With the fourth issue of this year, we say goodbye to a pleasant Summer and hello to a promising Autumn. Promising, as many of us will participate in or visit the various upcoming ofshore exhibitions such as Adipec and OMC Ravenna which was planned for May but was rescheduled to October due to the extreme foods in Italy in Spring. Participating in these shows will open up new opportunities for the entire industry, as exhibitions are excellent occasions for sowing what can be reaped later.

Also promising are the surveys that are conducted both in the Netherlands and the UK on decommissioning and re-use. About ten years ago, decom really was a hot topic, as it was expected to grow in an explosive way. Reality soon showed that things would develop at a much slower pace than expected. However, in both countries fgures now reveal that decommissioning has gradually become an interesting activity for now and the next decade. Apart from this, the re-use of ofshore assets looks promising too.

As the energy transition has commenced, it is expected that we will gradually become less dependent on fossil fuels. Still, the world we live in today shows that if we do not want to rely too much on other countries, we really should take care of our existing oil & gas activities. This is why the UK government recently decided to grant new oil licenses. On the other hand, the roll-out of ofshore wind continues, for example with the start of the construction of the currently largest ofshore wind farm Dogger Bank.

These and many more topics are featured in the magazine in front of you. I hope you enjoy reading this issue. Meanwhile, please do keep informing us about any interesting novelties from your company. We will be happy to write about it.

Kind regards,

Marco Geels MARCO@YNFPUBLISHERS.COM

Modular spreader beams up to 3,000t – Shackles up to 2,000t Grommets & roundslings – ROV hooks & shackles

Cherry pickers – Telehandlers – Waterpumps – Generators

Waterbags – Testweights – Pontoons – Fenders – Gangways

Snatchblocks – Lifting frames – Multi lugs – Hoists – Swivels

Masterlinks – Hydraulics – Container spreaders – Light towers

Safe Lifting Europe B.V. is aiming to become carbon neutral by having the largest rental feet of heavy lift equipment, which guarantees sustainability and the fastest route in your quest, with any type of demands. Many of our clients have already optimised their business and have chosen Safe Lifting Europe B.V. for their special heavy lift equipment needs. Interested in learning how renting or leasing your heavy lift equipment can lead to more sustainability? Inform about the possibilities for short- and long-term rental or lease of our heavy lift equipment via rental@safelifting.eu. www.safelifting.eu

NSW Al Yamama, the frst of three new Incat Crowther 33 crew boats designed for Nakilat Svitzer Wijsmuller (NSW), has been ofcially launched in Singapore by shipbuilder Lita Ocean. NSW Al Yamama, with its homeport of Doha, and her two sister vessels will serve as wellhead maintenance vessels for QatarEnergy in the Middle East. Designed specifcally for the transfer of special maintenance personnel and equipment, the three BV-classed vessels can transport 40 people at speeds of up to 24 knots in safety and comfort. The fnal two vessels comprising the new crew boat build contract, NSW Al Shuaiba and NSW Zikreet, are nearing completion and are expected to be delivered in August and September respectively.

i. incatcrowther.com

Jan De Nul Group’s newest crane vessel, Les Alizés, kicked of her maiden assignment by installing the frst monopile foundations for the construction of Ørsted’s Gode Wind 3 and Borkum Rifgrund 3 wind farms in Germany. Delivered early 2023, Les Alizés arrived in the Dutch Eemshaven at the end of June, where the frst monopiles were loaded before departing to the installation location in the German North Sea. In total Les Alizés will transport and install 106 wind turbine monopile foundations and one ofshore substation foundation, including associated topside. Ørsted will use monopiles without transition piece. Before installation, scour protection will be installed at all 107 locations.

i. jandenul.com

Following the results of ScotWind and the Innovation and Targeted Oil & Gas (INTOG) leasing rounds, Sectoral Marine Plans (SMPs) are being revised and developed to support the industry by planning the sustainable delivery of commercialscale ofshore wind energy in Scotland.

Crown Estate Scotland selected 20 projects under ScotWind and thirteen under INTOG; together they could enable over 30GW of ofshore wind energy. With a combined capacity of around 5.5GW, INTOG is the world’s frst leasing round designed to enable ofshore wind energy to directly supply ofshore oil and gas platforms. ScotWind, at a potential leased capacity of almost 28GW, puts Scotland at the forefront of the global development of ofshore wind, representing a massive step forward in the transition to net zero. The Scottish Government has appointed marine consultancy and survey company ABPmer to support the revision of its original SMP for Ofshore Wind Energy as part of its iterative plan review process, as well as the production of the SMP for INTOG. Adoption of fnal plans are anticipated in 2024 following a formal consultation process.

i. abpmer.co.uk

Japan’s expanding ofshore wind industry has added a further Seaeye Falcon underwater robot as a key operational resource for working in complex environments. Tokyo-based systems provider Marimex says Japan’s wind power construction operators value the Falcon for being a compact and powerful robot that is ideally suited for shallow waters and strong currents. The small footprint of the metre-sized Falcon is also important for ofshore energy operators as construction is carried out using feets of small service vessels needed in shallow waters. As the world’s top selling robotic vehicle in its class, the Falcon has a reliability record covering over a million hours

underwater.

i.saabseaeye.com

SMST has been awarded a contract by Fincantieri Marine Group for the delivery of a motion-compensated gangway with tower and height adjustment on the newbuild Service Operation Vessel for Crest Wind. Crest Wind is a joint venture between US-based Crowley and Esvagt. The smart SMST gangway with integrated crane function provides safe and smooth transfer of both people and cargo on board of the SOV that will support the emerging US ofshore wind industry. The newbuild vessel incorporates the latest innovations and performance capabilities, to which the SMST equipment contributes signifcantly.

i.smstequipment.com

Spirit Energy is experiencing its busiest year-to-date in decommissioning with ofshore campaigns across the CNS, SNS, and East Irish Sea. The most recent activity to complete is the fnal phase of the campaign to remove the DP3 and DP4 installations in the Morecambe Bay development in the East Irish Sea. Completed by Allseas with its Pioneering Spirit, a total of 9,000t of jacket structures were removed in tandem using the jacket lift system on the vessel and loaded directly onto the Iron Lady barge to be transferred to Fife for recycling. In the Central North Sea (CNS), a 14-well P&A programme across four felds; Chestnut, Birch, Larch, and Sycamore, is being executed from Well-Safe Solutions’ Well-Safe Defender vessel. Chestnut’s well decommissioning has been completed, bringing to an end the ffteenyear story of the Chestnut feld. In the Southern North Sea (SNS), during a single mobilisation, Heerema Marine Contractors has successfully removed three topsides and three jackets with SSCV Thialf crane vessel, and DeepOcean are set to recover subsea infrastructure from six assets later this year. The recycling of all structures will be performed by Thompsons of Prudhoe in the Port of Blyth, making Spirit Energy the frst users of the decommissioning alliance between the two companies.

i.spirit-energy.com

C-Kore Systems has successfully completed a decommissioning campaign ofshore Australia, using C-Kore Sensor Monitor units to interrogate the wellhead pressure and temperature sensors on the subsea oilfeld. With their automated test routine, the C-Kore Sensor Monitor units quickly and repeatedly tested and datalogged the information allowing the operator to complete their ofshore campaign swiftly and safely. C-Kore Systems has a range of subsea testing tools used globally by operators and contractors on decommissioning, fault-fnding, and new installation campaigns. The tools are easy to deploy and are operated without the need for C-Kore personnel to be present, providing rapid and accurate feedback. This combination of simplicity, accuracy, and reliability introduces signifcant operational savings to testing campaigns.

i. c-kore.com

Two specialists are combining their expertise. Aris Stellantriebe has expanded its worldwide sales organisation and since May has an experienced partner at its side with English actuator expert Kinetrol. With its headquarters in England, Kinetrol has sales ofces in ten diferent countries and a comprehensive global network. As a manufacturer, Kinetrol specialises in pneumatic actuator technology and has several production sites in Farnham, England, but does not produce its own electric actuators. This is where the Troisdorf-based manufacturer Aris Stellantriebe comes in, having made a name for itself with its innovative, high-quality electric actuators.

i. stellantriebe.de

WSG has announced it has sold its Well Intervention division and will use the funds raised to lay the foundations for a period of international expansion for the rebranded WSG Energy Services (WSGES). In a major reorganisation, WSGES has divested its traditional Well Intervention ofering – including coil tubing and slickline services – and will now focus on growing its market share in Process, Pipeline, and Industrial Services (PPIS). There are no redundancies aspects to the deal. The Netherlands-headquartered business retains its global footprint with a strong presence in the UK, mainland Europe, Asia, and Australia, and its next objective is to establish a permanent presence in North America to capitalise on recent project successes. Proceeds of the Well Intervention division sale to Excellence Logging (Exlog) will be used to fund further acquisitions and to maintain R&D for refning the company’s emissions management processes and technologies, which are in demand from energy companies looking to reduce emissions on the route to net-zero. i. wellservices-group.com

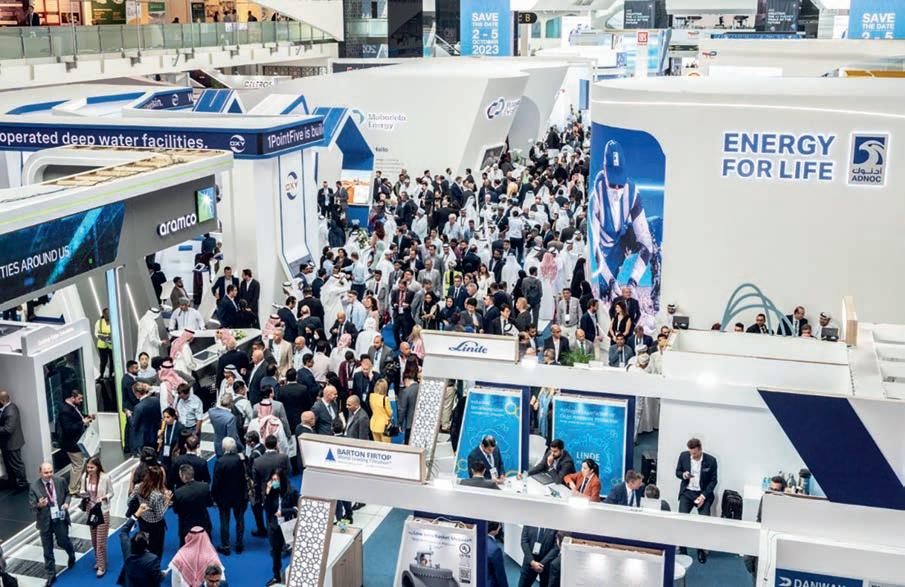

ADIPEC 2023 will take place in Abu Dhabi from 2-5 October, bringing together industry leaders, innovators, and policymakers to accelerate the practical action and credible solutions needed to tackle the biggest challenges in energy and climate.

ALL IMAGES COURTESY OF ADIPEC.

Held under the patronage of His Highness Sheikh Mohamed

Bin Zayed Al Nahyan, President of the United Arab Emirates, and hosted by the Abu Dhabi National Oil Company (ADNOC), the theme for ADIPEC 2023 is ‘Decarbonising. Faster. Together.’

Over 160,000 attendees from around the world will join leading energy producers, the biggest energy consumers, and enablers in government, fnance, and technology, to provide thought

leadership, foster cross-sector partnerships, and inspire the innovation needed to deliver the clean, afordable, and reliable energy the world requires. The event takes place less than two months before the UAE hosts the 28th United Nations Climate Change Conference (COP28), providing a platform for the energy industry to advance credible solutions and collective action towards eliminating methane emissions, phasing out carbon emissions across the value chain to achieve net zero by 2050, assuring energy security and investment in the

Venue: Abu Dhabi National Exhibition Centre. Al Khaleej Al Arabi St, Al Rawdah, Al Ma’arid, Abu Dhabi (UAE).

Opening hours:

Monday, 2 October: 10.00h - 18.00h

Tuesday, 3 October: 10.00h - 18.00h

Wednesday, 4 October: 10.00h - 18.00h

Thursday, 5 October: 10.00h - 17.00h

global south, as well as scaling-up clean energies and decarbonisation technologies.

Tayba Al Hashemi, Chair of ADIPEC 2023, and CEO of ADNOC Ofshore, says, “By 2030, the world will be home to an additional half a billion people, demanding more energy every year. At the same time, the global challenge of climate change calls for urgent, gamechanging solutions to eliminate emissions. Every government, industry, business, and individual have a role to play in decarbonising quicker, and creating the future of energy, faster, while safeguarding energy security and ensuring nobody is left behind. ADIPEC 2023 will be a progressive force for energy transformation and leadership. It will unite the expanding and increasingly diverse world of energy and help us work together to transform, decarbonise and future-proof our industry, by accelerating the innovation and tangible actions needed to enable a lower-carbon and higher-growth future for the world.”

Spread across 140,000m2, ADIPEC 2023’s exhibition will host more than 2,200 companies from 58 countries, including 30 ofcial country pavilions. The exhibition will include four dedicated industry zones – an expanded Decarbonisation Zone, the Digitalisation in Energy Zone, a Maritime and Logistics Zone, and a dedicated Manufacturing and Industrialisation Exhibition and Conference. These specialised exhibitions will enable the global energy industry to strengthen existing business partnerships and form new models of cross-sector collaboration to unlock and maximise value across businesses and drive future growth.

ADIPEC 2023 will host over 350 conference sessions across ten strategic and technical programmes – including a new Hydrogen Strategic Conference – with more than 1,500 speakers who will explore the strategies and solutions critical to achieving a cleaner, more

secure energy future. Christopher Hudson, President of dmg events, organisers of ADIPEC 2023, explains: “ADIPEC 2023 will actively support the transformative global energy agenda. As climate challenges intensify, the energy sector’s responsibility to lead the necessary progress on decarbonisation is greater today than ever before. ADIPEC 2023 will bring key industry decision-makers together to accelerate the innovation, collaboration, and investment necessary to drive us towards a lower-carbon future.”

• Strategic conference

• Technical conference

• Hydrogen strategic conference

• Decarbonisation conference

• Manufacturing & industrialisation strategic conference

• Manufacturing & industrialisation technical conference

• Maritime & logistics conference

• The ADIPEC forum for diversity, equity, and inclusion

• Future leaders conference

• Downstream technical conference

• Leadership roundtables – invite only.

A coveted recognition for the energy industry, the ADIPEC Awards are an important part of ADIPEC. Particularly signifcant in 2023, the ADIPEC Awards seek to unify the industry and accelerate urgent, collective action and gamechanging solutions to address critical climate challenges and future-proof the energy system. Under the theme ‘Leading the Transformation’, the ADIPEC Awards 2023 continue to recognise the pioneers in innovation and collaboration and the changemakers transforming energy toward a sustainable future for all. This year, the Award categories have been tailored to address energy industry challenges and support the global energy transition. Under eight new award categories, the winners will exemplify the type of global collaboration and innovation needed to navigate today’s energy, political and economic challenges and transform the

energy ecosystem for a better tomorrow. Judged by an enriched jury of global experts in decarbonisation, technology, fnance, and climate change, with robust judging criteria, the winners will be announced at an exclusive ceremony held on 2 October 2023.

ADIPEC awards categories

Aligned with the most important pillars driving the global energy transition today, the new 2023 ADIPEC Awards categories emphasise the need for universal access to cleaner, more secure energy; tangible and credible solutions to impact change; and transformational progress for the advancement of humanity:

• Game-changing partnership.

• Developing economies energy company of the year.

• Transformative hydrogen project.

• Clean energy technology innovation of the year.

• Decarbonisation at scale.

• Young changemaker of the year.

• Future energy workforce development programme.

• Leader of change: passionate driver of progress (this category is not open to public submissions).

i. adipec.com

The UK branch of steel wire and fbre products and services provider Hendrik Veder Group is celebrating the success of a recent trial project that saved 36,000kg of CO2 emissions.

Hailed as a landmark development by the company, the project, arranged and delivered on behalf of a global leader in the energy industry, was the trial stage for a new innovative and sustainable circular fbre rope project. Utilising its strong network of partners and a vendor relationship of more than ffteen years, Hendrik Veder Group’s Aberdeen ofce identifed the cost-efective and sustainable solution before coordinating the inspection, collection, and processing of around 18t worth of used lifting slings.

Following the collection of synthetic lifting and mooring equipment, the circular process applied allowed raw materials to be salvaged and adopted into a closed-loop recycling formula. From this, the raw materials can be repurposed into new products to be used by operators. The sustainabilityfocused project, delivered in collaboration with its Rotterdam branch, proved to be incredibly efective, saving not just emissions but the time and costs involved in comparison with incineration processing – the route which operators traditionally take, including both the cost of incineration and the necessary transport. Hendrik Veder also found that the commercial value of the initiative was much higher than the initial cost of the set-up.

As part of Hendrik Veder Group’s commitment to providing alternative, sustainable solutions to industry standards, the project allowed end-oflife equipment to be converted into new raw materials, with the slings and ropes being processed to minimise disposal and avoid concerns about landfll

The success of this pilot initiative has shown fantastic promise, providing a sustainable alternative to high carbon producing industry standards.

efciencies. The completion of the pilot initiative provided the promise of similar projects in the future for Hendrik Veder Group.

Discussing the success of the trial, Managing Director Bertwin Zonneveld says, “The success of this pilot initiative has shown fantastic promise, providing a sustainable alternative to high carbon producing industry standards. Early signs as a result of the trial showed that if

circular rope projects like this were implemented on a structural level, operators have the chance to substantially reduce their carbon footprint, saving as much as 36,000kg of CO2 emissions. An exciting solution that will contribute to operators who are looking to reach sustainability targets, it’s also cost-efective whilst providing an extra life cycle for products whenever possible.” i.

The operation, carried out by the Windstaller Alliance, used their anchor handling vessel, the Normand Sapphire, along with local tugboats, to tow DemoSATH from the construction site in the Port of Bilbao to the BiMEP test site, located 17.5km away. Once at the 85m deep BIMEP site, which is 3km ofshore in the Cantabrian Sea, the hook-up operation involved connecting the six pre-laid mooring lines to the structure’s single-point mooring turret.

Works in the BiMEP area are ongoing to fnalise the connection of dynamic and static cable and pull-in to the DemoSATH’s turret which will enable the energy export to the onshore electrical grid. DemoSATH is expected to generate the equivalent electricity needs of 2,000 Spanish households a year. The completion of this foating installation marks a major step forward in the project’s mission to harness wind power and generate sustainable electricity.

DavidCarrascosa,

Chief OperationsOfcer at Saitec Ofshore Technologies highlights, “This milestone in the installation of the DemoSATH foating ofshore wind project validates the years of steady commitment, resilience, and teamwork. Along the journey we have overcome some challenges that now serve as valuable lessons for future projects. We are proud of the achievements of our team, and the combined eforts of our collaborators. It’s thrilling to witness the DemoSATH project set sail, playing an integral role in the progression of renewable energy.”

During the two-year operational period at the BiMEP site, the SATH technology for foating ofshore wind developed by Saitec Ofshore Technologies will be tested, and the tasks related to its operation and maintenance requirements will be analysed. The project also aims to gain deeper insights into the metocean challenges in open sea, particularly in the harsh conditions of the Cantabrian Sea. Additionally, the collection of data will provide valuable knowledge regarding the coexistence of the platform with the environment and other maritime activities. The DemoSATH project benefts from the combination of Saitec Ofshore Technologies engineering design skills, RWE’s expertise in the ofshore wind industry and the vast experience brought by Kansai Electric Power (KEPCO) who joined the project earlier this year. In addition, the capabilities of multiple other companies involved and the institutional support from the Spanish Centre for the Development of Industrial Technology (CDTI) and the Basque Government institutions EVE and SPRI has ensured the success of the project.

With the installation of the unit now complete, the DemoSATH project will enter a period of commissioning, which will be followed by the operational phase when electricity generation will commence. The foating wind platform has been designed and equipped to harness the power of the wind in deep coastal waters and convert it into clean, renewable energy. This pioneering technology holds immense promise for reducing carbon emissions and contributing to the renewable energy goals of Spain and other countries around the world.

i.saitec-offshore.com

The project also aims to gain deeper insights into the metocean challenges in open sea, particularly in the harsh conditions of the Cantabrian Sea.

SeaVolt, a collaboration between DEME, Jan De Nul, and Tractebel, gets ready for its frst foating solar energy test platform to be installed ofshore. The platform foatation system is currently located in the port of Ostend, on the Belgian North Sea coast, where main contractor Equans is fnalising assembly.

The test platform will be the frst installation in the Belgian North Sea aimed at the large-scale development of ofshore solar energy and is scheduled to be towed ofshore, anchored, and put into operation to gather data for at least a year starting in August.

The potential of SeaVolt is unlimited. Unlike existing foating solar installations on lakes, SeaVolt has developed

a concept specifcally tailored to the conditions of rough seas. With its modular design, this technology is highly suitable for installation as a complement to ofshore wind farms. Under the framework of the Blue Cluster funded research project MPVAQUA, and additional support from the federal

government via BELSPO, the partners within SeaVolt together with Ghent University (UGENT) are ready to conduct a year-round open-sea testing inside the POM-West Vlaanderen owned ‘Blue Accelerator ofshore test zone’. This proof-of-concept installation will gather crucial data on the impact of waves, rain

With its modular design, SeaVolt’s technology is highly suitable for installation as a complement to ofshore wind farms.

In addition to technical tests, the SeaVolt test installation will also address ecological aspects. Various materials will be evaluated based on prevention of adverse efects on the marine environment.

and salt sprays on various solar panels with diferent PV panel confgurations. In addition, the impact of varying inclinations, caused by waves and wind, on the energy output will be closely monitored. The test aims to determine the level of protection required to shield the solar panels from seawater and bird droppings.

Amongst other materials suitable for this foating technology, SeaVolt has chosen to use novel light-weight carbon fbre material in this test installation. This material presents potential benefts for ofshore use however is not often used in such harsh marine conditions yet. Optical embedded fbres and sensors attached to the structure will assess if the structural integrity (vibrations/ fatigue) of the material is in line with the numerical models and results obtained from the ocean wave tank and wind tunnel tests. Since the foating structure and solar panels are driving the cost, these measurements are indispensable for further fnancial assessment.

In addition to technical tests, the SeaVolt test installation will also address ecological aspects. Various materials will be evaluated based on prevention of adverse efects on the marine environment. The test results will determine the selection of materials for further development. It is important not only to minimise the attachment of excessive marine growth to the foater to maintain its buoyancy. Lastly, specifc tests will be conducted to assess combining the foater systems with mussel cultivation and oyster farming, which present specifc challenges.

Tree Composites has constructed the frst-of-a-kind full composite ofshore platform with their unique TC-joint technology. The platform is specially designed as a solar energy test platform for Seavolt. Seavolt has developed a concept specifcally tailored to the conditions of rough seas, highly suitable for installation as a complement to ofshore wind farms. The innovative joint design enabled the construction of this platform using light-weight composite materials making it more resistance while reducing the usage of steel.

This crucial test, targeting all aspects of SeaVolt’s technology to develop a reliable, cost-efcient, and sustainable solution, will be the frst installation in the Belgian North Sea aimed at the large-scale development of ofshore solar energy. Since this test is only containing a few solar panels for a rather large foater construction, it is not to be seen as a frst prototype of the full scale. It is rather a laboratory to gain knowledge and push the technological development further. The expectations for this new application of solar energy are high. Ofshore solar energy provides an additional opportunity to produce local green energy. Combined with ofshore wind, it aligns with the strategy of multi-use sites and can optimise the use of existing electrical infrastructure.

The signifcant potential of ofshore solar energy is also recognised internationally. It has captured the attention of the European Green Deal plans, with an announcement by the Dutch

The signifcant potential of ofshore solar energy is also recognised internationally. It has captured the attention of the European Green Deal plans, with an announcement by the Dutch government to have 3GW of ofshore solar energy in operation by 2030, and concrete projects under development up to 100MW.

government to have 3GW of ofshore solar energy in operation by 2030, and concrete projects under development up to 100MW. Technology development is essential to achieve these ambitions. With this ofshore test, SeaVolt is taking the critical initial step to further advance large-scale marine foating solar energy.

Meanwhile, ecological research and economic research is ongoing amongst others covering future LCOE evolutions analysis. To ensure further development, Seavolt is preparing for a large-scale demonstration project within an ofshore wind farm. As such, the potential of integrating ofshore foating

solar inside an ofshore windfarm will be further assessed. If all goes well, large scale ofshore solar energy is expected to become a reality and, in this case, Seavolt hopes to secure a signifcant share in this new development of the already strong Belgian ofshore sector.

i. seavolt.be

USV AS has contracted Astilleros Gondán shipyard to build an unmanned surface vessel (USV), capable of signifcantly reducing emissions and operating expenses compared to conventional vessels utilised for subsea inspection, maintenance, and repair (IMR) work.

USV AS is a joint venture company established by DeepOcean, Solstad Ofshore, and Østensjø, whose main purpose is to invest and own USVs. It is estimated that the USV solution can reduce CO2 emissions with more than 90% compared to a conventional ofshore vessel when conducting subsea IMR operations.

The JV concept development for the USV began in 2018, and has been conducted in close collaboration with clients, Salt Ship Design, technology

providers, and the relevant authorities to enhance the capabilities of the USV. Maritime Robotics will deliver the system that enables auto remote control and navigation for the USV. The USV is 24m long and 7.5m wide. A hybrid dieselelectric propulsion system, which also includes a battery package from Seam, will allow the unmanned vessel to operate ofshore for up to 30 days without charging or refuelling. It will be equipped with a work ROV that is capable of operating down to 1,500m water depth.

The USV will be remotely controlled from shore but will have many autonomous features to ensure safety and integrity of the spread. It can operate in severe weather conditions. During operations, both the USV vessel crew and ROV operators will be colocated in the same remote operating centre. “With our new USV, we are moving the captain onshore who will still remain in control over the ofshore operations. We will operate the vessel and the ROV from an onshore remote operations centre. This is an excellent way of reducing cost and CO2 footprint and limit personnel exposure to ofshore operations”, says Øyvind Mikaelsen, Chair of USV and CEO of DeepOcean. Håvard Framnes, Investment Director of Østensjø, adds, “It is fantastic that we are able to provide new technology to the market that not only reduces emissions signifcantly, but also reduces costs and increases safety in ofshore operations. This shows that the Norwegian ofshore cluster is at the forefront of the energy transition. We have good experience in doing business with Solstad Ofshore

and DeepOcean, and we are pleased to grow the cooperation with this new winning technology.”

To increase the USVs workable weather window, it is equipped with a newly developed launch and recovery system which allows for work class ROVs to be operated from relatively small vessels, such as the USV. “Protecting the integrity of the ROV and its tooling is key to be able to deliver reliable and safe, unmanned ofshore operations. This is the cornerstone in developing this launch system instead of conventional moonpool or A-frame systems”, says Mr Mikaelsen.

In addition to the ROV, the USV will be equipped with a sizeable tool package to perform subsea operations. The USV will be capable of handling most of all subsea inspection work and a signifcant part of subsea intervention tasks.

Lars Peder Solstad, CEO of Solstad Ofshore, comments, “In practice, this concept represents a step change in ofshore operations. The collective expertise between the three JV partners, and our experience from the harsh environment of the North Sea, has allowed us to design this technology solution that can operate ofshore for up to 30 days.”

Delivery of the USV is expected by the end of 2024. The plan is that the USV, following ofshore testing, will be ready for operations in 2025, when it will go on charter for DeepOcean.

i. deepoceangroup.com

“It is fantastic that we are able to provide new technology to the market that not only reduces emissions signifcantly, but also reduces costs and increases safety in ofshore operations.”

HåvardFramnes – Investment Director of Østensjø.

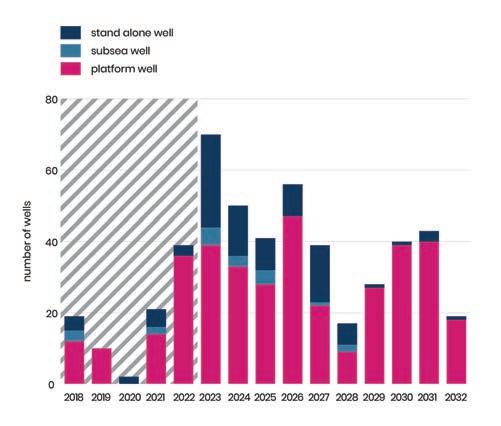

The optimisation of decommissioning activities, intensive cooperation between operators and innovative projects; the sixth Re-use & Decommissioning report reveals the impact of Nexstep in these and other policy areas.

ALL IMAGES COURTESY OF NEXSTEP, UNLESS STATED OTHERWISE.

Also, thanks to the facilitating role of Nexstep in the cooperation and exchange of knowledge between operators, the Ministry of Economic Afairs and Climate Policy, and other stakeholders, there has been huge growth in decommissioning activities since 2022. Against that background, the subtitle for this year’s Nexstep report is ‘Stepping up the pace’. On 5 July, Thijs Starink, General Manager of Nexstep, symbolically handed over the online report to Sybilla Dekker, Chair of the North Sea Consultation. This article summarises some highlights of the report.1

Kees Hansma, Director Deep Subsoil Transition at the Ministry of Economic Afairs and Climate Policy, describes in the report the latest legislation and regulations and the conditions that could be infuential in the future. Taking the next step goes hand in hand with monitoring recent developments and moving forward based on the latest insights, for example the current attention for nature-friendly decommissioning. Inspired by the North Sea Agreement and results of studies by Wageningen University & Research, earlier this year, Nexstep joined forces

with Element NL, the North Sea Foundation, and NWEA and signed up to a joint project headed by Energie Beheer Nederland (EBN).

The re-use of satellite topsides for new ofshore gas developments is being realised quite regularly, although this is typically limited to the same operator who operated the facilities initially. Repurposing of ofshore facilities for new activities is currently being considered mainly for CO2-storage. Whether the facilities and/or the production wells are ready for re-use will depend on many factors and it should be avoided that the facilities and/or wells are decommissioned prior to that assessment. In case a period is required to be bridged between the cessation of production and the moment for repurposing, clarity is needed which party will be responsible for the maintenance and insurance of the infrastructure during this intermittent period.

Decommissioning of ofshore wells is rising to an average of some 40 wells each year. Clearly marked in 2023 is Nexstep’s joint vessel-based campaign with six operators to decommission 30 stand-alone wells following the execution in 2022 of the cleaning and inspection of the wells. The mobilisation started in May 2023 and the campaign is expected to be completed in September. By executing this work using a vessel, the costs are expected to be reduced by some 30% compared to earlier estimates based on the use of a jack-up rig. This campaign may be followed by a next campaign to P&A some further 50 stand-

alone wells. The scope of work on these wells is likely such that the actual P&A work cannot be executed using a vessel and will require a jack-up rig.

As reported, last year the Q04-A and Q04-B platforms were removed to make room for the windfarm Hollandse Kust Noord. The two platforms are currently being dismantled onshore in Vlissingen. The forecasted removal activity for 2023 and 2024 is high with a total of 30 platforms; contracts have been awarded for 23 of these platforms. Besides removal also some new platforms are being developed. In the Netherlands, currently two major yards and two new entries are now active in the dismantling of ofshore installations and disposal of waste materials. To identify any potential capacity issues, insight is required into the storage and handling capacities of the onshore dismantling yards versus the expected

supply. A study is being carried out into alternative decommissioning techniques. This is especially of interest for the larger topsides, as they may require the use of larger crane vessels.

The Dutch Continental Shelf contains some 3,800km of pipelines which are used for the transportation of (mainly) natural gas and oil. When pipelines are taken out of service permanently, a notifcation is sent to the authorities together with a proposal on the recommended method for decommissioning. The formal policy is to decommission pipelines in-situ, that is leaving the pipelines behind in a safe and cleaned state in such a way that they cause no restrictions or risks to other users of the sea. Therefore, any contamination needs to be below the legal limits. The pipelines will be disconnected to enable removal of the connected installation(s). In case

pipelines are causing restrictions or risks to other users of the sea, the Minister of Economic Afairs & Climate can decide that the pipelines, or sections thereof, need to be removed. When pipelines are left behind after the production phase

they must be monitored for safety on a regular basis. The frequency will be determined on a risk basis, depending on the stability of the seabed and historic surveys during the production phase.

In some cases, re-use of the pipelines is possible. With the expanding development of ofshore wind and the growing interest in (green) hydrogen as alternative sustainable energy source, pipeline operating companies like NGT and NOGAT have already received certifcation from Bureau Veritas to use their trunklines for the transportation of hydrogen. Another promising re-use option for the ofshore pipelines is transportation of CO2 for underground storage.

i. nexstep.nl

The Dutch Continental Shelf contains some 3,800km of pipelines which are used for the transportation of (mainly) natural gas and oil.1 Source: Stepping up the pace, Re-use & Decommissioning report 2023, Nexstep, July 2023.

As one of the latest milestones for the growth of the US ofshore wind supply chain, ofshore wind joint development partners Ørsted and Eversource have designed and built the frst American-built ofshore wind substation, which has now been installed in the South Fork Wind project site at the end of July.

Kiewit Ofshore Services designed and built the substation, which will be deployed at Ørsted and Eversource’s 132MW South Fork Wind project serving Long Island, New York, and is set to begin operations by the end of this year. Kiewit built the 1,500t, 18m tall substation at its Ingleside facility near Corpus Christi. The substation will play a key role in enabling domestic energy production, strengthening America’s energy independence, and adding to the nation’s energy mix. The Kiewit team’s work is just one of several ways that Texas, and the Gulf of Mexico region, is playing in the buildout of a new domestic ofshore energy supply chain. America’s frst wind turbine installation vessel, Charybdis, is under construction in Brownsville. Ørsted and Eversource will be the frst ofshore wind developers to charter the Charybdis.

More than 350 workers across three states supported construction of this South Fork Wind substation, a topside structure that will sit on a monopile foundation within the wind farm, collecting the power produced by wind turbines and connecting it to the grid. The substation was designed and engineered in Kansas, fabricated in Texas, and will be installed in New York. “We’re putting American ingenuity to work as we build out a domestic ofshore wind energy supply chain with investments and job opportunities spanning the Northeast, down to Texas, and across the Gulf Coast region”, says David Hardy, Group EVP and CEO Americas at Ørsted. “The completion of South Fork Wind’s ofshore wind

substation is yet another frst for this groundbreaking project and moves us one step closer to the project’s frst ‘steel in the water.” “South Fork Wind continues to demonstrate the enormous power of ofshore wind to create a new, American-based supply chain as we work to grow the clean energy industry here in the United States, spreading economic opportunity to workers and local communities across the nation”, states Mike Ausere, Vice President of Business Development at Eversource Energy. “Today, we are proud to mark yet another signifcant milestone that will bring the promise of a low-carbon future ever-closer to fruition.”

Ørsted and Eversource are growing an American ofshore wind energy industry that’s creating jobs and driving economic development across almost every state in the nation. Today, Ørsted and Eversource are investing hundreds of millions of dollars into shipbuilding across the Gulf Coast, and workers from several of the region’s companies are putting their experience from other ocean-based industries to work in this new energy sector. That includes Edison Chouest Ofshore (ECO), which recently marked the 50% completion milestone for the US-fagged ECO Edison, the frst Jones Act-qualifed wind farm service operations vessel, which will support Ørsted and Eversource’s Northeast projects. More than 400 workers are

building the vessel at ECO shipyards in Louisiana, Mississippi, and Florida, with components of the vessel sourced from across 34 states.

Apart from the installation of the topside, the construction of the South Fork Wind ofshore wind project is well under way. The cable laying of the project’s 126km long submarine cable from its landfall below Wainscott Beach, in East Hampton, to the wind farm site roughly 64km east of Montauk, NY is progressing.

In June the installation of the monopile foundations took of when the monopile for the topside was installed using the vessel Bokalift 2. When everything goes according to plan, the ofshore wind farm should be operational by the end of this year.

i. us.orsted.com

i. southforkwind.com

Today, Ørsted and Eversource are investing hundreds of millions of dollars into shipbuilding across the Gulf Coast.The 132MW South Fork Wind project serving Long Island, New York, is set to begin operations by the end of this year. Artist impression of the Dominion Charabys. This US’s frst wind turbine installation vessel is under construction in Brownsville. Ørsted and Eversource will be the frst offshore wind developers to charter the vessel. Image courtesy of Edison Chouest Offshore. image courtesy of Ørsted. Image courtesy of Dominion Energy.

Energy and innovation for a just transition is the driving idea behind OMC Med Energy, the energy event rescheduled for 24 to 26 October after the postponement due to the food that afected the Emilia-Romagna region and the Ravenna territories.

The coming edition confrms the position of Ravenna at the centre of the Mediterranean energy agenda and will bring together again industry operators, stakeholders and national and international institutions to discuss and exchange ideas on decarbonisation, transition and energy security strategies. Over the course of its 30-year history, OMC Med Energy Conference & Exhibition (OMC) has always adapted to the changing international scenarios and today OMC Med Energy is the premier event in the Mediterranean area for all professionals and associations of the energy sector.

Clean, reliable, and economically accessible are the key words of today’s energy industry; showing the international energy industry your highest levels of efciency while strengthening your market positioning. For this purpose, OMC ofers the opportunity to meet investors and new partners, to build network and get new contacts, to get access to decision makers and specialists, to lay the base for future agreements and contracts, to recruit new talents, and to arrange B2B meetings. OMC has grown to become the premier industry gathering in the region and has helped hundreds of

companies achieved both growth and success through top level networking, matchmaking and the assessment of the latest drivers impacting the sector.

After rethinking energy leveraging alliances as major driver to achieve a sustainable energy future, it is now time to translate ideas into practical and viable solutions. Sustainable and equitable economic growth for the energy transition calls for new business models to be adopted by the industry globally taking advantage of cross-sector partnerships. OMC is the place to be for

energy authorities, industry CEOs, contractors, institutions, and consumers to fnd out how the Mediterranean Energy Scenario is evolving and to discuss about the best strategies, policies and fnance to accomplish the energy transition agenda. From operators and suppliers, policy makers and international companies as well as new start-ups, OMC brings the industry together in one place to meet and do business.

The Mediterranean Energy Scenario and transition prospects after Cop 26 and Cop 27, sector coupling as an example of real alliance amongst industry sectors to accelerate energy transition, the energy vectors of the future, partnerships between producers, and the hard to abate manufacturing industry are just some of the issues OMC will tackle in this year’s extensive conference programme. Over 200 technical and poster presentations will ofer insights and knowledge transfer in each technical stream: Operational Excellence, Carbon neutrality, Circular economy, and Technology, providing attendees a platform to share learn experience and know-how.

28,000m2

OMC has helped the oil & gas industry grow and now it provides a hybrid platform where the traditional oil & gas and the sustainable energy sectors meet

to set the driving routes and to face the growing global energy demand and sustainability needs. Therefore, the exhibition parallel which will run parallel with the conference programme, will be a showcase for technology and innovation within the entire ofshore industry. On the 28,0000m2 of the Palazzo Mauro De André, the 350 international exhibitors can not only showcase their innovations at their booth, but OMC also ofers additional opportunities, for example to hold a presentation or give a workshop in the OMC Commercial Presentation Theatre or the OMC Process Equipment Zone.

The call of Cop27 aims at transforming innovation into applied solutions for the global energy landscape and the new needs emerging around the world. To do so, OMC works closely with solvers, start-ups, and SMEs on challenges that span across the energy industry and business through the Innovation Room. This is a dedicated arena within the OMC venue where high school students, universities, research centres, start-ups, and experts have the chance to present and compare their perspectives, develop ideas and turn them into projects, devise solutions for the real-world energy challenges. In the Innovation Room several events will be organised such as the Start Up Challenge, the Energy Hackathon, and Call4Ideas Mediterranean Region.

Venue: Palazzo Mauro De André, Viale Europa, 1, 48122 Ravenna RA, Italy.

Opening hours: Tuesday to Thursday from 09.00-18.00 (on Thursday the exhibition ends at 15.00).

12,000 attendees

8,000 visitors

890 delegates

350 exhibiting companies

5 exhibition pavilions

25 nations

+200 papers and presentations

Rovco has been contracted by Flotation Energy to carry out a geo-environmental survey at its planned Cenos foating ofshore windfarm, 200km of the north-east coast of Scotland.

Located in the Central North Sea, the 1.4GW Cenos foating wind development will cover approximately 333km2. Following the recent launch of Rovco’s dedicated marine site characterisation business line, the company will deploy its multipurpose, custom-reconfgured DP2 survey vessel Glomar Supporter to carry out the work.

It is expected that the project will comprise subsea studies of the foating

wind turbine generators, mooring line anchor locations, inter-array cables, fxed foundation substation areas, and the portion of export cables that fall within these locations. The scope of work involves the acquisition of geophysical and benthic information to provide detailed data to inform environmental impact assessment (EIA) consents and the engineering processes from engineering to early front-end engineering and design (FEED) study. The geophysical element of the work scope requires the acquisition of multi-

beam echo sounder, side scan sonar, magnetometer, sub-bottom profler, and multi-channel seismic data along with associated analysis, processing, interpretation, and reporting.

Flotation Energy’s partner on Cenos is Norwegian ofshore wind company, Vårgrønn; a joint venture between energy company Plenitude (Eni) and investor HitecVision. The joint venture secured a lease earlier this year as part of Crown Estate Scotland’s INTOG (Innovation and Targeted Oil & Gas)

round. Craig Davis, director of site characterisation for Rovco, says, “We’re extremely pleased to be working with Edinburgh-based Flotation Energy on this project. The company has been a signifcant contributor towards the building of a strong ofshore wind industry in the UK and beyond. Our dedicated site characterisation division was launched specifcally to provide the full range of survey solutions to ofshore wind projects such as Cenos, in order to take it from pre-construction to frst energy as swiftly, efciently, and cost efectively as possible. Having access to the full range of tools, equipment, and technology on the Glomar Supporter, along with our highly experienced and specialist team, will be instrumental in helping Flotation Energy meet its timescale for this project utilising a local supply chain partner.”

Dan Wright, supply chain manager at Flotation Energy, comments, “Having secured Rovco’s extensive ofshore renewables experience to support the subsea studies will add immense value to our Cenos project and also reafrms our commitment to building a robust local supply chain for our ofshore wind projects. By focusing our eforts on creating fexible and collaborative partnerships with Scottish-based companies such as Rovco, we can provide opportunities to establish a foating wind supply chain ready to deliver for Scotwind licensing projects and beyond. The successful delivery of our survey campaign with Rovco enables us to maintain our fast-track delivery schedule for Cenos, a project that will decarbonise North Sea oil and gas assets and remove over two million tonnes of CO2 a year, helping to support Scotland towards its 2045 net zero targets.”

Launched at the turn of the year, Rovco’s marine site characterisation business unit was established to help address a critical industry shortage of companies with the all-round capabilities and expertise to support a rapidly emerging market during the earliest phases of ofshore wind farm development. At its heart is the multi-purpose DP2 survey vessel Glomar Supporter. On long-term charter from Glomar, the vessel

underwent an extensive rebuild and refurbishment in 2021 and has been reconfgured to permanently carry an entire suite of state-of-the-art survey sensors and equipment, aimed at providing the highest quality data capture, reporting and technologyenabled solutions for a streamlined and efcient site characterisation ofering. This package ofers complete fexibility while on site to adapt and respond to diferent challenges in a single ofshore trip.

i. rovco.com

i. fotationenergy.com

Set to be one of the world’s largest foating ofshore wind farms by 2028, the Cenos foating ofshore wind farm will consists of 70-100 foating turbines. The turbines will be foating since the water depths exceed 90m, which means bottomfxed foundations are not a viable solution. Each turbine will provide 14-20MW of power. The wind turbines will be installed on foating substructures which are connected by mooring lines to anchors in the seabed to hold their position. The turbines will be anchored across a carefully selected area of 333km².

“Having secured Rovco’s extensive ofshore renewables experience to support the subsea studies will add immense value to our Cenos project and also reafrms our commitment to building a robust local supply chain for our ofshore wind projects.”Dan Wright – supply chain manager at Flotation Energy. Image courtesy of Flotation Energy.

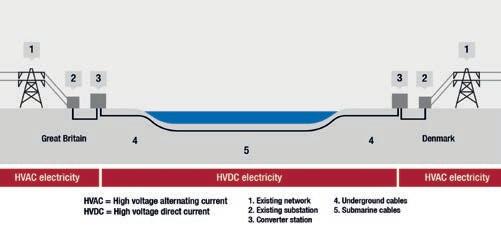

The British and Danish electricity grids are physically connected for the frst time, following the completion of cable works on the Viking Link interconnector.

The fnal section of the state-of-arthigh voltage subsea cable was completed ofshore in the North Sea by Prysmian’s cable laying vessel Leonardo da Vinci and its team.

765km

Viking Link is a 1,400MW high voltage direct current (DC) electricity link between the British and Danish transmission systems connecting at Bicker Fen substation in Lincolnshire, UK, and Revsing substation in southern Jutland, Denmark. The project involves the construction of converter sites and installation of onshore and ofshore cable in each country. These are then connected to the substations. Viking Link will be approximately 765km long and will enable the more efective use of renewable energy, access to sustainable electricity generation and improved security of electricity supplies. It will beneft the socio economy of both countries.

The USD 2.2 billion project is a joint venture between UK’s National Grid and Danish system operator Energinet. With its length of 765km, it will be the world’s longest land and subsea interconnector. Due to be complete by the end of the year, it will enable the sharing of enough green electricity to power 1.4 million UK homes. The complex cable joining process took place in Danish waters and took several days to complete. It involved lifting the sections of cables out of the water and expertly joining each conductor/strand together on the cable laying vessel. Viking Link is National Grid’s sixth interconnector. The company already has fve operational

cables joining the UK with France (IFA and IFA2), The Netherlands (BritNed), Belgium (Nemo Link), and Norway (North Sea Link).

Once in operation, Viking Link will enable fast and fexible energy to be shared between the two countries, from where it is generated to where it is needed most.

and our partners on both sides of the connection. Interconnectors bring huge benefts to the UK, acting as clean energy super-highways, allowing us to move surplus green energy from where it is generated to where it is needed the most. That means that we can import cheaper and cleaner energy from our neighbours when we need it, and vice versa. As energy systems build up their

Between 2020 and 2030, National Grid expects its interconnectors will have helped the UK to avoid around 100t million of carbon emissions and by 2030, 90% of the energy imported through the company’s interconnectors will be from zero carbon energy sources.

Flowing at the fick of a switch, interconnectors can respond quickly to changes in supply and demand, making them an ideal partner to intermittent renewable energy. Rebecca Sedler, Managing Director for Interconnectors at National Grid, says, “This is a fantastic moment for the UK and Denmark, and a key milestone for the world record project as we join the electricity networks of our two countries for the frst time. After years of planning and construction work, today’s announcement is testament to the hard work and dedication of our team

ofshore wind generation, interconnectors will become critical for transporting clean and green energy and helping to manage the intermittent nature of renewable sources.”

Construction on Viking Link started in 2019 and so far, more than three million working hours have been spent on planning and construction. The HVDC cable, manufactured and laid by Prysmian and NKT, is made from copper, steel, paper, and plastic and is buried on

the seabed. It weighs around 40kg per metre which is three times as much as a gold bar.

Between 2020 and 2030, National Grid expects its interconnectors will have helped the UK to avoid around 100t million of carbon emissions and by 2030, 90% of the energy imported through the company’s interconnectors will be from zero carbon energy sources.

Earlier this year, National Grid announced plans for a 1.8GW Ofshore Hybrid Asset (OHA) between the UK and the Netherlands, called LionLink. A second OHA called Nautilus, is also in the planning phase with the potential to connect with Belgium and supply enough electricity to meet the needs of 1.4 million UK homes. Ofshore Hybrid Assets are the next phase of interconnection, not only joining two countries together, but also connecting with ofshore wind generation. OHAs support UK and EU eforts to meet 2030 and 2050 ofshore wind targets, speed up the displacement of fossil fuelled power stations, and crucially, have the potential to reduce the impact on the environment and coastal communities with fewer individual connections.

i. viking-link.com

Salus Technical has successfully launched a working prototype of its artifcial intelligence (AI) tool, HAZOP AI, which is designed for Hazard and Operability Studies (HAZOP).

The software, which is applicable to all major hazard industries, will prompt users to consider risks they may have missed, assist in answering questions, and provide guidance on good practice as well as past incidents with relevant learnings. One of the main aims of the tool will be to reduce the time taken to complete a HAZOP by 50%, whilst increasing quality and consistency.

Following a successful product demonstration involving over 30 companies globally, the company set about completing a working prototype of HAZOP AI in the space of a week as part of a Hackathon. Founder and MD of Salus Technical, David Jamieson, says, “Saving lives in hazardous environments is at the very core of all that we do, and that is why it was crucial for us to

complete HAZOP AI and have the working version ready for use in this short timeframe. I am immensely proud of what the team achieved, and I welcome as many people as possible to trial the tool which will give individuals an insight into the potential future use of AI in HAZOPs. It is one of the most important exercises done to identify the sources of major accidents and utilising the latest technology should only

One of the main aims of HAZOP AI will be to reduce the time taken to complete a HAZOP by 50%, whilst increasing quality and consistency.

enhance the role of people, not replace them.”

The team at Salus Technical has invested heavily in AI in the process safety space and is currently working with several clients to develop bespoke tools that can be used to manage risks by using data from previous risk assessments and incidents. Mr Jamieson continues, “We know that a single solution may not ft every business and therefore, the real value lies in building bespoke products. We are delighted that so many organisations have already shown an interest in HAZOP AI, and with this, we hope to partner with several operators to build bespoke tools.” Although AI is a highly discussed topic at present, this is the frst time it has been used in this way for ofshore process safety and Mr Jamieson believes that the creation of HAZOP AI is an opportunity for the North Sea to lead the way on process safety.

Salus Technical is a process safety software and consultancy frm which works with customers to help them understand and manage the risks of

HAZOP AI is designed for Hazard and Operability Studies.

major accidents. Ultimately it is the company’s goal is to increase the competencies of individuals, teams and organisations, fostering a culture of continuous safety improvement across the industry.

For this it ofers three complementary services: process safety engineering support, software packages, and a range of tailored and on-demand training courses.

Since Salus Technical launched full-time in 2019, the frm has supported oil and

gas operators with technical safety engineering on a variety of brownfeld, greenfeld, and decommissioning projects, and is increasingly supporting a wider range of emerging and renewable energies as part of the energy transition.

i. hazop.ai

i. salus-technical.com

The campaign to install the frst of 277 turbines at the world’s largest ofshore wind farm is under way, marking a major advance in the industry and speeding up the transition to a cleaner, more secure energy system.

The 260m tall turbines – which are almost twice the height of the London Eye – will be installed approximately 130km of the coast of Yorkshire using the vessel Voltaire, with a lifting capacity of 3,200t, the largest of its kind in the world. Work to install the frst 260m turbine began early August.

On a visit to Able Seaton Port in the North East of England to mark the occasion, Deputy Prime Minister Oliver Dowden says, “I am pleased to be here in Hartlepool today as we install the frst wind turbine at the new Dogger Bank ofshore wind farm. This project will generate cheap, clean energy to power millions of homes and provide the UK with greater energy independence in the face of Putin’s energy ransom. Disruption to global energy supplies is one of the key risks we’ve highlighted in our new National Risk Register and working with

the Dogger Bank partners, we are making Britain more secure.”

The scale of the Dogger Bank Wind Farm is immense, occupying an area almost as large as Greater London, on seabed that once formed a land bridge between the UK and Europe. When fully complete, it will have an installed capacity of 3.6GW of renewable electricity and be capable of producing enough clean energy to power the equivalent of 6 million homes annually. SSE Renewables is lead operator for the development and construction of Dogger Bank Wind Farm. Equinor will be lead operator of the wind farm on completion for its expected operational life of around 35 years. Vårgrønn brings specialist ofshore wind expertise to the project. Dogger Bank has created and supported more than 2,000 jobs, principally in the North East of England.

Construction on this scale in the challenging conditions of the North Sea is unprecedented and the project has delivered several world-frsts that will signifcantly accelerate the speed at which future ofshore projects can be developed. These include deployment of new 13MW and 14MW turbine technology, the world’s frst unmanned ofshore High Voltage Direct Current (HVDC) substation platform, and frst use of HVDC technology on a UK wind farm.

The commencement of the campaign to install GE Renewable Energy’s 13MW Haliade-X turbines, one of the largest and most powerful in the world, was a pivotal moment for the landmark project. It also represents a major milestone for the UK’s global leadership on ofshore wind. Alistair Phillips-Davies, CEO of SSE, states, “Dogger Bank is one of the biggest and most complex

• At 260m, the turbines are almost twice the height of the London Eye and equivalent in height to the iconic Rockefeller Centre in New York.

• Each turn of its 107m long blades will produce enough clean energy to power an average UK home for 2 days.

• Once fully operational, Dogger Bank will generate annual CO2 savings equivalent to the emissions of nearly 1.5 million average internal combustion engine petrol cars.

• The installation vessel, Jan de Nul’s Voltaire, is the largest ofshore jack-up installation vessel ever built and is the frst ultra-low emission ship of its kind.

engineering and infrastructure projects anywhere in the world. Our progress here with our joint venture partners Equinor and Vårgrønn proves that ofshore wind projects of this size are now mainstream and will help turbocharge the transition to the cheaper, cleaner, and more secure energy system we all want to see. It is action, not ambition, that will secure our energy future and this project shows action on a massive scale. But we will need many more Dogger Banks to achieve our goals and we look forward to working with government to bring forward more projects at pace.”

Equinor EVP Renewables, Pål Eitrheim, adds, “The imminent installation of the frst turbine at Dogger Bank is a testament to the determination of the UK Government, the project partners, and the supply chain to deliver a worldclass ofshore wind project for the UK. To reach our net zero goals, we will need even more of this collaboration. We’re delighted to soon begin operating

Dogger Bank from our new O&M base at the Port of Tyne, which will host 400 jobs over the 35-year lifetime of the wind farm. We look forward to seeing the 277 turbines installed safely over the next three years, generating green electricity at scale and powering millions of British homes.” Vårgrønn CEO, Olav Hetland, comments, “Dogger Bank shows that extensive collaboration is key to developing ofshore wind farms that provide power at scale while driving innovation. Getting to this milestone has relied on the eforts of a huge number of local and international suppliers, and together we have now moved the boundaries of what is possible in ofshore wind. Dogger Bank now cements the North Sea’s new role as Europe’s renewable power plant and as the home to a world-leading ofshore wind supply chain.”

The CEO of GE Vernova’s Ofshore Wind business, Jan Kjaersgaard, voices,

“We are delighted that the frst campaign to install the Haliade-X turbine at sea at Dogger Bank Wind Farm is under way. We want to thank the partners in the Dogger Bank Wind Farm for the trust they have placed in GE and congratulate everyone involved. Together our teams are making a real contribution to the UK’s ambitious ofshore wind goals by helping to bring clean, renewable energy online.” Jan Van Impe, manager of Jan De Nul Ofshore Renewables adds, “Our Voltaire is more than a match for the scale and characteristics of the ofshore Dogger Bank turbines which ofer the perfect challenge for this next generation state-of-the art jack-up installation vessel. We are excited to be embarking on this campaign to install the very frst ofshore GE Haliade-X turbine on the Dogger Bank Wind Farm in a sustainable and efcient way, and we are looking forward to continuing this mission with industry leaders SSE Renewables, Equinor, and Vårgrønn to further construct the energy transition for the UK energy market.”

i. doggerbank.com

“Dogger Bank shows that extensive collaboration is key to developing ofshore wind farms that provide power at scale while driving innovation.”

Olav Hetland – CEO Vårgrønn.

The North Sea oil & gas industry spent USD 2 billion decommissioning redundant wells and infrastructure last year, more than in any of the previous fve years, new fgures show.

The latest North Sea Transition Authority (NSTA)

Decommissioning Cost and Performance Report reveals that the industry spent a total of around USD 10 billion from 2017-22 and activity levels are expected to remain high, with about USD 2.5 billion a year forecast to be spent on decommissioning in the next decade, a massive opportunity to keep developing skills and experience in the basin and help the supply chain win lucrative contracts overseas by reinforcing its status as global leader.

Encouragingly, UK suppliers are in line to secure around 70% of the work associated with UK North Sea decommissioning projects listed in Supply Chain Action Plans (SCAPs) lodged with the NSTA last year. This indicates the sector is living up to its North Sea Transition Deal pledge to ensure at least half of spending on decommissioning projects goes to the UK supply chain, as well as meeting its legal obligation to clean and remove infrastructure once felds stop producing. The industry has also built an impressive track record of carrying out decommissioning projects costefciently and safely due to its willingness to share learnings and data – and embrace new technologies and innovative commercial models. Achieving further improvements will be challenging, however, in the face of factors including heightened demand for equipment, vessels, and services from other regions and sectors, such as

The COVID-19 pandemic had a material impact on ofshore execution and spend during 2020 and 2021 however activity levels and spend returned to a six year high in 2022. Beyond the efect of the pandemic, the discrepancy between planned and actual spend can be attributed to a combination of;

• Re-scheduling/deferral of decommissioning

• Increased efciency of execution

Operators must strive to deliver their agreed schedules and commitments, work even more collaboratively with the supply chain, and share their plans earlier, ensuring resources are available at the right time.

ofshore wind – which have pushed up prices, taking the total cost estimate for decommissioning to USD 51 billion. The NSTA is confdent that the industry can overcome these hurdles and meet its cost-efciency target – lowering the estimate to USD 42.5 billion by the end of 2028. However, operators must strive to deliver their agreed schedules and commitments, work even more collaboratively with the supply chain, and share their plans earlier, ensuring resources are available at the right time.

The NSTA is providing ongoing support by introducing new key performance indicators and benchmarks – developed

USD 20bn

USD 22bn

USD 11bn

USD 11bn

USD 6.4bn

USD 7.7bn

USD 5bn

USD 5bn

USD 4bn

USD 4bn

Heightened demand for equipment, vessels, and services from other regions and sectors, such as offshore wind, have pushed up prices, taking the total cost estimate for decommissioning to USD 51 billion.

with industry and underpinned by the collection of new datasets, including the length of time taken to complete specifc tasks, the number of crew members employed, and the types of vessels used. The new metrics will provide a more

complete picture of how well decommissioning projects are being planned and executed, helping to identify opportunities for industry to improve its overall performance and realise cost efciencies. This

complements the NSTA’s existing eforts to support the sector by sharing best practice, setting clear expectations on well decommissioning deadlines, and encouraging operators to repurpose oil and gas infrastructure for energy transition projects.

The NSTA also promotes the use of its Energy Pathfnder portal which advertises upcoming tendering opportunities, and expects more operators to support and contribute to the Decommissioning Data Visibility project, launched in 2021 alongside the Decommissioning and Repurposing Taskforce (DaRT).

According to the report, decommissioning will span the next four decades but around 90% of spend will complete in the next 20 years, with the decade up to 2032 forecast to deliver peak activity. The next ten years (current decade 2023-2032) are regarded as pivotal for decommissioning across the UKCS basin. The window of opportunity to efect and embed a material change in the cost of decommissioning and drive sustainable long-term decommissioning performance efciency and cost reduction exists now and is a key priority and focus for both industry and regulators. Pauline Innes, NSTA Director of Supply Chain and Decommissioning, says, “The North Sea decommissioning sector is highly active and productive, and the industry is ideally placed to realise the massive USD 27 billion opportunity which will come its way over the next ten years. However, operators must redouble their commitment to collaborate with the supply chain and plan even more efectively if they are to overcome challenging market conditions and remain competitive on cost. The NSTA will continue to use its powers and infuence to support the industry as it strives for continuous improvement, including through the development of new benchmarks.”

i. nstauthority.co.uk

The North Sea decommissioning sector is highly active and productive, and the industry is ideally placed to realise the massive USD 27 billion opportunity which will come its way over the next ten years.

Hundreds of new oil and gas licences will be granted in the UK, the Prime Minister has confrmed Monday 31 July, as the UK Government continues to back the North Sea oil & gas industry as part of drive to make Britain more energy independent.

The Government and the North Sea Transition Authority (NSTA) announced a joint commitment to undertake future licensing rounds, which will continue to be subject to a climate compatibility test. By adopting a more fexible application process, licences could also be ofered near to currently licensed areas – unlocking vital reserves which can be brought online faster due to existing infrastructure and previous relevant assessments.

With the independent Climate Change Committee predicting around a quarter of the UK’s energy demand will still be met by oil and gas when the UK reaches net zero in 2050, the Government is taking steps to slow the rapid decline in domestic production of oil and gas, which will secure the country’s domestic energy supply and reduce reliance on hostile states. This will increase the UK’s energy security and reduce dependence

on higher-emission imports, whilst protecting more than 200,000 jobs in a vital industry.

The NSTA, responsible for regulating the oil, gas, and carbon storage industries, is currently running the 33rd ofshore oil and gas licensing round. They expect the frst of the new licences to be awarded in the autumn, with the round expected to award over 100 licences in total. Future

licences will be critical for providing energy security options, unlocking carbon capture usage and storage, and hydrogen opportunities, building integrated ofshore energy hubs that make the best use of the established infrastructure. This comes as new analysis released by the NSTA shows that the carbon footprint of domestic gas production is around one-quarter of the carbon footprint of imported liquifed natural gas.

As the UK is a rapidly declining producer of oil and gas, new oil and gas licences reduce the fall in UK supply to ensure vital energy security, rather than increase it above current levels, so that the UK remains on track to meet net zero by 2050. UK Prime Minister Rishi Sunak says, “We have all witnessed how Putin has manipulated and weaponised energy, disrupting supply, and stalling growth in countries around the world. Now more than ever, it’s vital that we bolster our energy security and capitalise on that independence to deliver more afordable, clean energy to British homes and businesses. Even when we’ve reached net zero in 2050, a quarter of our energy needs will come from oil and gas. But there are those who would rather that it come from hostile states than from the supplies we have here at home. We’re choosing to power up Britain from Britain and invest in crucial industries such as carbon capture and storage, rather than depend on more carbon intensive gas imports from overseas, which will support thousands of skilled jobs, unlock further opportunities for green technologies, and grow the economy.”

The UK’s oil & gas industry is also vital to driving forward and investing in clean technologies that are needed to realise net zero targets, like carbon capture

usage and storage, by drawing from the sector’s existing supply chains, expertise, and key skills whilst protecting jobs. On 31 July, the Government also confrmed that projects Acorn in North East Scotland, and Viking in the Humber have been chosen as the third and fourth carbon capture usage and storage clusters in the UK. The Government has already committed to deploy CCUS in two industrial clusters by the mid-2020s, the HyNet cluster in North West England and North Wales, and the East Coast Cluster in the Teesside and Humber, and another further two clusters by 2030, now confrmed as Acorn and Viking. Together, these four clusters will build a new thriving carbon capture usage and storage industry, which could support up to 50,000 jobs in the UK by 2030. The UK has one of the largest potential carbon dioxide storage capacities in Europe, making the North Sea one of the most attractive business environments for CCUS technology.

The Government has committed to provide up to USD 25 billion in funding for early deployment of CCUS, unlocking private investment and job creation. The Energy Security Secretary Grant Shapps says, “In the wake of Putin’s barbaric invasion of Ukraine, our energy security is more important than ever. The North Sea is at the heart of our plan to power up Britain from Britain so that tyrants like

“Now more than ever, it’s vital that we bolster our energy security and capitalise on that independence to deliver more afordable, clean energy to British homes and businesses. Even when we’ve reached net zero in 2050, a quarter of our energy needs will come from oil and gas.”

Rishi Sunak – Prime Minister.The Government has committed to provide up to USD 25 billion in funding for early deployment of CCUS, unlocking private investment and job creation.

Putin can never again use energy as a weapon to blackmail us. Today’s commitment to power ahead with new oil and gas licences will drive forward our energy independence and our economy for generations. Protecting critical jobs in every region of the UK, safeguarding energy bills for British families and providing a homegrown fuel for our economy that, for domestic gas production, has around one-quarter the carbon footprint of imported liquifed natural gas. Our next steps to develop carbon capture and storage, in Scotland and the Humber, will also help to build a thriving new industry for our North Sea that could support as many as 50,000 jobs, as we deliver on our priority of growing the economy.”

Representing one of the relevant stakeholders, David Whitehouse, CEO of Ofshore Energies UK, comments on the news, “Domestic production is the best pathway to net zero and the UK Government’s commitment to licences is a welcome boost for energy security and jobs. Oil and gas felds decline naturally over time. The UK needs the