What does that mean? It means that we are determined to support you in your journey towards greater profitability, safety and environmental stewardship. It means that we will help you forge new paths, shape key trends and offer new solutions to support you on that journey. And it means we will be with you for every step of that journey through application consultancy, personalized trainings; across numerous geographic territories and around the clock.

Tell us where you’re going and we will help you get there.

ON EVERY ROAD AND HIGHWAY, THERE ARE THOSE THAT FOLLOW AND THOSE WHO LEAD.

At Gencor, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. From the award winning Ultraplant® to the Green Machine, our record is unrivaled in innovative design. That’s the kind of leadership you’ve come to expect from Gencor.

THE LEADER IN PERFORMANCE AND EFFICIENCY

Call 407-290-6000 or visit www.gencor.com

53 Milling

55 Preservation Equipment

58 Preservation Supplies

Roadbuilding Support:

Tools, software, equipment and more to help asphalt contractors get the job done.

61 Technology: Products & tools that highlight the latest trends that can help improve productivity and quality for asphalt contractors.

62 Site Prep & Earthmoving: Motor graders, skid steers, haulers, excavators & more to assist in the development of infrastructure.

64 Trucks & Trailers: Equipment designed to safely haul your machines and materials.

ON THE COVER BOMAG BM 2200/65 Mill is the perfect match of engine power and milling speed, making it one of the most cost-effective planers in the light 2-metre class.

reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International).

We Discuss Emerging Equipment Automation with Asphalt Contractor Editor Brandon Noel

When the section of highway collapsed on June 12, the news didn’t look good, but in just two weeks time the repairs were made and it’s reopening. One perspective is that the much maligned state of U.S. infrastructure is a policy choice.

Read more at: http://asphalt. com/845au5

It’s a good time to talk about the Infrastructure Investment and Jobs Act (IIJA), its available funds for projects and how contractors can position themselves to take advantage of these new jobs by leveraging technology.

Read more at: http://asphalt. com/hnkt9q

The California Air Resources Board, leading truck manufacturers and the Truck and Engine Manufacturers Association joined forces to advance the development of zero-emission vehicles.

Read more at: http://asphalt. com/tl162a

When you’re laying a few ton of asphalt during peak of the season, you need to keep energy and hydration high without big interruptions on the job. Here are the top 10 snacks, according to the hard working people who know better than anyone.

Read more at: http://asphalt. com/fbhc67

As a decades-long leader for asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems. Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Sustainable Innovation

Sustainable Innovation

Brandon Noel, Editor bNoel@ACBusinessMedia.com

234-600-8983

This issue marks 12 months as the editor for Asphalt Contractor Magazine.

Ayear ago, I took over as the editor for this publication from Jessica Lombardo, who spent the previous decade with the brand and within this amazing industry. It's no secret that my success here wouldn't have been possible without her help in the transition, and even now, she continues to be an amazing support. At that time I didn't know anything about the asphalt business or the paving world, and I didn't really have a very deep understanding of our country's infrastructure for that matter. It's very interesting what can change in the matter of a year.

If you've been paying close attention to the articles that I write both here and on our parent website ForConstructionPros. com, you might have picked up on the sorts of things that I am passionate about. One of those themes is sustainability, and the other is labor.

While I've covered plenty of stories on technology, products, and some best practices too, I am very taken up with how the future is being shaped by the direction and influences of sustainability and labor. That’s because sustainability isn't just an industry or political buzzword. Actual policy, product, and practice is currently being implemented with it at the center, and the generation coming into the industry is playing a major role is this trend.

The next generation of labor is more environmentally conscious than any previous generation before them. And they're conscious in another way, too. Labor's "class consciousness" is more awake and active than it has been in the past 30 years. I will continue to cover

these two topics in the years to come, as they develop, change, and impact our industry.

Until this summer began, one of the biggest hinderances to my job education was a lack of hands-on opportunity with the real work of the asphalt world. As soon as the plants started kicking on and people were paving, I've tried to get out there and get my hands dirty. Thankfully, I've already had some awesome experiences in Long Island, N.Y.; Philadelphia, Penn.; and a handful of other places yet to come this season.

One of the biggest things that I've drawn from these in-person, on the ground moments, is that the work is full of dynamic decision making. Each site I've been to has had problems arise, right there in the moment, while I've been there trying to learn things. Unexpected breakdowns, no-shows, bad weather, and you name what else. The difference-maker is the ability to change strategically and effectively, adapt to the problem, and find an efficient solution. If you don't know what to do in case the plan fails, all the planning in the world can go out the door quickly, i

Everyone approaches these hiccups in their own way, and each time I'm with a different crew I've learned new things about how to tackle problems as they come. Maybe next time it will be with yours, because I'm always looking for my next chance to get out there!

See you on the road.

E ITORIAL

E Brandon Noel bnoel@acbusinessmedia.com

C E Jessica Lombardo jlombardo@acbusinessmedia.com

M E Gigi Wood gwood@acbusinessmedia.com

S E C

T IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

S E E IRONPROS Michael Cheng mcheng@acbusinessmedia.com

A IENCE A M Angela Franks

PRO CTION

S P M Cindy Rusch crusch@acbusinessmedia.com

A April Van Etten

A ERTISING SALES Amy Schwandt aschwandt@acbusinessmedia.com

S R Sean Dunphy sdunphy@acbusinessmedia.com

S R Kris Flitcroft kflitcroft@acbusinessmedia.com

S R Tadashi Soma tsoma@acbusinessmedia.com

AC SINESS ME IA

C E O Ron Spink

C O JoAnn Breuchel

C R O Amy Schwandt

S C G I Jason DeSarle

C Sean Dunphy

P A Ronda Hughes

P O IT Nick Raether

C Marina Mayer O M S Bethany Chambers

C M S Jess Lombardo

G E Jim Bagan

CIRC LATION S SCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

S A M Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SER ICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALTCONTRACTOR @ASPHALTCONTRCTR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

We were the pioneers of backhoe loaders, and no one knows the business of getting more work out of one machine and one operator like CASE. Now we’re adding to the trusted N Series lineup with the new Utility Plus model that dominates in value and four new Construction King models, two center pivot and two side shift. They’re all built to work harder so you can work smarter. See them at your CASE dealer or learn more at CaseCE.com.

Sponsored by

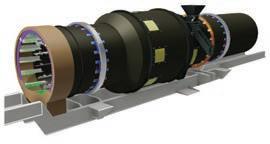

An Astec M-Pack plant has the capacity and size of a permanent facility with reduced setup costs. That’s a big advantage. The Astec M-Pack is engineered as a set of modules that are transported by truck. Each Astec M-Pack plant ships in ready to set up loads when it leaves the manufacturing facility. Level and pave your site, then lift the pre-piped, pre-wired modules off the trailer and bolt them up. The M-Pack foundations are heavy-duty and provide plenty of load-bearing surface to support the facility components. Sturdy steel construction of each component ensures that setup proceeds quickly and without difficulty. If you ever move the Astec M-Pack plant to another site, most loads

fit on lowboy type trailers, and the builtin foundations go with them.

High production, large storage capacity, full-size control rooms, highquality components, and excellent maintenance access make the modular Astec M-Pack asphalt mixing plant highly functional. Astec is renowned for producing durable and reliable equipment, and the M-Pack plant is no exception. Built with high-quality materials and components, it offers long-term performance and minimal maintenance requirements, ensuring a reliable and cost-effective operation. Plus, with any Astec product you get unbeatable customer service and support. There are a wide range of options on these robust, versatile plants. With a team

of experienced engineers and in-house technicians, Astec has the knowledge and the expertise to help you make the appropriate selections to meet your requirements.

Astec Advantages:

• Only Astec offers four exclusive mixing systems: Double Barrel, Double Barrel X, Double Barrel XHR or UniDrum

• Only Astec offers two full-size silo options: Long-Term or Short-Term

• Only Astec offers two baghouse options: Pulse Jet or Reverse Pulse

Learn more about the Astec M-Pack asphalt mixing plant.

Quick setup of durable equipment makes the Astec M-Pack™ relocatable facility an excellent value.

Sponsored By

Combo Plants combine new, used, or reconditioned equipment from different suppliers and manufacturers to create an effective, low cost alternative.

• Can save the contractor $1 million, $2 million or more over the price of an all new hotmix asphalt facility

Gencor designs and builds the biggest installed base of Megaplants across North America each producing over 50% RAP and achieving production levels of over 800 tph.

• Incorporates the Ultradrum design which maximizes heat transfer

• Use RAP and RAS

• Patented positive reclaim system

An affordable option for contractors with low production requirements.

• Includes all necessary components for drummixing asphalt production yet fits on a single trailer frame

• Available in 60-, 100- and 160-tph production rates and standard with a drying/mixing drum, wet wash, cold feed bin and surge system

• Portable or stationary configurations with the option of automated or manual operation

• Customized components include cold feed bins, hot oil asphalt cement tanks (both horizontal and vertical), direct-fired horizontal cement tanks, portable and stationary bag houses, mineral filler systems, RAP systems, self-erect and stationary silos, weigh and drag conveyors, weigh batchers and fuel oil tanks

The UF Series of Counterflow Drum Mixers from ALmix represent the harmony of details and durability. These units are built to incorporate the latest technology and a tough design that can be depended on daily. Combined with a full line of auxiliary equipment, the UF Series is the heart of a complete asphalt plant setup ideal for producers of all sizes.

• Offered in both portable and skid-mounted configurations, each available in multiple drum sizes with production outputs ranging from 120 to 500+ TPH

• Each drum features a simple, ‘Unified’ design capable of producing high-specification mixes, exceeding environmental requirements, and performing exceptionally for years in the field

• Each drum includes our bolt-in flight design, that when coupled with VFD-controlled rotational speed allows for maximum drying and mixing efficiency, lower stack temperature and reduced fuel consumption

The unified drum is a high quality counterflow design that is offered as portable or stationary arrangements.

• Offered as part of complete new plants and al for retrofit applications

• Long drum can produce a consistent, high-quality mix with up to 50% RAP content

• Range of production capacities from 200 to 700 tph

• Optional warm mix system

• Optional V-Pack Stack temperature system

Batch plants for the modification of asphalt with polymer or crumb rubber.

• Polymer Modified Asphalt (PMA) and Crumb Rubber Modified Asphalt (CRMA)

• A pre-heat tank for very quick and efficient heating, the plant ensures the availability of hot neat asphalt

• Two mixing tanks can be operated in parallel for continuous production

• Single or multiple passes can easily be set up to ensure proper homogenization prior to pumping the PMA or CRMA out to digestion tanks

• Fully automatic system is 100% PLC controlled

• Capacities from 6.6 to 13.22 and 11 to 22 tph

• 13.22-tph plant model is mounted on a 40-ft. skid frame

We’ve built our business and reputation through our unparalleled focus on equipment durability, attention to detail, and the ability to customize our products for each customer. We apply these foundations to our complete range of asphalt plants and asphalt plant equipment, designed for producers of all sizes.

The rugged 275 to 350 tph EX10248 Asphalt Plant from ADM meets production capacity demands and strict environmental regulations.

Designed for portability and a small footprint, this simple yet rugged design meets the needs of the small to midsize contractor.

• Judicious control of plant frills versus plant cost yields asphalt plants which allow the long time asphalt paver to become a first time asphalt producer

• The “Compact Series” is offered in production ranges from 60 TPH to 140 TPH

• The plant’s single-drum counterflow system uses the latest in innovative technology, resulting in the longest aggregates drying and mixing times in the industry

Versatility makes ABA 100-340 UniBatch one of the most popular Ammann plants. The plant is among the lowercost alternatives and is easy to operate, maintain, and is known for its reliability.

• Wide output range from 100 tph to 340 tph

• Maximum customization options combined with top performance and economic efficiency

• Designed for worldwide use, with mixing tower modules providing ease of transport

• Robust, tried-and-tested technology

• Optional feed for additives such as dye pigment, fibres and Ammann Foam

• Can be fitted and extended with numerous options

This plant allows contractors to increase capacity with up to 50% RAP in a compact package.

• Counterflow technology allows for maximum heat transfer and fuel efficiency via separate drying and mixing zones

• Efficient plant design provides single-operator capability, easy troubleshooting and simple on-site maintenance while virtually eliminating blue smoke and hydrocarbon emissions for clean operation

Features a custom-built chassis equipped with six hydraulic run-on jacks that quickly level the plant, eliminating the need for cribbing.

• Chassis stays level during operation, which minimizes equipment wear

• Producers can move and set up the portable F-Class in less than 30 minutes. The chassis’ hydraulic system raises the vibrating screen to its inclined operating position

• Takedown is even faster, requiring less than 20 minutes

The ABP HRT (High Recycling Technology) plant is an ideal fit for asphalt manufacturers who need to incorporate large proportions of RAP without sacrificing production capacity and quality.

• The HRT is a “two-in-one” plant featuring both warm and cold recycling systems that can be used in combination

• There are two warm recycling systems to choose from; one is the conventional RAP dryer for RAP additions of up to 60 percent and the second is Ammann’s latest development in warm recycling, the RAH100, which can utilize 100 percent RAP

• Vertical stacking of the RAP-bearing components reduces wear and sticking and shortens the travel distance of hot RAP material

• Production capacity is 440 U.S. short tph

For those who have a number of small jobs in varied locations, where frequent transport is required, and for paving contractors looking to introduce asphalt production into their businesses.

• The plant excels at specialty mixes, such as those used for paving tennis courts and running tracks

• The ACM 140 Prime offers output of up to 154 tons per hour

• Engineered for smaller volumes and therefore produces them efficiently, delivering cost savings in fuel and electrical energy consumption

• Recycled asphalt can be utilized with this plant

• The entire plant and three cold feeder bins fit on two axles during transport

SYSTEMS control centers are designed with attention to rugged construction, operator comfort, and safe, logical integration of plant controls and switchgear. Custom buildings sold as shell only or with full turnkey operability. Most structures include installed electrical outlets, lighting, heating and air conditioning, cabinets, countertops, controls, and outdoor security lighting.

Innovative custom-manufactured buildings are available in portable, stationary or relocatable models, as well as single-level, two-story, and split-level designs. All custom building specs considered. Structures can be used as asphalt plant control centers, offices, portable laboratories, weigh shacks, barge dredging control centers, switchgear enclosures, and more.

Some available features include:

• All-steel welded frame construction

• Fully insulated floor, sidewalls and roof

• Acoustical ceiling panels

•Air conditioning and electrical heat

• External vertical steel siding

•White interior glass board wall paneling

Many additional options offered. All custom options considered.

info@systemsequipment.com

(563)568-638 7

www.systemsequipment.com

ASPHALT PLANTS

The BG 1800 Batch Plant series features a modular design that is fully customizable to meet the needs of the plant owner.

• Can produce up to 70% RAP

• Easy set-up

• Perfect for municipalities who need to produce many different mix designs

Featuring a high-production capacity and total hydraulic and electrical autonomy, the versatile Blend Mobile A240 Plant can be transported easily on a standard low-loader truck without additional mounting operations.

• Transportable on a standard low-loader truck

• Maximum granulometry aggregate size: 2.3 in.

The Voyager 140 can produce up to 140 tph with up to 50% RAP.

• Portable plant can be transported and set up and tested in about a weeks time due to fixed duct work

• Double Barrel Drum with standard V-Flights provide uniformity of aggregate veil for effective and efficient heat transfer

EX Series plants produce up to 425 TPH and can handle up to 50% RAP. Using counterflow technology, these plants provide the longest aggregates drying and mixing times in the industry to ensure consistent, quality asphalt that meets all federal and state specifications. Also on display at the show will be a 12’ x 28’ ADM Control Room.

• Onboard PLC controls dosing of water, emulsion, and additives

• Remote control system provides complete management of production

The Astec Ventura asphalt mixing plant maximizes the performance capabilities for a compact, ultra-portable plant.

• This highly portable version of the Astec continuous mix asphalt plant effectively uses field-tested and proven core components to reliably deliver a production rate of 140mtph

• Can be transported in a single load

• Simple maintenance process

• Capable of producing up to 15% RAP

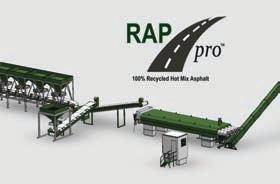

The RAPpro is an economically priced hot plant specifically designed to efficiently produce high quality HMA utilizing 100% RAP.

• This plant utilizes a revolutionary multi-tube in-direct heated, continuous flow patent pending drum design

• When coupled with PelletRAP rubberized binder material used as a RAP rejuvenator, very high quality mixes at economic pricing

The new Gencor G Series is the latest innovation in small portable hot mix plants providing asphalt producers and contractors with all the features of Gencor’s award winning Ultraplant in a smaller compact highly mobile plant that can be erected and operational virtually anywhere.

• The G Series is a rugged designed plant built with all the same premium features you’ve come to expect from Gencor for years of dependable service

• The firing end of the burner extends into the dryer beyond the mix section so as not to overheat the aggregates and liquid asphalt as they are mixed together

• Highly-efficient Ultraflo baghouse is coupled to the drum at a 90° angle with Gencor’s exclusive self-erecting ductwork and stack

• The G Series also includes Gencor’s proven and highly portable Silo that erects in minutes and provides an easy hot mix surge alternative without sacrificing storage capacity

The Cedarapids Magnum

Bullet 150 Super-Portable 150tph counterflow drum-mix, with 35% RAP capability, will be on display with a Roto-Aire RA3-14 baghouse.

The Magnum Bullet series has been designed with many upgrades including high efficiency drying and mixing zone, railroad bearing trunnion roller assemblies, direct drive gear motors, and drum insulation and cladding as standard. Designed with an emphasis on substantially reduced installation time to provide a market leading set up time within two days when combined with a portable self-erecting hot mix storage system.

• Field proven counterflow technology

• 30% + RAP with low maintenance costs and a single shell design

• Tuneable performance provided by indexing slingers

• Longest mixing zone in the industry produces high quality material

• Super-Portable, Portable, Relocatable and Stationary configurations

• Magnum “Bullet” Super-Portable series have hydraulic erect systems which provide unrivaled set up times

Designed for contractors demanding high mobility, rapid installation with minimal foundations and quality assurance of the final mix, the RoadStar range is renowned for being a true contractors plant and is considered to be the most portable range of batch production asphalt plants on the market today.

The 120tph RoadStar 1500 will be erected in its working position along with the portable dryer, burner and integrated primary dust multi-cyclone system.

The UF Series of counterflow asphalt plants has been designed for producers who appreciate the importance of the details at their hot mix asphalt production facility. The portable 92UF drum mixer is designed with features that allow portable operators to set up, produce efficiently, and move to another location quickly and cost-effectively without sacrificing heavy-duty drum and component construction.

Sponsored By

The Maxam SOLO Drum's patented technology advances counter-flow to a new level of efficiency.

• Separates the control of the exhaust stack temperature from the control of the mix temperature with the MAXAMizer heat Recovery System

• Directly heats the RAP without superheating the virgin aggregate and without producing blue smoke with the RAPTOR Recycle System

• Support trunnions continuously self-align with the TrooTrac alignment system

• Built for asphalt plant use in sizes up to 120,000 cfm

• Jet-pulse design great for retrofit applications

• Solenoid valves enclosed for easy operation in cold weather

• Even distribution of air across baghouse

Gencor's warm mix technology with the Ultrafoam GX2.

• Can achieve consistent foaming at varying production rates without the use of a powered mixing device

• AC and water can be introduced at widely different flow rates and pressures

• Compressed Air Purge releases remaining water in the piping and hose between the unit mounted on the drum when temperatures approach freezing

• Water Flow Alarm senses water and transmits alert to the operator if loss of water flow to the unit occurs

• Pump heater features a convective heat bulb used inside the pump enclosure to prevent pump and internal components from freezing

• Weatherproof enclosure provides freeze and dust protection to the pump and electronic parts

• Eco-friendly advantage of AQUABlack Solutions warm mix system

Systems Equipment's Asphalt Pump Skid is designed to accurately and reliably pump liquid asphalt over a wide range of delivery rates.

• Variable speed volumetric pumps for maximum life and stable proportioning

• Eddy Current, VFAC, or DC drive options available

• Direct coupled; no drive belts

• Liquid Additive Pump Skids also available

For situations where more aggressive cleaning is required, the pulse jet baghouses can provide significantly better bag cleaning due to "pulse" of compressed air that causes the bag to ripple down its length.

• CMI BH30R baghouses feature a large filtration area with high air volume and high filtration efficiency

• Constructed using alternating U-shaped steel plates

Tarmac’s counter-flow dryers offer longer combustion flights for better flame development.

• Moving slinger belt to adjust gas temperature to baghouse

• Three RAP entry location options for higher RAP percentages

• Insulation available

• Trunnion or chain drive

Maxam Accu-Flo Asphalt Additive System helps asphalt plants save on energy costs by removing the need to heat the additive tank.

• Heats only the metered additive

• Handles the most viscous additives

• Integrates with existing plant controls

• Installs easilyfully assembled in a steel, skid-mount

Sponsored By

Improve the cost efficiency of your plant and boost RAP utilization with the ADM Recycle System.

• Available in various portable and relocatable configurations, designed to tackle the many mix specifications you handle

• System allows your operation to produce hotmix asphalt with as much as 50 percent recycled material

• Multiple capacities available to suit almost any operation

A complete system that can provide direct heat to the asphalt tank, while also supplying hot oil for the plant.

• The primary feature of the system is the drywell-style electric heating elements that provide and maintain heat to keep liquid asphalt cement at the desired temperature

• System circulates oil through scavenger coils and thermostatcontrolled electric booster heating elements to provide hot oil to heat jacketed lines, pumps and valves, drags, silo cones, and other plant components

• Includes a high-temperature centrifugal pump

Designed to withstand the harsh elements of an HMA facility in portable, stationary and skid-mounted systems.

• Unique feeder belt mount design allows for belt removal/replacement without requiring to remove feeder

• ¼-in. bin wall construction

• 10-ft. x 14-ft. & 10-ft. x 16-ft. are standard sizes

• 60° sloped walls minimize build-up

• Adjustable slide gates to allow accurate metering

• Self-relieving throats allow for proper flow of material

• Multiple options available

• All-welded recycle bin can be reinforced with optional grizzly bars for superior durability

Starting with the HMS140, they're also available in 200, 260 and 320 ton sizes.

• Designed with features to economically store hot mix asphalt for extended periods of time, CMI’s silos are also designed with special features to reduce segregation

• Rugged slug feeders designed to reduce segregation are fitted with AR steel liner plates

• Also featured are CMI’s dual discharge gates of 48-in. x 12-in. wide with elastomer seals configured perpendicular to the driveway to reduce material segregation

• Safety gates with a 4-in. floor structure closes with a clam gate failure or loss of silo power.

• Drag conveyors armored with chromium carbide steel

Ruggedly built for years of use under the harshest conditions.

• Unique bin design provides steep sided tapered bin walls and a selfrelieving throat to virtually eliminate bridging and material flow problems

• A rugged rack and pinion gate design provides easy material height adjustment to suit a variety of material gradations

• All feeders include two material flow indicators

• Other optional features

Reduced energy consumption, lowered emissions, and elimination of visible smoke, and the latest generation simplifies production.

• Lower temperature and lower cost by eliminating the need for additives or special asphalt cement

• Injects a small amount of water into the liquid AC to create microscopic steam bubbles

• Reduces the viscosity of the liquid AC, allowing the mix to be worked at lower temperatures

One of only two companies building this style of dryer/mixer drum.

• As a result, BROCK now offers the market a viable option for drum replacement and/ or refurbishment in this style drum

• BROCK also offers in field construction services for hot mix asphalt plants including repairs, maintenance and plant relocation services

Developed in response to plant operators’ need for a better technology than existing burners.

• 125,000,000 BTU/hour multifuel burners delivers increased efficiencies and reduced cost

• This multi-fuel register-style burner for asphalt rotary dryers allows users to shape the flame by automatically controlling the register vanes to optimally fit their dryer and combustion zone

• The HDRA-RF is the first burner to introduce dynamic flame shaping to the aggregate drying industry

Designed to eliminate material bridging, with steep sided ¼-in. tapered walls, selfrelieving throat and welded beater plates on the sides of the bins.

• With the rack and pinion gate design, material height can be easily adjusted to suit any feed rate

• Variable speed drives assure steady consistent flow at varying production rates

• Feature unitized heavy I-beam construction and are available in portable, stationary, or skid-mounted configurations

• Dual no-flow sensors

• Variable-Frequency or Eddy Current drive system

• Lifetime lubricated idlers

• Self-cleaning tail pulley

Incorporates an individual motor control center and operators control room on one chassis.

• Control room is designed so that the operator has a higher vantage point to oversee plant operations with the added benefit of extra space underneath for storage

• Both the motor control center and control room have their own independent climate control

TOUGHNESS CASE STUDY

Gorman-Rupp Rotary Gear Pumps

Asphalt Rocky roads ahead

Heavy-viscosity, abrasive-filled asphalt? Bring it on. It’s no match for the fierce quality and reliability of Gorman-Rupp rotary gear pumps. Loaded with patented performance features and rugged, heavyduty components —from high-strength iron gear sets for handling higher viscosity, pressure and torque to thermal jacketing for temperature control — our rotary gear pumps are engineered to stand up to abuse and last longer.

Delivering total asphalt domination.

For more information, contact your nearest Gorman-Rupp distributor or visit GRpumps.com

Donnie & T.J. Reed, Madison Asphalt

Donnie & T.J. Reed, Madison Asphalt

With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs.

“ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.”

The Revolution D drum mixer is known for its heavy duty, rugged design.

• This line of rotary dryers are used for asphalt, sand and specialty dryer applications

• CWMF Revolution D rotary drums are manufactured for portable and stationary applications

ADM’s digitized fuel meter linked to the control house provides an easier and safer way to measure fuel consumption than having a worker stand on top of the tank and use a stick and tape measure to read levels.

• Accurate to a fraction of a gallon, more reliable and easier to read

• The benefit of realizing whether the plant is consuming too much or too little fuel

• Changes in fuel consumption can help determine if there is a problem

The Maxam Tank Level System allows for accurate tank leveling with no moving parts.

• Pressure type sensor, more reliable than radar

• Easy installation and set up

• Automatic unload pump shutoff

• Digital display in inches, feet (or tons on vertical tanks)

• High intensity readout - clearly visible in sunlight

• Weatherproof display mounts at tank or unload pump station

• Includes 100-ft. of signal cable

A great solution for asphalt producers looking to utilize RAP in their mixes, with customizable options that help any producer meet a wide range of mix recycling goals. Engineered to take the day-in, day-out abuse associated with high-volume plant production while incorporating the features that allow the precision required for today’s high-spec mixes.

• Incorporates direct connected helical gearbox and fully-digital flux vector tech

• Equipped with a material flow detector to alert the plant operator if material ceases to flow from any RAP bin

Tarmac's Tri-Mix is a simple yet effective warm mix injection system.

• Injects water at up to 2000 psi

• Delivers consistent, lower viscosity AC giving you better coating at lower temperatures

• Lower mix temperatures can save 20% on burner fuel costs

• Simple design and non-corroding components make the TriMix virtually maintenance free

• Fast installation and integration

• Continuous compressed air purge when not in use

• Standard controls with optional PLC controls

apable of producing mix consisting of more than 60% RAP.

• Maximizes RAP utilization and meets the world’s most stringent emissions guidelines

• Gentle pre-heating of the RAP, compared to traditional cold feed to superheated virgin aggregates, prevents thermal stress on the asphalt concrete (AC) content and ensures a highly homogenous final mix

• Incorporates a RAP dryer for the addition of recycled materials and a separate cold recycling feed

• Capable of incorporating shingles, liquid additives, fiber granulate and foam AC

• Continuous production capacity is 330 tph

Ideal for retrofit applications, the Versa Jet burner fits nearly any drum.

• One versatile platform can be quickly configured to fire at 25, 35, 50, 65, 75 or 100MM BTU/hr

• Combines three burner packages in one platform, can be easily adapted for the system at the install site

• Platform permits quick delivery and setup which minimizes downtime while maximizing profitability

• Streamlined design ensures that these burners are ready to ship to your site quickly and can be installed with minimal modifications needed

• 25, 35, and 50MM BTU/hr

• Low power – All 3 models are 25 hp

• Base burner does not include the fuel train

The ADM EX series was designed to provide high RAP usage (handles up to 50% RAP) and total performance. Features and benefits of the EX Series include:

• Generously sized diameter- to-length ratio to obtain higher tonnages

• Efficiently sized and flighted drying zone

• Self-relieving recycle collar with wear plates

• Recycle-virgin aggregate premixing zone

• Longer than standard mixing zones for higher mix qualities

• (EX)panded ends on the drum shell to incorporate lower velocities, extended drying and mixing zones

Offers increased performance and life of shell while maintaining the beneficial aspects of the Triple Drum design.

• Portable and stationary design, with no disassembly required for transport

• The RAP Eater drum is continuous throughout its length. This major design improvement eliminates the inherent weak structural points and high wear areas of the Triple Drum

• Eliminates the costly inner stainless steel combustion chamber on the Triple Drum by replacing it with individual stainless steel panels and flights.

Since 1892, Homestead continues to be the most reliable manufacturer of asphalt valves. With cast iron and ductile iron material options, we offer a complete source of valves for any liquid asphalt application.

Our full line of hot-jacketed 2-way shutoff & 3-way diverter valves provide a ready solution to meet your flow requirements.

Homestead’s cutting-edge actuation design allows you to easily add actuators to your existing Homestead valves, in-line, without modification

Our fully stocked warehouse of valves and actuators offers you security in knowing that the valve you need is only a phone call away.

The FREEDOM AIR reverse air baghouse features ½ compartment pulsing to allow even dust distribution in hopper, multi sequence pulsing, bags installed at factory, fold in place handrails, and tapered exhaust inlet with distribution holes to allow gentle flow of air entering baghouse.

• Reverse air design means there is no air compressor to operate

• VFD control of turrets allows operator to maintain desired static pressure in baghouse. This can also improve bag life

Sponsored By

The Meeker Equipment Rejuvenator Pump

Skid has progressive cavity pumps which are positive displacement pumps.

• Mass flow meters provide accurate and repeatable flow rates. Density of liquid is automatically compensated so you get accurate data

The Dust-Eater baghouse is offered in a portable or stationary configuration, ranging in size from 10,000 CFM to over 100,000 CFM

• 3/16-in. shell construction

• Inlet deflectors

• Side wall louvers

• 7-ft. x 10-ft. x 12-ft. inlet knockout box is equipped with a series of deflectors and louvers minimizes the amount of larger fines (+200 mesh) from entering the bag chamber. This allows the unit to collect the finer particulate for efficiency. It also aids in prolonged bag and component life.

• 2 ½-in. spacing between bags

The Blue Smoke Control division of Butler-Justice Inc. created X-VOCS to help eradicate odor-causing emissions produced as a byproduct during hot-mix asphalt production.

• The X-VOCS System features proprietary carbon absorption technology designed to filter and remove up to 99% of odors and VOCsfrom tanks

• X-VOCS incorporates a five-stage filtration system. In the first three stages, a series of filters remove more than 95 percent of targeted particulates down to 0.3 microns. In the final two stages, carbon filtration beds remove remaining odors and volatiles

• Variable frequency drive allows operators to control VFD locally or remotely

• Electric control valve is pre-plumbed into skid. Operators can run rejuvenator to drum, divert it back to a tank or for calibration

• On the discharge side of the progressive cavity pump

Has a lower initial investment and significantly lower maintenance costs compared to conventional liquid asphalt tank heating/agitating systems.

• Siphon jet pump induces a high speed, high volume flow

• The ConVector comes as a complete unit and is easily installed

Designed to provide a safe, refined, and fully mobile environment for your asphalt plant operators, plant automation systems, and load-out. 270-degree views, UL-Approved Motor Control Centers (MCC) complete with manual backups for each bucket, and rubberized flooring.

An innovative solution to mixing asphalt, rubber, polymer, or any dry powder. It effectively inline blends both small batches to continuous large-scale production.

• Proven to handle heavily-modified asphalt blending production rates from 10TPH up to 60TPH+ of continuous use

• 85 gallon, single-chamber, heat-jacketed chamber

• Two mixing stages featuring a combination of flighting, breaker bars, and mixing paddles

• 200rpm single-speed electric motor and gearbox

• Heat-traced with 2” high-density insulation

• Backflow preventative device with overflow and dual-redundant high-level safety switches

The simple, reliable design efficiently handles both low and high volumes of dust, providing plant operators the ability to return dust/fines. Continuous duty means that the baghouse filter bags are cleaned in sequence, one set at a time without turning the unit off. The filter bags encompass a large filter area in a small compact housing thus keeping the air velocity through the bag to a very low level when compared to traditional pulse jet baghouses. Dryer velocities are held below 1,000 FPM.

Sponsored By

The Silobot is a hi-tech tool that the Astec team will use to do thorough visual inspection and metal thickness testing inside hot mix storage silos.

• The remote control capabilities of the Silobot inspection device keep workers out of the confined space of the silos and out of harm’s way. It does the job quicker, safer, and typically more thoroughly

• The inspection record provided to the customer will include a metal thickness map, a video, and photos of the inside of each silo

• Engineering evaluations and recommendations, based on the inspection findings, is provided by Astec engineers

The Low Aggregate Alarm from Systems Equipment is designed to indicate when aggregate in a feeder bin is below a critical level.

• LED display provides visible “at the feeder” indication for setup of proper trigger angle

• Compatible with 10-120 volt (AC or DC) excitation at 20-100 milliamp loads

• Rugged, sealed housing suited for the asphalt industry environment

Offers advanced automation for asphalt drum mix plants.

• Adaptability for retrofit or total plant control of nearly any plant

• Extensive use of high-speed networking to increase accuracy and reduce wiring

• Integral manual control via software control "panels"

• Easy calibration of plant equipment

• Real-time trending of key process parameters

• Fully graphic operator interface

• Instantaneous production rate changes

• Tracks equipment maintenance and re-calibration schedules

• Facilitates future expansion

The eDry Upgrade Kit for the InstroTek CoreDry is the quickest and most effective method for drying asphalt emulsions.

• In less than 30 minutes, can dry up to 5 grams of asphalt emulsions

• Patented vacuum tech allows pavement engineers to quickly determine the appropriate binder content and application rates

Galileo Research from Controls Group is a fully electromechanical asphalt gyratory compactor designed with testing accuracy, repeatability, safety and efficiency in mind. All models use closed-loop control for axial load, rate of gyration and gyratory angle plus patented orbital motion to compact specimens with a level of stiffness and angle stability that exceeds the new requirements of AASHTO T312, ASTM D6925, D7115 and EN 12697-31 standards.

Provides the loader operator with a realtime dashboard of practical contextual information regarding plant production.

• All vital production information and statistics are now available inside the cab, in plain sight, updated in real-time!

• Current mix and percentages, next mix scheduled, feeders in use, amount of stone needed, levels and no-flow sensors, plus time-to-empty countdowns are displayed. Information is graphically displayed for intuitive understanding at a glance

A shutdown may result if the levels sink too low without the operator noticing and ordering material in time but the ADM tank level indicator gives operators the ability to see fuel or asphalt tank levels from the control house.

• Offered in a variety of types, including pressure gauges and radar, the indicators allow plant operators to see the levels from the control room rather

• This is useful on busy days when the operator may not have time to visit the tanks

The Document Management feature has been specifically designed in response to calls from existing PlanRadar subscribers for a way to collate and manage data between in-field and back-office teams. It answers the call by offering a way to track, plan and document approvals and sign-offs for maintaining a tamperproof audit trail and clear picture of all sign-offs during a project. This new feature helps minimize rework while maintaining documentation for claims protection.

Utilizes Programmable Logic Controller (PLC) technology and Windows based operator interface software to precisely control and monitor asphalt plant operations, on-site or remotely.

• Total plant control featuring plant diagnostics, remote plant monitoring, step by step instructions to guide the operator through the calibration procedure, data recordation, alarm log, activity log, mix cost analysis

• Impulse series comes complete with every new asphalt plant from CMI and is a popular choice as an aftermarket retrofit to other brand asphalt plants

Designed to proportion aggregates and additives according to prescribed mix design formulas, and to measure and control the liquid asphalt mass flow rate, so the blends are accurately interlocked to the measured aggregate flow.

• Available with text-based format OR with a WindowsBased Graphics enhanced User Interface.

• Integral belt scale totalizers

• Direct interface to all brands of asphalt pump skids and metering devices

• Asphalt tank inventory and selection monitor

Sponsored By

• Streamline ordering process allows plant operators, sales people, the QC team, managers and engineers to store information in a centralized location

• PlantDemand increases visibility by having a single true source of information which reduces the redundancy of order taking in multiple places

• Visual order calendar helps users understand what plant must do in seconds on an intuitive order calendar with optimized order entry

• Save time and frustration generating reports in a few clicks

The Stansteel Tank Tracker has the ability to accurately measure and monitor the tank and silo levels in real time and at multiple remote locations.

• Accurately measures liquids, solid materials and even bulk powders like mineral filler and can do so in cold or elevated temperatures

• From your smart device, you will be able to manage all your silos and tanks on one screen. You can see real time levels and temperatures

Suitable for all makes, models and mechanical configurations. Optimizes production, collects key performance indicators, standardizes workflows, simplifies maintenance, uniformizes operator training and improves workplace communication. Engineered to bring the best practices to production.

A unique product for effectively handling RAP content in various proportions and in varying conditions.

• This module is part of proprietary as Control System

• Dynamic RAP Addition allows modification of the RAP ratio – even during production runs

• The system helps plant operation and quality assurance staff compensate for the qualitative and quantitative attributes of the RAP being used

While Resource Management enables contractors to request and dispatch equipment and labor resources, Schedule allows for visibility of these resources across divisions and job sites in a single combined calendar/ Gantt chart view for equipment and labor planning and forecasting. With the addition of Schedule, equipment and project managers can see what’s down for maintenance, what’s currently operating on a particular site and what’s scheduled for six months down the road for a job. They can look back at project and asset history as a reference to compare against their construction forecasts, including how long machines were in use on job sites compared to where they were scheduled.

The NextGen Silo Safety System guards against the most dangerous and expensive accident that can occur at an asphalt plant – inadvertently opening the wrong silo. Equipment damage, personal injury, litigation and lost production are all consequences of a silo accident. The NextGen3 Silo Safety System is designed to dramatically reduce these risks.

• Significantly reduces the possibility of opening the wrong silo

• Independent of, and compatible with, existing automation and manual switches

Remote printing capabilities dramatically improve the speed and throughput of your operations, plus safety, by keeping drivers in their trucks and out of the control house.

• Custom built remote printer enclosure is designed to house either a thermal or laser printer

• When installed at cab height, the driver may pick up the scale ticket after weighing or loading without leaving the vehicle

• The enclosure is constructed of industrial steel and comes standard with a heater and cooling fan system

• Signatures, cameras and many other options that WEM provides can minimize the need for interaction between the plant and the drivers

Trimble Dimensions 2023 User Conference provides more opportunities to unleash the power of your Trimble technology than ever before.

With hands-on workshops and in-depth learning, you’ll discover new ways to get more value from the products you use.

While you’re at it, you’ll realize the network e ect of connecting with the Trimble community, sharing knowledge and working together move your business forward.

NOVEMBER 6–8, 2023

THE VENETIAN RESORT, LAS VEGAS

Rock Systems Semi-Portable Single Separation

Haver & Boecker Niagara N-Class Vibrating Screen

The N-Class Vibrating Screen is capable of screening as much as 5,000 tons per hour.

• Ideal for tough jobs, such as scalping and classifying ores, minerals, stones, sand and gravel in aggregates and mining applications

• Dynamically balanced to minimize dynamic loads transferred into the structure and allows multiple screens to be placed side by side in the same building

• Heavy-duty body design handles loads in applications with extreme material sizes up to 2,032 x 1,016 x 1,016 mm

The Eagle Crusher 1200-CC with Pre-Feeder Screen is designed for larger-sized jobs with high volumes of material at- or near-spec.

• Two-deck screen-feed system greatly increases total production as the millings and fines go through the screen to stop wear and tear on the impactor and dramatically increase tonnage

• Available in tri- or quad-axle versions, the two-deck inclined screen produces two cubical spec products

• The plant is also available with a twin-shaft screen option with third reliever deck

Rip-Rap Plant consists of a heavy duty feed hopper constructed of 1-in. thick plate with stiffeners and a 46-in. wide x 20-ft. long vibrating grizzly feeder complete with 14-ft. solid pan impact section and 6-ft. long adjustable grizzly bar section.

• Collecting hopper under the grizzly section constructed of ½-in. thick plate with stiffeners to bypass the fines to an optional side discharge conveyor

• Semi-portable steel fabricated support structure with skid frame and plate steel bulkheads on all sides of structure

• One rust inhibitor prime coat and one finish coat gray paint for all equipment; one finish coat safety

The SMI compact crushers and screening plants are especially suited for use in tight jobsite environments, including urban areas. Models include three tracked jaw crushers from 7" x 16" (10TJ) to 16" x 28" (50TJ); a 3’ x 8’ double-deck tracked screening plant (90TS); and 7" x 16" (10SJ) and 10" x 20" (20SJ) stationary jaw crushers.The 50TJ is capable of processing up to 50 tph, while the 20 and 10 models generate up to 20 and 10 tph, respectively. The 90TS can process up to 90 tons of material per hour. The units can be fed by hand or by a mini-excavator or skid-steer loader. At 26,000 lbs., the 50TJ requires a semi-tractor trailer for transport; all other models can be moved with a heavy-duty pickup truck and transport trailer.

Keestrack's R3 plant is available as diesel-hydraulic or fully hybrid "e"-version.

• Production rates up to 250 tph

• Flexible processing of a large variety of raw and recycling materials

• Pre-screening

• High-performance impact crusher 48 ICR 100-00 with 770 x 960 mm inlet opening

• Heavy-duty 920 mm rotor (44-in. diameter)

• Optional 9-ft. x 4-ft. single-deck with reciruclation conveyor after screening unit

With an output of up to 717 tons per hour, the MOBICAT MC 120 Zi PRO jaw crusher has a feed opening of 48-in. x 32-in. and is equipped with an extra long articulated crusher jaw.

• To ensure the best possible material flow, the continuous feed system (CFS) adapts the conveying speed to the fill level of the crusher

• Should material bridging occur in the jaw crusher, the crusher can be reversed with the aid of the electric crusher drive and in this way the blockage can be cleared in no time

• All components and functions can be controlled conveniently

For material processing can process recycled concrete, reclaimed asphalt and pit run materials into valuable salable products. From a single feed, owners and operators will be able to produce up to four unique products. The closed circuit crushing and screening arrangement includes a 4250 Superior brand Sentry Horizontal Shaft Impactor (HSI). It is fed by a 48 x18 Intrepid Vibrating Grizzly Feeder, which is equipped with interchangeable grizzly cassettes (bars, fingers or punch plates) to accommodate multiple applications. Additionally, a two-deck Anthem Inclined Screen screens up to three material sizes. Returning material is fed back to the HSI via a patent pending recirculating conveyor, which centralizes the feed for full utilization and extended wear life of the crushers blow bars. Onboard, the cross conveyors are universally designed to be interchangeable, which means owners invest in fewer conveyors since they can be mixed and matched throughout the plant. The plant is equipped to accommodate line power but can also be outfitted with a diesel drive genset unit. Its transport weight, dimensions and axle configurations make it permissible for road travel throughout all of North America.

• Process recycled concrete, reclaimed asphalt, and pitrun into valuable products

• Produce up to four unique products from a single feed

• Recirculating conveyor centralizes feed, whichextends life of HSI blow bars

• Rotate universally designed, interchangeable crossconveyors throughout the plant

• Accommodates line power, but can be outfitted with adiesel drive genset unit

Equipped with an 8-ft. x 18-ft. top deck and an 8-ft. x 12-ft. bottom deck.

• Patent-pending screen design features externally-mounted vibrators at the ends of the tappets for a more aggressive screening action which creates a higher G-force and reduces heat load from material to motors as compared to single, center-mounted vibrators

• Screen also allows for easier maintenance and adjustments and is equipped with hydraulic operating angle adjustment, a fines collection hopper, top- and bottomdeck discharge chutes and an aggregate spreader

• Similar to other PTSC plants, the 2818VM features a nominal 54-in. x 38-ft. delivery conveyor with hydraulic drive and full-length skirtboards

• Chassis is fitted with manually-operating support legs

From replaceable abrasionresistant steel wear liners to a ½ -inch steel pulverizing hopper, this machine is ready for wear and tear. Included is a two-way valve hydraulic power pack that performs a controlled close of the pulverizing hopper top so that safety is never compromised. It also crushes costs, with an average return on investment reflecting 1/8 the cost of other crushing operations. Here are some of the ways the Honey Badger delivers on cost savings:

• Typical six-month ROI (for a 300,000 ton/season plant)

• Reduced or eliminated crushing costs

• Lower fuel consumption due to reduced RAP moisture

• Minimal material handling

McCloskey International has unveiled the new J4 jaw crusher with new features for hard rock applications. Designed to withstand tough conditions, the J4 delivers high production due to its jaw chamber design and material flow. The large 1060mm x 700mm (42-in. x 28-in.) jaw opening accommodates large feed sizes, contributing to production in material processing. The material path is enhanced with the 1064mm x 4247mm (41.9-in. x 167.2-in.) grizzly pan feeder under the hopper that allows for sizing of material with a variety of mesh options. Options of either a short pan feeder to suit the pre-screen or a double deck grizzly pre-screen are available for sizing of material based on the required end product.

A choice of either a two deck or one and a half deck system. The two deck delivers an extra product spec over the mid-size product conveyor. Delivers stockpiling, with wide main and side conveyors for material flow. The angle adjustable 1200mm (48-in.) wide ToughFlex main conveyor has a 3.912m (12-ft. x 10-in.) high stockpile, and with quick release and ground level access, with the belt offering access for maintenance. It’s constructed with a special weave of two fabric plies and an additional binder warp (without the need for steel wire) resulting in reduced belt weight.

JANUARY 30 - FEBRUARY 1, 2024

Henry B. Gonzalez Convention Center - San Antonio, TX

You are invited to the inaugural immersive tradeshow, PAVE/X! And, we are excited to announce that OVER 45 industry-leading manufacturers and suppliers from across the paving and pavement maintenance industry will be in San Antonio for this NEW event.

The event will feature a robust educational program with FIVE TRACKS: a fast-paced demonstration showcase, and unlimited networking opportunities.

Paving, Striping, Sweeping, Sealcoating & Business Management,

We saw a distinct need in the market to evolve what an in-person event could mean to the industry. PAVE/X is already a reflection of that. As such, the experience significantly differs from other trade shows and conferences that serve paving and pavement maintenance contractors. Our goal with this event is to guide contractors towards deeper buyer insights as they make important purchasing decisions by utilizing high-quality curated education, live equipment demonstrations and networking opportunities that connect the right buyers and sellers, while maximizing the entire experience of both attendees and event supporters.

– Amy Schwandt, Chief Revenue Officer, ACBM

– Amy Schwandt, Chief Revenue Officer, ACBM

Sponsored by

The “Dash 3” paver generation for the North American market features the 8-foot SUPER 17003i track and SUPER 1703-3i wheel and the 10-ft SUPER 2000-3i track and SUPER 2003-3i wheel pavers. All

are available with an unparalleled range of screed offerings including front and rear-mounted vibratory screeds to highcompaction screeds. The pavers include the ErgoPlus 3 operating system along with a few enhancements including

Vögele EcoPlus and PaveDock Assistant. Learnmoreaboutthe Vögelelineofasphalt pavers. https:// pavemg.com/4jczeb

The P7110B tracked and P7170B wheeled pavers offer 360° visibility, improved fuel efficiency with 12+ hours of continuous runtime without refueling and options to enhance productivity and mat quality.

ASPHALT PAVERS Sponsored By

• Volvo D8J, 8-liter, Tier 4 Final engine uses continuous passive regeneration and boasts a more than 5% improvement in fuel efficiency

• Press of a button extends the two-stage, 42-in. hydraulic tunnels, allowing head of material control without bolt-on extensions

• Include a range of screed options and a four-sensor material flow system

• Choice of two control consoles for operation from the left or right sides

• Side air vents and a slightly higher seat improve operator comfort

The AP555E has an operating weight of 35,290 lbs. when equipped with the AS2252C screed, or 35,810 lbs. with the AS3251C screed.

• 142-hp C4.4 4-cylinder, turbocharged diesel engine with ACERT Technology

• Automatic speed control and three propel/steering modes for efficient paving operations, Dual swing-out operating stations with the Advisor Monitoring System

• Mobil-trac undercarriage with choice of belt designs

• Unique material handling system with independent auger and conveyor controls

Provides consistent material flow and delivers a paving width up to 15 ft. 6 in.

The RP-195 features a fully oscillating track frame to provide a smooth ride and lay a smoother mat. The RP-195 is also equipped with the exclusive antisegregation design of the feed tunnel, discharge and rear augers. The heavyduty frame, solid front axle and sturdy conveyors are engineered for durability. The RP-195 F series track pavers have upgraded styling, simpler maintenance and enhanced operator experience. Additionally, the upgraded models feature a new cooling system, which makes the paver run quieter and more efficiently. The overall design of the paver has been transformed and updated.

The 260-hp CR 1030 W wheeled paver has a standard 16.7-ton hopper capacity, or up to a 27-ton capacity with an insert, while the 225-hp CR 1030 T Series track model has a 14-ton hopper capacity or up to 22 tons with insert.

• Legend HD PRO screed features spring-loaded end gates, HD flight screws, heavy-duty crown and valley mechanism and an angle-of-attack adjuster with vertical height adjustment

• Includes independent hopper wings, reversible augers and conveyors, hydraulic tow point cylinders, material cut-offs that can be set to automatically close in reverse and a quick-change auger assembly

• Stylish operator platform includes dual operator control platforms, and multiposition, pivoting seats

• Stretch 20 hydraulically extendible screed enables infinitely variable paving widths from 10 to 20 ft. and a maximum paving width of 30 ft. with extensions

• Dual swing-out operator stations with SIDEVIEW enables seat and console to swivel outwardr screen display

The Weiler P395 incorporates proven designs with new innovations to provide optimal performance, reliability and mat quality in a wide range of applications. Its 4,400-lb., 7-ft. 8-in. front mount screed is hydraulically extendable to 15 ft. 4 in. The 96-in. track length with 74-in. of ground contact and 140-mm track chain pitch provide smooth ride and enhanced flotation. Automatic track tensioning ensures performance and maximizes component life. Swing-out consoles provide greater visibility, while the adjustable, magnetic-resistance intelligent steering system allows for reliable control. A joystick allows for automatic functions. Highway-class chains, conveyor and auger bearings.

Sponsored By

ASPHALT PAVERS

The 8515E has a height of 68-in. for improved operator visibility to the front of the machine.

• 74-hp Kubota Tier 4 final engine

• Enhance hydraulic system optimizes system performance

• Paving width: 8-ft.to 15-ft.

• Legend 815 or Legend 815 heavy-duty electric screed

• Poly pad tracks or continuous rubber tracks

• Under auger material cut-off gates

The AP1055F high-production, rubber track paver provides a 25-ft. maximum paving width using the SE60-Series or XW-Series screeds.

• 225-hp Tier 4 Final engine with Ecomode and automatic engine speed control

• 70-kW integrated generator

• Dual operator stations

• Mobil-Trac undercarriage

The CR 820 Series 8-ft. pavers come in rubber or track models with a 10-ton hopper capacity and a 160-hp Tier 4 Final diesel engine.

• Stretch 16 hydraulically extendible screed offers 8- to 16-ft. infinitely variable paving widths and a 12-in. maximum paving depth

• Quick-connecting extension kits deliver a maximum paving width of 20 ft.

• Three-Point floating suspension

Rear-mounted extenders provides stability, easy set-up and a versatile paving range.

• Ideal for parking lots, urban and rural roads, subdivision streets and highways

• Paving range utilizing the SE47 V screed is 8-ft to 15-ft, 6-in with a maximum width of 20-ft

• Walkway clearance height of 5-ft enables close starting capability next to curbs and other obstacles

• Screed operating consoles are equipped with mix height adjustment for the augers, providing the ability to modify material flow

• Screed plate depths of 12-ft on both the main and extenders providing stability

Improved fuel efficiency by up to 5% and provides superior quality, reliability, durability, and ease of operation.

• A true highway-class paver that takes you to the next level of paving, with an independent auger and conveyor system, and stable hydraulic screen extensions for delivering perfect placement of bituminous base, binder, or surface mixes

• The powerful and fuel efficient Tier 4 Final engine meets demanding emission regulations

The P4410B tracked paver comes factory fit with the 6,500-lb. Ultimat 16 front-mount screed, which can hydraulically extend to a full 16 ft. or up to 18 ft. with added extensions.

• 155-hp Deutz Tier 4 Final engine

• Ergonomically placed dual screed consoles and remote controls allow optimal visibility and precise speed control

• Includes power slope and power crown, a large hopper capacity and durable rolled hopper wings that prevent material buildup

• Adjustable auger-to-screed distance

Combining spraying and laydown produces a high-quality mat with a strong bond between layers. A spray bar just in front of the paver’s auger distributes the liquid through computercontrolled, self-cleaning valves. An onboard microprocessor precisely controls the rate of flow. Valves can also be controlled manually and are arranged in sets of three, providing plenty of spray capacity so you can move fast.

• High capacity 2,100 gallon heated oil tank. Four inches of insulation are placed around the oil tank so that emulsion does not require offloading overnight.

• HOT OIL HEATING SYSTEM - Oil is heated by a 500,000 btu diesel-fired helical coil heater. The system can operate at temperatures up to 450 degrees for liquid AC

• Spray bar extends to the full width of the screed for uniform tack coverage

Sponsored By

ASPHALT PAVERS

The 8-ft. class AP555 asphalt paver’s compact size and small footprint combine with enhanced maneuverability to enable paving in confined areas.

• Standard paving widths from 8 ft. to 20 ft. 6 in. depending on screed used

• Paving depths up to 10 in.

• Mobil-trac undercarriage design or available wheel undercarriage with sand-rib and radial tire options

The EZIV Screed provides a reliable, heavy-duty screed platform for commercial, municipal and highwayclass applications.

• Available in 8- and 10-ft. models

• Can be mounted to all current North American asphalt pavers offered by the major manufacturers

• Can be retrofitted onto nearly any previous North American highwayclass paver

• Low truck entry height and 14-in.-diameter augers efficiently move material

• Dual Operator’s Stations with Full Machine Controls, Including Dual Digital Gauge Displays

• Heaviest in Class Screed for Industry’s Best Compaction

• Standard Sonic Controlled Variable Speed Four Auger Material Feed System for Consistent Head of Material Control

• 110 HP Tier IV Final Turbocharged Diesel engine

• 9.5 Ton Hopper Capacity

Equipped with an efficient narrow conveyor management system, the machine is ideal for heavy commercial paving and large volume jobsites. The LeeBoy 8608 is powered by a 125hp Kubota Tier 4 engine and 14.4 kW belt driven generator. With an operating width of up to 15 ft., 6 in., this versatile machine will be easy to maneuver in tight spaces. The machine also includes a lowered SCR, exhaust and flat hood for enhanced operator visibility.

The SUPER 1300-3i is a highly compact paver yet features a maximum laydown rate of 385 tons per hour and a pave width of up to 16 ft 5 in. Whether for a combined footpath and cycle path, a farm track or a minor road or square, thanks to the AB 340 extending screed the Compact Class paver has the pave width range to match. With cut-off shoes, a pave width of just 2 ft 6 in is possible. The maximum pave width with the right bolt-on extensions is 16 ft 5 in. This makes the SUPER 1300-3i ideal for compact paving. The intuitive ErgoPlus operating system, featuring a wide array of convenience and automation functions, assures process reliability and quality when paving.

Weiler’s P385C paver continues to raise the standard for commercial class pavers with improvements to provide performance, reliability and outstanding mat quality in a wide range of applications.

The P385C features a Cat C3.6 Tier 4F/ Stage V engine with an increase to 120 hp (90 kw) for unmatched power and performance.

The best-in-class undercarriage features 90” (2286 mm) track length, 68” (1727 mm) of ground contact and 140 mm track chain pitch provides smooth ride and excellent flotation with automatic track tensioning.

The Dynapac range of highway class pavers & screeds are built specifically for the North American Market. The range offer includes four models of tractors, D30T – 10 ft. Track, D30W – 10 ft. wheel, D25T – 8 ft. Track, D25W – 8 ft. wheel and two models of screeds Mat Master 16R (8 ft. – 16 ft. screed), Mat Master 20R (10 ft. to 20 ft.). High transportation speeds, up to 10mph, allows fast repositioning of the machine at the start or end of the day. iTrack ultra duty rubber track design offers reliable performance with unmatched wear life.

Sponsored By

Engineered and built to exceed the demands of commercial paving, the Weiler P285 incorporates proven designs with new innovations to provide performance, reliability and outstanding mat quality in a wide range of applications. The Weiler designed 2,800 lb (1270 kg)screed delivers outstanding mat quality and a wide paving range. The 7’ 8” (2.3m) front mount screed is hydraulically extendable to 15’ (4.6 m). Highway class chains, conveyor and auger bearings provide long-term reliability.Remote grease lines located on the front counterweight provides easy daily maintenance. The P285 has three different operating positions allowing for optimal visibility while the adjustable, magnetic-resistance intelligent steering system allows for reliable control. All this and more!

The SUPER 1703-3i 8 ft paver meets the demands placed on asphalt pavers in the North American road construction industry, especially when combined with the VF 500 front-mounted screed.With its compact dimensions and Pivot Steer brake, the wheeled paver features excellent maneuverability, and enables pave speeds of up to 250 ft per minute. Achieving a maximum laydown rate of 770 tons per hour and pave widths ranging from 8 ft to 15 ft 6 in, and fitted with bolt-on extensions up to 19 ft 6 in, the Universal Class paver is ideal for large commercial applications. The paver and screed are equipped with the user-friendly ErgoPlus 3 operating system for automated grade and slope control.

The redesigned RD 27 2.5-ton double drum vibratory roller incorporates a multi-functional lever that contains buttons for all vibration options, water on/off and even the horn.

• Features a tapered front frame for optimal visibility to the front drum and ergonomically designed operator’s station with easy-to-read dashboard and control panel

• 5,470-lb. RD 27-100 comes with a 39.4-in. drum width and and produces a low/high total centrifugal force of 15,589/16,860 lbs.

• 5,950-lb. RD 27-120 has a 47.2-in. drum width and produces 15,285/20,232 lbs. of low/high centrifugal forces

The new Dynapac CP1200 pneumatic-tired roller features a flexible steel ballast is distributed evenly between tires for consistent ground pressure between the front and rear tires.

• Spacious platform, ergonomic controls and a rotating, sideway-sliding seat and steering assembly

• Tier 4 Final compliant engine

• Dual-circuit braking system maintains full braking effect even if one circuit is disabled

• Can be equipped with a cab with Automatic Climate Control

• Compacting width of 5.77 feet and maximum operating weight of 26,400 pounds

• Optional temperature sensor and DCA-A analyzer can play back the rolling pattern and produce a printout of all relevant information

The SD2500CS PROTAC spray paver is primarily designed for two application areas. The first is for the application of thin asphalt surface layers using “Thin layer in hot paving on sealant”. The second is for road repair, as well as for new road construction and everyday asphalting tasks. The use of thin asphalt surface layers, especially for maintenance construction, is ideal for weathered, but intact substrates. Thanks to the sealing via a binder film, it provides a permanent protection layer against moisture as well as offering more grip. The result: roads with significantly longer service lives.

The CB44B and CD44B offer 4-ft. 9-in drums and fit in the 7.7- to 11-ton size class, while the CB54B and CD54B have 5-ft. 5-in. drums and fall in the 8.8- to 12.5-ton class.

• Choice of solid- or split-drum designs

• 100-hp Cat C3.4B (CB44B) and 131hp C4.4 (CB54B) diesel engines

• Center-articulating hitch allows 6° of oscillation

• Offset option of up to 6 in.

• Versa Vibe provides four amplitudes and two frequencies

• Hand wheel steering technology

• Standard Eco mode and automatic speed control for added fuel savings

• TanGO directs vibration forces horizontally and the drum maintains continuous ground contact to deliver efficient compaction results after only a few passes

• Mainline 78.3-in. rolling width

• Front drum offers dual vibration frequencies (3,000/4,200 vpm) and dual amplitudes (0.036/0.013 in.)

• Rear drum boasts a highly wearresistant drum wrapper surface

• 114-hp Kubota liquid-cooled diesel engine

The BW190ADO-5 tandem vibratory roller offers traditional front-drum vibration and TanGO rear-drum tangential oscillation, increasing the machine’s flexibility.

Case’s DV209D and DV210D deliver 100% tractive effort due to a balanced drum design and a variety of standard features.

• 100-hp Deutz engine with EGR, DOC and SCR after-treatment technologies

• Updated cooling system and automatic idle control reduce fuel consumption by up to 15% compared to previous models

• Automatic vibration control

• Crab steering hydraulically offsets rear drum up to 6.7 in.

• Oscillating articulated roller joint oscillates +/- 6 degrees

• Pressurized triple-filtration water system

The CB54 XW Tandem Vibratory Roller offers compaction performance, application versatility and operator comfort to maximize productivity while providing exceptional product quality.

• Standard compaction width: 79-in.

• Max travel speed: 8-mph

• 137.0 hp Cat C4.4 engine with ACERT

• Machines are capable of performing effectively on a variety of mix types, while keeping pace with the paver, helps customers maximize resources and lower their capital investment

The 26,455-lb. SSR120C-8 roller compactor provides 62,947/40,015 lbs.-ft. of excitation force, 32/36-Hz vibration frequency and .07/.035-in. nominal amplitude.

• Features an 84-in. drum width and 59-in. diameter and offers 55% gradeability

• 160-hp Cummins QSB4.5 Tier 4 Final diesel engine

The Generation VI articulated tandem rollers feature temperature sensors on the front and rear drums so operators can better manage temperature drop while compacting.

• Tier 4 engines with optional ECO Mode system

• 7-in. LCD touch screen displays

The 5-ton RC50 has a 54-in. drum width and 15,512 lbs. of centrifugal force at a rate of 1,800 vpm, while the 7-ton RC70 has a 66-in. drum and 28,100 lbs. of centrifugal force. Both are available with a smooth drum for compaction of granular materials or padfoot drum for compaction of cohesive soils. Power is supplied by a 73.2-hp Kubota engine with a 32-gal. fuel tank. The threepoint articulated pendulum joint allows navigation of curves and turns as well as maneuverability on uneven ground. The rear wheels are driven by independent motors for more ground clearance and traction in a variety of conditions.