2 minute read

Design and Engineering Where and why textile based ventilation

Where our products are used.

Textile ducting can be used in almost any type of installation and building, irrespective of whether the requirement is for heating, cooling, ventilation or a replacement air system. Over the years, KE Fibertec and our partners have accumulated a large database of references covering every possible installation and we can safely guarantee that we have a solution to suit your inquiry. You will find a number of references at ke-fibertec.com.

Why choose textile based ventilation?

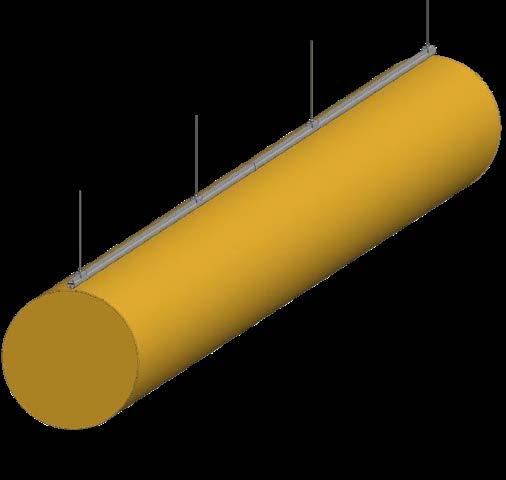

Flexibility and tailored products are the hallmark of our TBV solutions. This allows you to freely choose the size that best suits your design rather than having to be tied to a particular number of standard solutions.

In addition to this, the options offered when it comes to selecting system layouts, colours, offsets, elbows, sockets and materials are endless, not to mention that you can choose whether the TBV system will be passive (low impulse), semi-active (hybrid) or active (high impulse). In a nutshell, there could not be more options available for achieving optimum air distribution.

Unique materials

Our textiles are produced at our own weaving mill with the sole purpose of offering the most suitable materials for air distribution in the market. The selection of fibres, weight, weaving technology, dyed yarns and heat treatment are based on our desire to achieve totally uniform air permeability, a large dust holding capacity, the lowest possible shrinkage after washing and basic colours without any additional cost.

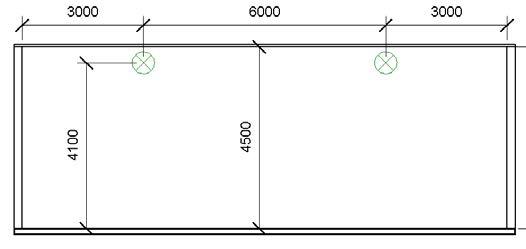

Textile ducts are very well-suited for efficient, uniform, and draught-free distribution of fresh air without ”dead zones”. Stale and stagnant air may cause fatigue and headache. KE Fibertec’s textile ducts create an effective air change and a good indoor climate in schools, offices, shops, showrooms, and other types of rooms where many people are assembled.

Easy to transport and install

Our materials weigh 260-330 g/m2 which is much lighter than metal spiral ducts. Addiitionally, textile ducts are much easier to handle and transport as they are folded and packed in cartons of a maximum weight of 25 kg. KE Fibertec’s suspension rails are delivered in exact lengths rendering installation easier and quicker than for similar systems.

Hygienic and easy to maintain

All TBV systems can easily be taken down and washed in a washing machine. The specially treated polyester materials absorb no more than 1% of water, even with a relative humidity of over 90%. This is why they are approved for the food industry. In extremely humid environments you may choose an antibacterial treatment that renders the textile ducts resistant to mould and microorganisms.

Sustainable ventilation

KE Fibertec offer a full sustainable ventilation solution, either certified according to the Cradle to Cradle standard with 100% recyclability and a disposal take-back-warranty, or sustainable Cradle to Cradle or OekoTex certified yarns. Our production is certified to ISO 14001:2015 standard (Environment). Transportation and disposal of textile duct systems produce less carbon pollutants than conventional steel ducts.