ShipBuilding industry

POSIDONIA 2024

SUSTAINABILITY TAKES CENTRE STAGE AT MARITIME EXHIBITION In the subsea domain FINCANTIERI AND SAIPEM JOIN FORCES IN SUBSEA ROBOTICS Lighting the way

Modular spreader beams up to 3,000t – Shackles up to 2,000t

Grommets & roundslings – ROV hooks & shackles

Cherry pickers – Telehandlers – Waterpumps – Generators

Waterbags – Testweights – Pontoons – Fenders – Gangways

Snatchblocks – Lifting frames – Multi lugs – Hoists – Swivels

Masterlinks – Hydraulics – Container spreaders – Light towers

LIFT EQUIPMENT

Safe Lifting Europe B.V. is aiming to become carbon neutral by having the largest rental fleet of heavy lift equipment, which guarantees sustainability and the fastest route in your quest, with any type of demands. Many of our clients have already optimised their business and have chosen Safe Lifting Europe B.V. for their special heavy lift equipment needs. Interested in learning how renting or leasing your heavy lift equipment can lead to more sustainability? Inform about the possibilities for short- and long-term rental or lease of our heavy lift equipment via rental@safelifting.eu.

EDITOR’S NOTE Safety in numbers

ShipBuilding

Other publications by Yellow & Finch Publishers:

In this issue of Shipbuilding Industry, we look at RV Wim Wolff for our ship report on page 16. The new national research vessel for the Netherlands is built by Thecla Bodewes Shipyards with the aim of providing Dutch coastal researchers with a versatile, modern and sustainable research vessel for decades to come.

We also swing by Huisman’s facilities to learn about the two subsea cranes the company is set to deliver for Toyo Construction’s cable-lay vessel. The full electric 250m hybrid boom subsea crane and 100m knuckle boom crane have been specially designed for the flourishing Japanese offshore wind industry (page 19). In Norway, we follow the progress of hybrid multi-purpose work boat, Mimmi, which is set to receive a Yanmar propulsion system with a seabed scanning echo sounder (page 29), while on page 42, we report on Damen’s new multipurpose support ship that is based on drone defence at sea.

We also learn about a new direction for smart networks and digital solutions company Marlink Now, which has installed a complete hybrid network solution on board a vessel for French expedition cruise company Exploris (page 40), and we follow Fincantieri and Saipem’s journey after the two joined forces in subsea robotics for surveillance and control of critical underwater infrastructure (page 22).

Within the world of workboats and tugs, Damen has been busy unveiling its new ASD Tug 1810 that is due to splash in February this year (page 26), while naval architecture and marine engineering company, Robert Allan Ltd., has successfully delivered the first of two 24.9m catamaran dive support vessels designed for Abu Dhabi National Oil Company in the UAE (page 34).

Our show preview on page 8 takes us to Athens for the international shipping exhibition, Posidonia 2024, while in Amsterdam, this year’s Electric & Hybrid Marine Expo and Conference is poised to deliver its most comprehensive gathering yet in June (page 33).

Finally, Kendrion and Lopolight bring focus to safety and security at sea with their door holding magnets and LED navigation lights, respectively on pages 12 and 38, both of which are designed to reduce onboard risk and address critical safety needs.

It’s a jam-packed issue that I hope you’ll agree is full of informative topics and engaging reads.

Julia Zaltzman – Editor INFO@YNFPUBLISHERS.COM

THE LOPOLIGHT IEC Ex/ATEX SOLUTION

has the exact same form factor as the regular Professional Series, the difference is in the manufacturing; the use of IEC Ex/ATEX certified components such as connectors, glands and grounding.

APPROVED

FOR BOTH IEC Ex/ATEX ZONE 1 AND 2

The Lopolight Professional EX Series is formally approved for use in IEC Ex/ATEX equipment group II, Category 2, Zone 1 - and therefore also Zone 2.

ShipBuilding Industry will bring readers an in-depth event preview and will have an extra distribution of the issue at the trade fair. This is a unique opportunity to put your brand in the right place at the right time. You can target your advertising to make the most of the show, before you even get there. Contact our sales team to make this happen.

In addition, if you have news related to SMM, or any other information you’d like to share, please send it to our editorial team.

COMPLETE SYSTEMS

From lights to monitoring and control, several options available. Proven solutions for both re-fits and new builds.

NEWS IN BRIEF

Damen to deliver two ASD Tugs to BOA Group

Damen Shipyards Group has signed a contract with Norway’s BOA Group for two ASD Tugs 3010 ICE. Due to Damen’s practice of constructing vessels in series for stock, the tugs were already under construction at the time of order and will be delivered later in 2024. BOA’s fleet consists of specialised offshore vessels, semi-submersible barges and harbour tugs. The order for the two Damen tugs is a part of the company’s strategic fleet renewal and aims at modernising the fleet while lowering fuel consumption. BOA’s CEO Ole Torberg Bjørnevik commented: “There are several advantages to reducing the fuel consumption of our vessels. For one, it lowers costs, which helps us become more competitive. Crucially, it also allows us to pursue our goals of increased sustainability.”

i. damen.com

ABB partners with Seaspan Shipyards

Technology leader in electrification and automation, ABB, has secured a comprehensive propulsion system contract with Seaspan’s Vancouver Shipyard for the first of the Canadian Coast Guard’s new-generation polar icebreakers. The icebreaker is expected to be the world’s largest and most powerful diesel-electric icebreaker when it enters service in 2030. Azipod propulsion has been selected to support the vessel’s operational efficiency, reliability and icebreaking capability, meeting the tightest emissions regulations. “ABB’s proven technology, along with their valuable insight, made them a natural fit for this project,” said Leo Martin, Senior Vice President of Programs at Seaspan Shipyards. “We have been pleased by the support and consultation Seaspan has received so far and look forward to more excellent collaboration moving forward.”

i. abb.com

AEGIR-Marine strengthens global coverage with a Greek office

In March, marine propulsion company AEGIR-Marine announced the acquisition of ABC Marine Services. The move follows 14 years of successful cooperation and will see the Greek sales agency incorporated into AEGIR-Marine’s global network of branch offices. The new office, which will be called AEGIR-Marine Hellas, will take over all operations and staff from ABC Marine Services, and represents the continuing provision of quality stern tube seal and propulsion system service in Greece. “Apostolos Athanassiou was the founder of AEGIR-Marine’s business in Greece,” said AEGIRMarine owner Ruud Muis. “It was his love of the maritime industry that built the strong foundations of our company there. We whole-heartedly thank him for his years of dedication to our customers in Greece, but most of all, his friendship.”

i. aegirmarine.com

JRC | Alphatron Marine introduces smart navigation system

With the future of smart ship navigation less about replacing humans and more about involving them in the process and providing support, leading marine electronics producer JRC | Alphatron Marine has introduced the AlphaRiverTrackPilot, a fully automated course and track control system for the inland shipping segment, allowing a ship to sail along a predefined line. Autonomous navigation systems are used to monitor and control the vessel’s performance and position. According to the manufacturer, in addition to potential safety benefits, autonomous navigation systems can also help reduce the need for manual labour in the navigation process, freeing up more time for other tasks, such as monitoring and control.

i. alphatronmarine.com

DeepSea Technologies partners with Ardmore Shipping to drive AI adoption

Maritime AI company and energy efficiency company, DeepSea Technologies, has partnered with Ardmore Shipping, a leading owner-operator of chemical and product tankers, with the aim of implementing its voyage optimisation tool, named Pythia, across Ardmore’s fleet. Pythia will enable AI-driven insights to help ship owners to meet their Energy Transition Plan (ETP) goals while driving business performance. The first year of the partnership involved a full-scale trial of the technology on Ardmore vessels, which enabled the two companies to refine a series of

algorithms powered by DeepSea’s AI-generated vessel behaviour models, coupled with Ardmore’s extensive historical data. This breakthrough allows an AI approach to be used within the context of tramp trade.

i. deepsea.ai

NEWS IN BRIEF

Kongsberg Maritime and EGGS win iF Design award

Kongsberg Maritime, a global leader in marine technology, and EGGS, a leading design consultancy, have been awarded a 2024 iF Design Award for their EcoAdvisor project, an intelligent decision support system aimed at optimising vessel operations to reduce fuel consumption and carbon footprint. The EcoAdvisor functions as a digital application used by a vessel’s captain, DP operator and chief engineer, with user interfaces located on the vessel’s bridge and engine room. Its innovative design facilitates a circular process, incorporating sensor utilisation to identify emission reduction opportunities, data analysis for optimising efficiency and safety, live feedback mechanisms to raise crew awareness on savings, and comprehensive reporting features to bridge communication between crew, managers and charterers.

i. kongsberg.com/maritime i. eggsdesign.com

Inmarsat Maritime and Aramco trial first over water 5G mesh network

Inmarsat Maritime, a Viasat company, has signed a Memorandum of Understanding (MoU) with Aramco, a global integrated energy and chemicals company, to undertake a 5G ‘mesh’ network trial that aims to provide high-bandwidth connectivity for Aramco’s offshore work in the Arabian Gulf. The technology is designed to provide high-speed communication capabilities while meeting the demands of the region’s climate – including extreme heat, sandstorms, wind and water evaporation – thanks to 5G’s improved reliability in challenging weather conditions. The MoU follows successful outdoor network testing in Rutland Water, UK, in February 2024, which demonstrated reliable and high throughput millimetre Wave (mmWave) signal propagation over water.

i. inmarsat.com

ASENAV selects MAN engines for 94m newbuild cruise ship

Chilean shipbuilder, ASENAV has ordered four MAN 6L21/31 Mk2 PLO GenSets for a newbuild 94m passenger cruise ship – the Magellan Discoverer – for Antarctica21, the world’s leading provider of air-cruises. Each GenSet will come integrated with MAN Energy Solutions’ proprietary LP-SCR (Low-Pressure Selective Catalytic Reduction) system that delivers NOx-reduction rates of up to 90% in fulfilling the latest IMO environmental requirements. The engines will be built at MAN Energy Solutions’ facility in Aurangabad, India where a highly compact RAMME PM (Permanent Magnet) alternator will also be integrated. Jaime Vásquez, President of Antarctica21, stated: “We are delighted to reaffirm our partnership with MAN Energy Solutions Chile by selecting the 21/31 Mk2 PLO engine for our new polar vessel. This engine sets the standard for the lowest fuel consumption in its category.”

Accelleron supports strong engine performance on new Makita twostroke engine

Accelleron, a global leader in turbocharging technologies and optimization solutions for engines, has been selected to supply turbochargers for Japanese engine builder Makita’s first smallbore twostroke marine engine featuring exhaust gas recirculation (EGR). The step follows a successful matching test in which Accelleron’s A255-L turbocharger demonstrated high efficiency, supporting both low NOx emissions and overall fuel consumption on the Makita-built MAN B&W 6G45ME-C9.7-EGRBP engine – the first of its type worldwide to feature EGR bypass. EGR bypass, which allows the engine to match EGR operation to engine load to deliver the required NOx emissions reduction, relies on good turbocharger efficiency, and the A255-L enabled the engine to reach Tier III NOx emissions limits with a relatively low power demand, contributing to better fuel consumption and therefore lower greenhouse gas emissions.

i. man-es.com

i. accelleron-industries.com

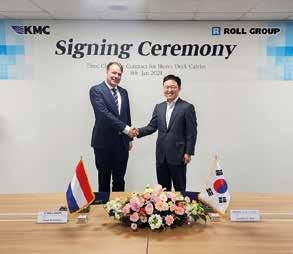

Roll Group and KMC Line sign contract for two wide deck carriers

Heavy transportation company, Roll Group, will be adding two vessels to its fleet from the global logistics company, KMC Line, commencing in the second half of 2025. The vessels will be renamed Bigroll KMC Beaumont and Bigroll KMC Busan. The collaboration stems from an MOU signed in June 2023. The addition of the two wide deck carriers will enable Roll Group to offer a larger fleet of 10 heavy transport project vessels, therefore allowing better scheduling, redundancy of risk, and higher flexibility for its clients. “This expansion is crucial to meeting increased demand from our clients and realising the company’s growth ambitions. We are grateful to KMC Line for making this expansion possible,” said Roll Group CEO, Peter Rondhuis.

i. roll-group.com

MAN 6L21/31 Mk2 PLO GenSet rendering with project-specific RAMME alternator.

Taking place on 3 - 7 June,

Posidonia 2024

Sustainability takes centre stage at international maritime exhibition

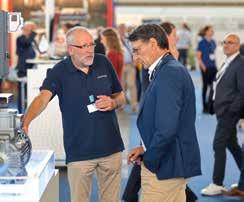

The international shipping exhibition, Posidonia 2024, promises to deliver insights into a new era for the maritime industry for the coming years, navigating geopolitical conflict, environmental regulations, and artificial intelligence (AI) emerging as a prominent player. The week-long event is organised under the auspices of the Ministry of Maritime Affairs & Insular Policy, the Hellenic Chamber of Shipping and the Union of Greek Shipowners and with the support of the Municipality of Piraeus and the Greek Shipping Cooperation Committee.

Taking place on 3-7 June, the show organisers predict the prestigious shipping exhibition is on track to be the biggest yet, with over 2,000 exhibitors and 40,000 visitors expected to converge in Athens’ Metropolitan Expo Centre. The international maritime community’s resilience in recent years and constant diversification is reflected by some 45 newcomers to Posidonia, who represent both software and hardware products, as well as government agencies from around the globe.

“The timing of this year’s Posidonia is perfect, as it will be held at a time when many parameters affecting shipping will have to be discussed and new initiatives will be launched,” says Theodore Vokos, managing director of Posidonia Exhibitions S.A.. “The past couple of years have been geopolitically challenging, with new crises erupting around the globe and shipping having to adapt to new challenges every six months. The wars in the Ukraine and Gaza, the temporary closure of the Red Sea passage, limitations to the Panama Canal, and other challenges have

the show organisers predict the prestigious shipping exhibition is on track to be the biggest yet.

affected planning and operations of the entire shipping industry.”

Meeting sustainability

Vokos also highlights that in addition to new regulations, the industry’s drive to meet sustainability demands has been the catalyst for new technologies, which will be showcased at the event. In addition, fuel options will be discussed as the industry rushes to meet new sustainability targets, including 2030 and 2050 environmental goals, and the decarbonisation of shipping will be on the radar more intensely than ever before.

“This interaction between policy makers and industry on the exhibition floor and the conference halls creates fruitful dialogue and creates the conditions which will allow shipping to become a sustainable industry,” he says.

Other sustainability topics on the agenda include route optimisation and weather prediction software services, sail rotors harnessing the power of wind, advanced hull coating systems and air lubrication reducing resistance and therefore fuel consumption, solar panels on ships, and engines running on alternative fuels or optimised to slow steam.

Forums and seminars

The extended Posidonia Conference and Seminars programme, including forums like the Tradewinds Shipowners Forum and the HELMEPA Conference, will address the most critical issues in the industry, while the Greener Shipping Summit, organised by Naftiliaki/Newsfront under the auspices of MARTECMA, the Marine Technical Managers Association, will bring a focus on evaluating new technologies and their potential use by shipping companies. As technology becomes mission critical, shipping companies have become early adopters and direct investors in new technologies, including the digitalisation of operations.

To help attract the younger generation to the shipping industry, this year’s event sees the launch of the Posidonia Masterclass in Shipping online course. Collaboration with the YES Forum (Young Executives in Shipping) platform and Isalos.net aims to introduce the next generation to the industry, showcase career opportunities, and nurture their interest in this dynamic sector.

Posidonia 2024

3 - 7th June 2024, Metropolitan Expo, Athens, Greece

Exhibition opening hours

Monday 3 June 18:30 to 21:00

Tuesday 4 June 10:30 to 19:00

Wednesday 5 June 10:30 to 19:00

Thursday 6 June 10:30 to 19:00

Friday 7 June 10:30 to 17:00

Over 2,000 exhibitors and 40,000 visitors expected to converge in Athens’ Metropolitan Expo Centre.

The extended Posidonia Conference will address the most critical issues in the industry.

BUILT TO PERFORM

Reliable

Posidonia’s growth is further propelled by the Posidonia Games, featuring events like the Posidonia Cup Sailing Race, Posidonia Running Event, Posidonia Shipsoccer Tournament, Posidonia Golf Tournament, and Posidonia 3x3 Basketball Tournament, providing abundant networking opportunities.

Artificial intelligence

Another topic earmarked for discussion at Posidonia is the transformative power of artificial intelligence (AI). Insights from key exhibitors promise to reveal a new landscape where industry leaders strategically align with the inexorable rise of AI and consider adopting it already. According to Vokos, demand for space from advanced technology and innovation companies providing services to the shipping industry has risen significantly for this summer’s edition of Posidonia.

“A comprehensive report on the future landscape of AI in the maritime sector, titled ‘Out of the Box’ and produced by Lloyd’s Register and maritime innovation consultancy Thetius, indicates that the market for AI-driven systems and vessel autonomy is anticipated to achieve a collective value of $5 billion by 2028,”

AI brings exciting possibilities to shipping by improving navigation, predictive maintenance and compliance, all of which will be showcased in Athens in June.

says Vokos. “According to the report, presently there are already 276 active companies identified in the maritime AI segment. The report underscores the significance of proactive investment by maritime organisations in enhancing their comprehension of AI across various levels. It recommends a strategic focus on workforce education and training initiatives to augment awareness of safety measures and regulations pertinent to advanced technologies within the maritime domain.”

The Posidonia 2024 week schedule

Event

Posidonia Cup Yacht Race

Posidonia Basketball Tournament

Posidonia Running Event

Posidonia Golf Tournament

Posidonia Shipsoccer Tournament

Posidonia 2024 Opening Ceremony

Posidonia 2024 Exhibition

The emphasis on data analysis and project development within maritime, including both the manufacturing and service sectors, reflects a keen awareness of AI’s potential to streamline processes and drive innovation. AI brings exciting possibilities to shipping by improving navigation, predictive maintenance and compliance, all of which will be showcased in Athens in June.

i. posidonia-events.com

Date & Venue

31 May 2024, Faliron Bay

1 June 2024, Eurohoops Dome, Kifissia

2 June 2024, Piraeus

2 June 2024, Glyfada Golf Course, Glyfada

2 June 2024, TBC

3 June 2024 (by invitation only)

3-7 June 2024, Metropolitan Expo

Demand from advanced technology and innovation companies providing services to the shipping industry has risen for 2024 Posidonia.

Lighting the way

With progress comes change, and that includes adapting all parameters. The advent of new fuels, such as methanol, requires increased scrutiny of existing onboard fire safety, particularly when considering more than 700 vessels in-build globally will be using methanol or similar alternative fuels soon.

Even out on deck, there are fire safety considerations and concerns. These

locations are categorised in zones in the ATEX or IEC ex classification. These zones are traditionally located around handling points for fuels and ventilation for tanks. With the regimen of the ‘new fuels’, exhausts are now also becoming ex zones.

Navigating fire safety

Ex zones are categorised into three zones, where in zone 2 there is a risk of the presence of flammable gases.

Lopolight navigates new onboard fire safety measures

ZONE 0 - CATEGORY 1

Zone 0 classifications for gases, vapours and mists are directly relevant to oil and gas platforms, drilling rigs and storage facilities

ZONE 1 – CATEGORY 2

Zone 1 is an area that is classified ‘as a place in which an Explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’.

ZONE 2 – CATEGORY 3

Zone 2 is a hazardous area classified as an atmosphere where a mixture of air and flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation, but if it does occur, will persist for a short period only.

Equipment for zone 2 can be selfdeclared to be intrinsically safe by manufacturers. Zone 1 is defined as locations where there is a high probability for the presence of flammable gases. Here, the demands for equipment to have official product certification and assembled under an approved management systems are high. Zone 1 equipment can also be used in zone 2. The last zone, zone 0, is inside the tank.

The number of vessels with an ATEX/IEC Ex zone is rapidly increasing. This includes the growing fleet of LNG tankers and the associated infrastructure, such as tugs, pilot boats, and service vessels. There are also hundreds of vessels currently in build that will use LNG, methanol, ammonia, and others – all with ATEX/IEC Ex zones. There’s also the additional need of oil rig signal and warning lights, which also require a no-compromise, robust and allencompassing light solution.

The expanding reach

One way to reduce onboard risk is to increase clear lines of sight and safety lighting. One example is the introduction of zone 1 Ex certified navigation lights. The location of onboard navigation lights leaves little room for flexibility. It is important that the vessel is displaying the correct lights, at the correct

positions, as described by the COLREGS to enhance safety at sea by lowering the risk for misunderstandings. Lopolight, which designs and manufactures LED navigation lights, control and monitoring systems and other functional lighting for use on vessels, is now offering a full range of Zone 1 ATEX and IEC certified LED navigation lights.

The first designs Lopolight brought to market 20 years ago — where the electronics of the lights was fully encapsulated in epoxy and power consumption was a tenth of the comparable incandescent lights — had scope to be safely used in areas where flammable gases could be present, says CTO and owner Peter Hancke. Once the

THE LOPOLIGHT ATEX/EX NAVIGATION LIGHTS CAN BE USED IN THESE ZONES!

company received its ISO 9001 quality management certification, which is a pre-requisite for any ATEX certification, it went to work on getting the Lopolight Professional Series certified for ATEX and IEC Ex.

“It was obvious to us that a zone 2 classification with a high temperature class was easy for us to achieve; this is where you find our competitors, but we wanted more,” says Hancke. “We knew from our other navigation lights series that having third-party certification of the products and the quality management systems is promoting trust and very beneficial to continuous improved product quality, so we went for zone 1 and importantly a low temperature class – T5. This means the Lopolight Ex navigation light can be placed freely on any vessel with any cargo or fuel, except for inside the tank.”

Setting new standards

The Lopolight Professional Ex Series is formally approved for use in ATEX/IEC Ex equipment group II Category 2 Zone 1 (and therefore also Zone 2). Whereas Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours, and mists is likely to occur occasionally during normal operation’,

The Lopolight Ex navigation light can be placed freely on any vessel with any cargo or fuel, except for inside the tank.

regular Professional Series; the difference is in the manufacturing. For example, the use of ATEX/ IECEx certified components, such as connectors and cable glands. The marking is ATEX/IEC Ex specific, and a certified grounding point is present for safe and simple installation. The full range of the Professional Series is available in the EX configuration, including ice-class lights.

Zone 2 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours, and mists is not likely to occur in normal operation but, if it does occur, it will be present for a short period of time only’.

The Professional Ex Series lights are kept in the same form factor as Lopolight’s

“It has been a wild ride with customers essentially wanting delivery immediately as the lights came out of our production facility in Denmark,” says Lopolight CEO and owner Jan Moeller. “We knew there would be a demand from ‘new fuel’ vessels, but we are also receiving strong demand from tug builders such as UZMAR, who are among the first to fully integrate the Lopolight Ex lights in their newbuilds 158 and 159. We are humbled by the interest we are receiving for this product series and very grateful to our customers for their trust in us.”

i. lopolight.com

A Deep Dive into Lopolight’s Professional Series

**TECHNICAL DETAILS.** Design dimensions and quality as the Lopolight Professional series navigation lights: Hard coat anodized aluminum housings, PMMA optics, fully encapsulated, all upgraded to ATEX/IEC Ex APPROVED TO: COLREG’72, MED (Wheelmark), UL1104, DNV, ABS ATEX/IEC Ex equipment group II, Category 2, Zone 1. STANDARDS: ISO/IEC 80079-34:2020, IEC 60079-18:2015, IEC 60079-7:2015 Ex eb mb IIB T5 Gb Ex = Explosion protected.

New national research vessel for the Netherlands

RV Wim Wolff

Dutch builder Thecla Bodewes Shipyards, headquartered in Kampen, the Netherlands, is a seventh-generation family business with a combined experience in shipbuilding spanning over 300 years. In February, the heritage company launched its latest flagship ship, the new national research vessel, RV Wim Wolff.

RV Wim Wolff was christened in the harbour of the Royal Netherlands Institute for Sea Research (NIOZ) on Texel in the presence of Caroline Visser, a member of the board of the Netherlands Association for Scientific Research (NWO), and Charly Wolff, granddaughter of ecologist Wim Wolff, after whom the ship is named. The event

was attended by friends, family and representatives of the NWO, NIOZ and Thecla Bodewes Shipyard.

RV Wim Wolff replaces research vessel RV Navicula after 40 years of faithful service in the Wadden Sea and in the Zeeland Delta. With an expected service life of more than 30 years, RV Wim Wolff

Thecla Bodewes Shipyards replaces its flagship vessel

will provide Dutch coastal researchers with a versatile, modern and sustainable research vessel for decades to come.

Sustainable design

RV Wim Wolff is the second of three vessels in the new research fleet for Dutch coastal, marine and ocean research. The support vessel RV Adriaen

RV Wim Wolff replaces research vessel RV Navicula after 40 years of faithful service in the Wadden Sea and in the Zeeland Delta.

Coenen was commissioned in 2022. A year later, construction began on RV Anna Weber-van Bosse, the new open sea and marine research vessel set to replace the RV Pelagia at the end of 2025. The Dutch research fleet is managed by the National Marine Facilities department of NIOZ, part of the Institutes organisation of NWO, the Dutch Research Council.

With a length of 37m and a shallow draft of just 1m, RV Wim Wolff is a unique vessel. Alongside an aluminium hull, it has an impressive range of deck equipment specifically designed to facilitate high-quality marine research in Dutch waters, especially in the Wadden

Sea and the Zeeland Delta. A special feature is the ship’s ability to easily go aground for extended periods of time, relying on batteries alone to provide the required energy to continue operating the ship’s equipment.

It also uses a sustainable diesel-electric propulsion system combined with an advanced battery pack, resulting in minimal energy consumption and emissions. Unlike similar vessels, RV Wim Wolff runs on EN590 diesel, DMA low sulphur/biodiesel and 100% renewable biofuel made from hydrotreated vegetable oils (HVO). This makes its operation highly sustainable and the combined energy-savings, together with

Speakers at the christening ceremony in Texel included Caroline Visser, a member of the board of Netherlands Association for Scientific Research (NWO), and Charly Wolff, granddaughter of ecologist Wim Wolff, after whom the ship is named.

Technical specifications

Builder Thecla Bodewes Shipyards

Year of build 2024

Flag state The Netherlands

Class Research vessel

Speed 10 knots in transit / 8 knots in ser vice

Length 37m

Beam 10m

Draft 1.2m

Gross tonnage 420GT

Main engines

2x 285-380ekW DieselGensets / 68ekW harbour generator

Propulsion diesel electric with 180kWh battery pack and 2x E-motors of 300ekW each

the advanced diesel-electric propulsion system, result in sustainable savings for NIOZ’s National Marine Facilities department, which manages the vessel.

Future proofing

In its efforts to make RV Wim Wolff as sustainable and future proofed as possible, Thecla Bodewes has developed a modular energy concept with a propulsion system that doesn’t require fossil fuel, ensuring RV Wim Wolff is ready for a zero-emission future. Because the ship has been designed with alternative energy sources in mind, it can be adapted to new technologies, such as hydrogen or methanol, without requiring any major conversions to its IMO Tier III and Stage V compliant Scania internal combustion engines.

Other sustainable factors that were focused on during the intensive design phase of the vessel included eliminating vessel noise in the water to minimise disturbance to the marine environment. By balancing the propeller and engine speed, noise and vibrations are significantly reduced. This also enhances the quality and type of ocean research that can be conducted aboard RV Wim Wolff.

i. tbshipyards.com

Lifting at sea

Huisman to deliver two subsea cranes for Toyo Construction’s cable-lay vessel.

Dutch company Huisman, the global supplier of technical solutions, has been awarded a contract with design and shipbuilder VARD for the delivery of two subsea cranes for Toyo Construction Co. Ltd.’s latest cable-lay and construction vessel, the VARD 9 15. The two new builds — a full electric 250m hybrid boom subsea crane and a 100m knuckle boom crane — are set to be the latest addition to the offshore construction specialist’s fleet and have been specially designed for the flourishing Japanese offshore wind industry. They complement the

advanced capabilities of the purposebuilt VARD 9 15, which is built for cablelaying and turbine foundation installation works in the Japanese offshore wind sector. Both cranes will be manufactured at Huisman’s facility in Zhangzhou, China.

“We are delighted with the opportunity to supply our new cable lay vessel with Huisman’s state-of-the-art offshore cranes,” says Haruhisa Obayashi, President of Toyo Construction. “Huisman’s proven track record of manufacturing cranes of superb quality

will boost our intentions to become a top-class contractor for offshore wind and other offshore construction projects.”

Commenting on the deliveries, Torgeir Haugan, senior vice president of sales and marketing at VARD, commented: “We are happy to be working together once again with Huisman to deliver the two offshore subsea cranes, that will become a vital part of this complex vessel to be designed and built by VARD for Toyo Construction, our new Japanese client.”

“We are delighted with the opportunity to supply our new cable lay vessel with Huisman’s state-of-the-art offshore cranes. Huisman’s proven track record of manufacturing cranes of superb quality will boost our intentions to become a top-class contractor for offshore wind and other offshore construction projects.”

Haruhisa Obayashi – President of Toyo Construction.

From left to right: Torgeir Haugan – Senior Vice President of Sales & Marketing at VARD, Haruhisa Obayashi – President of Toyo Construction, and David Roodenburg – CEO of Huisman.

Going fully electric

Huisman’s hybrid boom crane is a proven subsea crane concept that combines the high lifting height of a conventional lattice-type boom crane with the operational advantages of a knuckle boom crane. It includes a fully electric traction and storage winch design that ensures secure storage of large diameter subsea wire rope.

“We are honoured to announce our partnership with Toyo Construction as an esteemed new client in Japan. We take pride in supplying cutting-edge equipment for their multi-purpose construction vessel, empowering Toyo to excel in offshore construction in Japan and beyond.”

David Roodenburg – CEO of Huisman.

Its key features include a superior load curve for optimised deck handling and overboarding voluminous structures, such as suction anchors or pin piles. It can also lower the knuckle for an improved operational weather window, significantly reducing motion during offshore lifting operations, while the fully electric-driven subsea winch package enables significantly lower power consumption of the crane system.

“We are happy to be working together once again with Huisman to deliver the two offshore subsea cranes, that will become a vital part of this complex vessel to be designed and built by VARD for Toyo Construction, our new Japanese client.”

Torgeir Haugan – Senior Vice President of Sales & Marketing at VARD.

The crane guarantees superior workability offshore thanks to the fact it’s equipped with both passive and active heave compensation systems. The hydraulic active and passive heave compensation allows for the precise lowering of loads through the splash zone and accurate landing on the seabed. The crane is designed to meet Toyo Construction’s specific requirements and preferences, and will be certified to ClassNK regulations.

Compact and powerful

Complementing the setup aboard VARD 9 15, the knuckle boom crane is a compact yet powerful subsea-rated crane that features active heave

compensation. The crane is designed to assist in subsea work and handle cargo efficiently across the deck, and forms part of Huisman’s recently launched Subsea Crane range for offshore construction vessels.

“We are honoured to announce our partnership with Toyo Construction as an esteemed new client in Japan,” says David Roodenburg, CEO of Huisman.

“We take pride in supplying cutting-edge equipment for their multi-purpose construction vessel, empowering Toyo to excel in offshore construction in Japan and beyond.”

i. huismanequipment.com

With the renewed series of subsea Knuckle Boom Cranes for the use in the offshore subsea construction market, the company’s portfolio has been adapted to the latest trends in offshore construction vessels with respect to energy efficiency, automation, and safety.

Collaboration in the subsea domain

Fincantieri and Saipem join forces in subsea robotics for surveillance and control of critical underwater infrastructure

Italian shipyard Fincantieri and Saipem, a global leader in the engineering and construction of infrastructure for the offshore and onshore energy sectors, have signed a Memorandum of Understanding to evaluate commercial and industrial opportunities for cooperation in the field of autonomous subsea vehicles and their integration with surface and underwater units. The Memorandum, signed at the Italian Navy’s headquarters in Palazzo Marina, is among the initiatives aimed at promoting and

developing national excellence in the underwater sector.

The agreement aims to enable the two companies to participate in major programmes in the Italian and international markets in surveillance and control of critical underwater infrastructure and rescue activities. It hopes to do this using specific complementary technologies from Fincantieri and Saipem, including the integration of surface vessels and submarines built by

with the drone development programme ‘Hydrone’ developed by Sonsub, Saipem’s centre of excellence for subsea technologies and solutions.

Drone action

equipped

Saipem is the first company in the world to have qualified and commercialised resident autonomous subsea drones for intervention and inspection activities at depths of up to 3,000m. Designed and industrialised between Marghera (Venice) and Trieste, the drones have already been deployed for the control

Fincantieri

From left to right: Claudio Cisilino, Group Executive Vice President Operations, Corporate Strategy and Innovation, and Mauro Piasere, Chief Operating Officer of Robotics and Industrialized Solutions at Saipem.

and maintenance of underwater infrastructure in the offshore energy market at the service of major energy companies. The company has seven fabrication yards and an offshore fleet of 21 construction vessels (of which 17 are owned and four are owned by third parties and managed by Saipem) and 15 drilling rigs, nine of which are owned.

In turn, Fincantieri has placed itself at the centre of development programmes in the underwater sector, thanks to its ability to guide an effective integration between the Defence and civil industries. Since 1929, the Group has built 180 submarines, 105 of which were constructed at the Muggiano shipyard. Fincantieri is a leader in the construction and transformation of cruise, naval, oil and gas, and offshore wind vessels. With over 230 years of history and more than 7,000 ships built, Fincantieri maintains its know-how, expertise and management centres in Italy, alongside its worldwide production network of 18 shipyards operating in four continents.

By signing the Memorandum of Understanding, Fincantieri and Saipem aim to become a key reference for the subsea domain, whose strategic relevance is becoming increasingly evident in the current geopolitical context.

i. fincantieri.it i. saipem.com

By signing the Memorandum of Understanding, Fincantieri and Saipem aim to become a key reference for the subsea domain, whose strategic relevance is becoming increasingly evident in the current geopolitical context.

Rendering of a Hydrone subsea vehicle undertaking surveillance on undersea infrastructure.

Since 1929, Fincantieri has built 180 submarines, 105 of which were constructed at the Muggiano shipyard.

Photo courtesy of TFincantierie

Photo courtesy of Fincantieri.

Image courtesy of Saipem.

Damen goes compact

The Dutch shipbuilder unveils its new ASD Tug 1810

Damen Shipyards Group has been in operation for 95 years, and during that time has amassed a portfolio that includes 35 shipyards and 20 other companies in 20 countries. While its headlining grabbing explorer yachts and support vessels often win applause, it’s the Dutch builder’s latest vessel in its Damen Compact Tugs product platform that made the biggest splash in February this year.

The 18m ASD Tug 1810 is described by the builder as “the next piece in the puzzle” as Damen sets out to answer the needs of the modern port operation. As with all vessels in its portfolio, Damen has placed great emphasis on safety in the development of the ASD Tug 1810, underpinned by proven technology aboard other vessels in the Compact Tugs range.

“With it being a priority for us, you see safety return time and again throughout the entire design of the tug,” says Siebe Cieraad, Damen’s product portfolio manager for tugs explains. “The vessel boasts a high freeboard, keeping water on deck to a minimum. It also has the tumblehome so characteristic of the Compact Tugs range, enabling it to safely get up close when assisting a vessel.”

Smart design

The tug’s operation is further aided by the application of ergonomically designed consoles and a 360-degree view from the wheelhouse, enabling operators to see what’s happening both

fore and aft. It also enjoys clutter-free decks, and in the event of a tow line snapping, the use of Damen Safety Glass – shatterproof glazing – ensures that observers on the bridge are protected.

Most of the items conventionally found on deck have been incorporated into the deck house and bulwark. This includes the Damen Marine Components winch, which has an important role to play in the vessel’s efficient performance. The winch is installed in the deck house to shelter it from the elements and minimise the need for maintenance, but also so that towing operations both fore and aft can be undertaken with a single winch. >>

Where the ASD Tug 1810 really excels is its ability to answer the challenge of increasingly large seagoing vessels in ports, which require a tug with more power that can operate in less space.

alongside a quay where there is no shore connection available.

The result is a reduction in fuel consumption, emissions and maintenance that typically needs to be carried out on a conventional generator. Crucially, it’s this configuration that enables Damen to produce a more compact design.

Looking ahead

In addition to its compact nature, Damen has designed the ASD Tug 1810 to produce minimal noise and vibration. The four person accommodation, for example, is well insulated and finished with modern, durable linings, while the wheelhouse features a floating floor and acoustical ceiling.

“To help the crew maintain their focus during their work, and to help the captain gain a clear view on what’s taking place, we’ve tried to keep the decks as clear as possible and keep the potential of tripping to an absolute minimum,” adds Cieraad. “In addition to protecting the crew, it also helps protect the equipment.”

Problem solving vessels

The tug features Damen’s patented Twin Fin skeg, which helps to boost course keeping, manoeuvrability and predictable sailing behaviour during operations, improving both efficiency and safety. Another perk is the closed loop cooling system, which allows fresh water to run in a series of channels on the underside, radiating heat away from the vessel. “As such, no sea water enters the vessel and the internal system is protected from the abrasiveness of salt

water,” says Cieraad. “It helps to reduce docking intervals, sometimes by as much as seven years.”

Where the ASD Tug 1810 really excels is its ability to answer the challenge of increasingly large seagoing vessels in ports, which require a tug with more power that can operate in less space. Size wise, the ASD Tug 1810 meets this challenge head on, with 30 tonnes of bollard pull ahead, 28 tonnes bollard pull astern, and only 18m in length. Power wise, Damen’s electric power generation system includes two shaft generators, one fitted to each power train, and a back-up diesel generator. The system draws on power from the main engines to create electricity, which eliminates the requirement for a third diesel engine to provide electrical power when the vessel is sailing. The diesel generator can also be used when the vessel is

In addition to improving on board comfort for crew, the tug also minimises its environmental impact to those who desire it. Damen’s modular optional Emission Reduction System is IMO Tier III compliant and features an in-house developed exhaust gas aftertreatment solution that reduces NOX emissions, which can be retrofitted at any time. The ASD Tug is also remotely connected to Damen’s IoT solution Triton, which will closely monitor the vessel’s performance, and help determine the optimal speed and route for reducing fuel consumption and emissions. To that end, Damen is also developing zero emission or carbon neutral versions of its compact ASD Tugs.

“The aim of the Compact Tugs range is to serve the needs of today’s ports and harbours. That means addressing multiple questions in a single platform,” says Cieraad. “Such vessels need increasing amounts of power, situated in increasingly compact vessels, with zero compromises on safety and reliability, while advancing maritime sustainability. It’s a challenge, but at Damen it’s the challenge that motivates us and that has been the driving force behind our vessels over the years.”

i. damen.com

The power of propulsion

Yanmar provides an impressive powertrain to a new hybrid multi-purpose workboat.

Designed and built by Norwegian shipyard Fitjar Mekaniske Verkstead (FMV), Mimmi – a hybrid multi-purpose work boat – was commissioned by Finnsnes Dykk & Anleggservice (FDA) to perform a variety of offshore tasks, including pipelaying, placing sea cables and anchoring for fish farms. Named after the owner’s daughter, Mimmi went into service at the beginning of September in the Norwegian waters south of Nordland following a lightning-fast 11-month build. The vessel’s propulsion comes courtesy of a 1,340kW Yanmar 6EY22AWS fitted with a selective catalytic reduction system. As a hybrid,

We chose Yanmar because of the service and the spare parts availability. We cannot tolerate downtime.

the vessel has a two-step Finnøy output gear with 1,000kW PTI/PTO, and a battery pack offering an additional 1,444kW.

Captain Tommy Grønning, a veteran with 12 years of experience in the role, was involved in the design and specification from the start. “We chose Yanmar because of the service and the spare parts availability. We cannot

tolerate downtime,” he says. “Also, fuel economy and we wanted the SCR. The specification for the engine was to cope with 40 tonnes load, and this unit offered a safety margin of 43 tonnes.”

Yanmar’s setup

The propulsion setup, explains Grønning, is so that the diesel engine can be used to travel to the worksite, before

The FDA Mimmi in operation.

The vessel’s propulsion comes courtesy of a 1,340kW Yanmar 6EY22AWS fitted with a selective catalytic reduction system.

In addition to an impressive powertrain, the vessel has the capability to operate remotely to depths of 1,800m, with a seabed scanning echo sounder with 850 beams.

switching to electrics once there. “It’s about the environment in general, of course, and also the environment where the crew work,” he explains. “All the electricity on board comes via the battery package, this is not used in transit. It creates a very quiet workspace, particularly at night. It’s also economical, aided by a regeneration system on the winches. This type of hybrid setup is the future.”

Before going into service, Mimmi underwent successful sea trials, achieving 12 knots with a 70% load on the Yanmar, before relocating to just outside Bodø to commence pipelaying work.

“The thing that makes her unique is the power: whether that’s propulsion or the Palfinger crane capacity, we have three times the power of anything else this

size,” says Grønning. “She’s the toughest service boat in Norway!”

High-tech all round

In addition to an impressive powertrain, the vessel has the capability to operate remotely to depths of 1,800m, with a seabed scanning echo sounder with 850 beams.

“The bridge installation features a navy multi-view and navy ROV station, with fancy features that give us better undersea vision,” explains Grønning. “The Kongsberg HIPAP acoustic positioning system for the ROV allows us to know precisely where it is at all times. On the starboard side we have five underwater lights with cameras and two more astern watching the propeller.”

Two more contracts

Following the successful development of Mimmi, which began operations in

March 2024, FMV announced the commissioning of a further two new service vessels from FDA procured for maritime contractor activities and scheduled for delivery in April and August 2025.

“The yard has delivered good boats, on time and at the agreed price,” says FMV project manager, Kenneth Larson. “One reason why we are now entering into new contracts with FMV is the work they did on FDA Mimmi. Furthermore, we see that vessels built in Norway are consistently of good quality, which also entails less looting and heft in the operational phase, as well as a high second-hand value.”

i. yanmar.com

With the Palfinger crane capacity, Mimmi has three times the power of anything else in its size.

Shaping the future of the electrification and hybridisation of marine transportation

This year’s Electric & Hybrid Marine Expo and Conference is set to deliver the most comprehensive gathering of latest advancements and next-generation solutions and technologies tailored for the maritime industry. Will you be there?

Taking place from 18-20 June at the RAI, Amsterdam, this global gathering of industry experts, thought-leaders and regulators provides a one-stop destination to gain invaluable insights into the future of electrification and hybridization of marine transportation.

Conference programme

Throughout the three days, this global industry gathering will focus on innovative electric, hybrid and alternative fuel marine propulsion systems, designed to reduce emissions, fuel consumption and maintenance costs. Key insights into how to negotiate increasing environmental legislation governing access to harbours worldwide

will be presented in a not-to-be-missed conference programme.

The Conference features over 40 expert speakers and covers the crucial topics surrounding the electrification and hybridisation of marine vessels, ports and supporting infrastructure. The full line-up can be found at electricandhybridmarineworldexpo.com.

Moving forward

As the industry moved towards more progressive technologies, accelerating the pace towards zero-emission shipping and net-zero emissions, the delegate pass is a must to access the crucial data to ensure your next commercial decision is the right one.

Download the free event app to enhance the visit experience:

• Networking: Connect with other attendees and schedule meetings

• Exhibitor List: Access the list of exhibitors to plan your visit efficiently

• Conference Programme: Stay updated with the schedule of events and sessions

• Navigation: Easily navigate through the venue using the app’s features

Autonomous Ship Expo and Conference 2024

Co-located at this leading international event, visitors will find the Autonomous Ship Expo and Conference 2024 dedicated to delivering the latest insights into the future of autonomous shipping through expert-led conference sessions and panel discussions.

If you are a ship owner or shipyard operator, maritime technology provider, boatbuilder port authority, industry regulator or policymaker, this is an essential date in your professional calendar. Register now and be part of the conversation driving positive change in the maritime industry.

i. electricandhybridmarineworldexpo.com

Photo courtesy of Electric & Hybrid Marine.

Pulling on design

Robert Allan leads the charge with two successfully delivered revolutionary designs

Naval architecture and marine engineering company, Robert Allan Ltd., announced in January the successful delivery of ADNOC MD 01, the first of two 24.9m catamaran dive support vessels that the Canadian studio has designed for Abu Dhabi National Oil Company (ADNOC) in the United Arab Emirates.

The delivery comes hot on the heels of Robert Allan’s announcement earlier the same month confirming the delivery of ART 92-32W Rotortugs, the first of its two Advanced Rotortugs built by Signet Maritime that incorporate the patented triple Z-drive Rotortug propulsion layout, featuring omni-directional manoeuvrability and the benefits of a fully redundant and precise propulsion machinery configuration.

Catamaran dive support vessel

Built by Grandweld Shipyards, the 192GT ADNOC MD 01 aluminium catamaran is designed to support local diving

operations in the UAE. To this end, the vessel is provided with comprehensive equipment for shallow water dive support, including a decompression chamber, dive air compressors, compressed air and other gas cylinders, hose reels for underwater tools and diver air supply.

The wide 8m beam allows for a spacious, full-beam dive compartment on the deckhouse with a diver rest area, separated supervisor area and integrated decompression chamber with direct access to the open deck. Diving operations can take place on either side of the vessel or on the integrated swim platforms at the stern. A large 6.5 m workboat and crane with a 10m working radius is located on top of the deckhouse to avoid interference with dive operations.

Five crew and seven divers are accommodated in three double crew cabins with a crew mess and galley provided in the deckhouse. All below decks compartments are dedicated to

propulsion machinery and dive equipment. The wheelhouse is designed to provide maximum all-round visibility with clear lines of sight to the bow and sides, as well as dive operations on the aft deck via CCTV.

The tunnel clearance was designed to be particularly generous to avoid slamming of the wing deck structure. The vessel exceeded the design contract speed with a sea trial speed of 19.4 knots, while a comprehensive CFD program was used to predict resistance during early design work.

Advanced Rotortug

As the first ART Rotortug that Signet has built and operated in its fleet, the ART 92-32W is designed by Robert Allan in collaboration with RotorTug BV to offer increased redundancy for ship-handling, terminal support, and escort towing, as well as enhanced crew safety. It is also the most powerful 32m ART to date, used to escort deep-draft VLCCs in and out of the Port of Corpus Christi in Texas – the largest port in the United States >>

– not to mention the first to achieve greater than 90 tonnes bollard pull

Extensive analyses and simulations were performed to confirm the suitability of the ART 92-32W for the proposed operations, including simulations at the Seamen’s Church Institute and TDT-Sim analysis by RAL, in conjunction with Markey Machinery, to ensure proper winch selection for the tug to meet the environmental criteria for the escort and docking of the VLCC’s.

Industry firsts

Close collaboration between Signet, Robert Allan and Markey Machinery resulted in a next-generation Advanced Rotortug design that exceeded the initial design criteria. Signet’s selected vendors were also called upon to consult on the development of the highly capable escort/terminal tug with the combined manoeuvrability of three controllablepitch thrusters and the high-speed, high-torque performance of the AGILE winches. The entailed unmatched closequarters ship-handling and constant line

‘time under tension’ to safely manoeuvre laden 300,000 DWT+ ships.

The ART 92-32W is the first commercial vessel in American history to be produced using 3D structural models in combination with key plans in design, approval and construction. The process is reported to have significantly improved the production methodology of the Signet shipyard, with all future vessels constructed at Signet now set to follow the same design regimen. Benefits include reduced costs and time

investment, streamlined interaction between all stakeholders throughout the design, verification, and construction phases, without compromising safety.

In addition to using 3D structural design methods, the 32m ART is also the first towing vessel to receive ABS ENVIRO Notation, and the first vessel in the United States to achieve ABS Low Emissions Vessel (LEV) Notation and ABS CyberSecurity-1 (CS-1) Notation.

i. ral.ca

The ART 92-32W is the first commercial vessel in U.S. history to be produced using 3D structural models in combination with key plans in design, approval, and construction.

Holding tight

Kendrion magnets bring safety at sea

In the maritime sector, fire doors are integral components of ship architecture and play a crucial role in ensuring onboard safety standards. Among its extensive product offerings, Kendrion – a Dutch manufacturer of pneumatic brakes, clutches and door holding magnets – provides a reliable solution in fire protection for shipbuilding with its proven GTR main series of door holding magnets.

Specifically designed and successfully certified, the electromagnetic door holding systems are also used on conventional doors in business and entrance areas, as well as in maritime areas, and exemplify the company’s

commitment to addressing critical safety needs with proven and trusted solutions.

Force activation

With a holding force ranging from 490 to 1,372N and a power consumption of only 1.5W, the electromagnets GTR050 and GTR070 effectively hold fire doors in the open position. In the event of a fire alarm or activation of the smoke detection system, the door holding magnet releases the door lock immediately upon interruption of the power supply, thus delaying the spread of fire. With vacuumtight IP65 enclosures and rigorous VdS quality control, both series guarantee optimal functionality and reliability, meeting the standards of DNV-CG-0339.

The holding magnet GTR050.

“The door holding magnets GTR050 and GTR070 are characterised by a robust construction and high resistance to the extreme conditions at sea, ensuring reliable performance even under adverse circumstances.”

“The door holding magnets GTR050 and GTR070 have been specifically designed and certified for use in maritime applications,” says Laurence Setijoso, market segment manager for Solenoid Technology at Kendrion. “They are characterised by a robust construction and high resistance to the extreme conditions at sea, ensuring reliable performance even under adverse circumstances.”

Approved and certified Kedrion’s door holding magnets are designed to effectively secure doors and prevent the spread of flames and increase safety on board. The optimal functionality and reliability of the door holding magnets in critical situations are

validated through tests according to EN1155 and EN14637 standards. This ensures that they meet the stringent requirements for use in maritime environments.

As an experienced manufacturer of fluid, solenoid and control technology, Kendrion is committed to developing high-quality solutions in a variety of markets. The door holding magnets of the GTR050 and GTR070 series expand Kendrion’s diverse solenoid portfolio, delivering vacuum tight IP65 housing and strict VdS quality control to guarantee optimum functionality and reliability.

i. kendrion.com

The holding magnet GTR070.

Kendrion provides a reliable solution in fire protection for shipbuilding with its proven GTR main series of door holding magnets.

Cruise Control

Marlink delivers future-proof hybrid network for Exploris One

Smart networks and digital solutions company Marlink Now is well versed in integrating satellite, terrestrial and digital services into powerful and reliable solutions for the marine industry. Now it’s gone off the beaten track with new French expedition cruise company, Exploris, by installing a complete hybrid network solution on board the company’s Exploris One to provide passengers and crew with complete coverage and connectivity.

The advanced hybrid network solution was installed during the vessel’s refit in Valparaiso, Chile, and is designed to enhance customers’ digital possibilities by delivering high throughput and low latency in uncharted locations around the world. The services it covers includes LEO from Eutelsat OneWeb, Starlink and Iridium, Marlink GEO VSAT, TV-RO and 5G GSM. The network solution powers the onboard ethernet/ Wi-Fi network and a customer portal, so even when venturing into uncharted territories, guests can enjoy seamless, secure and unparalleled digital experiences on board.

Going digital

The 144-guest ship, Exploris One, entered service in December 2023, cruising to South America and the

Antarctic Circle. Marlink’s technical team organised the installation of the antennas, below decks equipment and integration to the ship’s network during an extensive refit which saw the icecapable vessel prepared for sailing to remote and polar regions.

“Exploris has a mission dedicated to bringing new and exciting locations to life for our guests and enabling them to share their experiences with friends and family in real time,” said Philippe Videau, president of Exploris. “Marlink shares our vision of providing excellence to our guests and keeping the vessel safe and connected wherever it is sailing.”

Off grid

Exploris One is designed to serve the French-speaking leisure market and will offer 32 further departures during its inaugural season to remote locations, including Antarctica, the Atlantic Islands, Western Europe, Svalbard, Iceland, Greenland, Canadian Arctic and South America. These isolated and sometimes harsh locations require a hybrid network that can keep the vessel and its guests connected regardless of conditions.

“Only Marlink has the expertise to orchestrate complex networks enabling digital services and possibilities onboard and provide them in a solution that

supports vessel operations and enables guests to share their experiences,” said Tore Morten Olsen, president of maritime at Marlink. “We are delighted to provide Exploris with the very best hybrid solution for Exploris One and wish her well during her maiden season.”

Hybrid network

It’s not only new cruise companies that are benefitting from Marlink’s next generation network solution. In April, the digital services provider also revealed it is working to enhance the digital experience onboard Mein Schiff vessels too, by

“Marlink’s

internet solutions provide us with the technology we need to make our guests’ wishes come true and keep our crews connected.”

providing its managed hybrid network solution with Starlink LEO connectivity to its long-term customer TUI Cruises. Marlink will install its Sealink NextGen network solution – combining lowlatency LEO connectivity with global 4G/5G and C/Ku-band VSAT – on TUI Cruises’ combined fleet of six existing

Mein Schiff vessels and two new builds, due in service by 2024 and 2025.

These different connectivity links will be orchestrated by Marlink’s SD-WAN solution, which manages and optimises the routing of traffic across the network and is backed by a service level

agreement with global uptime guarantees.

“Marlink’s internet solutions provide us with the technology we need to make our guests’ wishes come true and keep our crews connected,” says Dietrich Koch, director IT commercial, security and new build at TUI Cruises “Enabling LEO internet services across the Mein Schiff fleet represents a new era that will enhance the onboard experience.”

i. yanmar.com

Air, sea and sub-sea

In February this year, Dutch builder Damen Shipyards Group announced it has begun construction on a new multi-purpose support ship (MPSS), which has been designed with modern defence and security requirements in mind. Co-developed with the Portuguese Navy, the vessel’s launching customer, the ship provides a solution for the increasing use of drone technology in combat and surveillance. In addition to its primary function, the MPSS is designed to fulfil a wide range of additional tasks, including auxiliary roles.

Damen’s MPSS range, featuring 7,000 and 9,000 tonnes versions, combines the

Portuguese Navy’s vision with Damen’s proven process of shipbuilding. Benefits of this include a rapid construction period time built on a reliable, costeffective platform. While the electrical, communication and navigation equipment installed on the MPSS will be military class equipment, the vessel will also use commercial off the shelf technology. This includes the mission specific equipment modules, by which the vessel achieves its multi-functional capability.

Dual Mode

When required to perform its primary military function, the MPSS can also be

applied to a wide range of duties. These include managing drones (air, sea and sub-sea), conducting amphibious support, emergency/disaster relief, search and rescue, diving support, performing submarine rescue operations and helicopter operations.

The 107m MPSS 7000 will be operated by 48 crew. There are additional facilities for up to 100 special personnel (including scientific staff ) and temporary accommodation for 42 persons in the event of a disaster relief operation. It will also feature laboratories, a stern ramp for UUVs and USVs, a 650-square metre cargo deck, and space for 12 6m containers.

Damen delivers multi-purpose support ship based on drone defence at sea

IMAGES COURTESY OF DAMEN SHIPYARDS GROUP.

and manage all types of drones.

The 130m MPSS 9000 can conduct even more operations, with additional facilities reportedly involving containerised hospital facilities, hyperbaric chambers or remotely operated vehicle equipment.

Damen’s MPSS range, featuring 7,000 and 9,000 tonnes versions, combines the Portuguese Navy’s vision with Damen’s proven process of shipbuilding.

The 107m MPSS 7000.

The 130m MPSS 9000.

The MPSS range is a response to the increasing use of drone technology that we see in modern combat and surveillance situations.

Increasing value

As a result of its modular approach, the MPSS can be used year-round and is easy to maintain. Another key factor of the MPSS Series is the capability to remain at sea for up to 45 days, which contributes to the vessel’s overall value, significantly increasing uptime.

“The MPSS range is a response to the increasing use of drone technology that we see in modern combat and surveillance situations. We could see that such capabilities would be of growing importance for countries looking to sustain their sovereignty,” says Piet van Rooij, commercial manager at Damen’s Defence and Security department. “At the same time, this is a multi-purpose vessel that can be applied to a wide range of additional operations, thereby offering value for taxpayer’s money. This theme is further developed using commercial off the shelf technology, which ensure the costeffective construction of a reliable platform. We’re very much looking forward to showcasing this new vessel.”

The Portuguese Navy contracted Damen for the construction of a multi-purpose vessel in November last year. The project follows a European tender process and is funded by the European Union’s Recovery and Resilience Facility as part of the NextGenerationEU economic recovery package. Damen operates 35 shipyards and 20 other companies in 20 countries, supported by a worldwide sales and service network. It delivers in the region of 100 vessels per year, with a total production value of over EUR 3 billion.

i. damen.com

The 130m MPSS 9000.

Trifleet Leasing has announced that Robin Pol has been appointed as managing director. Since joining the company in 1995, Pol has held various leadership positions across the commercial and technical departments, including most recently, director of commercial, global accounts and strategy. “I am honoured to lead our exceptional team at Trifleet,” he says. “I look forward to working more closely across the organisation to further Trifleet’s business growth and mission to serve our customers across the globe at the highest level.”

Henrik Helsinghof

CEO

Trifleet Leasing IMTRA

Schottel has announced the appointment of Roland Schwandt, a qualified naval architect who joined the company in 2020, as Deputy CEO. After a brief period managing the Tug & Offshore Energy segment, Schwandt took over responsibility for the global sales activities of Schottel GmbH and its now 14 subsidiaries as Vice President Sales. He worked with his predecessor Andreas Block and with Stefan Buch (VP After Sales Service) on driving the strategic expansion of the subsidiaries, helping to achieve the company’s international success with azimuth propulsion units.

Viking Life-Saving Equipment

Viking Life-Saving Equipment is proud to announce the appointment of Henrik Helsinghof as its new Chief Executive Officer, effective from 1 June 2024. Helsinghof will return to Viking to ensure a continuity of leadership, following the sad death of former CEO Henrik Uhd Christensen in January. Helsinghof began his career at Viking in 2006 as student assistant and remained with the company for 14 years, holding various positions. He rejoins Viking from Bramidan, where he was CEO for three years, overseeing a period of continuous improvement.

IMTRA, the leading manufacturer and importer of quality solutions and products for the marine, energy and transportation markets, has announced the addition of two new team members: Connor Bailey, who has been hired as IMTRA’s new Lighting Product Manager and Christian Ambrosi, who has taken on the role of Commercial Sales Support Specialist.

Alongside directing marketing efforts, Bailey will work directly with customers, supply partners and IMTRA’s inside and outside sales team to bring forward new lighting offerings.

Interocean Marine Services

Interocean Marine Services, the specialist provider of support services to the offshore, energy, marine, and renewable sectors, has kicked off 2024 with the announcements of Simon Laing appointed as the new Chief Commercial Office (CCO) and Alex Clark as Chief Financial Officer (CFO), following his position as a marine technical advisor for bp Solutions. The two appointments strengthen the existing leadership team following Alex Reid stepping into the

Vard Interiors

Birgit Aarseth has been appointed general manager for Vard Interiors coming from the position as Vice President Operations. Ms Aarseth has been working at Vard Interiors since March 2022, first as Department Manager Interior and then as Vice President Operations. She possesses broad international experience and has led different procurement, logistics, and sourcing functions, as well as setting up production at suppliers globally.

Bailey brings over a decade’s worth of marketing management experience to IMTRA.

Ambrosi will help IMTRA capitalise on its growing commercial sales and expand product offerings by pursuing new and existing commercial business. Ambrosi comes to IMTRA with experience as the general manager of a family-owned dive tourism operation in Curaçao, where he was responsible for maintaining a fleet of seven commercial dive boats.

COO position and joining Fraser Moore as CEO who moved to Interocean in July 2023. The reinforced expertise builds on the proven track record in managing integrated marine services including engineering, survey, and remote inspection. Interocean (formerly Rigmar Group) incorporates the diverse portfolio of services across the oil and gas sector, offshore, floating wind, and marine industries.

Birgit Aarseth General Manager

Roland Schwandt Deputy CEO

Robin Pol Managing Director

Christian Ambrosi Commercial Sales Support Specialist

Simon Laing CFO

Connor Bailey Lighting Product Manager

Alex Clark CCO

THE YELLOW & FINCH PAGES

ADS van STIGT

Avelingen-West 30

4202 MS Gorinchem

The Netherlands

T +31 (0)183 650 000

E info@vanstigt.com

I www.vanstigt.com

Contact: Sander Snoek

ADS van STIGT was founded in 1970 with the main activity in transmissions and gearboxes for maritime and industrial applications. This is still an importent activity of ADS van STIGT, but a significant number of other products have been added to the range, such as planetary gearboxes, pump drives, control systems, monitoring systems, controllable pitch propellers, thruster systems, carbon fibre shafts, dampers, elastic couplings and sensors. ADS van STIGT’s expertise ranges from pleasure to mega yachts, and from fishery to commercial shipping, offshore, and dredging. A well-equipped service team is supporting the sales activities worldwide.

ADS van STIGT is competence centre for: Masson, Bonfiglioli, O&K, Plöger, Horn, Schaller, Katsa, Geislinger, Durst and ZF.

ANCOFERWALDRAM STEELPLATES BV

P.O. Box 190

4900 AD Oosterhout

The Netherlands

T +31 (0)162 491500

F +31 (0)162 429806

E sales@aws.dillinger.biz

I www.ancoferwaldram.com

Over 100,000 tons of quality heavy steel plates in stock

AncoferWaldram Steelplates B.V. (AWS) is a stockholding wholesaler and steel service center, specializing in the supply of hot-rolled heavy carbon steel (quarto) plates, and profiled parts for more than 40 years now. Over the years, AWS has developed into a business that sets the standard for its industry.

Plates from stock or profiled parts

The choice is yours! It is the combination of comprehensive stocks of over 100,000 tons of heavy carbon steel plates plus the sophisticated

profiling plant that gives AWS a decisive lead in experience, product range and customer service.

ART4 TECHNICAL SYSTEMS BV

Nieuwegracht 9-11

3763 LP Soest

The Netherlands

T +31 (0)35 582 2468

F +31 (0)35 642 4860

E Info@art4.nl

I www.art4.nl

Contact: Mr Paul Schraven

Art4 Technical Systems BV is an independent Dutch company. We design, build and deliver fully turnkey solutions for hydraulic and electrical systems for customers worldwide. Our clients use the hydraulic and electrical systems for various end products such as:Mobile drives, transport conveyers, winch drivers, jack up platforms, cranes, both onshore and off shore, a-frames, special equipment, fairground attractions.The systems can be custom built to fit the specifications of the product they are used for.

BACHMANN ELECTRONIC GMBH

Office Veenendaal:

Vendelier 65-69

3905 PD Veenendaal

The Netherlands

T +31 (0)85 210 0550

E r.epskamp@bachmann.info

I www.bachmann.info

Contact: R. Epskamp

Bachmann hardware matches the harsh conditions in the maritime and offshore industr y. We take pride of extremely high availability using stateof-the-art technologies.

Integration of AMS, PMS, CMS, etc. in a Redundant solution is realized with our modular and marine certified PLCbased product range.

The group of companies includes the CMS specialist Bachmann Monitoring and Certec EDV, the developers of the 1st fully web enabled SCADA software atvise®

BREMAN MACHINERY B.V.

Sasdijk 20

8281 BM Genemuiden

The Netherlands

P.O. Box 135

8280 AC Genemuiden

The Netherlands

T +31 (0)88-27 36 200

E info@breman-machiner y.nl

I www.breman-machinery.nl

Great challenges need sophisticated solutions, the work of a specialist.

Breman Machinery fabricates critical steel components with exceptional dimensions and extreme accuracy. This is the daily job of our craftsmen. Through our unique capabilities regarding machining, welding, conservation and assembling we serve our customers to make their ambitions reality.

The welders of high-quality steel are qualified by Lloyd’s Register or DNV for all welding positions. With 30 milling, boring and turning machines we have the possibility to offer unique services. Our preservation department can protect your projects. Our location is beside open water, we have a direct connection to the international ports. High quality is one of our most important standards!

EMIGREEN B.V.

Noordeinde 19

3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317

F +31 (0)184 415 582

E info@emigreen.eu

I www.emigreen.eu

Contact: Niko J. Dalpis

Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector. Emigreen also provides services including design, specification, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, flow dynamics, thermodynamics and noise and vibration control. Emigreen develops

and tests components including catalytic converters, particulate filters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot filter system has set the standard for others to beat. All Emigreen solutions are highly efficient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht.

Emigreen links science and the market.

HEINEN & HOPMAN

Produktieweg 12

3751 LN Spakenburg

The Netherlands

T +31 (0)33 299 25 00

F +31 (0)33 299 25 99

E pr@heinenhopman.com