02 19 www.bakingbiscuit.com Sydney Cake House Mak’Cik (Auntie) –Only the Best Bakery China 2019 International trade fair in Shanghai AIBI Congress The Bakery of the Future

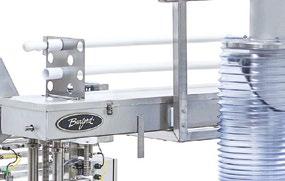

Right hand model 9840 shown with optional water spray, stacked water splitter, conveyor and MPA auto fill system. SMART SEEDER CALL US TODAY +44 1638 668563 THE TOPPING EXPERTS P.O. Box 748 • Maysville, OK 73057• Telephone (405) 867-4467 • Fax (405) 867-4219 • e-mail: sales@burford.com www.burford.com Unit 4 Sam Alper Court, Depot Road, Newmarket, Suffolk CB8 0GS UK • +44 1638 668563 • e-mail: sales@burford.com

The current hesitancy and partial insecurity among baked products manufacturers worldwide are understandable. Firstly, the global economy is cooling, and secondly there are challenges that have yet to be solved, e.g. trade disputes. Climate change will also affect the baking sector, and many corporate leaders fear large fluctuations in both the supply and quality of raw materials.

Media to the global baking industry

f2m food multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

Your commments or suggestions are always appreciated: phone: +49 40 39 90 12 28 borchfeld@foodmultimedia.de

All these challenges affect the whole world, so cannot be solved unilaterally. The baking sector and each producer can only start with him or herself, e.g. regarding climate protection or food overproduction, and the sector has been actively involved in problem-solving for many years. Thus many bakeries pay great attention to reducing their CO2 footprint by using renewable energies or fuel cells, and oven heat recovery and good insulation have been self-evident for many years. Freezer refrigerants are as environmentally friendly as possible, and no company makes baked products for the trashcan, instead of which scrap dough has always been reprocessed, and the returns rate of fresh baked goods kept as low as possible. These steps will all certainly help, the baking sector has done its homework and will continue to work on solutions. Ultimately, however, policy-makers will be called upon, because the task of bakeries is to supply the population with food, for which they need appropriate raw materials and resources. That’s why the baking sector cannot take care of this on its own.

Overall, however, I have a positive attitude. Bakeries worldwide face the same challenges, and new opportunities will certainly arise.

We should not forget that another reason why the baking sector throughout the world is successful is because it has repeatedly met the challenges. Nowadays, consumers on every continent eat baked products. There is an international demand for baguettes, ciabatta, croissants and white bread, as well as for cookies and waffles, and there is further growth in the need. Wheat consumption is rising and consumption habits are changing, especially in countries such as Indonesia, Malaysia, China or the Philippines, as well as in the Middle East or India.

Baked products manufacturers, machinery constructors, raw materials suppliers, farmers, breeders, and also we as a publisher, must make further efforts to survive in the future and also to improve, to enable us to hand something on to the next generation.

As a publisher for the baking sector we are pleased with the increasing demand for our e-paper editions. This confirms to us that our readers are interested in the contents, e.g. reportage and interviews and also in technical reports, conferences, trade fairs and market analyses, as well as new research reports.

The e-papers of our magazines offer several advantages: they save resources and our readers receive the issues quicker, can save the magazines as pdf files, and can also search through them for keywords when necessary.

If you are interested in an e-paper, please send an E-mail to Viktoria Usanova in our Readers’ Service department (usanova@foodmultimedia.de)

Best Regards,

baking+biscuit international

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors. Appears six times a year in English language.

Our Review series provides in-depth analysis of clearly defined issues, whether this involves market analyses or deals with a comprehensive, informative presentation of the state of the art in process engineering. The multilingual f2m dictionary helps clear away problems of understanding.

www.foodmultimedia.de/index-en.html

Bastian Borchfeld

EDITORIAL

Worldwide

++ Bastian Borchfeld, Editor-in-Chief

ADVERTISEMENT

02 19 www.bakingbiscuit.com Sydney Cake House Mak’Cik (Auntie) –Only the Best Bakery China 2019 in Shanghai AIBI Congress The Bakery of the Future BAKING STORAGE PROOFING f2m food multimedia gmbh www.bakingbiscuit.com THE FUTURE OF BAKING –SCIENCE –TECHNIQUE TECHNOLOGY THE FUTURE OF BAKING SCIENCE – TECHNIQUE – TECHNOLOGY ISBN 978-3-9817514-4-4 f2m foodmultimedia gmbH Ehrenbergstraße 33 22767 Hamburg Dictionary of bakery terms f2m food multimedia Dictionary of bakery terms Wörterbuch der Bäckereitechnik Dictionnaire des termes techniques pour la boulangerie Glosario de términos sobre tecnologías de panificación Термины хлебопекарной индустрии Ordbog over bageriudtryk English German French Spanish Russian Danish Japanese Ehrenbergstrasse 33 22767 Hamburg Germany Publishing house baking backwaren (German) backwaren (Russian) Dictionary of bakery terms DEU ENG FRA SPA RUS DAN JPN

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany

+49 40 39 90 12 27 www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil

+49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld

+49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk +49 40 39 60 30 61 baumfalk@foodmultimedia.de

Katrina Finley finley@foodmultimedia.de

ADVERTISING DEPT.

International sales director

Dirk Dixon +44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Wilfried Krause +49 40 38 61 67 94 krause@foodmultimedia.de

DISTRIBUTION

+49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide Linda Langhagen; design@landmagd.de

PRINTED BY

Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department. No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2019

www.bakingbiscuit.com 02/2019 CONTENT 04 IMPRINT

cover photo: © Sydney Cake House © f2m © f2m 14 26 Production 06 Markel Food Group: Transatlantic Alliance 14 Sydney Cake House: Mak’Cik (Auntie) – You Eat The Best! 22 Integrated Bakery: The other kind of consultancy company 42 Debag: A glance behind the scenes 44 Varimixer: Variable Mixer 48 REGO HERLITZIUS: Computer-assisted reproducibility 50 Zeppelin Systems: Cooperation for batch 54 WP Kemper: A dough sheeting plant for Mediterranean baked products Trade Fairs

Shanghai: Bakery China 2019

Milan: TUTTOFOOD 2019

Cologne: Record attendance at ProSweets Raw Materials

Yeast: GMO-free against acrylamide 56 Oilseed Monitoring: Protection against crisis situations Interview 26 AIBI: The bakery of the future 30 Germar Wacker: An appropriate philosophy Market 28 Organic : Double-digit market growth in Europe 36 Europe : Plant-based is booming Automation 34 H2 automatisering : Optimized process step 38 König : Combining work steps 40 Mineba : Precision, safety and security Research 60 BakeTran: Making Cakes and Cookies Healthier Regulars 03 Editorial 11 Trade fair calendar 46 News 58 News

10

10

32

52

20

© Iakov Kalinin –123rf.com

Introducing Hydrobond from Exact Mixing

Want superior hydration without adding excess heat to your dough? New Hydrobond technology delivers. Not only does it blend dry and wet ingredients with unmatched efficiency, it also:

• Requires no additional floor space

• Reduces your total mixing time

• Cleans quickly and easily

• Reduces heat attributed to mixing energy

• Allows you to mix more dough with same size continuous mixer

BY READING BAKERY SYSTEMS

BY READING BAKERY SYSTEMS

Perfect your mixing process with new Hydrobond technology. Visit exactmixing.com for details.

here.

Advanced hydration technology is

A Markel Food Group Company EXACT

MIXING

Transatlantic Alliance

The American Markel Group combines its Tromp Group subsidiary in the Netherlands and the AMF subsidiary in den USA. Both supply industrial bakery lines for fresh and frozen baked products. We talked to Hans Herman Doude , Vice President of Marketing & Sales for AMF Bakery Systems Europe.

+baking+biscuit: Mr. Doude, Tromp and Den Boer will put the abbreviation AMF in front of their company names in future. What does that mean in concrete terms? Will both companies lose their freedom to operate in the market as independent European suppliers?

+ Doude: Already 6 years ago, AMF took over Tromp and Den Boer. What has really changed, is the market. AMF customers were AMF customers, Tromp/Den Boer customers were Tromp/Den Boer customers. We see that typical bread and bun bakers need to diversify. This is where Tromp and Den Boer have great solutions for Cake/pies, pizza and pizza-like products, pastry and specialty bread. The opposite is also true. Typical Tromp/Den Boer customers are more and more looking for integrated solutions, where we can implement AMF equipment. It makes sense to make clear in the naming of the companies, that AMF, Tromp and Den Boer is one. AMF will benefit from the sales and service organization in Europe, Tromp and Den Boer can benefit from the sales and service organization of AMF in the Americas and Asia.

Markel Food Group

The Markel Food Group is part of Markel Ventures, into which the American insurance group Markel Corp. combines its widely scattered industrial interests. The list includes financial and consultancy services for various sectors, together with housebuilding, floor and panel manufacturers, a handbag producer and a plant breeder. The Markel Food Group comprises Markel’s investments in AMF, Tromp, Reading Bakery Systems (RBS) and Solbern. Solbern manufactures various kinds of filling machines that are also used in the food industry. RBS is a traditional supplier of snack systems, as well as cookie and cracker lines. Reading also offers five versions of the Exact family of continuous dough mixers for bread, rolls, crackers, baked chips, pizza, pretzels, pet treats, etc. +++

We will remain however the competence center for sheeting, depositing, handling and ovens, with all operating freedom as we have always had.

+ baking+biscuit: Which competences, which responsibilities, which decisionmaking authorities and which mechanical engineering departments will remain in the Netherlands?

+ Doude: All. Maybe this answer is a little short so let me explain a little. AMF and Tromp/Den Boer are truly additional to each other. The legacy AMF technologies are totally different from Tromp/Den Boer, and that makes that we have our engineering and manufacturing as independent entity. Sales in the Americas however will be lead by AMF in the USA, but of course we are strongly involved.

+ baking+biscuit: So as an existing customer of Tromp and Den Boer, my contact partner will still be in Gorinchem, The Netherlands. What benefits might I have from the collaboration with AMF?

+ Doude: We are the world strongest supplier of bakery equipment. We will bring our service to our customers to an even higher level. Also we can offer a much wider range of solutions to our existing customers.

+ baking+biscuit: Gorinchem will also look after the markets in Europe, the Middle East and Africa for AMF in the future. Conversely, are there markets in which AMF will offer Tromp and Den Boer plants in future?

+ Doude: AMF in the Americas will sell Tromp/Den Boer through their organization, with local project management and service. In Asia, AMF has local offices and production and service facilities. Tromp/Den Boer will benefit from that, and so our customers.

+ baking+biscuit: Synergies are expected mainly in the service area. AMF has a very large service network that operates worldwide. Are Tromp and Den Boer intending to participate in it, as well as or instead of their own service workforce? How quickly can all these AMF technicians be trained in the corresponding systems?

+ Doude: That is always a challenge. Let`s be honest, it will not be in place tomorrow. But all cross trainings are planned already. Additionally, we will have intensive trainings based on the type of equipment installed in that part of the world.

www.bakingbiscuit.com 02/2019 PRODUCTION 06

++ Hans Herman Doude, Vice President of Marketing & Sales for AMF Bakery Systems Europe

© AMF

+ baking+biscuit: What does the situation look like regarding integration into the remote maintenance of the systems? + Doude: News is to follow soon! Just to give a little insight, we are working on a centralized service, with really great solutions for our customers.

+ baking+biscuit: Although Reading Bakery Systems is not owned by AMF, all the companies share a common parent company, the Markel Food Group. Reading has a data base system through which a customer can not only look at information about his plant, but can also order spare parts.

Continuous dough production

The new structure consisting of AMF, Tromp and Den Boer has also yielded new tasks for the Group’s innovation center in Gorinchem, the Netherlands. The mixing technology of AMF and Reading Bakery Systems (RBS) is new. There is an AMF Sigma Mixer with a transverse mixing tool to produce bun doughs. On the other hand, Reading Bakery Systems’ Exact Mixing System is more versatile to produce a wide variety of doughs. Exact has more than 300 continuous mixing plants operating worldwide. RBS builds 5 different mixers depending on the required dough and development stage. 3 of these mixers are available at the Innovation Center.

The MX Mixer can be supplemented with Hydrobond Technology, anattachment in which dry materials are wetted before entering the mixer. Rotating at a speed of 2000 rpm, it turns inflowing water into a disk through which the flour or other dry ingredients fall and are wetted. The flowrate of the incoming water controls the degree of wetting, and depending on the dough or batter, 40, 60 or even 100% of the liquid can be added. Hydrobond Technology speeds up the continuous process.

RBS also offers an HDX Continuous Mixer with a two-part design for doughs that require high development, which of course is also available with Hydrobond Technology on request. The HDX consists of a first stage in which two powerful shafts mix the raw materials and a second in which shafts specific to the dough knead the resulting mixture and supply energy to it. A dough resting belt can also be implemented between the two stages if required.

At the Innovation Center, Exact also offers cookie producers is the LDX Mixer, which begins by beating together fats and liquid ingredients, and then adds solids, e.g. flour. +++

07 PRODUCTION www.bakingbiscuit.com 02/2019

++ Illustration of the Hydrobond Technology

© RBS

©

++ The AMF Den Boer Multibake® D is a directly heated oven

AMF Den Boer

Will there also be such a facility for AMF, Tromp and Den Boer?

+ Doude: Again, news will follow soon!

+ baking+biscuit: Tromp currently employs four bakers and two food technologists who commission plants, act as customer contact points etc. Will any of that change?

+ Doude: Our customers struggle with finding bakers and operators with a feel for the products. Our team of bakers and food technologists are able to train our customers in all aspects, like running and cleaning a line, but also to understand the process. It is not the only responsibility for our team of bakers and food technologists. They are involved in product tests and product development, together with our customers. They play an important role in the development of our machines as well. It is a team that is much more likely to be extended.

+ baking+biscuit: Both AMF and Tromp sell make-up lines, but with entirely different technologies. Will further process technology development be on a shared basis in future?

+ Doude: There is a huge potential in this. For example, we integrated an extruder from the US, for a European Pizza Line. We see many opportunities for combining the different technologies we have, in order to come to the best solutions for our customers.

AMF, Tromp, Den Boer

AMF ’s production program covers the entire universe of Anglo-American bakery technology. It starts with typical American mixers with a transverse mixing tool, and extends to dough dividers, make-up plants for bread, buns, tortillas and English muffins, molds and tray handling, transport systems, continuous proofers, baking and cooling systems, tunnel ovens and finally bread and bun slicers, packing & palleting plants, crate transport systems and complete lines assembled from them.

AMF Tromp ’s machine portfolio comprises lines to make up pizza, bread and bread rolls from a dough sheet, laminating plants to produce croissants, Danish pastry and other fine pastries, special pie lines for filled pies with and without a dough top, and the whole technology for making up and pre-portioning cake doughs or cake batters, regardless of whether they are cut, pre-portioned, punched out or molded. This special AMF Tromp segment also includes waffle plants for classic Dutch stroopwaffel (syrup waffles) (previously sold under the VanderPol brand) together with fun-cakes, which are small filled cakes that are baked in closed molds and can thus be made in the shape of a Teddy bear for example.

The third member of the Alliance is the traditional AMF Den Boer company in Dalfsen, the Netherlands, which builds cyclotherm tunnel ovens under the MultiBake name, of which there are four different variants. +++

+ baking+biscuit: AMF owns a production facility of its own in China – is it possible that this will also work for Tromp and Den Boer in future?

+ Doude: We are of course looking into this opportunity. Especially for the Chinese market.

+ baking+biscuit: Mr. Doude, thank you very much for the interview. +++

• Read the whole story on • backweltblog.com

PRODUCTION 08

++ At the Innovation Center in Gorinchem, The Netherlands

© Tromp

South africa: Baked goods at Pick n Pay

Bakery China 2019 in Shanghai

The 22st Bakery China – International trade fair for bakeries and confectioners – takes place in Shanghai/China from May 6 to 9, 2019.

+Bakery China is one of the leading trade fairs in the Asia-Pacific region, and covers the entire value-added chain of baked product and confectionery manufacture. The event in 2019 will occupy 220,000 m 2 in the Shanghai New International Expo Center. Participating companies will present their latest developments on more than 12,000 stands.

At the previous event last year, the event organizers counted 2,149 exhibitors and 238,263 visitors that had travelled to the trade fair from 115 countries. According to the organizer, the Chinese baking market has grown at double-digit rates in re cent decades. +++

www.bakingbiscuit.com 02/2019 TRADE FAIRS 10

©

Bakery China

©

–

©

© Akhararat Wathanasing –123rf.com

++ Bakery China 2019 will occupy all 17 exhibition halls and outdoor spaces of the Shanghai New International Expo Center

Iakov Kalinin

123rf.com

Landmagd

Key Show Facts

+ Date May 6-9, 2019

+ Opening Hours: 9:00 AM - 6:00 PM (General)

+ Founded in 1997

+ Frequency: once a year

+ Total exhibition space of 220,000 m 2

+ 2,149 exhibitors from about 30 countries and regions

+ 238,263 visitors from 115 countries and regions in 2018

+ Official delegations from USA, Germany, Italy and the Netherlands

+ Exhibits: Ingredients, Equipment, Machinery, Packaging Solutions

+ Coffee, Beverage & Fine Food Exhibition Area: 20,000 m 2

+ New: Bakery China Innovation Award for Ingredients, Equipment and Packaging

+ Organizers: China Association of Bakery and Confectionery Industry (CABCI); Bakery China Exhibitions Co., Ltd.

+ Website: www.bakerychina.com

Trade fair calendar 2019

April 26-28, 2019

Karachi/Pakistan

Food Technology Asia https://foodtechnologyasia.com

May 6-9, 2019

Shanghai/China

Bakery China 2019 www.bakerychina.com

May 6-9, 2019

Milano/Italy

TuttoFood www.tuttofood.it/en

May 9-11, 2019

Addis Ababa/Ethiopia

agrofood Ethiopia 2019 www.agrofood-ethiopia.com/ agrofood-ethiopia.html

May 15-17, 2019

Baku/Azerbaijan

WorldFood Azerbaijan/Ipack Caspian 2019

http://ifw-expo.de/exhib/worldfoodazerbaijan-ipack-caspian_2019_en

May 21-22, 2019

Amsterdam/The Netherlands

The World of Private Label www.plmainternational.com/tradeshow/exhibiting/general-information

May 21-23, 2019

Chicago, Illinois/USA

Sweets & Snacks Expo

https://sweetsandsnacks.com

May 28-29, 2019

Barcelona/Spain

Free From Functional Food & Health Ingredients (FFFHI)

www.freefromfoodexpo.com

June 18-21, 2019

Tehran/Iran

iran bakery + confectionery

www.iran-bakery.com

June 25-28, 2019

Nairobi/Kenya

Snack and Sweet Africa Expo

www.snackandsweetafrica.com

July 22-24, 2019

Tokyo/Japan

Patisserie & Boulangerie Japan 2019

www.bakery-expo.com/2019/en

11 TRADE FAIRS www.bakingbiscuit.com 02/2019

© rclassenlayouts –123rf.com

© Bakery China

• Auto-Bake on Demand; your next line is in stock ready to ship today, not in 52 weeks!

• Legendary technology producing the highest quality products at the lowest cost of ownership in the industry

• Optional direct fired convection or indirect fired radiant technologies

• Product flexibility with very low transition costs to produce these categories on the same line:

• Molded cakes (from mini-bites to large celebration cakes), cookies, and pies

• Artisan breads, buns, and pastries

• Savory meat pockets, lasagnas, quiches, and bites

• Pet Foods, energy bars, and even makeup sponges

auto-bake.com

• Customized industrial solutions

• High productivity and low maintenance cost

• Energy Saving Technology

• Effective Air Flow Turbo Zone for perfect baking result

• Unique high qualitative heating tube elements

• User friendly Oven Control Touch Screen System

• High Temperature Range. Gas: up to 645° F (340° C) Electric: up to 500° F (935° C)

/

sveba-dahlen.com

industrial@sveba.com |

• Indirect, DGF, and hybrid tunnel ovens for cookie and cracker industry

• Perfect for cookie, crackers, pet food products as well as crouton and crumb bread.

• Gold standard for QSR (Fast Food) high volume bun production in the world

• Unique Convection System reduces gas usage by 15% or more versus competition

• Go green with Stewart - Ask us about our Lube Free oven chain

• Lowest cost of ownership thanks to our technology and innovative features

• Steam Capability

spoonervicars.com /

stewart-systems.com

• Workhorse suitable for any products baked in a pan; bread, bun, pies and cakes

• High volume output (>10,000 lbs/hr)

• Efficiently moves from product to product with recipe and humidity control features

• Accommodates all pan size

• Profiled zone control allows allow the right amount of BTU input and air flow for you product

• Steam capability

bakerthermal.com

info@middlebybakerygroup.com

www.middlebybakerygroup.com - 1-844-BAKE 411 BAKERY

Mak’Cik (Auntie) – You Eat The Best!

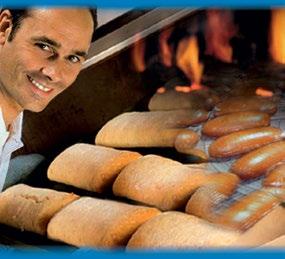

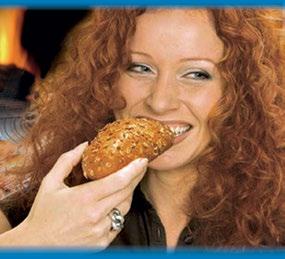

Sydney Cake House in Malaysia produces a wide variety of baked and frozen goods such as croissants, puffs, bread rolls and cakes. For these, the company focuses on products with Malaysian ingredients, together with western-style baked goods where it creates fusion style East meet West products.

Sydney Cake House bakery’s new, second production facility is situated near Malaysia’s capital Kuala Lumpur, in an industrial zone especially for the food industry. All the companies here produce foods in accordance with the Halāl standard. Companies receive a corresponding certificate only when specifications are complied with and the foods conform to Islamic dietary rules, and this has been verified by an external audit. It is the only way in which it is possible to supply the corresponding products to major clients, e.g. airlines or the food retail, since 60% of the population of around 32 million are Muslims, and Islam is Malaysia’s Major religion.

Jenny Chuang, Managing Director of Sydney Cake House bakery, recognized this market and Asia’s growing demand for baked products at a very early stage. She entered the baking sector in 1982 and saw the many opportunities as well as the potential for growth. Jenny Bee supported the family to expand a bakery, continued her education accordingly, and attended various seminars and training sessions to obtain information about baked goods production and the development of ever more new products.

The beginnings

Initially, the company supplied fresh baked products daily to customers such as school canteens, factories and cafeterias. The bakery capacity became too small as time went by,

because customer numbers steadily increased and demand constantly rose. The bakery also expanded its product range. A new building was needed, so the company bought a new production facility in 1991. All products made in the new

www.bakingbiscuit.com 02/2019 PRODUCTION 14

+

++ Sydney Cake House has become well-known for its Mak’Cik™ Shell Curry Puff – a filled, frozen puff pastry product looks like a shell

++ The grand opening

© Sydney Cake House

© Sydney Cake House

production was using Swiss manufacturer Rondo included European-style baked goods as well as the company’s own creations.

The company’s success was sustained and Jenny Chuang, supported by her family members, focused on enlarging the product range to allow further growth. The company provide frozen, preproof, prebake and fully baked frozen options for customer to choose from. Construction and move in of the second production facility followed in 2015, around 40 km from the first production unit, on a green field site at the Taman Perindustrian Pulau Indah industrial zone in Selangor. The company’s own Mak’Cik™ brand continue to be developed. The workforce of around 120 staff at the new location also made private label products. The Demand continue to grow, especially for Halāl products from China.

One of the main production line for the new production facility is from Rademaker, Netherlands. As Managing Director Jenny Chuang explains: “We see Rademaker as a partner.” The company offers good quality as well as good service in Asia Region. In addition, as Rademaker’s representative and local partners Mr David Chong, General Manager of Firmtec Engineering, support the bakery on site for better solutions in the plant. The businesswoman finds this particularly important. Explaining the situation, the Managing director says: “With these reliable partners, we can also meet our customers’ ever more rapidly changing requirements; for example we can develop and implement new products with good efficient monitoring.” One of the cases shared was, an airline wanted a baked product that did not shed crumbs in the aircraft when eaten. Because the more crumbs a baked item creates, the more likely it is that these crumbs will drop on the passenger clothing, seats on the floor too, thus increasing cleaning costs. The customer also wanted to receive the baked item in a special package. Christine Bee, Sourcing & Development Manager, and Jenny’s daughter, was able to fall back on support from Rademaker when developing a suitable baked product for the customer. Jenny explains: “We also send our team members to the Netherlands for continuous further training. As a company, this helps us to implement customer’s wishes better, and the Rademaker Academy offers us a large amount of inspiration and know-how.”

Production

Employees enter the production area through various hygiene airlocks, and must also pass through a disinfection bath. There are still plans for outdoor silos for dough production –only wheat flour is processed – but automation of the flour transport system is already planned and the concrete foundation is already in position. However, as Christine Bee points out, storing flour is another challenge due to the high outdoor temperatures in Malaysia. The subsoil in the area of the new building is also a challenge, and has its pitfalls. Managing Director Jenny explains, the ground subsides at a few points because the subsoil is rather swampy.

So at present, flour is still transported manually. Flour is cooled in the air-conditioned room and with the flaked ice the final mixed dough temperature can be obtained.

The VMI spiral mixing system uses bowls which are transported by the employee manually to the VMI bowl tipper, which transfers the dough to the new Rademaker full automatic Laminator. The dough is now rolled out and laminated in several steps. According to Sourcing & Development Manager Christine Bee: “We laminate using special pastry margarine or butter as required by the customer, and are flexible in this aspect.” A special feature of the line is its integrated cooling section, where the dough can rest, relax and develop. As Jenny explains: “We were convinced by the high quality and efficient performance of Rademaker lines, which is why we decided to choose a full line machine from Europe.”

After the dough has been rolled out to the necessary height and width, the dough sheet is cut, folded and filled according to the product. Removal is done by auto retractor which direct deposit the dough pieces onto trays. The trays with the dough pieces are transferred to a rack, and then further transported into the freezer or fermentation room, depending on the product.

VMI spiral mixer (Type SPI AV) at Sydney Cake House. The system uses bowls which are transported by the employee manually to the bowl tipper. The mixing system is designed for production 24/7. VMI offers a wide range of spiral mixer for 80 kg to 300 kg of dough. Their range of tools is suited for all types of dough whether moderately or highly hydrated.

15 PRODUCTION www.bakingbiscuit.com 02/2019

© f2m

At Sydney Cake House

www.bakingbiscuit.com 02/2019 PRODUCTION 16

++ The first lamination of the dough sheet takes place

++ A robot carries rack trolleys within the production area

++ Sydney Cake House offers different type of products range from frozen, preproof, fully baked frozen and fully baked products. The products weight range from 20 to 100 g

++ After lamination, the dough rests in an integrated cooling cabinet

Two folding stations give the plant its U-shape

Christine Bee, Sourcing & Development Manager, Sydney Cake House, Jenny Chuang, Managing Director of Sydney Cake House, and David Chong, Firmtec Engineering’s General nager

++ After sheeting, the dough is cut, filled and folded, depending on the product

photos: © f2m

A more intense taste, a higher bake-off volume and an improved crumb structure – bakery products produced with the new continuous dough extruder ContiMix™ represent superior quality. Combining the mixing and the kneading process in a row, ContiMix™ eases the production process. And results in direct cost savings for bakery producers.

ContiMix™. The secret

finest

Innovations for a better world.

behind

bakery.

Got a question? Let’s talk about it. bakery@buhlergroup.com

Markets and challenges

A short interview with Jenny Chuang, Managing Director of Sydney Cake House.

+ Borchfeld: Jenny, what is the origin of the bakery’s name?

+ Jenny: We have no connection with Sydney, but in the nineteen-eighties there was a trend in Malaysia to follow companies international cities names. Because there were already bakeries named after cities like Paris or New York, but so far there was no bakery called Sydney, and I named the company after the city in Australia.

+ Borchfeld: Why do you buy machines from Europe?

+ Jenny: Baked products originate from the European region, therefore the lines should also come from Europe. The plants represent quality and reliability.

+ Borchfeld: Which are your most successful products?

+ Jenny: We focus on croissants and products made from laminated doughs. Small puff pastry products with

Jenny says “The topic of Industry 4.0 plays a big role in Malaysia, and for us as well. We plan further automation of the production operation.” As wages are also increasing, and therefore the bakery is trialing the use of a transport robot. This robot receives rack trolleys with dough pieces and takes them to further processing. Moreover, empty trolleys from the freezer, can be automatically transported back and to be refilled with dough pieces.

Expansion

At present, employees in the production unit work two shifts on five days a week. As Jenny explains: “The aim is to introduce a third shift, which is easy to implement with Rademaker lines.” Furthermore, the employees currently still make fresh baked goods such as bread and bread rolls by another machine semi-auto machine. This is also to be changed, and the next step in the automation together with a building extension have already been planned. The company has already acquired the corresponding land and the neighboring plot. The building extension is planned for 2021. As Jenny say’s “Automation will be implemented even more systematically in the next building. Our aim is to become the Halāl leader of the bakery sector in Asia.” The company also wants to expand its export business further. In addition to China, Sydney Cake House also currently supplies to customers in Singapore, Japan, Korea and Australia. Another mainstay is its own kiosk chain operation. This is designed to help the Sydney Cake House bakery to be closer to its end customers, to observe the market accurately, and thus to meet customers’ wishes faster as well. +++

various sweet and savoury fillings that are very popular as finger food among the indigenous population and tourists in Malaysia.

+ Borchfeld: What is your company’s position in Malaysia?

+ Jenny: We are one of the major player in Malaysia that manufacturers frozen bakery products.

+ Borchfeld: How many employees do you have and how much flour do you consume?

+ Jenny: We have about 230 to 250 staffs, depending on demand. We consume up to 150 tons of wheat flour per month.

+ Borchfeld: Which challenges do you face?

+ Jenny: Climate change will certainly have an impact on raw materials prices and quality, and will thus affect our business. Rising wages costs in Asia, the shortage of skilled staff and the ageing population also present us with challenges, and will lead to more automation and the use of robots. Added to this, there are changing consumption habits to which we must respond quickly. So, we are always ready to serve customer.

+ Borchfeld: Many thanks for the interview. +++

Malaysia

Malaysia and its capital Kuala Lumpur are considered to be one of South-East Asia’s most stable countries, both politically and economically. With its population of around 32 million, the nation lives out its convergence of traditional and modern, Islam and capitalism. Since the nineteen-nineties, the country has become very open to foreign investors, and is seen as a capital-intensive industrial location with great development potential. However, the economy continues to be state-controlled, in spite of a few liberalization measures. The Khazanah Nasional sovereign wealth fund is regarded as the government’s strategic arm, and invests in numerous sectors of industry.

The state religion is Islam, professed by 60% of the population. Therefore it is especially important to food industry companies that they produce according to Halāl requirements, and are certified accordingly. Halāl means “allowed” and “permitted”. It guarantees that foods conform to Islamic dietary rules. +++

THAILAND PHILIPPINES

www.bakingbiscuit.com 02/2019 PRODUCTION 18

© f2m

INDONESIA MALAYSIA

OPTIMIZING FERMENTATION PROCESS ALL POSSIBLE DESIGNS: CONSTRUCTION, SIZE, THICKNESS, MATERIALS DIANE INDUSTRIES, SPECIALIZING IN SUPPLYING BLUEBOARDS FOR INDUSTRIAL LINES DIANE INDUSTRIES - Z.I. le Champ du Roy - 8 rue Voltaire - 02000 LAON - FRANCE technique@diane-industries.com +33 (0) 680 59 10 82 blueboard@diane-industries.com - +33 (0) 365 900 023

GMO-free against acrylamide

+R enaissance BioScience Corp. based on Vancouver, Canada, has developed a yeast that is able to lower the resulting level of acrylamide contamination in finished baked products. Applications for the yeast up to now have been mainly in the manufacture of crackers, crispbread and biscuits –with favorable results, according to the inventors and marketers.

The Canadians have patented the yeast, which they call “Acryleast”, worldwide and have registered it with the Canadian health authorities as a “novel food”. The USA Food and Drug Administration classified the yeast as “GRAS” (Generally Recognized As Safe), i.e. basically safe.

In scientific terms, although Acryleast is a completely “ordinary” yeast, it does not develop the same leavening power as the baker’s yeasts that are usual nowadays. Therefore normal baker’s yeast must be used for baked products that must show corresponding development. In return, however, Acryleast, which is produced without any genetic engineering, contains a high level of the enzyme asparaginase, which can split the amino-acid asparagine – an acrylamide precursor – and render it harmless.

The ability to do this is certainly also present in traditional baker’s yeast, but this tends to begin by using other amino-acids as a nitrogen source before attacking asparagine. By breeding and selection, Renaissance BioScience redirected the yeast’s preference towards chewing up asparagine first.

In the past, anyone who wanted to reduce the acrylamide content of his baked goods without making major changes in the recipe and process was compelled to add the enzyme asparaginase, and as a general rule that is produced by genetically modified microorganisms. On top of that, there are only a very few asparaginase suppliers in Europe, and their products are not exactly cheap. Thus Acryleast, with its GMO-freedom and in its price, represents an alternative to previous solutions.

Kerry, the Irish raw materials group, has now acquired extensive marketing rights for Europe. Excluded from this are the Scandinavian countries, the Baltic, Poland, the Czech

Republic and Slovakia – where the product is marketed by the Norwegian group Orkla, which also manufactures and markets bakery raw materials, among other things.

The list of bakery groups that do not come under Kerry’s and Orkla’s licenses, but have instead gone into business directly with Renaissance to enable them to drive forward other developments of their own, indicates the potential importance this GMO-free solution to the acrylamide contamination problem may have in the future. The list includes three heavyweights: the Swedish group Lantmännen-Unibake, a Europe-wide producer of breads, baguettes, rolls savory baked goods, croissants and cakes, Continental Bakeries in the Netherlands, which produces mainly cookies, crackers, honey cake, crispbread and zwieback, and the Barilla Group in Italy. Although the last of these is usually associated internationally with pasta, it definitely also maintains a range of baked products in Europe, for example under the Harry’s Toast-bread brand in France, bread and cookies under the Mulino Bianco brand in Italy, and crispbread throughout Europe under the name Wasa.

Mike Woulfe, Kerry’s Vice President Business Development Enzymes, says: “Initially, we focused our application work for Acryleast in the categories of baked goods, snacks and processed potatoes, however we will now broaden this further as the market for non-GMO acrylamide reduction solutions starts to grow in areas such as French fries, pretzels, breaded products, bread, coffee etc.”

When questioned about the advantages of the yeast compared to a purely enzyme solution, Woulfe points to the clean label and GMO-freedom of the production operation: “We passionately believe in a ‘from food, for food’ philosophy and are driven to find natural solutions to customers’ challenges. For us it was essential to launch a solution that was clean label and non-GMO so that both producers and consumers could trust that acrylamide was being reduced consistently, and in the right way. It is an extremely versatile solution for food producers and its use requires no or minimal changes to manufacturing processes.” +++

www.bakingbiscuit.com 02/2019 RAW MATERIALS 20

© Kerry

Rademaker Academy Quality in Knowledge

Knowledge is power. When detailed know-how about sheeting processes, production line operation and dough processing is lacking, problems affecting overall production costs and product quality might occur. In the Rademaker Academy, bakery knowledge is preserved and shared through education and training, enabling you to maximize the profitability of your bakery.

www.rademaker.com

Specialists in food processing equipment

The other kind of consultancy company

“Integrated Bakery” develops, designs and deliver bakery solutions and is therefore quite different compared to other consultants. The Dutch company acts as a system integrator and is turnkey supplier of technical solutions with performance warranties.

+A new build, modern or automated bakery production unit – it’s all “daily bread” for Frans van der Schoot and his team. From their location in Hedel, they travel around the world to advise clients. They undertake planning and implementation on their own responsibility as a contractor. They act as project manager and one-stop-shop supplier for the client with all the obligations. Equally they also support the client to choose for the right equipment suppliers if the customer decides to do so. Integrated Bakery guarantees the lines’ functioning, performance and time-schedule. Their geographic focus is on Western Europe, Eastern Europe, the Middle East, which is looked after by an office in Dubai, Africa and India. For two years, together with other Dutch companies, Integrated Bakery has also been part of a consortium that takes care of the Chinese market. Their clients are medium-sized companies who prefer to have a single contact and contract partner instead of a dozen of (individual) suppliers for their investment projects – it’s one-stop shopping for investors.

The company was founded by Frans van der Schoot, who now has at his disposal a core team of 15 staff together with contracted specialists or freelance employees, depending on the project. A Dutch citizen originally from a family of bakers, he studied Mechanical Engineering and then joined what was at that time one of the biggest bakery groups in the Netherlands, operating around 40 industrial bakeries, as a planning and bakery construction engineer. After that the company was sold, he started his own business 25 years ago as a consultant for bakery design concepts and equipment, from feasibility study to turnkey handover with a warranty certificate. Three examples will illustrate the width of Integrated Bakery’s work area: the integration of a second-hand tin bread line at Vermaut's Boerenbrood in Belgium, and building a new state-of-the-art production factory for the European production facility in Andover, UK of Rich Products Ltd, in which Integrated Bakeries molded 19 different suppliers into a single unit. Example Nr. 3 originates from the Far East, where the Dutch consultants helped a company to turn a large but rather artisan production structure into an efficient industrial, but nonetheless flexible, manufacturer of baked products.

Example 1: A second-hand tinned bread line from Spain to Belgium

Vermaut’s Boerenbrood (part of Diversi Foods) is an industrial bakery situated in Lendelede, Belgium, that delivers fresh bread and pre-baked frozen (bake-off) bread to various channels every day. The company has focused on traditionally stone-baked bread for several generations. Square bread,

pistolets (small French rolls), patisserie and viennoiserie (puff pastry) are also part of their range, together with round bread.

“Last year there was an urgent need to expand capacity to produce of tinned bread. A requirement for the capacity expansion was a short payback time on the investment. After comparison between a completely new line and a used line, it turned out that the solution for our business case was a used line, which Dubet, the sister company of Integrated Bakery found in Spain. The line proved to be a very attractive option and included a number of extra components that had added value for the bakery. For example, it included an infrared oven in which crustless bread could be produced. The turnkey-project which Vermaut's signed with Integrated Bakery and Dubet involved disassembly, transport, overhaul, engineering, project management, reinstallation and commissioning.

Frans van der Schoot: We began with adjustments on the layout (the plant had to fit in an existing building), and disassembly started at the same time. After dismantling in Spain and transport to Belgium, the line was gradually overhauled in Belgium and installed under our supervision.

www.bakingbiscuit.com 02/2019 PRODUCTION 22

++ Vermaut's bakery production line © Integrated Bakery

Based on the new layout, it was necessary to make various technical configuration changes (engineering). In addition, the building needed various modifications in order to continue to meet safety requirements (CE Standard) with the new layout. After installation, the assignment was to put the line into use together. To make commissioning a success, we went through four phases, dry testing, testing with dough, first production run, and the last phase: handover to the customer.”

Example 2: Building a new, state-of-the-art production factory

Rich Products Corporation (Rich’s) is one the world’s largest family businesses in the food industry, and is a leading supplier of a very wide range of bakery products, such as dairy-free toppings, cakes, desserts, pizzas, rolls, muffins, cookies etc. etc. Rich’s is also the founder of the non-dairy segment of the frozen-food industry and currently has 50 production locations in 6 continents, whose products are sold in more than 100 countries.

Their UK division, Rich’s Products Ltd. wants to realize a new European production facility in Andover, United Kingdom. This new bakery facility needs to be an example of the bakery of the future; with growth capabilities and equipped with the latest technologies and automation. The project contains several production lines, into which different equipment and technologies need to be integrated, from ingredient supply to palletization.

Integrated Bakery is contracted by Rich’s to develop and realize this facility, and supplies integral advice, bakery engineering and project management services with regard to both the technical solution, supporting technical installations and the building’s architectural design.

The first bakery production line was operational mid-January 2019 and the entire plant will be in operation by mid-2019. The total integrated solution includes equipment from 18 different suppliers. Each of them contributes from their specialization to obtain an optimally designed production plant with features like: small footprint, laborfriendly, low energy consumption, automated flexible production, scalable (capacity), upgradable (level of automation) etc. Such an approach assures a highly flexible asset with a long lifetime, capable of meeting the needs of the future production of (new) bakery products.

Example 3: Performance improvement

Early in 2016, Integrated Bakery was approached by a bakery in the Far East market that needed performance improvement at one of its bakeries producing a wide range of baked products that were delivered fresh on a daily basis.

MIXING SOLUTIONS for bread, pastries, cakes and snacking industries

Versatility Reliability Quality

VMI

www.bakingbiscuit.com 02/2019 PRODUCTION ADVERTISEMENT

++ Frans van der Schoot

© Integrated Bakery

offers state-of-the-art mixing technologies to meet the varied requirements of the baking industry

VMI is THE mixing company.

70 rue Anne de Bretagne, Saint-Hilaire-de-Loulay, 85600 Montaigu Vendée - France Tel. +33 (0)2 51 45 35 35 - contact@vmi.fr - vmimixing.com

ULTIMIX Planetary mixer

ROBOTIZED MIXING SYSTEM with suspended shuttle

A company of

The customer was operating on a large scale but still at an artisan level. During a site visit, the customer’s real need became very obvious: more output from a bakery that was already fully loaded with bakery equipment and extremely (over)crowded with production staff.

A highly flexible production system was the exact need. But how to free up space in such a productive environment with without jeopardizing the daily production. We managed to convince the client to let go one of his tunnel ovens, thus freeing up the needed space for a new system. During the Conceptual Design phase, various known technical solutions were projected in the limited space still available. Needless to say that the traditional linear production system, which is a space-consuming solution, was out of the question because it would not fit given the tight circumstances and would also not be able to cope with the wide variety of products at a very small batch size per product.

Evaluating systems like a tunnel/rack system or the innovative BOX system, which is a flexible solution built around thermooil heated stationary rack ovens, the decision was made for a

robot loaded Multideck system, a solution that was developed and built in a Dutch bakery about 10 years ago. Frans van der Schoot says: “Given the fact that Integrated Bakery is not an equipment manufacturer, thus giving us the position to think in solutions rather than trying to sell what we produce. We were able to check the various potential solutions available in the market and even customize towards the customer’s need, and finally find a feasible solution that was able to cope with the very challenging situation in the bakery. We were able to offer the customer the ability to produce a very wide variety of products at a high quality level within very limited space with a small number of production staff needed."

The capabilities of Integrated Bakery to source, create and contract tailored solutions makes them an unique player in the global bakeries market. They are flexible to merge different industrial machines with local market needs making them a perfect partner to move from artisan production to semi-industrial and automated industrial production while maintaining local flavors and tastes. +++

++ Performance improvement:

Evaluating systems like a tunnel/rack system or the innovative BOX system, which is a flexible solution built around thermo-oil heated stationary rack ovens, the decision was made for a robot loaded Multideck system

www.bakingbiscuit.com 02/2019 PRODUCTION 24

© Integrated Bakery

dough preparation

dough dividing

dough moulding

proofing

frying

baking

pasteurizing

cooling

deep-freezing

product handling

The bakery of the future

AIBI members will meet in England for the 36th Congress in Manchester from 30th May to 2nd June. Invitations were issued by AIBI President Joseph Street and General Secretary Susanne Döring . What else participants can expect in addition to top-class speakers, and how the Association will orient itself in the future, is explained by the two officers in an interview.

+Borchfeld: Mr. Street, the members of the International Industrial Bakeries Association (AIBI) elected you as their President in May 2017. What were your aims, and have you achieved them?

+ Street: 1. To increase membership, Switzerland have joined and there are encouraging conversations with Ireland, Sweden and Poland; Russia and Turkey are less likely, but remain as possibilities.

2. To maintain and improve relationships with other associations, I have been involved with the Bread-Initiative meetings which are a joint project with Millers, Craft Bakers, Yeast Manufacturers and Ingredient suppliers.

3. To host a purposeful AIBI Congress in Manchester.

+ Borchfeld: This year’s Congress takes place in Manchester, and you were able to obtain Jonathan Warburton, for example, as a speaker. Can you please give us a brief overview of the baking sector in Great Britain? Who are the market makers?

+ Street: Unfortunately Jonathan Warburton has had to withdraw; however, his cousin Ross Warburton will present, he was the previous company Chairman. There will be an impressive array of speakers hosted by Cyrille Fillott, Global Food Stategist, Rabobank.

Sir John Timpson, Chairman of a business with 1900 retail outlets as well as being a regular columnist in a daily newspaper will talk about staff recruitment and retention, he is famous for radical thinking. I think a must to hear especially for those bakers with retail outlets, as staffing becomes a problem.

Rob Mackie, President and CEO of the American Bakers Association representing a $102 billion industry, will tell us of trends and initiatives in the US.

Sebastian Marcu, Bake in Space, will tell us about the technical challenges providing fresh food in space. This research may well determine advantages for terrestrial bakers.

Jimmy Griffiths, a Champion Craft baker from Ireland will talk about the challenges and opportunities for his sector of the industry.

In addition, there will be a GIRA trends presentation and an EU briefing from Spain and Belgium as to how countries might achieve promotional funding. Each of the three sessions will be rounded off with Q&A panel.

The market leader in Great Britain is the Warburton brand with approx £500 million turn overall though it should be noted that two other brands, Hovis and Kingsmill appear in the top 10 food brands. Currently there is a swing albeit moderate back to own label.

+ Borchfeld: Are there any consumption figures for the trend in bread and baked products?

+ Street: I have none absolutely up to date, but in the last couple of years the market appeared to have flattened, my own thoughts are that there is currently a slight decline.

+ Borchfeld: How is the structure of baked goods providers in Great Britain changing?

+ Street: There remains consolidation in a tough market, however there are new businesses emerging and some growing, particularly with specialty products.

+ Borchfeld: What kind of role do supermarkets and discounters play in supplying baked goods to customers, and in your opinion how will the market develop?

About AIBI

The International Association of Plant Bakeries was founded in Paris in 1956. At present, 16 national member organizations are affiliated to AIBI, of which FOB (Federation of Bakers) is one. AIBI holds contacts to key Members of the European Parliament and the European Commission services. The association’s presence in Brussels also facilitates the collaboration with other chain partner associations located here. AIBI’s key task is to represent its members’ interests, especially vis-à-vis European and international institutions (EU Commission, European Council and European Parliament). Joseph Street (UK) is the current AIBI President. The Secretary General is Susanne Döring.

Website: www.aibi.eu

www.bakingbiscuit.com 02/2019 INTERVIEW 26

© melpomen –123rf.com

+ Street: The latter continue to take share albeit at a slower rate than the last few years, there remains a place for in-store bakeries in the larger stores with bake-off facilities elsewhere. Bake-off especially in treats and small items appears to be moving forward.

+ Borchfeld: What will Great Britain’s baked products market look like in 2025?

+ Street: I wish I knew, there may well be further consolidation amongst the main line suppliers, the specialty suppliers have to be careful re being aggressive otherwise their products become mainstream and attract the attention of the majors.

+ Borchfeld: Mrs. Döring, visitors from North America also already took part in the last Congress in Versailles, France, in addition to European participants. Rob MacKie, President of the American Bakers Association, will now give a presentation about the market in the USA. Does the AIBI have a strategy to enhance collaboration with other associations?

+ Döring: We are very proud to have started a fruitful cooperation and information exchange with the American Bakery Association in 2017 and we are confident that further contacts with other national associations all over the world will be established. The digital communication via e-mails etc. helps us a lot in his affair. However, AIBI’s members are mainly coming from Europe, however AIBI is open to any international contact and cooperation.

+ Borchfeld: Does the AIBI have any other objectives which you as General Secretary are pursuing?

+ Döring: AIBI’s tasks are reframed in the AIBI’s road map with the aim to strengthening the visibility and voice of AIBI and continuing a quality information management work for their members. Advocacy and monitoring of main legislative proposals are the main part of the work and supporting national large bakery associations in their questions and activities.

+ Borchfeld: The theme of the Congress is the “Bakery of the Future”. What role will the AIBI play in the future, and which challenges must members face up to?

+ Döring: I have to admit that bread and bakery products –although there are some challenges (acrylamide, wheat discussion, gluten free, salt) – are looking into a bright future. Bread from Europe is perceived in other parts of the world as an attractive lifestyle and therefore I presume that future activities will go more into bread promotion and showing the vast variety of our products.

From my personal perspective, I think AIBI and associations in general have to do more effort to attract younger bakers and CEO’s showing the advantages being part of an effective network in bakery.

+ Borchfeld: Another look back. What activities occurred in the AIBI in the past two years, and who made use of the offers?

+ Döring: AIBI was quite active in organizing together with fedima (European Association of bakery ingredients products) a bread promotion day http://www.breadpromotion.eu, which could attract around 60 experts from association, companies and bread ingredients producers on 18 April 2018 in Brussels. In 2019 there will be planned something similar and the organisation is in progress.

AIBI is strongly connected with other food and business associations to work on the topics of salt, wholegrain activities, bread promotion, iodine, food waste and enzymes.

+ Borchfeld: The AIBI’s office in Brussels is very effective, but is also small. Will you campaign in Manchester for an enlargement of the European representation?

+ Döring: The AIBI Board of Directors has to define and decide about how they will be represented and what are their visions for the future.

+ Borchfeld: Mrs. Döring, Mr. Street, thank you for the interview. +++

www.bakingbiscuit.com 02/2019 27 INTERVIEW

++ Secretary General Susanne Döring

++ AIBI President Joseph Street © AIBI © f2m

Double-digit organic market growth in Europe

Europeans spent around 10.4% more on organic products in 2017, so the European organic market showed double-digit growth for the third year in succession.

+On average, each European bought around EUR 47 worth of organic foods per year, and as much as EUR 67 in the EU-28. Overall, according to a joint assessment by the Research Institute of Organic Agriculture (FiBL) and the Agricultural Market Information Service (AMI), Europeans invested EUR 37.3 billion in organic products, EUR 34.3 billion of it in the European Union (EU-28).

The strongest-growing organic market in 2017 was France, where customers bought over EUR 1 billion more organic foods and beverages, equal to an 18% increase. The organic market also showed great dynamism, with double-digit growth in many other countries such as Spain, Denmark, Luxemburg, Finland, Austria, Ireland and Liechtenstein.

In the lead by far was Denmark, where organic had a 13.3% share of the food market. Its neighbor Sweden followed at 9.1%, just ahead of Switzerland with 9.0%. Germany took sixth place in the European comparison, with a 5.1% market

share. The Swiss spent the most money on organic food and drink in 2017 – as they already did in the previous years – a full EUR 289 EUR per person for organic foodstuffs and beverages, followed by the Danes (EUR 278) and Swedes (EUR 237). Germany, with EUR 122, followed in seventh place behind Luxemburg, Austria and Liechtenstein.

Supermarkets sold over 90% of all organic products, in both Denmark and Sweden. Retailers in both countries constantly enlarged their organic product range, even in remote rural regions. Government action plans also exerted pressure, e.g. out-of-house catering, which has become an important sales channel for organic in both Scandinavian countries. In 2017, the Danish 3-step system in out-ofhouse catering, the Organic Cuisine logo introduced in 2009, was already used by 1,800 communal catering kitchens. The logo shows the proportion of organic ingredients in the meal, thus revealing the commitment of canteens and restaurants. +++

www.bakingbiscuit.com 02/2019 MARKET 28

©

sources: FiBL, AMI Organic sales revenues in 2017 (excluding out-of-house catering and exports) Per capita turnover (in EUR) European Union (28 member countries) Europe USA (2017) China (2016) Canada (2017) Sales revenues (in EUR millions)

pasiphae –123rf.com

Passion for Dough

Top quality like handcrafted.

FRITSCH IMPRESSA bread – great-tasting, natural products with an artisanal look are no challenge. Proven SoftProcessing technology guarantees exceptionally gentle processing of soft dough and allows high output and absolutely stable operation. With the new Soft Dough Sheeter, the system is now ideal for artisan bread products of the highest quality. Find out more at www.fritsch-group.com

An appropriate philosophy

Germar Wacker heads the Swiss Bühler Group’s newly-created Consumer Foods segment. Together with Haas plants, the company offers machines all along the entire added value chain to baking and confectionery sector customers. The CEO explains more about the state of affairs in the interview.

Borchfeld: Mr. Wacker, what has changed in Haas, Meincke and/or Mondomix at the sites in Austria, Denmark and the Netherlands since the takeover by Bühler in January 2018?

+ Wacker: In terms of competences and responsibilities, everything has stayed the same as it was in the past. But much has also been accomplished. The greater depth of collaboration has yielded very many new approaches. For example, nowadays we can offer our customers a more seamless process chain and integrated solutions. This is also due to the fact that Haas and Bühler employees have shown an open approach to one another. There has been good collaboration at all levels and across the regions. New end-product creations have come into existence, and there has been a lively exchange over the technologies and about customers’ requirements. The wonderful aspect is that both groups have similar cultures which have now come together, and that the offerings complement one another very well. This has a positive effect in relation to current projects, since we can offer end-to-end solutions from silo to packing.

+ Borchfeld: But didn’t the takeover lead to any job losses?

+ Wacker: No, the individual sites remain in existence. We plan closer interlinking of the technology centers and further development of the locations. The workforce of around 1,700 employees need to have no fear of the notorious synergy effects.

+ Borchfeld: What was the response of customers to the collaboration?

+ Wacker: It was very good. Haas is a leading manufacturer of plants to produce waffles/wafers and biscuits/cookies. Bühler dominates milling and baking and is very strong in the

Bühler continues growth

The Bühler Group also continued its positive development in 2018. Explaining the position during a press conference, CEO Stefan Scheiber said: “We are pleased with the overall 2018 results. Volumes developed well, although profits were below the targets we had set. Despite risks such as trading conflicts, we are making good progress with our portfolio and global organization. We look to the future with optimism.” According to the company, the 2018 financial year was marked by further organic growth in all business units – with market gains, increased incoming orders and higher sales revenues. Sales revenues for Grains & Food rose by 9.2% to CHF 2.2 billion and for Advanced Materials by 5.6% to CHF 705 million, and Haas contributed CHF 373 million to the result. As a conse-

chocolate sector. We can now merge these component elements together and offer our customers solutions all along the entire added value chain. Our clients recognize the great potential of this, and have given the merger a very positive reception.

+ Borchfeld: Haas earned sales revenues of around CHF 373 million in 2018. How do you see this developing?

+ Wacker: It’s a record turnover and a wonderful starting point from which we can now join together to make the business grow further.

quence of the Group’s combined organic and acquisitionbased growth, Bühler was able to increase incoming orders by 17% to CHF 3.3 billion. Sales revenues rose by 22%, again to CHF 3.3 billion, while the order book at the year-end stood at CHF 1.9 billion (+5.9%). Regionally, European (+28%) and Asian (+40%) markets made the biggest contribution to sales revenues. Scheiber also said: “Following the successful integration of Haas in 2018, Bühler decided to add a new strategic mainstay to strengthen the leading position in the consumer foods market from 2019 onwards. The Bühler Group plans to use the new Consumer Foods business unit to strengthen the focus on this important global growth market.” +++

www.bakingbiscuit.com 02/2019 INTERVIEW 30

+

++ Germar Wacker has been CEO of the Bühler Group’s Consumer Foods business segment since January 1, 2019

© Bühler Gruppe

+ Borchfeld: What does the current order book look like?

+ Wacker: The order book is very good, and we are also very confident as far as the next few years are concerned.

+ Borchfeld: Where are your most important markets?

+ Wacker: Europe and Asia are certainly our most important markets. We continue to see the biggest growth potentials in various Asian regions, but we also see exciting prospects in Africa and in North America.

+ Borchfeld: And which kinds of plants do your customers ask for?

+ Wacker: Some of our customers have their own high level of competence. In most cases these want to design the entire process chain themselves. And we have customers who are specialists in marketing end-products. These are on the lookout for a dependable partner. In this case we are available as a turnkey supplier.

+ Borchfeld: In which areas do you see potential for further growth?

+ Wacker: We already have a very large share of the market in the waffle/wafer area. I see growth potentials in the areas of materials handling or biscuits.

+ Borchfeld: What impact has combining the businesses in the Consumer Foods area had on customers?

+ Wacker: We want to be in a position to make the manufacture of complete end products as easy as possible for our customers. That means we want to already support customers during the development of the product and, depending on their requirements, to be alongside as a partner to help them. With turnkey projects, we also guarantee the required endproduct, which means the customer no longer needs to tackle the integration of individual machines and plants. At the same time, we want to design collaboration with Bühler to be as simple and easy as possible, including as far as service, contactability and spare parts supplies are concerned. We also offer our customers special know-how together with

research and development to fulfill their needs. In that way, we want to offer customers solutions from a single supplier and to accompany them as partners.

+ Borchfeld: Will the brands remain unchanged?

+ Wacker: Yes, but on a different level. We will continue to sell products in the waffle/wafer area under the Franz Haas name. Meincke represents biscuits and cookies. Mondomix will be retained as a brand name for mixing and aerating systems. At a corporate level, the name Bühler will replace the name Haas, and the Bühler logo will also replace Haas logos.

+ Borchfeld: Mr. Wacker, many thanks for the interview. +++

Focus on Consumer Foods

Bühler has asserted its presence in the global food market since January 1, 2019 through the newly-created Consumer Foods segment. The Austrian Haas Group that was taken over in 2018 is also a part of the new segment. Customers are offered integrated solutions to produce waffles/wafers, biscuits/cookies, baked goods, chocolates, pralines, filled products, nuts, coffee and many others. Bühler has managed Haas as a separate business since the takeover in January 2018. The new organisation, which unifies all the technologies and solutions in the Consumer Foods area into one segment is said to be the next logical step to serve customers via a single contact point. Management of the new Segment is the responsibility of Germar Wacker, hitherto CEO of Haas, who also became a member of the Bühler Group’s group management through the realignment. Germar Wacker, now the Consumer Food CEO, was born in the Stuttgart region, and studied Business Management both in Germany and in the USA. Wacker started his professional career in the automobile industry, after which he worked for a rail transport technology manufacturer. +++

www.bakingbiscuit.com 02/2019

INTERVIEW 31

Italy’s most international Food & Beverage exhibition

More than 2,500 exhibitors from some 40 countries and over 80,000 professional visitors from more than 140 nations are expected: TUTTOFOOD is the no-miss event in Milan, the capital of Italian lifestyle and one of the world’s gourmet capitals.

TUTTOFOOD is the international B2B show dedicated to food & beverage and organised by Fiera Milano from 6th to 9th may 2019. More than 2,500 exhibitors from some 40 countries and over 80,000 professional visitors from more than 140 nations are expected. 32 countries have already confirmed their presence at the next edition, with important and numerous groups from Spain, Greece, Portugal, the United Kingdom, China and the USA.

Confirming the international character of the event, the U.S. Department of Agriculture recently issued an important acknowledgement that certifies TUTTOFOOD as the only Italian event in the agri-food sector capable of guaranteeing an effective contribution to U.S. exports, the organizer informed.

The ability to evolve, innovate and naturally expand product offerings is the focus of the 2019 edition. New areas are also dedicated to nutritional traditions, TUTTOKOSHER and TUTTOHALAL, consolidating the event’s international character.

The new product categories will be included in the sectors of the most consolidated areas of the event. Focus on the delicatessen and gastronomy world at TUTTODELI, the world of preserves with TUTTOBAKERY, TUTTOGROCERY; TUTTOSWEET, offering confirmation for the world of sweets and oven-baked products, while TUTTOPASTA consolidates the dry pasta segment with the expansion of historical producers and a focus on fresh pasta. This edition has two new entries TUTTOFROZEN and TUTTOSEAFOOD, sections dedicated to frozen food and fish products, and the

two historic pavilions dedicated to dairy products and fresh and cured meats, TUTTODAIRY and TUTTOMEAT, are characterised by increasing product innovation.

Evolution Plaza

It is this year’s biggest innovation, incorporated into a single authentic “digital village” with the TUTTODIGITAL part of the exhibition. This is the place where the latest digital trends are studied in depth, with technologies that look to the future 4.0: from product traceability to the use of "bolder" technologies such as Artificial Intelligence and solutions that are attentive to services such as accounting –on the fundamental theme of payments – or delivery, which is destined to grow even more. Evolution Plaza is also the space where companies and research centres can experiment and dialogue with each other.

Milano Food City

The appointment with the fuorisalone and the Milanese week dedicated to food is back too: this year, Milan Food City, from 3 to 9 May, focuses on solidarity, involving the whole city in a collective commitment. Gathered around the same vision, Comune di Milano, Camera di Commercio di Milano Monza Brianza Lodi, Coldiretti Lombardia, Confcommercio Milano Lodi Monza e Brianza, Fiera Milano, Fondazione Giangiacomo Feltrinelli and Fondazione Umberto Veronesi: a week of meetings, debates, talks, shows, live performances, cultural-gastronomic experiences and visits to key places in and around Milan, with hundreds of meetings open to everyone.

For more information visit: www.tuttofood.it/en +++

www.bakingbiscuit.com 02/2019 TRADE FAIRS 32

+

© Fiera Milano

AMFBAKERY.COM | sales@amfbakery.com USA | Netherlands | UK | China | Singapore | Canada | Mexico | UAE MIXING | MAKEUP | BAKING | PACKAGING | POST-PACKAGING overall energy e ciency, or take your first step into automation, AMF’s Den Boer, Vesta, and BakeTech Baking Systems o er best-in-class equipment solutions with unparalleled support for the life of your bakery.

Optimized process step

Hard to clean, inaccurate and sensors that constantly failed to operate – a major bakery in the Netherlands struggled with these problems when transporting a dough bowl. The solution was to install a new bowl transport system.

+ Occasionally, the small things are what ensure big changes, or even just optimize the production operation. The production manager of a large bakery in the Netherlands complained to Ton Hoogendam, Managing Director of H2 automatisering b.v. in ’s Hertogenbosch, the Netherlands, about constant production interruptions on the bread roll line. The breakdowns were caused by the mixing plant’s bowl transport system. A mixing system consisting of two bottomoutlet mixers provides a continuous supply of dough to the bread roll line. This involves fully automatic metering of the main raw materials directly into the bowl. For a few recipes, further raw materials and/or baking agents are weighed in by hand. Mixing and outgoing transport of the finished dough also takes place fully automatically. However, there were recurring problems caused by flour dust and dough residues. The sensors broke down, and the bowl transport system was also very hard to clean, as the production manager, whose business we are not allowed to name for competition reasons, confirmed to our editorial staff when they visited the site.

High cleaning costs

The position of the compressed air cylinder, which was responsible for transporting and positioning the bowl, caused increased cleaning costs. The cylinder was installed such a short distance (approx. 1 cm) above the floor that the staff were scarcely able to clean the narrow gap between the floor and the compressed air cylinder. They also had to clean the compressed air connections and a rail system, which also increased the cleaning costs.

www.bakingbiscuit.com 02/2019 AUTOMATION 34

++ The old bowl transport system with compressed air connections often worked inaccurately

before before © H2 © H2 © H2

++ After being filled with dough, the bowl travelled to the bowl tipper on a rail. Cleaning was difficult and costly