2 minute read

Life Cycle Cost (LCC

LCC Life Cycle Cost (LCC) Calculation.

Often, the most expensive material is not the most expensive solution when considering the entire product life cycle cost. KE Fibertec can provide a Life Cycle Cost (LCC) calculation, which provide a total financial overview. There are five main costs on which we base the calculation of the total lifetime costs of a TBV system:

• Initial investment for the TBV system • Installation costs • Operating costs (fan operation) • Service costs (primarily washing and maintenance) • End of life cost (taking the system down and scrap it)

The operating and service costs will be the most expensive part, the longer the system is in operation.

Fast and easy installation.

We have listed some of the main advantages you get by choosing a textile based ventilation system from KE Fibertec:

Fewer installation hours.

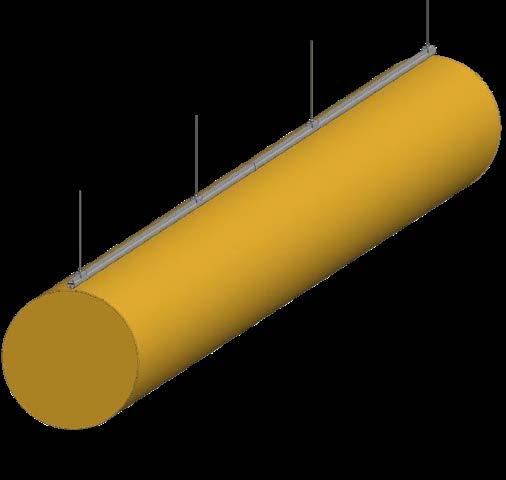

Compared to more traditional steel ducting solutions with air diffusors you will obtain a much faster installation by choosing a textile based ventilation system. It varies per type of installation, but TBV-ducts are typically 25-60% faster to install compared with the complete mounting of steel ducts, air diffusors and commissioning. Apart from a much lower weight and easier handling, all KE Fibertec’s suspension rails are delivered cut on exact lengths. It makes the complete handling and installation time much easier and quicker than for similar systems.

Better ergonomics with lower weight.

Our materials weigh 260-330 g/m2 which is much lighter than steel ducts and in total give a much lower weight per duct. At the same time textile ducts are much easier to handle and to transport as they are folded and packed in cartons of a maximum weight of 25 kg. With textile based ducting you get a solution with a unique image and an aesthetic expression. The system is self-balancing and a damper is not necessary.

Easy commissioning.

KE Fibertec provides a full documentation report together with the order confirmation. All necessary data for how to commission our system are available. A KE Fibertec system with plenum and branch ducts is designed to be almost self-balancing. No dampers are needed, which saves many hours during commissioning.

Facts on operating costs.

Typical factors that influence the clogging up and estimated washing intervals are:

• Outdoor air quality (actual particle rate at the building site) • Choice of correct prefilter (KE Fibertec recommends at least filter class M6 or MERV 13) • Air handler run time per year (the run time is very important for the energy consumption and washing frequency) • The dust holding capacity of the ducts (the amount of dust that the fabric can accumulate when it operates at a specific air pressure rise)

Example:

Duct Ø560 mm Length: 35,000 mm Installations per room: 2 ducts

Calculation of installation time

Steel duct Textile duct

Installation (hours) 23.6 17.5

Calculation of weight Steel duct Textile duct

System weight (kg) 789.0 102.7 Heaviest unit (kg) 32.6 4.7