SCIENCE FRICTION

LONG-LASTING SEALING TECHNOLOGY DEFIES WIND AND WEATHER

How can seals exposed to wind and weather cope with the powerful forces of multi-megawatt wind turbines with ever-larger shaft diameters? Our researchers and engineers have developed a low-friction, high performance seal that can tolerate strong shaft runout and reliably prevent leaks. This means high operational reliability, longer maintenance intervals, and signi cant cost savings. fst.com

EDITOR’S NOTE

Still going strong

Just like in the early months of last year, the world is startled by a disaster again. The earthquake in the Turkish-Syrian border area resulted in many casualties and tremendous damage which will both have a lasting impact on the lives of many families. Meanwhile, there are no signs of the war in Ukraine to end soon. We should not forget that every day, people die or get wounded as a result of this. What we have learned from both events is that all over the world people are joining forces to help the misfortune, and those in need. Also, when looking at the impact of the war, we see that governments and the industry show a high level of decisiveness and flexibility to cope with the challenges that have arisen. Let us hope that this will also help to overcome the damage and pain caused by the earthquakes.

Human nature shows a high level of resiliency and people tend to get back to normal life and business as soon as possible. Problems are there to be solved and alternatives are found. The supply of oil and gas from Russia came to a halt, which made countries successfully look for other options. Also, the energy transition gained momentum with governments raising their goals for green energy. However, aren’t things going too fast? With the saying ‘Don’t lose sight of the forest just because you think you are in the weeds’ in mind, we should all be aware of the fact that we will still heavily depend on oil and gas for the upcoming decades. Other than that, the industry must continue to invest in keeping the production reliable, safe, e cient, and sustainable wherever possible, as we should not bet everything on electrification.

When looking through the pages of this issue, you will notice that business is still going strong in our industry and in the many segments involved. New challenges, such as cybercrime and the e ects of bigger wind turbines, ask for new ideas and innovative thinking. Impressive projects, such as an 18km long tunnel between Denmark and Germany, display the capabilities of man and machine. Many companies cannot wait to showcase their o ers to the visitors of the sold out Wind Europe Copenhagen and in Brittany, the authorities and industry are looking forward to the start of the construction of several o shore wind farms nearby. You will find these and many other interesting stories on the next pages. It was a pleasure to compile them for you, and I hope you will enjoy reading.

Arno Dirkzwager ARNO@YNFPUBLISHERS.COM

Arno Dirkzwager ARNO@YNFPUBLISHERS.COM

Liftal Vlissingen

Groenlandweg 4

Havennummer 4056

4455 SN Nieuwdorp

(Vlissingen-Oost)

Tel: +31 (0) 118 - 488 450

Email: vlissingen@liftal.com

Liftal Rilland

De Poort 15

4411 PB Rilland

Tel: +31 (0) 113 - 571 523

Email: rilland@liftal.com

Liftal Rotterdam

p/a Admiraal de Ruyterstraat 24

3115 HB Schiedam

Tel: +31 (0)10 - 60 036 60

Email: rotterdam@liftal.com

Liftal Belgium

Duitslandstraat 4

9140 Temse

Tel: +32 (0)3 710 11 82

Email: temse@liftal.com

ROV training partnership advances industry skills agenda

DRIFT O shore has struck a partnership agreement to deliver technical training on Seatronics’ VALOR ROV system. The collaboration with Seatronics, a brand in Acteon’s Data and Robotics division, will serve to sustain a pool of skilled and competent pilots, and demonstrates DRIFT O shore’s training capabilities within its wider service o ering. The VALOR ROV technology is among the most up to date on the subsea market, bridging the gap between Observation Class and Work Class ROVs by using a network-based operating system and advanced sensor control.

DRIFT O shore is to lead the training courses in both the UK and USA, utilising the VALOR ROV and Seatronics test tanks. Kyle Pitman, Founder and Director at DRIFT O shore, says, “Our partnership with Seatronics gives us a new opportunity to show how our quality training services can support the industry and pilots in achieving their goals.”

i. driftoffshore.com

DNV to launch phase 2 of o shore hydrogen pipelines joint industry project

DNV is launching the second phase of H2Pipe, a joint industry project aiming to develop a new code for the design, requalification, construction, and operation of o shore pipelines to transport hydrogen – either pure or blended with natural gas. Phase 2 of H2Pipe is planned to start in Q1 2023 and lasts two years. It will consist of a comprehensive experimental test programme to enhance the understanding of the governing hydrogen embrittlement mechanisms and how hydrogen a ects the integrity of the line pipe material. In addition to the experimental test campaign, Phase 2 will also include tasks such as a feasibility level design of o shore hydrogen pipelines and a risk assessment study to look at safety aspects of o shore hydrogen pipelines. The primary outcome of Phase 2 is expected to be a detailed guideline o ering specific guidance for use in design and re-purposing of o shore pipelines for hydrogen transport.

i. dnv.com

Damen’s new o shore construction capability reveals

Damen Shipyards Group is leveraging its resources and shipbuilding expertise to become a major force in o shore construction. Damen Shipyards Mangalia (DSMa), Romania, the group’s largest facility, will play a significant role in this. Capable of handling very large structures, it is also equipped with a semi-automated panel line, modern blasting and painting cells, a 1,000t gantry crane and other equipment that make it highly e cient operationally, as well as economically. The company is currently delivering two HVDC (High-Voltage Direct Current) o shore transmission projects at DSMa, both of which are being constructed under contracts with Aker Solutions as the main EPCI contractor. Damen is undertaking the structural fabrication, surface protection, outfitting including insulation, lighting, ducting, local cabling and more, as well as the fabrication of the transport grillages. Work began last year and the first HVDC is due for delivery in the first half of 2023 and the second will be delivered in Q1 2024. Once complete, the HVDC topsides will set sail for Aker Solutions’ yard in Stord, Norway, where the HVDC equipment will be installed and commissioned before they depart for their final destinations.

i. damen.comThe world’s largest monopile foundation manufacturing plant

Sif has announced its USD 352 million final investment decision to construct the world’s largest monopile foundation manufacturing plant in Rotterdam, the Netherlands. Construction is expected to start in April 2023. Once the expanded manufacturing plant is fully ramped-up, which is expected in the first half of 2025, the total combined capacity of Sif will be increased to 500,000t a year and upgrade Sif’s capabilities to manufacture the equivalent of 200 XXXL, 11m diameter, 2,500t reference monopile foundations a year. Two launching customers together have committed to 348,000t of production (booked or in exclusive negotiation) bringing the present total orderbook to 662,000t. A long-term capacity reservation framework agreement with Equinor is in place while a second long-term capacity reservation framework agreement is currently being negotiated, which signifies strong commitment from both customers and the market. These launching orders and long-term capacity reservation framework agreements result in strong visibility of future projects and provide significant support to the long-term financial position of the company.All relevant procedures are on schedule for the start of the construction activities.

i. sif-group.com

Bourbon and Horizon Maritime join forces

Bourbon and Horizon Maritime have announced a new joint venture, Bourbon Horizon, dedicated to providing marine services and operations, focusing on the North Sea and Canadian o shore markets. Incorporated in Norway, the new company is strategically positioned in Fosnavåg (Norway) and St. John’s (Newfoundland and Labrador, Canada), with a base fleet of seven modern and capable o shore support vessels: five PSVs, a large AHTS with WROV and a MPSV currently configured for subsea and trenching services. The partnership builds on natural synergies and shared values between the two shipowners. With extensive experience in the harshest o shore environments, Bourbon Horizon will also o er comprehensive ship management services to other shipowners in the industry. With more than 200 dedicated and experienced employees, including a deep pool of experienced seafarers from all over the world, Bourbon Horizon is well equipped for any project.

i. bourbon-online.com

Lankhorst first for deepwater deployment and recovery ropes

In an industry first for deepwater deployment and recovery systems, Lankhorst O shore announces the development of a new DNV Endorsement of Qualification Plan End-toEnd rope splice for its LankoDeep rope. In the event the LankoDeep needs to be spliced o shore by certified personnel, an end-to-end splice can be made quickly, allowing o shore handling operations to continue uninterrupted, and safe in the knowledge that the integrity of the LankoDeep rope is assured. Developed in-house, the LankoDeep rope splicing procedure, which is being certified under DNV-SE-0160, significantly improves the viability of deep-water deployment and recovery projects.

LankoDeep is based on Dyneema DM20 XBO optimised for cyclic bending. Designed from the outset for deep water lowering and recovery projects, LankoDeep o ers significant operational and environmental benefits compared with steel wire ropes.

i. lankhorstropes.com

Fugro secures significant o shore wind programme on the US East Coast

Fugro has signed a letter of intent to optimise and perform a site characterisation programme for an o shore wind development on the US East Coast. The programme is focused on accelerating the construction and operations permitting process and represents Fugro’s latest work on the US East Coast. Fieldwork will begin in the second quarter of 2023 and involves collection of geophysical and geotechnical datasets. Supporting site planning and engineering design, the developing ground model will be made available to project owners in near real-time to facilitate faster decision-making by project engineers and improved collaboration with stakeholders, including regulatory agencies.

i. fugro.com

Siemens Gamesa intends to establish a nacelle facility in New York

Siemens Gamesa intends to build a major o shore nacelle manufacturing facility in New York state, subject to the company’s wind turbines being selected by the New York authorities in their third o shore wind solicitation. The planned facility will be located at the Port of Coeymans and represent an investment of around USD 500 million in the region. Siemens Gamesa is also committing to localising several new component supplier facilities, including steel component fabrication, bearings, and composite components,

demonstrating the further development of a sustainable local supply chain ecosystem. The proposed facility and supplier network in New York would supply components for all Siemens Gamesa o shore wind power projects along the US East Coast. It is part of the company’s integrated plan to localise its o shore wind power supply chain on the US East Coast and also builds upon Siemens Gamesa’s planned o shore wind turbine blade finishing facility in Portsmouth, Virginia as announced in October 2021.

i. siemensgamesa.com

By the industry, for the industry

WindEurope’s Annual Event is returning to Denmark – the home of wind energy. The entire industry will be in Copenhagen from25-27 April 2023.

ALL IMAGES COURTESY OF WINDEUROPE.

We are living through turbulent times and the coming years will be crucial for wind energy. Europe needs to be self-su cient in energy for its own security and the EU is calling for decarbonisation by 2050. Wind energy needs to take charge and meet these challenges. For the industry, the need to decarbonise comes with a new dimension. With electricity prices through the roof, clean, homegrown,

reliable, and a ordable energy for all Europeans is needed. In this challenge, wind energy has to take the lead, driving Europe’s response to this energy crisis and safeguarding European livelihoods.

When it comes to wind power, Denmark is one of Europe’s shining lights. The country is a global leader in the field, for both onshore and o shore wind. And a showcase for what we do best as an

industry. Therefore, it is only fitting that in 2023, the wind energy sector will come to life in the Bella Center in Copenhagen. This year’s conference will be looking at how to deliver the rapid buildout of wind and doubling down on the major obstacles. The objectives set out in REPowerEU, the EU’s energy response to the current crisis, aren’t necessarily being deployed on the ground. Many obstacles remain. And

Details

Date:25-27 April

Opening hours: 25-26 April:09:00h-18:00h

27 April:09:00h-17:00h

Venue:Bella Center Copenhagen, Center Boulevard 9

2300 Copenhagen (DK)

WindEurope’s goal is to tackle these head on, and get wind on the path to growth.

WindEurope’s Annual Event is developed by the industry for the industry and the conference programme has been set up in close collaboration with hundreds of experts from across the industry and academia, as well as with WindEurope’s Working Groups, Event Ambassadors and Content Partners. Conference key focuses include:

• Slow and cumbersome permitting and insu cient market scale.

• The supply chain, and how to ramp it up.

• Other societal interests, and how to engage with them.

•How to accelerate grid deployment.

• Engaging the demand side.

Across three days, visitors will be able to attend more than 50 sessions about

policy, industry, education, and finance in which they can listen to and interact with speakers from Europe and beyond, from policy to industry, education to finance, and from local authorities right up to European and international bodies.

Parallel to the conference, a completely sold-out exhibition takes place where visitors (an estimated +10,000)can meet more than 400 companieswho are ready to reach out, do business, and showcase their latest products to the entire sector. The wind industry is always on the lookout for fresh voices and new ideas to fulfil its potential. Dedicated to innovative solutions, the Startup Pavilion is a place designed for companies looking to showcase innovative technology to prospective partners and buyers.

i. windeurope.org/annual2023

Growing demand for low alloy steel solutions

Last year, most companies in the industry could throw away their short-term plans due to the crisis in Ukraine and its e ect on the energy market. Schelde Exotech, for example, experienced an unexpected growth, which causes lack of space in their brand-new facility. ALL PHOTOS COURTESY OF SCHELDE EXOTECH.

Schelde Exotech designs and constructs high-end equipment for various industries. The company is a 100% subsidiary of Pressure Thermal Dynamics (PTD) since 2019. Within the

PTD Group, there is a close cooperation with Verolme (Netherlands), Logan Industries (US), and Nordic Custom (Estonia). At the end of last year, the company moved into a brand-new

facility in the Vlissingen port area of North Sea Port. Next to modern o ce spaces, the new building is divided into four halls. One hall is a cleanroom, for example for the construction and

maintenance of vacuum systems. A second hall is equipped as semicleanroom for the machining of stainless steel and alloy work pieces. The third hall is used for machining carbon steel, and the fourth is an assembly hall. “Having everything under one roof and closely together yields ample logistic advantages,” Jos Mols, Managing Director of Schelde Exotech elaborates, “and on top of this, being located at North Sea Port, with deep sea quay facilities at a stone’s throw and close to the A58 highway, also is a large improvement compared to our former location in the city of Vlissingen.”

Growing demand

“Around eighteen months ago, the design for our new production facility in the Vlissingen port area of North Sea

Port was made, and soon after that construction started”, Mr Mols explains. He continues, “In the years before, we researched various options for moving from our original location near the city centre of Vlissingen to a larger and better located facility. First, we looked at various existing options, but soon we decided that new construction was the best solution for us.” At the end of last year, the company moved to its new location and so far, the team of Schelde Exotech is very satisfied with the new workplace. However, caused by a strong growth of the order book, the company is already looking for expansion. “When construction of our new premises started,” Mr Mols elaborates, “we could not foresee what would happen in the world. The energy crisis caused by the Ukraine war had a large e ect on demand for our services. The search for Russian oil and gas alternatives resulted in the construction of new nuclear power plants. Also, many governments decided to accelerate the energy transition, and this results in the fast development of for example green hydrogen plants. Because of the still low gas prices in the US, the chemical process industry in that country is booming which is profitable for us as well.” Mr Mols continues, “All these circumstances resulted in a growing demand for our products and services and suddenly we had to speed up our production and expand our sta . As a

result of this, only a few months after moving into our new premises, we are now planning to expand. Luckily, we have space for this next to our location and, depending on the permitting process, we hope to be able to start with the construction works soon.”

Low alloy steel riser and stress joint

Although the energy transition causes ample work for the company, this does not mean that the oil & gas industry has become irrelevant. “On the contrary”, Alfred van Aartsen, Material & Welding Engineer of Schelde Exotech states. “Caused by the Ukraine crisis, operators are doing their utmost to keep their o shore assets up and running to be able to meet the rising demand for oil and gas. Most recently, for example, we accepted a new order for the ID cladding of an 18.5m long tapered stress joint (TSJ), welded/fabricated to of a steel catenary riser (SCR). Both are made from high strength, low alloy steel. This is not our first order for this type of TSJ. In 2017, we did the ID cladding of six TSJs made of high strength low alloy steel for the first time. And in 2021, we did connections of di erent high strength grades TSJs to low alloy steel SCRs. Now we are going to construct an ID clad TSJ to SCR for another rig in the Gulf of Mexico for the same customer.”

With the previous orders, Schelde Exotech has built up some experience >>

with these types of work pieces, but this does not mean that it is just a matter of copy-pasting for the new project. “In the oil & gas industry many constructions are tailor made, and this certainly is the case for this new project,”

Mr Van Aartsen says, “and one of the biggest challenges in this new project lies in the relatively small diameter of the riser. The 2017 riser had an internal diameter of 183mm and this one will have an internal diameter of only 139mm. This di erence of 44mm seems hardly important but the smaller the work piece, the smaller the margins for deviations. This diameter only leaves a 5mm margin between the welding torch and the interior of the riser and with a total riser length of 18.5m, welding with such small margins becomes quite exciting. The small margins are also very demanding for the connection of the riser to the TSJ as everything need to fit perfectly.”

A competitive alternative

At the time of writing this article, the project is still in an extensive qualification phase before the actual production will start. “Due to the demanding standards in the Oil & Gas industry we have to take great care in this project”, Mr Van Aartsen explains. “We first tested the various ways in which we can connect the TSJ to the SCR. During the current qualification phase, which is partly supervised by representatives of a certifying bureau, we learn a lot about the right working methods. In the end, this will help us in the actual production phase. In this type of project, the testing and qualifying phases take more time than the actual production.” When everything goes according to plans, the qualification phase will last until the end of Q2, and the final product will be supplied at end of Q3. The low alloy steel that Schelde Exotech uses has tensile and toughness

properties that provide a competitive alternative to the conventional TSJ-SCR designs. Still, it is not a widely accepted design and material. “We see that the industry is quite conservative and prefers choosing proven solutions,” Mr Van Aartsen says, “and with this new project we will show the value of high strength low alloy steel in o shore and subsea use once again.”

i. exotech.nl

“This di erence of 44mm seems hardly important but the smaller the work piece, the smaller the margins for deviations.”Alfred van Aartsen – Material & Welding Engineer of Schelde Exotech. Image of the 2017 welding when the riser had an internal diameter of 183mm.

A flexible wind tunnel: TU Delft Wind AI Lab

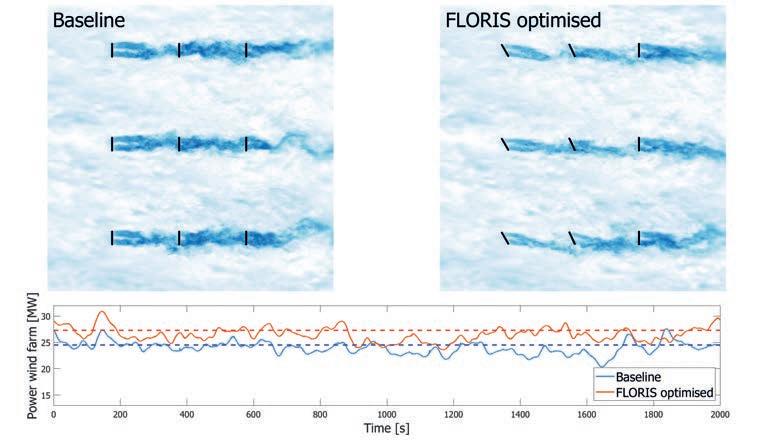

With o shore wind turbines getting bigger and bigger, wind conditions at sea have an increasing e ect on the e ciency of the power generated by an o shore wind farm. Therefore, it is good to know what exactly these e ects are.

For optimising the e ciency of wind turbines on o shore wind farms, operators have three options: they can individually adjust the rotor blades, they can turn the nacelles, and they can change the rotation frequency. To learn more about the most ideal combination of these three options, experiments are conducted in wind tunnels and digital simulation models before the construction of the wind farm starts. With the TU Delft Wind AI Lab, it is now possible to carry out experiments with wind fields in which wind speed is not the same everywhere.

Jan-Willem van Wingerden is Professor at Delft University of Technology (TU Delft) where he does research to find the optimum design for wind farms and to find ways to maximise the amount of energy a wind farm produces.

Small fans

“Usually, for testing and experimenting with wind turbines wind tunnels are used”, Mr Van Wingerden says. “The restriction of a traditional wind tunnel, however, is that it uses only one big fan. This way, the wind speed in the tunnel is the same everywhere in the tunnel. With the first generation of wind turbines this was no big issue, but with the current wind turbines, sometimes with rotors of 220m in diameter, the wind speed is never the same at all points on the rotating blade.” To find a solution for this static wind tunnel environment, TU Delft introduced the Wind AI Lab last year.

“Our Wind AI Lab is di erent from

traditional wind tunnels as it has a wall with many small fans that can all be operated individually. This way, we can simulate and reproduce di erent wind flows and speeds and see what the e ect of this is on the rotor blades and the energy e ciency of a single turbine and downstream turbines.”

Simulation

Also caused by the upscaling of turbines, digital simulation tools reach their limits of being able to simulate the e ects of weather conditions on the turbine. With the Wind AI Lab, TU Delft can first experiment with small scale turbines under various wind conditions and then use the results for further simulations in digital simulation tools. “In the Wind AI Lab, a maximum of three turbines at a time are used”, Mr Van Wingerden elaborates. “We could install more turbines but, if we would do so, they would need to be smaller, which will make the testing more complex. The models we use now are 60cm high, and we can test models with a size of up to 2m, although this will restrict the number of models to one. With three models it is not possible to give valid results for an entire wind farm. However, the results from the Wind AI Lab tests are implemented in the simulation models of entire wind farms.”

Wake

According to Mr Van Wingerden, an important issue when looking at the entire wind farm is the so-called wake >>

For Hollandse Kust Noord TU Delft is now conducting experiments of a completely novel wake mixing technology. Using individual pitch control, the fixed-frame tilt and yaw moments on the turbine are varied, thus dynamically manipulating the wake. This strategy is named the helix approach because the resulting wake has a helical shape.

e ect. “The energy that is extracted from the wind leads to a significant reduction in the wind speed immediately behind the turbine. However, in the wake, which can be an area of up to several hundred metres behind the turbine, the wind gradually returns to the wind speed that

would prevail without wind turbines. Interference among wind turbines however is inevitable as in a large wind farm even overlap of wake occurs, which causes a high load on the turbines’ power units and reduction of e ciency. Currently, it is possible to

By yawing a turbine slightly in relation to the wind, all or part of the wake behind the turbine is guided around the next turbine. This yawing generates less energy at the level of the individual turbine, but if you carry out this optimisation for each wind direction, and therefore for all the turbines within the farm, you can achieve energy gains for the entire wind farm.

automatically change the orientation (yaw) of the turbine. However, this is based on static information. For instance, you can steer the wake by yawing a turbine slightly in relation to the wind so that all or part of the wake behind the turbine is guided around the next turbine. This yawing means that you generate less energy at the level of the individual turbine because the turbine is not facing the front with the rotor in the wind. But if you carry out this optimisation for each wind direction, and therefore for all the turbines within the farm, you can achieve energy gains for the entire wind farm

Butterfly e ect

Yawing one turbine is not really a big issue. However, this yawing causes a kind of a butterfly e ect. “When you adjust the orientation of a turbine,” Mr Van Wingerden voices, “this will

immediately a ect another one that needs to be adjusted too, et cetera. To help adjusting the turbines of an entire wind farm in the most e cient way a great amount of data is needed, and this can be collected through our tests in the Wind AI Lab and digital simulation models. With this data, a certain level of artificial intelligence is realised to be used in smart control technologies. This even allows wind turbines to stand closer to each other, whereas today, with the upscaling of turbine they usually are constructed further away from each other to prevent the turbines to negatively influence each other’s e ciency.”

Floating wind

Currently, o shore wind turbines are still lined up neatly in a predefined pattern, even in floating wind farms. The distance between the turbines is not always the most e cient as this also depends on local circumstances, for example soil conditions, the presence of

pipelines, cables, shipping routes, et cetera. Gaining data from the Wind AI Lab is helpful in the construction and operation of bottom fixed wind turbine farms, but it also highly increases the opportunities of floating o shore wind. In the end, with the right smart control technologies, it would not only be possible to change the orientation as in the case of floating turbines it will even be possible to move the turbines within the wind farm to the most optimal location.

‘Smart’ turbines

One of the launching customers of the Wind AI lab is Crosswind, the consortium that will construct the Hollandse Kust Noord o shore wind farm on the Dutch part of the North Sea. “For Hollandse Kust Noord we are now conducting experiments of a completely novel wake mixing technology. In this technology, using individual pitch control, the fixed-frame tilt and yaw moments on the turbine are varied, thus

dynamically manipulating the wake. This strategy is named the helix approach because the resulting wake has a helical shape. The results of these tests will be implemented in 2025 when the wind farm will become operational”, Mr Van Wingerden says. “With the data that we gain from the experiments, we increase the freedom of design and optimise the smart control technologies. This way, we help operators and constructors to realise the most e cient wind farms. I hope that, in a few years, o shore wind farms will all have ‘smart’ turbines that will work together as a team. After consulting with the other turbines, a wind turbine will float o to the most energy-e cient o shore location and will get into the most e cient operating position. This way, energy production will be maximised and at the same time the load on the turbines will be minimised”, Mr Van Wingerden concludes.

Raising operational e ciency in o shore wind

With a fast expansion in the area coverage of o shore wind farms, operational teams require accurate real-time information without switching between many displays. Miros has now released new applications to optimise the operational e ciency and to reduce downtime in o shore wind projects.

The company’s real-time cloud service now includes an o shore wind map that enables operational teams to e ectively visualise sea state and weather data received from individual turbines across a site. In addition, it grants operators a global view of their wind farms removing the need to access multiple dashboards. Miros has also launched Data Explorer, a new solution allowing the easy creation of purpose-oriented all-in-one sharable dashboards to analyse real-time and historical data from one or multiple o shore wind sites. Data Explorer removes the need to access and maintain several data sources. Decisionmakers get an immediate complete preview of the most crucial information empowering them to make the best sense of the data, analyse trends, and

easily share historical and real-time seastate insights with di erent stakeholders.

Intuitive and easy to use

The o shore wind map and Data Explorer are easy to use and intuitive tools to help operations and maintenance teams significantly reduce energy consumption levels and emissions caused by cancelled o shore operations due to uncertainties around weather conditions and site access. This supports organisations to reach their environmental and sustainability targets.

A recent Miros study with Trios Renewables and the University of Strathclyde provided evidence of the potential benefits of direct wave measurements for o shore wind farms, estimating that minimising turbine downtime by using live data can save

o shore wind operators approximately USD 1.2 million per year.

Maggie McMillan, Vice President of Miros-Renewables, says, “Accurate, reliable data is critical to driving environmental impact reduction e orts and developing more e ective strategies to reduce operational cost. One of the key challenges facing o shore wind operators is accessing turbines at the optimum time to ensure crew safety and operational e ciency and to avoid lost production. Our solutions support operators to access and interpret the right data, at the right time, and in the right way, which is essential to enable informed decision-making for their assets.” Aurelia Paraschiv, IoT Product Manager at Miros, adds, “Analysing data can be a costly and often overwhelming process. Our Data Explorer solution is

secure, robust, and intuitive to configure, making it useful in all situations from daily operations to long-term life extension studies, especially for stakeholders engaged in time-sensitive tasks needing to impart critical information quickly.”

Ocean surface

Miros specialises in measuring the ocean surface. It provides real-time wave, current, and weather data to stakeholders involved in weather-sensitive operations o shore to increase safety, operational e ciency, and

optimise planning. The data are o ered as a service with easy and secure access from anywhere, anytime, and on any device. The sea state conditions are measured accurately, irrespective of weather, undisturbed by fog, rain, or

water spray using in-house developed, innovative sensor technology which is dry-mounted, and IoT- and cloudintegrated.

i. miros-group.com“Our solutions support operators to access and interpret the right data, at the right time, and in the right way, which is essential to enable informed decision-making for their assets.”

Maggie McMillan – Vice President of Miros-Renewables.

Battery pack for Deep Cygnus

Volstad Maritime has contracted Norwegian Electric Systems (NES) to deliver the battery package and associated control system for battery charging to the Deep Cygnus subsea construction vessel.

NES, a subsidiary of HAV Group, specialises in sustainable energy design and smart control and will provide the equipment to the Deep Cygnus in connection with a forthcoming vessel upgrade to battery power notation before the vessel enters a new charter contract in early 2024. During the past six months, Volstad Maritime has contracted NES to deliver similar battery packs and charging system to the Volantis, Grand Canyon II, and Grand Canyon III o shore construction vessels. Deep Cygnus will be the fourth vessel for which Volstad orders a battery system from NES.

Shared responsibility

As one of the first o shore owners to achieve the ISO 50001 accreditation for Energy Management Standard, Volstad Maritime continues the work towards a sustainable future at sea. “We are investing significantly in upgrading and future-proofing our fleet of o shore

construction vessels. Reducing the o shore industry’s CO2 footprint is a shared responsibility that we take seriously. An added benefit is that our vessels become even more attractive to customers who also want to reduce emissions associated with their o shore operations. To achieve this, we rely on close cooperation with key suppliers such as NES, who we have an open and trust-based relationship with”, says Trond Volstad, Member of the Board at Volstad Maritime.

Similar upgrade

The Deep Cygnus is a dynamically positioned multi-role subsea construction vessel incorporating a 150t

active heave compensated subsea crane. The vessel is 122m long and has operated in the North Sea in the recent years. “Upgrading the Deep Cygnus with a battery is similar to the upgrade we are doing onboard Volantis, where we placed the battery and charger under deck in custom-made rooms”, explains Egil Bremnes, Sales Manager at NES. NES will utilise competence across its three Norwegian facilities – Bergen (HQ), Egersund and Ålesund – to design, assemble and test the battery package and control system, which will be delivered in the fourth quarter of 2023.

i. norwegianelectric.com

“An added benefit is that our vessels become even more attractive to customers who also want to reduce emissions associated with their o shore operations.”

Trond Volstad – Member of the Board at Volstad Maritime.Photo courtesy of Volstad Maritime. Deep Cygnus will be the fourth vessel for which Volstad orders a battery system from NES.

A ground-breaking investment

ZF Wind Power invests in Test & Prototype Centre

With an increasing number of countries adding a considerable share of wind energy to their energy mix, the wind market is turning into a mature market. In their e ort to reduce the Levelised Cost of Energy (LCoE), the major players in the wind industry find themselves in a race, which will be won by the turbine with the maximum annual power output at the most competitive investment costs.

When looking at the wind turbine’s gearbox, this results in a rapid increase in torque requirements with new o shore developments exceeding 16,000kNm.

ZFWind Power is continuously increasing the torque levels of their

gearboxes and powertrains as well. For this, extensive validation is crucial. Recently, the company announced the investment in a new test rig that can deal with this upscaling. The test rig will have a length of 60m and two engines of 30MW each, which allows testing two

complete powertrains at the same time. This saves time and it optimises the use of power during testing. The 30MW test rig will be installed in a new to build test centre at the Belgian headquarters of ZFWind Power. The ground-breaking ceremony took place on 10 January, >>

accompanied by Flemish minister of economy, innovation, social economy, and agriculture, Jo Brouns, and Bob Nijs, the mayor of Lommel.

The world’s largest test rig

The rig will test the dynamic behaviour of the main bearings, the gearbox, and the generator on the system level under real conditions with functional load tests, dynamics, and robustness tests. It coversa maximum torque of 45MNm, a maximum bending moment of 64MNm, and a maximum axial force of 7,500kN. “To meet the growing demand for wind energy, larger and more powerful turbines are needed”, Felix Henseler, CEOof ZF Wind Power, says. “These new generation turbines will be powered by the world’s most powerful powertrains. Of course, these installations must be tested and validated extensively before o shore installation, which is why we started installing the world’s largest test rig.” Mr Henseler continues, “Extensive validation is the foundation of ZF’s innovations. Testing allows us to contain the risks inherent to the wind industry and it is essential to receive approval from customers, insurers, and certification agencies to launch new designs.”

Extreme forces

As the test rig must simulate the most extreme circumstances, it has to be more powerful than the products tested. Mr Henseler explains, “The forces acting on a turbine’s rotor blades, and powertrain are extreme. Torque, for example, is 40,000 times more than that of a sports car. Because each rotor blade experiences di erent forces during operation, also extremely large bending moments are caused. All these extreme forces will be simulated in our test rig and in a few months’ time we can test an extensive validation and simulation of the forces of 30 years of wind on the powertrain.”

Commitment to partnering

The installation will be in operation as of 2024 and it will secure ZF Wind Power’s position in the wind market for the upcoming decades. “The development of ZF Wind Power’s Test & Prototype Centre allows us to expand our o ering from modular wind gearbox platforms to complete powertrain systems. Together with our partners, we take on challenges,

build modelling tools, and introduce new production processes. This demonstrates our commitment to partnering with our customers for innovative projects to empower a sustainable future together”, states Mr Henseler.

“ZF is proud to contribute to sustainability and future energy independence through innovative wind

energy solutions. The ground-breaking investment in Lommel will secure ZF’s future portfolio and strengthen the European industrial base in a strategic sector,” adds Mr Henseler.

Strategic Transformation Support

From 2022 until 2024, ZF Wind Power invests around USD 54 million in the test

facilities and the Flemish government supports the investment with a funding of USD 2.2 million. “Thanks to the Test & Prototype Centre, ZF will not only be able to extend its existing activities, but it will also help us to start within the design, validation, and production of complete drivetrains. This is why we are grateful that we can develop this centre with the support of the Flemish

government”, Mr Henseler elaborates. “The importance of this Test & Prototype Centre cannot be underestimated, especially during the current energy crisis. The fact that ZF has selected Flanders for this centre proves, in my opinion, that we have everything it takes to attract international investments in essential sectors”, Mr Brouns states.

Authority

For o shore wind farm operators and constructors, the road to a sustainable future is paved with design challenges, building modelling tools, sharing results, testing, and validation energies and ZFWind Power acts as a proactive partner to deal with these challenges. Thanks to close collaborations, joint teams can develop pioneering solutions for the future wind market. For ZF Wind Power, a partnership does not stop when the product has been developed. For the company, each partner has its own requirements and ambitions and the diversity of wind turbines being a fact, all those systems, configurations, and operational locations with their specific geographical and meteorological conditions influence the appropriate type of service concept.

“The development of the Test and Prototype Centre strengthens our position, and it shows ZF Wind Power’s authority in the wind market to empower a sustainable future together with our partners,” summarises Mr Henseler.

i. zf.com/windpower

Holding strong cards

Ports of Brest and Lorient

Although France is gifted with a long coastal line, today o shore wind plays a minor role in this country’s power supply. However, with the plans of the government to realise 40GW of o shore wind by 2050, the French o shore industry can prepare itself for some busy years.

To be able to allocate future projects even better, the Port of Brest is going to realise an additional 40ha large terminal that will become operational in 2024.

The Brittany ports of Brest and Lorient hold strong cards for playing an important role in the realisation and the O&M phase of the Atlantic projects. Prompted by the Bretagne Regional Council, all marine renewable energy stakeholders in Brittany have joined forces in Bretagne Ocean Power to foster projects more e ciently. We speak to Philippe Thie ry, Manager of this organisation, to learn more about both ports and the plans to

further strengthen their position as o shore energy hubs.

Onshore hub

“As an accelerator”, Mr Thie ry explains, “Bretagne Ocean Power, seeks to facilitate access to industrial know-how for commissioning authorities, to facilitate skill development and market access for Brittany businesses, attract national and international players who wish to develop marine renewables, and

promote local know-how under a single banner. For the French plans to develop new o shore wind farms we depend on the well-known foreign contractors such as DEME, Jan De Nul, and Van Oord, as our country lacks this kind of expertise. However, this does not mean that our region cannot profit from the construction, operation, and maintenance of the wind farms. O shore wind farms always need an onshore hub. During the installation phase, >>

contractors need space to store equipment and turbine parts. Also, some parts may need pre-assembly facilities near shore which also requires space. Once operational, wind farms need an O&M base as nearby as possibly.”

Currently, in the port of Brest, the assembly of internal components of the 62 turbine towers for the 500MW Saint Brieuc o shore windfarm is taking place. The towers are constructed by Haizea

Wind in Bilbao and then transported overseas to Brest for final outfitting. Theassembly of platforms, cables, and ladders is being performed by SPIE Industrie & Tertiaire. “Although a large part of the construction of o shore wind farms is a foreign operation, French companies, including local ones, are profiting too,” Mr Thie ry says, “as ample additional services are necessary in which local content plays an important

role. Currently, in our region, 178 specialised companies are listed in the field of marine renewable energy, most of which have excellent international references.”

Perfect locations

The Port of Brest is one of France’s leading ship repair ports and includes a freight port and a logistic platform for European sea links. “Many larger components which are produced elsewhere are transported overseas before installation at sea, and the ports of Brest and Lorient both have optimal facilities for unloading, storing, and preassembly of the components”, Mr Thier ry says. “In the Port of Brest”, he continues, “we have constructed a new terminal dedicated to large o shore wind projects. It includes 40ha of industrial land linked to the sea and the transport network towards the hinterland. It has a 400m long heavy load quay.” He continues, “Located closely to the future floating wind farms, the port of Lorient also has a solid logistic hub for the installation and maintenance of o shore wind farms. 2.5ha are available for the installation phase, with 800m of quay, and a 13m draught. The complex is equipped with RoRo- handling facilities and suitable lifting equipment including a 30t crane (at 30m reach).” With their strategic position close to the existing and

planned wind farms, Mr Thie ry sees both ports as the perfect locations to become important o shore hubs. “Brest and Lorient are located right in between 6GW of o shore wind projects, of which today only the 480MW Saint Nazaire o shore wind farm is commercially operational. With a strategic location, in bays protected from harsh weather conditions, without any tidal restrictions, and excellent facilities, our ports o er the right package for servicing the o shore wind contractors and operators.”

Additional 40ha

To be able to allocate future projects even better, the Port of Brest is going to realise an additional 40ha large terminal that will become operational in 2024. “Space, as near as possible to the o shore construction sites, is very important,” Mr Thie ry elaborates, “especially when looking at floating o shore wind.” He estimates that around 50% of all o shore wind farms to be constructed will be floating. “Floating wind will be an important development

in France”, he says, “and therefore, ample space near shore will be necessary as the turbines will be completely assembled before transport to their o shore location takes place. With our ports we can accommodate the construction of the number of turbines worth 250MW per season. Halfway next year, the result of the South Brittany I tender will be announced. In this first round, 250MW of a 750MW large floating o shore wind farm will be realised. Next year, the remaining 500MW will be tendered. With our facilities we are ready to facilitate construction and we already had some promising conversations with the tendering companies. However, with the current plans, 1GW of o shore wind power will be installed annually in the upcoming years. As a result of this, the storage and assembling capacity of all ports in our region will be fully booked until 2030. Therefore, I think that it is important for them to collaborate. We will need each other’s help to accommodate all upcoming projects, otherwise contractors might choose to go abroad.”

Perfect fit

Although the main focus of Bretagne O shore Power lies on o shore wind, the region has more to o er for the energy transition as several Britton companies and institutions are involved in marine energy. “Not many locations are suitable for realising marine energy plants”, Mr Thie ry voices. “Today, various pilot projects are running near Brest and Lorient. We are convinced of the fact that floating o shore wind together with tidal energy are a perfect combination for the country’s sustainable power supply. However, to get things really o the ground, it should be helpful when our government, just like they did for o shore wind, will set goals for marine energy as well, as this will show the relevance of marine energy, which will help investors to step in and enable scaling up marine energy projects to commercialisation. As long as this is not the case, I think that initiatives like our tidal energy projects will remain small scaled and in a more or less experimental stage. With its facilities and experience, our industry is a front runner within this development, so it really would be a great opportunity if the government sets these targets and we are quite confident that they will”, Mr Thie ry concludes.

i. bretagneoceanpower.fr“Floating wind will be an important development in France, and therefore, ample space near shore will be necessary as the turbines will be completely assembled before transport to their o shore location takes place.”Philippe Thieffry, Manager of Bretagne Ocean Power. Philippe Thieffry – Manager of Bretagne Ocean Power. Various marine energy pilot projects are running near Brest and Lorient. Photo courtesy of Sara Minisini / Bretagne Développement Innovation (BDI). Photo courtesy of Yellow & Finch Publishers.

Exciting and motivating

Per-Erik Holsten, head of ABB Energy Industries for Northern Europe and Managing Director for ABB in NorwayIn the o shore industry, a lot of attention is paid to technical innovations and production improvements. However, the human factor cannot be overlooked as o shore projects highly depend on people’s hands, skills, and knowledge, too. In O shore Industry Insights, we introduce individuals that made their bones in this market.

Per-Erik Holsten is leading ABB’s Energy Industries division in Northern Europe, covering the oil, gas, power, chemicals, water, and life sciences markets. He started his career as engineer at ABB in 1986 right after graduating in Engineering at South Trondelag University College in Trondheim (Norway). Since then, he has held a variety of positions at ABB, managing di erent business.

Mr Holsten, since leaving the university college, you have always worked for ABB. It looks like you enjoy working at ABB. Do you?

Mr Holsten: “Yes indeed, I started my career at ABB when I was 22 years old and throughout the years I have always enjoyed working at this company. In these past 30 years the industry has developed quite significantly, and this has always resulted in presenting many interesting professional challenges.”

What, in your opinion has been the biggest development in the industry in these 30 years?

Mr Holsten: “When I started to work for ABB, the automation of the industry was in its infancy. In those days, moving switches, pushing buttons, and watching gauges was the usual way of operating production and only the first small steps in digitalisation were being taken. Over the last 20 years, since the introduction of distributed control systems to the o shore industry, we have fully automated control, operations and processes. This now acts as the brain of the facility, maximising e ciency with an aim to optimise production, increase safety, and reduce waste (energy consumption). All this is done via digital platforms that can o er operators complete visibility of operations in real time.”

Can you tell us a bit more about this?

Mr Holsten: “Automation of industry all started, more or less, with replacing mechanical components with digital alternatives. The handling and control of operational processes was still necessary to be conducted by people. This quickly changed by incorporating computers, which also made remote control possible, which is very convenient in the o shore industry.

Computers and sensors have taken over most of the process and today, with the Industrial Internet of Things, equipment all over the world is connected digitally, and in some cases can even operate almost entirely autonomously.

Over the past few years, the role of data collection has become increasingly important. One of the advantages of digitalising processes is that a lot of data can be collected, and the information derived from this can help operators make much more informed decisions

with a view to optimising performance of the site. One such example is regarding asset management and in the field of predictive maintenance. Instead of dealing with an equipment failure as it is happening, or worse after, we can now use digital solutions to predict problems in advance, monitoring the condition of assets in real time which, when it comes to the o shore industry, can massively reduce maintenance costs and downtime, minimising risks and this also increasing e ciency.”

Looking at your role in this, what makes working in the oil & gas industry attractive?

Mr Holsten: “Oil & gas, as part of the energy industry is a very interesting business for technical professionals as there are always many challenges to overcome. Take for example the energy transition we are currently in. This requires us to find solutions to further develop the provision of energy in a sustainable way and for me as an engineer it is a very exciting prospect. On the other hand, I also like the human aspect of my work, working with and for people. The energy transition cannot succeed by implementation of technologies alone. It is about people and partnerships and collaboration will be key in realising solutions for common goals. For me, working with people in such a collaborative way, and with the right spirit, is very motivating.”

You already mentioned the energy transition. Will automation and digitalisation be important for this?

Mr Holsten: “Yes, it is critical. I even dare to say that the speed of the energy transition highly depends on automation. Today, computers, big and small, are the heart and the brains of almost every operational system, so without automation, accelerating the energy transition will be almost impossible. From another perspective, digitalisation is essential, too. Before the construction of an o shore wind farm for example, a lot of research takes place to find the right location, and to learn more about the natural circumstances of the location, such as soil, wind conditions, and current. In fact, this is still the case for the o shore oil & gas industry, too. Also, predictions about weather conditions, wind directions, et cetera are needed. For this research and forecasting, the need for computers is also evident. What we should also realise is that, with the aid of automation, we are able to realise things that would not have been possible in the past, or only at high expenses, such as introducing new energy models into the energy source mix like CCS and the production of green hydrogen. Another good example of this can be found in the field of subsea infrastructure. Automation and digitalisation have highly improved inspection, monitoring, and maintenance.”

So we can conclude that you are looking at the energy transition and the role that automation plays in it with confidence?

Mr Holsten: “Yes, indeed. In the past ten years we have taken large steps, among other things in data collection and on the journey towards autonomous operations. By harnessing automation and digitalisation, high e ciency and large cost savings have already been realised by the industry. So yes, things are moving into the right direction. As we move forward, the focus of the o shore industry is changing in order to include new energy sources including renewables, carbon capture, and energy storage. Each of these have their own challenges that automation and digitalisation can help address. And as we have seen over the past year, ensuring energy security by adding as much capacity and diversity – as well as reliability and e ciency – to our energy source mix is critical. It is all about ‘net additions and minimising emissions’. And by this adding new energy sources into the mix, it is also about utilising technologies to drive e ciencies to enable them to scale at speed, whilst at the same time looking at how we can improve sustainability of our existing energy infrastructures.

I really am a promotor of the energy transition. What we should not forget, is that the current sustainability actions we are taking are beneficial for our own future but also for the future of the generations to come. Automation will be an important factor in this and people will always play a crucial role. Therefore, Ialways encourage young people to join our industry. This way, they will be able to contribute to their own sustainable future themselves.”

It is obvious that hacking is one of the largest challenges in automation. What can we do to avoid digital intrusion of o shore assets?

Mr Holsten: “Today, cyber security certainly is one of the top priorities in automation. Cyber-attacks have severe consequences, including loss of production, financial losses, and potentially even harm to employees and the surrounding community. It is therefore extremely important for o shore companies to adopt cyber security

in their sites because they pose a high risk for cyberattacks. Digital transformation has led to an increase in the use of direct or indirect internet-connected devices and systems which can potentially be exploited by cyber criminals.

There are various things that can help to protect against hacking. First it is critical to define what e ective risk management means for you and align your cyber risk strategy and related processes and procedures with that definition. A cyber security strategy should focus on value delivery, based on continuous improvement; the e ective utilisation of available resources is a key factor for success, especially given the actual OT cyber security resource shortages. We developed the Cyber Security Workplace solution at ABB, which helps organisations to empower their existing maintenance workforce to handle cyber security tasks where cyber security experts would have normally been needed. As soon as you have a plan (your strategy) to achieve the defined objectives, the next step within the development of a security program (the roadmap) is a gap analysis which could include multiple topics, for example, review of previous strategy, policies, standards, guidelines, risk assessments, audits, and regulatory requirements.

Another aspect for a good cyber strategy is a cyber security program where you have measurable performance improvements.

At ABB, we provide our customers with appropriate cyber security strategies that include a roadmap of solutions to help them with this. Should companies need immediate assistance to keep their firewalls closed, our 24/7 support is there to help them.”

As part of automation, artificial intelligence is becoming more and more important. What will be the future of this development?

Mr Holsten: “AI will play an important role in autonomous operating assets. However, instead of a revolution, we should strive for evolution. What we must not forget is that the owner of an asset will always be responsible for it, and this also counts for autonomous operating systems. As an industry, the o shore sector has been conservative when it comes to adopting this as an approach. Safe and secure operation of assets should always be priority number one. So before implementing AI and autonomous operating equipment, we need to be completely sure that things work as they should and then gradually work towards full autonomy from there on. Having said that, autonomous operations are picking up traction now as companies can see the benefits – both in regard to the sustainability agenda and to reduce costs. The technology is already available – we have the opportunity now to reduce the emissions of the o shore sector. If we get it right, investing in o shore will help accelerate the sustainability agenda. As we move forward, it is key to utilise the legacy of traditional o shore industries and to apply all our learnings to help define these new approaches.”

i. abb.com

Acta Marine integrates Starlink with its Walk-to-Work vessel fleet comms infrastructure

Shortly after the announcement of Castor Marine being an authorised Starlink reseller, the company signed a contract to outfit Acta Marine’s Walk-to-Work vessels with Starlink connectivity.

The contract includes the two methanol MDO/HVO powered DP2 Construction Service Operating Vessels (CSOVs) that Acta Marine ordered earlier this year. Castor Marine already manages Acta Marine’s entire fleet connectivity. Starlink will be integrated with the existing onboard communications infrastructure.

Low orbit

Most satellite internet services come from single geostationary satellites that orbit the planet at 35,786km. As a result, the round-trip data time between the user and satellite – also known as latency – is high, making it nearly impossible to support streaming, online gaming, video calls, or other high data

rate activities. Starlink is a constellation of thousands of satellites that orbit the planet much closer to Earth, at about 550km, and cover the entire globe. Because Starlink satellites are in a low orbit, latency is significantly lower— around 20 milliseconds versus over 600 milliseconds.

Successful o shore operations

Low Earth Orbit (LEO) satellite communications at sea is becoming increasingly important, because of its ability to provide high-speed internet at very low latency. With this project, Castor Marine’s strategy to o er Starlink to its portfolio is already paying o . The W2W vessels will each get four Starlink antennas and the full Fortinet suite for secure SD-WAN and SD-LAN network connectivity. This means that onboard operational and crew internet tra c is secure and fast because of, among other things, a download speed of more than 500Mbps. Castor Marine already serves Acta Marine’s fleet of o shore and DP2 workboats with VSAT and Iridium Certus services and recently installed the new internet security infrastructure as well. This is important, as good communications between all parties involved in an installation or maintenance project is the basis of successful and safe o shore operations. This goes especially for Acta Marine’s fleet and crew, whose combined capabilities mean that work can be performed around the clock in harsh o shore conditions.

Continued cooperation

According to Vince van den Belt, Manager IT at Acta Marine, the contract is a result of the way both companies work together. “We have found a reliable partner in Castor Marine thanks to their extensive technological expertise and driven team. Therefore, it was logical to have them integrate Starlink on our o shore wind fleet.” Mark Olthuis, Director of Castor Marine, adds, “We have been working for and with Acta Marine for more than five years and this project is a confirmation of our

continued partnership. That makes me grateful and happy, as that is what motivates us. Castor Marine aims to provide the best connectivity solution for Acta Marine and this is the right moment to implement Starlink as part of the mix for the Acta fleet.”

Crew welfare, improved operations, more control

Mr Olthuis continues, “One of the elements we very much appreciate in the relationship with Acta Marine, is that from our perspective, it is a very

forward-looking company, commercially and technologically. As to their fleet connectivity, Acta’s management wants the crew to feel at home on board. The fact that they now have a much faster internet connection, allowing the crew to stream videos or facetime with their families and friends, was one of the considerations for installing Starlink.” In addition, the moment a vessel has access to a higher bandwidth, a new range of operational capabilities becomes available. It’s possible to execute more remote operations

simultaneously, deploy and monitor more subsea cameras, VR- and ARenabled technologies come into view and controlling all remote assets becomes much easier. “Acta’s specialists have really asked themselves the question ‘What can we do with better connectivity?, What does it mean? Does it provide us with an extra advantage for our customers, Walk-to-Work fleet and projects?’ We spoke extensively about this and when it turned out the answer was ‘yes’, they took action”, Mr Olthuis elaborates.

No delays

The low latency of Starlink’s LEO satellite network shortens the delay in vessel-toshore communications considerably. This means better accuracy and reduced chances on misunderstandings when executing complicated o shore projects, real-time two-way communications comparable to a fiber connection in an o ce in fact. The Starlink system also enables the use of real-time applications, which means operators can expand their service portfolio. The expanded connectivity suite that Castor Marine now o ers creates a seamless user experience that was impossible a few months ago. Ivo Veldkamp, Castor Marine’s CEO, expects Starlink to become the dominant connectivity technology onboard merchant ships, o shore vessels, and yachts. “Ships that currently rely on VSAT,” he states, “will add Starlink for high bandwidth and speed, while continuing to use VSAT as a back-up and failover service. Castor Marine is well-positioned to meet this demand.”

i. castormarine.com

Dredging for the world’s longest immersed tunnel

Although many dredging companies have expanded their activities towards the installation of o shore wind farms, this does not mean that they relinquish their original activities. Currently, for example, a large dredging project is well under way between Denmark and Germany.

Femern, a 100% Danish state-owned company is tasked with the planning, building, and operating of the Fehmarnbelt tunnel between Denmark and Germany. The tunnel is earmarked as Denmark’s largest infrastructural project and the world’s longest immersed tunnel and it will create a fast and safe 18km long subsea connection between Denmark and Germany.

Fehmarn Belt Contractors

Before the installation of the 89 tunnel segments on the bottom of the sea can take place, a 16km long trench needs to be dredged first. In 2016, Femern and the Fehmarn Belt Contractors (FBC) joint venture, consisting of Boskalis and Van Oord, signed a contract for the construction of the Fehmarnbelt tunnel. The construction work started in June 2020 and the activity scope for FBC includes the dredging of a tunnel trench in the seabed over a distance of 16km. The joint venture also entailed the construction of a new working harbour which was put into operation in June 2022. In connection with the harbour, atunnel factory is constructed which will cast the tunnel elements before being floated out to sea for installation. This is expected to be fully operational by the end of 2023. >>

Dredging toolbox

The dredging of the trench by FBC is a challenging task according to Pedro daSilva Jørgensen, Deputy Technical Director at Femern. “So far,” he says, “the dredging, that started in July 2021 is going according to plans. Of course, there have been challenges but so far, the delays that might have been caused by this have been absorbed. At the dredging route, FBC meets eight di erent types of soils, and this soil can also contain unexpected boulders of various sizes. Based on the survey that has been undertaken in the preparatory phase to learn more about the soil conditions, a toolbox of di erent types of vessels is available. Both Boskalis and Van Oord have a huge number of di erent types of dredging vessels and

for this project, Van Oord uses for example the Vox Amalia, the Goliath, and the Simson. Boskalis has decided to include, the Willem van Oranje, the Magnor, the Fetsy, and the Manta on the job. Because of the di erent soil types, it is decided not to dredge in one direct line between Denmark and Germany. Instead of this, FBC is dredging from soil type to soil type. This way, it is easier and more e cient to discharge the dredged material.”

Well under way

In the end, the dredging will result in around 19m3 millions of sand, stone, and soil. According to Mr Da Silva Jørgensen, the largest part of the dredged material will be used to create 300ha of new nature. “With the dredged material, we

will create a nature-oriented landscape with dunes, grassland, and beaches on the Danish side east and west of Rødbyhavn, as well as on the German side at Puttgarden”, he explains. So far, the dredging is well underway and FBC expects to be ready in the summer of 2024. “In fact, dredging of the trench by FBC is only part of the job”, Mr Da Silva Jørgensen says. “FBC has been assigned to take care of the more or less rough dredging of the trench. Once they are finished, the Femern Link Contractors (FLC) consortium will take care of the finetuning of the dredging which means that the total surface of the trench will be further equalised to make the trench ready for the segments to be installed. The reason for this is that, in the contract for building the tunnel, it

was determined that the contractor that constructs the segments will also be responsible for the proper installation and locking of the segments at the bottom of the sea. Once the trench is ready, 89 tunnel segments will be lowered down to the seabed, after which they will be locked with locking fill and rocks. In the end, the current will cover the entire tunnel with sand in a natural way.”

One hour each way

Several years of preparatory work were required prior to the construction of the Fehmarnbelt tunnel. This included the most comprehensive EIA survey in Danish history. Marine and land flora and fauna were extensively mapped to minimise the impact on the

environment. The subsoil in the Fehmarnbelt was analysed through hundreds of drilling samples to ensure a completely accurate understanding of its properties and composition. Over the same period, a range of potential technical solutions for the link were studied. Bridges and both immersed and bored tunnels were assessed on price, risk, environmental impacts, and a range of other criteria. In 2011, it was decided that the Fehmarnbelt link should be built as an immersed tunnel. The reasons for this included the good experiences from the immersed tunnel on the Øresund link and because this type of tunnel has several advantages over a bridge, economically, in number of risks, and in operation. When the Fehmarnbelt tunnel

is completed, the journey between Rødbyhavn (Denmark) and Puttgarden (Germany) will take seven minutes by train and ten minutes by car. Road users and train passengers will save about one hour each way compared to the ferry crossing. The Fehmarnbelt link will also be open 24 hours a day as a tunnel is not a ected by wind or weather. When everything goes according to plans, the tunnel will be completed in 2029

i. femern.com

i. boskalis.com

i. vanoord.com

A new it-girl on the market

Recently, the Windea Leibniz upgrade was completed at Ulstein Verft. With an increase of cabins from 63 to 81, the vessel has transitioned from an SOV to a Commissioning Service Operation Vessel (CSOV). Additionally, the yard has installed one extra pedestal on the stern for Baltic Sea operations to complement the existing, now height-adjustable, North Sea pedestal.

The upgrade expands the operational range of Windea Leibniz and makes her even more attractive for the o shore market. The upgrade included a 50% increase in accommodation capacities on board. Therefore, extensive reconstruction of

the changing/drying rooms, conference rooms and day rooms was executed. In total, the cabin capacity was increased from 63 to 81 cabins. Windea Leibniz is now enabled to accommodate up to 85 technical sta for wind farms, service personnel, and crew.

New pedestal

Another major milestone was the installation of a new height-adjustable pedestal for the motion-compensated gangway, making the vessel more flexible in o shore wind farms. Now the gangway can operate in a range

Baltic Sea, service platforms are generally lower located than in the North Sea.

More flexibility for deployment in di erent wind farm markets

of the pedestal also needed to be strengthened. The upgrades made a capable vessel even more versatile.

Windea Leibniz is now enabled to accommodate up to 85technical sta for windfarms, service personnel and crew.

between 17.5m and 23m height above the waterline when fully extended. When Bernhard Schulte O shore decided to install a second pedestal for the gangway at the stern, it was based on the knowledge that hardly any other operating o shore wind service vessels could take on assignments in the Baltic Sea as well as in the North Sea. In the

The existing gangway can be used on both pedestals. Rainer Mueller, Captain on the Windea Leibniz says, “With the two new pedestals, we are more flexible when approaching the service platforms for the wind turbines. There is no uniform standard for the height of the platforms in North Sea wind farms. After the yard stay, we can now vary the height of our gangway. With the Baltic pedestal at the stern, we can easily switch our gangway from the North Sea height to the lower Baltic Sea height, which makes us even more flexible when working in di erent wind farm regions. The new cabins allow us to accommodate more technicians on board. All this really makes Windea Leibniz the new it-girl on the CSOV market.”

Structural engineering work

Ulstein’s designers and engineers have been involved in the structural engineering work for this upgrade. This includes enforcement of the bridge to carry the gangway which is now parked on the bridge roof. The area for the base

“Thenew upgrades make a very capable vessel even more versatile. Now our Windea Leibniz is more flexible and attractive for the market. The upgrade was perfectly planned and executed by Ulstein. My thanks go to everyone involved in this great project”, says Matthias Mueller, Managing Director of Bernhard Schulte O shore.

Ready to support expansion

The Windea Leibniz is an Ulstein SX175 design from Ulstein Design & Solutions and was delivered as a newbuild from Ulstein Verft in 2017. She features the X-stern and X-bow solutions for increased comfort and reduced noise and vibrations and is also X-bow vessel number 100 from Ulstein Group. Windea Leibniz is now ready to support the planned o shore wind power expansion in Northern Europe. The vessel functions as a reliable and environmentally sound platform for wind farm operations and maintenance support, technician accommodation and transport, and the provision of safe and reliable access to o shore installations.

i. ulstein.com

i. bs-shipmanagement.com

How to deal with cyber crime?

In the o shore industry, automation and digitalisation contribute to higher e ciency, sustainability, operability, and safety. However, there is a downside because the increasing digitalisation also entails a growing cyber security risk, which might ultimately also impact safety. This is of specific interest in times of geopolitical tensions.

In order to prevent o shore assets to be a target of cyber crime, their owners should take appropriate security measures and security specialist Secura (a Bureau Veritas Company) can help companies in their e orts.

Digital security

“In the past two decades, the development of automation and digitalisation have been taking large steps in most productions processes”, says Sjoerd Peerlkamp, Director Industrial Market Group at Secura. Secura acts as an independent, specialised security expert.

The company helps organisations improve their cyber resilience from a people, process, and technology perspective. Secura is active in all sectors and has a specific group focusing on industrial companies including critical infrastructure and renewables.

The company provides security advice, testing, training, and certification services.

Mr Peerlkamp continues, “The end of this development is not in sight yet as in this digitalisation, artificial intelligence (AI), big data, and autonomy are becoming increasingly important, also in

operational technology. This has many advantages for the industry, however it also o ers a new opportunity for bad actors to intrude o shore assets. And although this intrusion is only virtual, damage can be serious and even impact daily life.”

EU NIS 2 Directive

The fact that cyber crime is something to be taken seriously, is recognised by the European Parliament. As a result of this, the EU NIS2 Directive was approved and will come into e ect in Q4 2024 in all member states. The NIS2 Directive is

the EU-wide legislation on cyber security. It provides legal measures to boost the overall level of cyber security in the EU. The EU original cyber security rules introduced in 2016 (NIS Directive) were updated by this NIS2 Directive. It modernised the existing legal framework to keep up with increased digitisation and an evolving cyber security threat landscape. By expanding the scope of the cyber security rules to new sectors and entities, it further improves the resilience and incident response capacities of public and private entities, competent authorities, and the EU as a whole. The NIS2 Directive on measures for a high common level of cyber security across the Union provides legal measures to boost the overall level of cyber security in the EU. Businesses identified by the member states as operators of essential services (energy, transport, water, banking, financial market infrastructures, healthcare, and digital infrastructure) will have to take appropriate security measures and notify relevant national authorities of serious incidents. A new key aspect is that this also covers the supply chain of companies within scope. According to

Mr Peerlkamp, the EU NIS2 Directive certainly is a good step towards digital security in the energy industry. “However,” he says, “the restriction (and power) of this Directive lies in the words ‘appropriate security measures’, as this can be interpreted in many ways. What exactly is appropriate? You can only determine this with appropriate risk assessments relevant for your specific company. If done well, this is a very powerful way. However, we also see that the competency for appropriate risk assessments is not widespread yet and it should include people, process, and technical aspects.”

Reasons for hacking