Five trends influencing pet nutrition, health & wellness - Soothing your puppy -teething and dental - Protect Against Feed Processor Recalls - Mainstreaming alternative protein diets February 2023 www.internationalpetfood.com www.perendale.com Download your online version:

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect pet food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.com

Editorial team

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Community Manager

Levana Hall levanah@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Design PetFood Magazine

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706

tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

February 2023 10 Industry News COLUMNS 6 Roger Gilbert 7 Joseph P Kearns 8 Professor Simon Davies

International Petfood - Volume 5 - Issue 2 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com

2754-4680 www.internationalpetfood.com 28 Training 29 Troubleshooting 30 Production focus 34 Industry Events 39 The Market Place 40 The Interview 42 Industry Faces 9 The PetFood Journal REGULAR ITEMS 32 Industry Profiles

ISSN

FEATURES

14 Five trends influencing pet nutrition, health & wellness

18 Soothing your puppy -teething and dental

20 Protect Against Feed Processor Recalls

24 Mainstreaming alternative protein diets

Determining the ingredients and additives that should be included in a petfood formulation is not the sole domain of the petfood nutritionist - it is influenced by the views of pet owners who study the packaging and labelling of products and who are expressing their views through their connections with retailers. Their in-store selection of feeds and comments can make a difference.

Roger Gilbert Publisher – International Petfood

Obviously, petfood producers are continually attempting to produce products that allow them to show distinction within the market sector they serve while addressing basic nutritional needs based on the species and life cycle of the animal and then to include the ‘requests’ being expressed by the market.

There are many examples of where simple requests develop into industry trends.

For example, a recent survey of pet owners in North America, France, and the UK found that just over half of buying decisions (55 percent) were based on what is good for the pet’s gut and its digestion. This is likely to have a major impact on the formulation of feeds and how they are promoted over time.

This finding was just one of three main benefits that owners felt petfood manufacturers should focus on.

The other two factors identified were: boosting a pet’s immune system, strengthening its joints, and supporting cardiovascular health.

Meanwhile aspects such as weight control and improving the gloss of skin and coats were shown to be less important today when selecting foods than they had been in the past.

These findings cannot be overlooked when formulating a diet that pet owners feel their pets benefit from.

However, issues that Professor Davies and others in our magazine address, concern animal health and disease control in all their forms which must also be addressed through innovative and targeted formulations.

This is why we at International Petfood focus almost entirely on the production process and how the final product produced should meet a pet’s physical, dietary, and even its mental needs.

Another aspect that that may well determine whether a feed manufacturer can achieve the goals expected by today’s pet owner, is their ability to produce and bring to market shortrun production runs that may require additional or alternative processing steps. This often requires a manufacturer to invest in equipment that might not be too expensive to use in short-run product production.

Installing strategic machinery that can be re-purposed as

Our last edition

Did you miss our January 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https:// magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

The Interview

With Dr Martin Kropp, President Animal Nutrition EMEA, ADM Martin Kropp has an international career spanning 25+ years within the agricultural sector, including several senior executive and board member roles. He has extensive

customer requests are filtered back to producers is resulting in the development of flexible machines that allow changes even after their initial installation.

Petfood has long ceased to be merely a source of food for pets, but today reflects the lifestyle of their owners. Pets are family members, and their owners often express the same demands on behalf of their pet food as they have.

New issues such as sustainability or organic products, for example, are playing an increasingly important role in petfood selection. And as such these resulting new products are initially produced in smaller production runs.

The global volume for the petfood industry has steadily increase since 2015 and is expected to show a volume growth of 5.3 percent in 2023.

In 2018 there were 471 million dogs and 373 million cats kept as pets worldwide. This huge and ever-growing pet population is also reflected in the increasing turnover of petfood producers.

In this edition

We have a wide array of topics to pique your interest this February. On Page 14 you’ll find ADM highlighting trends that influence pet nutrition, health & wellness, of which include the consumers developing understanding of the role of the gut microbiome, premiumisation, and the increasingly more environmentally conscious consumer favouring responsibly sourced ingredients. From our editorial team, Shannon Parsons sheds light on the effects on puppies’ diets during teething on Page 18.

Finally, in the spirit of finding sustainable solutions, Veolia provides us with a feature on Page 24, regarding alternative insect-based diets, what nutritional and functional benefits they offer, and how it contributes to the circular model of bioconversion.

As you well know our International Petfood magazine is published monthly in both English and Spanish! We are offering free annual subscriptions should you wish to receive either our digital edition or our printed edition of our magazine mailed to your address. You can also manage your profile with us and use your username/password to login to our app and/or our digital library.

The registration page can be reached through our library at either: English - https://flickread.com/edition/Petfood

Spanish - https://flickread.com/edition/petfood_espanol

Enjoy this issue and I look forward to keeping you in informed about all things petfood related throughout 2023.

experience within oilseeds and animal nutrition business with strong interest in agricultural developments and emerging markets. Dr Kropp received his Ph.D. in agricultural economics, agricultural mechanization and software development from Justus Liebig University, Giessen in Germany.

To read more, go to: https://issuu.com/international_aquafeed/docs/ipf2301_web/40

THE PUBLISHER

6 | February 2023 - International Petfood

Aquaria feed for fish is in my mind considered a petfood. They must have a complete diet for long and healthy life. The process differences between aquaria and commercial aquatic feed for farmed fish is negligible. However, there are differences, mechanically speaking grinding of the raw materials, the extrusion dying, and the dryer configuration to name a few. Other than extrusion, drum dryers are also used to make steam flaked aquarium feeds. Extruded aquarium feeds can have a very small diameter, down in the 0.5 mm range. The future for aquarium feeds over the next 10 years or so looks good with a compounded annual growth rate, CAGR, predicted to be 5.5 percent. It is expected these kinds of feeds would be batch made in a controlled environment on smaller production equipment designed for micro feed production if extruded. Making them is the easier part, packaging small amounts in numerous various designed containers is in my opinion much more complex.

Joseph P Kearns Editor, International Petfood Magazine

Additional topics for Feb include freeze dried petfoods which are growing at a CAGR of 7.7 percent in the next 7 to 8 years. Driven by the desire to have shelf stable products and healthy snacks. This segment is predicted to close in on 30 billion in sales over the next decade. As pets continue to becoming available family members, we will see a move to more humanized petfoods become available.

The ever-increasing complexity in petfood production of all types will also see a continued growth in the control segment of the business. Regulations as well as product complexity and the stated nutritional and product characteristics on every bag requires exacting control. Throw in the benefits of efficiency, reduced losses, increase in productivity as well as improvements in the controls make this area one of the fastest growing activities in petfood production. Having started in the era where you were lucky to see an indicator of valve position on some valves and very lucky to see flow meters on the water and liquid inputs to today’s standards was most interesting to be involved. Steam was definitely a guess and the operators did have a major input in product quality. This historic period did generate the data and designs to predict and model extrusion as well as other production methods so the hardware became more predictable and long lasting. Example, if dryers improved to 0.5 percent +/- moisture variation then what use is a measuring device that is good to 1.0 percent? The industry did catch up and flowmeters liquid and dry, measuring sensors for temperature and pressures, pump accuracy, motor controls and many others have had big impacts on the petfood industry.

I do not recall lacking extruder head temperature controls and in historic photos only the earliest models did not have jacketed extruder heads for steam or water flow. It’s standard on any large capacity extruder

today with either liquid or electrical designs. My perspective over time is these jackets allowed greatly for getting into production by heating the heads to temperature, and it worked. Once running as expected the heads mostly went to cooling and specifically towards the discharge end of the barrel. Steam jackets back in the day of extruder stoppage or blockage allowed you to heat them up and possibly get them going without disassembly. Typically, if the heads are too hot the extruded might surge and produce non-uniform products. You might see a higher motor load, sticky clumping of product, as well as variation in density. Today computer control has all of these specifications entered for each product and can be monitored quite easily. In addition to temperature control, pressure reading along the barrel can give an indication of barrel fill in one or multiple areas. This allows for understanding where the cook is occurring and where liquid injections can be made. Ten bar steam pressure is the norm for having the ability to inject into the extruder barrel in the needed zones. Water normally added in the back of the barrel is lower as in the 4-bar range. Dryers as well as coolers have also greatly advanced with sensor capabilities to measure the air temperature, flow rate, dew point both wet and dry allowing for computer control for efficiency and product quality. Systems are available to collect a sample off the extruder for density and moisture content, feed a signal back to the control system to adjust density if needed as well as adjust dryer knowing the moisture into the dryer while running. Similar systems post dryer can do the same with the idea of adjusting the dryer based on discharge moisture and verify density before coating.

Long good pet treats of the extruded variety require a die where the flow through each orifice is adjustable so the strips travel downstream at the same rate. Normally these type of treats are high in meat and die cutting directly is not effective. Cutting at the end of a take away belt with a rotary cutter allows for product set up before cutting. Gentle conveying and handling are needed when using a dryer and/or cooler. A cooler, the moveable try style, only if it is a semi-moist style product.

Reader input asked about the Ukraine and Russia petfood industry. A bit of research has shown that Western major producers have slowed and even stopped production and shipments into Russia. This has placed a shortage on petfoods with specialty feeds hardest hit. The Russian market is changing, with less import petfoods pet owners are buying larger volumes of locally produced products resulting in increases in Russian local production. Ukraine is receiving aid from multiple sources internationally for pet needs with donations. If interested, google pet food donations for Ukraine and multiple sites will appear. These situations will remain until the crisis is resolved.

THE EDITOR

International Petfood - February 2023 | 7

Professor Simon Davies Nutrition Editor, International Petfood

Vitamin B6 Pyridoxine as a vital micronutrient for dogs

Vitamins are essential micronutrients in the diets of humans as well as all animals. The B-vitamins may be considered as a group of water soluble compounds mostly unrelated but acting in concert with each other on the basis of cellular metabolism. They work in tandem within a cascade of regulatory processes controlling energy production and the synthesis and degradation of protein during turn-over and bioconversion into other important metabolites. Dogs and cats are no exception and it is imperative that specific B-complex vitamins are present at optimal levels in the diet.

Vitamin B6, also known as pyridoxine, is an essential nutrient that plays a critical role in canine nutrition. It is required for the proper functioning of enzymes involved in the metabolism of proteins, carbohydrates, and fats, as well as the synthesis of neurotransmitters and hormones. Vitamin B6 is also involved in immune function, skin and coat health, and the production of red blood cells vital for the transport of oxygen to tissues.

Deficiencies of vitamin B6 can lead to many health problems in dogs, including anaemia, skin irritation and inflammation, and impaired immune function.

Symptoms of a vitamin B6 deficiency may include weakness, lethargy, weight loss, and anorexia. Severe deficiencies can lead to neurological problems, such as seizures, tremors, and poor gait.

Vitamin B6 can be found in a variety of foods, such as fish and meat as well as in eggs, and specific plant sources. It is also available as a supplement in the form of tablets or injections if a dog is on a critical threshold for this vitamin such as under a stress or clinical inadequate status such as in trauma. The recommended daily intake of vitamin B6 for dogs varies depending on their size and age, but a general guideline is to provide at least 0.2-1.0 mg per Kg of body weight per day.

It is important to note that while vitamin B6 is

essential for canine health, it is also possible for dogs to consume too much of it. Overdose symptoms may include nausea, vomiting, and loss of appetite. It is important to speak with a veterinarian before starting any new supplement regimen for your dog.

In addition to dietary sources, dogs can also de novo synthesize vitamin B6 from tryptophan, an amino acid found in protein-rich foods. However, it is still important for dogs to consume a diet that includes an adequate amount of vitamin B6, as the synthesis of this nutrient may not be sufficient to meet their needs. It is worth noting that certain medical conditions and medications may alter a dog’s requirement for vitamin B6. For example, dogs with kidney disease may have an increased need for this nutrient, as the kidneys play a role in its metabolism. On the other hand, certain medications, such as anticonvulsants and corticosteroids, may interfere with the metabolism of vitamin B6 and lead to a deficiency. In these cases, it is important to collaborate with a veterinarian to determine the appropriate dosage and frequency of supplementation. The young dog of course will have very different needs to older animals and this must be taken account of in feed formulations by the industry and owners alike. A very active dog using much energy will require a higher level than less active animals. There will be variation between the breeds and vitamin requirement is deemed also to be a function of body mass and what we may call ‘metabolic weight’.

In conclusion, vitamin B6 is an essential nutrient that plays a critical role in canine nutrition and welfare. It is important for the proper functioning of systemic metabolism. It can be found in a variety of foods and is also available as a supplement. High quality dog foods will be balanced and vitamin supplement premixes usually guarantee nutritional needs are satisfactory.

8 | February 2023 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion. The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief. These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

International Petfood - February 2023 | 9

UK to tackle Salmonella risks in raw petfood

The UK Food Safety Research Network, hosted by Quadram Institute, has announced that six food safety projects will receive between UK£30,000 to UK£62,000 (roughly $36,544 USD to $73,089 USD) in funds. One of the projects aims to improve food safety of raw petfood formulas.

All six projects involve academic researchers collaborating with commercial companies and/or government agencies within the human and petfood sectors to establish solutions to common food safety issues.

The raw petfood project involves using bacteriophages to help decrease Salmonella contamination in raw petfood products. According to the Quadram Institute, raw petfoods are growing in popularity throughout the United Kingdom as pet parents seek non-processed diets to improve their pets’ health. However, raw petfoods can carry higher risk of contamination compared to their cooked counterparts.

INTERNATIONAL

PETFOOD

International Petfood comes to you either in print or digitally.

Whichever way you want to receive, please sign up on our Flickread for your personal copy which will give you access, from your desktop, to our back-issue library.

https://flickread.com/edition/Petfood

The App can be downloaded from your favourite app store.

We invite you to use the code below for a free edition of our magazine either mailed to you or via our App

Use coupon code: HNY2023

Manna Pro® Products acquires Oxbox Animal Health to grow brand portfolio for small pets

Manna Pro® Products, a St. Louis-based manufacturer and marketer of pet care and nutrition products, has acquired Oxbow Animal Health, a 30-year-old small animal wellness brand that offers premium whole foods, supplements, treats and supplies for rabbits, guinea pigs, gerbils, hamsters, chinchillas and more.

The companion pet category, including small animal, continues a path of strong growth as pet ownership and engagement maintains momentum after its acceleration during the pandemic. Manna Pro has benefitted from this trend, growing its market share across several pet categories.

"Oxbow Animal Health started with one farmer's passion and grew into a category-leading brand with a global commitment to small animal health. It complements our diverse pet portfolio of wholesome products for animals small to large and shares our commitment to quality, innovation and overall advancement of pet health," says John Howe, CEO. This is Manna Pro’s largest acquisition and continues the company’s commitment to increase its offering to meet the comprehensive needs of pet owners.

"Oxbow is proud to join Manna Pro's family of premium brands, and we're confident in our combined ability to meet the needs of pets small and large. Manna Pro shares. Oxbow's longstanding commitment to make a meaningful difference in the lives of pets and the people who love them, and we're delighted to merge our knowledge and passion with theirs in pursuit of this important mission," says Deb Buhro, CEO Oxbow Animal Health.

Manna Pro is owned by funds managed by global investment firm Carlyle.

Download your online version

PETFOOD NEWS

Primal Pet Foods introduces ‘Gently Cooked’ line of food

Primal Pet Foods, a leading brand in the Primal Pet Group portfolio, launched a new Gently Cooked line of foods for dogs and cats. The naturally complete and balanced meals are precisely cooked at a controlled temperature using the sous vide method.

The new Gently Cooked line, which features six recipes for dogs and cats, will only be available in the freezer section at neighbourhood pet stores.

“The frozen and refrigerated pet food category has experienced double digit growth over the last year, and we expect that trend will continue to drive growth in the neighbourhood pet channel in the year ahead,” says Matt Pirz, president of Primal Pet Foods. “We’ve long believed that partnering with local pet stores and their knowledgeable associates is the best way we can properly educate consumers about the benefits of an innovative new product like Gently Cooked,” he adds.

Sous Vide Cooking Method

The Gently Cooked meals are prepared with the sous vide cooking method, which means the food is slowly cooked at a low, controlled temperature. Primal mixes the fresh, high-quality ingredients together and then, vacuum seals them in a food grade pouch that is placed in a warm water bath for several hours. Since the ingredients are lightly cooked in their natural juices, the meals are very palatable for dogs and cats.

“We chose the sous vide cooking method because it helps maintain the integrity and bioavailability of nutrients in every ingredient,” says Dr James Templeman, Companion Animal Nutritionist with Primal Pet Foods. He continues, “By cooking at a precise and controlled low temperature, we can retain the moisture, flavour, texture, and aroma of the food.”

Gently Cooked meals for dogs and cats

Primal Pet Foods was founded on the belief that a pet’s diet should include

real, fresh foods. As the company continues to innovate around this belief, it is launching new options like Gently Cooked to make it easier and more convenient for pet parents to start introducing fresh foods in their dog or cat’s bowl.

The new Gently Cooked meals are made with whole food ingredients without added synthetic vitamins and minerals. The individually wrapped 4-ounce pouch can be served as a complete and balanced meal or as a topper. Actual serving sizes vary based on a pet’s specific nutrition needs. The recipes are as follows:

Gently Cooked Sous Vide Chicken & Squash Recipe, Fish & Kale Recipe, and Beef & Carrot Recipe for Adult Dogs – Each 8-ounce offering includes two pouches of the same recipe, which is formulated for the adult life stage. Additionally, Primal offers a Variety Pack for dogs – it contains 12 pouches, four of each recipe for adult dogs.

Gently Cooked Sous Vide Chicken & Salmon Recipe for Puppies – This 8-ounce offering includes two pouches of the recipe formulated for growing puppies.

Gently Cooked Sous Vide Chicken Recipe and Fish & Beef Recipe for Cats – Each 4-ounce offering includes one pouch of the recipe that is formulated for all life stages. Additionally, Primal offers a Variety Pack for cats – it contains four pouches, two of each recipe.

The new Primal Gently Cooked recipes are available through strategic distribution partners in the United States, which includes ADMC, Animal Supply Company (ASC), Frontier, Fauna, Gen Pet, Middle West, Newco, Pet Food Experts, Southeast Pet and Sunburst and in Canada, which includes Pan Pacific, Leis and Avafina.

Adisseo acquires additive manufacturer, Nor-Feed

Adisseo entered an agreement to acquire Nor-Feed, a French animal nutrition additive manufacturer specialising in plant-based ingredients. The acquisition will support Adisseo’s expansion strategy, enabling the company to further its development of specialty animal nutrition ingredients.

Based in France, Nor-Feed was founded 20 years ago by Pierre Chicoteau, joint chief executive officer, and Cecile Chicoteau. The company strives to promote the use of botanical extracts produced from agricultural co-products in animal nutrition, limiting the use of antibiotics, coccidiostats and pesticides.

France, quadrupling its annual production.

The acquisition will further Adisseo’s natural and sustainable ingredient solutions, a market that boasts a nearly 10 percent annual growth rate, according to the company. The company currently offers a variety of animal nutrition ingredients, including palatants, preservatives, essential nutrients and digestibility aids.

“We are pleased to have signed an agreement to acquire the NorFeed Group, which is consistent with the Adisseo mission to offer its customers sustainable, affordable, qualitative and safe solutions,” says Jean-Marc Dublanc, chief executive officer of Adisseo. “This operation is part of our strategy to accelerate the growth of our specialty products on unique and differentiating technologies.”

Following the acquisition, NorFeed will continue to manage its R&D, production and sales network. Mr Chicoteau and Oliver Clech, co-director of Nor-Feed, will remain with the company.

“Nor-Feed has solid bases, and our purpose is unique on the market,” Mr Chicoteau says. “We have developed and registered botanical additives for animal nutrition, safe, effective and manufactured in France in a structured CSR framework.

Adisseo has worked alongside us since 2016 and will now allow us to take the Nor-Feed project much further.”

PETFOOD NEWS 12 | February 2023 - International Petfood

taught staff about the complexities of the industry and the challenges that Darling Ingredients’ customers face and have been used to train current and former pet food company buyers as well.

Darling Ingredients in 2010. Mr Thomas has been instrumental in developing many products for the two companies, including a dairy feed supplement, a baby pig supplement, a liquid fat delivery

recognises individuals who have made recent significant contributions to support the growth of the pet food industry. To date, seven people have earned this award.

International Petfood - February 2023 | 13 PETFOOD NEWS BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

Five trends influencing pet nutrition, health & wellness

by ADM, Chicago, USA

Global petfood market is growing and is at USD $115.50 and is projected to grow to USD $163.70 billion by 2029. The pandemic had its role to play in this boom as most people worked from home and chose to get a pet to keep them company.

ADM, a global leader in human and animal nutrition, has shared five drivers that will shape the pet industry and propel market growth in the new year. These pet nutrition trends build on ADM’s broader annual outlook of global consumer trends that are influencing the food, beverage and animal nutrition industries.

“Many of today’s consumers expect their pets’ foods to be made from ingredients on par with their own meals,” says Mark Lotsch, ADM’s President, Global Health & Wellness.

“This increasing humanisation of pets is cultivating a holistic approach to pet well-being, including weight management, digestive health and customised, premium solutions. With these key consumer insights in mind, innovations in pet nutrition and wellness solutions will help satisfy pet parents’ latest demands.”

A Comprehensive Approach to Physical and Emotional Well-being

Modern pet parents are treating their pets as good as—or better than—themselves. As human trends increasingly inform pet nutrition innovations, new ways to proactively support pets’ overall well-being will continue to emerge. Most pet

owners are seeking out foods, treats and supplements to help improve their pets’ physical and behavioural health. For instance, 57 percent of global pet owners say that health claims are important when choosing pet food to purchase, and 33 percent of U.S. pet owners would like to see calming and anxiety relief benefits in pet food and treats. Additionally, consumers want to see evidence of treat and supplement effectiveness, with label claims like “clinically tested,” “scientifically studied” and “vet recommended”. Research indicates a variety of functional ingredients may have promising pet nutrition applications. High-fiber diets and some biotic strains, such as BPL1™A,B,C (Bifidobacterium animalis subsp. lactis CECT8145) and BPL1™ HT, may help pets maintain a healthy weight. Prebiotics, probiotics and postbiotics may also support digestive health, oral health and help calm stressed animals. Additionally, health-oriented blends may be tailored with functional ingredients associated with certain benefits, such as immune function and skin and coat condition. Scientific breakthroughs are leading the way for proactive solutions that can help care for pets’ minds and bodies.

The Macro Effect of the Gut Microbiome

Many consumers are aware of the potential role their gut microbiome plays in their everyday lives, and now humans are gaining insight on how the gut microbiome can affect animal well-being. A reported 60 percent of pet owners would like the petfoods and treats they purchase to have a digestive health benefit. In the U.S., 27 percent of pet supplement shoppers looked for information about their pet’s microbiome in the

14 | February 2023 - International Petfood F

past 12 months. Notably, bacterial strains used for human wellness can be useful for pet care, too.

DE111® (Bacillus subtilis) A,B, for example, is a robust spore-forming probiotic strain that can persist through a wide range of processes, temperatures and acidic environments to remain viable. This capability is critical for applying gut microbiome-supporting ingredients to food and supplement applications. Research also shows that PreforPro®A,B, a next-generation prebiotic created based on a bacteriophage blend, has a growth-promoting effect on a broad spectrum of probiotic bacteria when competing with undesirable bacteria. Furthermore, Pro-Kolin Advanced®A, a leading digestive supplement for dogs and cats, contains a blend of beneficial microorganisms, several prebiotic sources, an optimal level of a dual-source binding agent and soothing fibers to support gastrointestinal function.

ADM’s cutting-edge R&D capabilities (including C. elegans and animal models) allow for the identification of potential health benefits early on during the screening of new probiotic and postbiotic strains and their subsequent confirmation in clinical trials. Additionally, ADM has entered a strategic partnership with Gnubiotics Sciences SA to develop and commercialise innovative microbiome solutions for pet well-being.

Taking A Proactive Approach to Customised Care

As with human nutrition, “one-size-fits-all” solutions may not be ideal for maintaining lifelong wellness of every pet. The industry is shifting to a new approach, with a deeper understanding of how cats and dogs eat, sleep, play

and behave throughout their lives. Unsurprisingly, human supplement trends tend to guide proactive solutions for pet well-being.

Research finds 88 percent of U.S. pet parents say it’s important to take preventative measures to protect their pets’ health. Products with targeted benefits give consumers confidence that the product will deliver desired results. Plus, with more health and wellness options to choose from, pet parents can see which products offer unique ways to address specific concerns. Owners of younger pets typically look for products that can support immune function and general wellness for lifelong benefits, while parents of older pets often seek out tailored solutions, such as those that address joints and mobility.

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT Mixers, conveyors, Ducting System, High Temperature enquiries@hydronix.com www.hydronix.com Contact us for more details Hydronix-Petfood-Advert Jan 2022 215x140mm.indd 1 20/12/2021 19:04 International Petfood - February 2023 | 15 F

Both functional treats, which are made with food ingredients that offer nutritional benefits, and pet health supplements, which support a specific structure or function of the body and are non-nutritional, are segments expected to grow rapidly in coming years. Top concerns supported by pet supplements include anxiety and calming, mobility and joints, immune function, skin and coat, liver and kidney, and digestion. Customised nutrition strategies that cater to an individual pet’s specific needs can enhance development and healthy aging.

The Power of Premiumisation

New product launches present the opportunity to create an elevated, enjoyable experience for consumers and their furry companions alike. Notably, two-thirds of global pet parents like to see products with new and unusual flavours for their dogs and cats, and over 80 percent of owners monitor whether their pets like the taste of the products that they purchase. Fun and playful foods in eye-catching colours, exciting flavours and interesting shapes are on-trend for pets and the people who shop for them. Dog-friendly ice cream, squeezable, lickable cat treats and biscuits inspired by seasonal holidays are just a few examples of the humanisation of pets. One way to catch pet parents’ attention is with bright colours and culinary flavours sourced from nature. For example, orange and yellow kibble can signal pumpkin, chicken or honey flavours, while rich browns suggest meaty and gravy flavors. Custom colour blending can achieve an infinite number of shades tailored to the application, like a deep green dental chew made with huito fruit juice blue and turmeric spice yellow. “Close-to-nature” and other “clean label” cues are frequently perceived as higher quality, with 70 percent of both cat and dog owners saying the quality of ingredients makes a product more premium. Many pet parents are searching for premium, nutritious products described as “all natural,” non-GMO or organic. These descriptors often signal premiumization to consumers, helping reassure them that foods and treats are free from artificial or other ingredients that could be detrimental to their pet’s health. Beyond the basics, some pet owners are also turning to food toppers and other mix-ins to enhance sensory appeal and pet pampering.

Better for Planet, Better for Pets

Modern pet parents are shopping for high-quality, responsibly produced foods for the entire family. Over 42 percent of pet owners say they want to purchase pet food with sustainably sourced ingredients. Plus, 72 percent of pet owners say they will pick one product over another if they deem it to be more environmentally friendly. In tandem with its corporate Strive 35 goals, ADM works to mitigate the environmental impact of sourcing, production and packaging throughout the entire pet nutrition value chain. For example, ADM’s portfolio of alternative proteins, including beans, pulses, ancient grains, nuts and seeds, is recognised as highly sustainable and traceable from farm to plate, with many growers involved in regenerative agriculture practices that support short- and long-term sustainability improvements.

The pet nutrition industry is buzzing with innovations that help conserve natural resources and reduce greenhouse gas emissions, including PetDine’s solar-powered operations, Innovafeed’s industrial symbiosis model to produce black soldier fly larvae (BSFL), and Bond Pet Foods’ animal-free proteins cultivated by precision fermentation technology. More environmentally oriented product packaging is on the horizon, like 100 percent recyclable packaging that maintains kibble quality and safety, preventing oxidation or spoilage to prolong shelf life. With these solutions and more ingenuity to come, the pet industry can help meet the ever-evolving needs of pet owners around the world.

“As a go-to partner to forward-thinking pet nutrition companies, ADM is invested in producing petfood the right way, benefiting pets as well as their parents, the industry and the planet,” says Jorge Martínez, President, ADM Pet Nutrition. “Brands that can nimbly adapt to a more holistic approach to pet well-being and a more responsible way of conducting business will be poised for success in 2023 and beyond.”

16 | February 2023 - International Petfood F

EVOLVING AQUAFEED TOWARDS MEETING A SUSTAINABILITY AGENDA IMPACT, Bangkok 7th March 2023 Find out more at: aqfeed.info/e/1732 ROOM JUPITER 4

SOOTHING YOUR PUPPY -TEETHING AND DENTAL W

by Shannon Parsons, International Petfood, UK

by Shannon Parsons, International Petfood, UK

ith sharp little teeth and their playful attitude, puppies are small balls of adorable nightmares. They explore the world through their powerful jaws and play with as much strength as they can muster in their grips by biting into everything possible. This includes your slippers, hands, and hair if it’s long enough. Nothing is safe from their little bites. It’s when they turn three months though, or 12 weeks, that puppies begin to teeth. It can be worrying for first time dog owners to witness their precious puppy lose a tooth and not eat as much as usual. It’s completely natural though, like a child losing their teeth, your dog will too. The teething process for puppies varies from each breed and their individual health but the average timeline begins and ends roughly between the ages of 3 to 8 months.

Feeding

The appetite of your puppy might diminish during these weeks which is completely normal, however, do keep an eye on their food intake. If it appears that your puppy isn’t eating enough then take them to the vets to get checked over. Whilst your puppy may seem to not want to eat their food, don’t change what you feed them. Altering their diet could cause them more stress both emotionally and physically and they’re already stressed enough from the pain of their teeth and sore gums.

If you’re feeding them canned, wet food, try breaking the food up into smaller chunks so it’s easier for them to chew and swallow. The moistness from the wet food is already good enough for their gums and teeth so no other changes are necessarily needed. If you so desire though, you can mix in some dry pellets with the canned wet food. Let the pellets soak in the wet food so they’ll soften and be easier to chew.

If the puppies primary diet consists of dry food, pellets, or biscuits, try to soften them by soaking them in a little warm water or dog friendly broth for roughly 10-15 minutes. This might make it more appealing to their achy gums. Feeding them the pellets and biscuits though can possibly speed up the process of teething as it helps loosens the teeth.

Nipping

Your puppy will be more likely to nip and chew during this period, so if they try to nibble on your fingers or slippers more than usual, don’t be too surprised: they’re trying to relieve the pain they’re feeling.

To redirect their biting and nipping if they’re going for your hands or clothes, have a suitable chew toy nearby that you can distract them with and replace whatever they had previously been biting. You can also use chewy treats to distract them, such as raw hide, goat ears, meaty raw bones and more. These are nutritious ways to distract your puppy from slobbering all over you and helps to distract and soothe their aches. It will also keep them entertained for hours so it’s a perfect opportunity to get some work or relaxation in.

18 | February 2023 - International Petfood F

Dental Care

Just like with people, brushing your dog’s teeth is incredibly important for their dental health in reducing the risks of any dental diseases. Despite your puppies’ teeth going to fall out, it’s better to begin the process of getting your dog used to the feeling of their mouth being touched and brushed sooner rather than later. With the use of pet safe, flavoured toothpastes and finger-brushes, brushing a puppy’s teeth can be simple if you have patience.

There are also dental sticks and treats that can be used to boost their oral health. As with every other treat though, don’t feed too many to your dog or puppy as they will gain weight. Too many sugary treats can also cause a build-up of bacteria on the teeth and cause bad breath.

Bad breath is also a sign for poor health- dental disease, kidney disease, diabetes, mouth tumour or something stuck in their mouth and building bacteria. By keeping up with the dog’s oral hygiene, it’ll be easy to notice bad breath from regular dog breath.

Other symptoms of poor dental health or pain are decreased interest in dry foods and hard treats, along with slow chewing and dropping food from their mouth. More obvious symptoms though are excessive drooling and pawing at the mouth, along with new or worsening resistance to having their face or mouth be touched and a change in colour of their teeth. If these symptoms begin showing, then a trip to the vets is advised.

Love or Avoid

There are a few things that your puppy will love while they teeth, and there’s a few things you should avoid helping benefit them.

Starting off with the things to be wary of; cooked bones. If the bones are cooked, smoked, fried, or steamed, they’ll become brittle and are incredibly likely to splinter, causing damage to both the already inflamed gums of the teething puppy and internal damage once swallowed. Bones are already a risk due to causing gastrointestinal obstructions, choking, cuts and wounds in the mouth and on the tonsils, but raw bones reduce the risks.

Something else to be aware of is left over wet food. With your puppy’s appetite reduced while they teeth, they’ll be more likely to leave food behind in their bowls. If you give them wet food, once they’re done eating, clean out their bowl. The wet food, if left, can breed unhealthy bacteria. To prevent the food waste offer smaller, but more frequent meals.

Things you can do to help your teething puppy is offer small, frozen chunks of banana and strawberries. Ice cubes or frozen beef /chicken broth can also offer relief to their sore gums too. The use of a chilled, wet cloth under supervision or a chilled dog chew can help also.

Frozen carrots are also a good snack for a puppy to chew on other than ice cubes or fruit. It’ll not only ease the puppy’s sore teeth and gums but will help improve their dental health too.

F International Petfood - February 2023 | 19

CONVEY

Protect against Petfood processor recalls with the right conveyor system

by Del Williams, Technical Writer, California, USA

Processors can mitigate risk and prevent many safety issues by utilising closed conveyor systems designed with sanitation in mind, and capable of automated wet cleaning

With the threat of contamination from harmful pathogens such as salmonella, listeria, and E. coli a continual concern, petfood processors are seeking to protect not only the public but also their companies’ bottom lines from the massive costs, reputational damage, and greater regulatory scrutiny associated with recalls. The goal is a safe, clean, sanitised working environment.

According to the FDA’s Food Safety Modernization Act (FSMA) Final Rule for Preventive Controls for Animal Food “Every facility that produces animal food with a hazard requiring a preventive control must have a recall plan.”

The FSMA Final Rule for Preventive Controls for Animal Food has various key requirements. Among these, covered facilities must establish and implement a food safety system that includes an analysis of hazards and, if necessary, risk-based preventive controls. The rule sets requirements for a written food safety plan that includes details about the facility’s hazard analysis and resulting preventive controls.

Given the increasing number of outbreaks and recalls traced to post-processing contamination of feed, it is no surprise that the Preventive Controls Rule requires manufacturers to implement a safety plan with the goal of preventing sanitation deficiencies. The rule covers sanitation practices for food-contact surfaces,

preventing microbial and chemical cross-contamination, and monitoring potential environmental pathogens for critical equipment like conveyors.

As a result, quality assurance teams are paying more attention to the type and design of conveyance systems used to help meet petfood processor safety standards. This includes identifying potential harborage points where debris and pathogens can collect, as well as implementing best practices to save on costs to clean equipment, perform regular testing, and maintain the environment.

“Every day we are asked for recommendations about the sanitary design of equipment,” says Justin Kerr, founder of Factor IV Solutions, LLC, a food safety consulting firm that has worked with hundreds of food processors and harvesting operations throughout North America. “With conveyors, ideally there should be minimal harborage points, they should protect products from the environment, and be easy to clean.”

Mr Kerr says Factor IV Solutions assists food processors to develop Sanitation SOPs (SSOP: Sanitation Standard Operating Procedures) related to conveyors that include regular verification testing of food contact and non-food contact surfaces. However, given the risks of contamination, the potential for recalls, and the additional costs associated with regular cleaning and testing, it’s advisable to select a conveyor that eliminates many of the potential risk factors.

Selecting a Conveyor System

In the petfood processing industry, open conveyor systems like bucket elevators and belt conveyors can be more vulnerable to

20 | February 2023 - International Petfood F

contamination. With open systems, products can be exposed to pathogens, contaminants, or moisture in the surrounding environment. Product can also spill onto the plant floor and make its way into drains. Consequently, processors that use such conveyors must maintain strict environmental controls including constant swabbing, testing, and quality assurance.

Closed conveyor systems, on the other hand, effectively seal off products from the outside environment. Even then, it is still necessary to control the environment. Although there are several types of closed systems, one popular example when conveying high-value foods is tubular drag cable conveyors. These systems gently move products that are prone to breaking or crumbling through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop. Solid circular discs (flights) are attached to the cable, which push the product through the tube without using air. The coated cable ensures that no debris accumulates within the strands of the cable, as the cable is totally sealed.

“An enclosed conveyor like the Cablevey provides a controlled environment that reduces the risk of exposure to contaminants and pathogens from outside the system when properly maintained,” says Mr Kerr. “Because

Proven Performance Put Your Conveyor on Pole Position! • Reduce Downtime & Maintenance Costs • Quick and Easy Chain Assembly • Bolt on Flight Replacement (No Welding) • Forged and Hardened Chain Links DOWNTIME IS A RACE... TIME IS MONEY 'N' Go™ Drag Conveyor Chain www.go4b.com www.go4b.com 4B GROUP Bolt'n'Go Advet (Half Page) - No Email_Layout 1 30/06/2015 12:17 Page 1

International Petfood - February 2023 | 21 F

it is closed, it is less susceptible to aerosols and over spray from adjacent lines.”

Oskaloosa, Iowa based-Cablevey

Conveyors is a specialty conveyor company that has designed, engineered, and serviced enclosed cable and disc tube conveyors for over 50 years, with installations in over 65 countries. The company’s product can be as small as powdered material or as large as whole potatoes, and is increasingly used to convey pet food, coffee, cereal, nuts, produce, and specialty foods.

“When we conducted trials and verification testing, we found that tubular cable conveyors maintain greater repeatability cleanliness over a longer period of time than open systems due to the controlled environment within the enclosure,” says Mr Kerr.

Additionally, Mr Kerr notes that closed conveyors significantly reduce potential harborage points for contamination.

“Tubular drag cable conveyors are very simple in construction, without standard joints, threaded bolts, and plastic-to-metal connections,” says Mr Kerr.

Superior Cleaning

Mr Kerr points out another advantage: the enclosed conveyors also enable a “wet cleaning” process without wetting the surrounding areas, in which the systems can be quickly and effectively flooded with water and sanitized without disassembly.

While not all feed processor materials are suited to wet cleaning, such as hygroscopic materials that readily absorb and retain moisture, the process minimises potential contamination for other types of food. The wet cleaning procedure begins with a water rinse followed by foaming agent, a sanitising rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which act like a “squeegee” to remove any residual water.

“Within the tubular system, all wash factors can be repeatably controlled – water chemistry, temperature, physical action, and time – so every surface is equally cleaned,” says Mr Kerr. He notes that clear tubes are available that offer the additional benefit of visual inspection or verification.

Since a complete and thorough cleaning can be accomplished without disassembly of the system, the entire process only takes 20-90 minutes, depending upon the layout, product, and desired level of cleanliness. This can substantially reduce disruptions and downtime during production changeovers and eliminate the need for additional dedicated conveyor lines. Regular cleaning can be automated through the plant’s distributed control system.

“A benefit of Cablevey is the repeatability and verification of surfaces cleaned and the ease of maintaining them,” says Mr

Kerr. “You can do verifications against cleanliness and hold [the cleanliness] over a greater period of time.”

When a petfood processor wants to ensure that a conveyor will meet its sanitation requirements, equipment suppliers like Cablevey often allow quality assurance teams to perform tests prior to purchase.

“Sometimes customers come to our test lab so they can run product and conduct swab tests before and after wet cleaning and review the results for themselves,” says Morgan Bailey, Communication Specialist at Cablevey Conveyors.

In the petfood processing industry, the stakes are high when it comes to preventing safety issues. With the threat of contamination from harmful pathogens always a concern, processors are seeking to protect both the public and their companies’ bottom lines from the massive costs associated with recalls. As a result, quality assurance teams are analysing the type and design of conveyance systems more closely.

Enclosed conveyors that are capable of automated wet cleaning can help mitigate risk and prevent many safety issues. These conveyors provide an extra level of protection by keeping debris and pathogens from collecting. They also save on costs by eliminating the need for manual cleaning. As processors continue to seek ways to improve safety, enclosed conveyors will become an increasingly popular choice.

F

Product Spotlight - The Samplex CS90 Bulk Truck Sampling Probe

Samplex is the UK's leading brand on the truck probe market, with many of the originally manufactured machines still in use worldwide today. The Samplex CS90 is robust, reliable, highly adaptable, and able to provide a truly representative sample of a bulk load.

The entire Samplex range of bulk samplers uses time proven electro-mechanical technology, completely eliminating the use of hydraulics and the associated risks of pressure hoses splitting, which could contaminate valuable loads.

Wide Range of Products

The C S90 and Unispear system is unique in its ability of being able to accurately sample, without modification, a range of dry powders including meal and flour, small seeds such as oilseed rape and linseed, plus cereals, maize, sorghum, soya beans, rice, pulses and animal feed pellets up to 16mm x 30mm. Due to the clever design of the spear, it is possible to vary the amount of product sampled to help to prevent excess product building up in the laboratory

More representative Sample

Samplex truck probes deliberately don't use the more common and potentially flawed method of suction to collect product, as this has been demonstrated to possibly bias the collected sample with dust. Instead, they use positive air in conjunction with cyclonic action, and the design of the Unispear probe allows the product to fall directly into the airflow under gravity, and therefore provide a smaller, but importantly, more representative sample. Uniquely, Samplex fit all their probes with a twin variable aperture, to allow more or less product to be sampled as required.

The 340° rotation and telescopic arm allows for the variable sampling patterns required to meet ISO 24333:2009(E) standards.

To access further free information on the entire range of Samplex mechanical samplers, exclusively Made in Britain by Tekpro, or to find out how you could join the ever growing number of companies already trusting Samplex equipment to sample their bulk products, scan the following QR code:

International Petfood - February 2023 | 23 F

MAINSTREAMING ALTERNATIVE PROTEIN DIETS

by Veolia - Southeast Asia, Singapore

In the last few years, the use of alternative proteins has become more prolific, along with a greater consumer interest in health, ethical considerations, and food security concerns. While the consumption of non-meat protein is not a new phenomenon, this renewed interest is finding its way not just into the human food space, but also into pet diets and livestock feed.

Insect-based Diets: Gaining Acceptance with Pawrents

Of all the alternative proteins available, the insect-based option is perhaps the most misunderstood and the least readily accepted, even though the nutritional benefits of edible insects are well documented. And while there is no denying that they are highly nutritious and a viable source of energy, protein, fat, minerals, and vitamins, the idea of entomophagy remains a difficult hurdle to cross for many.

That said, the insect protein market is set to boom in this decade and analysts have identified a confluence of push and pull factors that are driving the rapid growth — including shortages in animal-based protein supply chain, the need for a more diverse, sustainable food supply, and smart investment strategies by key players in the market.

According to Rabobank, the demand for insect protein, mainly as an animal feed and pet food ingredient, could reach half a million metric tons by 2030, up from today’s market of approximately 10,000 metric tonnes. The growth of insect protein as a pet food ingredient can be attributed to the rising premiumisation trend, where pet owners seek to nourish their

pets with better, more natural, and high-protein meals and treats. In homes where pets are part of the family just as humans are, this is a market with huge potential.

Functional Benefit Claims

Besides being an efficient source of nutrition, insects offer some interesting functional benefits when applied in pet food formulations. Some of the established ones include:

• Antimicrobial activity — A current area of global concern for both human and animal health is the continued rise in antimicrobial resistance and multi-drug resistant pathogens, and antimicrobial peptides in black soldier fly (BSF) larvae offer immuno-modulating effects for pets.

• Intestinal Immunity — Several studies report on how dietary medium chain fatty acids help improve intestinal immunity of monogastric animals. These fatty acids positively modulate intestinal morphology and barrier function, and regulate host intestinal immune response, thus suppressing intestinal inflammation.

• Hypoallergenic — As a novel protein, insect-based pet foods offer a hypoallergenic protein source for pets suffering from food allergies and sensitive stomachs.

• Digestibility — BSF meal and BSF oil are well tolerated by dogs and can be safely included in dog diets, making it an ideal protein source for healthy development.

As scientists uncover more functionalities, the insect-based protein market holds great potential for further development as it approaches maturity.

As sustainable andprovenscientifically as they are, will these diets becomeeverthe convention?

24 | February 2023 - International Petfood F

A Sustainable Move: Bioconversion Technology

Another compelling reason for industrial-scale insect production lies in the environmental benefits that it offers.

Globally, the demand for animal-based protein has been steadily climbing, and it shows no sign of abating. This creates mounting pressures on finite resources and poses a problem to the planet with consequences consumers do not yet realise. However, policymakers, agencies, and industry players are proposing viable solutions and finding ways to make them available. Insect farming has been proven to be much more

sustainable (than livestock) in the long run, requiring less resources while presenting an opportunity to use up agricultural side streams, generating natural fertilizers as a by-product.

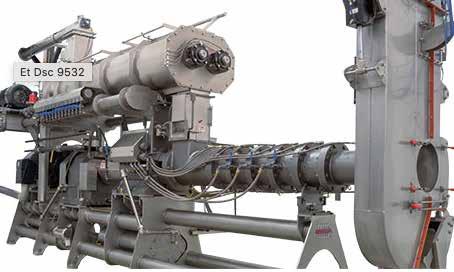

In 2017, Entofood and Veolia joined forces to provide a sustainable solution that enhances the circularity in the food chain. Veolia then successfully industralised its first bioconversion site in Malaysia, and it has been Asia’s largest industrial manufacturer of insect-based functional ingredients, with a capacity of 3000 tonnes of finished products per year, since 2019.

International Petfood - February 2023 | 25 F

The Veolia Bioconversion plant in Malaysia adheres to the highest industrial standards and the most stringent regulation requirements ensuring a consistent, premium product, with full traceability from black soldier fly eggs to finished products. The facility has undergone and passed ISO 22000, HACCP, and GMP+ certifications.

This circular model of bioconversion where insects help to upcycle food-grade, organic side streams into valuable biomass of insect protein meal, insect oil, and organic fertiliser is the next step in ensuring sustainable manufacturing practices.

At the end of the day, whether entomophagy becomes commonplace remains to be seen — changes in food culture take a long time to happen. But for the pet feed industry, things are certainly moving faster than they are in the human nutrition space.

About Veolia

Veolia group aims to be the benchmark company for ecological transformation. In 2022, with nearly 220,000 employees worldwide, the Group designs and provides game-changing solutions that are both useful and practical for water, waste and energy management. Through its three complementary business activities, Veolia helps to develop access to resources, preserve available resources, and replenish them. In 2021, the Veolia group supplied 79 million people with drinking water and 61 million people with wastewater service, produced nearly 48 million megawatt hours of energy and treated 48 million metric tons of waste. Veolia Environnement generated consolidated revenue of €28.508 billion in 2021.

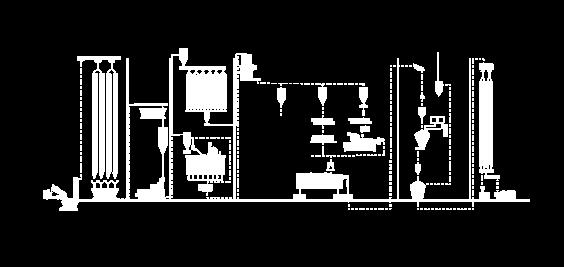

Table 1

A Typical Bioconversion Process

The feedstock of pre-consumer, organic by-products and agricultural refuse is first collected from food processing plants. It is then pre-treated to ensure the right nutrition profile and optimum assimilation by the larvae.

In a controlled environment, adult black soldier flies reproduce in the breeding centre, where hundreds of millions of eggs are harvested each day for incubation. The larvae hatch and develop under close watch so that they grow in a stable, safe environment.

Larvae are washed and go through a heat treatment before being minced. Through a centrifugation process, the solids, liquids, and oils are separated mechanically without any solvent. The oil becomes entolipid, while the solid and aqueous phases are dried and grinded to obtain entomeal™.

Typical Output for an Insert Farming Facility

Entomeal™

100% Black Soldier Fly (Hermetia illucens) Defatted Meal

The powder contains highly digestible proteins rich in essential amino acids, vitamins, minerals, medium-chain fatty acids, and bioactive peptides (antimicrobial peptides [AMPs]). It offers good palatability and is suitable for hypoallergenic pet diets.

Entolipid

100% Black Soldier Fly

(Hermetia illucens) Insect Oil

The oil contains a unique fatty acid profile and is rich in medium-chain fatty acids such as lauric acid (28%) and omega-6 (linoleic acid, palmitic acid), which can improve animal health and boost immune systems.

26 | February 2023 - International Petfood F

https://flickread.com/edition/Petfood SUBSCRIBE Available ONLINE, IN PRINT and on you favourite APP store Create an account on Flickread to view all of our editions on desktop ... Use your account to sign into our app (available from your favourite app store) ... Or manage your print subscription Sustainability goes mainstream A re-invention of capitalism in the matrix of our anthropocene diet - Swift guide to the diet & nutrition, hygiene and housing requirements of aviary birds - Vegan petfood production - NIR technologies in petfood production - Rendering:The unsung hero of sustainable petfood June 2022 www.internationalpetfood.com www.perendale.com International PetFood Volume Issue 11November 2022 An Axolotls Diet Calci- Worms - How A Commitment To Human Progression Created A New Us$75 Million Dog Chew Category - Commodity Handling Equipment November 2022 www.internationalpetfood.com www.perendale.com Download your online version: CAT FOOD 2022 A brief look at current cat food ingredient market trends - The evolution of petfoods - Multiple benefits and applications of yeast and yeast derivatives for pet nutrition - Sourcing components for petfood handling - Electrification of dryers for petfood February 2022 www.internationalpetfood.com www.perendale.com International PetFood Volume Issue August 2022 Nutrition from Nature Pet Food Plant Solution - Cat Food - Sharing Earth Animal's Wisdom on Sustainable nutrition - Sourcing Ingredients - Welfare in the Ornamental Fish Trade August 2022 www.internationalpetfood.com www.perendale.com Download you online version: IPF2208.indd 23/08/2022 09:43 PETFOOD SAFETY - Joint management & obesity in dogs - Developing effective natural nutritional support for joint ailments & weight management in canines - Insects in petfood - The continuing growth of the use of insect derived ingredients in petfood applications - Petfood technology in action - Achieving peak petfood packaging performance April 2022 www.internationalpetfood.com www.perendale.com International PetFood Volume Issue 1January 2023 Phytogenics in natural animals feed - Animal feed - The nutritional requirements of your froggy friend - Extrusion - Bucket elevator efficiency January 2023 www.internationalpetfood.com www.perendale.com Download your online version: F

Industry Training

Pet Food & nutrition training webinar

UK Pet Food are hosting a Pet Food & nutrition training webinar, running from February 21 to March 2, 2023. The course for pet professionals will be delivered by the UK Pet Food industry experts, nutritionists, and vets. In the first week (February 21-23), the focus will be on Animal nutrition. Day one, starting at 10am running until 1pm, will give an introduction to pet nutrition, and look at specific nutrition for cats and dogs. The second day focuses on small mammals’ nutrition, including bird nutrition and fish nutrition. The third day, which starts at 10am and runs until 2:30pm, features talks on clinical cat and dog nutrition, as well as pet obesity

The second week involves three days, the first two (February 28 – March 1) days focusing on Pet food legislation and marketing. Day one includes talks on UK/EU legislation, then animal by-products regulation, additives, and feed materials. Day two looks at pet food palatability and marketing regulations. Day three has a focus on manufacturing, including safety, quality, wet, semi-moist, raw, and dry pet food products. This opportunity is aimed at UK Pet Food members, pet food professionals, animal nutritionists, vets, petfood retailers, pet welfare charities, and students.

The webinar will be in the format of live zoom presentation and involve a Q&A opportunity at the end of each session, as well as polls and quizzes. Learning material, including lecture recordings, will be available to download, and a certificate of attendance on completion.

The price of general admission for the full webinar is £770, however there are several discount options, and a possibility to register for just daily or weekly webinars. Special rates are on offer to UK Pet Food members, veterinary professionals, pet welfare charities, university students and members of FEDIAF and GAPFA as well as group booking discounts

TRAINING

VIV ASIA 2023 BANGKOK, THAILAND 8-10 MARCH IMPACT THE COMPLETE FEED TO FOOD GLOBAL TRADE SHOW IN ASIA Scan to register Co-located with Guided Tours onsite Shuttle Bus service to and from the venue! Register now for FREE!

28 | February 2023 - International Petfood

Troubleshooting

Recently the question came up with regards to high main drive motor loads when making petfoods. This can be a good thing if your capacity is high as you simply back down just a bit and keep running. In the case where your motor load is elevated but your capacity is not as expected starts with evaluation of the situation. Extrusion moisture content is a big factor in this area. Too low water content and the extruder has to work harder, increases in steam and water inputs allows for easier flow and higher capacity as water addition acts similar but not as dramatic as adding oil in the system which is an option. The die also has an impact as the open area needed for capacity and the need for restriction to cook the food is dependent on the formula in many cases. Generally, 250 mm2 per tonne per hour is in the ball park but adjustments can increase capacity when it is seen that specific formulas cook easier thus lower motor loads or potential for increases in production rate.

Die design also varies on type of product made. Shaped products typically have a shorter land length and negligible taper behind the actual hole. This allows for a more defined shape being produced. Chunk products have the highest capacity when the land length, the final straight portion of the die hole, is backed by a taper inlet. Studies have shown this die design when everything is equally tested produced less rate but had the lowest motor load allowing for rate increases for the highest production possibilities. It should be noted shaped products as well as high protein formulas normally run at lower rates to achieve acceptable product. Starch sources also have an effect, corn normally achieves the highest possible extrusion capacity followed by wheat and then the rest of the possibilities.

Developments in restriction valves behind the die which creates the pressure in the barrel independent of the die allows for cook control while greatly increasing the possible die opening numbers for effectively increasing the production rate. Use of variable speed main drive motors with VFD, variable frequency drives, allow for screw speed changes which greatly increase the screw volume used over time with potential increases in production rate. Gradual rate increases with moisture and steam adjustments usually allow to push the system while keeping an eye on product characteristics should allow pushing a formula with a specific die to its maximum potential. Once achieved then mechanical changes might be the next move if increases are desired in production rates. What is your bottleneck?

The downstream equipment is what will control the extruder rate as dryer sizing as well as cooling and coating have maximum rates and thus production needs to be balanced for the line capacity.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The Extruder Barrel - Part 1

Forming extruders are used for some select products –thus this part of the discussion centres on single and twin designs.

6. Cook in the Extruder Barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - February 2023 | 29

Innovations this month

February 2023

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

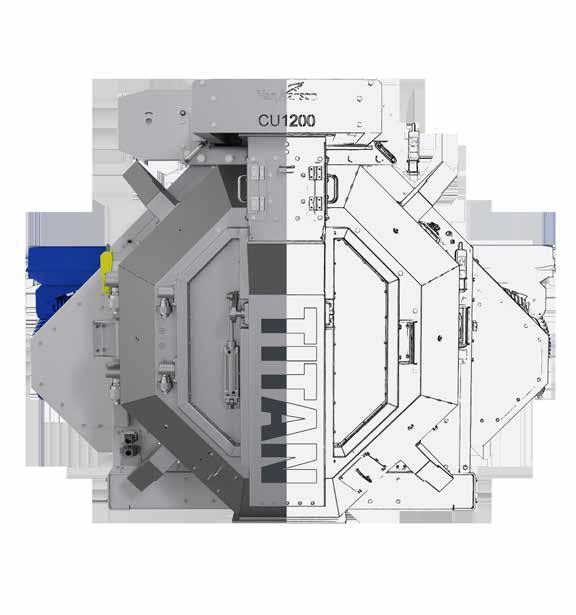

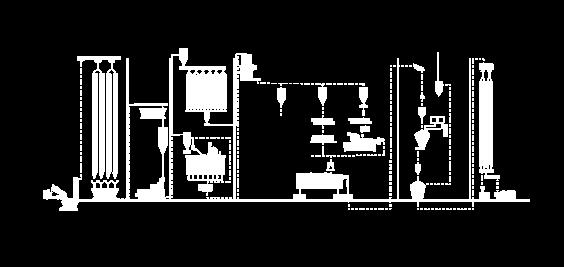

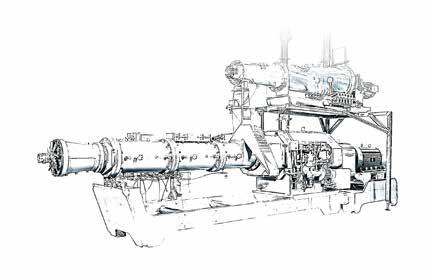

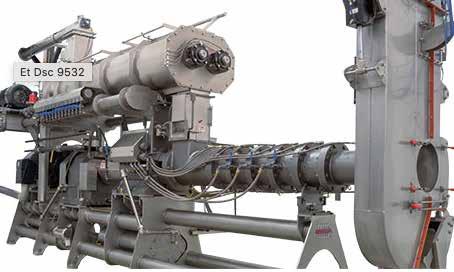

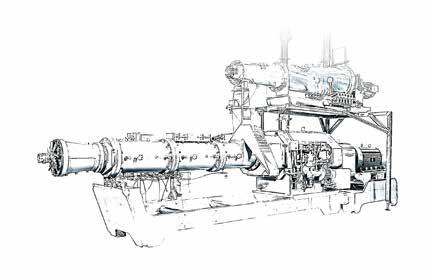

Extruder Barrels by Extru-tech

Extru-tech extruder barrels are already designed for broad production capabilities with maximum efficiency and minimal metal-to-metal wear. However, to further eliminate pathogens in the extruder barrel, extrutech advanced feature extruders utilize a modified barrel profile and increased steam injection into the barrel. Each extruder model can be equipped with multiple barrel length packages, each designed for the production of specific product types. Naturally, all extruder screws and liners continue to be constructed of high quality, wear-resistant stainless steel alloys that are subsequently polished, heattreated to required hardness specifications and then parallel ground to ensure proper fit between barrel components.

From unprecedented production capacities to exacting finished product quality, Extru-Tech Extrusion Cooking Systems have established the industry standards for performance and value. Extru-Tech’s Advanced Feature Extrusion systems were designed with two important criteria. The unit needed to be quick and easy to clean, and it needed to allow customers to control, reduce or eliminate contaminants in the system. http://extru-techinc.com/products/extruders/system--5

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: HNY2023 Leiber YeaFi® –Brewers’ yeast bound to functional f ibres! | dietetic and prebiotic active ingredients | supports digestion | promotes skin and coat quality | technological advantages Available with different fibre carriers like spent grain, DDGS or apple pomace. Visit our website: leibergmbh.de Leiber GmbH | Hafenstraße 24 | 49565 Bramsche Germany | info@leibergmbh.de Unique synergy! 30 | February 2023 - International Petfood

FOCUS

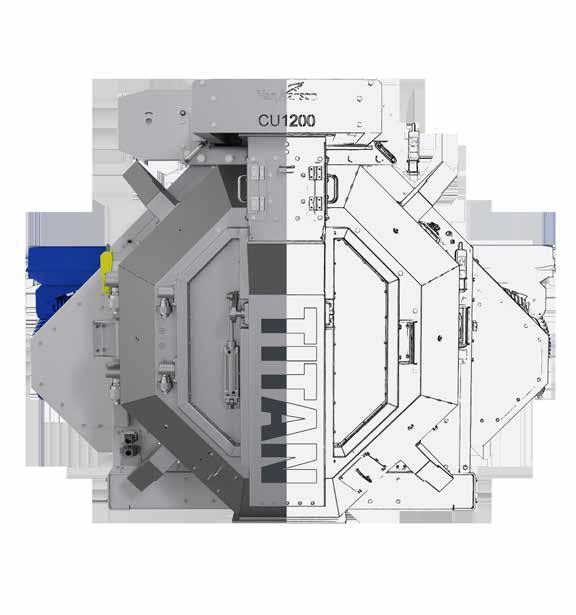

High Speed Dough Mixer by Baker Perkins

HS (High Speed) multi-purpose batch mixers feature heavy-duty construction and components, essential for mixing of pet food doughs. They offer high levels of automation, ease of use and cleaning, and outstanding reliability. A unique blade design ensures good dispersion and rapid dough development.