Cover image by Stefano Liessi If

Cover image by Stefano Liessi If

BY DARRYL SIMMONS

There has never been a better time to pursue a career in the collision repair space. It’s a field that captivates the hearts of those exposed to it. The hands-on nature of the work, the sheer satisfaction of turning bent or busted metal back to its former glory. Not to mention the constant innovation in techniques and technology. All of this—and more—makes collision repair an incredibly rewarding profession.

AutoCanada Collision Centres also fosters an excellent program to inspire young technicians. The network provides industry-leading education and mentorship for autobody apprentices working in the network. Not only do they have access to courses from I-CAR, OEMs, paint providers and more, AutoCanada will also provide each apprentice a complete MAC Tool Box valued at $10,000. Pretty sweet deal that

The opportunities in collision repair are vast, ranging from specialized roles in painting and body repair to advanced positions in computerized diagnostics and structural repair—not to mention the roles outside of an actual facility.

VOLUME 11, ISSUE 2, 2024

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ASSISTANT EDITOR

Sarah Perkins | sarah@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677 wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

MARKETING COORDINATOR

William Simmons | william@mediamatters.ca

It’s never too early to begin promoting the possibilities of a career in collision repair. In fact, it’s a heavily discussed topic in the industry at the minute—when do we start promoting our trade to the youth? How can we ignite their passion and curiosity to set them on a path towards a fulfilling and prosperous future? The opportunities in collision repair are vast, ranging from specialized roles in painting and body repair to advanced positions in computerized diagnostics and structural repair—not to mention the roles outside of an actual facility. The team at Bodyworx believes that the earlier we can engage young individuals, the more likely they are to pursue this exciting career path. Yes—exposure is key. It’s evident that the youth that do have a chance to experience a day on the production floor live it, and understand it. Fix Network’s recent event at their Calgary, Alberta, training facility is an excellent example of this. Partnered with the Calgary-based CAREERS organization, the network hosted two consecutive weekend sessions wherein a group of young ladies were shown the ins-and-outs of automotive refinishing. They learned about safety equipment and suited up for a panel-painting session in the paint booth. They did their own prep, base coat, spraying and clear coat, all with massive smiles on their faces.

sets the apprentice up for success. So, there you have it. The time is now— we have the tools needed to show the youth how rewarding a life in the industry can be. We need to seize this moment, capture their enthusiasm and embark on a bright future. The question to ask yourself now—what role will you play?

SUBSCRIPTION

One-year $25 / Student Discount is 10%

Bodyworx Professional ™ is published quarterly, and is dedicated to serving the professionals of the collision repair industry. It is published by Media Matters Inc. Material in BodyworxProfessional™ may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough ON K9J 3R2

“We acknowledge the financial support of the Government of Canada.”

Bodyworx Professional is published by Media Matters Inc., publishers of: INSPIRE AND EMPOWER THE NEXT GENERATION OF WORKERS

JF Launier, founder of JF Kustoms in Osoyoos, British Columbia won the top prize at Toronto’s Motorama in March, taking home the Grand Champion award. Motorama Custom Car and Motorsports Expo—which took place at the International Centre in Toronto, Ontario—judged Launier’s design to be “the cream of the crop” of over 400 eligible vehicles. The 1967 Ford Mercury Cougar won first prize and a $5,000 cheque for its innovative custom build. On top of winning this Grand Champion award, Launier also recently won his fifth Great 8 finalist award as well as $1,000 at Detroit’s Autorama on March 1st. This win positions Launier as the builder with the most Great 8 wins in history.

Color Compass Corporation has announced the opening of its newest location in Oshawa, Ontario. According to a recent press release, “this expansion marks a significant milestone for the company as it solidifies its commitment to serving customers in the Greater Toronto Area and beyond.” The new facility is located at 1155 Boundary Road, Oshawa and will offer a comprehensive range of products and solutions, including automotive paint, coatings and related supplies with the goal of catering to the diverse needs of professionals in collision repair, automotive refinishing and industrial applications.

A new Consumer Reports survey reveals that customers prefer independent shops over dealerships for automotive repairs. The survey–based on 10,973 responses from Consumer Reports members on 11,670 repairs at 36 auto repair chains, independent shops and dealerships–further revealed that Hyundai, Jeep and Kia scored lowest for overall customer satisfaction. Of Hyundai, Jeep and Kia customers, Jeep customers reported that repairs weren’t being done correctly the first time; while Kia customers downgraded their experience based on poor communication with repair staff. Also near the bottom of the rankings, Ford tied with Mercedes-Benz, Volkswagen and Nissan. Ford specifically scored low on repair pricing and the time needed to complete repairs. In the middle of rankings was GMC, Buick, Audi, Chevrolet, BMW, Dodge, Subaru and Cadillac. However, overall, consumers ranked independent repair shops the highest followed closely by dealerships such as Acura, Lexus, Mazda, Volvo, Toyota, Tesla and Honda.

A recent study from Experian Automotive shows that Generation X and Millennials tend to buy more electric vehicles (EVs) than Baby Boomers. Experian’s fourth quarter 2023 Automotive Market Trends report noted that, in 2023, 9.4 percent of new vehicles purchased by Gen X were electric. Gen X also purchased the most new vehicles of any generation over the year, as well as the most EVs in total when looking at comparative total vehicle data. Millennials, meanwhile, were close behind in terms of total EV sales with 10.2 percent of new vehicles purchased in 2023 being electric. Comparatively, only 5.9 percent of new vehicles purchased by Baby Boomers, and only 6.6 percent of new vehicles purchased by Gen Z were electric.

The study further indicates that although it’s still too early to gauge the full spectrum of Gen Z and new vehicle purchasing, while Boomers can afford current EVs, they’re simply not buying them.

For the first time ever, more than 10 percent of all new vehicles registered in Canada during the past year were zero-emission vehicles (ZEV), including purely electric EVs and plug-in hybrid (PHEV) models. According to Statistics Canada, the exact proportion of ZEV registrations in 2023 is 10.8 percent or 184,578 of a total 1.7 million. Of all the provinces, British Columbia led with 20.2 percent of new vehicle registrations last year being ZEVs. Quebec came second at 18.6 percent with 77,083 ZEVs registered, accounting for over 40 percent of the national total. In Ontario, where no provincial rebates are available, ZEV uptake only reached a rise of 7.6 percent in 2023.

percent, were PHEVs. When compared to 2022, these numbers represent an increase of 41.5 percent and 80.5 percent respectively.

Quebec’s National Assembly recently announced in a 2024 to 2025 budget meeting that it plans to extinguish the Roulez Vert electric vehicle (EV) rebate program by 2027.Currently, Quebec offers the most generous provincial rebate in the country at $7,000 for battery electric vehicles (BEVs). This amount is set to decrease over the next three years to $4,000 in 2025; while eligible plug-in hybrid vehicles (PHEVs) will see subsidization cuts from $5,000 to $2,000. Following this, in 2026, the rebates will be further diminished, becoming $2,000 for BEVs and $1,000 for PHEVs. Then, on January 1, 2027, the rebates will be wiped out completely. Despite these cutbacks, drivers in Quebec will still have an option of getting financial assistance for a time following the cutoff dates. Namely, the Quebec budget documentation specifies that “(electric vehicles) will continue to be eligible for the $5,000 rebate from the federal government until March 31, 2025, or until the exhaustion of funds.”

The Government of Saskatchewan has announced $1 million in additional investmests to increase the capacity of skilled trades in the province. The government’s total investment into the province’s Saskatchewan Apprenticeship and Trade Certification Commission (SATCC) program has now reached $22.4 million in the 2023 to 2024 period. The SATCC supports apprenticeship training in trades such as autobody and collision technician training, automotive refinishing technician training and automotive service technician training, among others. Immigration and Career Training Minister Jeremy Harrison said this additional funding ‘will’ create more capacity in our training system, supporting the Saskatchewan Labour Market Strategy and ensuring Saskatchewan people benefit from the opportunities our economy is creating.”

The Ontario government is introducing a new policy and legislative measures to allow 80 percent of high school students’ senior courses to be in trades-based co-op education. The goal of the new policy is to help attract more young people to the trades by specifically adding a new apprenticeship pathway and an online job matching platform. This change will allow students in Grades 11 and 12 to participate in more apprenticeship learning through additional co-operative education credits while completing high school. Graduates would receive a new seal on their Ontario Secondary School Diploma to signify their successful completion of the program and recognize them for their dedication to learning in the skilled trades.

Bodyworx reached out to William Speed, retired TDSB auto body teacher who “applauds the government for advocating for the skilled trades. However, as much as I support the idea of starting apprenticeship while still in high school, many of the apprentice-based trades are not represented in many, if at all high schools. The mid 90s saw the demise of many specialized programs, partly due to declining enrollment and partly due to the curriculum changes.”

The Mini-Ductor® Venom® HP is the 4th generation Mini-Ductor® from Induction Innovations. The Venom® HP runs on 120v/15 Amp, allowing for maximum power from a handheld unit. Packing a hefty 1800-watts, this unit can quickly heat a bolt in 3-5 seconds, making work more efficient and faster. Seized components are quickly freed up, saving time and frustration.

> Carry Case (MD50-003) > 7/8” Pre-Formed Coil (MD99-601) > 23” U-Form Coil (MD99-602) > 41” Bearing Buddy Coil (MD99-603)

On March 15, Apptronik, manufacturer of generalpurpose robots aimed to simplify work, announced its partnership with Mercedes-Benz to integrate their advanced robots into Mercedes-Benz manufacturing. As part of this collaboration, Mercedes-Benz is introducing Apollo–touted as one of the world’s most advanced commercial humanoid robots–into its manufacturing facilities with the hope of equipping staff with tools for enhanced productivity and efficiency. Apollo will be utilized for various tasks such as logistics, delivering parts to the production line, assisting in assembly processes, and inspecting components.

Toyota has filed a patent application for colour-changing paint, a technology that the automaker reports could let owners or dealerships quickly swap a vehicle’s style. The patent application describes how the technology could be beneficial for owners who want to change the colour of their vehicle to keep up with trends, or for dealerships that want to make cars easier to sell. Instead of using a complex repaint or vinyl wrap, Toyota claims to have developed paint that can be altered in reaction to heat and light. As the paint surface is heated, a lightemitting colour moderator device would be passed over the paint surface to complete the transformation. The colour modulator, which could be controlled by either a human operator or a robot, would then communicate with a remote server as well as temperature sensors embedded in the vehicle’s bodywork to determine the correct settings for a specific colour.

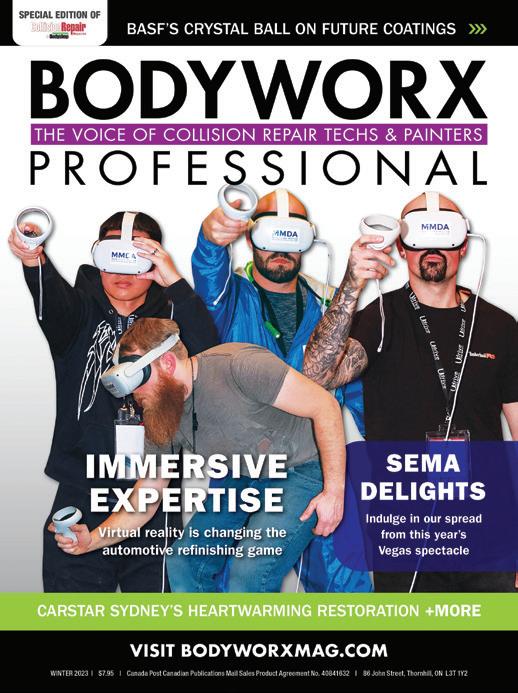

ENGAGEMENT IS KEY—SKILLS CANADA’S RECENT PROVINCIAL COMPETITIONS PROVE IT

BY ALLISON ROGERS

If you think the trades are lacking talent, you must be missing the news around Skills Canada’s provincial competitions this spring.

Anyone attending one of Skills Canada’s events would be impressed at the sheer grandeur of the festivities. With dozens of budding tradespeople competing in 46 different trades on a vast exhibition floor, the passion and energy is palpable.

For those that have not experienced the event in its ferocity, the gist is this: secondary and post-secondary students from various school districts around the province go head-to-head in skills competitions to test their talents in a variety of trades. So, in one corner you could have automotive painting; ten feet away, carpentry apprentices are working on their latest masterpiece.

The motive power section of the Skills Canada program includes: automobile technology, heavy vehicle technology, auto body repair and automotive painting. The size of these workspaces take up significant space—and contribute to much of the noise—inside the exhibition hall, making them hard to ignore.

Get the training and welding qualification you need to stay ahead of the game.

Automotive Welding Qualification is a must-have for all technicians that repair and weld vehicles in your collision repair facility. To achieve the highest quality repair, utilize best practices, and ensure vehicles are properly and safely repaired, choose the CWB Automotive Repair Welding Qualification program for your team. For over 70 years, the CWB Group has provided training and testing services to companies across Canada seeking Certification and Welder Qualification.

CWB Automotive Welding Qualification Benefits

• Automotive Welding Training and Qualification at your own facility with your own equipment

• Ensure all your technicians have the training and skills needed for welding

• Increased skill levels = quality assurance for Collision Repair Facilities

• Satisfies welding certification requirements for most OEM Certification programs

• Third party oversight and onsite training by certified welding specialists

• Enhanced credibility provided by CWB Automotive welding certifications

• Savings when you register multiple technicians to participate

• Technicians receive CWB Automotive Welding accreditation after completing training and testing

Outstanding performance, high-accuracy color, and tough durability … all from a waterborne system?

Utilizing the latest technologies means that PPG’s Envirobase High Performance waterborne paint system is easy to use and packed with benefits. Compatible with PPG’s digital tools, this advanced system helps body shops to increase their productivity potential by up to 15% while achieving an accurate OEM color match and a flawless finish every time.

Experience the benefits of PPG Envirobase High Performance, the most flexible paint system on the market.

“I know some apprentices that could be shown the door by these grade 11 and 12 students.”

— STEFANO LIESSI, SKILLS ALBERTA JUDGE TRAINING AND CURRICULUM COORDINATOR FOR COLOR COMPASS

Perhaps the best part of all—the collision repair competition pool is growing.

“We had 11 competitors for collision repair this year,” said Bill Speed, who has chaired the Skills Ontario collision repair competition for 29 years. “It’s more than we’ve seen in a long, long time.”

Bodyworx Professional attended the second day of Ontario’s competition at the Toronto Congress Centre, where, even after the competition ended, hundreds of young people—prospective future talent—wandered the halls.

Judge and CWB Collision Instructor JeanMarc Julien was impressed with the welding talent at the collision repair workspaces, as was Speed.

Stefano Liessi, Skills Alberta judge and training and curriculum coordinator for Color Compass Corporation, told Bodyworx the young talent was particularly skilled this year.

“I know some apprentices that could be shown the door by these grade 11 and 12 students,” he said during the Skills Alberta provincial competition.

“What takes place during ‘Skills’ week is nothing short of spectacular and monumental,” he said after the competition, adding a thank-you to all organizers and supporters of the event.

The local collision repair industry makes a point to attend and partake in Skills Canada events, with an all-star roster of judges on each provincial comp panel. Industry representation is also present with supporting sector-adjacent companies bringing their teams for additional support.

Attendees of the Ontario competition agreed that the audience this year was massive.

Collin Welsh, senior VP of operations for CARSTAR Canada, said his company brought 6,000 chocolate bars and basketball-themed stress balls to the event, in support of CARSTAR Canada’s partnership with the Toronto Raptors. By the end of day two, all 6,000 of those units were gone.

“They had the chance to win Raptors tickets if they found the special golden slip,” he told Bodyworx

At the Fix Network booth, students had to name car parts for the chance to be entered in a raffle. The prize: an Uber Eats gift card for their whole class.

“It’s incredible how their faces light up once they hear there’s food involved,” said Jamie Neuman-Rodrigues, Fix Network special projects manager.

“I was impressed at the number of students that immediately knew the part diagram they were looking at,” Neuman-Rodrigues added after our Bodyworx editor failed to correctly name a part.

This isn’t to suggest that we need to incentivize students with shiny things to get them to consider our field—but it does show that, when the carrot is tied to the stick just right, we have a real chance at engaging students that already have an interest in automotive. Especially at events like Skills Canada’s competitions, which showcase the grandeur and very best the industry has to offer.

So…how will you support your local Skills competitions?

BY SARAH PERKINS

When restoring a vehicle, it can be easy to get caught up in the drive for the finished product. In taking an old vehicle and turning it into something new—or better yet, something better than new—it can be easy to forget that the act of restoration is also an archival process that can help to preserve both the history of a vehicle and all those connected to it. While an often-overused phrase, it can be true that the journey and not the destination can reveal the spirit of the project being undertaken.

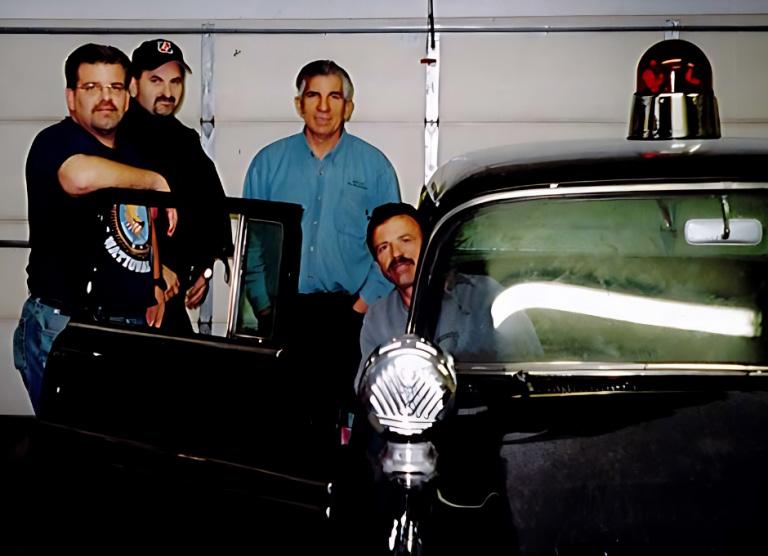

For the LaSalle Police Services in the town of LaSalle, Ontario, the restoration of a 1957 Pontiac Laurentian in partnership with Domenic Iannetta, owner of Fix Auto Windsor East in Windsor, Ontario, served as a project that not only honoured the past, but also celebrated the spirit of collaboration that comes from working on a true labour of love.

The story of this labour of love first began all the way back in 2003 when LaSalle Police

Sergeant, Dave Dean first proposed finding a car to restore in the style of the old LaSalle police cruisers. After speaking with Senior Constable Mauro Tonin and pitching the idea to then Lasalle councillor John Tedesco, and Police Chief John Leontowicz, the two formed a historical vehicle committee and began their search for the perfect vehicle. Also joining the committee was Duncan Davies, John Tedesco and Vito Campanaro who helped spearhead the project.

This vehicle, the 1957 Pontiac Laurentian—to become the award-winning Car 48—was found for sale by a private owner in Little Britain near Lindsay, Ontario and was originally outfitted with seats from an old Ford Mustang and a chassis done up in red and white paint. The original plan for the restoration was to debut the vehicle at the town’s Santa Claus parade. However, now over 20 years later, Car 48 has grown to become so much more than just a parade showpiece.

When speaking with Domenic Iannetta, owner of Fix Auto Windsor East, he noted that the vehicle has become a legacy that has touched the lives of several generations and helped forge community bonds.

Iannetta discussed how when the LaSalle police officers first approached Fix Auto Windsor to help with the restoration, the officers had no previous knowledge of fixing cars, let alone antiques. Now, “when they win events, they always call. It was really rewarding getting to show the officers how to fix the vehicle and teaching them to help work on it themselves. I remember one of the officers joking that after learning how to sand the panels, finally, his fingertips have come back from all the work. However, the most rewarding part of the whole thing for me, is the pride that the officers feel.”

Iannetta further commented that when they first began the project in 2003, his sons Nicolas and Max were toddlers who helped by being the excited faces that appeared in the back of

“When the LaSalle team wins events, they always call. It was really rewarding getting to show the officers how to fix the vehicle and teaching them to help work on it themselves.”

Car 48 during its parade appearances. Now, all grown-up, the same children, who are now business partners with their father, are handson in the vehicle’s latest touch-up project.

When Car 48 began its initial restoration, eighty percent of the vehicle was replaced or refinished in a frame off restoration. Ianetta also noted that the interior was redone as was all of the chrome work. The car was repainted, and the logo was brushed in rather than spray painted in order to be as historically accurate as possible.

The Fix Auto Windsor East team also sourced vintage sirens and a radio from an auto parts collector in Windsor.

With the original police officers who first began the project either retired or preparing

to retire, Car 48 is in the next generation’s hands to help ensure that it can continue to carry the LaSalle community legacy forwards into the future.

In October 2023, Car 48 began to show signs of wear and tear, including scratches, dents, and cracks, and so a decision was made to overhaul its body and apply a fresh coat of paint with the help of both familiar and new faces.

In particular, Maria Rosati, a local LaSalle artist, now residing in Halifax, is, according to Iannetta, more than prepared to help keep Car 48 looking better than new.

“Maria is painting the vehicle by hand and has done a lot of research to ensure that all of the steps she takes are as period accurate as

possible. She’s even using specialty horsehair paint brushes. From there, all the stainless-steel moldings will be polished and reassembled.”

In this way, when interviewed by the Windsor Star in 2013 after winning Best Police Car at the Lights and Sirens Cruise – the kickoff to the Woodward Dream Cruise in Michigan, police Sergeant, Mauro Tonin spoke about how “one day our kids, our grandkids can look at [the vehicle] and say, grandpa, nonno worked on that.” Having become “a jewel of the LaSalle Police Services,” Car 48 is not only something that friends and family can take pride in, but the community at large whose history is, in part, represented in the hard work of those willing to turn a dream into an automotive reality.

The ProColor PROcess is a winning formula.

A proven business model for 20 years, ProColor Collision provides an alternative to independent body shops that want to join one of the fastest growing networks in the world.

Local business owners are supported by a team of sales, operational and marketing professionals, and backed by proven tools and ongoing training programs.

ProColor Collision is committed to helping shop owners grow their business in their communities while leveraging strong established relationships with global insurers, suppliers and fleet companies.

Contact Amin Youssef at ayoussef@fixnetwork.com or visit the franchise page at Procolor.com to find out more.

Bodyworx magazine also sat down with Senior Constable Mauro Tonin and Sergeant Dave Dean of the LaSalle police force who were part of Car 48’s original restoration. Check out below for an exclusive scoop.

Bodyworx Professional: What was the initial inspiration for the project?

Mauro Tonin and Dave Dean: We had noticed that there were a large number of restored fire trucks in parades and shows, but we seldom saw restored police cars. We felt a restored replica police car would be beneficial for us in parades, community events, fundraisers as well as in promoting the LaSalle Police Service and the town. No police service in Essex County when we started the project in 2003 had a restored police car.

BWX: What was the most challenging part of the project?

MT and DD: One of the most challenging tasks was finding a photo of an original 1950s era LaSalle police car to use as a reference. With the help of the public, we were able to locate one photo of a car from the era. The original LaSalle police vehicle found in the photo was a two-door Pontiac Laurentian. This made it even more difficult to locate as the majority of the police cars from the 50s were either Chevrolets or Fords.

Another challenging part was trying to find parts for a Pontiac! There are lots of parts available for a Chevrolet, but you seldom find any for a Pontiac. As we had a Pontiac Laurentian (which is the Canadian version of the American Star Chieftain), parts were

very scarce! We could not use the parts of the American vehicle version as the Laurentian is about five inches wider. One of the only things we were able to change with a Chevrolet was the windshield, as it was the same for a 1957 Chevrolet Belair. Committee members attended swap meets to find parts and we made several contacts with car restoration clubs, Pontiac owner’s clubs and eBay.

BWX: What was your favourite part of getting to work on the project?

MT and DD: One of the best parts of working on the original project was having the participating police officers (who basically knew nothing about working on cars) be guided by Vito Campanaro, and Domenic Iannetta. With their vast knowledge of bodywork and how to restore vehicles, for us, this was priceless.

BWX: What does the vehicle mean to you and your team?

MT and DD: The proudest moments for us are the various community events we have attended and how well the car is received and the numerous compliments citizens have given us. We have also won three awards in the United States (most recently in 2023), Ferndale Lights and Siren Show’s Chief’s choice award (with a 21-year-old paint job!) as well as several awards in Canada. It validates for us the fact that all of those countless hours of hard work, sacrifices and dedication to this project made it worth it. Now, with the new paint and graphics, the car will continue to be enjoyed for many years to come.

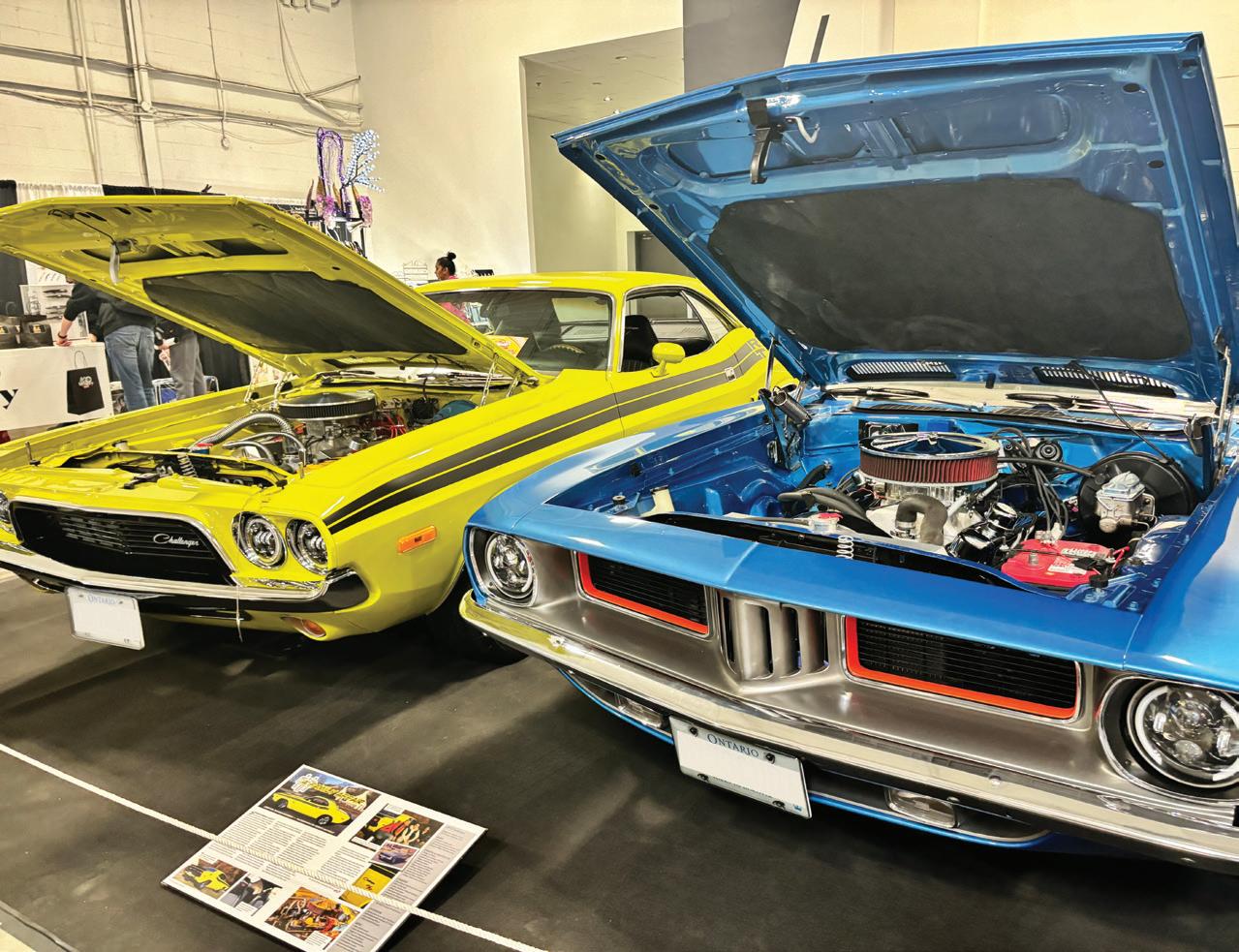

his year’s Motorama Custom Car and Motorsports Expo may have come and gone, but Bodyworx magazine was there to capture some photos that will make any car lover’s heart rev. Hosted at Toronto’s International Centre from March 8th to 10th, and spanning over 300,000 square feet, the event was rife with the latest hot rods, custom cars, trucks, classics, rat rods, tuners, exotics and racing vehicles. Check out the photos below and bask in the beauty of these meticulously crafted machines.

Serving your PBE needs for 50 years

CARSTAR Stouffville proudly celebrated its participation at this year’s Motorama Custom Car and Motorsports Expo by showcasing its restored 1966 Chevy II Nova SS.

The beloved family vehicle was recognized with several prestigious awards, solidifying its status as a top competitor in the custom car scene. The team placed in the top 10 for the Grand Champion final, won the Hagerty Class award and the Best First Time Shown Street Machine title.

“We are thrilled to unveil our now award-winning 1966 Chevy II Nova SS at the 2024 Motorama Custom Car and Motorsports Expo,” said Patrick Savella, general manager, CARSTAR Stouffville. “This event provides the perfect platform to showcase our passion for our commitment to automotive craftsmanship.

“It’s more personal for us as well because not only is this car the epitome of classic American muscle, it also carries with it a family history that adds a unique layer of significance. We are immensely proud of the accolades our restoration work has received and are grateful for the support of our team and sponsors.”

BY SARAH PERKINS

As the automotive industry continues to rapidly evolve, the push for electric vehicles (EVs) presents a new opportunity for innovation and technological advancements. However, this transition to electrification also presents unique challenges and a charged learning curve that for many, presents fears for the future.

We reached out to the industry as well as some EV experts to answer what challenges exist and why it’s imperative to be equipped with the knowledge and expertise necessary to effectively navigate the repairs that are quickly driving towards tomorrow’s horizon.

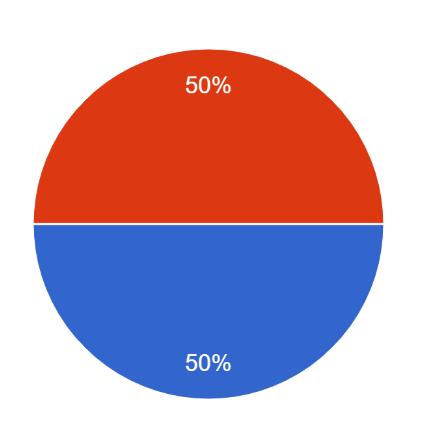

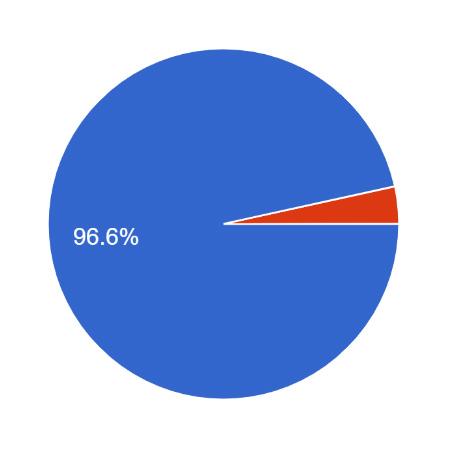

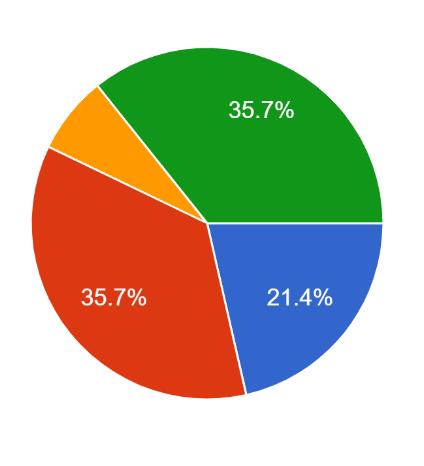

Bodyworx magazine polled the industry to ascertain what electrification means to those at the heart of repairs. Results found that the majority of respondents are concerned about the safety of technicians as well as access to training and investment in proper tools. Of those polled, 96.6 percent of respondents specifically felt that additional training and support should be provided to collision repair technicians to ensure their safety while working on high-voltage systems. Additionally, 50 percent of respondents stated that they had not received industry training on electric vehicles.

“Adherence to safety protocols and repair procedures is imperative for technicians servicing EVs, mirroring the caution required for gas vehicles—such as avoiding torching a gas tank out of a vehicle during repairs.”

Have you received any industry training on electric vehicles?

responses

Rate how concerned you are about the implications of electric vehicles in collision repair centres, from a profitable perspective.

Do you believe that additional training and support should be provided to collision repair technicians to enhance their skills and knowledge related to EVs?

responses 28 responses

Rate how concerned you are about the implications of electric vehicles in collision repair centres, from a safety perspective.

responses

“Enhanced training levels are necessary for seasoned repairers as they are working habitually and those habits driven by the subconscious mind could lead to a costly mistake. A new tech coming into the trade will have the advantage as EV repair will to them become nothing new, just the normal.”

“[What concerns me about EVs is] safety, both in the repair itself and for the techs involved.”

Similarly, when speaking with David Giles, electric vehicle specialist and co-founder of PoweredEV consulting, about the reason technicians new to EVs may be fearful towards the technology, he noted that the “the primary reason why untrained technicians may find electric vehicles (EVs) daunting isn’t due to the complexity of the tasks or necessary skills, but rather the apprehension surrounding high voltage and the potential for costly damage to the system.”

Although electric vehicles have less moving parts to their internal combustion engine (ICE) counterparts, with the average EV having around 20 moving parts versus an ICE’s 2,000, Giles further noted that “despite the straightforward nature of the work involved, understanding the critical aspects of safety, and comprehending how EV systems function are important. Once technicians acquire a solid understanding of vehicle electronics and logistics, they’ll realize that EVs aren’t fundamentally distinct from traditional vehicles, with training being the key investment for transitioning to electrification.”

“It’s the Wild West out there right now. It will take time and a clear path forward. Standardized training like ICAR or similar will be the key.”

“Training as usual lags behind when the vehicles have already been in the shop for repairs. I-car for example provides courses usually a year after I have already repaired the vehicle technology using my OE connections.”

When considering differences between an electric and an ICE vehicle, for Giles, “the most notable distinctions lie in the absence of combustion engines, multi-speed transmissions, and the presence of high voltage systems, alongside the elimination of fuel and emission components.”

Because of this, repairers preparing for electrification “will find themselves relying more on scan tools and electrical testing equipment for high-voltage systems, while mechanical systems remain largely unchanged from internal combustion engine (ICE) vehicles.”

Moreover, while the high-voltage systems and their potential risks are often the cause of the most fear, Giles stressed that “the perceived risk of fatalities or injuries from high voltage systems is minimal due to redundant safety mechanisms and the isolated design of high-voltage systems.”

However, “adherence to safety protocols and repair procedures is imperative for technicians servicing EVs, mirroring the caution required for gas vehicles—such as

avoiding torching a gas tank out of a vehicle during repairs.”

In embracing the challenge of the charged learning curve, Giles outlined how “several organizations now provide EV training, starting from basic electrical and electronic principles, progressing to safety protocols, and then covering maintenance, repair, and battery disassembly.”

And, “despite common belief, the core of EV training should prioritize understanding of service information, establishing a strong electrical foundation, comprehending power flow in EVs, adhering to safe work practices, and mastering equipment usage, rather than solely focusing on battery replacement and cell/module handling. This would be from more advanced training programs.”

Ultimately, for Giles, making the transition to electric vehicles is a process of “mastering the fundamentals of electricity, including Ohm’s law, and familiarizing oneself with service information and the appropriate utilization of safety equipment.”

Optimize your shop’s operations planning and capacity

Helps you plan repairs and manage capacity in your shop.

Combines both severity and load planning methods.

Smart visual planning.

Dashboard for informed decision-making.

Forecast cycle time and productivity.

Optimize resources, reduce waste of time.

The perfect addition to your collision shop management system.

Identify the best time to start a repair, based on the targeted daily volume

Display of daily repair capacity.

Display of repair severity.

Visual indicators give an overview of the shop’s daily capacity.

Ideal for shops looking for simplified tools.

Contact

“Training is available. It’s the shop owners and managers that do not mandate training. The lack of training leads to incorrect or unsafe repairs, low profitability through improper billing of labor operations and bring the overall trade down.”

“My market(s) would be considered rural and in a part of the country where EVs are not so popular. As such, I haven’t invested anything towards EVs yet. I’m not aware that any of my competitors have done anything yet either. Too few vehicles with the risk of not enough compensation.”

“Just want to add that EVs are safe to work on as long as technicians follow safety precautions.”

“Electric vehicles are here. Whether you like it or not, they will soon be rolling into your shop and out of warranty. Be ahead, before you fall behind.”

—SAIFULLAH SANAYE, PROFESSOR OF AUTOMOTIVE TECHNOLOGY AND EV EXPERT

Similarly, Saifullah Sanaye, Professor of Automotive Technology and EV Expert, echoes Giles in the belief that “the majority of today’s technicians are afraid of electric vehicles.”

For Sanaye, “the reason behind this is,” as Giles notes, “is the misconception that these vehicles are unsafe to work on due to the high-voltage that is present, and my response to those technicians is that if you get the proper training, it will ease your ‘highvoltage anxiety’ and also allow you to work safely on these vehicles.”

Moreover, Sanaye further echoed Giles in the assertion that “just because EVs have less

moving parts, it does not mean that they will be easier to fix. In my opinion, from a technician’s point-of-view, internal combustion engine (ICE) vehicles have more hardware and EVs have more software. Sometimes, software issues can be a lot more complex to diagnose than hardware issues.”

But, despite the potential complications, Sanaye encourages technicians to not get overwhelmed by high-voltage-havoc because manufacturers have made sure that EVs are built with systems “designed to be extremely safe.”

And, while many questions about electric vehicles exist, there are also many who are

willing to provide answers. In particular, Sanaye described how he, in partnership with AIA Canada and the Canadian Government, have worked to create and produce a complete EV training course (ev-training.ca), designed to “help today’s technicians navigate the new world of electric vehicle diagnostics and repair.”

In this way, while EV uncertainty may continue into the near future, for Sanaye, technicians need to “get ready!”

“Electric vehicles are here. Whether you like it or not, they will soon be rolling into your shop and out of warranty. Be ahead, before you fall behind.”

www.spraymax.com

www.arslanauto.com

The TECNA Automatic Smart Inverter Resistance Spot Welder Models 3664P and 3680 from Arslan Automotive can recognize types and thicknesses of metals and set all parameters automatically. The tool features a water-cooled transformer gun to help optimize your productivity and increase duty cycle. Plus, a support arm with balancer helps for safe and comfortable operation. A new touch screen with intuitive graphic design lets you choose between Automatic Smart+, Quick and Full modes, while an ergonomic, compact and stable cart allows for easy transportation throughout the facility. This device is also wifi enabled for factory updates and diagnostics.

SprayMax 1K E-Coat Primers

SprayMax 1K E-Coat Primers are designed for direct to steel and aluminum applications. They are paintable, corrosion resistant and compatible with OEM basecoats. Perfect for inner body panels, engine compartments, trunks, support rails, bodyfiller, fiberglass and SMC. They replicate OEM gloss levels, are fast drying and durable, while offering excellent adhesion. Now available in eight colours: White, light green, olive green, gray, black, tan, field drab, and olive brown.

For more information contact: order@Kwasny.us | 844.426.6330 or visit spraymax.com

www.theinductor.com

Release all types of adhesives bonded to the metal without the collateral damage of open flame with the Inductor Max Kit. The kit is completely portable with the induction inverter mounted in a carry case. It offers audible and visual power indicators.

For more information email info@theinductor.com or call Induction Innovations at 877-688-9633

www.ppg.com

The new ONECHOICE® UV-Cured Primer Surfacer from PPG achieves a high film build of 2.0-2.5 mils per coat and can be cured and ready to sand in two minutes. It’s the ideal solution for high production shops seeking to save time and increase the throughput of their paint operation. Available in spray gun ready quart or aerosol can.

For more information visit ppg.com or check out this you tube link www.youtube.com/watch?v=Oqxmw2nJTrQ&t=2s

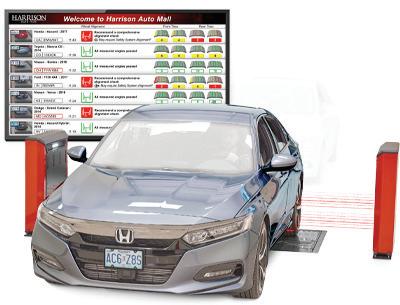

www.hunter.com

Opportunity doesn’t knock; it rolls: Vehicles need alignments and new tires, but you won’t know unless you look. Quick Check® Drive from Hunter Engineering is a fully autonomous inspection system that finds the opportunities you need. Twelve cameras and 32 laser sensors provide accurate alignment and tire tread measurements in seconds, displaying the easily understood results on the large Flightboard™ video monitor for convenient customer discussions. For more information visit www.hunter.com/vehicle-inspection/quick-check/

The 3M™ PPS™ family of products has helped painters save time, reduce solvent use, and deliver consistent results for more than 20 years. From the world’s first linered cup system, the PPS™ family has grown to include a family of paint cups that meet painters’ everyday challenges. Instantly ready to use—3M™ PPS™ 2.0 Vented Cups come with their valves preinstalled. They’re ready to start mixing right out of the box, delivering the excellent material flow you’d expect from a vented cup system.

Visit www.3mcanada.ca/3M/en_CA/collision-repair-ca/paint-preparationsystem/

www.carcone.com

With 28 years experience in the wheel refinishing industry, Carcone’s has a team of motivated individuals and an 8,500 sq ft state of the art facility dedicated to serving customers. Capable of working on a variety of wheel refinishing services from corrosion and clear coat peel to slightly bent wheels and powder coating finishes, Carcone’s offers services on any OEM aluminum wheel refinishing, any aftermarket aluminum wheel refinishing and any steel wheel refinishing. Other services include: curb rash; exact and exotic paint finishes, wheel balancing and more. For more information call 1-800-263-2022 or visit carcone.com

www.dominionsureseal.com

Dominion Sure Seal’s 3 in 1 Primers are quick to dry, easy to sand, and paintable in as little as 30 minutes. Apply direct to metal, aluminum, plastic, fibreglass and SMC. Surfaces can be sanded just 15 minutes after priming, and can be painted 30 minutes after. The products offer great flexibility, a film build, large paint gun style fan pattern, and great filling characteristics. They are suitable for metal, aluminum and plastics. The 3 in 1 Primers are available in black, grey and white.

For more information visit dominionsureseal.com

www.cardinalcouriers.com

The K-Power is KECO’s most powerful lateral tension innovation. The K-Power applies force extremely low to the panel with controlled finesse all the way to Port-a-Power strength. This allows for the cleanest lateral tension possible designed to maximize the output without the risk of creating collateral damage. Multiple shoes give technicians flexibility and options for applying force to flat panels and body lines with both perpendicular and in-line configurations. For more information email Sales@keco.com or call 888-532-6822

www.astech.com asTech® All-In-One

What would you do with the extra time? Cardinal Couriers can give you back time and help you start your business day earlier with Cardinal’s pre-8 a.m. transportation solutions. Cardinal understands the value of time, and that’s why the company’s unique night network provides a competitive advantage where first to market comes standard. Optimize your sales, improve customer service, loyalty and increase profitability through Cardinal’s unique night network with unattended pickups and deliveries.

The asTech® All-In-One® is the most comprehensive and powerful repair device with the best OEM vehicle coverage. The asTech® All-In-One® can perform both remote authentic OEM and car side OEM-Compatible diagnostic scans that are covered by asTech’s industry leading warranty. It also includes full support for ADAS calibrations as well as programming. For every vehicle in your shop, the All-In-One® is the only tool you’ll need.

For more information visit www.astech.com

Our largest product offering yet. Tailored systems, unmatched precision, crafted for your shop.

Our journalists put you right in the action at major industry events. The biggest trade shows and conferences can be viewed online in the Collision Repair mag flickr albums.

BY ALLISON ROGERS

An article titled “How Gen Z Is Becoming the Toolbelt Generation”, published in the Wall Street Journal, recently went viral on LinkedIn. In this article, author Ti-peng Chen outlines how Gen Z’s current “skepticism about the return on a college education,” along with “new technologies in fields from welding to machine tooling are giving trades professions a face-lift, helping them shed the image of being dirty, low-end work.” Bodyworx Professional, of course, celebrates this.

Toward the end of the article, Chen cites data from software company Jobber, which ran a survey among American high school and college-age youth last year. According to the data, 75 percent of respondents said they would be interested in vocational schools

Talking

that place supreme value in their personal autonomy. They want independence; to be treated as an individual. I know this for a fact, because I am Gen Z…right on the cusp, okay?!

Also in the article, Chen states that the number of students enrolled in vocational-focused community colleges in the U.S. rose 16 percent last year, reaching the highest level since regular data collection began in 2018. They note that, in the U.S., the number of students studying construction trades rose 23 percent from 2018 to 2023, whereas trades like HVAC and vehicle maintenance and repair rose seven percent.

A modest increase, compared to higher paying trades. The median pay for new construction hires rose 5.1 percent in the U.S. just in

to parents and educating them on modern collision repair facilities won’t suddenly spawn a new generation of workers we can rely on.

offering paid, on-the-job training. The primary driver for respondents, according to Jobber—the belief that ‘blue collar jobs’ offer better job security than ‘white collar ones,’ given the growth of AI.

In the same vein, nearly 80 percent of respondents on Jobber’s survey said their parents wanted them to attend traditional postsecondary—i.e., college or university. Earnings are the primary factor noted by parents: payroll service provider ADP data suggests collegeeducated workers earn more over time, Chen notes in the article.

The Wall Street story, backed with Jobber’s data, demonstrates that, despite their parents’ wishes, plenty of Gen Z is more than happy to (consider) going against their wishes.

This reiterates a point I made a few issues ago, where I discussed my constant bafflement with the fact that so many in our industry seem to turn to the parents of the people we’re recruiting, rather than to the individuals themselves. So many programs and efforts—ones run by renowned organizations!—place huge priority on speaking to parents; convincing parents collision repair isn’t the “dirty work” they think it is; and getting them on board with the fact their son or daughter could spend a significant portion of their life on a bodyshop production floor.

There are countless resources out there that will tell you that the youth we are looking to recruit right now—Gen Z—are a generation

the last year, according to payroll services provided ADP. It was the fourth year that median annual pay for new construction hires saw significant increases.

We need to take different steps to solve the skills shortage. Throwing money at the problem, promising vague action won’t work. Talking to parents and educating them on modern collision repair facilities won’t suddenly spawn a new generation of workers we can rely on. We need real action, and fast.

Partner with us to unlock the full potential of your advertising campaign and position your brand for success in the competitive marketplace. Join us in shaping the conversation and leave a lasting impression on our readership. Contact us at Media Matters today to explore the endless possibilities of advertising in our magazines.

– w hile stocks last !

SATA TRAVEL MUG –with every SATAjet X 5500

Always by your side!

SATA TRAVEL MUG PROMOTION: As of now you will receive with every SATAjet X 5500 a SATA TRAVEL MUG by Emsa! The perfect travel companion, ideal for hot or cold drinks, perfectly insulated, leak and dishwasher proof. Made from stainless steel, with a convenient Quick Press closure and a 0.5 litre capacity.

Only available at participating SATA dealers and only while stocks last.

www.sata.com/travelmug

When you invest in a Fix Auto franchise, you invest in a business model with a proven track record in 12 countries around the world. You invest in a fully branded business with a roadmap for success. You invest in the same values and work ethic that grew your local business to what it is today.

Drive your business forward with:

• Solid performance-driven operational model and ongoing training.

• Full branding and marketing support for local awareness and promotion.

• Proven experience in winning insurance work.

• Established global supply and fleet arrangements.

Our owner started as a franchisee, and this inspires our commitment to the success of the local business owner.