2 minute read

Energy optimisation and savings

Lifetime Extension.

Unlike products that are designed to fail after a certain time, our strategy of life extension is based on the fact that we will develop solutions and services that contribute to longer life and more value in our products such as maintenance, repairability, energy optimisation and recycling.

It’s our goal that all our products have an average lifetime of minimum 20-25 years, if properly maintained. KE Fibertec has manufactured and supplied Textile Based Ventilation systems since 1974 so we have the experience and knowledge to provide the necessary lifetime extension to all KE systems. It is a good investment which is clearly shown in payback period and our Life Cycle calculations. A well-operated and well-maintained system provides:

• A better indoor climate • Less energy costs over time • Longer product life of up to 20-25 years • More satisfied customers • Sustainable solution (material can be recycled after 20-25 years)

InTex - an intelligent sensor system

Energy optimisation by IoT.

KE Fibertec continuously works on developing and optimisation our products and services, so that we are always at the forefront of the latest technology and can offer energy-efficient solutions to our customers at all times. Below we have listed a few of the initiatives that we have been working on in order to provide a more energy-friendly solution to the market.

Monitoring of air pressure.

Dirty and therefore inefficient ventilation ducts is one of the biggest threats to a healthy indoor climate at a work site. A clean textile duct provides healthy indoor climate and energy savings that will benefit not only the environment, but also the operating economy of the plant.

With the intelligent sensor system InTex you are able to monitor the air pressure and temperature in the textile duct and be notified when the duct needs to be washed. That way you are guaranteed an energy-efficient solution and will get optimal washing frequency in relation to fan pressure loss.

Highest dust holding capacity on the market.

The material GreenWeave has longer washing intervals with staple fibre yarns that ensure largest possible textile surface with a dust holding capacity of more than 25 g/m3 textile surface according to EN779: 2012.

Lower pressure drop.

With a textile based ventilation solution you are able to have a lower system pressure drop compared to traditional steel based ventilation with distribution ducts (balancing dampers not necessary).

Nozzles ensure 100% active and directional air flow.

From a ventilation technology perspective, the KE-DireJet System can be regarded as an active high impulse system for mixing ventilation and with a 25% lower pressure compared to holes and microperforation.

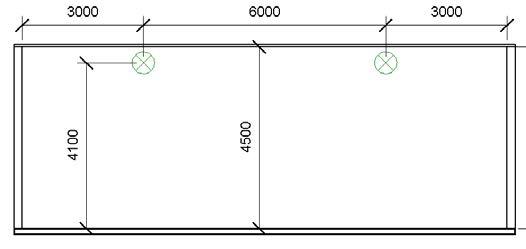

Diffuse or directional ventilation.

KE Fibertec offers ceiling panels for diffuse or directional ventilation with DFC baffles. Creating a healthy indoor air quality in rooms with low ceilings can be a challenge,however, it is possible with FBS panels. The panels can be designed down to 10 Pa.