Iam pleased to present to you the frst edition of this magazine for this year. The last weeks of the year and the frst ones of the new year always show a period of calm, one of both refecting and looking ahead. Yet this certainly does not mean that nothing has happened in our industry. It remains endlessly fascinating to report on all the ongoing developments, witnessing how our industry continues to work towards a healthy future.

Sustainability and innovation are being pursued in all fronts and sectors. The frst ofshore vessels powered by hydrogen have been put into operation, and methanol is also making its debut as a fuel. Meanwhile, the trend of scale enlargement in ofshore wind continues unabated, which also afects the installation vessels. For instance, Van Oord’s Svanen is due for a new upgrade to be able to install the new generation of ofshore wind turbines.

Electrifcation in Europe is currently taking on larger proportions. In some regions this is already leading to problems of congestion and overload, simply because more electricity is being supplied than the grid can handle. Fortunately, steps have been taken by the Transmission System Operators (TSOs) to realise a European ofshore infrastructure network. By connecting the networks of various countries, demand and supply of electricity within Europe can be better coordinated.

You can read about this and even more developments in the industry in this magazine. And to stay completely up to date regarding ofshore wind, you really cannot miss the WindEurope Annual Event in Bilbao. More on this is also included in our magazine.

I wish you happy reading.

Other publications by Yellow & Finch Publishers:

With kind regards,

Arno Dirkzwager Editor

ARNO@YNFPUBLISHERS.COM

40,000 TONS OF MARINE GRADE PLATES & PROFILES ON STOCK ACCORDANCE TO DNVGL-OS-B101 WITH 3.2 CERTIFICATION

MATERIALQUALITYFROM TO PlatesVL A 3 mm100 mm PlatesVL D364 mm80 mm

PlatesVLE36(z35)6mm250mm PlatesVLF36(z35)20mm150mm

PlatesVL E408 mm50 mm MATERIAL QUALITY

AUTOMATION, CONTROL & MEASUREMENT TECHNOLOGY

21 A three-year offshore analysis deal

36 A breakthrough year

38 Remote and autonomous ship operations driving the future of marine data management

CCS

14 Dutch CO2 storage project reaches FEED phase

GREEN PROPULSION

12 The first hydrogen-powered CTV Hydrocat 55 for the German offshore market

44 Methanol marine engines for cablelaying vessel Fleeming Jenkin

OFFSHORE CONSTRUCTION

16 DNV-ST-N001 upgraded to meet changing needs of the marine sector

30 ENTSO-E publishes the first Offshore Network Development Plans

OFFSHORE SOLAR ENERGY

18 SolarDuck secures EUR 15 million funding

OFFSHORE WIND

24 Lots of good news – and good figures – again in offshore wind

32 Ecowende contracts partners to build most ecological wind farm yet 42 Glamox to light the Sofia Offshore Wind Farm

OIL & GAS

35 Mooring pre-installation contract for Jumbo Offshore

REFITS & CONVERSIONS

22 Major upgrade for Svanen

28 Winds of change

WINDEUROPE ANNUAL EVENT 2024

08 Driving home the value of wind

REGULARS

01 Editor’s note

04 News in brief

45 People

46 Yellow & Finch pages

48 Next issues & Colophon

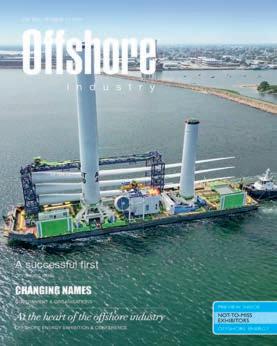

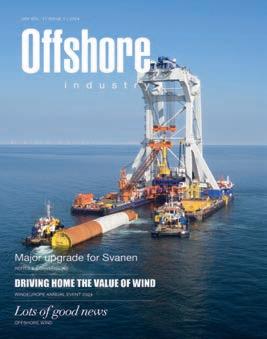

On the cover

Van Oord’s heavy-lift installation vessel Svanen will receive a major upgrade. Among other improvements, the gantry crane will be extended by 25m, making the vessel ready to handle the next generation of monopile foundations for offshore wind projects. Read more on page 22. Photo courtesy of Van Oord.

Wind Peak launched

Cadeler has launched newbuild wind farm installation vessel Wind Peak at Cosco Shipyard (Qidong, China). The launching of Wind Peak is a critical milestone that marks the completion of the vessel’s hull. Leading up to this achievement is two years of intricate engineering and eighteen months of construction with an uncompromising focus on safety and efciency. Now, the design of numbers and pixels is transformed into a real foating vessel for the future of transport and installation of ofshore wind turbines. After the launching, the jacking legs and cranes will be installed onboard alongside various technical installations. Commissioning and testing of all systems will then be initiated. The sea trial is planned for mid-2024 – all ship systems will be tested by Cadelers in close collaboration with the Classifcation Society. Wind Peak is scheduled to be handed over to Cadeler in Q3 this year.

i. cadeler.com

As anticipated in the preferred supplier agreement announced on 13 April 2023, Havfram and RWE have signed a contract for the transportation and installation of turbines for RWE’s Nordseecluster projects. The projects combine four wind farm sites in the eastern part of the German North Sea and will have a total capacity of up to 1.6GW. Havfram Wind is to transport and support the installation of 104 Vestas ofshore wind turbines with a capacity of 15MW each, which are to be installed throughout two construction phases. Both of Havfram Wind’s newbuild state-of-the-art wind turbine installation vessels will be utilised throughout both phases. Turbine installation of the two wind farms in Phase A is expected to start in 2026, and ofshore construction works for Phase B are scheduled to begin in 2028.

i. havfram.com

Ulstein Werft has ordered 2 × 3 × MAN 12V175D-MEV methanolready engines in connection with the building of two CSOVs for Bernhard Schulte Ofshore, the ofshore unit of international shipping corporation Schulte Group. The vessels are designed to support the ofshore wind energy market and are planned for delivery in 2025. An option for four additional vessels exists. The 175D variable-speed gensets enable the vessels to achieve a signifcant reduction in fuel consumption and emissions. Each comes with an integrated MAN closed-loop SCR (Selective Catalytic Reduction) system, a compact and fexible solution for the vessels. The MAN 175D gensets also feature reduced structural and airborne noise, as well as the lowest lube-oil consumption.

i. man-es.com

The UK division of Hendrik Veder Group has its sights set on a promising 2024, following a year of growth that saw the steel wire and fbre rope products and services provider achieve its highest earnings since 2019. Across 2023, Hendrik Veder Group UK completed several largescale projects throughout the UK, won due to the frm’s track record in providing tailored solutions for specifc client requirements. For 2024, alongside the continued output of carbon-reducing alternatives, the company intends to increase its service activities and double its existing service team.

i. hendrikvedergroup.com

Aberdeen-based Verlume has achieved the prestigious ‘Granted’ status from the Ofshore Renewable Energy (ORE) Catapult’s ‘Fit For Ofshore Renewables’ (F4OR) programme. Designed as a business improvement programme and to build energy sector specifc capability, F4OR has been developed with input from the ofshore renewable energy industry and is managed through ORE Catapult. Verlume was enrolled in the F4OR programme in late 2021 and was presented to the granting panel in November 2023. Obtaining F4OR Granted status signifes that Verlume is competent, capable, and competitive within the UK ofshore renewable energy supply chain.

i. verlume.world

His Majesty the King Frederik X of Denmark, Vestas CEO Henrik Andersen, Szczecin Mayor Piotr Krzystek, and WindEurope Deputy CEO Malgosia Bartosik recently took part in Vestas’ foundation stone ceremony for its new nacelle and hub assembly factory in Szczecin, Poland. The new factory is the latest example of the industry’s commitment to expand the European wind supply chain to help meet Europe’s energy security and climate objectives. National Governments across Europe must deliver on their own actions set out in the Wind Power Package as they have committed to by signing the European Wind Charter.

The new ofshore nacelle and hub assembly factory is expected to begin operations in 2025 and will create 700 direct jobs. Vestas also just announced plans to establish a second factory in Szczecin to produce ofshore blades. The two sites will play a vital role in supplying Europe’s and especially Poland’s growing ofshore wind feet. Poland wants to install 6GW ofshore wind by 2030, and 18GW by 2040.

i. vestas.com

Danos announces the signing of a new planning and scheduling contract with Shell Exploration and Production Company, a subsidiary of Shell. The agreement entrusts Danos to deploy a team of highlyskilled personnel to support Shell’s Upstream operations, underscoring Danos’ commitment to excellence in providing project management solutions. With the contract, Danos team members will bring a wealth of technical expertise to oversee the scheduling of ofshore projects and logistics for the energy giant’s construction, coatings, and maintenance activities. Operating at predominately onshore locations, the team will leverage its expertise to ensure skilful coordination and execution of activities.

i. danos.com

The latest addition to the United Heavy Lift feet, mv UHL Fresh, has set sails on her maiden voyage from Tianjin, China to Europe with project cargo onboard after being ofcially delivered to the shipping company on 24 January, 2024. The vessel has been put into service less than a year after the keel laying at the Hudong Shipyard in Shanghai, where she was christened in late 2023. Final sea trials were completed last month. MV UHL Fresh joins the Hamburg-based shipping company as vessel number eighteen in their homogenous F900 Eco-Lifter feet. The vessel is set to make her call at the port of discharge in Vaasa, Finland by the end of March. The technical manager of the vessel will be Zeaborn Ship Management.

i. unitedshippinggroup.de

Huisman receives ‘grade A supplier of the year 2023’ award

Huisman has been honoured with the title of ‘Grade A Supplier of the Year 2023 (strategic supplier)’ by COSCO Shipping Shipyard (Nantong & COSCO Shipping (Qidong, China) Ofshore. This award was presented during the 2023 supplier conference and the frst green supply chain sustainable development conference, themed ‘Chasing dreams in the blue ocean, joining hands for the future.’ Since 2019, Huisman has established a solid partnership with COSCO Shipping Shipyard & COSCO Shipping. The collaboration between the two parties achieved a milestone with the successful delivery of the world’s largest ofshore wind turbine installation vessel, the Voltaire to the Jan De Nul Group. Huisman designed and manufactured the 3,200mt Leg Encircling Crane (LEC), the world’s largest of its kind with the highest lifting capacity and lifting height to date.

i. huismanequipment.com

Sentinel Subsea proudly announces a successful installation of its WellSentinel Clam to monitor a subsea Christmas tree. This operation, in collaboration with Baker Hughes, was executed on a producing asset at a depth exceeding 400m and marks a signifcant advancement in subsea technology. The seamless installation of the Clam type system, a WellSentinel solution designed specifcally for subsea Christmas trees, not only showcases the robustness and adaptability of its passive technology, but also confrms the technology’s application to a wide range of subsea infrastructure.

i. sentinel-subsea.com

Strohm has supplied TotalEnergies with a thermoplastic composite pipe (TCP) Jumper, which has been commissioned in deep water (1,600m) in West Africa. This installation has followed a rigorous testing programme, during which TotalEnergies qualifed the Netherlands-based company’s TCP Jumper for permanent subsea applications. All pre-deployment inspections and tests were successfully passed, certifying it for its full life cycle on schedule. The installation of Strohm’s 5.2” ID, 340 bar design pressure TCP Jumper in the Egina feld was supported by a local Nigerian subsea services provider. The pipe’s lightweight properties allowed it to be transported by a small multipurpose vessel and installed by local contractors, greatly reducing carbon emissions and costs. Strohm personnel were mobilised ofshore to assist in the installation process. Strohm’s TCP provides a robust, corrosion-free and feld-proven solution for operators. TCP Jumpers can be manufactured and shipped in long continuous lengths, stored onsite for long periods of time, cut to length when required, and terminated within hours, with no change to its properties or lifespan. TCP for subsea jumpers as well as fowlines and risers have proven to reduce the CO2 footprint of pipeline infrastructures by more than 50%.

i. strohm.eu

From 20-22 March, WindEurope’s annual onshore and ofshore wind energy event will be heading to Bilbao for a three-day conference and exhibition.

2024 promises to be a defning year for European politics. The EU elections are coming up in June, and a new Commission takes ofce in November. Wind energy will come under huge scrutiny as governments weigh up the costs of energy transition.

It’s time to prove our worth. Wind isn’t just about fghting climate change. It’s about jobs, innovation, sovereignty, and much more. Wind equals 350,000 jobs in Europe. And with 250GW installed across the continent, it powers our factories, heats our homes, and sustains the livelihoods of millions of Europeans – with clean and homegrown power solutions.

When it comes to wind, Spain is one of Europe’s leading lights. In onshore wind, they’re one of the most important countries on the continent with 27GW of installed capacity. And their Ofshore Wind Roadmap aims to build up to 3GW of foating wind by 2030. Today the industry employs 28,000 people in Spain and adds USD 3.3 billion to its GDP. But their ambitions for wind continue to grow, and wind is at the heart of their long-term energy strategy. Bilbao is the jewel in Spain’s renewable crown. It’s the headquarters for two of Europe’s renewable energy leaders. Meanwhile the Basque Country aims to become a major ofshore energy hub in the years ahead. When it comes to the energy

transition, Bilbao’s future looks bright indeed. All the more reason why WindEurope is thrilled to be heading back to Bilbao for WindEurope’s Annual Event 2024.

WindEurope’s annual onshore and ofshore wind energy event will take place in Bilbao in March. Over 12,000 attendees are expected to join and look at the shape of European wind energy today. There’ll be dozens of conference sessions and hundreds of speakers. This year, the exhibition space is completely sold out, and more than 500 exhibitors from the whole value will showcase their innovations looking to seal new deals. The event will include social

This year, the exhibition space is completely sold out, and more than 500 exhibitors from the whole value will showcase their innovations looking to seal new deals.

events across the meeting for participants to reach out to new colleagues, and educational sessions showing all the ins and outs of wind energy.

From 18-20 March, alongside the WindEurope Annual Event 2024, Vestas,

PTI transmissions

Carbon shafts Geislinger

Planetary gearboxes O&K Bonfiglioli

in conventional and hybrid solutions

HUB Ocean, and Microsoft will host ‘Hack the Climate 2024’ – an exciting wind energy and climate hackathon. Taking place at the Bilbao Exhibition Centre just ahead of the WindEurope Annual Event, Hack the Climate is dedicated to moving the wind energy industry forward and as such is inviting designers, developers, data scientists, analysts, and wind energy experts to work with some of the biggest names in the industry to create use cases from three huge data sets: Vestas’ Climate Library, HUB Ocean’s Data Platform, and Microsoft’s Planetary Computer.

As part of the exhibition, the Startup Pavilion is a place designed to showcase fresh voices and new ideas. It offers the opportunity for everyone who wants to showcase innovative technology to prospective partners and buyers.

In the words of Ursula von der Leyen, wind energy is one of Europe’s ‘success stories’, and Bilbao is a chance to see this industry at its best. At this year’s conference, the focus lies on driving home the value of wind, and what it represents for Europeans at home and abroad. The conference will look at the net benefits of wind for five focus areas:

• Energy security;

• Jobs;

• Communities;

• Growth and investment;

• Nature.

Conference attendees can look forward to well over 40 sessions across three days. 250 speakers will appear from Europe and beyond, from policy to industry, education to finance, and from local authorities right up to European and international bodies. Every link in the value chain will make themselves heard. On the expo floor you’ll also receive updates on the hottest markets, across Europe and beyond on the Markets Theatre in partnership with SSE, as well as thought-provoking talks and discussions on the Powering the Future Stage with Iberdrola.

i. windeurope.org/annual2024

In the words of Ursula von der Leyen, wind energy is one of Europe’s ‘success stories’, and Bilbao is a chance to see this industry at its best.

Date: 20-22 March 2024

Venue: BEC – Bilbao Exhibition Centre Azkue Kalea, 1 – North Entrance 48902 Barakaldo, Bizkaia, Spain

Opening hours: Wed, 20 March Thu, 21 March Fri, 22 March

Conference 09:00 – 18:00 09:00 – 18:00 09:00 – 16:00

Exhibition 09:00 – 18:00 09:00 – 18:00 09:00 – 16:00

FRS Windcat Ofshore Logistics announces the deployment of the frst hydrogen-powered dual fuel CTV in Germany for 50Hertz. Following the delivery of the vessel in spring 2023, this marks the beginning of a joint operation in various wind farms in the German Baltic Sea.

The Hydrocat 55 is a CTV equipped with the dual fuel hydrogen technology of CMB.TECH, one of the FRS Windcat Ofshore Logistics (FWOL) shareholders. The vessel represents an innovation for the ofshore wind industry and marks a signifcant step in decarbonising operations for the Flensburg-based company FWOL. The vessel is part of a feet of six ships currently operated by FWOL in the German and Danish North and Baltic Sea – all sailing under the German fag.

The dual fuel hydrogen system of the Hydrocat 55 allows a signifcant

reduction in CO2 emissions during operation and a substantial decrease in NOx emissions. At 25m long, the CTV accommodates 24 passengers and two to three crew members. It has a tank capacity of 207kg of hydrogen in 27 cylinders. The engine is manufactured by MAN Engines for dual fuel use and retroftted by CMB.TECH with a hydrogen injection system. By using hydrogen, the Hydrocat 55 can signifcantly reduce diesel consumption and CO2 emissions. At the same time maximum fexibility and safety are ensured. The Hydrocat 55 is built the same way as the Hydrocat 48, which was launched as the frst hydrogen powered CTV in 2022 for operations in Belgium.

In collaboration with the Dutch joint venture partner Windcat, fve more CTVs of this type are under construction. Work is ongoing to further optimise the ship’s technology and reduce CO2 emission even more in future. A trial period is set to start in January 2024 and will run for a year with regular use of green hydrogen. As Tim Kunstmann of FWOL states, “Looking to the future, FWOL is committed making a signifcant contribution to the decarbonisation of ofshore logistics and supporting a green production of renewable energy with the Hydrocat 55 and the further vessels of this type.” FWOL and 50Hertz have

been working together for over ten years and the deployment of this innovative CTV can only strengthen their partnership. 50Hertz is the transmission system operator (TSO) responsible for connecting the grid to wind farms in the German Baltic Sea. Two other vessels from the feet are currently operating for the Berlin-based company. The Hydrocat 55 represents another step towards a more sustainable future in the ofshore wind energy sector for both companies.

No fundamental changes to the vessel’s main engine are required, which not only means that maintenance and repair remain simple, but also that the engine can easily be switched back to diesel fuel without any modifcations. Even if hydrogen is not available, the vessel can continue to run on traditional fuel, making it a very robust and reliable solution for the ofshore wind industry. Willem van der Wel of Windcat adds, “With this announcement, we are showing that our group strategy is becoming a reality with the focus on decarbonisation and optimisation. We are reducing the carbon emissions of our customers in the ofshore wind industry today. We’re grateful to have such great customers and local partners who help drive this strategy. ”

i. fwol.de

L10CCS, one of the large stores to be connected to the Aramis CO2 transport and storage initiative in the Dutch part of the North Sea, has entered the next phase in the project, Front End Engineering Design (FEED).

Neptune Energy and its partners EBN, Tenaz Energy, and ExxonMobil Netherlands CCS have successfully progressed the L10CCS project from the Concept Select phase, which includes various technical and economic assessments, into this next Defne/FEED phase.

L10CCS seeks to store 5Mt CO2 annually, equivalent to a third of the total CO2 emissions from Dutch domestic vehicles in one year1. All partners have signed up

1 www.cbs.nl

to a FEED Cooperation Agreement and Neptune has awarded the Facilities FEED contract to Petrofac, with the contract having kicked of last month.

The storage licence application for L10CCS was submitted in the second quarter of 2023. The project is awaiting award of the licence by the Dutch Ministry of Economic Afairs & Climate Policy. Talks with emitters, looking for a safe place to store their carbon in depleted gas felds under the North Sea,

are ongoing and necessary contractual arrangements will be progressed during this project phase. Completion of the technical FEED scopes is anticipated during the second half of 2024, with a view to progressing towards a project Final Investment Decision (FID) shortly thereafter in 2025. The timeline of L10CCS is fully aligned with the Aramis project timeline and is planned to be connected and operational as of day 1 of the opening of this CO2 transport system, now planned in 2028.

CCS is expected to account for nearly 15% of the cumulative reduction in CO2 emissions in the EU, according to the IEA Sustainable Development Scenario. Without CO2 storage, it would not be possible to meet the climate goals.

Lex de Groot, managing director of Neptune Energy in the Netherlands, the operator of L10CCS, says: “CCS is expected to account for nearly 15% of the cumulative reduction in CO2 emissions in the EU, according to the IEA Sustainable Development Scenario. Without CO2 storage, it would not be possible to meet the climate goals. To create a well-functioning CCS market, both emitters and storage providers need CO2 transport. The region around L10 has a potential storage capacity up to 120-150 MT, so it will play a crucial role in helping achieve climate goals and open up possibilities for many emitters that need safe CO2 storage in the North Sea at low costs.”

EBN’s business unit director CO2 transport and storage systems, Berte

Simons, adds: “We’re pleased to cooperate with our L10CCS joint venture partners in this carbon storage project where we can re-use existing infrastructure and that is linked to the Aramis project. With our subsurface knowledge and experience on storage, we’ll be able to contribute extensively to the development of this project. The ofshore storage of CO2 is pivotal in meeting climate goals and EBN is determined to contribute to a carbonneutral energy system.”

ExxonMobil’s Low Carbon Solutions EU business development executive, MarieLaure Halleman states: “ExxonMobil welcomes the opportunity to collaborate with industry and the government in support of the L10 carbon transportation and storage project. Carbon capture and storage is a proven, ready-to-deploy

technology that can help reduce emissions in some of the highestemitting sectors and advance society’s net-zero goals.” Anthony Marino, president and CEO of Tenaz Energy, concludes: “We’re proud to be part of this consortium with our industry partners as L10CCS progresses into FEED stage. The L10CCS project, with its application of promising CCS technology has the potential to help achieve climate goals for both the Netherlands and for other countries in northwest Europe.”

i. neptuneenergy.com

DNV has published a substantial revision to the ‘go-to standard’, DNV-ST-N001, for the design and planning of marine operations for the transport, installation, and removal of ofshore wind farms, subsea cables, and oil and gas assets.

The new major changes refect the changing nature of the ofshore industry in line with its support of the energy transition, ensuring that the standard remains relevant and supports the development of cost-efective marine operations during a fast-evolving energy transition. DNV estimates that ofshore wind will rise globally from 8% of total wind production in 2020 to 34% in 2050, totalling almost 2,000GW.

Through continuous engagement with industry, DNV-ST-N001 has been regularly updated and enhanced since it was initially created in 2016. This latest revision – the frst in fve years – follows an external hearing exercise, during which over 400 comments from the industry were received, of which over 350 were technical in nature. The

standard frst came about after DNV and Noble Denton legacy standards from the Seventies and Eighties were combined into one substantial and comprehensive document.

The standard can be applied to all marine operations and all key engineering requirements relevant to load-out, construction afoat, voyages, and installation, as well as the loads that should be addressed in the design of these marine operations. It also lays out the requirements from the perspective of the Marine Warranty Surveyor, who reviews the marine operations. Lucy Craig, director growth, innovation & digitalisation, and energy systems at DNV, states, “Following a high level of engagement from the industry, the latest revision of DNV-ST-N001 further

By using DNV-ST-N001, organisations are using a widely accepted standard for the planning and execution of their marine operations at all stages of project development.

reinforces its position as the de-facto standard used to safely undertake marine operations all over the world providing the needed assurance in the implementation of the energy transition.” She continues, “Since the standard was frst established, it has been vital that it has remained at the forefront of changes to the industry and these updates will ensure that our customers continue to receive the highest possible standard of assurance.”

Industry engagement drove DNV to update a body of work that spans almost 800 pages, with collaboration spanning across the organisation’s global network of marine operations and marine warranty survey experts, working in DNV’s Noble Denton marine services area. Ankor Raithatha, global service area leader for Noble Denton marine services at DNV, says, “It was particularly encouraging to note the number of industry comments stemming from developers and contractors engaged in ofshore wind farm construction activities, which demonstrates the importance of the standard to the industry and also infuenced updates to numerous areas of the standard.” By using DNV-ST-N001, organisations are using a widely accepted standard for the planning and execution of their marine operations at all stages of project development. This allows for a consistency in approach regardless of the parties involved.

i. dnv.com

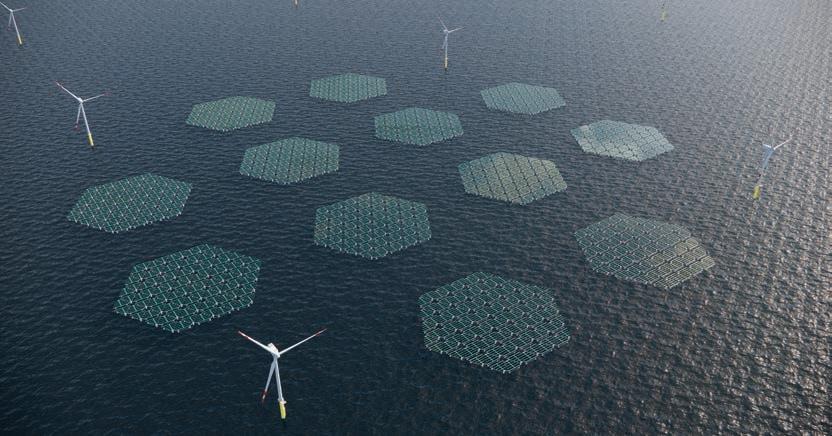

SolarDuck has secured additional funding for the development and deployment of ofshore foating solar power technology. This funding sets the company on a path of continued growth, able to further build on its leading position in the ofshore foating solar energy industry, deliver its frst commercial projects, and increase its impact as the company works towards its goal of deploying over 1 GW of ofshore generated solar electricity by 2030.

The funding has been provided by both existing and new investors. An international consortium of Katapult Ocean, Green Tower, Energy Transition Fund Rotterdam, and Invest-NL all share SolarDuck’s commitment to accelerate a sustainable supply of ofshore energy with ofshore foating solar power. With the new funding, SolarDuck can extend its leading position by deploying its frst commercial projects. In addition, its experienced and dedicated team can further optimise the technology to build markets around the world and accelerate further roll-out.

As the world is electrifying and a rising world population and urbanisation are resulting in land scarcity, the market for ofshore energy generation is increasing. SolarDuck’s technology can be deployed in wind-scarce, but sun-rich regions as ‘stand-alone’ ofshore foating solar farms. Co-locating SolarDuck technology with ofshore wind is also possible, as will be happening in the Dutch North Sea. SolarDuck is aiming to generate a sizeable impact by replacing fossil powered energy sources like coalfred powerplants and diesel generators.

This technology also enables island and ofshore installations – and even countries – to set up an independent supply of renewable energy.

SolarDuck has a pipeline of over 3.5GWp and has already secured projects around the world. Amongst other projects, work is being done on a 5MW demonstrator project to be installed at the Hollandse Kust West VII ofshore wind park in the Netherlands (North Sea) in collaboration with RWE. When completed, it will be the largest hybrid foating solar plant in existence. In addition, SolarDuck is providing Japan’s frst ever ofshore foating solar plant, to be installed in Tokyo Bay with local partners. A third project is underway with TNB Renewables in Malaysia. Ahead of these projects, SolarDuck will launch its ofshore demonstrator project named Merganser early next year. It will be installed and tested in the Dutch North Sea.

Koen Burgers, CEO and co-founder of SolarDuck, says, “We are delighted to have secured this latest round of funding. SolarDuck is introducing a new

SolarDuck ofers a unique addition to the existing energy mix, which will open a huge potential for further growth of renewable energy, both via standalone projects and in co-development with ofshore wind.

asset class of energy generation. With demand increasing, ofshore foating solar ofers real promise for the decarbonisation of our energy supply. This successful funding round provides us with the means to continue the development and deployment of both our team and technology.”

This view is shared by the existing investors. Katapult Ocean has been on board since the very beginning of SolarDuck. Jonas Svegaarden, CEO of Katapult Ocean, states, “We are very excited to announce our increased investment in SolarDuck and to support their next phase of growth. To harness the blue growth opportunity, we must also endeavour to build ofshore. SolarDuck represents a new category of ocean infrastructure, which has the potential to unlock signifcant resources towards the global renewable energy mix and to enable enhanced economics to existing ofshore renewable assets.” Rik Aalders, managing director of Green

Tower shares this view stating, “We strongly believe that to accelerate the energy transition, a mix of diferent technologies should be developed to cater for the needs of diferent geographical regions, all with their own characteristics. SolarDuck ofers a unique addition to the existing energy mix, which will open a huge potential for further growth of renewable energy, both via standalone projects and in codevelopment with ofshore wind. Green Tower is pleased to continue to be part of that journey together with the team of SolarDuck.”

Energy Transition Fund Rotterdam and Invest-NL are new investors. Ralph van Drooge, senior investment manager at Energy Transition Fund Rotterdam, voices, “We are pleased and proud to support SolarDuck in their promising journey in further developing and deploying ofshore foating solar around the world. This is a great addition to

accelerate the energy transition and very important for the Rotterdam region because of their positive social and environmental impact.” Invest-NL, the Dutch state-backed fund, believes that ofshore foating solar is a valuable ingredient in the Dutch energy mix. Corine Franken, senior investment manager at Invest-NL, adds, “SolarDuck is a front-runner in the ofshore foating solar sector. This innovative, scalable solution addresses the growing demand for renewable energy and the scarcity of land use. Invest-NL is excited to support their strong, professional management team, which has deep knowledge of the ofshore and energy industries.” Impulse has been supporting SolarDuck as its corporate fnance advisor during this project. According to Feddo Tamminga, managing partner of Impulse, current market conditions regarding funding are quite challenging, but due to SolarDuck’s easy-to-use and promising technology, their experienced team, and their strong traction in the market, it has been relatively easy to fund their next phase of growth and expansion. “Working together with the team has been an absolute pleasure and assured the success of this campaign,” he states.

i. solarduck.tech

Aquaterra Energy has secured a three-year contract with a leading UK independent exploration and production company to provide analysis services across the company’s global ofshore operations –delivering vital insights to optimise their operational performance.

The contract will see Aquaterra Energy deliver a comprehensive range of ofshore analysis services, including riser and conductor analysis for jack-ups and semi-submersibles, plus integrity management, decommissioning, and late life analysis. Aquaterra Energy will support the operator with insights and recommendations to manage risks and optimise ofshore designs for its full operational portfolio, ofering performance improvements, lower costs and supporting a reduction in operating carbon emissions. The contract covers work across the full ofshore project lifecycle, from extending or decommissioning late-life wells, to early-stage planning. Commenting on the contract win, James Larnder, managing director of Aquaterra Energy, states, “We’re delighted to strengthen

our partnership with this customer by signing this contract. We have dedicated signifcant time and resources to winning these long-term analysis contracts, and the success we’ve seen in this area is testament to the frst-class service delivered by our expert in-house team. To support this growth, we have doubled our analysis team over the last few years, with a focus on recruiting graduates through our award-winning graduate programme.”

“Providing an extensive range of ofshore analysis services, supporting oil & gas operators as well as ofshore wind, CCS, and hydrogen has been a pivotal aspect of Aquaterra Energy’s growth strategy. This contract represents the latest in a series of long-term ofshore analysis agreements secured by the business

with the company expanding its portfolio from one to four major contracts with operators in locations across Europe and the Middle East.” Martin Harrop, analysis manager at Aquaterra Energy, adds, “We’re an agile, solution-driven partner, and through these long-term agreements we can provide customers with assurances and recommendations from the earliest stages of their projects, where we can provide the most value to project delivery and identifying efciency gains. We work closely with our in-house project engineers to ensure the solutions we suggest to clients are not just what’s best from an analytical perspective but also an engineering one, and the growth we’ve seen in this area speaks to the quality of our service.”

i. aquaterraenergy.com

Van Oord’s heavy-lift installation vessel Svanen will receive a major upgrade. Among other improvements, the gantry crane will be extended by 25m, making the vessel ready to handle the next generation of monopile foundations for ofshore wind projects.

The extension of the gantry crane, the most eye-catching upgrade, makes the Svanen one of the largest heavy-lift installation vessels worldwide. The extension, weighing 1,200t, will be constructed by Holland Shipyards and installed using a 200m high Mammoet crane. Besides the

gantry extension, the upgrade programme includes an upgrade of the lifting hooks, which will increase the lifting capacity of the vessel from 3,000t to 4,500t, an upgrade of the gripper to handle increased loads, and an upgrade of the structure of the vessel to accommodate the latest hammer size.

The modifcations will take place at several locations in the Netherlands, mainly in the Rotterdam area. The upgraded Svanen will be operational in the third quarter of 2024. Arnoud Kuis, managing director ofshore wind, says, “Because of the global need for renewable

energy, wind farm technology is rapidly advancing, and turbines are becoming larger. The upgrade of the Svanen is preparing us for this increase in scale and allowing us to maintain our leadership position in the ofshore wind industry.”

The frst project the upgraded Svanen will be deployed on is the Baltic Power ofshore wind farm in the Baltic Sea. This wind farm will feature the new generation of wind turbines, with a generating capacity of 15MW. Due to the upgrade, the Svanen will be able to install the foundations of these new generation wind turbines. Besides the high lifting height and the signifcant lifting capacity, the low draught makes the Svanen well suited to operations in the Baltic Sea. It

Although the vessel has an extensive track record within the ofshore wind industry, it was originally designed for the construction of bridges.

has already played a leading role in several Baltic projects, such as Kriegers Flak, Baltic 2, Arkona, and Baltic Eagle.

The Svanen has an illustrious history. Although the vessel has an extensive track record within the ofshore wind industry, it was originally designed for the construction of bridges. In 2005, the energy transition kicked of the Dutch ofshore wind market and the Svanen was modifed for the installation of monopiles and transition pieces. Since then, the

vessel has installed approximately 700 monopiles and 223 transition pieces with yearly increasing dimensions and weight. To prepare Van Oord for this increase in scale, the Svanen already received a major upgrade in 2017 and it will now be upgraded again. By upgrading an existing vessel like the Svanen and by re-using much of its original construction and machinery, Van Oord is reducing waste and emissions, in line with its sustainability programme.

i. vanoord.com

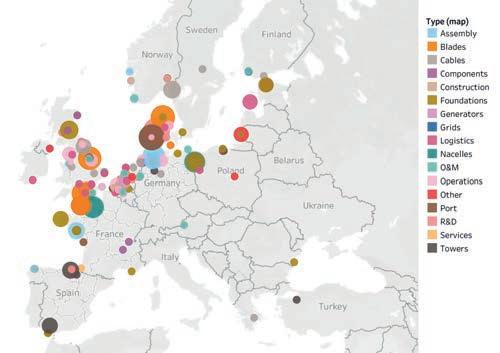

Things are looking up again for ofshore wind in Europe. 2023 saw a record 4.2GW of new ofshore wind farms come online, up 40% on 2022. And USD 32bn of new investments were confrmed – covering 9GW that’ll be built over the coming years. The supply chain is also seeing a turnaround, with new factories announced in Poland, Denmark, Germany, the Netherlands, and Spain.

2023 was the best year on record for new ofshore wind installations in both the EU and across Europe as a whole. Europe built 4.2GW of ofshore wind in 2023. That’s 1.7GW more than in 2022. 3GW of that was in the EU, an increase of 2.1GW year on year. The Netherlands, France, and the UK installed the most new capacity. This includes the 1.5GW Hollandse Kust Zuid project in the Netherlands – now the world’s largest operational wind farm.

Record investments in new ofshore wind

Ofshore wind investments in Europe also reached a new record. A total of USD 32bn was raised across eight wind farms. This will fnance 9GW of new ofshore capacity. This record comes

2023 saw several positive developments, leading to new confdence and optimism among Europe’s ofshore wind players.

after legal uncertainty and unhelpful market intervention had led to a drop in ofshore wind investments, falling to an all-time low of USD 0.4bn in 2022. It also means that projects which had to postpone their fnal investment decision in 2022 are now moving ahead –excellent news for Europe’s energy security and competitiveness. 2023 saw several positive developments, leading to new confdence and optimism among Europe’s ofshore wind players. The European Union published

its EU Wind Power Package with ffteen immediate actions to support the European wind sector. 26 European Governments signed the European Wind Charter, committing to swiftly implement the actions ascribed to them in the Wind Power Package.

Ceiling price raised

Over in the UK the Government raised the ceiling price by 66% for the upcoming ofshore auction round (AR6). Not a single ofshore wind developer

had bid in the 2023 CfD auction round (AR5) after the UK Government failed to adjust the maximum ceiling price to the market reality of infation and higher input prices. The new AR6 ceiling price could help the UK attract record investment in ofshore wind in 2024. That’s not the only good news from the UK: Ørsted reached fnal investment decision on Europe’s biggest project, the 2.9GW Hornsea 3 ofshore wind farm in the UK. RWE acquired the 4.2GW Norfolk Ofshore Wind Zone portfolio and underlined its determination to resume the 1.4GW Norfolk Boreas project, which had previously been halted.

If all countries run their 2024 auctions as planned, at least 40GW will be auctioned this year. Germany, Denmark, the UK, France, and Netherlands are the top fve countries auctioning capacity over the next two years. France will announce the results of Europe’s frst commercial-scale foating ofshore wind tender. Germany will auction almost 9GW in 2024 alone. As a comparison: Europe auctioned 13.5GW of new ofshore wind capacity in 2023. But 70% of all auctions in 2023 used uncapped negative bidding, asking wind energy developers to pay for the right to build an ofshore wind farm. This needs to change!

Uncapped negative bidding poses several big risks. Developers have to cover the additional costs of negative bids. They can either pass them on to the electricity consumers, who are already sufering from high prices, or on to the wind energy supply chain, which is already struggling with infation and cost increases. Negative bidding also adds to the overall project risk, which in turn drives up capital costs. This is particularly challenging with higher interest rates now. As a result uncapped negative bidding puts the realisation of projects at risk. Take Germany: none of the large projects awarded under their uncapped negative bidding auctions in 2023 has reached fnal investment decision so far.

Poland’s frst commercial ofshore wind farm, the 1.2GW Baltic Power project, reached fnal investment decision in 2023, >>

Offshore Industry will bring readers an indepth event preview and will have an extra distribution of the issue at the trade fair. This is a unique opportunity to put your brand in the right place at the right time. You can target your advertising to make the most of the show, before you even get there. Contact our sales team to make this happen.

In addition, if you have news related to SMM, or any other information you’d like to share, please send it to our editorial team.

Ambitious expansion targets, legal certainty, and clear visibility on future projects are key to attracting supply chain investments.

marking the start of Poland’s ofshore wind development plans. Poland wants to have 18GW by 2040. Today Poland does not have any ofshore wind. Ambitious expansion targets, legal certainty, and clear visibility on future projects are key to attracting supply chain investments. And Poland’s ambition is paying of. Vestas announced plans to build a new blade factory in Szczecin, Poland for its fagship V23615.0MW ofshore wind turbine. The factory is expected to start operations in 2026. Together with Vestas’ previously announced plans to establish an assembly factory for ofshore nacelles, Vestas could provide 1,700 direct jobs in Szczecin by 2026. Windar Renovables has signed a concession agreement with the Port Authority of Szczecin for a planned ofshore tower factory in

Poland, creating an additional 450 direct jobs. Baltic Towers are building another new tower factory in Gdańsk.

In addition to the investments in Poland, three new foundation manufacturing facilities for ofshore turbines are being built by Sif in Rotterdam, Baltic Structures in Esbjerg, and by SEaH in the UK. Europe needs more of these investments to avoid bottlenecks in the ofshore wind supply chain. Europe is set to build around 5GW of ofshore wind annually over the next three years. This is not enough to reach Europe’s climate and energy security targets. It adds to the need to install more ofshore wind towards the end of the decade. European countries will need to build 24GW a year in the period

2027-2030 to reach the 2030 targets. But today’s ofshore wind supply chain can only produce around 7GW each year.

Investments in expanded and new factories, like the one now announced by Vestas, are indispensable. In parallel, Europe needs to ensure the supporting infrastructure for ofshore wind is in place. This means investing in grids, ports, and vessels. Here we’ve seen the frst signs of progress. Europe’s leading manufacturers of ofshore power cables are all expanding their factories which should ensure they can meet the growing demand for cable to connect ofshore wind farms in Europe. Bladt Industries are building a new factory in Denmark for ofshore substations.

Smulders and Neptun Werft are building a new facility in Rostock (Germany) to make converter platforms. And Dragados are expanding their ofshore substation platform manufacturing operations in Cadiz (Spain).

i. windeurope.org

The power of wind brings new vessels and large revenue for geodata specialist, Fugro.

The ofshore wind market continues to grow rapidly. It’s supported by the UN Climate Summit COP28’s recent decision to triple the world’s renewable energy capacity by 2030, a large portion of which is expected to come from ofshore wind. For leading geodata specialist Fugro, its strategy to capture this market growth opportunity is exemplifed by the Dutch company’s recent addition of two geotechnical vessels to its feet.

The acquisition of two platform supply vessels, Sea Goldcrest and Sea Gull (built in 2019 and 2020 respectively), will, according to Fugro, be used as key geotechnical strategic assets to strengthen its position as a market leader, as well as its ability to address the market demands and shortage in geotechnical capable vessels. Fugro now operates a balanced feet of owned and chartered vessels, maintaining fexibility towards the future. It also continues to invest in remote and digital solutions for its feet of uncrewed surface vessels.

As communicated during the Capital Markets Day in November last year, part

of Fugro’s strategy for the coming four years is to secure long-term vessel capacity, especially for the global ofshore wind market, which has a particularly large need for mapping of soil composition and its associated properties via the extraction and testing of soil samples. For the foreseeable future, these activities cannot be executed with smaller platforms, either crewed or uncrewed.

Upon delivery of Sea Goldcrest in the course of 2024, Fugro will begin converting the ship to a geotechnical vessel, which is expected to be operational early 2025. Sea Gull, which is already under charter with Fugro and fully operational, will be delivered in late 2024 or early 2025. Furthermore, the purchase of these vessels supports Fugro’s net zero 2035 roadmap as both vessels are fuel efcient and suitable for the conversion to low-carbon fuels.

In 2023, Fugro published a 24.1% revenue growth for Q2 due to continued high client demand in energy markets, particularly for ofshore wind site characterisation solutions and related nearshore activities. Employing around

10,000 people in 57 countries, it serves clients around the globe, predominantly in the energy and infrastructure industries, both ofshore and onshore. In 2022, revenue amounted to EUR 1.8 billion.

“I am very pleased to report a strong set of results [for 2023 Q2],” says CEO, Mark Heine. “All regions contributed to signifcant higher margins and cash generation, in particular the Americas and Europe-Africa. Overall, better contracting conditions, increasing asset utilisation and better operational performance led to a signifcant improvement, particularly in the marine site characterisation business.”

“Across the globe,” he adds “we are beneftting from high client demand for climate change adaptation and energy transition solutions, in particular for ofshore wind developments, and we are continuing on our trajectory of further diversifcation into future proof markets. To remain successful in capturing the market opportunities and secure controlled growth, we continue to invest in our people and asset base.”

i. fugro.com

ENTSO-E has released the frst Ofshore Network Development Plans (ONDPs), as part of its Ten-Year Network Development Plan (TYNDP) for 2024, delivering on the important deployment of the ofshore infrastructure throughout all the European sea basins ensuring seamless integration of ofshore wind farms.

The European Union has set ambitious goals for the development of a decarbonised energy system and ofshore renewable energy sources are a key element on the path to carbon neutrality. The increasing importance of ofshore renewable energy in Europe’s electricity generation mix has underscored the essential role of grids to achieve the decarbonisation of the European energy system. The energy

potential of the European waters needs indeed a robust transmission system for consumers to harness this potential. ENTSO-E, the European Network of Transmission System Operators for Electricity, is the association for the cooperation of the European transmission system operators (TSOs). The 40 member TSOs, representing 36 countries, are responsible for the secure and coordinated operation of Europe’s

electricity system, the largest interconnected electrical grid in the world. In addition to its core, historical role in technical cooperation, ENTSO-E is also the common voice of TSOs. ENTSOE’s frst Ofshore Network Development Plans highlight the fnancial and technical needs for grids to be developed and upgraded to accommodate additional new generation capacity from European ofshore territories.

Ofshore wind has the potential to become one of the most important energy resources in the European Energy System, provided that the speed of installation of generation and transmission capacities is signifcantly increased. Importantly, the ENTSO-E report highlights that the development of the ofshore network infrastructure should take place in synergy with the protection of the marine environment to achieve a sustainable energy system coexisting with biodiversity. The ENTSO-E ONDP ensures that ofshore systems are at the centre of energy planning, and future editions will further integrate the ONDPs into the TYNDP process. Synchronised planning of onshore and ofshore development is essential to complete the holistic approach needed to maximise the benefts of a decarbonised power system.

Commenting on the release of the ONDPs, Zbyněk Boldiš, president of ENTSO-E, says, “Connecting ofshore wind generation to the grid is a challenge for all TSOs in Europe, as well

Ofshore wind has the potential to become one of the most important energy resources in the European Energy System, provided that the speed of installation of generation and transmission capacities is signifcantly increased.

as for generators, manufacturers, national governments, and all other interested parties. The ONDPs presented emphasise the need for close coordination and involvement of all European stakeholders. Only by acting together will we be able to successfully meet this tremendous challenge.”

Damian Cortinas, chair of the board of ENTSO-E, adds, “We are proud to present the frst European Ofshore Network Development Plan, as the development of ofshore wind generation and strong interconnections across all European sea basins are essential to create a carbon-neutral, resilient, and cost-efective European energy system. The deployment of the ft for purpose ofshore grids is a necessary condition to achieving the European energy transition to carbon neutrality.”

Kadri Simson, European Commissioner for Energy, comments upon the publication of the ONDPs, “The launch of the Ofshore Network Development Plans is an important delivery. Ofshore wind is set to become a crucial energy source in the European power system, which mirrors the direction set by the EU – and made even more ambitious by the Member States. I would like to congratulate ENTSO-E for delivering these important Plans, which will help us draft strategies for our ofshore grids needs, provide a wealth of information and data, and show the true potential and benefts of coordination and crossborder projects. This launch takes us a step closer to realising our ofshore ambitions.”

i. entso.eu

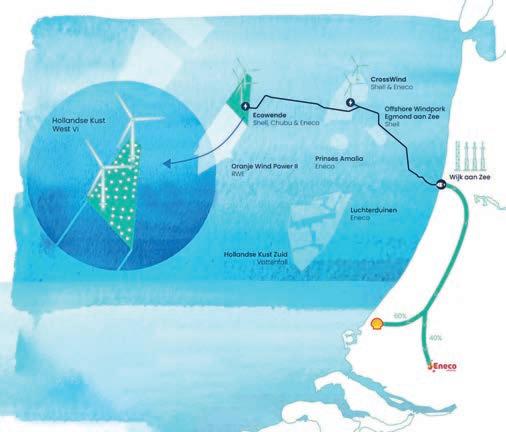

Following the announcement about their collaboration, Ecowende is pleased to confrm that Van Oord has been contracted for the construction of the ofshore wind farm Hollandse Kust West lot VI.

Ecowende, a joint venture of Shell and Eneco, is determined to contribute to a sustainable future for ofshore wind that positively contributes to the North Sea’s ecology. As Ecowende’s contractor, Van Oord will be responsible for transporting and installing the foundations. Van Oord will also lay, connect, and bury the cables between the wind turbines. Finally, Van Oord will be handling the transportation and installation of the wind turbines at sea. The Ecowende wind farm (Hollandse Kust West lot VI) will be located about 53km of the Dutch coast, near IJmuiden. The wind farm will have an operational capacity of approximately 760MW, making 3% of the current Dutch electricity demand greener. Ecowende plans to have the wind farm fully operational and commissioned in 2026.

Building wind farms in harmony with nature is an important condition for eventually achieving these targets. Besides reducing the negative impact of an ofshore wind farm, it is also necessary to implement ecological measures that can contribute to the development of wind farms with a netpositive impact. Ecowende and Van Oord will collaborate on implementing various innovations, large-scale mitigations, and stimulating ecological measures. In addition, the parties will join forces in various feasibility studies, and solution developments.

Van Oord will deploy its brand-new ofshore installation vessel Boreas, >>

Ecowende, a joint venture of Shell and Eneco, is determined to contribute to a sustainable future for ofshore wind that positively contributes to the North Sea’s ecology.

currently being built, for the transport and installation of the foundations and turbines. To minimise the noise of the construction of the wind farm, Van Oord will deploy an alternative installation method for the foundations. A vibro hammer will drive the monopiles to their required depths by means of vibrations. This will be the frst large scale implementation of this innovative technique at a Dutch ofshore wind farm. Van Oord’s cable laying vessel Nexus will be deployed for the installation of the connecting inter-array cables between the wind turbines.

The installation of scour protection is required to avoid the efects of erosion. This is achieved by high precision rock installation around the foundations. Van Oord has advised Ecowende on nature enhancing components in the design of the scour protection to help stimulate a diverse habitat for marine life. One of Van Oord’s fexible fallpipe vessels will be deployed to accurately and efciently install the eco-friendly scour protection.

Ecowende has chosen Vestas as the supplier of the wind turbines. The Danish wind turbine manufacturer will supply 52 wind turbines of type V23615.0 MW for this purpose. Vestas will also maintain the wind turbines for ffteen years. Sif will be responsible for the manufacturing of the 52 extended monopile foundations that will have no transition pieces, but secondary steel components, and that will have a total weight of approximately 70 kilotonnes. Transition pieceless monopiles were successfully applied by Sif in earlier projects ofshore the Netherlands, also in the Hollandse Kust Noord project for Crosswind, another joint venture of Shell and Eneco. In this transition pieceless design, the secondary steel components like boat-landings, ladders, main access platforms, and internal platforms will be connected to the monopile foundations once these are installed at sea. The secondary steel components will also be delivered by Sif in the same contract.

i. ecowende.nl

Jumbo Ofshore has been awarded a contract by MODEC for the pre-installation of the mooring spread of the FPSO Errea Wittu, which will be located ofshore Guyana.

The FPSO Errea Wittu, the name of which means ‘abundance’, will have the capacity to store two million barrels of oil. It will produce approximately 250,000 barrels of oil per day and will have gas treatment capacity of 165m3 million per day, and water injection capacity of 350,000 barrels per day. MODEC Group was authorised to proceed with the engineering, procurement, construction, and installation (EPCI) scope for the FPSO in May 2023, following a fnal investment decision on the Uaru project by ExxonMobil Guyana and its co-venturers. The FPSO mooring system will be supplied by SOFEC, a MODEC Group company, and consists of a total of nineteen mooring legs.

Jumbo Ofshore will be using its unique heavy lift construction vessel Fairplayer, which allows the transport and installation of the nineteen suction anchors, 8,800m of chain sections, and 43,168m of polyester rope in the minimal amount of installation voyages, simplifying the logistics involved. Igor Rijnberg, head of sales and business development subsea at Jumbo Ofshore, says, “The Jumbo Ofshore team is very grateful to MODEC for this opportunity. We will use the extensive deep-water mooring installation experience gained over the last years to deliver a reliable, smart and efcient project execution.”

Brian Boutkan, manager of commerce at Jumbo Ofshore, adds, “On behalf of the

entire team, we are very much looking forward to undertaking this project. MODEC can count on Jumbo Ofshore’s total commitment to providing a safe and reliable execution. As always, we will be approaching this project as a partner to our client, working in close collaboration with MODEC to ensure the outcome entirely meets their expectations.”

i. jumbomaritime.nl

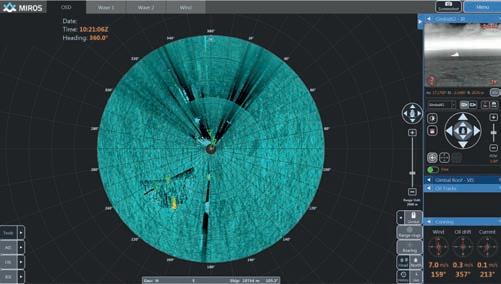

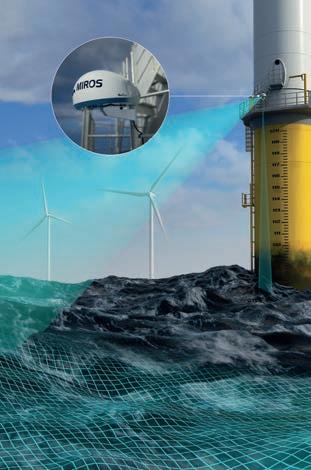

When Marius Five Aarset became Miros’ chief executive at the start of 2023, he set out three key aims for the year for the global oceans insights experts to work towards. To develop the company into renewables and support the acceleration towards net zero goals; to further boost Miros’ cloud technology and modern as-a-service business model; and to translate accurate measurements of the ocean surface into actionable information.

For the last twelve months, we have been laser-focused on developing our product suite and business models so that they can better help to drive enhancements in the marine and energy sectors, particularly in ofshore vessels and ofshore wind. We have had great success in this endeavour, and it will continue to be an essential priority for Miros as we move into 2024,” Mr Aarset explains. He continues, “Ofshore wind was in the media a great deal in 2023 – some of the coverage positive and some negative – but from our observation there is one point that is clear: the industry is moving. More than

ever before developers are more eager to adopt solutions and services for optimising operations and maintenance. Beyond that, digital business models are now being embraced and appreciated for the value they add across a wide range of industries and regions.”

From vessels and ofshore wind projects in Europe to oil and gas operations in Brazil, Miros’ wave and current measurement technology is continuing to inform operations across the world. In 2023 the company experienced solid growth in contracts, going beyond its

For the last twelve months, we have been laser-focused on developing our product suite and business models.

expectations and across various geographies and markets, as the industry becomes more aware of the value of real-time measurements over forecasts and the benefts of digital business models. Mr Aarset explains, “As an industry we are now at a point where there is established trust in cloud-based technologies, something that is encouraging collaboration between partners. Take our oil spill detection contract with Petrobras in Brazil, which allows ofshore data to be securely shared with multiple stakeholders in real-time. Environmental protection is now a major focus for companies, and we have seen demand for Miros’ market leading solutions globally. Partners and partnerships are core to Miros’ strategy, right across our value chain from innovation to development to sales, delivery, and customer service. We see customers as our afliates and this modern, transparent way of working translates into business-led innovation that shapes and drives our technology forward.”

As part of its drive to stay ahead of the curve, or wave, Miros is bringing nextgeneration wave and vessel motion prediction to market, with key ofshore customers being early adopters of the technology. It is a technology development that will take shape further in 2024 and in tandem with this, work is also ongoing to assess vessel behaviours and performance in transit to produce greater real-time insight for safety, efciency, and a more rounded service ofering in cooperation with the joint venture Miros Mocean.

Jonas Røstad, Miros’ chief commercial ofcer, states, “Unquestionably, 2023 has been a real breakthrough year for the adoption of digitalisation in the ofshore space, with a real uptake for our as-aservice solution. It is a model that we have been ofering and continuously improving since 2018 and companies, especially those that are futureorientated, are recognising and appreciating the value this brings to their businesses’ bottom line. As part of

this, we are closely cooperating with selected customers to help elevate the safety, sustainability, and performance of their maritime operations. We look forward to making an announcement to the maritime industry about this next year.”

On a personal level, the end of last year also ofered some time for Mr Aarset to refect on his journey to date with Miros. He elaborates, “Miros has a long and proud history, something that is encapsulated by the team’s unique and cooperative way of working. We span a wide range of industries, using Norwegian expertise to service a global market, and that is something I am immensely humbled to be a part of. I am confdent that our successes will continue into 2024 when we will also reach a major landmark in the ongoing history of our great company – Miros’ 40th anniversary.”

i. miros-group.com

Remote, lean crewed, and autonomous ship operations are playing a more extensive role than ever before in the maritime industry. This paradigm shift is not only revolutionising the way ships are operated, but also driving and being driven by signifcant advancements in data management and data handling.

WORDS BY SARAH BATE, BRAND AND COMMUNICATIONS MANAGER AT OCEAN INFINITY. ALL IMAGES COURTESY OF OCEAN INFINITY.

We sat down with a group of industry professionals from Ocean Infnity, a leading maritime technology company, to explore the pivotal role of data in this transformation. From the challenges of

data collection and bottlenecks to the power of picking the right data to process at the right time, our conversation provides a snapshot of the driving forces behind the maritime data revolution.

A sea of data

Ocean Infnity’s data experts play a crucial role in gathering and processing valuable subsea data. The types of data collected vary depending on the specifc client and industry needs, but can

include geophysical data, geotechnical data, bathymetric data, acoustic data, subsea imagery, and environmental data. The company envisages a time, in the not too distant future, where remote and lean-crewed operations at sea will overtake conventional crewed operations, but the magnitude of data generated in such operations is staggering. The data journey for conventional operations already involved extensive onboard data processing and quality control (QC) procedures. However, with the advent of remote operations, Ocean Infnity’s data

experts can now perform data QC and processing from onshore locations. This novel approach signifcantly alters the data journey, while still allowing for realtime analysis.

As André Reinlert, data innovation manager at Ocean Infnity explains, it extends beyond the data output to the client, such as hydrographic survey data, to encompass information generated by the vessels themselves. “This includes vessel telemetry data and prognostic health management data, providing the

valuable insights into vessel behaviour, weather conditions, and more that we need when operating remotely. The integration of these diverse data sources is crucial for improving operational efciencies, enhancing data quality, and planning future endeavours,” Mr Reinlert elaborates.

Darren Smith, data service designer at Ocean Infnity, highlights that the volume of data collected in the maritime industry is following the general trend of exponential growth observed across various sectors. He states: “One great example of this is that the frst ofshore

wind farm was established with just 30MB of subsea data, where modern projects deal with over 30TB.”

While the increasing volume of data presents opportunities, it also introduces bottlenecks along the data journey. One signifcant bottleneck lies in the transmission of data from the vessel to the shore station. Limited bandwidth and the need to prioritise critical data make this stage a challenge. Tom Bowden, a data analyst at Ocean Infnity, emphasises the importance of distinguishing between valuable insights and raw data. “It is essential to identify the data segments that hold the most value and optimise their transmission while fltering out lower priority data. This process ensures efcient utilisation of limited bandwidth and minimises the time spent sifting through less pertinent information”, he says.

All are agreed that any data management systems and protocols that enhance or enable lean crewed or uncrewed vessel operations have an immediate and valuable cross-over into all marine operations involving the handling of large quantities of data, and that includes current, fully crewed operations. To address these bottlenecks, Ocean Infnity is driving a movement of the data processing load from shore to the vessels themselves, and ultimately leveraging processing on the AUV/ ROV, ultimately even a sensor within the vehicle. Mr Bowden explains: “As machine learning and Artifcial Intelligence technologies are accelerated through our lean-crewed vessel operations, we begin to enter the realm of edge processing, a technique that involves distilling acquired data on the vessel itself. As these technologies develop, our data processing is fltering ever further down the journey towards the source of the data.”

During an Ocean Infnity ofshore operation, the company uses a suite of systems to optimise data fow, storage, and analysis. The process involves the continuous cleaning and fltering of incoming data, applying protocols to compensate for noise, and producing

During an Ocean Infnity ofshore operation, the company uses a suite of systems to optimise data fow, storage, and analysis.

QRPs (quality reference products), usually every 20 minutes during a data gathering operation. These reference products provide insights into data quality, enabling prompt adjustments to acquisition parameters and prevent the continued accumulation of out-of-spec data.

“The ability to generate and analyse these products at regular intervals has been a critical advancement in data management for lean crewed operations,” adds Mr Smith, “although we are working within a constantly moving arena. Our protocols are under constant review as new techniques, technologies and systems of working could provide a step up from our current ones and be worth adopting at short notice.”

The resource Ocean Infnity has put into data quality control has been something of a priority because with traditional crewed vessels, there is direct human interaction with the data collection and

processing – obviously erroneous data are usually spotted and fagged up quite quickly. However, in the case of remote and autonomous ships, there is a greater need for automated, efcient, robust, and scalable data quality control. A requirement for seamless data transfer has led to the development of advanced communication systems and protocols in all felds of life, not just ofshore. Highbandwidth connections and secure networks are essential to ensure the timely and accurate delivery of data. Additionally, data compression and optimisation techniques are employed to reduce the size of the transmitted data, optimising bandwidth utilisation. Ocean Infnity uses a combination of its own in-house developed systems for packaging and compression, along with a range of third party, industry state-ofthe-art products.

Remote operations enable the company to gather comprehensive subsea data for various industries, including ofshore wind, search and salvage, defence, and environmental sectors. This rich dataset provides valuable insights, supports decision-making processes, and helps clients optimise their operations. However, due to the unshiftable constraints of operating subsea and ofshore, the available bandwidth will never be enough, so the focus is not solely on collecting vast amounts of data but rather on extracting meaningful insights efciently. Filtering out less pertinent data and focusing on the valuable information streamlines the process and maximises the use of available resources. Moreover, the remote data collection process allows for increased data visibility and transparency. By standardising the data acquisition, fltering, compiling, and reporting procedures, Ocean Infnity ensures that clients have access to a robust lineage of information. This provenance of data instils confdence and empowers clients to trace and validate the decisions made based on the collected data.

Ocean Infnity envisions the integration of innovative technologies that will further propel remote maritime data collection. One such technology is the

deeper orchestration of automated systems, ofering centralised control and real-time monitoring of diverse operations. This highly advanced management system can seamlessly deploy and track the progress of tasks across multiple platforms, ensuring efciency and adaptability. Mr Smith paints a picture of the company’s near future capabilities. “Our data gathering platforms will operate with a vastly increased level of autonomy and collaboration,” he says. “For example, we are planning for our AUVs to be collaborating in position correction, so position drift noted by one will be corrected by all. This way we won’t need a Mission#2 to fll in the data gaps created by some position drift in Mission#1.”

He continues, “We are also working on dynamic re-tasking. This would mean an AUV that fnds a potential UXO (unexploded ordnance), for example, could re-task itself to gather a body of the highest possible resolution data in that area, then terminate its current assignment and return to the mothership to report. This level of collaboration could then mean that the remaining AUVs would ‘know’ to adjust their survey grids to pick up the potential gaps left by the frst.” The overarching mission is not solely focused on remote operations but revolves around the broader goal of transforming the maritime industry. With a commitment to sustainability, safety, and operational excellence, Ocean Infnity is paving the way for a future where remote, lean crewed, and autonomous ship operations are the norm, powered by advanced data management and handling practices.

i. oceaninfnity.com

Glamox has won a contract from Dutch engineering company Bakker Sliedrecht to provide specialist marine LED lighting for the foundation platforms for 100 14MW ofshore wind turbines for the Sofa Ofshore Wind Farm in Dogger Bank.

For the Sofa Ofshore Wind Farm, Glamox will provide 800 marinecertifed LED luminaires, which will illuminate the platforms upon which the giant turbine towers will be installed.

The platforms, pre-ftted with the marine-certifed luminaires, will be installed from 2024 at the RWE-owned wind farm which is expected to be completed and generating power in 2026. “We have undertaken many demanding power and automation projects and know very well how challenging the North Sea environment can be. Good lighting conditions are a cornerstone for safe operations and that’s why we chose a

partner with a proven record in lighting ofshore structures since the 1970s,” says Thijs van Hal, head of main contracting at Bakker Sliedrecht.

“The ofshore wind industry has ESG considerations top of mind for every facet of its operations. We are wellplaced to help it ‘walk the talk’ with our energy-efcient LED luminaires that are specially built for ofshore environments,” explains Tommy Stranden, chief commercial & sales ofcer for Glamox’s Marine, Ofshore & Wind division. “This latest win follows lighting projects from other companies to light substations and construction and support vessels for wind farms in the Dogger Bank area of the North Sea.”

For the Sofa Ofshore Wind Farm, Glamox will provide 800 marinecertifed LED luminaires, which will illuminate the platforms upon which the giant turbine towers will be installed. The luminaires include indoor and seawater-resistant outdoor linear LED luminaires and foodlights. These luminaires, which have a long life of 100,000 hours, are made with quality materials, are highly energy efcient, and designed to cope with harsh weather conditions.

The wind turbine platforms will be located 195km of the NorthEast Coast

of England in a 593km2 area of water which is roughly the size of the Isle of Man. They will be located in water ranging from 20m-35m in depth and are 80m and 90m in length and weigh between 1,200 to 1,400t each. The turbines will be ftted without a transition piece and have a height of 252m to the tip of the rotor blade – that is approximately 60m less than the height of The Shard which is the UK’s tallest building. The Siemens Gamesa SG14-222DD turbines will generate 1.4GW of power which is enough to power nearly 1.2 million UK homes.

Glamox is a leading lighting company that provides quality energy-efcient lighting for professional buildings in Europe and for the world’s marine, ofshore, and wind markets. Its mission is to provide sustainable lighting solutions that improve the performance and well-being of people. The company is committed to achieving Net Zero operations by 2030. Headquartered in Oslo, Norway, Glamox is privately owned by Triton and Fondsavanse and is a subsidiary of GLX Holding. Glamox AS employs around 2,000 professionals with sales and production in Europe, Asia, and North America.

i. glamox.com

Jan De Nul Group and ABC Engines are pleased to announce their partnership for hybrid marine engines. Both companies signed the order for four 7,200kW engines and one 1,800kW engine.

These innovative engines will ensure propulsion of the newest Jan De Nul Group’s cable-laying vessel, Fleeming Jenkin. Using green methanol, the engines are also climate neutral and due to the combination with the ULEv technology, they also meet the strict Stage V standard for particulate matter and Euro 6 standard for nitrogen.

Jan De Nul Group and ABC Engines are accelerating towards a more sustainable shipping industry with the development of these engines. Both companies take on a pioneering role to signifcantly reduce harmful emissions in the shipping industry and to contribute to a substantial positive impact on the climate and the health of man, fauna, and fora. An important step Jan De Nul Group is taking in making its feet more sustainable is switching to renewable fuels, such as methanol.

Notwithstanding signifcantly reduced emissions of harmful greenhouse

gasses, methanol also ofers the advantage of being already available in more than one hundred ports around the world. To further shape the internal sustainability strategy and to fully align with the renewable world economy, Jan De Nul Group enters this partnership with ABC Engines, which leads the way in the feld of marine engines running on alternative fuels, such as the promising methanol.

Jan Van de Velde, director newbuilding at Jan De Nul Group, explains, “The choice for ABC is based on a positive collaboration and shared vision of a sustainable future. Our cooperation results in high-quality engines that run on renewable fuel and are adapted to our vessels and needs of our customers. We prepare our feet for the future, achieve a milestone within our sustainability goals and above all ofer a positive contribution to the climate and health of man and animal.” Tim Berckmoes, CEO at ABC Engines, says,

“Jan De Nul and ABC are two familyowned companies that always focus on the long term and use innovative technologies to realise the energy transition both locally and internationally. Thanks to the longstanding trust of our customers, we can continue to innovate, produce, and invest in Flanders. This enables us to expand our export activities and further develop our manufacturing industry.”