millingandgrain.com Julio 2022 In this issue: Milling and Grain .Volumen 133 Número 7 . Julio 2022 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volumen 133 Número 7 Bühler Días de Networking 2022 - Agricultura China Informe del Panorama (2022-2031) - Molinos inteligentes - Control rentable de Salmonella en piensos - Escocia el ingenioso - Refrigeradores del ciclo de compresión de vapor

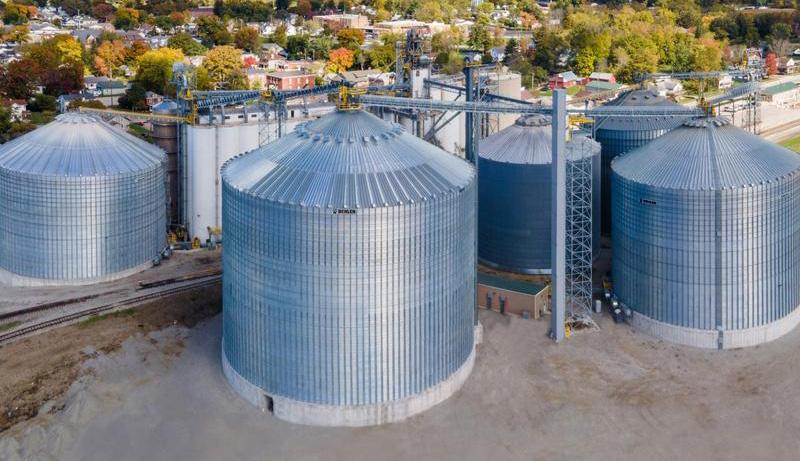

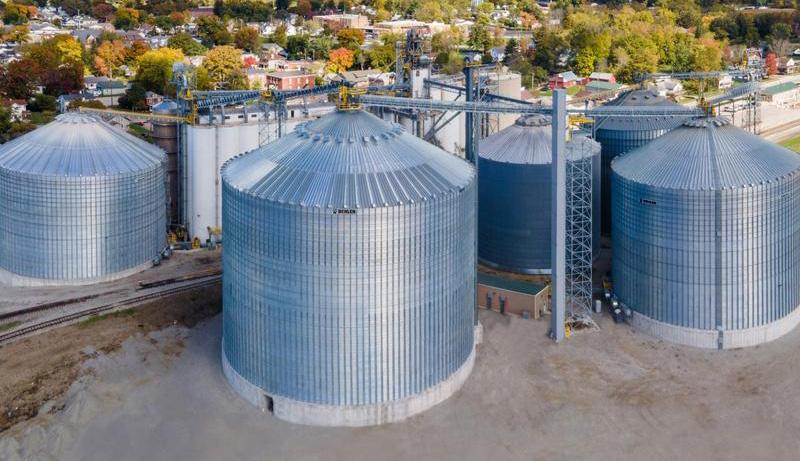

*Patent Pending More profitable grain drying? NEW TrueGrain™ Moisture Sensor System With Parallel Sensing Technology™ Whatever moisture level you set your grain dryer to hit, is what you get. With Brock’s exclusive* TrueGrain™ System, grain passes through a parallel sensing field in a fixed vertical chamber that isolates outside factors. This advancement allows your Brock dryer to output more accurate grain moisture levels and more consistent profitability. See this one-of-a-kind technology at brockgrain.com/TrueGrain Precisely! TrueGrain and Storage | Handling | Drying & Conditioning | Structures +1 866.658.4191 sales@brockgrain.com

Pneumatic and mechanical ship (un)loaders Up to 2500 tph for loaders and up to 1200 tph for unloaders. Low noise & no dust emission Turnkey solutions for cereals, soy flour, fertilizer, pellets and more... Handle bulk with efficiency and reliability

PINGLE. PROFESSIONAL MANUFACTURER OF GRAIN MACHINERY ★ INTEGRATED MILLING SOLUTION PROVIDER ★ ISO 9001:2015 CERTIFIED Аdd: Zhengding, Shijiazhuang,Hebei,China Tel: +86-311-88268111 Fax: +86-311-88268777 E-mail:pingle@pingle.cn / www.pinglemachine.com

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Editor

Roger Gilbert

rogerg@perendale.co.uk

Equipo de Marketing Internacional Darren Parris darrenp@perendale.co.uk Fred Norwood Tel: +1 405 834 2043 fredn@perendale.com

Equipo de Marketing de Asia Dante Feng Tel: +886 227930286 dantef@perendale.com

Equipo de Marketing de Latinoamérica

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Equipo de Marketing de Nigeria Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Equipo de Marketing Egipcio Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Equipo de Marketing de Turquía, Eurasia y Medio Oriente Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Director Editorial

Peter Parker peterp@perendale.co.uk

Subeditor Andrew Wilkinson andreww@perendale.co.uk

Asistente Editorial

Levana Hall levanah@perendale.co.uk

Caitlin Gittins caitling@perendale.co.uk

Editores Internacionales

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com Mehmet Ugur Gürkaynak mehmetg@perendale.com

Director de Diseño

James Taylor jamest@perendale.co.uk 0

Circulación y Eventos Tuti Tan tutit@perendale.co.uk

Director de Desarrollo Antoine Tanguy antoinet@perendale.co.uk

millingandgrain.com ISSN No: 2058-5101

ARTÍCULOS

VOLUMEN 133 NÚMERO 7 NOTICIAS 10-29 44 Bühler Networking Days 2022 47 Levantándonos para enfrentar juntos

los desafíos globales 50 Impacto en la Cúpula 58 Otras historias

Networking Days 62 Informe sobre las perspectivas de la agricultura en China

66 Molinos inteligentes 72 Escocia el ingenioso 76 Control rentable de Salmonella en piensos ALMACENAMIENTO 78 Refrigeradores del ciclo de compresión de vapor 8 EDITOR Roger Gilbert 116 ENTREVISTA Andy Sharpe ©Copyright 2019 Perendale Publishers Ltd. Todos los derechos reservados. Ninguna parte

esta publicación puede

reproducida

ninguna

medio

“Global

EVENTOS 100 Listas de eventos, reseñas y vistas previas COLUMNS 10 MAG TV 10 The Global Miller 22 Mildred Cookson 28 La colección Rex Wailes 30 Dr Mahmoud Riyad CARAS 118 Noticias de personas de la industria mundial de la molienda CAPACITACIÓN 35 Noticias de capacitación del sector ENFOQUE DE PRODUCTO 38 ESTUDIO DE CASO 98 PERFIL DE LA INDUSTRIA 96 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 Julio

más información

44

a

de

(2022-2031)

de

ser

de

forma ni por ningún

sin el permiso previo del propietario de los derechos de autor. Puede encontrar más información en www.perendale.com Perendale Publishers Ltd también publica el “International Milling Directory” y el servicio de noticias

Miller”

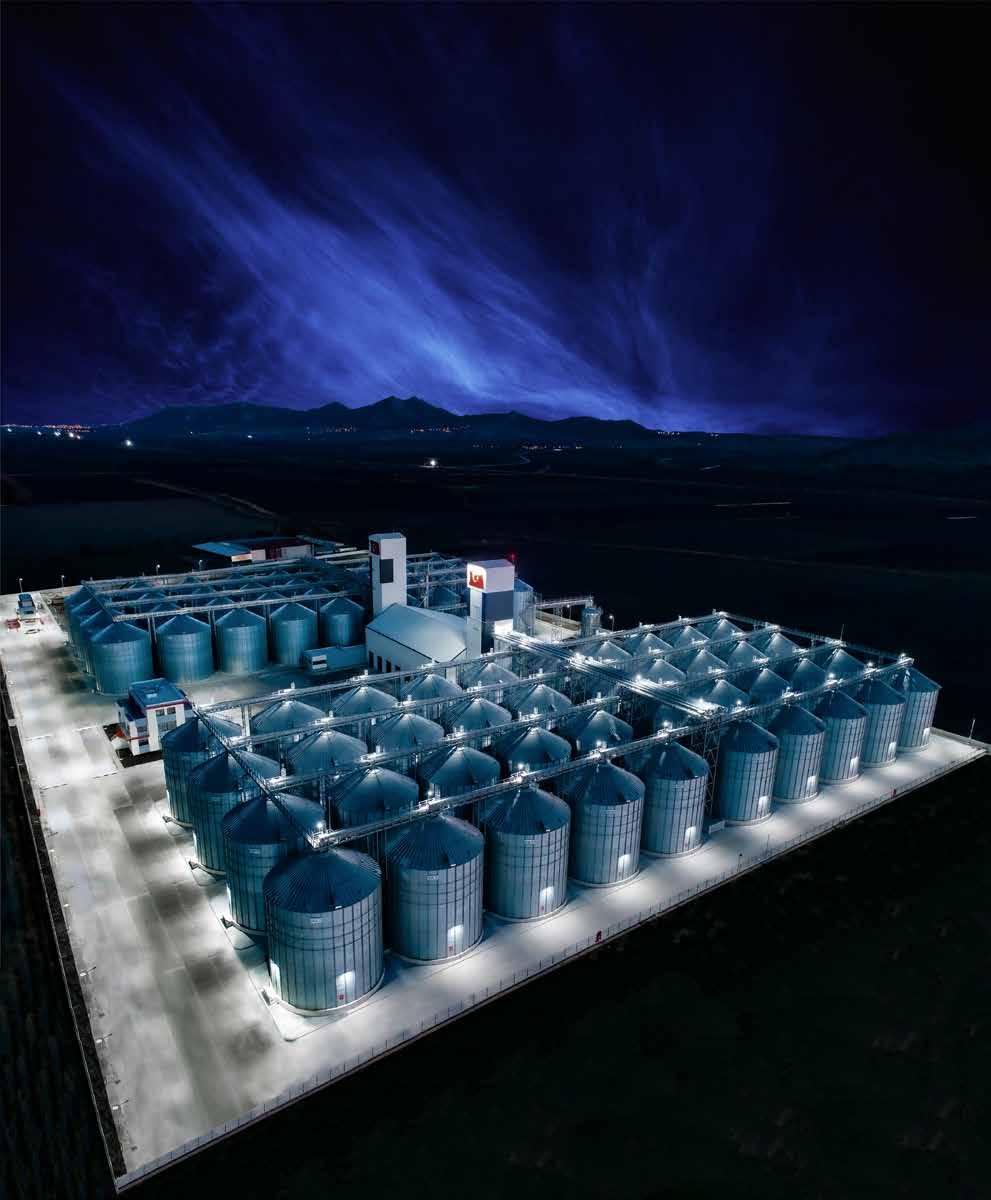

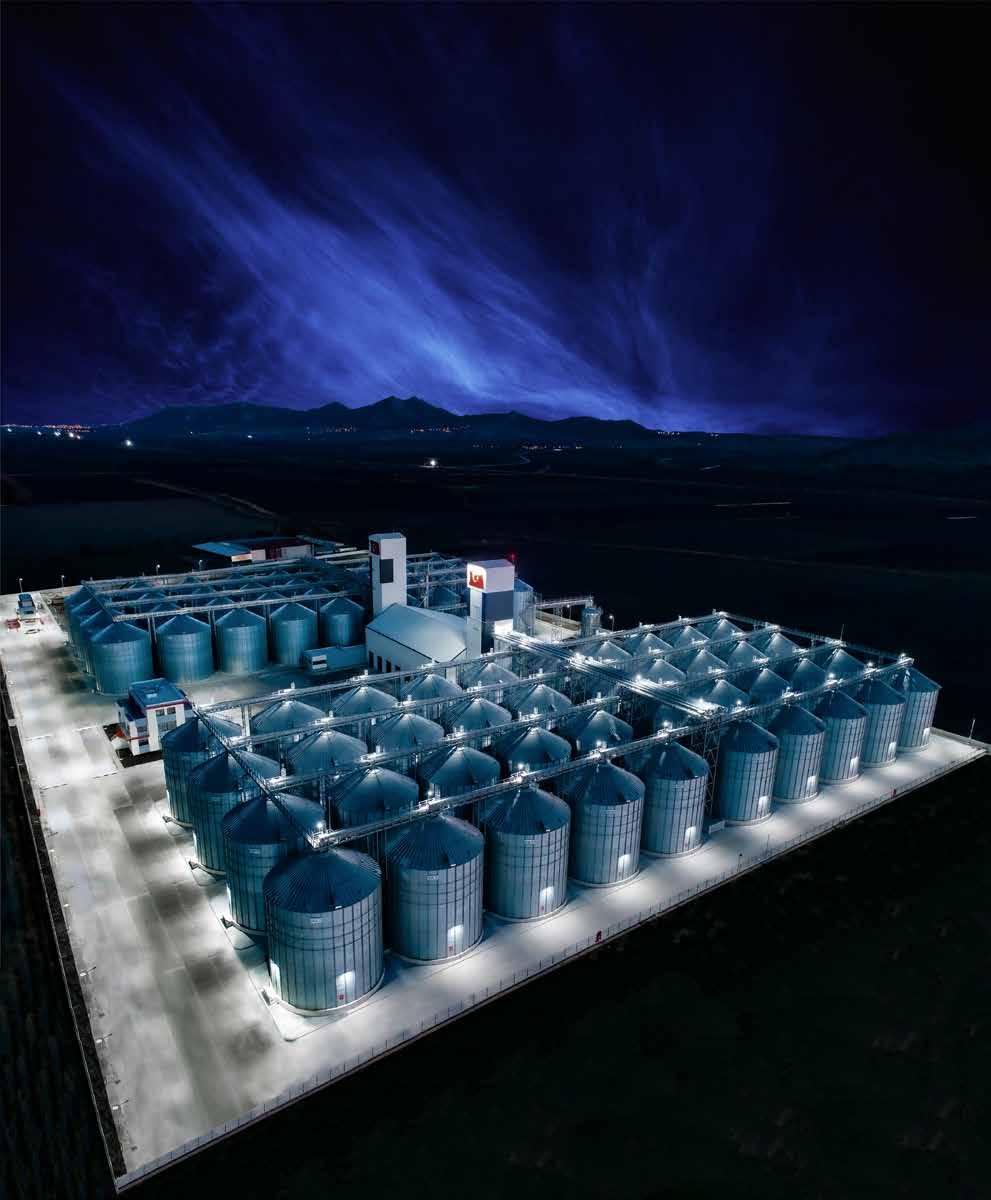

2022 IMAGEN DE PORTADA: Bühler Networking Days 2022 -

en la página

Networking Days 2022 Más información en la página 44

Bühler

90 MERCADOS John Buckley

¡No me esperaba eso!

¿Cómo podría una empresa superar su propio umbral de logro tan fácilmente, pero lo hizo y convincentemente. De lo que estoy hablando es el resultado de los Bühler Networking Days celebrados en la última semana de junio.

Los tres días que pasé con mis compañeros en la oficina central de la empresa en Uzwil, Suiza levantó totalmente la tapa de lo que nuestra industria –la molienda de alimentos y piensos, además de otras– está afrontando en el futuro inmediato en términos del cambio climático y el trabajo que tendremos que hacer para desempeñar un papel de liderazgo en la solución del problema.

Los más de 1000 clientes invitados y el personal de Bühler de todo el mundo (y participantes invitados que se presentaron desde el podio), se enfrentaron a la realidad de que nuestra industria debe dar un paso adelante y asumir la responsabilidad de la reducción de su huella de carbono, con el objetivo de alcanzar un net-zero para 2050. Y esa acción tiene que comenzar ahora en cada molino.

Sin embargo, este es el desafío que enfrentamos como industria: ¿Cómo proporcionar los alimentos para 9,5 millones de soles en el planeta y, al mismo tiempo, eliminar la producción de gases perjudiciales para el clima? Sí, eso es lo que tenemos que hacer si queremos evitar el desastre que ha sido prevenido por nuestra comunidad científica.

Aunque en el pasado se nos ha animado a «seguir el dinero», ahora debemos desviar nuestra atención y nuestros recursos y «seguir la ciencia»

Como prensa invitada, nos sentimos abrumados por el detallado programa establecido para nosotros: El número y el valor de las presentaciones; las numerosas conferencias de prensa que se centraron en casi todos los aspectos de estos desafíos; las entrevistas con los líderes de la empresa y los presentadores clave, así como las conversaciones con nuevos socios y empresas nuevas exitosas relacionadas con la empresa y apoyadas por ella.

Esta conferencia abordó toda una serie de temas, desde el cambio climático y la sostenibilidad, hasta la necesidad de reducir

los residuos y el uso de agua y energía, además de temas sobre liderazgo, alimentos con proteínas vegetales, carnes cultivadas en laboratorio (que no implican daño al animal implicado), nuevas fuentes de proteínas (incluyendo uno de un proceso de captura de carbono) y el mantenimiento de la biodiversidad.

Hemos hablado de salud humana, obesidad, igualdad y pobreza y del papel que nuestras industrias deben desempeñar en todos estos ámbitos. Hemos oído a los molineros individualmente lo que estaban haciendo para hacer frente a estos desafíos. La lista continúa.

En total hubo más de 50 asociaciones y nuevas empresas anunciadas y/o discutidas, además de conferencias y presentaciones sobre temas de liderazgo, gestión, capacitación, educación y aprendizaje, de una gama de directores ejecutivos de la industria o destacados especialistas en sus campos.

Este fue un evento muy estimulante, una inmersión no sólo en la tecnología que está moliendo hoy en día, Y los avances que se están haciendo en todos los ámbitos de la manipulación y el procesamiento de granos –y no deben pasar por alto el sector de la movilidad de Bühler, que está implicado en la fabricación de componentes para vehículos y la tecnología de procesamiento de baterías–, sino que abarcan todo lo relacionado con los puestos de trabajo que tenemos en la producción nuestros alimentos.

¿Ha llegado el mensaje a los operadores de plantas de producción del mundo?

Tal vez no todavía, pero el impacto de los días de Bühler Networking 2022 se sentirá durante muchos meses, y traerá un mayor entendimiento y reconocimiento de la cuestión que nos enfrenta y proporcionará el incentivo para tomar medidas.

Como he dicho en el pasado y se repitió en la sala de conferencias, una vez que se entiende una situación, se tiene la obligación de tomar medidas. Usted puede elegir no tomar ninguna acción, pero será responsable de su decisión en algún momento en el futuro.

Como dice Stefan Scheiber, director general de Bühler: El planeta no es nuestro, sólo lo hemos tomado prestado de nuestros hijos. Ahora es el momento de tomar medidas y hacer un impacto!

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information

Milling and Grain has a cooperative partnership with COFCOET

www.millingandgrain.com http://gfmt.blogspot.co.uk

Roger Gilbert

YOUR GLOBAL PARTNER https://store.magstand.com/milling_and_grain www.millingandgrain.com

Stefan Scheiber,

CEO,

Bühler:

The planet is not ours, we have only borrowed it from our children

Noticias Milling

Bienvenido a esta edición de julio de 2022 de su columna de Global Miller. Espero que te encontremos feliz, saludable y humilde y que estés afrontando la crisis financiera con amor, tolerancia y optimismo.

Aquí, en el hemisferio norte, los agricultores se encuentran en medio de uno de sus muchos períodos ocupados del año, con la producción de heno y la recolección de ensilaje teniendo lugar este mes. El campo está actualmente lleno de convoyes de grandes vehículos de gran altura, apilados hasta el borde de los recortes verdes asociados con estas actividades.

Otra actividad popular en este momento es el empacado, también forma gran parte del trabajo que se lleva a cabo en julio, con pacas cuadradas que normalmente se utilizan para alimentar caballos y pacas redondas son típicamente para ganado. Como he visto por mí mismo en el reciente evento de los cereales, las patatas siguen siendo mantenidas gracias al proceso de riego, y serán rociadas con pesticidas para evitar que el cultivo se dañe o se consuma.

Fue un placer contar con que el Dr. Mahmoud Riad, Secretario General de la Asociación Egipcia de Molienda - que representa tanto a los molinos de harina como a los molinos de piensos dentro del país - se uniera este mes al Rongorongo Live Video Studio. Nos conectamos a través de Zoom y le dio a Milling and Grain la oportunidad de preguntarle sobre el futuro inmediato de la industria, dadas las esperadas escaseces y dificultades a las que se enfrentará el mercado internacional del trigo en los próximos meses y posiblemente años.

El Dr. Riad declaró diciendo que a los egipcios les encanta el pan y mencionó el impresionante consumo per cápita y el número de panaderías que proporcionan pan; fascinante visión de un país donde el PIB nominal per cápita estimado para 2022 es de $4,176.00 dólares. En 2021 registró un crecimiento del PIB del 3,3 por ciento. Continuó describiendo el compromiso de su gobierno con el pueblo de Egipto en términos de mantener sus subsidios al pan suministrado a más de 80 millones de personas dentro de su población de 105 habitantes.

En marzo, el Primer Ministro, Moustafa Madbouly, fijó el precio del pan vendido comercialmente en 11,50 libras egipcias ($0,66) por kg, informó Reuters en ese momento. Reuters también declaró que los nuevos precios fijos para el «pan balady» plano y redondo se fijaban en 0,50, 0,75 y 1,00 libras egipcias para panes de 45, 65 y 90 gramos, respectivamente. (US$1:EGP€18,86).

El Dr. Riad confía en que el país puede capear la interrupción en los suministros de trigo en los próximos meses y temporadas. Ahora es un contribuyente regular a la Milling and Grain.

El vídeo del Doctor en el Rongorongo Live Video Studio puede verse aquí:

mymag.info/e/1472

Julio suele ser el comienzo de la temporada de cosechadoras para cereales como cebada y maíz, por lo que las cosechadoras serán una visión común en los campos y en las carreteras rurales, asegurándose de que llega tarde al trabajo o a esa cita si, como yo, tienes el placer de vivir ruralmente.

Dado que una serie de eventos del sector llega a su fin, hay mucha comodidad que se debe tomar de la aparente recuperación de ese aspecto de la forma en que hacemos negocios. Como he dicho innumerables veces, los eventos virtuales son geniales, pero realmente no son tan buenos como reunirse en persona.

Ni siquiera los mejores ingenieros informáticos podrían replicar la sensación de un cálido apretón de manos o contacto visual. Ahora lo intentarán y ciertos científicos afirmarán que lo han hecho con éxito, pero como los últimos años han demostrado, nunca lo clavarán 100 por ciento.

Tal y como fue promovido por nuestros amigos de Ocrim, este mes se celebra el lanzamiento del Festival de los cacahuetes y palomitas, con el evento que tendrá lugar del 23 al 29 de junio de 2022 en Mezzogoro, Italia. “Puede parecer un festival como muchos otros, una oportunidad de fiesta, pero hay mucho más detrás de la primera edición del Festival de cacahuetes y palomitas”, dice el artículo.

Descrito como un acontecimiento que «no debe perderse» para aquellos que aprecian el sabor del maní «100 por ciento hecho en Italia», esta ocasión se produce tras la reanudación del cultivo de esta fruta, Gracias a la recuperación de las semillas nativas de SIS - Società Italiana Sementi y Noberasco tras una ausencia de más de 50 años.

Así que, allí lo tenemos, el mundo de los eventos se está volviendo oficialmente loco y no puedo pensar en un mejor equipo que nuestros buenos amigos de Cremona para hacer que realmente suceda.

Hasta la próxima vez, arrivederci!

gfmt.blogspot.com

Vea más vídeos de todos los aspectos de la industria en millingandgrain.com/videos

10 | Julio 2022 - Milling and Grain

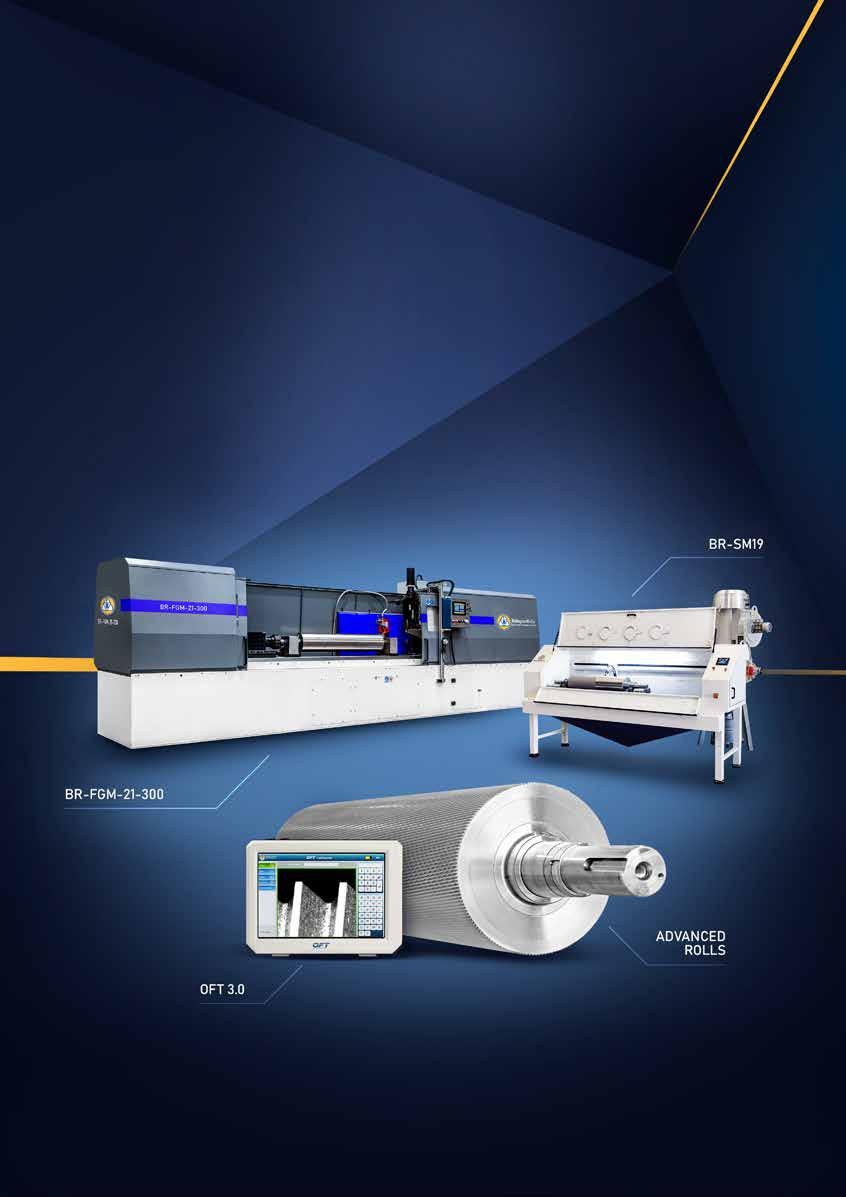

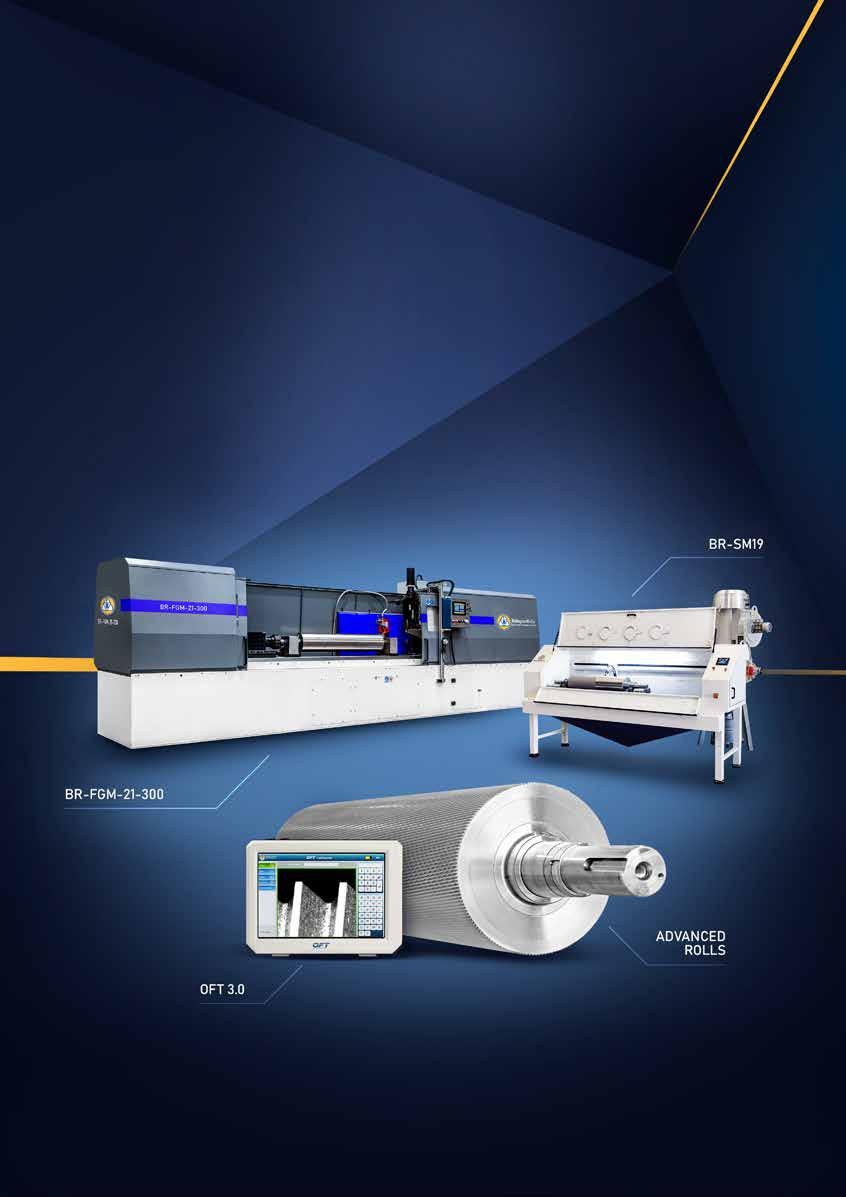

LATEST TECHNOLOGY

www.balaguer-rolls.com Facebook Youtube Linkedin

TO BOOST YOUR PROFIT

El Gobierno filipino trata de utilizar el libre comercio como herramienta deflacionaria

Filipinas anunció recientemente una decisión de reducir los aranceles restrictivos a la importación de maíz para el maíz no ASEAN de 35 a cinco por ciento.

La Orden Ejecutiva 171 citó la economía de la situación mundial actual impulsada por el conflicto entre Rusia y Ucrania y el papel fundamental del maíz en más del 50 por ciento del costo total de producción de las raciones de pollos y cerdos a gran escala para la decisión de reducir los aranceles a las importaciones de maíz.

El Consejo considera que se trata de un paso responsable del Gobierno filipino en la medida en que se enfrenta a presiones inflacionarias internas.

“Las industrias agrícolas de Estados Unidos y Filipinas han gozado de una sólida relación durante mucho tiempo”, dice Ryan LeGrand, Presidente y CEO de la USGC. “El Consejo está dispuesto a ayudar al gobierno y a la industria filipina a llenar cualquier escasez de suministro de materia prima que el país enfrenta. Los agricultores estadounidenses tienen un cultivo de maíz abundante y sostenible listo para su despliegue cuando sea necesario”.

La industria de piensos de Filipinas depende en gran medida de las importaciones de trigo forrajero debido a su historial de altos aranceles a las importaciones de maíz fuera de la ASEAN. Los recientes trastornos de la cadena de suministro mundial de trigo han tenido un impacto negativo desproporcionadamente en los precios de los insumos filipinos.

“Si estas reducciones arancelarias se mantienen a largo plazo, la industria ganadera filipina tendrá la oportunidad de volverse competitiva de nuevo con sus vecinos de la ASEAN. Cuando se dispone de un suministro constante de maíz, la demanda general de maíz crece, dado que el maíz sigue siendo la fuente de energía preferida por muchos nutricionistas”, dice Caleb Wurth, director regional de la USGC para el sudeste asiático y Oceanía.

“Esta mayor demanda de maíz también ayudará a los productores locales de maíz a unirse al mercado global de maíz, aumentando la eficiencia y la rentabilidad. El Consejo estará allí mismo con nuestros socios para asegurar que todas las partes en la cadena de suministro agrícola participen equitativamente en este movimiento histórico”.

… because that’s what we do, too. On every single FILIP cleaner, we monitor every detail throughout the entire manufacturing process. We know that our proven quality will guarantee effective sieve cleaning within your plansifters. And that, in turn, will ensure a high yield from your passages.

Efficient. Quality. Cleaning.

FILIP GmbH • Müllereibürsten • Anemonenweg 4 • D-33335 Gütersloh

Telephone: +49 (0)5241 29330 • Telefax: +49 (0)5241 20321

E-mail: info@filip-gmbh.com • www.filip-gmbh.com

Subscribe with our

new app!

mymag.info/e/1456

PARTNER

all

Get notified when new issues are available as well as access to our back catalouge of issues.

YOUR GLOBAL

SIEVE CLEANERS

12 | Julio 2022 - Milling and Grain Milling News

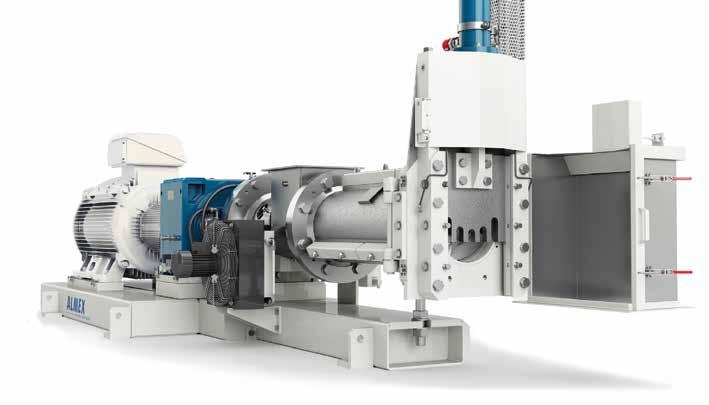

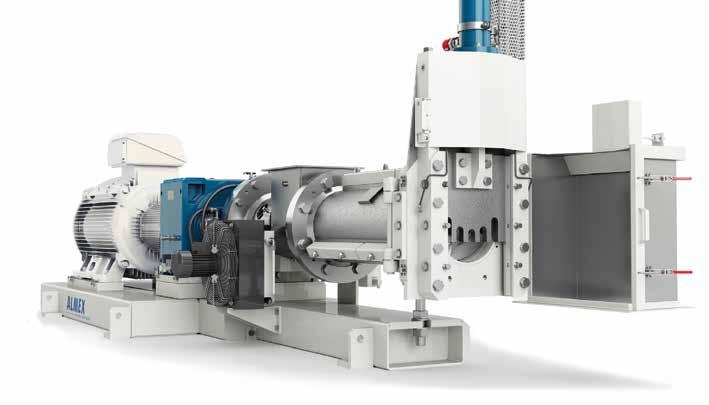

EXTRUSION AND EXPANSION TECHNOLOGY YOU CAN TRUST

Scan the QR-Code for more information www.almex.nl

Visit us at Victam International Utrecht - The Netherlands Booth 1.432 Milling and Grain - Julio 2022 | 13 Milling News

www.almex.nl Which improves the quality of finished feed as well as a more efficient process. The Almex expanders have a reliably and sturdy design and are equipped by an unique Active Disk system (AD-system) in order to control exact product input and assure the quality of the product. with the Expander AL300

DSM adquiere la empresa líder en tecnología de nutrición animal de Brasil

La agricultura de precisión está creciendo rápidamente, impulsada por la creciente demanda de sostenibilidad, eficiencia, trazabilidad y bienestar animal en los sistemas alimentarios bajo presión para proporcionar proteína animal a la creciente población mundial.

Royal DSM, una compañía global de base científica dirigida a este propósito, anuncia que ha llegado a un acuerdo para adquirir PRODAP, una compañía brasileña de tecnología y nutrición animal que combina ofertas tecnológicas, servicios de consultoría y soluciones nutricionales personalizadas para impulsar la eficiencia y sostenibilidad en la cría de animales.

Las soluciones de nutrición de precisión de la empresa para la nutrición y la salud animal incluyen Verax™, un sistema de gestión animal integrado único e innovador que aprovecha los datos para proporcionar una comprensión más profunda de la salud, la productividad y el bienestar de los animales, Y Sustell™, un servicio inteligente de sostenibilidad diseñado para mejorar la sostenibilidad ambiental de la producción de proteínas animales.

Con sede en Belo-Horizonte, PRODAP se encuentra a la vanguardia del mercado de soluciones digitales, que está creciendo particularmente rápidamente en Brasil. PRODAP combina servicios de nutrición, consultoría y tecnología para optimizar las operaciones de cultivo de rumiantes.

A través de su cartera de soluciones digitales, recopila datos y desarrolla conocimientos en tiempo real, que se traducen en soluciones nutricionales personalizadas para los clientes, con asistencia remota o en persona proporcionada por sus consultores experimentados.

PRODAP tiene operaciones en los estados de Mato Grosso y Minas Gerais y emplea a 330 empleados, sirviendo a más de 5000 fincas en todo Brasil con impresionantes tasas de lealtad de clientes.

Precisión y personalización

Al aprovechar el poder de las

soluciones digitales de PRODAP, DSM dará otro paso adelante en su viaje de precisión y personalización. DSM fortalecerá y desarrollará aún más sus soluciones digitales para llegar a más mercados globales y especies, permitiendo una toma de decisiones nutricionales más inteligente gracias a la inteligencia artificial y otras herramientas.

PRODAP complementará el profundo conocimiento de DSM en nutrición animal y sus capacidades de asesoramiento con su amplia experiencia en consultoría, facilitando un nivel aún mayor de experiencia del cliente.

Además, al apoyar una agricultura más eficiente, la adquisición contribuye al compromiso de DSM de permitir una reducción de dos dígitos en las emisiones de ganado en la granja para 2030 como parte de sus compromisos de sistema alimentario para 2021.

«La necesidad de una cría animal sostenible nunca ha sido mayor ni más urgente. La nutrición de precisión es un camino clave para mejorar la eficiencia y sostenibilidad de la cría de animales, creando valor para una serie de partes interesadas, incluidos los agricultores y la sociedad en general”, comenta Ivo Lansbergen, vicepresidente ejecutivo de DSM Animal Nutrition & Health.

“Como tal, estoy encantado de que estemos uniendo fuerzas con PRODAP para ofrecer soluciones de agricultura de precisión a nuestros clientes, lo que contribuirá a una ganadería más sostenible para todos. ¡Juntos, lo hacemos posible!'

Leonardo Sá, CEO de PRODAP, dice 'Estamos encantados de haber encontrado una empresa como DSM que sinceramente comparte nuestro propósito de transformar la ganadería en todo el mundo y la visión de adoptar las nuevas tecnologías esenciales para lograr una agricultura sostenible y eficiente. Esperamos acelerar la expansión de estas nuevas tecnologías en la industria, junto con DSM.

Se espera que la transacción, que sigue sujeta a las condiciones habituales, se cierre más adelante este año.

Milling and Grain - Julio 2022 | 15 Milling News

La Universidad Estatal de Oklahoma está desarrollando trigo de mayor calidad

La cosecha de trigo está en marcha en Oklahoma, y como preludio apropiado, los miembros del Equipo de Mejoramiento de Trigo de OSU están trabajando en variedades de trigo más fuertes y de mayor calidad.

Brett Carver, presidente de genética de trigo de la Universidad del Estado de Oklahoma, compartió con los productores de trigo en el reciente Día de Campo de Lahoma que su equipo de investigadores de trigo de OSU han estado criando variedades de trigo con una calidad excepcionalmente alta de gluten, excelente rendimiento y una resistencia fiable a las enfermedades.

“Con el trigo, podemos observar muchos factores de calidad diferentes, pero el que probablemente más destaca es la calidad del gluten”, dice Carver. “Cuanto mejor sea la calidad del gluten, mejor podremos hacer una hogaza de pan. Eso no es para descontar el rendimiento. Siempre vamos a pensar en el rendimiento, pero vamos a llevar la calidad a la conversación”.

Una mayor calidad del gluten podría significar más rentabilidad para los productores al aumentar el valor de un cultivo de trigo, y cuando ese rasgo se combina con una alta resistencia a las enfermedades, los productores también podrían ver un aumento en los rendimientos.

“Estas nuevas líneas fueron criadas con el propósito de maximizar la fuerza del gluten. Para hacer esto, tuvimos que usar la genética que nunca habíamos usado antes con la clase de trigo duro rojo de invierno”, dice el Sr. Carver sobre la nueva línea de variedades de trigo de OSU con linaje Gallagher.

Una variedad actualmente llamada 'OK15MASBx7 ARS 8-29' fue el enfoque principal del Sr. Carver para la presentación del día. Fue creado por la cría cruzada Gallagher y una variedad de la Universidad Estatal de Colorado llamada Snowmass.

Los agrónomos de OSU han creado este nuevo calibre de Gallagher para utilizar una proteína específica de gluten natural que no existe en otras variedades de trigo de OSU.

La variedad 8-29 serviría como ingrediente en el pan en lugar de como un cultivo independiente porque su gluten es increíblemente fuerte.

También tiene una fuerza equivalente o mejor que las variedades de primavera roja dura del norte de Estados Unidos y Canadá, y promedia dos fanegas más por acre que Gallagher.

“La adopción de la variedad 8-29 cambiaría lo que aparece en la etiqueta del ingrediente del pan”, dice el Sr. Carver. “El gluten vital del trigo se está agregando al pan para reforzar la fuerza y permitir el procesamiento moderno y rápido que se produce. Creemos que podemos hacerlo naturalmente en nuestras variedades de trigo por sí mismas”.

Mantener la alta calidad

El Sr. Carver dice que los investigadores de OSU han comenzado a experimentar con otros cuatro derivados de 8-29 que también tienen un fondo Gallagher, con la esperanza de crear un rendimiento aún mejor manteniendo la alta calidad.

“Este es un momento monumental para nosotros. En 2012, cuando iniciamos este programa de cruzamiento, no tenía idea de que aquí es donde terminaríamos –en una clase de trigo excepcionalmente funcional”, dice el Sr. Carver.

“Quiero asegurarme de que los productores tengan algo de lo que puedan crecer y captar valor, no sólo en la industria de la cocción sino también a nivel de los productores. Estamos tratando de averiguarlo lo más rápido posible”.

Espera que OSU lance las nuevas variedades de trigo Gallagher en los próximos dos años.

Milling and Grain - Julio 2022 | 17 Milling News

El consorcio de actores holandeses de la cadena avícola está uniendo fuerzas en una asociación públicoprivada en relación con los insectos como fuente de proteínas en las dietas avícolas. Protix, ForFarmers, Esbro, Venik y Wageningen Livestock Research, entidad holandesa del Grupo PHW, trabajarán estrechamente durante los próximos dos años.

Su esfuerzo conjunto es investigar cómo los ingredientes de insectos del soldado negro vuelan en el alimento de las aves de corral, afectan la sostenibilidad, la salud y los parámetros de bienestar de pollos de engorde lento crecimiento.

En su entorno natural, los insectos son una fuente favorable de alimento para las aves de corral. Alimentar a las aves de corral con insectos es ahora una oportunidad interesante para transformar subproductos orgánicos de bajo valor en ingredientes de alimentación de alta calidad, ya que la Comisión Europea aprobó el uso de harinas de insectos en piensos para aves de corral y cerdos en septiembre de 2021.

Esta oportunidad podría ampliar la gama de materias primas de piensos para los productores de pollo, pero aún se necesita más información para toda la cadena avícola. El consorcio va a avanzar diligentemente en un enfoque basado en la ciencia para evaluar elementos potencialmente de valor agregado de las dietas de pollo que contienen ingredientes de insectos de la mosca soldado negra (BSF).

El proyecto de investigación se llevará a cabo en tres fases, a partir del 31 de mayo de 2022, con un proyecto piloto para estudiar los efectos de los diferentes niveles de inclusión de ingredientes derivados de larvas de FBS en los piensos para aves de corral. Sobre la base de los resultados de este proyecto piloto, se probarán diferentes dietas para pollos de engorde a gran escala en granjas de

pollos. En la tercera fase se probarán productos de FBS en dietas de pollos de engorde en combinación con otras fuentes alternativas de proteínas cultivadas a nivel regional para estudiar estos efectos.

“La identificación continua y la evaluación científica de alternativas innovadoras a los ingredientes convencionales de piensos para aves de corral son elementos importantes de nuestra estrategia de sostenibilidad”, dice Marcus Keitzer, miembro del Consejo del Grupo PHW y responsable de Proteínas Alternativas.

“Por lo tanto, nuestro objetivo es investigar el impacto específico de la inclusión de componentes derivados de insectos en las dietas de aves de corral en pollos para asar de crecimiento lento desde diversos ángulos. Este PPP nos permite hacerlo conjuntamente con algunas de las instituciones más reconocidas en el sector de los insectos y la agricultura de Europa”.

Ambición y responsabilidad

Según Kees Aarts, fundador y director ejecutivo de Protix, “los tiempos sin precedentes de hoy revelan dolorosamente la urgencia de restablecer el equilibrio con la naturaleza. Los ingredientes sostenibles juegan un papel importante en esto. En Protix nacimos de la sostenibilidad, y estamos orgullosos de unir fuerzas con estos pioneros y trabajar juntos en un enfoque integrado de la cadena de valor.

“La creciente demanda mundial de proteínas animales exige soluciones innovadoras y sostenibles para los piensos y las granjas. La proteína de insecto podría tener un papel importante como fuente alternativa y sostenible de la proteína en alimento animal.

“Esta asociación es un gran ejemplo de la ambición y la responsabilidad de ForFarmers de desarrollar nuestro conocimiento e innovar para el futuro de la agricultura”, afirma Joost Sparla, Director de Marketing de ForFarmers.

Los actores clave de las aves de corral unen sus fuerzas para evaluar a los insectos como una fuente de proteína viable

Milling and Grain - Julio 2022 | 19 Milling News

El Gobierno del Reino Unido busca equilibrar la seguridad alimentaria y sostenibilidad medioambiental

Las críticas a la política de la Estrategia Alimentaria para Inglaterra publicada recientemente por el gobierno del Reino Unido han sido injustas y el gobierno ha dado prioridad correctamente a la producción nacional de alimentos.

Esa es la opinión de Mark Lumsdon-Taylor, socio de los contadores públicos MacIntyre Hudson (MHA), quien dice: “La estrategia alimentaria del gobierno y la respuesta al Informe Dimbleby se han enfrentado a muchas críticas, pero el sector necesita adoptar una visión más comedida”.

La mayoría de las críticas se centraron en la disminución, o el rechazo, de las propuestas del Informe Dimbleby que apuntaban a promover una alimentación más saludable y el trabajo ambiental en la Inglaterra rural.

“Aunque esto es lamentable, los críticos dejan de lado que el gobierno tuvo que tener en cuenta los acontecimientos recientes. La estrategia que el gobierno produjo prioriza sensiblemente la producción nacional de alimentos.

“A medida que Rusia estrangula el suministro mundial de cereales de Ucrania, este fue sin duda el enfoque correcto. Como indica la estrategia: «el éxito de la producción interna es lo que

nos da resiliencia nacional en un mundo incierto».

Si bien esto significó que las prioridades ambientales pueden haber ocupado más de un asiento trasero de lo esperado, la continua invasión rusa de Ucrania y el bloqueo del Mar Negro han forzado la mano del gobierno.

“Sin embargo, la estrategia todavía establece una visión para mantener el nivel actual de producción nacional de alimentos, reduciendo al mismo tiempo las emisiones de gases de efecto invernadero (GEI) y los impactos ambientales del sistema alimentario, en línea con los compromisos netos cero y las metas de biodiversidad.

Esta ambición demuestra que el gobierno todavía está tratando de unir los objetivos gemelos de la seguridad alimentaria y la sostenibilidad ambiental. Recientemente se ha convertido en un equilibrio más difícil de lograr, pero no imposible.

“Otro objetivo enormemente positivo de la estrategia es situar la producción sostenible de alimentos en el centro de la educación y el aprendizaje. Esto ha tardado demasiado en llegar. Pagamos menos por nuestros alimentos que las generaciones anteriores, pero los apreciamos menos: Esto tiene que cambiar”, añade.

IF YOU THINK YOUR FEEDMILL COULD RUN FASTER... >YOU’RE PROBABLY RIGHT Here at Anderson Feed Technology, we believe that building a successful feed milling operation is about more than just a building. With a combined 200 years-plus milling experience, we help you build efficiency into your entire process – unlocking more from your existing assets. In fact, our popular Feed Milling Health Check is proven to realize improvements of 10-20% for customers. So why not contact us to arrange one or visit our website to learn more. >www.andersonfeedtech.com/healthcheck 20 | Julio 2022 - Milling and Grain Milling News

Revistas de molienda del pasado en el Archivo de Mills

laminadas, sostenidas sobre columnas de hierro fundido. Un ascensor y una escalera de piedra daban acceso a todas las plantas.

El mes pasado resumí la historia de la familia de molinos Davidson hasta 1860, cuando John Davidson pasó a su hijo propietario de la fábrica que había reconstruido recientemente a partir de las cenizas de una horrible explosión en un edificio vecino.

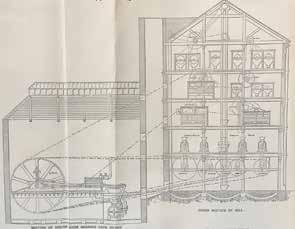

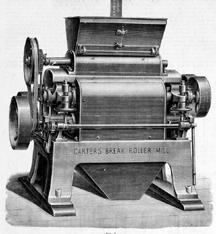

Algunos años más tarde, los señores Davidson e Hijos’, el nuevo nombre de la firma, adoptaron el sistema Harrison Carter para tener una mayor capacidad. Un nuevo edificio de cuatro pisos fue erigido además del antiguo molino que fue utilizado para la limpieza de granos.

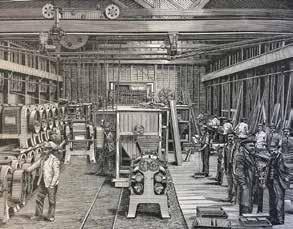

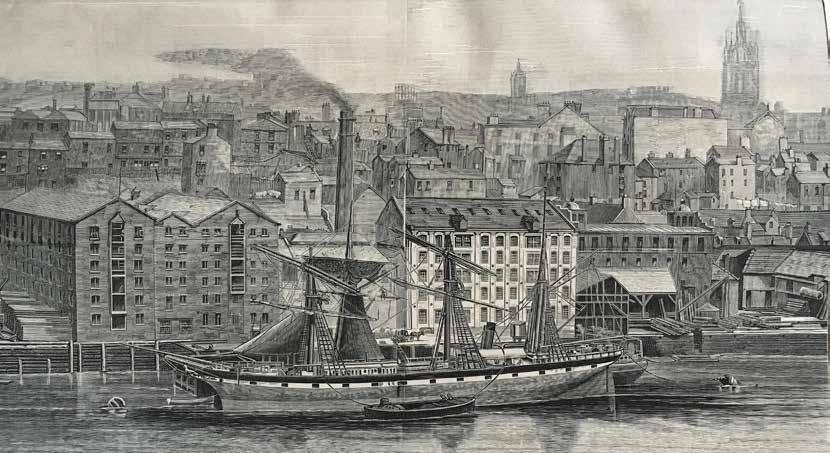

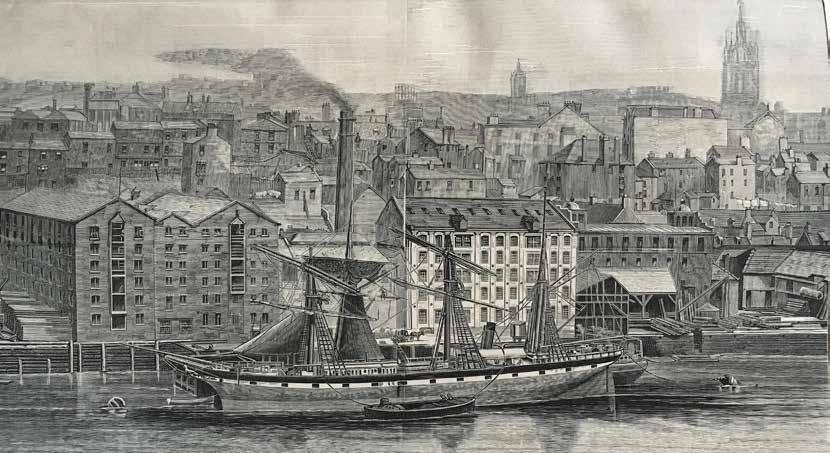

El nuevo molino, como se muestra en la ilustración, se enfrentaba a un amplio embarcadero, cuya longitud entera era servida por dos poderosas grúas de vapor. Por la noche el embarcadero podía ser iluminado por una linterna que encerraba seis lámparas eléctricas de 50 candlepower cada una.

Un carro cubierto de ocho pies, pasó a través del molino, conectando el embarcadero con la calle más allá. El nuevo molino se instaló para poner nuestros 35 sacos de harina por hora, y fue construido por el Sr. Walter Scott, a partir de diseños del Sr. Richard Cail.

Construido de ladrillo rojo con apósitos de piedra

El nuevo molino de rodillos fue construido de ladrillo rojo con apósitos de piedra, el interior está forrado con ladrillos de vidrio blanco, descansando sobre una fundación mantener de hormigón y arcos invertidos. Los cinco pisos eran llevados sobre vigas de hierro

Al entrar en el molino a nivel del suelo, había cinco líneas de fastillado que conducía a los molinos de rodillos en el suelo por encima, los ejes se ponen en movimiento por cuerdas, directamente desde el motor. Se colocó longitudinalmente una fila de fondos del elevador en el centro de este piso, y ocho fondos del elevador de un tamaño mucho mayor se colocaron en una línea contra la pared.

La harina de patente y la harina de primera rotura fueron «saqueadas» en este piso. Una escalera de piedra llevó a la primera planta, donde había cinco filas de molinos de doble rodillo con alimentación automática, los molinos que se manejaban de las cinco líneas de fastillado en el suelo de abajo.

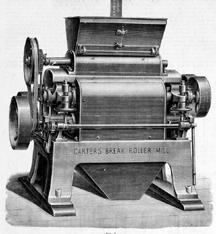

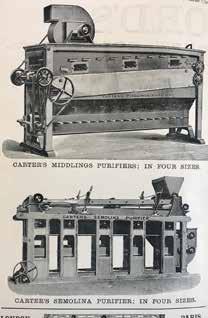

Había 50 molinos de rodillos en este piso, todas las máquinas dobles de las cuales 19 eran los molinos de rodillos de hierro refrigerados ranurados de Carter para la reducción del trigo, efectuado en el sistema de siete roturas.

El primer y segundo descansos se produjeron en dos máquinas dobles respectivamente, y tres máquinas dobles se utilizaron para cada uno de los descansos tercero, cuarto, quinto, sexto y séptimo.

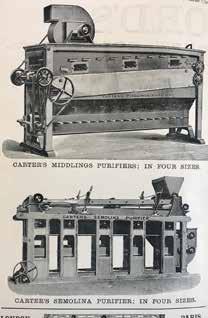

También había un molino de rodillos de hierro refrigerado doble ranurado para despojos finos y 30 molino de rodillos de hierro refrigerado suave, 20 molinos dobles Carter y 10 molinos Grays para reducción de enanos medios. Antes de ser reducido el trigo se clasificó en cuatro tamaños.

Por Mildred Cookson, The Mills Archive, Reino Unido

Los nuevos molinos de harina Phoenix de los Sres. J Davidson e Hijos, Newcastle-on-Tyne Parte 2: El Fénix se expande y se transforma

Harrison Carter four roller break mill

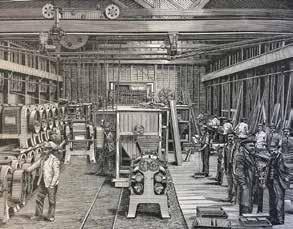

Interior view of erecting shop for centrifugals, scalpers, purifiers etc

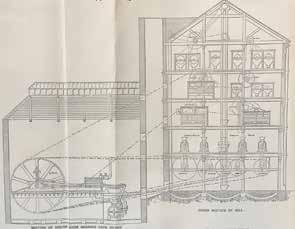

Cross section of the new mill

Por Mildred Cookson, The Mills Archive, Reino Unido

Los nuevos molinos de harina Phoenix de los Sres. J Davidson e Hijos, Newcastle-on-Tyne Parte 2: El Fénix se expande y se transforma

Harrison Carter four roller break mill

Interior view of erecting shop for centrifugals, scalpers, purifiers etc

Cross section of the new mill

SEFAR NYTAL ® . The name you can trust. Since 1830, Sefar is the single-source supplier to millers for all products for sieving, grading, and dust filtration as well as connector sleeves, sieve cleaners and tensioning equipment. FOOD SAFETY FDA COMPLIANT Headquarters Sefar AG Hinterbissaustrasse 12 9410 Heiden – Switzerland Phone +41 898 57 00 filtration@sefar.com www.sefar.com As your trusted supplier of precision woven fabrics, Sefar is proud to introduce our newest complimentary innovation: SEFAR NYTAL® Sieve Cleaners

Un efecto hermoso

El segundo piso contenía la primera parte de la maquinaria de vestuario y 10 escalfadores que operaban en los productos de la segunda, tercera, cuarta, quinta y sexta pausa. Aquí también había una línea de purificadores de tamiz de Carter, que consistía en 10 máquinas dobles, dos purificadores asignados a cada máquina.

Desde este piso hacia el viejo molino había una pasarela, los lados y el techo cubiertos de chapa de hierro corrugado. La pasarela también tenía tres transportadores, uno para traer el grano limpio del departamento de limpieza de trigo al molino donde fue elevado por medio de un gusano vertical a los niveladores: el segundo transportaba los despojos al antiguo molino, donde se separaba en salvado, pollards y punzones, y finalmente el tercero transportaba la harina de “tirada recta” por medio de una banda de 12 pulgadas al antiguo molino, donde se pesaba y saqueaba.

El siguiente piso fue equipado con dos alumnos de grado Davidson, dividiendo el trigo en cuatro tamaños diferentes antes de ir al primer rodillo de descanso. Además, había 26 máquinas centrífugas fabricadas por los propios molineros de la fábrica, un primer rollo de harina de rotura, que separaba a los enanos, de la harina de pliegue y 22 purificadores de sémola por gravedad de Carter. Un efecto hermoso fue logrado por las máquinas y sus varias boquillas en línea recta.

Un sitio para contemplar

Estas máquinas estaban sobre un transportador con tres «gusanos» paralelos separados de 38ft mm de longitud. En este piso también estaba el eje principal para poner en movimiento las diversas máquinas de vestir.

Un estriado, 8 pies la rueda del diámetro para recibir seis cuerdas, hecho de algodón 2 pulgadas de diámetro. Fue fijado a este eje, la rueda que está conectada directamente con la rueda estriada del motor. Desde

este eje se pusieron en marcha las máquinas del segundo y del piso superior. Las bandas para estos ejes fueron suministradas por los Sres. Angus & Co, de Newcastle.

El cuarto piso tenía el resto de la maquinaria de aderezo de harina, consistente en 9 centrífugas, dos de las cuales fueron usadas para harina patente, 2 escaladoras de séptima rotura, 2 escaladoras de primera rotura, 4 carretes de corte, 2 pulverizadores verticales de salvado Davidson, 3 carretes de doble grado para purificadores por gravedad, 2 carretes de clasificación dobles, 6 carretes de vestir re, y 1 carrete de germen.

El departamento de limpieza de trigo estaba en el antiguo molino y los diferentes tipos de trigo se limpiaron mediante 3 separadores de semillas de Davidson, 2 exploradores Victoria, 3 separadores de trigo de Young, 4 mantillos y 3 conjuntos de cilindros de Van Gelder, 2 máquinas Simplex, 2 exploradores, 2 Cepilladoras de lanzamiento y un secador y una lavadora utilizados para trigos extraños.

La nueva planta fue impulsada por un par de motores de condensación de superficie compuesta horizontal capaces de 80 libras por pulgada cuadrada de presión de caldera de desarrollo de 600hp. La casa del motor en sí era 50ft de largo por 26ft de ancho y 30ft de alto de madera abierta, techo acanalado curvado coronada por una luz linterna de 30ft de largo. Las paredes estaban acabadas en cemento de Keene, con pino dado enmarcado.

Milling and Grain - Julio 2022 | 25

Carter's purifiers

La escasez de nuevos candidatos hace que la industria cerealera francesa asuma el control

Los proveedores tradicionales de candidatos en Francia, como Ensmic o Aemic, ya no son suficientes ante la falta de atractivo del sector, con todo el sector en alerta para remediar esta situación.

Las cifras hablan por sí solas: mientras que casi 80 estudiantes se graduaron de Ensmic (École Nationale Supérieure de Meunerie et des Industries Céréalières) con BTS en las industrias cerealeras a finales de los años 1990s, ahora sólo hay una docena de estudiantes matriculados en el primer año.

El año 2021 fue casi sinónimo del cierre de la única clase BTS en la industria cerealera. Esta observación habla mucho sobre la desafección que experimenta la profesión de la molienda y explica en parte por qué el sector francés de la molienda está luchando por reclutar.

Esta situación es compartida por el sector de la alimentación animal y, de hecho, afecta a todos los procesadores de grano. Frente a esta preocupante situación, el sector -que hasta ahora ha sido bastante pasivo- ha decidido reaccionar, y de una forma nueva, colectivamente.

Esta doble observación, que se autoperpetúa, con, por un lado, una profunda falta de conocimiento de las profesiones de transformación de grano y, por otro, su atractivo muy limitado, no es nueva, pero el año 2021 parece ser el año de la conciencia colectiva de la urgencia de actuar.

Según la ANMF, en el sector de la molienda escasean casi 500 puestos, con preponderancia de puestos para conductores de cilindros y supervisores de molienda, técnicos y encargados de la entrega.

Después de un anuncio inicial de la ANMF, que hizo de esto su caballo de batalla para los próximos años en su convención nacional de septiembre en Burdeos, la Aemic (Asociación de Antiguos Estudiantes de la Industria del Molino y Cereal) organizó una mesa redonda durante la JTIC (Jornadas Técnicas de las Industrias del Cereal) El pasado mes de noviembre, titulado «Empleo, formación, carrera y atractivo de la industria cerealera». ¿El comienzo de una nueva era para el sector?

Comuníquese para salir de las sombras

Si el público en general siempre ha identificado al panadero, por razones de proximidad, o al agricultor que produce trigo en la cadena, el conocimiento del molinero, el vínculo esencial entre estos profesionales, es menos obvio. 'Durante años, hemos logrado arreglárnoslo. También es nuestra culpa», admite Lionel Deloingce, presidente de la fábrica de Paul Dupuis en Seine-Maritime y ex presidente de la ANMF.

«Ya es hora de que esta profesión, que crea valor, conocimiento y pericia, sea capaz de obtener reconocimiento», dice. Durante mucho tiempo, la ANMF

ha centrado su comunicación en el producto acabado, la baguette, dejando a un lado la harina y la propia profesión de molienda.

«Hemos estado cambiando nuestra forma de comunicarnos desde hace algún tiempo insistiendo en la harina, como un producto noble y esencial, Y sobre el comercio para sacarla de las sombras, cada vez más presente en las redes sociales en particular», explica Flavie Souply, directora técnica y de sostenibilidad de la ANMF. Los cortometrajes se han transmitido en las redes sociales, marcando este cambio hacia el público en general. Y para optimizar estos proyectos, la organización contrató a un gerente de comunicaciones a principios de año.

«Jean-Fraçons Loiseau, presidente de la ANMF, ha optado por recurrir a un experto en comunicaciones que también trabajará en nombre del Syndicat des industriels de la Nutrition Animale, en línea con los puentes que existen entre este sector y la industria de la molienda», explica Lionel Deloingce. Actualmente se está desarrollando una campaña de comunicación para el público en general para la industria de la molienda.

Si queremos una campaña de comunicación eficaz, además del papel del gobierno, debe ser llevada a cabo en los territorios y por las empresas. Esta campaña debe ser ambiciosa», añade Lionel Deloingce.

Las bolsas de baguette, los carteles, los videos, los medios de comunicación son numerosos. Dependerá del presupuesto asignado. Pero necesitaremos que todos los actores del sector sean eficaces, porque el presupuesto no carece de fondo. Empresas, claves de la comunicación territorial «Si cada miller pudiera ir a las escuelas secundarias vecinas a hablar sobre el oficio, con una presentación o una guía para ese propósito, sería un buen comienzo», propuso Karine Forest, directora de Minoterie Forest, en el JTIC en noviembre.

“Cuatro meses después, la ANMF, entre otros, ha puesto a disposición de muchas empresas kits de comunicación. «A partir de este verano, los molineros podrán reunirse con estudiantes de secundaria en particular», informa el molinero, entrevistado el 26 de marzo en el Salón de la Agricultura. Yann Foricher, director de la fábrica de Courneau, que asistió a la mesa redonda de JTIC, concuerda y señala el aumento de la visibilidad de las fábricas durante el periodo Covid-19. «Hemos visto un número sorprendentemente grande de personas viniendo a nuestras fábricas, y podemos ver que la imagen del molinero es un buen apoyo», dice, insistiendo en la dimensión de “herencia” del molinero más allá del “transformador”. «Podríamos aportar una dimensión territorial a este tipo de acontecimientos. Hay un día europeo de las fábricas, podríamos aprovecharlo», propuso miller.

26 | Julio 2022 - Milling and Grain Milling News

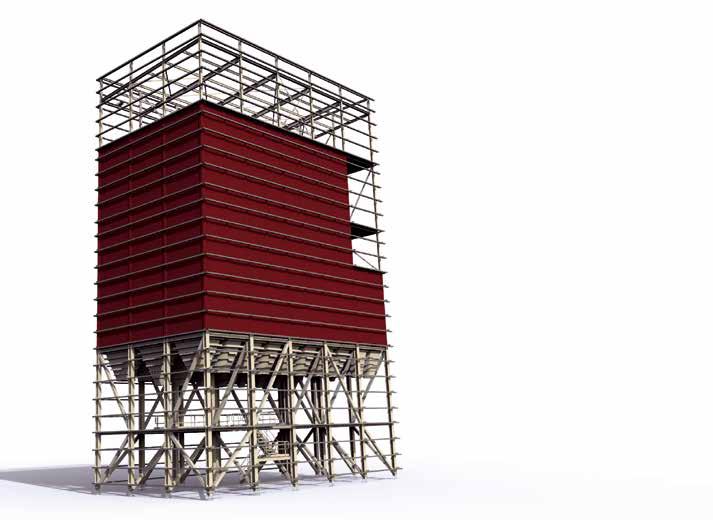

Silo block for dosing, 2.900 m 3 in 36 bins www.tsc-silos.com STORE SMART STORE SQUARE SPECIALIST IN THE DESIGN AND CONSTRUCTION OF TAILOR MADE SQUARE SILO BUILDINGS Scan the QR-Code for more information VictamVisitusatInternational Booth1.432 World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT Mixers, conveyors, Ducting System, High Temperature enquiries@hydronix.com www.hydronix.com Contact us for more details Hydronix-Milling and Grain-Advert Jan 2022 215x140mm.indd 1 15/12/2021 12:53 Milling and Grain - Julio 2022 | 27 Milling News

Rex Wailes

Los molinos de viento de Long Island PARTE 1

Por Nathanael Hodge, Mills Archive trust Tomado de un artículo escrito por Rex Wailes, febrero de 1935

Long Island se extiende hacia el Atlántico durante 120 millas al este de la ciudad de Nueva York, y los molinos que describiré están todos situados al este del puerto en Canoe Place y Shinnecot Hills. Sólo quedan muy pocos molinos antiguos, y estos son el molino Beebe en Bridgehampton, tres molinos en East Hampton, uno en Gardiner's Island, Hay Ground, Montauk Point, Shelter Island, dos en Southampton, Y el Mill Hill Mill en Shinnecock Hills.

Ninguno de estos molinos ahora cumplen su propósito original, que en Hay Ground se utiliza como salón de té, y en Montauk Point el viejo molino sirve como parte de una casa, y que en Mill Hill se utiliza como parte de una casa de verano. La mayoría de los molinos datan del siglo XVIII, pero algunos son de fecha posterior. El molino de Beebe fue construido en una colina en Sag Harbour en 1820 y fue trasladado a Bridgehampton en 1837. Se vendió y se trasladó de nuevo en 1882, cuando se añadió energía a vapor y funcionó hasta marzo de 1911, cuando perdió una vela. Este fue el último de él como molino operativo, y eventualmente fue comprado por John E Berwind y trasladado a su actual emplazamiento. East Hampton, que contiene tres molinos de viento, es el hogar de los Dominys, una conocida familia de constructores de molinos de viento, cuyo nombre aparece continuamente en los registros de estos antiguos molinos. El actual jefe de familia, el Sr. Felix Dominy, conoce bien el funcionamiento y la reparación de los molinos de viento.

La primera referencia a un molino de viento en East Hampton se refiere a un «molino de araña», es decir, un molino de caña, que en 1737 fue transmitido a su tatarabuelo, y que se encontraba en un terreno cerca de la carretera a Three Mile Harbor; fue sustituido en 1806 por el Mulford Mill.

Además de estos molinos hay mención de Merry Mill, Sandy Hook Mill, Hedges Mill (un molino de rejilla), Chelfield Mill, Derby Mill y Dominy Mill. Evidentemente, el municipio era un importante centro de molienda en ese momento. ¡Se registra que una fábrica en Hash Amonock fue vendida en 1788 por 21 libras!

La Colección de

The Gardiner Mill, one of the three remaining, stands on the site on the east side of Main Street Burying Ground, where it was built in 1771. It is in the grounds of the original mill house, now enlarged and owned by Mr Lion Gardiner, a descendant of the Mr Lyon Gardiner who had it built, and the mill is maintained in working order. Notes made by John Lyon Gardiner for whom Gardiner’s Island Mill was built have survived in MSS, and from them we learn that the mill was erected on Monday, May 23rd, 1795 by Nathaniel Dominy Junr and others and cost $773 or £309.7.0. It still stands in working order on its original site by the shore.

The Hook Mill was built in 1796 by Nathaniel Dominy, the timber for it being got on Gardiner’s Island. It was last run in 1907, and in 1920 was purchased by the village as part of a War memorial and repaired. It gets its name from the low tract of land at the east end of the Main Street on which it stands. It is in excellent condition.

28 | Julio 2022 - Milling and Grain

The Pantigo Mill was built, or more probably rebuilt, in 1771 on an artificial mound on the village green. In 1850 it was purchased by Mr Felix Dominy’s father, who moved it on to his land on the Panitigo – Amagamsett road. In 1915 it was bought by Mr George N Buck who had it removed to the garden of the cottage made famous by John Howard Payne as ‘Home Sweet Home.’ He had it repaired and used as a museum and on his death left house, mill and grounds to the village of East Hampton.

A HAVER & BOECKER Company OUR ROTO-PACKER® In comparison to conventional inline packers the filling spouts of the ROTO-PACKER® are mounted on a rotating machine frame.

Phone: +49 251 9796 252 E-mail: sales@behnbates.com

Milling and Grain - Julio 2022 | 29 Milling News

Contact:

www.behnbates.com

La crisis del aceite vegetal en Egipto

Con el estallido de la guerra entre Rusia y Ucrania el 24 de febrero de 2022, la crisis de seguridad alimentaria de Egipto representa ahora una amenaza para su economía. El Cairo depende de grandes volúmenes de importaciones fuertemente subvencionadas para garantizar suministros suficientes y asequibles de pan y aceite vegetal para sus 105 millones de ciudadanos. La obtención de esos suministros ha llevado a Egipto a convertirse en el mayor importador mundial de trigo y en uno de los 10 principales importadores mundiales de aceite de girasol.

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

La guerra entre Rusia y Ucrania catapultó los precios a niveles insostenibles para Egipto, aumentando el precio del trigo en un 44% adicional y el del aceite de girasol en un 32% prácticamente de la noche a la mañana. Aún más problemática, la guerra también amenaza el propio suministro físico de Egipto, ya que el 85% de su trigo procede de Rusia y Ucrania, al igual que el 73% de su aceite de girasol.

Con la actividad en los puertos ucranianos totalmente paralizada, Egipto ya necesita encontrar proveedores alternativos. Una nueva escalada que detenga todas las exportaciones del Mar Negro también podría sacar los suministros rusos del mercado con un efecto catastrófico.

Además del pan, la guerra entre Rusia y Ucrania ha comenzado a perturbar el suministro de Egipto de aceite de semillas de girasol, el principal aceite vegetal del país junto con el aceite de soya. El gobierno importa el 95% de su aceite vegetal y ofrece a los consumidores egipcios una mezcla altamente subvencionada de aceite de girasol y aceite de soya.

El USDA pronostica que el consumo de aceite de girasol de Egipto en el año 2021/22 alcanzará las 355.000 toneladas métricas (TM), de las cuales 350.000 toneladas métricas o el 98,6% serán suministradas por las importaciones. Ucrania y Rusia son los principales exportadores del mundo y representan colectivamente más de las tres cuartas partes de la oferta mundial de exportación de aceite de girasol.

En 2020, Egipto importó el 54,4% de su suministro de aceite de girasol de Ucrania y el 18,83% de Rusia. El 28 de febrero,

el aceite de girasol ucraniano fue evaluado en US$1.950,50 por TM, hasta US$470,50 frente al precio previo a la guerra de US$1.480 por TM del 23 de febrero de 2022. Ese precio era para aquellos que realmente podían adquirir un envío para la entrega física. La empresa de información de precios de las materias primas Platts ha puesto en pausa las evaluaciones del aceite de girasol del Mar Negro desde el 23 de febrero de este año.

Como Ucrania y Rusia son los exportadores dominantes, Egipto no puede encontrar fácilmente proveedores de reemplazo. Tampoco puede aumentar fácilmente el volumen de aceite de soya, ya que los productores Argentina, Brasil y Paraguay experimentarán un déficit de producción de soya de 9,5 millones de toneladas debido a las insuficientes precipitaciones en las regiones productoras de América del Sur.

El mercado mundial de aceites vegetales ya había sido testigo de una tormenta perfecta de precios en alza del petróleo en 2021. Al 1 de junio de 2021, Egipto aumentó el precio de los aceites vegetales no mezclados subvencionados en un 23,5%, mientras que la botella de un litro de aceite mezclado de soya y girasol fue sustituida por una botella de 800 ml al mismo precio, equivalente a una reducción del 20%.

Si bien la reducción de las subvenciones fue útil para combatir la ola de inflación mundial de los alimentos por petróleo de 2021, la guerra entre Rusia y Ucrania de principios de 2022 ha convertido esa ola en un tsunami de picos de precios, a medida que los países luchan por encontrar alternativas al aceite de girasol.

En enero de 2022, Indonesia, que produce el 58% de la oferta mundial de aceite de palma, impuso fuertes límites a las exportaciones para reducir sus propios crecientes precios internos del aceite de cocina debido a los aumentos de 2021.

Malasia, el próximo mayor productor de aceite de palma con un 26% de la producción mundial, experimentó una producción de aceite de palma más baja y no podrá hacer frente a la mayor demanda de las naciones que buscan un sustituto para el aceite de girasol, lo que deja a Egipto aún enfrentándose a una crisis de aceite vegetal.

Milling News 30 | Julio 2022 - Milling and Grain

TEK / SALES / AD VERTISING/Q3/2022OFFER We reserve the right to alter these specifications without prior written notice Email: info@tekpro.com Tel: +44 (0) 1692 403403 TekPro Ltd - Willow Park - North Walsham - Norfolk - NR28 0BD - UK *Place your order for an NHP300 Inline Pellet Durability Tester between 1st July 2022 and September 30th 2022 and receive your first Inline Sampler Absolutely FREE!^ Samplex IL50 NHP300 Inline Pellet Durability Tester Order This Get This Included for Free* ^Offer is valid for all customers on presentation of this voucher at the time of order only. No monetary equivalent value offered. A single Samplex IL50 will be included in the packing case with each Holmen NHP300 Ordered. Order and deposit must be received by TekPro before 30th September 2022 to qualify Not valid for use with any other offers or promotions. TekPro reserves the right to withdraw or limit this offer Samplex IL50 Inline sampler 8320010722300922

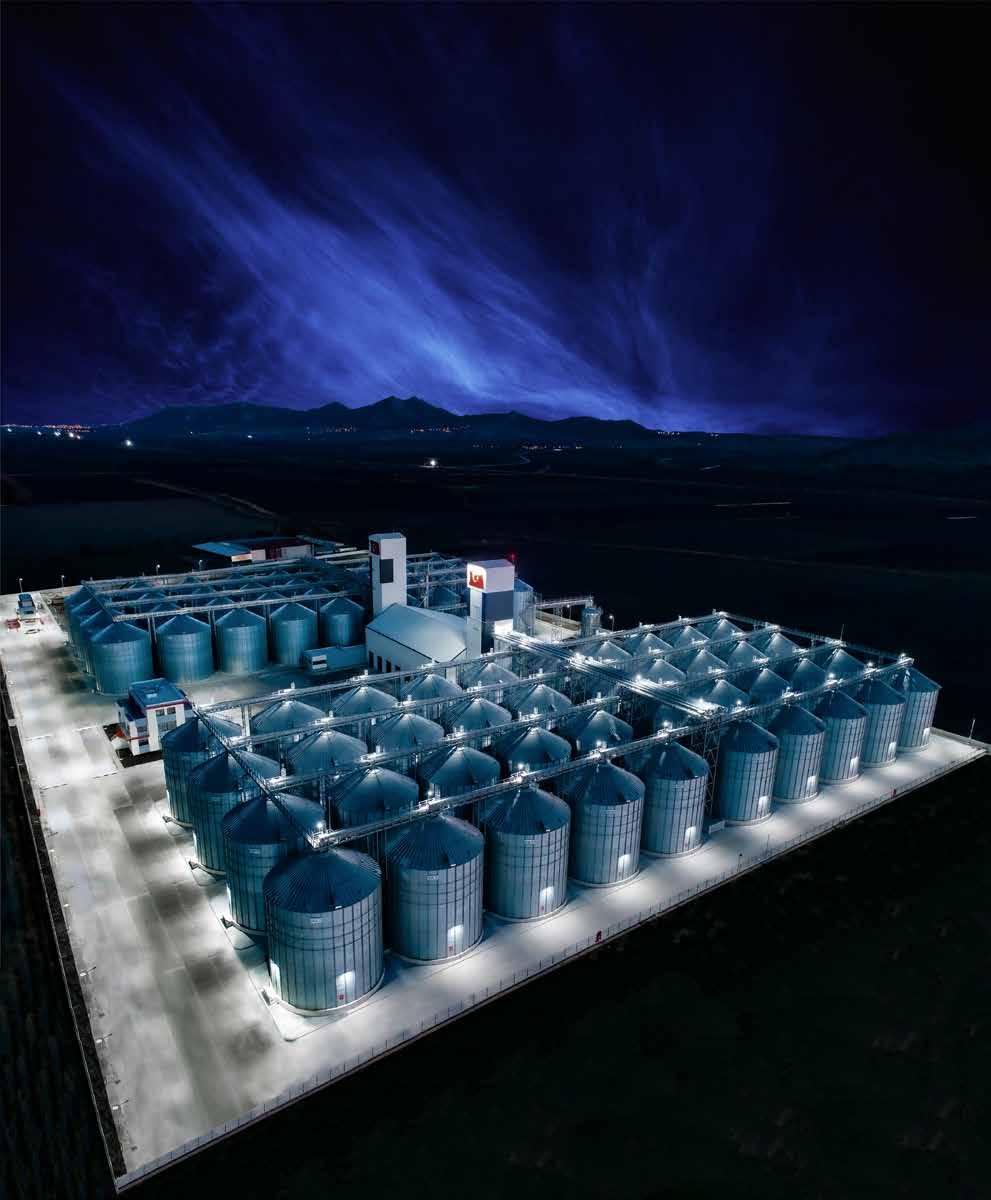

CONTINENTS more COUNTRIES than 5 80’ APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Online Aquafeed Production School

El tamaño del mercado mundial de la acuacultura se valoró en 285.359,7 millones de dólares EE.UU. En 2019, y se prevé que alcance los 378.005,5 millones de dólares EE.UU. En 2027, registrando un CAGR del 5,8 por ciento en sólo ocho años.

Con este crecimiento se presenta una gran oportunidad, razón por la cual ahora es más importante que nunca que los profesionales de la industria de piensos puedan obtener la procedencia de sus conocimientos especializados pertinentes, lo que convierte a este en el mejor momento para «asegurar» su CV añadiendo una cualificación específica del sector reconocida a nivel mundial.

En la primavera de 2022 se produjo el esperado regreso del curso Online Aquafeed Production School para su edición de primavera de 2022, con una nueva serie de emisiones en línea mejoradas y actualizadas.

Desarrollada y presentada en colaboración por Progressus Agrischools y Perendale Publishers Limited, la serie siempre fiable está diseñada para ayudar a los asistentes a comprender el diseño, desarrollo y operación de una planta de producción de piensos.

Este objetivo se alcanza con un nivel admirable a través de doce sesiones semanales de dos horas de duración en las que participan expertos del sector que comparten sus amplios conocimientos sobre los ingredientes de los piensos, el equipo utilizado, así como proporcionar una revisión nutricional general. A continuación, se realiza una sesión de preguntas y respuestas, que permite a los participantes interactuar en directo con los facilitadores del programa.

Entre estos operadores del sector, cuidadosamente seleccionados y con experiencia, que poseen siglos de servicios de primera línea combinados entre ellos, se incluye a Joe Kearns, que solo ha ocupado décadas cargos directivos en Wenger Manufacturing.

Una mezcla única de sabiduría y fiabilidad

En la edición de primavera de 2022 de Online Aquafeed Production School, el Sr. Kearns asume el papel de presentador principal, un papel que sin duda desempeñará con el mismo nivel de profesionalidad que le ha llevado a ganarse una sólida reputación a lo largo de su carrera por su sabiduría y fiabilidad.

La Escuela de Producción de Aquafeed en línea permitirá a las personas interesadas comprender las posibilidades y los

desarrollos a lo largo del tiempo con respecto a lo que se puede producir, así como examinar cómo todos los aspectos del proceso interactúan para lograr y mantener un estándar exitoso de producción de aquafeed.

Básicamente, hay cuatro áreas de importancia para la producción de alimentos acuícolas: los ingredientes, el equipo usado, cómo se opera, y las especificaciones finales deseadas del producto. Todos los aspectos interactúan como cada uno afecta al otro como el nutricionista hace la fórmula, las ventas o los clientes definen el producto final deseado mientras que la producción necesita funcionar eficientemente.

La comunicación entre estas áreas y las interacciones entre ellas incrementarán enormemente las posibilidades de producir resultados positivos, incluyendo excelente alimento acuático producido con márgenes aceptables.

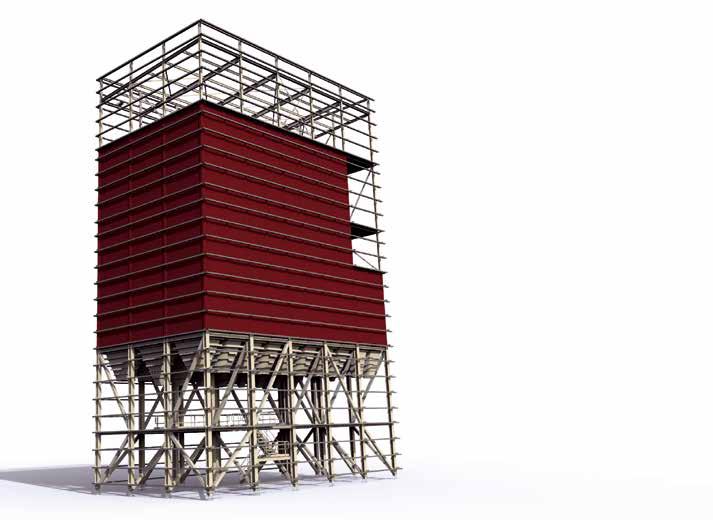

Resumen de las sesiones 3 y 4

La tercera sesión de esta nueva serie titulada “Contenedores, lotes y mezclas de ingredientes” se divide en cuatro secciones; Revisión detallada de la manipulación de ingredientes – Parte 2, Consideraciones sobre el almacenamiento de ingredientes vegetales, solución de problemas: Cilindro de extrusión y troqueles de extrusión: Troqueles y situaciones que se relacionan con el troquel y la cuchilla.

En la primera sección de este episodio, Giuseppe R Bigliani, el ejecutivo de cuentas internacionales de AG Growth International - AGI, líder mundial en la planificación, ingeniería y fabricación de soluciones integrales, presenta la segunda entrega de la detallada revisión de la manipulación de ingredientes.

El Sr. Bigliani aborda una serie de temas relevantes, como la dosificación, el procesamiento por lotes y la mezcla, y afirma que incluso el mezclador más eficiente no puede producir una mezcla homogénea si los componentes varían demasiado en granulación y peso específico.

A continuación, Joe Kearns analiza las consideraciones sobre el almacenamiento de ingredientes en planta antes de presentar su última entrega sobre solución de problemas de extrusión, que en esta sesión analiza los barriles de extrusión.

En la cuarta y última sección de esta sesión, antes de que concluya con la sesión de preguntas y respuestas, el Sr. Kearns presenta una sección titulada «Troqueles de extrusión –troqueles y situación relacionados con el troquel y el cuchillo»,

Milling and Grain - Julio 2022 | 35 CAPACITACIÓN Mill

Utilizando el martillo de los conocimientos adquiridos para romper el techo de cristal de la subcalificación

una presentación que abarca lo que puede bloquear un troquel, la densidad cambia a medida que cambia el troquel y por qué la distancia adecuada entre la cara de la cuchilla y el troquel es tan crítica.

La sesión de este último lote de sesiones de la Online Aquafeed Production School se centra en el rectificado y la micropulverización. Incluye una presentación titulada Hammermills, RollerMills, Micropulverizers, de Joe Kearns, favorito de OMS, seguida de Detalles sobre el rectificado fino, por Michel Bauer Pereira, Director de aplicaciones globales – Extrusión, Andritz F&B.

En la presentación final de la cuarta sesión de esta serie, Thomas Runde, director ejecutivo y director de ventas de Tietjen Verfahrenstechnik GmbH, presenta una presentación titulada «Molinillo ultra fino con Tietjen – Soluciones y servicio» que examina todas las cosas del rectificado fino, incluidos los conceptos básicos del rectificado, el servicio, además de echar un vistazo a conceptos y máquinas.

Esta presentación concluye con el Sr. Runde que el mantenimiento reactivo no es una opción. La combinación del mantenimiento preventivo, basado en condiciones y predictivo es clave, mientras que el programa de mantenimiento individual debe considerar todos los conceptos, basándose en los datos y el coste/tiempo.

No es demasiado tarde para inscribirse

Aunque esta temporada ya ha comenzado, todas las sesiones están disponibles a petición durante dos semanas después de la emisión final, con esta opción incluida para todos los asistentes sin coste adicional.

La Online Aquafeed Production School funciona todos los martes,

del 19 de abril al 12 de julio, a las 2pm h (hora de Bangkok) y a las 9am h (hora central). Para los residentes en Estados Unidos y América Latina, las sesiones comienzan el 21 de abril y concluyen el 15 de julio de 9am, hora de Chicago.

La certificación del curso es muy beneficiosa para el lugar de trabajo, ya que indica el interés de los asistentes en el sector y demuestra una adquisición de los conocimientos que han adquirido al asistir al programa.

Para inscribirse en el curso de la Online Aquafeed Production School, visite https://aqfeed.info/e/1393 para obtener más información.

TRAINING Mill Experts in Smart Industry Solutions for Feed Production Fully automated process control from order to product High quality product output with less operator actions Interaction with ERP, Formulation and warehouse software Track & Trace and Contamination module included Reporting services & KPI Dashboarding Turnkey projects including MCC cabinets, IT equipment and Fieldinstallation 24/7 remote support keeps you feedmill up & running Scan the QR-Code for more information www.inteqnion.com Visit us at Victam International, Utrecht - The Netherlands, Booth 1.432 36 | Julio 2022 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less

£12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME We will be seeking enrolments from June ... . . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

than

Julio 2022

En esta edición de la revista Milling and Grain, hemos dedicado nuestra sección Enfoque de Producto a mostrar toda una gama de productos vistos en VIV Europe y Victam International, que se ubicaron este año en los Países Bajos. Durante nuestra asistencia, hemos reconocido que, con el fin de hacer frente a los nuevos retos, la innovación en el sector alimentario sigue creciendo y evolucionando. Con esto en mente, creemos que para reflejar esto correctamente en nuestra revista, incluiríamos una página doble dedicada a cada programa. En esta nota, le animamos a leer y esperamos que disfrute de nuestro informe en la página X, donde podrá encontrar más información sobre las dos exposiciones. Si tiene un nuevo producto o servicio que le gustaría incluir en esta página en una futura edición de nuestra revista, asegúrese de ponerse en contacto con nosotros en e ditorial@perendale.co.uk.

Cangilones elevadores Jumbo CC-S de 4B

El Jumbo CC-S es una versión de servicio ultra pesado del cangilón elevador CC-S de servicio pesado y forma parte de la gama de cangilones de alta eficiencia. Fabricado en HDPE virgen, el cubo ofrece resistencia y durabilidad de servicio pesado. Está diseñado para aplicaciones severas, incluidos terminales de puerto, plantas de etanol y materiales abrasivos. Dispone de un reborde frontal grueso, esquinas y paredes, y están diseñadas para que se puedan montar en una proyección nominal de menos de una pulgada para aumentar la capacidad.

La parte frontal de Iceberg Edge ofrece resistencia a impactos y una larga vida útil, compartiendo las características de diseño del CC-S, al tiempo que incluye la ventaja de la capacidad de almacenamiento, lo que permite ahorrar en costes de transporte y espacio de almacenamiento. Sus principales ventajas son su resistencia y flexibilidad, y ofrecen un diseño apilable para un transporte y almacenamiento eficientes, y un fondo cónico para una separación vertical más estrecha.

go4b.co.uk

Sistema de dosificación Magi-con de Dinnissen

En reconocimiento a los retos a los que se enfrentan los fabricantes de piensos, el sistema de dosificación Magi-con de Dinnissen permite una producción flexible de una amplia gama de piensos en pequeñas y grandes cantidades en la fábrica.

El alimento se toma en un ambiente de vacío y se rocía con dosificación de precisión, seguido por los micro-ingredientes que se succionan profundamente en el grano a través del vacío. Esto es para protegerlos de que se desmoronen al mismo tiempo. Después de lo cual se aplica una fina capa de grasa, para hacer el material más elástico y asegurarse de que se rompe o se desmenuza menos rápidamente.

Al hacerlo, el sistema permite altos valores de energía en el alimento y la prevención de la contaminación. Los microingredientes se pueden dosificar en forma líquida o en polvo con la máxima precisión, para ahorrar costos.

Pesadora multicabezal serie RV de Ishida

El RV proporciona al operador una alta velocidad y un rendimiento de pesaje con varias cabezas de alta precisión, además del apoyo de expertos en pesaje con varias cabezas para productos alimenticios.

La báscula ofrece hasta un 100% de eficiencia, midiendo altas velocidades y niveles de precisión. Entre sus ventajas se incluyen el aumento del ritmo de producción y la vibración antisuelo para mejorar el flujo de productos incluso en aplicaciones pegajosas, con su diseño resistente al agua, fiable y robusto, que confirma que está diseñado para durar.

La serie RV se puede adaptar para incluir tolvas de hasta siete litros de tamaño, para aplicaciones en patatas y frutas grandes. Las capacidades oscilan entre 0,05 y siete litros, con hasta 400 ponderaciones por minuto.

Su diseño resistente al agua cuenta con un índice de protección IP69K para reconocer la protección contra el polvo, las altas temperaturas y el agua a alta presión.

www.ishidaeurope.com

Feedhopper de Eurosilos SIRP

Adecuada para aplicaciones en ganadería, agricultura e industria, la nueva línea de alimentadores con un contenedor de carga de fibra de vidrio y tapa superior se ha diseñado para garantizar la máxima integridad y un almacenamiento correcto de los alimentos.

Diseñado para su uso con granos, pellets y otros materiales, gracias a su estructura autosoportable de dos semicascaras de fibra de vidrio, el Feedhopper protege el aislamiento del contenido y tiene una capacidad total de 7m3.

Sus características incluyen una tapa superior de fibra de vidrio blanca redondeada para la conservación del alimento, cabrestante de apertura lateral para operaciones de carga y cuatro patas de soporte con tirantes, mientras que también tiene una parte inferior compatible con todos los productos de descarga inferior de Eurosilos SIRP.

Este producto se puede equipar con una tira graduada para mantener el nivel de alimento almacenado bajo control.

www.eurosilos.it

Imán de polo externo automático de Goudsmit Magnetics

El imán automático de polos externo, desarrollado recientemente por Goudsmit Magnetics de Waalre, es adecuado para procesar grandes capacidades de alimentos y productos a granel. El imán que se muestra en el stand Victam 1351 puede utilizarse para la admisión en instalaciones de descarga de buques y sirve para proteger la maquinaria.

Dos potentes imanes de captura están montados en el exterior de la carcasa completamente lisa y, dependiendo de la versión, separan partículas de hierro gruesas o muy finas de diversos flujos de material. El imán del núcleo exterior está equipado con imanes de neodimiohierro-boro (NdFeB) para montaje en líneas de caída libre. Una ventaja de este conjunto de núcleo exterior es que no se pueden producir puentes ni obstrucciones en el interior del material. Dado que la caja de válvulas está totalmente integrada en el diseño, la altura de instalación sigue siendo limitada.

El imán de polo externo está disponible en varias versiones hasta una entrada/salida de 300 x 1.000 mm. Es adecuado para grandes capacidades de hasta 200 m3 GB/hora.

www.goudsmitmagnets.com

ENFOQUE DE PRODUCTO

mymag.info/e/844 mymag.info/e/1468

www.dinnissen.eu 38 | Julio 2022 - Milling and Grain

ENFOQUE ESPECIAL

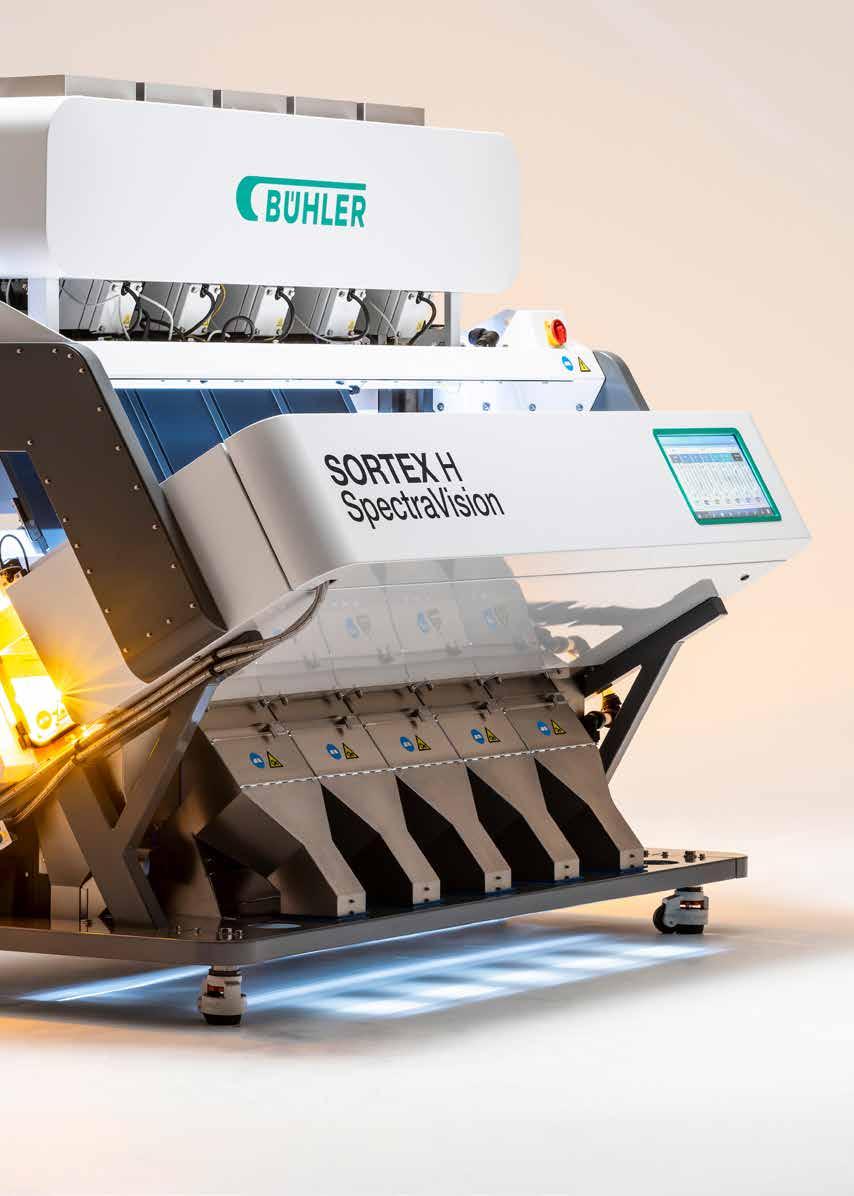

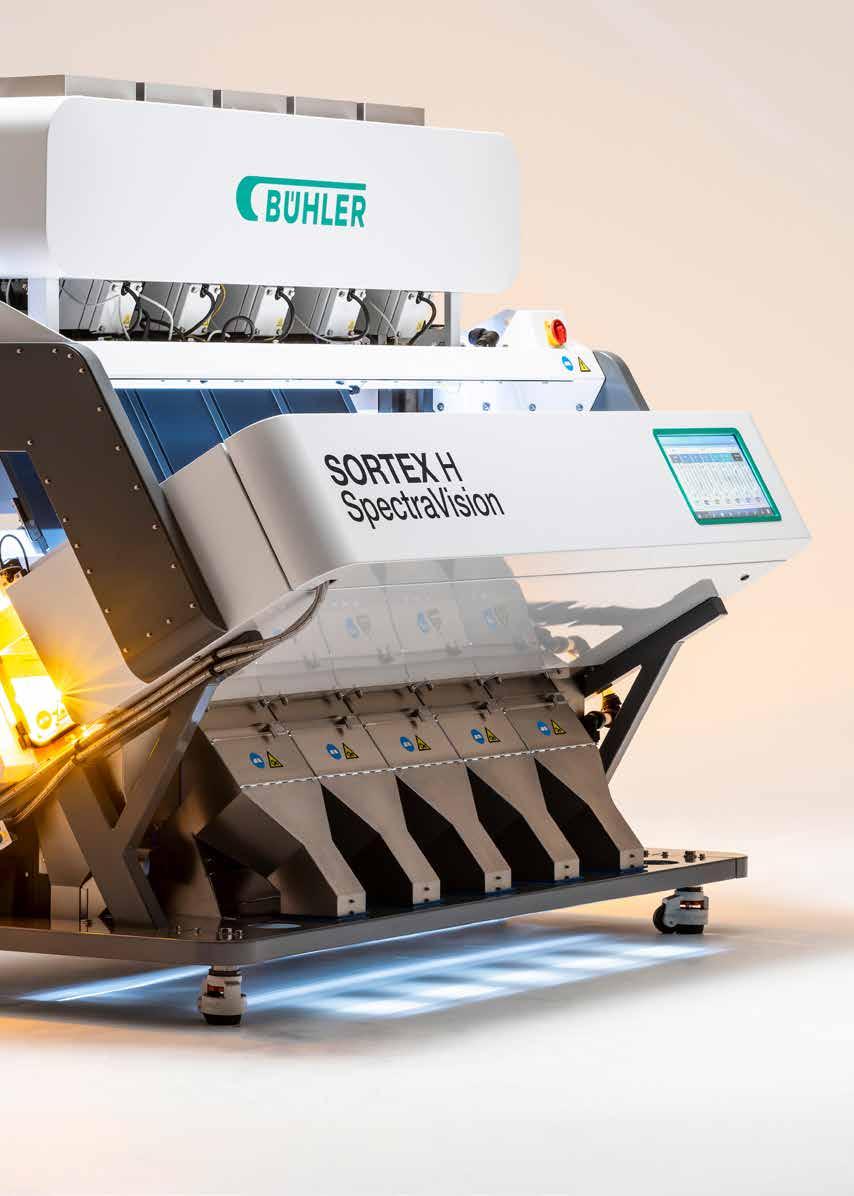

El grupo tecnológico suizo de molienda The Bühler Group ha lanzado su último clasificador óptico para trigo, centeno, avena, granos, café y legumbres: El Sortex H SpectraVision. Con la tecnología de los nuevos algoritmos de clasificación MerlinAi, la solución lleva la clasificación óptica a un nuevo nivel de usabilidad, rendimiento y trazabilidad del producto.

Utilizando los mejores conocimientos técnicos de ingeniería británicos y suizos, la Sortex H SpectraVision es el resultado de los 75 años de experiencia de Bühler en la clasificación óptica. Ofrece tres ventajas clave para los clientes: Facilidad de uso sin igual, alto rendimiento y conectividad mejorada, lo que contribuye a una mayor sostenibilidad.

Los procesadores de hoy deben abordar un número cada vez mayor de defectos como resultado del cambio climático y la reducción de pesticidas. Con su control individual de eliminación de defectos, esta máquina permite a los procesadores mantener la calidad de clasificación con facilidad. El Sortex H también ofrece concentraciones de rechazo hasta un 50% superiores.

El suministro de rendimientos máximos está en línea con el objetivo de Bühler de reducir la energía, los residuos y el agua hasta en un 50 por ciento en las cadenas de valor de sus clientes para 2025 y desarrollar soluciones sostenibles para alimentar a la población mundial de 10 mil millones de dólares para 2050.

Además, la conectividad mejorada aumenta el valor de los procesadores. Se pueden descargar más de 500 puntos de datos cada segundo y enviarlos a Bühler Insights para optimizar y realizar un seguimiento del rendimiento.

Los procesadores pueden supervisar y controlar el rendimiento de sus máquinas desde cualquier parte del mundo, de acuerdo con los estándares de la Industria 4,0. También es posible realizar un seguimiento en tiempo real del rendimiento de la clasificación y las advertencias de emergencia gracias al sistema de monitorización Sortex.

MerlinAi: Innovación, no magia Sortex H SpectraVision, capaz de gestionar una amplia gama de aplicaciones, entre las que se incluyen: Trigo, centeno, avena, granos, café y legumbres, Funciona con los nuevos algoritmos de clasificación MerlinAi. “MerlinAi es el nuevo cerebro de las máquinas de clasificación óptica Sortex de Bühler”, afirma Melvyn Penna, Jefe de Producto de Bühler.

“Sus avanzados algoritmos de ordenación multicapa garantizan un rendimiento consistentemente mayor para los procesadores, ya que se pierde un producto menos bueno en el flujo de rechazo”.

SORTEX H SpectraVision

Una reducción superior de defectos significa que la calidad aceptable puede satisfacerse incluso con material de entrada de menor calidad. “Estos nuevos algoritmos de calibración y seguimiento del producto garantizan que el rendimiento de la máquina se mantenga constante y alto, lo que proporciona a los procesadores una mayor flexibilidad”, añade Mr Penna.

Un sello de aprobación del cliente

Un cliente que ha estado disfrutando de las ventajas de Sortex H SpectraVision es Harivenasa. Como la primera fábrica de avena de España, la empresa se especializa en la producción y suministro de avena de alta calidad y otros productos a base de cereales, manteniendo la filosofía de que la buena salud se puede lograr disfrutando de la vida y la comida.

Harivenasa instaló el año pasado una máquina Sortex H SpectraVision de siete módulos en su flamante fábrica de avena. “Estamos muy satisfechos con el Sortex H porque es muy eficiente, aumenta nuestra productividad y ahora obtenemos una calidad mucho mejor que antes en cuanto a granos sin descascarar, defectos, manchas negras, etc.”, afirma Alberto Loizate, Director Gerente de Harivenasa, Alea.

Desde la instalación de la máquina, Harivenasa ha experimentado una mejora en la calidad de su avena y ahora está buscando entrar en nuevos mercados en nuevos países.

La facilidad de uso es también una ventaja importante. “Nuestro personal dice que es mucho más fácil navegar por el software y realizar el mantenimiento de la máquina. También nos dicen que es más fácil cambiar los parámetros. En resumen, el Sortex H hace que sus vidas sean mucho más fáciles”, dice Loizate.

“El retorno de la inversión también será muy corto. Ya hemos visto una gran calidad con un rechazo muy bajo del producto. El clasificador tiene muchas características completamente nuevas y funciona con las últimas conexiones remotas y conocimientos Bühler. Con Bühler Insights, la máquina está lista para el futuro”, añade.

La Sortex H SpectraVision, que se fabrica y valida en las instalaciones de Bühler en Londres, se ha instalado en numerosas instalaciones de clientes de todo el mundo y está disponible para su compra en todo el mundo. Está disponible con hasta siete tolvas. Se presentó a los procesadores durante una serie de seminarios web específicos de aplicaciones y regiones durante los últimos dos meses.

También fue exhibido en el Congreso Mundial de Semillas ISF de este año en Barcelona, así como en la IAOM en América del Norte e IPACK-IMA en Milán, donde recibió una gran respuesta.

FOCUS

mymag.info/e/1467 www.buhlergroup.com Milling and Grain - Julio 2022 | 41

www.ai-lati.eu

Let

www.paglierani.com www.ocrim.com

’ s w a l k t o g e th e r i nto a n e w E r a

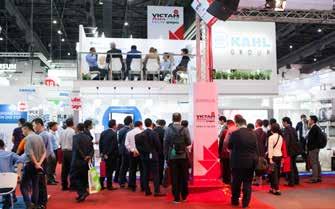

Bühler Networking Days 2022

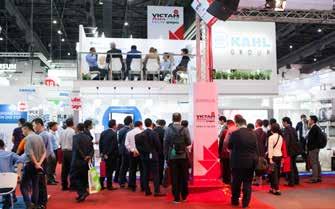

En una demostración del compromiso de las empresas de estar a la vanguardia de la lucha contra la crisis climática para proteger y restaurar la naturaleza y la biodiversidad, Y para cerrar la brecha en la distribución de la riqueza, 1000 representantes de las empresas líderes del mundo de 95 países se reunieron esta semana en Uzwil en la sede global del Grupo Bühler para discutir la necesidad urgente de que las empresas se unan para acelerar la transición hacia la sostenibilidad. Representando a empresas que entre ellas alimentan a cuatro mil millones de la población mundial y que mueven dos mil millones, los delegados que asistieron al evento Bühler Networking Days 2022 del 27 al 28 de junio, escucharon a destacados académicos, líderes empresariales, empresarios e innovadores sobre cómo las empresas pueden hacer frente mejor a los desafíos globales de hoy en día.

¿Cómo podemos permitir que 10 millones de personas (para 2050) vivan una buena vida dentro de los límites de nuestro planeta?

Esa es la pregunta que Bühler realizó en Uzwil, Suiza (a finales de junio) en 2022 días de trabajo en red, planteó a más de 1000 tomadores de decisiones invitados que representaban a los sectores de alimentación, piensos y movilidad bajo el tema: «Acelerar el impacto juntos»

Este evento único fue creado por primera vez por Bühler en 2016 y se celebra cada tres años presentando ponencias, paneles y demostraciones tecnológicas con un enfoque en el liderazgo, la tecnología, la educación, la inspiración y la acción más allá de las fronteras internacionales de la industria.

Destaca ejemplos de empresas que ofrecen un impacto tangible en la mitigación del cambio climático, la erradicación de la pobreza, la creación de empleo, la protección y restauración de la naturaleza y la mejora de la seguridad alimentaria.

“La industria global tiene excelentes ejemplos de empresas que son altamente responsables, aplicando tecnologías innovadoras en el centro de su transformación y, a través de ello, volviéndose económicamente más saludables y abordando la sostenibilidad al mismo tiempo”, afirma Stefan Scheiber, director ejecutivo de Bühler.

“De hecho, a pesar de todos los desafíos a los que nos enfrentamos –desde el cambio climático hasta la inseguridad alimentaria y energética, pasando por los problemas de la cadena de suministro y las perturbaciones sociales, pasando por las guerras–, estoy convencido de que podemos cambiar las cosas.

“Las tecnologías innovadoras ofrecen muchas oportunidades de negocio cuando también abordan cuestiones de

Una plataforma de colaboración excepcional para compartir, aprender, establecer contactos y proporcionar impacto e inspiración

Por Roger Gilbert, Editor, Milling and Grain con el apoyo del Equipo de Comunicaciones de Bühler

F 44 | Julio 2022 - Milling and Grain

sostenibilidad. No debemos avergonzarnos de aprovechar estas oportunidades”.