How

In the wake of the growing and overwhelming international popularity of panettone, the return of the pandoro is official. It is another Italian sweet specialty meant to increase the family of festive leavened products, and his origins date back to the Middle Ages. The word pandoro comes from pan d’oro, i.e. golden bread, and it refers to the sweet white breads consumed only by rich people, which often contained eggs, butter, sugar or honey. The actual dessert was first mentioned in the XVIII century and included in the cuisine of the Venetian aristocracy. Contemporary pan doro is a sweet festive bread made with flour, eggs, butter and sugar, which is served with some vanilla scented icing sugar sprinkled on its surface. Through the choice of excellent ingredients and accurate production, artisan pandoro can become a wonderful example of professional craftsmanship, able to cope with the industrial production and to stand out for its fragrance and festive charm.

“Pandoro certainly starts at a disadvantage, boasting less tradition and less history than panettone, but as far as I can evaluate, its popularity is growing, especially if done well”. This is the trustworthy , one of the best Italian exper ts in the field of baked leavened products, who is also the author of two successful books exploring these themes by our publishing ). Here starts explai ning the difference between the authentic version of pandoro

The real pandoro cannot be made using only natural yeast, because it does not ferment properly. There is too high osmotic pressure exerted by the abundant sugars in the recipe, which slows down the fermentation capacity. We must consider that the content of sugar ranges from 18 to 20% and this is why it is neces sary to add some brewer’s yeast to obtain a uniform structure and a constant alveolation.

What is the correct way of making it?

Due to its high content of butter (24%), eggs and sugars, pandoro requires not only the use of brewer’s yeast but also three kneading phases (the original recipe mentioned five). A careful production method first results in chewing: the pandorottone (with an alveola tion similar to panettone) can never reach the melt-in-the-mouth classic texture of pandoro. Not to mention the aromas.

The sale volumes of panettone are now unattainable, but there is room for other artisan products. In large-scale distribution, the various industrial brands of pandoro reveal similar tastes due to synthetic flavoring, while we can customize our production, for example through high quality vanilla and rum.

Pandoro could be released from festive consumption and intro duced in everyday life, but we have to take into account its long processing method and its scarce practicality, that can make it anti-economic.

How do you see the combination with spreadable creams? This kind of combination is a good option to diversify our offer and make it even tastier. But a spreadable cream must not to be used as a filling, in order to avoid mould formation.

In this period I am further studying food preservation issues and, according to my tests, a good pandoro can keep its softness for up to a month. This is thanks to mother yeast, which can improve shelf life if well balanced, despite the presence of brewer’s yeast; otherwise, after 10 days it dries. We must not forget that pandoro contains eggs and the albumen dries a lot. Therefore mother yeast must be carefully treated, to obtain a good bacterial balance. Are there other preventive measures to be taken into account? The first rule is to understand that yeast must be managed in a precise way. While in a panettone the acidity is normal up to a certain pH value, in the pandoro it can be dangerous, because of the risk of implosion at the end of cooking process. It is therefore necessary to start at about 4.40 pH, always working with young yeasts for the various mixtures. And you must never let dough rise until it has doubled in size, in order to keep excessive acidification under control. This is the real secret!

If the recipe follows the original with a lot of sugar, it is necessary to bake it at 20°C less than panettone and to lengthen the cooking times. As the dough has a high fat content which causes water proof effects, even the core temperature must be 97/98°C when it comes out of the oven. At that point, a minimum structural failure is inevitable, but it is enough to cool baked pandoro down to 50°C, remove it from the mold and let it dry on a grill or micro-per forated trays, to allow air to circulate.

Many think that a big leavened product must rest at least 12 hours before being bagged. However, according to a research by the Università di Parma, it was certified that, when the temperature gap between the core and the environment settles between 9° and 10°C, there is no risk of condensation, that could cause mould formation. If the products is packed before 12 hours, the process becomes easier and the presence of sterile humidity is ensured inside, thus enhancing tasting, softness and shelf life.

Of course! I add a mix of cocoa butter and rum and 1 hectogram is enough for a 1 kg of powdered sugar, to make it fragrant, less hygroscopic and well settled on the surface of pandoro.

For 20 pieces (1 kg each)

First dough at 11 sugar g 255 whole eggs

g 640 pastry flour

g 830 mother yeast g 1,340 skimmed milk powder

g 100 butter 82% fat (blocks)

g 255

g 3,420 Dissolve sugar and eggs. Add flour and yeast, knead for about 10 minutes, add the butter and keep kneading for 20-25 minutes, with a final temperature of 26 ° C. Leave to rise at 28 ° C for 3 hours and a half, up to 1.4 in volume (1,450 g of dough in a 2-liter jug, reaching the edge). Then go on with the second.

Second dough at about 2.40 pm 1st dough

g 3,420 pasty flour

g 1,970 sugar g 665 osmotolerant brewer’s yeast

g 65 whole eggs

g 1,275 butter 82% fat (blocks) g 510

g 7,905

Mix the 1st dough with flour, eggs, yeast and sugar. As soon as it is strung, pour the ointment butter and work for 18/20 minutes. Leave to rise at room temperature or at 22 ° C in the cell. Check the development, which must be equal to 1.7 (1,180 g of pasta in a 2-liter jug must reach the edge). Emulsion butter 82% fat (blocks)

3,825 inverted sugar

830

whole eggs

g 255 egg yolks g 385 rum at 40°

g 385 cocoa butter

g 510 vanilla pulp

25

Third dough at about 6 pm 2nd dough g 7,905 pastry flour

g 2,805 whole eggs

g 2,080 granulated sugar g 1,275 skimmed milk powder

g 105 sugar

g 660 brewer’s yeast g 26 butter 82% fat (blocks)

385 salt

92

g 21,548

the 2nd dough, flour and eggs in a planetary mixer and mix for about 10 minutes. As soon as the dough is tight and strong, pour the sugar and powdered milk and knead for about 7/8 minutes. Add the second part of sugar and, after it is tight and strong, add the yeast, butter and salt. Make it tight and strong again properly, add the emulsion in a single solution and finish. Put the dough in a tub and let it rest for 1 hour. Divide it into 1,060 g pieces, make them round to obtain regular shapes, then let them rest at room temperature for 10 minutes. Shape the pieces again and put them into the molds. Let them rise at 24°C with 75% humidity for 12 hours. When ready, put them in the refrig erator at 4°C for at least 15 minutes and bake at 160°C for 60 minutes (97°C core).

Pietro Macellaro is the soul of the Cilento Agricultural Pastry Shop in Piaggine, in the province of Salerno, together with his partner Raffaella Renda. Here they explain their “new love” for pandoro, that comes from “the combination of our two core businesses, i.e. leavened products and chocolate.

The recipe is the result of our studies about cocoa and it contains undeodorized San Martin cocoa butter, a fat with magnificent aromas, that we chose after 6 months of testing. Now we have 10 cocoa butters available and it would have been worth studying 10 classic pandoro recipes using one at a time. Sometimes we get lost looking for perfumes and alter nature, without realizing that they are in front of us! “.

“I think that pandoro is more fragrant than panettone and it is perfect for breakfast all year round”, Macellaro adds. Their one is obtained through three kneading phases and the use of natural yeast, and the proper texture comes from the addition of elements, i.e. changing flour at each kneading phase in order to increase the global gluten content and to have extra proteins. Various cooling techniques are then employed to avoid the risk of collapse. Current experimentation is on classic pandoro, but their future goal is the study of creamy fillings with a suitable shelf life. www.pietromacellaro.it

Giambattista Montanari is the author of the books “pH 4.1 – Scienza e artigianalità della pasta lievitata” and “Omnia fermenta” by Chiriotti Editori (shop.chiriottieditori.it)

You never stop playing, studying and evolving with chocolate. It may seem obvious, but this is also a statements which sums up what we learned in the making of “Sul Cioccolato”. We had already addressed this topic in the past with the first-rate authors published by Chiriotti Editori, but the subject is now expressed and expanded in new ways thanks to Davide Comaschi’s book written with Marta Giorgetti

This project came to light thanks to Davide’s perseverance. We have known and followed him for years through various events and competitions - first of all the prestigious World Chocolate Masters 2013 - and his long working career in Italy and abroad.

His professional path is the result of both an intense desire to go on and of the flame of ambition, which he was able to tame and channel during the years through the development of his personal style, techniques and visions. The synthesis is illustrated in this volume and both the authors infuse their experience and creative force, that they balance with rigorous techniques and an inclination towards design and images.

The volume is the fruit of teamwork with the contribution of experts such as Luca Govoni for historical research and Heikki Verdurme for photography, thus increasing the value of the book.

Davide Comaschi’s name is inextricably linked with chocolate,because he was the first and only Italian to win the World Chocolate Masters competition and because of his incessant exploration in this field, as described in his book “Sul Cioccolato”

“The volume contains the story of my professional life.

Each page tells of a visceral love for chocolate from every point of view: history, botany, processing, sen sorial qualities, malleability... Davide’s deep respect for the matter shows that he knows it thoroughly to offer a new modern, reasoned and dynamic vision of chocolate. He adds both ancient and very innova tive recipes so as to submit original hints to readers, while ensuring precision and an intense aesthetic linearity at the same time.

“At a certain point in my career, the desire to express my concept of chocolate was urgent – he says –, as well as the desire to share my experiences in a constructive dialogue, choosing a simple, clear and uncomplicated approach. Therefore, with Marta we chose a proper language so as to be understood by all and to give useful insights and information, while maintaining technical accuracy”.

The book is not just a basic collection of recipes (even if there are many!), because of their additio nal hands-on perspective, which is useful to better

understand the transition from theory to practice. “It makes readers understand how crucial is to study before acting, to do research and experiment before establishing the rules”, Davide adds.

Chocolate culture, design and interna tionality are the three concepts that best define Davide Comaschi. Some months ago he came back to Italy from Belgium, where he worked as global creative leader for Callebaut. Today he is the first Choco late Academy Ambassador of Barry Calle baut’s corporate brands and he personally manages his own lab in Bergamo. After a long project of rebranding, it is there that his Galaxy Collection is produced, as well as a whole range of chocolate products, and where new ideas are constantly deve loped. The new logo highlights the initials D and C and the packaging focuses on yellow, while the triangular motive repro duce the exact design of Davide’s Galaxy chocolate.

”A story that I love to tell every day, with the ambition to learn, always. That’s why I work with passion, asking myself many questions and comparing myself to others, so as to be sure that every concept and every step can be immediately understood. I also wanted to convey all my love for chocolate in this book, strengthened by precision and creativity, study and training”

The exhaustive “Sul Cioccolato” is also the result of Marta Giorgetti’s expertise. Born in Senigallia, she had studied anthropolo gy at the University of Bologna, but when she realized that her love for confectio nery could not find its right expression in a home kitchen, she enrolled at Alma, the International School of Italian Cuisine in Colorno, near Parma. This is where she was struck by the charm of ingredients, the precision of recipes, the techniques and everything that hid behind a dessert. Afterwards, as an intern at the Pasticceria Martesana in Milan, she met Comaschi and the urgency to deepen her professio nal skills concerning chocolate grew, lea ding her to Chocolate Academy Milano. She has worked there since 2017 doing international research and development projects, taking care of educational pro grams and supporting external chefs and pastry chefs.

The relationship of exchange, esteem, trust and friendship between Marta and Davide, as well as months of study and work in common, are expressed in this book, whose strength and usefulness come from two visions, two approaches and two different sensibilities, which fit together harmoniously.

After the historical introduction by Luca Govoni, the world of cocoa is described through several chapters: from bean to cocoa mass, cocoa butter and cocoa powder; from processing to recipes; from pre-crystallization to ganaches, from chocolate tast ing to more than 50 recipes, exploring different areas of chocolate making, such as creams, tablets, choc olates, cremini, truffles, ganaches, biscuits, cakes, single portions and subzero, including semifreddoes, gelatos and sorbets.

SUL CIOCCOLATO - Davide Comaschi, with the collaboration of Marta Giorgettiphoto Heikki Verdurme - 400 pages - € 80 available in Italian - Chiriotti Editori shop.chiriottieditori.it

For 4 ø 18 cm cakes

COCOA AND ALMOND SPONGE CAKE egg yolks ................ g 160 whole eggs ............... g 100 granulated sugar ........... g 150 fresh egg whites ............ g 150 granulated sugar ........... g 100 finely ground almond powder .... g 100 flour W160 ............... g 100 cocoa powder 22/24 g 50 butter .................. g 100 In a planetary mixer fitted with a wire whip, whisk the yolks and eggs with the first part of sugar. In another bowl, whisk the egg whites with the second dose of sugar. Sift the powders together at least twice. Make a batter with some whisked eggs, some powders and the melted butter, in order to obtain a mixture as close as possible to the whisked egg one. Then add the remai ning powders, alternating them with the egg whites, always stirring from the bottom up with a rubber spatu la. Leave some egg whites aside, add the butter-based mixture and then the egg whites left. Spread a 8 mm layer inside a ø 16 cm chablon. Remove the chablon, place a cooking ring of the same diameter and cook at 210°C for 7-8 minutes, valve closed. Put the obtained sponge cake in the blast chill at positive temperature. When cold, turn it over and remove the silicone mat.

CARAMEL FOR THE BAVAROIS water

g

granulated sugar

g 30 35% fat cream

g 50 In a saucepan, caramelize sugar, water and glucose syrup at 176°C, then de-cook with the boiling cream.

HAZELNUT BAVARIAN fresh milk

g 205 granulated sugar

g 290 egg yolks

g 130 hazelnut paste

g 165 72% dark chocolate .......... g 55 gelatin 100 Bloom

g 18 water g 90 caramel

g 65 35% fat cream

g 460 Pasteurize milk, sugar and yolk in a saucepan at 82°C, then pour it into a planetary mixer fitted with a wire whip with the hazelnut paste, chocolate and the rehydra ted gelatin. Add the decocted caramel and mix. Lighten with the semi-whipped cream, mixing from bottom to top with a rubber spatula.

g 290 granulated sugar

g 85 egg yolks

g 85 hazelnut paste

g 85 72% dark chocolate

g 290 80% dark chocolate

g 90 35% fat cream

g 590 Pasteurize milk, sugar and yolks in a saucepan at 82°C. Pour the cream into a jug with the hazelnut paste and the chocolates; mix with an immersion blender at high

until you reach a perfect emulsion. Finally, add the semi-whipped cream, mixing from bottom to top with a rubber spatula.

te and hazelnut paste, emulsify with an immersion blender at high speed; add the hydrated gelatin and emulsify for 2 minutes, taking care not to let air into the icing. Cover with a film and chill in the refrige rator.

g 150

g 100 granulated sugar

50 orange peel

DE glucose syrup

1/2 vanilla pod

1/2

25 Grand Marnier

dark chocolate

50 Bring water, sugar, glucose syrup and the flavoring in gredients to the boil in a saucepan. Pour it over the dark chocolate and cool. When the temperature is below 50°C, add the Grand Marnier, then emulsify with an immersion blender at high speed. Cool in a blast chiller at a positive temperature.

CRUNCHY BRITTLE corn flakes

the sponge cake discs with 50 g of the chocolate and orange syrup and freeze. Pour 300 g of hazelnut Bavarian cream into a silicone mold, then put it in a blast chiller at positive temperature for 5 minutes. Pour 250 g of dark chocolate mousse, making it adhe re immediately to the crunchy brittle. Add another 100 g of chocolate mousse and finally the soaked sponge cake.

g 200 cocoa butter

g 50

g 100 hazelnut praline

dark chocolate

g 500 Put the corn flakes in a cutter, pre-crystallize the cocoa butter and pour into the bowl of the cutter to waterproof them.

the pre-crystallized chocolate and the hazelnut paste and mix well until a homogeneous mixture is obtained. Spread the mixture to 3 mm and cut out 15 cm ø circles. Place in the refrigerator.

pods

2

the orange cocoa butter and draw very thin lines with a brush on an acetate sheet. Once crys tallized, sprinkle some gold dust. Pour some pre-crys tallized 41% milk chocolate on it, then place another decorated acetate sheet and spread it very thinly with the help of a rigid tube. When chocolate starts to turn to cream, press it with a nut-shaped mold. Let it crystallize between two trays to prevent the decoration from de forming.

Make a chocolate strip for the cake outline, using an ac etate band decorated with some orange chocolate butter and golden dust. Let it crystallize around a 18 cm ø ring. Heat the icing to 35°C and glaze the cake at -20°C. Place the decoration in an elegant and clean way and end with the chocolate strip around the cake.

fat cream

g 750 inverted sugar syrup

g 105 granulated sugar

Bloom gelatin

a nonstick saucepan, bring the cream, vanilla and sugars to the boil. Add the sifted cocoa powder and bring back to the boil. Pour over the milk chocola

This product can be stored at a temperature of -20°C for 6 months, stored and covered without sudden changes in temperature, after being chilled to -40°C. The regenera tion of the product must respect the cold chain.

Store at positive temperature +0-4°C for up to 2 days.

Davide Comaschi Marta Giorgetti Photos Heikki Verdurme“Sul Cioccolato”

Chiriotti Editori shop.chiriottieditori.it

It was 2013 when Davide Comaschi raised the trophy of the World Chocolate Masters in Paris, after a challenge involving 19 chocolatiers from all over the world competing on the theme of architecture of taste. This victory marked his professional destiny, supporting his peculiar and unique rise as an Italian professional, who was then able to reach the international organizational structure of Barry Callebaut. Davide was able to influence the Italian positive reputation in the world confectionery, as well as the evolution of the ways to face international competitions. At that time, we realized how innovative Davide’s approach had been, both in the training method (under the supervision of Iginio Massari) and during the competition, with a hyper organized and personalized working box. Furthermore, he introduced many innovations which were much admired front the technical point of view. For example, the various elements of his chocolate sculpture were not glued together but interlocked and superimposed, using an “engineered” self-assembly technique, not to mention the airbrushing and flowers.

This splendid victory traced not only Comaschi’s career path, but also the stylistic code on which his brand is based today, in a geometric game in which the triangle reigns, together with sobriety and linearity. His performance in 2013 in Paris stated his aesthetic orientation.

Vegetables are the lead actors on the stage of Unforgettable, the Michelin-starred restaurant in Turin owned by Christian Mandura. They are used as ingredients in both savoury and sweet courses, as in the sorbets conceived with Giulio Rocci and Emanuele Monero, the gelato makers of Ottimo! Buono non basta in Turin

They have known each other for 7 years and shared not only friendship, but also a common penchant for food culture and quality. This is where their fruitful collabo ration comes from, leading to a range of gelato and sorbets a step ahead. Christian Mandura is the young chef of the Michelin-starred Unforgettable re staurant in Turin, which was opened three years ago, and Giulio Rocci is the gelato maker and owner of Ottimo! Buono non basta in Turin as well, with his business partner Emanuele Monero . Mandura and Rocci took inspiration from their respective places of origin. Christian

began his career at his family-run restau rant Il Geranio in Chieri, near Turin, and then took off to open his own business, focusing on a “vegetables in the center and meat and fish as side dishes”-culinary attitude. Giulio was inspired by his grand mother Maria’s recipe notebooks and her homemade gelato, which she prepared with a few available ingredients such as ice and her cow milk, and by his mother Carmen’s respect for food, a sort of ante litteram cult of sustainability. Both then left for international experiences: after having been commis de cuisine at the Miche lin-starred Del Cambio restaurant in Turin,

Christian flew to Noma in Copenhagen, while Giulio found inspiration at Davide Scabin’s Combal Zero in Rivoli, worked in catering until 2006 and then turned to gelato making.

Being attracted by what lingers behind the scenes – such as the meaning of working in the food service sector, of food ethics and sustainability – Christian and the gelato makers carefully design new dishes and special gelato desserts. In addition to their own activity, Rocci and Monero conceive specific recipes for Unforgettable and their common ap proach is based on placing vegetables in the limelight, while leaving the rest in the background. An innovative attitu de, which brings out both their “childish hearts” and affinities. “We have made a small, but huge revolution within us”, the chef says.

At the single table of Unforgettable, guests share the restaurant experience together and vegetables are not “only” in the limelight, but the main courses themselves. The same happens in Dessert in a stone and radish with coconut gelato , served with a salad, or Gelato with cuttlefish and lettuce which, as we shall see, are both a prelude to Vegetables in the limelight , where some elements of the previous savory courses are transfor med into sorbets. These combinations are the result of Christian, Giulio and Emanue le research, which is focused on unpre cedented combinations of taste and the reduction of added sugars, making

best of the naturally occurring sugars contained in vegetables.

interesting experiment – Rocci says –was the recipe of a prizewinning gastrono mic gelato which was awarded the Premio Menzione Speciale per il Legame con il Territorio (a special prize for the recipe territorial links) last year, on the occasion of the Sherbeth Festival. Having to send it, we thought of a “Turin postcard”, a concentra te of our typical flavors. This is how Baci da Torino was conceived, a recipe expres sing a new concept which overcame the

distinction between gastronomic gelato and the artisan product sold in gelato shops. It included some typical Piedmonte se ingredients from different areas, such as the hazelnuts from the hilly area of Langhe, porcini mushroom from the mountains, cof fee and chocolate from the confectionery tradition of our city, noisette butter for its culinary role... A surprise for the palate!”.

The following dessert includes some vegetable ingredients already tasted during the meal. The photo shows seven sorbets and here there are four recipes. Depending on the season, other suitable vegetable ingredients can be aubergines, fennels, capers, fava beans, broccoli…

TOASTED LETTUCE SORBET toasted lettuce

500 water

250 trehalose

50 dextrose

130 pectin

4 white vinegar

4 lightly fired lettuce

200 inulin

10 Toast 500 g

obtain 350 g

white vinegar.

inulin.

POTATO AND OIL SORBET potatoes

trehalose

dextrose

“The difficulty consisted in obtaining a taste as faithful as possible to the corresponding vegetable chosen by Christian”, Rocci explains. The sorbets are the result of a long preparation time, in order to maintain the flavour intensity of each vegetable, in a balance between sugar and salt, and with a particular attention to the unconventio nal temperatures (-7 / -8 ° C instead of -10 / -12 ° C as usual) required to keep their structure. The same special care is taken to match the small vegetable sorbetto spheres to a suitable serving dish. Freshness, taste and a minimalistic aesthetic choice are thus included in a surprising dessert, that “summarizes” the menu and opens to new appealing vegetal scenarios.

Emanuela Balestrino Photos by Olivia Rotondosalt

6 extra virgin

the

blend

TOMATO SORBET sweet tomato

dextrose

trehalose

vinegar

2 tomato extract

70 pectin

4

a boil and add the salt.

the tomato water with sugars and

touches by the chef.

SORBET steamed

dextrose

trehalose

pectin

sift,

Mandura Unforgettable Torino Rocci ed Emanuele Monero Ottimo! Buono non basta Torino

Being attracted by what lingers behind the scenes – such as the meaning of working in the food service sector, of food ethics and sustainability – the chef and the gelato makers carefully design new dishes and special gelato desserts

When you mix passion with experience, the promise of a masterpiece is never far away. For over 75 years ICAM Professional and Agostoni have fed the creativity of pastry chefs, chocolatiers and ice cream makers worldwide. And now we are back with the origin of taste: we are back with our Italian chocolate.

CHOCOLATIER

CHOCOLATIER

Frigomat chose to preserve existing resources through environmentally friendly solutions with the lowest possible impact. The company initiated a process of ecological transition of its activities some years ago and they recently started to apply the concept of ecological sustainability to machinery production, also due to the current required industrial standards. Their new range now employs energy and water saving technologies and a natural refrigerant gas to reduce its environmental impact, while ensuring higher levels of efficiency at the same time. The goal is to convert the entire Frigomat range of gelato and pastry machines through sustainability standards, in order to preserve and transmit the “taste” of a cleaner world to future generations.

The GX series is included in the above mentioned ecological transition project through the use of an eco-friendly natural refrigerant gas, and the adoption of highly efficient refrigeration circuits, which allow consistent water saving (up

to 50%). The series is equipped with 7 electronic programs for the freezing of gelato and slush mixes, with the possibility to produce 8 different flavours in front of the customer. Moreover, a practical quick release system for spatulas protects gelato against the risk of contamination; the food-grade rings allow perfect thermal insulation of the tanks; an

For more than 75 years, ICAM Cioccolato has been a spokesman for the Italian excellence in the art of chocolate making and two professional brands have been conceived to satisfy the growing needs of chocolatiers, pastry chefs, and gelato makers. Icam Professional was launched in 2004 while Agostoni in 2018 and from then on their ranges are constantly being expanded to guarantee excellent performances. The latest additions include Chocolate Nuances range to the ICAM Professional and two new chocolates to the Agostoni Monorigine.

Chocolate Nuances are chocolate chunks for baking made with white or milk chocolate,

a truly unique product in terms of shape, texture, and taste. These 100% natural recipes are designed to withstand baking at high temperatures, making them perfect for leavened products, croissants, baking bases, cookies... and more. Moreover, with the addition of about 6 % of cocoa butter, these chocolate cubes turn into true chocolate couvertures to be used in pastry, chocolate, and gelato making. There are five available flavours: raspberry, pistachio, passion fruit, blueberry, and milk and coffee.

The Agostoni Monorigine range now includes Cuba Dark Chocolate 66% and

anti-fog system avoids condensation under the lids (optional). The series is certified by Italian university research labs which recognize the high hygienic and food safety standards of the GX machines, which can be installed in shops and restaurants in order to expand one’s offer and to have an independent gelato corner.

frigomat.com

Madagascar Milk Chocolate 40. The Cuba chocolate features a rich showcase of Cuban flavours, giving it an intense taste with multiple nuances: wood, hints of dried fruit and spices, accompanied by a slight acidity and delicate cocoa notes. It is ideal for enrobing and in the production of ganaches, chocolate cups, creams and mousses. The Madagascar milk chocolate has pleasant notes of yellow fruits and hazelnut endnotes resulting in a smooth and palatable taste. It is recommended for enrobing, chocolate cups, creams and mousses. Both products are excellent for chocolate tastes, that are particularly suitable in the cold season. icamcioccolato.com

The name seems to be echoing the shape of the new store of the artisan dairy farm located in Bagnolo Piemonte, in the province of Cuneo, even if calling it La Fetta (the slice) is really an understatement. It tells the story of a family-run business, whose roots date back almost a century ago in 1928, when great-grandfather Carlo del Clat began producing butter and cheese in the Piedmontese countryside. The story continues today and the innovations introduced by the young generation include both the respect of tradition and some novelties, such as the production of gelato, as Valentina Turina tells in the following interview

It is not only the icing on the cake for our family business, but also a new starting point. We didn’t have a shop before and our wish to come into direct contact with clients had been in the air for some time. We imagined a formative and informative place, where our dairy experience and culture could be transmitted. Therefore the store is like a window onto our world: design and materials are the same as those used in the dairy premises, ranging from stainless steel to the wooden boards which were salvaged from the old seasoning cells. The introduction of gelato making is another way to give value to milk production and to bring our family together.

Behind La Fetta there is a ninety-yearold story. Founded by Carlo del Clat’s, the dairy factory was handed down from one generation to another. Each of them innovated and developed the activity in his own way, introducing new produce and technologies. Today we –me and my brother Fabrizio – carry on the business, with the help of the other members of the Turina-Colomba family and 9 employees, while our brother Lorenzo did not follow the family footsteps. His passion for pastry making led him to travel around the world, at least until today, but his experience in gelato and chocolate making helped

us in introducing the production of high quality gelato.

You inaugurated during a difficult period. How did you live the first months of the pandemic?

There were moments of suffering: suddenly everything stopped, our customers closed or severely limited their activities and we had to do the same. However, this forced setback allowed us to analyze the market in order to re-examine our range and look for new opportunities. Our work is in symbiosis with the agricultural world and we feel responsible towards the

farmers we collaborate with every day. It was necessary to find a solution to make the most of the milk available and the production of gelato offered the opportunity to turn to reality a longcherished idea.

Local sources are the basis of your business: can you tell us more?

We have a close connection with our terroir. Milk collection takes place within a 20-km radius from our factory, involving some small farms which raise mostly native breeds, whose diet largely depends on long-duration pastures, and the same happens with other ingredients. Whenever possible, we buy locally sourced jams and fruits for yogurt and gelato, and choose local varieties because of their organoleptic characteristics. The hazelnuts come from our own groves, and one can glimpse them through the windows.

Is there a broader concept behind this? Because of our close connection with terroir, we are carrying out a hay milk project. Using milk of own production and the one supplied by 4 more producers, we launched a grass fed line called Fit-Milk. It consists in feeding the cows almost exclusively with grass and/ or hay to obtain a kind of milk which has very interesting organoleptic and nutritional characteristics. Unlike corn and concentrated feed, grass is rich in polyunsaturated fatty acids and especially omega-3, and these features remain in the end product.

It means having great respect for animals and much lower yields than the average (our cows produce on average 5-12 liters of milk per day, against 40-60 in intensive farming), but the result is exceptional in terms of quality and organoleptic profile, without considering animal health and longevity. It is no coincidence that our cows reach and often exceed 15-18 years, while the animals in the intensives now have an average life of only 4-5 years. We strongly believe in this project and we are convinced that the future of quality cheese-making can only go in this direction. And our customers agree too. We produce fresh milk, long fermented yoghurt, skyr (or Icelandic yoghurt), whey lactic drinks and some cheeses. The latest addition is gelato, which perfectly resumes our point of view, which is also respectful of nature, seasonality and well-being of those who consume it. In fact, our recipes require a minimum use of sugars, while enhancing raw materials.

This decision is not totally original. About forty years ago we produced it, but then, due to the expansion of dairy production, we had to make different choices. Today, thanks to the opening of our store and the new La Via della Pietra cycle path, which connects the most important small cities in this area (Saluzzo, Barge, Bagnolo and Pinerolo) and is just a stone’s throw away from us, it was natural to reconsider

gelato as a complementary product. Even more so by having specific skills in the family. We studied it in every detail with the idea of offering the best recipes we are capable of, ranging from the careful choice of ingredients to glutenfree waffles.

Identifying ourselves in just one product is really difficult. On the contrary, our strength is precisely having a structure of such dimensions as to be able to offer a great variety of products resulting from our passion and knowledge.

In recent years we invested a lot of energy in the Fit-Milk project, involving universities and sports trainers in our research. We felt the need to understand and know more. This is how the incredible qualities of our grass milk emerged.

Even today, there is very little scientific literature on the subject and we feel proud to have contributed to research in this field. We are going to develop our project further and we hope to obtain one day a production specification of hay milk, both for its qualities and for animal welfare. At the same time we would like to widen our gelato range with low-sugar-content tastes, obtained with few ingredients and suitable for also for athletes, who would thus be able to indulge in this pleasure without any problems. fit-milk.com

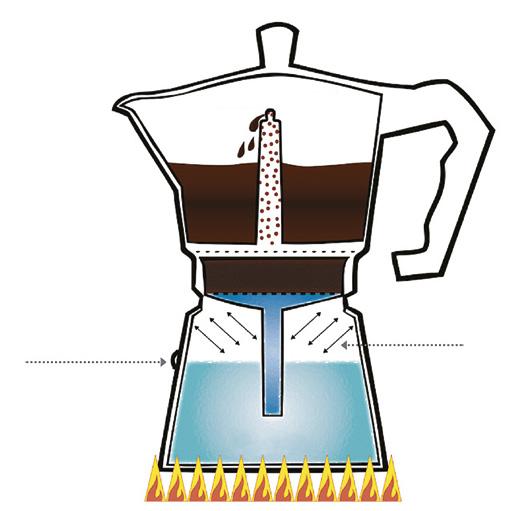

The moka pot is a stove-top or electric coffee maker that brews coffee by passing boiling water pressurised by steam through ground coffee. Named after the Yemeni city of Mocha, it was invented by Italian engineer Alfonso Bialetti in 1933 and quickly became one of the staples of Italian culture” (source Wikipedia).

Nowadays the spread of moka coffee goes beyond the Italian borders and I want to explain how to choose a moka pot and to give technical and practical information and tips for the proper use and maintenance of this fantastic object.

Today there are many models which mainly differ depending on materials.

Quick to warm up and light, it requires special precautions, especially due to the “softness” and porosity of aluminium. It must always be cleaned after each use and it must not be wet when you put it back. It requires constant decalcification and a close attention must be paid when emptying the filter “beating” it to remove the exhausted coffee, to avoid dama ges and to ensure an adequate seal of the gasket. Aluminum could tend to give a “metallic” or even burnt flavor to the drink, because it warms up very quickly and homogeneously.

Very sturdy, a steel moka pot ensures a good and homoge neous heat conduction, even if it is slower than aluminum in reaching high temperatures. In some cases the filter is made of steel while in others it is made of aluminum, with the conse quent recurrence of the problem indicated above. The latest models feature a silicone gasket that improves sealing. Steel pots are generally heavier, but they have the advantage of not giving any flavor to the coffee and keeping it hot for a long time.

Aesthetically beautiful, with steel or aluminum bottoms and ceramic tops, I consider them among the best coffee makers, as in the phase of passage in the chimney and subsequent descent, coffee passes at lower temperatures and preserves its aromas.

Although delicate, they are beautiful and allow to watch the coffee-brewing process. In some ways, I find them “hypnoti zing” but unfortunately, having a minimal heat loss, they tend to release a slight burnt aftertaste.

They are the latest generation models, suitable only in mi crowave ovens, and combine advantages such as lightness, aesthetics (there are available in all shapes and colors), the absence of coffee flavors transfer (as long as you do not leave the drink in the moka pot for a long time!), ease of cleaning, hygiene and quick usage. In about 2 or 3 minutes you can obtain a well-made coffee.

In general, all kinds of coffee must be stored at low temperatures. In the case of ground coffee for moka (in a can or packet), we must take into consideration some facts. According to a statistical analysis, more than 70% of consumers keep their ground coffee in a cupboard above the stove in the kitchen, as a convenient and usable place when they have to prepare their coffee pot in the morning, still a little asleep… But never forget that a 250 g can or packet lasts on average a week and let’s add that, when cooking, around 60°C develops in that cabinet. In those conditions, coffee is already rancid after 3 days! To provide an optimal solution to improve conservation, someone says that coffee should be stored in the refrigera tor. Better there than in a hot place, especially considering that moisture in ground coffee has a little influence on the extraction performance.

The use of a moka pot is among the simplest and most efficient ways of making coffee, but sometimes some practices “handed down” from generation to generation are not exactly the best. Here is the correct procedure, taking into account that the dose of coffee ranges from 5 to 7 g per cup, with a volume of water in the boiler of approximately 40-50 ml per cup. Grinding must ensure an adequate particle size, neither too fine as for espresso coffee, nor too coarse as for the filter system. In the first case we could have a difficult extraction, an excessively long percolation time, burnt coffee flavors and obstructions. In the second case, the passage of water is too rapid to preserve the coffee flavors.

After checking that the coffee pot is thoroughly clean and that it does not exhale musty or stale smells, fill the boiler with water up to approximately 0.5-1 cm from the valve. Many ar gue that cold water is a must, but the use of hot water speeds up the boiling process, thus reducing the risk of burning coffee. In some cases, if water lacks salts or is too rich in chlorine, I

suggest the use of bottled water with a medium fixed residue. Water salts are useful to dissolve oily coffee particles. Fill the filter but absolutely avoid pressing coffee! This would slow down the passage of water causing it to burn. Instead, try to settle it, lightly tapping the filter or gently “banging” the support base of the boiler.

Avoid making holes in the coffee panel after putting it in the filter. This would only create preferential passages for wa ter, without allowing it to “exploit” the coffee properly.

Check that the upper edge of the filter and the threads of the boiler are clean and free of coffee dust, which would compromise the seal of the gasket.

Prepare a cup full of cold water, about the same amount that you did not put in the boiler to reach the valve. Place the coffee maker on a flame (not too high) and consider that, thanks to correct grinding and an adequate ratio of coffee in the filter, 1 to 2 minutes should pass from when the water boils to when the dispensing from the column ends, according to the size and material of the coffee maker. As soon as you see the coffee pouring out, pour the cold water into the upper part. In this way the first drops, instead of encountering the boiling metal, will avoid burning thanks to cold water.

When the coffee brewing process ends, remove the coffee pot leaving the lid open, even if you still hear some gurgling puffs. Before serving, stir it slowly in order to mix the coffee resulting from the first and the last brewing phases.

Have a good coffee everyone!

The optimal coffee dose ranges from 5 to 7 g per cup, with a volume of water in the boiler of about 40-50 ml

Gelecta is a 100% pure gelatin in granular form that can be used directly as it is without pre-hydration, for a perfectly-defined texture. It has the capability to cross-link with the smallest free water particles in a recipe (brought in by milk, creams, fruit purees…). Therefore, professionals can take advantage of the easier, faster and more precise performance of this innovative product. Even if it could be pre-hydrated, when it is used without pre-hydration, hot and directly in a recipe, there is no extra water in-take which can be responsible of a a dramatic reduction of the texture performance. It can be employed if necessary to achieve the desired results and when needed during pastry production, thus leaving more room for creativity. In certain circumstances Gelecta can be the perfect solution, such in the case of a whipped white chocolate ganache that may need to cope with thermal and mechanical stresses, while maintaining a soft and creamy texture over time and without losing its shape. The compromise between creaminess and stability could be achieved rebalancing the recipe, but it is possible to obtain the same result quickly and easily by adding 0.5%-0.8% of Gelecta to guarantee a solid structure without altering its lightness.

fresh whole milk g 310 Gelecta g 10 white chocolate g 380 35% fat fresh cream g 500 Boil the milk and pour onto the chocolate and gelatin powder. Let the chocolate melt, and remove part of the milk to make a bright and elastic emulsion with a spatula. Add the milk little by little, starting to whisk with a blender. Drizzle in the cold cream, continuing to emulsify with the blender, and leave to crystallize in the fridge for 12 hours before using. Whip in the planetary mixer with the beater at medium speed until the texture is creamy and firm. gelecta.it/en/perfect-texture/

SIGEP - The Dolce World Expo will be the first exhibition organized by the IEG’s Food & Beverage Network (which includes Beer&Food Attraction and BBTech Expo,19-22 February in Rimini, and Cosmofood, in November in Vicenza) in 2023. The 44th edition will be held at Rimini expo centre from 21st to 25th January and simultaneously the 7th edition of A.B. Tech Expo dedicated to bakery technology and machinery, from storage to dough and preparation, will also take place. All the “traditional” sections will occupy the entire expo surface, giving room to the collaboration among artisan and industrial associations, national and international associations of gelato makers and pastry chefs and bakers, baristas and coffee specialists. Business, training, media and foreign professionals (with the support of the ITA-Italian Trade Agency) will make Sigep a true catalyst, where ingredients and products, the latest new machinery and systems will find their place, with and an increasing close attention for sustainability issues concerning furnishings, equipment and packaging. Products and visions will be closely intertwined to illustrate the evolution of the international markets, thanks to specialist medias and experts. The Vision Plaza format will welcome specialized analysts of the out-of-home network

including the major global macro-areas, providing useful tools to operate in foreign markets.

For over 40 years, Sigep has been synonymous of big international and national competitions. In the six Arenas, contests will alternate with live shows with renowned professionals and talks. The Dolce Arena will host the competing talents of the Gelato Europe Cup, which is the preliminary qualifying phase for the European teams leading up to the Gelato World Cup at Sigep 2024; the Junior World Pastry Championship; the Ladies World Championship, which will elect the next Pastry Queen, while the Gelato Arena will host live shows and talks. The Pastry Arena will host the Italian Senior Championship and the Italian Junior Championship, as well as SIGEP Giovani. In the Coffee Arena, the best Italian baristas will compete in seven national championships valid for the World Coffee Championship. In the Bakery Arena the international bakery contest Bread in the City will take place under the aegis of the Richemont Club. In the Choco Arena demos and talks will give room to master chocolatiers and cacao experts. sigep.it

FOR THE COFFEE CREAM 100% Arabica coffee beans

g 30 cream g 197 sugar

g 40 egg yolks

g 47 corn starch

g 10 rice starch

add the sauce. Pour everything into 4 straws capped at one end. Let it solidify.

FOR THE CHOCOLATE CIGAR Tanzania chocolate ....... to taste Wrap a cigar with food film. Melt some Tanzanian choco late in a tall, narrow container without exceeding 32.5°C. Dip the cigar in the chocolate and let it air dry. Repeat and then unmold.

1

g 6 salt

the coffee beans into the cream and let them rest overnight. Mix sugar, egg yolks, starches and salt. Strain the cream and bring it to a boil, then pour it hot into the bowl containing the yolk mixture and mix. Return everything to the saucepan and cook up to 84°C. Put the cream into a bowl and cover it with food film. Let it cool completely.

FOR THE RUM GELÉE water

50 glucose syrup (paste)

30 cream

45 rum

100 gelatin

2 To prepare the rum sauce, pour 100 g of into a saucepan and cook until it reaches 30 g. Then mix the water, glucose syrup and gelatin in another saucepan, bring them to a boil

FOR THE ASHES eggs g 119 sugar

g 62 espresso coffee

g 26 salt

g 1 00 150W flour

g 83 potato starch

g 9 salt................. to taste Whip the eggs, sugar and coffee. Sift the flour and star ch, then add the salt. Combine the powders with the egg mixture in several stages, mixing from bottom to top. Put everything in a mold and cook for 20 minutes at 190°C; let it cool, unmold and let it dry in the air. After that, crumble coarsely.

WINE Caluso Erbaluce Passito

to taste

Fill the chocolate cigar halfway with the coffee cream, then add the rum gélée. Dip the tip of the cigar into the dried ashes and place it on an ashtray. Serve with a glass of Calu so Erbaluce Passito wine.

This dessert is inspired by my passion for the Latin dan ces. Their historical origins go back in time to one of the greatest human tragedies in history, namely the slave trade of the 16th and following centuries. At that time, with the European surge in demand of products such as coffee, cocoa and sugar cane from the Caribbean colonies and the south of the USA, the deportation of African slaves to tho se luxuriant lands increased, in order to force them to work in the plantations and grab all the profits. It was precisely in the coffee and cocoa plantations that men and women, to brighten up their hard days a little, began to move to the rhythm of the claves (a percussion instrument composed of two sticks), thus giving rise to the first Caribbean dances.

This dessert includes a sweet version of the typical Cohiba Cuban cigar. It has a Tanzania dark chocolate “crust”, to represent the African lands through its intense flavor of cocoa and spices and a fruity final note. Inside, the crea miness and sweetness of the cream flavored with 100% Arabica coffee beans recall the Caribbean plantations, whi le in the “heart“ of the cigar there is gelée made with the 15-year-old Matusalem Cuban rum, which is produced by the historic distillery founded in Santiago de Cuba in 1872. In sharp contrast and deliberately separate, I wanted to represent Europe in a glass through one of its best “fruits”, i.e. wine. I chose the Erbaluce Caluso Passito from my ho meland, the Canavese area in Piedmont, with a fruity and flowery taste. Finally, the name of my composition refers to 20th parallel north, the imaginary line that unites Africa to the Caribbean, to connect these lands once again.

Samantha Rigotti IFSE student photo Saverio Pisano ifse.itROBOcream RT51 and R51 are precious tools for chefs and pastry chefs. Any recipe can be developed with great attention to details, minimum bulk and ease of use, ensuring high quality even in case of small quantities. These machines can freeze up to 2 liters of gelato and pasteurize and cook up to 5 liters, in addition to being employed for the making of other products such as semifreddoes, cakes, granitas, custard creams, choux pastry, jellies, jams, yoghurts, pannacotta, mousses, marshmallows, nappage, rice for pastry, béchamel, polenta, soups…

The ROBOcream range is a modern and advantageous innovation conceived for artisans, which helps them to work in a relaxed way and to enjoy each step of the development of their recipes, with the certainty of obtaining excellent final products. robocream.com

The Kyoto800 mould by Silikomart conceived with Laurent Moreno is made of high temperature resistant material (up to 180°C and 356°F). It ensures easy unmoulding thanks to its non-stick characteristics, it is dishwater safe and impact resistant. Kyoto800 comes with a cylinder insert for the shaping of a cake with an internal cavity, that can be filled with jelly, cremino, caramel… The result will be flawless and will attract everyone.

professional.silikomart.com

SINE range is the natural response by Menz & Gasser to the increasing demand for quality and to the trend of healthy eating. The word means “without” in Latin and it refers to some features of these extra jam line, such as the “clean” label and a limited sugar content, which is balanced by a high fruit percentage (60%), and they all contribute to an authentic and delicious consumer experience.

SINE is a versatile range of products which can be used in many different ways. For example, they are great as fillings before and after baking, as well as flavourings for doughs, and can even be frozen. Their low sugar content compared to traditional jams ensures a soft structure even after freezing, making them suitable as filling for cakes and single portion products and for gelato making. The range include 5+1 flavours: classic apricot, strawberry, cherry, berry, blackberry, and the unique peach and passion fruit.

“We have always paid close attention to the requests of consumers – they say in Menz&Gasser – and this is why we constantly take into account new market trends in order to offer innovative solutions to today’s needs and a high reliability to professionals”. menz-gasser.it

The latest development concerning Carpigiani in 2022 is a wider space dedicated to pastry technology. The world renowned Italian company based in Bologna presented the new Pastochef RTL-I, the latest models included in the Pastochef RTL range. The machine is equipped with an inverter that can vary the processing speed to improve the texture and structure of pastry mixes. It is available in three versions –Pastochef 18 RTL-I, Pastochef 32 RTL-I and Pastochef 55 RTL-I – each one with a different production capacity. The machines offer 18 pastry programs, 9 for chocolate, 8 special programs for desserts, 7 for savory mixes and 4 for gelato making. The entire Pastochef RTL range, with and without inverter, is designed to automate the processes that require time and manual effort. Heating and cooling are carried out thanks to a “dry bain-marie”, thus avoiding potential incrustations on the cylinder’s surface and guaranteeing heat exchange, optimal performance and a reduced energy consumption. A display guides the operator, showing the production steps, temperatures, and suggestions about the addition of ingredients during the various process stages. carpigiani.com