Canada Post Canadian publication mail sales product agreement No. 40841632. A special edition of Collision Repair Magazine. 86 John St. Thornhill, ON, L3T TY2 SPECIAL EDITION #1 SOURCE FOR THE INDUSTRY’S HOTTEST PRODUCTS! ABRASIVES | ADHESIVES | ALIGNMENT | RECYCLING | WELDING | TOOLS | SCANNERS | SOFTWARE | PAINT | PAINT HARDWARE AND MORE BUYERSGUIDE.COLLISIONREPAIRMAG.COM 100+ PRODUCTS AND SERVICES INSIDE

3M™ Net Abrasives Introducing For automotive repair. Learn more at 3M.ca/NetAbrasives For additional information, including important safety and warranty information regarding 3M Automotive Aftermarket products, visit 3M.ca/NetAbrasives. 3M, 3M Science. Applied to Life. and Cubitron are trademarks of 3M. Used under license in Canada. © 2022, 3M. All rights reserved. All other trademarks are the trademarks of their respective owners. 2201-22999-E Using the right abrasives can allow shops to improve productivity and help eliminate rework. Our dust extraction systems paired with our new 3M™ Net Abrasives can change the way shops work. Prime Performance Peak Productivity Virtually Dust-Free Premium 3M™ Cubitron™ II Net Abrasives Advanced 3M™ Blue Net Abrasives

CONTENTS BUYER’S GUIDE 2023 3 SPECIAL ANNUAL EDITION CONTENTS 06 PUBLISHER’S PAGE 22 GET A GAME PLAN 24 MORE TECH, MORE TROUBLES 26 IN FOR A SHOCK 28 STAY OR GO 30 GUESSING GAMES 35 COMPANY PROFILES 92 THE SYNTHESIS OF OUR INDUSTRY 98 THE LAST WORD 2023 08 18 78 FEATURES Looking for some upgrades to your business? Join us for a shopping trip through the hottest products on display at SEMA 2022.

There are those who understand artificial intelligence, and those who will be left behind, according to Columbia University’s Dr. Hod Lipson.

CARSTAR welcomed local franchisees to its Hamilton, Ont. training facility in early October, where some Ontario-based owners got a refresher on ADAS calibration.

CONTENTS 4 BUYERSGUIDE.COLLISIONREPAIRMAG.COM SPECIAL ANNUAL EDITION CONTENTS 2023 HEALTH / SAFETY TOOLS PAINT AUTO GLASS PAINT HARDWARE WELDING ABRASIVES 48 60 88 54 ADHESIVES 52 64 PDR/NON STRUCTURAL RECYCLING 82 84 SCANNING/ESTIMATING 80 58 72 SOFTWARE/MANAGEMENT 76 94 ALIGNMENT / MEASURING

BY DARRYL SIMMONS

BY DARRYL SIMMONS

In your hands, you hold an important tool for making your business run as effi ciently as possible in the modern age. With information drawn from the resources of Collision Repair magazine’s more than 20 years of publication, the 2023 Buyer’s Guide and Business Directory offers the most com prehensive overview of the products being used in the most forward-thinking colli sion repair centres.

There may have been a day back at the beginning of the collision repair industry when all the tools you needed were a good hammer, a paintbrush and a trusty wrench,

This is where the Buyer’s Guide comes in handy, it serves to guide shop owners through the maze of new products and possibilities. By delivering as much infor mation as possible, you are given the best tool to make the right purchasing decision. In this resource, you can find an overview of collision repair resources, with a broad directory of information.

The guide also acts as a reference for contacting the trainers, insurers, manufac turers and sales coordinators. You might already know how to reach out to them, but remember those times when you went

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER Orest Tkaczuk | orest@mediamatters.ca

EDITOR Allison Rogers | allison@mediamatters.ca

ART DIRECTOR Yvonne Maschke | yvonne@mediamatters.ca

STAFF WRITERS

Max Reid | max@mediamatters.ca Kate Ng | kate@mediamatters.ca

GRAPHIC DESIGN INTERN Cynthia Lee | cynthia@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT Wanja Mann 647.998.5677 wanjamann1@gmail.com

AUDIENCE ENGAGEMENT MANAGER James Kerr | james@mediamatters.ca

DIGITAL OPERATIONS MANAGER Cassie Doyle | cassie@mediamatters.ca

CONTRIBUTORS

Stefano Liessi, Nancy Rolland, Tyler Majer

SUBSCRIPTION $15.99 For the Special Edition

but today’s repairs are infinitely more com plex. Shops are inundated with possible purchasing decisions, many of which are relevant and cutting-edge products and services that have the potential to make a positive impact on getting the job done bet ter and more efficiently. It’s not an issue of if these new technologies will help you. Some of the best engineering minds in the world work on better solutions for the industry’s problems.

The question you must ask of every new product and service is whether it will ben efit your shop in the right way. Different shops face different problems, and it’s dif ficult to make an informed decision with so many diverse products claiming to ac complish the same thing. What you need to know is if this paint, welding machine, shop management software or scanning system is right for your business.

looking for that information, and you couldn’t seem to find it? Our directory is the solution.

Keep this by your desk. Keep it at your bedside table. This is your immediate refer ence. The power to advance your business is within these pages. If you need to expand your shop, to innovate in order to stay one step ahead of the competition or if you just want to see where the collision repair in dustry is going, this book is for you.

With the 2023 Buyer’s Guide, you have the key to your future business success in the ignition switch.

The Buyer’s Guide is an annual special edition of Collision Repair™ magazine which is published bi-monthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072 CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED Send change of address notices and undeliverable copies to: 317 Reid St., Peterborugh ON K9J 3R2 Collision Repair’s Annual

PUBLISHER’S PAGE 6 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

“We acknowledge the financial support of the

of

THE QUESTION YOU MUST ASK OF EVERY NEW PRODUCT AND SERVICE IS: WILL IT BENEFIT YOUR SHOP IN THE RIGHT WAY?

Buyer’s Guide magazine is published by Media Matters Inc., publishers of:

Government

Canada”

IN

YOU’RE HOLDING AN INSIDER’S

TO THE MODERN COLLISION REPAIR

KEYS

IGNITION

GUIDE

TOOLBOX

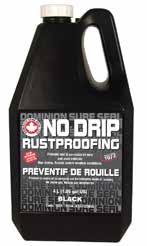

Division of RUST CHECK CORP. 6175 Danville Road Mississauga, Ontario L5T 2H7 1800-265-0790

SEEN AT SEMA

AN OASIS

This year’s SEMA Show was a true feast for the senses for anyone who fancies themselves an auto body enthusiast; whether welding is your thing, or paint is your preference, the aftermarket’s annual stop in Las Vegas had hot products befitting of the desert setting.

With nearly every step through the Las Vegas Convention Center’s show floor, Collision Repair reporters found themselves stuck in their tracks by one eye-catching piece of auto repair technology or another.

Canadian collision centre owners can rest assured that there are thousands of talented individuals in the automotive aftermarket working to develop things management systems, paint guns and dent-pulling mechanisms that are aimed to make daily life in the shop easier.

Check out this run-down of the most innovative and exciting new tools and tech on display at the SEMA Show 2022.

ALLDATA – ADAS QUICK REFERENCE

“Easy access to vehicle-specific ADAS (OEM) information on the ALLDATA Repair platform. Users can quickly identify ADAS removal/replacement requirements that could result in extra labour for calibration or sublet costs, and displays basic calibration information, required tools and prerequisites for servicing ADAS components.”

8 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

PRODUCTS SO HOT THEY MAKE THE MOJAVE LOOK LIKE

1 SEMA SHOW PRODUCT SHOWCASE

SEMA PRODUCT SHOWCASE FOR 2023

ASTECH CONNECT

“asTech’s next generation VCI that will allow Remote Diagnostics and Repairs on vehicles including those utilizing DOIP and CAN-FD.”

ASTECH MINI

“asTech Mini is a powerful, compact Bluetoothenabled scanning solution for OEM and OEMcompatible diagnostics. Paired with the asTech mobile app, it’s like having 1,000 OEM scan tools in your pocket.”

ASTECH RULES ENGINE

“asTech’s robust and proprietary diagnostic rules engine suggests when an alternative to the OEM scan tool can be safely and reliably used. The Rules Engine also allows shops to customize the conditions for the recommendation to suit their repair workflow.”

CAR-REP – 2K EPOXY DTM TOP COATS

“Car-Rep’s revolutionary 2-component, single compartment epoxy top coats have an unlimited potlife. Patented Wise 2K technology activates only when sprayed and delivers exceptional value to the user. Direct to metal allows for single stage application with chemical, corrosion and scratch resistance.”

SEMA SHOW PRODUCT SHOWCASE BUYER’S GUIDE 2023 9

2 4 3 5

SEMA PRODUCT SHOWCASE FOR 2023

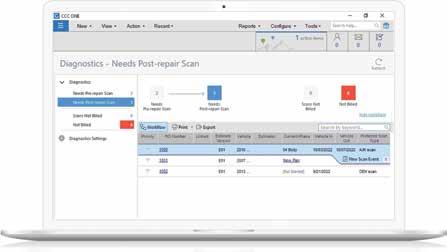

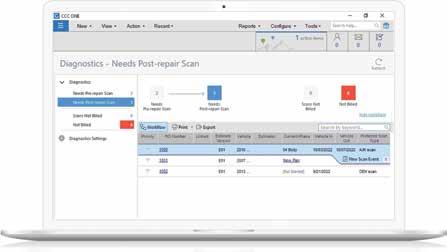

CCC DIAGNOSTICS –INTELLIGENT WORKFLOW

“CCC Diagnostics drives consistency and transparency. Create profiles based on shop, DRP, or OEM guidelines and software prompts users to include OEM or aftermarket diagnostic procedures on workfile. Dashboard view shows which repairs include pre-repair, in-process, or post-repair scans, plus reporting to drive performance by location or employee.”

CAMAUTO– PREMIUM ELITE LOADED CART

“The CamAuto Premium Elite Cart is a heavy duty, mobile cart that helps you carry all your PDR and GPR tools. Equipped with a drawer, a steel tab organizer top for better tools and tabs organization and two foldable trays that can be used as a side table and bent for better storage space. The cart comes loaded with an Elite Pro light puller, an I-Bar mini kit, CamAuto heat protection gel and glue sticks, and much more.”

COLAD – ULTIMATE PUMP SPRAYER

“Colad provides a superior, highly-solvent resistant pump sprayer with an adjustable spray mist and a high compression level for a flawless spray output. This solid pump sprayer is highly resistant to nearly all water and solvent-based degreasers due to the specially designed seals. Includes a set of Colour Coding Rings and an Identification Chart.”

SEMA SHOW PRODUCT SHOWCASE 10 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

6 8 7

⊲ Vast Inventory Across Our National Network ⊲ Fast and Safe Local Deliveries ⊲ New & Reconditioned ⊲ Industry Leading Safety Standards ⊲ Competitive Prices ⊲ Quick Order Turnaround ⊲ Knowledgeable Staff Wheels • Monitors tire pressure to prevent tire damage. • TPMS light illuminates when tires are underinflated 25% or more. • Automotive grade battery to handle severe weather conditions. • Match OE sensors in function and design. • No TPMS programming tool required. TPMS 69 SKU’S - COVERING 1,579 1998-2021 MAKES & MODELS TIRE PRESSURE MONITORING SYSTEM Don’t Forget! FIND THE WHEELS YOU NEED WITH KEYSTONE AUTOMOTIVE Best Quality In The Industry For more information or to place an order call 866-LKQCorp | 866-557-2677 or visit us at lkqcanada.ca

SEMA PRODUCT SHOWCASE FOR

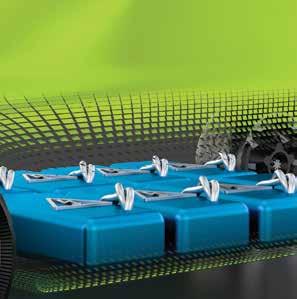

KECO – TRT ROBO LIFTER

“KECO’s TRT Robo Lifter provides technicians with an all-in-one tool to create lateral tension and simultaneously lift dents to improve metal flow with GPR. The TRT Robo’s lateral tension capability creates unique triple-action metal flow when pulling large dents and collision damage from panels, doors, seams and body lines.”

WIZARDS PRODUCTS – MIST-N-SHINE PROFESSIONAL DETAILER

“Highly regarded as an industry favourite for brightening paint and clean up after buffing. Use on all fresh and cured paints, glass, plastics and chrome without streaks, scratching or smears.”

STONER CAR CARE –MÖTSENBOCKER’S LIFT OFF PAINT STRIPPER

“Mötsenbocker’s Lift Off Paint Stripper is a new, patent-pending formula that safely removes automotive primer, paint and coatings. Lift Off Paint Stripper quickly works its way between the paint and your car’s surface to break the molecular bond, allowing easy removal with no harsh fumes.

SEMA SHOW PRODUCT SHOWCASE 12 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

2023 9

10 11

SEMA PRODUCT SHOWCASE FOR 2023

OECONNECTION – REPAIRLOGIC

“RepairLogic Repair Planning Platform is driving safety, trust and transparency in vehicle repair by providing a faster, easier way to create comprehensive repair plans using genuine OEM repair information to promote safe and proper repair through access to OEM repair information, digital collaboration tools and advanced documentation capabilities.”

BASF – RMP30

WHITE AND RMP32 BLACK PRIMERS

“The RMP30 White and Black Primers are a non-ISO, low VOC primer that offers L-shade mixing that gives more flexibility when priming. It is compliant in all VOC regions of North America. RMP30 fills and sands incredibly well. This product has the same simple 4:1 mix as traditional 2K primers with state-of-the-art performance, sustainability and safety.”

SEMA SHOW PRODUCT SHOWCASE BUYER’S GUIDE 2023 13

12 13

SEMA PRODUCT SHOWCASE FOR

HUNTER ENGINEERING – MAVERICK TIRE CHANGER

“Hunter’s new Maverick Tire Changer is designed for technicians who are serious about tire-changing. Built proudly in Mississippi, Hunter’s new tire changer really sets the wheels in motion by combining the convenience of hydraulic movement with the speed and responsiveness of manual operation. The Hunter Maverick will change how you change tires.”

15

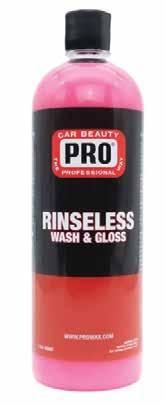

PRO PRODUCTS –RINSELESS WASH AND GLOSS

“Highly concentrated, ecofriendly, rinse-free car wash solution. Formulated with high gloss polymers that bond to the paint and encapsulate dirt. Leaves a clean, hydrophobic, high gloss finish. Dilute to make waterless wash, clay bar lubricant and gloss enhancer. Uses minimal water and requires no rinsing.”

NOVUS – NOVUS PLASTIC POLISH

“NOVUS Plastic Polish can rejuvenate and breathe new life into thousands of everyday products, such as toys, car headlights, boat instruments, appliances and so much more. Recommended by manufacturers of plastic products, our 3-step system can clean plastics without scratching, restore faded plastic and acrylic surfaces, and repair heavy abrasions.”

SEMA SHOW PRODUCT SHOWCASE 14 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

2023 16 14

“The green SATAjet X 5500 FUTURE is not only a reference to nature, but also a symbol for harmony and hope, especially for the future! SATA is striving for a sustainable and connected future that makes the most out of the potentials of the digital transformation. The SATAjet X 5500 FUTURE in RP or HVLP is unique and limited, while supplies last.”

SEMA SHOW PRODUCT SHOWCASE BUYER’S GUIDE 2023 15 17

SATA – SATAJET X 5500 FUTURE

Pre 8am Package Delivery Dedicated Logistics Pre 8am LTL Delivery Call 1-(800)-387-3199 | cardinalcouriers.com 6600 Goreway Dr., Unit D Mississauga, ON L4V 1S6 MOST RELIABLE PRE 8AM DELIVERY SERVICE SEMA PRODUCT SHOWCASE FOR 2023

SAGOLA

BY ELCOMETER – SAGOLASPRAY

REXALL SOLUTIONS – REX’ ALL BAG

“An innovative packaging solution for dispensing liquid and viscous products, it is the only packaging solution that uses compressed air as a propulsion force in a transparent box. An eco-friendly alternative to cartridges and flammable aerosols which can be used in various applications, almost three times more product than the same can of aerosol.”

VR TRAINING

“Learn how to be a spray painter with SagolaSPRAY. Learn through Oculus VR how to hold a painter’s spray gun. Spray objects on a real-world size scale as a spray painter would. Experienced spray painters have designed SagolaSPRAY. Overall positive environmental impact, painters would not need to use paint to learn how to spray paint with SagolaSPRAY.”

PROFESSIONAL DETAILING PRODUCTS

(PDP) – R200 IRON MELT

“Iron Melt is a fast acting, acid-free, pH balanced cleaner designed to dissolve ferrous particles and airborne chemical compounds that penetrate paint surfaces creating corrosive compounds that penetrate deep into the paint’s layers. This unique formula easily penetrates surfaces so it can really dig in and break down bonded ferrous contaminants.”

SEMA SHOW PRODUCT SHOWCASE 16 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

PRODUCT

2023 PRODUCT SPOTLIGHT For more information on how to be featured online in the monthly Buyer’s Guide Product Spotlight visit buyersguide.collisionrepairmag.com

SEMA

SHOWCASE FOR

20 18 19

OUR DRIVE SINCE 1894.

Our mission remains the same — deliver on the Sherwin-Williams repair promise with nothing short of high-performance, results-driven coatings and products. We pledge to drive our customers’ business with innovative solutions and programs, superior service and support, technical training and resources, and expert-led business consulting. Demonstrable, repeatable results — connecting color performance with labor optimization and improving process speeds.

That’s what drives us. It’s what drives you — and what drives your business.

Visit

Company

sherwin-automotive.com © 2022 The Sherwin-Williams

MIND THE GAP

DRIVEN BRANDS SEEKS TO INFORM INDUSTRY OF ADAS REQUIREMENTS

In early October, Driven Brands’ hosted an ADAS calibration and training event at its Canadian headquarters in Hamilton, Ontario, where Bill Davidge, CARSTAR’s director of innovation and technology, and Willy Williams, Uniban’s technical trainer, delivered an in-depth presentation and demonstration.

Attendees included collision repair facility owners, staff, and insurers representing various companies. About 70 industry professionals were in attendance—Driven Brands was actually forced to move the event to a larger venue due to industry interest.

The morning started with presentations from Davidge, Williams and the Repairify team before the crew moved across the street for a demonstration.

Attendees explored various Launch Tech targets while Lorenzo Pellicciotta of CARSTAR Oakville and Dave Marion of Launch Tech showed attendees how to complete two types of ADAS calibrations.

TECHNOLOGY 18 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

Story, photos by Allison Rogers

Driven Brands has quite the arsenal of glass experts, as showcased at the company’s recent training event.

Documentation was another point stressed. A critical step when performing ADAS calibrations, as it can be used to confirm a proper calibration was completed on the collision centre’s part. Williams showed various report samples several times over the afternoon.

Marion first demonstrated a failed calibration, blocking the path between the vehicle and the target, to show the audience the error message that appeared on his tablet. Pellicciotta had also placed washers behind the sensor to prompt a calibration failure.

When the washers were removed and the path was clear, Marion demonstrated how quickly a proper calibration was completed.

Williams then set up a glass calibration, marking targets on the floor and measuring precisely, down to the millimetre, with lasers.

There is also the string method—while not as reliably precise as lasers—that some use

TECHNOLOGY BUYER’S GUIDE 2023 19

Williams also set up a glass calibration, marking targets on the floor and measuring precisely—down to the millimetre—with lasers.

to verify their work using a taut straight line.

Williams also stressed the importance of checking OEM instructions between each step to ensure proper calibration, to OEM standards, is completed.

Documentation was another point stressed. A critical step when performing ADAS calibrations, as it can be used to confirm a proper calibration was completed on the collision centre’s part.

A full report is printed when the calibration is complete; there are also functionalities on several tools that allow collision centres to send reports directly to their records, or confirmation to the customer.

There were plenty of questions following the session—primarily on the topic of access to information.

Davidge was the first to admit that the industry is far behind where it should be in terms of ADAS calibrations, and much of that problem comes from a lack of access to information.

All in all, attendees left the session armed with more ADAS information than they arrived with—though plenty of work needs to be done to address the knowledge gaps.

TECHNOLOGY 20 BUYERSGUIDE.COLLISIONREPAIRMAG.COM Learn more at INTRODUCING COMPLETE SOLUTION TO COLLISION REPAIR. ADAS Insights

Attendees were well intrigued by the sessions and left armed with more ADAS information than they arrived with.

If the remaining eight brands meet the mark, more than 99 percent of all new vehicles sold in the United States will come with this proven life-saving feature that uses cameras, radar or a fusion of the two to “watch” traffic ahead and brake to avoid or lessen the damage of a crash. This in addition to the estimated 60 million vehicles on the road with some Advanced Driver Assistance System (ADAS).

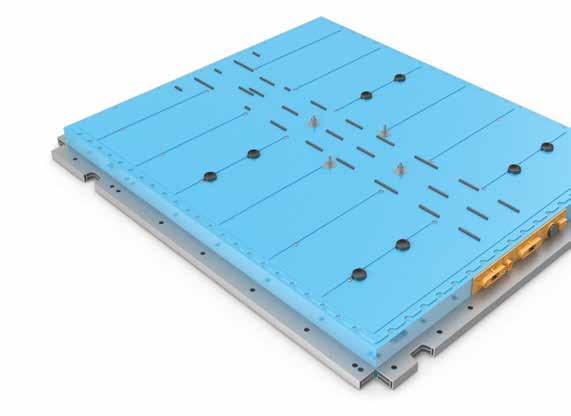

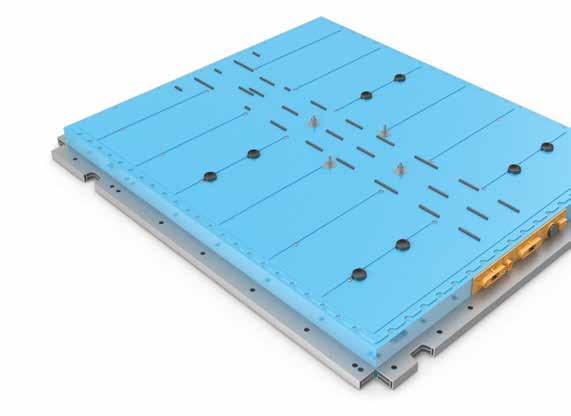

The exponential growth in the number of vehicles with ADAS should act as a catalyst for shops that perform calibrations to develop a process or seek out solutions that enables them to perform all steps needed in the calibration process as efficiently as possible. Well, Autel was listening. Its Intelligent ADAS IA900WA frame system is the first in the industry to combine all of it into one adaptable, interactive, robotic, dynamic, streamlined system.

The IA900WA offers shops a true turnkey solution to precision ADAS calibrations by combining vehicle inspection, including tire tread analysis, four-wheel alignment, steering angle reset, and ADAS calibration with detailed instructions, illustrations, and a graphical adjustment analysis. The benefit of integrated four-wheel alignment

into the system cannot be overstated as proper vehicle alignment is essential to the calibration of all ADAS components. The thrust angle, calculated in reference to the vehicle’s rear axle, determines its direction as it travels down the road.

the MaxiSYS Ultra ADAS tablet giving the technician all the freedom he needs.

ADAS calibration coverage includes camera targets and patterns and radar calibration components for equipped Mercedes, VW/ Audi, Hyundai/Kia, Nissan/Infiniti, Honda/ Acura, Mazda and Toyota/Lexus.

To see the IA900WA in action is quite extraordinary. The IA900WA features a folding crossbar and six in-frame high-resolution tracking cameras that automatically monitor vehicle height on the shop lift. Robotic frame movement allows for efficient use and alignment reading accuracy of 0.02 degrees.

Alignment coverage is for U.S., Asian and European vehicles, 1996 and newer, and the system guides the user through the complete process with illustrated alignment instructions, live readings, and required tools. Adjustment locations displayed on a mounted 24-inch touchscreen monitor mirror the alignment procedure executed on

The IA900WA system is offered in several packages, including an all-systems ADAS package that includes targets, patterns, and calibration components to calibrate cameras (including those used in Around View Monitoring), radar, LIDAR, and nightvision units. A Lane Departure Warning (LDW) package is also available that includes targets and patterns needed to calibrate systems on equipped vehicles and Alignment-only packages. All packages are available with or without Ultra ADAS tablet.

As vehicle manufacturers continue to share their safety systems throughout the entire lines, and more and more vehicles with these systems enter shops, solutions that provide technicians with a repeatable, efficient process to calibrate these input devices have become essential.

THE AUTEL IA900WA ADVERTORIAL USSUPPORT@AUTEL.COM 855.288.3587 I WWW.AUTEL.COM WHEEL ALIGNMENT BODY SHOP GLASS REPAIR THE IA900WA IS IDEAL FOR...

ONE OF

THE SEPTEMBER DEADLINE FOR AUTOMAKERS TO HAVE CITY-SPEED AUTOMATIC EMERGENCY BRAKING (AEB) ON 95 PERCENT OF THEIR NEW VEHICLES IS LOOMING. TWELVE BRANDS—AUDI, BMW, FORD/LINCOLN, HONDA/ACURA, HYUNDAI/GENESIS, MAZDA, MERCEDES-BENZ, SUBARU, TESLA, TOYOTA/LEXUS, VOLKSWAGEN, AND VOLVO—HAVE ALREADY MET THAT VOLUNTARY GOAL.

THE POWER

GAME PLAN GET A

OECONNECTION SEEKS TO ADDRESS INDUSTRY GAP WITH REPAIRLOGIC

By Max Reid

“We hope to help find a solution by changing the skill sets of the individuals who pull repair procedures today, to reduce all the demands that are expected of technicians.”

— Nicky Woerner, director, OEConnection

Running an auto body repair centre is busy work and every manager wants things to run smoother, but who has the time to make plans? Luckily, Nicky Woerner, director of the Richfield, Ohiobased OEConnection, has the skills and the experience to get your business running like clockwork.

A 27-year auto industry veteran and widely regarded as an operational efficiency expert, Woerner works directly with body shops on a daily basis to develop solutions to the many hiccups that can prevent a collision centre from performing its best.

Collision Repair caught up with Woerner as she made autumnal treks around Canada to inform the industry of the new platform.

In her travels to various conferences, Woerner spoke to how supply chain disruptions are still a reality for many shop owners and how OEConnection can formulate streamlined solutions that keep the parts ordering process in motion.

“At this particular time, with all of the new technologies that are coming in, from changing vehicles, certification, tooling and equipment, to how you order parts—we think it is really important to try and solve those inefficiencies

TECHNOLOGY 22 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

How much time does your team spend researching for repair plans?

and confusion that stakeholders within the collision market are dealing with today,” said Woerner.

She says that her company is currently planning a decade in advance to provide clients with the most proactive solutions possible to today’s issues affecting them.

“We [at OEConnection] said, ‘we need to plan for the next ten years,’ and so that strategic plan really homed in on some of the noise and the inefficiencies as it relates to parts ordering and distribution, as well as the ability to access the right information at the right time.”

“Ideally, the goal is to reduce the complexity and have the ability to restore that vehicle to pre-accident condition,” said Woerner.

To that end, OEConnection offers businesses solutions that start from the top-level, engaging a shop network’s processes overall to determine how best to consolidate and streamline business segments to open up new efficiencies.

“Our products are unique and some of them apply to the enterprise or corporate level in what we would call a top-down approach. With that approach, we are helping the organization streamline their processes and solve for gaps in those processes to connect everything, because we believe that when everything is connected, everything is more efficient,” said Woerner.

The company also approaches efficiency from the bottom up, addressing technicians’ skill sets individually, and putting them on track for success in a way that minimizes the burden on managers, says Woerner.

“These franchisees and collision shops need something that is easy to implement because they are tasked with talent issues.

“We hope to help find a solution by changing the skill sets of the individuals who pull repair procedures today, to reduce all the demands that are expected of technicians.”

Those interested in OEConnection’s services can visit the website at oeconnection.com/.

TECHNOLOGY BUYER’S GUIDE 2023 23

“We need to plan for the next ten years.”

— Nicky Woerner, director, OEConnection

Nicky Woerner, director, OEConnection.

MORE TECH, MORE TROUBLES

CUSTOMERS DON’T ‘GET’ VEHICLE TECH

“It was found that rear seat reminder technology has a range of total problems spanning from 1.9 PP100 to 26.2 PP100, demonstrating that the tech can be developed with minimal owner complaints. On the other end of the spectrum, fingerprint reading technology has been identified as the most problematic piece of technology when it comes to driver satisfaction, scoring a PP100 of 54.3.”

TECHNOLOGY 24 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

“The fact that the average PP100 for a technology is high should not discourage automakers from innovating, as there is often a wide range of total problems experienced for a technology across the brands. – Kathleen Rizk, senior director of user experience benchmarking and technology at J.D. Power

By Max Reid

By Max Reid

With the implementation of new technology in vehicles comes an understandable learning curve for drivers to get a hold of, though according to a report from J.D. Power, the way these additions affect driver satisfaction is more nuanced than it may seem.

In its press statement announcing the release of the 2022 U.S. Tech Experience Index (TXI) Study, J.D. Power claimed that while the “notion that advanced technologies always lead to significant problems is a misconception,” certain pieces of technology have been found to be easier for drivers to adapt to than others.

In its TXI studies, as well as in its Initial Quality Studies (IQS), J.D. Power measures vehicle quality via a problems per 100 vehicles (PP100) model.

“Of the advanced technologies included in the 2022 TXI Study, 46 percent of them had at least one problem with a PP100 higher than the most problematic attribute included in the 2022 IQS, with some exceeding it several times over,” according to the report.

In this most recent study, J.D. Power found there to be significant variation in the meeting of user expectations between different pieces of advanced technology.

For example, it was found that rear seat reminder technology has a range of total

problems spanning from 1.9 PP100 to 26.2 PP100, demonstrating that the tech can be developed with minimal owner complaints.

On the other end of the spectrum, fingerprint reading technology has been identified as the most problematic piece of technology when it comes to driver satisfaction, scoring a PP100 of 54.3.

J.D. Power expressed that it does not want to see automakers discouraged from developing more advanced technology based solely on how initial satisfaction is affected by change.

“Innovation is non-negotiable,” said Kathleen Rizk, senior director of user experience benchmarking and technology at J.D. Power.

“The fact that the average PP100 for a technology is high should not discourage automakers from innovating, as there is often a wide range of total problems experienced for a technology across the brands. This means that some are innovating more flawlessly for a particular tech, while others struggle with their execution. Automakers should consider benchmarking brands that innovate well for a technology, which would allow them to identify and then integrate best practices. Effective innovators understand that new technologies can be introduced successfully with proper design and execution.”

BUYER’S GUIDE 2023 25

TECHNOLOGY

IN FOR A SHOCK

Mandell says that, on average, EVs are found to contain more than double the number of semiconductors than a gas-powered vehicle and often have about 12 more repair lines on their estimates.

ELECTRIC VEHICLES WILL CHANGE THE WAY WE WORK

By Max Reid

By Max Reid

Talk of electric vehicles is abuzz lately— but what do collision centres really need to prepare for in the interim as EVs gain popularity?

“It is really a very different process, not only in terms of writing an estimate for an electric vehicle but blueprinting that repair as well to really make sure you’re bringing that vehicle back to pre-loss condition,” said Ryan Mandell of Mitchell International, in an interview with Collision Repair at the September’s Fix Network National Conference in Quebec City.

As director of performance consulting at Mitchell International, Mandell delved into the numerous factors that make EV repairs more complex, more costly, and more necessary than ever for shops to have a grasp on.

He touched on the weight of EV batteries and the subsequent lightweighting traditional gas-powered models must undergo to account for it, in turn causing a drive among OEMs to develop lighter materials and metals for parts.

ELECTRIC VEHICLES 26 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

Ryan Mandell, director of performance consulting at Mitchell International.

Mandell says that, on average, EVs are found to contain more than double the number of semiconductors than a gas-powered vehicle and often have about 12 more repair lines on their estimates.

He points to Subaru, Ram and Chrysler as the three major, non-luxury OEMs currently producing the most electronically complex vehicles on the road today.

With the aim of eliminating as much confusion for technicians as possible, Mitchell made a point of updating the language in many of its management platforms this year, in order to conform more repair procedures to EV-specific language, where previously placeholder terms were used.

Due to the nature of lithium-ion batteries and the way EV powertrains function, the vehicles are on track to run at higher overall temperatures as the technology grows more complex, which Mandell points out will likely force technicians to consider things like cooling lines running through a damaged vehicle.

Due to the nature of lithium-ion batteries and the way EV powertrains function, the vehicles are on track to run at higher overall temperatures as the technology grows more complex, which Mandell points out will likely force technicians to consider things like cooling lines running through a damaged vehicle.

On the consumer-facing side of things, the war in Ukraine and the spike in metal prices that resulted is currently threatening the path to price parity between EVs and gas-powered vehicles.

The wave of electrification is also having a unique effect on traditional brand loyalties, according to Mandell, who found that most drivers these days have one or two automakers they trust enough to buy a gas-powered vehicle from. When it comes to EVs, drivers were more open to buying from brands they have no prior experience with.

Mandell says Canada’s burgeoning EV infrastructure is progressing well in building charging stations, which he attributes largely to the vested interest various levels of government have in achieving certain emissions targets and meeting goals that would demand an adequate charging network

Near the end of his presentation, Mandell put forth the question to the repair centre owners and managers in the room of whether their business would be prepared for their repair mix to suddenly shift to 10 percent EV repairs.

ELECTRIC VEHICLES BUYER’S GUIDE 2023 27

STAY OR GO

KNOWING YOUR WORTH IS KEY IN EITHER SCENARIO

Column by Nancy Rolland

The pandemic has caused many business owners to reconsider their long-term goals of owning and operating their businesses. Shutdowns and personnel shortages have clearly been a drain on many, while severely impacting financial performance and their ability to effectively service customers.

If you are thinking about exiting the race, consider having a professional business intermediary, such as an investment banker review your business and provide a free, no obligation valuation. Most can perform this task quickly by reviewing your financials and asking a few preliminary questions about your operations. If you do this, make sure you find an intermediary that specializes in your industry. They will have the most current knowledge of what is happening in the marketplace and what buyers are willing to pay. Following are a few of the items they would ask you to provide.

Financial Statements

Gather your financial statements and tax returns for the last three years as well as the current year to date and the previous year’s comparable period. Many prospective buyers like to see how the business has operated on a trailing 12-month basis, so the two periods are necessary to calculate operating results.

Owner’s Benefits

Identify how much you are really earning from your business that a new owner can also expect. Also known as seller’s discretionary earnings (SDE), this takes into consider ation any personal expenses you are running through the company, such as personal car leases, cell phones, salaries to non-working family members, etc. SDE is calculated by taking your company’s profit as shown on your tax return and adding back potential

expenses that may not be incurred by a new owner as well as other expenses, such as non-recurring or non-related business items.

Staffing

Address any personnel issues or deficiencies in advance of a sale. If you are planning to completely exit the business, make sure you have at least one person in place who may be able to assume your role and duties. One of the biggest reasons buyers are attracted to and pay higher prices for businesses is knowing they have great teams in place. If you expect that the new owner is going to have to hire someone to perform your duties, anticipate a negative earnings adjustment.

Facility

Take a walk through your facility with ‘buyer’s eyes’. Could it use a thorough clean ing, a fresh coat of paint, or new equipment?

Selling your business is much like selling your home. You want to make it as pre sentable as possible, even in the collision industry. Having done numerous site visits during my career, clean, organized shops still stand out in my mind and command the best price. Keeping a well-organized and clean shop is like teaching your chil dren the importance of making their bed. It’s not the task itself, but the development of discipline and good habits that are learned during the process.

Rent Check

Double check your facility lease or rent rate. If you own the property, are you charging yourself fair market value? If you are uncer tain, contact a local commercial realtor for their opinion. If you are leasing it from a third party, how much time is remaining on the term? Are there any onerous conditions?

Customer Base

Who are your customers? How wide of a geographic region do you cover? Do you pro vide prospective buyers with an opportunity to expand into a new area or strengthen their existing territory? Do you have a diversified customer base that would help in the event one of them underperforms during a particular period? Companies with multiple sources of income to smooth out the economic hills and valleys almost always garner the highest valuations.

Suppliers

Similarly, be prepared to discuss your re lationship with your paint supplier as well as other vendors. Do you have an outstanding prebate that will need to be paid off at closing?

Our team has represented over 20 clients in the last few years with annual revenues more than $500 million. We would love the oppor tunity to discuss your specific situation.

954-610-3410.

MERGERS AND ACQUISITIONS 28 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

NANCY B. ROLLAND is a managing director of FOCUS Investment Banking with more than 20 years of experience in sourcing, managing and executing mergers and acquisition activities for small business owners and multiple Fortune 500 companies. She can be reached at nancy.rolland@focusbankers.com, or by phone at

GUESSING GAMES

No matter how long you’ve been in the industry, you’ve likely witnessed a bevy of different ways to process an estimate—whether it be via the pen-and-paper methods of yesteryear or finagling with the web- and cloud-based technology of today.

We asked Collision Repair readers for their feedback on today’s estimating platforms. What works? What can be improved?

Here’s what some of them had to say.

STAND UP SPEAK OUT 30 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

TODAY’S ESTIMATING PROCESSES—MORE STREAMLINED OR CONTINUOUSLY CUMBERSOME?

“We have had YEARS clicking the same checkboxes and flowing through the same menus. If someone hasn't become ‘fast’ at estimating after years of clicking the same program, they should look for another trade.”

“The most recent one we started using is slower than our last, partly because things are in different places than they used to be, but mainly because it feels like you have to click more times to get the things you want on the estimate.”

STAND UP SPEAK OUT

“The systems are bettergetting all the time.”

“[Modernsystems] arequickertoload, butsomewhat clunkytouse.”

Q: How many estimating systems do you use in your facility?

A. One platform — 11.8 percent

B. Two platforms — 74 percent

C. More than two platforms — 14.2 percent

Q: Are your current estimating system(s) mandated by any partner organizations?

Yes — 92.9 percent

No — 7.1 percent

Q: How long does it take to train your staff on your current estimating system(s)?

A. Just a few days/hours: 7.7 percent

B. 2-4 weeks: 36.5 percent

C. 1-3 months: 17.3 percent

D. 3-6 months: 11.5 percent

E. More than 6 months: 27 percent

Q: About how long does a simple estimate take?

A. Between 5 to 10 minutes: 14.7 percent

B. Between 10 to 20 minutes: 36.4 percent

C. Between 20 to 30 minutes: 21.6 percent

D. Between 30 minutes and one hour: 22.7 percent

E. More than 1 hour: 4.5 percent

Q: About how long does a complex estimate take?

A. Under 1 hour: 11.1 percent

B. 1-2 hours: 39.4 percent

C. 2-4 hours: 22.2 percent

D. 4-6 hours: 13.1 percent

E. More than 6 hours: 14.2 percent

Q: How long does it take to launch your estimating software at the start of each day?

A. Less than 30 seconds: 23.1 percent B. Less than one (1) minute: 43.8 percent

Less than three (3) minutes: 21.5 percent

Less than five (5) minutes: 5 percent

More than five (5) minutes: 1.7 percent

A. About 10 seconds: 17.2 percent B. About 30 seconds: 39.7 percent C. About one to two (1-2) minutes: 22.4 percent D. About two to three (2-3) minutes: 9.5 percent

More than three (3) minutes: 11.2 percent

STAND UP SPEAK OUT 32 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

Q:

document

average?

FAST FACTS: 127 facilities surveyed 81.1 percent of respondents are collision centre owners/ managers 67.7 percent of respondents have been in the collision repair industry for 20+ years A B C No Yes A B C D E A B C D E A B C D E A B C D E A B C D E

C.

D.

E.

How long is the

upload time, on

E.

WWW.DRIVEBUYSUPPLY.CA 1-833-9-SUPPLY Subscribe to our mailing list at sales@motivatedreps.com www.motivatedreps.com Contact us today to see the SAVINGS DRIVEBUY can offer you! HERE WE GROW AGAIN!! One Stop Service! We specialize in getting product to you on the spot! We use climate controlled vehicles to ensure safe Delivery of products to your door! Shop, buy, supply and invoicing at your shop! With decades of industry experience, DriveBuy Supply was formed to provide a core selection of products that would fit the budget of any facility, and do so in a way that is safe, efficient, and expedient. DriveBuy Supply is currently covering South Western Ontario and continuing to expand into New Territories! Online Ordering Available For Delivery In All Other Areas Offering competitive pricing on your collision repair supplies! FRANCHISE OPPORTUNITIES Contact: 1-833-9-SUPPLY 5770 Impact Resistant • Structural bonding of Aluminum and Steel • In resistant spot welding or rivets • Strut tower, frame rail, rocker or where ever OEM calls for it. • Purple color to match OEM GMW16252. OEM APPROVED PANEL BOND • Work Time: 90 minutes • Handling Strength: 10 hrs at R/T, 50-60 min at 180F • Paint Time: 16 hrs at R/T, 50-60 min at 180F • Size: 220ml •Stock #5770 BUYER’S GUIDE 2023 33

ACCUVISION-3D ® IS RECOGNIZED BY CERTIFICATION PROGRAMS - CCIAP - Honda QUICKEST, SIMPLEST AND MOST ACCURATE 3D MEASURING SYSTEM IN THE WORLD - NO Moving Parts - NO Lasers, NO Targets, NO Adaptors - NO Magnets, NO Arms, NO Extensions - NO Wires, NO Wi-Fi, NO Bluetooth - NO Calibration Needed - MITCHELL chassis data Made in Canada accuvision-3D.com ACCUVISION-3D® IS RECOGNIZED BY CERTIFICATION PROGRAMS - CCIAP - Certified Collision Care - Honda - ICBC Toll Free: 800-465-8575 NEW NOW INCLUDES WHEEL ALIGNMENT DIAGNOSTICS SOFTWARE

THE ARSLAN AUTOMOTIVE WAY

It’s no secret that Arslan Automotive is a staple name in the collision repair industry, due to the professional quality and reliability of its 3D measuring and welding equipment brands, which have become well-recognized in Canada among collision repair professionals.

Arslan Automotive Canada Ltd. has been going strong for over 43 years. The company is best known for its TECNA Smart/Smart Plus Inverter Spot welding equipment, including Accuweld-inverter pulse MIG/MAG welder models, both of which have captured a significant slice of the Canadian market. They also manufacture Accuvision-3D measuring system developed by Arslan Automotive Canada and made in Montreal. According to the company, the 10-AV700 3D measuring system is “the quickest, simplest and most versatile and accurate” 3D measuring system in the world. Arslan Automotive shows no signs of slowing down its sales of these systems with over 350 shops in Canada and US having adopted the system for their 3D measuring since its genesis approximately 3 years ago.

In 2021, the company introduced a new line of 3 Pulse MIG welding machines and an Inverter Arc Dent puller repair system for dents, under the brand name Accuweld, Pulse MIGs that are available in single torch (mdl.60-TM736), two torch, (mdl.60-TM742) and three torch (mdl.60-TM743) models with state of the art features as auto-setting torches, 4 wheel wire drive system and more.

According to the company, the Accuweld 60-TM750FK Arc Dent Puller system is a high-end synergic welder with programs dedicated to both aluminum and steel and is capable of repairing dents and strengthening thin metal sheets, especially when it comes to aluminum.

The system also features a colour graphic display with a simple-touse interface, with customizable and storable programs, plus an SDMemory Card to update and add programs. Arslan has been focusing

on the Canadian market, and introducing the Accuweld line to its U.S. sales agents and customers at 2021 SEMA Show in Las Vegas.

Further, Arslan Automotive continues to develop its export markets for the Accuvision-3D measuring system.

Last year, Arslan Automotive told Collision Repair it had signed an agreement with the Kia and Hyundai National Car Dealers Associations of Korea. The partnership seeks to promote the installation of Accuvision 3-D measuring systems in all Korean collision repair facilities. As part of the agreement, Arslan had to created a Korean version of Accuvision 3-D programmed with the chassis data specific to models sold in South Korea.

For reference, Hyundai and Kia vehicles comprise approximately 90 percent of new cars sold in Korea.

The company has now appointed a new distributor for Vietnam, KINGTECH ENGINEERING CORPORATION, where it can profit from a market that essentially can use the Accuvision-3 chassis databank that the company had created for entry to the South Korean market in 2022.

“We look forward to increased sales in 2023 with this new distribution agreement as we are dealing with a well established and respected equipment distributor for the country,” said Arman Gurarslan, president and owner of Arslan Automotive.

Notwithstanding the recent increases in interest rates and a looming worldwide recession which are challenges to contend with, the company continues to forge ahead with its marketing efforts and invest the necessary dollars to start the rolling out process for Accuvision-3D in Vietnam.

“We want to be there when things settle down and market growth starts up,” continued Gurarslan.

ARSLAN AUTOMOTIVE 84 Avenue Leacock Pointe-Clare, Quebec H9R 1H1 (800) 465-8575 arslanauto.com accuvision-3D.com

BUYER’S GUIDE 2023 35

PROFILE

YOUR SOURCE FOR OEM APPROVED EQUIPMENT

BETTER THAN EVER

INTEGRATED CAR PART PRO (IPRO) CONTINUES TO EVOLVE TO MEET YOUR NEEDS

Backordered parts, no delivery, sound familiar? Integrated Car Part Pro (iPro) can help. The iPro marketplace continues to evolve to meet the collision repair industry’s growing needs for alternative parts and with the current supply chain challenges this is important now more than ever.

Is your team struggling to source parts and get them when they need them? iPro’s new automation features may be the solution. This article highlights some of iPro’s newest features including automated part policy, assembly automation and expanded availability with a deeper Interchange catalog to help alleviate today’s parts challenges.

How it works: The insurance policy is applied automatically if the policy is in iPro. The end user doesn’t have to worry about selecting a part that isn’t permitted by the policy. For example, some carriers may restrict parts for newer cars with less miles. Parts are customized based on the insurer’s policy and the parameters set (e.g., A grade recycled front doors or CAPA certified front bumper reinforcements). iPro’s part policy automated enhancement manages these guidelines.

Car-Part.com CEO Jeff Schroder says, “iPro enables users to easily search and select parts, working within partner insurer guidelines. This optimization streamlines workflow and enhances customization while maintaining the maximum supply chain results, and the new Car-Part scorecard highlights even more part opportunities.”

MORE ASSEMBLY AUTOMATION

Going beyond the policy enhancements, iPro continues to enhance its assembly automation with additional functionality and more parts. A recycled assembly consists of multiple parts that are sold together as an assembly. Adding to the complexity, estimating systems are based on an OE component parts numbering system while the recycling industry is based on a recycled assembly Interchange so it can be challenging to source recycling parts. iPro helps fill this void by automatically matching the right components with their corresponding assemblies.

iPro has identified components on an estimate and mapped them to recycled replacement part assemblies for many years and now for even more assemblies. iPro’s newest assembly automation features include front and rear bumpers, front and rear doors, front-end assemblies, headlights and hoods with more to come. The simplified workflow:

• Helps increase overall alternative part usage by automatically associating more assemblies with components (e.g., a front bumper will automatically associate a bumper cover, reinforcement bar and an impact absorber)

ENHANCED PART POLICY SOLUTIONS

Introduced recently, iPro’s part policy feature can ensure that the parts searched and selected meet your insurance company’s guidelines and the new scorecard identifies claims with outstanding performance or additional opportunities. Parts that are not allowed (e.g., air bags, uncertified, etc.) are filtered out and cannot be searched, ideal for newer appraisers and shops that may not know which parts comply with which insurers guidelines.

• Ensures parts are not duplicated on the final estimate, reducing part costs by not paying for components already included within the assembly.

iPro’s latest automation expedites the parts sourcing process with simple workflow optimization.

If you would like more information about iPro’s latest features or to learn more about future enhancements, please contact 859-344-1925, visit Products.Car-Part.com or email ProTeam@Car-Part.com

CAR-PART.COM 859-344-1925

http://Products.Car-Part.com ProTeam@Car-Part.com

BUYER’S GUIDE 2023 37

PROFILE

Since 2013, CCS has been the network of choice for Canada’s most progressive new car dealer collision centres. For dealers, by dealers, our tailor-made solutions will help grow your business by retaining more customers and putting you on the map with our national insurance partners. For the road ahead and the road less traveled, CCS will be there for you. If you are a new car dealer anywhere in Canada, find out more by booking your test drive of CCS today.

© 2021 Consolidated Collision Services. All rights reserved. The CCS Logo is a registered trademark of Consolidated Dealers Co-Operative Inc. What you join matters, who you join matters MORE.

For more information visit us at www.ccsdealers.com Contact us at info@ccsdealers.com Over 85 locations. One mission. To be the best. Consolidated Collision Services

CANADA’S NEW CAR DEALER COLLISION REPAIR NETWORK

“We have successfully brought new car dealers together, been able to execute on improving performance, and have delivered for our partners an exceptional level of quality and customer service across the country,” says Sandy Liguori, President of Consolidated Collision Services (CCS) and the Woodchester Auto Group. “As President and as a member of CCS, I can confidently say that there has never been a better time to be a part of the network.”

matters, matters MORE.

Built from the ground up by dealers, for dealers, CCS’ tailor-made approach focusses on three key areas; retaining more of your current customers, improving the performance and profitability of your business and putting you on the map with national insurance partners. A dealer exclusive network, co-operative ownership structure and unique approach to how CCS supports its members has attracted some of the largest and most successful dealership owned collision centres to the network over the last 10 years, says the network.

for Canada’s most progressive new car dealer tailor-made solutions will help grow your business the map with our national insurance partners.

CCS will be there for you. If you are a new car booking your test drive of CCS today.

“What becomes immediately clear about CCS is the quality of the locations in our network, it really is a key differentiator for us compared to our competition,” says Mike Beier, General Manager of CCS. “These are names and brands that have been a part of their communities for decades, in some cases generations. This is what sets us apart. Leveraging the individual identities of our members, bringing the collision centre to the show room, and being the onestop automotive destination for all of our customers, this is what really makes CCS unique.”

mission. To be the best.

Consolidated

ver 85 collision centres. Over 225 new car dealers. Over 250 OE Certifications. After nearly a decade of CCS entering the market, its mission remains the same to this day: to become Canada’s largest and most preferred new car dealer collision networkNo two collision centres are the same; every management team has its own approach to achieving success and a culture of high performance within its organization. That is a fact CCS knows and celebrates, working closely with each of its industry partners to conquer collision centre-specific and sector-wide challenges alike.

Members tell our story best, Chris Laking, owner and president of Laking Toyota, Northern Nissan and Imperial Collision in Sudbury, Ontario says, that “CCS has been a vital partner in the growth of our business. From providing management tools, to hosting meetings with like-minded repair shops, CCS is a key partner in the growth and evolution of our successful collision repair business. The ability to share ideas on how to run our business and not be directed, makes CCS a unique partnership.”

Corrado Olindo, Collision Centre manager at Highland Chevrolet Cadillac in Aurora, Ontario says, “In the past, we felt that as a dealer we had to chase business for our bodyshop. Today, by implementing key CCS initiatives, Highland has elevated their game to compete not only at the dealership level but with the largest players in the industry while achieving record levels of customer retention, personnel development, and profitable growth.”

“We’ve have accomplished many great things so far, but the opportunity for CCS and our network in the years ahead is staggering,” says Sandy Liguori. “We are at a point where dealership owned collision centres have all the tools available to succeed, and a network that shares their values and vision. We are excited for what lies ahead.”

BUYER’S GUIDE 2023 39

NEW CAR DEALERS UNCOMPLICATING COLLISION REPAIR CONSOLIDATED COLLISION SERVICES

Rd.Woodbridge,

3T1

© 2021 Consolidated Collision Services. All rights reserved. The CCS Logo is a registered trademark of Consolidated Dealers Co-Operative Inc.

441 Hanlan

ON L4L

info@ccsdealers.com www.ccsdealers.com

www.ccsdealers.com Collision Services

Tom Langton, president and CEO and Consolidated Dealers Co-Op, and Sandy Liguori, president of Consolidated Collision Services.

PROFILE

Mike Beier, general manager, Consolidated Collision Services.

O

ADAS & Diagnostic all-in-one

• No more targets, now with TV screen.

• Takes less space.

• Quick and easy process.

• Bringing you Diagnostic, Alignment, Bench and much more.

• Accurate and easily understood measurement display.

• Quick detection of accident-caused damages.

• Lifting capacity: 11 tons.

Less than 7 minute process

• Precision: < 1 mm

• Arm length: 2.7 m

• Mobile: tripod stand

• Mechanics: IN/OUT

• Live pull

• Welds with pulses, therefore much cleaner in the application, even comparable to 3-phase products.

• Specialized in aluminum and silicon bronze welding.

• Its intuitive interface and ultraprecise wire feed offers bodyworkers unparalleled welding quality even on very thin sheets.

Model has higher pinching power yet consumes less energy 230V 40A

• Welds high strength steels such as UHLE and boron steels.

•Light weight: Move around without any strain.

•Ideal when working with heights.

• Essential for straightening various sizes of dents (rocker panels, wheel wells, fenders, etc.); complete kit for aluminum and steel assembly.

• Model works with wrenches instead of studs, makes job easier.

• Allows you to apply more pressure and gives you stronger welds.

Distributed by Equipment & Services Filco Inc 10740 Avenue Racette Montreal, QC, H1G 5H6 www.filcoinc.com sales@filcoinc.com 514-955-8870 1-888-837-6452

A 3-torch machine for the price of a 1-torch unit

Increase your profit margin while reducing downtime

AUTOPULSE 220-M3 ** NEW ** ADAS SYSTEM GYSPOT PTI-s7 6M - 220 V THE MEG 4-in-1 Bench Package INCREASE PROFITS SAVE TIME SAVE SPACE CONTACT EVOLUTION 3D DENTSTATION PREMIUM EXPERT 200 + ARCPULL 200 MAKE YOUR BAY MORE PROFITABLE Ref: 062481 Ref: 022195 Ref: 065345 All products can be purchased separately

If you are searching for a trusted partner in equipment and training, Filco is your fit. The company specializes in the sale, installation and after-sale service of state-of-the-art collision repair equipment.

Filco is the exclusive North American distributor for Termomeccanica spray booths, prep stations, paint mixing rooms, Car Bench electronic measuring systems and frame machines and GYS welding equipment— all available and in stock at the company’s warehouse.

Filco opened its own training facility in 2017, where the company provides hands-on, one-on-one learning approaches combined with theory. The training centre features a variety of equipment for mechanics and collision training: paint booths, alignment machines, various lifts, tire and balancing machines, frame machines, diagnostic tools, ADAS systems, welding equipment and more.

Half-day or full-day training options are available—plus, trainees can enjoy some top-notch coffee during their training, courtesy of Filco’s in-house café. Training services are also offered on-site at customer’s facilities.

Filco Academy hosts the latest technology in:

Filco Inc.’s training can be provided at many locations— their reps can even set up a session to bring the learning to a convenient location for you and your team.

“There are always more perks in store when you train at Filco Academy,” says Vince Filice, president and CEO of Filco.

The company is recognized as a training organization accredited by the “Commission des partenaires du marché travail” for the application of the Act to promote workforce skills development and recognition. Businesses can claim employee training with this law; one percent of their payroll $2M+.

Filco provides a certificate of achievement upon completion and offers foundational support in its learning opportunities, assures Vince Filice. The company is committed to industry training and has built many training centres in the past such as LAR (Leader Auto Resources) and Axalta Paints. The company was also involved in the recent development of the Canadian Collision Repair Academy, the new VW Training Centre in Milton, Ontario.

With over 30 years of industry experience, Filco’s qualified personnel and technicians can be trusted to install and provide aftersale service on all equipment. Filco also specializes in optimizing shop layouts and “shop flow” to increase profits and decrease operating costs. Free samples are available upon request.

Trainees are sure to gain the knowledge they need to confidently operate tools, machinery and ultimately increase their productivity—a sure win for any mechanics or collision center.

For more information, please visit filcoinc.com, call 514-955-8870 or 1-888-837-6452, contact filco@filcoinc.com.

Filco

BUYER’S GUIDE 2023 41

SUCCESS WITH FILCO UPDATE YOUR TOOLS AND YOUR SKILLS EQUIPMENT & SERVICES FILCO INC. 10740 Racette Avenue,

QC,

5H6

Toll free:

www.filcoinc.com PROFILE www.filcoinc.com

FIND

Montreal,

H1G

Office: 514-955-8870

1-888-837-6452

2-Post,

Tire

Wheel

Parking

3D

Systems

Vacuum Systems (Steel or

3D Quick Align • Fastlane Check Systems

also supplies mechanical equipment, including: • Welders - ALU/STEEL - Riveting - Glass Repair - Induction Systems - MIG/MAG, Autopulse and Spot Welders • Vast Selection of Hoists:

4-Post •

Machines •

Balancing Machines •

Lifts • 3D Measuring Systems and Universal Jig System •

Alignment Machines • ADAS • Spraybooths • Prep Stations • Paint Mix Labs • Electric Vehicles (EVs) • Lubrication Reel Systems • Exhaust Extraction

•

ALU) •

Auto Auctions is Now IAA CA.IAAI.com © 2022 IAA, Inc. All rights reserved. BID. BUY. REPAIR.

Impact

GET THE FULL PICTURE BEFORE YOU BUY

IAA (FORMERLY IMPACT AUTO AUCTIONS) IN CANADA ADDS FURTHER DIGITAL FEATURES TO MERCHANDISING PLATFORM

IAA in Canada provides the advantage in salvage auto auctions, with its digital auction model giving buyers more access across North America’s broadest salvage auction facility footprint, broad product selection and exceptional customer service. The global IAA (Insurance Auto Auctions) name boasts more than 210 facilities across the United States, Canada, and the UK.

technology’s benefits include enhanced imagery, zoom and pan capabilities as well as additional views beyond 5MB HD providing internal and external insight on critical areas of the vehicle.

The company has recently enhanced the 360-view program to include the Feature Tour tool, which allows buyers to identify value-added features and options present quickly and easily on each listed vehicle. In addition to these new features, IAA added Engine Starts to its merchandising platform this year, which offers 10-second under-the-hood video with full sound, allowing buyers to listen to the vehicle engine before considering purchase.

A subsidiary of the global brand, IAA in Canada provides vehicle suppliers and buyers with powerful solutions to process and sell insurance total loss, recovered theft, fleet lease, donation and rental vehicles.

In 2020, IAA introduced the salvage auction industry’s first 360 walk-around digital experience, IAA 360 View. Through the IAA 360 view, which provides high-resolution images and panoramic video, buyers can virtually inspect vehicle parts, components and damage through digital images and video. All IAA branch locations throughout Canada offer IAA 360 View for vehicles twelve years old and newer, unique classics, highend vehicles and exotics. The

“For recyclers, it’s huge,” said Vinesh Mistry, director of marketing and communications for IAA in Canada. “The engine and transmission are critical components when considering purchasing a vehicle, so we’re excited to bring that feature to Canada.”

The company is focused on bringing to market a complete merchandising capability including imagery, information, and personalization. The platform engages buyers with a vehicle digitally through unique, multiple touchpoints that provide the details needed to make confident online bidding and buying decisions. Merchandising tools and features provide buyers with an unmatched research process, improved purchasing guidance and greater trust. With its global reach, IAA attracts buyers across the globe.

To learn more about the company, visit ca.iaai.com.

BUYER’S GUIDE 2023 43

IAA CA.IAAI.com PROFILE

IAA’S NEW ENGINE STARTS OFFER 10-SECOND UNDER-THE-HOOD VIDEOS WITH FULL SOUND, ALLOWING BUYERS TO LISTEN TO THE VEHICLE ENGINE BEFORE CONSIDERING PURCHASE.

Multi-functional. Simple. No compromises.

SATA Special Edition 2021

SATA RPS Multi-Purpose Cup –

The cup system for mixing and painting

The SATA RPS (Rapid Preparation System) multi-purpose cup system performs four functions: mixing, painting, refilling, storing. The handling of SATA RPS is so easy because it consists of only three parts: cup, lid and sieve.

SATA RPS fits directly onto your SATA spray gun with QCC connector (Quick Cup Connector) without any adapters. It makes a technician's life much easier, considerably increases productivity and drastically reduces the consumption of cleaning solutions and solvents.

Bendable – allows the painting of sill areas or wheel arches "overhead" Stable – due to the screw connection between cup and lid, the cup always remains on the lid and gun even when touching obstacles. Easy removal of the lid in case of emergency – without soiling the working area.

Clean removal of the cup – by pressing the cup in, vacuum is created, which empties the material passage when pulling the trigger.

Constant material flow – helps the painter to achieve perfect coating results just like child's play.

Very quick colour change – cleaning becomes a minor matter

Available in 3 cup sizes: 0.3 l, 0.6 l and 0.9 l

Also available as UV version: 0.6 l

SATA Canada Inc.

125 Buttermill Avenue Vaughan, ON L4K 3X5

Phone: +1 905 660 1101

www.sata.com/sata-rps-multi-purpose-cup

Toll-free: +1 844 554 SATA (7282) Fax: +1 905 760 1250 contact@sata.ca www.sata.com

INFO

SATA CANADA

COMMITMENT, PRECISION, APPRECIATION, AND FUN AT WORK – THAT’S WHAT SATA STANDS FOR!

app and scan the QR code located on every box of SATA RPS cups to collect points and turn them into attractive rewards.

SATA continues a tradition of quality and technological leadership with the introduction of the SATA air vision 5000 system for health protection, the revolutionary SATAjet X 5500 spray gun and the SATA filter 500 series.

SATA is the first spray gun manufacturer to offer a nozzle system based on two distinct spray fan shapes for each nozzle size, parallel and oval shaped. The SATAjet X 5500 provides an incredible wealth of perfect solutions. For all kinds of painters. Using only one spray gun.

SATA Canada is headquartered in Vaughan, Ontario. The facility occupies a total of 15,000 sq. ft., including offices, warehouse, and training centre. The headquarters also features a service and repair facility with the goal of turning any product around within a 24-hour period.

SATA spray equipment has been available in Canada since the 1980s. When glossy surfaces are of utmost importance, painters swear by SATA. Our products are designed and manufactured in Germany, allowing demanding customers worldwide to obtain the perfect tools to create perfect finishes.

SATA sets the standard for paint spray guns, cup systems, breathing protection, filter technology and accessories. The company works closely with painters from various trades and industries as well as the research and development departments of leading paint manufacturers to allow us to produce superior products of the highest quality. “SATA Quality” is a firm conviction for any painter: reliability, durability and ergonomics of their SATA products are not something to be questioned.

The home of the SATA brand is Kornwestheim, a town in the district of Ludwigsburg, Baden-Württemberg, about 10 kilometres north of Stuttgart. SATA GmbH & Co. KG holds a leading position worldwide in the field of wet paint technologies, supplying distribution partners in 100 countries worldwide. SATA has a long history of producing high quality products dating back to 1907. The company’s original focus was the manufacture of medical instruments, beginning production of spray guns in 1925.

Throughout its history SATA has focused on meeting the demands of new technologies and perfecting its equipment to attain consistency for the industry.

In 1990 SATA introduced its High-Volume Low Pressure (HVLP) and Reduced Pressure (RP) technologies, which gave painters more options for atomization, while addressing growing environmental concerns.

In 2005, SATA pioneered a multi-purpose cup system, SATA RPS (Rapid Preparation System) for the efficient mixing, painting, refilling, and storing of paint. Paint facilities can participate in the SATA Loyalty Program and collect coins with every RPS cup. Simply download the

Launched in early 2021, the new SATA filter 500 series offers body shops 100% technically clean air. The SATA filter series 500 is available as a one-stage sintered filter with water and oil separator, as a two-stage combination filter with sintered and fine filter, or as a three-stage filter unit with additional sintered activated charcoal filter. Every six months, all filter stages are maintained together in a procedure that takes a few minutes without the need for tools, thanks to the bayonet lock and defined position of the filter cartridges, which are replaced by inserting them.

Sustainability is an integral part of SATA’s business activities. We assume responsibility in the areas of economy, ecology and social responsibility. The economic dimension implies securing the long-term success of the company, today and for future generations. This success enables us to engage in the social dimension. For many years, SATA has been supporting various local and global associations and aid projects.

At SATA, the ecological dimension includes the conservation of resources and avoidance of waste. SATA obtains 100% green electricity and district heating from a nearby biogas plant. Furthermore, SATA invests in environmentally friendly technologies such as geothermal energy and photovoltaics.

At SATA our success is an obligation to us. Our employees and distribution network will always do our best to ensure painting will remain plain fun.

SATA CANADA INC. 125 Buttermill Ave.Vaughan, ON, L4K 3X5 Office: +1 905 660 1101 Toll free: +1 844 554 SATA (7282) www.sata.com

BUYER’S GUIDE 2023 45

PROFILE PROFILE

224-SPANESI (224-772-6374) www.spanesi-americas.com facebook.com/spanesiamericas Spanesi Americas, Inc. 123 Ambassador Dr. STE 107 Naperville, IL 60540 14,500A welding machine 106 EXT structural straightening bench TOUCH electronic measuring system Multibench workstation PULL UP! repair system Q5.2 welding machine

The week before Orazio Spanesi’s 14th birthday, he was approached by a friend with exciting news—there was a job available.

Orazio was enthusiastic because his family lived in the country, and they were impoverished. So, he rushed over to meet with the business owner. During their conversation, the owner offered Orazio a job in a collision repair business and gave him a bicycle to use to get to work.

The bicycle was too tall. But that didn’t stop Orazio. He learned how to ride the bike by putting one of his legs under the crossbar and rode that bicycle to work for more than two years.

ORAZIO OPENS HIS FACILITY

In the summertime of 1969, Orazio Spanesi opened his first collision repair facility in the small village of Padova, Italy. Orazio used tools he created to repair his customer’s vehicles.

“Immediately, I knew that I could create equipment,” explained Orazio. “I never did it just for me, but I made it with the idea of selling it.”

While Orazio designed and tested his tools in his own business, he was also curious about what the rest of the world offered. He began traveling and visiting the national and international tradeshows, looking for the correct answer to his efficiency needs. Orazio realized that those tools just didn’t exist along the way, and the market was too slow to adapt to his business’s needs.

SPANESI BEGINS MANUFACTURING EQUIPMENT

Orazio took his passion, intuition, and experience to the collision equipment manufacturing industry in 1989, and when he founded his namesake business, Spanesi®, S.p.A. The very first frame straightening bench was manufactured in 1989, along with the Spanesi Universal Jig System. To date, the original Universal Jig System is still sold and has only had to be updated to accommodate aluminum vehicles.

In 1992, Orazio recognized there had to be a better way of measuring vehicles. So, he set out to show the world how to measure, repair, and document damaged vehicles. Designed from the ground up, Spanesi produced their first Touch electronic measuring system.

THE SPANESI 3600 CONCEPT

Spanesi’s vast and deep array of collision repair equipment offerings are widely accepted in most OEM repair programs today.

Spanesi is the only company to offer a complete Spanesi 360o Concept for the collision repair industry. From structural repair benches, threedimensional electronic measuring systems, vacuum systems, prep stations, spray booths, MIG / MAG welders (aluminum, steel, and silicon-bronze), squeeze-type resistant spot welders, office furnishings, paintless dent repair systems, and facility design services.

Even today, all Spanesi’s products are used in Orazio’s collision repair facility, which is now surrounded by his manufacturing plant in that small village of Padova.

BUYER’S GUIDE 2023 47 MORE THAN 50 YEARS OF PASSION AND INNOVATION

FAMILY COLLISION

A young Orazio

took his

intuition and experience

the collision equipment

A glimpse inside Spanesi America’s U.S. Training Centre. SPANESI AMERICAS, INC. 123 Ambassador Dr. STE 107 Naperville, IL 60140 USA 224 SPANESI | (224) 772-6374 www.spanesi-americas.com

SPANESI, A

REPAIR TRADITION

Spanesi. Orazio

passion,

to

manufacturing industry in 1989.

PROFILE

ABRASIVES ROUGHED UP

NEW MATERIALS AND EVER-INCREASING DURABILITY REQUIRE STELLAR ABRASIVES

If automotive technology is known for one thing, it is that as one area of focus advances, the others are obliged to follow suit, or risk the formation of a gap in which some repairs can be done, but others cannot.

As the paints and coatings we apply to vehicles become increasingly more durable and chemically complex, we must continue to innovate in the field of abrasives so that no matter how nice that paint job ends up being, it can still be sanded down and refinished again one day.

Materials like aluminum, high-strength steel and carbon fibre come with unique challenges to a refinisher and quality products are crucial to ensuring proper work is done, right from the very first step.

The world of abrasives has undergone significant change over the years in order to keep in step with automotive coatings, and that progress can still be observed in the advancement of new types of sandpaper and material smoothing technologies.

A quick glance under a microscope would show even the completely uninitiated a

Much has changed since we were gluing sand to a strip of paper and calling it a day.

world of difference between the capabilities of the common sandpaper of the past, to the carbon-based, precision-engineered paint-stripping tools that the techs of today keep on-hand every day.

Much has changed since we were gluing sand to a strip of paper and calling it a day.

With what was formerly cutting-edge paint technology now starting to come of age, especially when we consider the ongoing Honda Civic paint peeling debacle, the abrasives industry will have its work cut out for it in the coming years as many drivers attempt to return the shine to their shabby paint jobs.

The pages to follow will feature just about every product a repairer would need to bring a vehicle down to its bare bones, so that it can be brought back up as something even better.

48 BUYERSGUIDE.COLLISIONREPAIRMAG.COM

The world of abrasives has undergone significant change over the years to keep in step with automotive coatings, and that progress can still be observed in the advancement of new types of sandpaper and material smoothing technologies.

www.motivatedreps.com

www.3Mcanada.ca

3M™ Blue Net Disc