ONLY FIVE PERCENT OF EV BATTERIES ARE RECYCLED?!

CINQ POUR CENT DES BATTERIES EV SONT RECYCLÉES!

THINGS ARE GREENER

The case for green recycled parts—now and in the future

LES CHOSES SONT PLUS VERTES

Les arguments en faveur des pièces recyclées vertes— aujourd’hui et à l’avenir

MODERN MILLERS MODERNE MILLERS

Third-gen owners Natalie and Chris Miller talk technology, team-building and timely growth

Natalie et Chris Miller, recycleurs automobiles de troisième génération, parlent de technologie, d’esprit d’équipe et de croissance en temps voulu

WOMAN OF THE INDUSTRY — BONI EHMANN, SGI SALVAGE

FEMME DE L’INDUSTRIE — BONI EHMANN, SGI SALVAGE

JOSEPH CHUNG, CALL2RECYCLE ON BATTERY RECOVERY

JOSEPH CHUNG, CALL2RECYCLE SUR LA RÉCUPÉRATION DES BATTERIES

DONALD COOPER ON MODERN LEADERSHIP

DONALD COOPER PARLE DU LEADERSHIP MODERNE

$15.95 CAD l Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 86 John Street, Thornhill, ON L3T 1Y2 canadianrecycler.ca

NO WAY >> SEULEMENT

CE N’EST PAS VRAI >>

Meet Oleksii, a Warehouse Worker at our Winnipeg, Manitoba, Canada location. Oleksii is one of the more than 45,000 men and women of LKQ who share the passion for providing the best possible parts and service for our customers. We would like to honor those, like Oleksii, and all our employees, for the passion they bring to their job, every day. Feel the passion and find your next replacement part at www.LKQcorp.com Call Us : 866-LKQ-CORP Visit Us Online : www.LKQCorp.com New Aftermarket | Recycled OE | Remanufactured Engines & Transmissions | Paint Products The Passionate Par ts People Oleksii | 13+ Years of Service Warehouse Worker Winnipeg, Manitoba, Canada Join Our TeamVisit our Website

Annual Publication / Édition annuelle spécial

For cousins Natalie and Chris Miller of Miller’s Auto Recycling, the automotive recycling industry is not just familiar, but familial. The third generation in a family business that first began nearly 75 years ago, Natalie and Chris share their journey to homegrown success.

Pour les cousins Natalie et Chris Miller de Miller’s Auto Recycling, l’industrie du recyclage automobile n’est pas seulement familière, elle est aussi familiale. Troisième génération d’une entreprise familiale qui a vu le jour il y a près de 75 ans, Natalie et Chris nous font part de leur parcours vers la réussite locale.

Le parcours de Boni Ehmann dans l’industrie l’a menée sur les côtes, sur le charbon et dans les communautés intermédiaires.

With the increasing drive towards sustainability across the automotive industry, the Ontario Automotive Recyclers Association offers insights and industry solutions to the increased adoption of green recycled parts.

Alors que l’industrie automobile s’oriente de plus en plus vers le développement durable, l’Ontario Automotive Recyclers Association propose des idées et des solutions industrielles pour favoriser l’adoption de pièces recyclées vertes.

80 YEARS YOUNG | JEUNE DE 80 ANS

Inside the 80th annual ARA Convention in Kansas City. Au cœur de la 80e convention annuelle de l’ARA à Kansas City.

CARI CURTAIN CALL | RAPPEL DE CARI

Coverage from the ARAAC/CARI joint meeting. Couverture de la réunion conjointe ARAAC/CARI.

LIFESAVING TRAINING | FORMATION EN SAUVETAGE

How Standard Auto Wreckers stepped up to provide lifesaving training to local fire departments.

Comment Standard Auto Wreckers s’est mobilisé pour offrir une formation en sauvetage aux services d’incendie locaux.

Volume 18 Issue 1, 2024

Volume 18 numéro 1, 2024

PUBLISHER / DIRECTEUR GÉNÉRAL

Darryl Simmons > publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER / ÉDITEUR ASSOCIÉ

Orest Tkaczuk > orest@mediamatters.ca

EDITOR / RÉDACTEUR EN CHEF

Allison Rogers > allison@mediamatters.ca

ASSISTANT EDITOR / ASSISTANT RÉDACTEUR

Sarah Perkins > sarah@mediamatters.ca

CREATIVE DEPARTMENT / DÉPARTEMENT CREATIF

Yvonne Maschke > yvonne@mediamatters.ca

VP INDUSTRY RELATIONS & ADVERTISING/ V.P. RELATIONS AVEC L’INDUSTRIE

Gloria Mann > advertising@collisionrepairmag.com

SALES ASSISTANT/ASSISTANT DES VENTES

Wanja Mann > advertising@collisionrepairmag.com

DIRECTOR OF SALES & MARKETING/ DIRECTRICE COMMERCIALE & MARKETING

Ellen Smith > ellen@mediamatters.ca

DIGITAL OPERATIONS MANAGER/ DIRECTEUR DES OPÉRATIONS NUMÉRIQUES

Cassie Doyle > cassie@mediamatters.ca

MARKETING COORDINATOR/ COORDINATEUR MARKETING

William Simmons > william@mediamatters.ca

CONTRIBUTORS / CONTRIBUTEURS

Steve Fletcher, Becky Berube, Joseph Chung, Donald Cooper, Wally Dingman, Dalbert Livingstone

Gloria Mann at 647-998-5677

Pour les demandes de message publicitaire téléphonez à Gloria Mann au 647-998-5677.

of address notices and undeliverable copies to: 86 John Street, Thornhill, ON L3T 1Y2. Canadian Auto Recyclers magazine is published by Media Matters Inc. publishers of; Collision Repair magazine, Bodyworx Professional magazine and the 2006 Collision Repair Training Directory

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage.

317 Reid St, Peterborough, ON t. 905-370-0101 f. 1-888-868-7072

Collision Repair magazine is published by Media Matters Inc., publishers of:

CONTENTS | SOMMAIRE ON THE COVER EN PAGE COUVERTURE GLORIA’S NOTE | NOTE DE GLORIA ASSOCIATION UPDATES | MISES À JOUR DE L’ASSOCIATION NEWS-IN-BRIEF | ACTUALITÉS EN BREF COMPANY PROFILES | PROFILS D’ENTREPRISE 06 28 32 36 18 14 66 REGULARS | AFFAIRES COURANTES FEATURES | ARTICLES VEDETTES Canadian Auto Recyclers magazine is dedicated to serving the business interests of the automotive recycling industry. It is published by Media Matters Incorporated. Material in Canadian Auto Recyclers magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing within this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher. Media Matters Incorporated would like to thank the Ontario Media Development Corporation and the Province of Ontario for the generous support in helping launch Canadian Auto Recyclers magazine. PRINTED IN CANADA ISSN 1707-6072 CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED. Send change

canadianrecycler.ca MODERN MILLERS MODERNE MILLERS The case for green recycled parts—now and in the future Third-gen owners Natalie and Chris Miller talk technology, team-building and timely growth Natalie et Chris Miller, recycleurs automobiles de troisième génération, parlent de technologie, d’esprit d’équipe et de croissance en temps voulu THINGS ARE GREENER Les arguments en faveur des pièces recyclées vertes— aujourd’hui et l’avenir LES CHOSES SONT PLUS VERTES ONLY FIVE PERCENT OF EV BATTERIES ARE RECYCLED?! NO WAY >> SEULEMENT CINQ POUR CENT DES BATTERIES EV SONT RECYCLÉES! CE N’EST PAS VRAI >> WOMAN OF THE INDUSTRY — BONI EHMANN, SGI SALVAGE FEMME DE L’INDUSTRIE — BONI EHMANN, SGI SALVAGE JOSEPH CHUNG, CALL2RECYCLE ON BATTERY RECOVERY JOSEPH CHUNG, CALL2RECYCLE SUR LA RÉCUPÉRATION DES BATTERIES DONALD COOPER PARLE DU LEADERSHIP MODERNE CANADIANRECYCLER.CA 5

50 38 22

Boni Ehmann’s industry journey has taken her to coasts, coals and communities in between.

PIONEER OF THE FUTURE

This sector is on the cutting edge of cars

PIONNIERS DU FUTUR

À la fine pointe de l’industrie automobile

Canada’s auto recyclers are on the forefront of sustainability.

By/Article de Gloria Mann

Did you know that this is the eighteenth year we have published Canadian Auto Recyclers?! Over those years, I have had the privilege of witnessing the evolution of the Canadian auto recycling industry firsthand. Across my entire time in the automotive aftermarket, I have marveled at the resilience and resourcefulness of the men and women who work tirelessly to ensure that end-of-life vehicles are transformed into valuable resources through sustainable practices.

It was evident by conversations, themes and ideas at last year’s events that Canada’s auto recyclers are on the forefront of sustainability. We are building an industry to close the vehicle lifecycle loop. Last year’s OARA Convention and Trade Show was preceded by an incredible talk on electric vehicles—everyone in the audience walked away with a wallet of new information on electrification and, more importantly, what it means for the auto recycling business; from logistics and shipping to dismantling, selling batteries and beyond.

Our team at the magazine had the privilege of attending; I can tell you, in earnest, that the facts we learned that day helped set the foundation of what became Collision Repair magazine’s EV Repair Tour, which brought aftermarket EV insights to major cities across Canada. You all did that! Whether you attended the event in-person, read about it in our publications or have ever shared even the smallest idea about closing the loop, EV batteries or zero-emissions vehicles—you are on the forefront with us.

This is all to say that watching your dedication, the Automotive Recyclers of Canada’s endless efforts and, of course, seeing your ever-smiling faces— these all represent a mere fraction of the ways you all keep me inspired!

Canadian Auto Recyclers is not just a magazine; it is a vibrant community. We encourage our readers to actively engage with us by sharing their experiences, knowledge, and concerns. Your contributions will enrich the discourse surrounding the industry and foster a sense of camaraderie among fellow recyclers. Together, let us build a sustainable and prosperous future for the Canadian auto recycling industry. I have all the faith in the world that you, the auto recyclers of Canada, will lead this grand venture! CAR

Les entreprises de recyclage automobile du Canada sont à l’avant-garde du développement durable.

Saviez-vous que c’est la dix-huitième année que nous publions le magazine Canadian Auto Recyclers? Pendant tout ce temps, j’ai eu le privilège d’être aux premières loges pour observer l’évolution de l’industrie canadienne du recyclage automobile. Tout au long de ma carrière dans le marché secondaire de l’automobile, j’ai été émerveillée par la résilience et l’ingéniosité des hommes et des femmes qui travaillent sans relâche pour s’assurer que les véhicules en fin de vie soient transformés en ressources précieuses grâce à des pratiques durables.

Les conversations, les thèmes et les sujets abordés lors des événements de l’année dernière montrent clairement que les recycleurs d’automobiles du Canada sont à l’avant-garde de la durabilité. Nous sommes en train de construire une industrie qui fermera la boucle du cycle de vie des véhicules. La convention et le salon professionnel de l’OARA de l’année dernière ont été précédés d’une incroyable conférence sur les véhicules électriques. Chaque personne présente est repartie avec un portefeuille de nouvelles informations sur l’électrification et, plus important encore, sur ce que cela signifie pour l’industrie du recyclage automobile depuis la logistique et l’expédition, jusqu’au démantèlement en passant par la vente des batteries et au-delà.

L’équipe du magazine a eu le privilège d’y assister et je peux vous dire, en toute sincérité, que les faits que nous avons appris ce jour-là ont contribué à jeter les bases de ce qui est devenu la tournée d’information sur la réparation des véhicules électriques du magazine Collision Repair, qui a permis de faire connaître le marché secondaire des véhicules électriques dans les grandes villes du Canada. C’est ce que vous avez fait! Que vous ayez assisté à l’événement en personne, que vous l’ayez lu dans nos publications ou que vous ayez partagé la moindre idée sur la fermeture de la boucle, les batteries de VE ou les véhicules à émissions nulles, vous êtes à l’avant-garde avec nous.

Tout cela pour dire que votre dévouement, les efforts incessants des recycleurs d’automobiles du Canada et, bien sûr, vos visages toujours souriants ne sont qu’un exemple de la façon dont vous m’inspirez tous! Canadian Auto Recyclers n’est pas seulement un magazine; c’est une communauté dynamique. Nous encourageons nos lecteurs à s’engager activement avec nous en partageant leurs expériences, leurs connaissances et leurs préoccupations. Vos contributions enrichiront le discours entourant l’industrie et favoriseront un sentiment de camaraderie parmi les autres recycleurs. Ensemble, construisons un avenir durable et prospère pour l’industrie canadienne du recyclage automobile. J’ai confiance en vous, les recycleurs d’automobiles du Canada, pour mener à bien cette grande entreprise! CAR

6 CANADIAN AUTO RECYCLERS 2024 GLORIA’S NOTE | NOTE DE GLORIA

Your trusted source since 1978 for recycled OEM Parts. Providing quality wheel refinishing for 29 years. Your source for quality recycled OEM parts on all makes and models with 1 million parts guaranteed in stock. 24-48 hour deliveries to many of the surrounding areas including: Toronto | Mississauga | Scarborough | Port Hope | Brampton Barrie | Orillia | Cookstown | Alliston | Tottenham OPEN 8 AM - 5 PM MONDAY - FRIDAY Go to www.carcone.com | Call Toll Free 800.263.2022 Or visit us at 1030 Bloomington Road, Aurora, Ontario L4G 0L7 Our state of the art equipment and quality craftsmanship makes us the industry leader in Wheel Refinishing and CARCONE’S CARCONE’S AUTO RECYCLING & WHEEL REFINISHING WE SHIP CANADA WIDE WHEEL REFINISHING RECYCLED PARTS

autoMotIve recyclerS oF caNaDa PROGRAM OF THE AUTOMOTIVE RECYCLERS ASSOCIATION Who We Are coAst to coAst

We do member associations Information: Steve Fletcher, Managing Director e: steve@autorecyclers.ca t: 519-858-8761 www.autorecyclers.ca the voIce oF auto recyclerS accreditation progressive recycling environmental stewardship cost savings ARM AUTOMOTIVE RECYCLERS OF MANITOBA

WhAt

A TRADITION OF EXCELLENCE

The Canadian auto recycling industry continues to progress

UNE TRADITION D’EXCELLENCE

L’industrie Canadienne du recyclage automobile continue à progresser

CANADIAN AUTO RECYCLERS

2018 EDITION

With Greg Lane, Emile Hogue and George Shae

“Canadian Auto Recyclers has always reflected the spirit of friendly competition that has made our industry such a great place to work. To stand beside Emile and George, my own long time co-petitors really brought that feeling home. After all, we help each other out so much that clients often think we are sister companies!”

“Canadian Auto Recyclers a toujours reflété l’esprit de compétition amicale qui a fait de notre industrie un endroit formidable où travailler. Pour rester aux côtés d’Emile et George, mes propres co-participants de longue date ont vraiment ramené ce sentiment à la maison. Après tout, nous nous entraidons tellement que les clients pensent souvent que nous sommes des sociétés sœurs!”

— Greg Lane

CANADIAN AUTO RECYCLERS

2019 EDITION

With Frank Serravale, Thorold Auto Parts

“Just read our issue! It looks great. Thank you. It is an honour to have been featured on the cover of Canadian Auto Recyclers.”

“Lisez juste notre publication ! Ça a l’air très bien. Merci. C’est un honneur d’être en couverture de Canadian Auto Recyclers.”

— Frank Serravale

CANADIAN AUTO RECYCLERS 2020 EDITION

With Terry Carter, Aldon Auto

“Being on the cover of Canadian Auto Recyclers[it] was a chance to give the industry a look at my dad’s on-site museum, Al’s Toy Barn and its fifty collector cars.”

« Faire la couverture de Canadian Auto Recyclers [c’était] l’occasion de donner à l’industrie un coup d’œ coup d’œ regard sur le musée sur place de mon père, Al’s Toy Barn et une cinquantaine de voitures de collection. »

— Terry

Carter

To view past issues of Canadian Auto Recyclers magazine or to advertise or subscribe visit canadianrecycler.ca

IN YEARS PAST | DE NOS ARCHIVES CANADIANRECYCLER.CA 9

Canadian Auto Recyclers magazine 12-1 Canadian Auto Recyclers magazine 13-1

Poles Apart: The global auto recycling sector in 2020 Tout le monde: Le secteur mondial du recyclage automobile en 2020 THE AUTO MUSEUM ON THE PRAIRIE LE MUSÉE DE L’AUTOMOBILE DANS LA PRAIRIE Terry Carter’s visionary transformation of Aldon Auto La transformation visionnaire de Terry Carter de la société Aldon Auto DIAGNOSIS: SCANNING SHOCK THERAPY Can recyclers effectively capitalize on diagnostic tools? Recyclers step forward to solve the EV battery crisis Les recycleurs peuvent-ils tirer parti efficacement des outils de diagnostic? Les recycleurs font un pas en avant pour résoudre la crise des batteries de VE DIAGNOSTIC: BALAYAGE THÉRAPIE DE CHOC Dealing with dangerous drug residue; Auction shops step up their game; Canadian recyclers descend on Alberta; and much, MUCH MORE! Traiter les résidus dangereux de stupéfiants les encanteurs augmentent leurs activités les recycleurs canadiens s’installent en Alberta et bien plus encore, BEAUCOUP PLUS! CAR_14#1.indb 2020-03-05 10:31 AM Canadian Auto Recyclers magazine 14-1

INDUSTRY TORCHBEARERS HÉRAUTS DE L’INDUSTRIE

CANADIAN AUTO RECYCLERS 2021 EDITION

With Ron Bastarache, Bastarache Auto Salvage

“It was a great honour for our family business, Bastarache Auto Salvage, to be recognized and featured on the cover of Canadian Auto Recyclers. This magazine has made for outstanding exposure of our late father’s dream in visualizing and achieving his goal. The positive feedback of the people who read this interesting story were truly impressed with our remarkable success.”

« C’est un grand honneur pour notre entreprise familiale, Bastarache Auto Salvage, d’être reconnue et de figurer sur la couverture de Canadian Auto Recyclers. Ce magazine a fourni une exposition exceptionnelle du rêve de notre défunt père de visualiser et d’atteindre son objectif. Les commentaires positifs de ceux qui ont lu cette histoire intéressante ont été vraiment impressionnés par notre succès remarquable. »

— Ron Bastarache

CANADIAN AUTO RECYCLERS 2022 EDITION

With Pierre Robitaille, Recycleur Duvernay

“Just received my issue of Canadian Auto Recyclers in the mail—very nice. Thank you to Canadian Auto Recyclers magazine for all your hard work on the story. You did a nice job and the story came out great.”

« Je viens de recevoir mon exemplaire de Canadian Auto Recyclers par la poste - très bien. Merci au magazine Canadian Auto Recyclers pour tout le travail que vous avez fait sur l’histoire. eVous avez fait un excellent travail et le produit fini était très bon. »

— Pierre Robitaille

CANADIAN AUTO RECYCLERS 2023 EDITION

With Stuart Ady, Ernie’s Auto Parts

“Seeing our facility highlighted in the annual edition of CanadianAutoRecyclers was an incredible feeling. To see the story of my career and to look back on how far we’ve come as a business was the greatest part of this feature opportunity.”

« Voir notre installation mise en évidence dans l’édition annuelle de Canadian Auto Recyclers a procuré un sentiment incroyable. C’est principalement grâce à mon expérience professionnelle et au chemin parcouru en tant qu’entreprise que nous avons eu cette occasion. »

— Stuart Ady

Pour voir les anciens numéros du magazine Canadian Auto Recyclers ou pour annoncer ou vous abonner, visitez canadianrecycler.ca

10 CANADIAN AUTO RECYCLERS 2024 IN YEARS PAST | DE NOS ARCHIVES L’AUTOMOBILE PRAIRIE Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 86 John Street, Thornhill, ON L3T 1Y2 canadianrecycler.ca year Tony Carcone on leaving Italy for auto recycling in Canada Bruce Woodbeck’s industry insights and MUCH MORE! l’année Tony Carcone en quittant l’Italiepour le recyclage automobile au Canada Perspectives de l’industrie de Bruce Woodbeck La et beaucoup plus! SURVIVING ARMAGEDDON SURVIVRE À ARMAGEDDON Ron Bastarache on keeping business going through a global catastrophe! Ron Bastarache sur le maintien affaires en cours une catastrophe mondiale! An up-close look at Australia’s auto recycling sector Brace for the battery barrage! OPPORTUNITIES DOWN UNDER STORM WARNING Préparez-vous au barrage de la batterie! AVERTISSEMENT DE TEMPÊTE Un regard de près sur le secteur australien du recyclage automobile OPPORTUNITÉS EN BAS SOUS Canadian Auto Recyclers magazine 15-1 Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 86 John Street, Thornhill, ON L3T 1Y2 canadianrecycler.ca KING OF THE CASTLEGAR ROI DU CASTLEGAR ARC shares plastics survey results Stuart Ady has his finger on the pulse of the industry Stuart Ady a le doigt sur le pouls de l’industrie. ROADMAP RESULTS L’ARC partage les résultats d’une enquête sur les plastiques RÉSULTATS DE LA FEUILLE DE ROUTE EVFRIENDLY EXPANDS NATIONALLY // EVFRIENDLY SE DÉVELOPPE AU NIVEAU NATIONAL WOMAN OF THE INDUSTRY // FEMME DU SECTEUR: AMANDA JAMES EMPIRE AUTO LEGENDS OF THE INDUSTRY // LÉGENDES DU SECTEUR: ED PLAZEK PLAZEK AUTO RECYCLERS Canadian Auto Recyclers magazine 16-1 Canadian Auto Recyclers magazine 17-1

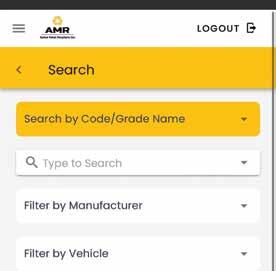

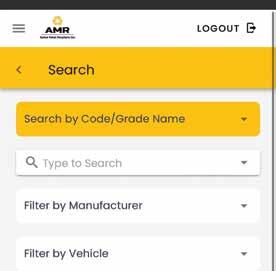

SOLUTIONS CONNECTED TO TODAY’S RECYCLERS BUSINESS!

Des solutions connectées aux activités des recycleurs d’aujourd’hui !

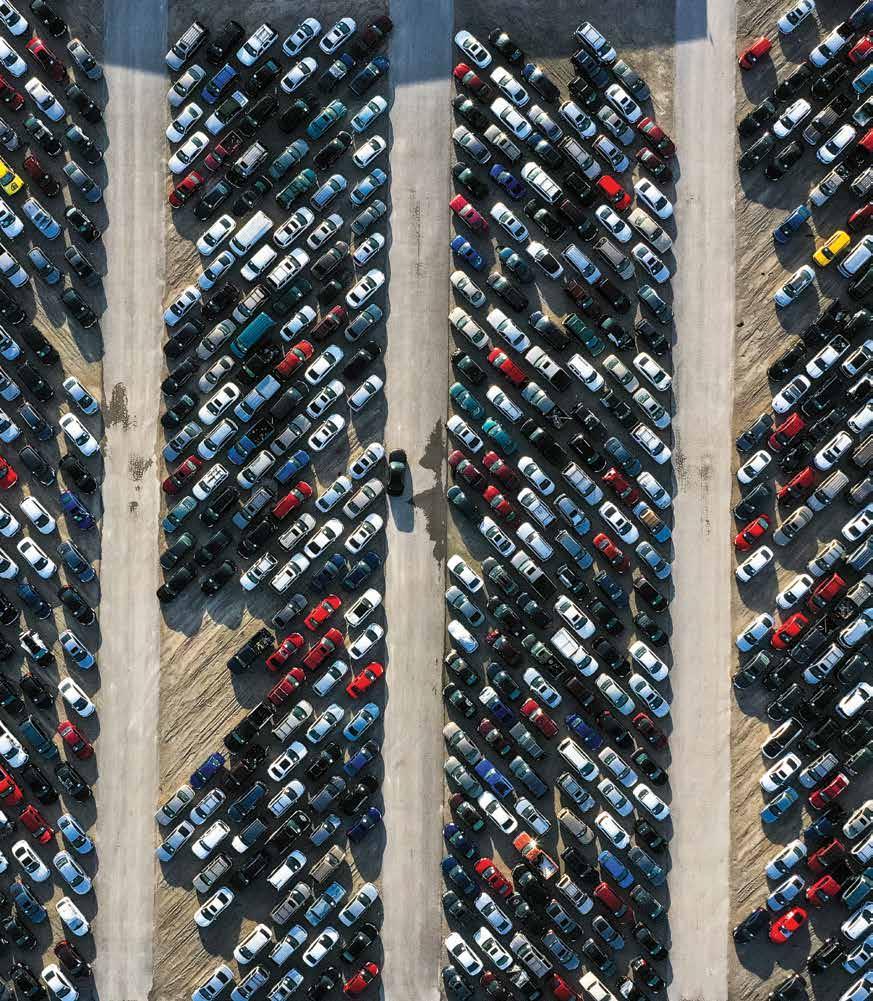

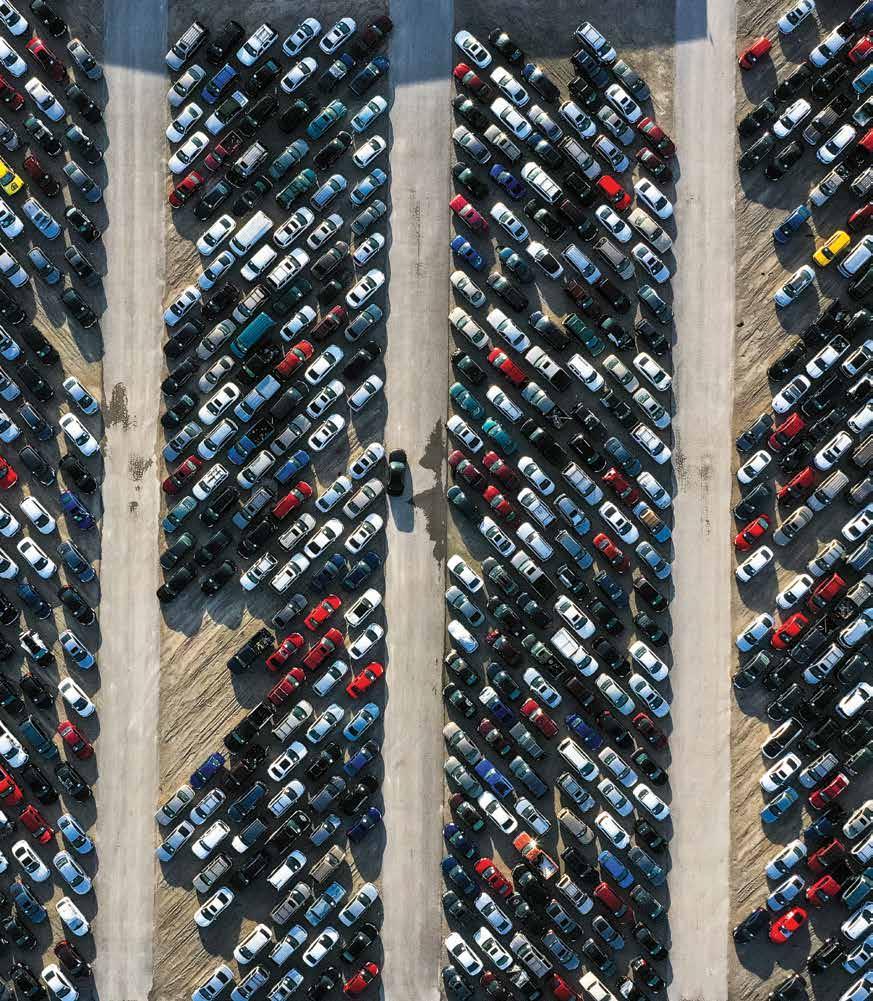

Salvage Vehicles Supply

Source de véhicules accidentés

• The auction that offers competitive advantages to recyclers L’encan qui offre des avantages compétitifs aux recycleurs

• Vast inventory of vehicles from insurance companies and automotive recyclers

Large inventaire de véhicules provenant de compagnies d’assurances et de recycleurs

• Turnkey services from shopping to delivery Services clé en main de l’achat à la livraison

• Online auction accessible 24/7

Encan en ligne accessible 24/7

• Join a network of over 130 accredited recyclers! Rejoignez un réseau de plus de 130 recycleurs accrédités !

Manage Your Organization

Gestion d’entreprise

1 2

Part Sales Platform

Plateforme de vente de pièces

3

• The most comprehensive recycling yard management solution

La solution de gestion de cour de recyclage la plus complète

• Fully integrated, cloud-based web software Logiciel web entièrement intégré et basé sur le cloud

• User-friendly, compatible with any device, from anywhere Convivial, compatible avec tous les appareils, de n’importe où

• Client Accounting Portal Portail comptabilité client

• Handles all your daily activities

Gère toutes vos activités quotidiennes

• Adapts to your business’s growth S’adapte à la croissance de votre entreprise

• An avant-garde way to showcase your recycled parts to collision repair centers during their buying process

Une méthode avant-gardiste de présenter vos pièces recyclées aux carrossiers durant leur processus d’achat

• Reach new markets Accédez à de nouveaux marchés

• Precise quote requests based on your data structure Demandes de prix précis selon votre structure de données

• Get more opportunities to sell parts Multipliez les occasions de vendre vos pièces

let data work for you les données à votre profit

www.progi.com

CALL YOUR PROGI REPRESENTATIVE TODAY!

Appelez votre représentant Progi dès aujourd’hui

1-855-310-6343

! 1-877-776-3198

CHAIRMAN’S CHECK-IN

Welcome to another issue celebrating this great industry

Last year, 2023, was a year of change for the Automotive Recyclers of Canada (ARC). Firstly, we had four new members join the board: Joel Bouckaert from Alberta; Derek Nissen from Ontario; Stephane Gravel from Quebec and Andrew MacDonald from Atlantic Canada.

This changing of the guard has led to a younger board, but no less interested and involved in helping shape the future of the auto recycling industry in Canada.

We renewed our regular board—executive calls with the Automotive Recyclers Association (ARA) in the United States, and these quarterly calls allow us to share deep information and keep abreast of the mutual challenges and opportunities we face on either side of the border.

Many of the emerging issues we do discuss revolve around electrification. There are so many things going on in that area that it is hard to keep up, but both ARA and ARC have had a multitude of conversations, meetings, and exchanges with stakeholders up and down the supply chain. The challenges for our industry are there, but so are the opportunities that we are trying to create.

Steve Fletcher, our long serving managing director has taken on an informal secretary role with the International Roundtable on Auto Recycling (IRT). While ARC has always hosted the IRT website (www.irt-autorecycling. org), the website has been dramatically updated, and a series of virtual IRTs are planned throughout 2024, leading to an in-person event in Liverpool in 2025. Direct involvement in the IRT has kept ARC at the forefront of many international initiatives and ideas that have benefited ARC and its members.

In somewhat sad news that we are trying to delay, Mr. Fletcher has announced his plans to retire from the auto recycling industry. No dates are set, but we are in discussions as a Board and with the Ontario Auto Recyclers Association (as we share Steve’s expertise with OARA) regarding Steve’s departure and an effective succession strategy.

While Steve has been a tremendous asset to the industry over the years, we need to be in a place where he won’t be the main go-to guy for our industry, but he is working towards an effective transfer of power, and has pledged to be there for the industry as required.

I will once again be attending the 2024 OARA Convention & Trade Show in March in Markham Ontario. This event, which I believe stacks up against any auto recycling event in North America, is of great value and a delight to attend. Auto recyclers from across Canada—and at least one from the Yukon territory! We will be there—you should plan to attend.

ARC continues to be the voice of the Canadian auto recycling industry, and through programs like CAREC, Retire Your Ride and Car Heaven, along with discounts from IAA, Copart and Freightcom—it provides value for the Direct Members of the seven provincial/regional associations it represents.

But I think the best benefit that ARC provides is the strong and consistent industry representation that it provides.

Happy and profitable recycling! CAR

LETTER FROM THE CHAIRMAN | LETTRE DU PRÉSIDENT 12 CANADIAN AUTO RECYCLERS 2024

Dalbert Livingstone, ARC Chairman, Island Auto Supply

Dalbert Livingstone, chairman, ARC.

BILAN DU PRÉSIDENT

Bienvenue dans un nouveau numéro célébrant cette formidable industrie

L’année dernière, 2023, a été une année de changement pour Automotive Recyclers of Canada (ARC). Tout d’abord, quatre nouveaux membres se sont joints au conseil d’administration : Joël Bouckaert de l’Alberta, Derek Nissen de l’Ontario, Stéphane Gravel du Québec et Andrew MacDonald du Canada atlantique.

Cette « relève de la garde » a conduit à un conseil plus jeune, mais pas moins intéressé et impliqué dans l’avenir de l’industrie du recyclage automobile au Canada.

Ces appels trimestriels nous permettent de partager des informations approfondies et de nous tenir au courant des défis et des opportunités qui se présentent de part et d’autre de la frontière.

Bon nombre des questions émergentes dont nous discutons tournent autour de l’électrification. Il y a tellement de choses qui se passent dans ce domaine qu’il est difficile de suivre, mais l’ARA et l’ARC ont eu une multitude de conversations, de réunions et d’échanges avec les parties prenantes en amont et en aval de la chaîne d’approvisionnement. Les défis pour notre industrie sont là, mais les opportunités que nous essayons de créer le sont tout autant.

Steve Fletcher, notre directeur général de longue date, a accepté un rôle informel de secrétaire de la table ronde internationale sur le recyclage automobile (IRT). Alors que l’ARC a toujours hébergé le site Web de l’IRT (www.irt-autorecycling.org), celui-ci a été considérablement mis à jour et une série de tables rondes virtuelles sont prévues tout au long de 2024, menant à un événement en personne à Liverpool en 2025. L’implication directe dans l’IRT a permis à l’ARC de rester à l’avant-garde de nombreuses initiatives et idées internationales qui lui ont été profitables ainsi qu’à ses membres.

Nous avons également appris la nouvelle d’un changement quelque peu triste, que nous essayons de retarder, soit le départ de M. Fletcher de l’industrie du recyclage automobile. Aucune date n’a été fixée, mais notre conseil d’administration et l’Ontario Auto Recyclers Association (puisque nous partageons l’expertise de Steve avec l’OARA) sont en discussion avec Steve à cet effet et au sujet d’une stratégie de succession efficace.

Bien que Steve ait été un atout considérable pour l’industrie au fil des ans, nous devons faire en sorte qu’il ne soit plus la principale personne à contacter pour notre industrie. Il doit maintenant se concentrer à effectuer un transfert de pouvoir efficace et s’engager à être présent pour l’industrie en cas de besoin.

Je participerai une fois de plus à la Convention et au Salon de l’OARA 2024 en mars à Markham (Ontario). Cet événement, qui, à mon avis, n’a rien à envier à aucun autre événement de recyclage automobile en Amérique du Nord, est d’une grande valeur et c’est un plaisir d’y assister. Des recycleurs d’automobiles de tout le Canada et au moins un du Yukon seront présents! Nous serons là – vous devriez prévoir y assister.

L’ARC continue d’être la voix de l’industrie canadienne du recyclage automobile et, grâce à des programmes comme CERAC, Adieu bazou et Autos-o-ciel, ainsi qu’aux rabais offerts par l’AAI, Copart et Freightcom, elle offre de la valeur aux membres des sept associations provinciales/régionales qu’elle représente.

Cependant, je pense que le meilleur avantage qu’offre l’ARC est la représentation forte et cohérente de l’industrie qu’elle assure.

Joyeux et fructueux recyclage! CAR

CANADIANRECYCLER.CA 13 LETTER FROM THE CHAIRMAN | LETTRE DU PRÉSIDENT

Dalbert Livingstone, Président de l’ARC, Island Auto Supply

Dalbert Livingstone speaks on a panel at the OARA Convention and Trade Show 2023.

Dalbert Livingstone participe à une table ronde lors de la convention et du salon 2023 de l'OARA.

AUTO RECYCLING ACROSS CANADA

BRITISH COLUMBIA AUTOMOTIVE RECYCLERS (BCAR)

ara.bc.ca/b-c-auto-recyclers-division

The Ministry of Environment and Climate Change Strategy has updated the implementation timeline for electric vehicle batteries under the Extended Producer Responsibility Five-Year Action Plan (2021 to 2026). British Columbia will be the first province to regulate EV batteries under extended producer responsibility (EPR).

With this updated timeline, the Ministry will be seeking an in-depth consultation with the sectors affected on how to assign EPR responsibility to producers, which promotes remanufacturing and repurposing of large batteries under a competitive regulatory framework. The first phase of large batteries will proceed in 2024, with consumer batteries for personal and recreational use, such as small energy storage applications or golf carts. EPR programs are expected to be operational in 2026.

Moreover, beginning April 30, 2024, the Insurance Corporation of British Columbia (ICBC) will require B.C. auto recyclers to include pricing on a minimum of 60 percent of their A-grade auto parts inventory listed in the Car-Part system. This requirement only applies to the top 20 requested auto parts categories, in the B.C. market, via the Car-Part system. If an auto recycler does not meet this requirement, they will be removed as an ICBC preferred supplier.

Finally, the Automotive Retailers Association (ARA) is in its final phase of developing a new operational program for the Automotive Recyclers Environmental Association (AREA).The plan, which has yet to receive final assent, will effectively transfer operations over to the ARA. By using the ARA’s administrative infrastructure, and ability to advocate, the plan will help ensure the program remains viable and relevant to the industry.

Le ministère de l’environnement et de la stratégie de changement climatique a mis à jour le calendrier de mise en œuvre des batteries de véhicules électriques dans le cadre du plan d’action quinquennal de responsabilité élargie des producteurs (2021 à 2026). La Colombie-Britannique sera la première province à réglementer les batteries de véhicules électriques dans le cadre de la responsabilité élargie des producteurs (REP).

Avec ce calendrier mis à jour, le ministère demandera une consultation approfondie avec les secteurs concernés sur la manière d’attribuer la responsabilité de la REP aux producteurs, ce qui favorise la refabrication et la réutilisation des grandes batteries dans un cadre réglementaire concurrentiel. La première phase des grandes batteries commencera en 2024, avec les batteries grand public à usage personnel et récréatif, telles que les petites applications de stockage d’énergie ou les voiturettes de golf. Les programmes de REP devraient être opérationnels en 2026.

De plus, à partir du 30 avril 2024, l’Insurance Corporation of British Columbia (ICBC) exigera des recycleurs d’automobiles de la Colombie-Britannique qu’ils incluent le prix d’au moins 60 % de leur stock de pièces automobiles de catégorie A répertoriées dans le système Car-Part. Cette exigence ne s’applique qu’aux 20 catégories de pièces automobiles les plus demandées sur le marché de la Colombie-Britannique, via le système Car-Part. Si un recycleur automobile ne satisfait pas à cette exigence, il ne sera plus considéré comme un fournisseur privilégié de l’ICBC.

Enfin, l’Automotive Retailers Association (ARA) en est à la phase finale de l’élaboration d’un nouveau programme opérationnel pour l’Automotive Recyclers Environmental Association (AREA). Le plan, qui n’a pas encore reçu l’approbation finale, transférera effectivement les opérations à l’ARA. En utilisant l’infrastructure administrative de l’ARA et sa capacité à défendre les intérêts de l’industrie, le plan permettra de s’assurer que le programme reste viable et pertinent pour l’industrie.

14 CANADIAN AUTO RECYCLERS 2024 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES

RECYCLAGE AUTO AU CANADA

ALBERTA AUTOMOTIVE RECYCLERS AND DISMANTLERS ASSOCIATION (AARDA) aarda.com

With a new Executive Director, Joel Bouckaert, the Alberta association is modernizing its communication and approach to the auto recycling industry. Bouckaert’s first task was to update the AARDA website, making it easier for Members and the public to find information on the industry, and for the public to engage directly with auto recyclers.

Next up was a lively Convention in Calgary in September, where Bouckaert was introduced to the members. Steve Fletcher from ARC was their special guest speaker for that event, and he brought all the good things happening in Canada and around the world that auto recyclers need to know.

Bouckaert and AARDA are focussing on bringing direct value to Members, through discounts and partnerships with suppliers and vendors, and expanding the membership with great information, industry advocacy, and dollars and cents savings.

Avec un nouveau directeur exécutif, Joel Bouckaert, l’association albertaine modernise sa communication et son approche de l’industrie du recyclage automobile. La première tâche de Bouckaert a été de mettre à jour le site web de l’AARDA, afin de permettre aux membres et au public de trouver plus facilement des informations sur l’industrie, et au public de s’engager directement avec les recycleurs d’automobiles.

L’étape suivante a été une convention animée à Calgary en septembre, où Bouckaert a été présenté aux membres. Steve Fletcher, de l’ARC, était le conférencier invité pour cet événement, et il a présenté toutes les bonnes choses qui se passent au Canada et dans le monde entier et que les recycleurs d’automobiles doivent connaître.

Bouckaert et l’AARDA se concentrent sur l’apport d’une valeur directe aux membres, par le biais de remises et de partenariats avec des fournisseurs et des vendeurs, et sur l’augmentation du nombre de membres grâce à des informations de qualité, à la défense de l’industrie et à des économies en dollars et en cents.

The Saskatchewan Automotive Recyclers Association’s (SARA) Annual General Meeting for members was held on October 21, 2023 in Regina at the Four Points by Sheraton. Representatives from six of SARA’s 17 member yards were in attendance. SARA has one probationary member, J.S. Truckmart of Estevan, who is awaiting their Canadian Automotive Recyclers Environmental Code (CAREC) audit to become a full member.

SARA is headed by Jack Smith of Top Line Salvage in Moose Jaw, Vice-President; Dale Nagel of Dale & Lisa’s Farm & Auto in Mossbank and Secretary-Treasurer, Michele Morrison of SGI Salvage in Regina.

At the 2023 AGM, SARA welcomed Brendan Heggs and Dylan Crozier of Southside Auto Wreckers to their board, joining Shawn Conarroe of 5 Mile Auto Wreckers in Prince Albert.

SARA members continue to operate in compliance with CAREC. Like all auto recyclers, our members are concerned about the impact of electric vehicles on our industry and are closely following the industry updates provided by the Automotive Recyclers of Canada (ARC) and the Canadian Auto Recyclers magazine.

L’assemblée générale annuelle des membres de la Saskatchewan Automotive Recyclers Association (SARA) s’est tenue le 21 octobre 2023 à Regina, au Four Points by Sheraton. Des représentants de six de nos 17 chantiers membres étaient présents. La SARA compte un membre probatoire, J.S. Truckmart d’Estevan, qui attend son audit du Code environnemental des recycleurs d’automobiles du Canada (CAREC) pour devenir membre à part entière.

La SARA est dirigée par Jack Smith de Top Line Salvage à Moose Jaw, vice-président, Dale Nagel de Dale & Lisa’s Farm & Auto à Mossbank et secrétaire-trésorière, Michele Morrison de SGI Salvage à Regina.

Lors de l’AGA 2023, la SARA a accueilli Brendan Heggs et Dylan Crozier de Southside Auto Wreckers au sein de son conseil d’administration, rejoignant ainsi Shawn Conarroe de 5 Mile Auto Wreckers à Prince Albert.

Les membres de la SARA continuent d’exercer leurs activités en conformité avec le CAREC. Comme tous les recycleurs d’automobiles, nos membres sont préoccupés par l’impact des véhicules électriques sur notre industrie et suivent de près les mises à jour de l’industrie fournies par Automotive Recyclers of Canada (ARC) et le magazine Canadian Auto Recyclers

CANADIANRECYCLER.CA 15 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES

ASSOCIATION

AUTOMOTIVE

CANADIANRECYCLER.CA 15

SASKATCHEWAN

OF

RECYCLERS (SARA) saskautorecyclers.ca

ONTARIO AUTOMOTIVE RECYCLERS ASSOCIATION (OARA)

oara.com

The year 2023 was another interesting year for Ontario auto recyclers. OARA continued to host the largest auto recycling convention & trade show in Canada, with another planned in 2024.

The association undertook a major research project with an environmental consultancy out of the UK to quantify the environmental benefits of the reuse of auto parts. The study, entitled The Environmental Benefits of Green Recycled Parts in Ontario, was meant to document the real-world benefits in using recycled parts to not only help meet emissions reduction and net-zero objectives, but also the positive impact they have on the entire automotive ecosystem. The report provided a real opportunity to put some facts and figures behind what we do as recyclers, allowing our members to gain confidence in what they are doing, as well as enabling other sectors to gain greater insight into our world and how we operate.

Who We Are coAst to coAst member associations

The emergence of electric vehicles in Ontario is a concern with OARA members as it is with auto recyclers around the world. This major change in propulsion creates opportunities and challenges that we are all grappling with. One bright spot was the emergence of, and OARA’s work with, Cyclic Materials in Kingston on the recovery of valuable and critical rare earth magnets from EVs. This demonstration project shows that there are more profit opportunities with EVs beyond just the battery itself. But the economical and safe recovery of the batteries for reuse and repurposing remain elusive goals.

The membership remains strong—the organization has lost (and gained) members, but is generally holding steady. With 96 direct members and 50 associate members, OARA remains one of the largest State/Provincial auto recycling associations in North America.

L’année 2023 a été une autre année intéressante pour les recycleurs d’automobiles de l’Ontario. L’OARA a continué d’organiser le plus grand congrès et salon du recyclage automobile au Canada, et un autre est prévu pour 2024.

L’association a entrepris un important projet de recherche avec une société de conseil en environnement du Royaume-Uni afin de quantifier les avantages environnementaux de la réutilisation des pièces automobiles. L’étude, intitulée The Environmental Benefits of Green Recycled Parts in Ontario, visait à documenter les avantages concrets de l’utilisation de pièces recyclées non seulement pour atteindre les objectifs de réduction des émissions et de net-zero, mais aussi l’impact positif qu’elles ont sur l’ensemble de l’écosystème automobile. Le rapport a fourni une réelle opportunité de mettre des faits et des chiffres derrière ce que nous faisons en tant que recycleurs, permettant à nos membres d’avoir confiance en ce qu’ils font, ainsi qu’à d’autres secteurs d’avoir une meilleure compréhension de notre monde et de la façon dont nous fonctionnons.

L’émergence des véhicules électriques en Ontario préoccupe les membres de l’OARA, tout comme les recycleurs d’automobiles du monde entier. Ce changement majeur dans la propulsion crée des opportunités et des défis avec lesquels nous sommes tous aux prises. Un point positif a été l’émergence de Cyclic Materials à Kingston et notre travail avec cette entreprise sur la récupération d’aimants de terres rares précieux et critiques dans les VE. Ce projet de démonstration montre qu’il existe d’autres opportunités de profit avec les VE que la batterie elle-même. Mais la récupération économique et sûre des batteries en vue de leur réutilisation et de leur reconversion reste un objectif difficile à atteindre.

L’organisation a perdu des membres (et en a gagné d’autres), mais elle reste généralement stable. Avec 96 membres directs et 50 membres associés, l’OARA reste l’une des plus grandes associations nationales/provinciales de recyclage automobile en Amérique du Nord.

L’ASSOCIATION DES RECYCLEURS DE PIECES D’AUTOS ET DE CAMIONS (ARPAC)

arpac.org

Since December 11, 2023, ARPAC has been collaborating with the MELCCFP (Ministry of the Environment, Fight Against Climate Change, Wildlife and Parks) to implement an electric vehicle battery recovery program with a group of 40 participants called the “tactical task force on the recovery and reclamation of electric vehicle batteries.” ARPAC is supporting Recyc-Québec in becoming the administrator of this soon-to-be program.

A first meeting set up by the MELCCFP took place in Québec City about the reduction and responsible management of plastics. Automobiles generate more than 40,000 tons of plastics annually in the province of Quebec. Following that meeting, ARPAC started discussions to implement a plastic recovery and recycling strategy for automotive vehicle plastics with the company Polystyvert.

L’ARPAC collabore depuis le 11 décembre 2023 avec le MELCCFP, le ministère de l’environnement de la lutte contre les changements climatiques de la faune et des parcs du Québec, pour la mise en place d’un programme de récupération des batteries de véhicules électriques avec un groupe de quarante participants nommé le « groupe tactique de réflexion sur la récupération et la valorisation des batteries de véhicules électriques ». l’ARPAC appuie Recyc-Québec pour devenir l’administrateur de ce programme qui verra le jour bientôt.

2021-02-02 3:44 PM

ARPAC’s 2024 congress will be organized by Pièces d’Autos Fernand Bégin (Bégin Group) and held at Le Georgesville hotel in St-Georgesde-Beauce on September 13 and 14.

Une première rencontre organisée par le MELCC a eu lieu à Québec au sujet de la réduction et de la gestion responsable des plastiques. L’automobile génère plus de 40 000 tonnes de plastiques annuellement au Québec. Suite à cette rencontre, l’ARPAC a débuté des discussions pour mettre en place une stratégie de récupération et de recyclage des plastiques de véhicules automobiles avec l’entreprise Polystyvert.

Le congrès de l’ARPAC 2024, sera organisé par Pièces d’Autos Fernand Bégin (le Groupe Bégin) et se fera à l’hôtel Le Georgesville à St-Georges-deBeauce les 13 et 14 septembre.

16 CANADIAN AUTO RECYCLERS 2024 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES

autorecyclers.ca

www.autorecyclers.ca AUTOMOTIVE RECYCLERS OF

t: 519-858-8761

AUTOMOTIVE RECYCLERS ASSOCIATION OF ATLANTIC CANADA (ARAAC) araac.ca

The 2023 Convention that ARAAC held in Halifax with the Canadian Association of Recycling Industries (CARI) and the Automotive Recyclers of Canada (ARC) board was a great success. There were changes in the representation of ARAAC on the ARC Board of Directors. Ed MacDonald stepped down after years of service dating back to the start of ARC in 1995. He was replaced by his son, Andrew MacDonald from Maritime Auto Parts, so a MacDonald continues on the ARC Board.

“We sincerely thank Ed for his service and look forward to Andrew bringing Atlantic Canada concerns and perspectives to the national Board. Andrew is joined by Dalbert Livingstone from Island Auto Supply who chairs the ARC Board of Directors,” writes ARAAC.

ARAAC continues to follow the demise of American Iron Metal’s auto shredder at the federal docks in Saint John New Brunswick. After a series of fires and explosions the shredder has been shut down, and this has prompted a thorough review of the licensing of salvage operators in the province. AIM’s initial approval required that they only purchase vehicles processed to the standard of ARC’s Canadian Auto Recyclers Environmental Code (CAREC), which is something ARAAC does not believe they were following and may have led to the environmental problems AIM encountered. This is a great opportunity to demonstrate the power of CAREC and membership in ARAAC.

In June 2024, ARAAC will meet in Charlottetown, Prince Edward Island, and invite all ARC Members to attend this beautiful part of our country.

Le congrès 2023 que l’ARAAC a organisé à Halifax avec l’Association canadienne des industries du recyclage (CARI) et le conseil d’administration de l’Automotive Recyclers of Canada (ARC) a été un grand succès.

Il y a eu des changements dans la représentation de l’ARAAC au sein du conseil d’administration de l’ARC. Ed MacDonald s’est retiré après des années de service remontant à la création de l’ARC en 1995. Il a été remplacé par son fils, Andrew MacDonald, de Maritime Auto-Parts, de sorte qu’un MacDonald continue de siéger au conseil d’administration de l’ARC.

« Nous remercions sincèrement Ed pour ses services et nous nous réjouissons qu’Andrew apporte les préoccupations et les perspectives du Canada atlantique au conseil d’administration national. Andrew est rejoint par Dalbert Livingstone, de Island Auto Supply, qui préside le conseil d’administration de l’ARC », écrit l’ARAAC.

L’ARAAC continue de suivre l’évolution de la destruction de la déchiqueteuse d’American Iron Metal sur les quais fédéraux de Saint John, au Nouveau-Brunswick. Après une série d’incendies et d’explosions, la déchiqueteuse a été fermée, ce qui a entraîné un réexamen approfondi de l’agrément des entreprises de récupération dans la province. L’approbation initiale d’AIM exigeait que l’entreprise n’achète que des véhicules traités selon les normes du Code environnemental canadien des recycleurs d’automobiles (CAREC) de l’ARC, ce qui, selon l’ARAAC, n’était pas le cas et pourrait avoir entraîné les problèmes environnementaux rencontrés par AIM. Il s’agit d’une excellente occasion de démontrer le pouvoir du CAREC et de l’adhésion à l’ARAAC.

En juin 2024, l’ARAAC se réunira à Charlottetown, Île-du-Prince-Édouard, et invite tous les membres de l’ARC à se rendre dans cette magnifique région de notre pays.

Aurélie Bergeret, Polystyvert Director of Communications, Marketing and Government Relations, Nicolas Cottenye, Polystyvert Vice-President, Research and Development, and Simon Matte, ARPAC Chief Executive Officer.

Aurélie Bergeret directrice des communications du marketing et des relations gouvernementales chez Polystyvert, Nicolas Cottenye vice-président recherche et développement chez Polystyvert.

CANADIANRECYCLER.CA 17 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES CANADIANRECYCLER.CA 17

BOOSTING BUMPERS

Ultra-Poly and Autoneum North America, have collaborated to develop a composite material that utilizes recycled bumper material as a rigid backing substrate for a fibrous layer. This composite is used for vibration and noise attenuation in a chassis component, contributing to improved performance and functionality, according to the partners. The development was inspired by Ultra-Poly’s participation in the Plastics Industry Association’s End-of-Life Vehicle (ELV) Recycling Project when the company recognized the potential of recovered fascia in polypropylene (PP) compounds and nonappearance applications within the automotive market. To obtain the recycled bumper covers required for this product, Ultra-Poly directly collects them from bodyshops. These bumper covers have been carefully removed from vehicles and stripped of any usable connected components.

TRANSFORMATION DES PARE-CHOCS EN PLASTIQUE

Ultra-Poly et Autoneum North America ont collaboré à la mise au point d’un matériau composite utilisant des pare-chocs recyclés comme substrat rigide afin d’obtenir une couche fibreuse. Ce composite est utilisé pour atténuer les vibrations et le bruit dans un composant du châssis, contribuant ainsi à en améliorer la performance et la fonctionnalité, selon les partenaires. L’initiative a été inspirée par la participation d’Ultra-Poly au projet de recyclage des véhicules hors d’usage (VHU) de la Plastics Industry Association, lorsque l’entreprise a reconnu le potentiel pour le marché de l’automobile des fascias récupérés dans les composés de polypropylène (PP) et les applications qui ne sont pas visibles. Pour obtenir les pare-chocs recyclés nécessaires à ce produit, Ultra-Poly les récupère directement auprès des ateliers de carrosserie. Ces pare-chocs ont été soigneusement retirés des véhicules et débarrassés de tous les composants connectés utilisables.

BE THERE OARA BE SQUARE

Two American companies have collaborated to develop a composite material that utilizes recycled bumper material as a rigid backing substrate for a fibrous layer. Steve Fletcher, managing director for the Automotive Recyclers of Canada, commented that the organization’s own ELV Plastics Roadmap, cited similar recommendations, but for the Canadian industry.

Deux entreprises américaines ont collaboré à la mise au point d’un matériau composite utilisant des pare-chocs recyclés comme substrat rigide pour obtenir une couche fibreuse. Steve Fletcher, directeur général de l’Automotive Recyclers of Canada, a indiqué que la feuille de route de l’organisation, publiée l’année dernière, contenait des recommandations similaires, mais pour l’industrie canadienne.

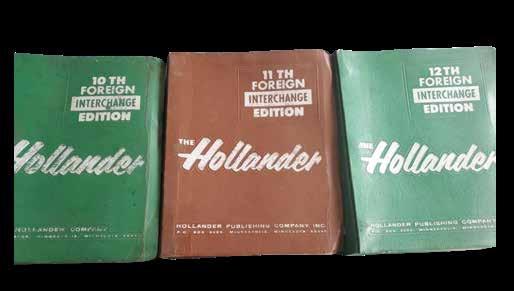

OARA’s annual convention and trade show is set for March 21-23, 2024. With companies like Copart, Solera/Hollander, IAA and PMR are set to exhibit, in addition to keynote addresses from JC Cahill and Donald Cooper, this highly anticipated meeting of OARA members will truly be a can’tmiss event.The Thursday afternoon preceding OARA’s two full convention days will feature a roundtable discussion with a select number of invited industry stakeholders. By Friday, educational programming, as well as a trade show will be in full swing. Breakfast, a few more panels and seminars will end Saturday afternoon. OARA’s 2024 Convention and Trade Show is set to run from March 21, 2024, to March 23 at the Hilton Toronto/Markham Suites Conference Centre just north of Toronto.

L’OARA FIDÈLE AU RENDEZ-VOUS

De par la nature de leur travail, les recycleurs automobiles ont tendance à être un groupe organisé, alors bien sûr, une date a déjà été choisie pour la prochaine édition de la convention annuelle et du salon professionnel de l’OARA, prévue pour mars 2024. Avec les présentations d’entreprises comme Copart, Solera/Hollander, IAA et PMR, et le discours d’ouverture de JC Cahill et Donald Cooper, ce rendez-vous très attendu des membres de l’OARA sera vraiment un événement à ne pas manquer. Une table ronde à laquelle participeront des acteurs sélectionnés de l’industrie se tiendra le jeudi après-midi précédant les deux journées de convention de l’OARA. Le vendredi, le programme éducatif et le salon professionnel battront leur plein alors que le tout sera clôturé le samedi avec un petit-déjeuner et quelques tables rondes et séminaires supplémentaires en après-midi. La convention et le salon professionnel 2024 de l’OARA se tiendront du 21 au 23 mars 2024 au centre de congrès Hilton Toronto/Markham Suites, au nord de Toronto.

NEWS | NOUVELLES 18 CANADIAN AUTO RECYCLERS 2024

Canadian Auto Recyclers always attends OARA’s annual convention and trade show to get the salvage scoop on all things auto recycling.

Canadian Auto Recyclers participe toujours à la convention annuelle et au salon professionnel de l’OARA afin d’obtenir des renseignements sur tout ce qui concerne le recyclage automobile.

LOOK AT LKQ

LKQ Corporation recently released its 2022 Global Sustainability Report in which the aftermarket salvage giant says it processed 770,000 vehicles in 2022, recycling 97 million pounds of aluminum, nearly seven million pounds of copper and more than 123 million pounds of scrap steel.The company says the total number of individual parts it sold in 2022 was approximately 13 million. LKQ also recovered more than 1.4 million catalytic converters; recycled more than two million tires and processed nearly one million tons of crush auto scrap materials. Other highlights from the report include LKQ’s progress toward a net-zero greenhouse gas emissions goal for 2050; details on the company’s first inclusion group, the LKQ Veterans Network; the newly adopted Global Supplier Code of Conduct; LKQ Community Foundation activities in 2022 and more.

GENUINE USE

Mitchell shared its 2023 second-quarter insights for Canadian and U.S. EV repair claims where it said electric vehicles use OEM parts in repairs far more than ICE vehicles. According to Mitchell’s data, 90.75 percent of parts used in EV repair claims are OEM; for ICE repair claims, 66.5 percent of parts utilized are OEM. Mitchell data also says just 13.49 percent of parts are repaired on EV claims, compared to 19.20 percent on ICE vehicle claims. Claims severity is also higher with electric vehicles. Mitchell’s Plugged In reports also outline the top North American markets based on its claims data. British Columbia has claimed the number one spot in all reports since Q4 2022, when Mitchell released its first report, and continues to rank number one in Q2 2023, with 5.22 percent EV claims. California is second (4.32 percent EV claims), while Quebec takes third (3.10 percent EV claims).

UTILISATION DE PIÈCES D’ORIGINE

La plateforme de gestion des sinistres Mitchell a dévoilé ses données du deuxième trimestre 2023 pour les réparations de VE au Canada et aux États-Unis, qui indiquent que les véhicules électriques utilisent beaucoup plus souvent des pièces d’origine pour les réparations que les véhicules à moteur à combustion interne. Selon les données de Mitchell, 90,75 pour cent des pièces utilisées pour répondre aux demandes de réparation de VE sont des pièces d’origine contre 66,5 pour cent pour les véhicules à moteur à combustion interne. Les données de Mitchell indiquent également que dans le cas des VE, seulement 13,49 pour cent des pièces sont réparées, contre 19,20 pour cent pour les véhicules à moteur à combustion interne. La gravité des sinistres est également plus élevée pour les véhicules électriques. Les rapports Plugged In de Mitchell décrivent également les données relatives aux sinistres des principaux marchés nord-américains. La Colombie-Britannique occupe la première place dans tous les rapports depuis le quatrième trimestre de 2022, lorsque Mitchell a publié son premier rapport, et continue de se classer au premier rang au deuxième trimestre de 2023, avec 5,22 pour cent de sinistres liés aux véhicules électriques. La Californie est deuxième (4,32 pour cent de réclamations de VE), tandis que le Québec est troisième (3,10 pour cent de réclamations de VE).

REGARD SUR LES PIÈCES DE RECHANGE

LKQ Corporation a publié son rapport mondial de développement durable 2022 dans lequel le géant de la récupération de pièces détachées déclare avoir traité 770 000 véhicules en 2022, recyclé 97 millions de livres d’aluminium, près de sept millions de livres de cuivre et plus de 123 millions de livres de ferraille d’acier. L’entreprise indique que le nombre total de pièces individuelles qu’elle a vendues en 2022 était d’environ 13 millions. LKQ a également récupéré plus de 1,4 million de convertisseurs catalytiques, recyclé plus de deux millions de pneus et traité près d’un million de tonnes de matériaux de ferraille automobile broyés. Les autres points forts du rapport comprennent les progrès de LKQ vers l’atteinte d’un objectif d’émissions de gaz à effet de serre nettes nulles pour 2050, des détails sur le premier groupe d’inclusion de l’entreprise, le réseau des vétérans LKQ, le Code de conduite mondial des fournisseurs nouvellement adopté, les activités de la Fondation communautaire LKQ en 2022 et bien plus encore.

MOST RELIABLE PRE 8AM DELIVERY SERVICE

Understanding the importance of time within your transportation strategy, means you can move at the speed of your customer, not your carrier. Cardinal’s Pre 8am transportation solutions and unique night network provide a competitive advantage where first to market comes standard. Expect Cardinal’s night network with unattended pickups and deliveries to deliver a competitive advantage to your business.

Cardinal is a wholly owned Canadian company that has built its reputation as the most reliable Pre 8am delivery service for time-sensitive goods and parts, servicing communities across Ontario and Quebec.

NEWS | NOUVELLES CANADIANRECYCLER.CA 19

Pre 8am Package Delivery Dedicated Logistics Pre 8am LTL Delivery Call 1-(800)-387-3199 | cardinalcouriers.com 6600 Goreway Dr., Unit D Mississauga, ON L4V 1S6

MAGNETIZING MANUFACTURING

Cyclic Materials has recently launched a pilot plant in Kingston, Ontario, aimed at recycling magnet materials from end-of-life products. The pilot plant project is specifically employing Cyclic’s proprietary technology, Mag-Xtract, which separates rare earth elements in permanent magnets from end-of-life products and parts such as traction electric motors. Initial results show that the pilot plant has processed several tons of the magnet feedstock per day and has the capacity to produce 1,000 kg/hour or 8,000 tons per year of material. Since 2021, Cyclic Materials has been developing a two-step hub-and-spoke model recycling process for rare earth materials. The company aims to economically, sustainably and domestically turn end-of-life products and parts into valuable raw materials that can be reused in the supply chain of electric vehicles and other technological products.

FABRICATION PAR MAGNÉTISATION

Cyclic Materials a récemment lancé une usine pilote à Kingston, en Ontario, dans le but de recycler les aimants des produits en fin de vie. Le projet d’usine pilote utilise spécifiquement la technologie exclusive de Cyclic, Mag-Xtract, qui sépare les éléments de terres rares contenus dans les aimants permanents des produits et pièces en fin de vie, tels que les moteurs électriques de traction. Les premiers résultats montrent que l’usine pilote a traité plusieurs tonnes d’aimants par jour et a la capacité de produire 1 000 kg/heure ou 8 000 tonnes de matériaux par an. Depuis 2021, Cyclic Materials développe un processus de recyclage en deux étapes pour les matériaux à base de terres rares. L’entreprise vise à transformer de manière économique, durable et nationale les produits et pièces en fin de vie en matières premières précieuses qui peuvent être réutilisées dans la chaîne d’approvisionnement des véhicules électriques et d’autres produits technologiques.

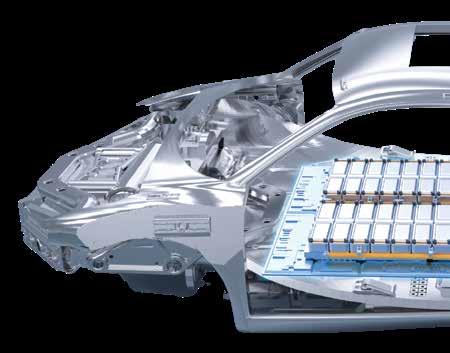

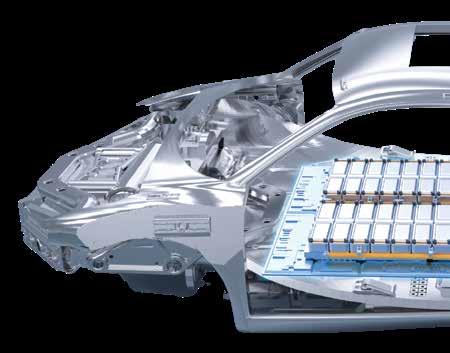

BOOST FOR BATTERIES

Quebec recently launched a “first-of-its-kind” electric vehicle (EV) battery recovery program designed to collect, transport, repurpose, remanufacture and recycle end-of-life EV batteries—specifically, fuel cells that fall outside of the established OEM management programs. The EV Battery Recovery Program is the result of a collaboration between vehicle manufacturers that worked with Call2Recycle to develop and launch the EVBatteryRecovery.ca platform, leveraging the organization’s extensive experience in end-of-life battery management for multiple businesses and sectors across Canada. The program is funded by the participating OEMs—which include Honda, Acura, BMW, Dodge, Fiat, Nissan, Tesla, Volkswagen, Mercedes-Benz and many more—and offered to dismantlers, shredders, independent repair and service facilities, dealerships, fleet operators and even individual vehicle owners. The program also supports the sustainable management of EV batteries and the further development of a circular economy for these valuable resources.

COUP DE POUCE POUR LES BATTERIES

Le Québec a récemment lancé un programme de récupération des batteries de véhicules électriques (VE), le premier du genre, conçu pour collecter, transporter, réutiliser, refabriquer et recycler les batteries de VE en fin de vie; plus précisément, les piles à combustible qui ne font pas partie des programmes de gestion établis par les fabricants d’équipement d’origine. Le programme de récupération des batteries de VE est le résultat d’une collaboration entre les fabricants de véhicules qui ont travaillé avec Appel à Recycler pour développer et lancer la plateforme EVBatteryRecovery.ca, en tirant parti de la vaste expérience de l’organisation dans la gestion des batteries en fin de vie pour de multiples entreprises et secteurs à travers le Canada. Le programme est financé par les équipementiers participants (Honda, Acura, BMW, Dodge, Fiat, Nissan, Tesla, Volkswagen, Mercedes-Benz et bien d’autres) et proposé aux démanteleurs, aux déchiqueteurs, aux ateliers de réparation et d’entretien indépendants, aux concessionnaires, aux exploitants de parcs automobiles et même aux propriétaires de véhicules individuels. Le programme soutient également la gestion durable des batteries de véhicules électriques et le développement d’une économie circulaire pour ces ressources précieuses.

UNITED EFFORT

A paper from a team of U.S.-based researchers claim that a more robust electric vehicle battery recycling infrastructure will be the key to keeping automakers stocked with the necessary precious metals. Dr. Linda Gaines of the Argonne National Laboratory, alongside her four co-authors, put forth a research paper asserting that the U.S. does not currently have enough nickel or cobalt to support even a single year of solely domestic EV production, but that some hope may lay in the recycling sector. About 54 percent of end-of-life EV batteries wind up in an auto recycling yard, though only about ten percent of those yards are in the U.S., while the rest are in China, according to data cited from 2019. However, the paper points out that end-of-life batteries “will not make a significant contribution to the overall U.S. battery material supply until well into the 2030s because of the long product lifetime and rapid demand growth for the dominant products.”

EFFORT COMMUN

Un article rédigé par une équipe de chercheurs américains affirme qu’une infrastructure de recyclage des batteries de véhicules électriques plus robuste sera la clé pour que les constructeurs automobiles disposent des métaux précieux nécessaires. Linda Gaines, du laboratoire national d’Argonne, et ses quatre coauteurs ont présenté un document de recherche affirmant que les États-Unis ne disposent pas actuellement de suffisamment de nickel ou de cobalt pour soutenir ne serait-ce qu’une seule année de production nationale de véhicules électriques, mais que le secteur du recyclage pourrait apporter un peu d’espoir. Environ 54 pour cent des batteries de VE en fin de vie finissent dans un centre de recyclage automobile, mais seulement 10 pour cent de ces centres se trouvent aux États-Unis, le reste étant en Chine, selon des données publiées en 2019. Toutefois, le document souligne que les batteries en fin de vie « ne contribueront pas de manière significative à l’approvisionnement global en matériaux de batteries aux États-Unis avant une bonne partie des années 2030, en raison de la longue durée de vie des produits et de la croissance rapide de la demande pour les produits dominants ».

NEWS | NOUVELLES 20 CANADIAN AUTO RECYCLERS 2024

Canada.

We specialize in Used Heavy Equipment (buy/sales/parts)

Over the years we have built a strong, trustworthy and long standing reputation in the market. If you are in the market to buy /sell / parts of used heavy equipment of any size and condition for any projects, call us!

We understand your operations cannot thrive without the used backhoes, used excavators and used lifts to keep the work going to get the job done in time. When you work with us we find you the right piece of equipment you need as quick as we can to keep you working as efficiently as possible. Time is money, we get that.

PARTS…

The Strength of an efficient and profitable Fleet is its Preventive Maintenance and Critical Parts Availability. We supply all parts for heavy machinery to ensure their productivity.

We work closely with our clients, we become an extension of their business, as we have on file the relevant information to be able to supply them the correct parts at the right price.

We Are coAst to coAst

We supply good quality used parts for a cost effective fix. We have access to vehicles that are stripped with parts that are readily available. We refurbished them at our factory with the best experienced and knowledgeable team.

associations

We can easily assist you with Service Items and Preventive maintenance schedules, which we have experience in as we work closely with leading Manufacturers, as well as experienced Technicians who assist us with great insight into common problems and the sometimes simple solutions.

We are a supply chain solution to all of our customers who benefit from our competitive pricing and fast and reliable shipping solutions.

BUILDING LONG TERM RELATIONSHIPS…

Equipment Pro Cat network of international clients is testament to our success. Whether you are in Africa, Caribbean or The Americas we can supply you a full range of OE and Alternative Parts as well as a full compliment of Service Items, Vehicles and much more… We offer our clients technical assistance and email and telephone support to ensure confidence in all aspects of maintaining, servicing and repairing their vehicles. We are considered by many of our trade customers as an extension of their business.

Member of / membre de

Nous vendons, réparons, échangeons de la machinerie lourde et des pièces d’occasion. Expédition rapide dans le monde entier depuis le Canada

Nous nous spécialisons dans l’équipement lourd d’occasion (achat/vente/pièces)

Au fil des ans, nous nous sommes forgé une réputation solide, digne de confiance sur le marché. Si vous êtes sur le marché pour acheter / vendre des pièces d’équipement lourd d’occasion de toute taille pour tous les projets, appelez-nous!

Nous comprenons que vos opérations ne peuvent pas prospérer sans les rétro caveuses, les excavatrices et les élévateurs usagés pour que le travail se poursuive et soit fait à temps. Lorsque vous faites affaires avec nous, nous vous trouvons le bon équipement dont vous avez besoin le plus rapidement possible pour que vous puissiez travailler aussi efficacement que possible. Le temps, c’est de l’argent, nous l’avons compris.

PIÈCES...

La force d’une flotte efficace et rentable est sa maintenance préventive et la disponibilité des pièces critiques.

Nous fournissons toutes les pièces pour la machinerie lourde afin d’assurer leur productivité.

Nous travaillons en étroite collaboration avec nos clients, nous devenons une extension de leur activité, car nous avons dans nos dossiers les informations pertinentes pour pouvoir leur fournir les bonnes pièces au bon prix.

Nous fournissons des pièces d’occasion de bonne qualité pour une réparation rentable. Nous avons accès à des véhicules démontés et des pièces facilement disponibles. Nous les avons remis à neuf dans notre usine avec l’équipe la plus expérimentée et la plus compétente.

Nous pouvons facilement vous aider avec les articles de service et les calendriers de maintenance préventive, dans lesquels nous avons de l’expérience. Nous travaillons en étroite collaboration avec les principaux fabricants, ainsi qu’avec des techniciens expérimentés qui nous aident avec une grande perspicacité dans les problèmes courants et les solutions parfois simples.

Nous sommes une solution de chaîne d’approvisionnement pour tous nos clients qui bénéficient de nos prix compétitifs et de nos solutions d’expédition rapides et fiables.

CONSTRUIRE DES RELATIONS À LONG TERME...

Le réseau international de clients d’Equipment Pro Cat témoigne de notre succès. Que vous soyez en Afrique, dans les Caraïbes ou en Amérique, nous pouvons vous fournir une gamme complète de pièces d’origines et alternatives, ainsi qu’un ensemble complet d’articles de service, de véhicules et bien plus encore... Nous offrons à nos clients une assistance technique et une assistance par courriel et par téléphone pour assurer la confiance dans tous les aspects de l’entretien et de la réparation de leurs véhicules. Nous sommes considérés par beaucoup de nos clients professionnels comme une extension de leur activité.

ARPAC is proud that Equipement Pro-Cat joined as a new member in 2023. Mr. Steve Perron and Nicolas Thomassin recycling centre is located at 20 rue du Parc Industriel, Saint-Urbain, G0A 4K0, and is known for parts in heavy machinery.

L’ARPAC est fière d’avoir intégré Equipement Pro Cat en 2023.

Le centre de recyclage de MM. Steve Perron et Nicolas Thomassin est situé au 20 rue du Parc Industriel, Saint-Urbain, G0A 4K0 et est reconnu pour ses pièces de machineries lourdes.

We sell, repair, trade used heavy machinery and parts. Fast shipping Wolrdwide from

519-858-8761 www.autorecyclers.ca RECYCLERS OF

member

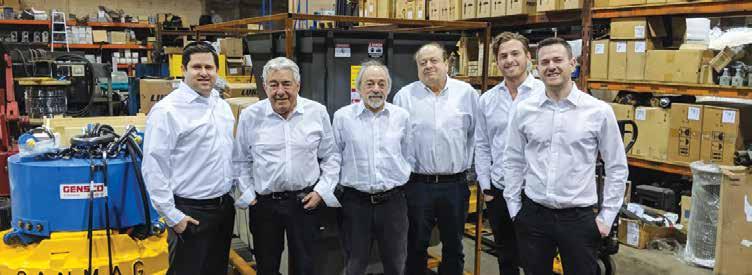

MODERN MILLERS

Cousin—owner duo Natalie and Chris Miller on operating the family ’biz, Miller’s Auto Recycling

MODERNE MILLERS

Natalie et Chris Miller, deux cousins propriétaires, parlent de l’exploitation de l’entreprise familiale, Miller’s Auto Recycling.

TBy/Par Sarah Perkins

he automotive recycling industry has always been one to build on the foundations of the past to create something new. From repurposing materials previously manufactured to bringing new lives to old parts, automotive recycling is about finding a fresh focus in familiar places.

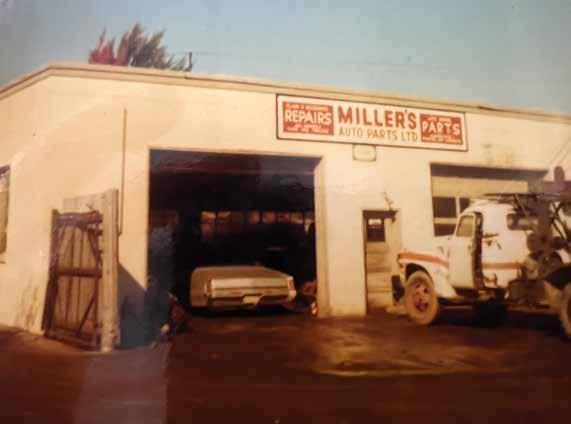

However, for cousins Natalie and Chris Miller of Miller’s Auto Recycling, the automotive recycling industry is not just familiar, but familial. The third generation in a family business that first began nearly 75 years ago, Natalie and Chris spoke with Canadian Auto Recyclers to discuss how a blend of homegrown knowledge passed down from branch-to-branch of their family tree, mixed with modern technology and business practices, has created continued and ongoing growth while also preparing them for continued future changes.

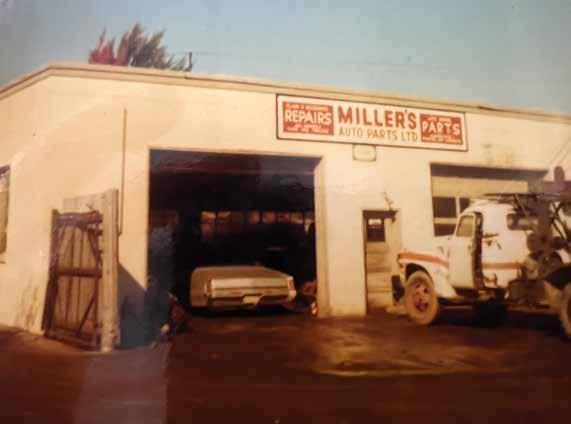

The family business that would become Miller’s Auto Recycling—now a large-scale operation on a sprawling 45 acres in Fort Erie, Ontario—first began on a humble two-acre lot on Robinson Street in downtown Fort Erie in 1952.

Here, Chris proudly noted that he and Natalie’s grandfather opened the original business purchasing end of life vehicles for the resale of used parts at the Robinson Street location. A move that would ultimately shape the lives of the next two generations of Miller kin.

ON THE COVER | SUR LA COUVERTURE 22 CANADIAN AUTO RECYCLERS 2024

Both Natalie and Chris’s fathers, Jim and Bill Miller grew up working on the vehicles on the Robinson Street lot and eventually came to purchase the business from their father as co-owners with the intention to help grow and expand both the size and scope of what had been started. This growth included purchasing land and building a new facility in 1975 at 1557 Bowen Road where the business operates today.

Like their own fathers, Natalie and Chris similarly spent a childhood that was equal parts lived in the schoolyard as much as the family business. When asked about their early years in the automotive recycling industry, Chris jokingly told Canadian Auto Recyclers that his career began with a bang.

“I first started helping out by cutting copper as a kid and helping to get the rubber off,” Chris said. “The process back then was a little different and best practices for safety were not in place as they are today.”

As he grew older, Chris transitioned from copper-cutting-capers to helping with more hands-on jobs. He worked summers until he was done with high school, attended night courses at college and worked during the day, and then came into the business full time in 1988.

For Chris, there was “not necessarily a plan to get into the family business,” but the transition was natural and welcomed. As he began to help his father out with more and more tasks, he grew into the role and accepted that he was “hooked from day one.”

“It’s a good place to be,” Chris told Canadian Auto Recyclers. “It’s close to home and I feel fortunate to work in the community I live in.”

For Natalie, the path to the automotive recycling industry was initially less straightforward. Performing some administrative work over the summer for the family business while attending university, Natalie then pursued a career as a physician’s assistant specializing in Orthopaedic Surgery in the United States. It wasn’t until 2009 that Natalie returned to work at Miller’s full time, taking on the role of managing human resources.

Having just had her daughter, Natalie saw the return as an opportunity to achieve more freedom for herself and her family.

En matière de recyclage automobile, le secteur s’est toujours appuyé sur les fondations du passé pour créer quelque chose de nouveau. Qu’il s’agisse de réutiliser des matériaux déjà fabriqués ou de donner une nouvelle vie à de vieilles pièces, le recyclage automobile consiste à trouver une nouvelle orientation dans des endroits familiers.

Cependant, pour les cousins Natalie et Chris Miller de Miller’s Auto Recycling, l’industrie du recyclage automobile n’est pas seulement familière, mais familiale. Troisième génération d’une entreprise familiale qui a vu le jour il y a près de 75 ans, Natalie et Chris se sont entretenus avec Canadian Auto Recyclers pour discuter de la façon dont un mélange de connaissances transmises de branche en branche dans leur arbre généalogique, combiné à la technologie et aux pratiques commerciales modernes, a créé une croissance continue et permanente tout en les préparant à des changements futurs continus.

L’entreprise familiale qui allait devenir Miller’s Auto Recycling—aujourd’hui une opération à grande échelle sur un vaste terrain de 45 acres à Fort Erie, en Ontario - a d’abord commencé sur un humble terrain de deux acres sur la rue Robinson dans le centre-ville de Fort Erie en 1952.

Chris est fier de rappeler que son grand-père et celui de Natalie ont ouvert l’entreprise initiale en achetant des véhicules hors d’usage pour revendre des pièces d’occasion à l’emplacement de la rue Robinson. Une décision qui allait façonner la vie des deux générations suivantes d’enfants Miller.

Les pères de Natalie et Chris, Jim Miller et Bill Miller, ont tous deux grandi en travaillant sur les véhicules de la rue Robinson et ont fini par racheter l’entreprise à leur père en tant que copropriétaires, avec l’intention de contribuer à la croissance et à l’expansion de la taille et de l’étendue de ce qui avait été commencé. Cette croissance s’est traduite par l’achat d’un terrain et la construction d’un nouvel établissement en 1975 au 1557 Bowen Road, où l’entreprise exerce aujourd’hui ses activités.

Comme leurs propres pères, Natalie et Chris ont eu une enfance qui s’est déroulée autant dans la cour d’école que dans l’entreprise familiale. Inter-

ON THE COVER | SUR LA COUVERTURE CANADIANRECYCLER.CA 23

Miller’s Auto Recycling, from above. Miller’s Auto Recycling, depuis le haut.

“I liked the idea of having more flexibility and loved the idea of the business,” she said.

It wasn’t until 2015 that the cousins finally fully followed in the path originally laid out by their fathers and grandfather, and bought into the family business with the intention of growing Miller’s Auto Recycling even further.

Since then, Chris and Natalie, who oversee the daily operations, along with Jim and his son Patrick, have helped lead Miller’s through a series of transitions—both planned and unforeseen.