CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Hatton-Brown Publishers, Inc.

Street Address: 225 Hanrick Street

Montgomery, AL 36104-3317

Mailing Address: P.O. Box 2268

Montgomery, AL 36102-2268

Telephone: 334.834.1170

FAX: 334.834.4525

Publisher: David H. Ramsey

Chief Operating Officer: Dianne C. Sullivan

Editor-in-Chief: Rich Donnell

Senior Editor: Dan Shell

Senior Editor: David Abbott

Senior Editor: Jessica Johnson

Publisher/Editor Emeritus: David (DK) Knight

Art Director/Prod. Manager: Cindy Segrest

Ad Production Coordinator: Patti Campbell

Circulation Director: Rhonda Thomas

Online Content/Marketing: Jacqlyn Kirkland

Classified Advertising:

Bridget DeVane • 334.699.7837

800.669.5613 • bdevane7@hotmail.com

Advertising Sales Representatives:

Southern USA

Randy Reagor

P.O. Box 2268

Montgomery, AL 36102-2268

904.393.7968 • FAX: 334.834.4525

E-mail: reagor@bellsouth.net

Midwest USA, Eastern Canada

John Simmons

32 Foster Cres.

Whitby, Ontario, Canada L1R 1W1

905.666.0258 • FAX: 905.666.0778

E-mail: jsimmons@idirect.com

Western USA, Western Canada

Tim Shaddick

4056 West 10th Avenue

Vancouver BC Canada V6L 1Z1

604.910.1826 • FAX: 604.264.1367

E-mail: twshaddick@gmail.com

Kevin Cook

604.619.1777

E-mail: lordkevincook@gmail.com

International

Murray Brett

58 Aldea de las Cuevas, Buzon 60

03759 Benidoleig (Alicante), Spain

Tel: +34 96 640 4165 • + 34 96 640 4048

E-mail: murray.brett@abasol.net

Volume 48 • Number 1 • January/February 2023

Founded in 1976 • Our 492nd Consecutive Issue

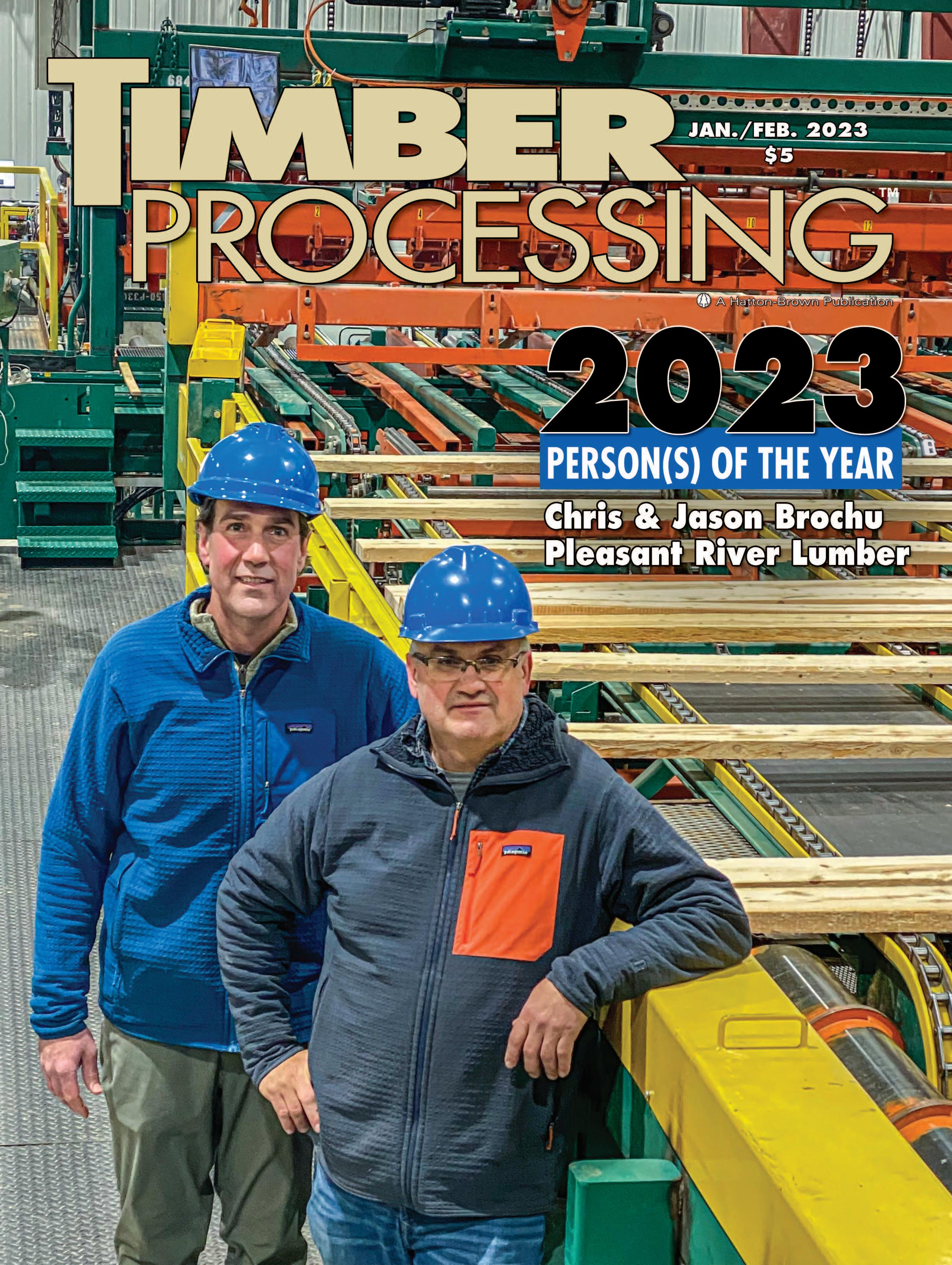

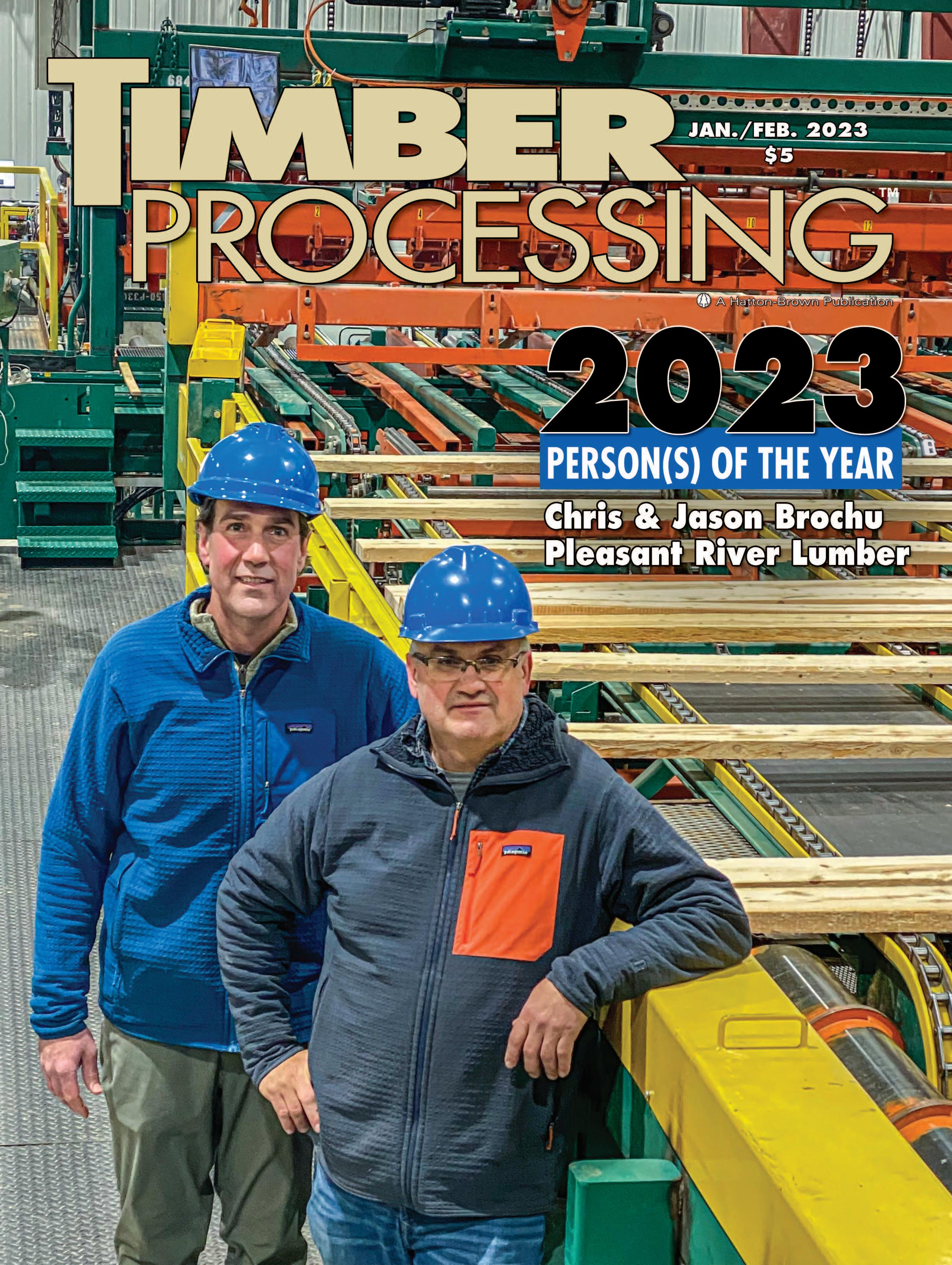

COVER: Left to right, brothers Chris and Jason Brochu, co-presidents of Pleasant River Lumber based in Dover-Foxcroft, Maine, are tapped as Timber

35th

Member Verified Audit Circulation

Timber Processing (ISSN 0885-906X, USPS 395-850) is published 11 times annually (monthly except Jan./Feb.) by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—TP is free to qualified owners, operators, managers, purchasing agents, supervisors, foremen and other key personnel at sawmills, pallet plants, chip mills, treating plants, specialty plants, lumber finishing operations, corporate industrial woodlands officials and machinery manufacturers and distributors in the U.S. All non-qualified U.S. Subscriptions are $55 annually: $65 in Canada; $95 (Airmail) in all other countries (U.S. Funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries— TOLL-FREE: 800-6695613; Fax 888-611-4525. Go to www.timberprocessing.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Timber Processing magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorse nor makes any representation or guarantee as to the quality of goods and services advertised in Timber Processing. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed in U.S.A.

Postmaster: Please send address changes to Timber Processing, P.O. Box 2419, Montgomery, Alabama 36102-2419

Other Hatton-Brown publications: Timber Harvesting • Southern Loggin’ Times Wood Bioenergy • Panel World • Power Equipment Trade

ISSUES

A Large Family Matter

5 NEWSFEED Mill Closes But Hope Remains 6 SKIDMORE LUMBER From Logging To Lumbering 30 PERSON(S) OF THE YEAR The Brochu Brothers Lead In Many Respects 20 SPRUCE PRODUCTS Fine-Tuning Primary Log Handling 34 AT LARGE New Plant Manager At Snider Industries 36 MACHINERY ROW Mill Camera Overcomes Log Collision 48 Renew or subscribe on the web: www.timberprocessing.com A Hatton-Brown Publication

WEBSITE: www.timberprocessing.com

It’s

Processing’s

annual Person(s) of the Year. Story begins on PAGE 20. (Jessica Johnson photo)

VISIT OUR

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Jessica Johnson Senior Editor

TWO BROTHERS, ONE BIG FAMILY

Iam going to start this one like I always do—by talking about myself and my family. Stay with me. I am the Person of the Year specialist. I love these stories. I love talking about why a person does what they do. How they help their community in big ways and in small ones. I often wonder how many tball teams are out there with “Such And Such Lumber” proudly displayed on the front of their jerseys. This story each year reminds me why I love this industry. After I pulled out of the Pleasant River Lumber Enfield (Maine) location, I immediately voice dialed my mother.

My mom, whose sole understanding of the lumber industry comes from me and an annual dinner with my fellow editors Rich Donnell and Dan Shell when we are in all in Atlanta for various trade shows, had sent me a text while I was interviewing the brothers Brochu (Chris and Jason), our Timber Processing 2023 Person(s) of the Year. “Hi. Hope Maine is going well. I know you love this story and this family,” she wrote. See, this was my third time to visit the Brochus, the third in the middle of winter, because it’s been well documented how stupid I am when it comes to reading weather forecasts. And she remembered how much I’ve enjoyed their facilities, interviews and whom they are. It will probably embarrass him, but I am going to tell the story anyway (sorry Chris!) of when I realized these two brothers needed to be our Person(s) of the Year. And the time when my respect for them as humans skyrocketed.

Last year, I was sitting down with Chris and Burley Higgins, Head Of Sawmill Operations, discussing the COVID-era installation of the first Valutec continuous dry kiln in North America. Chris excused himself from the conversation and then returned with a burbling bundle in the form of Edith Brochu, the youngest of his brood at under a year. As a working mother with little ones at home, the idea that this man would feel comfortable enough to just go about his day while also parenting was like receiving an IV of oxygen, motivation and happiness all at once. Chris didn’t miss a beat as he bounced Edith up and down while talking to me about the finer points of installing new technology via remote startup. Just to see with my own eyes, this big, powerful man whose company employs 800 in the state he loves so much to humanize himself was a powerful sight.

I often babble on about the families of our Persons of the Year. I worry that our magazine by default loses too much of the human element to machinery installation. Sure it is important to note that over the last five years the Brochu brothers have put more than $100 million in capital expenditures into their multiple sawmills. But there’s much more than that. Between the two, they are in the trenches of parenting nine children in ages ranging from 16 down to baby Edith.

Halfway through our recent conversation about the Brochu growth strategy, Chris checked his phone and excitedly told his older brother, “She got fifth!” and turned to me, explaining his daughter, Ella, was in a ski race that afternoon. He was proud. Then, we grabbed some hardhats and headed to look at the new MoCo stacker.

Contact Jessica Johnson, ph: 334-834-1170; fax 334-834-4525; e-mail: jessica@hattonbrown.com

20 30 34 THEISSUES

TP

TIMBER PROCESSING ■ JANUARY/FEBRUARY 2023 ■ 5

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Jason, left, Adrian, and Chris, right

NEWSFEED

VAAGEN PINPOINTS MIDWAY CLOSURE

Vaagen Fibre Canada (an affiliate of Vaagen Brothers Lumber) announced it is shutting down its Midway, BC sawmill indefinitely, while indicating it is looking for solutions to keep the operation going, and encouraging those impacted throughout the Boundary, West Kootenay and Okanagan regions to appeal to the Ministry of Forests.

The company said that on January 5 it informed the dedicated mill staff of 85 employees, as well as nearly 100 contractors, vendors, and/or suppliers that it will be shutting down the Midway mill. “Although the news we are sharing is not good news, we are steadfastly committed to continue to look for solutions for every possible way forward,” the company states.

Vaagen Fibre Canada is a non-tenured mill and has been operating in Midway without forest tenure for the past 10 years. As a non-tenured mill, it does not have forest licenses to manage Crown forests, which means it must purchase all logs on the open market including the procurement of logs from local private landowners and woodlot owners.

“Although our team has been creative for years in finding logs to run our mill, there are a few challenges that have compounded for us, and without resolution, the future of our operation is uncertain. This is an access to wood fiber at market price issue,” the company states. “We have put forward several solutions to the Ministry of Forests to help us reopen Vaagen Fibre Canada.”

The company noted that in 2008, Pope & Talbot, the previous owner of the mill, closed the mill, but the community

rallied to save the mill, which Vaagen purchased.

“We encourage you to respectfully email MLA (Member Legislative Assembly) Roly Russell, who is also the Parliamentary Secretary for Rural Development. Let him know how important the mill is to our communities and ask him to bring the voice of the people forward to the Minister of Forests to find solutions to help Vaagen Fibre Canada reopen.”

Vaagen released a form letter for supporters to e-mail to the MLA: roly.russell.MLA@leg.bc.ca

Dear MLA Russell,

I am saddened to hear that the 85 team members/employees of Vaagen Fibre Canada and nearly 100 contractors/ vendors/suppliers who work in collaboration with the mill were told that the Midway mill will be closing indefinitely. This closure will impact not

only many employees and their families, but local businesses, and many others who work and live in our rural communities.

In a press release to the community, Duane Vaagen, President of Vaagen Fibre Canada, shared that there may be several solutions to help solve the challenges the mill is facing.

As our MLA and the Parliamentary Secretary for Rural Development who is committed to helping local families and communities thrive, I am signing this letter asking you to bring the voice of your constituents to the new Minister of Forests and his team to find solutions to help Vaagen Fibre Canada re-open.

BLACK HILLS TAKES ANOTHER LOOK

Black Hills Forest Resources Assn. (BHFRA) has

6 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

prevailed in an appeal of a 2021 decision to drastically reduce future timber harvests on the Black Hills National Forest. In February 2021, the Forest Service (FS) Rocky Mountain Research Station in Fort Collins, Colo., issued general technical report (GTR) 422. The report detailed timber inventory assessments and projected growth rates that led to FS officials reducing future timber harvests on the Black Hills NF by 50% during the next three years.

At issue is the GTR’s assessment that the forest had lost 50% of its timber inventory, requiring the drastic harvest cuts, and how FS officials came to that conclusion. The BHFRA argued that the GTR modeling and survey data reflected only certain areas and not conditions of the overall forest.

With timber harvests scheduled to go from 18 million cubic feet (CF) to roughly 9 mil-

lion CF by 2023, BHFRA officials filed the appeal in late 2021. That action was initially denied by the research station, but a request for review by an interagency panel upheld several of BHFRA’s concerns.

The interagency panel didn’t agree with all BHFRA’s concerns, but did find that the initial GTR had improperly reached its timber inventory assessment. The action doesn’t mean timber harvests will be completely restored, but FS officials have directed research station personnel to come up with a corrective action process and particularly a more collaborative and transparent approach going forward.

WEST FRASER IDLES PERRY SAWMILL

West Fraser Timber Co. announced in January it will indefinitely curtail its sawmill in

Perry, Fla., citing high fiber costs and softening lumber markets.

The indefinite curtailment will impact 126 employees and reduce West Fraser’s U.S. lumber production by 100MMBF.

West Fraser expects to mitigate the impact on effected employees by providing work opportunities at other West Fraser operations.

SLB ANNOUNCES BOARD LINEUP

United States Secretary of Agriculture Thomas Vilsack has appointed Ricky Stanley to serve his first term on the Softwood Lumber Board (SLB) Board of Directors. He has also reappointed Jim Neiman, Tim Biewer, and Ray Ferris to serve their second terms on the Board.

Representation on the Board is proportional to re-

gional production, and domestic manufacturers and importers of a variety of softwood lumber products from a broad range of size and type of company are represented. Directors will serve a three-year term of office beginning immediately to December 31, 2025. On January 1, 2023, current Director Brian Luoma began his twoyear term as Board Chair, taking over from outgoing Board Chair Caroline Dauzat.

Stanley is President and CEO of Brewton, Ala.–based T.R. Miller Mill Company; he starts his first term on the Board representing the U.S. South. He comes to the SLB as a veteran leader in several other industry associations and has already been active in the SLB, recently serving as a non-board member on its Industry Relations and Governance Committee.

Neiman is President and CEO of Hulett, Wyoming–

NEWS

8 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

based Nieman Enterprises and affiliated companies. He currently serves as Treasurer of the Executive Committee for the SLB’s Board of Directors and as Chair of the Finance Committee. This marks the start of his second term on the Board, representing the U.S. West.

Biewer is Owner and President of St. Clair, Mich.–based Biewer Lumber. He currently serves on the SLB’s Industry Relations and Governance Committee. This will be his second term on the Board, representing the U.S. Northeast and Lake States.

Ferris is President and CEO of Vancouver, BC–based West Fraser. He currently serves as the First Vice Chair of the SLB’s Executive Committee and Ex-Officio of the Finance and Industry Relations and Governance Committees. This will be his second term on the Board, repre-

senting Canada West.

Luoma is President and CEO of The Westervelt Company. He currently represents the U.S. South region on the SLB Board of Directors and has most recently served as the Second Vice Chair of the SLB’s Executive Committee and Chair of the SLB’s Programs Committee.

The 2023 Board will have 14 members, including 10 domestic manufacturers and four importers. Members can serve up to two consecutive threeyear terms.

FOREST PROJECT MOVES AHEAD

The U.S. Forest Service recently prevailed against a 3year-old lawsuit seeking to halt a forest health project in coastal California’s Los Padres National Forest that sought to thin timber stands to reduce the

threat of crown fires. Forest officials say the Tecuya Ridge Shaded Fuelbreak Project is an effort to prevent wildfires from reaching several small communities in the area.

When the project was initially approved in 2019, several environmental groups filed suit, claiming parts of the 1,600 acre project were in roadless areas and had been improperly included. The FS won the case in 2020, and has now won the appeal as well. Local news reports note that while the project has faced opposition, residents in the communities affected are overwhelmingly in favor of the project.

PROPOSED PELLET MILLS ADVANCE

A proposed project that would build two wood pellet facilities—one in the foothills of the Central Sierra Nevada

Mountain range, in Tuolumne County, Calif., and one in the Modoc Plateau of northern California, in Lassen County— released a Notice of Preparation (NOP) of a Draft Environmental Impact Report in midNovember, which allowed a 30-day public review and comment period and included four public meetings.

Golden State Finance Authority (GSFA), acting as the California Environmental Quality Act (CEQA) lead agency, released the NOP for the Golden State Natural Resources (GSNR) Forest Resiliency Demonstration Project. As part of the project’s scope, the finished pellets will be shipped by rail to a port for international shipping. The preferred port location is currently being selected, and will be either the Port of Stockton, or the Levin-Richmond Terminal in Richmond, Calif.

The project is a response to

NEWS

10 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

the growing rate of wildfires in California, which has been exacerbated by hazardous excess fuel loads in forests, and the need to promote economic activity within California’s rural counties, according to the participants. The project would improve the resiliency of California’s forestlands by sustainably procuring and processing excess biomass into a pelletized fuel source for use in renewable energy generation overseas.

There would be two primary feedstock types: roundwood and residuals. Roundwood would be procured through vegetation treatment activities, including prescribed thinning, occurring on public and private lands within a 100 mile radius of each production facility. Residuals include material (bark, shavings, sawdust, wood chips) left over from the milling process, and may include forest slash or material

left following timber harvesting and treatments (such as the limbs and the tops of trees), and vegetation from fire management activities performed by utilities.

The NOP emphasizes that forest material my come from pubic or private lands, and noted that in October 2019, GSFA executed a 20-year Master Stewardship Agreement (MSA) with the U.S. Forest Service to provide for the mutual benefits and interests of GSFA and the USFA in achieving resilient forests within U.S. Forest Service Region 5, which includes all of the 18 national forests located in California. The MSA would allow FSFA to undertake forest thinning and fuel reduction activities identified in individual Supplemental Project Agreements.

The NOP describes planned capacities of 300,000 tons per year at the Tuolumne site and

700,000 tons at the Lassen site. The Tuolumne site was previously used as a bark facility by Sierra Pacific Industries. The Lassen site is a portion of a larger property that included a mill site (which is not part of the proposed project site) and an area used by the mill operators to load rail cars.

GSFA is preparing an EIR (Environmental Impact Report) to determine if the project may have a significant effect on the environment, including air quality, forestry resources, greenhouse gas emissions, hazardous materials, etc.

Golden State Natural Resources was unveiled in 2018 as a public benefit, non-profit corporation. The web site shows Greg Norton as President/CEO, a position he previously held with Rural County Representatives of California (RCRC).

TREATING GIANT PLANS EXPANSION

Great Southern Wood Preserving, known for its YellaWood brand pressure-treated pine, announced a $5.9 million expansion of its Louisiana Avoyelles Parish facility’s remanufacturing division with the installation of four new production lines. The additional equipment will increase the facility’s production capacity and allow for the manufacturing of components used in the oil field and for storm relief and mitigation.

The company will create 25 new direct jobs and retain 79 existing jobs.

With the facility enhancements, production of supplemental decking components, including rails and balusters, will shift from out-of-state facilities to the Mansura plant. These products will be used

NEWS

12 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

on-site as well as at Great Southern locations throughout the U.S.

“Our expansion in Mansura is phase two of the long-range plan we had in mind when we began operations here in late 2011,” says Great Southern President and CEO Jimmy Rane. “With the growth of various manufacturing segments in Louisiana, our goal is to be able to support these industries by providing both a greater volume of products as well as more variety in the products they need to continue their growth. We’re looking forward to getting underway in early 2023.”

The company projects construction to begin in January and be complete in October. This is Great Southern’s second investment in its Louisiana location. Last April the company announced a $22.5 million, 200,000 sq. ft. expansion of the Mansura facility that included

a new warehouse, office building and maintenance shop.

To secure the project in Mansura, the state of Louisiana offered Great Southern Wood a competitive incentives package including a performance-based retention and modernization tax credit of up to $200,000, and the services of LED FastStart, Louisiana’s recruitment, customized training and workforce development program.

The company is a participant in the state’s Quality Jobs program and is expected to participate in the Industrial Tax Exemption program.

CLUTTER WAS RESOURCES EXPERT

Dr. Michael Lee Clutter, who served as Dean of the University of Georgia Warnell School of Forestry and Natural Resources from 2007-2015, and was a noted expert in his

field, died on December 24. He was 63.

Born in Durham, NC, Clutter grew up in Athens and attended Clarke Central High School, where he graduated with honors in 1977, was captain of the soccer team, and lead trumpeter for the school’s band. He pursued his undergraduate education at Ohio University, playing collegiate soccer, and later at Mississippi State University, where he earned a bachelor’s degree in forestry resources in 1981. Returning to his hometown, Clutter received a master’s degree in 1982 and a doctoral degree in 1991, both from Warnell.

Clutter was considered an authority on the economics of the forestry industry, including finance, budgeting, timberland management and timber supply and sizing trends. Early in his

career he held various management positions with two leading forest products companies, Georgia-Pacific Corp. and Union Camp Corp. in Savannah. Joining Warnell’s faculty in 2001, he was later named the Hargreaves Distinguished Professor of Forest Finance and received the Warnell School’s Faculty Award for Outstanding Teaching.

Assuming the role of Dean on August 15, 2007, Clutter was determined to keep students at the forefront of his scholarship and research, continuing to teach forestry courses until his departure in January 2015. Along with his Warnell classes, he also was an adjunct professor at the Terry College of Business, where he taught corporate finance. One of his proudest accomplish-

NEWS

14 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Dr. Michael Clutter

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ments was his lifetime affiliation with Warnell as a dean, professor, student, and the son of a professor at the school.

Desiring to return to the private sector, Clutter became an executive with Forest Investment Associates Timber Partners, a timber and timberland investment fund. He worked there until 2021, when he was named Chief Analytics Officer at F & W Forestry, a position he held until his death.

Along with his academic and professional accomplishments, Clutter was the co-editor of a book on timberland investment, author of numerous articles and other publications, a recipient of several research grants, an editorial board member of the professional journal Forest Science, a member and past chair of American Forest and Paper Assn.’s forest inventory committee, and a member of the U.S. Forest Service’s forest inven-

tory and analysis review committee. He was an inductee of the Georgia Foresters Hall of Fame.

He is survived by his wife of 38 years, Catherine (Cathy) Nemetz, and their three children, Matthew, Emily and Maggie. Clutter was predeceased by his father, Dr. Jerome Clutter, also a leading professor at Warnell for 20 years.

Visitation was held January 6 in Watkinsville, and a funeral mass was January 7 at The Catholic Center at the University of Georgia. Interment was at Oconee Hill Cemetery.

In lieu of flowers, the family kindly requests that donations be made to: The Dr. Michael L. Clutter Fellowship, University of Georgia Warnell School of Forestry and Natural Resources, attention: Bridget Harden (bharden@uga.edu). In addition, donations may be made to Trout Unlimited, at gifts.tu.org.

SUMITOMO PLANS COMPONENTS PLANT

Sumitomo Forestry America, Inc. will create 129 jobs in Randolph County, NC and establish a $19.5 million investment wood components manufacturing facility in Archdale.

Sumitomo Forestry America is a wholly owned subsidiary of Sumitomo Forestry Co., Ltd., headquartered in Tokyo. The project in North Carolina will establish a component manufacturing and distribution facility to produce building materials such as roof trusses, floor trusses, and wall panels used in residential housing and wooden commercial and multi-family buildings.

Another wholly owned subsidiary of Sumitomo Forestry America, Charlottebased Crescent Communities, will help develop and build the new production facility.

Sumitomo Forestry’s project in North Carolina will be facilitated in part by a Job Development Investment Grant (JDIG) approved by the state’s Economic Investment Committee.

Because Sumitomo Forestry chose a site in Randolph County, classified by the state’s economic tier system as Tier 2, the company’s JDIG agreement also calls for moving $77,300 into the state’s Industrial Development Fund – Utility Account. The Utility Account helps rural communities across the state finance necessary infrastructure upgrades to attract future business.

NEWS

16 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

By Jessica Johnson

Brothers Jason and Chris Brochu have quietly built a large and successful forest products enterprise in Maine.

Brothers Jason and Chris Brochu have quietly built a large and successful forest products enterprise in Maine.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

While greenfield sawmill announcements have dominated the sawmill news cycle in recent years, another approach was being executed in the Northeastern corner of the U.S., where Pleasant River Lumber Co. was gathering lumber mills, timberland, and other diversified forest products interests like Southern squirrels do for the winter. Today, Co-Presidents and brothers Jason and Chris Brochu lead a family business of than 800 employees, with major ongoing capital expenditure investments throughout multiple sawmills, while maintaining and building on a family culture that bodes well for the future. In addition, Brochu leadership and involvement in local and national affairs of the industry has settled into a family tradition as well.

Timber Processing gladly names Jason, 50, and Chris, 42, as the 35th annual recipient of the magazine’s Person of the Year award for 2023, marking the fourth time the award has gone to a lumberman in the state of Maine.

With a logging background, the Brochu family (four brothers including Chris and Jason’s dad, Adrian) first entered the sawmill business as Stratton Lumber in the early 1980s, building a sawmill in partnership with a Quebec family. In 2004, with Chris and Jason now in the fold, they purchased an antiquated sawmill operation in Dover-Foxcroft, Pleasant River Lumber, and began investing in machinery and production capacity, while selling out of the Stratton Lumber business.

The opportunistic growth strategy hasn’t stopped since in spruce-fir and pine lumber markets. In 2008, Pleasant River acquired an idled sawmill in West Enfield, Me. and in 2011 and 2012 purchased struggling mills at Ellsworth and Sanford, Me. The two brothers became co-presidents after those purchases, and in 2015 when their biggest competitor for spruce raw material came up for sale, Moose River Lumber in Jackman, Me., the purchase was a no-brainer.

The first in a series of diversification moves came in 2016, with the acquisition of Chaffee Transport, helping to control a seemingly uncontrollable part of the industry—trucking and logistics. The “COVID years” have seen more diversification, including the purchase of their aunt and uncle’s log home fabrica-

tion business, and acquisition moves into retail store and lumber distribution, meanwhile formally re-establishing A&A Brochu Logging, the original name of the family logging business started in 1968 (which at the end of 2022 received the Maine Forest Products Council Outstanding Logger honor).

So, how does all of this work with two brothers? Both point to their age difference as a huge benefit. Jason has eight years on Chris, so while the two grew up together as brothers, Chris was just nine when Jason went off to college. Jason explains, after finishing his degree at Bentley University in Massachusetts, he “stayed away” working for other companies, doing other things. “When I am 30, he’s 22 and we come together to start working at Pleasant River. Before that we had never worked together. I think there’s an advantage there for us not having spent our entire lives growing up together. There’s no competition; we think alike. We both

further as cheerleaders, and they’re quick with praise for all employees. Key positions who report directly to the brothers include Burley Higgins as Head Of Sawmill Operations; Mike Lebrun, Enfield GM/Project Manager; Bill Ossenfort, Head Of Sales; Rich Smith and Jeff Desjardin in procurement; Stephanie Smith, Pleasant River Lumber CFO; Barry Ivey with MCLH log homes; Joel Reed, A&A Brochu Trucking GM; Toby Pineo, A&A Brochu Logging GM; and Alan Orcutt and Scott Wellman heading up the retail division. Jason says, “You may think we have a ton going on, but we have the greatest people involved in running each department that we have. If Chris and I disappeared tomorrow, everything would still run. We have people that know what needs to be done. One of the benefits of growing that we’ve found is that when you start getting to a certain size, the caliber of people that you can bring into the company is pretty incredible.”

The “just sort of happened” growth strategy started with West Enfield. The brothers were attracted to it because it was close to their existing lumber mill. Upon purchase, they started the planer mill back and ran 1 in. lumber through it—while making plans and decisions to bring the mill to its current state, a fully functional, redesigned and modernized small dimension lumber facility.

have our own things outside of the mill. We live in separate towns, but we work together every day.”

Chris also graduated from Bentley University. “We play good cop, bad cop with our own ideas,” before a big laugh to add, “When we were growing, we ran out of office space and got stuck together. So, we spent five years working in the same office.”

While the two might not have an inherent competition between them, they definitely act as one another’s balance beam. Chris says the ability to pull the other back on various crazy ideas has helped tremendously as capital expenditures have risen. What makes one angry might not carry over to the other, and vice versa. “It does help us make fewer stupid decisions,” Chris adds emphatically.

OPPORTUNITIES

The growing conglomerate of companies and massive employee expansion has defined their job description even

Chris says that every purchase was encouraged by their father, Adrian. “What really allowed us to grow a lot was our father. He enabled us to grow and diversify. He was the guiding force behind the whole the thing.” The Ellsworth operation put them into sawing pine lumber.

As to the Moose River Lumber spruce sawmill acquisition, Jason doesn’t mince words, saying, “Our biggest competitor for raw material came up for sale, so we jumped all over that. That was the biggest acquisition since Dover.”

Trucking, logging and retail distribution all came after, in a combination of opportunities from poking at owner-operators who might be ready to retire, to owner-operators just up and calling and offering their businesses for sale to the brothers.

The company’s current capital investment and expansion plans focused on West Enfield, first with the purchase and then in 2018 with the plan to redevelop the sawmill to where things currently stand today—construction of a new facility that will be completed at the end of

DOVER-FOXCROFT,

Me.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

“One of the benefits of growing that we’ve found is that when you start getting to a certain size, the caliber of people that you can bring into the company is pretty incredible.”

River have gone away. A real need for an efficient small wood sawmill in this part of Maine existed. The original plan was to create a rough green mill and ship lumber to Dover for drying in the new Valutec kilns.

“We changed our plan,” Chris says. “It has developed further than that and at the end of this year, capacity-wise, it will be the biggest mill in the state with two lines sawing small wood at about 120150MMBF annually.”

The investment at West Enfield is

that had been struggling. A similar path brought the retail distribution and lum-

ber stores into the fold. A deal that originally gave the brothers three stores in 2020 has quickly grown to 15 stores across Maine.

Within the retail business, the company also has a kitchen cabinet division and wall panel plant, and log home fabrication division. Chris comments. “We like the idea of log homes because it complements our retail and pine divisions. Our first full year we made 50 log homes while completing a new automated production line with capaci-

These moves mean that the brothers’ companies touch literally all aspects of the forest products industry, from standing timber to a register receipt for a 2x4. While everything is consolidated at the Pleasant River headquarters in DoverFoxcroft, each company is an individual entity with its own team working on its

The Brochus also view each sawmill capital expenditure project on a case-bycase basis. They pride themselves on doing business with all the major manufacturers of sawmill equipment and technology. Finding the right equipment

22 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING

Chris Brochu

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Jason Brochu

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

at the right time for the project they have designed in their heads is most important to them.

“Ours is a hodgepodge,” Jason comments. “We just think that when we have in our heads what we are going to put in, there might be three or four vendors who can accommodate it. We’re not stuck on one.”

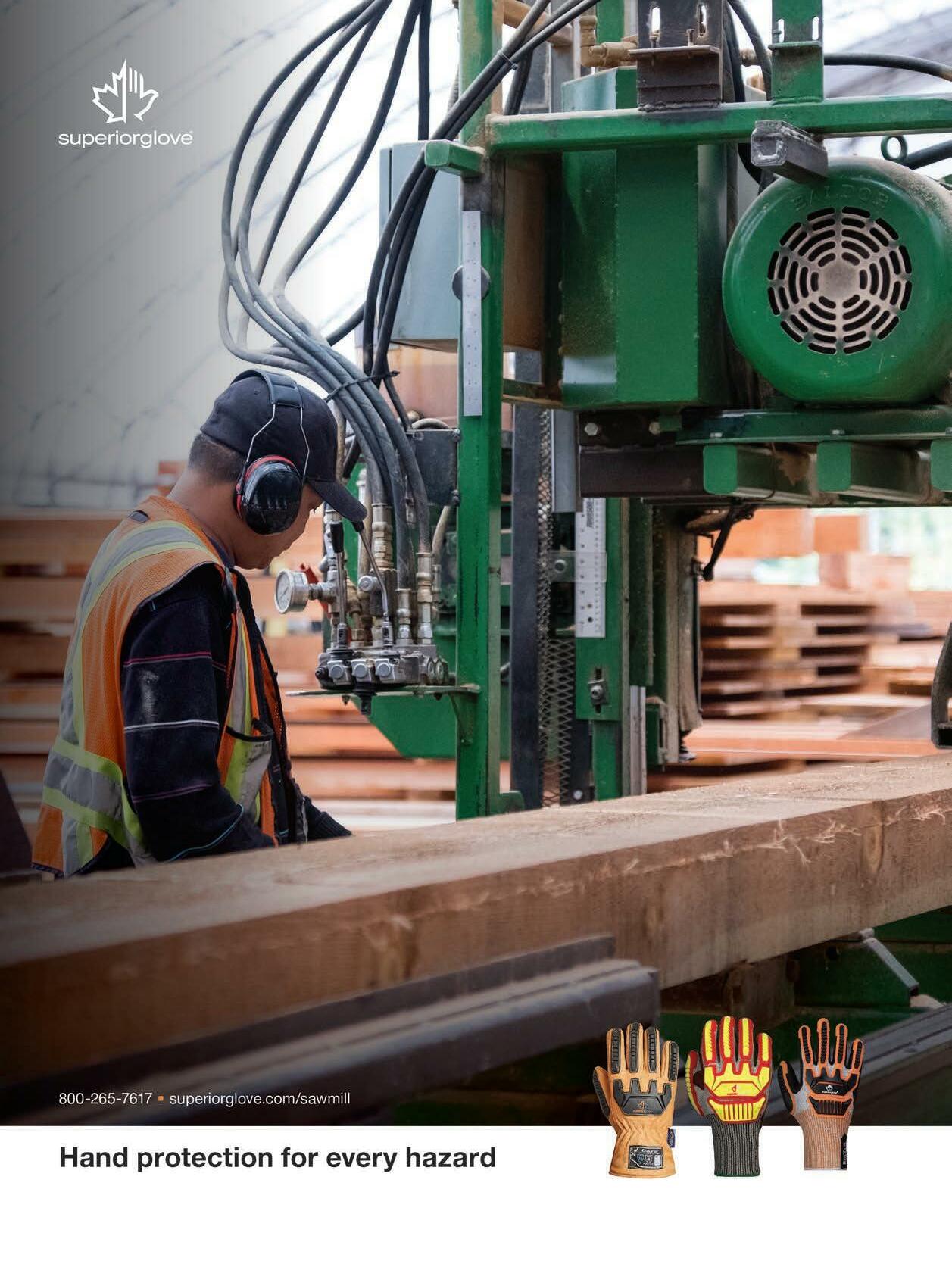

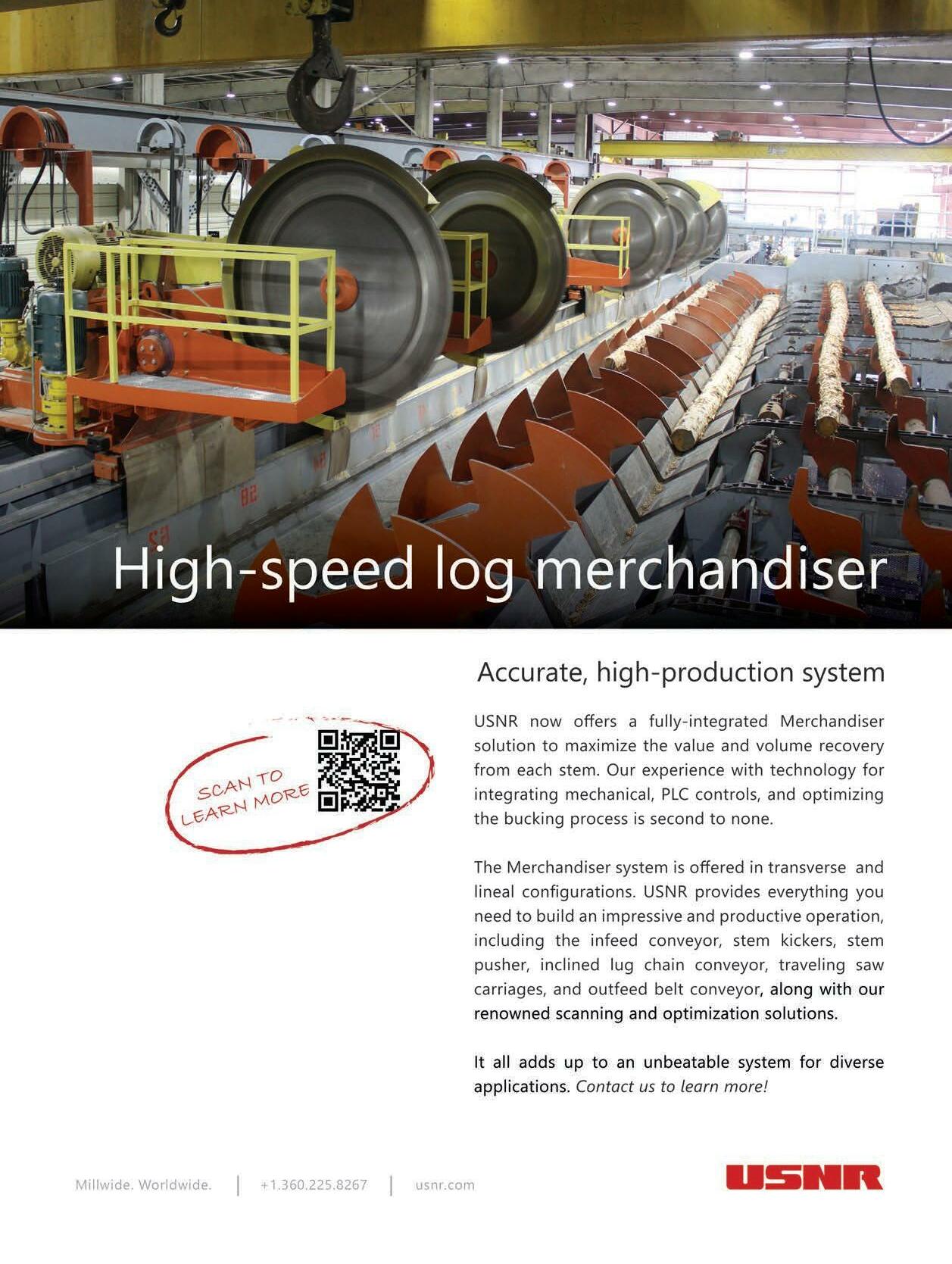

Though both brothers agree, they are Valutec loyalists, having gone out on a limb in being the first to install a Valutec continuous kiln in North America, and ultimately commissioning three more to bring the total to four. “It would be very difficult for us to put something other than a Valutec in because they are so good,” Chris says. “Likewise, if we do more boilers in the future, there’s no reason to go anywhere other than Hurst.” Similarly, the bulk of optimization company-wide has landed on Autolog (now part of Carbotech), while some of the other brands frequenting their sawmills include BID, USNR, Endurance, Gilbert, Piché, Volvo and HewSaw.

CREATING CULTURE

One thing the brothers believe has helped them greatly through the years is that they have both worked for other businesses and other bosses. They have a clear vision for how they want the culture of their company to be, based on their own value systems, and have communicated it clearly and thoroughly to their divisional management. “Culture starts at the top,” Jason believes. “Everyone we have in charge of everything knows what we think and what we believe our culture needs to be: Flexibility in work, go see a kid’s game, be yourselves. We don’t want anyone tied to a job they can’t leave.”

This flexibility also means that the brothers make every effort to be visible to their employees across all the businesses—going back to the cheerleader statement.

Chris agrees and adds that a huge part of the company’s success is because of the communities they live and operate in. Recognizing that, they try to give back as much as possible, through donations to sporting events of both time and money: “Anytime we can put a uniform on a team, it’s the most important thing we can do.” Jason helps coach basketball, Chris coaches soccer (or at least they say they attempt to).

Jason says they both feel the weight of responsibility in knowing that for most of the communities they operate in, they are the single largest private employer. It is important for the community to know they want to make a difference, he explains, and says that a lot of the help they are giving financially is in increments of $500 at a time, and it can truly make a difference as to how many can attend Boy Scout camp, for example. “There’s a lot of ways you can give back if you don’t care about the publicity. Anytime we can help, we try to help.”

The brothers are also visible in industry organizations. Chris is the current Chair of Northeastern Lumber Manufacturers Assn. (NELMA) and Jason has recently finished up a four-year stint as chairman of the U.S. Lumber Coalition, the longstanding group that has taken on the subsidized import of Canadian softwood lumber. Chris believes having representation at industry groups is important for peer interaction. He is quick to point out that it is also important to have a balance—be involved in the industry but also be focused on your own business.

For the Brochu family specifically, the Lumber Coalition has long been a family matter. Their uncle Luke was one of the early leaders in the fight against subsidized Canadian lumber. “We believe in the fight against unfairly subsidized imports, and we will continue to support it,” Jason says.

24 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

WHAT’S NEXT?

Cognizant that the lack of succession planning by other operations has in a sense contributed to their growth, Chris and Jason say their situation is everdeveloping, both still working hard and with children ranging in age from 16 to 1. Jason says, as their father did, he wants to model the same behavior for the next generation, leaving it totally up to them about whether they will work for the company. “We like to describe it as a puzzle,” Jason says. “The

pieces have gotten a little bit bigger, but we are still always moving pieces around. Just because a piece fits for a while, maybe it doesn’t fit at another time and needs to be adjusted in some way.”

The short-term strategy is to maximize the pieces already in play. Both note opportunities for growth on the retail side, while the mill side is always trickier. Predicting is the hard part. Everything hinges on raw material availability and cost, Jason explains, and that will dictate how the mills are han-

dled going forward in terms of production scheduling.

Chris adds, “We don’t need to be the biggest in sawmilling and produce the most in Maine. We need to do it the best in the amount the roundwood allows you to produce in the area.”

In the last five years, the company has committed to more than $100 million in project-based capital expenditures, with the remaking of West Enfield receiving the largest share. “This is the biggest single investment we’ve ever done,” Chris says.

Because of the confidence in their employees, they believe the company will continue to thrive as everyone shares the same vision. The brothers pride themselves on paying good wages, having low turnover and creating a positive culture. Jason acknowledges that it is hard to bring cultures together when acquisitions happen, but they have been fortunate enough to get the right people in the right places to develop the environment they want from the top-down. And having so many different types of businesses has allowed the company flexibility in placing and moving around employees.

All the pieces appear to be in place for a positive run for a while. Chris points to the decades of housing underbuild. He believes interest rates will come down and things will make another turn to high demand. “Any lumber mill in the U.S. will kill a good market by out producing it,” he adds. “That’s the situation we are in now that will find a balance. We just need to produce lumber at the lowest cost possible all the time in order to make sure our mills can continue to run. The pendulum swings so far and so quickly. COVID showed how much lumber we can produce in a short amount of time when lumber’s at a thousand bucks. We can produce a lot when we really, really try.”

As with many ramp up announcements, the decision to invest in West Enfield was not driven by the COVID confused market, but the wood basket. A lot of small fir is growing in abundance, which is different than what the Dover mill needs.

“It’s the right mill in the right wood basket and the right location,” Chris reemphasizes. “Our father preached that forever; you don’t want a dinosaur.”

With the way these two have grown their forest products company over the last 20 years, it is hard to imagine anything the Brochus touch ever going the way of the dinosaur.

TP 26 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

TO MILL WOODS

By David Abbott

FREEBURG, Mo.

Skidmore Lumber Co., which includes sawmill and logging operations, is a family business. Current owners

Howard, 62, and Doug Skidmore, 60, bought out the shares of their oldest brother, Odis, in 1992 and their dad, Oreal Skidmore, in ’94.

Doug and Howard each play an active role at Skidmore Lumber. Doug is the business manager, handling paperwork, finances, sales orders and so on at the mill; on top of that, when they added logging back into the mix a few years ago, he took on managing that side as well. Howard focuses more on day-to-day production operations at the mill, and performs an engineering role applying industry knowledge into mechanical solutions.

Sibling rivalry can sometimes sabotage family businesses, but the Skidmore brothers attest that isn’t a problem for them. “I couldn’t ask for a better partner,” Doug says. Howard concurs: “We get along great.” It’s a rare enough thing; not every family can make it work when they work together, often butting heads and sometimes falling out with one another. The Skidmores are grateful to have no such drama in their working relationship. “That’s what our banker and our CPA tell

us, to be thankful,” Howard acknowledges. “We are blessed,” Doug agrees.

All three Skidmore boys started out cutting cord wood as kids with their dad when Oreal went into logging. The family got into sawmilling almost by accident; someone owed Oreal a lot of money he didn’t have, so he signed over a sawmill he owned as payment for the debt. That was in the late ’70s when they acquired the original Skidmore mill.

It was a few years after that before they moved mill operations to the current location. In 1981, Oreal lost his right leg at the knee in a sawmill accident. “He was working on the guide on a friction feed slip belt with the carriage behind him,”

Doug recalls. “The carriage crept forward and threw him into the saw. So because of that we bought the sawmill here in Freeburg because it was an automatic, so our father could continue working.”

Even after Howard and Doug bought him out in 1994, Oreal continued working at the mill until his retirement in 2000. He lived until 2021, just shy of his 100th birthday.

OPERATIONS

In its current building and setup, the sawmill is about 15 years old. It is in an enclosed building, with everything closed off during the winter. “It’s proba-

30 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Brothers Howard and Doug Skidmore make a good team, working together to manage their family business, a lumber/logging enterprise.

bly one of the cleanest sawmills in the state,” Doug figures.

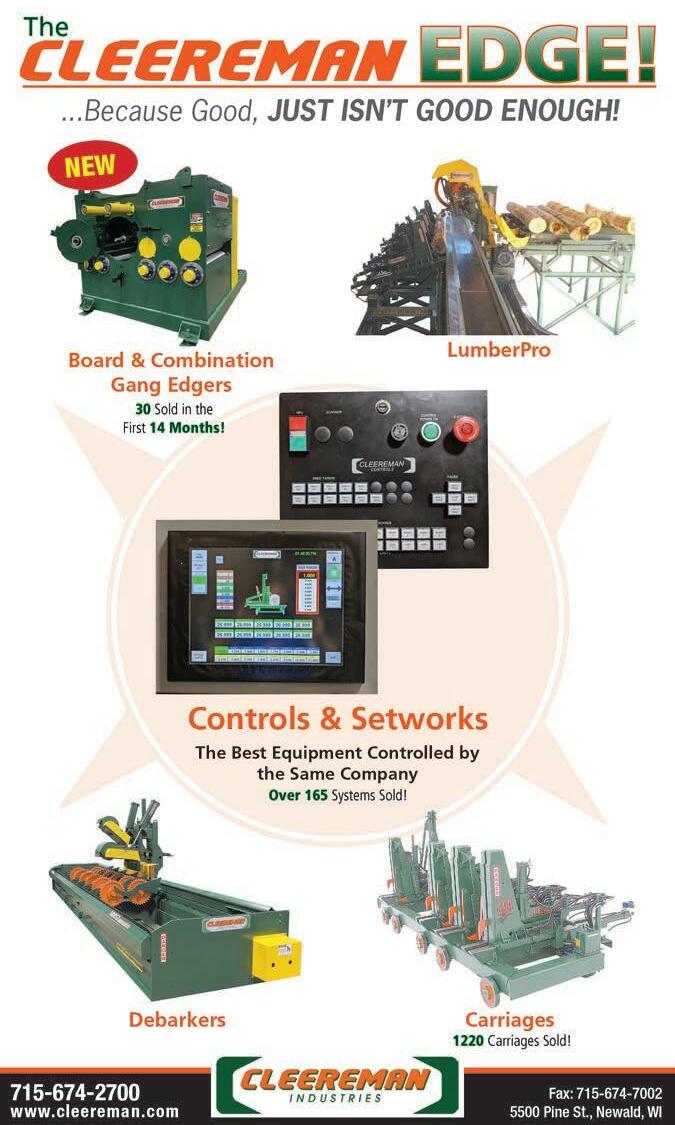

Skidmore Lumber used to have a top saw but removed it and replaced it with a L-M Equipment LS-2000 log splitting system. “It’s a far better way to go than a top saw,” Howard believes, citing safer sharpening. Outside the mill, a Mellott LMR 48 in. debarker preps logs for transport by Deere wheel loader to the infeed deck.

Inside, the mill’s Cleereman 38 linear positioning carriage processes each log with a circle saw. Pieces flow downstream to an edger from American Built Machinery out of West Plains, Mo. “This is edger number one,” Howard says, meaning serial number 1, the first one built by American Built. The Skidmores had a hand in helping design it to their specifications, just as they make adjustments to any machine in their mill. “We tweak everything, change this and that, to get it the way we want it,” Doug says. That applies to the carriage, the edger and log turners, which were also by American Built.

The Skidmore company logging crew sends most of its logs here, besides stave wood. The mill also takes in logs from other area loggers to complete its supply needs.

“We run about three truck loads of lumber a day on four 10-hour days,” Doug says. “We cut about 12 loads of lumber a week, and we save Fridays for maintenance.”

MARKETS

Skidmore Lumber processes rough green material for grade hardwood flooring, railroad ties and blocking, the latter of which goes to customers in Chicago and Texas. Despite having customers so

far away, Skidmore avoids long distance freight; once upon a time, they did haul through contractors, but that changed after 9-11. “When the towers fell, trucking went crazy,” Doug recalls of the aftermath of that dark September day more than 21 years ago. “We lost a ton of money because we had contracts on lumber in Chicago and freight went from $424 to $1,250 a load to get it up there. So after that, when things leveled out, we decided no more.” Since then, they leave it to out-of-state customers to pay freight and handle delivery.

White and red oak are the major species, though the Skidmore Lumber logging crew goes into river bottoms to cut sycamore, soft maple and cottonwood for the company mill. The brothers sell walnut and some veneer logs elsewhere, and a lot of the white oak to

McGinnis Wood Products, a stave mill in Cuba, Mo.

The hardwood market right now could be better, the brothers agree—a LOT better. But there are bright spots. “The red oak market is dropping like a rock,” Doug laments. “The white oak market is dropping in the lumber but not near as much as the red oak. The stave market is fabulous and white oak veneer market is good.”

LOGGING

The Skidmore family started out in logging before they went into sawmilling, but they stepped away from logging for a while and focused exclusively on sawmills for a number of years. “We got plum out of logging,” Doug says.

Cleereman carriage breaks down mostly oaks.

Cleereman carriage breaks down mostly oaks.

TIMBER PROCESSING ■ JANUARY/FEBRUARY 2023 ■ 31

Howard, left, and Doug Skidmore know their way around the timber business.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Mellott debarker processes the big ones.

“We wanted to know how to expand our sawmill business without needing to buy more logs,” the younger Skidmore explains. “The answer to that question was to get back into logging.”

If they were going to log again, they determined they were going to do it as safely as possible, and that

meant modern mechanization, something that still isn’t all that common in the woods in their area of Missouri. “We are not against the idea of cutting trees the old fashioned way,” Howard stresses. “That just isn’t what we wanted to do. Around here it is still mostly a man on the ground felling with a chain saw; that is still very common here, the most common by far. There are getting to be more machines in the woods though; 10 years ago there weren’t very many.”

In lieu of chain saws, the Skidmore crew fells with a Timber Pro TL745D tracked feller-buncher with a Quadco 2900 intermittent sawhead. A pair of John Deere 748L-II rubber tired skidders pull logs to the landing, where a Barko 595B knuckleboom loader paired with CSI pull-through delimber and ground saw sorts and merchandizes. Company log trucks, Western Stars and Internationals, also have Rotobec and Barko self-loaders mounted on the back and pull pup trailers.

Notably, a third skidder, this one a Tigercat 610E, is mounted on a set of tracks from G&R Manufactured Solutions, instead of riding on rubber tires. The brothers saw a video of these tracks online and got in touch with G&R sales manager Robert Reeves. The tracks have enabled the logging crew to pull wood out in both wet and steep terrain where tires would bog down or lose traction.

“They have so much flotation,” Doug says. “You don’t realize how low the ground pressure is because you have eight feet tracks that are two feet wide to spread all that weight out.” The G7R tracks have kept the crew working when conditions would likely have otherwise halted production, especially since many of the hardwood tracts this crew tackles for the mill are in difficult to access areas. In fact, Doug estimates that those tracks on that skidder have probably pulled about 75% of the wood for the sawmill for the last two years.

Skidmore’s operations aim to do more than just profit from the woods; they strive to act as responsible stewards of timberland. For instance, Doug points out, they take pains with skid steer and dozer to build logging roads that are clean and passable. “We focus on land management as well as logging,” he says.

The family is also active in the industry. Doug is a former board member of Missouri Forest Products Assn. and a current board member of the Missouri Wood Industry Trust, through which Skidmore Lumber obtains workers’ comp insurance.

TP 32 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

American Built Machinery edger is truly number one.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ADVANCED PNEUMATIC CONTROL

Reduces downtime, air use and maintenance for Spruce Products.

By Francois Tremblay and Alexandre Girard

In the early days of timber harvesting, log jams were a common site as felled trees floated downriver on the way to the sawmill. In today’s modern sawmills, however, log jams equate to equipment downtime, lost productivity, reduced profits and even potential safety risks. For one Canadian lumber company, upgrading the pneumatics on its

PRIMARY LINE

In the typical primary cutting process, debarked logs ranging from 10 to 16 ft. long are fed continuously on a narrow chain conveyor past two cutting heads to square off the sides. As each log goes down the line, a total of nine overhead press roll arms with guidewheels pivot down automatically in sequence on top of the log, keeping it positioned on the chain as it passes through the machine. As the

toba winters are notoriously cold, so the mill must work with hard-to-handle frozen and slippery logs. In addition, log shapes can be curved or crooked, so the movement follows a non-linear path, making it harder to control. Finally, the force of the press rolls dropping on the logs as they pass underneath must be firm but not too strong, as too much pressure will kick the logs off the chain.

Hydraulic press roll actuation is fast and powerful but can be very stiff and unforgiving, as hydraulic oil is not compressible. Hydraulic press rolls can also apply too much force, kicking the log off the conveyor chain. Consequently, the inelastic qualities of a hydraulic actuator combined with variations in the log’s diameter or shape could cause a jam, requiring a shutdown to remove the log manually and get the system back online.

Sawquip sawline vertical press roll actuators helped make log jams a thing of the past while increasing performance, lowering maintenance and saving on air consumption.

Headquartered in Manitoba, Spruce Products Ltd. makes premium lumber and wood products for the construction and integrated wood products industries. The company has supplied products for Canadian and international markets since 1942. As part of its success, Spruce Products believes in using the latest technology available to use every aspect of a log in its product lines. That’s why the company decided to upgrade its pneumatic motion control with advanced components and technology from Emerson.

log moves through, the press roll arms automatically retract in sequence to get ready for the next log.

In many sawmills, these press arms are typically actuated using hydraulic cylinders, pneumatic cylinders or a combination of both mounted back-to-back, where the hydraulic cylinder provides the positioning, and the pneumatic cylinder provides cushioning (a very cost-prohibitive and maintenance-heavy setup).

PRESS ROLL CONTROL

The pivoting press arms are meant to keep logs from shifting on the chain during the cutting process. However, several issues can affect productivity. First, Mani-

Pneumatic actuation is a simple, inexpensive and very efficient solution for press roll control. However, traditional pneumatic actuators typically could only fully extend or fully retract, with stroke positioning dependent on the air pressure on either side of the piston. A full stroke extension and retraction requires higher air flow. The accuracy of the pneumatic positioning can also be affected by several factors, such as air temperature, amount of air pressure and the load on the actuator, which will change depending on the position of the press roll.

ADVANCED SYSTEM

In this case, Spruce Products was using an existing pneumatic system on a Sawquip unit, which handles logs with diameters under 14 in. About 80% of Spruce Products’ lumber manufacturing takes place on the Sawquip line.

Seeking to improve efficiency and reduce downtime, Spruce Products brought in Francois Tremblay, an expert in sawmill automation, who partnered with Emerson

34 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Emerson upgraded the vertical press roll actuators on a Sawquip line at Spruce Products Ltd.

to upgrade the pneumatics by adding highperformance proportional valves, pneumatic-specific control algorithms and a fieldbus-compatible manifold.

Working with the machine’s existing NFPA pneumatic cylinders, PLC and scanning laser, Tremblay recommended Emerson’s AVENTICS Sentronic proportional pneumatic control valve, combined with an AVENTICS G3 electronic fieldbus manifold system.

The AVENTICS Sentronic proportional valve is a 3-way, direct-operated digital control valve. With fast response times and high sensitivity, it was an ideal solution for this application, which required exact and responsive pressure control based on feedback for position and force. Using motion control algorithms specific to pneumatic positioning, valve control loop parameters are easily configured and optimized for specific customer requirements through AVENTICS Data Acquisition Software (DaS) and a PC connection.

For connectivity and control, the AVENTICS G3 electronic fieldbus valve system replaces conventional hardwired solutions. The platform integrates communication interfaces to the pneumatic valve system with input/output (I/O) capabilities. It provides easy access for connections and is simple to assemble, install, commission and maintain. Its functionality allows PLCs to turn valves on and off more efficiently and channel I/O data from sensors such as the scanning laser, other relays, individual valves and other I/O devices via various industrial networks. In addition, the G3 valve manifold contains a graphical display used for configuration, commissioning and diagnostics.

Although the pneumatics upgrade

added many sophisticated capabilities, switching from traditional control to the new system was straightforward and quick. The changeover was accomplished during coffee breaks and at lunchtime, and the “plumbing” setup only took a few minutes per cylinder.

IMPROVEMENTS

By updating the press rolls with advanced pneumatic motion control, the process softened the high-velocity impact of the pivoting arms by using only the amount of pressure needed to hold the logs in place on the chain vs. the constant 100 psi required with the old system. This translated to a significant reduction in air consumption.

As a log approaches the cutting area, the scanning laser sends an input signal to the G3. Based on that input, the system calculates the distance between the press roll arm and the stroke of the actuator. Next, the G3 sends a signal to the valve, which converts the electric signal to the pneumatic pressure required to move the actuator piston as the press roll holds the log in place on the chain.

Regardless of the log shape or velocity, the saw line can now use feedback to preposition the press rolls at the right height and subsequently apply the right downward force. As a result, the pressure exerted on the logs is more accurate, eliminating the frequent jams due to the press rolls dropping too soon or too late. If a press roll drops too low, it will gently bounce to its correct position once the log hits it, thanks to the system’s feedback and proportional pressure on the actuator.

In addition, consider the weather extremes at the Spruce Products facility, from frigid winters to hot and humid summers. Feedback to the PLC enables the

variables that can influence air compressibility in the pneumatic system. Responding to signals from the PLC, combined with pneumatic-specific algorithms developed by Emerson, the Sentronic valve can automatically provide the correct pressure for each press roll and log.

BENEFITS

Within the cylinder, the variable positioning capability alleviates the piston from being fully extended/fully retracted. As a result, the pneumatic system uses significantly less compressed air, reducing compressor operating time. In addition, reducing the stroke length minimizes the number of times the piston makes fullpressure contact with the head of the cylinder. This prolongs the life of the cushion and the U-Cup seal on the cylinder and lowers the maintenance and replacement requirements.

As an additional benefit, lights on the G3 indicate if the device is working correctly during operation. It can also provide historical data that Spruce Products technicians can use to refine system efficiency and further reduce compressed air usage.

Thanks to the recent development of high-performance pneumatic proportional control valves and manifolds supported by motion control algorithms specific to pneumatic positioning, PCI and Emerson overcame the challenges of controlling Spruce Products’ pneumatic actuators. Their approach to the saw line makes press roll operation more intelligent and more responsive for handling logs, saving on air consumption and maintenance while improving uptime.

Francois Tremblay is a technical expert in the sawmill industry and Alexandre Girard is a technical specialist for pneumatics and motion control at Emerson (www.emerson.com).

T P

Emerson’s AVENTICS Sentronic pneumatic pressure control valve was the right solution.

TIMBER PROCESSING ■ JANUARY/FEBRUARY 2023 ■ 35 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

AVENTICS Series G3 electronic fieldbus valve system integrates communication interfaces to the pneumatic valve system with input/output (I/O) capabilities.

ATLARGE

Snider Industries Names Fleming Plant Manager

Snider Industries, LLC, Marshall, Texas, announced that Wayne Fleming has become plant manager, bringing more than 30 years of forest products industry experience, including domestic and international experience as an automation and controls specialist.

As plant manager, Fleming’s official responsibilities include management of the plant operations covering lumber production, and operations of the log yard, planer mill, and power plant; as well as maintenance, lumber shipping and shavings plant.

Fleming succeeds Jimmy Brewer, who was plant manager for 23 years. Brewer remains firmly involved with the strategic planning for the operations of the company.

“We expect Snider Industries to benefit from the exceptional managerial and technical expertise that Wayne brings to our company,” comments Jill Snider Brewer, third-generation owner. “He has consulted with Snider on various projects and installations going back over 20 years and has an excellent understanding of our operations. To boot, he has been involved in many projects across the spectrum of wood fiber operations and production and we are fortunate to have him.”

Fleming assisted various industries in increasing productivity and reducing downtime through facility modernization and control upgrades. He began his career as an electrician in a sawmill in south Alabama. He was managing partner of an automation and controls engineering business for more than 25 years, and served as managing partner in several other businesses including mechanical design and machine fabrication. Throughout his career, he partnered with customers to work through some of the most sophisticated projects in sawmills, plywood/OSB, and pellet plant facilities throughout the U.S.

SFPA Announces Communications Mgr.

Christian Moises has joined Southern Forest Products Assn. as communications manager. He will lead SFPA’s efforts to tell the association’s story, including promoting members, raising further awareness for southern pine, and establishing the association as a leading industry resource. That includes, but is not limited

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ATLARGE

to, traditional and digital marketing and communications, member services and support, and becoming a go-to resource for all things related to the SFPA’s Forest Products Machinery & Equipment Expo.

Moises spent the past eight years in professional services marketing, including as digital marketing advisor with Inovautus Consulting, where he worked with accounting firms of all sizes from coast to coast; as practice growth advisor with Ericksen Krentel CPAs and Consultants in New Orleans, where he was a one-man shop doing all things marketing, communications and business development; and marketing/communications for an Am Law 200 regional law firm.

He spent the first 10 years of his career in journalism, serving as an editor with New Orleans CityBusiness, before moving into death care marketing and communications, and health care public relations (including internal communications) for a multi-facility community hospital network. His experience in myriad industries, in addition to his close relationship with C-suite decision-makers during his time at CityBusiness, gives him an inside perspective to effectively connect with a broader audience while helping SFPA and its members grow and achieve success.

Moises earned his bachelor’s degree in journalism from Louisiana Tech University and his Accreditation in Public Relations from the Public Relations Society of America in 2015.

Oregon Dishes Out Timber Revenues

Out of almost $100 million in overall timber sale revenues in 2022, the state of Oregon has returned $61 million to the counties that have state forest acreage. State law requires two-thirds of forest revenues to be distributed to the Forest Trust Land Counties, with the remainder earmarked for state forestry operations.

Oregon operates five state forests that cover 729,000 acres of timberland. Overall, 12 counties shared in the revenues, led by $19.1 million to Clatsop County which contains the 147,000 acre Clatsop State Forest. The 357,000 acre Tillamook State Forest is Oregon’s top producer, generating $30 million shared by three counties.

Arkansas Group Gains USDA Bottomlands Grant

Dr. Homer Wilkes, Under Secretary for Natural Resources and Environment

Dr. Homer Wilkes, Under Secretary for Natural Resources and Environment

38 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

at the U.S. Dept. of Agriculture (USDA), met with faculty from the University of Arkansas at Monticello (UAM) and the Arkansas Forest Resources Center (AFRC) of the University of Arkansas System Div. of Agriculture housed at UAM to award them a grant for $3.7 million. The meeting took place at Five Oaks Ag Research and Education Center in Humphrey, Ark., where part of the work for the project will be conducted.

The grant provides funding for USDA Partnerships for Climate-Smart Commodities projects, which are aimed at supporting sustainability in agriculture. AFRC at UAM is the lead on the project and will partner with the University of Arkansas at Pine Bluff (UAPB) and Texas A&M University (TAMU), as well as with recruited landowners. Dr. Nana Tian, assistant professor of natural resources economics and policy at UAM, developed the proposal for the grant and will serve as the project director.

The project will support small and underserved landowners in the river-influenced forest regions of Arkansas to develop and harness climate-smart commodities from restoration of the region’s hardwood forests. Bottomland hardwood forests have shown high potential for producing climate-smart commodities including carbon sequestration and storage, wood products, wildlife and other ecosystem services. Despite their importance, 70% of bottomland hardwood forest areas have been lost in the past 100 years.

The project aims to plant 500 to 600

acres of oak forests in the agriculturally dominant floodplain of the Red River Valley of southwestern Arkansas, the Ouachita River Valley of southcentral Arkansas and the Bayou Meto Watershed in eastern Arkansas. The project will also quantify and demonstrate the ecological and economic benefits of bottomland hardwood forest restoration on working lands and help landowners manage the plantations and market climate-smart commodities.

Timber Companies Will Combat CWD

Seven timber companies and four conservation organizations are joining together to fight the spread of chronic wasting disease (CWD) among deer, elk and other species of the deer family (known as “cervids”). The new CWD coalition will promote practices that help discover, manage, and mitigate the negative impacts of CWD. The Coalition includes the Forest Investment Associates, Molpus Woodlands Group, PotlatchDeltic, Rayonier, Resource Management Service, The Westervelt Company, Weyerhaeuser, Alabama Wildlife Federation, Boone and Crockett Club, Georgia Wildlife Federation and National Deer Association. This footprint spans to well over 20 million acres across the nation.

“We are pleased to join with so many other private landowners and other stakeholders in addressing this critical problem,” comments Brian Luoma, The Westervelt Company President and CEO. “Fed-

eral and state agencies, the U.S. Congress, state legislatures, researchers and sportsmen conservationists are all doing their part in educating the public about this critical issue. We are fully supportive of all efforts to prevent further spread and are grateful to everyone who is participating in the coalition, including our own employees, who have taken the lead in combating CWD.”

The group has developed a list of voluntary best management practices to help monitor, manage and prevent the spread of CWD. The coalition will also support communication, research, policy and public health.

Chronic wasting disease is transmitted animal-to-animal and from contact with infectious material. The disease is contagious and can be transmitted freely within and among cervid populations. No treatments or vaccines are currently available, and CWD is 100% fatal to cervids.

Long-Running SAF Project Has Life

LanzaJet, a sustainable fuels technology company and producer, joined government officials, industry leaders, and investors in mid-December to celebrate a major construction milestone at the LanzaJet Freedom Pines Fuels facility in Soperton, Ga.

LanzaJet Freedom Pines Fuels is building an ethanol-based alcohol-to-jet sustainable aviation fuel (SAF) production plant. Construction will be completed in 2023, according to the company. The plant

ATLARGE 40 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ATLARGE

will produce 10 million gallons of SAF and renewable diesel per year from ethanol, using a range of sustainable, low carbon intensity ethanol, including from waste-based feedstocks. LanzaJet Freedom Pines Fuels reports it will approximately double the amount of current SAF production in the United States.

LanzaJet was joined at the event by its shareholders International Airlines Group (IAG), LanzaTech, Mitsui & Co, Shell, and Suncor Energy, investors including Microsoft Climate Innovation Fund, Breakthrough Energy, and All Nippon Airways (ANA), and government representatives from the Federal Aviation Administration (FAA), the U.S. Department of Energy (DOE), and the U.S. Dept. of Agriculture (USDA) as well as representatives from the state of Georgia and local and county officials.

In 2012 LanzaTech purchased the bankrupt Range Fuels facility in Soperton at auction for $5.1 million. Range built the biomass gasification plant with the intention of making ethanol from wood chips, but the firm was unable to produce the biofuel.

➤

42 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

44

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

PotlatchDeltic Sets GHG Emissions Targets

PotlatchDeltic Corp. has established a 2030 greenhouse gas (GHG) emissions reduction target for Scope 1 and Scope 2 emissions of 42% and a Scope 3 value chain GHG emissions reduction target of 25% from a 2021 baseline. The targets are in accordance with the non-FLAG Science Based Targets Initiative (SBTi) to keep global temperature increases to less than 1.5°C compared to pre-industrial levels and a

commitment letter will be submitted to SBTi for validation in 2023.

Key components of the initiative include increased utilization of wood residuals, electrification of mobile equipment, energy efficiency efforts, the purchase of green power from electricity suppliers, and working with the company’s value chain. The company also committed to a goal to achieve net-zero GHG emissions by 2050, including the development of non-FLAG SBTi 2050 GHG reduction targets.

PotlatchDeltic owns nearly 2.2 million acres of timberlands in Alabama, Arkansas, Georgia, Idaho, Louisiana, Mississippi and South Carolina. The company also operates six sawmills, an industrial-grade plywood mill, a residential and commercial real estate development business and a rural timberland sales program.

Biochar Plant Chips Feedstock Will Come From Nearby Sawmill

Standard Biocarbon Corp. is building a biochar plant in Enfield, Maine, on a two-acre parcel purchased from Pleasant River Lumber, whose sawmill will provide chips for the biochar operation.

Foundations for the prefabricated building were raised in early January and a shipment of machinery arrived just before Christmas. The company intends to move the machines into the building in February and start production in the spring.

The plant will produce 100 tons of biochar monthly initially, selling to local farms for agriculture use. Also, the waste heat steam from the biochar plant can be supplied back to Pleasant River Lumber for lumber drying.

PYREG of Germany manufactured the machinery for the plant, composed of the reactor chamber, furnace and filter.

Standard Biocarbon has received grants from the U.S. Dept. of Agriculture and Maine Technology Institute, in addition to raising equity funding.

PYREG has formed a subsidiary in Portland, Maine.

ATLARGE 44 ■ JANUARY/FEBRUARY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

SAWMILL CAMERA HIT BY A LOG

When a camera or any other piece of electronic equipment gets hit with something as heavy as a log, the kneejerk reflex is to start looking for a replacement. Sawmills are harsh environments—these things happen. Understandably, the first priority of a sawmill manager is to protect the team members.

Electronic equipment for sawmills is designed to endure dust, wood splinters, vibration and more. Still, when you get a message that says: “One of the cameras you installed for me got hit by a log,” your interest is piqued.

Even though Opticom performs hundreds of tests on its products before releasing them, they’re always interested in real-life extreme situations. And this one checked every box! Opticom knew it was going to be an excellent case study for its R&D team. But it also turned out to be a great case study for its marketing team.

A video camera that can withstand log debarker vibration is quite a technical feat—but one that can withstand an actual log hitting it? This is something that you need to see for yourself: https://www.youtube.com/watch?v=f4U

AQxxw64U

Briefly put, one of Opticom’s sawmill customers in Mississippi sent in a photo you can see in the video link above. The camera got hit by a log and survived. It still works flawlessly, and the client only needed to replace the bracket around it. This is what happens when you choose the right type of camera for your sawmill application.

This was Opticom’s CC04 camera, one of the top choices for sawmill

operators due to its rugged characteristics and compatibility with Opticom’s vibration-resistant mount. When you invest in the right sawmill video equipment, you can stop replacing sawmill cameras every few months. Choosing rugged cameras specifically designed for sawmills means:

—Fewer surprise expenses (like replacing the cameras often)

—Zero gaps in your safety and security procedures

—Better protection for your employees

—Consistent image quality

If you know you’re going to replace the cameras every few months, why bother investing in top-quality ones? However, the image quality you get from your cameras is reflected in your operations monitoring. Poor image quality can mean you’re getting less

value from your monitoring system.

Yes, buying rugged, industrial cameras means that your initial investment will be larger than buying off-the-shelf products. But in a camera that’s specifically designed for a sawmill, everything’s built to last, from the lenses to the brackets and mounts.

Opticom cameras will work through temperature changes, high levels of vibration, and sometimes, yes, they work even after they’ve been hit by a log.

Rugged cameras aren’t all built the same. More importantly, if you want to make sure that your investment is future-proof, you need to pay extra attention to whom you’re buying the camera from. There are different types of cameras built for different types of industrial applications, and Opticom prides istelf in being a partner, not just a vendor to help you find the right solutions.

Opticom has lasted in this business for four decades because it never toyed with clients’ safety, security and budgets. If Opticom sells a camera for a sawmill, the camera is going to last there. From sawmills to a tunnel boring machine and everything in between, Opticom clients have tested the durability of its cameras in the harshest conditions all over the world.

If you want to know more about how Opticom helps its clients choose the best video monitoring systems for their specific applications, visit opticomtech.com. TP

Article and image supplied by Opticom Technologies.

Peak North America Acquires Endurance Equipment

Peak North America is acquiring Endurance Equipment of Irvington, Ala., known for it log cranes, drum debarkers and log merchandising systems, and plans to invest $24 million at Irvington, near Mobile, to provide equipment and services to various production segments in the wood products industry.