The year progresses steadily, and once again we are gradually approaching one of the most important fairs in our industry. The 26th edition of OTC Houston will soon take place. Visitors will discover that this fair keeps up with the times. Originally starting as a platform for the oil & gas industry, visitors can now also familiarise themselves with all developments in sustainable offshore energy during this four-day event. Further information about this fair can be found in this magazine.

While reviewing the various articles in this issue, I noticed there is currently considerable investment in sustainable propulsion systems in offshore shipbuilding, including new builds as well as refits and conversions. These ships also contribute to a smaller ecological footprint of the offshore supply chain.

This magazine again demonstrates that the industry continues to develop on many fronts. Although still in its infancy, and with quite a few question marks, Norway has taken a next step in ocean mining. If applied correctly, this new industry can play an important role in providing important and valuable raw materials for, among other things, the batteries for electric cars. In this issue, you can also read about how data collection on the seabed plays a crucial role in maintaining biodiversity in the construction and operation of offshore wind turbines.

All in all, this edition has become yet another varied issue demonstrating the diversity of our industry.

Happy reading!

industry

With kind regards,

Arno Dirkzwager Editor ARNO@YNFPUBLISHERS.COM

Hydraulic

Railway technology

Offshore technology

Machine construction

AUTOMATION, CONTROL & MEASUREMENT

TECHNOLOGIES

32 From decline to restoration: navigating the offshore wind biodiversity opportunity

EPCI

16 From the bottom of the sea to outer space

36 Three years of independency in retrospect

HEAVY LIFTING & TRANSPORT

10 A reassuring thought

31 A large order

40 Peters & May Commercial’s vital role in supporting offshore projects

GREEN PROPULSION

27 A hybrid power system for new cable-laying vessels

OCEAN MINING

20 Seabed minerals on the map

OFFSHORE CREW TRANSFER

14 Equinor secures new helicopter capacity

28 Three new SWATH CTVs

OFFSHORE WIND

13 A joint collaboration agreement

24 Uptake in permitting and investments brings 2030 wind target within reach

OTC HOUSTON 2024

07 Meet the future of energy

REFIT & CONVERSION

39 Advanced vessel upgrades for Harvey Gulf

TRAINING & EDUCATION

43 The Lankhorst Academy

REGULARS

01 Editor’s note

04 News in brief

45 People

46 Yellow & Finch pages

48 Next issues & Colophon

On the cover

Since September 2021, Liftal has a presence in the Rotterdam port area through the acquisition of Damen Hoisting. Following the successful integration of this company, the acquisition is now bearing fruit.

Read more on page 10. Photo courtesy of Liftal.

In the largest tender round for offshore wind energy in the Netherlands to date several applications were admitted. The Netherlands Enterprise Agency (RVO) has received several applications for both permits for the IJmuiden Ver Wind Farm Zone Sites Alpha and Beta (IJVWFZ Alpha and Beta). The IJVWFZ is located more than 60km off the west coast of the Netherlands. The two wind farms will produce renewable electricity and each have a capacity of at least 2GW. A total of 4GW will be licensed in one round, equal to 14% of the total current electricity needs in the Netherlands. The wind farms are being built without subsidies. The tenders consist of a comparative test with a financial offer. The Dutch government hereby wants to stimulate wind farms to contribute to nature of the North Sea and to the integration of electricity generated into the Dutch energy system onshore. For both sites additional criteria considering International Responsible Business Conduct (IRBC) and circularity also apply. The winners of the IJVWFS Alpha and Beta tender round are expected to be announced in June 2024. It is planned that both wind farms will produce electricity by the end of 2029/beginning of 2030.

i. rvo.nl

Hughes Subsea, an OEG Renewables business, has been awarded the contract to undertake the unexploded ordnance (UXO) identification and clearance campaign on the East Anglia 3 wind farm being developed by Scottish Power Renewables in the Southern North Sea. This is expected to be a six-month project, commencing in mid-March, and continuing until early October 2024 utilising the Glomar Wave, a DP2 66.4m long vessel. The offshore operations will involve the identification, investigation, and disposal of confirmed UXO (cUXO) targets across an area of approximately 305km2. Hughes Subsea will deploy its work class remotely operated vehicle (WROV) and specialist divers, and be supported by another OEGR business, Geosight, who will be providing surveying and calibration services. In addition, maritime archaeologists will be enlisted to handle historic findings, and marine mammal observers (MMOs) will support the monitoring of local wildlife, underlining the company’s commitment to environmental stewardship.

i. oeg.group

Spirit Energy has reached a major milestone for its Morecambe Net Zero (MNZ) project with the successful securing of a seismic survey vessel to undertake a scope of work in the East Irish Sea as the company continues its journey to net zero. The survey will acquire and process around 500km2 of highresolution 3D seismic data over the Morecambe Bay gas fields to provide the detailed definition of the potential carbon storage sites. The survey fulfils a requirement on the recently awarded carbon storage licence, and the data acquired will support all subsequent models and mapping for Carbon Capture and Storage (CCS) initiatives. Spirit Energy has contracted Shearwater GeoServices Holding to enable the progress of the MNZ project. The survey will acquire a much higher resolution dataset than previously seen to enable detailed characterisation of the subsurface and, in conjunction with other existing data, provide confirmation of the significant potential for CO2 storage identified in the Morecambe Bay gas fields. MNZ has the potential to be one of the largest carbon stores in the UK and Europe, offering industrial emitters a world-leading decarbonisation solution.

i. spirit-energy.com

KENC Engineering has secured multiple contracts with offshore energy contractor DEME. For KENC, the contracts involve a broad scope of work that will encompass engineering and fabrication of seafastening and auxiliary structures that DEME requires for its work on several international offshore wind farms. KENC will be carrying out the concept, basic and detailed designs on all projects. “We are pleased to be working with DEME on these projects,” KENC’s lead engineer Cor Hilbrink says. “I am confident that our team’s dedication and expertise will meet all expectations, delivering our solutions on time and helping to shape the future of sustainable offshore energy.”

i. kenc.nl

On Tuesday, 5 March, Danos Group Holdings finalised the acquisition of Performance Energy Services (PES), a 24-year-old Houma, LA-based company. The acquisition includes all PES business units, the Houma administrative office, and waterfront operations facility. PES will remain a separate entity and join Danos LLC as part of the Danos family of companies. Danos Ventures facilitated the transaction on behalf of Danos Group Holdings.

i. danos.com

Massterly, the world’s first autonomous vessel operations company, announces the opening of its Remote Operation Centre (ROC) in Horten in Norway. Massterly, a jointly owned venture between Kongsberg Maritime and the Wilhelmsen Group, has rapidly evolved over the past six years to become a trailblazer in autonomous maritime solutions. The new ROC in Horten represents a convergence of advanced technology and unparalleled experience in ship operations. The ROC serves as the control centre where Massterly’s portfolio of autonomous ships are monitored. It encompasses a wide spectrum of operations, from navigation and maintenance management to safety control, ensuring the seamless functioning of the fleet. The collaboration between Kongsberg Maritime and the Wilhelmsen group has been instrumental in bringing this project to fruition. By har nessing cutting-edge technology and fostering a culture of innovation, Massterly is redefining standards of safety, efficiency, and intelligent solutions in the maritime industry.

i.kongsberg.com

Liftal Vlissingen Groenlandweg 4 Havennummer 4056 4455 SN Nieuwdorp (Vlissingen-Oost)

Tel: +31 (0) 118 - 488 450 Email: vlissingen@liftal.com

Liftal Rilland De Poort 15 4411 PB Rilland

Tel: +31 (0) 113 - 571 523

Email: rilland@liftal.com

Liftal Rotterdam p/a Admiraal de Ruyterstraat 24 3115 HB Schiedam

Tel: +31 (0)10 - 60 036 60

Email: rotterdam@liftal.com

Liftal Belgium Duitslandstraat 4 9140 Temse

Tel: +32 (0)3 710 11 82

Email: temse@liftal.com

The conversation about the world’s energy needs and demands has never been more dynamic than it is today. Therefore, OTC is excited to welcome attendees, speakers, and exhibitors from countries around the globe from 6-9 May for their annual event in Houston.

Since 1969, the Offshore Technology Conference (OTC) has served as a central hub convening energy professionals from around the world to share ideas and innovations, discuss, debate, and build consensus around the most pressing topics facing the offshore energy sector. OTC connects over 31,000 offshore energy professionals from more than 100 countries to collaborate and discuss the challenges, solutions, and changing energy landscape of the offshore energy sector. Across four days, industry thought leaders, investors, buyers, and entrepreneurs will meet in Houston, the energy capital of the world,

to develop business partnerships and learn about the latest advances, challenges, and opportunities.

OTC Houston’s large international participation provides excellent opportunities for global sharing of technology, expertise, products, and best practices. As the world transitions to a more sustainable and low-carbon future, no other event provides attendees with more diverse conversations focused on the latest developments needed to accelerate the global energy mix. Whether it’s oil & gas, solar, wind,

hydrogen, and other marine resources, these conversations will be centred around the innovations that could help shift and drive the world’s energy mix. More than 1,300 exhibiting companies from over 100 countries will showcase their products and services, and thirteen international pavilions convene the strength and innovation of international businesses with decision-makers from around the world.

Parallel to the exhibition, the fully-packed conference programme has a strong

• Quality: 450+ peer-selected technical presentations, leveraging thirteen societies’ collective knowledge and covering topics from the wellbore to topsides and everything in between.

• Value: over 81,000m2 of exhibit space with ground-breaking innovations and 1,300+ leading providers of products and services in one place, at one time.

• Networking: 31,000+ energy professionals from 100+ countries are there.

• Always something new: connect with 100+ speakers to discover what innovations we can expect over the next 50 years.

• Investing back in the Industry: OTC’s sponsoring organisations use the revenue to provide many other important programmes for its members such as training and technical journals.

• In the world’s energy capital: combine OTC with client meetings, business proposals, and company training.

reputation for bringing together some of the highest calibre professionals from around the world to discuss the future of offshore energy. Attendees will be able to engage and explore a wide variety of topics such as:

• Carbon capture utilisation and storage.

• Decommissioning & abandonment.

• Digital transformation, digital technologies & data management.

• Drilling technology.

Advancements in offshore wind energy have expanded the offshore sector on a global scale. In support, OTC 2024 will present a three-day dedicated wind energy thread to discuss the technological advances that play a vital role in offshore wind farms. During this dedicated thread, visitors will hear from energy professionals from organisations such as Ørsted , Atlantic Shores Offshore Wind, TotalEnergies, SBM Offshore, Technip Energies, and the

With more than 30 hours of technical, panel, keynotes, and networking sessions, there are many opportunities to exchange ideas and opinions, collaborate, and develop business partnerships.

US Department of Energy as they discuss cutting-edge technologies on topics like site characterisation, AI applications, and project design challenges and advancements.

With Houston as one of the world’s most significant energy hubs, OTC is the perfect meeting place to unite energy professionals to convene and discuss successes, current activities, and how to be successful in the future. With more than 30 hours of technical, panel, keynotes, and networking sessions, there are many opportunities to exchange ideas and opinions, collaborate, and develop business partnerships.

Featured offshore wind sessions

• Site characterisation: geophysical and environmental aspects for offshore wind

An overview of environmental, geophysical, and geotechnical aspects of site investigation will be explored in this technical session.

• The future of offshore wind: opportunities and challenges

Keynote speaker Troy Patton will review the current status of the offshore wind market in the North East US, as well as compare how it sets itself up with the more mature market in Europe and offshore UK.

• Offshore wind design challenges

This technical session encompasses recent breakthroughs in the detailed design and analysis of fixed and floating wind turbine support structures, mooring system development, and permitting processes.

• The four winds of connection: offshore wind networking social End day two of the offshore wind thread with a networking event. Hear from four industry experts on their latest innovations and collaborations.

i. 2024.otcnet.org

OTC Houston 2024 details

Venue: NRG Park, Houston, Texas

Date: 6 - 9 May 2024

Opening hours: all days from 08.00h – 18.00h.

Since September 2021, Liftal has a presence in the Rotterdam port area through the acquisition of Damen Hoisting. Following the successful integration of this company, the acquisition is now bearing fruit.

It’s nice to see that our Rotterdam branch is now contributing to the success of our company,” says Hans Hirdes, business manager of Liftal. “First, we made the necessary adjustments to various facilities, reorganising things logically. We also adapted various operational processes to our methods and underwent an internal reorganisation. For example, the supply sales operation is now consolidated at the Vlissingen location.”

Mr Hirdes continues, “We now see that our various test benches, combined with other test methods, result in a high degree of synergy between our various activities. What’s great is that we’re not the only ones noticing this. Our customers see it too, which helps them find us more easily. Both locations complement each other in the services we can now offer. Companies that used the test benches in Rotterdam can now turn to Vlissingen for smaller-scale tests, and vice versa we can also serve our original customers with the testing capacity in Rotterdam. Altogether, with our test benches, we can handle loads ranging from almost zero to as much as 2,000t. This is separate from the tests we can perform on-site using methods like water bags and other mobile testing

equipment. It’s no wonder that even our colleagues-in-business come to us with testing work.”

According to Mr Hirdes, the acquisition has led to new orders from existing clients and also attracted work from new clients. Recently, a two-month project was completed for Heerema Marine Contractors (HMC). “For HMC,” he explains, “we recently tested and recertified the towing and mooring equipment of their pontoons. This involved the equipment of five pontoons in total. Four sets with a diameter of 76mm and one with a diameter of 86mm.

This may not sound very spectacular, but it’s important to realise that each tested set has a tare weight of over 25t each, and we tested them at a maximum load of 300t. The pontoons were located at the Damen shipyard, where they were cleaned, disassembled, and transported to our on-site workshop. The sets were then transported to our workshop by truck. There, inspection took place, first visually for damage and subsequently by measuring lengths to check for any elongation. Finally, the chains were tested on the test bench. So all chains, cables, and fittings were individually tested and Lloyd’s certified. This project

Various businesses have found their way to Liftal to have their equipment assembled, welded, upgraded, anode-protected, painted, tested under Class supervision, reported, certified, and packed/palletized, ready to go.

New Lloyds certification for

Liftal recently achieved the Lloyd’s Register certificate for “Recognised proving establishment for anchoring and mooring equipment”.

This approval is subject to compliance with the Lloyd’s Register Rules for the Manufacture, Testing and Certification of Materials.

With this approval Liftal may execute load tests of described equipment, which is prohibited to a few test facilities in the region.

“We are currently undergoing a digitalisation process in which all equipment is being fitted with digital displays.”

was completed to HMC’s full satisfaction. It’s clear that despite our experience and knowledge, we wouldn’t have been able to execute this project relying solely on our facilities in Vlissingen. We are therefore pleased with the new location and proud of the people there who executed the project so well.”

Mr Hirdes mentions that Liftal not only tests existing equipment, but also new products and performs related tasks. Various businesses have found their way to Liftal to have their equipment assembled, welded, upgraded, anodeprotected, painted, tested under Class supervision, reported, certified, and packed/palletized, ready to go.

This varies from complex offshoredamping systems to laminated foundry hooks.

After the complete assembly process, we offer the possibility to have the final product temporarily stored in our warehouse.

This service is provided for smaller and larger series of equipment.

Meanwhile, the company continues to improve its various testing facilities. “We are currently undergoing a digitalisation process in which all equipment is being fitted with digital displays,” Mr Hirdes explains. “This makes our work even more efficient and precise as the measurement data is directly stored in our database. It also makes it much easier to access and compare the history of previous tests.”

Mr Hirdes concludes, “The offshore sector is a significant market for us, especially with the scaling up and growth in offshore wind. Additionally, we are active in other industries within the energy sector. We have a fine reputation in the nuclear sector for testing activities in nuclear power plants and the supply of custom-made test equipment, and we expect significant growth in this sector in the coming years.” So, there’s still plenty of work ahead for Liftal. On one hand, to further optimise testing processes, and on the other to assist clients in various sectors in keeping their heavy-lifting and hoisting equipment safe. However, given the track record of satisfied customers, Liftal can confidently face these challenges.

i. liftal.com

James Fisher and Tokyo Gas Engineering Solutions have signed a Joint Collaboration Agreement (JCA) to provide construction and operations and maintenance (O&M) services.

The partnership will focus on Japan’s offshore wind market, aligned to the region’s target of delivering 10GW of offshore wind by 2030. Together, James Fisher and Tokyo Gas (TGES) will play a pivotal role in supporting customers to deliver efficient and effective operations at a crucial point in time for the industry, with a significant number of projects due to be under construction or operational by the end of 2030.

The James Fisher Renewables team has already delivered 29 offshore wind projects in Asia Pacific through its local Taiwanese office, with a global portfolio of 6.1GW. James Fisher’s Balance of Plant (BoP) O&M capability will also play a pivotal role in supporting customers to deliver efficient and effective operations. The company’s knowledge of the offshore wind sector will complement TGES’ experience in Liquified Natural Gas (LNG) and gas fired power plants, alongside established local infrastructure and deep set understanding of the Japanese market, particularly in engineering and O&M.

The signing of the agreement took place in Tokyo on 6 February 2024, as both companies began mapping out their ambitions for the year ahead. Jean Vernet, CEO at James Fisher, says, “We are excited to partner with TGES at such a crucial time in the country’s energy transition, recognising that industry collaboration is a critical enabler to delivering 36% to 38%of total energy capacity from renewables, by 2030. James Fisher will provide the guidance, expertise, and exceptional services, alongside TGES’ strong engineering expertise, extensive local knowledge, and established supply chain, providing customers with high-quality, cost-

effective construction support and O&M services. This not only builds on our capability to deliver offshore wind services in Japan; it aligns with our long-term ambitions for the Northeast Asia Pacific region.”

Yasuhiro Konishi, CEO at TGES, adds, “We are delighted to be working with such a great partner in James Fisher. Offshore wind plays a crucial role in the decarbonisation of Japan and its stable operation is critical to supporting energy decarbonisation. TGES’ strength in engineering and O&M know-how in energy infrastructure, combined with James Fisher’s extensive capabilities in offshore operations, will provide significant value in terms of low cost and high reliability for offshore wind projects, an important renewable energy source in Japan. The company is committed to contributing to the reduction of environmental impact, the

promotion of decarbonisation and the development of a sustainable society by providing significant value in the form of low costs and high reliability for Japan’s important renewable energy source, offshore wind power.”

To further support the partnership, and in response to the growing skills gap facing the offshore wind industry, engineers will be given the opportunity to enrol on the James Fisher Academy Senior Authorised Person (SAP) internal pathway. The Academy pathway offers online, classroom, and field-based learning to upskill employees and provide them with the critical skills needed for the offshore wind industry.

i. james-fisher.com i. tokyogas-es.co.jp

After an extensive process, Equinor has qualified new helicopter types for passenger transport on the Norwegian Continental Shelf (NCS). Under these contracts, Equinor will receive ten new Bell 525 helicopters and five AW189 helicopters.

These helicopter types will supplement the current Sikorsky S-92. All three helicopter models meet stringent safety requirements. By increasing from one to three helicopter models on the NCS, we gain more flexibility and regularity,” says Kjetil Hove, executive vice president, exploration & production Norway at Equinor. The first two helicopters will be delivered from Leonardo in the first quarter of 2025. In 2026, Leonardo will deliver three, and Bell four helicopters. The additional six helicopters from Bell will be delivered in line with the agreed production plan for the period 2027-2030.

“All Equinor unions, including the safety delegates, have been thoroughly involved in the process and are positive that the company has taken this initiative. These helicopters have the quality and characteristics that we need offshore,” the unions and safety delegates announce in a joint statement. Ørjan Kvelvane, Equinor’s senior vice president for joint operations support, elaborates, “We depend on safe and efficient logistics operations to maintain a high activity level on the NCS well into the future. The new models feature technological improvements in terms of

pilot support systems, passenger comfort, and noise reduction.”

On the NCS, operators Bristow and CHC currently have 24 Sikorsky S-92 machines under contract with Equinor. The helicopters are mainly used for transport services, but also for search & rescue (SAR). On 25 January 2024, Equinor also signed a contract with Lufttransport RW AS to operate two new search and rescue helicopters for the Troll and Oseberg areas. The helicopters to be used are Leonardo AW 139 machines. They will be ready for

operation in early 2026. “This agreement strengthens our resilience and ensures increased helicopter capacity.

Lufttransport RW AS is a Norwegianowned company based in Tromsø, with extensive experience from operating both search and rescue helicopters and transport helicopters. We look forward to working with them,” Mr Kvelvane says. The two helicopters will be ready for operation from 2026. Taking effect in early 2026, the term of the agreement is five years, with an option for five oneyear extensions.

i. equinor.com

• The Bell 525 is produced by US company Bell. The company produces helicopters globally, including for offshore and defense industries.

• The Leonardo AW189 is manufactured by Italian Leonardo, which also produces the AW139. Since 2016, Equinor has only used Sikorsky S-92 machines (after replacing EC225) for personnel transport and search and rescue services on the NCS.

• Both the Bell 525 and the AW189 feature technological innovations in terms of helicopter safety, reduced CO2 emissions, pilot support systems, passenger comfort, and external noise reduction.

• Equinor has an extensive flight programme and annually transports 160,000 offshore employees to and from the NCS. This amounts to more than 24,000 flight hours annually.

• Annual landings on Equinor-operated installations on the NCS total approximately 16,000.

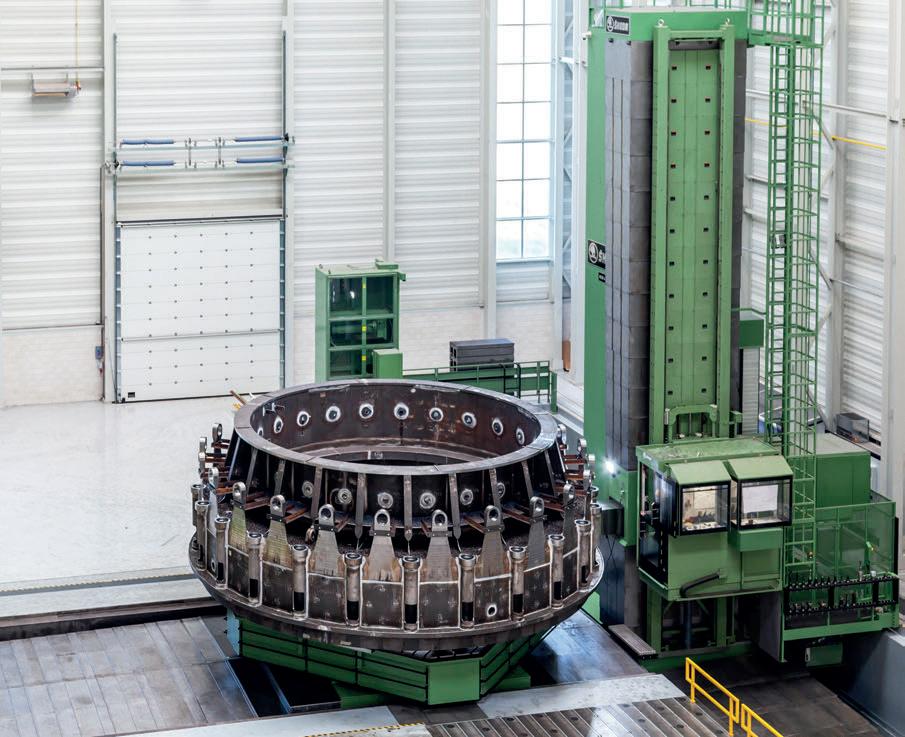

Busy times at Breman Machinery. The company, with a history dating back 160 years, has evolved into a multidisciplinary enterprise.

“

We don’t often think about it, but 160 years ago the foundation of our company was laid,” says Henk Breman, director at Breman Machinery. “Starting out as a traditional blacksmith, we have over time grown into a company proficient in various disciplines of metalworking and construction.” Niek Breman, general manager of Breman Bending, adds, “In doing so, we have amassed a wealth of knowledge and experience across numerous industries. We have built a client portfolio in the offshore industry, defense, aerospace sector, medical industry, and food industry. From the bottom of the sea to outer space, from submarines to Ferris wheels, you’ll find our products everywhere.”

One of the sectors in which Breman has been active for a long time is the offshore industry. “Offshore is truly in our DNA,” explains Henk Breman. “In this sector, we have over the years evolved alongside the shift from oil & gas towards wind energy. The parties we already served in the oil & gas sector appreciated our knowledge and expertise and sought us out when they themselves ventured into offshore wind. And thus, we have also built up a considerable track record here.” “Our work,” Jan Boer, sales engineer at Breman Machinery voices, “is characterised by often involving large workpieces with extremely heavy weights, which require meticulous precision. The offshore industry demands this level of precision because even with large structures, everything must be precise. Mistakes at sea can translate into high costs, not just economically but also ecologically. It’s gratifying to see we have built a substantial portfolio of loyal and satisfied customers here. This has also resulted in a shift in our role from being a

straightforward supplier to being a partner who collaborates with the client from the outset of a project. With many clients, we have transitioned from customer-supplier relationships to genuine partnerships. This early-stage involvement allows us to better address our customers’ needs and provide even better solutions.”

Henk Breman continues, “We don’t like to stand still, which is why we’re always on the move. By keeping abreast of the market, but also by continually investing in our people and resources. For example, we have responded to the scaling up in the offshore wind industry. As turbines grow larger, so do installation vessels and equipment. This is one of the reasons why we have heavily invested in new machinery and in expanding and enlarging our production facilities in recent years.”

“With our skilled workers, we are adept in many areas,” says Niek Breman. “Our clients demand knowledge, capacity, and space, and these are things we offer like no other. We see knowledge disappearing from the market, and we consider ourselves fortunate to still have genuine experts with knowledge and experience. We address this by introducing young people to our company through internships, for example.”

Jan Boer continues, “We provide our clients with challenging complete products or critical steel components. Our strength lies in doing much of the work within each project ourselves, and for what we can’t do we have reliable partners, although we often act as the ultimate responsible main contractor. Machining, welding, bending, preserving, assembling, and conducting load tests, >>

“In everything we do, we act with our hearts, think with our heads, and create with our hands.”

et cetera, are all done in-house. We outsource the engineering, for which our customers provide us with the technical drawings, and integration of software, mechanics, and hydraulics to our partners. The coordination of the project rests entirely with us. This offers the client significant assurance because it allows us to maintain tight control over the schedule. This is invaluable, especially in the offshore industry, where working at sea is costly, and lost time is therefore precious. Our clients know they can in this regard trust us because for us, a promise is a promise.”

“In the offshore industry, projects are still carried out on a project basis, with almost every job requiring new tools. Our strength lies in our ability to respond quickly and flexibly to this. We have the knowledge, space, and machinery to switch gears rapidly,” explains Henk Breman. “While it’s not customary in our work to name names, in recent times we have completed many exciting projects for the offshore

industry. One project that certainly deserves mention is the delivery of four tensioners for the Pioneering Spirit, each with a capacity of 500t. This was truly a game-changing project that showcased our capabilities. Additionally, we have built gripper systems, noise mitigation systems, pin piling templates for installing jackets, motion compensation systems, walk-to-work systems, and components for subsea stations, among others. We’ve also manufactured ample new heavy-lift hooks and refurbished existing ones. In short, we have successfully demonstrated that we can deliver a wide variety of workpieces.”

Reflecting on the past years, one thing stands out for Henk Breman: “It’s gratifying to see that companies like ours, which used to be primarily asked for our hands, have now proven ourselves with our projects, and as a result we are increasingly asked for our minds. I am truly proud of our team because they make it possible. The fact that we are recognised by the market as

a collaborative partner perfectly aligns with our vision: in everything we do, we act with our hearts, think with our heads, and create with our hands. In that sense, not much has changed compared to the blacksmith where it all began.”

i. breman-machinery.nl

The Storting (Norwegian parliament) has given the go-ahead for opening parts of the Norwegian shelf for exploration and possible production of minerals.

ALL IMAGES COURTESY OF THE NORWEGIAN OFFSHORE DIRECTORATE, UNLESS STATED OTHERWISE.

In the years ahead, more knowledge needs to be acquired about these resources, and their surrounding environment. “When the companies gain access, there are plenty of things they’ll have to figure out, but there’s also much that we already know. The Norwegian Offshore Directorate (NOD) has mapped the areas in question, systematically, since 2017,” says Hilde Braut, assistant

director technology, analysis, coexistence at the NOD.

In simple terms, the Norwegian Offshore Directorate is responsible for maintaining an overview of the resources both above and below the seabed. They have made projections regarding oil and gas all the way back to

the early 1970s, and mapping minerals has been included in recent years. So far, the NOD has determined that there may be significant deposits of sulphides and manganese crusts on the Norwegian shelf. These are found in locations such as along older and current spreading ridges, as well as on ridges on abyssal plains several hundred kilometres from shore. Water depths at these sites

generally range from 3,000-4,000m. The reason for the focus on these deposits is because they contain interesting volumes of metallic elements. Demand for these metallic elements is growing, as they are essential to the energy transition.

Mapping minerals in water depths of many thousands of metres is a painstaking endeavour. In recent years, the NOD has conducted a number of expeditions with ships – both under its ‘own flag’ and in cooperation with the academic community, first and foremost the University of Bergen and the University of Tromsø, the Arctic University of Norway. These expeditions can take weeks or even months. “It’s a

good thing to cooperate and share, researchers gain access to data and samples they can examine, while we benefit from their knowledge and expertise,” says geologist Nils Rune Sandstå.

An interesting area is typically surveyed in three rounds – but using different tools and with different purposes. The first step is to gain an overview of the seabed terrain. Using ships, the seabed is first mapped using multibeam echo sounders, which provides a map of these deep-sea landscapes with resolutions down to 20-50m.

The depth data acquired from the ship mapping forms the basis for the next phase of exploration, which is conducted by AUVs (autonomous underwater vehicles). An AUV is released into the depths to conduct detailed mapping of the areas that need to be examined more closely. The AUV moves around 50 to 70m over the seabed, automatically adjusting its path according to the terrain. “We bring it back up after 40-45 hours, download the data, replace the battery, and then release it back down into the sea. The

depth data from the AUV yields a seabed resolution of 1x1m,” says Mr Sandstå. The third step of the mapping is typically done with ROVs (remotely operated vehicles).

Mr Sandstå continues, “The ROV allows us to get even closer to the seabed. It can be used for purposes such as taking physical samples, video, and photos.”

Bathymetry and data collected using AUVs and ROVs provide a good image of the seabed – but the mapping job is not complete. “We know a lot about the areas we’ve mapped but we need more knowledge, including about the environment, before extraction could

possibly become relevant,” says Ms Braut. She knows that the tools used to find out more about the minerals are also well-suited to map the environment. “Using bathymetry, we can collect various types of water column data. We can also observe and take pictures of living organisms and stocks, and obtain environmental data for the seabed itself.”

Whether the seabed terrain is formed by volcanic activity (basalt) or by sediments (soft-bed) tells something about life and organisms. “The Norwegian Offshore Directorate has mapped the relevant deepwater areas using the best-suited methods since 2017. This makes us wellequipped to continue our exploration

and investigation, including with a focus on the environment,” adds Ms Braut.

In January, the Storting endorsed the Government’s proposal to open parts of the Norwegian continental shelf for exploration for and production of minerals. A final resolution will be processed through a Royal Decree. If mineral activity on the seabed is given a green light, areas will be opened for exploration and production. In the initial phase, exploration licences will be awarded before a potential discovery can be developed. If a development plan is submitted, it will have to include a project-specific impact assessment that must be approved by the Storting. Interested companies will apply for licences, and the authorities will require the players who are allowed to explore to implement a specific work programme with milestones. This is based on the practice applied in the petroleum activities. “We know there are a handful of companies that may be interested,” explains Ms Braut. The authorities’ own technical efforts will continue in parallel. The NOD will continue to map the resources, while Mareno will contribute in the work to map environmental data.

i. nod.no

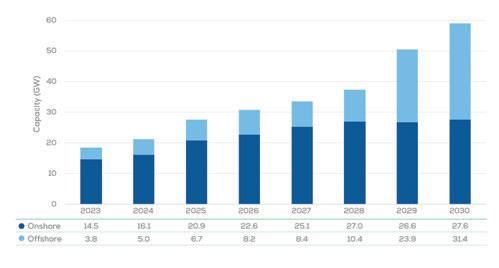

WindEurope’s annual statistics and seven-year outlook show the EU wind energy target for 2030 is within reach. This is mainly thanks to improvements in permitting and a rebound in investments.

2023 also saw a major political turnaround for the EU’s Wind Power Package which 26 governments then endorsed in the European Wind Charter. But obstacles remain. The biggest threat now to the accelerated expansion of wind is the timely expansion of Europe’s onshore and offshore electricity grids.

The European Union installed a record amount of 16.2GW new wind energy capacity in 2023. 79% of that was onshore wind. And more than 1GW came from the repowering of old turbines. Germany installed the most new capacity followed by the Netherlands and Sweden. The share of wind in total EU electricity consumption

in 2023 was 19%. Another 8% came from solar. Renewables in total were 42% of the electricity mix. Denmark had the biggest share of wind in its electricity mix with 56%. Seven other countries got more than a quarter of their electricity from wind, Germany got 31%. Total electricity generation from wind in the EU was 466TWh, up from 412TWh in 2022.

The report includes an outlook for new wind installations over the period 2024-30, based on the project pipeline, announced investments, permitting data, and government auction volumes. WindEurope forecasts that the EU will install 29GW a year on average over 2024-30. This will bring the EU’s installed wind capacity to 393GW in 2030, compared to the 425GW needed to deliver Europe’s climate and energy targets. Over the period from 2024-2030, two-thirds of new installations will continue to be onshore. But offshore wind installations will rapidly pick up towards the end of the decade. In 2030 new offshore installations will be almost the same as new onshore installations.

2023 saw significant improvements in areas critical to the expansion of wind energy. Things are improving on permitting. Europe approved significantly more permits for new onshore wind farms in 2023 than in previous years. This is thanks in large part to the new EU rules on renewables permitting. Germany and Spain permitted 70% more onshore wind than in 2022, with Germany seeing an impressive 7.5GW. France, Greece, Belgium, and the UK also saw higher permitting volumes. Investments in new wind energy capacity were also up on 2022. An easing of inflationary pressures, better tariff indexation by governments, and greater certainty on electricity markets created a more favourable investment climate. New investments in offshore wind alone amounted to EUR 30bn, a stark contrast to the EUR 0.4bn invested in 2022.

Europe’s wind supply chain is returning to profit and building the new factories needed to deliver the EU’s targets.

Crucially, the political outlook on wind energy changed in Europe in 2023. The EU and national governments recognised that Europe’s wind industry was struggling and needed urgent support. The EU Commission’s Wind Power Package in October set out fifteen concrete and immediate actions to strengthen the industry. In December, 26 EU Member States and 300 companies signed the European Wind Charter endorsing the Package and committing to take the actions in it that fall to them. The Package and

Charter commit national governments to support the European wind industry by improving auction design: fully indexing prices so that revenues reflect costs, tightening pre-qualification criteria to raise the bar on what sort of turbines can be built in Europe, and giving clearer visibility on auction schedules to volumes so the industry can plan better. The Package also commits the EU Commission to support the wind industry through the Innovation Fund and the European Investment Bank to offer counterguarantees to support equipment sales.

The recently-agreed EU Net-Zero Industry Act (NZIA) now enshrines in law the need to tighten pre-qualification criteria and sets an ambitious target of 36GW a year for the manufacturing of wind turbines in Europe. “Things are looking up again for wind in Europe,” says WindEurope CEO Giles Dickson. “Permitting has improved thanks to new EU rules. Investments are up. Record volumes are being auctioned and built. And governments have committed with the Wind Power Package and Charter to strengthen Europe’s wind energy industry. The industry in turn is recovering. Europe’s wind supply chain is returning to profit and building the new factories needed to deliver the EU’s targets. We’re now confident that we can get close to the EU goal that wind is 35% of electricity by 2030, up from 19% today, provided Europe accelerates the build-out of grids to connect all the new wind farms.”

Grids are the new main bottleneck

To increase annual wind installations from 16GW in the EU last year to 29GW on average up to 2030, Europe needs to urgently accelerate the build-out of new and optimised electricity grids. Grid connection queues are delaying the timely connection of new wind farms. Hundreds of GWs of new wind farms are currently waiting for their grid connection. Delays in the build-out of onshore and offshore grid connections put the timely commissioning of new wind farms at risk. In Germany authorities recently announced that up to 6GW of offshore wind capacity are affected by grid connection delays. The affected wind farms will now come online with a delay of up to two years. The EU has fully grasped the issue with its Action Plan on Grids. Implementing this Plan must be a top energy priority for the current and incoming EU Commission – and for all national governments.

As well as building out the grid, Europe also needs to invest more in ports and other transport infrastructure.

i. windeurope.org

ABB has secured an order with Norwegian shipyard Ulstein Verft to supply an advanced power and propulsion system for a forthcoming cable-laying vessel (CLV) of Nexans, a global player in energy transition headquartered in Paris, France.

On delivery in 2026, the vessel will join Nexans Skagerrak and sister ship Nexans Aurora, also equipped with ABB technology, as the third and most advanced CLV in the Nexans fleet.

An integrated system comprising main power generation and distribution, energy storage, and electric propulsion will allow the new CLV to execute its cable-laying, recovery, and repair tasks in a safe and efficient manner. With a closed-ring configuration providing high fault tolerance and optimal engine use in dynamic-positioning (DP) operations, the system will minimise the risk of power loss for enhanced safety and reliability while maximising operational flexibility and fuel efficiency. The

onboard energy storage system (ESS) will also reduce engine running hours to keep engine wear and tear to a minimum. In addition, the ESS will provide spinning reserve and peakshaving capabilities, acting as a back-up power source in case of engine failure and supporting the vessel’s more energy-intensive operations.

“Following the success of Nexans Aurora, ABB is proud to be involved in this project to deliver the new sister ship,” says Rune Braastad, global business line manager of marine systems at ABB Marine & Ports. “Nexans appreciates the benefits that our closed-ring system, ESS, and RDS provide to support safe, efficient, and reliable cable-laying operations. We look forward to

strengthening our relationship with both Nexans and Ulstein Verft.”

Alongside main system components, generator, switchboards, transformers, frequency converters, motors, DC switchboard for batteries, and ESS, ABB’s scope of supply includes the remote diagnostic system (RDS) for propulsion, thruster inverters, and rectifiers as well as cyber security configuration for the RDS. By providing precise and timely fault detection and continuously monitoring equipment health status, the RDS improves system performance and minimises the need for onsite service. This results in significant savings in downtime and maintenance costs.

i. abb.com

Ad Hoc Marine Designs (AHMD) has announced a new design of small waterplane area twin hull (SWATH) crew transfer vessels (CTVs) for Maritime Craft Services. Initially, three vessels to the new design will be built at the Työvene yard in Finland.

ASWATH ship is a twin hulled vessel which concentrates a large proportion of its floatation volume into bulb-like hull sections deep beneath the waterline. These torpedo, or submarine shaped flotation bulbs support the weight of the vessel through narrow, hydrodynamically efficient hull struts, and in the case of the AHMD design have additional motion stabilisation with zero speed heave mode controllable fins. The vessel’s engines, fuel, and other heavy equipment are contained within the upper haunch region for easy access and maintenance from the main deck, allowing the struts to only require minimal wiring and plumbing to pass through them, thus enabling them to be made very narrow and hydrodynamically efficient.

The main advantages of a SWATH hull form over a more traditional monohull or catamaran are twofold: the efficiencies derived from a low waterplane area and decreased vertical accelerations in rough sea conditions which allow a wider window of operation with more comfort for passengers and crew. The waterplane area is the part of a vessel’s hull that would be seen if it was sliced horizontally along the waterline. It is a major contributor to wave making drag and hence a vessel’s overall drag, as well as the vessel’s natural period of motion. A SWATH vessel design reduces the waterplane area to a great extent by having only the two foil-shaped, knifelike support struts intersecting the

waterline. Particularly at slow speeds, a correctly designed SWATH hull offers significant CO2 reductions over a comparable catamaran or monohull. At much higher speeds monohulls and catamarans are able to utilise their hull shape to minimise resistance, whereas the efficiency advantages of the SWATH hull form begin to reduce with increasing speed. It is also the reduced waterplane area that brings the improved seakeeping of a SWATH hull. A vessel’s volume distribution and waterplane area are what causes it to heave and pitch as it passes through waves. Reduce the waterplane area and the designer reduces the heaving and pitching forces that waves can exert on the vessel. Adding motion control fins to the SWATH hulls as in this design

“The major advantage of the SWATH design is its superior response to high seas, allowing operation up to an extra 100 days a year over a conventional catamaran.”

reduces these vertical accelerations even further, making for a supremely seakindly ride, at any speed and seastate.

While SWATH designs have been around for many decades, and even more on paper alone, the number of naval architects and shipyards worldwide that can routinely produce SWATHs delivering all the promised advantages can be counted on the fingers of one hand. As John Kecsmar, naval architect at AHMD says, “For more niche designs such as SWATH hulls, there is nowhere near as much prior art as there is for more conventional hull forms. Ad Hoc Marine Designs has been involved in highly successful and proven SWATH designs for more than 30 years, and

these range from 13m in size up to current SOV designs of 71m. Our back catalogue of successful SWATH designs spans from our first SWATH MV Patria in the late 1980s, still the world’s fastest SWATH, as well as the naval architecture design of the Lockheed Martin Slice SWATH, to our latest range of world-class typhoon Class of CTV SWATHs that are extending the North Sea operational window by more than three months per year.”

An extension of the existing two Typhoon Class SWATH CTVs, these new fully IMO Tier III compliant designs offer an IMO specification ballast water management system, and are hybrid ready. The vessels will carry 30t of deadweight along with

24 technicians in comfortable business class seating with low risk of seasickness thanks to the extremely low motions of a SWATH hull form. This new design is a larger version of the hugely successful Typhoon Class of SWATHs currently operated by MCS, thereby pushing the safe operational envelope from their existing Hs (significant wave height capability) of 2.5m even higher to the holy grail of Hs = 3.0m. As noted by Menno Kuyt, commercial director at MCS and operator of two AHMD SWATH CTVs, “The major advantage of the SWATH design is its superior response to high seas, allowing operation up to an extra 100 days a year over a conventional catamaran.”

i. adhocmarinedesigns.co.uk

We will help you to clear things up! Meet our portable ballast water treatment containers. High flow rate, low power consumption. A 20ft container with a filterless active substance, USCG/IMO approved BWTS, reducing carbon footprint and cost per cubic meter. Ideal for barges, FPSOs, jack-ups, drill rigs and semi-subs. Contact us on info@uniballast.nl www.uniballast.nl

MacGregor has received a large order for cranes to be installed onboard a state-of-the-art cable layer due delivery from global shipbuilder VARD.

The contract has been booked into Cargotec’s first quarter 2024 order intake, with crane supply scheduled for the third quarter of 2025.

MacGregor will deliver a 100t active heave-compensated (AHC) crane, a 20t offshore crane, and a 3t deck crane to Prysmian, to equip the Italian owner’s third NB970 cable laying vessel from VARD. In addition, MacGregor has been contracted to supply its OnWatch solution, including 24/7 technical service support worldwide.

Developed for advanced subsea operations, the 191m long Prysmian cable layer will be capable of complex installation works, including

simultaneous lay and burial with heavyduty ploughs. It is equipped with cutting-edge DP3 positioning and seakeeping systems. At 19,000t, the vessel will take its place among the highest cable loading capacity ships in the market. According to Pasi Lehtonen, senior vice president, offshore solutions at MacGregor, the company has been a reliable supplier for VARD on multiple projects over many years.

“This is a significant order for MacGregor’s offshore handling business, and we are pleased to supply VARD with yet another package of our high performance cranes,” he says. “The market continues to respond well to our unique and modern designs, which

combine resilience in service and lightweight round-shaped jibs.”

MacGregor’s wide range of well proven AHC cranes, including its subsea cranes, offer accurate lifts in all conditions, including extreme environments with temperatures from plus to minus 40°C. They can be delivered with hydraulic or electric winch drives.

The initial phase of construction on the new vessel will take place at VARD Shipyards Romania – Tulcea, with completion in Norway and handover to the owner due by the beginning of 2027.

i. macgregor.com

Our activities over many decades have led to an unprecedented decline in the diversity of living creatures and their habitats. Following global agreements to protect oceans, the offshore wind sector is leading the transition to biodiversity-positive project development.

Biodiversity refers to the variety of life on earth, encompassing different species, genetic diversity within species, and the vast array of ecosystems. Every ecosystem is a community of organisms interacting with each other and their physical environment. It includes living (biotic) elements such as plants, animals, and

microorganisms, as well as non-living (abiotic) elements like soil, waste, and climate.

Biodiversity has a positive effect on ecosystems and the ecosystem services that underpin our societies. Healthy

ecosystems are finely balanced. However, there is now scientific consensus that many are going out of balance, resulting in biodiversity loss worldwide. This, in turn, negatively affects the resilience of human societies and other species’ population. The declining biodiversity within many coastal and marine ecosystems has

Offshore wind developers consistently assess and monitor five main elements of marine life, which are bird life, intertidal habitats, fish travel, marine mammals, and ecology on and in the seabed.

multiple intertwined causes, with human activities such as overfishing and pollution, along with climate change altering the abiotic conditions of ecosystems, being the main contributors. This loss of biodiversity is setting off alarm bells, not least because it reduces the ocean’s ability to mitigate climate change. It’s a vicious circle: climate change accelerates biodiversity loss, which, in turn, reduces carbon absorption, further accelerating climate change.

The transition from fossil fuels to clean energy is the only viable way to avoid the worst effects of climate change and minimise biodiversity loss. Big plans are already in place to build the offshore wind infrastructure necessary to produce affordable and clean energy and targets have been set to deliver an additional 380GW of offshore wind capacity by 2030 and an impressive 2,000GW by 2050. That’s a lot of offshore wind to design, construct, and operate, which creates an enormous opportunity to leverage investment to observe our oceans to restore marine ecosystems. In fact, recent research by the Economist Impact World Ocean Initiative into the value of ocean observation data shows that offshore wind provides the single largest valueadding area of all marine-centred climate change mitigation activities –equal to the value of ocean observation data in green shipping, other ocean renewable energy, marine carbon dioxide removal, and blue carbon combined.

How do offshore wind projects interact with nature?

In comparison to many marine activities, offshore wind projects are generally benign. Over the past twenty years, one

after another, environmental assessments have shown relatively low levels of negative effects. That being said, offshore wind developers consistently assess and monitor five main elements of marine life, which are bird life, intertidal habitats, fish travel, marine mammals, and ecology on and in the seabed.

Although offshore wind projects generally have a limited impact, the scale of each project and the scale of the industry create an opportunity to enhance biodiversity.

Fugro is an active member of the UN Global Compact, particularly within the Offshore Renewable Energy working group, biodiversity-related working groups for WindEurope, RenewableUK, and the Powering Net Zero Pact –Biodiversity Working Group. These workshops and debates have deepened the understanding of the challenges that offshore wind developers face in keeping their construction schedules and budgets on track while also implementing their company’s new biodiversity net gain policies.

On every project, developers are now walking a tightrope while also juggling a range of tasks such as:

• financial management – delivering projects on time and within budget;

• market considerations – not only delivering more offshore wind projects but also prioritising which markets to focus on;

• risk exposure – managing exposure to various risks, including delays due to stakeholder opposition, supply chain bottlenecks, and the capitalisation of early phases of project development;

• social impact – maximising societal benefits through local employment (balanced against international supply

chains) and environmental enhancement (balanced against practicalities of project delivery within budget).

With a finite number of skilled personnel, equipment, and vessels available, and now with the added complexity of biodiversity net-positive requirements, developers face an even more challenging balancing act.

The transformation has begun

To meet the challenges, the global community took a major step at COP15 in Montreal back in December 2022, when a landmark agreement known as the Kunming-Montreal Global Biodiversity Framework was reached. Taking up the baton, European offshore wind developers have already launched biodiversity net-positive policies, including Ørsted, RWE, Vattenfall, and SSE Renewables. Similarly, many major suppliers, including Fugro, have embraced these policies. Although companies vary in their level of commitment at this stage, a common aim is for all new projects commissioned from 2030 (essentially, all projects currently in development) to be biodiversity net positive. This marks a giant leap forward for the offshore wind sector.

Offshore wind developers face numerous obstacles and temptations along their path, including:

• jargon – a proliferation of new terms, such as ‘net-positive impacts on biodiversity’, ‘nature net-positive’, and ‘biodiversity net gain’, along with a long list of acronyms has begun to creep into offshore wind discussions. This jargon can alienate communities, leading to disengagement >>

In contrast, the offshore wind sector is adopting the Mitigation Hierarchy as recommended by the Cross Sector Biodiversity Initiative, drawing from lessons learned during the Environmental Impact Assessment process.

from conversations, permitting delays, and costly misunderstandings. Clear, simple, jargon-free communication is key.

• national and regional guidance –despite increasing policy at government and corporate levels, there is still a lack of clear guidance on what constitutes a sustainable seascape at national or regional levels. This guidance should include a shared understanding of the species or habitats to focus on regionally and why they are suitable measures of biodiversity improvements. Fugro’s project to map seagrass along the entire length of the Italian coast exemplifies the level of data needed to develop this understanding.

• measurement – without national and regional leadership, companies struggle to acquire appropriate baseline data, design interventions, and plan monitoring to demonstrate positive cumulative effects. Measuring anything at sea is expensive due to the need for rugged equipment and vast deployment and maintenance distances. Fugro is integrating ecological data measurements into existing campaigns. For example, the

company is developing visual and eDNA sampling technologies to deploy from its Blue Essence uncrewed surface vessel and Blue Volta electric powered remotely operated vehicle, enabling ongoing monitoring of ecology during asset inspection campaigns.

• sharing data – despite the vastness of the ocean, individual offshore wind projects are relatively small. However, with plans to build 2,000GW of offshore wind, over 200GW of it in the North Sea alone, there is a unique opportunity to observe the ocean like never before. Organisations like the European Marine Observation Date Network (EMODNet), of which Fugro is a partner, are leading efforts to collate and make marine data available. Fugro’s contributions to Seabed 2030 have been facilitated through EMODNet’s data services. Sharing data across projects will significantly contribute to our understanding of wide-area biodiversity damage or enhancement.

The mitigation hierarchy outlines the steps necessary to achieve biodiversity-

The biodiversity mitigation hierarchy outlines the steps necessary to achieve biodiversity-positive outcomes in project development.

positive outcomes in project development. The ultimate goal of such projects is to leave the area in a better state than it was found. While some argue for targeting pre-industrial levels, this goal is admirable yet practically immeasurable due to ongoing human activities shifting baselines.

In contrast, the offshore wind sector is adopting the Mitigation Hierarchy as recommended by the Cross Sector Biodiversity Initiative, drawing from lessons learned during the Environmental Impact Assessment process. The hierarchy consists of four key steps:

• avoidance – the first and most important step involves avoiding any potential impacts by conducting thorough environmental baseline studies, creating detailed maps, engaging in consultations, and designing out potentially harmful activities. Developing an integrated earth model of the seabed, metocean, and ecological conditions can aid in this process.

• minimisation – the second step is to design projects based on robust data and consultation to minimise potential impacts that cannot be entirely avoided. Where necessary, mitigating activities through additional management techniques should be implemented. For instance, using a lower energy piling hammer to reduce underwater noise and installing additional bubble curtains

plus marine mammal observation can mitigate the remaining potential impacts.

• restoration – this step involves the most important remedial action of the hierarchy, directly reversing any harm caused by the project. A common example is recreating habitats on the coast or seabed that were harmed during construction. These activities effectively achieve net zero biodiversity impact.

• enhancement – while theoretically possible to measure a unit of biodiversity and then create another unit elsewhere to offset damage from a project, it is not recommended. Ecosystems are complex and often degraded over many years. Therefore, the focus should be on enhancing biodiversity with project boundaries. This approach also has the added value of potentially benefiting local communities, thereby increasing support for project development.

The energy transition is at a turning point, with a global agreement to move

away from fossil fuels, and the installation rate of all renewable energy sources continues to break annual records year on year. This transition holds enormous potential to restore and enhance biodiversity around and between project sites, both on land and in the sea.

To achieve this, there are four key elements:

• Act on science-based targets and rigorously apply the mitigation hierarchy. Gather the best data and use it to engage stakeholders and communities early on to avoid impacts and maximise benefits.

• Set ambitious targets to support ecosystem health and restore lost biodiversity. This requires the creation and adoption of standardised approaches to measurement and monitoring, enabling investment in large area scalable solutions.

• Act collectively to advocate for policy, regulation and standards. Share data, information, and knowledge by forming close working relationships across projects and the supply chain.

• Proactively engage communities to

advance the best outcomes for those who rely most on ecosystems. Build capacity in organisations around projects, especially in the global south, so people can contribute to nature-positive offshore wind initiatives.

i. fugro.com

This article was originally published in an extended version as longread on www.fugro.com.

Vuyk Engineering Rotterdam

Vuyk aimed to step out of a corporate environment and return to its core: designing and engineering to meet its clients’ requirements.

Three years ago in March, Vuyk Engineering Rotterdam signed for full independence: “back to the core of Vuyk: designing and engineering to customer requirements.

Since becoming independent, strategic steps have been taken to chart its own course and strengthen the independent position within the maritime sector. Erwin Put and Floris Toetenel look back and ahead. “After the closure of the Vuyk shipyard in Capelle aan den IJssel in 1979, marking the end of all shipbuilding activities, former employees established a new company: Vuyk Engineering and Trading. Founded on the principles of technical know-how combined with experience in cost calculation, they gained a reputation as an expert market player, able to provide a wide range of services in vessel design and marine engineering, in particular to the dredging industry. In 2021 a new course was set. Once it became clear that Vuyk would be sold, we defined how we envisioned Vuyk’s future,” says Floris Toetenel, commercial director of Vuyk Engineering.

He continues, “The objective was to be independent, and not being affiliated with any specific shipyard, builder or other engineering firm. We aimed to step out of a corporate environment and return to our core: designing and engineering to meet our clients’ requirements. That is what our people are good at, and we shouldn’t lose sight of that. In March 2021, agreement was reached on a takeover by Royal Doeksen. The Rotterdam-based maritime investment company stepped in as major shareholder, allowing Vuyk to continue operating under its own management and as an independent engineering office. This strategic decision was made to ensure and strengthen autonomy.”

Within the Rotterdam engineering office, a multidisciplinary collaboration thrives.

Three different specialisations – vessel design, equipment design, and operational engineering – work together under one roof. “We are the last remaining independent maritime engineering office in the Netherlands and are also the only maritime engineering firm to represent three specialisations. This means we not only possess in-depth knowledge and experience in each of these disciplines, but we also have the ability to seamlessly integrate our three specialisations within one project. By continuously investing in knowledge development of new technologies, we remain at the forefront of innovation,” Erwin Put, director of operations of Vuyk Engineering refers to the company’s commitment to new technologies. “We are not only involved in improving existing solutions, but also strive to develop knowledge of new solutions that respond to market needs. In-house knowledge of topics such as methanol,

hydrogen, and even nuclear power demonstrate the dedication to exploring sources beyond traditional methods. By connecting to customer needs, sharing our knowledge and thus promoting an open dialogue, we want to contribute to the development of the entire maritime industry.”

A strong foundation to build on Vuyk’s engineering team has laid a solid foundation for further development. Nearly the entire staff was retained after the acquisition in 2021. Mr Put continues, “Our people are the backbone of Vuyk. Last month, two employees celebrated their twenty-fifth and even forty years of employment. These older colleagues are our foundation. Senior employees are the best tutors for younger colleagues by sharing their expertise and career lessons with the younger generations. This only benefits the professional development of young

talent in the organisation, and thus the future of Vuyk. We consider it important that our engineering team is composed of different perspectives and backgrounds, in order to strengthen our innovative power and creativity. In addition, our focus is not only on attracting talent, but also on retaining it. We strive for a working environment where employees feel valued and can develop, which is essential for achieving our long-term goals.”

The renewed independence also brought challenges. Mr Toetenel acknowledges that this is an ongoing process of improved visibility and full transparency. “In an industry where partnerships and affiliations are often the norm,” he elaborates, “we have to be clear that we are completely autonomous from external parties, and that we operate on the basis of client’s wishes,” he explains. “The bottom line is that we can work with anyone the customer considers important. A proactive approach to the market and transparent working methods have

“In an industry where partnerships and affiliations are often the norm, we have to be clear that we are completely autonomous from external parties, and that we operate on the basis of client’s wishes.”

allowed us to strengthen our commercial activities, both in the Netherlands and internationally. Our independence brought us back to the table with major contractors, and we have also carried out several dredging and offshore wind projects in the US in the past three years. We have also been heading further into Europe, working for a number of dredgers, OEMs, and suppliers within the offshore wind industry.”

A look into the future reveals ambitious plans. “With a vision to strengthen our global presence, we are in the advanced stages of opening new subsidiaries in a couple of strategic locations. This expansion will allow us to offer our

services to a wider range of international clients and to serve their local needs. Official announcements are scheduled at the beginning of the second quarter,” Mr Put states. Mr Toetenel looks ahead with an open mind, emphasising plans to reinforce core values of knowledge, synergy, and innovation. “Our aim isn’t merely growth; it’s about futureproofing, fortifying our position, ensuring continuity, and most importantly: continuing to listen closely to our customers and partners.”

i. vuykrotterdam.com

Harvey Gulf International Marine is propelling the industry forward with the modification and enhancement of its fleet of five dual fuel LNG/diesel electric powered offshore supply vessels (OSVs).

Emphasising their commitment to innovation and meeting evolving industry demands, Harvey Gulf has implemented significant upgrades to these technologically advanced vessels. A key enhancement includes the segregation of liquid mud tanks into six isolated independent tank systems, each equipped with dedicated pumping, valve, loading, and discharging systems with zero chance of cross contamination.

The first vessel to undergo these modifications, the 310’ DP2 Harvey Liberty, has undergone successful transformation, with sister vessels Harvey Power, Harvey Energy, Harvey Freedom, and Harvey America set to follow suit.

A key enhancement includes the segregation of liquid mud tanks into six isolated independent tank systems, each equipped with dedicated pumping, valve, loading, and discharging systems with zero chance of cross contamination.

Central to the conversion process are the installation of six pumps and multiple isolation flanges for each set of liquid mud tanks. These isolation flanges effectively separate the original fill and discharge lines from the newly installed pumps and deck discharges to allow six different products with zero chance of cross contamination.

Innovatively, the liquid mud tanks are configured to maximise flexibility and efficiency. For instance, the Liquid Mud tanks #1 port and #1 starboard share a pump, allowing for simultaneous product addition and complete isolation from the original system. Similarly, liquid mud tanks #3, #4, and #5 on both port and starboard sides are individually equipped with dedicated pumps, enabling the isolation of separate products. Moreover, each vessel can independently isolate the liquid mud

tank #2 port and starboard sides, each with its own pump, adding further versatility to the system and facilitating the handling of additional products.

i. harveygulf.com

As the world transitions towards renewable energy and sustainable practises, the significance of offshore projects has become increasingly paramount. From harnessing the power of offshore wind, solar, and tidal energy, to the innovative technologies of wave energy converters and carbon capture and storage initiatives, the offshore realm serves as a key element for sustainable innovation.

The beauty of offshore projects lies in their ability to harness renewable energy without encroaching on land resources, yet the construction and maintenance of these projects pose unique logistical challenges. The transportation of equipment and supplies plays a vital role in supporting the operation and growth of this industry, demanding reliability to meet the diverse and intricate needs of the stakeholders.

Peters & May Commercial, a leading logistics provider, contributes essential support to offshore initiatives by ensuring the safe and secure transportation of commercial cargo. Its approach is simple yet effective: prioritising the safety and security of cargo, regardless of its size or weight. Its clientele encompasses a wide array of sectors’ vessels and cargo types, from windfarm operator vessels, submarines, and military vessels to CTVs, turbine blades, shore cranes, and shipping containers. Their ability to cater to such diverse and complex requirements is evident through its comprehensive portfolio. Peters & May Commercial recognises the critical role and support it can provide in overcoming the challenges faced in offshore projects and is able to tailor its solutions to the needs of offshore endeavours. It ensures the seamless and

timely delivery of essential vessels and equipment to their destinations.

Whether it’s wind farm support vessels, which support the construction, operation, and maintenance of wind farms, crew transfer vessels designed to transport personnel, technicians, and other crew members to offshore installations, or fast support and intervention vessels designed to provide rapid response and support services, there is no limit to which Peters & May Commercial can extend its expertise. An example that highlights its expertise and dedication to offshore operations is the shipment of the 24m, 600t multipurpose vessel, Voe Earl, in late December 2023. The Voe Earl, purpose-built for offshore renewable energy and oil & gas projects, is able to perform survey, cable laying, diving support, and anchor handling tasks. Peters & May Commercial loaded and shipped this essential multipurpose vessel from Taiwan to Rotterdam, providing the vessel operator with a reliable service in readiness for any offshore task.

A recent shipment of three CTVs from Singapore to Southampton demonstrates the company’s versatility. Weighing approximately 100t each,

recent shipment of three

these specialised vessels play a crucial role in ensuring the safe and efficient transfer of crew, facilitating crew rotation, conducting maintenance activities, and responding to emergencies on offshore farms. Equipped with lifting lugs and Peters & May Commercial’s custom modular

support system, these vessels were successfully unloaded in Southampton in February 2024 after navigating the challenging waters around the Cape of Good Hope in early January. Looking ahead, Peters & May Commercial has several additional CTVs scheduled for delivery in the upcoming months.

Working with MHO-Co, A Danish company which specialises in providing CTVs and other offshore support vessels for the offshore wind industry, Peters & May Commercial was able to ensure the smooth delivery of two of their 35m MHO Boreas vessels, aptly named after the Greek god of the violent north wind, from China to Denmark. These windfarm support vessels were designed for the northern sea and are equipped for 24/7 operation with a crew of 3-8 members depending on the task. These versatile ships are capable of handling tasks in any weather conditions, location, and at any time.

As the landscape continues to transform and the demand for sustainable offshore solutions and offshore projects continue to surge, Peters & May are committed to facilitating these offshore initiatives and dedicating its efforts in contributing to a greener and more sustainable future.

i. petersandmay.com

Lankhorst Ropes has opened Lankhorst Academy, providing practical and theoretical courses in maritime and heavy lift rope handling and splicing at its refurbished Dordrecht facility in the Netherlands.

The academy offers industry and application-specific courses for Lankhorst customers designed to increase crew knowledge of rope behaviour, handling, and inspection. The overall aims of the one-day courses are to ensure crews are well placed to properly and safely use their ropes and, as a result, help them optimise rope service life aboard their vessel.

Developments such as the OCIMF’s Mooring Equipment Guidelines, MEG4 and the recent introduction by the IMO of ‘Guidelines for Inspection and Maintenance of Mooring Equipment including Lines’ has placed maritime ropes and their handling centre stage in the drive to increase safety offshore.

Lankhorst Academy builds on the company’s many years of experience in crew training for both maritime and offshore energy industries. All courses cover fibre rope construction, rope inspection, and rope maintenance, and typically last one day. Industry-specific courses are available for Inland Shipping, Mooring (practical and theoretical), Tug and Towage, Offshore Installation, and Heavy Lifting. Practical courses include rope splicing and a full rope break test on the facility’s rope test machine.