate third party inspections by accredited agency

y' Manufacturer's lifetime limited warranty available from CSSB member manufacturer when applied by a CSSB member approved installer

y' Renewable and recyclable products courtesy of Mother Nature

y' Many Cedar Shake and Shingle Bureau members are family businesses with multigenerations and decades of quality focus. Founded nearly one hundred years ago, the Cedar Shake and Shingle Bureau is known as: The Recognized Authority Since 1915.

WE'RE HERE TO HELP:

Tony Bonura, District Manager, Northeast (651) 645-7859

Tony Hyatt, District Manager, Northern Midwest:

Peter Parmenter, District Manager, Southeast: Clay Walker, Cedar Quality Auditor:

(608) 848-2667

(er2) 8e8-sr75 (604) 820-7700

tony@cedarbureau.com

hyatt.t@cedarbu reau.com

peter@cedarburea u.com

clay@cedarbureau.com

Gsdar $haks & $hinllo Bursau

Printed in Canada April 2012 vuuvw.ceda rbu rea u. o rg

Fiber cement to lead siding comeback

f T S I)r,\r \\r) non sirlirrq is firrccast

ILJ to gr.orr 8.-1Ci urrrrLtrllr tht'orrgh 20 I6 1o t)(r.-5 ntillion stlrurlcs. r rLlucrl lt S l0.l [rillion. uccor.tlin-u to l nc\\ stLrdr b,r Iilccclctniu (iroLr1t.

Glon tlr ri ill bc slturrccl br un increasc irr housinlt eonrltlction: llont tlieir rlcprcsscd 20 1 I basc. ,\ltltoLrgh housilts complcliorrs will lcrnain bclori thc lcr cl: r'cachc-rl lrt thcir c1'clie rrl pcak in l(X)(r. thc r.ce o\ cfv vu'ill sPulk abovc-ur crage glins in tlte rcsrrlcntiaI sitlilt1t tnarkct thr-ur,rgh 1016.

Thc crltectctl rcbctuncl in ltousinq corrplctions through l0l(r n ill rce stirblish the rrcr.r' housing nlllkct u\ thc lurgest cnrl use l'or siclins..

[)cnrrrncl 1ol siding irr lcsiclcntiul irttlllovcnrcnt lLntl lcplrir lryrpliclitions u'ill risc ul lr nroclcratc l)ucc throLrqh

10 16. Thosc ltontcowncls tltat put oll inrprovcnrcrrt projccts such ls thc r-cltlaccnrcnl ol' u of t) ()l-lt oI ()utol'lashion sirl ing ri ill Lrnclcrtlkc thetn in thc I'uture. lroostin-u denlrntl

Nonr.cs irlcntial rlenurnrl fbr sitlirrg is also lolccast t() gl()\\ rlltirllv

throush l0 | 6. albr-it n()t ut thc lcr cl ol' the rcsirlcn(ial ntarkct. Gains l ill be tlrir cn bt advancirrg nonrcsitlcntial bui lrl i ng c()ltstruct i()n cxltct'rrlitrrlcs.

Thc rll'l'icc unrl con.rr.ncrcill and loclging sc-sntcnts. ri hich crpclrcnced thc nrost rapitl rlcntancl rlcclines

bctuccn 2006 lncl l0 lI. r,r,ill cxhibit thc stfongest 9r'o\\ tlt goin! lirr'\\'arcl as nrolc office builtlings anrl r.ctrril sitcs lulc crccted. Muny of thcsc stllrcturcs t ill hc bnilt ri ith such nlrtclials us f ibcr ccmcnt unrl stLrcco that scrvc as Iori cost ultcrnatires to brick. uoorl. itnrl s(clne.

,\rnc'rng rrratcrial tyl)cs. stLlcc(). br.ick ancl tibcr ccment sicling arc lirrccast to scc thc'most fal)icl clenlirntl

guins through l0 l (r. incrcasing at dou blc tli!rit paccs.'[-hc reboLrnrling resi rlcrrtial rnalkcls in the South uncl West rcgions o1'thc U.S. uhcle thesc Irittcrials arc nrost oticrr installcdrrrc pro.jcctctl to erpcricncc thc stron.gest gfo\\ th in populltion untl lrousing activity through 20 16.

Brick lncl I'ibel ccrrrent scc r,r'iclc ttse itt (itt'So11111. *ltilt':lueeo is rrro:I comnronlr uscd in tltc We-st reeion. Thus. as nrorc honrcs ure bLrilt ancl rcn'rocle lctl to mcct thc needs ol' thc regions' incrcusing popull(i()n. clcnlrnrl lirr thosc siilin!' ntatc-rials w'ill also lrrlvlnce.

Fibcr cement sitling \.r'ill contirrue to takc nrarket shlrr-c ll'clm clther rnaterials. such as vinvl ancl u,ood. Dcnlrnd for f ibcl cct'nent sidinl: rvill bc spurred by its abilitr to be pro-

clucccl into siclin-g thirt r-csernblcs rlorc costly nraterials. srrch as brick or stonc. liibcr centcnt siding clcrnand r"ill ulso be sultltortcd by continuing conslilIcf acceptilr)cc o1' thc ntatcrial betrttts.' ol its 1'rr't lirrt)irltLe l)lr)l)r'ltie\. such ils resistancc to dcgluclation citusctl bt' insect atlack ancl nroisture.

\rinvl siclins accountccl lirr thc largcsl sharc ol sicling rlclnand in 20 ll and will continuc lo lclcl the rttalkct in 20 l(r. as such innovations rus insulatccl r invl sidinc anrl ltroducts thitt bcttcl rcscnrble nltur-al rnateri alssuch ls r,' ood ancl stone u ill pnrrrote clcnrancl. Howcvcr'. contpctition fl'onr f ibcr ccrnent uncl stucco siding.,"ill chcck grou,th. [;iber ccntcnt ancl stucco siclins arc srricl to ol'l'cr e ncl-usels bcttcr l<trrg tcltn clurabilitv and requirc lcss maintcnunce.

r-_! Np UIIBy #"p'e,tsr*f3t r.. lili:.

FIBER CEMENT siding wrll cont nue to take market vinyl will remain the top-seller

share away from competing materials. although

June 2012 r Building Products Digest r 9

Building- Products.com

Redwood siding rising

New investments, second-growth availability drive resurgence of upper-grade redwood

Now, after more than a decade of declining demand, Redwood Empire is poised to help redwood reclaim lost market share. The company acquired its second remanufacturing facility last August, in Redding, Ca., and has been investing to bolster operations there since. The facility, which once produced mostly specialty products for Hawaiian markets, primarily manufactures siding and trim from upper-grade redwood.

fHrne wAS A ttvs when redwood I- was among the more preferred and popular siding materials for fine homebuilding. There never has been any question as to redwood's beauty or durability. Its authentic natural look blends in particularly well in mountain or lakeside communities.

The increased acceptance of vinyl and the introduction of composite materials such as fiber cement have chipped away at the market share for

all natural wood species. Vinyl now commands 4O7o of the $6 billion siding market, while wood products hover around 107o. Pricing spikes for redwood's highest grades before the turn of the 21st century likely helped accelerate its market-share drop, as did prior changes in harvesting practices that resulted in less upper-grade redwood coming to market. The perception grew rapidly that upper-grade redwood simply was not available.

The proximity of Redwood Empire's primary sawmill in Cloverdale and manufacturing facilities in Asti, Ca., to southern-range redwood forests provides easy access to quality logs. Each mill is customdesigned to cut for grade rather than to maximize throughput. Though the milling process often takes longer, the result is greater output of upper-grade redwood and more availability of vertical grain lumber, which feeds Redding's siding-production operation.

A Sustainable Product

The redwood siding popular throughout the 20th century largely was the product of old-growth trees harvested from California's San Mateo. Santa Cruz. and Mendocino counties. Now these areas, the first to be logged, are the source of secondgeneration forests managed for

PRODUCT Upper-Gr

10 r Bulldlng Produds D'rgest r June 2012

&riHit4rhodudsom

CHECK OFF; Moses Perez, production supervisor, inspects a board of clear redwood,siding at Redwood Empire's manufacturing facility in Redding, Ca,

decades under California's sustainability laws-the toughest in the nation. Many second-growth trees in the southern end of redwood's natural range exhibit qualities similar to the wood harvested in the hevdav of redwood sidine.

Redwood harvested from sustainably managed forestlands along California's coast has proven to be the source of eco-friendly, long-life products. A renewable resource, redwood trees remove greenhouse gases from the air through photosynthesis, absorbing carbon dioxide and releasing oxygen. Life Cycle Assessment research, which studies cradle-to-grave environmental impacts of building materials, has shown that redwood products store more carbon than is used in their manufacturing. The net result of using sustainably harvested redwood is a decrease in greenhouse gas emissions.

Geography Correlates to Preferences

Even in the lean years for redwood siding, there were pockets of demand across the country with interesting and fairly constant geographic preferences. The East Coast, for instance, has shown the greatest demand for beveled siding, particularly 112"x6" pattern 322R, followedby |12"x8" beveled pattern 323R and some lx6" tongue and groove patterns. Texas markets have generally preferred thickbutted rabbeted siding like pattern 477 The Midwest typically has leaned more heavily toward 1"x6" tongue and groove options, while the West Coast has favored shiplap patterns (particularly pattern 793) and some bevels.

Economic, Consumer & Architectural Drivers

Remodeling efforts that allowed homeowners to seamlessly replace damaged siding on existing structures or

match home additions to established looks drove much of Redwood Empire's initial manufacturing at its Redding facility. Indeed, remodeling of aging homes is still forecast to play a significant role in the overall siding market.

Recently, however, new home construction has accounted for a larger share of production. Several factors may be behind the increase in demand for redwood siding for new homes, including price. Once consistently the most expensive option among natural wood siding products, shifting market dynamics have made redwood price-competitive with cedar siding.

Green building trends may also be having an influence. Research indicates consumers are placing greater emphasis on environmental performance and sustainability issues in their purchase decisions. Redwood siding is recyclable and biodegradable, and offers a favorable carbon footprint.

Perhaps the greatest influence has come from the architectural community. Architects have long been attracted to redwood-especially vertical grain redwood-for interior and exterior applications because of the wood's natural beauty. Increased awareness that vertical grain redwood is again available appears to have spurred a rise in architectspecified redwood siding. While vertical grain availability remains somewhat limited in the top Clear All Heart grade, Redwood Empire has produced significant quantities of vertical grain siding in all upper grades, including Heart B, Clear, B grade, and selected commons.

As consumer interest and demand for redwood-helped by architects and designers-moves inside the home, interior trim will likely experience an uptick as well.

For Redwood Empire, the availability of redwood logs whose characteristics resemble their historic predecessors and the increased recognition of redwood's environmental attributes have laid a foundation on which the company plans to build. The Redding mill has the machinery to produce all patterns in the CRA pattern book, and can match virtually any pattern produced in the past 100 years. The siding business is growing, and the firm plans to make the investments necessary to market siding successfully.

Keep your eye on redwood in the siding market. Watch the trends to see how architects and consumers approach and use high-end redwood.

&riHingiRodu<!s.om

CLEAR, VERTICAL GRAIN 1/2"x8" pattern 323R plain beveled siding is stacked for shioment.

REDWOOD'S NATURAL durability makes it a preferred choice for exterior applications.

lwe.?fll2 r Building RoducbDigcd r lt

Boost customer relatiohsr sales with online contests

f ooxtNc FoR wAys to increase traffic on your compaI-lny's website or Facebook page? An online contest can encourage customers to return to your site-and even get them to share it with others.

"Years ago, contestants mailed their entries and photos in," says Chris Fox, marketing manager at Universal Forest Products. "Those days are over with the advent of turnkey website tools."

For the past three years, UFPI has run its best deck contest through its Deckorators website. "We don't want to exclude builders or d-i-yers that aren't currently using Facebook," he says. "This may change in the near future with more builders promoting their business through social media activities."

Conducting the contest through its website also allowed uploading of large photos and comments from builders and consumers without any restrictions. "Facebook places certain restrictions on contests and sweepstakes, which can be a significant hurdle," says Fox. "You must use an approved Facebook application or risk having your account suspended."

However, submitted photos are periodically posted on Deckorator's Facebook fan page, as are contest winners. Past contest photos are also posted on Deckorators' Flickr page. By using more than one kind of online media, UFPI ensures that online visitors remain interested and engaged-in both the contests and in the company's products.

A successful contest will encourage communicating, subscribing, and sharing-all of which will increase traffic to your company's site. Just make sure social media buttons are prominently displayed and easy to use. Another way to build traffic to your site is to let online visitors rate contest entries, but be prepared to handle and post the feedback.

Viance keeps online visitors interested in its Ecolife Fish-More Deck Challenge by awarding monthly prizes. Professional deck builders and d-i-y-ers enter the contest by submitting photos and material receipts through the Ecolife website. The best entries are posted online, showcasing the company's decking products.

"We are excited to review the creativity of deck builders and homeowners across the country," says Christopher Kollwitz, director of marketing at Viance.

Once the final prizes have been awarded, Viance maintains interest in the Ecolife brand by posting photos of the best entries-providing inspiration for potential customers and creating an audience for the next contest.

Building and maintaining a fan base is one of the main reasons to conduct an online contest. That was the goal of CertainTeed's contest, which is conducted on its new Living Spaces Facebook page-which, in turn, promotes the company's exterior building products to consumers.

"This is our first major effort at social media," says Ken Warshaw, director of marketing communications for CertainTeed's siding products group. "Building our Facebook community was the motivation for the contest."

As for dealing with Facebook restrictions, he says that apps from third-party companies are needed to run contests on any social media site.

ACCEPTING SUBMISSIONS online has made participating in and operating contests, such as TimberTech's Deck Disaster promotion, easier than ever.

To enter, homeowners upload 30 to 90 second videos showing why their home needs a facelift. To keep online visitors engaged, the top l0 videos will be chosen by Facebook users. CertainTeed will select the grand-prize winner, who will receive exterior building productsincluding installation-and star in a "webisode" series that will be available on CertainTeed's Facebook page and

Online Contests a{ta

12 r Buildlryhodu6Direst l ltnne?f,t2

le youa dsck in d€spe.ate need of a Building-hodudscom

How to Run a Successful Online Gontest

Before the Internet, conducting a contest meant paying for print ads and hoping people would take the time to fill out an entry form-then actually mail it.

In contrast, online contests are easier to participate in, easier to run, and a good way to learn about your customers. But they do require a certain amount of preparation:

Determine your target audience and appropriate channels. Acknowledge the assets and limitations you have to work with. Take time to understand your audience and what you expect from them. Think about the appropriate channel for engagement: brand website or blog, Facebook. Twitter. etc.

Encourage creativity. Usergenerated content such as photos and short videos help participants engage with your products. They also take advantage of the natural urge to compete, giving participants their turn in the spotlight.

Make it easy to enter and stay involved. Ensure that the entry process is easy to navigate and the entry requirements are clearly explained. A contest that requires participants to upload photos and videos on one platform, share through another, and vote on a third will generate confusion and frustration.

Facilitate communication. A contest is an opportunity to engage in an active dialogue with your current and prospective customers. fans. and followers. Share contest updates, respond to questions, and encourage participants to share their entries and rally for votes. Make sure appropriate social media buttons are prominently displayed.

Collect information. If you ask the right questions, you'll learn a lot about your contestants through the entry process. You'll also learn a lot from the interaction and conversation that takes place around the contest-if you take the time to listen.

Wom Building Products also uses Facebook to conduct its contests, which are offered twice yearly. This spring's competition introduced the company's new focus on Americanmade products. The winner-selected at random from nearly I ,600 entriesreceived two free airlines tickets to anywhere in the U.S.

"We had an overwhelming response to the contest, which drew far more entries than either of our two previous sweepstakes," says Wolr's chief marketing officer Jim Groff. "It just reaffirms the fact that contractors and homeowners prefer high-quality products that are made here at home."

Although Groff acknowledges that Facebook does have contest rules, he says they are easy to follow. The contest application required by Facebook wasn't a problem either: it was developed by the company's outside web resource.

As for the focus of this year's fall contest, Wolp is soliciting suggestions from its Facebook fans. "We wanted to start a conversation. a positive dialogue about building products," he says. "We did all that with the contests."

ilGG GO N T E

Bnildinghodudsonr YouTube channel.

N F o N T s June 2012 r Building PrcduG D(;est r 13

DECKING PROJECTS have proven a popular theme for online contests staged by manufacturers, wholesalers and retailers.

Go-ops help dealers excel in social media

ll'-lolavoN BUSTNESS wtsDoM is that \-rretailers should have an active social media presence to maintain constant, interactive communications with their customers. For many dealers, however, the problem is that word constant. Most independents don't have the time and manpower to supply a daily flow of Tweets and Facebook posts.

So, their co-ops are beginning to step in, to provide tools, content and

training. According to Jeff Gooding, director-consumer marketing for Ace Hardware Corp., "At a high level, we educate our retailers on what Ace is doing on behalf of the entire brand from a national level, as well as provide them with best practices and trends in the space."

Specifically, Ace:

. Provides retailers with a page on acehardware.com, customizable for their store, showing the customer their

hours, services, brands, departments, special offers, events, etc.

Offers feeds to all local search engines to make sure member stores appear when customers are searching online.

. Utilizes a dedicated social media section of its intranet to post information on Ace's efforts and provides best practices for its stores.

. Educates its field marketins staff

FEATURE Social Media

broadcast branded, zoned digital content highlighting 14 r hrildlry hodudDbest r tune 2012 q t

DIGITAL DISPLAY hangs from the ceiling of Ridgefield Supply Co., Ridgefield,

Ct., to

Buildiryihoducb.com

the dealers' suppliers, products, services, and Twitter feed.

through monthly calls, so they are able to answer retailer questions in the field.

. Hosts training sessions at its national conventions twice a year, educating dealers on what the co-op is doing in the digital space.

. Meets throughout the year with dealer groups for updates and education.

Grand Rapids, Mi.-based Progressive Affiliated Lumbermen has been heavily promoting the use of social media to its members, starting with its monthly webinars for retailer members and featuring social-media presenters at its annual show.

"We continue to pass on best practices or good ideas from our members to other members," said Joe Myers, membership service manager for PAL. "One member received 1,400 'likes' when they ran an Ugly Kitchen Contest in their market. At last count, we have 70Vo of our members with some level of Facebook page for their company."

Wayne, Pa.-based Lumbermens Merchandising Corp. has also been experimenting with a way to stretch its members' social media arm-even after customers have walked through their front door. LMC members have teamed with Spectrio to install indoor digital signage that can promote their Twitter and RSS feeds and Facebook pages.

LMC members Ridgefield Supply Co., Ridgefield, Ct., and Economy Lumber Co., Campbell, Ca., were already Spectrio customers, using the tech firm's on-hold messaging services, when they began looking into digital signage. The in-showroom screens display their social media feeds, highlighting current specials and video ads, along with local information, news and entertainment items.

"We are now at a moment where the costs for flat panel screens has dropped so low that they have become a viable option for many small businesses, include lumber dealers," said Aaron Kleinhandler, c.e.o. of Spectrio. "Our VideoCasts usually cost around $75 and $150 a month, with some of our customers updating their displays more frequently than others. The outside feeds are refreshed daily, and dealers' messaging can be varied by time of day."

Lyle Lee hos been building custom homes for over 20 yeors. Here is whot he hos to soy obout Roseburg's Engineered Wood Products.

"When building o quolity home, it's importont for oll the froming moferio/s to motch.ln olher words come fogelher os specified in fhe design plons. lf the froming is off by even o 1/.t of on inch, it con cosl me lhousonds of dollors in time ond moleriols I find Roseburg's RFPI@-Joisf ond Rigidlom@ IVL fo be very consislent in width ond deplh. When I use Roseburg's RFPI@-Joist, my floors ore more level, stiffer qnd truer, moking my iob much eosier.

fhis home is 6,000squore feetso I used lJoist ond LVL from severol different unifs ond the monufocturing consislency wos exoctly fhe some. lf you wont to moximize your profit, I would recommend using Roseburg's Engineered Wood Products".

Lyle Lee

L. Lee Building Compony

TF 800-24s-l I t5

1 I

Bullding-hodudsorn June2012 r BuiHinghoducbDlest r 15

ROSEBURG

-K'

Engineered

Wood Products I

Reol Wood Siding

I

Softwood Plywood I Lumber RFPl6, RigidLom@, RigidRim@ ond Quolity Engineered Wood Products for todoy,s builder@ ore regislered trodemorks of Roseburg Foresl Produch, Roseburg, Oregon

By Carla Waldemar

City slicker

f, sronre. On.. is a feisty little city lLhugging a bay etched into the Pacific coastline that separates Oregon from Washington. (Well, boasting a population of just 10000, one's tempted to call it a fishing village.)

Indeed, that's a major industry here, where the wild Columbia River meets the sea-where nature is so unruly that episodes for Ax Men and Deadliest Catch have been filmed for reality TV. Earlier, it charmed and unsettled Lewis and Clark in equal measure when they arrived in 1806, making it the oldest northern settlement west of the Mississippi

City Lumber Co. wasn't a project of those explorers' axes, however, but-launched in 1904, it can lay claim to being the oldest lumberyard in the state-abetted, in large part, by all those fisheries that needed boxes for the cannery (another stat: the largest in the country).

After a succession of ownerssome more savvy than others-in 1975 it caught the eye of Jerry

Newenhof, an entrepreneurial type who'd previously managed a warehouse, served as Sheetrock buyer, and as a manufacturers rep for ceiling tiles. His focus, until his death in 1995, was on the folks in town who needed his services: a strong retail thrust. And that's what continues to drive City's business today, recently voted Best Home Improvement Store in Astoria.

Sons Greg and Jeff, who grew up sweeping sawdust and stocking shelves, pledged to continue that legacy-well, after they took it on as their life's calling. Finishing college, Greg decided to take the summer off to bum around, until an injury at the store found Dad on the phone with a plane ticket back. Jeff's post-college dream was to play golf on all courses in the state. "I got to two or three" before he, too, was corralled. No regrets, they swear. It's all they know and all they love.

Greg manages purchasing, payroll and accounting, while Jeff oversees advertisins and sales. "I'm the one

who gets to talk on the phone," he says on the phone. (He's also the one with the Internet savvy, which we'll get to later.)

And, although they haven't been tapped by the cameramen yet, the business of keeping a home center afloat-nay, prosperous-in this day and age tops many a survivor challenge on reality TV. Business admittedly is down 307c, but, true to Dad's ethos, all I 1 staffers are still on board. "We've never laid off anyone for lack of work-part of Dad's philosophy," says Jeff. "And if we did, it'd take a couple of years to get a new employee up to speed. Besides, we're operating in the black; we're very careful."

Close to lOTa of City Lumber's business is generated by small remodelers and the town's valiant d-i-y brigade. Despite close quarters ("at 6,000 sq. ft., we're jammed to the rafters"), City offers a full panoply of building products: fancy and commodity lumber, myriad types of plywood, moulding, roofing, insulation, toolsand tool rental-and the list goes on. A popular home d6cor department, launched early on by the brothers' mom, flourishes with everything from cabinets and lighting to wallpaper and paint. with in-home measuring services offered.

Lawn & garden also has taken off. The building's exterior is lined with dozens of pallets of soil, bark and mulch-plus vibrant pots of posies. "They add a spot of color-the only one on the block-which sets us apart and brings in traffic." As do the frontand-center Weber grills on sale and also utilized by vendors cooking treats for the public as they showcase their latest and greatest-another facet in that Best in Town award.

Other contributors: Backed by Dad's emphasis on service, "We greet people at the door and take 'em to what they need, and either my brother or I are always on the floor," says Jeff. The service ethic continues to loading and delivery (take that, Home Depot!), so when you order 25 bags of concrete and scores of heavy pavers, there's a boom truck at the ready. Plus a cement mixer in the rental department, or a sander when you buy floor stain.

The Home Depot behemoth that arose five miles away doesn't present a problem. But just before it opened, City's purchasing partner, Do it Best, cautioned to expect a 2OVo drop in sales. "But the first month, we were only down $1,000," smiles Jeff. Chalk

AT 108, Astoria's City Lumber lays claims as Oregon's oldest lumberyard.

up a win for superior service-and services, including propane exchange, pellet storage after payment. pipe threading, key cutting, and free popcorn.

Another business driver is City's Best Rewards Club, offering participants $5 off every $250 in purchases, plus notices of special members-only sales. And how about the annual chance to win $1,000 in a shopping spree? (Again, check out the website; this year's winner looked pretty darn ecstatic.)

Jeff's the go-to guy for the web. "It's my baby, I guess," he allows. "We segued from our first computer in 1983 to a software feature designed to facilitate online sales." City (okay, Jeff) also makes good use of the company's Facebook page and keeps folks titillated with Twitter tweets. such as a recent "Sign of spring, just like the swallows returning to Capistrano: The Adirondack chairs have arrived." "We tweet to announce new products, but with a sense of humor because a simple hard sell gets tuned out."

But City has not abandoned print. It distributes a monthly Do it Best circular and regularly purchases the back page of the newspaper's TV section. And just this week, City moved its message to a full page every Friday, to catch the eyes of the Weekend Warriors about to gear up.

All forward moves in trend with the times. But the best push forward ever, insist both brothers, came in 2006 when they attended a trade show that allowed them to reevaluate their purchasing partner and-bottom lineswitch to Do it Best. "Our former buying association hadn't been honest with us, so we started looking around," says Jeff. "Changing to Do it Best was one of the best moves ever. After making the switch, our business tripled. We only wish we'd done it earlier. lt was an eye-opening experience, offering us a huge variety of products with consistent tracking and deliver service, and a store design crew when we were thinking of expanding, including a survey of 3.000 of our customers."

And the future? "Things are starting to bounce back. Oregon is always behind the rest of the country, so when other dealers were moaning in 2008, we were still doing fine. Now, it's down some. But I'm 52, and I plan to stick around. And my son, Jerry, who's 8, comes in to pop the popcorn and pick up nails-just like I started, a lifetime ago."

Two Coat lxterior Prime

0ur two-coat process starts with an al.kyd sealer to btock tannin migration, fotlowed by a high-performance acrytic primer. The result: RESERVE quatity, inside and out.

Superior Wood

Made of qual.ity, clear, finger-jointed Western Red Cedar or Redwood, these products are naturatty designed for exterior use-both soecies are ideaI for endurinq extreme weather.

Surfacing + Sizes + Lengths

RESERVE products come in a wide range of sizes, lengths and finishes" Whether the project catts for SI52E or S4S, we offer l^engths ranging from 16' to 20'. Pattern stock is atso availabte.

Ix4 - )"x12 s/oy!s/ax!l 2x4 - 2x12

The Finest Stock, The Best Coating

Our Siskiyou Forest Products RESERVE line is specially manufactured and treated to create the highest quality product available. Using state-of-the-art application and curing equipment, our premium Western Red Cedar and Redwood stock is made to last for many generations. We are proud to offer a beautiful, durable product that is ready for installation and final painting the moment it reaches the craftsmen.

-t

Bullding- Products.com

S I S ruyOu. FOREST. PRoDUCTS www. siskiyouf orestprod ucts.com 8O4.427.8253 6275 Hwy 273. Anderson, CA 96007 lurc?Ol2 r BuiHinghoduclsDircst t 17

By fames Olsen

Why you?

[rvenv sEcMENT of the lumber industry has a value I-llproposition: the mill, the remanufacturer, the office wholesaler, the hybrid office/inventory-on-the-ground wholesaler, the full-service wholesaler, the retailer, and the specialty retailer. Whoever we are, we must be able to know and articulate (sell!) our value.

Let's talk about the wholesale distributor and broker value. They are similar. What value does a good broker bring?

Credit. Most accounts want to use more money than their bank allows. Using a broker can expand and leverage a customer's credit.

Time. It takes time to stay on top of markets. Brokers spend 1007o of their time thinking about-living in-the market. A good broker is looking for deals for us all the time.

Non-standard Product or Delivery. Producers usually have a production mentality. Producers want to sell their product the way it comes out of their plant. When customers need a customized tweak, brokers can often bridge the gap.

Example: The mill produces 2x4 in ratio l-l-2-3-4-4. That is the way they want to sell it. If the customer wants to buy it 0-0-0-6-10, often a broker will sell the shorts to one customer and sell the longs to another.

Consistent Quality, Competitive Price. If the customer wants consistent quality at a competitive price, brokers are a good option. Buying from a single high-line producer will solve the quality issue, but may leave the customer uncompetitive. If the high quality producer is on another product when the need arises, or has sold their production to a higher price level, consistency will be difficult. A broker will be able to keep us in a variety of high-quality product, competitively priced, on a regular basis.

Expertise. A broker may have an expertise in a product or market that is foreign to the buyer. A buyer or business owner may buy 150 products, whereas the broker may deal all day with six to 10 products.

Global Market Knowledge. Producers see the market from their point of view. Customers see the market from their point of view. A broker has the advantage of seeing the market from many points of view.

Hustle. A single supplier can hustle only so much; they have fewer options. A broker has many options to "hustle" for the account.

Negotiation Expertise. Brokers are expert negotiators (or should be). If the account does not want to or is not good at negotiating, using a broker is a great option.

Creativity, New Ideas, Best Practices. Because brokers talk to many different businesses, they are exposed to more ideas than the average person. A good broker always asks questions about what is working. A good broker will keep his accounts up to date on all changes in the market, be it price, product and other trends.

Risk Insurance. Having all our supply eggs in one basket is risky. Brokers are a good balance against supply problems (from a single source).

Market Insurance. The broker who takes positions in the market takes the risk out of the market for their clients. The position of the position-taking broker is, "I am always ahead of the market-heck, I make markets-therefore I will always be your most consistently competitive option."

Proprietary Relationships. Brokers can get accounts into suppliers that are beyond their reach for whatever reason. Accounts can also use brokers to buy from suppliers with whom they have a poor relationship.

Flexibility. Brokers can supply flexibility on terms. Not all, but many, brokers will give preferential terms.

Broker Value Example: We are experts at _ and We have lifetime relationships with producers. These producers count on us to move X amount ofproduct for them every month. We have access to lumber that the average broker doesn't because we are close to and live with the suppliers.

In addition, we have a fleet of truckers who work for us exclusively. While many are having trouble booking loads, we are able to get our customers' product when needed.

We also run many programs and contracts that allow us to mix and match tallies for our customers that are otherwise difficult to find. These

ffiw' programs also keep our customers consistently competitive.

We are financially strong. We have grown with our customers. in very competitive markets, and continue to do so.

What's your value proposition?

James Olsen Reality Sales Training (503\ 544-3572 james@realitysalestraining.com

OTSEN On Sales

lE r Building hoduds Dlged I lune 2012

&dldinghodurtsom

PTJRN IDAHO GOLD

OUR PREMIUM IDAHO FOREST GOLDTM LINE is in demand the world over - including Cedar, Idaho White Pine, Ponderosa Pine and Export.

RICK PALMITER

GARTH WTTLTAMS I

'r:'' ' ..?a::.; : 't-'

In,qF{o6FoREs'r GROUP 208.7 62.6630 | idahoforestgroup.com

Mill Creek Grows in Wichita

Mill Creek Lumber & Supply, Tulsa, Ok., has leased a 37,000-sq. ft. facility in Wichita, Ks., that it plans to tum into a door shop, truss manufacturing operation, and showroom. Once the new facility opens on July l, the company's smaller truss shop in Belle Plaine. Ks.. will close.

About 2,400 sq. ft. of the new facility will be used for a sales office and showroom. The remainder will be split between a door shop and the automated floor and roof truss facility.

"We think we can increase our production capability four to five times with this move," said Jay Robinson, who manages the company's operations in Wichita.

NEBM Acquisition Doubles Size of Deering

Deering Lumber, Biddeford, Me., is increasing to four locations after acquiring stores in Sanford and Springvale, Me., from bankrupt New England Building Materials, Sanford.

NEBM filed for Chapter 11 bankruptcy protection and closed its three yards in Massachusetts in February, four months after shuttering yards in Springvale and Windham, Me., and

selling three mid-coast Maine branches to Hammond Lumber. NEBM was left with its store and Lavalley Pine eastern white pine sawmill in Sanford.

At the end of April, the Sanford showroom reopened under the Deering name, while the Springvale location is being remodeled in hopes of reopening this month. NEBM retained the sawmill, and its products will be sold at Deering stores.

The firm started with just the mill in 1943, operating as Lavalley Lumber until 2009, when it purchased the three Massachusetts yards from Stock Building Supply and became NEBM.

LiteSteel Packs lt ln

Australian steel manufacturer OneSteel has shuttered its LiteSteel Technologies light structural beam business.

LiteSteel's three-year-old plant in Troutville, Va., discontinued production March 30.

Although the division was unable to turn a profit marketing "the first new structural building product to be introduced into the U.S. market since engineered wood," it reportedly achieved 70Vo recognition in a mainly commodity market.

r DEALER Briefs

Timberline Enterprises, Gloucester, Ma., applied to add a lumberyard in Newburyport, Ma.

People's

Do-lt Center,

Galesburg, ll., lost its lumber warehouse in an April 29 fire.

Builders FirstSource early this month opened a 25,000-sq. ft. yard on 5 acres in Clarksville, Tn.

Woodson Lumber hetd a June 1-2 grand opening for its new store in Groesbeck, Tx., after merging its Woodson Feed & Farm location with the nearby Woodson Lumber & Hardware.

84 Lumber closed its Riverhead, N.Y., yard, consolidating operations at its recently remodeled store in Patchogue, N.Y.

Wise Ace Hardware, Lake City, Mn., opened an 8,000-sq. ft. branch in Stewartville, Mn., May 8.

Bassett's Do-lt-Best Hardwafe, Port Clinton, Oh., has expanded by 5070 to 15,000 sq. ft.

Pellicci Ace Hardw?ro is no longer renting in Farmington, Mn.moving to a slightly larger, 11,000-sq. ft. building that it owns.

Ace Hardware, Fox Lake, ll., closed at the end of May after 57 years.

Habitat for Humanity netd grand openings April 21 for new Restore discount home centers in Albert Lea, Mn.; Sheboygan, Wi,, and Wlliamsburg, Va.

Gary's Ace Hardware, Culpeper, Va., opened May 15 in the former 12,000-sq. ft. home of Matt's Ace Hardware, which closed a year ago (Gary Walker, new owner).

Panther Valley Lumber, Lansford, Pa.; Sunbuly Ace Hardware, Columbus, 0h., and Porters Building Centers, Kearney, Mo., added U-Haul truck and trailer rentals.

Rocky's Ace Hardware opened a 12,000-sq. ft. "new concept" store May 19 in Westfield, Ma.

Gillards True Value. Albion and Grayville, ll., received the go-ahead to build a 15,000-sq. ft. store in Carmi, ll., for a fall opening.

of Hardwood Decking, lumber & Flooring TRIM 6( LUMBER CO. Bt azilirn Hardwood Specialists Your direct source for Ipe, Tigerwood, Garapa, and Cumaru decking Many OptiorsTo Choocc Rom: l) Shipping from our Bmzilian Mills direct to your job site or lumberyard 2) Custom Millingavailablefro- ou, U.S. Facilities ^tab\e 3l Blindshippingisalsoavailable .-q\X I m;u#H.r*nr. co m/wholesare $ 20 r BuiHing hoducDig€d r tune20l2 BuiHinglhodudsom

Direct lmporters

Unlike Fake $hakes, Cedar $hakes & $hinules are Genuine!

Rgal lfaClt figC0fd used, tested, and proven for centuries!

Rgal Pf0tegti0n nignest wind resistance, highest insulation value, available with Class 4 Hail Resistance and warrantied Class A Fire Treatment

Real IOW MaintenanGe Avairabre with 5O year warrantied factory pressure preservative treatment, virtually eliminates upkeep.

Hgal BgaUly Natural Enduring charm, often lmitated, but never Duplicated.

Rgal EC0l0giCSl n truty renewabte resource, lowest in energy use and pollution in production.

Real UalUg Check with your distributor for cedar prices compared to fakes, or contact us for supply assistance.

) \ \ \ ,^

{n BIrlEl L la2 tr1" I Forestry lnrovaflor hveslfielt

UFPI Buys Southeast's MSR

Universal Forest Products, Grand Rapids, Mi., has purchased the assets of MSR Forest Products, Haleyville, Al, a supplier of roof trusses and cut-to-size lumber to the region's manufactured housing producers.

UFPI will merge its existing Haleyville operations with the operations of MSR. Also included in the deal was MSR's plant in Waycross, Ga.

In 201l, MSR had annual sales of $10 million.

"MSR has been a strong company that has grown its success with great determination and skill," said UFPI c.e.o. Matthew J. Missad. "However, with shrinking volume in the manufactured housing arena, it was difficult to maintain efficiencies and create profitable business. This move will benefit both companies. In addition, it allows Universal to underscore our commitment to maintain our leadership position in the industry in which we got our start, manufactured housing."

MSR principals Richard Roberson and Eddie Gamble will stay on as consultants to the Universal operation for five years.

Shuttered Door Plant Revived

Millwork Products LLC, Paducah, Ky., has expanded to the Carolinas, Tennessee and Virginia, after taking over Jeld-Wen's prehung door plant in Wilkesboro, N.C.

Jeld-Wen closed the six-year-old, 48,000-sq. ft. facility in early April. Millwork Products subsidiary Jenkins Millworks moved in about six weeks later, rehiring most of the 54 former workers.

OsmoSe has agreed to be acquired by Oaktree Capital Management, Los Angeles, Ca.

Osmose's existing management team, led by presidenUc.e.o. James Spengler, will remain.

Beacon Roofing Supply has agreed to acquire 6-unit roofing dishibutor Cas'sady Pi6rce Cb., eittsourgn, ea. BillVernal will remain Cassady Pierce president.

Masonite International Corp., Tampa, Fl., completed its acquistion of Algoma Hardwoods, with door manufacturing operations in Algoma, Wi., and Jefferson City, Tn.

Superior Gedar Products, Carney, Mi., lost a 21,000sq. ft. production facility in a May 19 fire.

Post Hardwoods, Hamilton, Mi., suffered $3 million in damages from an April27 fire that destroyed four of its six buildings.

Redwood Empire, San Jose, Ca., has launched a new website-www.buyredwood.com-as part of a new marketing campaign to emphasize the increased availability of uppergrade redwood.

The site provides the distribution community, architects, contractors and homeowners with information on the environmental attributes and natural durabilig of redwood.

Capital Lumber's DCs in Dallas and Houston, Tx., are now distributing Railing Dynamics' new pre-assembled RDI Metal Works Excalibur railing system.

American Building Components, Rome, N.Y., was named Vendor of the Year by Ward Lumber, Jay, N.Y.

Hancock Lumber, Casco, Me., has been nameo exporter of the year by the Maine International Trade Center.

Parksite, Apex, N.C., now distributes Arborite nign pressure laminate in Florida.

3" to 48'

Airport Runway/Parking Lot Golf Course Storm Drains

lndustrial Waste Water Applications

. Constructed Wetlands

Landfill Drainage

. Sewer Sludge Compost Pipe

3tt to 48tt

For the Best Quality and Service Call WEB SITE: www.cpp-pipe.com

Feldman Wood Products, Garden City, N.Y., now distributes fasteners from Screw Products Inc.

CertainTeed is expanding production of metal building insulation to its plant in Kansas City, Ks.

Eastman Chemical Co.'s Perennial Wood received honorable mention for the Mrorurrr Award for Material of the Year from Material ConneXion.

Deceuninck North America's window products have been GreenCircle certified for recycled content and closedJoop oroducts.

Anniversaries: LeBlanc's True Value Hardware, Manchester, N.H., 75th Porters Building Genters, Kearney, Mo., 60th Busy Beaver Buildin-q Genters, Harmai Pa., 50th Madison Township Eumber & Supply Co., Matawan, N.J., 50th Gedai Siding Inc., Rochelle, ll., 25th

New site: ProVia, Sugarcreek, Oh., proviaproducts.com.

rffqr)fl, l:::3$::^?J',','.',', Wd/ ilil";,11?J?3."i"

22 r &rilding Producb Dlged t June 2012 &rildingrftodudsom

Uf$fttr***,n*ffi IOO-333.rQnI

m#ffinr

0isbribution from Milwaukee, Wl, Chicago, lL qnd &&bite, AL

$tocking lp6, Garapa, Tigenruood, Cumaru mdsther exnCic species

Decking in 1 x4, 1 x 6, 1 x8,5/4x4, V4x 6,

Dimensional sizes inW4 x8,514 x 12, ? x4,2 x 6, P x 8,3 x1?

Heavy Sections 3x 3, 3 x 8, &x 4,4 x6, 4 x 12, 6 x 6

0ther sizes available,sn rsquesf

Grooved for hidden fastenqrs, T&G porch decking, Sidings and Rain $crcens

Ability to produce specialty patterns

0ver four decades of providing ,e6e Ferrbrmence

Lumb Fo*M

* I * ] ) t I ) *

r

MOVERS & Sftakers

Paul Burke, ex-Cape Cod Lumber Co., is new to the purchasing department at Boston Cedar, Mansfield, Ma.

Ty Babb, ex-Pella, has joined Buck Lumber & Building Supply, Charleston, S.C., as sales mgr. of the window department.

Nick Fitzgerald, ex-Universal Forest Products, has been named branch mgr. at Building Products Inc., Council Bluffs,Ia.

Lori Grenier has been promoted to director of customer satisfaction for Emery-Waterhouse, Portland, Me.

Steven Salter is a new buyer at Great Southern Wood Preserving, Abbeville, Al.

Webb Moncure has joined Fiberon, New London, N.C., as a Product specialist for Virginia.

Derek DeMeo has been named treated sales mgr. for Holbrook Lumber, Albany, N.Y.

Jason Olding, ex-Krosswood Doors, was named Midwest territorY sales mgr. for Boral TruExterior Trim, covering In., Oh., Il., Mi., and Wi. He is based in Indianapolis,In.

Jim Jenkins, ex-Boise Cascade, has joined Huber Engineered Woods, as region sales mgr. covering central Va. and eastern W.V.

Judith Taylor is a new account mgr. at Capital Lumber, Houston, Tx.

Dennis Lowry, ex-Builders FirstSource, is a new wall panel sPecialist at American Builders SuPPlY, Sanford, Fl.

Ben Cobb has been promoted to v.p. of finance & operations at Home Builders Supply Co., Greenville, N.C.

Dave Sorichetti is the new controller at Universal Builders Supply, New Rochelle, N.Y.

Kent Gardner, Beacon Roofing Supply, Peabody, Ma., has been promoted to executive v.p. of the west division. encompassing Pacific Supply, Shelter Distribution-Southwest, and Shelter Distribution-Midwest.

Michael Hennessy is a new commercial sales rep at McCoy's Building Supply, Tomball, Tx.

Bob Frederich is new to sales at Sitka Forest Products, Chicago, Il.

Steven P. James has been named chief financial officer for Frank Miller Quartersawn Hardwood, Union City,In.

James Ian Brandt has been named wood products division mgr. for Robert Weed Corp., Bristol,In.

Ruth Lee-Clark has joined Habitat for Humanity as mgr. of the ReStore discount home center in St. Johns, Mi.

Erin Kersten is now product marketing mgr. for James Hardie Building Products, Chicago,Il.

Charlie Meyer has retired as v.P.sales at Ferche Millwork, Rice, Mn. Ted Willougby, ex-Milgard, is now v.p.-sales & marketing.

Tim St. Louis is general mgr. of the new Menards in Owensboro, Ky.

Julie Roberson, ex-Georgia Pacific, is now manager of human resources, safety & environment at Anthony Forest Products, El Dorado, Ar., after the retirement of Lynda Anthony. Larry Horn, exMcGehee Equipment, is now mgr.operations and quality control at the mill in Urbana, Ar.

Scott Sproul has been promoted to national retail performance mgr. for Do it Best Corp., Fort Wayne,In.

Rick Damron has been promoted to chief operating officer of Lowe's, Mooresville, N.C. Gregory Bridgeford is now chief customer officer; Bob Gfeller, customer experience design executive; Tom Lamb, chief marketing officer; Mike Mabry, digital interfaces executive; Dennis Knowles, U.S. stores executive; Brent Kirby, sales & service fulfillment executive; Richard Maltsbarger, new business development executive; Brian Peace, corporate administration executive, and Doug Robinson, head of international operations & development.

Anne Brannan, ex-Akzo Nobel, is a new product mgr. at LouisianaPacific, Nashville, Tn., handling CanExel and SmartSide products for Canada and Europe.

Dale Skiles is now national account mgr. at Nissan Forklift Corp., Marengo, Il.

Bob Thompson retires June 28 from Western Forest Products, Vancouver, B.C., after 38 years.

David Wiley, ex-Valley Power Equipment, is heading the new 4,000-sq. ft. rental business at Milton True Value, Milton, N.Y.

Jeffery Letherer is now v.p. of Letherer Truss & Wall Systems Inc., Clare, Mi.

Jason Stapleton, owner, Buck's Building Supply, Williston, S.C., was honored by the North American Retail Hardware Association as a Young Retailer of the Year, along with Chris Miller, v.p./c .f .o., Parker Lumber, Beaumont, Tx.; Isaac Smith, head of marketing & purchasing, Matt's Cash & Cany Building Materials, Pharr, Tx.; Michael Townsend, v.p.-operations, Townsend Building Supply, Enterprise, Al., and John Obermeier, store mgr., Obermeier Hardware & Rental Rockport, In.

Turner Hoff is the new company electrician at Mungus-Fungus Forest Products, Climax, Nv., report owners Hugh Mungus and Freddy Fungus.

Cedar Siding Inc. Upgrades Composite Coating System

Cedar Siding Inc., Rochelle, Il., is installing new industrial mixing equipment to provide composite siding with improved color matching, durability, and resistance to fading

and scratching.

Traditionally, the company has produced paint like a typical paint store would, starting with a base and adding colorants to arrive at the desired color. Unfortunately, the added colorants actually reduce the quality of the coating.

"While our customers and the siding installer out on the jobsite like the DuraColor coating we have been using from PPG, they will love the new DuraColor Intermix," said CSI director of sales & marketing Shawn Enoch. "It's the same resin technology people have grown to trust with the DuraColor product. However, by taking nine base colors and mixing them in various proportions as deemed by a computer generated formula, we will arrive at the desired color. The paint will only contain factory ground pigments and no colorants will be added."

In addition to the Intermix system from Rexon, CSI is also installing a spray line designed specifically for fiber cement and engineered wood products. Real cedar siding will continue to be prestained using its modified flow coat system, considered the premier technology for coating wood.

Ca ry H a mi lton, Ho mi lton Construction

How does Cary Hamilton weather the challenges of building high-end homes in Steamboat Springs, Colorado? For one, he uses pointSlX Durastrand Flooring with its innovative tapered edge. Learn why, along with other insights into creating success long-term, by watching "Three Things I've Learned: Tips from Seasoned Pro3rtt one in a series of short high-value videos from pointSlX and Ainsworth Engineered.

(Spend money onGe."

olntSIX' DURASTRANDFLOORING f*OW WITH I-YEAR ntCI*SATWS &'*r&&K**Vfy SCAN TO vtEw vtDEo www. p oi ntsixexpe rts.co m lca ry

Southern pine industry eyes recovery signals

f\unlNc rHrs FrRSr uer-p of 2012, some faint glimmers of Lf hope have appeared for the recovery of home construction markets, perhaps in the not-too-distant future.

Building permits are up one month, down a bit the next. Indexes measuring builder confidence have reached a plateau, while production volume of southern pine lumber runs ahead of last year's pace-a good sign. Uncertainty prevails. The lumber industry remains cautiously optimistic, recalling the last prosperous days of 2005, when a modern-era record of 19 billion bd. ft. of southern pine was produced; 13.34 billion bd. ft. was produced in 201l.

With those facts as context. SP lumber dealers can rest assured that America's first lumber species will be readily available in a wide range of sizes and grades to meet the demands of most any construction project. Add the features of pressure treatment with the latest preservatives, southern pine outshines nonwood alternatives for building outdoors, too, or where conditions for decay and termite attack warrant added protection from the elements.

The Southern Forest Products Association provides a

collection of resources to help dealers and distributors improve their southern pine sales. SFPA materials not only help train employees, but also educate customers on the proper selection and application of SP lumber. Dealers know the value southern pine provides for their customers: dependable strength, exceptional treatability, and attractive appearance. And on a daily basis, SFPA supports dealers and distributors with the sales help they need.

Remodeling market features southern pine patterns

With new home construction creeping along, contractors are staying occupied with remodeling projects. Southern pine offers a long list of possibilities: exterior siding for room additions, plus flooring, paneling, ceiling patterns, and trim to dress up the inside. Mark Junkins of McShan Lumber Co., McShan, Al., offers some insights: "I've been surprised at how well the pattern market has held up in view of the drastic drop in housing. Of course, this is understandable since patterns have a strong position in the remodeling market. A contributing factor has been the rediscovery of wood as a green building product. It doesn't hurt that southern pine is beautiful and strong, which makes it well suited for indoor applications... plus, its sustainability is beyond question."

Dealers must remember that wood is a natural insulator, contributing to energy efficiency and lower utility bills. The look of real wood for wall paneling and ceilings adds a dramatic flair to all rooms. SP patterns are readily available in long lengths to eliminate or reduce splices. Clear or semi-transparent finishes draw attention to southern pine's distinctive grain. Not sure which pattern will be a bestseller? Review the information and product samples pictured in SFPA's booklet "Southern Pine Patterns," available as a PDF download at www.southernpine.com.

SP flooring can enhance the look of any indoor space, whatever the d6cor. A wood floor adds comfort and value, not to mention being a premium alternative to carpeting or ceramic tile. Selling more southern pine flooring, paneling and other specialty items starts by knowing the proper installation and maintenance tips. SFPA offers a comprehensive guide to both interior flooring and exterior porch flooring. "Southern Pine Flooring" can be downloaded as a PDF from southernpine.com.

lncrease treated lumber sales

Deck builders and handy do-it-yourselfers can find the key information needed to build durable, code-compliant

SPECIAL Focus Southern Forest Products

SOUTHERN PINE dimension lumber remains shong and dependable, 26 r Building hoducDigea r lurrc?fll2 Building-Produdsom

Wfb- lllv'pBlG" 1,9 E K^/rd, qr,/"* ! i.til i;;1 \-;; eetm,ngcr lminatad hnamlnS 1:l^tt aM 811e" $tasdffiil wiffihs at l.iolst eolryatihls de$ln, tsr lss$ Gwt! 1.9E-2400F0 design property offered l-joist compatible depths (lJC) of 9112, 1171a,14,16 & 18 inches plus lumber depths of 91/+ & 111/q inches Balanced lay-up, no camber for multi-span and cantilever applications Call 1-800-221-2926 for distributor locations MK Power Lof Qn,im* ffi Treated Glulam 309 N. Washington I El Dorado, AR 71730 I 800-221 -2326 | www.anthonyforest.com @Anthony Farest Products Conpany I I T I I Certified Green Product Easy to specify Available from El Dorado. AR and Washington, GA Reduced SKUs Vtr/rrl, Trruttrw* ex w@*t6 rceqAi l+#-_?s t* Power 1eanl@ Power Jois9 SYP Lumber

Solid. Resilient. Enduring.

At PLM, we understand that you need an insurance company with property and casualty insurance products and services that you can trust today and tomorrow.

For over 100 years, our experts have been providing quality claims and risk management services to the lumber, woodworking and building material industries. Remember, "you get what you pay for." We understand wood. We know your business... because it's our business too. Wood is all we do.

lf you're looking for quality and value from your insurance provider, please contact us at 800.752.1895 or log onto www. plmins.com/adlBP.

Grow

fohn K. Smith, CPCU President and Chief Executive Officer

decks and porches by visiting SFPA's website, southernpinedecks.com. The site covers steps in the building proccss, explains why treated southern pine decking is the preferred material, and even offers specification tips. Links to American Wood Council's Prescri;ttive Residential Wood Deck C o t s t r uct o rt G u i de appear throughout thc site.

"This sitc tells peoplc why prcssure-treated southern pinc remains thc best material when building outdoors," says SFPA's Richard Kleiner. "There's a lclt of infbrmation and nrisinformation out there about the pros and cons of using real wood versus composites."

Help for buiiding outdoors is available in print, too. SFPA has highlighted the online information and published a l2-page booklet, Southern Pine Decks & Porches. Aimed at professional deck builders and advanced d-i-yers, it offers design and construction guidance. Photos of completed decks and porches showcase what treated southern pine lumber can do to naturally enhance any landscape. Like the online material, generous references to AWC's construction guide are included. A PDF download of this new publication is available at www.soulhernpine.com.