1 minute read

Cradle to Cradle

Cradle to Cradle.

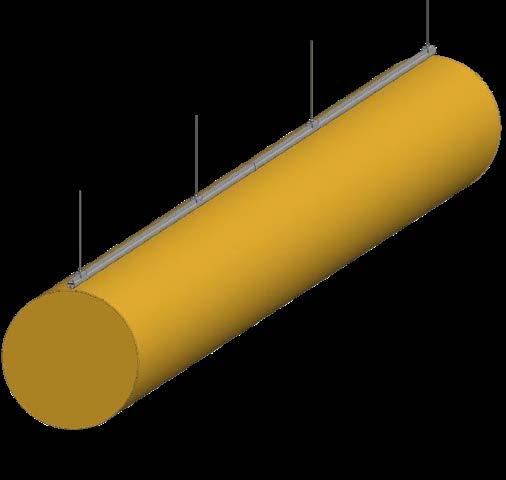

Since KE Fibertec obtained a Cradle to Cradle certification in 2012 by the EPEA institute in Hamburg a lot has happened. At the beginning it was only a white CradleVent duct, but today we can offer a large part of our material range in a number of colours (dope-dyed yarns) approved according to the sustanability standard.

The Cradle to Cradle standard consists of five fundamental building stones (see below) and it is much more than just recycling a percentage of bottles or other waste materials in one cycle (cradle to grave). In the Cradle to Cradle concept you see waste as food for a new production, which creates balance in the cycle.

The definition and description of the Cradle to Cradle standard is:

Material Health

Inventorying material chemistries as low as 100 ppm and assessment in relation to chemical risks and exposure.

Material Reutilization

Assessment of recycled or rapidly renewable materials. Which parts of the product can be recycled or repurposed (technical circuit).

Renewable Energy

Survey of energy consumption and the share of renewable energy used for manufacturing the product.

Water Stewardship

Survey of water consumption and waste water quality. The aim is to ensure clean water for future generations.

Social Fairness

Does the company act in accordance with recognised standards of social responsibility? The aim is to ensure fair working conditions for the employees at all levels of the supply chain.

Goal

The goal is that KE Fibertec’s products only consist of materials and substances that are 99.99% harmless to humans.

Goal

The goal is to reach as high a recycling rate as is technically possible. The recycling rate on our products is 18-25% in 2021 figures. KE Fibertec offers a repurchase agreement on all CradleVent orders.

Goal

KE Fibertec currently uses 100% wind power, and we are working on a conversion from gas to a carbon neutral energy source for heating. KE Fibertec’s goal is to be carbon neutral by 2030.

Goal

All waste water is collected and treated at a treatment plant. Yarn dyeing is used instead of piece dyeing, which gives a saving on waste water of approx. 67%.

Goal

All of KE Fibertec’s main suppliers have signed the ten principles of the UN Global Compact.