DECEMBER 2022 / JANUARY 2023 SAWMILLING • LOGGING • BIOMASS SAWLINES Felling Heads Biomass Steep Slope Harvesting

Horizontal Grinders • Whole Tree Drum & Disc Chippers • Flails • Forestry Mulchers • Mulching Attachments MORBARK WOOD HOG HORIZONTAL GRINDERS MORBARK DRUM CHIPPERS MORBARK CHIPARVESTOR® DENIS CIMAF MULCHING ATTACHMENT You begin each day before dawn with a drive and determination to do more than the day before. When you move at this pace, you know to do more you need equipment that is made for more. That’s why our forestry, biomass, and recycling equipment is built from the ground up to meet your needs, delivering: More Power and Production Consistent, Quality End Product Lower Operating Costs Ease of Maintenance Greater Longevity and Resale Value Find your local Morbark, Denis Cimaf, and Rayco Dealer at www.morbark.com/b/international-dealer-network

COVER - STEEP SLOPE HARVESTING

Ponsse’s cut-to-length forest machines have proved to be excellent harvesting solutions, also on steep slopes. Environmentally friendly and safe harvesting solutions for slopes are in high demand, especially when harvesting takes place in areas with varying terrain and steepness. One of the most important solutions for harvesting on steep slopes is

PONSSE Synchrowinch. It helps the forest machine remain highly productive in an environmentally friendly and safe way compared to alternative manual methods also in demanding conditions. Read more about Ponsse’s solutions for steep slope harvesting on page 42 & 43. www.ponsse.com

International Forest Industries | DECEMBER 2022 / JANUARY 2023 1

The

42 STEEP

Environmentally friendly and safe harvesting solutions for slopes are in high demand 30

When

drum chipper came

13 years ago it set a new industry standard for drum chipper efficiency 42 30 38 FELLING HEADS LOGGING • BIOMASS CONTENTS DECEMBER 2022 / JANUARY 2023 REGULAR FEATURES 6 Logging News 48 Advertising Index LUMBER PROCESSING CONTENTS DECEMBER 2022 / JANUARY 2023 SAWMILLING • LOGGING • BIOMASS SAWLINES Felling Heads Biomass Steep HarvestingSlope 46

46 CABLE YARDING - KONRAD

machines work with a skyline cable that is tight up between the tower yarder and a strong tree in the forest

SLOPE HARVESTING

BIOMASS - ASTEC

the Peterson 4310B

on the forestry scene

2 International Forest Industries | DECEMBER 2022 / JANUARY 2023 LUMBER PROCESSING 20 BID GROUP BID’s Recent Mechanical Innovations for Sawlines 22 DELTA COMPUTER SYSTEMS Swedish Sawmill Upgrades Edger with RMC

Controller 22 20 27

The new Rauma pine sawmill of Metsä Fibre, part of Metsä Group, was inaugurated on Monday, 10 October 2022. 19 RemaSawco RemaSawco receives an order of just over SEK 1.4 million from Gällö Timber AB 26 SmartMill This innovative trimming technology, a Quebec invention, is already benefiting of a significant success in Canada and the United States 27 19 SAWLINES 26 25 USNR The contract is a complete sawmill –from the debarker/log sorter optimizer, through the log breakdown equipment, finishing with the trim/sort/stack line 29 IMAGE SYSTEMS RS-BoardScannerQ is a system for automatic inspection, quality determination and cutting optimization in a raw sorting, an adjustment plant or a planer 18 MICROTEC The MiCROTEC Logeye 900 Stereo has been installed to assist in peeled veneer production for the Arbor Group 29 USNR USNR is replacing the Headrig system at Lampe & Malphrus Lumber Company with a new End Dogging Carriage line, including several new machines 25 29 18 29 LIGNA 2023 Hannover from 15 to 19 May 2023

Motion

METSÄ

Millwide. Worldwide. +1.360.225.8267 usnr.com

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Annual Subscription UK and Europe £160, €230 Rest of the world US$270

EDITORIAL

T: +44 (0)1442 877 583 F: +44 (0)1442 870 617 www.internationalforestindustries.com 2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Editor Chris Cann chris@internationalforestindustries.com

Editorial Board

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland) Mr Kim Carstensen

Director General Forest Stewardship Council Eduardo Morales South American Forestry Consultant

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd Advertising Manager Phil Playle phil@internationalforestindustries.com +44 (0)1442 87 77 77

Associate Editor Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTER: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2019 IFI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

EDITOR’S COMMENT

EU regulations highlight tough balancing act

The European Union was fine-tuning the wording for a ground-breaking piece of legislation aimed at curbing global deforestation and degradation at the time this column was being penned.

The Act, which will find into way into European Parliament in the near term, aims to force global traders of timber and forestry products to ensure the processes through which those products have been delivered have not contributed to deforestation or degradation, by threatening to cut off access to businesses within the 27-nation bloc.

The move has been rightly hailed by environmental – and specifically climateactivist – groups as a breakthrough moment in the fight for our forests, and against the continued destruction of our natural world and anthropogenic climate change.

“The EU is a large consumer and trader of commodities that play a substantial part in deforestation — like beef, cocoa, soy and timber,” Czech Republic Environment Minister Marian Jurečka said when the news broke.

The EU accounts for 16% of tropical deforestation associated with international trade, according to nature-focused news service, Mongabay.

WWF European policy office Senior Forest Policy Officer Anke Schulmeister-Oldenhove said those behind the legislation had “made history with this world-first law against deforestation” and hoped other governments would follow suit.

“As a major trading bloc, the EU will not only change the rules of the game for consumption within its borders, but will also create a big incentive for other countries fuelling deforestation to change their policies.”

However, some environmental groups were typically dissatisfied the law did not go far enough. The dissatisfied voices even included senior figures from within groups responsible for the milestone legislation. These voices clashed with reservations from some within the timber trade or economies with material exposure to the timber trade, which have called for refinement to definitions around forest degradation and greater efforts to ensure regulations were not unnecessarily burdensome on sustainable timber trade.

These calls have been led by Canada’s Ambassador to the EU, Ailish Campbell, who was reportedly “greatly concerned” that some

elements of the law would establish trade barriers.

These are reasonable concerns to voice. The world is being gripped by rising costs and logistical challenges that make life more difficult and expensive, and threaten livelihoods. It is only sensible that we do not inject additional challenges into the mix through clumsy wording or poorly thought through covenants.

Campbell made it clear Canada was supportive of the law’s objectives and broadly happy with the deforestation elements. The Canadian government also has its independent nature restoration programs in play.

The response to Campbell’s comments from advocates of the bill on the left were overblown, with groups calling her requests “shocking”, among other dramatic adjectives. Language in mainstream, left-leaning newspapers was derisory in describing Campbell’s suggestion that more care was needed before throwing the forest industry baby out with the bath water. She has been under attack.

This is wrong.

The situation is complex. Sustainable industries must be able to operate with limited obstacles to protect national incomes and individual opportunity to earn a living. Establishing a regulatory framework that allows for that while still providing adequate protection to the environment is not straight forward.

Environmental groups who take a fatalistic line on behalf of the Earth as a reason for refusing compromise over regulations are disingenuous or delusional. Humans and are not destroying the planet. We are potentially destroying a planet habitable for humans – the Earth has endured far more extreme temperatures over its 3.6 billion year history than those forecast, and will again; it will chew us up and spit us out as it has countless other species.

Fighting climate change is an understandably selfish and necessary endeavour for humans, driven by humans. We must be able to have a conversation around key changes to the way we live and work for the benefit of all humans.

4 International Forest Industries | DECEMBER 2022 / JANUARY 2023

ISSUE 90 December 2022 / January 2023

Chris Cann

Ponsse North America, Inc expands to southern USA

Ponsse North America, Inc has expanded its operations to Midway, Florida which is right outside of Tallahassee. The main factors that influenced this development are the growing demand for cuttolength wood and an increase in machine sales in the south. Our goal at Ponsse is to provide our customers with the best parts and service performance that we can offer.

“Forestry is our focus and all we do. We are extremely excited about our expansion to the south because of the number of mill investments with new facilities opening, reopening of shut down mills and capacity increases. It is time for cut-to-length to be more dominant in the south like it is currently in the northern part of the USA. We want to provide all of our customers with the best machines in the world, exceptional service and

the best parts availability in the industry,” states Pekka Ruuskanen the President and CEO of Ponsse North America, Inc.

Ponsse North America, Inc is a subsidiary of Ponsse Plc and was established in 1995. The headquarters is currently located in the heart of the cut-to-length region in Rhinelander, WI. Ponsse has branches in Wisconsin, Michigan, Minnesota, Oregon and now the latest addition in Florida. Ponsse also has fullline dealers and service dealers in various locations around the nation.

Today, Ponsse Plc is one of the world’s largest manufacturers of rubbertired cut-to-length forest machines. The roots of the family-owned company, grown from a machine entrepreneur’s dream into an international export company, lie deep

in the Finnish countryside. The company is still based in Vieremä, Finland in the same location in which it was founded in 1970.

PONSSE forest machines are based on environmentally friendly cut-to-length (CTL) logging, where trees are felled, delimbed and cut into various log assortments before they leave the forest. Our product range covers all size categories of forest machines, from first thinning and the harvesting of forest energy to heavy-duty regeneration felling, as well as all logging sites, from soft soil to steep slopes.

PONSSE products and their key components are designed and manufactured by Ponsse in Vieremä.

Forestry is our focus and all we do. We are extremely excited about our expansion to the south because of the number of mill investments with new facilities opening, reopening of shut down mills and capacity increases. It is time for cut-to-length to be more dominant in the south like it is currently in the northern part of the USA

Ruuskanen Ponsse North America, Inc President/CEO

6 International Forest Industries | DECEMBER 2022 / JANUARY 2023 LOGGING & BIOMASS NEWS

The innovative reversible fan. The original from Rethink. Reverse! www.cleanfix.org

Pekka

For a forwarder, an efficient grapple design is key to ensuring high productivity. Komatsu is now introducing a new grapple range encompassing ten completely redesigned models. The grapples have a new design with a larger opening, which offers better wood pile penetration and makes it easier for the logs to roll into the grapple.

Grab logs like a proKomatsu’s new grapple range for enhanced productivity

If the crane is the long arm of the operator, then the grapple is the hand that grips the timber. This makes it important to have a grapple that is optimised to gather, roll in and grip the timber both quickly and powerfully. Komatsu’s new grapples boast many upgrades to their productivity, making them

efficient and dependable forest companions.

New design with larger opening

The most striking difference is that the opening width is noticeably larger, which enables the grapple to penetrate the wood pile more quickly and easily. The logs roll

Zelenskky tells climate forum Russia has ruined 5 million acres of Ukrainian forest

Ukrainian President Volodymyr Zelenskyy told participants at the COP27 climate conference Tuesday 8th November that Russia’s invasion has led to the destruction of 5 million acres of forest in his country while dramatically raising fossil fuel prices worldwide.

“That has forced dozens of countries to resume coal-fired power generation in order to lower energy prices for their people,” he said in a video address.

Zelenskyy said Russia’s “insane and illegal war’’ is keeping other countries from

working collaboratively to confront climate change, adding that military aggression like the one Ukraine is confronting forces nations to focus on immediate protection at the risk of longer-term threats.

into the grapple more readily as well, saving precious time. The new grapples have also been refined when it comes to gathering and straightening the timber.

In addition to the new features, naturally the grapple range has retained the key advantages of the previous models, such as the robust and durable design. The new grapples also come with several improvements for a longer service life, ensuring their durability for demanding forest environments. With these old and new advantages combined, Komatsu grapples ensure the efficient forwarding of timber to the roadside.

Ten new grapple models

The new grapple range encompasses no fewer than ten grapple models, divided into six size classes. The range spans from the G82, which holds 0.26 m², to the G87H, which holds a full 0.50 m². The range is divided into standard, bioenergy (brushwood) and heavy-duty applications as well. The new generation of grapples are also compatible with the most common forwarders make as well as with most types of truck cranes and other vehicles that handle timber.

“There can be no effective climate policy without peace on Earth,” he said.

8 International Forest Industries | DECEMBER 2022 / JANUARY 2023 LOGGING & BIOMASS NEWS

FAE is upgrading the DML/SSL mulcher for skid steers, now available with Sonic and Bite Limiter technology and new tooth options

FAE is upgrading one of its most popular and loved products on a global scale: the DML/SSL forestry mulcher for skid steers. All innovations are aimed at optimizing the head’s efficiency and productivity when combined with 50 to 75 hp skid steers.

First, the frame and push frame’s design has been redesigned to offer greater visibility in all working conditions. It’s one detail that will make a big difference in operator’s comfort and efficiency, with the ability to monitor the tasks at hand with

blades, both ideal for making the most out of the efficient Bite Limiter technology.

This technology makes it possible to achieve more productivity in less time when mulching any kind of wood. The Bite Limiter rotor comes with special wear-resistant steel limiters that limit the teeth’s reach (bite) so that there is less power demand and a consistent working speed. The Bite Limiter technology also minimizes rotor stalling and optimizes fuel consumption.

The new DML/SSL is available with FAE’s exclusive Sonic technology. This Sonic system ensures that the skid steer and the FAE mulcher are completely aligned by automatically calibrating the

mulcher’s parameters. Sonic continuously manages the mulcher’s hydraulic settings, for a significant boost in overall productivity of up to 30%. The Sonic system also minimizes rotor stalling and shortens recovery time thanks to the quick recovery of the rotor’s rpm.

There is more that the new DML/SSL offers. The new Spike Pro counter blades ensure low power absorption and

a finer granulometry of the processed material. The new interchangeable and adjustable skids offer greater precision. The optional integrated oil cooler ensures the best performance even in hotter climates.

The new DML/SSL is available in 4 models, DML/ SSL/VT, DML/SSL/BL, DML/ SSL/SONIC, DML/SSL/BL/ SONIC and in two widths for each model.

From waste to money.

Use JENZ Shredders. www.jenz.de LOGGING & BIOMASS NEWS

Brandt Tractor selected by Morbark, Rayco & Denis Cimaf

Morbark, LLC, and its affiliated brands Rayco and Denis Cimaf have selected Brandt Tractor Ltd., a wholly-owned subsidiary of the Brandt Group of Companies, as the exclusive, authorized dealer for their tree care (brush chippers, stump cutters, articulated wheel loaders), forestry/biomass (whole tree drum chippers, Chiparvestors™, flails), recycling (horizontal and tub grinders), and Rayco Forestry/ Denis Cimaf (forestry mulchers and mulching attachments) equipment lines in Canada.

“For Morbark, it was an easy choice to sign Brandt as our exclusive dealer in Canada,” said Michael Stanton, vice president of sales and marketing. “Their 56 fullservice locations will provide our Canadian customers with the complete support they need and deserve.”

Brandt was founded in 1932 as a small electrical contractor in Regina, Saskatchewan, Canada. After nine decades of impressive growth, the company has become the world’s largest John Deere

Dealer, owning and operating a total of 120 full-service equipment dealerships in Canada, Australia, and New Zealand.

“Brandt has a lot to offer Morbark customers in Canada,” said Brandt owner and CEO Shaun Semple. “We’ve built the largest, best-equipped support network in the country and are eager to earn the loyalty of our new customers by supporting their needs for equipment, aftermarket parts, and highquality 24/7/365 customer support.”

Since executing the contract, Brandt sales and service teams have been busy preparing to support Morbark, Rayco, and Denis Cimaf customers by participating in sales and service trainings and building their inventory of equipment and aftermarket parts. To find a Brandt location in Canada, go to www. brandt.ca/Divisions/Tractor/ Branch-Locator or www. morbarkdealers.com.

About Morbark: An Alamo Group Inc. (NYSE:

ALG) holding, Morbark, LLC, has innovated and manufactured durable, high-performance equipment for 65 years. Morbark’s equipment helps customer process and convert wood and organic waste materials into valuable, useful, and profitable by-products. The company produces a full line of brush chippers, stump cutters, mini skid steers and articulated wheel loaders, forestry mulchers, whole tree drum and disc chippers, flails, horizontal and tub grinders, and mulcher attachments for excavators and skid steers under the Morbark, Rayco, Denis Cimaf, and Boxer equipment brands.

About Brandt Group of Companies

The Brandt Group of Companies, headquartered in Regina, Saskatchewan, Canada, is a privately owned manufacturing and distribution company that serves a growing international audience in industries such as agriculture, construction, forestry, rail, mining, steel, transportation, material handling, and energy.

Demo run with the SIEBO 5000 – excellent screening

The SIEBO drum screen was developed together with customers, extensively tried and tested. The screen is designed for use in recycling and disposal plants. The screening machine is characterised by its robust construction and highperformance components.

During our live demo, we screened excavated soil into two fractions for qualitative upgrading. The extra-long and large screening drum achieves first-class results.

With a width of 4 metres, the spacious feed hopper (6 m3) offers sufficient space for easy feeding with large wheel loaders. Baldus Tiefbau GmbH

was convinced of this during our demo and loaded our SIEBO 5000. The extra-long discharge belts are perfectly adapted to high throughput rates and all belt frames are also hot-dip galvanised.The machine can be optionally adapted to your individual needs, please contact us for more information.

Further benefits of the SIEBO are: The drum drive by chain guarantees powerful yet low-noise operation, the positive-locking hopper belt prevents “slipping” and is nearly maintenance-free, the hydraulically adjustable cleaning brush cleans the drum automatically, the huge

side door for convenient maintenance operations.

Optionally, the machine can be individually customised to your needs, so please do not hesitate to ask for more information.

SIEBO is convincing –flexible, low service and low fuel consumption, can be used

in less than 5 minutes and operated by just one person. Ideal for excavated soil, compost, biomass or similar materials.

10 International Forest Industries | DECEMBER 2022 / JANUARY 2023

Michael Stanton, vice president of sales & marketing

Brandt owner and CEO Shaun Semple

Komatsu - Improved measurement calibration

The calibration of the diameter and length measuring is improved, using a new method to secure better statistical data and reduce the risk for human error. Another new feature is the integrated analysis function for visualisation of the control measurement result.

An important prerequisite for a good calibration result is that the calibration basis is as good as possible. The new system ensures that a suitable number of stems are used as statistic base for each calibration, which increases the precision of the calibration. The default setting is for the calibration to be performed on ten stems, but it is possible to adjust according to the customer’s own needs (please note that one tree is measured every time, but the system uses data from the last ten

calibrations).

When a new tree is added, the oldest tree will automatically be excluded from the data collected. In order to ensure the quality of the machine measurement, MaxiXT will filter and select trees where the head had good clamping of the trunk during the processing, meaning that they are suitable for calibration.

With the new system, diameter calibration is done in diameter intervals. This makes it possible to calibrate only the intervals where there are deviations and where enough measurement data is available. The documentation remains after the calibration has been performed and the graphics show how the active calibration would have measured on these stems. All in all, these

improvements contribute to minimizing the risk of errors when calibrating.

Another new feature of the new calibration system is that length and diameter calibration can easily be copied between tree types.

In addition to the improved calibration method, the visualisation of the results has been improved. The system provides a visual analysis of the stem profile where all measuring points are displayed and categorised according to colour codes. The system also clearly visualises the measurement errors between the machine and the data caliper.

The basic calibration is done in the same way as before, with a measuring pipes.

New valve bank increases reliability and performance for Komatsu C144

With the year model update comes the introduction of a new kind of valve bank that offers several benefits. It is the same type of valve bank that was developed for C164, where it has proved to work well.

To start with, the new valve bank has a longer service life than the previous one, which has been verified in tests. The resilience against wear increases the reliability of the harvester head and contributes to more uptime and reduced costs of repairs. With the new valve bank, there will also be lower losses, which saves fuel.

Better stem holding performance during felling is another improvement, which comes from inverting the direction of oil flow in the feed system. Test operators who have tried the new Komatsu C144 say that they get more response from the head and summarize the feeling when

operating as “distinct”.

The design of the saw box has been improved in a way that simplifies maintenance and increases reliability.

Furthermore, the feed rate for the smaller feed roller motor (627 cc/315 cc) increases from 5 m/s to a full 6.5 m/s, which helps increase both productivity and profitability for the forest entrepreneur.

Tried & Tested

The Komatsu C144 year model 2023 comes with new benefits. Komatsu global method instructor Tobias Kopp had his first test with the head last week and is happy with the development:

- My experience is that the new valve reacts very accurately and quickly, and I also see a lot of improvements to reach hose connectors when doing maintenance and

adjustments. There are also some new good settings to improve the performance. Overall, I’m very pleased with the updated C144.

International Forest Industries | DECEMBER 2022 / JANUARY 2023 11

Vermeer Rolls out redesigned Horizontal Grinder HG4000

Equipped with a 536-hp (399.7 kW) CAT C13B T4F Stage V diesel engine, this new generation of the HG4000 delivers performance in various wood waste recycling applications and landscaping material production

Vermeer has introduced a redesigned version of the HG4000 horizontal grinder. This new generation of the HG4000 delivers performance in various wood waste recycling applications and landscaping material production. It’s equipped with a 536-hp (399.7 kW) CAT C13B T4F

Stage V diesel engine, a Series III duplex drum, an infeed to accommodate a variety of materials and many performance and durability features. It has a working sound level of 112 decibels.

According to Vermeer product manager for environmental equipment Jeff Bradley, the Vermeer HG4000 horizontal grinder is designed for professionals looking to expand their service, as well as for bulk landscaping material producers.

“It’s a great unit for tree care professionals looking to minimize dump fees on bulkier material and turn waste into a useful end product. It’s also a productive machine for small to midsize mulch producers with limited space for the material. The size of the HG4000 also makes it efficient to transport in congested urban environments making it an ideal machine for small land-clearing operations. And

while this horizontal is smaller than other machines in the Vermeer grinder product line, it still can handle a variety of materials ranging from loose, bulky materials like leaves, branches and yard clipping to hardwoods, pallets and logs,” said Bradley.

The HG4000 has a feed table capacity of 4.6-cu. yd. (3.5 m3). It features the cutting performance of the Vermeer patented Series III duplex drum with reversible hammers and tips for reliable wear life, compared to single-sided designs, while offering bolt in replacement parts. The hardfaced anvil on the HG4000 delivers cutting action with the drum and a redesigned anvilmount structure minimizes the hard-faced wear edge replacement process.

The HG4000 features an updated feed roller with teeth and down pressure to maintain control of the fed material. A fully enclosed feed roller planetary drive helps provide

(399.7

protection and a tight clearance between the roller and mill housing to optimize material feeding while minimizing material catch points.

A wireless remote control comes standard with the HG4000, allowing operators to run machine functions from up to 300-ft. (91.4 m) away. “With the remote, operators can adjust infeed settings, engine speed droop, conveyor height and more, which means maximum time grinding throughout the day,” explained Bradley.

The redesigned Vermeer HG4000 incorporates several service and maintenance enhancements, including a drive belt tensioning system that does not require the engine to be moved when adjusting, large-hinged side shields for maintenance access, added power rotation to the screen hoist for changing screens and a CAT engine with worldwide support. It can also be outfitted with an optional

cross-band magnet and magnetic head pulley to pull metal from the top and bottom of material on the conveyor after it has gone through the machine for clean finished material.

The HG4000 has a transport width of 8.2-ft. (2.5 m), a height of 13-ft. (4 m), a fifthwheel hitch trailer length of 32-ft. (9.7 m) and a weight of 52,910-lbs. (24,000 kg) or a pintle hitch trailer length of 37-ft. (11.3 m) and weight of 55,155-lbs. (25,000 kg).

12 International Forest Industries | DECEMBER 2022 / JANUARY 2023 LOGGING & BIOMASS NEWS

Vermeer Product Manager for Environmental Equipment Jeff Bradley

Equipped with a 536-hp

kW) CAT C13B T4F Stage V diesel engine, this new generation of the HG4000 delivers performance in various wood waste recycling applications and landscaping material production

Shell signs agreement to acquire ECL business of PANOLIN

Wholly-owned subsidiaries of Shell plc (“Shell”) in Switzerland, the UK, US and Sweden (Shell (Switzerland) AG, Shell U.K. Limited, Pennzoil-Quaker State Company and Shell Aviation Sweden AB) have entered into agreements to acquire the Environmentally Considerate Lubricants (ECLs) business of the PANOLIN Group. The transaction includes the PANOLIN brand, ECL product formulations,

intellectual property, technical expertise and technology, international customer base and portfolio of products – for hydraulics, gears, universal tractor transmission oils, biodegradable engine oils (HDEO), turbine oils, chainsaw oils and greases for machine lubrication, including leading OEM-approved products.

ECLs are biodegradable lubricants and can help contribute to a more sustainable future, offering greater protection for wildlife and ecosystems in the event that they come into contact with the environment, in comparison to conventional lubricants. They enable customers to reduce the risks of operating in sensitive environments.

The global market for ECLs is expected to grow significantly over the coming years. Following completion of the transaction, Shell will manufacture, distribute and

market the PANOLIN portfolio of ECL products alongside its established Shell Naturelle branded products. The acquisition will strengthen Shell’s presence in the mining, construction, agriculture, renewable power, hydropower and offshore wind sectors.

Shell expects to fully integrate the business into its global lubricants business within two years after completion, aligning with Shell’s Powering Progress strategy to accelerate the transition to a net[1]zero emissions energy business by 2050.

Machteld de Haan, Global Executive Vice President of Shell Lubricants, said: “We are entering into this strategic acquisition to grow our presence in the global industrial lubricants market, through differentiated, valueadded propositions for our customers. Once completed, the acquisition will enable us

PONSSE HH360 rotator for harvester head

Ponsse launches new PONSSE HH360 harvester head rotator. The new rotator is an innovative solution in which the harvester head can rotate 360° degrees freely without limitations. With PONSSE HH360 the hoses stay in a fixed position from crane tip to rotator, all the time. Now launched rotator enables the harvester head rotating freely without worry about unexpected downtime caused from twisted hoses.

“We’ve developed an innovative solution by listening to our customers’ needs. The rotating harvester head speeds up processing wood, makes working easier for the operator and reduces hose failures,” says Janne Loponen, Product Manager for harvester heads. “Compared to competing

products, the rotator is strong, powerful and above all, energy efficient, and Ponsse has exclusive rights to the product in forest machine use,” Loponen continues.

The powerful and exceptionally energy efficient PONSSE HH360 rotator is available for H6, H7, H8, H7 HD, H8 HD, H7 HD Euca, and H8 HD Euca harvester heads when installed as a loose head installation.

All PONSSE harvester heads are designed to withstand the toughest conditions. They are characterised by a simple and solid structure which is why they can be used in various harvesting applications. Comprehensive design applies to both mechanical components and the electronic control system, controls, and

software. The manufacturing process is highly automated, guaranteeing a high level of quality and measuring accuracy.

All PANOLIN staff who currently support the ECL business in Switzerland, the UK, US and Sweden are expected to join Shell. Subject to regulatory clearance and the satisfaction of closing conditions, the deal is expected to be completed by early 2023.

International Forest Industries | DECEMBER 2022 / JANUARY 2023 13

Machteld de Haan, Global Executive Vice President of Shell Lubricants

to complement our existing range of sustainable products in response to increasing customer demand.”

Blue Machinery appointed as new dealers for Morbark

Blue Machinery have been appointed as the exclusive distributors for the Morbark brand across the UK and Ireland. The new agreement means that Blue Scotland, Blue Central, Blue Southern and Blue Ireland will now supply Morbark’s industrial product range within the regions in which they operate.

Based out of Winn, Michigan, Morbark LLC has been innovating and manufacturing durable, high-performance equipment since 1957. With more than 60 years of ideas, invention, and phenomenal growth, Morbark is now widely recognised as the number one brand globally.

Morbark’s industrial range includes a wide collection of premium horizontal grinders and chippers which complement Blue Machinery’s current portfolio of world leading brands, including Doppstadt and Fuchs – A Terex Brand. These new product lines will help us to bolster our offering to customers within existing recycling markets, who require machines with higher horsepower and throughput, whilst also enabling the planned expansion into the forestry sector. As well as being able to supply Morbark’s range of mobile machines, Blue Machinery will also be able to offer static, electric grinders and chippers.

Blue Spares now become the authorised supplier of genuine OEM parts across the UK and Ireland for the full Morbark industrial range. They have parts stocked ready to service existing Morbark customers from both their Warrington and Stirling depots, which collectively hold an inventory of over £5million. Their dedicated team of parts experts offer customers with 24/7/365 availability to keep their machines up and running.

Blue Machinery acquired the dealership from previous distributors, Steel Viper and

are working closely with them throughout the transition period. The teams from sales, service and spare parts are all undergoing a training programme on the Morbark product range. Director at Steel Viper, David Harper, comments: “It’s been a pleasure supplying the world leading Morbark brand over the last 6 years, however we recognise that Blue Machinery provide an opportunity to take the brand to the next level within the market. Our existing Morbark customers will benefit significantly from Blue Machinery’s localised service, sales and spare parts. I would like to thank all our customers for their continued business and support over the years, and we wish Blue Machinery every success for the future”.

Managing Director at Blue Scotland, Austin Carey, comments: “We are delighted to have concluded commercial terms with David Harper at Steel Viper, to become the new dealers for Morbark. In October Blue Machinery’s regional directors had an excellent visit to the very impressive 1,000,000 square foot Morbark facilities in Michigan. We met the Morbark senior Management team and had time discuss where the opportunities exist in UK &

Irish markets. Our strategy is to expand our existing customer base by entering the forestry and sawmill markets, where we will be adding additional products to complement the Morbark range. Our six regional depots provide a national footprint, meaning that we are well positioned to stock a large inventory of machines and spare parts to give maximum uptime to our customers. We have an excellent opportunity to heavily penetrate the market, and we plan to allocate extensive resources towards establishing the brand and fulfilling its potential in the UK and Ireland. We are excited to meet all the existing Morbark customers and welcome some new ones along our journey.”

Michael Stanton, VP of Sales and Marketing at Morbark,

adds: “The addition of The Blue Group, which has a long history of offering premium support for both sales and aftermarket, aligns with our desire to be partnered with the very best organisations globally. We look forward to working closely with Blue Group, who will provide the opportunity to grow our brand across the UK and Ireland”.

Our four regional business are now taking orders for 2023. We currently have a 3000XT Wood Hog Horizontal Grinder in the UK and available for demonstration, so be sure to get in touch with your Blue representative if you’re interested.

14 International Forest Industries | DECEMBER 2022 / JANUARY 2023

Austin Carey, Managing Director, Blue Scotland

Michael Stanton VP of Sales & Marketing, Morbark

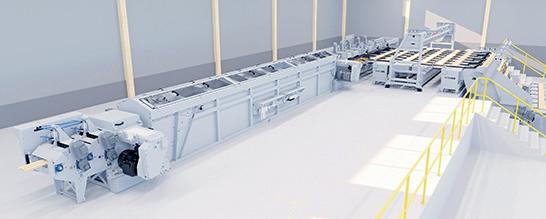

Stora Enso upgrade reaches completion

Stora Enso invested EUR 80 million to centralise and modernise wood handling at Imatra Mills to enhance its production capabilities for premium packaging board. The investment will additionally reduce the use of process water and mitigate environmental impacts. The project, which started up in the first quarter of 2021, is now complete.

The modernisation of Imatra Mills’ wood handling was completed on schedule. From now on, wood will be debarked and handled centrally on Kaukopää Mill’s new debarking line. The project included the installation of a third debarking line, improvements to chip handling systems, and modifications to the infrastructure of the existing wood yard. The centralised and modernised wood handling capacity will improve the stability and efficiency of the process.

The investment will significantly reduce the water use in the wood

handling process. Water use will decrease by 85 per cent compared to the old debarking line, which translates to 500 million litres less water consumed per year. The noise level at the Tainionkoski Mill will also decrease, as wood handling there comes to an end.

The wood handling upgrade was carried out over two winters in challenging outdoor conditions. Special attention was paid to safe working practices, and this investment worksite marked the first time that a Stora Enso mill used the House building (TR) Audit, a method widely used in the construction industry to assess safety, tidy working environment and behaviour on worksites. The TR Audit provides an overview of the entire worksite, focusing on small areas at a time, and has been found to be a good predictor of accidents.

“Despite the challenges brought by the pandemic, construction progressed as

usual, and the investment was completed on time and within budget. Most importantly, the work was completed safely. Cooperation between the various players was very smooth. The investment will serve Imatra Mills for decades to come,” states Mill Director Mikko Nieminen.

Close to 700 000 working hours were spent on the project. More than 500 companies, nearly 40 per cent of which from South Karelia, were involved in the project. During the construction phase of the investment, 700 steel pipe piles and 100 boring piles totalling roughly 18 kilometres were installed into the ground.

Two new silos were built in the Kaukopää Mill area for chip storage. The largest silo has a diameter of 38 metres and is 25 metres high.

International Forest Industries | DECEMBER 2022 / JANUARY 2023 15

Mill Director Mikko Nieminen.

SPRINGER´s answer to the great demand for fully automatic wrapping and stapling machines Cycles duration: 50 sec (20‘ pack.) Package length: 6‘ to 22‘ Film width: 4‘ 6“ – 12‘ Film rolls in magazines: 6 pcs Staples in magazine: 2 x 2400 pcs Your Advantages: > Easy to integrate into existing mills due to its short and compact design > Continuous production without any process interruptions > Film magazine for six rolls > Easy to maintain thanks to the easy accessible individual components ED 3000 WRAPPER* www.springer-usa.com *patent granted

Southern Forest Products Assn. (SFPA) elects new officers

The Southern Forest Products Assn. (SFPA) elected its new officers during the board of directors session at the association’s annual meeting October 21, 2022, in Nashville.

The 2022-23 SFPA officers are Chairman of the Board, Mark Richardson, The Westervelt Co.; Vice Chairman of the Board, Rich Mills, Hood Industries, Inc.; Treasurer, Pino Pucci, LaSalle Lumber Co.; Immediate Past Chair, Will Lampe, Lampe & Malphrus

Lumber Co.

SFPA also gave a big note of thanks to outgoing board officer and immediate past chair Craig Forbes of Weyerhaeuser. Executive Director Eric Gee noted that Forbes will still be around, but the entire association and its membership is so grateful for his hours of time and resources.

Twin Rivers Paper announces sale of its Eastern Canada Lumber Mill to longtime supplier Groupe Lebel

Twin Rivers Paper Company, a leading producer of specialty and kraft paper products, has reached a definitive agreement to sell its softwood lumber mill in Plaster Rock, New Brunswick, to eastern Canadian lumber manufacturer and North American forest products leader Groupe Lebel reports Pulp & Paper Technology.

Group Lebel is a longtime supplier to Twin Rivers Paper. The transaction includes a long-term supply agreement for the Plaster Rock mill to continue providing Twin

Rivers Paper with by-product chips and biomass utilized by the company’s pulp and cogeneration operations in Edmundston, New Brunswick.

“The decision to sell the lumber operation is aligned with our strategy of investing in and growing our core business of specialty and kraft paper production,” stated Tyler Rajeski, Chief Financial Officer of Twin Rivers Paper. “Groupe Lebel has long been a valued supplier to our Edmundston pulp operation and we’re pleased to have found a

home for our Plaster Rock team members with a trusted partner. We look forward to expanding our relationship with the completion of this sale.”

Pending regulatory and provincial review, the transaction is expected to close early in the first quarter of 2023.

“We’re committed to ensuring a smooth transition for our Plaster Rock employees, customers and suppliers,” added Rajeski. “With Groupe Lebel’s extensive sawmill

Westervelt Announces Leadership Changes

The Westervelt Company recently announced a new Chief Operating Officer role.

Cade Warner has been promoted to Chief Operating Officer, effective January 1, 2023. He is currently Chief Sustainability Officer.

In Cade’s new role, he will be responsible for the five business operations of The Westervelt Company – Forest Resources, Wood Products, Ecological Services, Real Estate and New Zealand, as well as Business Development and Information Services. He will

work closely with President and CEO Brian Luoma in overseeing operations and implementing the strategic plan of The Westervelt Company.

“We are continuing to prepare our next generation of leaders,” said Luoma. “I have tremendous confidence in Cade’s leadership ability as we continue our focus on disciplined growth, operating sustainably and ensuring that we promote operational excellence across the Company. This is an exciting move for us as we work to constantly

improve the effectiveness of our organization.”

About The Westervelt Company

The Westervelt Company, a privately held company headquartered in Tuscaloosa, Ala., was founded in 1884 and is currently under the fourth generation of family leadership. Westervelt is an industry leader in land management, wood products manufacturing and environmental mitigation.

operations experience and a proven record of investing in their assets and driving operational improvements, we’re confident this transaction will positively impact mill employees, business stakeholders, and the community of Plaster Rock.”

Stifel is acting as Twin Rivers’ exclusive financial advisor for the transaction.

16 International Forest Industries | DECEMBER 2022 / JANUARY 2023

From left, Pino Pucci, treasurer; Mark Richardson, chairman; Rich Mills, vice chairman; Will Lampe, immediate past chairman; and Eric Gee, SFPA executive director

Cade Warner

Change in Stora Enso’s Group leadership team

18 November 2022 - Jari Suominen, Executive Vice President (EVP), Forest division and a member of the Group Leadership Team, has decided to leave Stora Enso. After more than 25 years with the Company, Jari will now pursue career opportunities outside of Stora Enso. Per Lyrvall, currently EVP Legal, has been appointed as new EVP Forest division. Per will assume the role beginning of December and continue as a member of the Group Leadership Team (GLT).

Jari Suominen joined Stora Enso in 1995 and has led the Company’s Forest division since its inception in 2020. Previous to that, Jari was EVP and head of Stora Enso’s Wood Products division since 2014.

“I would like to thank Jari for all his contributions in Stora Enso throughout the years, it has been a true pleasure working together. Jari has driven transformation in the Wood Products division setting up our Building Solutions business, and now lately established the new Forest Division. On behalf of all colleagues, I would like to wish him success and good luck in his future endeavours,” says Stora Enso’s President and CEO Annica Bresky.

“After a long and rewarding career at Stora Enso it’s now time for me to take the next step. I am very grateful for the opportunities that I have had in the company and of course all the fantastic colleagues that I have been fortunate enough to work with over the years,” says Jari Suominen.

Per Lyrvall joined the company in 1994 and has been

a member of the GLT since 2012 and General Counsel since 2008. Per will continue his current responsibilities as Stora Enso country head in Sweden in addition to the new role as head of the Forest division.

“I am excited to take on the opportunity to lead the Forest division. Our forest assets and operations are at the very foundation of our growth platform. I look forward

to continuing Jari Suominen’s work to advance our forestry operations with focus on sustainability, biodiversity and wood supply services that support Stora Enso’s strategic ambitions,” says Per Lyrvall.

The search for a new General Counsel has been initiated. In the interim period Christian Swartling, currently Senior Vice President Group Legal, will assume the acting role in the position.

Per

Lyrvall,

Lyrvall,

EVP Forest division

International Forest Industries | DECEMBER 2022 / JANUARY 2023 17

Get your free Design Guide for servo motion control. 1 to 50 axes Delta RMC Motion Controllers

up faster. Cut waste & stack productivity sky-high. An advanced motion controller gets forest product machinery to move faster, smoother, and more precisely, which enables higher productivity, improved product quality, and ensures less wasted raw material. The difference with Delta is measurable. Precisely coordinate multi-axis applications 10X faster. Scrap will diminish, throughput will rise, and profits will stack up as a result. More throughput. Higher valued product. More profit. N ET PR O F I T C M Y CM MY CY CMY K 12012022_IFI_DeltaStackFaster_7.375x4.975.pdf 1 11/29/2022 12:56:54 PM

Delta motion stacks

The MiCROTEC Logeye 900 Stereo has been installed to assist in peeled veneer production for the Arbor Group

Logeye 900 Stereo on the road to global success

With its forestry partner, the Arbor Group harvests in one of the most important tropical eco-managed and certified forests in Gambon, central Africa. Located in Libreville, the company specializes in the production of peeled Okoumé and other exotic wood veneers (sapele, movingui).

For MiCROTEC, these are the first installed scanners in Central Africa. Thanks to a great partnership with the group, the first MiCROTEC Logeye 900 Stereo was installed in 2021.

The Arbor Group chose again to purchase MiCROTEC’s measuring system, recently ordering a second Logeye 900 for installation in 2022.

MiCROTEC’s Logeye 900 stereoscopic imaging system is the only worldwide scanner that provides a full 360° scan of a rotating log.

Both MiCROTEC Logeye 900 Stereo measuring systems at the Arbor Group have been installed on a veneer production line, linked to a double-head centering device specially designed to adjust precisely both ends of the log.

The log is first scanned on a 360° rotation, and the optimization calculates the setting of the axes for the optimum center point. This provides the best position after transferring into the peeling machine and obtains the optimum yield.

Since the scanning takes place at the beginning of the line, before loading into the machine, the log is already fully optimized and ready for peeling the instant it is dogged. Thus, the customer can save wood and adjust the peeling process with the veneer prediction.

Increasing wood yields is very important to Arbor Group for both the environmental and economic aspects

This innovative technology also provides a very interesting measuring solution for the rotary-cutting industry.

FEATURES

Installation: Veneer – Peeling machine Wood type: Okoumé

Log range diameter: 600mm - 1.500mm

Log length: 1.000mm – 3.200mm Log surface: Debarked

18 International Forest Industries | DECEMBER 2022 / JANUARY 2023 SAWLINES

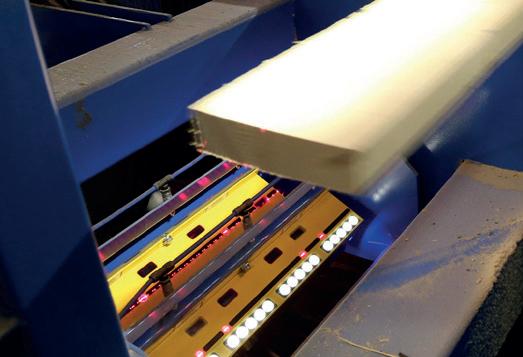

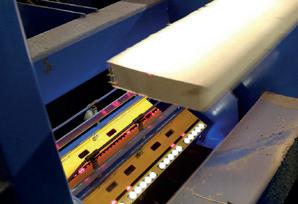

RemaSawco AB and Gällö Timber AB recently signed an agreement regarding the upgrade of the existing control system in the dry sorting to RemaSawco’s latest generation of the product RS-ProSort, a system for automation and control of board lines in sawmills.

RemaSawco receives an order of just over SEK 1.4 million from Gällö Timber AB

The agreement includes delivery, assembly and commissioning as well as signal exchange with systems from other suppliers.

Gällö Timber AB is partowned by AB Persson Invest and SCA and is part of the SCA group.

Deliveries and installation will take place during the first quarter of 2023 and the system should be in operation at the end of March 2023.

RemaSawco is a Swedish high-tech company and a leading supplier of products and services that optimize the production process within the sawmill industry

Reconnect with the entire wood products manufacturing community.

“It feels very good that one of our old and loyal customers chooses to once again renew their trust in RemaSawco as a supplier and partner. Our products are world class and will help Gällö Timber increase the efficiency of its sawmill”

Says Emilien Saindon, CEO

International Forest Industries | DECEMBER 2022 / JANUARY 2023 19

Emilien Saindon, CEO of RemaSawco AB

SAWLINES

NOW SAVE DATE THE Visit SFPAEXPO.com Today! August 23-25, 2023 • Music City Center • Nashville, Tennessee

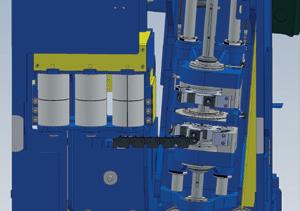

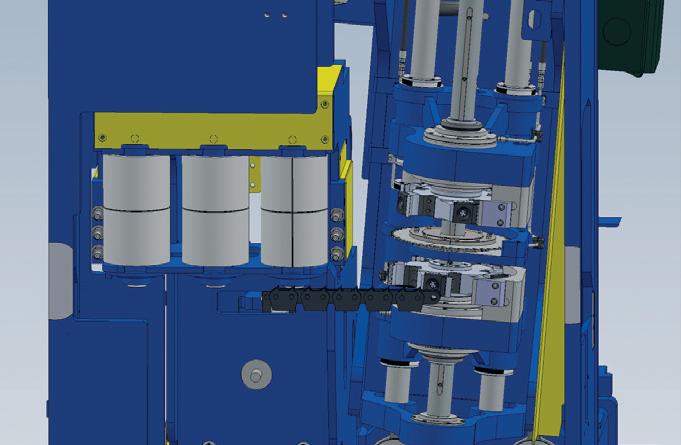

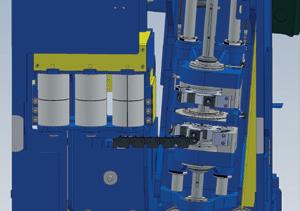

Backed by several decades of experience in the sawmill industry, BID Group and its Comact brand have all it takes to offer high-performance and innovative sawing technology. BID understands that quick and efficient equipment is an integral part of the optimal solution. Recent mechanical innovations have enabled sawmills to increase productivity, consequently increasing profitability.

Splitting saw with profiling heads at primary breakdown

BID’s Recent Mechanical Innovations for Sawlines

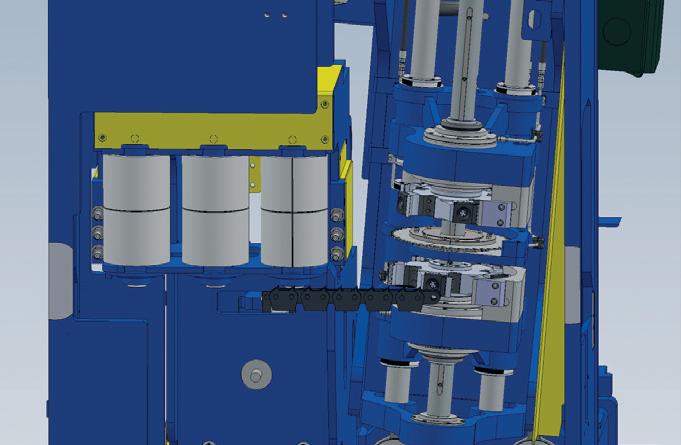

Press Hydraulic Pressure Control

BID Group is upgrading its press roll pressure control at the secondary breakdown by introducing its new hydraulic solution. The innovation now allows proper press pre-positioning and hydraulic control of the applied pressure. Both the pre-positioning and hydraulic control can be adjusted to any value, no matter the pattern being used. Since pressure is better controlled and applied accordingly, the process is smoother on the mechanics as well as on the production flow, reducing the risk of breakages. Hydraulic pressure control can be applied to any of BID’s Comact secondary breakdown solutions (TBL, CPG and gang saws).

New Lubrication Panels for Secondary Breakdown

Still adjusting the water flow on your saws manually, receiving no feedback, and worrying

about how much water is passing through? BID’s new lubrication panels now allow the adjustment and full control of the water and oil flow from

BID lubrication panel for secondary breakdown

20 International Forest Industries | DECEMBER 2022 / JANUARY 2023 SAWLINES

the HMI. The data is digital giving you the right amount of water when you want it (and will auto correct). The process is integrated into the PLC and automation systems.

Double Profiling at Secondary Breakdown

For a greater sawing quality and reduced yield/recovery loss, BID separates the entry modules of the Comact secondary breakdown. For this specific configuration, the canters and profiling modules are combined. The gang saw is placed afterward in a different module. Since the modules are separated, the equipment is not chipping at the same time as the sawing therefore no lateral pressure is being applied on the saws. This results in better quality of sawing, less variation and better durability of the saws. The gaps are also shorter. This configuration is a good fit for mills transforming larger logs with bigger dimensions (10-12 inches) with no edgers.

Splitter at Primary Breakdown

BID Group also introduces new sawing lines with double profilers combined with a splitter on Comact primary breakdown solutions, a game

changer for the breakdown of logs with a larger diameter.

The new double profilers allow the production of two side pieces of different widths and in addition, it offers an endless range of widths and up to 4 inches for the thickness of a block or a side cant. As for the splitter, it is a horizontal saw that allows the resaw of the first and/or second side board, in two pieces of different widths (2x4-2x4, 2x4-2x6 …), with high accuracy to avoid damage to the central cant. This module also has two profilers that finish the pieces to the proper width. Without limitless profiling, it would be impossible to produce two pieces of different widths in the second side board. The main benefits for this type of profiling are:

• Improvement of the production performance

• Improvement of the breakdown line speed by up to 30%

• Improvement of the sawmill flow: fewer pieces in re-run

• Reduction/Elimination of the edger operating costs

For companies that don’t sell wide lumber or that want to adjust quickly to

Double profiling at secondary breakdown

the market demand, this is the ideal technology since a simple adjustment of the optimization parameters will maximize the production value. Everything is done in the same process, there is no additional manipulation.

Innovation is fundamental for BID Group since it values its achievements and is constantly thriving to meet

the client’s needs. Each saw line is adapted to the client’s specific needs. Contact your BID representative today to learn more.

1-843-563-7070 www.bidgroup.ca

BID Group, a global leader in transformational wood processing technologies and integrated solutions

www.halcosoftware.com

International Forest Industries | DECEMBER 2022 / JANUARY 2023 21

Optimise your production plan... Optimise your operations

Whatever your mill... Maximize profit by resolving trade-offs between recovery, production rate, and value HALCO Software Systems Vancouver, Canada• Tel: 1 604 731 9311 HALCO AD:Layout 3 3/8/10 17:22 Page 1 OVER 25 SYSTEMS SOLD

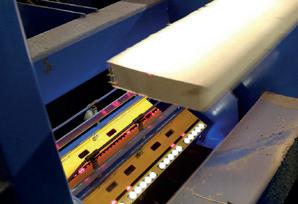

The edger controls failed at the worst time - in the middle of the pandemic’s high lumber demand and shortage of electronic controls

Swedish Sawmill Upgrades Edger with RMC Motion Controller

Can you tell us a little about the company Knäredssågen?

Knäredssågen AB is a familyowned sawmill since 1969 in the town of Knäred in southern Sweden, which is run today by the second and thirdgeneration Mårtenssons with 10 employees.

Approximately 20,000 m3 (850,000 BF) of sawn timber is produced annually. The main product is short joists (2.4 – 3 m, 8 – 10 ft) which are planed and cut according to the customer’s requirements.

Knäredssågen has always been active in technology and development. At the end of the 1980s, we built our hydraulic servo actuators for the saw line. Today, all the automation, IT, machine design, and fabrication are done exclusively by ourselves.

I (Johan Mårtensson) am the son of one of the owners and have been working with

automation since completing a three-year electrical installation/automation training at a local school.

You performed a machine upgrade. Can you tell us about it?

Which machine?

The Söderhamns Verkstäder (today USNR) Millomatic edging machine that measures, optimizes, and cuts away uneven edges on boards.

Sensors measure the boards with high resolution and the measurement data is processed in a powerful PC.

When the optimization is complete, the desired position of the blades and rotation of the board is sent to a PLC. The PLC processes the data and sends it to a Delta Computer Systems RMC150E controller that turns the board to the correct position and positions the two blades. When all three servos are in position, the board is fed through the blades at high speed.

What problems did you have with the machine?

In the summer of 2021, an electrical fault occurred

22 International Forest Industries | DECEMBER 2022 / JANUARY 2023

RMC150E

in a voltage supply to the measuring equipment. The optimizer computer was damaged and the measurement and optimization stopped working. With the high demand for sawn timber, we had to make some quick decisions. Neither spare parts nor help with repairs were available from the supplier, only new software and hardware were offered at a high price.

Which goals did you want to achieve with the upgrade?

The first goal was to get the edger up and running provisionally so that production in the saw line could continue. Once this was done we could focus more on what we really wanted in an upgrade. We concluded that full control over the various systems was most important. In this way, we can maintain and troubleshoot the system with our staff, which is a great advantage. Good support and service were also some of the main requirements.

What areas did the upgrade involve?

Hydraulic-related: Replacement of position sensor and motion controller

General controls: New PLC with Ethernet communication for easier implementation together with Delta’s motion controller.

Optimization and sensors: BoardProfiler 3D-T from LIMAB.

Structural:

the saws yield is significantly worse without optimization.

How did the planning proceed?

Did you encounter unexpected challenges?

The delivery time for the sensors was almost 6 months. Such a long time without optimization on an edger is not a good deal. It was a challenge for production and sales as

The first step was to find a new motion controller that we could program ourselves. Once we had chosen the controller, we were able to Cont’d on next page

International Forest Industries | DECEMBER 2022 / JANUARY 2023 23

Adaptation of the existing stand to the measuring frame for the new sensors.

RMCTools was fast to learn, easily accessible with great support

proceed with choosing the optimization system. Early in the procurement of the optimization system, a long delivery time was pointed out. The installation of the systems and hardware was planned to be carried out when the saw line was at a standstill.

How did you choose components?

First, we needed to be able to control the servos from our PLC. After some searching (we also asked Hewsaw) a Delta Computer Systems motion controller was the obvious choice. Then it was time for new sensors and optimization programs for the edger system. We chose a local supplier who had delivered similar systems to us before. The choice of a Mitsubishi PLC was obvious as we always use the same manufacturer.

What was the cost and estimated payback period?

Approximately SEK 1.5 million (approx. $150,000) included optimization software, sensors, motion controller, PLC, and

work. We have lost a lot of money due to the lack of optimization for 6 months. The repayment period will therefore be very short, perhaps weeks.

The payback period for the motion controller is more difficult to calculate as it does the same task as the old one. But now we have full visibility into its operation and in the event of an error, we can very easily read error codes. Production stoppages in the event of errors will now be significantly shorter with the new motion controller.

How was the result? Did it go as planned within the schedule?

The result was very successful, upgrading a more than 20-year-old machine with today’s controls. Better interoperability, a clearer user interface for operators, tools for troubleshooting, and the possibility of increasing production are just some of the benefits. The schedule slipped when the delivery of the sensors was delayed by another 2 months.

Which parts went particularly well?

I thought the change from the original motion controller to the Delta RMC150 would be a very complicated job. But the RMCTools software was quick to learn, as was the RMC’s communication to the Melsec IQ-F PLC. It is very easy to get support from Delta through technical support, YouTube, the

Do you have plans for other similar projects in the future?

In the planer, there are saws (trimmers) that cut the pieces of wood to the right length, and hydraulically position them. A motion controller fits perfectly here.

The main saw line today has 14 hydraulic servos. The machine positions the logs, tools, and all the auxiliary wheels to the desired locations between each log. Today we have independent analog servo boards that work, but with a modern motion controller, we foresee the advantages of troubleshooting, adjusting speeds, etc. In this application,

both position and position/ pressure will be used.

Delta Computer Systems has 40 years of experience in manufacturing motion controllers with specialized expertise in hydraulics and sawmill machines.

To learn more, visit www.deltamotion.com

24 International Forest Industries | DECEMBER 2022 / JANUARY 2023

NOW SAVE DATE THE Visit SFPAEXPO.com Today! August 23-25, 2023 • Music City Center • Nashville, Tennessee

Reconnect

with the entire wood products manufacturing community.

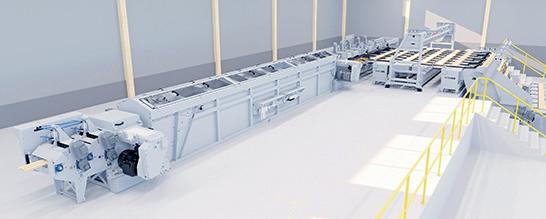

USNR has announced the order of a complete sawmilling system to the Chilean company Foraction Chile. This highly advanced production line is designed to process Radiata Pine and will be installed at a greenfield site in the Los Rios region about 800 km south of Santiago.

Major order for USNR in Chile

The scope of the contract is a complete sawmill –from the debarker/log sorter optimizer, through the log breakdown equipment, finishing with the trim/ sort/stack line. This project marks one of USNR’s most comprehensive undertakings outside of North America and Europe.

The saw line will be a European-style Merry-GoRound line that has proven to be very successful in Chile throughout the years. The primary sawing machines

will be Sawmaster 1600 band saws arranged in a quad configuration. In this iteration of USNR’s ever-evolving MerryGo-Round concept, there will be an additional chipper canter and a Circular Saw 700 gang saw. This arrangement makes it possible for certain log sizes to pass straight through the saw line, thus maximizing the productivity on all sawing patterns.

A complete, 45-bin green sorting and stacking line completes USNR’s portion of the project. Main components

in the sorting line include a Revolver Lug Loader, MultiTrack Fence, and a Multi-Saw Trimmer. The stacker line features a catching lug tierforming table in front of USNR’s Low-Profile Stacker with an overhead tier management system to ensure maximum productivity.

In addition to the equipment supplied by USNR, USNR’s partner in Chile, Solecia, will be responsible for supplying the log sorting line, log infeed equipment, and residual handling equipment for this project.

USNR along with our partner Solecia has a long history in Chile, with many installations and devoted customers. This order reinforces USNR’s strong position in the Chilean market and USNR’s position as the leading supplier of Radiata Pine processing technology.

The saw line will be backed up by a Catech XT edger optimizer line. The edger will be equipped with an additional twin-blade split saw for maximum versatility.

International Forest Industries | DECEMBER 2022 / JANUARY 2023 25 SAWLINES

SmartMill breaks into the Eurozone with the sale of a Smart Trim system in Germany

“

Jean Bérubé, president of SmartMill, confirmed the signing of a new contract that includes the sale and installation of the Smart Trim system to Ante-Holz GmbH, the largest timber producer in Germany.

This innovative trimming technology, a Quebec invention, is already benefiting of a significant success in Canada and the United States. Today, I am very proud to confirm the breakthrough of the Smart Trim in the European market, hand by hand with one of the largest players in the wood industry in Europe,” adds Mr. Bérubé.

This new partnership confirms SmartMill’s position as a leader in the forest industry with a unique offer of technological solutions for sawmills. In this regard, Mr. Bérubé confirms “we are currently in discussions with other mills in Europe and we are convinced of its success in this new market”

ABOUT THE SMART TRIM

The SMART-TRIM combines three pieces of equipment in one: a Lug loader, a positioning system and a multi-saw trimmer. The result of this technology is the capability to produce infinite lumber lengths.

3-IN-1 INTEGRATED SYSTEM

Lug Loader

Positioning/Fencing System

Multiple Saw Trimmer

SMART-TRIM ADVANTAGES

Smallest footprint Versatility: all possible lengths Access to value added niche markets

Eliminates production setup time

ABOUT SMARTMILL

SmartMill is a team of experts committed to the success of the wood processing industry. They foster the development of sustainable partnerships with all its customers. They design, manufacture, and install state-of-the-art automation equipment that is a customizable solution to improve the profitability of their clients. SmartMill is present in all Southern Yellow Pine States.

26 International Forest Industries | DECEMBER 2022 / JANUARY 2023 SAWLINES

Jean Bérubé President, SmartMill

Metsä Group’s pine sawmill inaugurated in Rauma

President, Communications, Metsä Group, tel. +358 10 465 4541

Metsä Group

The new Rauma pine sawmill of Metsä Fibre, part of Metsä Group, was inaugurated on Monday, 10 October 2022. The sawmill was inaugurated by Prime Minister Sanna Marin with Ilkka Hämälä, Metsä Group’s President and CEO, and Jussi Linnaranta, Chair of the Board of Directors of Metsäliitto Cooperative.

With a value of EUR 260 million, the Rauma pine sawmill is the largest ever sawmill investment in Finland. The investment decision was based on the strong growth in global demand for sustainably produced premium sawn timber.

The construction of the Rauma sawmill began in the spring of 2020, and continuous production was launched on 30 September 2022. The new sawmill has an annual production capacity of 750,000 cubic metres of pine sawn timber, and it uses around 1.5 million cubic metres of pine logs sourced in Finland annually. The sawmill will reach full production capacity by the end of 2023.

“The carbon that trees bind while growing is stored in wood products and buildings made of sawn timber throughout their life cycle. The newly inaugurated Rauma sawmill will help Metsä Group boost its production of products that store carbon in the long term very resource efficiently and provide its customers with even better support for sustainable growth and the phasing out of fossil-based raw materials,” says Ilkka Hämälä, President and CEO of Metsä Group.

The sawmill will be a worldwide forerunner in technology and efficiency. It will directly employ around

100 people and around 500 people across its direct value chain. Metsä Fibre’s Rauma sawmill and pulp mill form an efficient integrated mill, whose synergies are employed in energy production, side stream utilisation, logistics and services.

Requests for further information, please contact: Juha Laine, Senior Vice

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

International Forest Industries | DECEMBER 2022 / JANUARY 2023 27 SAWLINES

BSW Group announces acquisition of Scott Group

BSW Timber Ltd, the largest integrated timber and forestry business in the UK, and a member of Binderholz, has acquired Scott Group, a leading supplier of timber pallets and bespoke timber packaging solutions.

Based near Dunfermline in Scotland, with an annual turnover in excess of £250m and 1,300 employees, Scott Group is an award-winning, sustainable manufacturer of new, bespoke, and reconditioned timber pallets, producing over 30 million pallets per year.

The Scott Group was founded in 1987 and operates across 32 sites, from Shetland to Devon, working with customers to promote the circular economy, which is emphasised by its pallet recovery, repair and reuse service, while it also operates a

timber sourcing arm in Latvia.

Tony Hackney, CEO of BSW Group, said: “We’re absolutely thrilled to have acquired Scott Group. It’s a move which further strengthens our product and service offering.

“It ties into our vision of not only making use of the full value of timber, but also of achieving the best uses for timber across the BSW Group, whilst fully utilising the logistical firepower of the combined businesses. This strategic acquisition means that we are poised ready to serve our customers when we see the economic recovery and upturn.

Much like us, Scott Group has grown organically and through acquisition over the last decade, and we’re confident that with the expertise and experience of BSW and Scott together we can

continue to build on this both in the UK and further afield.”

Norman Scott, owner and Group Operations Director at Scott Group, added: “This is a huge move for both Scott Group and the wider timber industry, helping us to cement our status as the UK’s most innovative manufacturer and supplier of timber pallets. It also helps us to ensure that we can work even closer with customers to provide solutions that fit their requirements and deliver value.”

With the acquisition of Scott Group, BSW Group now employs 3,000 people across the sector, and has an annual turnover of approximately £900m, with Binderholz Group turnover reaching almost €2.8bn.

BSW CEO Tony Hackney and CFO Alan Milne will join the existing Scott Group Board of

Directors, who will continue in their current roles.

Reinhard Binder, CEO of Binderholz Group, noted: “This transaction is a further step for our group to enlarge our product range, and a consequent step in following our strategy to invest in the value chain. Scott Group fits perfectly into our sustainable business model and zero-waste principle.”

Kilmer Group completes sale of Chaleur Forest Products

Kilmer Group has announced the completion of its sale to Interfor Corporation (“Interfor”) of 100% of the equity interests in the entities comprising Chaleur Forest Products (“Chaleur”). Chaleur owns two sawmill operations located in Belledune and Bathurst, New Brunswick.

Chaleur is the secondlargest producer of lumber in Atlantic Canada, with an aggregate annual lumber production capacity of 350 million board feet. Chaleur also operates a woodlands management division based out of Miramichi that manages 2.3 million acres of Crown forests (representing approximately 30% of total Crown forest land in New Brunswick).

Chaleur has been a pioneer in New Brunswick’s forestry industry since its Belledune sawmill first began operations in the early 1990s. Kilmer Group’s investment in Chaleur, which is held through Kilmer Forestry LP, began in March 2016, when it acquired Chaleur sawmills.

In May 2018, Kilmer Forestry acquired Fornebu Lumber Company and in May 2020, Miramichi Lumber Products. Under Kilmer Forestry’s management, Chaleur invested more than $40 million in capital projects, allowing Chaleur to make meaningful improvements to its operations including mill automation, just-in-time equipment reporting, asset improvements and projects to improve

environmental sustainability.

As part of the acquisition of Miramichi Lumber Products, Chaleur was able to add a third shift at the Bathurst sawmill, which provided much needed employment when the closure of the Belledune smelter in 2019 resulted in over 400 people losing their jobs.

Kilmer Forestry has been committed to sustainable forestry practices and meeting the needs of its customers and stakeholders through responsible management of public and private forests under its stewardship.

The Bathurst sawmill is the focus of a current biomass boiler project, to be completed early in the new year, which will reduce the consumption of propane by 5,000,000

litres annually. –“I am very proud of the accomplishments Chaleur and Kilmer have achieved together, said Larry Tanenbaum, Chairman and CEO of Kilmer Group. “And the transaction with Interfor is a strong opportunity for Interfor to leverage New Brunswick’s competitive market and generate long-term benefits for shareholders, customers, and employees alike.”

28 International Forest Industries | DECEMBER 2022 / JANUARY 2023

LUMBER PROCESSING NEWS

Reinhard Binder, CEO, Binderholz Group

Johan Friberg, CEO Image Systems

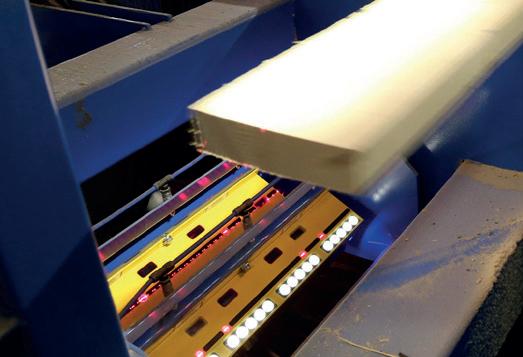

RemaSawco AB and Estonian Nordwood have signed an agreement regarding the delivery of the board handling system

RS-BoardScannerQ to one of Nordwood’s three sawmills, ViruNigula Saevski AS. The agreement also includes training and a maintenance agreement that runs over two years.

USNR is replacing the Headrig system at Lampe & Malphrus Lumber Company with a new End Dogging Carriage line, including several new machines such as:

• Log infeed using belts, chains, and ending screws

• Pinnacle feeder

• USNR carriage optimization with LASAR

• Reciprocating EDC with rotation

• Conical chip-heads with board and cant separators

• A single pass resaw

• An inertial separator to separate the split cants

• Numerous belted and chain transfers

This comes on the heels of another significant investment for Lampe & Malphrus, a new

Image Systems’ business area RemaSawco receives an order of approx. 5.7 MSEK from Nordwood

RS-BoardScannerQ is a system for automatic inspection, quality determination and cutting optimization in a raw sorting, an adjustment plant or a planer. The system detects all defects and geometric errors and performs a cut-off and quality optimization.

The Baltics are an important market for us and that

Nordwood now with this order confirms its confidence by choosing our Boardscanner and thus having it in all 3 of its sawmills, consolidates our continued strong position in that market” says CEO of RemaSawco Emilien Saindon.

RemaSawco’s delivery will take place in the spring of 2023.

Lampe & Malphrus Lumber to receive new End Dogging Carriage line

Optimized Edger line slated for installation in early 2023.

A strong business needs constant updating and revitalization, and that’s exactly what a new carriage line will do. Once the new systems are installed, logs will move through faster and with a higher-quality end result.

USNR enjoys working with

Lampe & Malphrus Lumber on all of their upgrades and expansion projects.

The new primary breakdown will allow us to meet our customer’s growing demand for quality lumber while improving recovery and the health and safety of our team members

Will Lampe, President & CEO, Lampe & Malphrus Lumber Company

International Forest Industries | DECEMBER 2022 / JANUARY 2023 29 SAWLINES

Drop the Downtime