Volume 22, Number 1, 2023 PREFERRED EVENT PROGRAMMING: OPINIONS FROM INDUSTRY INSIDE >> Canada’s top-ranked networks, as per the Romans Group IN THE RANKS CARSTAR Peterborough’s Jim Shirtliff inspires clear communication in the collision industry FIVE TRENDS IN 2023 | ARTIFICIAL INTELLIGENCE DEFINED | DECIPHERING ADAS Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 86 John Street, Thornhill, ON L3T 1Y2 www.collisionrepairmag.com LEADING BY LEARNING

Meet the new 3M™ Performance Spray Gun.

The smarter spray gun. Designed for the modern painter.

The first ever spray gun designed specifically to deliver top-of-the-line performance with revolutionary replaceable nozzle technology that saves you time. Experience faster cleanup, faster changeovers and faster cycle times. Bringing you the best of 3M Science, all packed into the smartest, lightest spray gun in the world.

Faster cycle times. Precision performance. Cleans in seconds. Lightest in the world.

CollisionSprayGun 3M and 3M Science. Applied to Life. are trademarks of 3M. Used under license in Canada. © 2021, 3M. All rights reserved. 2102-19736-a-E

Experience the smarter way to spray. 3M.ca/

Jim Shirtliff of CARSTAR Peterborough has seen all angles of this industry, and is using that expertise every day to deliver OEM-quality repairs.

42 46 48 56 61

WHAT TO WATCH

With every new year comes a new list of trends and challenges to watch out for; this year, labour retention, training gaps and DRPs are on the menu.

MANAGING THE MACHINES

Artificial intelligence has likely worked its way into your repair shop in one fashion or another—get informed with the basics of how these systems work, and how they can work for you.

ADAS INTERVIEW

Driver-assistance systems are one of the collision industry’s biggest challenges right now—join two experts in the field for a back-and-forth on why shops need to get educated on ADAS.

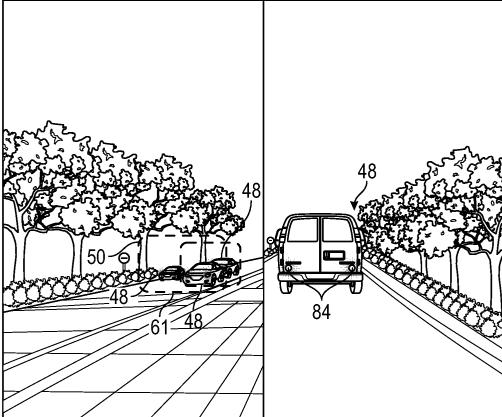

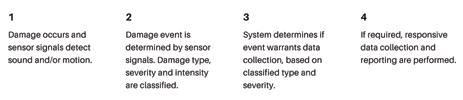

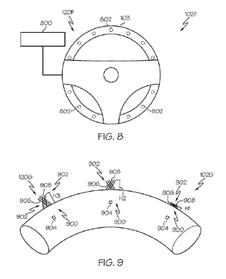

PURSUING PECULIAR PATENTS

The automotive industry is a constant race to the top, as major OEMs scramble to invent the next great piece of tech that will reshape how we approach vehicles.

ROMANS RANKS

Check out this year’s rankings of collision industry banners and how they stack up with one another, courtesy of the latest Romans Group whitepaper.

STAND UP, SPEAK OUT

Our industry has declared that it is back and ready to tackle the real challenges at this year’s slate of industry events.

ISSUE 22#1 | COLLISION REPAIR 3 CONTENTS

VOLUME 22, ISSUE 1, 2023 ON THE COVER CONTENTS 38 FEATURES PREFERRED EVENT PROGRAMMING: OPINIONS FROM INDUSTRY INSIDE >> Canada’s top-ranked networks, as per the Romans Group IN THE RANKS CARSTAR Peterborough’s Jim Shirtliff inspires clear communication in the collision industry FIVE TRENDS IN 2023 ARTIFICIAL INTELLIGENCE DEFINED DECIPHERING ADAS www.collisionrepairmag.com

LEADING BY LEARNING

34

28

Nothing exemplifies the Canadian collision repair spirit quite like the annual Budd’s Pig Roast, held every year in honour of the late industry giant.

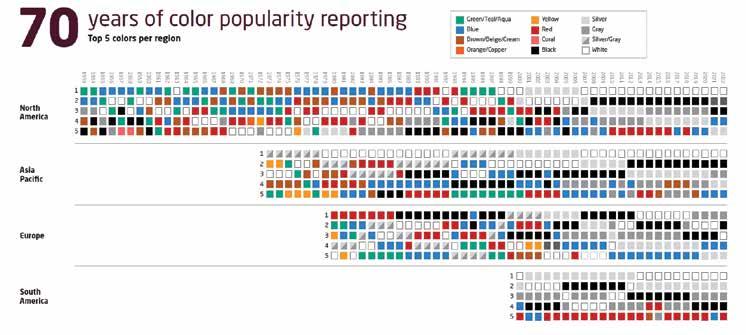

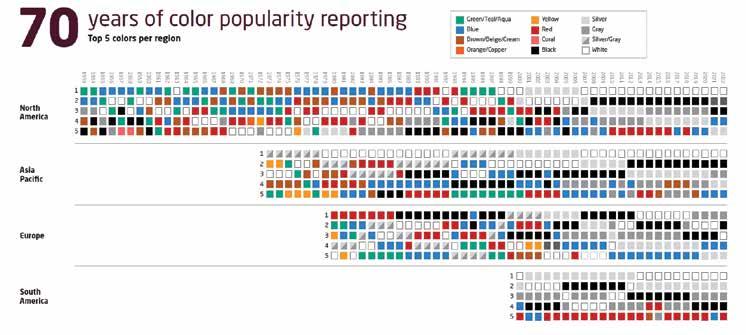

4 COLLISION REPAIR COLLISIONREPAIRMAG.COM CONTENTS FREE DIGITAL ISSUE AVAILABLE! CONTENTS 08 80 72 66 68 69 70 82 06 64 PUBLISHER’S PAGE by Darryl Simmons AN INTRICATE WEB By Venessa Di Vito LET’S TALK TRAINING by Stefano Liessi GROUND RULES By Meghan McEwan WHO’S DRIVING by Jay Perry TOM’S TALES by Tom Bissonnette LAST WORD by Allison Rogers PEOPLE ON THE MOVE Powerful people and the places they go. REGIONAL NEWS In some places it’s dinner, in others it’s supper, but here it’s always news. RECYCLING NEWS These recyclers have the parts, and the news, you need. COLUMNS DEPARTMENTS HAVE YOUR SAY. SUBSCRIBE TODAY! We welcome your comments on anything you see in Collision Repair magazine. Send your feedback to editor@collisionrepairmag.com. YOUR ONLINE SOURCE Canada’s collision repair information resource. New articles and top news stories daily. For more info visit collisionrepairmag.com 52 Axalta knows better than anyone that yearly automotive paint trends are anything but black and white. Electric vehicles are simply a different beast when it comes to body design and recycling. This has led the Auto Recyclers of Canada to put in place an EV roadmap to help sort out some confusion. 58

Measure Your Success. Right Down To The Millimeter. 224-SPANESI (224-772-6374) www.spanesi-americas.com facebook.com/spanesiamericas Spanesi Americas, Inc. 123 Ambassador Dr. STE 107 Naperville, IL 60540 Live Measuring, Vehicle Frame and Structural Items, Mechanical Parts, User Added Points With Photos, Suspension Parts, Comparative Measurements Scan For More Information ACCESS CHALLENGING MEASUREMENT POINTS Multiple Probe And Extensions Included ACCURATE Exact Measuring INTUITIVE USER EXPERIENCE Exclusive WinTouch Software MEASURING IN MINUTES Fast Measuring Setup UNIVERSAL Measuring Any Vehicle On Any Bench, Rack Or Lift Touch Electronic Measuring System

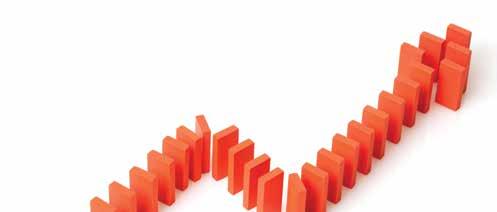

EVOLUTION, NOT REVOLUTION

It seems like the quest for the lowest repair price will soon be over. Thank goodness!

By DARRYL SIMMONS

It may be a new year, but here’s a not-so-new prediction: well-trained and well-equipped collision repair centres will be in high demand in 2023.

In my opinion, we will see facilities with the knowledge and capability to perform proper, compliant repairs soon turning ample profits as we venture deeper into the increasingly complex world of vehicle repair.

The number of shops has been thinned already, and many shops are already backlogged. Starting as a whisper, the mantra is getting louder… Profitability for shops is needed in the new Auto Claims Economy. A growing number of insurer “partners” are not just paying lip service, but they are starting to pony up to the bar. I predict

Traditionally, repairers sat at the bottom of the food chain when it came to the Auto Claims Economy—at the mercy of those who paid them. Insurers have always had the negotiating power as they were the ones who controlled the purse strings.

Now, as repair capability declines, new questions demand profitable answers. Who is going to pay for storage while waiting for the repairs and the parts? Who is going to pay for the increased administration needed for the estimates that are now much more complicated as they include EV materials as well as other alternative options, such as self-drive and ADAS.

The key is not just volume, it’s profitability.

we’ll soon see increased labour rates across the board, flat fees for appraisals, payments for admin duties and much, much more.

Insurers have painted themselves—well, their customers, actually—into a corner by trying to get the cheapest price as opposed to the best partnership at the local levels. Thank goodness the quest for the cheapest repair price is over. That race to the bottom is soon to be reversed. They are realizing a cheaper price does not bode well in today’s market. At the end of the day, insurers need their customers’ cars repaired properly. They will be reliant upon the progressive collision centres who can conduct these repairs safely and profitably . Insurers can no longer put one shop against the other to get the best price.

This is not a revolution, it’s an evolution. For the first time, repairers are well positioned as insurers and customers scramble to get their cars repaired according to procedural dictates, supply chain and chip shortages, and an ever-growing backlog at the shop level.

Savvy insurers recognize the importance of profitability and will pay more for qualified repairs in order to get better service. That’s where the customer wins. And, with OEMs eyeing cycle times and cradle-to-grave strategies, progressive shops—i.e., the good ones—will get more business.

But the key is not just volume, it’s profitability. If shops don’t make a profit, sooner, rather than later, they will close down. And insurers know this.

The tide is turning. Collision repair facility owners and managers now have a platform to voice their concerns on a national level and actually be heard. Yes, I can see just over the horizon—higher labour rates, better payout tables, better pay for administration costs, and much more.

Stay tuned. This is bound to be collision repairers’ brightest hour.

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

STAFF WRITERS

Max Reid | max@mediamatters.ca

Kate Ng | kate@mediamatters.ca

GRAPHIC DESIGN INTERN

Alecia Basdeo | alecia@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677 wanjamann1@gmail.com

AUDIENCE ENGAGEMENT MANAGER

James Kerr | james@mediamatters.ca

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

CONTRIBUTORS

Tom Bissonnette, Venessa di Vito, Jay Perry, Stefano Liessi, Steve Fletcher, Meghan McEwen

SUBSCRIPTION

Single edition $7.99 One-year $39.95 ( 6 issues) Collision Repair ™ magazine is published bimonthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing in this publication have been compiled and included with the permission, though not necessarily the endorsement, of the editor, or of independent columnist contributors, and are in no way to be construed as those of the publisher, or as endorsements of them.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL

SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough, ON K9J 3R2

“We acknowledge the financial support of the Government of Canada”

Collision Repair magazine is published by Media Matters Inc., publishers of:

6 COLLISION REPAIR COLLISIONREPAIRMAG.COM PUBLISHER’S PAGE

Impact Auto Auctions is Now IAA CA.IAAI.com © 2022 IAA, Inc. All rights reserved. BID. BUY. REPAIR.

PEOPLE ON THE MOVE

JOHN TURNER | SIMPLICITY CAR CARE

John Turner has joined Simplicity Car Care as brand development manager, he announced on LinkedIn in early December. Turner brings vast experience in several sales roles and previously owned his own service centre, collision repair facility and auto jobber location.

EMMANUEL GYEBI | FIX NETWORK

Fix Network is pleased to announce the promotion of Emmanuel Gyebi to global vice president of procurement, having previously served as a director of procurement. Gyebi will provide executive leadership, direction and strategic vision to the company’s global procurement framework and processes, according to a press release from Fix Network.

JEFF

MURRAY | BOYD GROUP

The Boyd Group recently announced the appointment of Jeff Murray as interim CFO, effective January 1, 2023. Murray joined the finance team at Boyd in 2004 as the manager of external financial reporting. Prior to joining the Boyd Group, Murray worked at the accounting firm Ernst & Young LLP for approximately 10 years. Since 2013, he has held the role of VP of finance at Boyd. He holds a Bachelor of Commerce (Honors) degree from the University of Manitoba and is a chartered professional accountant.

AZIM

LALANI | AUTOCANADA

National dealer AutoCanada has announced that Azim Lalani will take over as CFO at the beginning of the 2023 fiscal year. Lalani brings more than 25 years of experience in the real estate industry to his new role at AutoCanada, having most recently served as senior vice president of finance and accounting at a real estate development firm. He is currently co-vice chair of the board of governors and chair of the finance committee at the University of British Columbia. He is also a corporate director with UBC Investment Management Trust and the chair of the audit committee of the Family Services of the North Shore.

8 COLLISION REPAIR COLLISIONREPAIRMAG.COM NEWS MOST RELIABLE PRE 8AM DELIVERY SERVICE Call 1-(800)-387-3199 | cardinalcouriers.com Pre 8am Package Delivery Dedicated Logistics Pre 8am LTL Delivery 6600 Goreway Dr., Unit D Mississauga, ON L4V 1S6

On average, new franchisees grow their business by 23% Call: 1-800-871-7612 | Click: simplicitycarcare.ca/franchisee Connect: contact@simplicitycarcare.ca Grow your collision repair business with one of Canada’s fastest growing automotive franchise networks Operational E ciency Simplify your workflow to increase e ciency and profitability. Insurance Partnerships Connect with and meet the requirements of major insurers. Business Growth Use our proprietary system to service customers and help drive sales.

Division of Division of RUST CHECK CORP. 6175 Danville Road Mississauga, Ontario L5T 2H7 1800-265-0790 ESTABLISHED IN 1972

ON THE MOVE

KEN CHUNG | SIMPLICITY CAR CARE

Ken Chung has been named VP of operational excellence and technology for Simplicity Car Care. According to Simplicity COO Domenic Prochilo, Chung will “bring innovative ideas to the already successful performance-based agreements in which Simplicity Car Care participates, and those that will come in the future.” Chung’s expertise in technology and programming will also complement the company’s technology stack by analyzing all of Simplicity Car Care’s infrastructure and creating a road map for improved reporting and efficiencies.

CSN announced in January that Al McNeil had joined its corporate team as a field technical analyst. McNeil will support Western Canadian licensees as part of the organization’s field operations team. He brings more than 28 years of experience, previously working for MSO as a group appraisal reviewer and process trainer. Prior to that role, McNeil owned and operated his own independent appraisal firm after a lengthy career with Intact Insurance as a field appraiser.

Jack Landry is the latest account manager to join CSN Collision Centres, the network announced in January. Landry’s new role has him responsible for maintaining growth with insurance partners, customers and licensees as part of the insurer relations team. Previously, Landry spent more than two years in key account management for a leading aftermarket distributor operating in North America, Japan and the United Kingdom. Prior to that, Landry worked for more than six years for the largest global rental replacement network in a management role.

ISSUE 22#1 | COLLISION REPAIR 11 NEWS OF COLLISION REPAIRERS CANADIAN COUNCIL GET CONNECTED! Join now, it’s free at collisionrepaircouncil.ca AN ASSOCIATION OF SHOP OWNERS/MANAGERS FOR SHOP OWNERS/MANAGERS Make sure your voice is heard SIGN UP TODAY! INTRODUCING

PEOPLE

AL MCNEIL | CSN COLLISION CENTRES

JACK LANDRY | CSN COLLISION CENTRES

PEOPLE ON THE MOVE

Fix Network has announced the appointment of its new director of operations for Western Canada, Lauren Reynolds. According to a company press release, Reynolds will be responsible for managing Fix Network and ProColor Collision’s operations across Western Canada. She previously served as Fix Network’s strategic partner developer and possesses over 15 years of experience in the collision industry.

SCOTT KRAFT | FIX NETWORK

The sales department at Fix Network is excited to unveil a new shake-up to its management team, announcing that Scott Kraft has been nominated to the new role of key account manager for sales and relationship management. Having previously served as director of operations for Fix’s Western Canada division, Kraft has developed both a strong set of skills and reputation to match, as he was instrumental in leading his section of the company through the development of the Western Canada Hail Program. He is also a graduate of Fix Network’s inaugural Leadership Program.

Benjamin Perrier recently joined BASF Canada as strategic account manager – Eastern Canada. Perrier joins the team from BASF France, where he served as national sales manager and strategic account manager. Perrier also brings extensive experience in the automotive aftermarket, exports and distributing, and has worked as a country manager for KYB Europe, an OE supplier to vehicle manufacturers. “I’m looking forward to meeting the teams and partners in the coming weeks and to start supporting them on all our industry challenges,” Perrier wrote on LinkedIn.

12 COLLISION REPAIR COLLISIONREPAIRMAG.COM NEWS

LAUREN REYNOLDS | FIX NETWORK

BENJAMIN PERRIER | BASF CANADA

Are you ready to embrace change for a secure future? PROCOLOR IS YOUR ANSWER Operational field support Exclusive territory –adds equity to your business Proven experience in winning Insurance work National supply arrangements Full branding and marketing support The power of a global brand Contact Daryll O’Keefe at dokeefe@fixnetwork.com or visit procolor.com/franchise to find out more.

TECH TAKES THE WHEEL

By SYLVAIN SEGUIN, president of Fix Network Canada

Change is inevitable and to make it in any business, you must be flexible to stay relevant. And the evolution of technology is keeping all of us on our toes.

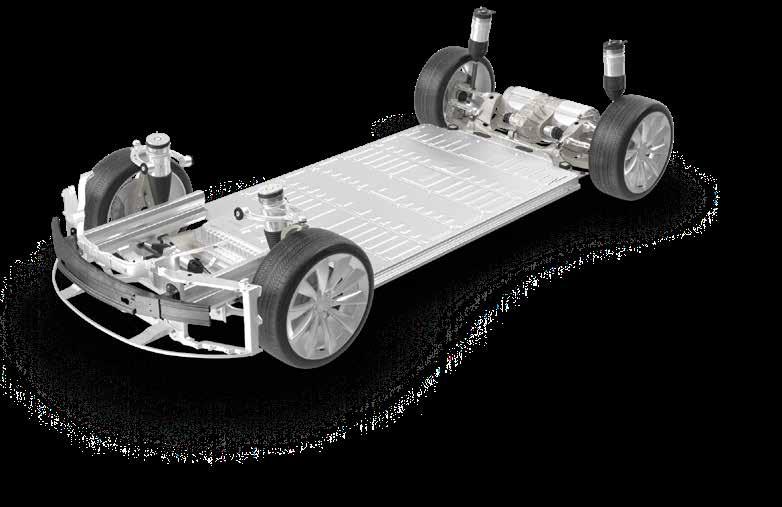

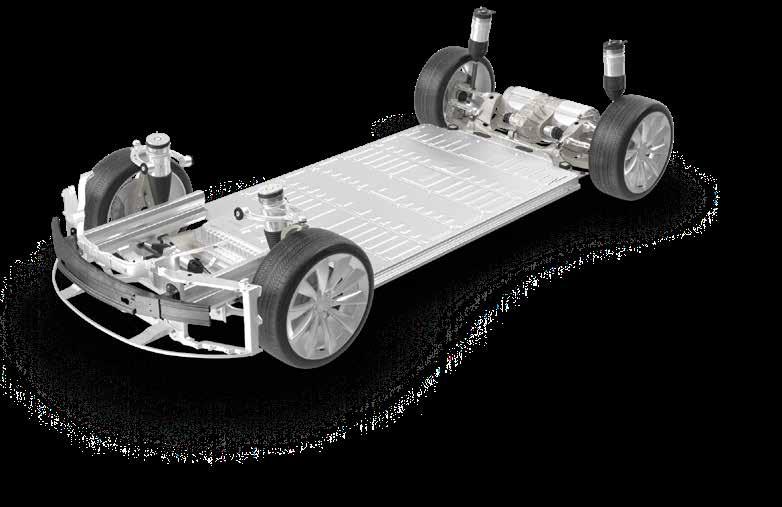

The aftermarket business is no different when it comes to innovation in technology. We’ve been shifting gears and learning more and more about the state-of-the art advanced technology that is coming our way. From Electric Vehicles

(EVs), Advanced Driver-Assistance Systems (ADAS) including adaptive cruise control, collision avoidance, GPS integration – it is imperative we learn all there is to know about these advancements and how to repair them to OEM standards.

Industry experts predict that the future of passenger vehicles will be electric, propelled by consumer interest and the regulatory environment. Electric vehicle (EV) adoption

ADVERTORIAL

The automotive aftermarket is not immune to technological advancements—and changes will come rapidly

accelerated in the second half of 2020 and has remained steady. According to SEMA’s Future Trends 2023 report, the EV market is poised for significant growth in the next decade, with new sales projected to hit 39 percent by 2035.

Electric vehicles present exciting opportunities for our industry. Electric vehicles may take some time to reach the same level as internal combustion engines in terms of sales and adoption (according to SEMA, there are nearly 300 million gas-powered cars and trucks on US roads and displacing them will take many decades) but those of us in the aftermarket industry must determine if we are prepared to repair these sophisticated machines. In case of a collision, electric vehicles demand a completely different approach than just tending to dent repair.

We are several years away from fully autonomous vehicles on the road. But it’s never too early to prepare for the next technological evolution and understand how it might disrupt the aftermarket industry.

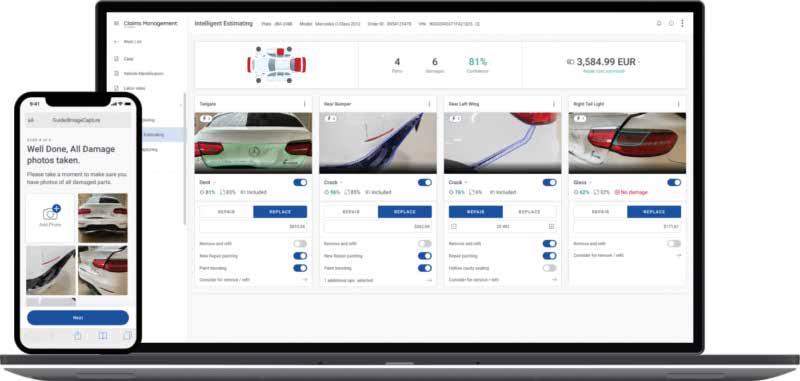

Artificial Intelligence (AI) is now turning the notion of a traditional automotive body shop upside down. AI and computer vision systems are playing key roles in streamlining diagnostics and inspection processes in critical aftermarket operations. Sophisticated AI algorithms and machine learning processes can manage every aspect of repair shop operation at lightning-fast speeds—from computing to quick photo estimation, to complete inspection of the vehicles, to providing customers real-time information about the extent of the damage. At the same time, it is also speeding up transmission of repair-related information.

From EVs to AI, just having the right equipment and knowledgeable technicians is no longer an option. Body shops must understand the latest auto manufacturing and technology developments to support their customers better. And training employees is key.

The processes and requirements change from one year to the next due to new equipment complexities or raw materials used in the construction of different components of the structure of the vehicle. Training therefore should be considered as an ongoing priority for shops.

At our Fix Network World training centers, technicians working for our strategic partners are continuously trained in the latest AI processes and repair procedures to ensure that they can repair the most advanced vehicles. Through ongoing

mentoring, virtual reality-based training, we are successfully preparing hundreds of next-generation technicians who can confidently work on these sophisticated machines.

As consumers expect more from their vehicles, OEMs and technology companies ramp up development to meet demand. In this situation, franchise networks are better positioned to pivot and adapt and support their customers.

For technicians, continuous learning should be a lifelong learning process. We need people with an open mind to agree that the repair process will evolve from year to year. Regular training and refresher courses for skilled technicians in the most advanced collision repair technologies prepare them to be better prepared for the future.

As technology evolves, electronic components become more sophisticated and alloys used in the construction of cars become more complex, technicians can no longer rely on past experiences only. They need to read every OEM technical data sheet prior to any structural repair to ensure they meet OEM recommendations and standards for a particular vehicle.

Another important element taking the AI technology forward is certification for shops and technicians. Certification methods such as I-CAR demonstrate to customers and insurance partners that the team has been trained to manage the most complex mechanical and collision repair requirements and that the shop has the latest equipment to ensure all repairs and services are according to manufacturer specifications.

Many believe that the technology is very complicated and requires a great deal of training and investment. While the benefits of incorporating AI technology in shop operations are many, the biggest challenge is obviously the cost. Shop owners are apprehensive if their investment in the technology and the time can translate into significant returns quickly. As the saying goes ‘you have to spend money to make money’.

If shops do not make the right investments to keep up with innovation, body shops risk being left behind. The benefits far outweigh the disadvantages and the investment in both time and money will certainly pay off in the longer run. As the former Chairman and CEO of General Electric, the late Jack Welch, said, “Change before you have to.” Whether collision repairers adopt the technology or not, there’s no doubt about it – change is here to stay.

ADVERTORIAL

GOODBYE TO GOTSCH

The automotive aftermarket is bidding farewell to an industry legend, as CCC Intelligent Solutions’ Susanna Gotsch prepares for retirement, closing the book on a prolific 30-year career. Gotsch worked in the many different avenues of CCC since her 1992 start with the company, having built up skills in product development and management, before moving on to head up CCC’s data warehouse development team. In 2000, she also began serving as the company’s industry analyst, a role which would become her full-time responsibility. Gotsch also developed and has led CCC’s Crash Course publication since 1995.

SPOTLIGHT AND SHOWCASE

Lordco’s 33rd annual trade show is slated to occur this April 3 and 4, says the company. Registration closes on March 30, 2023, at 5 p.m. PST. Please note that registration for suppliers is invitation-only. The event is traditionally held at the Pacific Coliseum and PNE Agrodome. Last year, the company said it hosted “hundreds of partners representing the best tools, equipment and chemical lines the industry has to offer.”

16 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY NEWS

Photos from last year’s Lordco Trade Show, which marked the first time in two years that attendees connected at the Vancouver-based event.

Gotsch was recognized as a “Most Influential Women in the Collision Repair Industry” in 2011 and served on the board of the Women’s Industry Network from 2013 to 2019.

PRESENTING PROJECT ARROW

Markham, Ontario’s Pfaff Autoworks recently hosted the Automotive Parts Manufacturer’s Association (APMA) and other Project Arrow stakeholders for the reveal of Project Arrow. Suppliers were treated to a super-secret glimpse at the Canadian-built car on December 20, where 80 attendees met at a tightly guarded event at Pfaff Autoworks. Viewers were forced to abandon their smartphones and tape over any camera lenses before they were permitted a walkaround of the four-seater ZEV. Every part of the Arrow model is Canadian-made, according to Flavio Volpe, president of the APMA–aside from the infotainment screen, which he says is made by Lenovo in absence of a Canadian supplier.

“This is going on a two-year tour [to] auto shows, tech demonstration centres and direct visits to OEMs,” said Volpe.

ISSUE 22#1 | COLLISION REPAIR 17 INDUSTRY NEWS

CRISIS COORDINATION

Ford released an emergency response guide (ERG) in its recent OnTarget newsletter. The free document was distributed with the aim of equipping technicians with a deeper knowledge of the locations of various safety features, including airbags and sensors, as well as detailed procedures on how to safely approach and deactivate a damaged EV. “The ERG provides a lot of detailed information on how to approach a damaged EV, what to listen for, what to look for,” said Gerry Bonanni, senior damageability engineer at Ford. The ERG also provides steps for what to do if a Ford vehicle’s charging cord lock does not release after charging, including how to safely disconnect the charging cord itself from the vehicle.

JUNK IN THE TRUNK

Observers of Tesla’s Texas Gigafactory were seen doing dramatic double-takes after images of the yet-to-be-released Cybertruck’s massive single-piece rear megacast were leaked. The images, which found their way online in the days following Tesla’s recent Q3 earnings call, depict several versions of the huge part; one appearing to be an aluminum megacast while the other is likely hydroformed stainless steel, according to Teslarati. The use of megacasting first began with the production of the Model Y’s chassis in 2020. This time around, Tesla engineers have been using a far larger casting to account for the Cybertruck’s large body and long truck bed.

UPSTANDING EV

Rivian’s 2022 R1T electric pickup has earned an International Institute of Highway Safety (IIHS) Top Pick Safety+ award. The all-electric pickup was shown to withstand the small overlap quite well, as a video released by the IIHS saw the occupant compartment of the R1T remain secure, while its driver-facing airbags successfully kept the test dummy cushioned from the brunt of the impact. To be eligible for a Top Safety Pick award, a vehicle must earn “good” ratings in six IIHS crashworthiness evaluations, including the driver-side small overlap front, passenger-side small overlap front, moderate overlap front, original side, roof strength and head restraint tests. It must also be available with a front crash prevention system that earns “advanced” or “superior” ratings in both the vehicle-to-vehicle and daytime vehicle-to-pedestrian evaluations.

THIN-SKINNED

An American vehicle detailing shop has an interesting discovery— the OEM coating on a new Lucid Air Grand Touring is so thin that polishing can damage the paint. According to a Youtube video by Out of Spec Detailing, the Lucid Air’s Grand Touring paint was too thin to even polish. In fact, paint thickness measurements regularly scored below 3mm but went as low as 2.24mm. For context, most vehicle coatings vary between 4mm to 7mm—enough for a polishing abrasive material to polish scratches away. Nevertheless, a solution was found. The Out of Spec Detailing team used a paint protection film to cover scratches, and highlighted vinyl wrapping as another possibility.

CCCR ANNOUNCES CO-CHAIRS AND REGIONAL REPS

The Canadian Council of Collision Repairers (CCCR) has announced the introduction of Co-Chairs Kelvin Campbell and Max DiFelice as well as the Regional Representatives from across the country. Regional Reps are: Atlantic: Kelvin Campbell Southern Ontario: Max DiFelice

Eastern Ontario: Shawn Stenson GTA: Jeff Pabst

Northern Ontario: Daniel Trevisanutto Manitoba: Joel McPhail Saskatchewan: Mike Mario Alberta: Steve Hammond British Columbia: Wade Bartok. The CCCR was formed to provide a voice for owners and managers to promote the highest standards of safety, quality, and professionalism in the industry. The council will also provide a platform for members to share their knowledge, expertise, and best practices. For more information visit www.collisionrepaircouncil.ca

18 COLLISION REPAIR COLLISIONREPAIRMAG.COM OEM NEWS

Tesla Giga Texas observer Kim Java uploaded a video of the Cybertruck megacast to YouTube.

In addition to a strong showing in the driver-side small overlap front impact test, the R1T comes equipped with “good-rated” LED projector headlights and a standard front crash prevention system that the institute said also posted “superior” results.

Paint thickness measurements regularly scored below 3mm but went as low as 2.24mm. Collision Repair magazine is unable to verify the accuracy of the readings.

Serving your PBE needs for 50 years

DRIVING DISPARITY

The New Brunswick Insurance Board continues to approve insurer requests allowing credit scores to determine driver insurance rates, despite criticism that the practice carries discriminatory implications. Former attorney general Kelly Lamrock said that the use of poor credit to determine auto premiums was comparable with price discrimination by gender and age, saying in an interview with the CBC, “Poverty tends to lead to bad credit.” Similarly, the Office of the Attorney General (OAG) raised concerns with the insurance board about how credit discrimination allows companies to subvert anti-discrimination laws, potentially targeting groups such as seniors and single people. “The OAG argues that the inclusion of credit scores in the rating formula may adversely impact those in vulnerable socioeconomic groups as it may lead to increased premiums,” wrote the board in summarizing the government’s legal argument. New Brunswick is not facing this issue alone: Ontario’s Auditor General, too, voiced concerns about credit-based insurance in its 2022 annual report.

New Brunswick’s largest auto insurer, Wawanesa, defended the practice in 2021, saying that credit score reflected an individual’s level of risk-taking, risk tolerance and financial responsibility—bad driving being an example of risk-taking.

UPS AND DOWNS

The office of Ontario’s Auditor General released its 2022 Annual Report in December, where more light was shed on the province’s growing disparity between low crash frequency rates and high auto insurance premiums. Penned by Auditor General Bonnie Lysyk, this year’s report found the average Ontario auto insurance premium rose by 14 percent from 2017 to 2021, totalling an annual rate of about $1,642, despite the fact that the province often records the lowest crash frequency nationally. The report laid out several suggestions for initiatives that could work to make Ontario’s auto insurance industry more efficient, affordable and equitable for the province’s many drivers. “Like Alberta, Ontario could develop more protocols to treat automobile accident injuries instead of providing cash for those injured to seek their own treatment,” read an excerpt of the report. “Ontario could also follow British Columbia and Saskatchewan in implementing a mandatory licensing or certification regime for automobile repair businesses to protect consumers against poor repairs and fraud.”

20 COLLISION REPAIR COLLISIONREPAIRMAG.COM INSURANCE NEWS

TM Remote work just isn't for everyone! As a part of the CSN network, you’ll become part of a genuine collision repair community. Whether you’re ascending the industry’s peak, or just leaving base camp – we know your business. At CSN we give you the freedom, choice, and support needed to grow and perform. Visit csncollision.com/join for more information! FEELING ISOLATED?

A POWERFUL PAIRING

3M has extended its status with the International Bodyshop Industry Symposium (IBIS) partnership, the companies announced in December. The agreement to remain a Global IBIS Partner will be in place for three years, said 3M. The companies have maintained a relationship since the inaugural IBIS Global Summit in 2001. “We’re thrilled to be continuing this journey with IBIS,” said president of 3M’s automotive aftermarket division, Dave Gunderson. “Through each year of our longstanding partnership, 3M has had the opportunity to connect with some of the best and brightest in collision repair, all around the globe. We view this partnership as integral in our ability to learn, grow and further advance in the industry” IBIS CEO, Jason Moseley, echoed a similar enthusiasm, saying “We are thrilled to have 3M as our global partner again. This agreement shows the commitment to supporting a strong and sustainable sector. Over the last few years 3M have used the IBIS platform to inform and educate hundreds of industry leaders.

22 COLLISION REPAIR COLLISIONREPAIRMAG.COM BUSINESS NEWS

A PROCESS YOU CAN TRUST. Catalytic Converters • ECUs • Hybrid Batteries UNITED CATALYST CORPORATION UNITED CATALYST CORPORATION • PGM prices DIRECT to your phone twice daily - It’s Free! • Get market prices for Platinum, Palladium, and Rhodium twice each business day. PGM DAILY DOUBLE Subscribe Today! Text “DAILY” to: 844.713.PGMS (7467) www.UnitedCatalystCorporation.com 100 Industrial Blvd. | Fountain Inn, SC 29644 | 864.834.2003 YEAR ANNIVERSARY YEAR ANNIVERSARY

“We will start the extended agreement at IBIS Middle East – Dubai In February moving on to the Exclusive IBIS USA Nashville [event] in April, followed by the flagship Global Summit – Milan in June,” added Moseley. The theme for IBIS’s 2023 lineup of events is “Sustainable Strategies for Success.”

A NEW NAME

Following a year of steady acquisitions in the auto glass sector, most recently including the purchase of Discount Auto Glass, Driven Brands has announced that it will be unifying its numerous glass repair brands under the new banner of Auto Glass Now,”in the states. Driven Brands has added about 175 glass repair facilities, as well as more than 700 mobile repair units, to its portfolio since last year through a series of strategic acquisitions in the American glass repair market. The company says this new Auto Glass Now branding will be reflected online and in future advertising materials, as well as at its remodelled facilities and on mobile service vans.

SHACKING UP

Treschak Enterprises in Welland, Ont. has been acquired by Color Compass Corporation, expanding the Canadian footprint of the autobody supply distributor. According to Color Compass, this is part of the company’s historic practice of strategic market growth and acquisitions, with the addition of Treschak Enterprises being part of their continued expansion within the Ontario marketplace. Treschak Enterprises has serviced the Ontario collision market for 35 years and boasts a solid reputation with its customers according to Color Compass. The acquisition of, Treschak Enterprises “aligns with Color Compass’s values, and mission of providing sustainable and profitable business solutions of fostering continuous improvements by creating a culture of caring for our people, our suppliers, and our customers,” said Gord Milford, president of Color Compass.

ISSUE 22#1 | COLLISION REPAIR 23 BUSINESS NEWS

“[This branding] gives us an incredible platform to continue our national expansion through tuck-in merger-and-acquisition activity and greenfield openings, which has helped us become the second largest player in the U.S. glass servicing category in just a few short months after entering this space,” added Macaluso.

accuvision-3D.com arslanauto.com Contact your distributor or Call (800) 465-8575 ACCUVISION-3D IS RECOGNIZED BY CERTIFICATION PROGRAMS - CCIAP - Honda QUICKEST, SIMPLEST AND MOST ACCURATE 3D MEASURING SYSTEM IN THE WORLD NEW NOW INCLUDES WHEEL ALIGNMENT DIAGNOSTICS SOFTWARE ACCUVISION-3D® IS RECOGNIZED BY CERTIFICATION PROGRAMS - Certi ed Collision Care - CCIAP - Honda - ICBC Made in Canada “ICBC” Recognized - NO Moving Parts, NO Lasers, NO Targets, - NO Adaptors, NO Magnets, NO Arms, NO Extensions, - NO Wires, NO Wi-Fi, NO Bluetooth - NO Calibration Needed, MITCHELL chassis data

Jamie and Don Treschak of Treschak Enterprises.

COLD-HEARTED

Tesla models appear to fare better in cold weather when compared to other popular EVs, according to an updated range study by Recurrent Auto. Recurrent Auto obtained data from 7,000 vehicles across the United States and analyzed “tens of thousands” of data points from onboard devices providing data on energy usage. According to Recurrent’s data, the Model X and Model Y Long Range loses 15 percent of range when operating between -6°C and -1°C (20°F to 30°F); the Model 3 Long Range lost 17 percent and the Model S lost 19 percent of its range. For comparison, Ford’s Mach-E Premium AWD lost 30 percent—as did the Volkswagen iD.4. A 2020 study performed by the Norwegian Automobile Federation showed a 34 percent range reduction for the Tesla Model 3; Recurrent notes that this model did not have a heat pump, which now comes standard and has been shown to increase cold weather ranges. The Model Y uses a “more sophisticated heat pump system”, “help[ing] to regulate temperatures without drawing on the battery.” Teslas are also aided by localized cabin heating—from heated seats, steering wheels or other parts. Ultimately, the study concludes that though some range is lost when driving a Tesla in cold-weather conditions, “Tesla’s thermal management is still great at controlling cold weather range loss.”

MAKE SOME NEW NOISE

New sound requirements for hybrid and electric vehicles have been announced by Canada’s transport minister, citing increased collision risks towards cyclists, pedestrians and Canadians with disabilities among others. Minister Omar Alghabra announced mandatory minimum noise levels from hybrid and electric vehicles and equipping them with sound emitters that produce noise at low speeds. Under these new requirements, all hybrid and electric vehicles will be required to have sound emitters that produce noise at low speeds. While automakers can determine the actual noise sound made, the volume and pitch must clearly indicate if a vehicle is speeding up or slowing down. Most automakers have voluntarily added sound emitters to hybrid and electric vehicles prior to the announcement, which is currently in effect.

FLASH SALE

Few things are bad enough to be called a burning wreck. Unfortunately for one man in Cambridge, Ontario, his 2015 Hyundai Sonata turned into one when his car burst into flames right as he pulled into the driveway. In an interview with the CBC, Mike Tennant described how a “large flame came up over the hood,” warning his wife that his car was on fire. According to the CBC, it was only 15 minutes since he picked up the car from a dealership after servicing on November 9, 2021. More than a year later, there remains no official cause or agreement over who or what was responsible. The CBC’s Go Public investigators contacted two experts with videos of the burning car and service records from the dealership. Eli Melnick, an electrical engineer, licensed mechanic and forensic investigator says that the intensity of the flames suggests it might have been fueled by an accelerant. The remains of the vehicle were sold by Allstate, who did not say whether an investigation was conducted before or after they sold the vehicle for salvage.

Matt Carpenter, an instructor and expert in automotive mechanics at the Southern Alberta Institute of Technology made a similar assessment, highlighting that an accelerant accounts for the size and spread of the fire but not the root cause, with Melnick saying that 15 minutes was the approximate time for engines to reach operating temperature— hot enough to start a fire.

BUMP IN THE ROAD

Image from Recurrent Auto. Estimated winter ranges are based on onboard telematics and reflect the OEMs proprietary range calculations and software. Verified winter ranges are based on original Recurrent research using a combination of onboard devices and real-time usage data providing more than 35,000 data points.

News site CarBuzz recently unearthed a document indicating BMW’s exploration of a new suspension designed to harvest energy from potholes, speed bumps and other road defects. Whereas traditional suspension seeks to mitigate the bumps felt by a driver and their passengers, this new design aims to translate this jerky force into energy that feeds back into the vehicle. At the time of publishing, there are no details for when this system may rollout to customers or how much it might cost, though sources suspect the tech will be present on incoming electric models.

24 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY NEWS

TWICE AS NICE

THE ONLY FRAME TO PERFORM ADAS CALIBRATIONS & WHEEL ALIGNMENTS

INTELLIGENT ADAS IA900WA SYSTEM

The Next Step In ADAS Calibration Now Includes Wheel Alignment Technology. One Frame To Perform 4-Wheel Alignment & ADAS Calibration.

IMPROVE SHOP EFFICIENCY & PROFITABILITY

• PRECISE OPTICAL MEASUREMENT WITH 6 HIGH RESOLUTION CAMERAS

• SELF CALIBRATING CAMERAS, ALWAYS ACCURATE, EVERY TIME

• CAMERAS AUTOMATICALLY TRACK VEHICLE HEIGHT ON LIFT

• MAXISYS INTERFACE FOR WHEEL ALIGNMENT

ADAS CALIBRATION SELF-CALIBRATING AUTO HEIGHT TRACKING 6 HI-RES CAMERAS WHEEL ALIGNMENT

WEB: AUTEL.COM | SUPPORT: 1.855.288.3587 EMAIL: USSUPPORT@AUTEL.COM FOLLOW US @AUTELTOOLS

BMW’S BFF

You’re lying if you say you’ve never talked to yourself. Seriously—have you never rattled off a story or idea while alone in the comfort of your own car? If you’re of the majority, be forewarned; your car may soon speak back to you. BMW unveiled a talking concept car at the Consumer Experience Show this January, equipped with a digital assistant the OEM has dubbed ‘Dee’—which stands for digital emotional experience. “She’s a digital companion that interacts emotionally with you,” says BMW. “The ultimate companion, Dee has a voice full of personality that can also be heard outside the vehicle. She intelligently responds to you and the surroundings.”

FEELINGS ON FIRE

In the latest installment of the Florida Man Chronicles, an inebriated culprit turns himself in for “doing stupid things.” After departing a local bar on December 7, police say an intoxicated Florida man sauntered down the street to find an unaccompanied police patrol car— which he promptly set on fire, using garbage from a nearby dumpster and a lighter. He fled the scene, but returned several minutes later to confess his crime, citing he “felt bad” and that he does “stupid things when drinking.” The arsonist maintains that he merely happened to choose a police car to set ablaze; “it may as well have been a minivan,” he told police.

CHEESED

You’ve probably heard of people leaving notes to indicate a driver’s poor parking skills. Some drivers even keep a handy business card-sized stack in their glove box to exercise their entitlement everywhere they go. Others take it one step further and make threats—cheesy ones, at that. A driver was left surprised when they returned to their vehicle to find a note threatening to “line [their] car with slices of cheese” if they ever dared to take up two spots again. While this magazine cannot confirm whether the recipient of said note was lactose intolerant; we can assume they were based on the angered reaction.

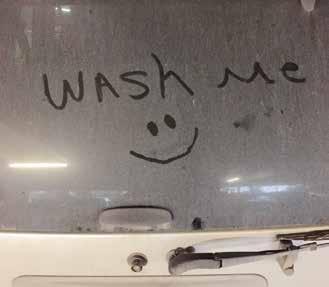

DIRTY DEEDS

A U.K. car leasing company issued a seasonal warning last month, cautioning drivers to think twice before scrawling ‘Wash Me’ on salt-stained vehicles this winter. Select Car Leasing says U.K. offenders could be prosecuted for their pranks. “Some motorists go to great lengths to protect their paintwork. There’s a whole car detailing scene where enthusiasts swap advice on how to clean, polish and protect the paint on their pride and joy,” said Graham Conway, the company’s managing director. “Swirling your finger in that muck can scratch the paintwork—especially if you catch your fingertip as you write.” Further, if enough pressure is applied while the wrongdoer leaves their message, a “ghost of a word” can be left on the paint, “even after the owner washes the car,” stressed Conway.

26 COLLISION REPAIR COLLISIONREPAIRMAG.COM CAN YOU BELIEVE THIS?!

A whole bunch of British seven-year-olds could face federal fees if people actually start pressing charges.

Settle down. There are far worse threats than those that result in free cheese.

Your car could soon be your best friend. BMW wants to make ‘Dee’ your ultimate companion.

⊲ Vast Inventory Across Our National Network ⊲ Fast and Safe Local Deliveries ⊲ New & Reconditioned ⊲ Industry Leading Safety Standards ⊲ Competitive Prices ⊲ Quick Order Turnaround ⊲ Knowledgeable Staff Wheels • Monitors tire pressure to prevent tire damage. • TPMS light illuminates when tires are underinflated 25% or more. • Automotive grade battery to handle severe weather conditions. • Match OE sensors in function and design. • No TPMS programming tool required. TPMS 69 SKU’S - COVERING 1,579 1998-2021 MAKES & MODELS TIRE PRESSURE MONITORING SYSTEM Don’t Forget! FIND THE WHEELS YOU NEED WITH KEYSTONE AUTOMOTIVE

For more information or to place an order call 866-LKQCorp | 866-557-2677 or visit us at lkqcanada.ca

Best Quality In The Industry

CARSTAR Peterborough’s vision for a united industry ON THE COVER

28 COLLISION REPAIR COLLISIONREPAIRMAG.COM SUM

THE OF ALL PARTS

Story by MAX REID

The truly progressive business leaders recognize our industry for what it is—a living, breathing organism that demands the proper function of all of its parts to achieve unified goals.

That being said, if you view your current relationship with the collision repair industry as more exploitive in nature, we couldn’t hold that against you either.

Shop owners across Canada are feeling caught in middle of competing interests of banners and insurance companies, often with less and less reward trickling down to the franchisee level.

Jim Shirtliff, owner of CARSTAR Peterborough, has touched nearly every angle of the automotive aftermarket, having put in time working for insurers as an independent appraiser, managing a dealership collision centre, in addition to being a licensed collision technician.

If there is anyone who knows how to make the many tentacles of our industry function more like the intelligent cephalopod they are attached to, it would be Jim.

“I’m a second-generation owner, just like many other people in this industry. I started in a family business, went to work on the insurance side as an appraiser for several years, and then started with CARSTAR as a franchisee 20 years ago,” Jim said in a chat with Collision Repair.

I’m a second-generation owner, just like many other people in this industry. I started in a family business, went to work on the insurance side as an appraiser for several years, and then started with CARSTAR as a franchisee 20 years ago

ON THE COVER

ISSUE 22#1 | COLLISION REPAIR 29

Jim Shirtliff, owner | CARSTAR Peterborough

CARSTAR Peterborough’s big beautiful sign sticks out at one of the first things you’ll see when driving through the city’s residential east end.

From a humble beginning as an apprentice at his dad’s shop in Mount Albert, Ontario, the automotive world was what Jim knew well, so he followed the path of collision repair wherever it took him, leaving him with countless learned lessons along the way.

“I was a dealership bodyshop manager for several years, which was a great learning experience as I was educated about budgets, forecasts, income statements, payroll, hiring and firing; I came into that culture 40 years ago,” he said.

“I took the 3M ARMS management course in the early 80s, which was a great eye-opener into how to run an efficient and profitable collision repair business”. Jim has also been actively involved in continuous education in lean management principles under the direction of industry leader, Mike Anderson.

“Mike Anderson has been a great mentor over the years, and I appreciate his guidance immensely. I proactively manage our business with KPIs and not opinions or emotions.”

According to Jim, the collision industry currently sits in a “crisis situation” where the demands on insurer-affiliated repair facilities are heavily outweighing the ability of these shops, banner or otherwise, to actually meet these high production numbers.

30 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

The team at CARSTAR Peterborough may be small, but the smiles they deliver to customers every day are many.

“You can see that from the lead times when you’ve got shops booking two to four months out,” said Jim.

“You have shops now telling insurance companies to remove them from their DRP because they can’t service them, due to lack of staff—that’s the first time I’ve ever seen that in my career. If we can offer a $5,000 signing bonus and not even get an applicant, is that not telling you that something is wrong?” he said.

Jim feels that, were the collision industry to have an equal seat at the table when decisions are being made, shops would be able to better advocate for and against larger business decisions that would trickle down to affect the operation of high volume shops.

“I’m not blaming insurance companies; we are all responsible for the current state of the industry. Banners, bodyshops and insurance companies are all responsible for where we are today. Again, collaboration from all stakeholders is required to move forward, sound economic principles are required to ensure sustainability.”

Having had a direct hand in all these various avenues of the aftermarket, Jim recognizes the value that would come from a unified group who could advocate for the industry, in a way that would be comparable

to institutions like the Financial Services Regulatory Authority of Ontario, which is in place to support the insurance industry and the consumer.

The industry needs a national association— it needs a voice. The insurance industry has the FSRAO, who they can approach for rate increases if they are not making a reasonable ROI. The collision repair industry does not have this regulatory body.

“We’ve been talking about this at every CCIF for the past 15 years and nothing changes. Well, we’re here now. Now we are dealing with the inactivity,” said Jim. “If we don’t work in collaboration, we’re not going to solve this problem. We can’t solve this problem while residing in silos.”

In fact, Jim says that some of his most valuable professional experiences have been simple conversation with fellow shop owners, from within and without his own banner.

“I love 20 Groups. I’ve learned the most in my career through my peers in 20 Groups,” said Jim.

In these groups, Jim has the ability to compare and contrast processes with other shop owners in order to make adjustments at his own business, whether it be a new piece of equipment he ought to buy or better practices for customer relations.

What can’t be solved through just conversation, however, is how insurance companies choose to do business.

“I hear every day [from insurers], ‘Oh, we don’t pay for that.’ Well, if it is a required operation to restore the vehicle to pre-loss condition, the repairer should be compensated. This approach to the approval of the estimate needs to stop; not compensating for operations that the technician must perform is another reason we cannot attract or retain technicians; no one works for free.”

“If insurance companies are not making a sustainable return on their investments, they may need to look internally at their administrative overhead and the actuarial practices underwriting the risk?

These persistent financial squabbles with the insurance industry do little to improve the actual day-to-day reality of modern bodyshop’s who are attempting to complete more and more work with fewer and fewer staff.

“I think there is a monumental lag between the perception of insurers and their underwriters to the reality of what’s happening on the floor of a modern collision repair facility,” he said.

“I think a lot of that comes down to the financial ability of the shop to be able to afford to supply that training. Flying technicians

ISSUE 22#1 | COLLISION REPAIR 31 ON THE COVER

When it comes to customer service, everyone at CARSTAR Peterborough lends a paw.

Having recently scaled down from working as an MSO, Jim says operating on a smaller scale outside the GTA takes some getting used to.

to the U.S. or to Europe for OEM training is a considerable cost to any shop; the days of bodyshops being able to afford to do that are over, and yet it is a necessity.”

When it comes down to CARSTAR Peterborough specifically, however, Jim appears to have most of all he needs within his 6,000 square-foot facility in the city’s east end.

Having come up in the bustle of the Greater Toronto Area, Jim says he is still getting attuned to the slower pace of life out in Peterborough, but is proud to consider the city his home, five years following his purchase of the facility, and takes active steps to give back.

“We support all the local sports clubs, including the Peterborough Petes, Peterborough Lakers, in addition to multiple charities. We’re very active in the community and my wife was born and raised here,” said Jim.

Much has changed since he first started out at his father’s shop in Mount Albert, but there are few people with a keener view on the collision industry than Jim.

It feels safe to say that whatever new industry challenges present themselves, Jim will have some amount of prior experience or critical insight that will guide him and CARSTAR Peterborough toward a long and successful future in their community.

32 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

Pump Up Your Business with GoMobile Tires!

Attention Auto Recyclers!

Get ready to take your business to the next level with the ultimate mobile tire solution. Join our team of successful franchise owners and offer your customers convenient and reliable tire services right at their doorstep. Go with the GoMobile brand, co-brand, or go on your own. Raise awareness of your company and your brand by turning the fully-equipped and modern Mercedes van into a mobile billboard.

Our cutting-edge mobile tire trucks are equipped with state-of-the-art technology, ensuring efficient and accurate services. Our highly trained technicians provide quality services in a timely manner, making us the leading mobile tire company in the industry.

As a franchise owner, you’ll benefit from our established brand recognition, comprehensive training, and ongoing support. With our proven business model and low startup costs, you can be up and running in no time.

You know the business. Now expand on it. Take it on the road.

Email Us william@gomobiledetail.com Call Us Anytime 904-844-5280 For more info visit gomobiletires.com Don’t miss this exciting opportunity to join a rapidly growing industry. Contact us today to learn more about becoming a GoMobile Tire franchise owner!

BACK AT

BUDDS' BUDDS'

Annual holiday pig roast returns in support of Sam

The iconic Budds’ Collision Pig Roast was back in action this year following two consecutive years of cancellation, courtesy of COVID-19.

The wintry weather did little to dampen holiday spirits as the industry showed up to celebrate. A lavish food spread was set up—as per usual—featuring desserts, mini quiches and an oyster bar.

34 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Photos by GLORIA MANN

The Oakville, Ontario-based company has been unable to host its iconic event for two years.

The event was held in memory of Bonnie Budd and Sam Piercey and run in support of the Sam Piercey Foundation, which launched in 2016 and supports young apprentices in the collision repair industry. The foundation is in honour of the late Sam Piercey, general manager of Budds’ and a long-time columnist for Collision Repair magazine.

Piercey Foundation

Dennis Rodrigeus, technician at Budds'.

ISSUE 22#1 | COLLISION REPAIR 35 EVENTS

Oysters are a given at the holiday event.

Mike Beier, Consolidated Collision Services (CCS); Bing Wong, Collision Builders; Craig Kirby, CCS.

Tom Langton, Consolidated Dealers; Jeb Aarts, BASF; Don Teevens, Consolidated Collision Services and Tony Ionno, BASF.

The event is a Christmas staple for the industry and all ages are welcome to attend.

36 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Gloria Mann, Media Matters; Joe DaCunha, Allstate.

The last time Budds' hosted its iconic Pig Roast was 2019. Guests were more than thrilled to be back at the annual affair.

Far left: J.R. Martino, event host and general manager of Budds'.

Melissa and Bing Wong.

Allie Wood, an estimator at Budds', was responsible for doling out raffle tickets—so if you lost, she's responsible.

ISSUE 22#1 | COLLISION REPAIR 37 EVENTS

Juan Saurez, technician at Budds', and friends.

It wouldn't be a Budds' Pig Roast without the photo booth and goofy props.

Larry Jefferies, Collision Builders.

The Piercey family was there to show their support; Sam Piercey's son Joe Piercey, is on the far right.

Jeff Moore, TD Insurance; Todd Noble, BMW Group/Dekra Canada; Andrew Neufeld, Collision Repair Experts.

WHAT TO WATCH

Five trends to track in 2023

By ALLISON ROGERS

By ALLISON ROGERS

New year, new problems to face. Or you could try your hand at being optimistic and taking initiative to educate yourself on the road ahead. Either, or.

Using reports and information gathered from collision industry analysts and facility owners, Collision Repair mag has collected a list of five trending topics to keep an eye on in 2023. While many of these trends are topics we’ve been centred on for years, plenty of industry members foresee 2023 as the year where progress begins. See our findings on the following pages.

“As shorter-term roles become a norm for today’s workforce, employers can no longer afford to discount potential candidates based on the length of time they’ve stayed in previous roles. Compared to how long they stay in a job, skills, aptitude and cultural addition are all better indicators of success in a job today.”

1HELP, WE’RE HIRING!

The story goes like this: the young technician, upon completing their training at your facility under your staff, seeks a new opportunity and moves on from your business. Many collision centre owners will label this type of employee as ungrateful; after all, it was the businessowner that sponsored and trained them.

The mistake made by the owner? Assuming the newly licensed technician would stay put for at least a little while after training was complete.

“Many of today’s workers regard job hopping as the new normal,” believes Paul Wolfe, senior vice president of human resources for job posting website Indeed.

In fact, research from Indeed actually indicates 24 percent of Canadians have a positive view of the phenomenon dubbed “job hopping”; they say it's given them the opportunity to learn new skills in short periods of time. On the contrary, 73 percent of Canadian employers admit to passing over candidates because of their extensive job history; 27 percent of employers say they have a negative view of job hoppers.

As noted by Wolfe, younger employees tend to place importance on workplace culture, though financial compensation obviously remains an important factor. According to the Harvard Business Review, the main reasons employees leave their roles lay in their feelings about their boss and management style; a lack of growth or lack of opportunity for growth or in offers of higher-paying options.

If you seek to retain a young staff member, make sure they know it. While financial bonuses and pay increases can be used to communicate your appreciation for their commitment to your business, be sure you foster a workplace where “props” are also a common occurrence.

38 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY INSIGHTS

BACK IT UP

As a result of a leaner workforce and ongoing parts delays, many facilities are recording higher-than-average cycle times. Plenty of collision repair centres across Canada have complained about booking repairs weeks out in the latter half of 2022. Add staff shortages to the mix and the equation checks out.

In many cases these backlogs are unavoidable— you can’t wave a magic wand and make a parts order appear—but there are always steps to take.

There are backlogs in more areas than supply and materials; according to data from claims company CCC, claimants took longer to report losses in 2022, with the average driveable loss taking 8.6 days to report in 2022 (from January to September) and the average non-driveable claim taking 4.4 days to report between January and September 2022. CCC data says it took the average driver 7.6 days to report vehicle damage in 2022.

The time from assignment to when the estimate is completed and uploaded also increased, though photo estimating did ease the situation. According to CCC and its 2023 trends report written by Susanna Gotsch the technology allowed for faster initial appraisals on losses.

“Photo estimation continues to see strong adoption,” wrote Gotsch.

From the Romans Group's perspective, such advances in technology will add delays as the new methods are rolled out to the industry. The company notes in its most recent whitepaper that “insurtech claims processing operating models [that] reinforce insurers’ preferred business economics, which are frequently at odds with the OEM repair model…will continue to have a material impact and influence on the collision repair industry.”

DROP IT LIKE ITS HOT

Some industry sources also note a marked departure from direct-repair programs (DRPs) in 2022. The Romans Group notes a “nascent movement” by several multi-location operators, away from DRP relationships while opting into OEM certification preference models.” Others cannot walk away from guaranteed work as easily; MSO scale “remains a competitive advantage,” notes the Romans Group.

Tensions regarding labour rates are also on the rise, with the collision repair industry poised to “aggressively pursue labour rates with insurers.” The industry is also hopeful insurer premium increases will allow for progress.

ISSUE 22#1 | COLLISION REPAIR 39 INDUSTRY INSIGHTS

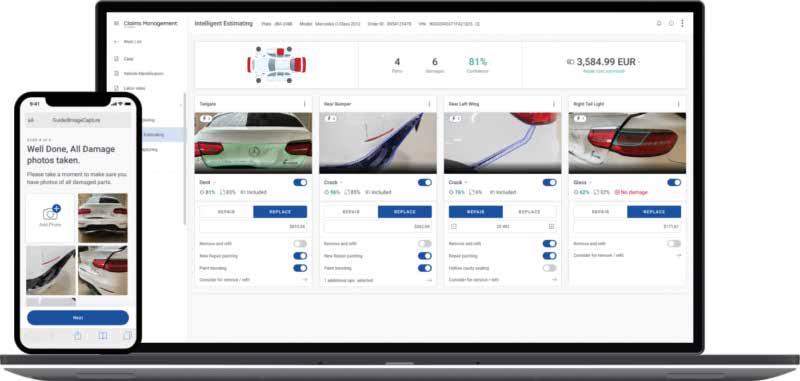

Claims platforms like Solera’s Qapter now offer AI-driven estimates.

2

Cutting ties with certain industry partner was a trend noted by the Romans Group.

3

MIND THE GAP

There are knowledge gaps in the collision industry—and it’s not always the average collision centre owner or their staff dropping the ball.

A recent survey conducted by Collision Repair showed results indicating OEMs often fail to provide education where artificial intelligence is concerned. Many still cite confusion on the topic, saying they know little to nothing about how the technology works or how it will affect their roles in the future.

Artificial intelligence, telematics and advanced driver assistance systems (ADAS) are three tech topics boggling minds in 2023.

Plenty of claims today are incorporating artificial intelligence (AI) technologies. Solera’s Qapter platform has built-in AI capabilities, detecting damaged parts and recommending repair options from photos. Pro Spot demonstrated automatic welders, dustless sand systems and more at SEMA 2022. There’s no need for production floor folks to bite their nails yet, though; robots are far off yet from stealing your jobs.

ADAS is not a new concept, says John Marlowe of Level5Drive. In fact, Google will tell you the first piece of advanced driver safety tech came in the 1950s in the from of anti-lock braking systems. Nowadays, they’re a tad more advanced.

There is one thing the average collision repair will admit around ADAS: that they don’t know what they don’t know. In a nutshell, a considerable amount of industry learning is needed—both on the repairer and insurance sides.

Luckily for anyone scratching their heads on these topics, we have two articles in this very magazine—one on artificial intelligence and a conversation with ADAS experts. Check the contents page for further information.

COMING TOGETHER

In the face of the above-outlined challenges (and others not mentioned on these pages), many industry analysts and experts are confident that consolidation will continue. The Romans Group’s five-year industry forecast predicts that Canada’s top-three consolidators—Fix Network, Driven Brands and CSN—will continue to “aggressively grow their business while maintaining their significant market share lead.” The Group predicts the top-three consolidators will grow from 18.4 percent market share in 2021 to between 24 percent and 28 percent of the market by 2026.

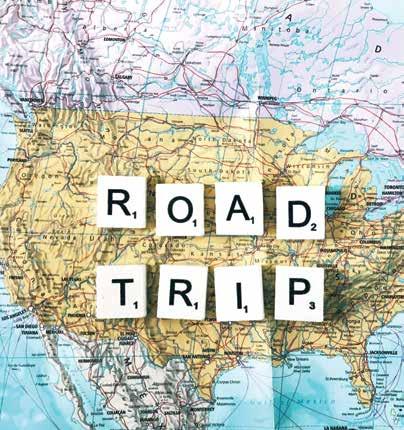

The Romans Group estimates continued United States-Canada trans-border market entrances, as reflected by CSN’s merger with 1Collision; ProColor’s U.S. market entry and the Lithia Group’s acquisition of Pfaff Automotive Dealer Group.

One of the primary goals pursued by large consolidators is the ability to offer a one-stop-shop, or repair network wherein all bases are covered, including glass, express service, total loss processing, advanced repair, mechanical repair, diagnostics and more. The Romans Group suggests these groups will market the strength of these models to insurers.

Further, Romans predicts private equity to continue its displayed interest in the automotive aftermarket.

“Despite the growing market share of the larger platforms and segments tracked and analyzed, there is still a long tail of smaller independent repairer fragmentation in the market, which will be the basis for the next wave of industry contraction and consolidation,” the Romans Group wrote in its recent whitepaper.

40 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY INSIGHTS

4

Knowledge gaps aren’t always the repairers’ fault.

5

Some consolidators are predicted to take cross-border road trips in future acquisitions, like trends of recent years.

Older Canadians are the most likely to leave their jobs for a five percent raise, says the 2022 Canadian Workplace Culture Report.

Adjustable Brightness. Uniform Light Distribution.

Adjustable Brightness. Uniform Light Distribution.

SATA Special Edition 2021

SATA trueSun – T he Daylight Solution

SATA trueSun – T he Daylight Solution

The SATA trueSun daylight solution has a wide colour spectrum and reproduces colour tones true to original: The even light distribution over the illuminated surface reliably helps bodyshops to find the right colour and to avoid wrong decisions and thus extra work.

The SATA trueSun daylight solution has a wide colour spectrum and reproduces colour tones true to original: The even light distribution over the illuminated surface reliably helps bodyshops to find the right colour and to avoid wrong decisions and thus extra work.

The continuously adjustable light intensity remains constant over the entire battery life. Even avoiding one rework covers the purchase cost for this high-quality product.

The continuously adjustable light intensity remains constant over the entire battery life. Even avoiding one rework covers the purchase cost for this high-quality product.

Best near daylight reproduction of different color shades

Uniform distribution of the light intensity across the entire light cone

Best near daylight reproduction of different color shades

Battery life approx. 70 minutes at full light intensity

Uniform distribution of the light intensity across the entire light cone

Uniform light intensity - independent of the battery charge level

Battery life approx. 70 minutes at full light intensity

Charging cycle time of 50 minutes only

Uniform light intensity - independent of the battery charge level

Infinitely adjustable light intensity

Charging cycle time of 50 minutes only

Built-in charging condition display

Infinitely adjustable light intensity

Near daylight reproduction of effect pigments

Built-in charging condition display

Near daylight reproduction of effect pigments

Coating flaws such as mottling can be easily detected

Coating flaws such as mottling can be easily detected

SATA Canada Inc. 125 Buttermill Avenue Vaughan, ON L4K 3X5 Phone: +1 905 660 1101 Toll-free: +1 844 554 SATA (7282) Fax: +1 905 760 1250 contact@sata.ca www.sata.com SATA Special Edition 2021

www.sata.com/satatruesun

INFO SATA Canada Inc. 125 Buttermill Avenue Vaughan, ON L4K 3X5 Phone: +1 905 660 1101 Toll-free: +1 844 554 SATA (7282) Fax: +1 905 760 1250 contact@sata.ca www.sata.com

www.sata.com/satatruesun

INFO

MANAGING THE MACHINES

Meet your new colleague—artificial intelligence

By MAX REID

By MAX REID

Cutting-edge artificial intelligence technology has very quickly found a place in nearly every corner of the modern collision repair facility.

For nearly every new tool or piece of software you purchase, somewhere in the instructions is likely a phrase that reads “powered by Artificial Intelligence,” “driven by machine-learning,” or something along those lines.

It sounds impressive, but how many of those currently working in the collision repair field understand what these terms mean?

The average repair tech, or manager for that matter, could be forgiven for not fully grasping how the 15-year-old computer on their desk is not an artificial intelligence, but the colour-matching app on their phone is.

While the nitty gritty details of how this technology works have not traditionally been within the purview of a hammer-wielding

body technician, it has become crucial that the aftermarket repair industry get informed, or risk losing a seat at the table when wider vehicle data decisions are made.

Professor of robotics and computer science at Columbia University, Dr. Hod Lipson, said it well at Fix Network’s Fall Conference in September 2022, pointing out to a room of aftermarket executives that “the automotive industry has been changed by robotics in the past—it was the first industry to adopt robotics at full-scale—and it is going to be transformed again.”

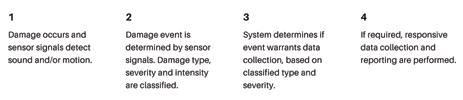

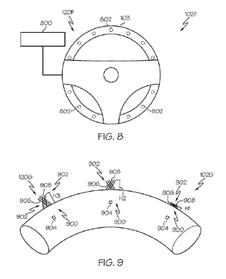

To put it very simply, machine-learning is the process by which an AI is “taught” how to operate, and within what parameters, as determined by an algorithm. Different algorithms make use of different methods to compile data.

For example, a decision-tree model gains information about a piece of data by having

it pass through a series of gates, or forks in the decision tree, that answer a certain question about the data, narrowing the possible results as it goes.

Other common algorithms include basic rules-based “if/then” models, where an AI makes binary decisions based on individual criterion being met; and cluster algorithms, where data with similar characteristics are grouped together and the AI decides on the most suitable result, often on a majority basis.

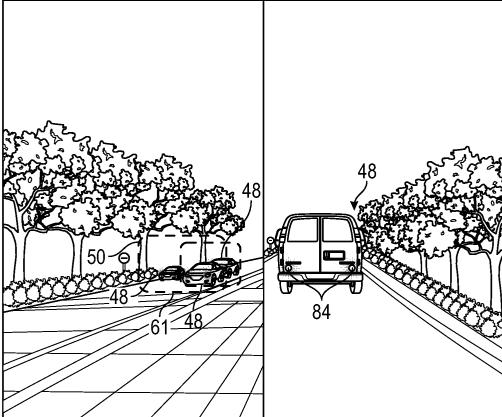

From here, it can be easier to see how these algorithms present themselves within a vehicle. For example, a vehicular camera system may use an “if/then” rule system to make decisions that affect whether a safety system activates. “If the object passing the camera is a leaf, then ignore.” Versus, “if the object passing in front of the camera is a pedestrian, then engage automatic brakes.”

According to Lipson, this advancement in

42 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY

the ability of AI to actually recognize the objects they see is actually quite recent.

“They could detect objects and avoid them, but we don’t just detect objects. We understand what us and how other cars is around are likely to behave,” he said

“For the first time, cars can finally understand what is around them.”

Think of machine-learning like a government and the algorithms as the building in which it operates. If you want a democracy, you need a parliament, and parliaments have an understood process by which they function (i.e., debates, voting, representation).

Every form of government has its possibilities and its limitations, and it is important that the collision repair industry get a grasp on what serves them best.

A spokesperson for Blackberry’s automotive data platform, IVY, in conversation with Collision Repair, said they consider the ideal of AI for drivers as for it to function as a “digital butler” within the vehicle.

Modern driver-facing, AI-powered ADAS helps

ISSUE 22#1 | COLLISION REPAIR 43 TECHNOLOGY accuvision-3D.com arslanauto.com Contact your distributor or Call (800) 465-8575 #60-TM736 ACCUWELD® SINGLE TORCH PULSE MIG WELDER #60-TM742 ACCUWELD® 2 TORCH PULSE MIG WELDER #60-TM750 ACCUWELD® ARC DENT PULLER SYSTEM #60-TM743 ACCUWELD®3 TORCH PULSE MIG WELDER Smart Spot welder Automatic setting of parameters Water cooled for hi productivity 22 ft. long cable, No EMF emissions Output 14,000 Amps, 450 daN or 700 daN Input 50 Amps, 208-240V, 3 Phase Approved by OEMs 3680 model wi-Fi, enabled for factory Updates and diagnostics AUTOMATIC, INVERTER RESISTANCE SPOT WELDERS 3664 & 3680

To put it very simply, machine-learning is the process by which an AI is “taught” how to operate, and within what parameters, as determined by an algorithm. Different algorithms make use of different methods to compile data.

“[The automotive industry] was the first industry to adopt robotics at full-scale—and it is going to be transformed again.”

– Dr. Hod Lipson

Professor of robotics and computer science, Columbia University

operate features like adaptive cruise control, automatic emergency braking, hands-free driving, as well as predictive traffic reporting.

Extending beyond the individual driver and into the aftermarket, they said that Blackberry’s AI is capable of forecasting maintenance repairs for entire fleets of vehicles, and thereby offering fleet managers a leg-up in efficiency, even down to the local level.

“Some markets may require more brake changes; some markets need less. Some people do more city driving; some people do more highway driving,” they said.

“Across the vehicle, these maintenance and repair elements can actually be more targeted and focused, versus based on a rudimentary estimation.”

When put toward our readers, a common thread echoed throughout a recent Collision Repair survey voiced concern over the idea that an AI can effectively estimate repairs, with many respondents claiming that given the many tiny exceptions and nuances involved in modern collision repair, no intelligence could fully replace the learned eye of a human estimator.

While true to an extent, the issue with that line of thinking, however, is that by the nature of a machine-learning intelligence, it must be continually taught and fed new data so that

it may expand its knowledgebase and carry out correct estimates faster and more often. Essentially, the level of machine intelligence we currently sit at today—approximately 95 percent as powerful as a human brain, according to Lipson—must learn and make mistakes the same way that an up-and-coming human estimator might.

them best, as there is no magic computer program that will make your shop run on autopilot, nor is it realistic to attempt to opt out of AI altogether.

Part of the impetus behind software like Blackberry’s IVY is to provide more avenues for the monetization of your vehicle data for the profit of OEMs—the company is forthright about that on their website.

As readers of our last issue will recall, the fight for vehicle data rights for repairers is a hard-fought battle and automakers are not making it any easier for our industry’s technicians to access the information they need.

The difference lies in the fact that the AI will get a handle on the job far faster and with greater efficiency than one of those flesh-covered desk jockeys. After a while, the AI requires little more than a handler to keep an eye out for potential outlier data.

With these variables in mind, shop owners must decide for themselves where in their shop an AI-powered system would serve

Middleware developers like Blackberry and their IVY platform are actively making it easier for OEMs to funnel vehicle data back in-house for the express purpose of monetization.

This is why it is imperative that whether it be the vehicles you work on, or the tools you equip your shop with, if you see that “powered by Artificial Intelligence” sticker somewhere on it--do some research, follow the money and stay knowledgeable as the right to repair movement grows ever more complex.

44 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY

Dr. Hod Lipson, professor of robotics and computer science at Columbia University, speaking at the Fix Network National Conference in Quebec City, Quebec, September 2022.

Essentially, the level of machine intelligence we currently sit at today— approximately 95 percent as powerful as a human brain—must learn and make mistakes the same way that an up-andcoming human estimator might.