WESIENN wooD$

lllhcl do you need todag?

What do you need today?

DOUG FIR Allsizes & lengths. EVERGRAIN COMPOSffi DECKING

FASCA Raw or Primed, Resawn, Gombed or S4S 'CEDAR FENCING

WRC & lC STK & Clear, Pattems & Trim KLEARCHOICE Trims & Pattems

EWP Glu Lams, LVL & Rim Boards, l-Joists, Big Beam 'TREATED STOCK

KD PINE (Porderosa & Sugar)All pattems PLYWOOD

Con Common, Con Heart, Bee Grade, Posts, Rails, Baluslers, Fencing

Our remanr.rfacturing facilrty has he ability to make a wide rarge of products. Let us help you with hard to fird items.

An FSC Supplier (Boo) Bzz-BLS7 or go to \M\M\,V. We Ste rnWO O dS in c. com

tr cc by#runJ i'r'zr t t r.;a l,?'t r[;*cr r'; -*"" _/ ** **"/ .f'#*-ffit6it"$g tJasxztr*52"* rx:lt "rrci rus.*tys"l rcduy first crport cluality 100(70 clear all hct scratch rcsistant splinter resistant termite resistant lire resistant . 25+ years durabili ' fivc times harclcr Lhan softwoocls or cornposite material 'r & ,L##Jr# A Redwood f lr . LJErnpgg_ A Divirion ol Po.ll Sror"i lri rri' ir-, lrc I'j.O. llor 1300. !lorlirrt I Iill. CA !15038 (800) 800-5609 Tcnrec ulrr. ( A (8oo) 743-6991 (951) 296-96rr l)irqi'nc. OR (541) 895-2f5f Norlh ( irroliit:r (9f 9) 363-2240 www.redwoodemp.com www.ipelumber.com 3!,!t.etuyj#&& sr-ru trssrg-Fj

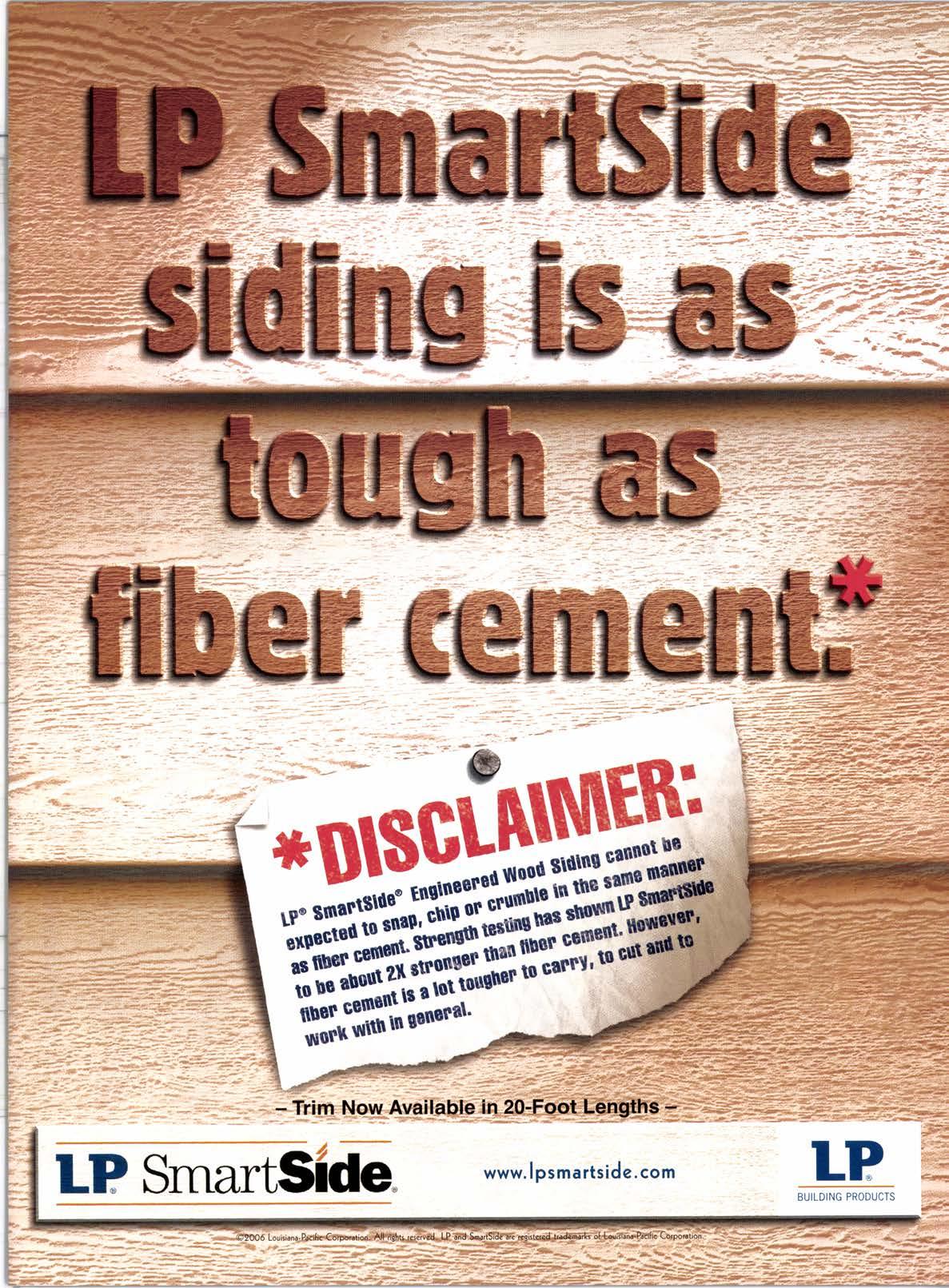

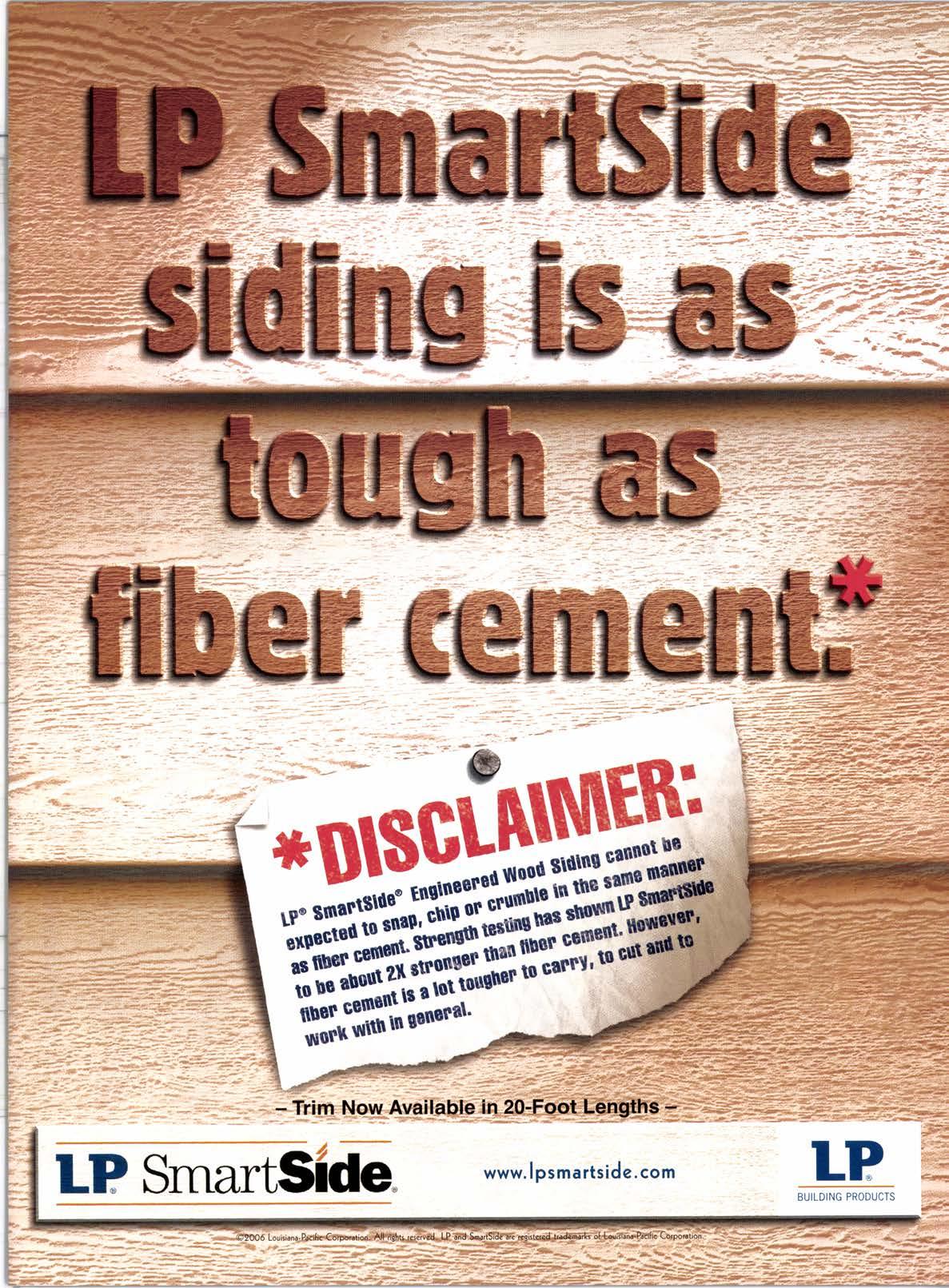

Kw l,- t LLru Lr au *; ffiL ffk*1. u*LmLILLL:' td-frl$H#ffi:.', s'' '*::':S-Jio+****" '?r** .***'****o' (t * - Trim Now Available in 20-Foot LengthstP SmartSlde r ;"r' .,, a I .fs rr!."cd l-l' ,',,1 Siid iS "lr r. i l I ., ri.Ll.md

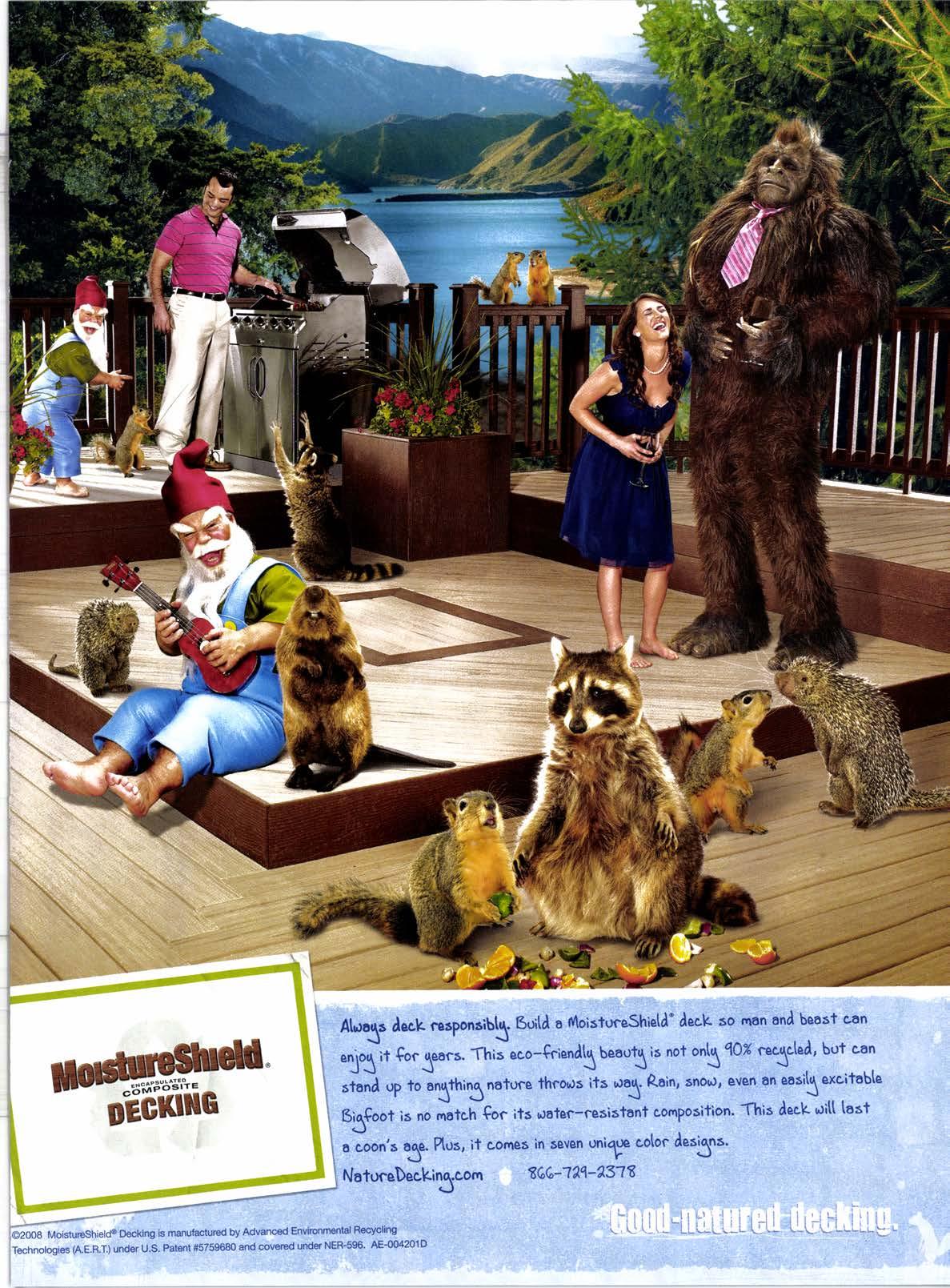

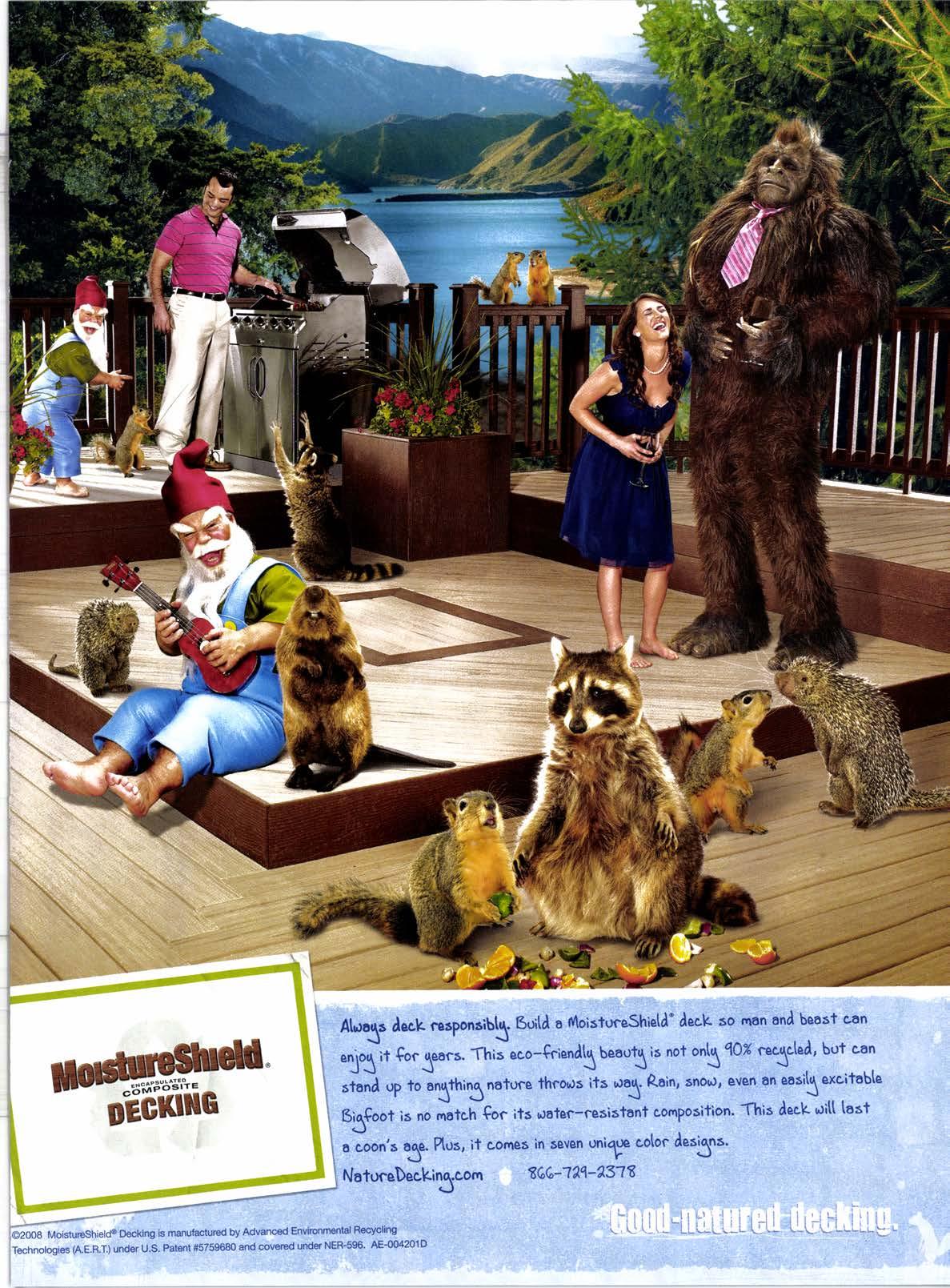

Abt, deck $sponaiu$. 6,ltd a flloistoeeshietd' dech so man and beast can "tt-',t Socgracs. Thil""o-€.iend\bea{is not on\ 102 recSctef't":::

"ti"-i up toinqthinlnatuce thco,,.ls it" ,u1' Aain, tnod, Even an eali\excitabte Biqsoot i" * it"i"$oc its r,latec-ceristait cornposition. Thia deck r^litt tast ':;" ;;", ,;:"*" in seven ',ni1e cotoc i""*"'

NattrreDeckinq.com rJ

8GG-1Aq-A318

ll' -:: t',".l:.:r: ;i9i l$jrri|'iF': i + = 1, L ':i= i\' i [\ i\ ,.,.e1

d26* ffi;d@ Decking,is manuferured by Advanced ewironmentar Fecycring Technologies (A.E.RT.) unddr U.S. Patsilt #5?59680 and tovered urilsr NER-596' AE-004201 D

addres-s changes to The Merchant Magazirie, 4500bampus Dr., Ste. lgo, iietport Biictr. Ci. gzOOo-roz.

I he^Mercnant Magazine (USPS 796-560) is published monthly at 1500 Campus Dr., Sts. 480, leinort Beach, Ca. 92660-1072

Dy uurer PuDllsnlng, Inc. Periodicals Postage paid at Newporl Beach, Ca., and additional lost ofiices. lt is an independenfly. owned publication follhg re_!ai!, wiolesale and distributiori levels of itre ltimber and buildihg products markets in 13 western slales. Copyright@2008 by Cutler Publishing Inc. Cover and entire contents are tutty protectid'and musi not di ieproduced in ryJ.Uej-llllgglwritlen permrssr0n. All Rights Reserved. !t reserves the right to aicept 0r reiect any editoriat oi aOvertrsrng matter, ano assumes n0 liability f0r materials lurnished to it.

S€illng t3 Wortam Statca, l|tcludlng Alaaka.nd al.wdl

(Sbtet publication Euilding ProducE Digast seves the East)

PUBLISHER Alan 0akes (ajoakes@aol.com)

PUILISHER EMERITUS David Cutter

EDIT0R David Koenig (dkoenig@building-products.com)

ASS0CIATE EDIT0R Karen Debats (kdebats@building-products.com)

COI{TRIBUTIIIG EDITORS

Dwight Cunan, Carla Waldemar, Rov Burleson

AD SALES M;ilAGER ChucK Casev (ccasey@building-prodticts.com)

ClBCUtATl0l{ Heather Kellv (hkelly@building:products.com)

ADMIiIISTBATIOTI DIREGTOR/SECRETABY Marie Oakes (mfpoakes@aol,com)

How to Advertise

Conlacl 0u adrorllslng ofllces for rales:

WEST, MIDWEST, SOUTHEAST: Chuck Casev. Newport Beach, Ca.; (949) 852-1990; Fu 949-8520231 ; Email ccasey@building-products.com

II0RTHEAST: Paul Mummolo (N.J.); {732) S998102; Fax 732-899-2758; Email mummolop@ c0mcast.nel

How to Subscribe

Contacl Heat[er at (9tg) 852-1S90

U.S.: 1 year (12 issues), 922; 2 years, 936; 3 years, $50

F0BElGll (Per year paid in advance in US funds): $48 for Canada and Mexico, $60 for all other countries: Air rates also available.

$lllGLE C0PIES: $4 + shipping; Back issues (when available), $5 + shipping www.building-producb.com

$ '{ &Ning&ilding I tdirorial 20 Conpetitivelntelligcnre 22 on sctct 25 ilcws Bdets 26 colendrr 28 Assoriotion llews 30 Instolled Scles 32 Grccn Retoiling 44 lonily Business 48 Personols 54 obituorics 55 le* Products 56 Ctssified torketplorc 58 Buyers'Guide 70 tdvenisers Inder About the Cover The tront cover is a paid advertisement. this month sponsored by West*n Woods, Inc. a \ Q o *cft *fef I I ttow ro ovold a Worchouge tonogement Syslen horor slory New technology con increose production ond picking occur0cy-or couse nightmores. 12 Oedgn fiends ddve denond fol yltryl sldlng ond trftn 14 Sidlng monulocrulel lntroducer nw llnel In WR(, exdlc hodurcods 15 hnovslton erpondr ilre urel ol hlG tdrn 16 sty-hlgh breotfu rcoftng l0 ttow bullding coder oftecr lBt mo*e oppoiluntrlel CHATGE 0f ADDRESS Send address label from recent issue if possible, new address and g-digit zip to address below. P0STiIASTEB Send

The Merchant Magazine

A CaHfornia Timberline, Inc. -TSugor ond Ponderosq Pine, Douglos Fir, Redwood, Western Red ond Colifornio Incense Cedor Dimension - Commons - Cleors Serving the Wesfern LJnited Stotes ond Mexico Since t 976 4650 Edison Ave., chino, cA 9t 7io . (909) 591-4Bl I . FAX (909) 591-4818 6 Tnn MpncruNr Mtclznr Jur.re 2008

/ ROSE.l0599 Old Hwy 99 South tel 800-347-7260 | web www.Roseburg.com I BURG I Dillord Oregon 97432 fox 541 -679-2612 emoil ewpso les@rfpco.com

Maybe it's party time!

When times are tough, it is difficult to maintain morale in a company. When sales and profits are down, and colleagues are leaving for pastures new or due to layoffs, and this continues for a period of time, inevitably morale slips. It is particularly hard to give employees confidence that things are under control and will improve if management hides the truth.

The reality is that whether you are an owner or an employee, you have debts, mortgages and expenses to pay. As individuals we all have fears, and when we read or hear daily of layoffs, the worst thing that can happen in a company is to have a workforce sitting waiting for the chop. How great do you think your customer service ratings will be when your clients are dealing with people who think they might not be around much longer.

It is my experience that management often treats employees like mushrooms by not being completely upfront about the changes that are going on around them and the chal-

Ienges that the company faces. You cannot stick employees in a closet and feed them manure and expect that morale can be maintained on the front lines. I believe most people can accept the truth if they understand the issues and where they stand and have confidence in their leaders. You get the best out of people when they are prepared for the fight, know where the company is going, and understand their role in getting there.

Frankly, no one knows in a down situation if the bottom is reached, or is still months or a year away. But you cannot turn a company around unless you have everyone positive about the future. Management must come up with a plan to aid the turnaround and continue to grow the company and make it thrive in a new economy.

The face of management has to be one of resolute determination to put things right, and not show fear of the unknown. Plans need to be transoarent. Of course, there should be contingency plans in place. Reality may not

be as you envisage it, but companies have to be led by management with vision, passion and integrity. Bad news has to be told plainly. I can be motivated in tough times when I understand the problems. I cannot be motivated if I work for a company that hopelessly awaits its fate.

So often, management is afraid of telling the truth and, unfortunately, employees know only too well when the truth is not told. Leaving employees awake at nights worrying if they will be able to pay the mortgage at the end of the month is not fair. If there is bad news to be given to some employees, do not taint all employees with the same fears. Tell those affected and get it over and done with. There is nothing worse than hearing bad news the wrong way, like from the newspaper or getting an email from management or sweating it out over weeks or months.

Indeed everything needs to be done to hold on to your best and brightest, because, guess what, these are the ones that will be readily snapped up by your competition and will be the first ones to have their resumes on the street. They already know where they will be welcomed with a raise.

Equally, if expenses have to be cut, cut them where it least impacts the business. But, more importantly, don't cut programs that are needed to turn the company around. This across-theboard cuts business is completely wrong-yes, you want to be seen as fair. but you are not doing your company any favors for the future. Many companies try not to upset the broadest section of the company by spreading whatever monies there are around. Wrong! Spread monies where they can be most effective. If you are working on new products, speed them to market with every dollar you can afford and drop expenditures on failing products or programs.

Let's be truthful: downturns and constant bad news does not create an easy environment for management and staff alike, but this is the environment where we really earn our pay. Protecting jobs and creating wealth for the future is what separates and the good managers from the bad. Just don't expect to accomplish it without your troops at your side, charging from the trenches. Thank your staff for their good work and effort and maybe throw a good, old-fashioned party just to say thank you for sticking with us.

BVC Doweled Lodgepole pine post, poles & rails l-112" to 12" Diameter in Stock . Doweled Rail Fencing 2" BVC Tree Stakes ' 3" BVC Tree Posts . Light Posts Standard and Fancy Bollards 'Special Milling: Split, Quartered, Slabbed. Sanded. Smooth Peeled & Hand Peeled 'Available Textures Natural (No Bark) I TnB MpncruNr MlclzrNe Jurue 2008

ALAN OAKES publisher ajoakes@aol.com

OPPORTUNITY Become a stocking dealer of a high quality, engineered, treated against rotand termites, preprimed, all wood range of exterior siding, trim and mouldihgs, with a 3O-year performance guarantee. www.itiamericas.com A full support promotional package with excellent terms is available to dealers who are looking for growth. Guaranteed NOT to Rot! @mgnPrne O orn (ry 30 Yeors 6v,aravtVeeA ?-e??ormaw?e E rilt It,.'*

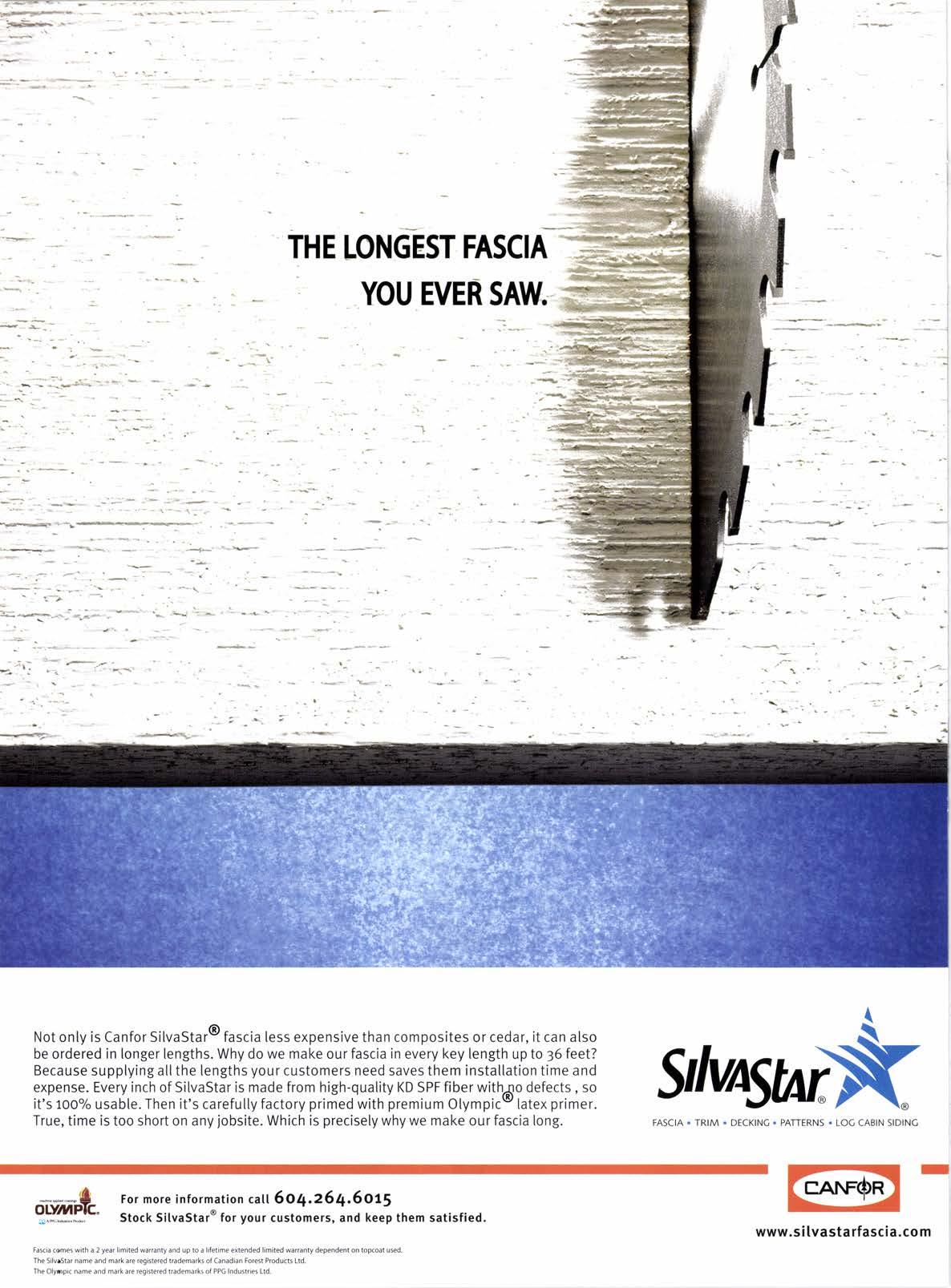

THE LONGEST FASCIA

YOU EVER SAW.

Not only is Canfor SilvaStar@ fascia tess expensive than composites or cedar, it can also be ordered in longer lengths. Why do we make our fascia in every key length up to 35 feet? Because supplying atl the tengths your customers need saves them instaltation time and expense. Every inch of SilvaStar is made from high-quality KD SPF fiber with4o defects , so it's 10o% usable. Then it's carefully factory primed with premium Olympic* latex primer. True, time is too short on any jobsite. Which is precisely why we make our fascia long.

;**

-"1 *'itj .;..=i -f;**,== - -"' '* .h'

StftlrSN FASCIA. TRIM DECKINC PATTERNS LOG CAEIN SlDlNC I **=-S- For more information catt 6O4.264.6Ot5

anu

Fascia comes wth a 2 year limtdwaranty and up to a lifetimeextended limled wariantydependenton topcoatused. The Silv.Sta. name and markare rqbterd tademarks ofCanadian Foren Prducts Ltd. freOlynpic 6ame and markare rqbieredrademarks ofPPG Indusries Ltd. www.si lvastarfascia.co m

gy#:fc Stock SilvaStart for your customers,

t<eep them satisfied.

Howto avoid a Warehouse Management System horror story

Bv Dick Friedman

Bv Dick Friedman

A WAREHOUSE Management

.Cl.System might increase productivity and picking accuracy, which could cut costs and improve customer service. But a WMS is expensive. And it's tricky to find a WMS with the right combination of helpful features and cost-justification.

It's also easy to spend a lot of money, despite the availability of cheaper systems that can produce the same savings and benefits. And often changes to the warehouse are needed before installing a WMS or it won't produce any savings or benefits.

There are steps a distributor can take to avoid selecting the wrong WMS, overpaying or setting up a system in a way that makes things worse.

tfp-Front Planning & Prep

Involve top management, because a WMS impacts customers as well as employees-even if that means a top manager has to learn something about computers and WMS.

. Organize a team consisting of someone from top management, all warehouse managers and supervisors, MIS management, and the people responsible for sales order entry and customer service.

. Estimate growth and identify expected changes for the company as a whole and for the warehouse. A WMS must be able to handle future company and warehouse needs as well as the obvious current ones.

. Tighten warehouse procedures and controls for receiving, put away, etc., and for information and product flow. Do it now. Failure to do this is the primary reason for WMS horror stories.

. Determine if the main business system has the functions and data that are "expected" by a WMS; e.g., expected arrival date of a purchase order. Furthermore, the data in the business system must be very up to

date and accurate.

. Estimate long-term costs: software, education, training, bar code equipment and spares, annual support fee.

. Be conservative when estimating personnel reductions, personnel avoidance, and other cash savings. Don't ignore the impact of non-cash benefits, such as happier customers..

Selection & Installation

. Define detailed, long-term WMS needs. Without such a list it is impossible to judge whether a particular WMS contains specific needed functions-and impossible to compare different systems.

. Solicit written bids. Ask WMS vendors to categorically compare their software against the list, and to quote all the costs involved.

. Examine each vendor's bid, for cost, missing features, and prior experience with similar distributors. Narrow the field to two or three WMS, and then ask those vendors to

demonstrate their systems. Call a few references of the vendors, and visit one or two references ofeach vendor.

. Select the most cost-effective WMS, based on long-term cost of ownership and non-financial facts, such as the degree of software suitability (vs. the list of needs) and vendor experience.

Before delivering the system, the vendor should make any planned WMS modifications and create any programs needed to interface the WMS with the ERP system. Test it all, using real data for the test, which should be conducted by the people who will be using the new WMS.

Don't skimp on user training. A WMS is so complex that the only way to learn more is to spend a lot of time in formal classes and on-site trainins sessions.

- Dick Friedman has 25+ years of experience helping distributors select Warehouse Management Systems. For a free consulttttion, contact him at (847) 2 56- 3260 or v ia www.ge nbu scon.com.

I L t

WAREHOUSE Management Systems can save distributors time and money and improve accuracy-if they're chosen and implemented properly.

Design trends drive denrand for vinyl siding and trim

By Drew C. Brandl CertainTeed Coro.

fiVER the past 50 years, vinyl sid\-fins and trim have become the leading-choice for residential projects. Now, three major building and design trends-GreenBuilding, New Urbanism, and Aging in Place-are further driving demand for these durable and low-maintenance products.

The "green" movement has produced one of the most influential building and design trends in American history, and it will only continue to grow in importance. Sustainable building and design has completely changed the way that the building industry and its customers look at construction and renovation. As an outgrowth of this, the demand has gone up for building products that are longlasting, are made with recycled con-

tent and those that can be recycled once their life cycle is finished. Vinyl siding and trim meet many of the requirements defined by this movement. According to a recent study by Sustainable Solutions Corp., vinyl emits much lower levels of carbon dioxide over its lifetime than other common siding materials, making vinyl a better ma terial choice for the environment. Plus, properly installed vinyl and polymer siding create an efficient building envelope that does not conduct heat or cold. Insulated vinyl siding products such as CertainTeed CedarBoards contribute to a home's energy efficiency by increasing the Rvalue of the building envelope, which reduces energy consumption and relat-

INSULATED vinyl siding products such as CertainTeed CedarBoards contribute to a home's energy efficiency by increasing the R-value of the building envelope, which reduces energy consumption and related carbon dioxide emissions.

ed carbon dioxide emissions. It also contributes to Energy Star certification for new homes.

Vinyl siding is also low-maintenance, eliminating the need for painting and caulking, and it is made using up to 807o post-consumer and industrial recycled content, requiring minimal raw materials, energy, and water to produce. Vinyl products can also be recycled at the end of their life cycle and all scrap from manufacturing is reintroduced into the manufacturing process, eliminating waste. These factors make vinyl siding a sustainable, environmentally friendly product.

New Urbanism is based on principles of planning and architecture that work together to create human-scale, walkable communities, much like those found in American cities before World War IL The idea is to revitalize old urban neighborhoods with remodeled housing and shopping, work and entertainment, all within walking distance.

Vinyl siding and trim are valued by the New Urbanism movement for its design flexibility, one of the material's biggest advantages. Vinyl can be shaped and formed to emulate classic wood siding profiles, such as clapboard, dutchlap, beaded, and board and batten panels, as well as and cedar shakes and shingles. And it comes in an ever-increasing variety of colors.

Using colored vinyl eliminates the need for painting, and the increased selection of colors available on today's market allows for endless combinations and variations throughout residential communities. Vinyl siding's wide variety of classic profiles and accessories allows builders to renovate older homes with exterior

BESTORATION Millwork is manulactured from cellular PVC so there are no worries about rotting, warping, moisture, or insects.

cladding that emulates siding of the original era. Additionally, today's insulated vinyl siding can provide these homes with added weather resistance and energy efficiency over traditional wood siding.

Finally, the option of polymer shake and shingle sidings and decorative trims gives New Urbanist builders increased flexibility to produce more elaborate architectural designs such as Victorian or Craftsman, where rich shape or texture is a prominent feature. Add low-maintenance and affordability, and you have a true winning choice.

The Aging in Place design movement addresses the growing number of active healthy retirees across the nation who prefer living out the rest of their lives in their family home rather than moving to a retirement home. The movement provides solutions for renovating homes to make them more accessible and mobility easier, without sacrificing aesthetics. Vinyl siding, trim, railing, decking and fencing products are all a big advantage here, as they are low-maintenance and will not rot, warp, crack or split, as wood does over time. With vinyl siding,

homeowners can realize significant savings in maintenance costs.

According to industry estimates. maintenance costs can add up to approximately $170 per month on a 2,500-sq. ft. home. There's always the do-it-yourself approach, but most homeowners would prefer not to deal with the time-consuming repainting or repairing of siding every few yearsespecially after retirement. Vinyl siding allows them to avoid much of this. All that vinyl requires is an annual cleaning with a garden hose and soap. This leaves more time for other, more enjoyable activities and significantly cuts maintenance costs.

All these factors add up to continuing demand for vinyl siding and trim products. After years of refinement by manufacturers, vinyl sidings and trim products are excellent substitutes for wood. These products also complement other siding materials, such as stucco, fiber cement, and brick. Aesthetics. low maintenance. superior perlormance. and competitive costvinyl siding and trim has it all.

- Drew C. Brcndt is the director of marketing-new product development for CertainTeed's siding products group. He can be reached at (610) 341-7833 or drew .c .brandt@ saint-pobain.com

A growing number of deck failures have emphasized the need to build decks to meet code requirements just like any other structure. To help your customers build safe, code compliant decks, Simpson Strong-Tie@ introduces our new Deck Framing Connection Guide. The guide recommends structural connectors and provides best practice guidance based upon specific building codes.

Understanding the critical connections 0n a deck has never been easier.

To request a copy of the Deck Framing Connection Guide call (800) 999-5099 or visit www.strongtie.com/codeguides.

( Photos by CertainTeed)

( Photos by CertainTeed)

O2008 Simpson Stong-Tie Company Inc. 00R07 JuruE 2008 Tnn MnncnnNr MnclzrNn13

Expanding manufacturer sides with wood

THE OWNERS of Lazy S Lumber.

|. Beavercreek. Or.. and Columbia Cedar, Kettle Falls, Wa., are betting big on wood siding, by rolling out new lines of siding panels in western red cedar and in Okoum6 hardwood.

Four years ago, Ralph and Merry Schmidt opened Panel Crafters, Inc., as a specialty hardwood manufacturing plant in White City, Or.It recently began production of Cedar Craft siding panels. The line has earned the APA grade stamp for T1-11 sidings

and is manufactured to APA 303 sidings specifications.

"We are in a very competitive market, and Merry and I have over 35 years in the cedar lumber industry with Lazy S Lumber and Columbia Cedar," said Ralph Schmidt. "It was a natural progression to bring that experience to our panel company."

The Schmidts have relocated from Kettle Falls to Eagle Point, Or., to spearhead the new company. "When we commit to a company, we do what

it takes to make it successful," she said. "So the transfer was easy."

For the Cedar Craft line, said Ralph, the "skins come from selected cedar logs taken at Columbia Cedar. We've selected sound, secondgrowth, tight-knot logs, and shipped those to be peeled and composed, and then bring the skins to Panel Crafters, where they are graded, sorted and laid up into the Cedar Craft line."

What makes Cedar Craft unique is that the skins are exactly as nature made them. "We don't cut or blow out the knots and replace them with a synthetic putty," he noted. "We only repair the knots that fall out during the creation of the skins, so the natural look of tight-knot cedar is graded into our product line.

"The added rough saw will texture and pattern the panels exactly as specified by the APA. We've worked very closely with them to assure our customers are getting a product they are familiar with in construction, but unique and natural in appearance."

To be able to offer a more versatile selection, the Panel Crafters facility is also producing an Okoum6 hardwoodfaced line called Craftsman. "It's an A-grade Okoum6 panel that will have the same textured finish as the Cedar Craft panels, but is a true clear, light wood color," Ralph said.

Craftsman will be sold through sister companies Columbia Cedar and Lazy S Lumber. "Some of our customers have been misled to believe that Okoum6 is cedar," noted Columbia Cedar sales manager Chris Retherford. "I think it's important to know the difference. Okoum6 is an African hardwood and is also known as gaboon. It has a light salmon to tan color, and in veneers it rarely has knots. Our Cedar Craft panels are (Please turn to page 55)

PANEL CRAFTERS' office in White City, Or., fealures its two newest products: Cedar Crafl "Deschutes Rive/'grade knotty western red cedar siding with 0koum6 hardwood for the soffit.

14 TnB MnncsaNr MlclzrNn Jurue 2008

Innov gfo PVC trim

rflHE growth of exterior PVC trim has come as no sur.l- prise, as builders increasingly use the products in place of wood. But there's also been an unexpected contributor to their success: builders inventing clever new applications for the versatile products.

KOMA Trim Products became aware of the trend while analyzing entries in its annual Building Professional of the Year competition. Countless projects had used their trim in innovative ways not originally intended, ranging from interior stair risers to church steeples and beach club showers.

The contest's most recent winner, mid-Atlantic roofing and siding contractor Sean O'Connor, used the trim throughout a northern New Jersey swim/beach club.

"Looking at the entry pictures, we couldn't believe the extent to which Sean's team had been able to use KOMA trim and our other products," said Patrick Shabal, national sales and marketing manager. "We saw extensive use of accent mouldings, fabricated components, panel work, door casings/returns to accommodate shingle-whips, cope and stick columns and pilasters, scribed-in transitions between windows and columns on bays, and possibly the largest PVC trim project we have ever seen."

In its booth at this year's Inter-national Builders Show, KOMA played a video montage of O'Connor's work, piquing the curiosity of other builders anxious to learn the

install technique he used to vent soffits through space created with blocking outfitted with a breather element behind frieze boards.

The beach club's outdoor dressing rooms were clad entirely in KOMA products. Beaded sheets were applied to the walls and the ceiling, as well as throughout the interior of the dressing rooms, including peg boards for hanging towels and clothing.

The previous year's Building Professional of the Year truly went a different direction, using the exterior products indoors. Luciani Building Group utilized the trim for interior paneled walls, stair risers, custom size/style door casings, and numerous "durable trim" applications.

Owner Peter Luciani grew so confident in the trim's ability to withstand the demands of coastal New England that cladding the front of interior stair risers was a natural transition. Besides being incredibly durable, the material bends easy and holds paint well.

He also utilized these same attributes to justify the trim's use in interior raised panel work, one-off door casings/trim, beam cladding, special need jamb extensions, and other architectural elements. His team literally sets up a PVC millwork shop in the basements of its jobsites.

According to Luciani, the trim's hardness allows his "workers to use it on the jobsite without worrying about it being too delicate or easily damaged. Anywhere we need durability or bent boards we use KOMA."

In designing new products, KOMA is taking into consideration the expanding applications, as well as demands for greater curb appeal and lower maintenance. A new heat bending system enables contractors to bend the trim boards for radius work. Additions to the base trim board and sheet lines include one-piece corner boards, edge and center bead boards, extruded profile mouldings, edge and center beaded sheets, one-piece water table, and soffit system panels.

"As manufacturers, we always listen to our customers, look for reoccurring requests, determine what product innovations are within our skill sets," said Bob Lambert, field sales manager. "Our converting and fabricating customers will always grow the market with their own creativity."

INNOVATIVE aoolications for exterior PVC steeples (top right), and fencing (bottom left).

Jurue 2008 Tun MBnquNr MacazrNn 15

trim board include beachside changing stalls (top /eft), church

Slru:nign fo_reoast fot rootinU

f T S roofing demand is forecast to lL,/ grow nearly 2Vo a year through 2Ol2 to 280 million squares, valued at over $15 billion, according to a new forecast by Freedonia Group.

Gains will be sparked by an expected improvement in new resi-

dential construction, following the sharp slowdown that began in 2006. As housing construction recovers through 2012, demand for roofing is projected to surge.

Although the biggest growth is expected in new roofing applications,

Iile Bools 0o GrBGn

A new campaign sponsored by the Tile Roofing Institute highlights the environmental benefits of using concrete and clay tile roofs, which can save energy and earn LEED credits.

"This campaign is about being smarter, stronger and cooler," said TRI spokesperson Jeanne Sheehy. "Tile roofing has always had a environmentally fiiendly story, and we believe this is a great partnership for us. Green is here to stay."

She added that the campaign establishes TRI as the singlesource authority for information on tile roofing's green benefits, including life-cycle cost, recycling, reflectivity, and sustainability. Another benefit is that tile roofing

is very durable and can wi&stand harsh weather conditions, including high winds, snow and ice buildup, hail and earthquakes.

"Another part of our story is what we're doing with the solarpanel industry," said Sheehy. "We've worked with solar-panel providers who are building solar panels right into tile. It's flat, you can't see the solar panels at all, and it's very subtle."

Components of the campaign will include an informative brochure, articles in building and home improvement publications, a "Go Green" section on TRI's website (www.tileroofing.org), and technical experts who will speak at green-building conferences.

U.S. Roofing Demand (256 million

squares in 2007)

Asphalt shingles

58%

Bituminous low-slope roofing 13olo

Metalroofing

Elastomeric roofing

8%

7o/o

All other roofing materials 141o

the majority of demand will continue to come from reroofing applications. In2007, reroofing accounted for more than three-quarters of total roofing demand.

Product-wise, roofing tile and plastic roofing will lead the gains through 2012.Demand for roofing tile will be driven by the recovery of the residential market, especially in the South and West, where roofing tile demand is greatest. Demand for plastic roofing (for example, PVC, thermoplastic polyolefin, and spray polyurethane foam), which is typically used in nonresidential construction. will increase as plastic materials supplant more traditional bituminous low-slope roofing products.

Asphalt shingles are projected to remain the most popular roofing product, accounting for nearly two-thirds of new roofing demand, owing to their dominant position in the large residential market. They should accelerate markedly through 2Ol2 as the residential market recovers.

The West is expected to provide the best prospects for roofing demand through 2O12. The West has experienced one of the sharpest declines in housing construction, enabling the biggest gains in a recovery. Growth will be led by the Mountain subregion, which is expected to outpace the average in terms of growth in population and economic output.

16 Tnn Mnncnlxr Mnc.rzrnn Jurur 2008

Siding BB-O Wb Do Specialty Plywood... .1" i:-: r iirf ij..fu ".r? "i.l; t,1 I

(spesh'al rc), n., adj. -n.1. a special line of work, skill, or the like on which one is dedicated, such as outstanding service in selling and delivering plywood. 2. an article or service particularly dealt in, manufactured, and rendered, such as manuf'acturing mariner plywood. -adi. 3. producing or offering an unusual or specitic product, such as concrete form panels. We Do It Right. SffiiM Sanded ff,j' il -'j,: t *ri" t|,$fl i*,|t A member of the Swanson Group, Inc. family of companies 541-956-4300 . 800-331-0831 ' Fax 541-956-4301 Grants Pass, Oregon . www.swansongrouprnc.com

Spe.cial.ty

How buildin$ codes affect LBM market opportunities

\ZOU'RE drivin-e along and see a I new four- or even five-story hotel being built with wood framing. But, you've always heard that building codes greatly restrict the size of nonresidential buildings framed with wood. Wondering how it's possible that wood is the construction material of choice for these buildings?

Much of that "restriction" is now only a perception, not reality. Thanks to a little-known group, over the last few years the wood products industry

has been very successful getting building codes to permit larger and taller wood buildings. That group, AF&PA's American Wood Council (AWC), has ensured that building code changes, now being enacted in all 50 states, provide tremendous opportunity for wood in markets historically dominated by steel and concrete.

The International Building Code (IBC), the content of which is used virtually everywhere in the U.S., provides architects, engineers, contractors

Index of Maximum Allowable Area

and other building professionals with guidelines and design options, along with the new-found freedom to build all types of wood-frame buildings. In addition, groups such as AWC offer powerful tools to help building professionals design with wood for these new opportunities, and for the traditional residential market as well.

A little History

Publication of the IBC marked the end of regional code development in the U.S. by the three former model building code agencies, which historically governed most construction.

. The Building Officials Code Administrators International (BOCA), predominant on the East Coast and in the Midwest

.

The Southern Building Code Congress International (SBCCI), commonly found in the Southeast

.

The International Conference of Building Officials (ICBO), used by code officials in the western states ln 1994, these three groups joined forces to provide a comprehensive, coordinated set of national building standards under the International Code Council (ICC) banner.

AWC. with its staff of former building officials, is the industry's advocate to the building codes. Throughout every year, changes are proposed to building codes and design

ll\ rl IT tl II II INTT c0D _ftft @RNAIIONAL E C(IUNHT **A

400 300 200 100 0 South West East IBC IBC permits increased wood building area compared to the three legacy model codes. 18 THr' MBncu,qNr MlclznrB Jurue 2008

standards. AWC staff are the watchdog for wood products, continually seeking to ensure that codes and standards allow the greatest appropriate use of wood, and that competing material industries do not succeed in changing these regulatory documents to the detriment of wood.

Wood Provisions in the Gode

Although we don't always think of it, the use of wood products in construction is highly regulated. While we generally see wood as a simple, environmentally friendly and carbonsequestering material. benign in every way, wood does not get used in construction except where buildings codes permit it to be. If those codes were changed to limit wood use, the industry would suffer immediately.

Chapter 23 of the 1BC covers wood use primarily for non-residential buildings (a separate publication, the International Residential Code, regulates construction of one- and twofamily dwellings). Chapter 23 governs materials, design, construction, and quality of wood members and their fasteners. Aside from some provisions that address traditional construction methods, Chapter 23 in large part simply references the consensus standards of AF&PA, most notably the Natir,tnal Design Specification (NDS) for Wood Construction.

IBG's lmpact on Construction

Provisions of the NDS, used in conjunction with the building code, give designers the information they need to design wood buildings bigger and better than ever. When Chapter 23 design allowances are applied with building height and area limits found elsewhere in the building code, it results in increased opportunities for woodframe construction as compared with that which was allowed under the three legacy model code agencies (see graph on previous page). And these new IBC provisions offer a number of advantages for wood use in a wide range of non-residential applications.

Tools

AWC has several free tools on its website to help commercial building designers use wood-frame construction effectively and efficiently.

Allowable Heights and Areas

Calculator: The calculator demonstrates how large a building can be built with wood under the building code. The calculator shows the maxi-

mum height and area for various types of occupancies and levels of fire protection, all based onthe 2006 IBC.

Span Calculator: This web-based tool provides span calculations for all species and grades of commercially available softwood and hardwood lumber under common loading conditions. One option even allows users to select multiple species and grades for comparison purposes.

Fire Related Publications: Since wood is a combustible material, fire performance of these products is an important consideration. A series of free web-available publications addressing flamespread, fire design of exposed wood members, and fire rated assemblies helps designers tackle this critical issue.

Gode Experts

The map shows the various areas of the country where AWC's building code experts work closely with model, state, and local building code organizations to gain the broadest possible acceptance of wood products. With their regional location and focus, they are able to operate at a grass-roots level, assisting wood products manufacturers by helping local building officials and designers with code interpretations related to wood products, even interceding where necessary to gain product approval.

Although they are the industry's front line, they are supported in the technical details of these efforts by a superb group of structural and fire protection engineers at the headquarters office. And these building code experts and engineers all participate in development of a myriad of non-

industry standards that could impact wood construction as well.

But the key activity which makes AWC so indispensible is their advocacy on industry's behalf during the building code change process. For example, since 2000, AWC's success rate in defending the wood industry from detrimental code-change proposals is 897o. Case in point: a code change proposal by the Masonry Alliance for Codes and Standards was submitted this year seeking more restrictive fire separation assemblies for "unlimited" area buildings. The proposal would have required higher fire resistance ratings for these buildings, likely resulting in a switch to masonry walls. AWC vocally opposed this change, persuasively testifying why such a change was unnecessary, and it was disapproved.

Proposals such as this are quite common and if left unchallenged, would quickly change what products can be used in construction. It is in this sometimes arcane world that AWC successfully operates, quietly protecting the industry.

So, next time you're driving along and see that new hotel going up, remember, that there is a whole set of building codes and standards that regulate construction but at the same time provide tremendous opportunities for wood products. And, rest assured that industry technical representatives from AWC are working every day, behind the scenes, to ensure that those market opportunities are protected and expanded for wood products.

- If you need help with a building code issue on wood products, contact the AWC at www.awc.org or (202) 463-4713.

Northern Alaska, Hawaii Jim Bowman

.t[''.,.

Northeast Sam Francis

Soulhwest Dave Tyree

Central Dennis Pitts Southeast Jeffrey Stone

JuNe 2008 Tnn MencH.rrlr MlclzrNn 19

AMERICAN Wood Council's code experts are strategically located around the U.S. to work closely with model, state and local building code organizations to gain the broadest possible acceptance ol wood products.

Longevity, backed by new blood

By Carla Waldemar

Searching for a successor to lead the company via a big-business version of Match.com, he located young Kevin Hughart, a computer pro.

"I was in my 30s, looking for new challenges, the chance to build a business and take it forward," Hughart said as he signed on, and by 1996 he purchased the company he'd guided to continued success.

cating new hires.

Sure, it set a few to trembling, but not for long. Aiming to put folks at ease, "I went around the yard in jeans and a T-shirt the first few weeks," he explains, learning the operation from the sawdust up before he tackled procedures in the office, where he now resides.

II/HAT do you do when the hardY Y wood is stripped and gone? If you're a lumberyard owner with a little moxie, you go looking for the Next Big Thing.

That kind of thinking has kept Norvell & Wallace on the Nashville map since its start-up in 1880. Tennessee was occupied by the Federal Army during the War Between the States (as it's called in these parts), when Union forces cut down everything bigger than a lilac bush to build their forls and quarters. So enterprising co-owner William Norvell hopped a train to Alabama to see if whatever grew down there might keep them going, and the answer was-oh, I'll bet you already guessed it-southern yellow pine. Never used it before in Tennessee, never stopped using it since.

The company prospered through three generations of family owners until, in the early 1990s, William Norvell II, grandson of the co-founder and now in his 60s himself, began to think of retirement. The business environment was looking tough back then and called for bold new blood.

Two changes, right off the bat: First Hughart, accustomed to the electronic world of doing business. completely upgraded the computer system, which "helped immensely," he relates. (Cries of "But we've always done it this way" echoed all across Nashville as he emptied closet after closet of old paperwork.)

Longevity and name-recognition had amassed a loyal following, but nobody's resting on laurels around here. Building on that strong foundation, Hughart has gotten to know his pro customersand Norvell & Wallace's customers are 10070 pros. "Dealing with builders is what attracted me to this company-no ma-andpa walk-ins" to distract from focusing on the needs ofthe pros: good quality, fair prices, and good service. Right off, the new boss bought a forklift to deliver materials within inches of where carpenters were waiting, a miracle near as welcome as the Second Coming in those builders' eyes.

He reinforced the company's credo of "under-promise, over-deliver." Deliveries, in fact, are still free and show up on time or-gulp!-even early. "If a truck breaks down on the interstate, we'll call and let them know. Otherwise, they can count on that we do what we say we'll do," he states.

Next, he more than doubled the staff from 20 to 50, building a stronger sales force inside the store and on the road alike. He bulked up staff training, replaced dead wood with live-wires, added regular staff meetings to the company calendar, and initiated a mentor system for edu-

Hughart also launched an estimating department to supply his customers with take-offs. He entertains and informs them at contractor breakfasts and seminars, including one last week on building green.

That's another new position he's championing. "We've always handled engineered wood and OSB, produced from [otherwise wasted] scrap wood, and we're going forward from there. We're walking the talk," he notes.

For years the company has main-

titivee

gence

li

RUNNING THE SHOW: (Left to right)David Kunkel, executive v.p. in charge of sales, and Kevin Hughart, owner.

20 TnB Mnncslnr MlcnzrNn Jurue 2008

tained its own truss and panel plant, making life easier for its builders, who relish the one-stop shopping. Hughart himself relishes the ample margins these items supply.

Although Norvell & Wallace purchases some print advertising-including mailing stuffers-Hughart indicates that the company's newsletter, distributed to prospects and customers alike, is more effective. "Instead of a shotgun approach, it's more of a .22," he laughs.

So arejobsite and prospecting calls by his outside salespeople. Most effective of all, he insists, is word of mouth

And that harks back to the firm's strong local standing, forged in 1880. The company has been the supplier of choice for Nashville's most beloved city icons, from The Parthenon and Ryman Auditorium to Opryland Theme Park, The Coliseum where the Titans play, Belle Meade Country Club, and commercial landmarks such as Bell South and a Dupont plant-and that's in addition to the many custom and production homes built by Norvell & Wallace's builder clients.

BORATE TNEATED I^/OOD

Hi-boro brand treated wood is a borate treated termites and numerous household

i oroduct desisned for interior house framing in Ha bHi:boro trealed wood resists attack by Foinosan

The company

"gives as good as it gets," as they say in this neck of the country. Favorite charities that count on Norvell & Wallace for major support include Habitat for Humanity, Second Harvest, Boy Scouts, and St. Luke's Community Center. As Hughart explains, "We get calls and letters all the time asking for our help, but I choose to be very selective, then fund [our choices] in a big way. We do it because we believe it's our duty, but I also like to think that the goodwill comes back to roost."

Even in this soft-and-softer economy, Hughart is not one to be overly concerned about the future ofthe industry. Like the company itself, the city's eggs are not all in one basket. "Nashville's economy is diverse, based on health care, sports teams, and entertainment. Plus, we're close to three major interstates, allowing us to extend our base" deep into the competition's zipcodes.

All I can say to them is, "watch out." And you've gotta bet he's selling them some of the prime Alabama pine that's been the outfit's pride andjoy since 1880.

- Aformer award-winning LBM trade magaTine editor, Carla Waldemar writes frequently on the industry. Contact her at cwaldemar@ comcast .net

*SirePR0'brand interior fire retaxdant is the consEuction "industrt's newest and most advanced fire protecton s:wtem for wo<id. The unique FirePro ctremisw is a pamt pehdins formuldion tlr:* codains no phosphoroubbased confoundsl

NORVELL & Wallace moves plenty of engineered wood products by stressing their environmental benelits.

i-bor

Prouidi,ng Customer Satisfaction in All We Do P.O. Box 75 . McMinnville, OR 9712{t Phone: 503-434-5450 r FAX: 888-TSO-WOOD (888-876-9663) Call toda.y and seeJust utbat Royal Pactfic Industdes ffi,RqYALPtfftr6 7 --fr rNDUsrR,ss -fHtbrr, FtcPRo, ,nd Adrre Gud e Rghdtd Eddado of $T-N hldl'|gi h In"bd, FlrclRO, .trd AdviG Gurd ptod& ft prodrced by todepef,dandy (,mcd edd opdlcd wd FaflLU Fdlhld o zwl JuruE 2008 Tnn MpncnaNr MlclztNB 21

The Call Reluctance Masquerade

By James Olsen

By James Olsen

originally agreed to give them. All we have is our time; we must charge for it one way or another.

I'm the only one who can service my accounts. I work with a great manager, Mike Mordell, who recently told me, "I tell my salespeople, if they don't delegate service work, they are making a mistake. I understand that some service work has to be done by the account rep, but much of it can be delegated."

We must keep demanding customers in check-or charge for our time. We must delegate tasks when possible.

If,/HEN we think of "call reluctance," we picture a Y Y salesperson sweating, fidgeting and hesitating with their finger poised over the numbers on the phone, trembling with fear, unable to make the call.

Call reluctance is real, but it seldom manifests itself in such an obvious way. As professional salespeople, we need to be aware of this insidious phenomenon and protect ourselves against it.

Imagine a dry cleaning business that cleans about 300 shirts per day. Three people work in the shirt room. But the work doesn't come in evenly. If 400 shirts arrive on Monday, it takes eight hours (24 man hours) to complete the work. If 200 shirts arrive on Thursday, how long does it take? The same amount of time!

Work expands to fill the time available. This concept was introduced in 1955 by Cyril Northcote Parkinson, an English civil servant, in his essay, "The Economist." He was speaking of bureaucracies and how they will grow regardless of the work they have (or don't have) to do.

What does this have to do with call reluctance?

Disguises

In my own sales and my work with salespeople, I find that we disguise our call reluctance. Let's introduce ourselves to the guests who regularly attend the Call Reluctance Masquerade:

Service of current accounts. This is the most common place to hide for the salesperson who doesn't want to prospect. "I have to service my current accounts, don't I?" they will say, with an accusatory tone. (How dare we question their service relationship with their current customers!)

Service to our current accounts is important, but many sellers are giving customers too much service or service the customer is not paying for! Customers will always ask for more. We must give them what thev need and what we

Detail work. Computer work. Bid work. Many salespeople hide behind the detail work or administration work of their jobs so they don't have to do the most important and profitable part of theirjob - getting in front of the customer.

Talking to the boss-itis. Your boss may have time to talk to you, but that doesn't mean you have time to talk to him. Kissing up to the boss in sales seldom works. The numbers tell the tale (and the boss isn't buying, so...).

Whining about the economy. We are salespeople, not economists. Our job is not to predict what the economy is going to do; our job is to sell no matter what the economy is doing. A sales manager was preaching the doom and gloom to me the other day. I asked him, "The economy may have slowed some, but how many of your salespeople are making 40 outbound phone calls per day?"

"Not many," he said. That put an end to the "whining about the economy" talk.

Spending too much time with the wrong customers. Many sellers give an inappropriate amount of time to customers that will never be "A" accounts. They get along with the buyer-and the buyer will talk to them all day-so they give that buyer more time that they deserve, keeping the seller from calling new accounts and growing his or her business.

Who is in charge?

We are not victims. We are entrepreneurs or intra-preneurs. We are running our own businesses. We decide (and are responsible for) how we spend our time. Call reluctance is real and can strike even the most experienced seller. The outbound sales call is our life's blood as salespeople. The next time we receive an invitation to the Call Reluctance Masquerade,let's decline and make an outbound sales call.

Happy selling!

22 TsB Mnnculnr Mlclzrnp JuNE 2008

- James Olsen, Reality Sales Training, specializes in sales training for the lumber industry. Reach him at james@realitysalestraining.com or ( 503 ) 544-3572.

srDrNGlrRlM

{/z^ " Viance -. 4' ffiod Quan groMh. Not to mention supplemental protection against wood decay and termite attack. Get all the details about the new purple framing, truss and sheathing products at www.treatedwood.com. il{0tD RrsrsrAlrT [il00D Protect your customers - and your reputation - with new QuanTlM Mold Resistant Wood. When properly installed in interior, weather-protected applications, the EPA-registered, mold-control formulation provides 20 years of protection against discoloration, odor and deterioration caused by common mold Serving California and Nevada Woodland, CA 530-666-1 261 ffi= 'See QuanTlN4 limited warranty Jor details

Rrrrrr:ns

Kelseyville Lumber, Kelseyville, Ca., will complete construction by the end of the year on a 120,000-sq. ft. replacement store on 17 acres, replacing its 50-yearold, 1,500-sq. ft., 3-acre yard; the workforce will gradually grow fromT0ro 100...

Pete's Ace Hardware. Castro Valley, Ca., has added 4,000 sq. ft. of sales area to the rear of its store and in time will increase parking, improve its facade, and expand its main sales floor

Stock Building Supply has relocated its 3-acre yard in Cedar City, Ut., to a new 11 .4Z-acre facility

The ReUse People, a nonprofit that operates surplus LBM warehouses in Oakland, Ca., and Boulder, Co., opened an outlet in Pacoima. Ca. ...

Habitat for Humanity ReStore moved its Tangent, Or., outlet to a larger location in Albany, Or., and held aJune 3 grand opening

Home Depot opened a new store May 8 in Snohomish, Wa., and plans an October opening in Huntington Beach, Ca.

Home Depot submitted a new application to build in SunlandTujunga,Ca....

Send us your news!

Have your recent expansion, promotions or other company changes published in the next issue of The Merchant Magazine.

Just Fax your news to 94$852-0231 or send by email to kdebats@buildingoroducts.com.

(a lree seNice)

Inwe's Cos. opened a new store June 10 in Bonney Lake, Wa., and expects new store openings in 3rd quarter 2008 in Madera, Ca., and in 4th quarter 2008 in Hanford, Ca....

Lowe 's plans to move into a vacated WaI-Mart building in Rialto, Ca., and continues seeking approval to build in Springfield, Or. ...

Friedman's Home Improvement, Rohnert Park, Ca., now offers residential and small commercial solar energy systems from Solar Craft, Novato, Ca.; is completing an addition and remodeling at its store in Sonoma. Ca.

Ace Hardware, Corona de Tucson, Az., added a contract post office

Wrorrsnrrs/trrurrcrurrrs

Stimson Lumber Co., Portland, Or., permanently shut down its sawmills in Bonner, Mt., and Coeur d'Alene, Id., in mid-May and its Bonner planer mill in late May...

Trumark Industrie s, Spokane, Wa., permanently closed its fingerjoint stud mill June 9 ...

Fiber Composites LLC suffered a late night fire May 15 at its composite plant in Meridian, Id., previously owned by LouisianaPacific; fire officials suspect combustion from excess wood dust ...

Silver City Lumber, Three Forks, Mt., is the new sales agent for Montana Renewable Resources, Eureka, Mt.

Weyerhaeuser Co.. Federal Way, Wa., is exploring the possible sale of its Weswood Shipping Line and four regional short line railroads, including Longview, Wa.-based Columbia & Cowlitz

Railway... Weyco sold its DC in Council Bluffs, Ia., to Building Products, Inc .,Watertown, S .D.

iLevel by Weyerhaeuser has introduced Performance Connection, a web-based interface that provides a list of appropriate building products based on local environmental conditions

Silvaris Corp. is now the exclusive sales organization for Louisiana-Pacific's North American offgrade OSB products through its OSBMarket.com online marketplace,beginning June 2

Lo ui s i ana - P acific completed the initial phase of its purchase of a 75Vo interest in Brazilian OSB producer Masisa OSB Industria e Comercio S.4....

Owens Corning is seeking LEED certification for its foam insulation plant in Gresham Or.

Simp son Strong -Tie, Pleasanton, Ca., opened a mid-Atlantic distribution center in Jessup, Md. (Kevin Dill, sales mgr.)

Pacific Western Wood Products, Los Angeles, Ca., is stocking more bamboo panels, including vertical and horizontal grain, natural and carbonized finishes. and bamboo decking...

Anniversaries: Safford Builders Ace Hardware, Saffotd, Az.,70th Neiman Reed Lumber Co., Panorama City, Ca., 60th ... Trader Horn's True Value, Portales, N.M., 50th

Housing starts in April rose 8.2Vo to a seasonally adjusted annual rate of L032 million, thanks to a 4O.5Vo swell in multifamily construction single-family starts slipped l.7vo to an annual pace of 692,000 ... permits increased 4.9Vo a 978,000 rate ... regionally, starts jumped l9%o rn the West.

briefs

Jur.re 2008 ltm Mrncn,q,xr Mlclznn 25

Custom Millwork - Patterns in Softwoods & Hardwoods - Custom Runs of Paint

Grade

Poplar Mouldings a Specialty

Mouldings - Siding - Trim Pieces

Wholesale Lumber - Redwood - Uppers

Douglas Fir - Pine - Hardwoods - Western Red Cedar

BEAVER TUMBER COMPANY

1400 Orchard. Hollister, CA 95023 (831) 636-3399 . Fax 831-636-3335

Listings are often submitted months in advance. Always verify dates and locations with sponsor before making plans to attend.

futr

National Lawn & Garden Show - June 10-12, Westin Chicago Northshore, Chicago, Il.; (888) 316-0226.

SierraPine - June 12, sustainable building products forum, Portland, Or.; (800) 54'7-9520.

Seattle Hoo-Hoo Club - June 13, golf tournament & dinner, Mount Si Golf Course, Snoqualmie, Wa.; (253) 796-7 155.

Western Wood Preservers Institute - June 15-17, summer meeting, Sun Valley Resort, Sun Valley,Id.; (800) 729-9663.

Tuolumne Lumber Jubilee - June 19-23, Tuolumne, Ca.; (800) 266-6436.

Forest Products Society - June 22-24, international convention, HyattRegency St. Louis,Mo.; (608) 231-1361.

Guardian Building Products - June 23-24, summer show, Hyatt Regency, Atlanta, Ga.; (800) 569-4262.

National Retail Federation - June 23-25, loss prevention conference & expo, Orlando, Fl.; (202) 783-7971.

PCBC - hne 24-27 , Moscone Center, San Francisco, Ca.; (916) 443-7933.

Temperate Forest Foundation - June 24-27, teachers tour, Portland, Or.; (503) 579-6762.

Remodeling & Decorating Show - June 27-29, Los Angeles Convention Center, Los Angeles, Ca.; (818) 557-2950.

fuw

SierraPine - July 10, sustainable building products forum, Denver, Co.; (800) 547-9520.

Western Hardwood Association - July 12-15, annual meeting, Fairmont Chateau, Whistler, B.C.; (360) 835-1600.

Mountain States Lumber & Building Material Dealers Association - July 14, golf tournament, Ranch Golf & Country Club, Westminster, Co.; (303) 460-9700.

Western Building Material Association - July 16-18, mid-summer management meeting, Salishan Lodge, Gleneden Beach, Or.; (360) 943-3054.

Wood Moulding & Millwork Producers Association - July 1619, summer business meeting, Hyatt, Newport, RJ.; (800) 5507889.

Lumber Association of California & Nevada - July 17-19, annual 2nd Growth summer conference, La Quinta Resort & Club, La Quinta, Ca.; (916) 369-7501.

North American Retail Hardware Association - July 28-30, convention & annual meeting, Hyatt Regency Monterey Resort, Monterey, Ca.; (317) 290-0338.

SierraPine - July 31, sustainable building products forum, Eugene, Or.; (800) 54'l-9520.

National Wood Flooring Assn. - July 31- Aug.2, summer meeting, Portland Regency, Portland, Me.; (636) 391-5161.

Aucusr

Humboldt Hoo-Hoo Club - Aug. I, golf tournament, Baywood Golf & Country Club, Eureka, Ca.: (7O7) 268-3082.

North American Wholesale Lumber Association - Aug. 3-6, Young Distribution Professionals conference co-sponsored by North American Building Material Distribution Association, Eaglewood Resort & Spa, Itasca, Il.; (800) 527-8258.

Orgill Inc. - Aug. 14-16,fall dealer market, Chicago, Il.; (901) 754-8850.

International Woodworking Fair - Lag.20-23, Georgia World Congress Center, Atlanta, Ga.; (404) 693-8333.

Remodeling & Decorating Show - Lug.22-24, South Town Expo Center, Sandy, Ut.; (818) 557-2950.

26 Tun MnncslNr MAGAZTNE JuNE 2008

OrePac Buys DCs, Moulding Plant

OrePac Building Products, Wilsonville, Or., has gone on an acquisition spree, purchasing Dallas Planing Mill, Dallas. Or.. and Welco Lumber USA's distribution yards in Tumwater, Wa., and Kansas City and Springfield, Ms.

OrePac hoped to complete its purchase of hemlock moulding manufacturer/distributor Dallas Planing Mill by the end of May. Current owner Doug Brittingham will continue with OrePac as general manager. Steve

Rupea will transition from sales manager to millwork manager.

Sales at the newly acquired Tumwater DC will be coordinated with OrePac's facilities in Tacoma. Wa.. and Wilsonville, Or.

OrePac has also become the Pacific Northwest distributor for all Welco cedar fencing products manufactured at Welco's mills in Shelton. Wa.. and Naples,Id.

BMC West Parent Consolidates

Building Materials Holding Corp., San Francisco, Ca., will unify and streamline its BMC West and SelectBuild operations.

"BMC West and SelectBuild have traditionally maintained their independence not only in terms of branding, but also with regard to strategy, purchasing, administration and leadership," said president and chief operating officer Stanley M. Wilson. "While maintaining the unique brand identities of each, we intend to flatten our management structure and reduce our

operational organization from 13 regions into seven regions."

The seven new regions are Pacific (California, Northern Nevada), Southwest (Arizona, Southern Nevada), Intermountain (Colorado, Idaho, Montana, Utah), Midwest (Illinois), Northwest (Oregon, Washington), Southeast (Florida), and Texas.

The company also will shut down a number of underperforming units and has identified another group of business units for potential consolidation. BMC West is closing its millwork and

LBM distribution centers in Merced and Bakersfield, Ca. Two nearby DCs in Modesto and Fresno, Ca., will service the region.

SelectBuild Arizona will discontinue operations in Tucson, Az., July 18, and service the area from Phoenix, Az.

At the corporate level, the group's accounting, accounts payable, purchasing, payroll, and information technology support will be absorbed into existing corporate support operations.

lnland Timber Plans Move

Inland Timber plans to relocate from Grand Terrace, Ca., to a new 36.2-acre site in nearby San Bernardino. Its current location has been acquired through eminent domain so a new high school can be built.

"They're a $100 million a year business," said local councilman Tobin Brinker. "I want the city to help this go as quickly as possible."

Inland wants to build a 5,322-sq. ft. office building, 12,000-sq. ft. storage shed, and 29O00-sq. ft. milling business at the new property. The site is adjacent to a store owned by Stock Building Supply, the North Carolinabased parent of Inland Timber.

Treating Services Only (TSO)

ACQ BORATES D-BLAZE' ACZA(CHEMONTTE) CCA

Heat

Treating Drying Services (KD, KDAT) Staining Service Rail Siding (BNSF) Central Califomia Location: 3400 Patterson Rd.. Riverbank,Ca.95367 WWW.THUNDERIZED.NET

Sacramento. CA

Bob Palacioz, Sales/Marketing Mgr. (916) 402-3248 Fax (916) 339-2477

bobpalacioz@ sbcglobal.net

Portland. OR Jerry Farley, Sales (5O3) 936-9916 Fax (503) 492-1355 thunderboltnw @ verizon.net

Marine & Industrial Sales Misuel Gutierrez

(2O9) 7 4'l -'77'7 3 Fax (209) 367 -1917

mrel833@vahoo.com

I|:IO fnbc tod@ 16,{4h

"We TfeatWood Right"...Quality Wood Tleating Services Since 1977 BOLT WOOO TnntrtXC

6Mt Vln AnsoALE.HARRls LuttlgER C0 1snce1'B8 lTffrluilrntl{[r.l' I!rrn6'fr rrrrgr 595 Tunnel Ave., San Francisco, CA 94134 41 5 -467-8711 Fax 415-467-81 44 tpecialrsfs in upper grades of clear, dry soltwoods DougfasFirC&BetterV/G&F/GKilnDriedFullSawnRough.l",5/4",2',3',4',6"&SxS.3x6DFSelectDexDoubleT&GDecking Sugar Pine , 4t4 -1614 C & Btr. , 514 &814 D Select ,614 &814 Mldg. 5/4 #1 Shop. 514 x12 #2 Common ,4x4 #2 Common Ponderosa Pine .4/4 Clears, Moulding, #3 Clear, Commons .2x4,2x6,2x12 Std. & Btr. Dimension Western Red Cedar Clear V/G & F/G Full Sawn Rough ,1",514",2' Kiln Dried 3", 4", 6" Air Dried Timbers Alaskan Yef fow Cedar C & Btr. Kiln Dried Rough , 414,814 Poplar. FAS .414,514,614,814,144 Sitka Spruce B & Btr. V/G Kiln Dried Rough ,414,814 Honduras Mahogany. FAS Pattern Grade ,414,514,614,814,1014,1214,1614 JuNe 2008 Tnn MBncnlNr MlclztNp 27

otion news

Western Building Material Association has slated its mid-summer management and board meetings for July l6- I 8 at Salishan Lodge, Gleneden Beach, Or.

Lumber Association of California & Nevada has scheduled its annual 2nd Growth summer conference for July 17-19 at the La Quinta Resort & Club, La Quinta, Ca.

The event will start with a golf tournament at the La Quinta Resort Dunes course. The next two days will feature speakers such as Dr. Joe Lstiburek, who will discuss why "Wood Is Good."

Mountain States Lumber & Building Material Dealers Association has a trio of regional golf tournaments planned for the summer.

The Colorado WOOD Council tourney takes place July l4 at The

Ranch Golf & Country Club, Westminster, Co., followed by the Wyoming Golf Tournament in August and the Western Slope Golf Tournament at the Rifle Creek Golf Course. Rifle. Co., in September.

National Lumber & Building Material Dealers Association has named SmithBucklin's Russ Snyder interim president, following the departure of Diane Swenson after three months on the job.

Los Angeles Hardwood Lumberman's Club meets Sept. 18 at Costa Mesa Country Club, Costa Mesa, Ca., for its Sth annual golf tournament.

Western Hardwood Association holds its annual meeting July l2-15 at the Fairmont Chateau, Whistler, B.C.

Featured speaker is Ryan Walter, former NHL playerlcaptain and co-

author of Simply the Best. Other presenters include Glenn Ahrens. OSU: Brian Hawrysh, BC Wood; Mike Snow, American Hardwoods Export Council, and Grace Terpstra, Hardwood Federation.

North American Wholesale Lumber Association is co-hosting with North American Building Material Distribution Association a Young Distribution Professionals conference Aug. 3-6 at Eaglewood Resort & Spa, Itasca, Il.

Opening day is golf, followed by a networking dinner that evening.

Day two focuses on personal development with seminars on "The Big Picture," "Outgrowing Your Cubicle," "How to Solve the MultiGenerational Puzzle," and "How to Work Effectively with Customers, Associates & Employees."

Day three seminars include "Sales Managing through the Tough Times," "Managing the Supplier/Distributor Relationship," and "The Road to Distributor Profitability."

The last day is a half-day program about managing yourself and others, followed by a networking lunch.

National Retail Hardware Association announced honorees of its 2008 Young Retailer of the Year program, who will be special guests at its annual convention July 28-30 at the Hyatt Regency Monterey Resort, Monterey, Ca.

Honorees include John Bettendorf, owner and general mgr., Bettendorf Hardware, Isanti, Mn.; Terry Byers, co-owner, Town Center Hardware, Harrisburg, N.C., and Todd Kirschner, general mgr., Trio Hardware, Plainview, N.Y.

Hoo-Hoo International will meet Sept. l3-16 at The Hotel Murano, Tacoma, Wa., for its 116th annual convention.

Fax 5119-422-7034

American Architectural Manufacturers Association has scheduled its western region fall meeting for Aug.27-28 at Marriott Portland City Center. Portland. Or.

Proudly grown and manafactured by the Colville Indian Tribe tr, cotvlt LE TNDIAN S(O, PnpcrsroN Prnp Co. H- Ponderosa'pine boards & Ww industrials; Douglas fir lamstock, dimension & industrials from Omak, Wa.

Corvrlr,p INDTAN Powpn & Vpuppn Producerc of high qaality Plywood & Dry Veneer from Omak, Wa.

or

Gatl Bob Bretz (509) 422-7550 Fax 5tl9-422-7541

Call Billy Eann (509) 422-7099

Terry Johnson (509) 422-7023

28 Tnn Mnncnlxr M,lclzrxo Jurue 2008

Our decks go equally well with red winen BBO sauce or ketchup.

AZEK Deck, the #1 brand of stain resistant decking, is a superior decking option that is refining - and redefining - the very notion of builciing a deck. Engineered with Procell'"'Technology, AZEK Deck virtually eliminates the shortfalls associated with wood and composite decking so you can forget the stain problems that are common with the leading decking products

Built to withstand a houseful of household objects, homeowners can actually live on their AZEK Deck. Spillecl wine, fruit punch, even hamburger grease are no match for AZEK Deck's stain resistance. And since it's scratch resistant, you won't have to worry about scuffs during installation and AZEK Deck will keep looking

great for years.

AZEK Building Products has more than 2O years of experience in cellular pvc manufacturing. We make AZFK Trim. the #l brand of trim, and ,AZEK Moulciing. A,nd now we're bringing our leadership and innovation to AZEK Deck.

)

"

i

E? q ! a ! o c Aizq.ls AZEK) AZEKW, AiZE""tf) A(EIS AZEK)

es Tips for employing subcontractors

By Roy Burleson

By Roy Burleson

[NSTALLED sales programs suclceed or fail based on their ability to offer superior service.

The service quality the program offers will, in large part, be based on your installers' ability meet or exceed your customers' expectations. If jobs are not up to par or can't be completed on time, it's not likely the program will be of much value.

While it is recommended to use inhouse employees for most installed programs, it may not always be practical. Frequently dealers that use subcontractors are disappointed when their installers are not responding to their program as originally anticipated. Keeping quality-conscious, reliable subcontractors loyal to your installed program is sometimes a challenge.

Here are tips to consider:

Tip #1

Asking installers to bid on work can sometimes have a negative impact. It suggests that they will only get work when they are the lowest bidder. It also pits your installers against each other.

To earn an installer's loyalty, they should be treated more like a partner or team member. Establishine a unit-

pricing system that pays everyone a predetermined price for each unit of work completed might be a better approach than offering work based on a bidding system.

The unit-pricing system is fair because everyone is being offered the same unit-priced pay. However, the system will still benefit your better, more experienced installers because they are typically more efficient and will make more money on an hourly bases.

Tip #2

Don't make installers wait for their pay. Most don't make much, if any, profit in addition to the salary they draw from their business. I have seen a number of dealers let their accounting departments make installers wait two or more weeks for their pay. Many subcontractors will gravitate to customers that pay quicker. The faster you pay your installers, the greater likelihood of earning their loyalty.

Tip #3

Another way to earn an installer's loyalty is to pay them well. Dealers that enjoy successful, profitable installation services always speak of the fact that they take care of their installers.

Many pay their installers more than they would make on other jobs and point to several advantages of this practice. Installers that make more money tend to produce a superior product compared to their lower-paid counterparts. And when something goes wrong, installers that feel they haven't been beat up on price are more inclined to quickly take care of the problems. These installers help add value to the installed sales program, eliminate callbacks, and help justify

the dealer's installation pricing.

Tip #4

Make sure you have a competent installed sales manager. If your subcontractors don't have confidence in the abilities of your installed personnel, they will shy away from the program. They need to feel confident in the staff's skills and abilities to properly sell, price and schedule jobs.

Motivated installers want to stay productive. And since they are being paid for what they produce, they don't want to be slowed down by mismanaged jobs or scheduling issues. They lose valuable time and money if they have to wait for other issues to be resolved before they can perform their duties. lf your job manager is not adept at scheduling the installations properly, installers will quickly lose confidence in your program.

Tip #5

When asked, most professional subcontractors will gladly take care of their installation problems in a timely fashion. However, they don't feel they should be asked to re-install a defective product without being paid for the second install. If they installed the product properly the first time, they did their job. They should be paid for re-installing defective products unless some other arrangement has been made in the unit pricing matrix.

Maintaining an "inventory" of good installers is essential to the success of any installed program. When using subcontractors, treat them like team members and enjoy more meaningful, symbiotic relationships.

- Roy Burleson is director of Builder Solutions for Guardian Building Products, Greer, S.C. Contact him at (248) 760-5791 or r oyburle s o n@ bp.g uardian.c om.

lqlled

30 Tnn Mrncn.qxr Mlclzrxr Jurue 2008

TruCnolcr"

Walking the talk Making your store a little greener

rnHE demand for greener product choices is clearly I growing from both pros and consumers.

Last month we talked about what makes a product green and how to identify them. Stocking greener products will help retailers take advantage of this growing business opportunity. But is that enough?

Not necessarily. Advertising and other communications are essential, of course, but to effectively connect with the green customer, there has to be credibility behind the claims. If you, the retailer, are not "walking the talk," it may all be for naught.

Most everyone these days has heard the term "greenwashing." Cynical attempts to jump on the green bandwagon, misrepresentations of environmental claims, and hypocrisy are the kinds ofthings that earn the "greenwash" label and can result in losing customers fast.

So, what can retailers do to build lasting relationships with their new green customers? There are three really

By Jay Tompt

easy things a retailer can do to start building their green credentials: (l) become a community resource, (2) reduce operational impacts, and (3) increase staff's product knowledge.

Many cities have programs in place that make it easy for retailers to become a community resource for recycling batteries, paints, and fluorescent lighting. Being a collection point for these kinds of items provides a valuable service to your community. These programs, whether through your local city government, utility or third parties, also provide opportunities to connect with local schools and nonprofits that will be happy to promote the good work you're doing.

Make sure your store and yard are recycling their own waste, and inform your pro customers about recycling on the job site.

Operational impacts are sometimes hidden from customers, but doing something in this area can save money and build brand loyalty, especially when your efforts are known.

Change lighting from inefficient incandescents and Tl2's to CFLs, LEDs and T5's. Swap out your inefficient toilets for high efficiency toilets and/or waterless urinals. These measures often come with aggressive rebates-take advantagel

If your area has a green business program, participate!

Getting your staff educated about the greener choices on the shelf is the easiest of all to accomplish. Most manufacturers and distributors are more than willing to come into your store and educate your staff on the ins and out of their soy-based sealer, energy-saving-device, or zero-voc paint.

Product knowledge sessions are a good way to get even your crustiest department heads on board, and you can incorporate these classes into an in-store event for customers.

There are other things retailers can do, of course, such as put solar panels on the roof or use bio-diesel in your delivery vehicles. The main issue, however, is that retailers that make a genuine effort to reduce the impact of operations, educate staff, and take advantage of community programs, while stocking greener products, will establish themselves as the green leaders in their communities.

- Jay Tompt is vice president of green product development at Plan-It Hardware, San Francisco, Ca., which distributes green products for hardware and home improvement stores throughout Calfornia, and a leading expert in sustainable business and supply chain issues. He can be reached at info@plan-ithardware.com or 4I5) 359-9914.

GREEN-BLOODED: Friedman's Home lmprovement, Santa Rosa, last year launched a Green lt Yourself campaign at its stores in Santa Rosa, Sonoma, and Ukiah, Ca.

32 Tnn MBncruNr MlclzrNr Jur.re 2008

Btrls Pr@b q

Radladt

Blocks sun's radiant heat

. Enhance comfort

r Superior energy etficiency

r lncreased home value

o Cost-effective 0SB sidewall solution

o 0versize oanels eliminate need for horizontal joint

. Fast and easy to install

. Less wasted material

Oriented Strand Board

o Strong and durable Screen textured for a skid-resistant finish

r Excellent dimensional stability and surface uniformity

Roy0Martin manufactures a complete range of qualily oriented strand board, plywood, treated utility poles & piling, and lumber.

FsCCertificalions SW-tM-C0C-000186 SW-C0C-000695 SW-C0C-0005S6 Panel pr0ducts naIufactured by l||arte0 [imited Parinership

Available in 0SB

. Cost-effective, la bor-savi ng sol ution

. Meets shear and uplift code requirements in hurricane zone

.--, l.IftlafrA^-ltldr ttr t\F \7vr I ftr\t tLgTffiiCilA

rutrsrR^Na ,?#MrRAGE" RoyoN,tartin

Structural 0ne Rated 0SB Sheathing

o 0versize panels eliminate need for horizontal joint Royoilanh

Available in 0SB and Plywood

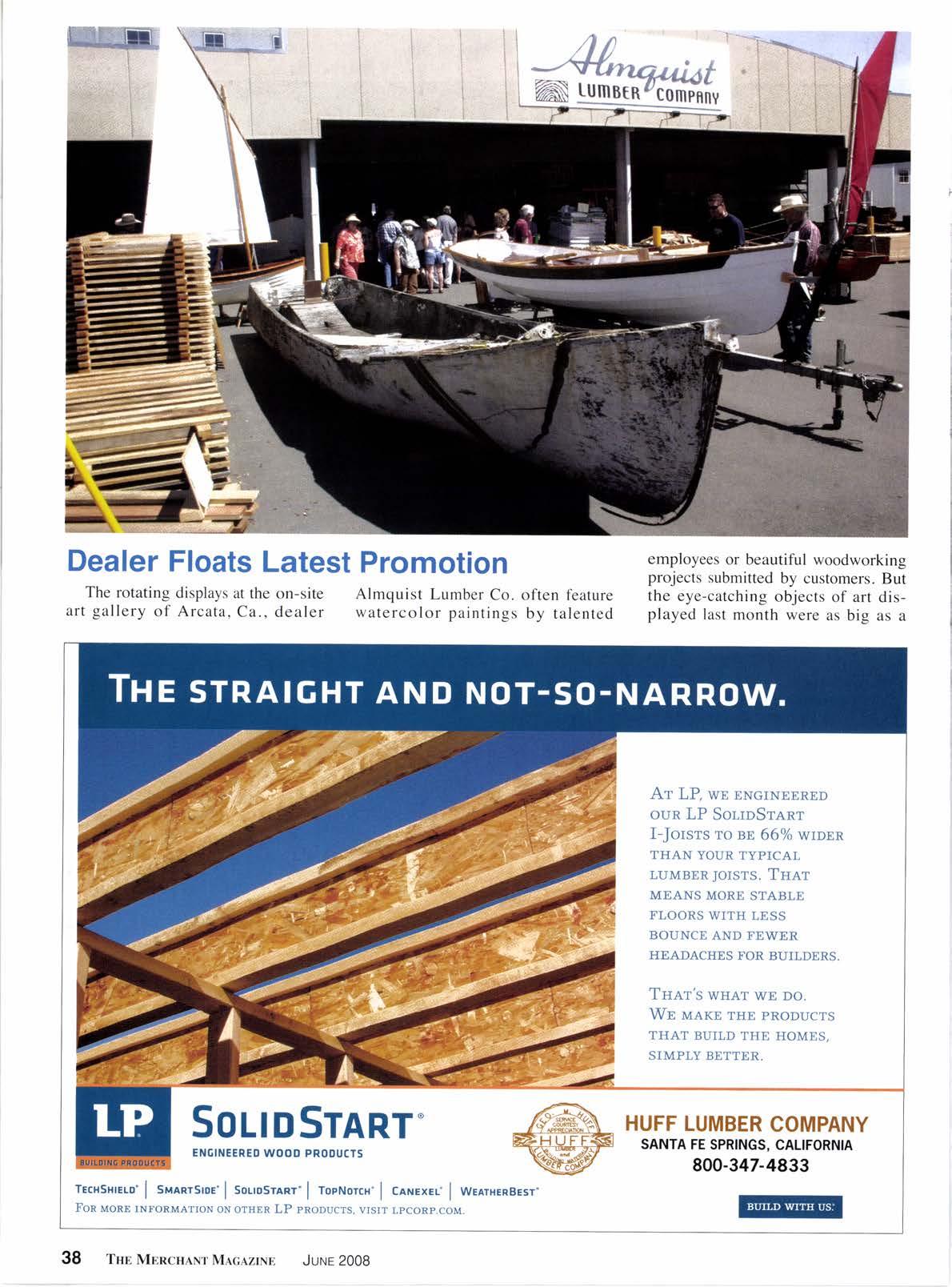

For complete details, contact: P.0. Box lll0. Alexandria, LA 71309.800-2S9-$174 tax: 318-443-01 59 . www.r0y0martin.com