OSI 2016 | VOLUME 9 | ISSUE 3

OSI VOL. 9 ISSUE 3 | 2016

i n d u s t r y

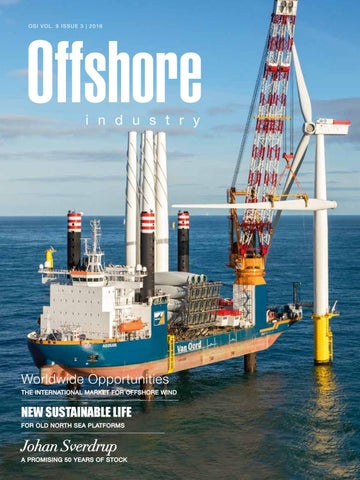

OFFSHORE WIND

worldwide opportunities the international market for offshore wind OFFSHORE-INDUSTRY.EU

New sustainable life FOR OLD NORTH SEA PLATFORMS

Johan Sverdrup a promising 50 years of stock