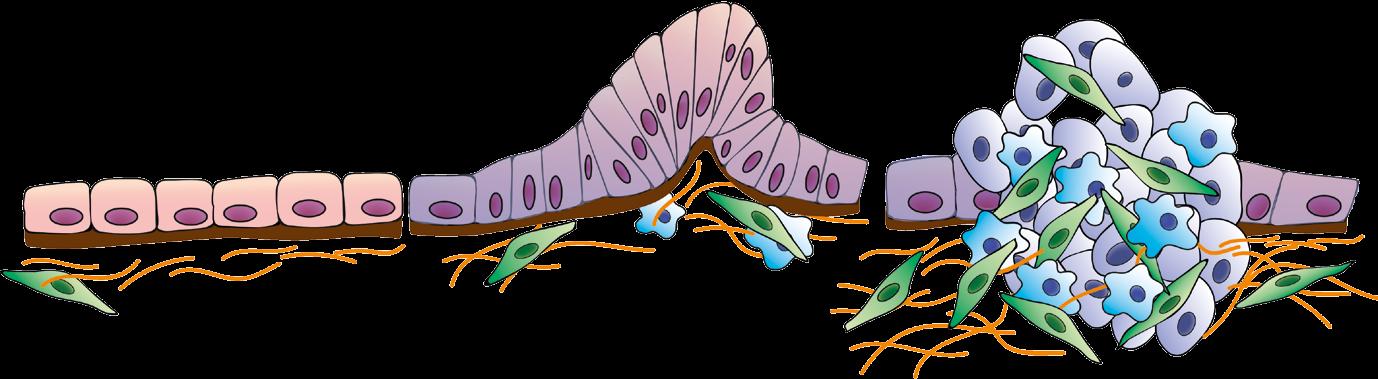

Behind the dynamics of material fragmentation Is the importance of inertia in the process of material fragmentation currently understated? The Purpose project seeks to challenge the established framework by which material fragmentation is understood, work which holds important implications for material design and development, as Professor José A. Rodríguez-Martínez explains. The process of dynamic fragmentation is currently understood largely as a statistical phenomenon, in which defects play a fundamental role in the fracturing of a material and therefore limit its capacity to absorb energy. While this approach to understanding dynamic fragmentation is fairly well established, Professor Jose Rodríguez-Martínez and his colleagues in the Purpose project are now exploring an alternative framework. “We think that the effects of inertia are important. Inertia could reduce the effect of defects – either material or geometric – on the final fragmentation of a structure,” he explains. This suggests that defects could play a secondary role in dynamic fragmentation, with inertia controlling the process to some degree. “There is a kind of competition, but when inertia becomes dominant the role of defects may turn to be secondary,” says Professor Rodríguez-Martínez. “It is inertia, together with other properties, that controls dynamic fragmentation, and therefore the energy absorption capacity of a structure when it is subjected to impact loading.”

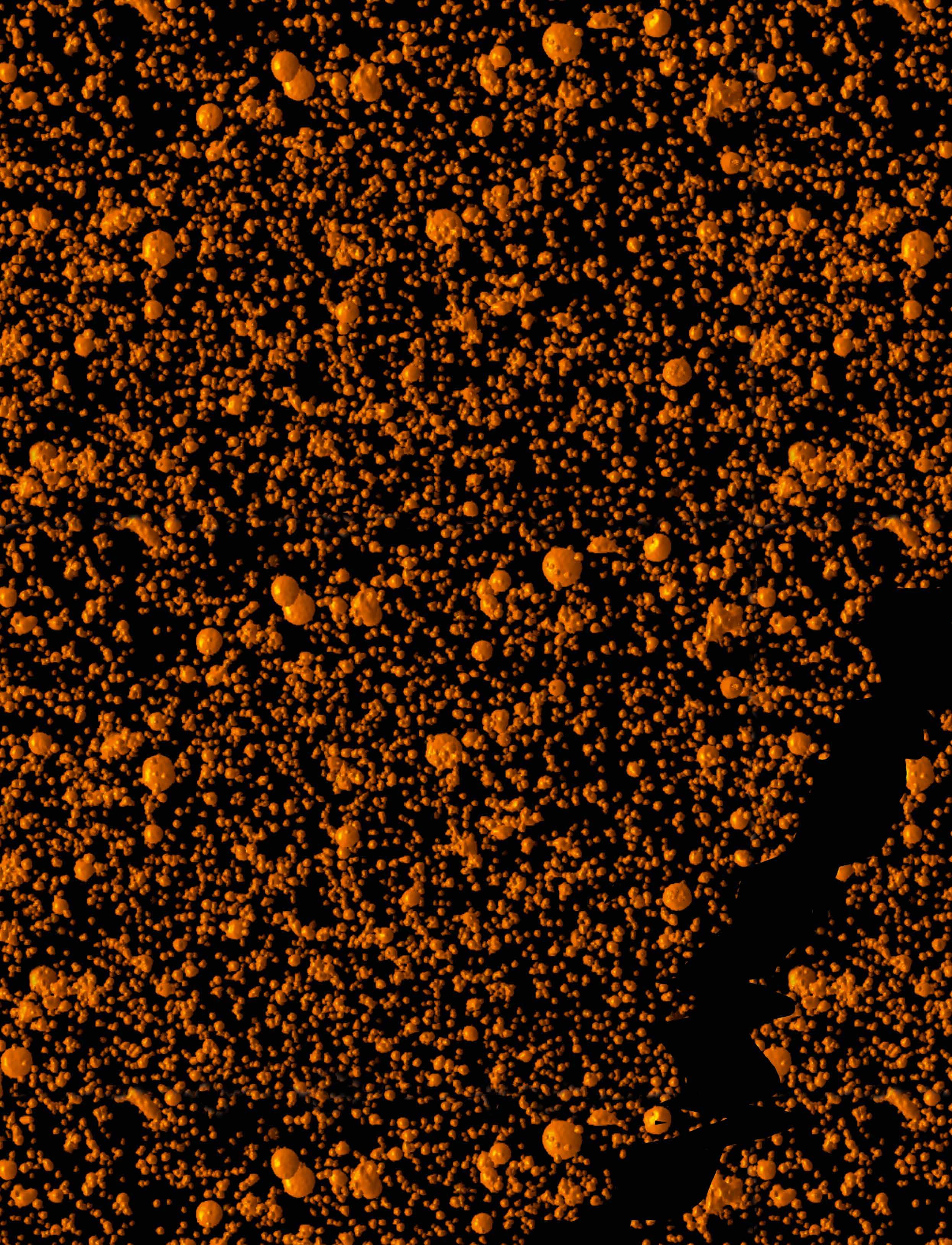

Purpose project This theory is the focus of interest in the Purpose project, with researchers looking to test it on both traditionally manufactured and printed metals supplied by a manufacturer. Professor Rodríguez-Martínez and his team are taking a three-pronged approach to this work, involving numerical calculations, analytical models and experiments. “We are developing numerical calculations, based on computational mechanics, while we are also developing analytical models. These analytical models are simple, but they capture the basic physics behind the fragmentation process,” he outlines. In the experimental work, Professor RodríguezMartínez is essentially investigating four different configurations. “First, we are analysing the fragmentation of expanding rings. We are manufacturing extremely thin rings, with a thickness of let’s say 1 millimetre. In collaboration with a university in the US, we are then performing experiments in which these rings are expanded at very high

60

velocities, at rates of up to 250 metres per second,” he explains. The rings are placed under great strain by this expansion and eventually they fragment into several pieces, with researchers in the project investigating the mechanisms which control the number of fragments and their size, as well as a variety of other topics. Metallic materials behave in a non-linear manner, so identifying the factors which affect how they fragment is a complex and demanding task. “From an experimental point of view, it’s much more complicated to interpret the data,” says Professor Rodríguez-Martínez. The second type of experiment that is being performed in the project involves expanding thin wall tubes, which Professor Rodriguez-Martinez says is subtly different to the first experiment with the rings. “The stress state in the structure is different, and this changes the fragmentation pattern,” he explains. “We will analyse, by the comparison between the ring expansion experiments and the tube expansion experiments, the effect of the stress state on the fragmentation process.” A third experimental arrangement involves the axial penetration of thinwall tubes. Instead of expanding the tube

radially, the experiment here centres on penetrating the tubes axially in a certain manner, leading to the formation of what are regularly called petals, a specific type of material fragment. “We are analysing the number of petals that are formed,” outlines Professor Rodríguez-Martínez. The fourth experimental arrangement centres around the dynamic collapse of thick-wall tubes. “In collaboration with a high-tech Israeli company, we are using an electromagnetic field to collapse quite a thick cylinder, in such a way that the cylinder will fragment by the formation and development of multiple shear cracks,” continues

EU Research