The Scottish Bakers association warned the country’s politicians that the industry was “facing an existential threat” because of rising costs, asking the UK government for urgent action to support, and provide relief to the trade. French associations FEB and ANIA issued a joint statement of their own, over the availability and soaring prices of energy in the context of an impending winter without gas being sourced from Russia. In Italy, retail and foodservice businesses are putting their bills on display, showing that energy costs are now three times higher than last year.

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

Bakeries in Germany are probably among the businesses that have felt the impact of the energy crisis the most, as they fight for survival amid exploding costs, staff shortages and cracks in the supply chain. The Association of German Plant Bakeries called for bakeries to be prioritized in the event of bottlenecks in energy supply, to ensure uninterrupted bread supply throughout the country. Governments have been asked to step in with a safety net to stop the bakeries’ freefall, before even considering the when and how of a bounce back. And to add insult to injury, Russia smuggles Ukrainian grain to finance Putin’s war, an Associated Press/FRONTLINE inves tigation revealed.

How to survive the week, the month and then the winter? How might winter be turned into summer’s glory again? Conversations are burning around possible answers. One thing is for sure, they are not to be found back in the coal mine, looking at the long-term sustainability of the industry and all future generations of bakeries. In the short term, switching to any other energy sources than those already existing in the baking facilities is technically out of the question. Yes, phasing to more sustainable energy sources is the direction, but this is a radical move that cannot be made overnight. To support this search for answers, we recently organized a panel discussion at IBIE, looking into efficiency and sustainability in Germany and the US. My guests were Daniel Schneider, Secretary General of the German Bakers’ Confederation, and Rasma Zvaners, VP of Regulatory and Technical Services at the American Bakers Association. While Germany suffers from losing 50% of its gas supply, which used to come from Russia, labor disruptions top concerns in the US. My guests see promising advancements in sustainability, with everything it entails, from transparency to efficiency and people and business resilience, on both sides of the ocean.

Struggling bakeries are not just waiting for a lifeline to be extended to them; in the meantime, some creative ideas have already hit the shelves. For example, I recently read about the ‘inflation bread’ as an answer to ingredient and energy costs not being passed on to the customer. Following a simple recipe, Mario Fritzen’s bakery is now selling this bread for EUR 2.50 at 750 grams in his shop in Kürten, east of Cologne – significantly less than his other varieties. Although it is sold at no profit, customers should like the idea and support the bakery with loyalty. I know that I would.

While it might seem like this ‘perfect storm’ will make future prosperous summers forgotten, there is strength in community – that of the industry, to pool together resources, and that which is built with loyal customers. Spring will come.

One characteristic shared by different types of bakeware, from trays to pans or cake molds, is their shared mission to make the baker’s life easier.

Juri Winkler was recently appoint ed Sales and Marketing Director of DIOSNA, a LINXIS Group company. He shared with us his views on the current and future direction of the company, the ‘dough experts’, based in Germany, and its latest developments, including a new IoT solution.

To manufacture rolls and buns with consistent quality for the lowest possible costs, efficient systems are a must, to produce the required volumes and varieties and provide solutions to any number of production challenges.

FROZEN IN TIME, EFFICIENTLY Formulating and perfecting the recipe is only the start to having great-tasting, crunchy or soft bakery products. The freezing process is essential to how their properties will be captured and preserved.

The name is well chosen. ‘Helden brot’ (Hero Bread) is the label under which the start-up Kultimativ gives leftover bread a second chance by processing it into cookies or other products. And the consumer also feels good from being a ‘food savior’.

Food2Multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

Our specialist journal concentra ting on production professionals in large companies in the industrial and chain-store sectors. Published six times a year in the English language. Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presen tation of the state of the art in process engineering.

The f2m dictionary translates bakery terms into a mulitude of different languages.

Juri Winkler was recently appointed Sales and Marketing Director of DIOSNA, a LINXIS Group company. He shared with us his views on the current and future direction of the company, the ‘dough experts’, based in Germany, and its latest developments, including a new IoT solution.

+Catalina Mihu: Can you give us an overview of DIOSNA’s current work, from working with customers to R&D and consultancy?

Juri Winkler: Our to-do lists are built around serving our customers with our applications and solutions, as well as always keeping an eye on the market, to see what the customers need, not just today and in the near future, but also in the long term. Day-to-day customer work means not only providing technical solutions but also it is much more about being closely involved with routine service require ments. We have recently set up our IoT platform to support our daily work with bakeries. Our mission is to make our customers happy, and we need to ensure we invest in additional customer touchpoints to do this effectively. One of our newest developments to support R&D is our DIOlab, a technological center being built here at our Osnabrück headquarters. It is aimed at providing a platform for technological R&D, to develop together with our customers the products of tomorrow.

Mihu: The IoT solution features a cross-machine recipe editor and integrated account management for transparent process control. Are bakeries already using it? And if so, what feed back are you receiving?

Winkler: We have already started working with some bakers and have just concluded the Beta testing stage, which provided a great opportunity to ask existing and potential customers to join and pool together our expertise. Anyone who is interested in it and its features is warmly welcome to contact me, as development advancements are according to everyone’s needs and input.

Mihu: What can it be currently used for? What goals did the R&D team have for this platform?

Winkler: We are setting it up in different subsequential phases, or packages. With the basic package, a user gains

access to the platform, where they can see the machine KPIs as well as process parameters, anything from mixing times to energy consumption and batch information, for example, to give a clear overview of all the operations the equipment is performing. This transparency allows the customer to recognize deviations from the standard values, so that we can be notified whenever an event occurs that requires our attention. The solution is intended as a tool for troubleshooting various issues, not only technical but espe cially technological, knowledge-related questions, such as mixing times and how they are influenced by different in gredients. This can include how to adapt the process when a new flour delivery arrives with slightly different properties to the one previously used. The IoT platform is the best way to have transparent information exchanges with our cus tomers.

Furthermore, another package will include a tool for main tenance planning. The IoT platform is able to notify in advance whenever a maintenance procedure is necessary. This means that the customer can plan for the long term to maximize the availability of the machine for production and minimize downtimes.

The maintenance itself is performed through our experts regardless of whether it’s an industrial or artisan-capacity machine. We can intervene on technical issues worldwide because we have invested in a decentralized service network to bring us much closer to our customers and literally speak their language anywhere in the world, from Spain to China, the US, UK and LATAM, or the Czech Republic. In combination with the IoT packages, we are also offering different service packages including 24/7 first level support and remote online service.

Mihu: With the Beta version finalized, is the IoT solution now complete? Or is it meant to be under continuous up dating and upgrading?

Winkler: There is no limit to further improvements to the IoT platform for the future. This is precisely what makes it so interesting. We are now able to provide the basic package. It is ready to be used now.

Mihu: You mentioned training. Who can enroll for seminars/ webinars, and what specializations are available? What is the structure of these training programs?

Winkler: Maintenance teams and operators can enroll for technical training, which can be done on-site. The main focus is on performing first-level, support maintenance and troubleshooting. For technologists and R&D employees, we provide training on technological matters, for example recipe formulations, or using pre-dough technology in com bination with our starter cultures to reach the best possible end product. The program in this case is flexible and can be done either on-site or at our headquarters. The structure of the training sessions is determined on a case-by-case basis; this gives a good example of the customizations that we provide. A training program is always oriented toward the customer’s needs and focuses on maximizing their pro cess efficiency (and can be independent of the equipment we provide). For example, over the past few months, there have been several requests for training sessions for R&D and product management teams from regions where predough is not largely used or even well-known, outside of Europe. We provided them with introductory training on pre-dough technology and the opportunities of working with it and the benefits to their products. Other markets are very familiar with this technology and training sessions are more focused on specific tasks that need to be solved. We take on the challenge! Unique situations we come across are also opportunities for us to advance with our own R&D and develop new solutions, in a partnership approach.

Mihu: What strategies, practices and concepts are being revised for the future, and how?

Winkler: Our creed is to be the market leader in innovative equipment and value-added services by enabling our customers worldwide to provide healthier food. This is our mission. We are known in the market as an equipment provider. But, we are much more than that. We are under taking a major transformation to expand the conversation from equipment to also include solutions and technology – the customer’s process and products, all rounded up with top-level service. When we think of services, we do not only refer to spare parts servicing, but to what we call ‘valueadded’ services. As an integral part of customer retention, it also covers the technological side, anything from recipe formulation to raw material analysis. We have invested in equipment and manpower to be able to make analyses, for example of flour, and provide consultancy to our cus tomers based on the results regarding setting the right process parameters for dough preparation. Along with our

machines and pre-dough and sourdough technology, testing is also an important component here; we visit our customers with our demo machines to conduct on-site tests and we are also hosting sessions in our technological center in Osnabrück.

“Looking at the entire process, DIOSNA stands out by providing pre-dough solutions, which greatly contribute to the overall efficiency of the complete line.”

Juri Winkler, Sales and Marketing Director, DIOSNA

Mihu: How does DIOSNA work on a project to provide consultancy regarding process optimization?

Winkler: Many things can be done from the beginning of a project that will significantly influence its later stages. A universal problem, for example, is the acute labor shortage in the industry; it’s not just about finding the right people with the right expertise, it is about finding any people willing to join the industry. This scenario brings with it two major tasks: securing the know-how within the process and the equipment, and advancing the degree of automatization. We have learned that automatization does not always imply big investments, despite what many bakeries might fear. It can also be incorporated into existing equipment, such as in the case of RFID control systems. Entry-level automatization can help streamline manual operations, while at the end level, operator intervention is not needed at all. Incorporating robotics and self-driving devices are currently part of our major R&D projects. This enables customers with existing equipment to invest in automatization without having to replace the entire line.

Mihu: What concept and practice-related changes can bakers expect going forward, starting from these new goals?

Winkler: Our aim is that customers see us as a partner in their new product development, going beyond being an equipment provider. We are focusing on understanding their processes, keeping in mind the end product and consumer. With quality being an integral part of the cus tomer’s product, we want to ensure that they can make a good product. We can then look at the process and the ways of optimizing it, which can always be found: reusing by-products and minimizing waste, for example, will also count towards the bakery’s sustainability efforts. Only after this analysis, we can start talking about the equipment itself.

Mihu: How does DIOSNA develop customized solutions?

Winkler: A custom-made solution needs to match the bakery’s unique needs with a direct link to the end product. It also indicates a certain level of flexibility and automati zation in the equipment that we provide in each case. At DIOSNA, we have a portfolio of approved principles and products; the right combination between them represents a custom solution that we develop. One case can be that of customers who are looking to expand existing plants and want to include the latest available technology while doing so. Trending products imply long dough resting times, for example. Solutions catering to them can be further customized by deploying self-driving devices for product handling in the factory.

Mihu: Looking at the technology itself, what are some of the latest equipment upgrades and what are DIOSNA’s unique offerings?

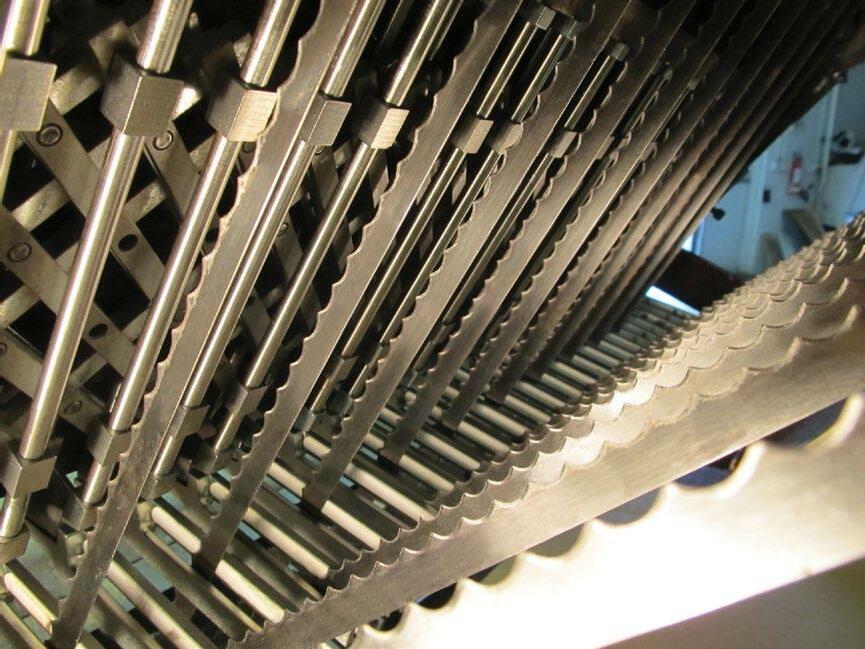

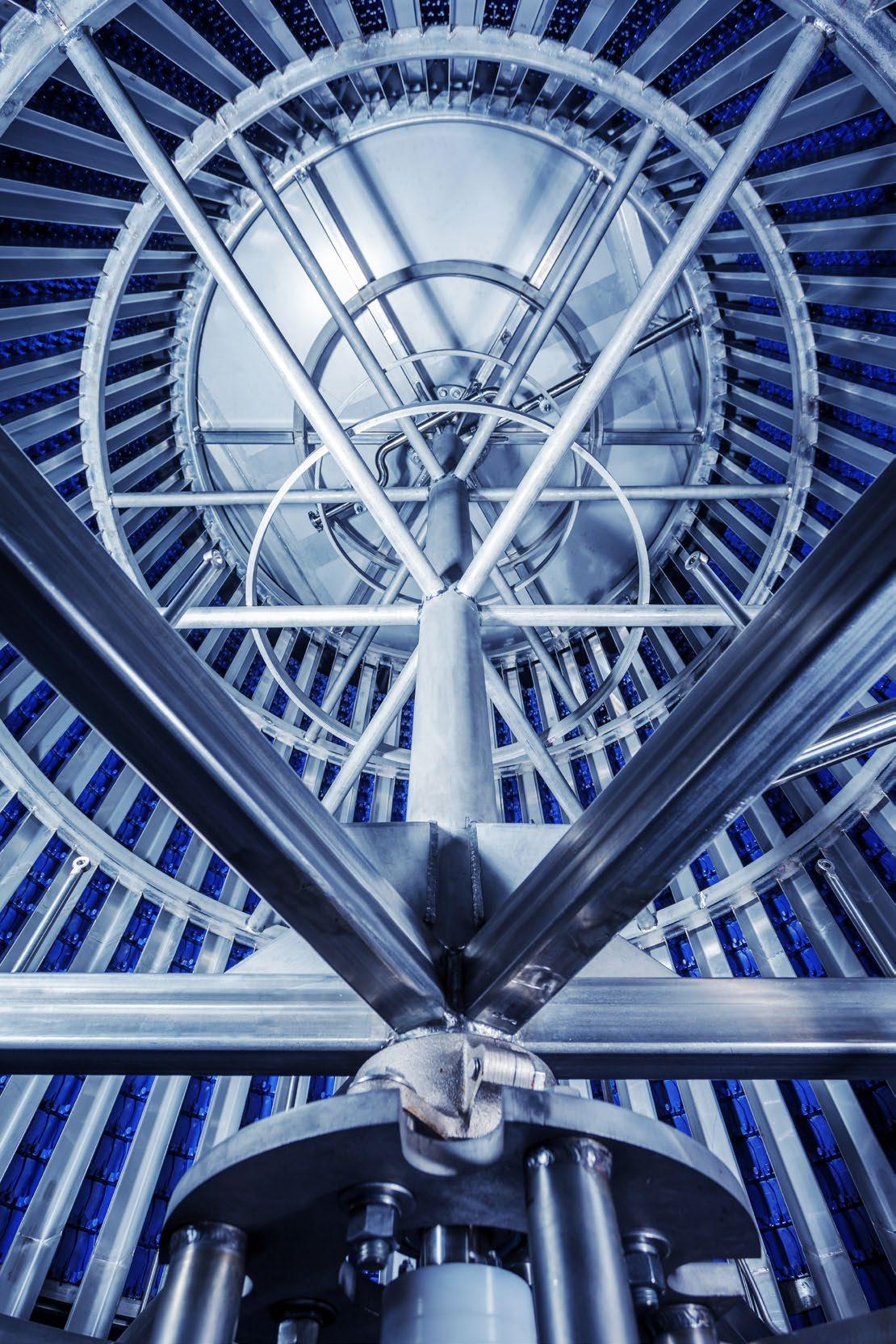

Winkler: The most important is the hygienic design of the Wendel Mixer. The revised design has an open structure

with access to the body of the machine, to easily allow the highest possible level of sanitation. The staff can clean the Wendel Mixer in a very short time and even while using low-pressure water, without having to disassemble the machine. The design itself is very lean in order to minimize the surfaces that need cleaning.

Looking at the entire process, DIOSNA stands out by pro viding pre-dough solutions, which greatly contribute to the overall efficiency of the complete line. Pre-dough is essential to a wide range of applications. Here, we not only provide the pre-dough equipment, but also the biotechnology – the starter cultures in the DIOStart range, which help achieve different effects. Just to give an example, they can help modify the taste, while also extending the product’s shelf life. Pre-dough also helps to optimize the mixing process. We offer solutions to combine the two. Moreover, another aspect of working with pre-dough is reusing leftover dough, which is gaining more and more interest and is providing answers to both costs and sustainability concerns.

Furthermore, within the LINXIS Group, we can provide solu tions for bakeries beyond pre-dough and mixing solutions. Our partners at Shick Esteve provide support with raw material handling, for example, which also allows us to synchronize interfaces and optimize the efficiency of the systems we provide together.

Mihu: How are the DIOStart cultures developed and how should they be used with the pre-dough and sourdough systems? Can you give us the benefits of this range?

Winkler: They are based on biological strains that we have developed. Some of them have decades-long history, and are multiplied to create new DIOStart cultures. DIOStart can be supplied on a subscription-based program. The starter cultures were developed to answer various customer challenges, such as salt or sugar reduction, lowering the amount of yeast used, or replacing the functionality of improvers for the sought-after 100% clean label products. Digestibility is also a considered aspect. We can easily combine DIOStarters with the equipment we provide, since the technology was built with settings based on the starters.

Mihu: What are advances towards sustainability at DIOSNA? How can they help optimize production?

Winkler: Our fully-automated systems liquify leftover dough, or even baked products that reenter the production cycle in a controlled way. This also has the advantage of bringing the product’s aroma and flavors into the mix. Alternatively, thanks to using the liquified dough/bread, the water ratio in the product can be increased even more –because part of the water is already bound in the liquified mix giving great results regarding the freshness of the end product. With the current prices of flour, it helps save on ingredient use.

Mihu: Thank you for our interesting conversation! +++

Invest in bakeware that has proven its value in bakeries around the world for over 40 years. Achieve maximum product quality and consistency while minimizing your cost per bake by partnering with us to select the right design, coating, and pan refurbishment schedule for your tins and trays.

Select from our stock bakeware or create a custom pan designed for your bakery’s exact needs and specifications to maximize throughput and increase efficiency.

Work with our experienced team to select the optimal silicone or long-life coating to reduce the use of oil and provide clean release from your bakeware.

Maximize pan life and product consistency with a refurbishment program personalized for your bakery’s product, pan usage, and production requirements.

Jesper Albertsen | EUROPEAN SALES DIRECTOR Tel: +45 23 68 51 85 | jalbertsen@americanpan.com

ROMANIA | SPAIN | SWEDEN | UK

I

One characteristic shared by different types of bakeware, from trays to pans or cake molds is their mission to make the baker’s life easier.

Traditional cake pans, bundt cake pans, cupcake or mini cake pans, springform pans, silicone cake molds, and sheet cake pans – bakeware for cakes is as diverse as the delicious products that are their guests while baking or even afterward. Correctly caring for their delicate visitors is what makes all types of trays essential in supporting bakers. They can be sponge cake trays that carry the cake from the workshop to the store and also make product presentation literally ‘a piece of cake’. Or, molded trays for industrial use, where imprints ensure that every product produced has the same shape to ease packaging and match customer expectations. Non-stick coatings suited to the requirements of individual products are also part of the same conversation, Marc Schulze, Key Account Manager Export, Anneliese, says.

However, for more complex shapes, such as bundt cakes, alusteel is the better option, as it can be pressed into shape easier and can be molded into various shapes, while aluminum would not stand the pressure of stamping, he adds.

That’s not all, production volumes are also a part of the equation when choosing a pan for cakes. Anneliese differ entiates between three levels of operations: “First, we have bakers who are happy with individual molds or trays because their production volume does not require a convection wagon oven or a different type of an equivalent baking area. As the business grows and such means of production become interesting, we can work with the baker to design their individual equipment. For example, we could put several cake molds on a strap to be inserted on a rack. This makes handling efficient, as the baker can use their hands to handle three-four cakes instead of only one, in a single mold. Finally, the third level concerns the industrial

The shape, size and material of the pan directly influence the baking process. Pan selection depends on the cake’s shape and size. For ‘easy’ shapes such as rectangular or round, one can choose between aluminum and alusteel. “While aluminum heats up quickly and is very lightweight, alusteel can store heat for longer compared to aluminum, which gives a different baking result,” Schulze explains.

“Most bakers ask for our patented F-profile system to remove the crossbar for display, because it offers the easiest handling and is more robust than other options”Marc Schulze, Key Account Manager Export, Anneliese © Anneliese

producers. Of course, pan straps and trays can be customized to fit any industrial bakery line. Those would have a (rein forced) frame and edge bumpers. Moreover, solutions for automated stacking or handling are requested frequently at the moment,” Schulze shares.

Ingredients in cake formulations pose no particular chal lenges when it comes to pan selection, with the notable special care for free-from products. One consideration that should be kept in mind, however, is that, even if the pan can have relatively complex shapes, e.g. animals, or cars, the cake made with that mold usually lacks details and can look very different from the original concept. “For example, while the eyes of the teddy bear might have irises in the pan, the resulting cake will not have a visible iris. Sharp and small outlines usually don’t work very well,” Anne liese outlines. The company can provide 3D-printed pans at a relatively low cost for testing.

Coatings, however, are an important factor. Cakes usually contain fat, sugar and egg; more often than not, all three. Even a single one of these ingredients can kill most non-stick coatings. Anneliese recommends sharing information about the ingredients in advance with their experts, for appropriate pan recommendations. “However, only real-life tests over several months, or an equivalent number of baking cycles, will tell the whole truth about the suitability or failure of the coating,” Schulze adds. Looking at these difficulties, it becomes apparent why many bakers, regardless of their size and daily production output, do not choose a non-stick coating but use release agents instead. “However, the Anneliese team is convinced that non-stick coatings save work, time, and resources in the long run.”

The most requested type from Anneliese is the simple sponge cake tray still, which can be customized in any size – to fit anything from window displays to ovens and transportation boxes. “Most bakers ask for our patented F-profile system to remove the crossbar for display, because it offers the easiest handling and is more robust than other options. Especially in Germany, people love sponge cakes with different fillings, toppings and icings. Plus, we’re always happy to see people get creative and reinvent the way to use them,” the specialist explains.

The depanning method will also depend on the type of cake and production requirements of the line. Sponge cakes can be simply removed from the tray in front of the customer with a cake shovel, for example. Individual pieces are cut either in the factory or at the point of sale, but the cakes stay inside the trays and are also presented inside the tray. This supersedes some production steps and pack aging, while also giving the customer a feeling of freshness and proximity to the workshop where the cake was made.

For cleaning any cake trays or molds of any shape and size, Anneliese lists the following rules:

+ Cleaning them regularly – depending on how dirty they are and/or the frequency of baking

+ Avoiding moisture

+ Avoiding lye or acid

+ Selecting an appropriate, ph-neutral cleaning agent with a soft water jet, and using a soft cloth or brushes to clean them

+ Taking pastries out of molds immediately after baking (to avoid moisture as they cool down)

+ If the pans are not coated, greasing them for an anticorrosion effect. If they are coated, greasing must be avoided, as it will reduce the coating’s lifetime.

+ Ensuring the trays and pans are dry before storing them

Spanish specialist Coatresa provides custom-made tins for bread, which it has been devel oping in partnership with baker ies for over 40 years. “Our Kaizen philosophy has allowed us to develop changes both in bakeware design and coatings. For example, we developed the Lock Pan patented design for one of our clients to optimize their crustless bread production, reducing their product waste by up to 30%,” says Eduard Castaño, Vice President of Marketing and Business Development.

New products are developed, either from scratch or by adapting an existing line. Castaño shared an example: “One of our main clients had problems regarding the stacking of their baguette trays. We developed a specific system that allowed them to increase storage capacity in existing pallets. In this way, they have been able to reduce their storage space more safely (the stacking does not twist when pan-straps are added). This system has since been provided to other clients as well.”

Quality-brand and freshness with long tradition

Hazelnut- and Peanut-Products, roasted, sliced, diced and slivered. Hazelnutfilling and Multi-Crunch. Please ask for products meeting your specifications.

The company also notably developed a patented system called ‘TheSquarestBread’ (TSB), which was first developed to produce crustless bread in a regular form as well as a bigger slice size, using less dough and reducing as much waste as possible. The TSB is a mold with a lock system and a lid. “It has patented features that make the bread grow in a regular and controlled way inside the mold’s enclosure. The lid also has special features that achieve this perfect fit in the mold, while obtaining a completely regular shape of the production with a perfect square. Naturally, this mold incorporates all the improvements that we have made, such as vertical corrugation, an edge designed to give the mold more resistance, etc.,” explains Castaño. Currently, the TSB system is also used for ‘regular’ sliced bread, to improve the way it fits the packaging, and for catering manufacturers.

Another improvement, introduced by Coatresa’s founder Tomas Marin, was the change from a lateral corrugation system of 45° to a vertical one, to eliminate the use of release agents, with only the aid of its Testrong ® range of non-stick coatings for the job. For sliced bread, Coatresa developed the Testrong ® Pyros segment. The Testrong ® ROC was de signed for the production of glazed burger buns, Testrong ® Terracota – for cake trays, and Testrong ® Red Metallic, for baguette trays. To match the best coating to each product, the company conducts tests to develop new Testrong ® Systems that answer each requirement that comes from the final product, considering the characteristics of the dough.

The way the pans and trays are used plays a determining role in preventing the product from sticking. To get the best use out of the coating’s benefits, both the cleaning and the depending processes are key. Sticking issues are usually caused by the deterioration of the coating. “Besides, we have specific technical equipment in our R&D department. There, we constantly trace both the non-stick properties and the interlayer fusion of our coatings in a controlled en vironment,” Castaño explains. Coatresa provides guide lines regarding the use and care of the coatings to ensure optimal performance of Testrong ® Coatings, which include:

+ The safest cleaning process is by using pressurized air; it is recommended to avoid the use of brushes

+ Using a soft stacking system, either automatic or manual

+ Avoid having empty molds or trays should in the oven at temperatures over 200°C

“We developed the Lock Pan patented design for one of our clients to optimize their crustless bread production, reducing their product waste by up to 30%.”

Eduard Castaño, Vice President of Marketing and Business Development, Coatresa© Coatresa

Bread and bun production is challenging with variables like temperature, environment, recipe accuracy, fl our quality, and operator errors affecting the fi nished product. Exact Mixing’s automated Continuous Mixing technology eliminates these variables and makes fl awless buns at rates exceeding 15,000 pounds per hour.

Choose Exact Mixing to perfect your process and your product.

• Automated system operation and controls

• Just in time dough means less waste from line stoppages

• Less labor and energy usage vs. batch mixing

• Eliminates variables due to batch process

• Consistent bun size and color

• Excellent dough temperature control

Markel Food Group Company

in improving your mixing process?

us

Maintenance and recoating also ensure product will not stick to pans. In addition, recoating and refurbishing old sets can save up to 50% of the investment in new bakeware, while also making production more sustainable.

Coatresa focuses its R&D improvements on those elements that are more susceptible to suffering damage due to line automation, related to the pan and their use. On the lines where it is possible, for example, the tin is a little bit elevated from the frame to expand pan life by minimizing friction with the line which may cause abrasion.

Austrian company Precisma focuses on custom-made clean ing machines for baking trays, release agent applicators, aside from predusters and conveyor and handling systems. Virtually every machine is configured to customer require ments, in its 600-sqm production area. “This means that every customer will receive their orders from a single source, including budgeting, planning, specifications and

design, and down to manufacturing, commissioning and maintenance of the machines,” Precisma explains.

“Feeding is done with brush rollers, which helps prolong their life compared with conventional transport systems used by tray cleaning equipment.”

Precisma specialists

Precisma specialists

The company recently started offering its Kobra cleaning technology internationally, which is said to be a nearly maintenance-free machine that is designed to prioritize hygiene, of the equipment and of the trays throughout their daily cleaning processes.

This cleaning system is available for double-rimmed trays measuring 580, 780 and 980 mm. “The trays enter with the baking side facing upwards; feeding is done with brush rollers, which helps prolong their life compared with conven tional transport systems used by tray cleaning equipment,” according to the company. The integrated disk brushes automatically change their rotating direction during the cleaning process. The inner rim is also targeted for cleaning.

The machine has a toothed belt drive to virtually eliminate the need for maintenance. Kobra is made of stainless steel to allow high-pressure cleaning without dismantling the brushes. In addition, individually adjustable disk brushes ensure optimum contact between the brush and tray. Its quick-change system allows the round brushes to be removed by hand for cleaning, with no additional tools. +++

Part II will be published in the next issue of Baking+Biscuit International, with insights from American Pan and KEMPF.

Exports of bread and bakery goods from Germany continued to increase in the first half of 2022, data from the Association of German Plant Bakeries shows. Almost 753,100 tons of bread and baked goods were exported in the first half of 2022, around 30% of which was bread. By comparison, non-EU countries accounted for just 36,000 tons. The rest was made up of fine and long-life baked goods. The vast majority (594,000 tons) was exported to countries in the European Union. The biggest share of the exports goes to the Netherlands (20%), Poland (19%), France (13%), Italy (11%) and Belgium (9%).

“The figures for the first half of 2022 for the export of bread and baked goods from Germany once again show the

great popularity of our products,” Armin Juncker, General Manager of the Association of German Plant Bakeries commented on the published foreign trade figures. He added that the large branches and delivery bakeries, in particular, have a dominant share of bread exports and contribute to “strengthening the image of German bread abroad”. +++

Food packaging is an art. And we’ve been honing our craft for 150 years and counting.

Whether you are looking for a stand-alone machine or a complete system solution, we will support you with our long-standing expertise. With our proven technologies, your bakery products will live up to your customer’s expectations and have an overall improved quality with a fresher taste and aroma.

Scan QR code for further information

Formulating and perfecting the recipe is only the start to having great-tasting, crunchy or soft bakery products. The freezing process is essential to how their properties will be captured and preserved.

+Freezing baked products or dough requires special care, to ensure their structure is not damaged in the process and shelf-life is optimized. They can be frozen for longer storage or shipment; in both cases, shock freezing has its benefits, with the products reaching the correct cold temperature very fast, which ensures their properties will keep. The lower the required temperature, the bigger the refrigeration unit will be, comprising one or two-stage compressing units, Peter De Naeghel – Managing Director, iceCool, explains.

The icePower shock freezing equipment developed by iceCool can reach temperatures as low as -35°C. Pastries, as an example of notoriously delicate products, are best frozen at temperatures between -25°C and -35°C. Shock freezing timings are set according to the product's weight; when the process is complete, most products will do best if stored at -18°C.

The freezing speed has a direct influence on the kind of ice crystals that are formed when the moisture freezes inside the product. Fast freezing creates numerous small ice crystals, leaving the cell wall of the products intact. This means that, after defrosting, products will have the original cell structure and retain the original tenderness and aroma. Alternatively, slow freezing creates large ice crystals destroying the product’s cell walls, as the ice expands. In this case, after defrosting, considerable moisture, including important nutrients, will leak from the product, which also loses its

firmness. Through a proprietary process, “iceCool installa tions are designed to guarantee the principle of small ice crystals retaining the fine cell structure and moisture, thus resulting in very good quality and freshness of the product,” De Naeghel details. Custom designs include various tunnel versions, a choice between ceiling or standing evaporators, and countdown systems for each trolley – among others that can be identified on a case-by-case basis.

Shock freezing with the icePower equipment can be moni tored and closely controlled via its switch box and control panel. “All the electrical switching components are placed neatly and clearly above the entrance door, for easy access for service and operating,” iceCool’s managing director explains. The company uses this control panel and stand ardized interface for every type of installation, including its freezers, or retarders/proofers. The icePower comes with new smart features, including:

+ Network, backup, remote controlling

Product menus and weekly schedules can be saved and backed up using download/upload functions. iceCool installations can be connected via the four-port Ethernet switch to the local data network, to control installations remotely from the office or via WiFi, from mobile devices.

“If you have an Internet connection on your network, then you can control your installations worldwide, via the Internet,” De Naeghel highlights.

If the installations are connected to the Internet, possible errors will be reported via e-mail.

The standard integrated HACCP log table and graphics help with regulation compliance, for the mandatory tem perature registration. “The stored data will be kept for more than one year in the control panel and it can be accessed directly for quick analyses – in table or graphic form. The data can also be extracted and saved on USB or via PC-network, directly onto computers,” the specialist details.

All iceCool installations, including icePower, feature an industrial magnetic door-closing system – the iMagnet, which automatically closes (almost shut) behind the operator, to keep the warm and moist air out of the freezer. “This innovative and robust door-closing system is the newest form of hygienic mechanisms on modern cooling and freezing compartments. It eliminates moving parts that can break or impede the smooth movement of the racks,” he details. Also, there are no obstacles or frames in the way, for easy door cleaning.

The energy improvements help achieve savings for a twoand-a-half-year ROI, iceCool calculates. When an additional swing door is used, there is less ice in the freezer and evaporator, which means that fewer and shorter defrosting sequences are needed. There are multiple additional advantages: improved hygiene while less frequent cleaning is required, shorter running times for compressor and fans are achieved, and the properties of the dough are improved, the company says.

In addition, iceCool is also prepared to offer regulationcompliant refrigerant solutions. Since 2020, refrigerants with a so-called GWP value (‘Global Warming Potential’)

higher than 2,500 may no longer be used. Further steps will be introduced by 2030, as part of the EU’s initiative to phase them out. “iceCool has long been using the green house gas-reduced refrigerant R448A, which has a GWP of 1,380 – well below the limit value. Since further steps by the EU are foreseeable, we offer two future-proof alternatives, namely the natural refrigerant R744, known as CO 2 (GWP=1) and the future refrigerant R455A (GWP=146),” De Naeghel explains. Depending on the application, both alternatives have their strengths and the company provides consultancy on choosing the correct version.

iceCool systems are built to run all year long, in summer just as in winter, which is made possible by the generously dimensioned design of their cooling components. “The pressure build-up is significantly lower than in standard sys tems. The compressors, including the weightlifter, have to do less mechanical work, which reduces CO2 emissions and saves considerable energy and money over its lifetime,” adds De Naeghel.

The equipment also features the iSave HeatRecovery system, which manages the heat generated during refrigeration. With iSave, this heat can be used in various areas including rinsing or heating water. Thawing and fermentation are among the processes with high energy-saving opportunities.

De Naeghel points out that, “The iceCool heat recovery systems iSaveHeatRecovery can be quoted and supplied by iceCool. In this way, iceCool refrigeration concepts achieve eligibility for state subsidies in Germany when selecting eligible refrigerants and if the requirements for waste heat utilization are still met.”

Cold-generating equipment is continuously improved for optimized process efficiency. For Heinen, this means their active spiral cooler – acticool®, the proofline® spiral proofer and their spiral freezer, called arctic. The company places emphasis on precision in the coiling process to meet pro cess demands from bakeries. There are numerous cooling applications in the bakery industry and not all require precision, such as in the case of precooling products for

freezing them at a later time. However, in certain areas (for example, freshly sliced bread), “Absolute temperature accuracy is necessary,” says Jochen Hottinger, Managing Director, Heinen Freezing GmbH & Co. KG. If the product is too hot, then the slicing machines tend to smear and destroy the product. If the product is too cold, the slicing process shatters the crust, causing both unnecessary product loss and the unappealing appearance of the cut product. To this, he adds: “Therefore, we thought about how we could improve the accuracy of our temperature control system. We have changed the number and position of sensors in our system, the control systems (by improving our in-house built PID software controllers) and the airflow through the system – here, our aim was to avoid all unnec essary air baffling plates and air resistance in the system.”

The airflow in Heinen cooling and freezing equipment is generated by frequency-controlled fans that blow the air horizontally through the system. An open airflow through the system ensures that the product comes into contact with the cold air from all sides. “An open and product-oriented

air flow is the basic concept of the acticool,” he illustrates. To avoid too sharp and fast airflows, Heinen uses frequency-controlled fans, with a unique wing design. The company’s managing director details: “It is a bionic wing design based on the wings of owls; they are designed this way to save energy and make less noise.” Airflow intensity is among the parameters included in the product recipes saved into the machine. The acticool normally operates with temperatures around +20°C. Lower temperatures can dry out the product and the system tends to produce condensation if it is too warm.

HeinenSpiral coolers require specific cooling and heating media. For cooling, this medium can be any kind of refrigerant, glycol, or cold water, depending on immediate availability. A closed airflow system and a heating medium are also needed. The specialist goes on to elaborate that, “In a closed system, we also have to eliminate the humidity leaving the product. We control the condensation at the air cooler and reheat afterward as needed.” Energy consump tion can be lowered by using outside air for eliminating humidity instead of the condensation principle and by reducing the pressure loss of all involved components. This means wide fin spacing at the air cooler and baffling plates with little or no air, as well as well-synchronized components,” Hottinger adds.

There are two reasons behind the design of Heinen spiral coolers without air guide elements. First of all, slow air movement in the system is the better alternative for treating the products as gently as possible, as it uses no direct, forced-air stream. “It should be more like a light breeze touching the product from everywhere. If you have air baffling

plates, the air speeds up and aggressively engulfs the product, which can dry out the surface,” explains Hottinger. Secondly, forcing air to go in a certain direction leads to higher energy consumption, because of air pressure loss as it is forced along the baffling plates.

At the core of any spiral system is its belt. Heinen’s spiral coolers use modular plastic belts with their inherent advantages in the process: they are lighter, help save energy, are easy to repair and are more reliable. Since they weigh less, they are also less prone to friction. “As machine builders, we prefer light, plastic belts as they require less force to run in the system which adds up to smaller drives and lower energy consumption, respec tively,” Hottinger shares. Spirals are also known for their flexibility in layout options. Heinen customizes them, especially for bakeries, with designs that match the factory or process layout. “If a double drum twin belt system is needed, Heinen can do this as well. We will recommend the one that best fits the customer's layout because it will benefit them the most,” he explains.

On all Heinen spiral systems, from active spiral coolers, or spiral proofers to spiral freezers, all fans are run via frequency converters, which means that they can be ad justed according to the individual needs of every product. Some of the latest features that Heinen has brought to its spirals include options to enhance the cleaning process. “We have redesigned major parts of the machine so that they are self-draining, easy to access and can be disas sembled without tools,” Heinen’s specialist highlights. For example, the newly-launched freezerfoamer PRO series is a pump unit connected to Heinen’s integrated cleaning system, which saves water and detergents during the cleaning process. The freezerfoamer PRO, in combination with the cleaning system, adjusts water pressure, detergent concentration and foam consistency on each nozzle head and nozzle bar. The investment is amortized by the savings made over time in water and detergents. A complete record of the entire cleaning process is also available with this system.

One of the mottos of Heinen’s design team is that ‘the best spiral freezer has not been built yet’, and that they are continuously under development. This is something the company has learned in over 40 years of working on proofers, coolers and freezers: there is always room for improvement and always a next step. It will be interesting to learn what the future will bring in the world of cooling and freezing. Heinen anticipates that the next generation of proofers, coolers and freezers will precisely and con tinuously adjust to the actual demands of the processed product and point out further optimization and efficiency opportunities. The future sounds ‘cool’. +++

With König vacuum technology, breads, cookies and pastries (e.g. Danish pastry) can be cooled and stabilized for further use in just a few minutes. This enables enormously improved product quality in terms of freshness, crispness, volume and stability, im mediate further processing of the further processing of the past ry and optimization of your operating processes.

Austria

To manufacture rolls and buns with consistent quality for the lowest possible costs, efficient systems are a must, to produce the required volumes and varieties and provide solutions to any number of production challenges.

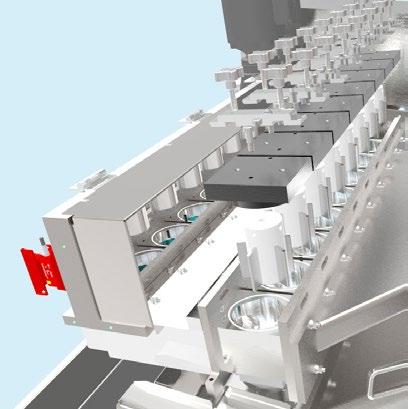

By Catalina Mihu+While manufacturing buns and rolls in high volumes is in itself a challenge, having the product variety to meet changing consumer trends takes challenges to the next level, in everything from mastering production scaling to the equipment itself. Operator skill is also essential to maintaining efficiency, and especially so when experi enced bakers and operators are hard to come by. To sustain high-volume production, absolute control over each step of the process is a must. Automated equipment is essential for this. Bruce Campbell , Vice President – Global Product Technology at AMF Bakery Systems, illustrates: “When bakers run a 96,000 buns/hour line, that means about 27 pieces are made every second. At such a produc tion rate, the system must be well balanced and must react to variable operating conditions.” To support this kind of system, the company recently developed the AMFConnect data management system, which provides live reports about Key Performance Indicators (KPIs) and Diagnostics. The line also includes a newly-redesigned make-up system, which is now easier to clean and comes with additional food and operator safety features, based on EHEDG guidelines.

The line can manufacture soft hamburger buns, assorted rolls and hot dog buns.

AMF designed its high-speed systems for buns and rolls with these challenges in mind, with input from bakers. The line of Accupan Make-Up systems focuses on maintaining constant product quality and safety during production. It can produce rolls ranging from 25 grams to 150 grams. For the production of hot dog rolls, the size range is from 3” (mini hots) to ‘foot longs’ (approx. 300 mm). Special options can also be produced with Twin Roll Splitters at up to 120,000 units per hour.

In addition to the Accupan, AMF also offers the ComboMat, a make-up system for buns, rolls and bread, which allows bakeries with lower production volumes, operating with one mixing system, proofer and oven, to use a single make-up system.

Based on extrusion technology, the HBDFlex and RollFlex Dividers use patented auger technology and precise pressure feedback control loops to process the dough with a minimum of work. “The FLEX pumps, that are at the heart of these dividers, are controlled by servo drives to maintain excellent scaling accuracy, which can be documented and maintained through the use of the new ‘Gram-Saver’ integrated checkweigher,” Campbell explains, which auto matically weighs every fifth row of dough balls and records the weights. High-speed processors analyze the scaling trends and make small adjustments as needed to the divider parameters to ensure scaling accuracy.

The recipe management system in the Accupan allows all parameters to be automatically set, based on the values selected during the initial setup or by using the successful parameters from the previous day’s production. Change overs can be made in a matter of seconds, by selecting the desired recipe via the HMI. “There are no change parts needed for different sizes or rates of products. Even the swap of molder boards and imprinters can be automated in certain configurations,” Campbell explains. Options that can be set on the HBDFlex Accupan include the auger pressure set point, the UltraFLow RPM, metering pump speed, knife and intermediate proofer speed synch, rounder belt speed, servo gate controls, the speed of the sheeter roller and the molder belt, pan pre-indexing speed and magnetic pan indexer settings, pan shaker settings, and the flour reclaim sequence. All these automated operations contribute to the system’s high manufacturing speeds of up to 72,000 buns per hour per make-up system. The system only requires minimal intervention from operators to run.

The system also features the AMF Fusion Dough System, which mixes and delivers dough at constant rates and tem peratures to the AMF Flex divider – this ensures the pieces of dough accurately match the required weights and shapes. The AMF Convay system then transports pans and

products, working with smooth transitions through process steps, to protect product integrity.

The AMF BakeTech proofing and baking technologies are also incorporated into the system, and contribute to product consistency by keeping processes under control. The AMF Workhorse system is responsible for the high-speed handling of pans. “This is a key process for balancing the exact pan rate with the production needs,” Bobby Martin, Global Product Systems Leader at AMF, also explains. The buns and rolls are then cooled through an AMF Vesta Spiral Cooler and brought to the AMF PackTech packaging station. At the end of the line, AMF Workhorse and AMF Convay

will then team up for handling and loading: plastic baskets and cardboard boxes, which can also run simultaneously, are placed onto the shipping docks via palletizing systems.

There are two basic AMF Flex dividers available for buns, rolls and English Muffins, with design differences that enhance their efficiency and flexibility based on the types of roll and speeds.

Providing high quality blades for 85+ years. Partner with our experience to optimize your slicing.

sales@hansaloy.com

1. The HBDFlex divider is available in 4, 6, 8 and now 10 pockets; Campbell recommends this equipment for high-speed bun production: “The servo knife can run up to 155 cuts per minute. Scaling accuracy is typically a standard deviation within 1% of the target weight. For a 60-gram dough ball, the STDEV is 0.6 grams.”

2. The RollFlex, available in 4, 6 and now 8 pockets uses a single auger pump with built-in dough developer. This is excellent for a bun and roll line that has more changeo vers and has products with inclusions like fruits. The Roll Flex has two options for augers, 6” and 8” depending on speed and dough types.

The MuffinFlex is a version of the RollFlex, but with a smaller auger, which is specifically designed for the slack English Muffin dough on a raised frame, to feed into a Sugden Proofer and Griddle.

The FLEX pumps on AMF’s dividers use a simple sliding vane technology that can manage the flow of dough from each port with accuracy and low pressure. “The flow is au tomatically balanced across the ports and using recipe control can be reliably repeated every day. Each pump has its own servo control, which also allows the speeds to be adjusted individually if needed,” Campbell details. Moreover, if a port or two needs to be blocked off (e.g., when a 6-across pan runs on an 8-across bun system), this is done automatically via the recipe management system, by simply setting the speed of that port to zero.

The UltraFlow Dough Developer is critical to achieving consistent dough quality. It is based on the popular DoFlow system, which has been used in the production of buns for almost 40 years. The UltraFlow has received improvements

for higher capacity than its predecessor and can run over 15,000 pounds per hour. This production rate means it can even be used on some bread lines. Campbell explains: “The theory has always been to use vacuum to degas the dough just before dividing. This was originally invented for use on Volumetric Dividers, where significant gas built up in the dough over the 15-minute batch cycle. This improves scaling accuracy and also eliminates defects due to large holes from gas.” Additionally, the action of the developer paddle ensures the dough is consistent from the start to the end of the dough batch as it enters the divider, a critical feature for the ultra-high accuracy and volumes needed in today’s QSR market.

AMF has an optional UltraFlow Bypass hopper, which allows the unit to be rolled back and the dough will skip this step in the process. This bypass benefits stiffer doughs and products that need the Accupan to make a more ‘open’ grain look.

The S-Series Conveyor keeps products on the move along the bun line, bringing an upgraded sanitary design. “The AMF Convay engineering team was inspired by the highest food industry sanitary design standards, reviewing the design with bakers and continuously making sanitary design assessments. Hollow structures, sandwich catch points and flat surfaces have been eliminated from the design, reducing the sanitation time requirements,” Martin adds. Moreover, the S-Series is configurable based on unique preferences, to comply with specifications for controllers, panel views, motors, bearings, type of levelers, type of carrying belts and type of sprockets. All AMF Convay systems are de signed for the application, so trays of any size can be used.

“Application engineers will select the proper widths and belt types for conveying dough balls, pans, lids, baked

products, packaged products, plastic baskets, basket stacks, cardboard boxes, pallets and pallet stacks. AMF Convay is the brand connecting all AMF family of brands technologies into one complete system,” he explains.

This bun and roll line also caters to the QSR manufacturer's needs by incorporating a pan shaker, which centers the buns with a simple, linear shaking motion, to eliminate the risk of defects in the products’ shape. “The AMF Pan Shaker design is unique as it allows up to 10 shakes for each pan, while also never stopping the pan. The high-frequency shaking action can also eliminate doubles if one dough piece is overlapping another when they initially reach the pan,” Campbell explains.

Time is money, especially so in high-speed bakery produc tion. All process steps, and the connections in between, run at a similarly fast pace on AMF’s bun and roll line. This includes pan and product cooling. For pans, cooling allows them to reenter a new production cycle faster, saving time, and money. The line specialist incorporated the AMF Bake Tech pan coolers to help here. The system, on the one hand, protects the fresh and cool dough pieces from the heat of the pans by either allowing the pans more time to cool at ambient temperature or by speeding up their cooling process with controlled airflow in a tunnel. Cooling products, on the other hand, takes into consideration the bakery’s location and environment; some can constantly cool buns and rolls, throughout the year, with an AMF Vesta Spiral Cooler running at ambient temperature and humidity. But, for bakeries where the ambient conditions within the production area change with the seasons, a fully controlled environment is key; here, the AMF Vesta Spiral Cooler Enclosed option helps control both humidity and temperature, maintaining values within the same range all year long, regardless of weather changes.

Once cooled, the buns and rolls are ready for their last stop: packaging. Products are automatically brought to the packaging machine with another conveyor system, which offers several handling choices. Martin explains: “AMF Convay has developed many different solutions for handling individual products with round, square or oblong shapes, as well as for clustered products of many cluster configura tions. Once products are delivered to the infeed of AMF PackTech packaging machines, the products are accumu lated making sure the packages are filled with the exact number of products, and then automatically released to the continuous sequence of slicing, bagging and tying machines.” AMF PackTech technologies automatically deliver packaged products at a constant rate downstream to the AMF Workhorse product loading station.

Over the past decades, existing technologies have been constantly challenged by high consumer demand. That has put pressure on engineering teams to develop faster units and more reliable equipment, running at more than 99.5% run rate, Martin points out. Higher production speeds brought about new challenges, as the impact of food waste impact grew simultaneously. “The oven is often declared as the heart of the bakery, and rightfully so; but, industrial bakers recognize the importance of the whole system running at cruising speed,” he says, acknowledging the importance of having automated, continuous operations and keeping up with consistent quality, with the support of data collection and machine learning capabilities.

For fully-automated bakeries, the AMF LineGuardianTM brings a network connection, providing real-time dashboards from all AMF NexGen equipment built on AMF Connect specifi cations. Martin: “The interconnectivity of all the units reporting real-time status is the future of industrial bakers, helping them make decisions based on data and trends.” +++

Ashworth Bros., Inc. has revolutionized the future of conveyor belts since 1946 by leading the market with the most conveyor belt patents in the food processing, and baking industry. Companies around the world depend on Ashworth’s quality products, reliable customer service, innovative solutions, and experienced AshPro team.

Maintains consistent belt tensions between sanitation cycles.

Remotely monitor multiple spirals at different plants in real time.

An affordable solution for standard and wide belt stackers.

+König has developed two new turnkey solutions that are specifically tailored to manufacturing flatbreads: the cross-sheeted pizza line and the new Pinsa Romana line are aimed at condensing its bakery equipment knowl edge in tailored industrial lines for special products.

König Technology Projektmanagement GmbH was set up within the König group a few years ago to delve into the design and building of special projects. Nicola Perbellini Head of König Technology Projektmanagement Italy says, “In some cases, like these two lines, the focus has been on the peculiarity of the product and the need to compose a specific line that is able to offer an industrial approach to a specific artisan recipe”.

The pizza market has continuously grown over the last 30 years. Besides traditional recipes, numerous variations and hybrid concepts have appeared on the market. The Cross Sheeted Pizza Line proposed by König respects the initial preparation of a traditional Italian pizza. It was designed to accurately support artisan recipes, with no dough scrapes in the process and with a hygienic design.

The line comprises the following types of equipment for the main process steps: dough mixer, divider and rounder, proofer, cross-sheeting section, sauce depositor, oven, topping station and freezing spiral.

The well-known REX Dividing & Rounding machine can be found in this line’s setup, which “has been recognized over the last 30 years as the reference machine for this job and creates the right starting point for a top product, both in terms of quality and weight precision,” says König. After the dough proofing module, a cross-sheeting section handles the make-up part of the line, where the target thickness with the desired dough structure is reached. “Here, a slight irregularity factor in the circular shape will even add an artisan touch to the product,” König highlights.

The SDD EOS oven is König’s solution for the baking needs of these kinds of products, to help the products measure up to the artisan quality of an Italian pizza. It can be set to run at very high temperatures of up to 900°C on the radiant surface, which are key to baking pizza and flatbreads, along with the corresponding energy flux. The tomato sauce depositor and topping equipment are provided in cooper ation with a partner supplier and a freezing spiral com pletes the line. This turnkey solution can come in different layouts and sizes.

Pinsa Romana is an example of an artisan bakery product using a dough made with a combination of soy, rice and wheat flour, a healthy alternative to traditional pizza. It is expanding its market from its origins in Rome thanks to its lightness and organoleptic characteristics. Transferring this traditional recipe and the experience of a master baker’s hand in curing the dough, while avoiding addi tives to industrial volumes is a challenge for industrial baking technology. König says that Roman bakers approved the solution developed by the Austrian company.

The line features solutions for dough mixing, dough resting, dividing and rounding, board handling, proofing, manual make-up and oil spraying, baking, spiral freezing and conveying. CERES is the machine used for dividing, as it is suitable for all doughs, including those typically artisan products with extremely high-water content and long resting times. The CERES protects the dough structure and has a high level of accuracy in dividing pieces of the required weight. “The way the dough is handled from hopper to weighing and cutting unit is unique. For a product like Pinsa Romana, this is the key to getting the correct production process,” König explains. Pinsa Romana is another hightemperature baking product, which is why the SDD EOS oven is also included in this line. A freezing spiral and a buffering conveyor complete the Pinsa Romana line.

It was designed to provide similar product and processrelated advantages to the cross-sheeted pizza line, focusing on custom-made solutions that help automate the production of artisan recipes, with a hygienic design and no wasted dough. +++

König

König

König

König

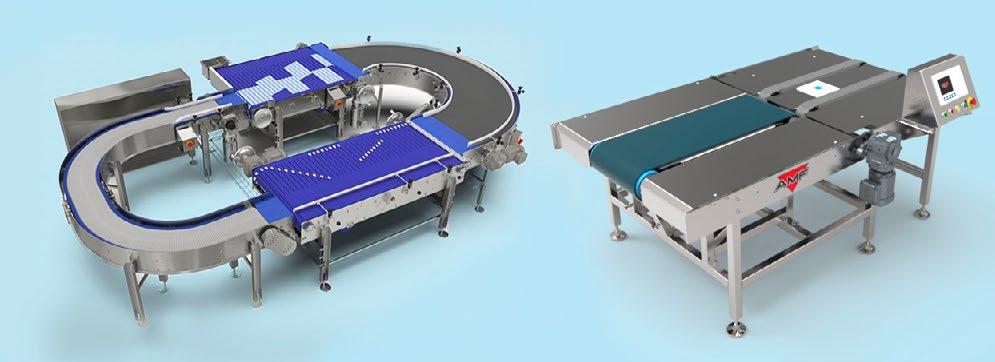

Reliable product transfer between processes is essential to maintaining the rhythm in production sequences, with continuous, automated adjuste ments. To optimize efficiency in industrial baking, everything is riding on conveyor systems.

+As products move along the production cycle, their charac teristics evolve to the next desired stage. Conveying systems need to be mindful of that, especially for the belts that o perate on them. What is the cor rect belt for each process step? To identify the right type for each convey ing job in a bakery, the first step is having a clear understanding of the product and the application, as each can greatly vary compared to its down- or upstream counterparts, from proofing and cooling to baking and packaging or general conveying.

Ashworth provides a comprehensive range of conveyor belts and provides us with a ‘guided tour’ of the various types of belts that are the best match for each process in a bakery. How is the right type of belt for each conveying job in a bakery deter mined? What are the criteria to match the best option for belt materials and construction with the process stage?

Understanding the application (gen eral conveying, proofing, cooling, bak ing, packaging, etc.) and the product is the first step. There are numerous factors that play a role in this pairing endeavor, including the application temperature, the product support re quirements and even cleaning proto cols, for example. “Once these condi tions are known, we frequently talk to users to understand any past chal lenges or concerns before we recom mend any particular belting,” Ash worth says about the thought process. Challenges in finding the optimum choice in belts, and then working with it over time, are often product related. When handling bakery goods that are sticky, soft, oily, or sugary, products can easily get damaged or be left with unwanted markings as they

advance along conveyor belts. These products can also be challenging to remove as they are transferred along the line. Here, experience is an inval uable asset in making an informed se lection of the best belting solution for each segment of the processing line. Ashworth illustrates: “For baking, a close or tight mesh may be best. How ever, after baking, a more open mesh may be necessary to facilitate cooling prior to packing. For applications requiring short transfers, a sprocketdriven belt is a better choice than a friction drive because the sprockets aid in tracking these short belts.”

In bakeries, products start off as pliable pieces of dough that require more support at this stage, compared to their characteristics after baking, then through the cooling and packaging segments of the process. Ashworth can offer different belts to best accommo date the product as it travels through each processing step, among them plastic and metal spirals, high-density mesh, and woven belts, flat wire belts, and belt and sprocket systems.

“Material choices can also be evalu ated to offer the best options for the process such as salting, freezing, or baking,” Ashworth explains.

Beyond material selection, there are several customization options to meet the processing conditions in each case. Ashworth can provide flights or lifts for inclining systems, side guards for product retention, or belts with added chains for precise timing, for example.

Once the best choice of belts for the process is found, optimizing that pro cess can begin. Ashworth offers instal lation support in this regard, through

its Factory Services. “We believe our precision, custommanufactured belts will perform and last longest when installed and tracked properly. Should an issue arise, our Factory Service Technicians will assist the user with troubleshooting and training,” the company shares.

Processing conditions are constantly changing in any system, which is why frequent inspections for proper belt operation are critical to belt operation. Ashworth: “We are releasing our SmartOven ™ system, which monitors key operating parameters of the oven. This data is relayed to your smart device, offering real-time monitoring.” Through this app, alarms can be set to send notifications to smart devices about deviations from standard or baseline operating conditions.

As different as the belts throughout processing stages may be (and should be), monitoring does not need to share this variety. On the contrary, there are advantages to align not just belts, but all types of equipment to a standardized ‘language’. For belts, monitoring is made even easier to achieve as they operate essentially the same, regardless of their construction differences. “Consideration is necessary when choosing a specific sensor that is dependent on belting material, open area, or edge construction,” Ashworth recommends.

Ashworth launched the SmartOven ™ Monitoring System at IBIE this year, joining the SmartSpiral ™ in this range. It monitors critical oven operating parameters and pro vides real-time feedback to Maintenance, Engineering and Plant management, compiling graphical representa tions of the collected data, to show past and current operating trends that can be analyzed to anticipate the system’s future performance, including potential failures before they happen. Maintenance work can be planned when convenient and prevents failures – and the down times they would bring – from occurring altogether. The SmartSpiral ™ Monitoring System provides real-time monitoring of multiple spirals, even over different facilities, and manages maintenance as well.

“Our SmartSpiral ™ and now our SmartOven ™ technology notifies the user of trending data from the system. By monitoring collected trend data, they can observe changes in the system. This can indicate potential belt or component failure. Being able to ‘fix’ problems before they become catastrophic means the belt and system remain in operation. Predictive maintenance can be performed during off hours or down time instead of during a crash mid-production run,” the company highlights.

Opportunities to have belts throughout the processing plant that work smarter, not harder, are here. The key is in the choice and operation setup. +++

Several methods can be used for depanning baked products safely. Automation provides the next-level tools for maximum flexibility and reliability. The good news is that it does not require replacing a whole line to incorporate.

+Depanning is traditionally performed with methods including inline conveyorized solutions and gantry systems. These depanning stations can be retrofitted with robotics, which comes with multiple benefits.

While they have some limitations, inline depanning systems are effective in performing a basic continuous movement, lifting the product with the vacuum heads of the conveyor and depositing it onto another conveyor. They do so by using a vacuum belt that runs atop the pan conveyors, in the direction of travel. As trays pass underneath the vacuum conveyor, suction is engaged, drawing the product out of the pan and adhering it to the vacuum belt. While it is very efficient in terms of space utilization and overall line design, this method can only be used for a limited variety of prod ucts that match the positioning of the vacuum cups and can be easily lifted from their pans, such as baguettes in perforated fluted pans. In addition, inline systems can only be adopted where the layout allows for the product to continue straight on after depanning.

In addition, gantry depanning systems are typically used for products that are not easily handled by the more traditional inline systems. The suction cups are arranged to match the

layout of the pan. “For example, muffins that are baked in individual cavities of a large pan will have fixed spacing and require an individualized picking and handling approach for optimal placement following depanning,” ABI Ltd illus trates. The gantry moves the product from the pan to the product conveyor. The pick-up location, movement path, and drop-off location are dependent on the bakery layout and are fixed, once determined. “However, gantry systems offer the additional flexibility of providing three planes of movement - X, Y and Z axis (forward/back, side to side and up and down), where Inline systems are limited to running with the existing direction of pan and product travel. They can also be set up in parallel with the pan conveyor and can use a broader range of tooling, including suction or needles.

Needle tools are frequently used for products that are heavily seeded, to mitigate the risk of removing the seeds, which is an inherent risk with vacuum tooling. They can also be used for depanning sweet goods like pound cakes, as they provide a means to establish a much firmer grip on the product during depanning and flight. Using tool changers, operators can efficiently swap tools to match a variety of products and pans.

Robotics can be installed on existing lines, used for a diverse range of products (including loaf breads, buns, cakes, cup cakes, or muffins) and replacing a depanning system is not required. ABI states that it can create custom tools and solutions for a large range of bakery products, with both conventional and robotic solutions.

Robots bring the maximum degree of flexibility to the table, regarding possible movements and tooling options. An automatic tool changer allows the depanning system to switch between a wide variety of different end-of-arm tools (EOATs), safely and efficiently.

Robots bring added benefits in addition to conventional depanning solutions in several key areas, starting with their location and orientation. ABI explains: “There is such a broad selection of robots to choose from that you can hang Delta robots over a line, place a six-axis robotic arm atop and parallel to the product travel for expanded reach and diverse approach paths, or place SCARA robots adjacent to the line for high speed, repetitive picks and places… The variations are endless.”

In addition, robots can perform complex movements, beyond the capabilities of gantry and inline systems – especially robots operating on a six-axis movement. For example, if products need to be depanned into a container, these robots can approach the container at an entirely different angle and orientation than the one used to pick the product.

Robots are also consistently accurate, compared with tradi tional systems. They can run at varying speeds, depending on their type and the way they are mounted. Moreover, they tend to require less maintenance than any other type of automation. “If the right type and number of robots are deployed and the load is managed correctly, robots have an extremely long life, with very wide Mean Time Between Failures (MTBF) windows.

Different options that can be used for tooling include suction, needles, soft or hard mechanically-actuated gripping tools, soft or hard air-actuated gripping tools, or scoops of varying configurations. ABI details: + Suction cups use vacuum to lift the product from the pan.

Depending on the type, size and weight of the product, various styles are used. Products can be lifted with a single cup, or by combining several cups into a particular pattern. Releasing the product into the downstream process involves either a quick vacuum release mechanism or supplying low-pressure compressed air into the suction cup.

+ Needle grippers are a set of thin needles that are inserted into a product to form an ‘X’. The robotic arm lifts the

product out of the pan and moves it to the desired loca tion. Then, the needles retract and release the product.

+ The grippers are similar to the touch of human fingers: during the pick, the dual durometer ‘finger’ is inflated, causing the finger to curl around the product with a pre determined pressure. Strategically positioned fingers, in a pattern best suited to the product, allow for gentle but firm handling of the product. For product release, the air is extracted from the finger cavity, causing the finger to flex outwards.

In addition, scoop tools with shapes (such as spatulas, or spoons) can be used to take the products out of a range of different types of pans. In this case, the release is typically carried out by flipping or quickly pulling away, which causes the product to drop. This method is not very precise, which is why it is not widely adopted.

The Canadian company has recently developed several upgrades for its robotics-automated depanning systems. ABI has shortened changeover times down to seconds, while manual switchovers may take several minutes. This is done through the use of interchangeable tool mountings and automated tool-changing setups. “With automated tool changing in particular, the robotic arm automatically goes into its changeover position and releases the attached tool. It then moves to a secondary position, attaches to a tool in waiting and travels to its home or cycle start position, ready to begin operation,” ABI explains. These changeovers are entirely automated, without the need for an operator.

ABI’s robotics-powered depanning technology also features an enhanced vision system, which accurately locates the product being manipulated. Robots use vision systems to guide their operation – from locating and correctly identi fying the products, to performing QA by comparing them to predefined parameters. “Previously, a pan and all the product in or on it would need to be perfectly positioned for depanning, but with our improved vision system, we can accommodate variability in pan positioning and still depan the product with precision,” ABI LTD elaborates.

The company has also built a broader range of custom EOATs that support unique requirements for products with different densities, textures and surfaces. The variety of pans that bakeries use was also taken into consideration when developing these tools.

With the new vision system, some configurations allow the use of a quality control function: sub-standard products can be automatically rejected by programming robots to only pick out the products that passed inspection. “This type of feature can be used as a means to gather important performance data and also to improve overall process efficiency at the line,” ABI specialists explain. Robots programmed this way will not waste cycles and resources on products that will be discarded.

The robotic systems, together with the vision platform, can collect a vast array of data on productivity for analytics. They can provide insights into the depanned and rejected products, production rate statistics and other KPIs.