BY DARRYL SIMMONS

Do you love your job? If you can answer with a “yes,” and you work in the collision repair industry, you’re off to a great start.

The automotive world is changing at a breakneck pace. That’s the simple truth. Just think about how much the job has changed in the last decade, if you’ve been around the space for that long. If you’re unaware, here’s a little picture: the materials, tools, processes, technology...even the very vehicles we work on are becoming more and more impressively advanced with each and every model year.

collision repair techs, that means a whole new skillset is required—a skillset focused on precise calibration, programming and integration. It’s a challenge, to be sure, but also an incredible chance to showcase your value and expertise.

The more you invest in your own development, the more valuable and indispensable you become.

The pace of change can feel dizzying. It’s understandable if you feel the desire to cling to the familiar. But, as members of this industry, we can’t stay still for long. If you crave long-term success in this industry, you need to leave the familiar behind and jump head-first into the future.

The collision repair professionals who will thrive in the years to come are those that embrace change, who see it as an opportunity rather than a threat. They’re the ones constantly upskilling, seeking new ways to leverage themselves as a valuable employee, seeking the latest stateof-the-art certifications and training. They position themselves as the go-to experts on the production floor. They understand emerging technologies. Their colleagues seek them when they need an answer to tough questions.

Take ADAS and full-on autonomous vehicle systems, for instance. These hyper-advanced driver assistance features are becoming increasingly common, not just in luxury models, but in everyday consumer cars. Every new model sold in North America next year will incorporate some kind of ADAS. For

Or consider the shift towards lightweight, high-strength materials like carbon fibre and aluminum. Painters have had to completely rethink their approach, mastering new colormatching processes and paint technologies. But the shops and individuals who have risen to that challenge? They’re the ones commanding premium prices and attracting the most discerning customers.

The bottom line is that the future of collision repair is happening right now. And the surest way to future-proof your career is to embrace that future with open arms. That means getting comfortable with the idea of lifelong learning, of continuously expanding your skillset to keep pace with industry changes.

It might seem daunting, I know. After all, you’ve already put in countless hours honing your craft. But think of it this way—the more you invest in your own development, the more valuable and indispensable you become. The collision repair shops of tomorrow aren’t just going to want talented techs and painters—they’re going to demand tech-savvy, forward-thinking problem-solvers who can tackle any challenge that comes their way.

VOLUME 11, ISSUE 3, 2024

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

ASSISTANT EDITOR

Sarah Perkins | sarah@mediamatters.ca

STAFF WRITER

Michael Vavaroutsos | michael@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677 wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

MARKETING COORDINATOR

William Simmons | william@mediamatters.ca

INTERACTIVE MEDIA DESIGNER

Dayna Dicuangco | dayna@mediamatters.ca

SUBSCRIPTION

One-year $25 / Student Discount is 10%

Bodyworx Professional ™ is published quarterly, and is dedicated to serving the professionals of the collision repair industry. It is published by Media Matters Inc. Material in BodyworxProfessional™ may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632

RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough ON K9J 3R2

“We acknowledge the financial support of the Government of Canada.”

Bodyworx Professional is published by Media Matters Inc., publishers of:

The provincial governments of Ontario and Alberta have announced a cross-provincial collaboration to support the development of a framework for international credential recognition and post-journeyperson certification. According to a recent press release, “this partnership [aims to] put Canadian workers first by reducing interprovincial barriers and red tape for credential recognition and encouraging the flow of labour between Ontario and Alberta.” Under the Memorandum of Understanding (MOU), the provinces will work together to share expertise and information and explore an international credential recognition framework for skilled trades workers. This partnership will also aim to expand offerings of post-journeyperson certifications to support graduates of apprenticeship programs in upskilling and achieving pathways to further their career prospects.

Shelley Gray, CEO for Skilled Trades B.C. says that the perception of the trades as a career is shifting as record numbers of both first-year apprentices and overall apprentices in the province have increased. Approximately 15,000 new apprentices registered in 2023 to 2024, up 21 percent from the previous year and above the provincial annual average of between 12,000 to 13,000. Skilled Trades B.C. also noted that approximately 10 percent of apprentices registered are women. The organization further announced three automotive trades will be introduced to the certification program. The three trades include heavy-duty equipment technician, automotive service technician and autobody collision technician. Currently, no phase-in date has been announced.

18.0

In response to the record number of registered apprentices, Gray commented that “this is the highest recorded in B.C. The process has been one of breaking down the stigma of trade jobs and showing they are well-paying jobs and offer lots of opportunity.”

The Minister of Employment, Workforce Development and Official Languages, Randy Boissonnault, alongside Ministers Jonathon Wilkinson and Seamus O’Regan, have launched a call for proposals from the industry under the new Sustainable Jobs Stream of the Canadian Apprenticeship Strategy’s Union Training and Innovation Program (UTIP). With an investment of over $95 million, the Canadian government hopes this funding will help unions and their partners provide green training to approximately 20,000 apprentices and journeypersons over the next five years. The UTIP Sustainable Jobs Stream is part of a new focus under the Canadian Apprenticeship Strategy to respond to the skilled trades workforce’s most pressing needs, including addressing barriers to successful entry, supporting progression and completion of apprenticeship, addressing financial crisis, and increasing net-zero manufacturing to unlock Canada’s economic potential. This call for proposals will be open until September 5, 2024.

SEMA Show attendees will have the exclusive opportunity to become electric vehicle (EV) and EV safety certified. The 2024 SEMA show will take place from November 5 through November 8 in Las Vegas, Nevada, with each of the two EV certification sessions to be run by Legacy EV on November 6 from 9:00 a.m. to 4:00 p.m. PST at the SEMA Show campus. The program, “Electric Vehicle 101, Presented by Legacy EV,” will be capped at 20 participants “to ensure an intimate, hands-on setting for attendees to upskill themselves with a new understanding of EV powertrains and safety,” said a SEMA press release. The full-day course will be divided into two sessions—“Understanding EV Anatomy and Electrical Theory” and “Applications with EV Specifications, EV Tooling and HV Safety.”

Trainees who complete the course will receive an official “EV 101 certification” from Legacy EV. Additionally, during the training, attendees will work with real EV powertrains and tooling on Legacy EV training benches.

Starting in September 2024, Grade 12 students who meet provincial graduation requirements at the end of the first semester can enter skilled trades programs at the Nova Scotia Community College (NSCC) before graduating. The pilot program will see 34 eligible students begin at the NSCC in February. “Skilled trade careers are high-paying, in-demand opportunities throughout our province. It’s an excellent time to become a skilled trades professional,” said Premier Tim Houston. The program will include nine months of training, allowing students to graduate in November 2025 and to enter the workforce sooner.

The CWB Group and Canadian Collision Repair Academy are hosting an instructor-led Progressive Repair Planning Program on various dates from August 12, 2024, through March 2025, and sign-up is open now. Geared toward repair planners, estimators and insurance personnel proficient with current estimating software–though beneficial to front office staff and technicians alike–the CWB Group states that the content of this four-day program is aimed at: accessing, researching and implementing complete repair guidelines; following OEM repair manuals and industry resource information to successfully collaborate with the payer; the mandatory steps of addressing the requirements of these changing construction technologies to return vehicles to their precollision structural integrity; and fit and finish to ensure that the collision management and safety systems function as designed. Completion of a pre-class task will be required before attending the main course.

The Canadian Automobile Dealers Association (CADA), the Canadian Vehicle Manufacturers Association (CVMA) and the Global Automakers of Canada (GAC) have developed The Countdown to 2035 as part of a larger initiative aimed at helping industry leaders understand the steps needed in the country’s shift to electrification. The Countdown to 2035 specifically aims to offer leading automotive industry associations with a dashboard that offers up-to-date information on the charging and infrastructure gaps that need to be addressed if Canada is to achieve its zero-emission vehicle sales targets by 2035.

The J.D. Power 2024 U.S. Initial Quality Study (IQS) indicates that battery electric vehicles (BEVs) and plug-in electric hybrid vehicles (PHEVs) require, on average, more repairs than gas-powered vehicles in all repair categories. Specifically, according to the yearly study, gas and diesel-powered vehicles average 180 problems per 100 vehicles (PP100), while BEVs and PHEVs are 86 points higher at 266 PP100. However, the report further notes that the gap between Tesla’s EV quality and that of traditional OEM’s EV quality has narrowed, with both ranking at 266 PP100. In the past, Tesla has performed better, but this year was brought down in rankings by customer dissatisfaction with the removal of traditional feature controls such as turn signals and wiper stalks.

A W123 Mercedes 240D has been operating as a cab on Grand Canary Island, Spain, since 1988 and has racked up 4.35 million miles (7,000,646 kilometres). The 17.6-foot-long vehicle has been operating three-to-eight-hour shifts since it first began its career. with a mileage of 3,100 miles (5,000 kilometres) per week, the 240D requires up to 52 oil changes every year. The vehicle’s OM 616 engine is also thoroughly checked every 621,371 miles. The current engine is only the second unit in the vehicle, with a replacement available as needed. While efforts were made to retain as many original parts as possible, the vehicle’s seats had to be modernized as well as the steering wheel. The body of the vehicle was also reinforced to prevent fatigue fractures. Brakes were also taken from a more modern Mercedes.

Nissan has created an ultra-violet (UV) absorbing glow-in-the-dark automotive paint in partnership with STARPATH for its all-electric model Leaf. The automaker specifically worked with inventor Hamish Scott, creator of STARPATH, to design the paint coating that absorbs UV energy during the day and then releases this energy as light to glow-in-the-dark for between eight to ten hours. If you’re sick of ultra-bright headlights—or want your vehicle to be even brighter—or are part moth, then this glow-inthe-dark paint will surely make you beam.

Although glow-in-the-dark paint is not a new concept, Nissan’s UV-energized paint is different in that it is solely made up of organic materials. The paint contains a material known as Strontium Aluminate, a solid, odourless and chemically inert material, making it safe to use in automotive manufacturing.

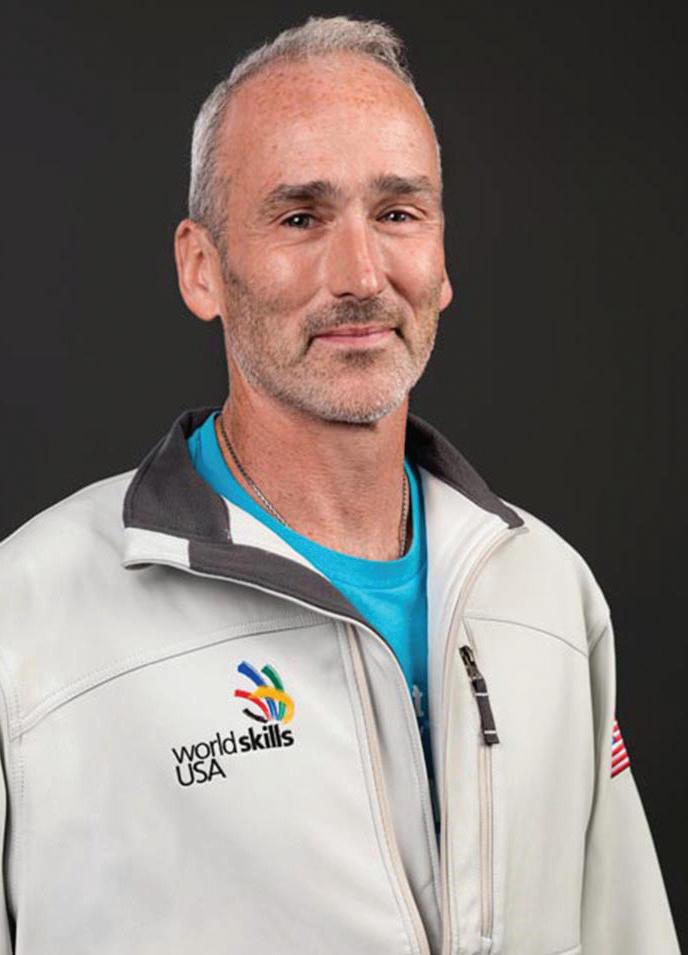

FOR SYLVAIN SEGUIN, PRESIDENT OF FIX NETWORK CANADA, WORKING IN THE COLLISION REPAIR INDUSTRY IS ALWAYS AN OPPORTUNITY TO LEARN SOMETHING NEW

TBY SARAH PERKINS

he world of automotive repair holds an abundance of knowledge waiting to be shared. Every vehicle in need of repair comes with its own story, and collision repair experts are always eager to divulge insights about the industry. Just ask Sylvain Seguin, the president of Fix Network Canada, and he will explain that his journey to success has been powered by hard work, industry connections and a commitment to forging his own path.

Sylvain reflects on his beginning in the automotive world, he maintains that the “the story is pretty simple.”

“I was raised in the industry working at the bodyshop where my father, once a painter, was

acting as manager. I would do odd jobs on weekends and help after school,” he recalls.

Although he was immersed in the automotive industry during high school, Sylvain harbored dreams of becoming a carpenter and building homes.

A pivotal conversation with his father changed everything.

“He encouraged me to consider learning a trade at the shop while being paid. It made sense,” Sylvain admits.

Following his father’s advice, Sylvain started performing more hands-on responsibilities, such as small painting jobs.

“While I was doing these early painting jobs, I began to think, I kind of like this.”

“I would regularly interact with Steve Leal, and one day, he mentioned needing someone to lead the Canadian operations at Fix.

At first, I didn’t realize he was referring to me,” Sylvain commented. “But as he introduced me to new initiatives, I became excited about the opportunity.”

“If you push to break barriers, then this means that the barriers will no longer be there.”

Consequently, he decided to forgo trade school and dive deeper into his newfound passion for collision repair.

Sylvain earned his first apprenticeship card while working alongside his father. After four-and-a-half years, he proudly became a certified painter, fully committed to the collision repair industry.

“In my 15 years as a painter, I immersed myself in training. I sought out any opportunity to build my knowledge and skills,” he explains.

This dedication paid off when Sylvain was eventually approached by AkzoNobel to become a technical representative for the company.

“I had steady career at the time, but I saw this as a chance to learn something new.”

While working there, he discovered that companies like AkzoNobel offer extensive training programs.

“As long as you’re eager to learn and push yourself, companies will support your growth,” he says.

This commitment to self-improvement propelled Sylvain through various roles within

the company. Starting as an account manager, he progressed to sales manager for Quebec, district sales manager for the Eastern market, national strategic manager and ultimately, country manager for Canada by 2017. This ascension was made possible by the multiple training projects Sylvain actively participated in.

From basic sales training to advanced leadership skills, conflict resolution, financial training and numerous multiple multinational projects offered by the paint manufacturer to high-potential employees, Sylvain’s commitment to personal and professional development has been evident throughout his career journey.

“Being surrounded by the industry in this role forced me to quickly apply everything I had learned. Even my family noticed my growth,” he notes.

While Sylvain may have viewed his lack of higher education as a potential obstacle at the time, he believes that his hands-on experience has played a crucial role in developing his confidence.

“In the beginning, I had to work two to three times harder than those with university degrees,” he asserts.

Sylvain also found pride in his ability to overcome language and culture differences in his national leadership role.

“Pushing those barriers further encourages other to do the same. If you strive to break barriers, they will no longer exist,” he said.

Sylvain’s industry journey took a significant turn when he met Steve Leal, president and CEO of Fix Network, during his tenure at AkzoNobel.

“I would regularly interact with Steve, and one day, he mentioned needing someone to lead the Canadian operations at Fix. At first, I didn’t realize he was referring to me,” Sylvain chuckles. “But as he introduced me to new initiatives, I became excited about the opportunity.”

Upon joining Fix Network, Sylvain and Leal devised a two-year plan.

“In the first year, Steve advised me to observe and learn; the second was to implement and execute the strategies. This methodical approach was incredibly valuable and a lesson we can all take to heart,” he emphasizes.

When asked about what advice he would give to newcomers looking for a career in the collision repair industry, Sylvain told Bodyworx

“If

“If you’re new to the industry, open your horizons and try to stay ahead of the learning curve.”

Professional about the importance of getting involved.

“If you’re entering the industry, broaden your horizons and stay ahead of trends. The nature of this industry means no two days are the same, which fuels my passion. Every day brings a new challenge, and there’s always something interesting on the horizon.”

As technological advancements in vehicle repair accelerate, Sylvain insists that continuous education is paramount.

“The methods that worked yesterday are outdated today, and they certainly won’t work tomorrow. With the rapid emergence

of advanced driver assistance systems and electric vehicles, staying informed is essential as vehicle technologies evolve. Electric vehicles might represent just a small fraction of the work, but they dominate industry conversations.”

Ultimately, Sylvain Seguin’s journey—from a young painter to a national leader in collision repair—embodies a deep-seated passion for the automotive industry and a commitment to lifelong learning.

By emphasizing adaptation and education, he continues to inspire those within the collision repair community to embrace change and progress.

Are you ready to shine? Don't miss the chance to showcase your journey in the upcoming issues of Bodyworx Professional magazine!

We're on the lookout for inspiring stories from professionals like you who are making waves in the industry. Whether it's a groundbreaking innovation, a transformative business journey, or a personal triumph, we want to hear from you. Being featured in Bodyworx Professional magazine is not just about recognition it's about sharing your expertise and experiences with our diverse audience of professionals. Seize this opportunity to amplify your voice, connect with like-minded individuals, and leave a lasting impact.

Submit your story today to info@mediamatters.ca and let your achievements take center stage!

As a global partner of WorldSkills, SATA routinely provides equipment and expertise as well as hosting SATA Challenge events on-site at both its Canadian headquarters and in Germany.

Worldskills is the global hub of skills excellence and promotes vocational education and training for young people in 85 member countries and regions around the world. The competition, which is the world’s largest vocational skills competition, is held every two years.

This year, the SATA Challenge ran from

July 15 to July 19, and offered WorldSkills participants the opportunity to practice under competition conditions and to familiarize themselves with the SATA equipment before the actual competition to be held in Lyon, France from September 10 to 15. The team at the SATA training centre in Vaughan, Ontario, then scored competitors and timed their ability to complete tasks, offering certificates for their overall placement on the final day.

The WorldSkills car painting finalists from Barbados, Canada, Germany, the United Kingdom

and the United States specifically met at the SATA training centre to test out their skills and connect with one another, with Miguel Harvey, a WorldSkills competitor representing the United Kingdom, taking home first place. In second place was Jason Scheter, representing Germany, and in third, was Holly-Ann Bayley, representing Barbados.

Bodyworx Professional was on the scene to see the competitors in action and to learn what it means to them to compete both within the industry and on the world trades stage.

Holly-Ann Bayley will represent Barbados at this year’s WorldSkills event. She first got involved with WorldSkills when her college instructor introduced her to the competition. She then met her WorldSkills expert, Negas Alleyne-Browne, who became involved with WorldSkills through his workplace, Automotive Art.

“My college instructor encouraged me to put myself out there and show others what I can do. I’ve been painting for two years and WorldSkills is a once-in-a-lifetime opportunity.”

But the experience does not end at WorldSkills, adds Bayley.

“This experience is something that you can cherish for life, it’s something that sets you up for life. I’m really, really proud to be here and really proud to be representing my country.”

Gabrielle Leclerc first started painting cars during the pandemic, when she sought new challenges in the face of boredom.

“I originally wanted to be a veterinarian, but ever since beginning car painting—it feels like this is more my passion.”

Leclerc had been interested in the idea of painting cars since childhood. She’s been out of school for two years now, working on her skills as an automotive refinisher.

“WorldSkills means a lot to me,” she told Bodyworx. “It’s allowed me many opportunities and opened doors for me. This competition will end up being a great experience for me, meeting new people and constantly improving my skills.”

Jason Scheter will represent Germany at WorldSkills Lyon 2024. Scheter first discovered the field when building motorcycles with his cousin at 15 years old.

“I’ve now been a car painter for about four years,” said Scheter. “I was restoring motorcycles with my cousin and decided to also learn about car painting.”

Scheter sees WorldSkills as a stellar opportunity to prove yourself.

“I believe WorldSkills is a really great opportunity to prove yourself, and this week’s SATA Challenge has given us a chance to meet the other competitors.

“It’s really, really cool and I’m excited to have had the opportunity to practice in Canada and compete in France this September.”

Representing the United Kingdom is Miguel Harvey, who also came out with the top score during the SATA Challenge training week.

“I first got into car painting because I’ve always been a massive fan of cars. I never thought I’d be working on them—I was a big motorsports fan—but I’ve been painting cars since 2020, when I started my apprenticeship straight out of school.”

Harvey became involved in WorldSkills two years ago. This is his first time competing at the international level.

“This was my first trip to Canada. It’s been an amazing experience here at SATA and I can’t wait for WorldSkills Lyon 2024.”

When speaking with the other countries’ experts—whose job is to mentor and chaperone the competitors throughout the competition—Negas Alleyne-Browne, expert from Barbados emphasized how important WorldSkills and regional competitions are to the field overall.

“Obviously WorldSkills is a great opportunity for my competitor, Holly, to get exposure and to see car painting at the highest level and be trained and be mentored to perform at that level. She will be able to take those skills with her to become great and build a life for herself, even after the competition.”

Cecile Bukmeier, Canada’s expert, and autobody chair at the Northern Alberta Institute of Technology (NAIT), expressed excitement for this year’s WorldSkills competition as well as the future of the industry at large.

“I’m really excited this year. I mean, I’ve been in the industry for the last 15 years and it has been a little bit lonely for me being the only woman that I could really see. I’m seeing more women come through the trade, I’m seeing more women participate in these events, and I’m excited this year.”

“I believe this will be a record-setting year for WorldSkills with the women participation as competitors as well as experts. I won’t be alone anymore. I’m really, really excited.”

Mariusz Dechnig, the expert from Germany, further echoed Bukmeier’s feelings of camaraderie.

“I’m very happy I can come here to Canada to do training at this organization for SATA and Cecile,” Dechnig said.

“I am well prepared for the WorldSkills challenge. The SATA competition is a great opportunity to see what our competitors can do and what we need to continue working on in order to be successful in Lyon.”

Finally, Rich Wheeler, the expert from the United Kingdom told Bodyworx Professional that he feels very privileged to be part of this process.

“It is such a rewarding job and the challenge to get competitors to the international standard is amazing. I feel quite proud and privileged to be part of that process. We’ve been quite fortunate in the United Kingdom that the competitors have come away with medals in recent years and to be part of that process is really heartfelt.”

Local collision industry representatives also showed out in support of the global competitors.

“It’s great for Pfaff Autoworks to be part of the WorldSkills competition,” said General Manager of Pfaff Autoworks, Jeff Pabst, who brought a car by for the students to practice on. “We’re thrilled to help support the program, see it grow and see the young talent compete. We’re excited to see the outcome when they go to France. Go Canada!”

George Varagic, president of SATA USA and SATA Canada, said the company is honoured to partner with WorldSkills globally.

“We’re very excited to host WorldSkills practice in our state-of-the-art facility, and thankful to our team members to help organize everything—especially Joern [Stoever] and our operational team in Canada.

“We worked very hard to provide the competitors and experts the best possible environment to perform their best and to their greatest potential,” added Varagic.

Joern Stoever, global key account manager for SATA, was thrilled to have the chance to celebrate top-notch skills and success.

“We have certificates that we’ll give the competitors, showing their points [scored] for the week. They will see what tasks they scored well in, and what modules they may need to work on.

“It’s through events like this that competitors can learn how to grow, and this, for me, is the most important part of WorldSkills.”

With the completion of the SATA Challenge, the car painting competitors will prepare for the Lyon, France WorldSkills competition which will see over 250,000 visitors from around the world meet to watch a total of 1,400 competitors and 1,300 trades experts from over 70 countries navigate the trials of 59 different trades professions categories.

IBY SARAH PERKINS

n May, the Alberta government implemented an Advisory Council of Skilled Trades Youth Ambassadors as one strategy to help expose more young people in the province to the opportunities of the trades while also seeking to amplify the voices of youth looking to make a start in apprenticeships.

The program intends to help provide apprentices and interested youth with a gobetween so that concerns and questions about the trades can be more easily raised with the right government officials. The province’s twelve youth ambassadors—one per skilled trades category—were nominated by their postsecondary institution based on performance excellence on their apprenticeship path, with each ambassador set to serve a six-month term.

Bodyworx Professional recently had the opportunity to sit down with Trinity Mehlhaff, youth trades ambassador for automotive repair from Taber, Alberta, to learn more about the role as well as why, when it comes to the automotive industry, it’s important to learn that you can “always make yourself big.”

Bodyworx Professional: In your own words, can you describe the Skilled Trades Youth Ambassador program?

Trinity Mehlhaff: The Skilled Trades Youth Ambassador program is a kind of fellowship of tradespeople all sharing their experiences within their own trades. It’s a bridge between the Alberta government and youth in trades. As an ambassador, I point out upcoming challenges and opportunities within automotive industry-related apprenticeships. We have regular meetings where we can share any important details related to our specific trade.

FOR TRINITY MEHLHAFF, SKILLED TRADES YOUTH AMBASSADOR FOR THE AUTOMOTIVE REPAIR INDUSTRY, THE TRADES ARE ALWAYS AN OPPORTUNITY TO MAKE YOURSELF BIG

BP: How did you learn about the program and how were you chosen for the role?

TM: I attended the pre-employment automotive course at Lethbridge College. I was in the mechanics shop at the college training for my first year attending Skills Alberta when my teacher, Eric, got an email about the program. He and my other teacher Dave elected me to be a part of the program and then I was chosen based on academic performance.

BP: How will the program benefit the province?

TM: I believe that the program will help benefit the province in terms of introducing more young people to the opportunities of the trades. Through this program, we, as youth, can voice upcoming challenges within our trade and can bring awareness to what is needed to bring new passion to the industry. I’m hoping to be able to introduce more youth to the opportunities

that the trade can offer, the new skills that can be learned and bring new voices to the table.

BP: Why did you choose to enter the automotive repair industry? What has been your biggest accomplishment in the industry so far and what are your goals within the industry for the future?

TM: I’ve been working on vehicles for numerous years now and I’ve always had a passion for it. As a result, the automotive industry just suited me to a T. I have a Nissan 300zx drift car and a second-generation Cummins, and whenever I have spare time, I’m always tinkering on one of my vehicles at home.

My biggest accomplishment so far has been participating in Skills Alberta. This year was the first time I had heard about the competition and now, I wish I could compete again; unfortunately, I’ve aged out, but it was very cool to get to see so much of the industry competing on such a large scale.

Currently, my goal for the future is to get into diesel repair. I drive a diesel truck and I just think that combustion engines are super cool. Even with the transition to electric vehicles on the horizon, I think that there is value in being able to understand the foundations of how combustion engines function.

BP: What do you love most about cars?

TM: I genuinely love everything about cars. I love the sounds and looks of vehicles; I even love their smell, except for differential fluid that is.

I do barrel racing and compete in competitions across Canada. I’ve been riding horses for 15 years and find that while horses and vehicles are obviously different, the thrill of working with both is similar.

BP: How can young people benefit from the trades and the automotive industry?

TM: There are so many ways that young people can benefit from the trades and the automotive industry. From a practical perspective, you can learn to fix your own vehicle and save some money in the process, but also, when you work in the trades and the automotive

trades especially, you get to learn new things constantly. The skill sets you learn also present huge gateway opportunities and there’s lots of room to transition and grow based on your interests.

BP: What advice would you give to young people who are looking to get a start in the automotive trades?

TM: My main advice would be to avoid getting discouraged. The automotive industry has traditionally been a male-dominated space and as a young woman who’s also five feet

tall, I’m not the typical person you think of when someone imagines an auto repairer. However, I’ve found that you can always find ways to make yourself big—both physically and mentally.

Physically, auto snipes are my best friends, but mentally, I think it’s important to keep reminding yourself that at the end of the day, if it’s something you’re interested in, just go for it. The automotive industry is a very welcoming environment, and you can learn so many things from the people you meet along the way. My mind is constantly growing from being in the trades and I’m loving the journey.

BY SARAH PERKINS

As the summer reaches its peak, the importance of protection from the sun’s sizzle becomes paramount—not just for our skin, but also for automotive coatings.

Automotive coating protection acts like sunscreen for vehicles, safeguarding them from the harsh effects of sunlight, extreme temperatures and environmental contaminants. While paint protection films (PPF) have existed since the mid 20th-century, recent advancements in automotive technology have propelled automotive SPF into the 21st-century in the form of self-healing automotive coatings.

These coatings are said to not only protect a vehicle’s coating, but also possess the ability to repair minor scrapes and scratches on their own using advancements in materials science, nanotechnology and smart systems.

Self-healing automotive coatings primarily revolve around the development of smart materials and technology that can automatically repair damage. These materials are categorized into three main types.

Self-healing polymers are engineered to respond to damage through chemical reactions that restore their original state. Microcapsules filled with healing agents can be embedded in these polymers. When the material is damaged, these capsules break open, releasing the healing agent that fills the scratch or crack and solidifies, effectively repairing the damage.

Advances in metallurgy have led to the creation of self-healing metals that can mend themselves when exposed to heat or certain chemical reactions. These metals contain microvascular networks that transport healing agents to damaged areas, similar to how blood vessels in the human body function. However, given the general immobility of metal atoms, this option has proven more difficult to achieve than other methods.

Self-healing coatings are applied to the surfaces of a car to protect against scratches and minor dents. These coatings can similarly contain capsules with a healing agent or possess intrinsic self-healing properties that activate under specific conditions, such as exposure to sunlight or heat.

There are two main self-healing coating types. The first and most common option is a clear coat layer that is applied over a vehicle’s colour coat as a liquid by the vehicle manufacturer. Comparatively, a thin plastic sheeting such as a paint protective film works more like a vehicle wrap and can be applied over existing vehicle paint. In both instances, these coatings have the chemical properties that allow internal molecular structures to rearrange themselves to an original state.

While self-healing coatings may be an ongoing technological development, the technology in its current state offers many potential applications for the automotive industry in the form of material protection, repair time savings and vehicle longevity.

While the concept and application of self-healing coatings may be a more recent development, the idea of paint protection film was originally developed in the mid 20th-century with military applications in mind in order to protect helicopter blades from debris. In the 1980s, this protective concept was then adopted by NASCAR professionals who began applying the material to the nose cones of vehicles to better protect advertising decals. From here, the technology then transitioned more broadly throughout the automotive industry.

The idea of self-healing materials dates to the late 20th-century with early research primarily focused on polymers and composites. The goal was to create manufacturing materials that could repair themselves much like a biological system. In the early 2000s, selfhealing coatings began to gain traction with researchers exploring options such as reversible polymers and microencapsulation—a process involving embedding tiny capsules filled with healing agents within the coating. When the capsules are damaged, these capsules break open, releasing the healing agents to fill the cracks and restore the surface.

The early 2000s also marked the beginning of significant interest in self-healing coatings within the automotive industry. Early prototypes used microencapsulation technology, but these initial attempts faced challenges, including limited durability and effectiveness under varying environmental conditions.

The development and production of self-healing materials can be expensive. Reducing costs through research and large-scale production is needed for widespread adoption.

Ensuring that self-healing materials can withstand harsh automotive environments over the long term is crucial. Continuous testing and refinement are necessary to meet industry standards.

Integrating self-healing materials with existing automotive manufacturing processes requires significant changes in current automotive design and production techniques.

The mid-2000s to 2010s saw the development of reversible polymers which allowed automotive coatings to heal repeatedly. Another notable breakthrough at this time was the use of supramolecular chemistry which relies on non-covalent interactions to enable self-healing. As a result, these coatings could heal at a molecular level.

Some automotive manufacturers that began offering vehicles with self-healing paint during this period included Nissan with the 2009 Infiniti G37, which received a clear coat called Scratch Shield—a technology that today is also used to help protect cell phones.

Present developments in automotive self-healing coatings include the introduction of ultraviolet-curable coatings as well as heat-responsive polymers that allow for faster and more efficient healing processes.

While self-healing automotive coatings can’t repair severe damage to a vehicle’s chassis, they are perhaps one solution for future dents and scratches. In order to continue being developed for future automotive manufacturing, continued education, training and research is needed so that the technology can overcome current challenges.

Currently, specific training courses and certifications for self-healing coatings in the automotive industry are not as widely available, established or recognized as those for PPF. However, professionals working with self-healing coatings can benefit from certain related certifications and training programs that focus on advanced coating technologies and surface protection. For PPF training in general, organizations such as XPEL, 3M and Suntek offer a variety of courses teaching industry members on effective methods to apply PPF to vehicles.

BY SARAH PERKINS

Despite the rumours, car culture is not dead. In fact, according to a survey from Hagerty, Gen Z expresses a greater interest in car culture than the Baby Boomer generation.

The “Future of Driving” survey polled more than 2,000 Americans about the role that cars play in their life. Sixty percent of Gen Z-ers polled—people born between 1997 and 2012—indicated an interest in owning a classic vehicle, compared to just 31 percent of Baby Boomers.

“The next generation of car enthusiasts is here,” said McKeel Hagerty, CEO and chairman of Hagerty. “The data is clear that Gen Z isn’t just playing car video games, watching YouTube or creating social media content. They’re also finding ways to participate in the collector car community.”

Gen Z is about more than just the glitz and glamour, though—77 percent of Gen Z respondents said they either love or like driving. Most surprisingly, perhaps: 32 percent of Gen Z respondents said they either own or have owned a classic enthusiast vehicle. Thirty percent of Millennials said they own or have previously owned a classic car.

The classics are great—but so is a little bit of luxury. Gen Z respondents—23 percent of them—expressed an interest in luxury vehicles; 26 percent said they are most interested in SUVs.

Survey data also revealed that Millennials, born between 1981 and 1996, are the most likely to complete DIY repairs. Most respondents said they manage maintenance via dealership or service centre. Of all those surveyed, 27 percent said they perform their own repairs.

When looking at overall car culture, 43 percent of Hagerty survey respondents indicated that classic cars are an integral part of history and should be systematically preserved like historic buildings and architecture.

The younger generations are broadly interested in cars from the past four decades, according to Hagerty data. This wide range is likely due to increased exposure to classic vehicles via social media, as well as other communities— in person or online—that have acted as a gateway into the car community. Gen Z-ers indicted that YouTube is where they consume the most car-related media; 38 percent said they get most of their car-related content from Instagram.

Forty percent of respondents said their first exposure to classic and enthusiast cars was from attending car shows, making them a critical point of entry into the hobby.

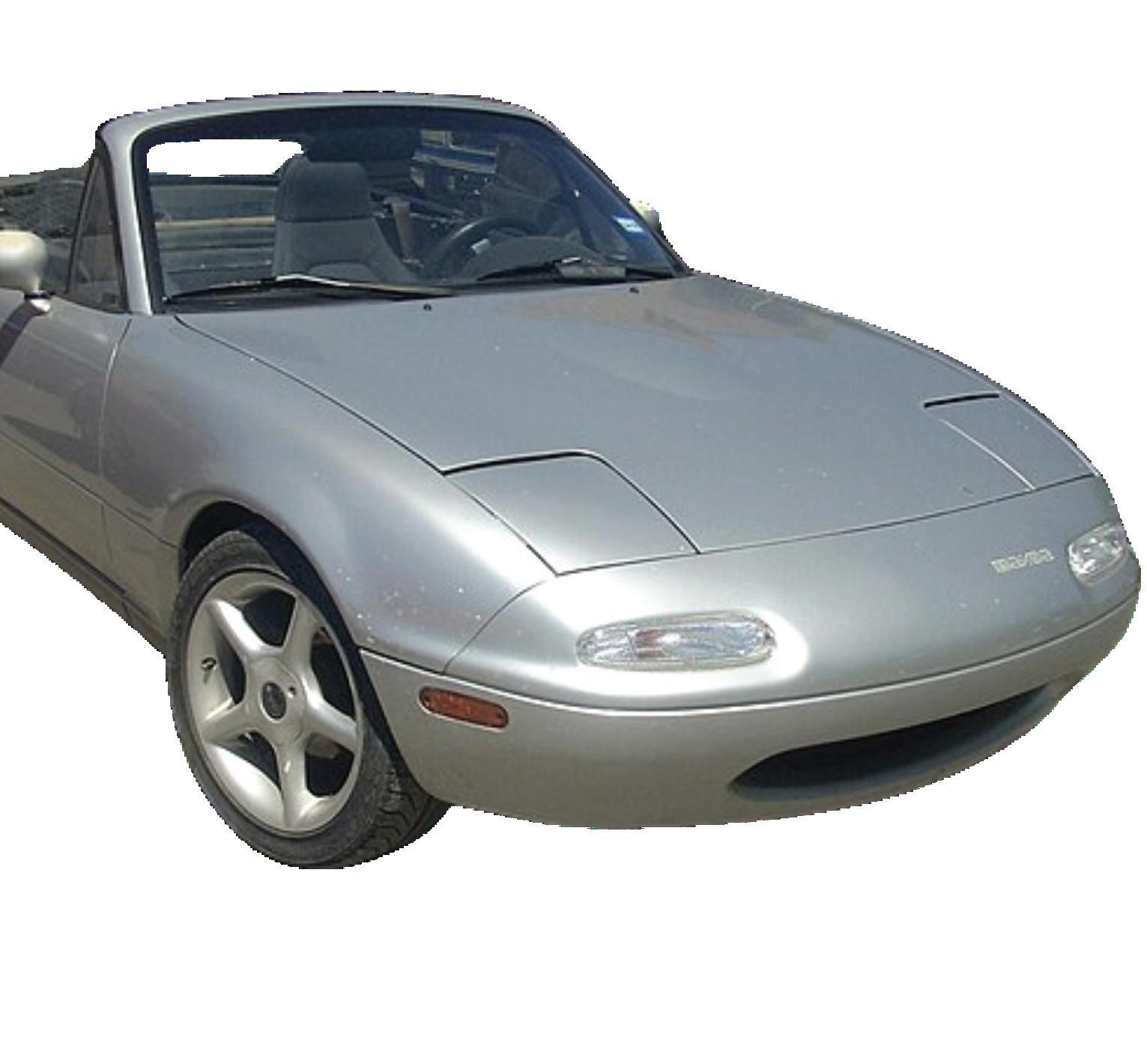

Finally, the most popular Gen Z “classic”, according to Hagerty’s data on insurance inquiries from car enthusiasts: Mazda Miatas, specifically those built from 1990 to 1998. Millennials, on the other hand, are most interested in GMT400 series trucks from 1988 to 2000.

BY MICHAEL VAVAROUTSOS

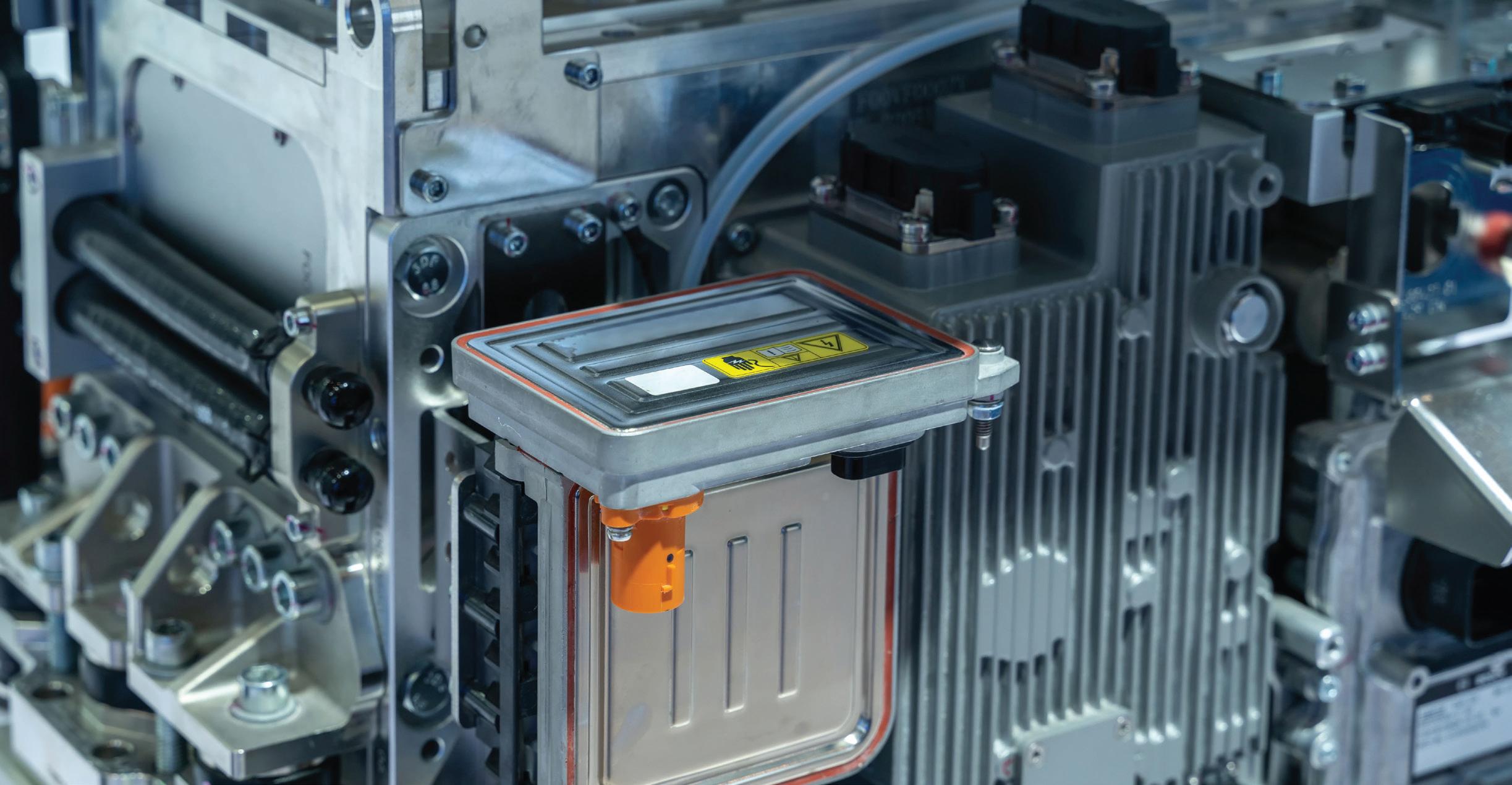

Electric vehicles (EVs) are beginning to dominate the streets around us. As more and more people continue to make the switch from internal combustion engine (ICE) vehicles to fully electric and hybrid vehicles, collision repair shops should start thinking about the differences between repairing an ICE vehicle and an EV.

When it comes to collision repairs, there are some major differences and tools required for EVs compared to ICE vehicles. For starters, EVs have a high voltage battery and voltage wiring throughout the whole unit. This can make it extremely dangerous for technicians without proper training, as they have to have the ability to remove and replace the high voltage components, including the battery.

David Mayers, CEO of Environmental Motorworks, stresses the importance of taking the proper precautions when repairing an EV.

“EVs have a high voltage battery, and they have voltage wiring throughout the unit, they can be in the weirdest spots. When it comes to collision repair, it can be quite dangerous,” Mayers explained.

“You don’t have that in an ICE vehicle, you never have to worry about a wire that’s hanging down. But you really must power down these EVs in order to work on them safely.”

Mayers emphasized that the cables and wires in the body of the vehicle can pose threats and need to be addressed. He says

that EMW has done small training courses to help show the dangers of working with these high voltage vehicles.

“In one situation at our training course, we had an example where we show that even the smallest of wiring—maybe around 18-gauge—carries some pretty high voltage.”

While there is the electrical aspect for EVs that ICE vehicles don’t have, there are also certain components of the vehicle that can be different. Mayers says that in recent years, body parts for EVs are much different than ICE vehicles. Although, this wasn’t the case when EVs first became available to customers.

“Going back to the first generations of EVs, they were not really built as electric vehicles, they were ICE vehicles that have been adapted. So, at that time, many of the body parts and things like that were very much the same,” he said.

“But in the next generations, you’re seeing that they are different. Now there are different components, different areas that need to be changed or adapted.”

David Giles, EV education product specialist for ConsuLab and president of PoweredEV, says that manufacturers are continuously experimenting with different materials and processes for EVs.

While the materials in EVs are similar to ones in modern ICE vehicles, the way they are used can be quite different.

“Aluminium forming is a big thing. So rather than having separate sections bolted together, they’re all in one piece,” Giles said.

“Where we conventionally would have rails, rear frame rails and so on that could be attached and removed, some of these newer cars don’t have that capability.

“So that means in a severe rear end collision, it’s more likely the car will be a total loss in comparison to ICE vehicles.”

The question of if EVs take longer to repair than ICE vehicles has been raised since EVs came into popularity. The fact of the matter is that EVs can sometimes take longer to repair, due to the electrical components mounted and placed in different areas within the engine bay and elsewhere inside the vehicle.

“I don’t think [repairs] take longer on EVs, but there’s an inherent respect for the vehicles, knowing there’s high voltage there. At the end of the day, the vehicles themselves run the same, but having to remove the high voltage components can be a little more time consuming,” Giles said.

As EVs continue to increase in popularity, bodyshops should take the time to understand the differences of how to repair these types of vehicles. Since these vehicles are still relatively

new to the market, it is important to take on as much specialized training as possible to ensure that technicians are EV-ready.

“Collision centres need to look at their own capacity, technician skill level, tooling requirements, charging infrastructure, model mix of vehicles, partnership with local dealers and insurance relations, as well as to stay on top of industry trends, to ensure it makes business sense for them to offer and provide EV repairs,” said Paul Stella, manager of

collision repair and refinish at Toyota Canada.

This not only involves the understanding of different components in an EV, but also being trained in safety precautions, proper repair procedures and handling, repairing and replacing the high voltage batteries.

“Again, it’s extremely important for any collision repair centre to follow all manufacturer instructions and guidelines, especially the repair manual, to ensure proper steps are followed,” Stella added.

BY ALLISON ROGERS

The future of collision repair is inexplicably exciting...but I’ll try to frame it out for you in the next 400 words.

It wasn’t so long ago that many collision repair shops relied on what we’d now call archaic technologies. Mere years ago, we were using string to complete ADAS calibrations—and that was the automaker-recommended method. Compare that to today, where advanced sensors, predictive analytics and augmented reality are standard parts of the job and learning how to do the job. Remember, plenty of programs use virtual reality headsets to train welders and painters on muscle memory and movement.

environment. Mastering how to repair the intricate programming and methods behind modern vehicles will soon be a valuable skill that ranks all-star technicians at the top of the field. You are presented with the chance to dive deep into the cutting-edge technology that is shaping the future of our industry.

One of the most lucrative opportunities presented by the technological shift is the “cool factor” that can be used to attract and retain new talent. Plenty of the technologies mentioned in this article are still considered to be emerging—meaning there’s plenty of time for collision centres, technicians, painters and even apprentices to consider the

These systems, despite their somewhat scary complexity, present a wealth of opportunities to the industry—and to you, should you choose to take on the task and learn how to operate in this new collision repair environment.

Let’s start with the basics: we all know that the materials used in model-year 2024 cars are starkly different than decades ago. Gone are the days of hammering out dents in heavy steel panels. Now, collision repairers work with lightweight, high-strength materials with traits of carbon fibre and aluminum, which demand a whole new level of specialized knowledge and techniques.

The rise of electric vehicles is undoubtedly one of the most significant technology shifts facing our industry. As more consumers adopt these eco-friendly alternatives, collision centres will be forced to adapt to new challenges (and opportunities) presented by EVs, should they want to survive the shift. The underlying principles may remain similar, but EVs demand specialization in the handling of high-voltage systems. If you are adept in the repair of these technologies, you are positioning yourself as a leader and securing yourself a stable path for the future. Need we remind you that the Canadian government wants all new vehicle sales to be zero-emissions by 2035? That’s only 11 years away. How long do you plan to work in the industry?

Autonomous vehicle systems are yet another emerging technology. Self-driving cars may seem daunting—and it can be, when you consider how sophisticated the systems that drive them are. Those systems, despite their somewhat scary complexity, present a wealth of opportunities to the industry—and to you, should you choose to take on the task and learn how to operate in this new collision repair

opportunities facing them and position themselves as a leader in the space.

So, we at Bodyworx Professional encourage you to set aside any fears or hesitations about the industry’s technological revolution. Instead, lean in and become a champion of these advancements. The more you can demonstrate your mastery of the latest tools and techniques, the more you’ll be able to attract the best and brightest, whether that be in your pursuit of the perfect workplace or your hunt for the future-friendly technician.

The future is today. Prepare accordingly.

The spray gun that works for you.

It comes with a completely new nozzle concept and is available with new digital functionality. And a completely new shape - but one that is still characteristically SATA.

It comes with a completely new nozzle concept and is available with new digital functionality. And a completely new shape - but one that is still characteristically SATA.

The jet X is available in four versions; jet X BASIC, jet X DIGITAL ready, jet X DIGITAL and jet X DIGITAL pro. The best paint spray gun that has ever left our factory.

The jet X is available in four versions; jet X BASIC, jet X DIGITAL ready, jet X DIGITAL and jet X DIGITAL pro. The best paint spray gun that has ever left our factory. jet X. Works for you. The spray gun that works for you.

jet X. Works for you.

www.sata.com

www.sata.com

When you invest in a Fix Auto franchise, you invest in a business model with a proven track record in 12 countries around the world. You invest in a fully branded business with a roadmap for success. You invest in the same values and work ethic that grew your local business to what it is today.

Drive your business forward with:

• Solid performance-driven operational model and ongoing training.

• Full branding and marketing support for local awareness and promotion.

• Proven experience in winning insurance work.

• Established global supply and fleet arrangements. Our owner started as a franchisee, and this inspires our commitment to the success of the local business owner.