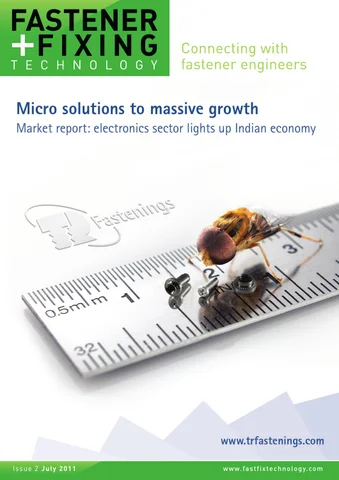

Micro solutions to massive growth Market report: electronics sector lights up Indian economy

www.trfastenings.com Iss u e 2 J u ly 2 0 1 1

www.fastfixtechnolo g y. co m

Micro solutions to massive growth Market report: electronics sector lights up Indian economy

www.trfastenings.com Iss u e 2 J u ly 2 0 1 1

www.fastfixtechnolo g y. co m