INVESTMENT UNDER $50,000

Part of Fix Network – Canada’s largest automotive aftermarket services provider

Global expertise –operating in over 1,300 locations in over 30 countries

Choose NOVUS Glass, a true partner in your success. We believe in our business and so should you!

Turnkey opportunity with NOVUS mobile van supplied

Offer both chip repair and full crack repair up to 12 inches

Currently have 27 patents for glass repair products with our R&D team

Extensive operational training program provided with dedicated support manager

Established supplier relationships & buying power

Creative & target marketing solutions provided

14

Desirae Ellingsen has painted Lamborghinis, McLarens and more. She originally wanted to be an English and Spanish teacher— now, she’s set to mentor others on how far confidence can drive your skills career.

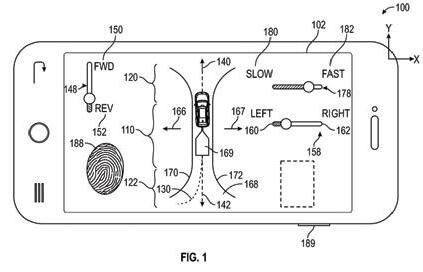

26 BAMBOOZLING BLUEPRINTS

Five of the strangest patents currently being pursued by OEMs.

29 ARTIFICIAL INTELLIGENCE CHECK-IN

How much does the industry understand about AI in the bodyshop? We asked—you answered.

33 TIME TO WIN

Women’s Industry Network gets to work on a new Canadian branch. See how you can get involved, regardless of gender.

04 PUBLISHER’S PAGE by Darryl Simmons

32 GROUND RULES by Meghan McEwen

34 FINAL DETAIL by Allison Rogers

For this magazine, this industry always has something to celebrate. This year is a bit special for Bodyworx Professional though, 2023 marks this magazine’s tenth year in publication.

For the last ten years, our focus at Bodyworx Professional has been on people. This magazine is for the people of our industry, no matter your role. Whether you’re spraying magic in the paint booth or shooting sparks in the welding bay; at the front desk answering phones or sitting in

simply honouring the tradition of performing safe, high-quality, compliant repairs.

The entire automotive world is amid a shift—longtime members of the sector know that’s a constant around here. But, despite the onset of electric vehicles, explorations in newer and lighter materials, ever-changing paints and the like, Canada’s love affair for the car will forever reign strong. Perhaps it was stronger back when teenagers hung around laneways, clinging to the one guy who had his license and that lemon that

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

STAFF WRITERS

Max Reid | max@mediamatters.ca

Kate Ng | kate@mediamatters.ca

GRAPHIC DESIGN INTERN

Alecia Basdeo | alecia@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677 wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

AUDIENCE ENGAGEMENT MANAGER

James Kerr | james@mediamatters.ca

CONTRIBUTORS

Meghan McEwen

SUBSCRIPTION

One-year $25 / Student Discount is 10%

a classroom learning the ins and outs of collision repair. No matter where you’re at in your automotive career, this magazine is for you. We are here to tell your story, to be your voice and to provide top-notch insights for techs, painters and the like, all across the Canadian collision sector.

The mission of Bodyworx Professional will forever remain the same: to inspire, educate and celebrate the hard-working, often unrecognized people of our industry. As I wrote in the very first issue, we understand that the work by the hardworking members of Canadian bodyshops is not all about glamour—there are enough glossy photos of pretty paint jobs and perfect welds elsewhere. This magazine is about problem solvers, the people who think before they react; the people with creative visions they can express in a myriad of ways, whether it be through custom paint, building hot rods or

always seemed to need tweaking. Maybe it was stronger, or maybe it was just different. The way people love cars has evolved in the very same way the cars themselves have advanced.

The community is still alive. There will always be a strong semblance of passion associated with this industry. Change is upon us, and it’s time to reintroduce the youth to the joys of our world; to show them the various opportunities this fantastic field offers. And Bodyworx will be there the entire time.

Here’s to celebrating this industry via Bodyworx for the last decade. We hope you stick around for the next.

Bodyworx Professional ™ is published quarterly, and is dedicated to serving the professionals of the collision repair industry. It is published by Media Matters Inc. Material in BodyworxProfessional™ may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL

SALES PRODUCT AGREEMENT

No. 40841632

RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough ON K9J 3R2

“We acknowledge the financial support of the Government of Canada.”

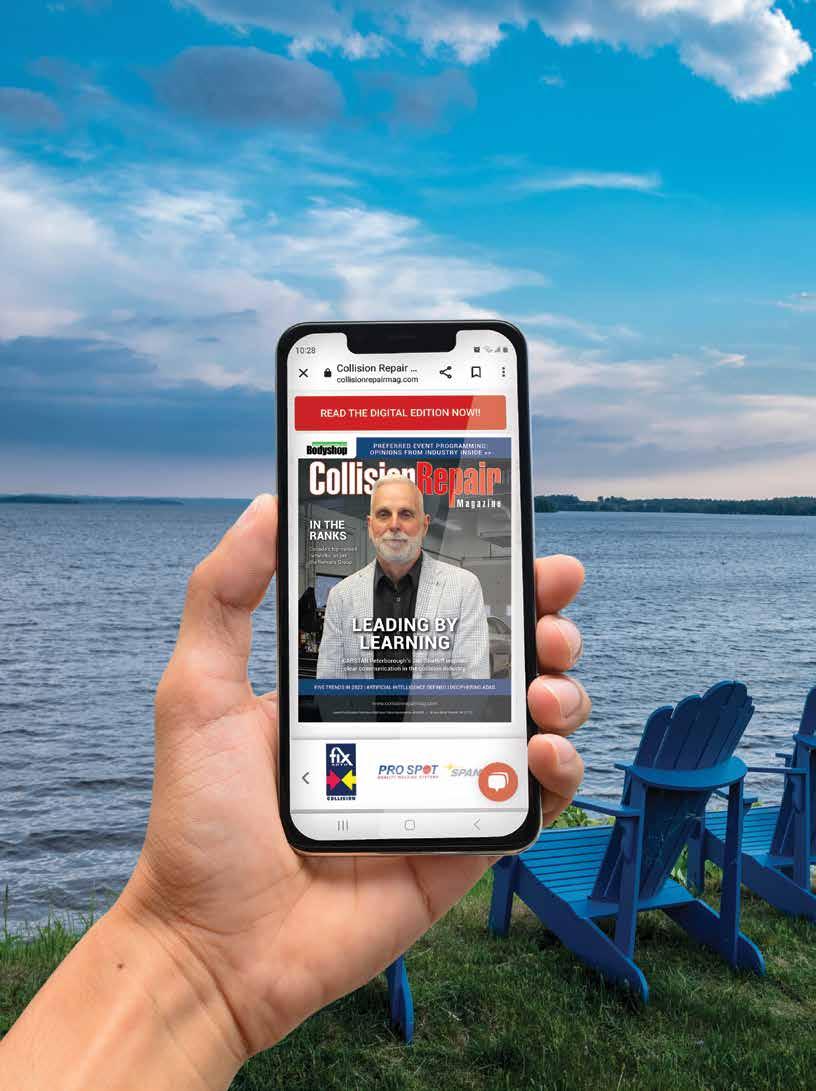

Bodyworx Professional is published by Media Matters Inc., publishers of:

PASSION FOR YOUR WORK HAS THE POWER TO INSPIRE

The mission of Bodyworx Professional will forever remain the same: to inspire, educate and celebrate the hard-working, often unrecognized people of our industry.

The Automotive Industries Association of Canada (AIA Canada) has appointed Stuart Klein as the organization’s senior director of collision, a newly created position. According to AIA Canada, he will join the association’s senior leadership team, directing AIA Canada’s efforts in the collision sector of the industry. Klein brings more than 45 years of collision industry experience to AIA Canada and previously worked in Fix Network’s training facility in Milton, Ont. He is an advocate of continuous training, and has been involved in industry-youth outreach programs.

The Society of Collision Repair Specialists’ (SCRS) recent blend study is making estimating system providers “reevaluate” the numbers they’ve been reporting, SCRS executive director Aaron Schulenberg told attendees at a recent board meeting. The study results, first released November 1, showed blending took 31.59 percent longer than a full refinish–not 50 percent less time, as reported by three estimating platform providers. The study involved five primary North American coatings companies, who were not identified, and a full week of blend tests on 45 2018 Ford F-150 parts: 15 RT front door shells, 15 RT fenders and 15 hoods. Both CCC/Motor and Mitchell told Repairer Driven News in November they were reviewing the results of the SCRS’s audited blend study, in collaboration with five primary North American coatings companies. Mitchell told the outlet it was “always open to discussions with SCRS on the subject,” while CCC is working to “review observations, including scope, conditions, techniques and materials used.” The latter said it would share more once its review is concluded. Schulenberg also stressed that none of the information providers in the study–CCC/Motor, Mitchell International and Audatex–were given the results in advance.

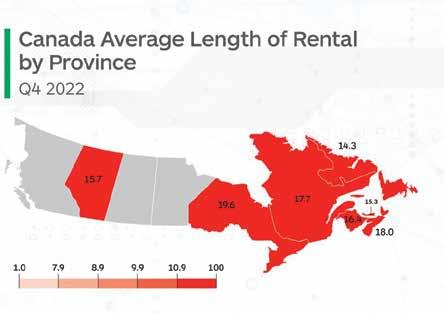

Enterprise published its length of rental report for Q4 2022 on Tuesday, with results that, in one respect point to pre-pandemic levels of stability, but otherwise bear much of the same disheartening news as LOR reports of the recent past. Enterprise says that despite an average length of rental (LOR) increase of 4.3 days year-over-year, resulting in a new national average of 17.1 days, the quarter-over-quarter findings of this report are in line with historical LOR trends of Q3 and Q4 pre-pandemic. The rental car company points to the U.S.’s year-over-year increase of only 1.7 days from Q4 2021 as a marker of some return to pre-pandemic normalcy. On a provincial level, Ontario yet again posted the highest LOR nationally, with the province experiencing a 5.3 day year-over-year increase, thus bringing its average Q4 2022 LOR to 19.6 days. Nova Scotia tailed Ontario just slightly, recording an average LOR of 18 days, up 4.6 days from this time last year. Quebec saw the most significant change in LOR over the past year, with the province’s average jumping 5.8 days from 11.9 to 17.7. On the other end of the spectrum, Newfoundland and Labrador posted the lowest LOR across the board at 14.3 days, followed by Alberta and Prince Edward Island, coming in at 15.7 and 15.3 days respectively.

“I’m excited to bring my experience to this newly created role,” Klein told Collision Repair at CCIF Toronto in February. “It feels like a very natural progression for me, and I’m looking forward to helping the entire collision sector toward a bright future.”

For ten years, Bodyworx Professional has been the only magazine of its kind serving the Canadian collision repair market, a magazine for techs, painters, and all the folks on the shop floor that make collision repair possible. Bodyworx Professional has spent the decade highlighting the importance of training, sharing stories from up-and-coming people in the collision repair industry, and providing exciting, up-to-date news. If you’re on the shop floor then Bodyworx Professional is made for you.

We’re committed to bringing you the very best with Bodyworx Professional. Come celebrate our birthday with a FREE subscription to Bodyworx Professional magazine, in print or digital format.

To subscribe scan the QR code here, visit our website and click ‘subscribe’, or email circulation manager James Kerr at james@mediamatters.ca.

Tesla has expanded the use of automated assembly robots to its Fremont, California factory, following the City of Fremont granting Tesla a permit to install “power and structural anchorage to support two new robots required to automate fascia inspection.” According to a Drive Tesla Canada, this decision may have come from build quality complaints regarding Fremont factory vehicles—a contrast to newer factories which use quality control robots, automatically scanning vehicles for various deficiencies. A source familiar with plans said these robots are produced by EINES, a company that develops automated systems suited for measurement, error detection and machine vision in the automotive manufacturing sphere.

General Motors has issued an updated position statement on its standards for aftermarket glass replacements, hammering home the opinion that non-OEM glass could compromise the safety standards of their vehicles. The legacy automaker asserts that any glass but its own will cause problems with sensor systems that are housed within the windshield. “With the safety of our customers at the center of everything we do, it is critical a service point calibration/learn to be performed whenever a front view windshield camera or sensor is removed and reinstalled or replaced, or when a windshield is removed and reinstalled or replaced,” the statement said. Several other OEMs, including Ford and Volvo, have issued similar position statements regarding windshield replacements.

Two years after the first announcement of Project Arrow, the all-Canadian concept car made its debut on the international stage. Unveiled in January at the Consumer Experience Show in Las Vegas, Project Arrow showcases the design efforts of 58 Canadian industry partners. Everything from seats to advanced cyber security has been sourced from a Canadian company, says the Automotive Parts Manufacturers’ Association (APMA). “The Ontario government challenged us to build this vehicle and they were the first to support us when we launched Project Arrow,” said Flavio Volpe, president, APMA. “This investment is just another part of this government’s incredible and unprecedented commitment to Ontario’s automotive industry.”

While there are critics who say that such position statements allow OEMs to have a monopoly on certain parts, a spokesperson from GM insists aftermarket glass cannot be tested and appraised in the same way the company’s proprietary offering can.

A BMW owner has discovered a new restriction imposed by the OEM: vehicle software that won’t update when the vehicle is parked on an incline. “In ‘sentences that would make your nan’s head explode’: I can’t update my car because I live on a hill,” tweeted Clare Eliza, the owner of an electric i4 vehicle. This tweet is accompanied by a photo of her vehicle’s screen, which instructs the driver to park the vehicle on level ground as “the road is too steep to start the installation.” For some context to this seemingly unreasonable limitation, this restriction is explained by a former BMW software developer as a precautionary safety feature, rather than a grudge against people on hills. In an interview with Drive Tesla Canada, a BMW Canada spokesperson confirmed that there is no way for owners to override the limitation.

Get ready to take your business to the next level with the ultimate mobile tire solution. Join our team of successful franchise owners and offer your customers convenient and reliable tire services right at their doorstep.

Go with the GoMobile brand, co-brand, or go on your own. Raise awareness of your company and your brand by turning the fully-equipped and modern Mercedes van into a mobile billboard.

Our cutting-edge mobile tire trucks are equipped with state-of-the-art technology, ensuring ef cient and accurate services. Our highly trained technicians provide quality services in a timely manner, making us the leading mobile tire company in the industry.

As a franchise owner, you’ll bene t from our established brand recognition, comprehensive training, and ongoing support. With our proven business model and low startup costs, you can be up and running in no time.

You know the business. Now expand on it. Take it on the road.

BETAG North America recently celebrated the first graduating class of its Outer Panel Repair Specialist (OPRS) program at Saskatchewan Polytechnic, where participants fine-tuned their ability to perform top-notch panel repairs. Supported by the Saskatchewan Association of Automotive Repairers, BETAG’s four-month OPRS program aims to equip participants with the skills to complete various sizes of panel repair on steel and aluminum, in addition to plastic restoration and glass removal.

Axalta Coatings and SATA have announced a new training partnership, replacing the Axalta Training Center in Ajax, Ontario, with Axalta Training at SATA Canada. According to a press release from Axalta, this partnership will provide Axalta and its refinishing customers access to the new SATA Ontario location. Axalta refinish customers will have access to paint technician courses including tri-coat colour application, matte finishing, micro repair and more classes using Axalta tools. This new location features two spray booths, a classroom, a lunchroom and a fully equipped work area.

The Canadian Welding Bureau (CWB) Welding Foundation has launched a new program, aiming to promote education, confidence, personal growth and experiential learning for women interested in welding-related skilled trades. According to a CWB press release, this is a 64-week pre-employment program that started in June 2022 and will run until Aug. 2023 across Canada, offering practical theory, hands-on welding training and skills development in a supportive and flexible learning environment. Furthermore, participants can obtain up to eight CWB welding qualifications, preparing successful candidates for a future apprenticeship, post-secondary education, or employment.

Suburban parents looking for the latest in luxury combat cars can look forward to Rezvani’s Vengeance SUV, starting at US$285,000. The vehicle is best showcased in a viral video by Mobile Mama, a TikTok channel specializing in quick reviews of family vehicles. The video has clocked in 5.7 million views and showcases a variety of comfort features you might expect in a luxury SUV: cupholders, heated leather seats, air conditioning and a curved OLED display. Those with a military background may be bemused to learn about the vehicle’s steel ram bumper, blinding lights, smoke screen emitters and strobe lights: features perfect for the silver screen, but not the real world.

While the civilian armoured vehicle market has cornered its niche market in civilian VIP protection by security agencies and the ultra-wealthy, real-world-tested vehicles like the Huron and Mercedes G63 AMG typically run for twice the cost of the Vengeance.

Toyota fans of yesteryear often ask themselves: whatever happened to the Previa? Well, to answer their question, people did stuff like this to them. That’s why the Japanese OEM stopped making them. We can’t have anything nice.

Some people like car shopping, but two people took it literally when they drove an Audi through the front doors of the Vaughan Mills shopping mall on Wednesday. According to Global News, York Regional Police said the break-and-enter happened after 1 a.m., when two suspects used a stolen black 2011 Audi A4 from Quebec to enter the mall and steal from an electronics store.

“When I was a kid, automotive wasn’t something I thought I would get into. My brother, dad, grandparents were all in the automotive industry, dealing with the mechanical aspect.”

— DESIRAE ELLINGSEN, Head painter at Mervyn’s The Body Shop

In the age of keyboards and digital work, making a handcrafted masterpiece is a dream that few people will ever achieve. For one Okanagan, British Columbia, resident, its just another day’s work in the shop’s paint booth.

Desirae Ellingsen has already established herself as a confident, expert painter with seven years of experience under her belt. Since graduating from Okanagan College, she has joined Mervyn’s The Bodyshop as the shop’s head painter, earning her journeyperson certification and completing Red Seal certification.

All that’s left is for the certificates to arrive in the mail, she says. But, as with most valiant life efforts, this was the culmination of years of hard work and sweat.

Later on, she uncovered a passion for vehicle restoration, working at Prestige Collision in her hometown of Kelowna, B.C.

This piqued her interest “mainly because of the artistic aspect. I don’t have to work on the motor or anything like that—I can deal with the panels and make it look really nice, and I’ve always been a perfectionist at heart.”

She began work, learning from her co-workers and proving herself on the shop floor.

“Right out of the gate, I got to paint Lamborghinis, McLarens and all of these really cool vehicles that not a lot of people get the opportunity to paint. That’s always been really, really fun for me and it is nerve wracking, At the same time, being able to start on these vehicles has given me such a base set for working on everything else.”

Today, she is the head painter at Mervyn’s The Body Shop, with most of her work taking place in the shop’s high-end production booth. Beyond that, she boasts another five years of painting experience across her career.

Like many others painters, looking at the final product made the process worth it. Going layer by layer, finishing it with a glossy clear coat has an indescribably warm feeling—a tangible, physical reward for hours of focus and perfect application.

None of this disguises the common issue of harassment and discrimination facing women across multiple industries, which Desirae says ultimately comes down to luck of the draw. She has been lucky to have a supportive environment, but knows friends with less fortunate experiences.

“I’ve been really lucky. I grew up in a household with a lot of men in it, so I understood their humour and the things they say. As I’ve gotten older, I find there’s a lot less disrespect than people think there is.”

“I worked very hard to earn respect [from my peers], but I think it really comes down to the people you work with. I have friends in other fields and they’re not treated half as nicely as I am in my day-to-day routine.”

— DESIRAE ELLINGSEN, Head painter at Mervyn’s The Body Shop

While satisfied with her career in autobody, she is less than thrilled with the lack of attention placed on the trades in high schools. Her entry into the trades was the result of having family members already involved in the automotive sphere—her school pushed university as the only viable institution for aspirational young adults.

While she initially wanted to become an English and Spanish teacher, plans changed when she discovered the sheer expenses involved with a university education.

“They wanted me to come up with this whole presentation of how I was going to go to university, take out all of these loans and pay for this over the years. I never really told them that I can’t afford university, so I’m not sure why I’m making this plan.”

“They never really offered me the lower cost option of college, or even community college. They said if you want to be successful, you go to university.”

While Desirae went through some exposure to trade school through metal and woodworking courses, she describes them as mandatory classes she took when she was 15—mandatory classes taken for credit, not for practicality.

Effectively, the school presented a falsely restricted picture of the post-secondary education

landscape, with university taking precedence over all others. For students with economically challenged backgrounds and women, it gets worse, with targeted advertising serving as an inadvertent gatekeeper against those who are simply not targeted.

“It was never really given to me as an opportunity.”

“I wish that they would push trades more in general, specifically for women. Towards [athletically inclined] men they said, look at these trades you can get into. Where I was, they didn’t that much with the girls.”

While Desirae is proud to overcome one of these examples of gender inequality, she still wishes one of her teachers in school said, “you can be a badass woman in a male dominated industry if you want.”

Until she gets the chance to inspire the next generation, she plans to keep doing what she already does—refine her paintwork, keep working with her team, and create better works than yesterday. Despite being the head painter on the team, she never has the chance to let a skill go rusty.

“It’s 2023, everyone is doing everyone’s job. We have our positions but whenever one of us needs something, we switch and finish what needs to be done.”

“I try to learn something every day. And hopefully, I’ll get to the point where I can be that person that goes around schools and inspires kids to get into trades, especially girls.”

— DESIRAE ELLINGSEN, Head painter at Mervyn’s The Body Shop

Tropicana Employment Services hosted its long-anticipated Collision Repair and Auto Body pre-apprenticeship graduation, where the not-for-profit honoured three classes of now-working apprentices.

The celebration honoured three graduating classes—the classes of 2020 and 2021 had their originally scheduled ceremonies cancelled due to the pandemic—and was held at Centennial College’s event centre.

The night kicked off with a cocktail reception overlooking the sunset over the Toronto skyline.

Graduates, families and industry delegates were treated to a first-class dinner spread, catered by the students of Centennial College’s culinary program.

Scarborough Ontario-Guildwood MPP, Mitzie Hunter, and many other community representatives showed their support at the event.

“Graduates, this is only the beginning of your journey,” said Hunter during her address.

“There will be hard work ahead and the advanced technologies and repair procedures on today’s vehicles do not always come easy

“The advanced technologies and repair procedures on today’s vehicles do not always come easy, but this is what makes a trade qualification so valuable.”

— ALAN MCCLELLAND, dean of Centennial College School of Transportation

Locally owned and operated, CARSTAR facilities employ certified and dedicated technicians to provide premier repairs to their communities.

Learn why CARSTAR is the leader in collision repair excellence by visiting CARSTAR.ca

but this is what makes a trade qualification so valuable,” advised Alan McClelland, dean of Centennial College’s School of Transportation. “As a Red Seal technician myself, I can say with confidence that over my 40-year career, I have found the work extremely rewarding and have never been without employment.

“I wish the very same for you. Celebrate this moment with your family, friends and classmates; and then catch your breath because your journey has just begun!”

Tropicana also honoured its industry partners I-CAR Canada, 3M Canada, LKQ Toronto East, AkzoNobel Coatings, CARSTAR, the Toronto District School Board, Centennial College, Assured Automotive and CSN 427 Auto Collision.

Tropicana’s classes of 2020, 2021 and 2022, who completed their pre-apprenticeship training through Tropicana’s partnership with Centennial College, have all embarked on Level 1 apprenticeship training and are placed at facilities across the Greater Toronto Area. Some students have even begun their Level 2 training.

Let’s give a big collision repair congratulations to Robert Bearchell, who was recently named 2022 Technical Instructor of the Year by Axalta. Bearchell, once a student of the much acclaimed auto body program at the Northern Alberta Institute of Technology (NAIT), and an Axalta instructor for the past 17 years, says 2022 was a busy year, but a great deal was accomplished.

Working largely out of Axalta’s Vancouver training centre, Bearchell is being recognized for his ongoing support in training painters, as well as for supporting the Skills Canada National Skills Competition that took place in Vancouver last May, and where Axalta was primary paint supplier.

Additionally, he told Collision Repair that the award is given to the instructor who meets and exceeds goals, achieves high levels of satisfaction from students and supports their regional sales team.

News of Bearchell’s award spread via a LinkedIn post from Axalta’s North American training manager Normand Cormier, who wrote that the honour was, “well deserved.”

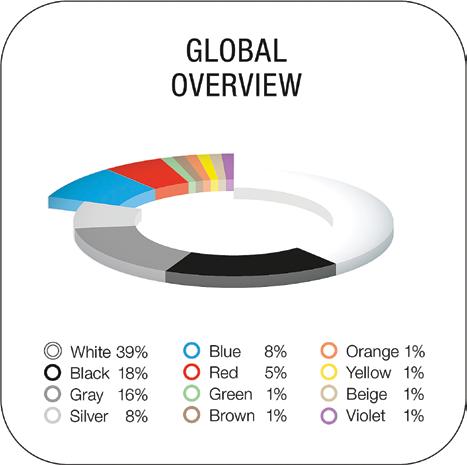

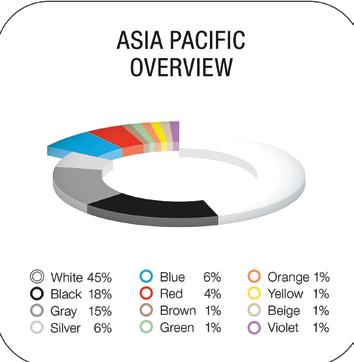

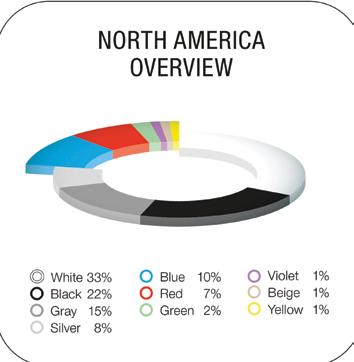

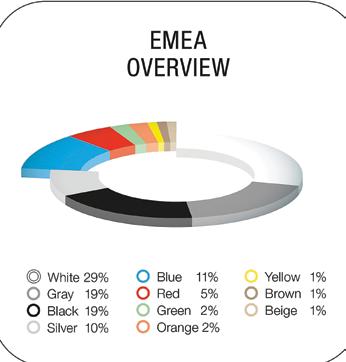

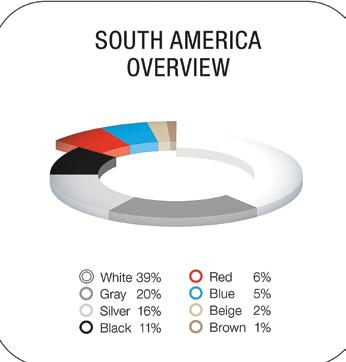

White and black car coatings remain king across the world, but the rainbow of automotive colour broadens, according to BASF’s 2022 Color Report for Automotive OEM Coatings.

According to the report released on Jan. 18, 2023, achromatic colours continue their dominance, largely due to their prevalence on non-commercial vehicles produced in 2022–in other words, fleet vehicles.

White remains the most popular car colour globally, with BASF describing it as a timeless classic with a high resale value.

Outside of the achromatic scale, red and blue remain especially popular colours in North America. However, yellow, orange, green and violet grow in market share, which BASF explains as automakers embracing a wider range of diverse colours than before.

“If you look at the heavy hitters among the chromatic colours, blue and red are on top. But with people turning more to nature, natural colours like green, yellow, violet, and beige are making their mark,” said Liz Hoffman, head of design.

Meanwhile in Europe, the Middle East and Africa (EMEA), white and black saw gains, though BASF says the region has gotten more colourful. Besides losses in market share for grey and silver, yellow, orange, brown and green increased by a few percentage points.

Asia Pacific saw a six percent increase in grey shades, with solid and pearl colour effects being notable for adding diversity in the same hue. While white remains the most popular,

growing colour ranges in small vehicle and neighbourhood electric vehicle sales have translated to fairly consistent demand for brown, green and violet.

South America’s preference for the achromatic tones continues, with brown gaining market share, especially among smaller vehicles. While red and blue remained stable, development in paint effects for achromatic hues continues.

“Car buyers are also looking for a vehicle color that conveys their positivity,” explains Liz, head of design.

You may not have the same variety but within each colour space, there are some really exciting and different effects,” said Marcos Fernandes, South American director of regional business management.

“Some gray shades with blue or violet undertones are working their way into the market, with solid-like and added-colour pearl effects showing great diversity.” said Chiharu Matsuhara, head of design.

“When you add the market share of yellow, orange, brown, and green, you can see more hues and diversity that has developed in the last year or two,” said Mark Gutjahr, head of Automotive Color Design.

BY ALLISON ROGERS

BY ALLISON ROGERS

Innovation is a staple of this industry. Every single day, automakers and other industry stakeholders file patents aimed to revolutionize the modern vehicle.

While trends of today tend to centre around driver safety systems and electric or autonomous vehicle endeavours, other systems are, frankly, far less practical. And we know those at the top likely aren’t considering how the production teams on the bodyshop floor could repair such emerging technologies.

The Collision Repair team collected a list of some recent head-scratchers in the area of OEM patent pursuits. Check out our top-three findings below.

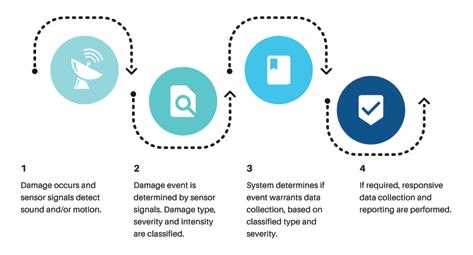

Ford’s latest patent seeks to revolutionize the first-notice-of-loss process.

Ford’s patent seeks to allow connected and non-connected vehicles to not only identify vehicle damage in real-time, but to perform incident management and reporting. The system would be able to detect damage and alert the driver in real-time, via an incident claim form automatically passed to the required third party, if indicated; i.e., an insurer, police, EMS or tow services.

The OEM says the patent is designed to detect often-unnoticed dings, dents and scrapes that can occur when a vehicle is left unaccompanied in a high-traffic area, like a parking lot. Damage may be determined using sensors on a vehicle using machine learning models, says Ford.

“Once a [machine learning] model is trained, a continuous signal output response from the sensors may be integrated into the trained model, which can then classify damage into different categories or types. Another model can be trained to identify the type and/or intensity of the damage. Constant noise or vibration present in a static vehicle can also be trained and eliminated by this [machine learning noise] model. Inputs

can be integrated from multiple sensors, like accelerometers, gyroscopes, sounds or vibrations—just to name a few to identify the type of damage and its intensity.”

The OEM stresses that the system and methods described in the patent could also be used to determine vehicle damage when a vehicle is not in motion, or turned off entirely. Some methods for communicating damage on non-connected vehicles could include blockchain processes to communicate the damage with relevant parties. Communication with an insurance company of either the damaged vehicle or the damage-causing vehicle could also be used to initiate first-notice-of-loss and the claims process.

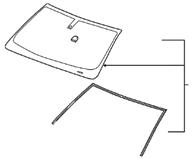

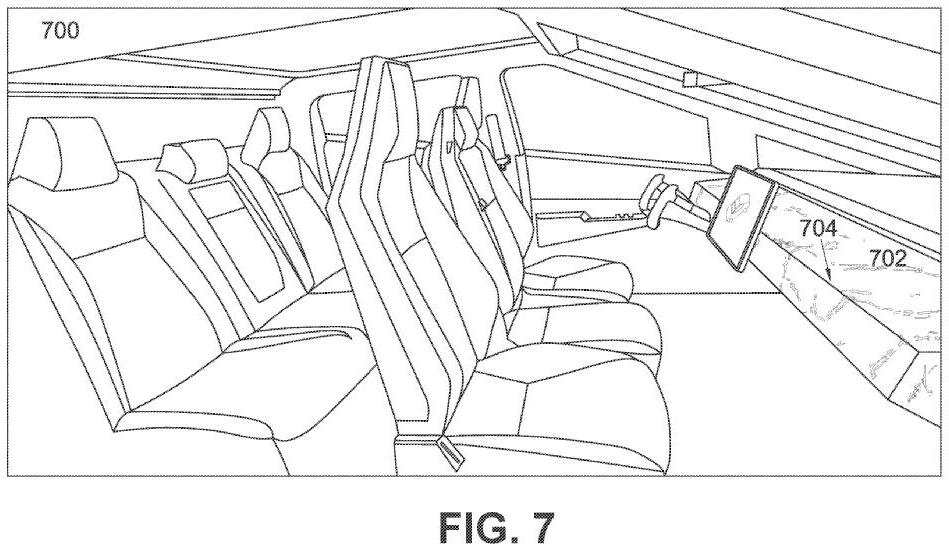

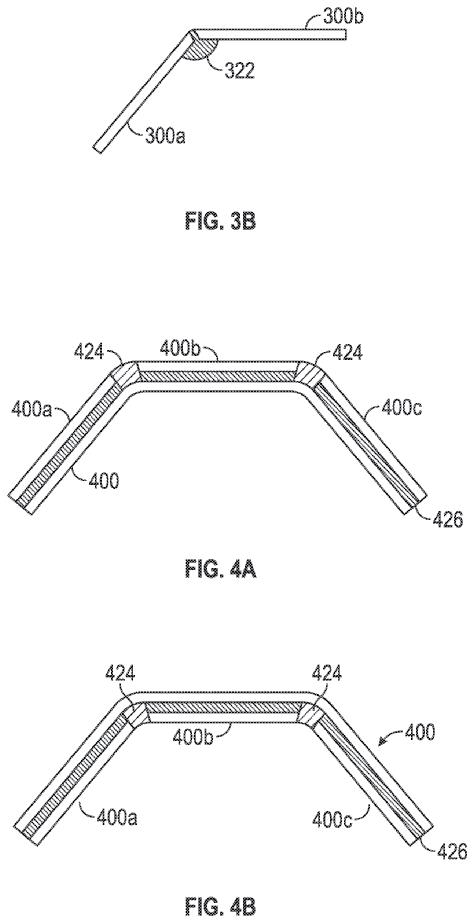

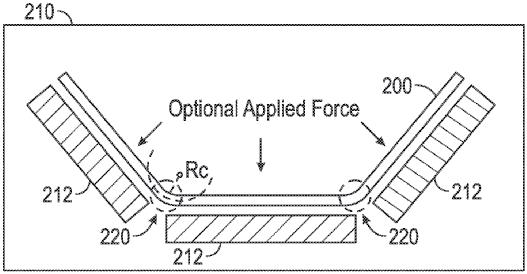

Tesla has some unique plans for the Cybertruck windshield, according to a patent filed to the United States Patent and Trademark Office (USPTO)—and it’s pretty mind-bending.

A patent titled ‘Automotive Glass Structure having featured lines and related methods of manufacture’ was granted on January 19, and explains that heat can be used (i.e., applied to the glass) at certain locations so the Cybertruck windshield can be bent to achieve curvatures between 2mm and 5cm. The EV automaker also said the windshield could incorporate “additional layers of curved or joined glass…to form a curved multi-layer glass structure for automotive use.” The patent says that, typically, only smooth, high radius of curvatures (between one metre and three metres or more) are used for automotive glass structures.

“An example method [in the patent] includes applying localized heat [e.g., via a laser, heating element] to a location of a substantially planar glass structure and bending the glass structure at that location [e.g., along a line of the planar glass structure] to form a feature line in the glass structure,” reads the patent. “The techniques described herein. May allow for forming glass structures with aggressive curves or folds.”

Bends in the glass could be between five degrees and 120 degrees, or between 45 degrees and 60 degrees. Glass pieces may also be connected using adhesive.

“This adhesive may be similarly locally heated to allow for aggressive feature lines.”

The patent suggests that tools like lasers, heating resistors (e.g., tungsten wire, rod), flame, plasma radiative (e.g., diode) could be used to provide the required heat for the bending process.

We know those at the top aren’t likely considering how production teams on the bodyshop floor could repair such emerging technologies.Figures 3A, 3B, 4A and 4B illustrate a process for forming a glass structure “according to another embodiment,” reads the patent. The conventional process for bending automotive glass structures, according to the patent. The vehicle interior as drawn in the patent.

In December 2022, Ford filed a patent for vehicular remote control capabilities using a smartphone as a controller.

The system described in the patent indicates it would be used to aid the towing of a trailer. Control input on the user’s smartphone could be used to generate a signal for controlling the movement of the vehicle and trailer.

“Operating a vehicle with a trailer in tow can be very challenging for many drivers,” writes Ford in the filing. “A system with a remote device may be used to assist with operating a vehicle with an attached trailer. It is desired that the operation of the vehicle with the system is done when the user is actively using the remote device.”

“For example, the display is a touchscreen display and the mobile device is configured to display inputs that can be selected or manipulated through contact or gestures on the display,” reads Ford’s filing to the USPTO.

“A trailer is coupled to the vehicle via a hitch such that the vehicle is able to push or pull the trailer to another location.”

The remote-control capabilities are to be used for towing trailers, says Ford in the patent filing, but who’s to say the technology’s applications are limited there.

Cutting-edge artificial intelligence has quickly found its way into much of the equipment collision repair technicians use on a daily basis, as well as the systems that help manage repair facilities.

When we see the phrase “powered by artificial intelligence” or “driven by machine-learning” on a new welder, spectrometer or estimating system, it sure does sound impressive, but how many currently working in this industry actually understand what those terms mean?

With issues like vehicle data access and the right to repair movement near the top

of many collision managers’ list of looming concerns, it is imperative that repairers and managers have a grasp on what sort of data is being collected within their shop, how they can use it to their benefit, and ultimately be given a seat at the table when ownership debates inevitably arise.

To that end, we reached out to our readers to get a gauge of not just how knowledgeable they are about AI on an individual level, but how supported they feel by an aftermarket industry that is loading up bodyshops with “smart” equipment en masse.

Of those who responded, which ranged from collision managers to suppliers and front-end staff, the majority of our readers said that they felt they had a reasonable understanding of the AI at work in various corners of the workplace, though opinions were split as to whether they consider AI to be a general good for the industry.

The field of AI is, by its nature, ever-evolving and holds the potential for both positive and negative industry disruption. Follow along with our survey results and get analytical about AI.

81.8 PERCENT COLLISION CENTRE STAFF/OWNERS

9.1 PERCENT FRONT-END STAFF

9.1 PERCENT SUPPLIER/DISTRIBUTORS

“There is so much variability in what we do. No two accidents are the same. Using AI to tell us how we should be doing our job is absurd.”

“There are many basic, but time consuming tasks that AI should be able to do. Like the setup of customer and vehicle info into the softwares.”

“I feel [AI] will have a net positive benefit, but that its impact is overstated hugely.”

“AI could save time for all from the FNOL to handing the keys back to the customer when repairs are complete.”

“Get yourself a copy of Digital Minimization and absorb the information. The knowledge found in those pages are founded!”

Q: WHERE CAN YOU FIND AI IN YOUR WORKPLACE?

On estimating/management systems — 63.6 PERCENT In welding technology — 27.3 PERCENT Paint mixing/spectrophotometers — 54.5 PERCENT Using frame/measuring machines — 18.2 PERCENT Online chatbots/automated receptionists — 36.4 PERCENT Scan tools/calibration systems — 63.6 PERCENT

Q: ON A SCALE OF 1-5

(1 being no understanding; 5 being strong understanding)

HOW WOULD YOU RATE YOUR UNDERSTANDING OF THE ARTIFICIAL INTELLIGENCE PRESENT IN YOUR WORKPLACE?

1: 27.3 PERCENT

2: 45.5 PERCENT

3: 9.1 PERCENT

4: 18.2 PERCENT

5: 0 PERCENT

“There isn’t enough information to really understand where AI is used and whether it is helping the process. I do not understand the five levels of vehicle autonomy.”

“I wish to be more knowledgeable regarding how AI will alter the repair process.”

Q: DO YOU FEEL THAT THE IMPLEMENTATION OF AI AS GENERALLY POSITIVE OR NEGATIVE MOVE?

54.5 PERCENT said POSITIVE 45.5 PERCENT said NEGATIVE

Q: HOW WOULD YOU RATE THE PERFORMANCE OF BUSINESS PARTNERS IN EDUCATING SHOPS ON HOW AI WORKS?

(From 1-5)

1: 63.6 PERCENT

2: 36.4 PERCENT

3: 0 PERCENT

4: 0 PERCENT

5: 0 PERCENT

There are two large forces in play which, together, are wreaking havoc within the automotive service industry. A rapidly aging and exponentially disappearing workforce combined with significant difficulty recruiting young, new talent have already made for dire consequences throughout the sector. Let’s look under the covers and see workplace culture as it exists in Autobody today.

required to spend an estimated $40,000 on tools when options like plumbing, electrical, and numerous others subscribe to much higher pay programs right away? Let’s be real—it’s insulting to enter a trade at minimum wage.

The post secondary institutions who provide the technical training component in the automotive service sector are woefully behind the rapidly advancing technology being produced by automotive manufacturers.

I won’t lie—automotive trades are not for the faint of heart, in no small part due to old-school values (or lack of values) and disregard for safety are still prevalent on certain shop floors today. This goes a long way to explaining why women make up barely two percent of the workforce within the automotive trades for all North America. Not exactly accommodating numbers!

Wages in automotive still populate the lowest end of the scale, as compared to other skilled trades. Where is the incentive to become an automotive technician, and be

The manufacturers themselves can barely keep up with their own technological pace. Is it any wonder that there is a severe lack of interest in the autobody trade from young people entering the workforce?

Employers, manufacturers, and educators must do better. The entire industry must do better. The situation as it stands is unsustainable and there is very little time left on the clock, if any. Without immediate positive structural change by all industry parties, the fate and integrity of our trade hangs in the balance.

MEGHAN MCEWEN is a dual-trade automotive technician and motorsports enthusiast in Vancouver, British Columbia. She can be reached at bullitt1516@gmail.com.

MEGHAN MCEWEN is a dual-trade automotive technician and motorsports enthusiast in Vancouver, British Columbia. She can be reached at bullitt1516@gmail.com.

For those unfamiliar with the not-for-profit, WIN works with many women—and men—in management roles; individuals seeking strategies on how to improve retention for female employees and attract more women to the sector. Through the organization’s focus, WIN aims to sustain a healthy dialogue that continues to advance the marketplace as a whole.

The organization sponsors several programs aside from its annual conference, including sponsorships for female apprentices in the automotive space.

WIN also fosters the Most Influential Woman program, an award established in 1999 to recognize women in the aftermarket whose leadership and commitment to excellence have enriched the collision repair industry.

The Women’s Industry Network has a mission to support and enhance the role of women in the collision repair industry, promoting education, professional advancement and networking.

The all-volunteer group represents various collision industry segments, including repair facilities, suppliers, consultants, information providers, insurance companies and more.

• BECOME A WIN MEMBER

• JOIN A WIN COMMITTEE

• ATTEND WIN EVENTS

• BE A WIN CHAMPION

No matter your identity, you are free to join WIN! The organization is open to anyone who wishes to participate in endeavours supporting women in trades, regardless of your gender.

https://thewomensindustrynetwork.site-ym.com

BY ALLISON ROGERS

BY ALLISON ROGERS

Could you imagine the chaos our world would be in if no one ever spoke their mind?

In the same vein, can you imagine the turmoil a business would suffer if no one spoke up to spur change?

Providing constructive criticism to a superior can be a delicate dance—one that many are afraid to choreograph. The fear of judgment is a large contributor to that fear, but sharing ideas is no more difficult than any conversation if you play your case right.

Would you start spewing a nihilist manifesto in the middle of the breakroom?

That’s no way to make friends.

Others are afraid to share concerns for fear they’ll be labelled “not a team player” or as a troublemaker—but offering suggestions or constructive criticism is not the same as causing trouble, provided you broach the topic thoughtfully. Of course, it’s important to ensure your ideas are communicated in a respectful and professional manner, without frustration or finger-pointing.

There is a generic formula that can be used as a framework for these sometimes difficult discussions. The first step is to go in with a clear head—i.e., don’t let your frustrations bubble up for months, resulting in volatile disagreement no one wants a part of. Choosing the right time, or determining the headspace of your superior, is another crucial step. You wouldn’t want someone coming in and interrupting your lunch, would you? Would you start spewing a nihilist manifesto in the middle of the breakroom? That’s no way to make friends. Think more one-on-one meetings with your superiors and less full-on brawl on the bodyshop floor.

Take the same approach with the recipients of your feedback. Pick an appropriate time to address concerns—a morning check-in meeting, perhaps—and ensure all parties give their undivided attention. And don’t ambush people with negative feedback; it won’t get you very far. Focus on the facts and potential solutions. Blaming others is a futile play.

You must also remember that speaking up is not a one-way street. You are more than likely going to get a rebuttal from the receivers of your message, whether it be in agreement or otherwise. You must be prepared to keep a level head amid all outcomes. Nobody likes a tantrum.

In most cases, your employer values your opinions and ideas (if they don’t, well, you probably won’t hang around long). They hired you because they have faith in your skills and believe in your ability to contribute to the company. Whether you know it or not, you play a significant role in the success and overall functionality of your workplace. So, turn the megaphone to 10,000 decibels and get to betterment. Happy 2023!

The SATA air vision 5000 offers a completely redesigned way of supplied breathing air. The respiratory hood not only ensures high breathing air quality but also a low noise level. The modern, ergonomic design fits with almost any head shape and can be individually adjusted in size, height and position.

The SATA air vision 5000 offers a completely redesigned way of supplied breathing air. The respiratory hood not only ensures high breathing air quality but also a low noise level. The modern, ergonomic design fits with almost any head shape and can be individually adjusted in size, height and position.

Little operating costs, quick pay-off of purchase costs

Soft-stream flow-optimised air distribution in the hood

Little operating costs, quick pay-off of purchase costs

Absolute safety through external supply of clean air to the cabin – up to 100 times TRK* value and suitable for continuous use

No inhalation resistance, very comfortable breathing

The SATA air vision 5000 offers a completely redesigned way of supplied breathing air. The respiratory hood not only ensures high breathing air quality but also a low noise level. The modern, ergonomic design fits with almost any head shape and can be individually adjusted in size, height and position.

Absolute safety through external supply of clean air to the cabin – up to 100 times TRK* value and suitable for continuous use

Ergonomic design with individual adjustment options and one-hand operation of the visor

No inhalation resistance, very comfortable breathing

Ergonomic design with individual adjustment options and one-hand operation of the visor

Absolute safety through external supply of clean air to the cabin – up to 100 times TRK* value and suitable for continuous use

No inhalation resistance, very comfortable breathing

Ergonomic design with individual adjustment options and one-hand operation of the visor

Reduced sound level: 64 dB (like a conversation in 1m distance)

Soft-stream flow-optimised air distribution in the hood

The SATA CCS Discs (Color Code System) allows personalization of hood, SATA air regulator and SATA air carbon regulator

Reduced sound level: 64 dB (like a conversation in 1m distance)

The SATA CCS Discs (Color Code System) allows personalization of hood, SATA air regulator and SATA air carbon regulator

Little operating costs, quick pay-off of purchase costs

Single solvent resistant tear off visors over an aperture in the front of the mask, ensuring 100% visibility and reduction in light reflection

Soft-stream flow-optimised air distribution in the hood

Reduced sound level: 64 dB (like a conversation in 1m distance)

Single solvent resistant tear off visors over an aperture in the front of the mask, ensuring 100% visibility and reduction in light reflection

* TRK – Technische Richtkonzentration

The SATA CCS Discs (Color Code System) allows personalization of hood, SATA air regulator and SATA air carbon regulator

Single solvent resistant tear off visors over an aperture in the front of the mask, ensuring 100% visibility and reduction in light reflection

* TRK – Technische Richtkonzentration