Volume 22, Number 5, 2023 TOOLS: DO YOU BUY ’EM OR SUPPLY ’EM? >> EXCLUSIVE EXEC VISION: BOB KIRSTIUK & TIM SCHARNBERG OF ADVANTAGE PARTS SOLUTIONS | BASF’S ANNUAL GOLF TOURNAMENT | INSIDE SATA’S GLOBAL HQ Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l $7.99 CAD l 86 John Street, Thornhill, ON L3T 1Y2 www.collisionrepairmag.com ELECTRIC EV Repair Tour embarks across Canada SUPER SAPUTOS

industry does not lack

“This

talent—it lacks leadership.”

THE IT’S

— Joe Saputo, next-gen collision entrepreneur

Open the door to body shop innovation. Introducing 3M™ RepairStack™ Performance Solutions. 3M 2022. All rights reserved. 3M and RepairStack are trademarks or registered trademarks of 3M Company. All the products shown inside the 3M™️ RepairStack™️ Performance Solutions storage cabinet are sold separately. All products shown inside the cabinet are for illustration purposes only. The 3M™️ RepairStack™️ Performance Solutions storage cabinet works with both 3M and non-3M products. Unauthorized use prohibited. All other trademarks are property of their respective owners. Please recycle. Printed in USA. Keep track to be on track. Discover now at repairstack.com. Inventory management Billables invoicing Performance analytics For more information or to schedule a demo, please scan the QR code to connect with a 3M digital expert.

ON THE COVER

The Saputos were one of the first two shops to sign with CARSTAR Canada—and the business has grown bigger than ever imagined. Here from the start, Joe Saputo now embarks on a new journey as an MSO. We know—how have we not had them on a cover?! Well— it’s about time!

FEATURES

55

58

BUY OR SUPPLY?

Who purchases the starter tools for your new apprentices? We asked the industry.

WHAT THE STUDENTS SEEK

Kids these days, eh? See what they really want to learn in this exclusive feature with four major education providers with skilled education backgrounds.

EVENTS

28 32

EV TOUR TORONTO

The Collision Repair magazine EV Repair Tour, supported by Fix Network, presented a wealth of EV information—and we’ve got more stops booked across Canada. Check out the programming that could soon be in a city near you.

SASKATOON’S GRANDEST

The largest-ever trade show from Saskatchewan’s Association of Automotive Repairers was a mustattend affair—see what you missed!

34 44

CLIMATE POSITIVE, CARBON NEGATIVE

Simplicity Car Care hosts its second-ever carbonnegative growth conference for its network. Exclusive pics inside!

BASF MAKES BIRDIES

Glasurit hits the green for an annual golf tournament.

ISSUE 22#5 | COLLISION REPAIR 3 CONTENTS VOLUME 22, ISSUE 5, 2023

CONTENTS

39

22

We took a spray gun vacay—to SATA’s German headquarters! Check out where your spray gun was born, with behind-the-scenes photos.

TOOLS: DO YOU BUY ’EM OR SUPPLY ’EM? >> EXCLUSIVE EXEC VISION: BOB KIRSTIUK & TIM SCHARNBERG OF ADVANTAGE PARTS SOLUTIONS BASF’S ANNUAL GOLF TOURNAMENT INSIDE SATA’S GLOBAL HQ $7.99 CAD www.collisionrepairmag.com ELECTRIC EV Repair Tour embarks across Canada SUPER SAPUTOS “This industry does not lack talent—it lacks leadership.” — Joe Saputo, next-gen collision entrepreneur THE IT’S

4 COLLISION REPAIR COLLISIONREPAIRMAG.COM CONTENTS CONTENTS 67 70 82 06 64 62 PUBLISHER’S PAGE By Darryl Simmons GLOBAL OUTLOOK By Andrew Marsh GETTING INTO ADAS By John Marlowe LET’S GET TECHNICAL By Stefano Liessi WHO’S DRIVING By Jay Perry LAST WORD By Allison Rogers COLUMNS 08 75 10 PEOPLE ON THE MOVE Familiar faces, new roles! NEWS-IN-BRIEF Bit-sized updates from across the industry. REGIONAL NEWS Local news from coast to coast. DEPARTMENTS HAVE YOUR SAY. SUBSCRIBE TODAY! We welcome your comments on anything you see in Collision Repair magazine. Send your feedback to editor@collisionrepairmag.com. YOUR ONLINE SOURCE Canada’s collision repair information resource. New articles and top news stories daily. For more info visit collisionrepairmag.com. 62 28 46 Industry

for the industry’s future. Check out

expert insights. Leading the charge at the Collision Repair magazine EV Repair Tour, supported by Fix Network.

consultant Andrew Marsh shares his global

outlook

the

tell us how the now-global

gained its advantage in this exclusive executive vision.

Bob Kirstiuk and Tim Scharnberg, founders of Advantage Auto Parts,

parts

supplier

EMBRACING AN OPEN DIALOGUE

On insurer and repairer reluctancies

By DARRYL SIMMONS

It truly baffles me why our industry hesitates to foster open dialogue between insurers and repairers, particularly when it comes to agreeing upon safe and effective repair practices, as outlined by OEM and I-CAR standards. This hesitance risks unnecessary confrontation and discord.

Why should there be barriers hindering such crucial discussions, especially about adherence to established procedures? When a process meets the rigorous standards it should be the benchmark to follow. It only makes sense to establish the terms of engagement upfront in any

dire consequences for both vehicle occupants and road safety.

Shifting our focus to education, it is apparent that uniform training standards for repairers, owners, appraisers, and adjusters are a necessity rather than a luxury. The absence of such standards is akin to playing a board game with each player using their own set of rules, resulting in chaos. Fortunately, there are signs of progress in this area, with increased accessibility to standardized training and information.

The reluctance to embrace open dialogue between insurers and repairers remains a

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

ASSISTANT EDITOR

Sarah Perkins | sarah@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677 wanjamann1@gmail.com

AUDIENCE ENGAGEMENT MANAGER

James Kerr | james@mediamatters.ca

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

MARKETING COORDINATOR

William Simmons | william@mediamatters.ca

CONTRIBUTORS

Andrew Marsh, Jay Perry, Stefano Liessi, John Marlowe

SUBSCRIPTION

collaborative endeavor, reducing the likelihood of misunderstandings and disputes.The era of a Goldilocks-style approach to negotiations, where we strive to find the perfect middle ground between estimates and supplements, has outlived its usefulness. In today’s automotive landscape, safe repairs encompass far more than mending sheet metal and applying Bondo. Modern vehicles are replete with intricate electronic and computer systems. Mishandling these components during repairs can jeopardize not only the driver’s safety but also the security of those sharing the road.

The question of authority in the repair process deserves contemplation when it comes to assigning responsibility in the repair process. It appears logical that repair facilities, armed with their expertise, should play a significant role in decision-making. Presently, repair shops shoulder the lion’s share of liability for repairs, operating within the confines of proper procedures and guidelines. The weight of responsibility undoubtedly falls on the repair facility, as they are the custodians of safety. Failure to adhere to standardized procedures can have

challenging hurdle within our industry. Nevertheless, it is a hurdle we must overcome. The Canadian collision repair sector stands at a crossroads, and it is imperative we bridge our differences and move forward collaboratively. Our shared commitment to safety and professionalism should be the guiding force as we navigate the path ahead.

Ultimately, let us remember that our only goal is a safe repair, and the only safe repair is a proper repair. It’s about getting our customers back on the road safely and confidently.

Now on a much lighter note, we are getting ready for SEMA. Make sure to drop by our booth and say hi. We will have something special ready for you!!!

Single edition $7.99 One-year $39.95 ( 6 issues) Collision Repair ™ magazine is published bimonthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing in this publication have been compiled and included with the permission, though not necessarily the endorsement, of the editor, or of independent columnist contributors, and are in no way to be construed as those of the publisher, or as endorsements of them.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL

SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough, ON K9J 3R2

“We acknowledge the financial support of the Government of Canada”

Collision Repair magazine is published by Media Matters Inc., publishers of:

6 COLLISION REPAIR COLLISIONREPAIRMAG.COM PUBLISHER’S PAGE

The era of a Goldilocks-style approach to negotiations, where we strive to find the perfect middle ground between estimates and supplements, has outlived its usefulness.

#60-3680 AUTOMATIC SMART INVERTER RESISTANCE SPOT WELDER #60-3664P SMART SPOT WELDER #40-EP02 BATTERY OPERATED SPR RIVETER ELECTRO-HYDRAULIC accuvision-3D.com arslanauto.com #60-31878 NITROGEN GAS PLASTIC WELDER #60-TM736 ACCUWELD® SINGLE TORCH PULSE MIG WELDER #60-TM742 ACCUWELD® 2 TORCH PULSE MIG WELDER #60-TM750 ACCUWELD® ARC DENT PULLER SYSTEM #60-TM743 ACCUWELD®3 TORCH PULSE MIG WELDER Contact your distributor or Call (800) 465-8575 Complete Line of Tools and Equipment for the Professional Bodyman Most OEM approved and Best Intelligent TECNA Spot welder ever made SD Memory Card SD Memory Card New Smart Inverter TECNA Spot Welder with wi-fi for updates and diagnostics WITH HOT STAPLER GUN FORD APPROVED “SEMA Booth” 12243

PEOPLE ON THE MOVE

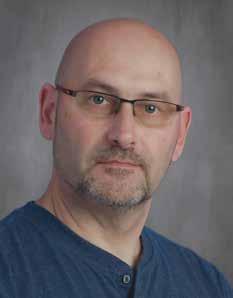

STEFANO LIESSI | COLOR COMPASS

Color Compass Corporation is pleased to announce the appointment of Stefano Liessi as the new Training and Curriculum Coordinator. In his role, Liessi will play a pivotal role in shaping and delivering comprehensive training programs within Color Compass University. Drawing on his extensive experience in both automotive repair and educational program development, Stefano will be responsible for designing, implementing and managing training initiatives.

KEITH TUTTOSI | RETIRED

After a 36-year career across the UAP, Napa and CMAX brands, Keith Tuttosi has decided to retire. Tuttosi served as the director of major accounts for PBS-CMAX for three years, and previously worked with UAP as the regional manager for CMAX’s paint and body accounts in the Western/Pacific region. He also previously served on the CCIF Steering Committee and has made significant contributions to the betterment of the industry over his near four-decade career with Napa. Congratulations on your retirement, Keith!

BRITTANY HUBER | SASKATOON MOTORS

Brittany Huber, the former manager of Dodge City Collision Centre in Saskatoon, Saskatchewan, is now the collision centre manager for Saskatoon Motors, an AutoCanada-owned company, Huber announced on LinkedIn in mid-September. Her announcement was met with much congratulations from her peers in the industry. Huber is also a member of the Saskatchewan Association of Automotive Repairers (SAAR) Board of Directors.

8 COLLISION REPAIR COLLISIONREPAIRMAG.COM NEWS

FROM ALIGNMENT ACORNS, MIGHTY ADAS OAKS GROW

Q: Fair enough, but most collision shops have enough to do without taking on ADAS work. Why isn’t it just easier to continue doing as many are doing, and sub it all out?

RG: That’s where the missing out comes in. The path of least resistance does offer the least resistance, but that doesn’t mean it’s the best path.

Collision shops are tailor-made for calibrations. By definition, nearly every single vehicle coming on the lot will need ADAS work.

Subbing it out is the worst of all worlds. It’s almost as if the process is designed that way. You give up control over the quality of the work but retain responsibility for it. You give away most of the profit but retain all the liability. You increase customer inconvenience with longer cycle times for no offsetting gain.

Q: What’s the relationship between alignments and ADAS calibrations?

RG: Pretty much every ADAS calibration starts, or should start, with an alignment. If the wheels aren’t going straight, then neither is the ADAS, which can defeat the whole purpose. So if you’re already doing alignments every day—and I know not all collision shops are, but they should be—it’s a logical next step to ADAS. Do one; do the other. They’re connected.

Q: Why aren’t more collision shops doing ADAS work now? What’s holding them back?

RG: It’s still early in the game. Most shops have yet to sit down and do a careful analysis of how they could get in on ADAS work. That’s understandable, although shops that have taken that step are definitely ahead of the game. The longer a shop waits, the further behind it’ll be.

I think there’s also some “what somebody told me about ADAS” slowing the process down: You need rocket-science techs, you need an acre of space, the work is complicated and a big investment, and so on.

But really, while there are always things to consider when making any business decision, none of that is true. None of that is true.

Q: So you’re saying ADAS work isn’t complicated and expensive to do?

RG: Some shops have the notion that ADAS work is something exotic. The more you learn, the less mysterious it gets.

The technology is highly sophisticated, but calibrations are not. At all. Any patient, conscientious tech can do them. And the investment into tools and equipment is proportional to your revenue, like anything else.

This is a key point, because some believe ADAS work requires that you have the end-all, state-of-the-art system before you can do your first calibration. Not so. To get into ADAS work, you start small with brands you’re familiar with, gain experience and confidence, and go from there. When your ROI justifies a bigger investment—and it will—that’s the time to move up.

It’s your shop, your alignment system, your customers, your revenue. Make ADAS your work.

In time, I think most collision shops will see that. Why would they not?

Q: But what about space, then? Not every shop can simply clear out a bay or two all day, every day.

RG: That may be true now, but in time they may well want to! ADAS work requiring wide open spaces is a frequent misconception. To perform the lion’s share of ADAS work, the typical shop likely has sufficient space as it is. Most forward-facing calibrations can be done in 10 feet or less, and very rarely will you encounter a calibration requiring room around all four sides of a vehicle at the same time.

A little workaround creativity may be required from time to time, such as moving the vehicle this way or that to perform this or that calibration, or backing it a bit out the door, or clearing space by moving shop equipment around (most is on wheels, after all!). Just as you don’t need 100 yards to play touch football, you don’t need a textbook amount of space to perform ADAS work.

Q: What’s the most important advice you can give to collision shops that do wish to branch out into ADAS?

RG: I think what may hit home the hardest is that given the growing—and growing—amount of ADAS work now and in the near future, you may not choose to do it, but someone else surely will. Subbing it out will make less and less sense, as you simply give away control and tons of profitable work but keep all the headaches. And the best way to get started is to pair up with an experienced and reputable partner who can guide you every step of the way.

In other words, you don’t have to do it alone. Get help, get equipment, get experience, and get going on building a profitable ADAS business. Rather than being a collision shop that gives ADAS work away, become the shop others bring work to.

A Q&A with Hunter Engineering’s Ryan Gerber on how collision shops are missing out www.hunter.com

ADVERTORIAL

COAST TO COAST IN 18 CHARGES

Rainer Zietlow recently drove a Volkswagen ID.4 electric vehicle across Canada, stopping just 18 times to recharge—a feat the adventure driver has won a Guinness World Record for. Zietlow and his cameraman, Elric Popp, departed St. John’s, Newfoundland, on July 25, 2023. The pair traversed 7,133 kilometres across Canada and ended their trip in Victoria, British Columbia on August 1, 2023. Zietlow is now making another journey, in the opposite direction, stopping at 145 VW dealers across the nation to spread news of his mission. Pierre Boutin, VW Canada’s president and CEO stated: “The Volkswagen family is thrilled to celebrate Rainer’s new Guinness World Record.”

CYBER SMASH

Crash-tested Tesla Cybertrucks have been spotted travelling on cargo trucks in the United States, according to photos circulating on social media app X. According to the original poster, you can “see the crash tape as well as damage/missing pieces.” According to Tesla CEO Elon Musk, Cybertruck deliveries will commence “very soon,” with a special delivery event hopefully taking place before the end of Q3.

NO MORE TIME

Tesla has changed how it bills its Canadian customers for charging. Instead of being billed for the time spent at the charging station, users will be charged according to the amount of electricity put into their vehicles. The move comes after an extended wait—six months after Measurement Canada granted a temporary dispensation order allowing charging providers to bill customers per kWh, and more than two years after the government first began the process.The temporary dispensation was granted in late February this year, prompting some charging operators to make the switch. Drive Tesla Canada reports that rates are consistent across the nation.

10 COLLISION REPAIR COLLISIONREPAIRMAG.COM EV NEWS

The Volkswagen team celebrates Zietlow’s Guinness World Record.

Depicted above, an image of a Cyber Smash featuring the red and white checkered tape used in crash testing.

A LESSON IN LABOUR LAWS

The Canadian Federation of Independent Business (CFIB) issued a statement on the British Columbia port workers’ strike saying the work stoppage serves as a “case study in the urgent need to rethink Canada’s labour laws” to ensure the needs of the broader economy are met. The organization said that, while it is relieved the port workers have accepted a new deal, it will take weeks for the backlog to be addressed, causing significant financial consequences for small businesses across Canada.

WITHHOLDING WALKOUTS

After reaching an agreement with Ford Motor Co. two hours before its second strike deadline, Unifor announces a tentative deal that will ensure Canadian auto assembly plant workers avoid striking. On September 19, Unifor President Lana Payne released a statement saying that the “tentative agreement addresses all of the items raised by members in preparation for this round of collective bargaining.” In avoiding immediate strike actions after six weeks of bargaining processes, Unifor has averted what would otherwise have been the first automotive strike in Canada for the past 33 years. Unifor did not release details of the agreement, but sources did confirm that Unifor was asking for a “substantial wage increase north of 20 per cent.”

POWERED BY PARTS

Canadian retail sales grew ever so slightly in June (0.1 percent from the previous month), and that growth was mostly driven by car sales, according to data released by Statistics Canada in late August. The gain was led by increases at motor vehicle and parts dealers (2.9 percent gain and 2.5 percent gain, respectively), as well as gas stations and fuel vendors, said Stats Can. When auto and auto parts sales are removed from the equation, retail sales declined by 0.9 percent.

ISSUE 22#5 | COLLISION REPAIR 11 INDUSTRY NEWS

ProSand® is a leading-edge supplier for the automotive collision industry at a value price that delivers performance and results. Increase your productivity and reduce your costs with the ProSand® product line. COLLISION REPAIR ABRASIVE PRODUCTS Visit us at www.colorcompass.com

The entire B.C. port network shutdown lasted for 13 days and the Canadian Manufacturers and Exporters estimate approximately $500 million of trade was disrupted daily through the work stoppage.

TOYOTA TOPS TESLA

Overall customer satisfaction has grown among American car buyers, according to the American Customer Satisfaction Index (ACSI). The ACSI Study—highlighting the overall satisfaction based on interviews with 8,941 customers, chosen at random between July 2022 and June 2023—noted that overall customer satisfaction with the automobile industry has improved following last year’s decline with an overall satisfaction rating of 79 percent. Of mass-produced vehicles, Toyota leads with an overall ACSI score of 84 percent. Of luxury brand vehicles, Lexus remains on top with an overall satisfaction rating of 83 percent. However, following a one percent slip, they now share the top spot with Tesla. While drivers of both electric and hybrid vehicles are, on average, more satisfied than customers who drive gas-powered vehicles, EVs rank last for dependability, reliability, and have the highest complaint rate from customers.

ROBOTIC RATINGS

Audi is using artificial intelligence (AI) to test its spot welds for quality control purposes. The automaker said so in a press release at the end of June, where it announced an AI system developed and tested at its site in Neckarslum, Germany. The tech allows Audi to analyze approximately 1.5 million spot welds on 300 vehicles per shift at the Neckarslum site. The previous method, which used ultrasound, was capable of checking only 5,000 welds per vehicle, says Audi.

ROUND TWO

Nissan said that it would be recalling more than 230,000 Sentra units in the United States, plus 20,135 units in Canada, because front steering tie-rods can warp and break.This recall covers certain 2020-2022 models; versions of the vehicle first introduced in 2019. In a document to the NHTSA, Nissan states that, if the tie-rods are bent, they can be damaged, deformed and potentially affect the efficiency of steering, increasing the risk of an accident. This is the second time Nissan has recalled Sentra models for this steering issue. The OEM recalled nearly 13,000 vehicles for the problem in 2021.

VIVA VINFAST

Vietnamese electric vehicle manufacturer VinFast went public on the Nasdaq with a whopping US$85 billion valuation—almost twice that of General Motors or Ford, the two largest automakers in the U.S. VinFast secured a Nasdaq listing thanks to its merger with a special purpose acquisition company (SPAC) Black Spade Acquisition.

12 COLLISION REPAIR COLLISIONREPAIRMAG.COM OEM NEWS

The tech allows Audi to analyze approximately 1.5 million spot welds on 300 vehicles per shift. (PHOTO: Audi)

The deal valued VinFast at approximately $23 billion, according to a filing with the U.S. Securities and Exchange Commission from June. (PHOTO: VinFast)

ADAS CALIBRATION. SAFER ALIGNMENTS. ONE MAXIMIZED BAY.

MAXISYS IA900AST ADAS BAY

ADAS CALIBRATION. SAFER ALIGNMENTS. ONE MAXIMIZED BAY.

FOUR-WHEEL ALIGNMENT & ADAS CALIBRATION SYSTEM

FOUR-WHEEL ALIGNMENT & ADAS CALIBRATION SYSTEM

ADAS CALIBRATIONS IN-HOUSE SUBLET TO YOURSELF Maxisys COLLISION SIMPLIFIED A WORKFLOW-DRIVEN SOLUTION FOR A COMPLICATED PROCESS

IA900AST ADAS

KEEP

MAXISYS

BAY MAX LIFT

MAXISYS ULTRAADAS AUTEL ACADEMY TECHNICAL TRAINING Visit autel.com/us/academy and register today for hands on automotive diagnostic, repair, service, and ADAS instruction. AUTEL.COM FOLLOW US @AUTELTOOLS

ADAS CALIBRATIONS IN-HOUSE SUBLET

YOURSELF Maxisys COLLISION SIMPLIFIED A WORKFLOW-DRIVEN SOLUTION FOR A COMPLICATED PROCESS

Access to OEM Solutions KEEP

TO

MAX LIFT

MAXISYS ULTRAADAS AUTEL ACADEMY TECHNICAL TRAINING Visit autel.com/us/academy and register today for hands on automotive diagnostic, repair, service, and ADAS instruction. AUTEL.COM FOLLOW US @AUTELTOOLS

SIMPLIFIED

Access to OEM Solutions

POLYGLOT PLATFORM

Arslan Automotive is currently finalizing the Korean translation of its Accuvision 3D measuring system and its associated software, company owner Arman Gurarslan told Collision Repair. Gurarslan hosted a team of Korean automotive professionals at Performance Collision Brampton, managed by Gary Dunn, in mid-August. The Korean team had the chance to receive training on and provide feedback on the newly translated version of the program. Once the equipment is all certified in its Korean language translation, Kia Motors will have exclusive first access to the 3D measurement technology.

STRONG COLLISION PERFORMANCE

AutoCanada reported its Q2 financials in early August, citing a “robust performance” in its parts, services and collision repair operations. Consolidated gross profit increased to $318.7 million, up 14.1 percent. The primary drivers of gross profit were higher new vehicle sales volumes and strong performances from AutoCanada’s used retail vehicle division; its parts and services business and in collision repair. Recent acquisitions were also a driver, wrote the company. In Q2 2023, AutoCanada acquired a dealership and collision centre in Windsor, Ontario, and London Auto Collision in London, Ontario. Revenues for the quarter range in at $1,548.6 million, marking an increase of 7.7 percent.

14 COLLISION REPAIR COLLISIONREPAIRMAG.COM BUSINESS NEWS

Sylvain Landry of Arslan Automotive shows the team the new translated version, with the language interpretation assistance of Andy JH Lee.

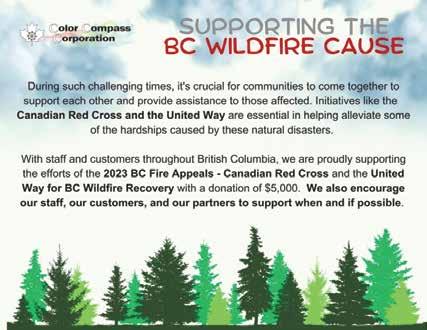

SUPPORTING THE CAUSE

Color Compass has donated $5,000 to the Canadian Red Cross Fires Appeal and the United Way for BC Wildfire Recovery, the jobber announced via a LinkedIn post. Color Compass wrote that, “it’s truly inspiring to see the dedication to making a difference in the face of such important challenges in the BC Wildfire Cause.” They noted that, “such initiatives highlight the optimistic influence businesses can have beyond their regular operations.” Color Compass encourages “staff, customers and partners to join in the support; you’re fostering a sense of unity and community engagement that can have a lasting impact.”

ROAD TO RECOVERY

Motor vehicle parts shipments have exceeded pre-pandemic figures by 12.5 percent. This figure marks over $2 billion, according to a recent release from DesRosiers Automotive Consultants. While the motor vehicle assembly industry shipments remain behind 2019 figures, it is only by 4.3 percent, representing significant growth. This growth is further complemented by growth in other key industries. Metalworking machinery manufacturing increased by 33.7 percent compared to 2019, with the motor vehicle body and trailer manufacturing industry seeing shipments grow by 49.4 percent. With these upward trends and stronger performance, the industry is entering a period of transformational growth as it moves to BEV-focused assembly.

ISSUE 22#5 | COLLISION REPAIR 15 BUSINESS NEWS

OPEN 8 AM - 5 PM MONDAY - FRIDAY Go to www.carcone.com | Call Toll Free 800.263.2022 Or visit us at 1030 Bloomington Road, Aurora, Ontario L4G 0L7 CARCONE’S CARCONE’S AUTO RECYCLING & WHEEL REFINISHING Our state of the art equipment and quality craftsmanship makes us the industry leader in Wheel Refinishing and OEM aftermarket wheels. Your trusted source since 1978 for recycled OEM Parts. Providing quality wheel refinishing for 29 years. Your source for quality recycled OEM parts on all makes and models with 1 million parts guaranteed in stock. We have new products arriving daily. WHEEL REFINISHING RECYCLED PARTS WE SHIP CANADA WIDE. 24-48 hour deliveries to many of the surrounding areas including: Toronto | Mississauga | Scarborough | Port Hope | Brampton | Barrie | Orillia | Cookstown | Alliston | Tottenham C M Y CM MY CY CMY K ai1673372384116_Carcones_COLL_AR_HalfPage_7125x475_FIN copy.pdf 1 2023-01-10 12:39 PM

Compass

Color

offers a message of support for the B.C. wildfire cause.

ONTARIO LAWYER GROUP CALLS FOR INVESTIGATION INTO AVIVA INSURANCE’S CONDUCT

The Ontario Trial Lawyers Association (OTLA) issued a press release early August regarding the “troubling revelation” that Aviva Insurance hired Thérèse Reilly, a government insurance adjudicator, while she was employed with the Licence Appeal Tribunal (LAT). Reilly had been involved in a number of case decisions involving her future employer between May 2022 and November 2022. The OTLA wrote: “At issue is the (...) revelation that Reilly was offered and accepted a position with Aviva Insurance in June 2022 but stayed with the LAT until November of that year.” The LAT claimed to not know of Reilly’s employment plans with Aviva and wants to implement a policy where adjudicators cannot be employed by companies with a vested interest in collision claims. Reilly shared the OTLA’s concerns and believes that Aviva should reconsider its policies and procedures regarding adjudicators with offers of employment.

EYES TO CANADA

Wawanesa has entered an agreement to sell its U.S. subsidiary, Wawanesa General Insurance Company, to focus its efforts on the Canadian market, the insurer announced on August 1. Jeff Goy, president and CEO of Wawanesa, did not specify what that would mean for Canadian customers; just that “[Wawanesa] look[s] forward to further strengthening of the products and services we provide Canadian families and businesses, and to providing exceptional service to even more members across Canada.” The insurer’s U.S. operations will be acquired by the Automobile Club of Southern California, the largest member of the AAA Federation of motor clubs.

Global Finishing Solutions (GFS) is dedicated to helping body shops be more productive, efficient and profitable, while achieving flawless paint finishes. Whether you are investing in your first paint booth or looking to increase throughput within your current footprint, we will work with you to find the right solution for your needs.

16 COLLISION REPAIR COLLISIONREPAIRMAG.COM INSURANCE NEWS

globalfinishing.com See Us at SEMA Booth #31067

PRECISE PAINTING

Axalta has announced a new venture with an inkjet manufacturer, in which the coatings company plans to provide a “next-generation sustainable digital paint technology for the transportation industry.” More specifically, this planned technology could contribute up to a 30 percent reduction in CO2 emissions for two-toned vehicle manufacturers, according to Axalta. Digital paint, also referred to as an overspray-free application, is an advanced paint application that allows for precise paint placement. Through Axalta and Xaar’s patented technology, Axalta NextJet™ enables design flexibility for two-tone vehicles and allows customers to create patterns, details, and images in a sustainable way. The combined technology solution is being tested with customers and could be in production as early as 2024.

FORD’S NEW HAT

Electric vehicles are pretty advanced, but they’ve always been missing one thing–a fancy hat. Thankfully, Ford is here to change that with its new patent, wherein the OEM outlines a battery pack that comes attached to a vehicle’s roof. According to the patent, this “backup battery assembly is configured to recharge the traction battery pack through a charge port in the electrified vehicle” and can “include one or more battery modules within an enclosure.” The pack, which looks like something that would be carried on the roof rack of a vehicle, would sit on the car’s roof, because of its portability, and would be “particularly useful for vehicles that frequent areas lacking high numbers of charging stations, such as vehicles used for off-roading.”

PLUGGED IN

“The frequency of electric vehicle collision repair claims grew to 2.64 percent in Canada last quarter,” Mitchell stated in its latest Plugged In: EV Collision Insights report. One of the first notes in the report makes the claim that EVs tend to be designated non-drivable at a lower frequency than ICE counterparts, contrary to popular belief and erroneous news reports that circulated last spring. “The relative lack of moving parts means that an EV’s critical powertrain is less likely to be compromised during an accident. While certain ADAS components may be disrupted due to an advanced level of interconnectivity, the vehicle still has a higher likelihood of remaining drivable. EVs are, however, more apt to be considered non-drivable after a rear-end impact (10.87 percent) than ICE automobiles (9.72 percent). This is primarily due to the presence of powertrain components in the rear of the vehicle—such as an electric motor—that are lacking in ICE automobile design,” wrote Mitchell.

MOLDING A GIGA BREAKTHROUGH

Tesla is reportedly nearing a breakthrough in technology that could ‘gigacast’ an EVs entire underbody in one solid piece. The electric automaker already uses “Gigapresses” with 6,000 to 9,000 tonnes of clamping pressure to mold the front and rear structures of its Model Y. A newly developed process would allow Tesla to die cast nearly all of the complex underbody of an EV in one piece. Two inside sources from Tesla further claimed that if the company were to be successful in the giga-casting process, it would be able to develop a car from the ground up in just 18 to 24 months compared to rival companies which can take anywhere from three to four years. To cast subframes with hollows as part of one giga-casting, Tesla plans to place solid sand cores printed by jets within the overall mold. Once the part has been cast, the sand is removed to leave the voids. Currently, design questions still remain for how Tesla will mold larger vehicles, but at the moment technological shifts for its smaller EVs are creating a sandstorm of change.

18 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY NEWS

EVs may be written off at a lower frequency than ICE vehicles, but Mitchell’s data says claims severity is often greater with electric vehicles.

PLATINUM GOLD STANDARD LIMITED LIFETIME WARRANTY All Keystone Platinum Plus products offer the highest standards and Industry-leading Limited Lifetime Warranty. CAPA CERTIFIED Over 90% of Keystone Platinum Plus aftermarket collision repair products are CAPA Certified. NOTE: Eligible parts only. Wheels are excluded from CAPA certification but are subject to strict SAE standards. ABSORBERS • BUMPERS • BUMPER BRACKETS • BUMPER REINFORCEMENTS • DOORS FENDERS • GRILLES • HOODS • LIGHTING • MIRRORS • STEP BUMPER ASSEMBLIES • WHEELS An LKQ Company ® Call Today! (866) LKQ-CORP | (866) 557-2677 or Order Online at LKQCanada.ca/en/ ©2021 LKQ Corporation. LIMITED LIFETIME WARRANTY All Keystone Platinum Plus products offer the highest standards and Industry-leading Limited Lifetime Warranty. CAPA CERTIFIED Over 90% of Keystone Platinum Plus aftermarket collision repair products are CAPA Certified. NOTE: Eligible parts only. Wheels are excluded from CAPA certification but are subject to strict SAE standards. ABSORBERS • BUMPERS • BUMPER BRACKETS • BUMPER REINFORCEMENTS • DOORS FENDERS • GRILLES • HOODS • LIGHTING • MIRRORS • STEP BUMPER ASSEMBLIES • WHEELS An LKQ Company ® Call Today! (866) LKQ-CORP | (866) 557-2677 or Order Online at LKQCanada.ca/en/ ©2021 LKQ Corporation.

PROLONGED PAINTING

Bugatti issued a press release this past March detailing its whopping 600-hour process in painting a vehicle. Before the paint is even opened, specialists check panels for minuscule pits that may affect the finish and other imperfections. After clearing the car, a layer of primer is applied and sanded, followed by a second layer. Before the painters apply this first shade, they undertake a comprehensive process of clear coating and sanding. Once the car is painted to the high standards required by Bugatti, there are still four days of polishing in its future. Finally, the paintwork is scrutinized for no less than ten hours. In total, this extremely meticulous process is the equivalent of one person working 24 hours a day constantly for nearly a month.

HERE’S THE T

Tesla has won a trademark infringement lawsuit against Sino Drinks, which was selling ‘Tesila’ branded beers and sodas bearing a logo suspiciously similar to Tesla. The case against Sino Drinks was filed over a year ago. Tesla accused the company of unlawfully using its trademarks and requested approx. $928,000 in compensation. The Shanghai High Court ruled in favour of Tesla, and Sino must halt its use of the OEM’s trademark. Thankfully, the two companies were able to reach an agreement and Giga Bier launched in March 2023.

MIND YOUR BEESWAX

Burlington, Ontario, was quite literally buzzing with activity after a truck carrying five million bees spilled its contents onto the road. Halton regional police stated that they received a call reporting the bees had come loose from a truck and spilled onto a road in Burlington, Ontario. The boxes containing the beehives had slid off the trailer that was transporting them due to being improperly strapped down. Police reached out to several beekeepers in the area who were able to safely collect the bee crates as well as most of the bees themselves. Thankfully, no one was seriously injured–although, the driver of the transport truck did receive over 100 bee stings and was attended by paramedics.

BOTTOMS UP

While North America has faced concerns over Tide pod ingestion, Spain recently confronted a new challenge concerning the potential consumption of cleaning products after the European grocery store, Lidl, was forced to recall an apricot-scented paint cleaner. The car paint cleaner called Robbyrob, came in a one-litre bottle with a red screw-top lid. The actual cleaner was orange coloured and apricot scented. Instructions were only listed in German and English, and this created concerns that Spanish shoppers would think the product was meant for consumption. The Ministry of Consumer Affairs stepped in following a complaint made by the FACUA-Consumers in Action Group and agreed that the lack of Spanish instructions compounded with the product’s qualities made it a potential risk. The product has since been removed from shelves.

20 COLLISION REPAIR COLLISIONREPAIRMAG.COM CAN YOU BELIEVE THIS?!

Sino Drinks’ ‘Tesla’ branded beer logo.

Robbyrob’s apricot-scented paint cleaner.

ADAPTING ANCASTER

Joe Saputo continues the family legacy with his own twist

ON THE COVER

“Our industry doesn’t lack next-gen employees. We lack leadership.”

— Joe Saputo, owner, CARSTAR Ancaster

22 COLLISION REPAIR COLLISIONREPAIRMAG.COM

Sam Saputo was one of the first two CARSTAR Canada franchisees after Sam Mercanti, his boss at Ontario Auto Collision and the eventual founder of CARSTAR Canada, saw potential in the talented repairer. His son, Joe Saputo, has spent his life in the industry and now continues his family’s legacy in the sector.

Sam Saputo first learned to repair vehicles in a 40,000 sq. ft. bodyshop in Germany.

Upon moving to Canada, the Sicilian-born body repairer was recognized as one of the more skilled employees at Ontario Auto Collision, which was run by Sam Mercanti, the eventual founder of CARSTAR Canada.

As a man extremely dedicated to his craft, with a boss who saw potential in him, Sam Saputo went on to become one of the first two franchisees of CARSTAR Canada back in 1994. Today, his son Joe runs operations at the legacy shop—which has marked some major milestones in recent years.

“I have always looked up to my dad,” Joe Saputo, owner of CARSTAR Ancaster and CARSTAR Canada’s 2023 Franchisee of the Year tells Collision Repair mag. “I wanted to be exactly like him.”

Joe started “working” at his father’s place of work—Ontario Auto Collision’s Gage Avenue location—when he was around eight years old, coming to the shop on Saturdays to help detail customer cars.

When Sam Saputo took on operations at CARSTAR Ancaster, Joe was working “like crazy.” He spent that entire first summer detailing cars, emptying garbages and—without explicitly being told he was allowed to—he might have dabbled in the paint department.

ISSUE 22#5 | COLLISION REPAIR 23 ON THE COVER

Story by ALLISON ROGERS

With the acquisition of CARSTAR Gueph, the Saputo Capital Collision Group has three stores; CARSTAR Ancaster and CARSTAR Ancaster West are also under Saputo ownership.

The whole crew at CARSTAR Ancaster.

“I mean, it was better that I was making trouble in paint than on the street with my friends.”

It wasn’t rare for Joe to be stirring up trouble. Sam and his wife Rosa were quite familiar with getting calls from their son’s school.

“My mom would pick me up and we’d head right out of the parking lot, headed toward the shop. Honestly, I loved it.”

But one day, Sam and Rosa decided enough was enough.

“Instead of turning right, my mom turned left. I said, ‘where are you going? The shop is that way.’ She said, ‘Nope. You’re done. You will never work for us.’”

When Sam came home from the shop that night, he told Joe he had one week to find a job, or he could go live elsewhere.

“I went to Remo Mercanti at the CARSTAR Hamilton Rymal Road location and told him I needed a job. He immediately took me on. I mean, he was getting this kid who had been raised in the industry and knew that all I wanted to do was fix cars.”

Joe worked at CARSTAR Hamilton Rymal for his entire apprenticeship.

“The best way I can describe it, going from CARSTAR Ancaster to Rymal Road—it was like going from the rural suburbs to being dropped in the Times Square of collision repair. I mean, it was doing 12 times the volume that Ancaster was at that time.”

Once Joe achieved his bodyman license,

Sam and Rosa allowed him back. He immediately took over Sam’s rack on the production floor, allowing him to get back into the office with Rosa and oversee his duties as owner.

In 2003, Joe was promoted to general manager of CARSTAR Ancaster. An accident later tragically kept him away from the business for four years. He nearly lost his life through the incident and ensuing complications—but he credits the unwavering support of his family and friends for getting him through.

“I couldn’t get away with just sitting around—everyone was like, ‘What’s wrong with you? You’re better than this. So I came back to the business in 2007.”

At the time, the CARSTAR Ancaster team had “very strong hands,” says Joe, and could easily repair vehicles in a very profitable way. But, in about 2013, things took a turn.

“I watched repair profitability plummet. Half of these super skilled repairers—the average age is high—and it seemed we were hiring people that, truthfully, wasn’t so excited about fixing these lightweight, thinner exterior panels on cars.”

Meanwhile, Joe looked at the profit margins for CARSTAR Ancaster and wondered how they could grow when employee wages were rising each year while labour rates stayed the same.

“I saw ways that high-tech tooling could help us achieve better results. I’d show Sam and Rosa a $10,000 dent puller and they’d be

like, ‘Are you out of your mind?!’ Meanwhile I’d just watched our team try to pound out a dent that took a full four hours and looks terrible.”

In 2018, Sam and Rosa began to transition out of the business—and Joe was ready to outfit the facility with a new vision.

Enter Natasha Woods. At the time, Natasha was office manager—though she first joined the business in 2011 as an accountant. Joe saw how instrumental she was to their success and noted her advanced mindset in the new ethics of the collision business.

“As an office manager, she was far beyond that. She had incredibly innovative ways of closing files and taking a more granular look at our P&L statements, and she really understood repair methods.”

“Joe’s leadership skills had a huge influence,” said Natasha.“He always pushed me to do better, and questioned a lot of the things I did, which fuelled me.”

The two started to work together to build out their vision for a future-proofed CARSTAR Ancaster.

“I now had the check book to myself, and I’m going to Sam and Rosa with new racks, new equipment, asking, ‘can we do it?’” said Joe. “They told me to go for it.”

Meanwhile, Natasha’s bookkeeping and efforts in keeping staff up-to-date with maximizing profitability at Ancaster proved an extremely successful strategy.

24 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

Natasha Woods, general manager of CARSTAR Ancaster—or the Scottie Pippen to Joe’s Michael Jordan, in the team’s own words.

“Natasha did all of that, without me dictating any of it, and we showed significant dividends. The company was growing, and we were profitable.”

When asked what Natasha’s official title would be, the pair—who often refer to themselves as Michael Jordan and Scottie Pippen— looked at each other and laughed.

“We just had this conversation this morning,” said Joe.

“We seriously talk about it all the time,” Natasha added.

“I don’t think there’s any other title than general manager, 100 percent,” said Joe.

Two years after the first wave of digital investments, CARSTAR Ancaster had grown operations by more than 35 percent.

Joe and Natasha continued the same tactics through 2020 and 2021, showing significant growth across the board both years. In 2021, Joe says they had a “clear vision” of CARSTAR Ancaster’s future for the next 10 years.

They transformed the production floor, investing in new technology and breaking down their strategies in repair versus replace.

“We started to replace more parts because, for one, the OEM doesn’t want you repairing them.”

Each tech at CARSTAR Ancaster has a laptop and access to an entire library of OEM procedures.

“If I bring a green person in and hand them a grinder, a hammer, a dolly, and gog-

ISSUE 22#5 | COLLISION REPAIR 25 ON THE COVER

Joe Saputo was named Franchisee of the Year for CARSTAR at the 2023 Driven Brands combined Canadian Conference.

gles, they’re going to spend maybe a day in here and quit. Now if I give them a laptop, shiny tools, shiny new parts, a shiny new car and every procedure on how to do the job, they are incredibly interested in sticking around.

“With all due respect to the incredible business owners and managers out there—I think a lot of collision facilities are still running the business how they did 30 years ago. This industry doesn’t lack next-gen employees—we lack leadership.”

In outfitting new ideologies and technologies, CARSTAR Ancaster was able to scale its volume by 80 percent.

“We went from $2.4 million in annual sales to $4.5 million,” added Joe.

A big part of the company’s performance can be attributed to a relationship with Sam Malatesta and CCi Global Technologies, who came in and aggregated “every single piece of data known to man” inside the store, says Joe.

“Administratively, financially, productively, technologically—they aggregate the data for us and we look at it and see the gaps to grow, almost double, our sales.”

Joe added that the company’s growth and scale would not have been possible without the support of their paint partners at BASF.

“Since 1994, transitioning from the RM line to Glasurit 55 line; onboarding 90 line in the early 00s and, most recently, being the first CARSTAR facility in Canda to introduce Glasurit 100 line—our lineage with BASF demonstrates a compelling partnership,” said Joe.

He added that CARSTAR Ancaster was about a year away from making a significant investment in a double-wide fix-line spray booth set when they were approached about piloting 100 line.

“After three months of training, we quickly realized it was BASF’s science that would escalate our scale and performance, rather than more equipment.”

With 90 line, CARSTAR Ancaster’s max paint hours booth cycle was approximately 8 hours per RO, with booth load at one hour, 25 minutes. With 100 line, that number grew to 12.5 paint hours per RO at 42 minutes.

CARSTAR Ancaster is on track to break its own financial records this year, and Joe recently took over ownership of CARSTAR Guelph, where he’s employed the same technology-based tactics with great success thus far.

As the business continues to grow, Joe can’t help but smile as he watches how full-circle things have come for his father—who, during the interview for this story, was hard at work on a bumper replacement on the shop floor.

Sam may have transitioned out of the business in 2018, but the lifelong collision repairer missed being in the bodyshop and told Joe he wanted to come back to work in 2022. Today, you’ll find Sam Saputo bustling around the bodyshop with the rest of the CARSTAR Ancaster team.

“There’s no better, more graceful way for my father to exit the business than letting his children take over and going back to do exactly what he has always loved to do —fix cars.”

26 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

Nowadays, you’ll probably find Sam Saputo working on a car on the production floor at CARSTAR Ancaster. It’s a perfect “full circle” moment, says Joe.

Natasha Woods and Joe Saputo, two of the dynamic minds behind CARSTAR Ancaster’s explosive growth.

Every technician at CARSTAR Ancaster and CARSTAR Guelph receives a laptop and access to any OEM procedure they could possibly need.

WITH TELWIN.COM MADE IN ITALY CHARGERS & STARTERS WELDING SPOT WELDING SMART REPAIR (905) 364-5093 crescentindustries.ca NOW IN CANADA via

LEADING THE CHARGE

EV Repair Tour kicks off in Toronto

Collision Repair magazine is taking electric vehicle repair education across Canada. In Toronto, we welcomed more than 100 industry members for a full day of electric vehicle education. Speakers included David Giles, a long-time repairer of hybrid technologies and president of Powered EV Consulting; Joseph Chung, account manager responsible for EV battery recycling and repurposing initiatives at Call2Recycle; Martyn Johns, national director of emerging technologies for NAPA/ UAP and Alan McClelland, dean of Ontario’s Centennial College, School of Transportation. Our EV Repair Tour, supported by Fix Network, also made stops in Saskatoon, Saskatchewan; Calgary, Alberta, and Vancouver, British Columbia this year, followed by a stop in Blainville, Quebec, next year. Visit evrepairmag.com for more information on a tour date near you, or to view videos from our past events. In the meantime, check out our scrapbook from our stop in Toronto. It was electric!

Martyn Johns, NAPA/UAP.

Mark Lockwood, Desjardins; Serge Babineau, IAA.

Martyn Johns, NAPA/UAP.

Mark Lockwood, Desjardins; Serge Babineau, IAA.

EVENTS 28 COLLISION REPAIR COLLISIONREPAIRMAG.COM

Joseph Chung, Call2Recycle; Frank Phillips, Rivian; Daryll O’Keefe, Fix Network; Gloria Mann, Media Matters; Zakari Krieger, Fix Network; David Giles, Powered EV Consulting.

ISSUE 22#5 | COLLISION REPAIR 29 EVENTS

Frank Serravale, Thorold Auto Parts.

Paulo Santos, Centennial College; Greg Aguilera, IAC Consulting.

Rodelo Harrilal, Greater Toronto Appraisal; Howard Berg, Fuyao Group; Kate Tapley, Fix Auto Stratford.

Paul Nestorowich, Enterprise Holdings; Ritu Shannon, Enterprise Holdings; Howard Berg, Fuyao Group.

Frank Phillips of Rivian was kind enough to bring along an R1S for attendees to view up-close. They aren’t even available in all of Canada yet!

Sonia Bouthiliette, Fix Network.

Zakari Krieger, Fix Network, and David Gold, Standard Auto Wreckers.

Don Teevens, Consolidated Collision Services, and Jean Paul Kleniewski, SATA Canada.

Brian Chiu, Nissan Canada.

30 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Amin Youssef, Fix Network and Mike Minardi, Ontario Spray Booths.

Gloria Mann threatening to steal the Rivian R1S.

Chad Baltzer, FlatLine; Craig Kirby, Consolidated Collision Services.

Alan McClelland of Centennial College, EV Repair Tour speaker in Milton.

The registration crew! Wanja Mann, Sarah Perkins of Media Matters, and Pat Francisco of Fix Network.

Spencer Loback of Media Matters making sure all is swell behind the camera. Check out our site for video coverage!

John Marlowe, Level5Drive.

The Media Matters / EV Repair Tour Toronto team. Back: William Simmons, Spencer Loback, James Kerr, Wanja Mann, Gloria Mann, Orest Tkazcuk. Front: Sarah Perkins, Allison Rogers.

GOOD TIMES IN THE ’TOON

SAAR hosts its largest-ever trade show at fall conference

Another Fall Conference from the Saskatchewan Association of Automotive Repairers (SAAR) has come and gone–and this sure was one for the books.

More than 150 industry members hit the Dakota Dunes Golf Course on day one of the event, while a delicious steak supper topped off the evening before a full day of programming.

This year’s event featured the largest-ever SAAR Conference trade show, which featured dozens of exhibitors and more than 200 attendees, plus a skills competition for Saskatchewan Polytechnic students to win some pretty incredible prizes and much more.

Collision Repair was honoured to be part of the event with our Saskatoon EV Repair

Tour stop, which featured Kim Kos of Kavia Auto Body and Scott Kucharyshen of Saskatchewan Polytechnic.

Kos delivered valuable insights on what it’s like being Saskatoon’s only Tesla-certified shop. Some key takeaways from the presentations were the fact that Kavia has yet to write a single Tesla off in their four years of holding certs–the average repair order is $30,000 and Teslas take up about 10 percent of the shop’s total claims, said Kos–and that all of Kavia’s Tesla training has been via the OEM’s online portal.

Kucharyshen covered Saskatchewan Polytechnic’s approach to the electric future, which includes an emphasis on Tesla vehicles—he has an ongoing goal to

become the first Tesla-certified technical college in North America–and plenty of inter-industry recruitment. Kucharyshen added that as soon as Kavia or any other local shop has a Tesla to write off, he’ll be over in a flash to collect it as a learning vehicle for his students.

Other presentations that garnered immense interest included updates from SGI, who gave a timeline for their incoming improvements and rate increases; Dave Luehr of Elite Bodyshop Solutions, who was as inspirational as ever on the main stage and Mitchell International’s Ryan Mandell gave a thorough presentation of EV claims insight.

Check out our photos from the event!

32 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Story, photos by ALLISON ROGERS

Chelsea Stegner, Parr Auto Body, and Trista Anger, BASF.

Dave Luehr of Elite Bodyshop Solutions had the best team, fashion-wise.

Mike Gilliland and Jenica Bennett, AutoHouse Technologies.

ISSUE 22#5 | COLLISION REPAIR 33 EVENTS

A skills competition saw Saskatchewan Polytechnic students go head to head for some pretty sweet prizes any starter apprentice would love to have in their kit.

Tom Bissonette, SAAR, and Brittany Huber, Dodge City Collision Centre and SAAR board member. John Turner, Simplicity Car Care.

Greg Wing, Simplicity Car Care, and Patrick Aiello, AkzoNobel.

All smiles from BASF’s Chad Melchert and Trista Anger.

Saskatchewan industry legends: Lloyd Giles with his wife, Sandy, and Bill Ziebart with his better half. Giles owned Midtown Auto Body for years, while Ziebart was the former SAAR director.

The Axalta crew was raffling off speakers at their booth, which proved to be one of the most popular holes of the day.

The best way to close out an industry event? Karaoke.

Andy Boyd, 3M, and Daryll O’Keefe, Fix Network.

The Akzo crew.

SIMPLIFIERS IN NIAGARA FALLS

Simplicity Car Care’s second Growth Conference deemed climate positive

Simplicity Car Care recently hosted its second annual Growth Conference in Niagara Falls, Ontario, where the franchise network cinched a “climate positive” event certification for the second time.

The process of becoming climate positive certified means the Simplicity team had to verify how many kilometres each attendee had to travel to reach the conference—as well as the method of travel—to offset all emissions produced.

Prochilo also delivered an overview of company operations, where he said cycle times across the network currently sit at 14.3 days—“in line with market rises,” he said.

He also said 27 Simplicity stores have adopted the company’s net-zero journey strategy, compared to 10 on the beta version of the program last year.

Speaker presentations ranged in topic, from recruitment and retention tactics from Sharon Romahlo, former exec of McDonald’s Canada to deep collision KPI talks with industry consultant Steve Trapp. Simplicity’s own corporate staff also took the stage to deliver updates on company strategy.

A trade show closed out day one, but the energy moved into Saturday with further speaker presentations and networking opportunities before finally closing out with a lavish Gala, complete with Duelling Pianos and the delightful singing voices of our industry.

Check out our photos from the event!

34 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Story, photos by ALLISON ROGERS

ISSUE 22#5 | COLLISION REPAIR 35 EVENTS

36 COLLISION REPAIR COLLISIONREPAIRMAG.COM EVENTS

Call: 1-800-871-7612 | Click: simplicitycarcare.ca/franchisee Connect: contact@simplicitycarcare.ca Grow Your Business With Simplicity. Join the Simplicity Car Care team, and take your collision repair business to the next level.

WHERE SPRAY GUNS ARE BORN

Inside SATA’s German headquarters

The Collision Repair magazine team was recently invited to Germany to visit SATA’s headquarters, where we received an exclusive tour of the global leader in spray gun technology’s impressive facilities.

Joern Stoever, interim general manager of SATA Canada, served as gracious host, and even showed the team the recently released SATAjet X 5500 universe before it was unveiled to the public.

We were able to capture some of SATA’s inner workings for our Canadian crew back home—check it out! Plus, see more on our YouTube channel at youtube.com/@collisionrepair

ISSUE 22#5 | COLLISION REPAIR 39 INDUSTRY EXCLUSIVE

Darryl Simmons, publisher of Collision Repair magazine; Gloria Mann, VP of Industry Relations with Joern Stoever, interim GM of SATA Canada.

40 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY EXCLUSIVE

Joern Stoever, interim GM of SATA Canada.

Gloria Mann, Collision Repair magazine sporting her custom Sata suit.

Did you know?! SATA is the first spray gun manufacturer to offer a nozzle system based on two distinct spray fan shapes for each nozzle size: parallel and oval.

SATA offers nozzle sizes in both RP and HVLP technology.

SATA has been producing spray guns since 1925.

SATA’s spray guns are made from an anodized aluminum body and stainless steel nozzle.

An interior view of SATA’s production site in Kornwestheim, Germany.

SATA Special Edition 2021

Your spray gun, your SATA universe.

Your spray gun, your SATA universe.

SATA Special Edition 2021

SATAjet X 5500 universe - Your ticket to the exclusive world of SATA

SATAjet X 5500 universe - Your ticket to the exclusive world of SATA

The SATAjet X 5500 universe is two things: a SATA premium paint spray gun, and your key to the SATA universe – a whole world full of exclusive content, benefits and promotions. Within the SATA universe, you can participate in special raffles. You'll be among the first to know when new SATA products appear on the horizon. Moreover, immediately following your registration you will be granted access to exclusive content.

The SATAjet X 5500 universe is two things: a SATA premium paint spray gun, and your key to the SATA universe – a whole world full of exclusive content, benefits and promotions. Within the SATA universe, you can participate in special raffles. You'll be among the first to know when new SATA products appear on the horizon. Moreover, immediately following your registration you will be granted access to exclusive content.

Don't hesitate to get your SATAjet X 5500 universe. Scan the QR code on your SATA universe gun. Register. And become part of something big. www.sata.com/jetx-universe

Don't hesitate to get your SATAjet X 5500 universe. Scan the QR code on your SATA universe gun. Register. And become part of something big.

SATA Canada Inc. 125 Buttermill Avenue Vaughan, ON L4K 3X5 Phone: +1 905 660 1101 Toll-free: +1 844 554 SATA (7282) Fax: +1 905 760 1250 contact@sata.ca www.sata.com

www.sata.com/jetx-universe

INFO

limited edition SEE YOU AT SEMA! Booth #31017 second floor, South Hall SATA Canada Inc. 125 Buttermill Avenue Vaughan, ON L4K 3X5 Phone: +1 905 660 1101 Toll-free: +1 844 554 SATA (7282) Fax: +1 905 760 1250 contact@sata.ca www.sata.com

INFO

limited edition

Booth #31017 second floor,

SEE YOU AT SEMA!

South Hall

“OH FFF....Fix Auto!” The first words that should come to mind after an accident. Do you want to join our successful car care network? Contact Amin Youssef at ayoussef@fixnetwork.com | +1 365-355-5363 or visit the “Join the Network” page at fixauto.com to find out more.

Evolving to Meet

Aftermarket Car Care Needs of Today and Tomorrow

Evolving to Meet

Aftermarket Car Care Needs of Today and Tomorrow

“We work hard to support our network (strategic day-to-day operations; Sylvain Seguin, president provide a total value chain that supports our franchisees’ tomer demands but also helps us plan a roadmap that require responsive and long-term business planning.”

FIX Network Canada is growing

Sylvain Sequin, President Fix Network Canada

FIX Network Canada is continually growing –the number of shops, our team and, of course, our expertise. With more than 500 shops in Canada dedicated to providing collision, mechanical and glass repair coast-to-coast, we are also proud of our global network expansion in Europe, Mexico, Saudi Arabia, Australia, and the US markets.

“We work hard to support our strategic partners partners in their day-to-day operations; Sylvain Seguin, president Fix Network Canada, said. “We provide a total value chain that supports our franchisees’ responsiveness to customer demands but also helps us plan a roadmap to address emerging trends that require responsive and long-term business planning.”

Similar to many industries, 2023 is shaping up to be a year still defined by recovery as supply chain restrictions relieve themselves and other post-pandemic stabilization continues. Amidst ongoing change, FIX Network Canada’s collision aftermarket care service is well positioned to embrace the advantages of keeping pace with the changing requirements from our industry partners including insurance providers, OEMs, and of course, customers.

For our FIX centers, there intersect, business the fleet is imperative the newest Powering Human were top gional meetings City; Halifax, AB. Attended suppliers, these meetings networking key trends

fixnetwork.com

Sylvain Seguin, President

Fix Network Canada is growing

Fix Network Canada is continually growing – the number of shops, our team and, of course, our expertise. With more than 500 shops in Canada dedicated to providing collision, mechanical and glass repair coast-to-coast, we are also proud of our global network expansion in Europe, Mexico, Saudi Arabia, Australia, and the US markets.

Similar to many industries, 2023 is shaping up to be a year still defined by recovery as supply chain restrictions relieve themselves and other post-pandemic stabilization continues. Amidst ongoing change, Fix Network Canada’s collision aftermarket care service is well positioned to embrace the advantages of keeping pace with the changing requirements from our industry partners including insurance providers, OEMs, and of course, customers.

For our Fix Auto and ProColor Collision repair centers, there are two key evolving realities that intersect, for which we are undergoing detailed business readiness planning – electrification of the fleet and human capital requirements. It is imperative that our technicians be trained in the newest processes.

Powering our franchise network

Human resources and changing technology were top of mind during our 2023 Evolution regional meetings held in Mt. Tremblant; Quebec City; Halifax, NS; Mississauga, ON; and Calgary, AB. Attended by nearly 450 of our franchisees, suppliers, vendors, and other strategic partners, these meetings provided business updates, networking opportunities and insights about key trends affecting our industry.

Addressing the labour crunch is not unique to our industry and is ready present. Across our business, we focus heavily on the employee experience and that is especially true at the frontline. The technicians of today will hopefully be our shop owners and Fix Network leaders of tomorrow, helping to move the business forward in meeting market trends and demands. We are focused on the total employee experience, from recruitment to training and retention.

The electrification of the fleet is a transformative shift in the automotive industry, presenting both challenges and opportunities for aftermarket auto repair brands within

fixnetwork.com

the Fix Network. As electric vehicles (EVs) become increasingly prevalent, our network is committed to staying at the forefront of this technological revolution. Our sponsorship of the Collision Repair Magazine EV Repair Tour underscores our dedication to providing the necessary training and resources for our repair centers to adapt and thrive in the EV era. This tour not only showcases our commitment to sustainability but also highlights our determination to remain leaders in the collision repair industry.

In the current automotive aftermarket, being part of the Fix Network is a competitive advantage. The value chain we provide includes sales, operations and marketing expertise and supports our owners so they can focus on the day-to-day shop operations and invest their time in delivering the best customer experience. Through ongoing training opportunities and events like annual meetings where we share insights to emerging trends affecting their business -- such as servicing electric vehicles, attracting and retaining top

Although addressing workforce needs as well as the evolving technology in our industry is crucial, equally as important is our network’s impact on the communities where we work and live. Our strategic partners come together in a big way to support one of our national charitable partners, the Ronald McDonald House Charities (RMHC). We are proud and humbled to have raised more than $125,000 at our Evolution regional meeting tour stops this year – all to support the amazing work of RHMC which is integral to families in their greatest time of need.

talent and building teams that support their business continuity—we strive to drive long-term value at the shop level and across our industry.

To find out more about the ways in which we support our franchise owners or for information on joining our collision care network in Canada, please visit Fixnetwork.com

ADVERTORIAL

“It is incredible that our Network franchisees show up in this way all year long for many different charitable organizations,” Sylvain said. “We are a global network with huge local impact and a passion for supporting our communities and neighbours.”

Clear Vision for the EV Revolution and Beyond

Seguin, President FIX Network Canada

NOVUS is preparing shops for the future

Addressing the labour crunch is not unique to our industry and is ready present. Across our business, we focus heavily on the employee experience and that is especially true at the frontline. The technicians of today will hopefully be our shop owners and FIX Network leaders of tomorrow, helping to move the business forward in meeting market trends and demands. We are focused on the total employee experience, from recruitment to training and retention. The electrification of the fleet is a transformative shift in the automotive industry, presenting both challenges and opportunities for aftermarket auto repair brands within the Fix Network. As electric vehicles (EVs) become increasingly prevalent, our network is committed to stay-

Why is an ADAS Calibration Necessary?

ADAS calibration is required on 100% of new vehicles on the market due to changing government safety standards. Calibration is necessary to ensure Advanced Driver Assistance Systems (ADAS) operate safely to manufacturer’s standards after a customer’s windshield replacement or collision repair.

(strategic partners?) partners in their FIX Network Canada, said. “We franchisees’ responsiveness to cusroadmap to address emerging trends planning.”

FIX Auto and ProColor Collision repair

Pre

Plus

there are two key evolving realities that intersect, for which we are undergoing detailed readiness planning – electrification of and human capital requirements. It imperative that our technicians be trained in newest processes.

Many More What NOVUS Offers:

Dedicated Support Team:

Powering our franchise network resources and changing technology of mind during our 2023 Evolution re meetings held in Mt. Tremblant; Quebec Halifax, NS; Mississauga, ON; and Calgary, Attended by nearly 450 of our franchisees, suppliers, vendors, and other strategic partners, meetings provided business updates, networking opportunities and insights about trends affecting our industry.

Technologies: Proprietary Tools & Resins

Proposition

Network Access & Training for Insurance Conversation

Mobile

TAG Network: Development of Insurance Claim Revenue - Claim Management

ing at the forefront of this technological revo lution. Our sponsorship of the Collision Repair Magazine EV Repair Tour underscores our ded ication to providing the necessary training and resources for our repair centers to adapt and thrive in the EV era. This tour not only showcas es our commitment to sustainability but also highlights our determination to remain leaders in the collision repair industry. Although ad dressing workforce needs as well as the evolv ing technology in our industry is crucial, equally as important is our networks impact on the communities where we work and live.

Our strategic partners come together in a big way to support one of our national charitable partners, the Ronald McDonald House Charities

Training,

Selling

For more information on franchise opportunities with NOVUS Glass, contact Zakari Krieger at zkrieger@fixnetwork.com (SP):

Operations, Marketing

Service: Fully Equiped Mobile Unit

We train our technicians to carry out programming and calibration for: Blind Spot Monitor Adaptive Cruise Control Lane Departure Camera 360 Degree Camera Technology

Collision System

Supporting the Local The ProColor PROcess is a winning formula. A proven business model for 20 years, ProColor Collision provides an alternative to independent body shops that want to join one of the fastest growing networks in the world. Local business owners are supported by a team of sales, operational and marketing professionals, and backed by proven tools and ongoing training programs. ProColor Collision is committed to helping shop owners grow their business in their communities while leveraging strong established relationships with global insurers, suppliers and fleet companies. Contact Amin Youssef at ayoussef@fixnetwork.com | +1 365-355-5363 or visit the franchise page at Procolor.com to find out more.

PUTTSPAINTERS SINKING

Friends of BASF take to the course for annual golf tournament

BASF's collision industry partners swapped mixing green hues for the literal greens this past July 26 as the chemical company hosted its annual golf event.

With a new venue this year—Glen Eagle Golf Course in Caledon, Ontario—BASF customers from various industries, including automotive refinishing clients, gathered for a day of camaraderie, golf, food and prizes. The event is a seasonal favourite in the local market, drawing a grand crowd to the golf course each year. Of course, Collision Repair mag was on the green to capture all of the action. Check out our pics!

44 COLLISION REPAIR COLLISIONREPAIRMAG.COM

Don Teevens, CCS; Brian Busby, BASF and Chris Chinn, CCS, corner Gloria Mann for a quick selfie.

Story, photos by ALLISON ROGERS

EVENTS

ISSUE 22#5 | COLLISION REPAIR 45 EVENTS

Jeff Pabst, Pfaff Autoworks; Gloria Mann, Collision Repair mag.

The winning team: Jeb Aarts, BASF; Domenic and Joseph Lucarelli, CARSTAR Stoney Creek; Peter DeGiuli, BASF.

Dave Black, Color Compass, shows off his CFL ring to Sabrina Thring's son, of Driven Brands.

Sabrina Thring and Dave Foster of Driven Brands/CARSTAR Canada.

Mark Huisman, BASF; Allison Rogers, Collision Repair mag.

Don Teevens, CCS; Michael St. Germain, MercedesBenz Oakville Collision; Chris Chinn, CCS.

Darryl Simmons, Collision Repair mag; Ashley Butts, BASF; Colin Asselstine, Definity; Trista Anger, BASF.

CREATING YOUR OWN ADVANTAGE

When you’re entrepreneurial in nature, the sky is the limit

Some people were simply built for business—and you’ll find plenty of them in the automotive aftermarket.

It may look easy from afar but, in actuality, it takes clever minds and—above all else, a willingness to learn and grow with this fast-changing industry.

We sat down with two members that demonstrate these qualities to a tee: Bob Kirstiuk and Tim Scharnberg of Advantage Parts Solutions. As longtime members of the automotive aftermarket and parts business, and the minds behind global parts leader Advantage Parts Solutions, Kirstiuk and Scharnberg know how to adapt to a variety of industry change—and come out stronger on the other side.

See how Advantage got its advantage in the industry in this exclusive interview.

Collision Repair magazine : How did you first become involved in the collision industry?

Bob Kirstiuk: Fresh out of university, I was introduced to Tim through a mutual friend when he was operating his own auto glass and upholstery business. Since he was already connected to the broader auto space, we discovered an opportunity within the parts department of dealerships, wrote the business plan of what we now know as Advantage Parts Solutions, and became partners. Our first day as a business was October 1, 1988, in Vancouver. From there, we made it our personal mission to learn and grow.

Tim Scharnberg: For me, it was my upholstery and glass business that first connected me to the local auto community, and ultimately, Bob. That’s where I really learned about business, relationships, and networking. So, I was able to take everything I learned through running that business and pour it into Advantage.

CR: So, how have you climbed to your current role today?

BK: From the very beginning, part of our approach and strategy was to build relationships with every facet of the industry. By doing so, we’ve been able to position ourselves and Advantage to be part of conversations and

influence outcomes that ultimately resulted in a better experience for vehicle owners. So, when the book Never Eat Alone by Keith Ferrazzi was published, it became part of our ethos and validated our journey.

TS: Bob and I have always been very entrepreneurial in nature, and that’s served us well. Because the spirit of Advantage is entrepreneurial, when we subscribed to the Scaling Up framework early on, it really accelerated our ability to launch new markets, new products and focus on what’s most important as part of our macro, global strategy. This framework continues to provide us with rigor and discipline that, now, is just part of our DNA.

46 COLLISION REPAIR COLLISIONREPAIRMAG.COM EXECUTIVE VISION

Bob Kirstiuk, CEO and co-founder, Advantage Parts Solutions. Tim Scharnberg, executive vice-president and co-founder, Advantage Parts Solutions.

CR: What are some of the biggest changes your company(ies) have had to adapt to?

BK: When any business scales from $100,000 to $1,000,000 to $10,000,000 and beyond it is forced to evolve and meet the growing needs of the business, and Advantage is no different. We climbed those plateaus and mountains amidst the introduction and evolution of the internet, vehicle technology, operating in multiple countries, and now A.I. Change has been a constant, we’ve chosen to lean into it and found a rhythm to meet this proactively and positively.

TS: The single biggest change we, and the industry, have had to adapt to, since we launched in 1988, was how parts were ordered. When we first started, shops would place orders over the phone, then it was fax, then email and now it’s on platforms that come with an entire suite of capabilities. So, all positive change, but bodyshops today operate with much more sophistication than they did 35 years ago.

ISSUE 22#5 | COLLISION REPAIR 47 EXECUTIVE VISION

“From the very beginning, part of our approach and strategy was to build relationships with every facet of the industry.”

— Bob Kirstiuk, CEO and co-founder, Advantage Parts Solutions

Tim Scharnberg, and Bob Kirstiuk from the archives.

CR: What advice do you have for fellow executives/business owners dealing with massive change?