As I am writing the editor’s note of this last edition of ShipBuilding Industry, I cannot help but reminisce about 2022. Fortunately, 2022 has brought back the maritime industry together again in the form of live and well-attended trade fairs, such as Asia Pacific Maritime, Electric & Hybrid Marine Expo, and SMM. There is nothing like seeing each other in person and exhibiting live, meeting, having a drink together, and connecting.

In this issue of ShipBuilding Industry, we focused on the current developments in the Dutch shipbuilding sector. We have some fascinating articles about important suppliers of the shipbuilding industry, such as Kooiman Marine Group, Poly Marine Fender Systems, and Safe Lifting. Read all about their latest updates and developments.

In addition to the aftermath of the pandemic and the current war in Ukraine, there is also global warming, which remains an existential problem facing mankind. A problem that the maritime industry is also dealing with. How do we go about making it climate-neutral as quickly as possible? We will keep you informed on new developments in the maritime industry in this race against time. We have dedicated some articles to green shipping technologies in this issue. This and many more awaits you in this edition of ShipBuilding Industry.

We, as the Yellow & Finch Publishers team, would like to thank you for sharing your news with us this year. You are the driving force of the shipbuilding industry, pushing the limits of your possibilities further with every innovation, and we love to put you in the spotlight.

Daniela Markovic Editor

Numarine celebrates its 20th anniversary year with a new model and its first ever with diesel-electric propulsion. The brand enjoys a sizeable slice of the market for high-quality explorers and the new addition to the fleet responds to the needs of its clients. With demand for the 26XP and 32XP high, the new 30XP neatly fills a space in the Numarine line-up. Construction of the molds is under way and three units are already sold. The shipyard is aiming to launch the first 30XP in May 2024. The 30XP can accommodate ten guests in five ensuite staterooms: four guest cabins on the lower deck and a master stateroom on the main deck forward with floor-toceiling windows and cut-outs in the bulwarks to maximise the sea views.

i. numarine.com

Inmarsat provided SEA-KIT International’s uncrewed surface vessel (USV) Maxlimer with connectivity services to transmit data and video from the site of the recent underwater volcanic eruption in Tonga. As part of an international project to assess the environmental damage caused by the eruption, the 12m remotely operated vessel mapped the volcano’s submerged caldera and measured local marine conditions. In 2021, Inmarsat installed a Global Xpress antenna and Fleet LTE hardware on board Maxlimer, adding to the USV’s existing FleetBroadband antenna and allowing it to access full Fleet Xpress capabilities and seamlessly switch between networks. Following a successful pilot, SEA-KIT has signed up for a high-upload plan and the services of Inmarsat Certified Application Provider (CAP) Videosoft Global to support the vessel’s survey activities in Tonga.

i. Inmarsat.com

Scaldis is proud to have safely and successfully concluded the installation of six water intake and -outlets for the Hinkley Point Project. An impressive total weight of 25,000t was installed by Scaldis at the seabed within tolerances of centimetres in challenging tidal conditions of the estuaries of the Severn and Parrett River. In order to achieve this, Scaldis had mobilised its two Heavy Lift Vessels ‘Gulliver’ and ‘Rambiz’ in a unique dual lift set-up. A thorough preparation phase and a highly motived crew and sta has resulted in an on-time delivery of the project. Once more, Scaldis confirms its position as one of the leading heavy lift contractors for both o shore and civil works.

i. scaldis-smc.com

With a festive ceremony, Damen Shipyards Group delivered the Fairplay-37 to Fairplay Towage Polska in Gdynia, Poland on 13 October. This Damen Shoalbuster 2711 ICE is set to play an important role in the development of the emerging o shore wind energy sector in the Polish sector of the Baltic Sea and beyond. Thanks to her Ice-class properties, the vessel can operate all year round in the Baltic. The shallow draft tug can perform towing operations in both shallow an in deep waters, it can assist with installation operations thanks to her line handling equipment and a deck crane. The 27,06m length vessel has a max beam of 11,55m and a working draught of 2,90m. She is propelled by twin Caterpillar 3512C engines, driving two propellers in nozzles and providing a bollard pull of 47t.

i. damen.com

Kongsberg Digital recently signed an agreement on the Vessel Insight infrastructure with Gaslog LNG, a leading global provider of LNG shipping services. This means the entire fleet, counting 35 vessels, will be digitized, resulting in better data collection and utilization for the company. Gaslog LNG operates world wide focusing on safety and operational excellence. Connecting to Kongsberg Digital´s Vessel Insight Infrastructure ultimately provides Gaslog LNG with instant and easy access to fleet overview, vessel specific dashboards and analysis tools. The consistent and standardized way of collecting data through Vessel Insight enables quality reporting, empowers transparency, and allows for in-depth analysis to optimise vessel and fleet performance. i. kongsbergdigital.com

OffshoreEnergy 29-30Amsterdam,November2022TheNetherlandsoffshore-energy.biz

Colombiamar 2023 8-10March2023Cartagena,Colombia colombiamar.co

SeaAsia 2023 25-27April2023MarinaBaySands, Singapore sea-asia.comMaritime Industry202323-25May2023Gorinchem,The Netherlandsmaritime-industry.nlNor-Shipping2023 6-9June2023Oslo,Norwaynor-shipping.comElectric&HybridMarineExpo2023 20-23June2023RAIAmsterdam,The Netherlands electricandhybridmarineworldexpo.com

Van Oord’s new cable-laying vessel Calypso is on its way to the Vard Brattvaag yard in Norway for construction finishing, after a successful and safe launch at the Vard Tulcea shipyard in Romania late October. This next-generation, custom-built vessel will be a key strategic addition to Van Oord’s o shore wind fleet, being equipped with the latest sustainable technologies.

Construction is progressing well on schedule and the vessel is expected to be operational from the end of 2023 on. The Calypso is Van Oord’s second cable-laying vessel in addition to the Nexus. It measures 131m in length and 28m across the beam and will be Dutch flagged. The new DP2 vessel will not only be fitted with a carousel on deck but also with a second, below-deck cable carousel, with a total cable-carrying capacity of 8,000t.

i. vanoord.com

Liebherr Transform is the new upgrade, modification and overhaul service that has a tailor-made solution for customer needs. Itis available for ship to shore container cranes, rubber tyre gantry cranes, rail mounted gantry cranes, mobile harbour cranes, o shore and ship cranes. The new Liebherr Transform provides tailored solutions that respond to the continuously growing demands on today’s businesses. A range of ingenious upgrades, clever retrofits, machine overhauls and service modifications breathe new life into customers’ existing machines. Using the latest technology and years of experience, Liebherr brings a combination of sustainability, smart technologies, maximum productivity and coste ectiveness in one complete solution.

i. liebherr.com

Late August, the new cruise ship Arvia for the British cruise line P&O Cruises left Meyer Werft’s covered building dock II (Hall 6). The float out manoeuvre began in the morning at around 9:00am. The newbuilding then moored at the outfitting pier in the shipyard harbour, where the masts and funnel were lifted onto the ship by crane. The cruise ship has lied in the shipyard harbour until the Ems conveyance in October. The Arvia thus formed the backdrop for the NDR2 Papenburg Festival on 2 and 3 September of this year. Until the conveyance, the interior work on board will be continued and further technical tests will be carried out.

N358 ‘Vertom Patty’ was successfully launched at Thecla Bodewes Shipyards at the end of September. MV Vertom Patty is the first 7,000DWT Diesel-Electric Multi-Purpose Dry Cargo vessel of a series of six of the LABRAX design the Dutch yard is building. The vessel is ordered by Vertom, one of the leading short sea shipping operators within Europe. To emphasize the importance of this event, this first vessel in the series of no fewer than six, was festively christened by Mrs Patty Pols, the wife of the late Mr Pols, founder of Vertom. The vessel will be commissioned in Kampen in October and delivery is scheduled for the end of 2022.

i. tbshipyards.com

i. meyerwerft.de

As a result of the current surge in sustainability developments in the maritime sector, a major shift is taking place in winch technology. After having dominated the playing field for decades, hydraulic winches are losing ground to electric-powered systems.

Dromec, a Dutch company specializing in winch technology, realized the potential of electric-powered winches years ago. They have been actively developing the technology, adjusting and modifying electric drives to accommodate their customer’s requirements. It wasn’t always smooth sailing, however. As is generally the case with innovative technology, there are still some teething problems to overcome. Luckily, they love a good challenge at Dromec. So, when the owner of a fishing vessel approached them in 2015 to see if Dromec could transform the hydraulic winch drive on his trawler to an electric drive, the project sparked their interest.

Cees Drost, Dromec’s sales representative and co-owner, discussed the project with Geerart de Vree, the engineer in charge of Dromec’s technical department.

The first step was to measure the specific surroundings of the hydraulic systems on board. Dromec collected the data regarding

cable speeds, vessel speed, maximum working load, as well as tension levels on the winches. These data served as a basis for the configuration of the winch drive and gearboxes. After three years of preparing, manufacturing, and installing, the vessel took to sea. Most elements in the converted winch system functioned properly right away; others needed some adaptations. When all other issues had been resolved, one crucial kink remained: the gearboxes kept breaking down. No matter what Dromec’s engineers tried, they couldn’t keep them going.

But what was going wrong? Were the calculations o ? Did they overlook something?

To answer those questions, Dromec needed to find a way to monitor the gearboxes during operation. To do so, they joined forces with the automation experts at Bachmann to set up a vibration monitoring system. Three sensors were placed on each 200kW gearbox, another two were set up on each electric winch motor. Bachmann supplied the sensors, cables, and software. They also monitored and analyzed the collected data. The two companies set up meetings at regular intervals to assess the data reports. The vibration sensors provided Dromec with an incredible amount of information. “They basically allow us to observe the gearbox as if through a microscope,” says Mr de Vree. “They provide such meticulous insights. We

can distinguish engine speeds, frequencies, bearing elements, and even gearbox components. They all have their own, specific vibration signals.”

Over time, the sensors detected several defects. At one point, they picked up a distortion on the output switching frequency of the frequency inverter. “Probably a wiring issue on the motor, we figured. One check on the EMC later, the problem was fixed,” explains Mr de Vree.

Another time, the sensors registered an unusually high vibration at the back of the engine. When Dromec investigated it, a small bearing in the forced ventilation turned out to be the culprit. It had been a ected by corrosion. “The wear on the bearing had altered its vibration profile. What’s so remarkable about the sensors picking up this signal, is that the bearing wasn’t even broken,”

clarifies Mr Drost. “It was still turning, just with a little more friction.”

“To us, that really was an eye-opener,” adds Mr de Vree. “It showed us the great potential this technology has for early damage detection.”

However, in the case of the gearboxes, the monitoring system didn’t work. Small hairline cracks seem to have damaged the material without changing the vibration profile. Then, without prior warning, one of the gearboxes broke down.

“We expected gearbox failure to occur when both load and torque levels were high. But when the gearbox actually broke down, the load was low, while the speed was high. Apparently, this combination also caused heavy vibrations,” explains Mr de Vree. “Being able to test whether your assumptions are correct, is so valuable,” says Mr Drost. “But it is a long-term process. You need to monitor during a longer period of time to determine the regular patterns. Only then will you recognize anomalies in the data,” he concludes.

Another important factor in the recurring gearbox problems seems to be the tremendous forces that the equipment on trawling vessels is exposed to. Trawlers will make 90 degree turns at full throttle during some parts of the fishing process, for example, causing extreme vibrations.

After consulting with the client, Dromec configured some limitations in the control management software. When the ship speed is too high during the last leg of its track, the control screen sends out a warning signal by blinking. “The speed loss is absolutely minimal. On a full, 90-minute fishing track, the limitations cause a delay of merely 30seconds, adding up to a maximum of five minutes a day,” states Mr Drost.

Even though the conversion project wasn’t a success in all respects, it proved to be of great value to Dromec. “This project o ered great insights in the future potential of sensor-based monitoring,” says Mr de Vree.

Mr de Vree is particularly enthusiastic about the potential for critical, non-stop processes that involve great speed variation. Water injection dredgers, for example. “It could prevent unexpected downtime on ships, or be used to optimize revision planning,” he concludes.

i. bachmann.info

i. dromecwinches.nl

Fender Innovations of Wieringerwerf, manufacturers of lightweight, ultra strong fender systems for fast-sailing vessels, has completed a commercially important acquisition this year. The new partner is PolyMarine Fender Systems based in Vlaardingen, manufacturers of cast fender systems for slightly heavier workboats. Both companies will form part of the Fender Innovations Group.

For Fender Innovations, this is the first acquisition since the company was founded in May 2012. The company continues to grow and has reported a 25% rise in production across the whole of 2021. Some 85% of the fenders manufactured by the company

are intended for export to around 40di erent countries. Technical director of Fender Innovations, Koos Bijsterveld, expects the acquisition of PolyMarine Service to lead to further growth in production, “As a result of the acquisition, from now on we will be able

to o er our international customer base a much wider range of innovative fender systems. The products from the two companies complement each other perfectly.”

Erik de Neef, Chairman of the Board of the Koninklijke Roeiers Vereniging

Eendracht (KRVE), share this opinion. “We are delighted that PolyMarine Service, a company established in 2007, finds itself in good hands with a solid partner like Fender Innovations, and will be able to expand further in the maritime sector.” The Vlaardingen base of the newly acquired company will continue to operate. Because many of the customers of Fender Innovations are located in the port of Rotterdam, it is useful to also have a production location and a warehouse in which stock products can be stored, in the area. Although the shares of PolyMarine Service were o cially transferred on 24 March, the acquisition of the company is e ective retroactively, to 1 January 2022. In the words of Managing Director Roemer Boogaard of Fender Innovations, “The name of the company in Vlaardingen will be changed to Poly Marine Fender Systems. That new name better reflects the scope of the business. Both companies are now o cially part of the Fender Innovations Group of Wieringerwerf.”

Poly Marine Fender Systems manufactures the highest quality fenders in the Heavy duty industry. The unique production process ensures that the fenders are both optimally resilient and durable. The used material has been specifically designed to withstand the most extreme and heavy duty forces and to absorb energy as well as to withstand friction between moving objects. Therefore the Poly Marine Fender Systems are extremely strong and wear-

resistant and have a long lifespan, allowing the ship to remain operational for longer. This makes it possible to schedule any necessary fender replacements at the same time as major maintenance activities, substantially reducing costs and facilitating logistics operations.

The KRVE in the Netherlands, founded in 1895 is a mooring company with main o ce in the Rotterdam harbour in the Netherlands. Their specialty is to provide a complete package in mooring and unmooring of vessels/o shore activities with precision, accuracy and e ciency. These operations are executed with well-trained personal and innovated equipment.

Their marine fleet does contain several Pilot & Crew tenders, mooring launches, work vessels and pontoons. Every 24 hours, over 500 controlled collisions occur with their vessels. This intensive use of equipment made them choose a Poly Marine Service fender system.

The five crew tenders equipped with C600 fenders have been operational for over five years and no hull damages recorded. This makes the vessels very e cient and gives an average cost reduction of EUR 15,000 per year per vessel; as each high-speed water yet tender makes more than 5,000 running hours a year.

Other positive aspects of the fender systems are reduced shock loads through the vessel at every >>

(un)controlled collision. This fact has reduced mechanical damages on engine, jet systems, drive shafts and electronic systems.

The fenders of Poly Marine Fender Systems are specially designed for the heavy duty operations of the KRVE Rotterdam Boatmen. Therefore they are ultra strong, extremely durable and have an unique high buoyancy (up to 80% more) and very high energy absorbing power. To this end, a partnership has been entered into with Poly Marine Fender Systems. Already 30 ships of the KRVE Rotterdam Boatmen and various ships of customers have now been fitted with these Fender Systems. The composition of these Fender Systems ensures that when ships are mooring or coming alongside, the impact is damped, which leads to less hull damage and also makes mooring more comfortable and safer. The fenders can be supplied in any desired colour and thickness (weight).

We talked to Gerrit van der Burg, Board Member of the KRVE. Mr Van der Burg shares, “In the past, we tried and tested numerous fender suppliers to find fenders strong enough to endure the many controlled and uncontrolled collisions of the vessels, but not one was strong enough. Until we stumbled upon

the two founders of PolyMarine (Fender Systems), who were active in the o shore sector at the time.” Mr van der Burg goes on, “After a successful round of testing, we saw that their fenders did not break, yet they remained strong and sturdy. We decided to sign a contract for the fenders immediately. The first fender that we acquired from Poly Marine Fender Systems is now thirteen years old and still going strong, the vessel doesn’t have any hull damage.” “This is a real success story”, Mr van der Burg adds, “And we look forward to continuing this success story with Poly Marine Fender Systems.”

Another great success Mr van der Burg is very proud of is the development of ShoreTension. Sleeves available in the market didn’t satisfy the KRVE and were not su cient to deal with the (high)

mooring forces, so they developped ShoreTension, an innovative mooring system to make the mooring of seagoing vessels run smoothly. ShoreTension has a heavy duty sleeve with a Dyneema inlay to reduce the friction and minimise the potential damage to the mooring lines and fairleads. The system makes mooring of sea vessels much safer and ensures, that even with strong winds or suction, the vessel stays in place. A power pack puts the cylinders at the correct tension just once and then uses the forces of the ropes to keep the vessel in place. “All in all,” Mr van der Burg proudly concludes, “The Rotterdam area is a breeding ground for innovation!”

i. polymarinefendersystems.nl i. krve.nl

Throughout the years, Safe Lifting has been providing lifting and hoisting equipment to many well-known internationally operating customers.

With assets growing in weight and size, much is asked of the lifting and hoisting tools used in the shipbuilding industry. To meet this development, Safe Lifting Europe is constantly working on keeping its portfolio of rental equipment up to date.

Shipbuilding and ofshore professionals use Safe Lifting Europe to source lifting and rigging equipment for short- or long-term rental. Being specialised in serving the dynamic and demanding heavy lifting sector, the company works with the lifting industry’s top manufacturers to deliver solutions up to any capacity.

Throughout the years, Safe Lifting has been providing lifting and hoisting equipment to many well-known internationally operating customers.

Jacques Vroegop, Operational Manager at Safe Lifting Europe, explains, “When considering the costs associated with purchasing lifting equipment, the rental solutions ofered by Safe Lifting often are more favourable. In addition to initial purchase price, equipment owners must also budget for maintenance, periodic re-certification, storage, and more.”

Apart from this cost advantage, renting lifting and rigging gear at Safe Lifting also adds value and efficiency in other ways. “We not just supply a tool,” Mr Vroegop adds, “as from start to finish we can supply everything for a project, including drawings, engineering, people, and planning.”

A look at Safe Lifting’s rental portfolio shows a comprehensive list of equipment. It includes a huge range of lifting, testing, site operations, marine operations, ROV, and hydraulic equipment. Mr Vroegop continues, “We started our business as a reply to market demands, and today we serve clients around the globe by providing high

quality equipment. Clients reach out to us for single items, but also for all the equipment they need for an entire project. They know us as a company that delivers only world-class equipment. Whether it is a force measurement device, a spreader beam, a shackle, or any other below-the-hook tool, all our products are supplied with the high safety standards of the industry in mind.”

“With our background”, Mr Vroegop elaborates, “we are familiar with deadlines, SHEQ requirements, and high standards. Each order involves thorough consultation. This way the products supplied are designed specifically for the application in hand. Our experts carry out quality assurance (QA) checks before any lifting and rigging gear leaves the facility and upon its return from site. Of course, we advise our customers on

>>

“In terms of products, we have everything from A to Z, but having our own specialist personnel means that we are a true one-stop-shop.”

Jacques Vroegop – Operational Manager at Safe Lifting.ALL PHOTOS COURTESY OF SAFE LIFTING. Shackles for heavy lifting supplied by Safe Lifting.

using the equipment, but on request we can also ofer our own trained and qualified personnel to do the lifting operations. In terms of products, we have everything from A to Z, but having our own specialist personnel means that we are a true one-stop-shop.”

Based in Vlaardingen, in the heart of the Port of Rotterdam, the company started business with a focus on the ofshore oil & gas industry, however, the

company’s services are also highly suitable for sectors outside of the oil & gas realm. “Today, we have clients from sectors as diverse as onshore construction and engineering, and inland shipping”, Mr Vroegop states. “We are of course still involved with ofshore clients, where the energy transition is significant. As wind turbine components become bigger and heavier, the relevance of safe lifting operations becomes even more important. For our customers, Safe Lifting is a trusted brand. It is this confidence that puts the ‘safe’ into Safe Lifting’s name. In a complex lift with multiple components, it is imperative to know exactly how each element will behave. And because we know all the ins and outs of all our products, we can call ourselves Safe Lifting.”

i. safelifting.eu

“As wind turbine components become bigger and heavier, the relevance of safe lifting operations becomes even more important.”Jacques

Vroegop – Operational Manager at Safe Lifting.Jacques Vroegop, Operational Manager at Safe Lifting. Modular spreader beams

Qua-vac designs, manufactures, and markets environmentally friendly vacuum wastewater collection and treatment systems for the rural sewage-, building- and marine industries, and is the ofcial and exclusive Evac Oy distributor for the Benelux countries.

One of the Evac’s Sustainability spearhead products, the Evac Membrane Bioreactor (MBR), is an advanced wastewater treatment process that can treat all wastewater streams to current standards – and beyond. Evac MBR allows vessels to operate in environmentally sensitive areas, treating and discharging all wastewater generated by passengers and crew without threat to human health or the marine environment. It is based on proven membrane bioreactor technology, which can flter out nutrients and even microplastic particles. “Our biological membrane technology MBR ensures pure results”, says Jolanda Vervaart of Qua-vac. “This is very important so as not to adversely afect

life in rivers and other waters.” The wastewater treatment units contain 6 to 7 million bacteria, which process almost all pollution. Only 3% to 5% of the residue is released.

Environmental matters are critical for all vessels, as ecosystems are highly vulnerable. Qua-vac systems are installed on all kinds of vessels; from yachts to cargo ships and on hundreds of Rhine cruise ships. The systems ensure that 95% of the waste water on board is purifed, after which it can be discharged into the surface water within the strict Rhine and IMO standards. Qua-vac also supplies complete food

and galley waste systems and dry solid waste systems that ofer simple, costefective operation. Rigorously tested for marine conditions, Evac systems fulfl all marine and ofshore standards. Qua-vac is committed to minimise impact on safety and environment in all their products and services.

The advanced wastewater treatment solution is a reliable process to meet the most stringent efuent regulations everywhere in the world. These technologies also remain risk-free and economical throughout the lifetime of the vessel. Evac treatment plants are certifed to meet the IMO MEPC 227(64), River Rhine certifcation and U.S. Coast Guard (USCG) type approval.

“All our systems are fully in line with our vision to be able to use our expertise to contribute to a more sustainable living environment.”

Jolanda Vervaart – Qua-vac.

Evac Online Vac – highly effcient vacuum generator.

The collection and treatment systems are supplied in standard Evac confguration or are designed and supplied by Qua-vac according to the customer’s wishes. The equipment meets all maritime and ofshore standards, has low service and maintenance intervals, low operating costs, and high ease of use. “All our systems are fully in line with our vision to be able to use our expertise to contribute to a more sustainable living environment”, according to Ms Vervaart. “The need is greater than ever. That is why we continue to innovate and invest with passion for our profession, also in sustainable relationships with our customers worldwide.”

Qua-vac/Evac systems are focused on simple and reliable construction. The builders of the fnest cruise vessels in the world rely on their systems. Within yachts and superyachts, they focus on passenger comfort and aesthetics, high quality materials, and elegant design. With regard to navy vessels, they focus

on military requirements.

Shock, vibration, airborne and structural noise, and electromagnetic interference (EMI). Qua-vac/Evac has thousands of references for work boats, support vessels, exploration vessels, ice breakers, hospital ships, and more. These all have varying needs and operational conditions, as well as limited opportunities for service and maintenance, and the focus is always on the best customer solution.

Every year, the company of the year award is awarded to companies within Almere that make a diference. This is determined based on several criteria. Within the category ‘small business’, they look at: distinctiveness in the market, appearance in the working area, sustainability (people, planet and proft), social involvement in Almere, and innovation.

Evac MBR allows vessels to operate in environmentally sensitive areas, treating and discharging all wastewater generated by passengers and crew without threat to human health or the marine environment.

As we are composing this issue of ShipBuilding industry, we learned that, to their great honor, Qua-vac has been nominated for Company of the Year 2023 in the category ‘small business’. The selection of the nominee for the company of the year 2023 was chosen by a jury of experts chaired by alderman Maaike Veeninga. The winner will have been chosen before this edition of ShipBuilding Industry comes out, thus for the results, please keep an eye on the website and social of Qua-vac.

i. quavac.com

The world’s largest ice-rated ConRo vessel with multi-fuel operation, Botnia Enabler and her sistership Baltic Enabler are characterised by high environmental performance and a design specially suited to the Swedish and Finish shipping requirements.

PHOTOS COURTESY OF WALLENIUS SOL.The frst of Wallenius Sol’s two new vessels, Botnia Enabler, was launched in July 2021, and in October it was time for her sister ship, Baltic Enabler. The shipyard team

reached the next major milestone in February of this year, when Botnia Enabler left Yantai CIMC Rafes Shipyard for her frst sea trials.

“It’s like commissioning a hospital;

everything has to be tested and double checked. Cabins are furnished and systems put into operation simultaneously. For example, we cannot start the engines until we’ve made sure

emergency stops, temperatures and pressures are all working properly”, says Henrik Sundkvist, Site Manager.

On 8 September 2022, Botnia Enabler was christened in the Port of Skellefteå. Botnia Enabler is not only the world’s biggest ice-rated ConRo vessel with multi-fuel operation, but also the biggest ship that has ever called at the Port of Skellefteå. It was with much due pomp and ceremony

that invited guests, politicians, and representatives of trade and industry bore witness to the ship’s godmother Ulla Löfven when she according to tradition broke a bottle of champagne against the ship’s 242m long hull.

“I am honored to be given an assignment like this. I myself have a background in this industry and with climate change in mind it is important that we use the shipping industry” said Ulla Löfven.

The name Botnia Enabler has its origins in Wallenius Sol’s business idea of being an enabler for the base industry in the Gulf of Bothnia, and according to managing director Ragnar Johansson, it was natural that the Port of Skellefteå should host the ceremony.

“The ship sails under the Swedish fag and we are a Swedish company, so we were keen to christen her in Sweden. We began calling at Skellefteå regularly last year, so it seemed natural to carry out

Environmental benefts of the new vessels

• 57% reduced fuel consumption per transported unit

• 63% reduced greenhouse gas emissions per transported unit

• 99% reduction in oxides of sulphur (SOx)

• 96% reduction in oxides of nitrogen (NOx)

• 99% reduced particulate emissions (PM2.5)

Botnia Enabler will share the ZeebruggeAntwerp-Kokkola-Oulu-Kemi-SkellefteåTravemünde route with her sister ship, Baltic Enabler. This means weekly calls with a total capacity of 6,442 lane metres where trailers, containers, industrial freight and project freight will rub shoulders.

“We have promised to deliver a sustainable infrastructure for northern Sweden and Finland. Now we have kept that promise” concluded Wallenius Sol’s board chairman Anders Boman, before godmother Ulla Löfven wished the ship

and its crew happy and a safe passage across the seas.

Baltic Enabler is the second of two newly built sister ships that ply the weekly route Zeebrugge-AntwerpKokkola-Oulu-Kemi-SkellefteåTravemünde. Today, the ship transports goods for e.g. Metsä, Stora Enso and BillerudKorsnäs.

“Baltic Enabler will make the green expansion along the Gulf of Bothnia possible by shortening the distance to and from the continent of Europe. With the highest possible environmental performance we will also reduce greenhouse gas emissions by 63% per shipped tonne compared to our older vessels,” says Ragnar Johansson, managing director at Wallenius Sol.

Baltic enabler has been christened on 2 November at the Zeebrugge Terminal with a traditional naming ceremony. Anette Johansson has been appointed as the ship’s Godmother.

i. wallenius-sol.com

the ceremony here as a tribute to the magnifcent industrial investments in the north.”

“We have promised to deliver a sustainable infrastructure for northern Sweden and Finland. Now we have kept that promise.”Anders Boman – Board Chaiman Wallenius Sol. Godmother Ulla Löfven.

At the end of September, Vard proudly announced that they have delivered Viking Polaris, the second of two ice-strengthened expedition vessels to Viking.

Built at Vard Søviknes in Ålesund, Norway, Viking Polaris represents an excellent and innovative way to explore the world’s most remote destinations and is specifcally geared for adventure cruises in polar destinations.

The vessel has a length of 205m and a beam of 23,5m, especially designed and developed for comfortable expeditions in Antarctica and North America’s Great Lakes. The vessel hosts 378 guests in 189 staterooms.

Vard signed the Letter of Intent (LOI) for the two cruise vessels with Viking in April 2018. The contracts for the vessels became efective in July 2018. Viking

Polaris was delivered from Vard Søviknes on 27 September 2022. The foat out ceremony took place in Vard Tulcea in July 2021. The vessel arrived at Vard Søviknes in Norway on 22 January 2022 for further outftting, testing and fnalisation. Her sister ship, Viking Octantis, was delivered from Vard Søviknes on 22 December 2021.

The two expedition cruise ships have been christened simultaneously on 30 September of this year. The Viking Polaris was christened at the Amsterdam Passenger Terminal after which she started her maiden voyage to Antarctica, as the Viking Octantis was christened in Toronto.

“The vessel is fantastic, and with a very high standard. Considering the sistership efect, and that we brought the synergies from the frst vessel, we are very satisfed with the result. Viking Polaris is equipped with the latest technology and automation systems, all commissioned and tested by Vard in a very close cooperation with Viking.”

“Together with her sister Viking Octantis, Viking Polaris is an amazing and unique ship that represents innovation and development of the cruise segment for both Viking and Vard,” says General Manager for Business Unit Cruise at Vard, Attilio Dapelo. “Both vessels are over 200m long and the largest vessels built by Vard so far and once again confrm Vard’s capabilities to build excellent vessels at the highest standards of cruise ships. I am grateful to everyone involved in the project for being dedicated to their tasks and to the commitment to deliver Viking Polaris on time and with high quality’s levels. A special thanks to Viking for the trust and for the excellent, fruitful, and continuous cooperation all along the designing and building process.”

Viking Polaris is an ice-strengthened Polar Class 6 vessel with a longer hull, straight bow, and state-of-the-art fn stabilisers to provide the calmest

possible journeys in remote regions. The u-tank stabilisers will signifcantly decrease rolling when the ship is stationary. The hull is built at Vard Tulcea in Romania. Vard Tulcea has also partly outftted the ship. “We are proud to deliver the second ice-strengthened expedition vessel to Viking,” says yard director at Vard Søviknes, Arnt Inge Gjerde.

“The vessel is fantastic, and with a very high standard. Considering the sistership efect, and that we brought the synergies from the frst vessel, we are very satisfed with the result. Viking Polaris is equipped with the latest technology and automation systems, all commissioned and tested by Vard in a very close cooperation with Viking. Our inhouse competence in innovative design and technology, executed at our yards through all the steps in the process, is a huge strength which is supported by our owner Fincantieri.”

On 30 September 2022, Viking celebrated its 25th anniversary with a historic celebration in Amsterdam. To commemorate the milestone, for the frst time ever, three classes of Viking ships – a river ship, an ocean ship, and the company’s newest expedition vessel, the Viking Polaris – met in Amsterdam

and sailed in a special convoy to IJmuiden, the Netherlands. Participating in the convoy with the Viking Polaris were the Viking Longship, the Viking Mani, and the ocean vessel, the Viking Mars.

During the Amsterdam event, Viking also named the Viking Polaris and her identical sister ship, the Viking Octantis,

which is currently sailing her inaugural season in the Great Lakes. Both ships will spend the Austral summer in Antarctica, before traveling north to the Great Lakes for a series of voyages during spring and summer.

i. vard.com i. fncantieri.com i. vikingcruises.com

The Swedish company will bring to the project technological and engineering expertise to help understand the challenges and opportunities of deploying carbon capture technology on ships. This project will be another big step towards Alfa Laval´s decarbonisation roadmap.

Alfa Laval is proud to partner up with the Global Centre for Maritime Decarbonisation (GCMD), the Oil and Gas Climate Initiative (OGCI), Stena Bulk, and other leading players from the energy and shipping industries, to

initiate a two-year project to demonstrate shipboard carbon capture at scale. Project ReMarCCAbLE (Realising Maritime Carbon Capture to demonstrate the Ability to Lower Emissions) is the world’s frst project aimed at demonstrating end-to-end shipboard carbon capture at scale. The seven-member consortium will test a carbon capture unit onboard a Stena Bulk MR tanker to assess the operational challenges on a ship at sea and identify potential cost reduction measures for future commercial applications. The success of project ReMarCCAbLE has the

potential to accelerate commercial deployment of shipboard carbon capture technology by 2026.

Professor Lynn Loo, CEO of GCMD, says, “GCMD is proud to convene a strong group of stakeholders to pilot one of the mid-term solutions needed to help the maritime sector to decarbonize. Project ReMarCCAbLE is in line with GCMD’s goals of lowering the barriers for adoption so international shipping can meet or exceed the International Maritime Organization’s (IMO) GHG emissions reduction targets for 2030 and

“Since the production of zero-carbon fuels to scale will take some time, we see carbon capture coupled with low carbon fuels as one of the potential pathways to help the shipping industry navigate to a net zero future.”

2050. We look forward to tapping on Alfa Laval’s expertise in this domain to enable the pilot.”

Project REMARCCABLE comprises three phases and is inspired by a feasibility study that was carried out and completed by TNO on behalf of OGCI and Stena Bulk in November 2021. The frst phase involves conceptual design and front-end engineering design study (FEED) of the carbon capture system; this study is ongoing and is expected to be completed in the frst quarter of 2023. Following the successful completion of phase one, and once consortium partners provide their backing, a second phase encompassing the engineering, procurement, and construction (EPC) of a prototype shipboard carbon capture system, including onshore commissioning, will be initiated.

Phase three will focus on integrating the carbon capture system with the identifed MR tanker and conducting sea trials. Concurrently, GCMD will be issuing an Invitation for Proposal (IFP) to study the challenges and address the needs to operationalise ofoading of LCO2. The fndings from the ofoading study will inform the pilot in phase three of Project REMARCCABLE. The transition from one to each subsequent phase of the project will be governed by a rigorous gated review of key performance metrics.

Alfa Laval has been part of carbon capture testing projects and studies in the past, and project ReMarCCAbLE will help in expanding its knowledge further in this feld. By being part of this prestigious project, Alfa Laval aims at exploring the potential of the technology to meet decarbonisation goals, assess the validity of the technical assumptions made during the feasibility study done by the consortium, and analyse the integration and operation challenges of ftting and running the technology while sailing.

Sameer Kalra, President of the Marine Division at Alfa Laval says, “Since the production of zero-carbon fuels to scale will take some time, we see carbon capture coupled with low carbon fuels

as one of the potential pathways to help the shipping industry navigate to a net zero future. This partnership is therefore an excellent opportunity towards developing such a solution. We want to evaluate the commercial and environmental implications as well as identify the challenges and opportunities in the implementation of a carbon capture system on board a vessel. The fndings will help in the development of the technology at scale.”

Project ReMarCCAbLE is one of many Alfa Laval projects with sustainability in focus. By leveraging its technical knowhow in thermal management and emission-reducing technology, Alfa Laval will play a vital role in facilitating this project for carbon capture on board. The project is divided into three phases. Right from the frst phase of the project, Alfa Laval will be a key contributor in designing, engineering, testing and installing the solution on board the MR tanker. Not only will Alfa Laval support the project with its technological experience in this feld, but it will also make Alfa Laval Test and Training Centre available for testing the carbon capture installation and to provide training to the crew before it is installed on a ship.

“For us, it is about being right at the forefront in the evolution of new sustainable technologies and supporting

their development into an environmental and economically viable solution that can beneft our customers,” says Mr Kalra. “Decarbonising the marine industry demands a wide range of emission-reducing technologies in addition to shifting towards green fuels. We want to facilitate the development of such technologies and help reduce vessels’ carbon footprint.”

Stena Bulk’s participation in the consortium of the seven organisations will help guide the technical design and integration of the system onboard, as well as help evaluate the operational and commercial opportunities and challenges when capturing CO2 at sea.

Erik Hånell, President & CEO of Stena Bulk, comments, “We are constantly working to push sustainability and technology boundaries to drive our industry forward. By participating in this initiative and collaborating with our consortium partners, we hope to step closer to making carbon capture a reality for the global feet. We are eager to see and share the results of this project as they unfold over the next couple of years.”

i. alfalaval.com i. stenabulk.com i. gcformd.org

Cimolai Technology is a worldwide, leading company that provides special and innovative solutions for handling and lifting purposes since 2004. The company’s lengthy experience and valuable expertise enable it to be at the forefront of the special equipment feld. It aims at studying and designing the best tailor-made solutions so as to be a key partner in its customers’ challenges and projects.

The company’s main facilities are based in the Northeast of Italy, in Carmignano di Brenta (PD) where the machines are designed, developed and assembled and in San Quirino (PN) where all the machines’ structures and mechanisms are produced.

Cimolai Technology designs and manufactures special equipment to be used in diferent sectors, mostly in shipbuilding, shipyards, marinas and ports; but also for civil works in precast yards, in industries, steel mills and

renewable energy felds, for special and innovative equipment when tailor-made solutions are required.

For the Shipbuilding, the fagship of Cimolai Technology are the selfpropelled portal cranes on tyres. For Fincantieri, the company has supplied two units with a capacity of 1,000t each, which are used for the manufacturing and the setting up of cruise boats. Each of the two units has a span of 60m, a height of 60m and four independent

lifting points so as to lift ship blocks up to 1,000t and turn elements up to 500t. The two portal cranes travel on 64 tyres and are provided with Diesel engines that supply a total power of 1,600Hp. The control of the machines is managed by remote control and the system is assisted by GPS. The equipment is also provided with a tele-system which allows for the supervision from a remote workstation.

Cimolai Technology Spa can also supply solutions on rails, such as lufng and

goliath cranes, that are used to manufacture ships, as the goliath crane supplied for Cantiere Navale Visentini at Porto Viro (RO). The crane with a capacity of 320t is equipped with two independent hooks that allow combined manoeuvres at max loads, aimed to facilitate the operations of lifting, turning and positioning of ship blocks.

Moreover, the company has recently installed four lufng cranes for Vard Braila SA in Romania, each of them with a capacity of 100t at 30m, and a lufng crane in San Giorgio del Porto in Italy, with a capacity of 30t at 20m.

Cimolai Technology Spa is delivering 23 lufng cranes that will be installed at the IMI Shipyard located at the King Salman International Complex in Saudi Arabia. The shipment will be fnalised by March 2023 and required almost 1,000 containers to stow the crane parts.

Regarding the lifting and transportation operation in the Shipbuilding industry,

Cimolai Technology has implemented the range of its products with the manufacture of the frst CIMOLIFT, a ship lifting platform of 19m x 95m having a capacity of 3,300t, which has been installed in Palumbo Superyachts Shipyard in Ancona. The CIMOLIFT has been completely developed, designed and manufactured by Cimolai Technology which has also taken care of the on-site installation of the whole system.

The wide range of Cimolai Technology Spa’s products also includes selfpropelled modular trailers SPMT and rail transfer systems to support the ship lifting platform or to be used independently to perform the transportation and parking operations of the vessels within the shipyards.

For the shipbuilding and the reft yards, Cimolai Technology has recently supplied a Mobile Boat Hoist 1500 in Mauritius – which is actually the biggest unit in the world. Moreover, by the end of next year, the company will supply another unit with a capacity of 1,500t to Hyak Maritime in Oregon, USA. This machine will be fully electric, showing once again the Veneto-based company’s innovative capacity and its orientation towards environmentally friendly and sustainable products meeting the market needs.

The know-how of the company and the commitment to always produce more and better allow Cimolai Technology to be a worldwide ideal partner for the supply of lifting and transportation of equipment for the shipbuilding industry.

i. cimolaitechnology.com

The know-how of the company and the commitment to always produce more and better allow Cimolai Technology to be a worldwide ideal partner for the supply of lifting and transportation of equipment for the shipbuilding industry.

Kooiman Marine Group is an independent group of multidisciplinary shipbuilders with a huge capacity for problem solving. Technical expertise and an eye for quality form the basis for ships made precisely to size.

With their entrepreneurial spirit, Kooiman Marine Group eagerly responds to new technologies and developments. The company continually invests in product innovation and engineering as they strive for satisfed repeat customers, and to deliver progressive and distinctive value to the maritime sector.

The model patrol vessel that Kooiman Marine Group has designed, developed, and built is at the top of this specifc

market segment. This battery hybrid powered, aluminium ship has been developed completely customer-specifc and meets the highest-class requirements. With the completions of this energy-efcient patrol vessel from Kooiman Marine Group, a new standard has been set in the market.

The recently delivered POA1 and POA2, two hybrid patrol vessels built by Kooiman Marine Group for the Port of Antwerp Bruges are a further development after the RPA-8, which was delivered in 2018. So far, patrol activities were carried out from shore at the Port of Antwerp-Bruges, but due to a change in work activities, the port decided to purchase these two patrol ships.

The Port Authority Ofcers on board the POA 1 and 2 are responsible for specifc control tasks in the framework of supervision and enforcement in the port area. In the event of incidents, they work together with emergency services. This is how Port of Antwerp ensures safety and smooth trafc in the port of Antwerp.

The underwater hull of the patrol vessels is a Fast Displacement Hull Form which, together with the Hull Vane®, both developed by Van Oossanen Naval architects, ensures very low resistance and very low wave generation during sailing.

As an energy source, in addition to diesel, it is also possible to add electrical power directly via an electric motor mounted around the propeller shaft.

1 and 2 interior.

This electrical power can be generated by a diesel engine or from a battery pack. In the latter way, you can sail emission-free at patrol sailing speed for up to 2.5 hours.

The wheelhouse is equipped with air suspension, which, together with other measures, greatly reduces the noise in the wheelhouse. In addition, a lot of attention was paid to ergonomics with these ships.

Both vessels are equipped with Kooiman Marine Diagnostics, a user-friendly innovative data platform in which all ship data can be collected, stored and made accessible. Herewith the status and performance of the vessel can be monitored and analysed, from the ofce

or any location in the world. This can be for example analysing for savings of fuel consumption, or analysis for optimising of sailing profles, or monitoring of maintenance needs.

Length overall 25.0m

Beam 5.4m

Depth mld 3.1m

Draught 1.40m

Class Bureau Veritas Max speed 33km/h

Crew 3 persons

Propulsion 2x 405kW each i. kooimanmarinegroup.com

Knowing the right way to navigate has been essential to maritime activities since mankind’s earliest days on the sea. In the days of the Vikings, it was the ancient sun stone that provided this ultimate guidance and insight for waters across the globe. When placed in a direct line with the presence of sunlight, the stone would glow brightly. Even on an overcast day with the sun visually obscured by clouds, rain, or snow, the stone would light up when pointed in the direction of the sun, identifying a ship’s course.

Today, with decades of expertise and hands-on experience, SunStone operates the world’s largest feet of expedition vessels available on charter. SunStone is NOT a cruise company, but a provider of tonnage to cruise companies, tour operators, and travel companies around the world. With the new building series, Infnity delivered between 2019 and 2023, and Boundless to be delivered from 2025, SunStone will stay in front in the development of the expedition and small ship cruise tonnage.

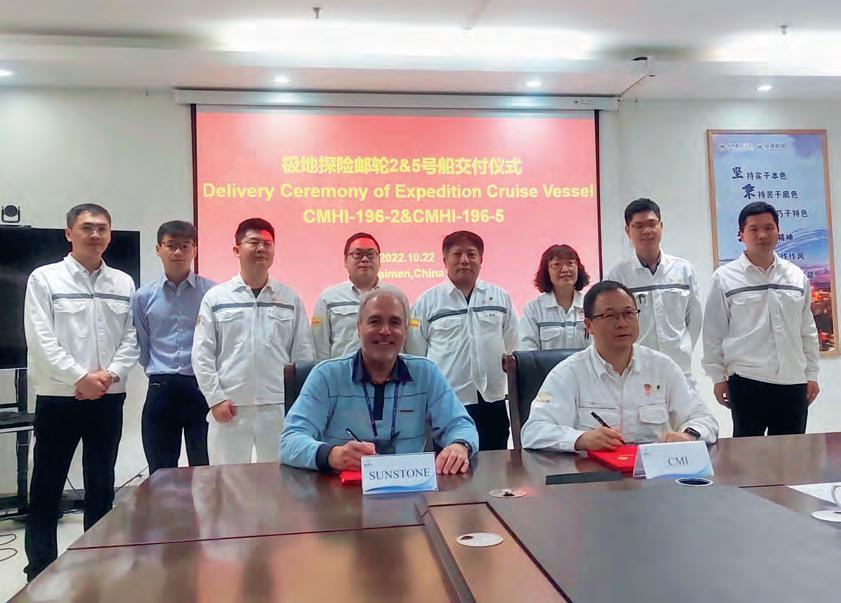

The fnal documents were signed on 21 October for the Ocean Odyssey and the Sylvia Earle, completing delivery of the two vessels from the CMHI Shipyard in Haimen, China to the SunStone companies. They will now begin repositioning before going on long-term charters.

The Sylvia Earle and the Ocean Odyssey are vessels four and fve being delivered in the Infnity series being built at China Merchant Heavy Industries in Haimen,

China. Both vessels will be on long-term, year-round charter – the Sylvia Earle with Aurora Expeditions, and the Ocean Odyssey with Vantage Deluxe World Travel.

The Infnity series is the product of a unique collaboration between European design and technology and Chinese shipbuilding efciency resulting in an expedition cruise vessel with best-inclass safety and comfort features, and high operating efciency. For two consecutive years, Infnity series have been awarded the Magellan Awards Gold Medal. In 2021 Albatros Travel won the gold medal Overall-Eco-Friendly “Green” Cruise Ship for the Ocean Victory, and in 2022 Aurora Expeditions for the gold medal Overall-Eco-Friendly ‘Sustainable’ Cruise Ship for the Greg Mortimer. Infnity Class Vessels are 104m long, and 18m wide, having a draught of 5.1m. Delivery

Sylvia Earle

Vessel type

Cruise Design Cx103

Built by China Merchants Heavy Industry (CMHI), China

Year 2021

Owned by Sunstone Ships

Designed by Ulstein Design & Solutions

Operated by Aurora Expeditions

Length 104.4m

Beam 18.4m

Draught (max) 5.3m

Speed (max) 15.5kn

Accommodation 144 PAX

Accommodation 249 POB

Ocean Odyssey

Vessel type Cruise Design Cx103

Built by China Merchants Heavy Industry (CMHI), China

Year 2021

Owned by Sunstone Ships

Designed by Ulstein Design & Solutions

Operated byVantage Cruise Line

Length 104.4 m

Beam 18.4 m

Speed (max) 15.5 kn

Accommodation 165 PAX

Accommodation 300 POB

They feature a passenger capacity between 130-200 and a crew capacity between 85 and 115. The Vessels are Ice Class 1A, Polar Code 6 and are being built with Safe Return to Port, Dynamic Positioning and zero speed stabilizers. The Vessels are featuring the X-Bow® by Ulstein Design & Solutions. They are small enough to give an exclusive atmosphere and yet large enough to yield all expected services and facilities such as a swimming pool, bar and restaurants, lounges, boutique, gym, spa, and sauna.

Five Infnity Class new-builds, the Greg Mortimer, the Ocean Explorer, the Ocean

victory, the Sylvia Earle and the Ocean Odyssey have now been delivered, and the next vessel Ocean Albatros will be delivered in March 2023. All vessels ordered have long-term charter agreements in place.

history, and stately lounge and deck areas for taking in the views. Thanks to the ship’s revolutionary bow design, seasickness is also likely to be less of an issue.”

i. sunstoneships.com

review of the vessel

According to Aurora Expeditions, “In addition to excursions for hiking and honing wildlife photography skills, there’s plenty to do onboard the Sylvia Earle, which features state-of-the-art perks like an ocean-view sauna, a quiet library for reading up on Antarctic

Liebherr’s range of mobile harbour cranes (LHM) are extremely versatile, making them an universal all-rounder. The LHM is a key asset for handling all types of cargo from containers to bulk commodities, general cargo, and even heavy lifts up to 308t at 18m outreach and up to 100t at 47m outreach. The product range covers all vessel sizes up to megamax and capesize.

Recently, two LHM 420 and one LHM 550 have been shipped to Noatum Terminals in the West Mediterranean. The three LHM models are joining an LHM 420 that was deployed earlier in the year and is operating at Noatum Terminal Sagunto. With the fexibility to handle bulk, containers, project cargo, and more, Liebherr’s LHM mobile harbour cranes are among the most popular in the portfolio due to their adaptability in handling the most common cargo types at port terminals

The frst crane arrived on 5 January 2022. Three new Liebherr mobile harbour cranes are joining the feet at Noatum port terminals in Castellon,

Sagunto, and Tarragona. The cranes will enable the terminals to improve their handling efciency for various cargo types.

Boarding the Heavy Load Carrier MERI in the morning hours of 5 September, three Liebherr mobile harbour cranes were prepared for their journey to Spain. Three terminals operated by the Spanish company will beneft from the performance of the LHM 420 and LHM 550 models.

Port terminals operated by Noatum support a variety of commodities around

“Liebherr is pleased to contribute to our customers’ strategic value to provide continuous improvements. For our Spanish client Noatum, this includes supporting them in their aim to reduce their overall environmental footprint while still meeting the demands of increased global cargo trafc both in terms of volume and mass.”

their global supply chain. Agricultural goods, minerals in bulk, steel, project cargo and containers, and more are all part of their logistic network. With their carrying capacity of 124t and 144t, respectively, the LHM 420 and LHM 550 can lift and handle a variety of cargo.

Liebherr mobile harbour cranes ofer efective solutions for reduced energy consumption while improving cargo handling productivity. This is in part achieved by Liebherr’s proprietary hydrostatic drive, in which closed hydraulic loops are used for all main functions such as lifting, turning, and lufng. The hydrostatic drive allows the operator extremely precise control. Additionally, service personnel beneft from a minimum number of components, and the operating company benefts from reduced fuel consumption.

Maritime Cranes in Liebherr Ibérica, remarks, “Liebherr is pleased to contribute to our customers’ strategic value to provide continuous improvements. For our Spanish client Noatum, this includes supporting them in their aim to reduce their overall environmental footprint while still meeting the demands of increased global cargo trafc both in terms of volume and mass. The LHM 420 and LHM 550 meet their specifc tonnage and diverse cargo needs at their Castellon, Sagunto and Tarragona terminals. With the LHM 420 model alone, they anticipate an improvement in productivity of up to 38 containers per hour.”

i. liebherr.com

Liebherr mobile harbour cranes ofer efective solutions for reduced energy consumption while improving cargo handling productivity.

Mr Marsh joins the Board of Directors with over ffteen years of experience in the maritime industry and over 30 years working in senior positions within various businesses. Most recently, Mr Marsh held the position of CEO at Lloyd’s Register, where he was integral to the development and execution of the corporate strategy, with a particular focus on growth, digital transformation and customer interaction. Mr Marsh is a graduate in Business Studies & Accounting from The University of Edinburgh and studied at The Wharton Business School. He is a qualifed chartered accountant.

Hamilton Marine International has named David Ross as CEO of its emerging US Division. Former Owner, President and CEO of Burger Boat Company, CEO of Yachtzoo LLC and VP Superyachts for Reel Deal Yachts, Mr Ross brings 30 years’ coal-face experience to the table, as well as a shared commitment to providing reliable, trustworthy yacht consulting services. Born in Regensburg, Germany, but growing up in Chicago, on the shores of Lake Michigan, Mr Ross served in the US Marine Corps before founding a photographic business which grew to more than 200 employees.

Lisa Edvardsen Haugan has recently been appointed as the new President of Kongsberg Maritime, the largest business area of Kongsberg. She takes the helm after Egil Haugsdal. Ms Edvardsen Haugan has long and extensive experience from both the defence and civil business area in Kongsberg Gruppen (Kongsberg), including having been EVP Finance at Kongsberg Maritime and Finance Director at Kongsberg Protech Systems. She currently heads the Deck Machinery & Motion Control division of Kongsberg Maritime.

Dr Jörg Stratmann has been appointed as CEO of Rolls-Royce Power Systems AG, a Rolls-Royce business unit. Mr Stratmann will join Rolls-Royce on 15 November 2022 reporting to CEO Warren East as part of the wider Executive Team.

Separately, Dr Andreas Strecker will join Power Systems as Chief Financial Ofcer from 1 December 2022. Mr Stratmann, who holds a doctorate in industrial engineering, was most recently CEO and chairman of the executive board of the automotive

Vetus, the global innovation company for complete marine product systems, has appointed Daniele Torretta as Sales Manager for Northern Italy in a move that will enable the company to be even more pro-active with original equipment manufacturers and key clients in this key market. Most recently, Mr Torretta was Sales Manager in the Marine Pleasure Yacht Sector Italy for Twin Disc, and earlier, Mr Torretta worked as Senior Sales Manager for RTN.

Diesel outboard engine specialist Cox Marine has announced the appointment of marine industry specialist Harry Heasman as its Sales Director for EMEA. The new regional position strengthens the company’s focus on wholesale activity within EMEA as it builds a global sales structure capable of responding to growing demand for the high-performance CXO300 diesel outboard engine. Bringing over a decade of experience working with some of the industry’s most prestigious brands to his new role at Cox Marine, Mr Haesman has been immersed in the UK sailing scene from a young age and now cruises in the Solent on both power and sail vessels.

Swan Hellenic announced that Patrizia Iantorno has been appointed VP of Global Marketing to take the newly-revived cultural expedition cruise pioneer into its next phase of growth and beyond, consolidating its position as the leading innovator in this unique sector. Ms Ian torno is reporting directly to Alfredo Spa don, Swan Hellenic’s Senior Vice President of Global Sales and Marketing. Respected for developing powerful integrated strategies that blend traditional high-end brand and service approaches with data-based digital marketing innovations, She has an enviable reputation for generating strong results.

supplier Mahle. In this role, he signifcantly expanded the business outside the area of combustion engines towards customised solutions for e-mobility and successfully developed new business opportunities based on sustainable technologies for global markets. Mr Strecker has extensive experience in the fnancial management of international corporations, primarily in the automotive and industrial sectors. Most recently, he was President Europe & Asia at Accuride Wheels.

ANCOFERWALDRAM STEELPLATES BV

P.O. Box 190 4900 AD Oosterhout

The Netherlands

T +31 (0)162 491500

F +31 (0)162 429806

E sales@aws.dillinger.biz

I www.ancoferwaldram.com

Over 100,000 tons of quality heavy steel plates in stock

AncoferWaldram Steelplates B.V (AWS) is a stockholding wholesaler and steel service center, specializing in the supply of hot-rolled heavy carbon steel (quarto) plates, and profled parts for more than 40 years now. Over the years, AWS has developed into a business that sets the standard for its industry.

Plates from stock or profled parts The choice is yours! It is the combination of comprehensive stocks of over 100,000 tons of heavy carbon steel plates plus the sophisticated profling plant that gives AWS a decisive lead in experience, product range and customer service.

BACHMANN ELECTRONIC GMBH

Offce Veenendaal: Vendelier 65-69 3905 PD Veenendaal

The Netherlands

T +31 (0)85 210 0550

E r.epskamp@bachmann.info

I www.bachmann.info

Contact: R. Epskamp

Bachmann hardware matches the harsh conditions in the maritime and offshore industry. We take pride of extremely high availability using stateof-the-art technologies.

Integration of AMS, PMS, CMS, etc. in a Redundant solution is realized with our modular and marine certifed PLCbased product range.

The group of companies includes the CMS specialist Bachmann Monitoring and Certec EDV, the developers of the 1st fully web enabled SCADA software atvise®

direct connection to the international ports. High quality is one of our most important standards!

ART4 TECHNICAL SYSTEMS BV

Nieuwegracht 9-11 3763 LP Soest

The Netherlands

T +31 (0)35 582 2468

F +31 (0)35 642 4860

E Info@art4.nl

I www.art4.nl

Contact: Mr Paul Schraven

Art4 Technical Systems BV is an independent Dutch company. We design, build and deliver fully turnkey solutions for hydraulic and electrical systems for customers worldwide. Our clients use the hydraulic and electrical systems for various end products such as:Mobile drives, transport conveyers, winch drivers, jack up platforms, cranes, both onshore and off shore, a-frames, special equipment, fairground attractions.The systems can be custom built to ft the specifcations of the product they are used for.

BREMAN MACHINERY B.V.

Sasdijk 20 8281 BM Genemuiden

The Netherlands P.O. Box 135 8280 AC Genemuiden

The Netherlands

T +31 (0)88-27 36 200

E info@breman-machinery.nl

I www.breman-machiner y.nl

Great challenges need sophisticated solutions, the work of a specialist.

Breman Machinery fabricates critical steel components with exceptional dimensions and extreme accuracy. This is the daily job of our craftsmen. Through our unique capabilities regarding machining, welding, conservation and assembling we serve our customers to make their ambitions reality.

The welders of high-quality steel are qualifed by Lloyd’s Register or DNV for all welding positions. With 30 milling, boring and turning machines we have the possibility to offer unique services. Our preservation department can protect your projects. Our location is beside open water, we have a

EMIGREEN B.V.

Noordeinde 19 3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317 F +31 (0)184 415 582

E info@emigreen.eu I www.emigreen.eu

Contact: Niko J. Dalpis

Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector. Emigreen also provides services including design, specifcation, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, fow dynamics, thermodynamics and noise and vibration control. Emigreen develops and tests components including catalytic converters, particulate flters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot flter system has set the standard for others to beat. All Emigreen solutions are highly effcient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht.

Emigreen links science and the market

air duct cleaning. Founded in 1965, the company is renowned for being an innovator in the design, engineering and installation of customised solutions. We work in four specialist areas: Superyachts. Commercial shipping. Offshore industry. Navy vessels. Our mission is to ensure that the climate ‘indoors’ will perfectly meet the needs of people and products alike, whatever the weather outside. Heinen & Hopman offers a worldwide, 24/7 service via a network of subsidiaries and sales centres.

KLAY INSTRUMENTS B.V.

P.O. Box 13 7990 AA Dwingeloo

The Netherlands

T +31 (0)521 591 550 E info@klay.nl I www.klay.nl

Klay Instruments is a Dutch manufacturer of ‘All Stainless Steel’ Pressure- and Level transmitters for the Marine & shipbuilding. All our transmitters are ATEX and IECEx Ex ia certifed and have fve different Marine Type Approvals.

Our Pressure transmitters are available in threaded and Flanged process connections with fush diaphragm for all pressure applications.

The available accuracies are 0.2% (series 8000) or 0.1% (series 2000). For Level measurement we manufacture Compact transmitters (series 8000 and 2000) and submersible level transmitters (series Hydrobar).

Typical applications: Ballast Level

Oil / HFO and (waste) water level

Manifold pressure

HEINEN &

Produktieweg 12

3751 LN Spakenburg

The Netherlands

T +31 (0)33 299 25 00

F +31 (0)33 299 25 99

E pr@heinenhopman.com

I www.heinenhopman.com

Contact: J.W.E. Hopman Heinen & Hopman Engineering is a world leader in air conditioning, mechanical ventilation,central heating, refrigeration, sanitary systems, fre protection, environmental systems and

More than 30 years experience in the Marine and shipbuilding industry!

MEN TECHNIEK BV

Caïrostraat 55 3047 BB Rotterdam

The Netherlands

T +31 (0)10 820 8717 E info@mentechniek.nl

I www.mentechniek.nl

Contact: Lucien Tuinfort

Safety, quality and innovative entrepreneurship. Men Techniek BV is a company with a very broad feld of activities. We are specialised in general repair on and offsite and have a lot of experience in welding, fre work and mechanical and electrical work. We can also offer a full NDT examination.

Repairs and adjustments of propellers are done with the same care as new buildings. Piening Propellers scope of supply includes:

Propellers FPP > 800mm Ø CPP > 1.100mm Ø

Shafts up to a several length of 16,000mm

Sterntubes with sealings and bearings Shaft brackets complete Gearboxes Brand ZF

a lot, and it will bring substantial savings! With two state-of-the-art machines, we offer a huge range, superb accuracy, and great effciency. Round tubes up to Ø 2,500mm OD, with thicknesses of up to 150mm (oxyfuel and plasma), and robot cutting of beams and sections up to 1,200mm wide, plate up to 1,200mm wide and 3,000mm long. Fast, accurate, and cost effective.

a complete in-house service package which includes 3D design, engineering, testing, manufacturing, assembly, project management, support & logistic services.

Algerastraat 20

3125 BS Schiedam

The Netherlands

T +31 (0)10 238 0999

F +31 (0)10 238 0988

E info@nicoverken.nl

I www.nicoverken.nl

Contact: Jacco Vermunt

Distributor, 24/7 service & spare parts agent of marine equipment.

In our programme there are stainless steel marine pipes and drains, fltration, anti-fouling & cathodic protection, reverse osmosis desalinators (water makers), wastewater treatment, vacuum sanitary systems for yachts, deck equipment (doors & hatches) and watertight sliding door systems.

Our Ship Repair department is specialised in the overhaul of all types of main and auxiliary engines, including attachments i.e. governors, turbochargers, fuel equipment and the sales of spare parts and engines. We are capable of crankshaft grinding. Our service is 24/7 worldwide!

De Ruyterstraat 62 4335 GN Middelburg

The Netherlands

T +31 (0)6 190 358 20 E info@rbimarineconsultancy.com I www.rbimarineconsultancy.com

Contact: Ruud Bimmel

RBi Marine Consultancy provides full-service 24/7 worldwide. This is the core of our business. We advise, manage and carry out projects with expertise and experience; a result of years in supporting the Marine industry both locally and internationally. Our business conduct inspection, surveying, new-build, repairs, refurbishment, regular maintenance, feet management, site management, owner representative, and of course project management. Our network contains more than just that. Together with established partners we provide delivery of genuine marine parts, blasting and painting, welders, ftters and sorts of craftsmen. For more details please call us or view our website.

SUHBO INDUSTRIAL CO., LTD. 6, Mipyeong-ro, 106 beon-gil, Wonsam-Myeon, Cheoin-gu, Yongin-si, Kyunggi-do, Korea

T +82 31 334 6979

F +82 31 334 1789

M +82 10 4999 6979 (Korea), +61 434 509 501 (Australia)

E joeykim@suhbo.co.kr

I www.suhbo.co.kr

Contact: Joey Kim, Export Sales Manager

Established in 1985, Suhbo Industrial Co., Ltd is the major leading Korean manufacturer and supplier of high performance roundsling for heavy & shipping building industries. We have been supplying high performance roundslings to major heavy industries companies and projects in Korea and Asia.

Our Suprime roundsling with Ultrapowerful Poly Arylate fber is highly recognized from many customers due to its excellent performance, the maximum lightening, the optimum handing effciency (slim in size) and optional functions such as anti-cutting, anti-fame and multi-checking.

G.J.WORTELBOER JR. B.V.

Quarantaineweg 5 3089 KP Rotterdam

P.O. Box 5003 3008 AA Rotterdam

Harbournr: 2637 – The Netherlands

T +31 (0)10 429 2222

F +31 (0)10 429 6459

E info@wortelboer.nl

I www.wortelboer.nl

Every now and then anchors and chains must be replaced, so we understand your need for quality and speedy delivery. Wortelboer has what you are looking for. Our enormous stock of anchors and chain cables of all sizes and diameters in both our Rotterdam and China ports gives you the certainty that we can deliver the required materials very quickly and to any port in the world! All our materials are approved by any of the well-known class societies such as LRS, BV, RINA, DNV/GL, ABS and RMRS.

Do you have problems with fnding the right anchors? Could you use a hand while ftting anchors and chain cables aboard your vessel? We are more than happy to help you with it. Wortelboer has been a reliable partner in the shipping industry for more than 50 years. And that is why our customers keep coming back for more.

Do you need anchors and chain cables? Come to WORTELBOER.

Am Altendeich 83

D-25348 Glueckstadt

Germany

T +49 4124 9168-0

F +49 4124 3716

E pein@piening-propeller.de

I piening-propeller.de

Contact: Mathias Pein

Noise reduction relies upon the quiet operation of a yacht´s propulsion system. Piening Propeller fulfls its briefs in:

Consideration of all hydrodynamic aspects during the design and an accurate manufacturing of propellers and shafts according to highest ISO classes.The company is approved by all common classifcation societies.

SSC STEEL SHAPE CUTTERS BV

‘s-Gravendeelsedijk 200 3316 AZ Dordrecht

The Netherlands

T +31 (0)85 760 3226

E staat@ssc.nl

I www.steelshapecutters.nl

Contact: Peter Staat

SSC Steel Shape Cutters BV is a new, competent provider of 3D-profling: computer-controlled machine cutting of tubes, beams, hollow sections and plate. Subcontracting does not have to cost

WINEL B.V.

P.O. Box 70, 9400 AB Assen

The Netherlands

T +31 (0)592 366 060

F +31 (0)592 312 392

E sales@winel.nl

I www.winel.nl

Contact: Bert Knijp

Since its foundation in 1956, Winel has grown into a leading global supplier of high quality products and services tot the world’s maritime industry. An experienced team of specialists offer a wide range of doors, hatches, platforms, tank venting systems and special engineered products. Winel’s strength is offering

We have already started preparing our upcoming issues of ShipBuilding Industry. Below, you will fnd some of the main topics we are planning to cover. Please feel free to provide our editorial staf with any relevant information, so they can take your input into consideration for publication. Our commercial department will be happy to assist you with your marketing needs.

Reft & conversions

Marine propulsion & power generation Cruise vessels / river cruise vessels

Focus on Germany

Copy deadline | 11 January 2023

Advertisement deadline | 01 February 2023 Release date | 07 March 2023

COLOPHON

COMMERCIAL DEPARTMENT

MARCO GEELS | Director marco@ynfpublishers.com ROB DE KERF | Account Manager rob@ynfpublishers.com

EDITORS

ARNO DIRKZWAGER arno@ynfpublishers.com DANIELA MARKOVIC daniela@ynfpublishers.com

NATHALIE PUTMAN | Art Director nathaliep@ynfpublishers.com

SUBSCRIPTIONS

To subscribe, send an email to subscribe@ynfpublishers.com. Subscriptions will be automatically renewed unless written cancellation is given three months prior to expiry date. Annual subsciption is EUR 110

Nor-Shipping 2023

Ship design & naval architecture Focus on Northern Europe Workboats & tugs Deck equipment & machinery

Copy deadline | 07 March 2023

Advertisement deadline | 28 March 2023 Release date | 02 May 2023

Subjects can be changed without prior notice.

ShipBuilding Industry is owned and published by Yellow & Finch Publishers.

The publisher, authors and contributors reserve their rights in regards to copyright of their work. No part of this work covered by the copyright may be reproduced or copied in any form or by any means without the written consent of the publisher. No person, organisation or party should rely or on any way act upon any part of the contents of this publication whether that information is sourced from the website, magazine or related product without frst obtaining the advice of a fully qualifed person.