Volume 22, Number 2, 2023 THE TOP FIVE TRAITS OF RESILIENT LEADERS Save money on modern repair tools ECONOMICAL EQUIPMENT GM Marcus Newman makes Capital Collision shine ARE PROFIT SHARING PROGRAMS RIGHT FOR YOUR BUSINESS? MORE INSIDE Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 86 John Street, Thornhill, ON L3T 1Y2 www.collisionrepairmag.com EXPERIENCE BEFORE AGE

Unlock more opportunities for profit at your body shop. Introducing 3M™ RepairStack™ Performance Solutions. Several body shops across the country have already successfully implemented the innovative 3M™ RepairStack™ Performance Solutions. It’s time to take your collision repair business to the next level and benefit from our new hardware and software inventory management platform. *Based on a review of body shops that used the 3M™ RepairStack™ Billables Invoicing software for at least 60 days between Oct. 1, 2021 – Jun. 30, 2022. 3M 2022. All rights reserved. 3M and RepairStack are trademarks or registered trademarks of 3M Company. All the products shown inside the 3M™ RepairStack™ Performance Solutions storage cabinet are sold separately. All products shown inside the cabinet are for illustration purposes only. The 3M™ RepairStack™ Performance Solutions storage cabinet works with both 3M and non-3M products. Unauthorized use prohibited. All other trademarks are property of their respective owners. Please recycle. Printed in USA. Keep track to be on track. Discover now at repairstack.com. “The ability to … track and, more importantly, provide an invoice and receive reporting based on that specific repair in regard to materials used is critical to the profitability of body shops.”

Anderson,

Collision

“The main reason for implementing 3M™ RepairStack™ was to

profitable

Join the top 10% of 3M™ RepairStack™ repair facilities that recovered over $1,000 in repair materials per month* and get paid for costs you never knew were recoverable. For more information or to schedule a demo, please scan the QR code to connect with a 3M digital expert.

Mike

President and Owner of

Advice Group

become

with

my

paint material

and that happened right away. It’s cut my bill in half!” Adan Ibarra, Owner of Leading Edge Collision

50 FEATURES DECISIONS, DECISIONS

With today’s price tags and pressures, equipment purchasing can quickly become a headache—but there are ways to alleviate pressure.

66

FIVE TRAITS OF GREAT LEADERS

Dr. Robyne Henley-Dafoe describes the common traits and practices of powerful leaders.

ISSUE 22#2 | COLLISION REPAIR 3 CONTENTS VOLUME 22, ISSUE 2, 2023 CONTENTS Marcus Newman of Mount Pearl, Newfoundland’s Capital Collision sure knows how to turn a ship around. Hear how the team prospers on in this issue’s cover story. ON THE COVER THE TOP FIVE TRAITS OF RESILIENT LEADERS Save money on modern repair tools ECONOMICAL EQUIPMENT GM Marcus Newman makes Capital Collision shine ARE PROFIT SHARING PROGRAMS RIGHT FOR YOUR BUSINESS? MORE INSIDE www.collisionrepairmag.com EXPERIENCE BEFORE AGE

26 32 38 CCIF Toronto, through Collision Repair’s camera lens. Industry reps in Saskatchewan show up for the SAAR Spring Conference. See our exclusive scrapbook!

4 COLLISION REPAIR COLLISIONREPAIRMAG.COM CONTENTS CONTENTS 70 72 74 76 78 98 06 68 PUBLISHER’S PAGE By Darryl Simmons TOM’S TALES By Tom Bissonnette GROUND RULES By Meghan McEwan EYES ON ADAS By John Marlowe WHO’S DRIVING By Jay Perry LET’S TALK TRAINING By Stefano Liessi AN INTRICATE WEB By Venessa Di Vito LAST WORD By Allison Rogers COLUMNS 08 82 92 94 12 PEOPLE ON THE MOVE Familiar faces, new roles! NEWS-IN-BRIEF Bit-sized updates from across the industry. REGIONAL NEWS Local news from coast to coast. RECYCLING NEWS The latest news processing through the recycling sector. TOWING NEWS Your hook-up for the latest towing industry news. DEPARTMENTS HAVE YOUR SAY. SUBSCRIBE TODAY! We welcome your comments on anything you see in Collision Repair magazine. Send your feedback to editor@collisionrepairmag.com. YOUR ONLINE SOURCE Canada’s collision repair information resource. New articles and top news stories daily. For more info visit collisionrepairmag.com 58 62 Profit sharing—is it a fit for your team? Find out in this special financial focus. What’s out there for education on EVs? We asked the industry for their opinions on electric efforts. ENTER PETS OF THE BODYSHOP AND YOU COULD WIN A $25 PETSMART GIFT CERTIFICATE 53 Details on page

SRSSIDEAIRBAG COUSSINGONFLABLELATÉRAL

TOAVOIDSERIOUSINJURYORDEATH: •Donotleanagainstthedoor. •Donotuseseatcoversthat Seeblocksideairbagdeployment. owner’smanualformoreinformation.

WARNING AVERTISSEMENT

POURÉVITERDESBLESSURES

GRAVESOUMORTELLES: •Nevousappuyezpascontrelaporte.

•N’utilizezpasuncouvre-siège quipeutbloquerledéploiementdu Voircoussingonflablelatéral.lemanuelduconducteurpour deplusamplesrenseignements.

CONTROLVEHICLEEMISSIONINFORMATION

Fuel: Gasoline

Conformstoregulations: 2015

Californiaclass/stds: PC/ULEVqualified

U.S.EPAclass/stds: LDV/TIER2

Group: FGMXV01.80111.2L

Evap:SFI/HO2S/TWCFGMXR0095805

TIREANDLOADINGINFORMATION

Thecombinedweightofoccupantsandcargoshouldneverexceed352kgor776lbs.

SEEOWNER’S MANUALFOR ADDITIONAL INFORMATION

VEHICLEEMISSIONCONTROLINFORMATION

Conformstoregulations:2016 MY

U.S.EPA:T2B4 LDV

VEHICLEEMISSIONCONTROLINFORMATION

Conformstoregulations:2016 MY Not for sale in states with California emissions standards.

FEDOBDII

TWC/HO2S/WR-HO2S/CAC/TC/DFI

2.3L-Group:GFMXV02.3VJW

Evap:GFMXR0125NBV

Fuel:Gasoline ABZ

California: Not for sale in states with California emissions standards.

Noadjustmentsneeded.

U.S.EPA:T2B4 LDV

TWC/HO2S/WR-HO2S/CAC/TC/DFI

Fuel:Gasoline ABZ

Noadjustmentsneeded. FEDOBDII

2.3L-Group:GFMXV02.3VJW Evap:GFMXR0125NBV

VEHICLEMFD.BYFORDMOTORCO.INU.S.A. DATE: 01/03 GAWR: 2735LB 240 kPa/35 REARGAWR: 3325LB 1508KG P235/70R16SL 16X7.0J GVWR: 5880LB/2667KG WITHTIRES WITHTIRESRIMS PSICOLD TIREANDLOADINGINFORMATION TIRE SIZE COLDTIREPRESSURE 303kpa 44psi 303kpa 44psi 303kpa 44psi Thecombinedweightofoccupantsandcargoshouldneverexceed 505 Kg or 1114Lbs. P265/70R17 P265/70R17 P265/70R17 FRONT REAR SPARE SEEOWNERS MANUALFOR ADDITIONAL INFORMATION SEATINGCAPACITY TOTAL 3 FRONT 3 REAR 0 VEHICLE MFD BY: TOYOTA MOTOR MANUFACTURING, GVWR 4233LB GAWR FR 2668LB RR 2668LB THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY , BUMPER , AND PREVENTION STANDARDS IN EFFECT ON MANUFACTURE SHOWN ABOVE . PASS. CAR 00000000000000000 KENTUCKY, INC. 02⁄ 04 VEHICLE MFD. BY HONDAOFAMERICA MFG ’10 THIS VEHICLE CONFORMS TO ALL APPLICABLEFEDERAL MOTOR VEHICLE SAFETYAND THEFT PREVENTION STANDARDS IN EFFECTON THE DATE OF MANUFACTURE SHOWN ABOVE.V.I.N.: 00000000000000000 TYPE:MPV STK A AA5 --NH737M --A --A GVWR 2200KG(4894LBS) TIRESIZE RIMSIZE GAWRF 1155KG (2546LBS)P235/55R18 99V 18X7 1 2J GAWRR

99V 18X7 1⁄2J

1080KG (2381LBS)P235/55R18

Order Labels From Our Easy To Use App Download By Scanning Below! New and Improved ADL App Now Available! APPLE STORE GOOGLE PLAY Auto Data Labels

DATE: EXTPNT: RC: DS0: WB BRK INTTR TP/PS R AXLE TR SPR 114 4 GP K 45 V DB F05 UTC THISVEHICLECONFORMSTOALLAPPLICABLEFEDERALMOTOR VEHICLESAFETY STANDARDSIN EFFECTON THEDATEOF MANUFACTURE SHOWNABOVE. 01/03 VIN:TYPE:00000000000000000 MPV

2735LB AT AT 205 kPa/30 240 kPa/35 1240KG P235/70R16SL 16X7.0J REARGAWR:

1508KG P235/70R16SL 16X7.0J

WITHTIRESRIMS PSI COLD WITHTIRESRIMS PSICOLD F0085T0183 UA 13 3U51B

VEHICLEMFD.BYFORDMOTORCO.

FRONTGAWR:

3325LB

GVWR: 5880LB/2667KG

, OBD:II 00000000 FRONT REAR SPARE 215/55R1697H215/55R1697HT125/85R1699 SEATINGCAPACITY TOTAL 4 FRONT 2 REAR 2

240kPa,35PSI420kPa,60PSI

240kPa,35PSI

TIRE SIZE COLDTIREPRESSURE

(SRS)

VEHICLE MFD .BY: TOYOTA MOTOR GVWR 4233LB GAWR FR 2668LB RR THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY , BUMPER , AND THEFT PREVENTION STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE . PASS. CAR C⁄ TR : 4Q2 ⁄ LA43 ACV30L--CEPGKA A ⁄TM: --01A ⁄ U241E MADE IN U.S.A. 08270 00000000000000000 KENTUCKY, INC. 02 To Visit Our Website SCAN HERE FOR ADDITIONAL INFORMATION ABOUT AUTO DATA LABELS: visit our website at www.AutoDataLabels.com email us at labels@AutoDataLabels.com or call us at (631) 667-2382 4 EASY WAYS TO ORDER LABELS! DON’T RISK LOSING YOUR VEHICLES IDENTITY! ORDER REPLACEMENT VIN LABELS TODAY! Federal Safety Certification (VIN) Label C /TR : 218 FA2 0 AXAA54L– ANZMBA A/TM : -01A ⁄U B 80F MADE IN U.S.A. 512 THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFE TY AND THEF T PREVENTION STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE. 11 /18 VEHICLE MFD. BY: TOYOTA MOTOR CORPORATION GVWR: 2090KG ( 4610LB ) GAWR: FRT. 1150KG ( 2535LB ) WITH 225/65R17 TIRES, 17X7J RIMS. RR. 1150KG ( 2535LB ) WITH 225/65R17 TIRES, 17X7J RIMS E Replacement label: Not from Toyota JTMP1RFV1KD000000 MPV Contact Us : Contact your LKQ/Keystone Local Sales Rep Upload your photos to the Website: www.AutoDataLabels.com Email your photos: Labels@AutoDataLabels.com Use the App: Download the ADL App And Upload your Photos VIN labels contain vehicle-specific safety information. This information is critical for safe operation and proper repair procedures. • Tire Pressure • Gross Vehicle Weight (GVW) • Paint and Trim Codes • Spare Tire Size

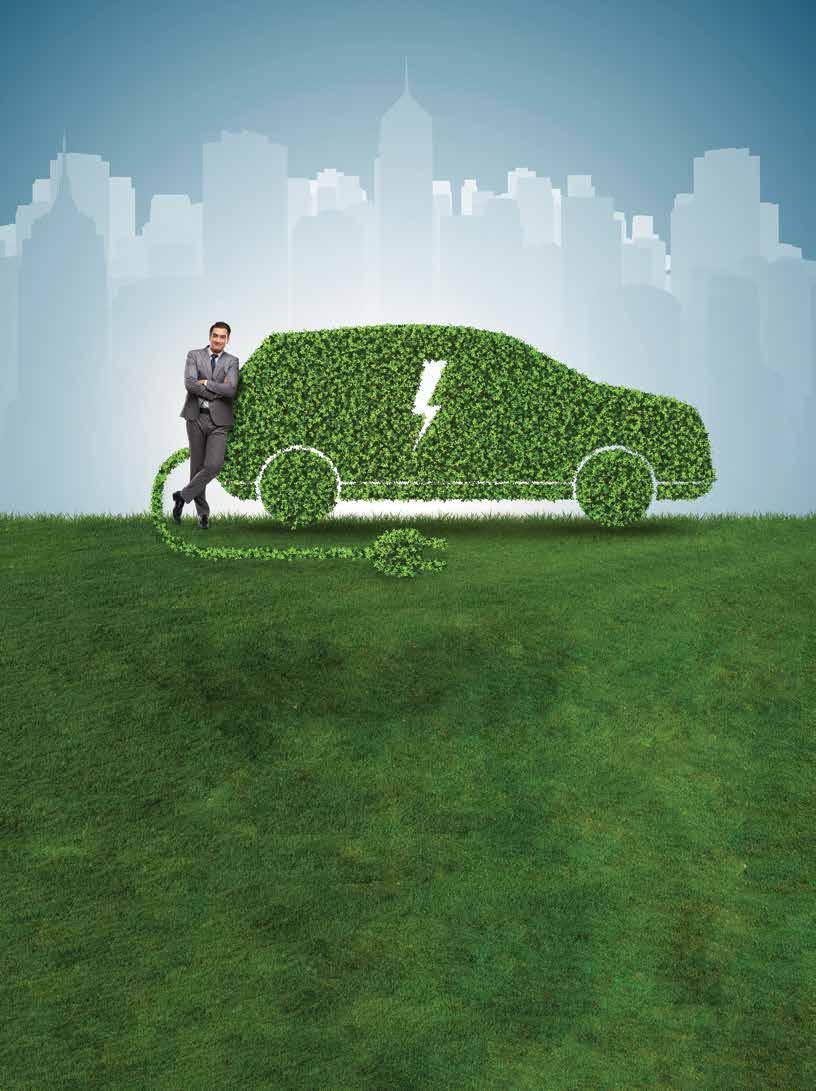

KEEP CURRENT

Lead the charge, power your profits

By DARRYL SIMMONS

The number of electric vehicles (EVs) on Canadian roads is growing. About 95 percent of the Canadian vehicle parc remains gasoline-powered, according to 2022 numbers from Statistics Canada, but small waves are starting. In other words, it’s time to decide whether your collision centre will stay current or fade into obsolescence as we stride into the future.

Stay grounded, though. We still have time before EVs claim the bulk of the average bodyshop’s work mix. And Collision Repair mag is here to help you along the way.

According to Mitchell International’s EV collision insights report from February, EV repairable claims frequencies rose to 2.26 percent in Canada during Q4 2022. Of the EV repairable claims processed through Mitchell in Q4 2022, 45 percent were Tesla Model 3s; 17 percent were Model Ys. Nissan Leafs, Hyundai Kona EVs and Chevy Bolts claimed the remaining 38 percent.

ability to repair EVs is cost. The cost of training, the cost of specialized tools, the cost in subscriptions to specialized procedures, the cost of space on the repair floor. Cost in money, cost in time. Cost, cost, cost. If you haven’t caught on…this isn’t breaking news. Plenty of the challenges noted by readers of our magazine revolve around fair pay and the ever rising of being a credible collision repairer.

To truly prepare for the future of our industry— the future of repairs—we all need to understand EVs, and the niche skills takes to properly repair them. This is not a project that can simply be forwarded to the next person in your chain of command. This is serious business. And it needs to start now.

obstacles in a collision centres’ ability to repair EVs is cost. Cost in money, cost in time.

So, the numbers are rising. More EVs on Canadian roads, more EVs in Canadian repair bays. But who is equipped to repair these vehicles? The shops proudly bearing certification seals like Tesla, yes; but those facilities are still found few and far between in most corners of Canada. Our editorial team ran a survey in February 2023, asking readers whether they felt prepared or supported for the incoming onslaught of EVs. As

we expected, were heard many nos.

In the news-in-brief section of this magazine, you’ll read that Teslas are often sent to salvage at severely premature rates. In a compilation of 120 Model Y vehicles (2022 and 2023 models) found on salvage auction listings, the “vast majority” had less than 160,000 kilometres clocked, Reuters reported in February 2023. In our current state, it’s cheaper to send an often-repairable vehicle to the auctions. There are plenty of reasons why this isn’t right—but most importantly, we’re leaving big dollars on the table.

You’ll see in the later pages of this book that one of the biggest obstacles in a collision centres’

That’s why Media Matters and Collision Repair magazine are launching our exciting Keep Current EV Collision Repair Tour, along with our new annual publication, EV Repair magazine; a Special Edition print publication of Collision Repair’s Guide to Electric Vehicles a complementary website, and a new bi-weekly e-zine addressing the situation.

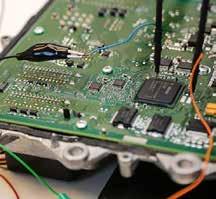

The Keep Current EV Collision Repair Tour will bring expert speakers to discuss the unique challenges and opportunities involved in repairing EVs. Attendees will also see a dismantled display EV, giving them a 3D model of the car’s components.

We’ll be parading this package across Canada, with stops in five major cities. It’s bound to be electrifying! We want you there—visit evrepairmag.com/keep-current-tour or contact james@mediamatters.ca.

Join us in increasing your knowledge and familiarity with EVs. Together, we can ensure that collision repair shops are properly equipped to handle the repair of these advanced vehicles.

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

STAFF WRITERS

Max Reid | max@mediamatters.ca

Kate Ng | kate@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT Wanja Mann 647.998.5677 wanjamann1@gmail.com

AUDIENCE ENGAGEMENT MANAGER

James Kerr | james@mediamatters.ca

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

MARKETING COORDINATOR

William Simmons | william@mediamatters.ca

INTERNS

Nicole Cooper | nicole@mediamatters.ca

Kayleigh Treverton | kayleigh@mediamatters.ca

CONTRIBUTORS

Tom Bissonnette, Venessa di Vito, Jay Perry, Stefano Liessi, John Marlowe, Meghan McEwen

SUBSCRIPTION

Single edition $7.99 One-year $39.95 ( 6 issues)

Collision Repair ™ magazine is published bimonthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing in this publication have been compiled and included with the permission, though not necessarily the endorsement, of the editor, or of independent columnist contributors, and are in no way to be construed as those of the publisher, or as endorsements of them.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL

SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough, ON K9J 3R2

“We acknowledge the financial support of the Government of Canada”

Collision Repair magazine is published by Media Matters Inc., publishers of:

6 COLLISION REPAIR COLLISIONREPAIRMAG.COM PUBLISHER’S PAGE

One of the biggest

PEOPLE ON THE MOVE

JIM SAVAS | SPANESI AMERICAS

Spanesi Americas announced that marketing master Jim Savas of Savas Communications has joined the team and will work as a marketing consultant with the repair equipment manufacturer. Savas has more than 40 years of experience representing industry-leading brands like Hot Rod, MotorTrend and National Speed Sports News, including the past 14 years at the helm of ABRN, Motor Age and Aftermarket Business.

AMIN YOUSSEF | FIX NETWORK

Amin Youssef has joined Fix Network as the new regional vice president for Ontario. Youssef will be tasked with representing the repair banner’s brand in Ontario, as part of his new role within the Fix Network. Youssef has found himself in many corners of the automotive aftermarket over the past 12 years of his career, having most recently worked as a general manager for LKQ, in addition to some time spent at UAP.

STU KLEIN | AIA CANADA

The Automotive Industries Association of Canada (AIA Canada) has appointed Stuart Klein as the organization’s senior director of collision, a newly created position. He will join the association’s senior leadership team, directing AIA Canada’s efforts in the collision sector of the industry. Klein brings more than 45 years of collision industry experience to AIA Canada and previously worked in Fix Network’s training facility in Milton, Ontario. He is an advocate of continuous training and has been involved in industry-youth outreach programs.

8 COLLISION REPAIR COLLISIONREPAIRMAG.COM NEWS MOST RELIABLE PRE 8AM DELIVERY SERVICE Call 1-(800)-387-3199 | cardinalcouriers.com Pre 8am Package Delivery Dedicated Logistics Pre 8am LTL Delivery 6600 Goreway Dr., Unit D Mississauga, ON L4V 1S6

Impact Auto Auctions is Now IAA CA.IAAI.com © 2022 IAA, Inc. All rights reserved. BID. BUY. REPAIR.

THE POWER OF PROCOLOR COLLISION

Customer satisfaction is key to the success of any business. So, too, is establishing standards to navigate operations, support the customer journey and grow. But it’s also important to stay nimble and respond to change. The automotive aftermarket isn’t excluded from this. But it adds peace of mind to know strong relationships with insurers, suppliers and fleet companies are there when you need them most.

For the customer, it’s witnessing dedication to safety and quality that provides peace of mind. Knowing that each member of a service team is qualified provides peace of mind.

A team’s commitment to continuous learning provides peace of mind. It takes an awareness of these principles and a formula to implement them that drives success.

Being considered a choice establishment is an achievement in any industry. Providing personalized service that exceeds expectations makes a brand stand out. Ensuring work quality through warranties instills the customer with confidence.

ProColor Collision prioritizes customer experience. It strives to be a repairer of choice. Its shops have deep roots in the communities they serve. Dedication to providing the highest standard of safety and quality repair for customer vehicles is a key element of its operations. And to further evaluate the sentiment of those served, the Customer PRO Satisfaction Program helps reinforce its offerings to deliver a high-quality personal experience for customers.

Each member of ProColor Collision goes through rigorous evaluation, and ongoing training is provided to ensure

teams deliver quality workmanship on every vehicle. A national lifetime warranty that covers labour and paint gives the customer peace of mind.

But guaranteeing a great customer experience can be difficult for independent shops without adequate resources. Advancements in technology are resulting in fewer vehicle repairs. Rising claims costs, decreasing revenue and a longer repair cycle are putting pressure on body shops. Shop owners want to pursue all business available but are being spread thin. The support of a global network can help shield shops from that pressure and offer relief in a highly competitive market.

For 20 years, ProColor Collision has provided an alternative to independent auto-body shops. Belonging to a global network, it presents the balance of local, personalized service with the support of

ADVERTORIAL Join the global brand with a local touch

a large base of resources. Streamlined processes, improving recruitment and retention, marketing support, training opportunities, and guidance on safety standards are just some of the benefits.

Independent shops join ProColor Collision for many other reasons. The partnership helps boost performance, capture more business and improve operational processes. It allows for the transparent relationship with insurers and work providers. Access to newly constructed training facilities and an established training regimen makes it easier for ProColor Collision shops to certify technical staff.

Most ProColor Collision bodyshops have achieved certification from national and international industry bodies like I-CAR. These certifications provide a seal of approval that technicians have the knowledge and training in the most complex mechanical and collision-repair requirements for modern vehicles and based on manufacturer specifications.

Shops within the network are trained on OEM repair methodology. They are provided with support to hold multi-channel local area marketing campaigns. They are part of a consolidated global network that employs best practices from around the world. The brand helps attract, recruit and retain technicians, painters, estimators and other talent.

ProColor Collision shops grow their presence, business and bottom line.

Appreciation for identifying and implementing best practices is a testament to ProColor Collision’s commitment to

excellence. Another measure is taking a consultative approach to business processes, operations, procedures and insurer relationships. In a world rife with uncertainty, insurers in particular value transparency, predictability and quality assurance.

ProColor Collision has built a relationship of trust with insurance companies. That relationship means more business is streamlined to the brand’s shops. And because commitment to quality and delivering peace of mind for customers is paramount, insurers refer their clients to ProColor Collision with confidence.

At the end of the day, becoming a franchisee is a smart business decision that can help take independent bodyshops to the next level. Joining a global network means access to a range of benefits that help provide better service to customers, streamline operations and tap into preferred-provider partnerships with insurers.

Ready to drive your business forward? Learn more about becoming a ProColor Collision franchisee by visiting procolor. com/en-ca/franchise-opportunities or by simply scanning the QR code below.

ADVERTORIAL

HIGH TECH TASK FORCE

Chaired by top executives from industry leaders like Rivian, Lucid Motors and the Automotive Recyclers Association (ARA), those who choose to join CIECA’s new electric vehicle and battery committee will surely be in good company, as the organization devises its path forward for the emerging field. CIECA says its new committee aims to bring together companies and individuals from all industry segments to discuss how EVs will change the current business workflows and data. “The goal is to create new workflows that will show the lifecycle of an EV and its battery,” said CIECA technical project manager, Paulette Reed. To meet this goal, CIECA has selected Frank Phillips, senior manager of Rivian’s North American collision network, his counterpart at Lucid Motors, repair program operations manager Jake Rodenroth and Ginny Whelan, executive director of ARA’s educational foundation, to serve as chairs of the board. This new CIECA committee is open to all member and non-member industry stakeholders who are interested.

DIRE PREDICTIONS

A study backed by electric vehicle (EV) manufacturers Polestar and Rivian warns that the automotive industry will likely miss climate goals by 75 percent, further highlighting that targets would be missed even if all cars sold tomorrow were electric. According to Reuters, the pathway report provides three recommendations to achieve climate targets by the Intergovernmental Panel on Climate Change to limit global warming to 1.5 Celsius by 2050: a firm end date on the sale of fossil-fuel cars, investing more in EV production and creating more renewable energy sources and more sustainable supply chains. The report agrees with Greenpeace’s analysis of the auto industry, which warns that auto sales of combustion engine vehicles are on track to jeopardize the 1.5 Celsius by 2050 target. “Leading auto manufacturers, including Toyota, Volkswagen, and Hyundai, are transitioning far too slowly to zero-emission vehicles, which has dangerous consequences for our planet. As the climate crisis intensifies, governments are enacting stricter bans on diesel and petrol vehicles,” said Benjamin Stephan, climate campaigner at Greenpeace Germany. “If traditional automakers fail to electrify, they will lose out to newer, all-electric competitors and risk stranded assets.”

BLEND BRIEF

The Society of Collision Repair Specialists’ (SCRS) recent blend study is making estimating system providers “reevaluate” the numbers they’ve been reporting, SCRS executive director Aaron Schulenberg told attendees at last week’s board meeting. The study results, first released November 1, showed blending took 31.59 percent longer than a full refinish—not 50 percent less time, as reported by three estimating platform providers. The study involved five primary North American coatings companies, who were not identified, and a full week of blend tests on 45 2018 Ford F-150 parts: 15 RT front door shells, 15 RT fenders and 15 hoods. Both CCC/Motor and Mitchell told Repairer Driven News in November they were reviewing the results of the SCRS’s audited blend study, in collaboration with five primary North American coatings companies. Mitchell told the outlet it was “always open to discussions with SCRS on the subject,” while CCC is working to “review observations, including scope, conditions, techniques and materials used.” The latter said it would share more once its review is concluded.

12 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY NEWS

Chairs of the new committee board: Ginny Whelan, ARA; Jake Rodenroth, Lucid Motors; Frank Phillips, Rivian.

Schulenberg also stressed that none of the information providers in the study–CCC/Motor, Mitchell International and Audatex–were given the results in advance.

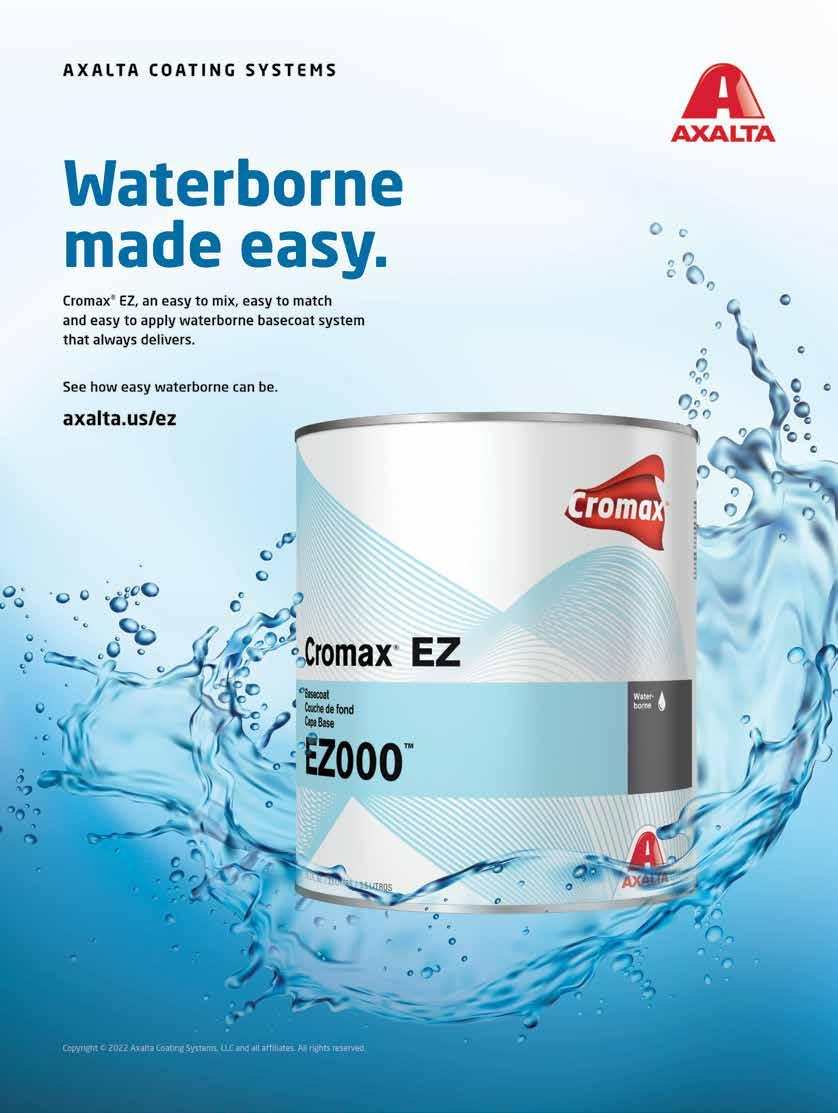

SCHOOL IN SESSION

Axalta Coatings and SATA have announced a new training partnership, replacing the Axalta Training Center in Ajax, Ontario, with Axalta Training at SATA Canada. According to a press release, this partnership will provide Axalta and its refinishing customers access to the new SATA Ontario location. Axalta refinish customers will have access to paint technician courses including tri-coat colour application, matte finishing, micro repair and more classes using Axalta tools. This new location features two spray booths, a classroom, a lunchroom and a fully equipped work area.

GLUE PULLING TOOLS LIKE NEVER BEFORE

Quality products for professional collision repair & PDR technicians

PREMIUM ELITE LOADED CART

CAMAUTO PREMIUM ELITE CART is a heavy duty, mobile cart that helps you carry all your PDR and GPR tools. Equipped with a drawer, and with a steel tab organizer top for better tools and tabs organization, and with two foldable trays, that can be used as a side table, and that can be bent for a better storage space.

INCLUDED IN THE CART:

• ELITE PRO LIGHT PULLER

• ELITE DOUBLE FEET

• LONG LEVER PULLER 3FT

• CAMAUTO HEAT PROTECTION GEL

• CAMAUTO GLUE STICKS (pack of 20)

• UNIVERSAL ADJUSTABLE TABS 24pcs kit

• MINI LIFTER

• BIG KNOCKDOWN

• KNOCKDOWN KIT 4PCS

• 3D TABS 8pcs kit

• 3D CURVE TABS 8PCS

• FLAT TABS 18pcs kit

CRT9920

• 300W UL APPROVED GLUE GUN with temperature adjustment control

• 4 LONG TABS in 2 different sizes

• 15 FLEX TABS in 3 different sizes

• 20 BLACK PLASTIC HOOKS

• 3 PULLING RODS

CONTACT US TODAY FOR MORE INFORMATION OR PRICING!

We currently ship all over the world

camautopro.com

• UNIVERSAL CREASE TABS

• 2 BAR TABS

• SLIDE HAMMER 5LBS

• I-BAR MINI KIT (4 I-bars in 2 different sizes, and 3 aluminum hooks)

100 PREVOST, UNIT 107, BOISBRIAND, QC. J7G 2S2 CANADA

F | T+1 (514) 567 5404

info@camautopro.com

ISSUE 22#2 | COLLISION REPAIR 13 INDUSTRY NEWS

The SATA facility is located at 125 Buttermill Ave. in Vaughan, Ontario. Classes are available two weeks per month. For more information, visit Axalta.ca.

TESLA TAKESIES-BACKSIES

The U.S.’s National Highway Traffic Safety Administration (NHTSA) decided Thursday that they have finally had enough when it comes to Tesla’s Full Self-Driving software, ordering a recall of 362,000 from U.S. roads, which covers 2016 to 2023 Model S and Model X, 2017 to 2023 Model 3 and 2020 to 2023 Model Y vehicles. The call was made to address the potential for the technology to infringe upon local traffic laws, increasing the risk of crashes. The NHTSA said Tesla’s FSD allows its vehicles to “exceed speed limits or travel through intersections in an unlawful or unpredictable manner increases the risk of a crash.”

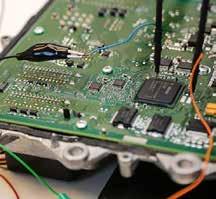

CALIBRATION CONFUSION

A recent report from the Insurance Institute for Highway Safety (IIHS), entitled “Consumer experiences with crash avoidance feature repairs”, sheds light on the increased prevalence of post-repair issues on components like front crash prevention tech, blind spot detection and cameras, being experienced by drivers today. Of those who responded to the institute’s survey, more than half of those who sought repairs for one of those three components experienced post-repair issues that required a follow-up visit, with blind spot detection being the most frequent offender, requiring a second repair for 62 percent of respondents. Perhaps most interesting to repairers is the finding that despite the majority of drivers reporting that calibrations were performed on their vehicle as part of the repair, those who did not receive calibrations reported fewer post-repair issues with their safety systems. The report suggests this may stem from a common complaint among repairers that access to OEM repair and calibration information is updated extremely frequently, and the cost to access it is often prohibitive for smaller independent repair businesses, therefore forcing some facilities to use outdated scanning equipment.

FLASH SALE

Few things are bad enough to be called a burning wreck. Unfortunately for one man in Cambridge, Ontario, his 2015 Hyundai Sonata turned into one when his car burst into flames right as he pulled into the driveway. In an interview with the CBC, Mike Tennant described how a “large flame came up over the hood,” warning his wife that his car was on fire. According to the CBC, it was only 15 minutes since he picked up the car from a dealership after service on November 9, 2021. More than a year later, there remains no official cause or agreement over who or what was responsible.

The IIHS also found a majority of frequently faulty calibrations are performed on vehicles for crash damage or windshield repair, as opposed to those brought in on the advisement of a recall order or personal recommendation, meaning that many vehicles damaged in collisions are not being adequately restored to preaccident safety levels.

SYNTHESIZED SCANS

Autel and Repairify announced an exclusive collaboration agreement on March 1, with Repairify’s diagnostic, allowing calibration and programming solutions to be exclusively offered through Autel’s remote capable products across North America. According to a company press release, Repairify will integrate its diagnostic, calibration, and programming solutions into a revised version of Autel’s Remote Expert platform. Additionally, customers will have the choice of using certified OEM remote solutions from Repairify or independent remote experts currently on the platform.

14 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY NEWS

The NHTSA elaborated further, saying “the system may respond insufficiently to changes in posted speed limits or not adequately account for the driver’s adjustment of the vehicle’s speed to exceed posted speed limits.”

A photo the owner submitted to the CBC. The remains were sold by Allstate, who did not say whether an investigation was conducted before or after they sold the vehicle for salvage.

Call: 1-800-871-7612 | Click: simplicitycarcare.ca/franchisee Connect: contact@simplicitycarcare.ca Spend more time focusing on your customers and let us simplify the rest. Operational Efficiency Simplify your workflow to increase efficiency and profitability. Insurance Partnerships Connect with and meet the requirements of major insurers. Business Growth Use our proprietary system to service customers and help drive sales. Join One Of Canada’s Fastest Growing Collision Repair Networks

AKZO’S ASCENSION

AkzoNobel reported its Q4 2022 and full-year 2022 financial results in early February, reporting increased revenues driven by price increases. The company reported a 13 percent revenue increase for 2022, compared to 2021. Pricing was up 14 percent. Operating income for the year was reported at €708 million (2021: €1,118 million), resulting from lower volumes, higher raw material and freight costs, inflation on operating expenses and €46 million negative impact from hyperinflation accounting. Adjusted EBITDA was €1,157 million (2021: €1,436 million) For Q4 2022, revenue was up eight percent and nine percent higher in constant currencies; pricing was up 11 percent through the quarter. AkzoNobel also noted the completion of wheel liquid coatings business Lankwitzer Lackfabrik in December 2022; it also finalized a €500 million share buyback.

16 COLLISION REPAIR COLLISIONREPAIRMAG.COM BUSINESS NEWS

FASTENERS BACK GLASS

DENTS BEDLINERS INDUCTOR® PRO-MAX Tag us in your photos #InductionInnovations www.theinductor.com 877-688-9633 Available at www.theinductor.com Do it Faster - Do it Better - Do it Safer The Inductor® Pro-Max uses high frequency magnetic fields to generate Invisible Heat® in metallic car parts without the collateral damage of an open flame to nearby parts. Quickly and easily remove vinyl graphics, moldings, auto glass, windshields, mechanical and suspension parts. > Power supply > Fast-off® Pad > Concentrator > Glass Blaster® > (2) L-Wedges INCLUDES:

AkzoNobel company reported a 13 percent revenue increase for 2022, compared to 2021. Pricing was up 14 percent.

FRAME RAILS

SOFT

UP AT AXALTA

Axalta Coatings posted earnings of 20 cents per share (U.S. dollars) in Q4 2022, compared with 23 cents per share in Q4 2021. In the company’s overall results for 2022, revenues were up nine percent year-over-year to US$1,236.7 million, beating the Zacks Consensus Estimates of US$1,216.6 million. According to the press release, Axalta benefited from higher average price and product mix, as well as improved volumes from 2021.

PPG PROFITS

As with the other big automotive coatings players, PPG also reported increased sales—record-breaking full-year results, in fact. Sales for 2022 were reported at US$17.7 billion, aided by eight percent organic growth, said PPG. Meanwhile, overall sales volumes fell by five percent year-over-year. The company also delivered record net sales for Q4 2022 in the automotive refinish and PPG Comex coatings businesses, said Tim Knavish, PPG president and chief executive officer. PPG said Q4 2022 automotive refinish coatings organic sales grew by “a low double-digit percentage” driven by both higher selling prices and sales volumes.

SHINING AT SHERWIN

Sherwin Williams reported 11.1 percent growth in consolidated sales for 2022, while net sales from retail stores opened for more than 12 months in the U.S. and Canada increased by 11.7 percent through the year. The company said consolidated net sales increased primarily due to selling price increases in all segments, as well as higher sales volumes in the Americas Group. “These factors were partially offset by higher raw material costs across all three segments [in which the company operates],” said Sherwin Williams in a press release.

ISSUE 22#2 | COLLISION REPAIR 17 BUSINESS NEWS

Axalta also reported higher sales across the performance coatings and mobility coatings units; the latter of which was driven by global automotive production recoveries and strong pricing.

“ICBC” Recognized Lasers, NO Targets, NO Adaptors, NO Magnets NO Wires, NO Wi-Fi, NO Bluetooth MITCHELL chassis data QUICKEST, SIMPLEST AND MOST ACCURATE 3D MEASURING SYSTEM IN THE WORLD NEW NOW INCLUDES WHEEL ALIGNMENT DIAGNOSTICS SOFTWARE ACCUVISION-3D® IS RECOGNIZED BY CERTIFICATION PROGRAMS - Certi ed Collision Care - CCIAP - Honda - ICBC accuvision-3D.com arslanauto.com Contact your distributor or Call (800) 465-8575

DIY DAYS

Canadian Tire shares grew nearly 12 percent from January 1, 2023, through February 14, 2023, largely thanks to recent inflation and consumers’ cautious spending habits. Analysts from the Motley Fool expect inflation control to result in further growth for Canadian Tire stocks, the stocks site wrote on Monday, pointing out that the retail giant provides “a top choice for Canadians seeking auto parts” during an economic downturn.

MAGNA’S MARGINS

Magna International shares dropped more than 17 percent after announcing lower-than-expected results for 2022. The company said it earned US$95 million (33 cents per share) in Q4 2022, down from US$464 million (US$1.54 per diluted share) in Q4 2021. Analysts had expected profits of US$1.02 per share, according to Refinitiv. Shares dropped 15 percent in the immediate hours following the news.

18 COLLISION REPAIR COLLISIONREPAIRMAG.COM BUSINESS NEWS

The Sentinel™ allows one technician to remove and replace a l type of glass on a wide variety of vehic es including large busses and RV’s

sales@equalizer.com • 512 . 388 .77 15 • equalizer.com

Powered with AirForce™ Techno ogy, the Sentinel™ vacuum cups provide a constant hold to allow movement in a variety of angles to get the right posit on in lifting or setting glass

“Canadians are likely to move back toward [Canadian Tire’s] stock for more than just new tires in the months to come,” wrote Canadian market watch site the Motley Fool.

Magna’s total sales for 2022, however, were US$9.57 billion, up from last year’s US$9.11 billion.

CWB Automotive Repair Technician Welding Program

NOW AVAILABLE

Get the training and welding qualification you need to stay ahead of the game.

Automotive Welding Qualification is a must-have for all technicians that repair and weld vehicles in your collision repair facility. To achieve the highest quality repair, utilize best practices, and ensure vehicles are properly and safely repaired, choose the CWB Automotive Repair Welding Qualification program for your team. For over 70 years, the CWB Group has provided training and testing services to companies across Canada seeking Certification and Welder Qualification.

CWB Automotive Welding Qualification Benefits

• Automotive Welding Training and Qualification at your own facility with your own equipment

• Ensure all your technicians have the training and skills needed for welding

• Increased skill levels = quality assurance for Collision Repair Facilities

• Satisfies welding certification requirements for most OEM Certification programs

• Third party oversight and onsite training by certified welding specialists

• Enhanced credibility provided by CWB Automotive welding certifications

• Savings when you register multiple technicians to participate

• Technicians receive CWB Automotive Welding accreditation after completing training and testing

Register for Welding Education and Certification today at: www.cwbgroup.org/autorepair Direct Testing scheduling at: cwbautomotive@cwbgroup.org | 1.800.844.6790 ext. 290

GONE TOO SOON

Tesla has been talking big about its in-house insurance platform recently, but some recent reporting from Reuters has found that far too many of the electric automaker’s vehicles are turning up as salvage prematurely. In a compilation of 120 Model Y vehicles found on salvage auction listings, Reuters found that a “vast majority” of the listed vehicles had less than 10,000 miles (approx. 160,000 km.) on the odometer, according to data obtained from Copart and IAA.

ALUMINUM EXCLUSIVITY

BMW North American has restricted more than 100 aluminum structural parts for its vehicles “due to complexity of repair and the requirement of highly specialized tools, training, and repair procedures.” Going forward, parts on the list can only be ordered by facilities with technicians who have completed the required BMW paint and body training courses, including instruction on the OEM’s specific list of approved frame benches, belt sanders, glue cartridge gun, riveting tools, welders, oscillating tools and saw blades. The automaker wrote in its bulletin that it “will be restricting certain aluminum structural parts to ensure the correct repair process is followed and crash performance is not compromised.” The bulletin states that, to be considered eligible to order from the restricted parts list, the technician completing the repair must have completed the BMW Bonding and Riveting Techniques online course (OL5510) and the in-class Aluminum Structural Repair course (SB061), or the BMWi Body Repair Level 2 and 3 courses (SB026E), which are no longer offered but are still recognized.

OE CLARITY

General Motors has issued an updated position statement on its standards for aftermarket glass replacements, hammering home the opinion that non-OEM glass could compromise the safety standards of their vehicles. The legacy automaker asserts that any glass but its own will cause problems with sensor systems that are housed within the windshield. “With the safety of our customers at the center of everything we do, it is critical a service point calibration/learn to be performed whenever a front view windshield camera or sensor is removed and reinstalled or replaced, or when a windshield is removed and reinstalled or replaced,” the statement said.

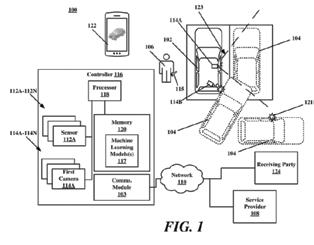

BODY WATCH

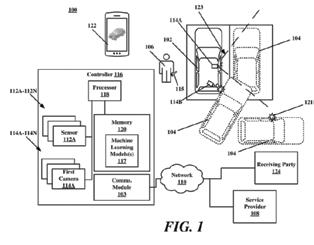

A new patent secured by Ford aims to record and report vehicle body damage instantaneously from the point of impact for immediate communication directly to partners such as insurance and rental companies, according to reporting from Ford Authority. Filed on October 6, 2020, published on January 24, 2023, and assigned serial number 11562570, this latest patent from the Ford Motor Company describes a system that uses cameras integrated into a vehicle’s body to capture damage, from a large collision to a small parking lot door ding. In this way, it will both open immediate dialogue with insurers and emergency services in the case of larger collisions, but also alert drivers to smaller damage they may not have otherwise noticed.

20 COLLISION REPAIR COLLISIONREPAIRMAG.COM OEM NEWS

All the Model Ys in the analysis were 2022 or 2023 models and were built at either the Fremont, California, or Austin, Texas, plant, according to Reuters. Of the 120 listed vehicles, 14 of them were identified as long-range variants of the Model Y that were likely only built within the last year.

Ford’s proposed patent system would be capable of distinguishing between different types of damage, gauging damage severity, and filling out a claim rapidly.

An email obtained by Repairer Driven News from BMW states that more aluminum parts will be added to the list of restrictions in the future.

Over 90% of Keystone Platinum Plus aftermarket collision repair products are CAPA Certified.

Eligible parts only. Wheels are excluded from CAPA certification but are subject to strict SAE standards. An LKQ Company ® Call Today! (866) LKQ-CORP | (866) 557-2677 or Order Online at LKQCanada.ca/en/ ©2021 LKQ Corporation. PLATINUM GOLD STANDARD IS LIMITED LIFETIME WARRANTY All Keystone Platinum Plus products offer the highest standards and Industry-leading Limited Lifetime Warranty. CAPA CERTIFIED Over 90% of Keystone Platinum Plus aftermarket collision repair products are CAPA Certified. NOTE: Eligible parts only. Wheels are excluded from CAPA certification but are subject to strict SAE standards. ABSORBERS • BUMPERS • BUMPER BRACKETS • BUMPER REINFORCEMENTS • DOORS FENDERS • GRILLES • HOODS • LIGHTING • MIRRORS • STEP BUMPER ASSEMBLIES • WHEELS An LKQ Company ® Call Today! (866) LKQ-CORP | (866) 557-2677 or Order Online at LKQCanada.ca/en/ ©2021 LKQ Corporation.

NOTE:

BATTERY STATUS

Canadian repairers are becoming more capable when it comes to complex EV repairs, according to the debut “Plugged-In: EV Collision Insights” report by Mitchell. The Canadian collision industry has seen EV repairable claims frequency rise to a rate of 2.26 percent in Q4 2022, along with the average percentage of EV parts repaired, which climbed from 11.05 percent to 12.16 percent quarter-over-quarter, demonstrating an improved capability on the part of repairers to fix the lighter weight materials commonly found on EVs. On a model-by-model basis, the Tesla Model 3 makes up 45 percent of the EV repair mix for Canadian collision shops, followed by the Model Y at 17.29 percent, the Nissan Leaf at 7.24 percent, the Hyundai Kona EV at 6.91 percent and the Chevrolet Bolt at 5.19 percent. Concerning repairable claims frequency in various North American EV markets, British Columbia leads the way with an average of 4.47 percent, followed by California with a rate of 3.37 percent and Quebec, which sits at 2.75 percent.

WHO PAYS FOR WHAT?

Of the more than 400 U.S. repair shops that responded to the annual “Who Pays for What?” survey from industry expert Mike Anderson, two out of five reported that they never bill insurers for safety inspections. Among those who do bill, 38 percent say that these charges are either “always” or “most of the time” paid out by one of the U.S.’s eight major insurers, while a nearly equal portion of respondents say they are only paid “some of the time.” Progressive and USAA were found to be the most reliable insurers, in terms of tendency to pay for safety inspections, followed by GEICO, Nationwide and State Farm. Concerning in-process scans, 36 percent of shops that bill for them say they “always” or “most of the time” receive payment. American insurance companies do appear to be mostly on board with pre and post-repair scans, however, with 88 percent of billing shops saying they are always or usually paid for the former, and 91 percent in the case of the latter.

22 COLLISION REPAIR COLLISIONREPAIRMAG.COM INSURANCE NEWS

Repairers are also putting in, on average, 1.7 more labour hours into completing EV repairs as compared to ICE, according to damage appraisals analyzed by Mitchell.

In a press release issued alongside the report, Anderson levelled with shop owners about the difficult position charging for safety inspections tends to put them in, saying “My heart bleeds for shops. There are some out there really trying to do the right thing by doing these safety inspections but they’re getting stuck in the middle.”

The men and women of LKQ are passionate about parts and providing the best possible service to our customers. Our world-class product sourcing, recycling, and remanufacturing operations and our more than 20,000 North American employees are the difference between delivering a part that’s just OK and one that’s just right for the job. Feel the passion and find your next replacement part at www.LKQcorp.com Call Us : 866-LKQ-CORP Visit Us Online : www.LKQCorp.com The Passionate Parts People New Aftermarket | Recycled OE | Remanufactured Engines & Transmissions | Paint Products

MIRROR, MIRROR

The penny tread-checking trick won’t work here. The original poster specified that the vehicle owner had to sign a waiver to release the car back into their care. What’s better, yet—it was clearly pouring rain that day.

INSTANT DRIVE-THRU

Some people like car shopping, but two people took it literally when they drove an Audi through the front doors of the Vaughan Mills shopping mall on February 1, 2023. According to Global News, York Regional Police said the break-and-enter happened after 1 a.m., when two suspects used a stolen black 2011 Audi A4 from Quebec to enter the mall and steal from an electronics store.

HEADLIGHT HANDICRAFT

Headlights are expensive nowadays—and customers are getting craftier with DIY replacement methods. Illusions are the latest tactic, as a Reddit user posted a DIY repair involving an orange prescription pill bottle zip-tied to the headlamp housing, accompanied by a clear Tupperware container. As long as you stick to driving during the day, you might be in the clear.

PEDESTRIAN PSA

A threatening bus advertisement recently went viral for seemingly provoking Virgina, United States, drivers to hit jay-walking pedestrians to “let them learn a lesson.” Fear not, Virginia-based pedestrians; the ad was allegedly first seen on TikTok and is believed to be fake.

PREVIA PICKUP

Toyota fans of yesteryear often ask themselves: whatever happened to the Previa? Well, to answer their question, people did stuff like this to them. That’s why the Japanese OEM stopped making them. We can’t have anything nice.

24 COLLISION REPAIR COLLISIONREPAIRMAG.COM CAN YOU BELIEVE THIS?!

The stolen, damaged Audi has since been returned to its original owner, a woman in Quebec, though it still dreams of its mallrat days.

Definitely top-ten cringe-worthy repairs.

You’d better have your tetanus shot if you plan on driving this bad boy.

Spotted in Virgina, U.S.A. This magazine has yet to confirm the effectiveness of the campaign.

At Fix Auto, we are committed to helping ensure your hard work can be passed on. Our training, systems, technology and support give your business the tools it needs to stand the test of time. BECAUSE THE NEXT GENERATION MATTERS FIX AUTO. IT’S A FAMILY THING Contact Daryll O’Keefe at dokeefe@fixnetwork.com or visit fixauto.com/jointhenetwork to find out more. fixauto.com

ON THE COVER 26 COLLISION REPAIR COLLISIONREPAIRMAG.COM

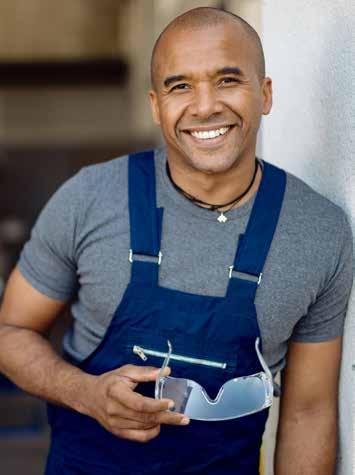

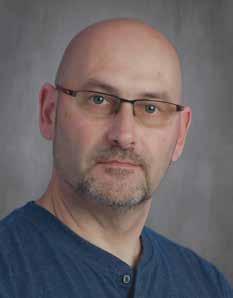

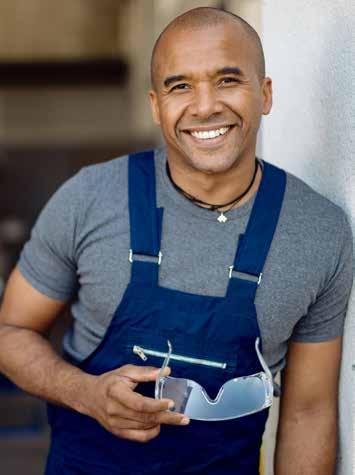

WISE BEYOND HIS YEARS

Marcus Newman proves that ideas beat age in collision repair

Story by MAX REID

As we all surely learned from a popular TV ad campaign about taco shells, sometimes we need to look to our young people for the solutions that may go unseen by aged eyes.

Consider the little girl who first thwarted the binary choice between a soft- or hard-shell taco; so too does Capital Collision of Mount Pearl, Newfoundland cast off the chains of age prejudice and embrace a manager possessive of a rare combination of youth and experience.

Twenty-six-year-old Marcus Newman has only been in the collision repair game for about six years, but the wealth of industry knowledge and technical acumen he has under his belt would make even the most seasoned bodyshop foreman jealous.

In fact, under the young professional’s leadership, Capital Collision was recognized as Consolidated Collision Services’ (CCS) shop of the year, at the banner’s conference this past fall.

There were no tricks or special favours involved in this rapid stream of success—just a natural sense for efficiency and a hell of a lot of legwork.

ISSUE 22#2 | COLLISION REPAIR 27 ON THE COVER

When he got his start in the collision department of the local Mount Pearl dealer group back in 2017, Marcus hit the ground running as an entry-level apprentice and seemed to be set on an upward trajectory from there.

Eventually proving himself a highly capable technician around Capital, being one of the few on staff selected to pursue BMW certification, Marcus’ responsibilities began to expand alongside new opportunities for growth, such as in the estimating department.

“I was doing estimates, but I was also acting as the shop foreman, overseeing everything on the floor,” said Marcus.

As his toolkit of technical skills grew, so too did his knowledge of the industry at large—and with a sudden change of leadership hitting the collision centre around the peak of the second COVID-19 lockdown in 2021—Marcus decided to throw his hat into the ring.

“I put it out there that I could do it,” he said. “I made it my goal to show that I could do it and that age shouldn’t really be a factor.”

And luckily for him, his age really wasn’t a factor. Marcus says he is privileged to work with a team of technicians that he has trained alongside for his entire career.

The thought of some 26-year-old calling the shots for a stable full of seasoned Newfie body techs may cause some managers out there to scoff, but Marcus quickly proved he had a plan to get Capital back on its feet after a particularly rough lockdown period.

And if there was any doubt, his team had his back every step of the way.

“At the time when I took over, we had some structure in place, but we also had some issues with our insurance partners and relationships that had to be mended,” he said, alluding to some administrative changes made to the Capital Collision business over the course of his rise to management.

So, Marcus hit the bricks and started reaching out to all of Capital’s industry contacts, in the hopes of pulling in some consistent repair work and learning along the way how to back his grand plans with positive results.

“We put in place a couple of things, like keeping on top of vendor managers and trying to be open in showing our data and that things are on the mend. Your customer feedback, CSI scores—all that stuff plays a big role in that kind of decision from the insurance companies,” he said.

28 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

“You kind of have to go knocking on doors a little bit when you’re not already in with some of these people.”

Knock and eventually you shall be let in, it turns out, as Capital Collision has since secured repair agreements with Intact and Aviva, which Marcus says was “definitely something we needed to help get back on our feet.”

Since then, Marcus and Capital have been on the slow and steady path toward modernizing the business, putting in place top-ofthe-line estimating and calibrating software, measuring systems, and integrating Axalta Cromex Pro as a primary paint system.

Additionally, Capital Collision’s 1,300 square metres (14,000 sq. ft.) production

space features three prep stations, three paint booths and a full suite of Car-O-Liner welders.

The shop has completed the BMW and Mini Body and Paint Training Program, is a member of the Ford National Body Shop Network, and has certifications from numerous other major OEMs, including Hyundai, Genesis, Infinity, Subaru, Dodge, Jeep, Ram, Nissan and Kia.

While the last few years have put strain on the ability of many collision repair facilities to draw new technicians, Marcus is proud to report that Capital Collision currently has four apprentices working the floor, three of whom are first year apprentices, while the fourth is in their third year and on track to achieve journeyman and Red Seal status.

Some managers reading this may have just had a small heart palpitation at the thought of having not one, but four relatively green technicians working the production floor, but having been one not so long ago himself, Marcus understands the value of investing in his team’s skills early.

“I’ve been leaning on them more as we’ve been getting busier and they have been doing really well,” he said.

“Efficiencies tend to struggle a little because of that, but I feel that in the long run what they are gaining in knowledge will benefit all of us—that way they won’t have to rely on the experienced techs for help.”

It is this sort of attention to quality and perseverance that Marcus attributes the

ISSUE 22#2 | COLLISION REPAIR 29 ON THE COVER

Capital Collision’s 1,300 square metres (14,000 sq. ft.) production space features three prep stations, three paint booths and a full suite of Car-O-Liner welders.

Capital Collision currently has four apprentices working the floor, three of whom are first year apprentices, while the fourth is in their third year and on track to achieve journeyman and Red Seal status.

30 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

centre’s recent shop of the year award win to, as he admits that Capital is by no means the biggest or most profitable shop in the area.

What really impressed CCS enough to recognize Capital, was Marcus’ ability to pull the business from the brink and put what was once a repair centre in between networks, and during a pandemic, back on the radar and into good standing with the Mount Pearl community.

“We had a lot of work to do,” said Marcus. “They saw all the numbers and all the strides we had to take to progress over the last couple of years.”

If there is a lesson that could be taken from Marcus’ story, it is that when conventional wisdom is failing you—challenge it. Seek out new voices and new perspectives from within your team and you may find solutions to problems you didn’t even know you had.

There are no awards for the most cynical shop manager, so there’s no sense competing for that. Why not try to be an open and collaborative manager and see where that gets you.

ISSUE 22#2 | COLLISION REPAIR 31 ON THE COVER

TO REMEMBER A FORUM

Canadian Collision Industry Forum hosts Toronto event

It had been three years—nearly to the date—since the Canadian Collision Industry Forum (CCIF) hosted its annual event in Toronto. It was clear from attendance that the industry had missed the event.

The sold-out event kicked off with a networking reception, where guests were treated to lavish spreads and drinks to complement a five-star networking opportunity. The next day, the festivities continued with a lineup of speakers to highlight current industry happenings—including the state of partner relations, labour shortages, parts delays and more.

The Collision Repair mag team was there with cameras in tow—check out our scrapbook from CCIF Toronto 2023.

32 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Story, photos by ALLISON ROGERS

Flavio Battilana, CSN; Paul Carrobourg, PPG Canada.

Roger Schroder, Car-Part.com; Gloria Mann, Media Matters; Vinesh Mistry, IAA; Steve Fletcher, Automotive Recyclers of Canada; Wanja Mann, Media Matters; John Turner, Simplicity Car Care; Howard Berg, Fuyao North America.

Jeff Labanovich, CARSTAR, incoming chairman for CCIF, with Paul Prochilo, Simplicity Car Care, outgoing chairman of CCIF.

ISSUE 22#2 | COLLISION REPAIR 33 EVENTS

Allison Rogers, Collision Repair magazine, and Vince Mattozzo, CARSTAR Canada.

Danny Frangione, CSN Bemac Group.

Wanja Mann, Media Matters, and Chloe Devine Drouin, AIA Canada.

Daryll O’Keefe, Fix Network Canada.

Derek Florczyk, Assured Automotive; David Black, Color Compass; Craig Jalbert, 3M.

Joe Saputo, CARSTAR Ancaster, and Bing Wong of Canadian Hail Repair.

Michael Carcone, Carcone’s Auto Recycling; Gloria Mann, Media Matters.

Lion Lang, SATA Canada.

Paul Souliere, Trista Anger, BASF Canada; Michael O’Callaghan, Craftsman Collision; Mark Huisman, BASF Canada.

Glory Garisto, Kent-Automotive; John Turner, Simplicity Car Care.

Joern Stoever, SATA Canada, and Patrice Marcil, Axalta.

34 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Bruce Carrick, Audatex; John Donald, Uniparts O.E.M.

Rebecca Fyfe and Jenica Bennett, AutoHouse Technologies; Ken Chung, Simplicity Car Care, and Mike Gilliland, AutoHouse Technologies.

Sylvain Seguin and Sonia Bouthillette, Fix Network.

Steve Gallance, 3M Canada and Terry Groves, Uni-Select.

Sean Donaldson and Ryan Bruno, CSN Collision Centres; Gloria Mann, Media Matters and Howard Berg, Fuyao North America.

Emile Fremont, Lordco Auto Parts.

Stefano Liessi, Canadian Collision Specialist; Trevor Mccullagh, Leader Auto Resources.

Serving your PBE needs for 50 years

36 COLLISION REPAIR COLLISIONREPAIRMAG.COM

Richard Marsh, Justin Brown of Brown’s Auto Supply.

Benjamin Perrier and Trista Anger, BASF Canada.

Michael St. Germain, Mercedes-Benz Oakville and Marlene Van Zyl, Norton Saint-Gobain Canada.

John Marlowe, Level 5 Drive; Allison Rogers, Collision Repair magazine.

Mike Beier, Consolidated Collision Services; Larry Jefferies, Collision Builders; John Harvey, CrashBay.com.

Ishra Mohammed, Holly Switzer-Pitts and Nalini Faizool, Certified Collision Care/OEC.

Kari Barton, Sharon Ashley and Destiny Earle of Bodyshop Connect.

Max Reid, Collision Repair magazine; Kim Roberts, Fix Auto Barrie.

At CSN, we charge a flat monthly fee, not a percentage of your sales. That way, you can keep more of your hard-earned money to grow your business. LESS IS MORE. ® csncollision.com Insist on CSN

MEETING IN MOOSE JAW

Saskatchewan Association of Automotive Repairers prove that teamwork makes the dream work

The Saskatchewan Association of Automotive Repairers (SAAR) got a head start on spring, hosting its seasonal conference on February 10 and 11, 2023.

Attended by more than 100 industry representatives and hosted at the luxurious Temple Gardens Hotel and Spa, SAAR’s Spring Conference featured a jam-packed day of insightful speaker sessions, followed by a catered dinner.

Collision Repair mag was in Moose Jaw to capture all the action. See our Saskatchewan scrapbook on the following pages!

38 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Tom and Barb Bissonnette, SAAR.

The SGI crew, with Jessica Hill Flaman and Ryan Smith of Saskatchewan Government Insurance.

Don Pogoda, formerly of Parr Auto Body; Constantino Uliano, Spanesi Americas.

Story, photos by ALLISON ROGERS

EVENTS

Sharon Ashley, Bodyshop Connect.

Scott Kucharyshen, Saskatchewan Polytechnic, awards Randy Vold of Vold’s Collision a $500 raffle prize.

Don Pogoda; Raj Kavia, Kavia Auto Body.

Craig Alvaro, 3M, presents on the company’s new RepairStack platform.

Bill and Denise Fonstad, Ideal Auto Body.

Marty Coonan, LKQ Canada. Domeni Prochilo, Simplicity Car Care.

Scott Schkopich, NAPA Auto Parts; Jarred Henrickson and Brock Paul, Cruiser’s CARSTAR Collision.

Koos Reineking, Lift Auto Group, and Christie Hall, CARSTAR Canada.

Greg Wing, Paul Prochilo, Simplicity Car Care.

40 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Rob Dick, Mitchell, and his wife Sherri; Dave Kohonick, Bennett Dunlop Ford; Rose and Bryan Leier, Bennett Dunlop Ford.

Terry Hrabowy, Dodge City Collision; Jeryl Olorenshaw, SGI; Bert Cormier, PPG, and wife Tanis.

3M’s Brett McNeil with Garth Wicks from Valley Collision Centre, who went home with a brand-new Festool dust extractor.

Donny Hall, CSN Collision Centres; Greg Smith, Lift Auto Group; David Ribeiro, Automotive Retailers Association.

Carla and Colin of AAA Dent Repair.

Nathan Rust, Chuck’s Auto Body, and Jolene Watson, networking expert and keynote speaker at SAAR.

Division of Division of RUST CHECK CORP. 6175 Danville Road Mississauga, Ontario L5T 2H7 1800-265-0790 ESTABLISHED IN 1972

FLAUNTING THE FUTURE

Latest in products, tools and training at the Auto Electric Service Show

Story by ALLISON ROGERS

Held every five years, the Regina Auto Electric Service Trade Show hosted its 80th event in mid-March, where more than 100 vendors gathered to show the latest products, tools and training the industry has to offer.

Collision companies in attendance included BETAG North America, Saskatchewan Polytechnic, the Saskatchewan Association of Automotive Repairers (SAAR), PPG, 3M Automotive Aftermarket, Spanesi Americas and Specialty Product Sales.

BETAG took the opportunity to promote its Outer Panel Repair Specialist (OPRS) course offered through Sask Polytech, which instructor Scott Kucharyshen says, “takes repairs to the next level.” The course is designed to help collision centres repair more parts, rather than replace, and is said to drive production by increasing the technician’s capability and efficiency.

Given recent interest, Sask Polyech has upped its course offerings, with four separate classes set to run from August through December this year: two in Saskatoon, and two in Regina.

Brett McNeil was at the show representing 3M Automotive Aftermarket, where he demonstrated the company’s Cubitron II abrasive line and the Festool dustless sanding system.

Josh Stoez of Specialty Product Sales showed off some Canadian-made products, like Uniram’s best-selling UG5000W and UG2000DM gun washer models, as well as Dominion Sure Seal products and “classic equipment” from Innovative Tools, like the new Spray Gun Cabinet Deluxe and various stands.

Constantino Uliano, the Canadian rep for Spanesi Americas, was also in attendance to show off Spanesi’s “360” arsenal of products, from the FLASH pulling system to the Spanesi Touch 3D measuring system, the PULL UP! glue system and more.

PPG’s booth featured the exciting Moonwalk automated paint mixing machine. While popular in Europe, Gilbert Cormier of PPG Canada said the coatings giant is now ready to “get everyone in Canada excited about it.”

“It gives your painters the opportunity to go do something more productive than mixing paint. Mixing paint takes time, we can make mistakes, we can overmix, we have spillage—what this helps is do is stay accurate up to hundredth of a gram—compared to most conventional mixing systems, which stick to a tenth of a gram.

After the user fires a paint code, toner is manually loaded (in no specific order), and a “robot” scans all the barcodes to kickoff the mixing process.

“Me, as a painter—I can do something else. I can go prep, go mask; if I have another job going, I could go finish painting something while Moonwalk does my mixing for me.”

Cormier says Moonwalk is highly efficient in large shops doing between six and eight mixes per day.

“If we look at the cost of a labour minute per technician; say it takes eight minutes to mix paint. Six mixes per day, times eight minutes each time,” explained Cormier.

PPG is offering a five-year lease program for the tool, at approximately US$750, or just over $1,000 per month.

“After that, [shops] have the option to purchase,” he added. “But the benefits of a lease versus a purchase—shops don’t own the maintenance. It’s PPG’s responsibility to fix it, and we will fix it.”

For more information on the Regina Auto Electric Service Trade Show, visit the SAAR Facebook page at www.facebook.com/saarsk for Tom Bissonnette’s exclusive coverage.

42 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Brett McNeil of 3M Automotive Aftermarket. Constantino Uliano, Spanesi Americas.

Gilbert Cormier, PPG Canada.

Art Ewing, BETAG North America; Tom Bissonnette, SAAR; Scott Kucharyshen, Saskatchewan Polytechnic; Dave Flockhart, BETAG North America.

EAST COAST EXPO

Collision community gathers for a lucky St. Pat’s weekend in New Jersey

As the North American automotive aftermarket collectively wakes from winter hibernation it would appear that enthusiasm for industry events has not waned one bit, as the AASP/NJ’s Northeast 2023 Automotive Services Show went off without a hitch on St. Patrick’s Day weekend. Featuring a trade show floor packed with familiar faces from across the collision industry, educational sessions from some of those same experts, and even a friendly bodywork skills competition, this year’s Northeast show had something for everyone.

Collision industry mainstays, like BETAG, AirPro Diagnostics, Axalta, CARSTAR, AkzoNobel, Car-o-Liner and KECO Body Repair, all exhibited their products on the Northeast show floor this year.

Charles Aoun, CEO of Quebec-based CamAuto Pro, told Collision Repair that this year’s show was a true return to form following several years of postponement and poor attendance, on account of the COVID-19 pandemic.

“I believe things are getting back to how they were in previous years,” he said.

“Northeast is the second-biggest show after SEMA, especially for collision repair, so that is why we come.”

Aoun said that his company had its entire suite of products on display for show-goers to take for a spin.

“We did a glue-pulling demo on a used door. We made sure to let everyone use, touch and feel the glue pull tools so that they know how they work.”

Fellow players in the paintless dent repair space, KECO Body Repair was also in attendance at Northeast, displaying its own line of fine dent-pulling products.

“The main thing we were demonstrating was our Level 2E glue pull repair system. Our lateral tension tool, which is also pretty popular, is really a system in of itself,” said Scott Stayton, KECO’s director of marketing and portfolio management.

“Basically, what it does is apply lateral tension away from the damaged area, making it very easy to restore the damage as close as possible [to pre-collision condition] and be ready for paint.”

For KECO, the trip to Secaucus actually proved rather convenient, despite the 20 hour drive from home base in Oklahoma, as Stayton said the team managed to squeeze in a few extra training sessions at some technical institutions along the way.

The show’s main stage was graced by

influential collision industry experts, like Chuck Olsen from AirPro Diagnostics, who spoke on ADAS procedures and how to get paid for them; Mike Anderson from Collision Advice, who offered up proven negotiation tactics for shop managers; and Tim Morgan from Spanesi Americas, who delivered best practices on effective pre-repair planning, to name a few.

On the technician side of things, this year’s Northeast show saw the debut of the Bodywork Bowl Skills Competition for welders, painters and estimators.

Technicians squared off for $500 cash prizes in a variety of collision repair competitions, including a virtual reality painting competition where the top three winners also came away with gift bags from AkzoNobel.

Additionally, winners of the welding competition received, in addition to cash prizes, a new welding mask and smart TV donated by Spanesi Americas, with the top performing tech earning a brand new welding unit.

The AASP/NJ’s Northeast 2023 Automotive Services Show ran from March 17 to 19 at the Meadowlands Exposition Center in Secaucus, New Jersey.

ISSUE 22#2 | COLLISION REPAIR 43 EVENTS

Charles Auon, CamAuto Pro.

Dave Luehr, Elite Bodyshop Solutions

Danny Gredinberg, Database Enhancement Gateway.

Scott Stayton, KECO Body Repair.

Tim Morgan, Spanesi Americas.

Mike Anderson, Collision Advice.

Story by MAX REID

LKQ Monthly Specials

LKQ Monthly Specials

spot and panel refinishing to provide excellent DOI range of topcoats. 1K Low Sealer can be applied over primers on replacement This product is tintable basecoat.

April 1st - 30th, 2023

April 1st - 30th, 2023

On Special!

2 in 1 Primers

Buy 12, Get 1 Free

Buy 12, Get 1 Free

On Special!

1K Low VOC Speed Sealer

1K Low VOC Speed Sealer

Buy 12, Get 1 Free

Buy 12, Get 1 Free

is a ready-to-spray acrylic sealer with good holdout properties and excellent adhesion. This non-sanding sealer is ideal for spot and panel refinishing and is designed to provide excellent DOI under a wide range of topcoats. 1K Low VOC Speed Sealer can be applied over sanded factory primers on replacement parts and panels. This product is tintable with tint paste or basecoat.

is a ready-to-spray acrylic sealer with good holdout properties and excellent adhesion. This non-sanding sealer is ideal for spot and panel refinishing and is designed to provide excellent DOI under a wide range of topcoats. 1K Low VOC Speed Sealer can be applied over sanded factory primers on replacement parts and panels. This product is tintable with tint paste or basecoat.

1 Gallon

2 in 1 Primers

2 in 1 Primers

Buy 12, Get 1 Free

1 Gallon

is a specialty coating designed and convenient priming parts. These primers help seal out moisture, while base for topcoat application metal substrates.

Buy 12, Get 1 Free

is a specialty coating designed for easy and convenient priming of metal and plastic parts. These primers help prevent rust and seal out moisture, while providing a smooth base for topcoat application on metal substrates.

Want to Mix

is a specialty coating designed for easy and convenient priming of metal and plastic parts. These primers help prevent rust and seal out moisture, while providing a smooth base for topcoat application on metal substrates.

20 oz. Aerosol

Want to Mix & Match?

20 oz. Aerosol

Buy12, Get 1 Aerosol

See reverse side for product details and pricing.

See reverse side for product details and pricing.

Buy12,Get 1 Aerosol Primer, Free!

Want to Mix & Match?

Buy12,Get 1 Aerosol Primer, Free!

Transtar 1K Low VOC Speed Sealer

Buy 12, Get 1 Free

Transtar 1K Low VOC Speed Sealer is a ready-to-spray acrylic sealer with good holdout properties and excellent adhesion. This non-sanding sealer is ideal for spot and panel refinishing and is designed to provide excellent DOI under a wide range of topcoats. 1K Low VOC Speed Sealer can be applied over sanded factory primers on replacement parts and panels. This product is tintable with tint paste or basecoat.

Transtar 1K Low VOC Speed Sealer is a ready-to-spray acrylic sealer with good holdout properties and excellent adhesion. This non-sanding sealer is ideal for spot and panel refinishing and is designed to provide excellent DOI under a wide range of topcoats. 1K Low VOC Speed Sealer can be applied over sanded factory primers on replacement parts and panels. This product is tintable with tint paste or basecoat.

Transtar 1K Low VOC Speed Sealer is a ready-to-spray acrylic sealer with good holdout properties and excellent adhesion. This non-sanding sealer is ideal for spot and panel refinishing and is designed to provide excellent DOI under a wide range of topcoats. 1K Low VOC Speed Sealer can be applied over sanded factory primers on replacement parts and panels. This product is tintable with tint paste or basecoat.

Part No.

Transtar 1K Low VOC Speed Sealer Transtar 2 in 1

Part No Description

Description

TRN6091 Gray; 1 Gallon $119.95

TRN6091B Black; 1 Gallon $119.95

Price

TRN6091B Black; 1 Gallon $119.95

Gallon $119.95

TRN6091B Black; 1 Gallon $119.95

TRN6091W White; 1 Gallon $119.95

Want to Mix & Match? Buy 12, Get 1 Aerosol Primer, free!

Transtar

designed for easy of metal and plastic help prevent rust and providing a smooth application on

Safety & Handling

LKQ Dartmouth | 877-301-2639

LKQ Hamilton | 800-747-0601

LKQ London | 888-826-8666

Buy 12, Get 1 Free

2 in 1 Primers are a specialty coating designed for easy and convenient priming of metal and plastic parts. These primers help prevent rust and seal out moisture, while providing a smooth base for topcoat application on metal substrates. 2 in 1 Primers also have excellent flexibility and adhesion properties that enable them to be applied to flexible and rigid parts. 2 in 1 Primers are fast drying, provide superior fill and build, and are easy to sand. They are compatible with virtually all automotive paints.

2 in 1 Primers are a specialty coating designed for easy and convenient priming of metal and plastic parts. These primers help prevent rust and seal out moisture, while providing a smooth base for topcoat application on metal substrates. 2 in 1 Primers also have excellent flexibility and adhesion properties that enable them to be applied to flexible and rigid parts. 2 in 1 Primers are fast drying, provide superior fill and build, and are easy to sand. They are compatible with virtually all automotive paints.

TRN6091W White; 1 Gallon $119.95 Part No.

Description Special

Price

20 oz.

Part No Description

TRN4603 Gray; 20oz. Aerosol $19.95

Special Price

TRN4613 Black 20oz. Aerosol $19.95

TRN4603 Gray; 20oz. Aerosol $19.95

TRN4613 Black 20oz. Aerosol $19.95

TRN4633 White; 20oz. Aerosol $19.95

TRN4613 Black 20oz. Aerosol $19.95

TRN4633 White; 20oz. Aerosol $19.95

Read all directions and warnings prior to using Transtar Products

LKQ Moncton | 877-445-5537

LKQ Niagra Falls | 800-668-9593

LKQ Ottawa | 888-834-3666

LKQ Trenton | 800-267-6306

us

online

TRN4633 White; 20oz. Aerosol $19.95 Offer expires April 30, 2023

Offer expires April 30, 2023

LKQ Upper Brookside | 800-565-2433

LKQ Whitby | 800-747-0601

LKQ Windsor | 800-265-7372

refinishing and is designed DOI under a wide Low VOC Speed over sanded factory replacement parts and panels. with tint paste or Primers 1 Gallon

Aerosol

Mix & Match? Aerosol Primer, Free! Transtar

VOC Speed Sealer

Buy 12, Get 1 Free

1K Low

Safety & Handling Read all directions and warnings prior to using Transtar Products

Transtar 2 in 1 Primer

Part No. Description Special Price TRN6091 Gray; 1

expires

Visit us online at www.LKQCanada.ca/en/ Buy aftermarket parts at Portal.LKQCorp.com/login

Brampton | 800-747-0601 LKQ Dartmouth | 877-301-2639 LKQ Hamilton | 800-747-0601 LKQ London | 888-826-8666 LKQ Moncton | 877-445-5537 LKQ Niagra Falls | 800-668-9593 LKQ Ottawa | 888-834-3666 LKQ Trenton | 800-267-6306 LKQ Upper Brookside | 800-565-2433 LKQ Whitby | 800-747-0601 LKQ Windsor | 800-265-7372 Buy 12, Get 1 Free Buy 12, Get 1 Free Want to Mix & Match? Buy 12, Get 1 Aerosol Primer, free!

Offer

April 30, 2023

LKQ

Primer

Special

Description Special

Price