2 minute read

Why maintenance

Good indoor climate for everyone’s benefit.

Buildings are ventilated in order to create a satisfactory indoor climate and guarantee a healthy working environment. It is therefore crucial that the buildings we occupy have a good indoor climate. Poor air quality affects our ability to work as it can make it difficult for us to concentrate and irritate our eyes and nose. A poor indoor climate can therefore increase the level of absence through sickness, which has major financial consequences both for the individual company and for society as a whole.

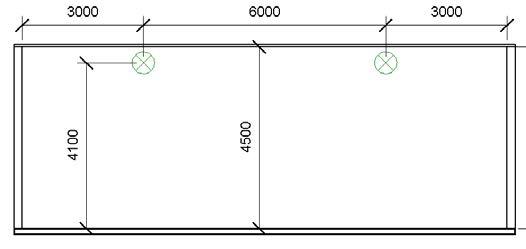

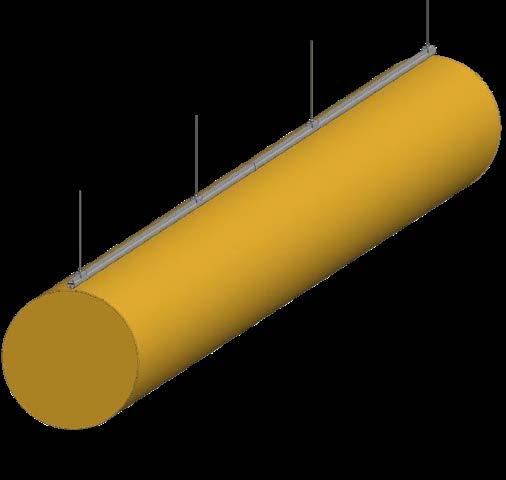

All ventilation ducts (steel or textile) require regular washing and maintenance. The advantage of textile ducting is that the ducts can easily be taken down for washing again and again so that functionality and hygiene are as new.

Dust Holding Capacity and washing intervals.

No matter how well the air is prefiltered, a certain amount of dust particles will always exist - partly deposited in ventilation ducts and fittings, and partly entering the room via the supply air of the ventilating unit. A KE textile duct filters out much of the residual suspended dust. In rooms with recirculation this is important for the quality of air since prefilters are hardly ever applied to filter the amount of air being recirculated. KE Fibertec offers two types of materials, MultiWeave and GreenWeave with high dust holding capacity and long washing intervals.

Spare sets.

In environments that require frequent washing of the ducts it may be a good idea to have a spare set ready. In that way you can install clean textile ducts and take down the soiled ducts in one process. That saves both time and money and the running of the ventilation system will not be interrupted for maintenance.

Long service life.

KE Fibertec’s low impulse systems can have a long service life if used properly. They have been developed so that they can be washed and serviced up to 100 times without decreasing their porosity compared to that of a new product. The following precautions must be observed to achieve the longest possible service life: • The systems must hang freely so that the textile material does not rub against fixed objects, thereby causing damage.

• The systems must hang still as pulsations can damage the textile material. Violent jolts must also be avoided when starting up the system as this can cause the suspension system or textile duct to come loose or sustain serious damage.

• The systems must be protected when being installed and removed so that the textile materials are not damaged.

• Outdoor air passing through the systems must be prefiltered – Class M6 – to avoid them quickly becoming clogged up.

• The systems must be washed, centrifuged and dried according to KE Fibertec’s instructions to prevent them from getting damaged.

Washing service.

KE Fibertec in Denmark and a number of KE Fibertec partners have established inhouse professional washing services of textile duct systems and ensure professional and correct handling of the duct systems.

KE Fibertec offers customised washing concepts that ensure a good washing result, no matter where the ducts are installed.

Washing Service.

Green thinking by KE Fibertec