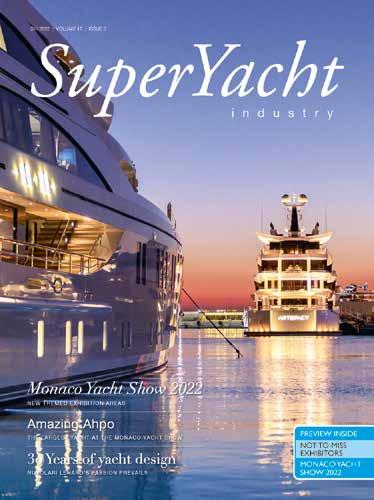

Pink Shadow

SUCCESSFUL SEA TRIALS FOR NEW SEAXPLORER

Dutch Superyacht Tech Campus

EXPERTS WORKING TOGETHER IN ONE LOCATION

Interior and furnishing

FINISHING TOUCH FOR 115M MY AHPO

SUCCESSFUL SEA TRIALS FOR NEW SEAXPLORER

EXPERTS WORKING TOGETHER IN ONE LOCATION

FINISHING TOUCH FOR 115M MY AHPO

Welcome to this year’s second edition of SuperYacht Industry. In this edition, we shine a light on the Netherlands, which is among the world’s top superyacht builders.

In the recent years, the demand for large superyachts with luxurious nishes has increased to a great extent. In the Netherlands alone, 70 superyachts with a length of more than 50 meters have been built in the past ve years. We also see a trend in completely customising new and second-hand yachts. Every year, dozens of these re ts take place. Let’s take a peek in the kitchen of some of the most renowned Dutch shipyards and yacht suppliers together.

In addition, we focused on the latest naval architecture and design developments within the superyacht industry, both interior and exterior. This and much more awaits you in this freshly pressed edition of SuperYacht Industry.

Feel free to contact us if you have interesting and inspiring news about your company that you eagerly want to share with your markets. We will gladly inform you about all of our online and o ine advertisement opportunities.

Enjoy the read!

Daniela Markovic Editor DANIELA@YNFPUBLISHERS.COM

DANIELA@YNFPUBLISHERS.COM

WERKVREUGDE is made up of a team of skilled professionals with extensive experience in stainless steel for the Superyacht building industry. They are one of the largest companies in the Netherlands specialised in the design and manufacture of stainless-steel yacht equipment.

The company distinguishes itself by their traditional working methods, the time, care, and attention they invest in their products. This, in combination with modern machinery and the latest digital measurements and design techniques, ensures the highest possible standard of stainless-steel quality. The company’s design department can turn each sketch or idea into a three-dimensional representation.

MARRON JACHTBOUW has a longstanding experience with teak for the yachting industry. Gradually, they discovered the wish and the need for alternative materials for teak.

In cooperation with Herculan Marine, EcoDeck was introduced in 2012. To stop human-induced deforestation, EcoDeck invented a nautical deck application that satisfies the highest standards in the yachting industry while reducing the impact on our environment.

EcoDeck® is a safe product according to SOLAS and IMO regulations. During its lifetime, EcoDeck® will maintain its properties and is easy to repair. The material is non-skid and easy to maintain at low costs. It is ecofriendly and is produced with renewed and solvent free resins. At the end of its life cycle, EcoDeck® can be recycled to be used in new products.

Bilgin Yachts is proud to announce that one of its latest projects, the 80m M/Y Leona 2023, has been nominated for the prestigious World Superyacht Awards 2023 in the Displacement Motor Yachts 1500gt and Above category. M/Y Leona 2023 is designed in partnership with Unique Yacht Design and H2 Yacht Design, with a focus on combining design and comfort elements to create a unique and attractive superyacht. The eco-friendly yacht features a special exhaust system that provides 100% clean air emissions. Equipped with two 2,560kW engines, M/Y Leona 2023 has a top speed of 19kn and a cruising speed of 12kn, while keeping fuel consumption at 250l/h. The World Superyacht Awards, celebrate the best in superyacht design, engineering, and construction. The awards ceremony will take place on 19-20 May 2023 in Istanbul, Turkiye.

i. bilginyacht.com

On 9 and 10 March, Besenzoni opened its doors to fifteen of the captains of this prestigious Italian association, which led to an interesting discussion about ways in which we could further improve the service levels we provide to shipowners. Besenzoni invited the Chairman, Captain Gino Battaglia and a group of skippers of superyachts over 40m long from the Italian Yacht Masters association to its headquarters. There, they were able to visit the design and construction departments of the world-renowned Italian marine accessories company. The build quality and design technology behind Besenzoni’s products was much appreciated by those who are the first to use them on their boats. In particular, the company offered participants the opportunity to test some of its technological innovations.

i.

besenzoni.it

‘Build Your Ideal Yacht’ was the title of the two-day event on technology and design innovations in yachting, organised to chart the course together to an ever more respectful relationship with the environment. The hugely successful 23rd Benetti Yachtmaster, an event for industry professionals was held this year from 15 to 16 February in Abu Dhabi and was attended by over 200 participants, including 110 captains, surveyors, stewardesses and professionals, who brought the two-day event to life with discussions about the future of the international yacht industry. A programme packed with meetings, in-depth discussions, and opportunities for networking sparked an interesting debate on innovative solutions to sustainability issues.

i. benettiyachts.it

The SeaXplorer 58 has successfully completed a series of sea trials ahead of her delivery later this Spring. Taking to the waters at the Damen Yachting SeaXplorer build location in Antalya, the SeaXplorer 58 Pink Shadow will be the third yacht delivered from the Dutch yacht builder’s range of luxury explorer yachts.The SeaXplorer 58, with her Ice Class hull for safe operations in polar waters and customised configuration, has been built and designed to meet the adventurous Owner’s globe-trotting lifestyle with family and friends to explore polar and tropical regions alike. Damen Yachting’s SeaXplorer Design Manager Enrique Tintore shares, “We are very happy with how the sea trials are going and are looking forward to delivering this SeaXplorer She performed and looked great sailing for first time andis certainly a head-turning yacht with her unique colour scheme and design features.”

Super yacht tender cranes, SOLAS cranes and special function cranes custom-built according to your requirements.

Phone: +49 40 7 100 100

eMail: sales@fuchs-cranes.de

www.fuchs-cranes.de

For over 75 years already, REINTJES Benelux – based in Antwerp – handles sales and services of REINTJES gearboxes and reversing gears for Dutch shipping for short-sea, sea going, dredging, fshery, inland vessels and luxurious yachts …

Our service department is available for all spare parts as well as repairs. Whether it is an inspecton or repair, our team of experienced service engineers is always there for you and assures you the reliability and quality REINTJES represents.

“Over the years, we have strengthened our presence in almost all markets. We have gained the trust of mature, experienced owners throughout the world as we specialised in the construction of explorer yachts that combines top technical aspects (robust steel hull, construction quality, machineries, high-end systems and equipment, large storages, seaworthiness, extraordinary range) with beauty and comfort (eye-catching lines, generous volumes, almost unlimited personalisation, functional layouts, large tenders and all sort of equipment to enjoy life at sea to the fullest). One of our goals was to win the US market over and, with three recent sales to American Owners, we can say we did it, eventually!”, says Vasco Buonpensiere, co-founder and CEO of Cantiere delle Marche.

i. cantieredellemarche.it

i. iyc.com

Reckmann Yacht Equipment supplied important parts for a 127m Oceanco sailing yacht. Custom made, of course. When the 127m Koru sets sail soon, the crew of the world’s largest sailing yacht will also use important components from a Deutsche Yachten member. Reckmann Yacht Equipment from Rellingen near Hamburg supplied three giant furlers for the Oceanco build, which is said to have been commissioned by Amazon founder Jeff Bezos. Each of them is made entirely of stainless steel and weighs around 900kg – together they serve one of the largest sail areas ever seen in yachting. Reckmann CEO Marcus Schuldt says, “The first discussions about the three furlers began back in the fall of 2018, and then some time passed before all the technical details were clarified.”

i. reckmann.com

ISA Yachts, a brand of Palumbo Superyachts, announces the sale to a European customer of a new bespoke 66m project to be built in Ancona. An exceptional team that involves the Vallicelli studio for the exterior lines and Pinto for the interiors: the extraordinary pairing that in the past created for the ISA brand a timeless icon called M/Y OKTO. Naval engineering is by Palumbo Superyachts. With steel hull and aluminium superstructure, ISA Custom 66m will be characterised by a dynamic profile with the typical ISA’s hallmark of the threearchesconnecting the decks. In addition, at beach club level the easily opening platforms will create a large living area equipped with gym, lounge and spa.

i.palumbosuperyachts.com

Lürssen Yachts is pleased to announce the launching of Project 1601, a 90m displacement Motor Yacht. The exterior design is by Monaco based studio Espen Øino International, while the Interior design was created by Dölker & Voges Design from Hamburg. Owners team project management is by Cornelsen & Partner. 1601 is currently undergoing sea trials and was delivered at the end of April. The project has a utilitarian character with a reverse bow, narrow rectangular windows, and greenhouse-style glazing on the upper deck. The shipyard and studio had previously collaborated on the 70.7m Skat, which shares a number of design features with Lürssen’s latest launch.

i. lurssen.com

| Read more on superyacht-industry.com

For generations, we have been realizing the most extraordinary living spaces with dedication and expertise. On water and on land. As a leading international partner in interior+ outftting, we turn visions for living into reality – for both indoor and outdoor areas.

We are crafting visions.

Pearl Yachts presented the Pearl 62 and Pearl 95 at the Palm Beach International Boat Show with Atlantic Yacht and Ship Co, official Pearl dealer for the East coast. These two exciting models represent the British brand’s growing range, with alluring design by the exclusive duo of Bill Dixon for the exteriors and Kelly Hoppen CBE for the interiors. Pearl Yachts Managing Director, Iain Smallridge says, “It’s been a while since we’ve put the spotlight on the Pearl 62, our most successful model to date, and our flagship the Pearl 95. Palm Beach ranks high among our favourite events, and we love welcoming old friends and new ones, together with our partners at Atlantic Yacht & Ship Co.”

i. pearlyachts.com

Celebrated French yacht designer Philippe Briand is exciting to unveil a new 60m ketch concept, dubbed KAZE. Comfort under sail and huge volumes below deck are the mainstays of the design, which aims to deliver a fabulous quality of life aboard. Renderings just released show the sleek, balanced lines and low-profile coach roof of a thoroughly modern-looking yacht. Mr Briand firmly believes that a designer has to be focused on the lifestyle component especially on a big 60m sailing boat by sharing the sail area between two masts. But also capable of passing beneath the Bridge of the Americas on the Panama Canal. With its volume of 499gt KAZE will provide amply for an incredible lifestyle.

i. philippebriand.com

The owner’s request to the architect Tommaso Spadolini was clear: a feasibility study for a yacht around 50m in length, therefore more spacious than the owner’s current 35m yacht, which would allow them to better enjoy their large family during the summer holidays. The owner has also made some precise requests regarding the interior common areas, with a large galley aft of the owner’s cabin, followed aft by an 11m salon, while another 7m salon is planned on the upper deck. The strictly displacement hull measures 48.5m in overall length, which becomes 46 at the waterline, with a maximum beam of 8.8m and a 2.5m draught. Steel will be used for the construction of the hull and aluminium for the superstructures, with a gt of approximately 490t.

i. spadolini.com

Award-winning Dutch high-end performance yacht builder Vitters’ high-performance yachts explore the oceans of the world and are distinguished by their immaculate nish, innovative sail systems, and on-board comfort.

Founded 30 years ago, Vitters is a family owned and managed shipyard and has enjoyed the opportunity of being trusted to build a signi cant number of magni cent yachts, the in-house team working closely with specialist subcontractors and suppliers. During the start-up phase, in 1990, Vitters was considered the underdog in the industry and critics said that building their rst project would be virtually impossible, defying convention. The founders, who are still today’s owners of the shipyard, rebelliously took up the challenge, with what was then a small team, and proved them wrong. This mentality (some call it disruptive innovation) still resonates through Vitters’ values – one reason that a Vitters yacht is a boat length ahead of the competition!

Vitters’ operation comprises some 80skilled and dedicated employees, including engineers, cra smen, foremen, and project managers backed up by support departments. The business model relies on subcontracting larger parts of the yacht. Subcontractors’ work is treated as an integral part of the Vitters’ responsibility. They are parties with whom we have longstanding relationships. Having the opportunity to match a speci c job with the right supplier, gives Vitters the opportunity to pick the best specialist for the project, at precisely the time when it is needed, giving an e cient, optimum overall result. When the company pioneered this way of working in the early nineties, it was quite revolutionary. Today, it has become the industry norm.

At Vitters Shipyard, the owners’ vision and design brief is the main guideline for any project. The translation of the owners’ ideas and wishes is what custom yacht building is all about. The design brief is transferred into a design document, which is the guideline for the project manager and the team as well as a benchmark tool to check milestones during the design and >>

build. To translate the owners’ ideas into a custom sailing yacht is a team e ort. This team starts with the owner, the naval architect, and the designer. Each member of the team has a speci c task and responsibility.

One of the early and most important stages in the process of building a custom yacht is to transform the ideas of the owners, the lines of the naval architect and the design of the interior stylist into information that can be used for construction. Each new yacht constructed at Vitters advances on

the technology and sailing performance of previous yachts, providing constant progression and innovation opportunities.

We asked Vitters Shipyard to share a glimpse of what is yet to come and they proudly shared with us that the following projects are currently in build:

Project 3090, named Maximus, will hit the water in summer 2023. This 59m ketch, designed by German Frers, is a real wolf in sheep’s clothes.Her classic hull lines, teak deck houses, and sheltered cockpits are a

true showcase of classic elegance.However, below the waterline of Maximus, it is all about performance. Twin rudders, a li ing keel, and an optimised wetted surface area will accommodate need for speed. Her sail and deck plan are optimised for competitive racing. Maximus will make her debut on the race course in 2024.

Technical specs Project 3090

Design Frers Design

Interior designSpencer-Churchill Design

Overall hull length 59m

Delivery Summer 2023

Project 3093 is a unique 44m fast cruising sloop. Characteristics of project 3093 include a contemporary interior styling combined with exterior sporting dynamic lines, with a modern touch.The superstructure, with ample glass, provides a panoramic view from all positions and gives that extra spacious feeling.Delivery of project 3093 is scheduled for the summer of 2024.

One of the early and most important stages in the process of building a custom yacht is to transform the ideas of the owners, the lines of the naval architect and the design of the interior stylist into information that can be used for construction.

Technical specs | Project 3093

Design Reichel Pugh Yacht Design

Interior design Design Unlimited

Overall hull length

44.3m

Delivery Summer 2024

Project 3094, better known as project Zero, will change the world of sailing superyachts. This highly innovative project will have no combustion engines and will therefore be zero emission.The required energy on board will be generated by solar and wind power.Apart from the

high level of innovations, this project will be a true head turner on aesthetics. Long overhangs, classic looks and two powerful rigs will make Zero a true Grand Dame

Technical specs Project 3094

Design Vripack / Dykstra Naval Architects

Interior design Vripack

Overall hull length 68.9m

Delivery Summer 2025

i. vitters.com

Built

It is not just her size, but most of all her stylish exterior and interior design that impress yacht lovers and make this superyacht an exclusive dream home on the high seas. Austrian interior+ out tter List General Contractor (ListGC) was commissioned with the project management of the yacht interior on four decks and a total of 745m2 and furnished the yacht with handcra ed special surfaces and exclusive ttings. In completing this project, the company from Bad Erlach in southern Lower Austria once again highlights its long-standing position as a leading international partner for highly complex interior+ furnishings for luxury yachts and private residences. The largest and most famous yachts in the world already bear the signature of the specialists from ListGC – and now MYAhpo is no exception. The ListGC scope on the main deck, consisting of

thesalon, dining room, wine storage and board room, covers almost 290m2. The owner’s deck is equipped with an informal lounge and the sky lounge deck with a tness room. The yacht’s pièce de résistance, the spacious spa area, is located on the lower deck of the ship.

Exclusive furniture, special surfaces and metal elements – the execution plans of a yacht interior include every detail, no matter how small. ListGC’s strength lies not only in its understanding of design, but also in its complete project management. The company coordinates countless surveying and elaborate feedback and approval processes with the shipyard, design studio and subcontractors, including quality controls, until the assembly process on the yacht, which is accurate to the millimetre, can begin. This was also the case with MYAhpo, which was handed over to the owner in 2021.

that the project ran without a hitch. “In terms of construction, the project was an extremely small-scale and precise job. There was a substantial number of components and countless speci c requirements and designs: communication on an equal footing and tact were our ingredients for success on this project.” Managing the expectations of the various project partners is also crucial. “The more the designers, owners, shipyard, and ListGC team agree, the better things will go. And things could not have gone better on the Ahpo project”, adds Schmallegger.

The stylish mother-of-pearl 3D varnish nish by ListGC is one of the highlights: it adorns the walls and parts of the ceiling of the spa area and the informal lounge. The handmade special surfaces designed especially for the project make the yacht one-of-a-kind. In collaboration with the top-class design studio Nuvolari Lenard, the surfaces were perfectly matched to the customer’s wishes. Details speci ed by the design team, in the form of samples or visualisations, had to be created and recreated in detail – for example, from a 10x10cm reference sample to an entire wall with a total area of 200m2. The sampling process continued for several months and required a high degree of creativity and cra smanship. An essential step here was to ensure that the surfaces were not only visually appealing but also hard-wearing. “When developing the special surfaces, we bene ted greatly from our experience working on past superyacht projects. We knew exactly how to integrate all the processes into the tight schedule – and which steps required a particularly close eye or even sensitivity at times”, says Christof Hack, Senior Engineer at ListGC.

Another highlight in the Spa area besides the mother-of-pearl surfaces is the teak ceiling in leaf form, consisting of three large and two small leaves. A single one of these leaves has a dimension of ve to six metres with seven to eight segments each, separated by curved joints.

Karl Lechner, Team Coordinator

Karl Lechner, Team Coordinator

Production at ListGC, comments on the production of the teak ceiling, “The work processes of the project were practically mirrored. The material was worked on the oor, but ultimately applied to the ceiling

“When developing the special surfaces, we bene ted greatly from our experience working on past superyacht projects. We knew exactly how to integrate all the processes into the tight schedule – and which steps required a particularly close eye or even sensitivity at times.”

of the yacht. This requires a high degree of spatial thinking and extreme accuracy. The size of the individual sheets also presented us with challenges in terms of space. Every single step had to be weighed in the mind beforehand. When you see the result and everything works perfectly together, you get an unparalleled sense of achievement every time!”

This is just one of the projects that the specialists in southern Lower Austria are working on with dedication and passion. Projects of this magnitude are only possible thanks to perfect interaction between the cross-divisional teams. At ListGC, the roles and areas of work are as diverse as the yachts that are furnished. Every project presents new challenges and variety, which is a great motivator in the company. Christof Hack says, “When the steel of the ship is ready, that is when we get to work – down to the last piece of

decorative upholstery. Employees could be taking care of the stonework, the furniture, the lighting, the fabrics, or the leather. The interior design is always di erent. You do not get that variety in any other profession, and that is the most exciting thing!”

Over the past 20 years, working on many exceptional projects, such as the motor yachts Artefact (80m) and Alaiya (111m) or the sailing yacht Ribelle (32.5m), has given ListGC unrivalled expertise and a valuable wealth of experience as an interior+ out tter, which is re ected in the success of the superyacht Ahpo. “Since strict secrecy is paramount in our industry alongside high quality standards, we are all the more pleased to be able to report on this a er successful implementation and provide insights into our varied, unique projects”, says Christian Bolinger, Managing Director at ListGC.

i. www.listgc.at

With their Dutch quality, reliability, innovation, and design, the Netherlands is among the world’s top superyacht builders.

The demand for large superyachts with increasingly luxurious nishes is increasing. In the past ve years, 67 superyachts with a length of more than 50m have been built in the Netherlands alone. There is also a tendency for new

owners to have (second-hand) yachts fully customised to their own wishes. Every year, dozens of these so-called re ts take place. This creates the necessary challenges for the facilities and waterways of the shipyards.

In 2021, investment company Larendael, headed by Wim Beelen, had purchased a historic 53ha plot of land in the western port area of Amsterdam, with the view of

The site will be designed to encourage specialists to work together in one location, to innovate together, and to create concepts that are world leading.

establishing the Dutch Superyacht Tech Campus. The Campus will be built at a location in the Amsterdam harbour where hundreds of ships were already rebuilt, re tted, and built in the 19th and 20th centuries. The Campus is highly accessible and tidal and can accommodate yachts up to 200m long. The site will be designed to encourage specialists to work together in one location, to innovate together, and to create concepts that are world leading.

Another unique feature is that the Campus o ers the space to design and produce the entire yacht on site, as well as space for training. This reduces the need to travel to a minimum. Fewer travel and transport movements contribute to making the sector more sustainable. In addition, the construction of the various facilities, energy neutral or even energy generating is the starting point and transport on the Campus will take place by bicycle or electric baby carriage.

The Dutch Superyacht Tech Campus o ers every opportunity to further strengthen the strong position of the Netherlands in

this market and to grow employment in the sector.

The construction preparation of the Dutch Superyacht Campus started from November 2021 to March 2022. Construction works on dock 1, 2, and 3 started in March 2022 and completion is scheduled for June 2023. Construction of the quays and the oating pier began in April 2022. The pier has been commissioned in June 2022, and the quay in April 2023.

The Dutch Superyacht Tech Campus is easily accessible for superyachts via the North Sea Canal. The Campus will be set up in such a way that several superyachts up to 200m in length can be newly built and/or re tted and o ers space for mooring 40superyachts up to 200m.

The Campus will be designed to optimise communication and cooperation between various specialists. With R&D units and innovation labs, high-tech companies and vocational schools will come up with

FROMSTARTTOFINISH Integratedwaterandwaste managementsystems formarine&offshoreapplications.

Qua-vacsignificantlyreducesyour environmentalimpactwith innovativeandsustainablesolutions.

At Kohler, we are guided by a single purpose: your experience. Those quiet moments when you forget your generator exists. That’s why our new marine generators are exponentially quieter with even less vibration. The most advanced, most reliable machines we’ve ever made—not that you’d notice. From engines to generators, we give the world power.

info@quavac.com|www.quavac.com

By providing an environment where the future of superyachts is taking shape, while the current generation of yachts is being created in plain sight, we o er both professionals and students a unique and stimulating environment.

ground-breaking innovations of the yacht building industry here. By providing an environment where the future of superyachts is taking shape, while the current generation of yachts is being created in plain sight, both professionals and students are o ered a unique and stimulating environment.

Each production hall is assigned a function, so that specialists and performers in areas such as design, electrical systems, interior and exterior can work together more e ectively and e ciently. By placing value-added activities back-to-back in the production process, quality improves, and the number of transport movements is reduced.

A total of seven covered docks will be constructed, four large docks up to 200m in length and three large docks up to 155m in length. These docks will be used for re ts and maintenance of existing superyachts. A yacht elevator is available for yachts up to 80m, allowing maintenance to take place on the shore. Outside, with a water depth of up to 9m, there will be space for mooring 40superyachts up to 200m in length. There will also be a bunker station.

The accessibility of the Campus is also ideal for visitors and crew. There is a HeliCentre right next to the site. Amsterdam Airport Schiphol, the third largest airport in Europe, is een minutes

away, and it is only ve minutes to the center of Amsterdam. A vibrant city with leading museums, culinary restaurants and a variety of luxury stores.

And when the yacht is ready, this is the ideal starting point for the increasingly popular route to the top of the world, London, or other destinations.

i. dutchsuperyachttechcampus.nl

Ecodeck, a Dutch company which has a longstanding experience with teak for the Super yacht industry, gradually discovered the wish and the need for alternative materials for teak.

EcoDeck was introduced in 2012 in cooperation with Herculan Marine, a er which they introduced a nautical deck application that satis es the highest standards in the Super yacht industry while reducing the impact on the environment.

Last year, EcoDeck underwent a signi cant transition and determined a new strategy. Since then, investments have been made in a completely new production facility. The

professionalisation of the overall organisation of the company has intensi ed the cooperation with the stainless-steel specialist Werkvreugde Contracting. It is their ambition to become a leading global brand in the industry by investing in various partnerships worldwide, such as Germany, Italy, Sweden, and Australia. They have been able to expand signi cantly in a short time, while maintaining the high quality and

the level of nish that is among the most prestigious in the industry. The product and concepts are developed at the Dutch headquarters in Medemblik in a state-ofthe-art design and production facility. This makes the company very exible and highly e cient. That being said, their focus is on functionality, inspired by the environment. Much research focuses on regulations and user requirements.

EcoDeck® is a safe product according to SOLAS and IMO regulations. During its lifetime, EcoDeck® will maintain its properties and is easy to repair. EcoDeck® is a DNV GL certi ed product and Green tag veri ed. EcoDeck can o er customers a complete custom designed proposal for their vessel. There is a lot of freedom and there are many opportunities in the design, such as plank width, joint width, the possibility of personalised design, lettering, and logos, and all available in fourteen astonishing standard colors.

EcoDeck® is a strong, exible, solvent free, UV-proof, non-skid, ame retarding, and polyurethane resin-based ooring system, which is easy to maintain at low costs.

This prefabricated, viscous-elastic composite material has a stylish and warm e ect, a seamless and durable nish, and is suitable for numerous applications, suchas:

•decks,

• ooring(interior),

•cladding,

•ceilings, •caprailing,

•toerailing,

•steps, •gratings.

According to digital measurements and AutoCAD-drawings, EcoDeck® is supplied in Prefabricated panels and is produced with the latest CNC-techniques. The prefabricated sections can be fully bonded to the substructure, whether it is aluminium, steel, GRP, or mineral based. Unlike the current alternatives in the market, EcoDeck® uses a unique backing for the panels. EcoDeck has a patent for its unique backing system that distinguishes EcoDeck® on quality compared to other brands. The EcoDeck® backing is produced

The raw material for the backing has been modi ed for excellent dimensional stability and durability through a toxic-free environmentally friendly process.

with a high-quality formaldehyde-free glue, it is easy in use, and will last for decades. The raw material for the backing has been modi ed for excellent dimensional stability and durability through a toxic-free environmentally friendly process.

EcoDeck anticipates on making the production process more sustainable. Alternatives are sought when the commodities market behaves erratically and they are continuously improving their own products to take them to an even

higher level. In summary: The vision of Ecodeck is to enable their company to design, develop, and manufacture the best possible products for their customers while increasing social- and reducing environmental impact. The only way forward and the aim is to gradually replace the use of conventional materials, including teak, to a great extent, with new, sustainable alternative materials. So when it is desired, EcoDeck® can have the appearance of Teak and the responsibility in sustainability.

i. m-ecodeck.com

i. werkvreugde.nl

In issue 3 of SuperYacht Industry of last year, we shared a rst glimpse of Amels’ project Witchcra , the second Amels60 Limited Editions yacht, which now goes by the name of Entourage.

The rst Amels 60, Come Together, was delivered in the spring of 2022. It is not only the Espen Øino exterior that is shaping up. Winch Design was appointed by the Owner to create the bespoke interiors of this rst Amels 60 hull. The tour we received on Come Together during the Monaco Yacht Show of 2022 is still fresh in our memory, impressive as it was. We cannot wait to check out the latest members of the Amels 60 series in real life during the next yacht show season. Just recently, in late February, the team at Damen Yachting proudly announced the delivery of Entourage, number two in the Amels 60 range.

Featuring an exterior from Espen Øino, the Amels 60 is focused on o ering the ultimate onboard experience with the freedom it o ers expressed in spaciousness throughout the Sun Deck and Swim Platform as well as the folded Owners suite balcony. Additionally, the yacht features space for a 9m tender on the foredeck. Onboard accommodation hosts up to twelveguests as well as twelve crew, plus Captain.

The Owner has worked with Moran Yacht & Ship throughout the build and has been heavily involved in the process, bringing several custom touches to the yacht. This

includes an adaption to the Amels 60 signature windows, allowing maximal light to ood the monochromatic interior. For the interior design, the Owner has selected to work with Canada-based design studio Burdi lek. The studio has developed a luxurious interior, notable for its sense of serenity.

The Amels 60 has been developed to carry the spirit and philosophy of the Amels Limited Editions forward. Featuring a range of cutting-edge equipment and technology, including IMO Tier III compliant hybrid power and propulsion, >>

Amels 60 Limited Editions yachts

Length overall 60m

Beam overall

10.40m

Gross tonnage 830GT

Designer Espen Øino

Architecture Studio Indigo

Developer Damen Yachting

Speed

Range

15.5kn

4,500nm at 13kn

Guests 12 + Captain

the design is the advanced guard of a new generation of yachting.

At the same time, the Amels 60 remains true to its heritage, retaining the innovative build process that has made the Amels Limited Editions such a renowned success. The yacht o ers optimal customisation potential, combined with fast delivery of a proven platform, featuring naval architecture and seakeeping characteristics both tried and tested.

Following delivery, Entourage will undertake a busy charter season overseen by Moran Yacht & Ship.

Arie Midavaine Project Manager at Damen Yachting says, “It’s been great to see how all parties involved have pulled together and given so much e ort during this busy project. The result of their work speaks for itself; the yacht looks stunning. We hope that the Owner will enjoy stepping on board for the rst time this spring.”

Sean Moran from Moran Yacht & Ship comments, “We at Moran Yacht & Ship would like to take this opportunity to thank the Owner for his trust in our team throughout the build process. We would also like to thank and congratulate the talented workers at Damen Yachting and the Owner’s team for this tremendous achievement – we look forward to many more successful projects with the Damen Yachting organisation in the future.” Soon a er the announcement in late February, in early March, Damen Yachting also announced the launch of the Amels6003 yacht at its yard in Vlissingen,

the Netherlands. The yacht will now undergo out tting in preparation for her completion.

The Amels 60 represents Damen Yachting’s vision for the future of super yachting. The design combines generations of heritage with the latest developments, forming a bridge to the yachting world of tomorrow. In addition to her distinctive, elegant lines from Espen Øino, she boasts hybrid power and propulsion technology for both sustainable performance and improved on board comfort.

Joppe Osté, Project Manager at Damen Yachting shares, “It’s a proud moment to see the yacht launched successfully today. She looks stunning in the winter sunshine, a true testament to all who have worked so hard towards this moment. I know I speak for the whole team when I say how much we are looking forward to the next few months as we work on taking the build through its nal phases.”

Jorrit Pilaar, Sales Manager at Damen Yachting says, “We are very excited to see the yacht enter the water for the rst time. With this milestone moment behind we’re very keen to move forward to the next stages and prepare this third Amels 60 for this year’s yachting season.”

i. damenyachting.com

“It’s a proud moment to see the yacht launched successfully today. Shelooks stunning in the winter sunshine, a true testament to all who have worked so hard towards this moment.”Joppe Osté – Project Manager at Damen Yachting. The 6003 is currently undergoing outfitting in preparation for her completion.

Tillberg Design of Sweden (TDoS), part of The Viken Group, has designed a luxury superyacht, also called a yacht liner, for Four Seasons, a renowned brand that runs 127 luxury hotels and resorts all over the planet.

The studio has been appointed for the designing and master planning as well as the complete exterior styling of the 207m vessel that is scheduled to be launched in 2025. TDoS also designed all the guest suite accommodation, including the illustrious funnel suite, and a few of the most iconic guest shared areas onboard. The yacht is engineered and constructed by Fincantieri.

“This project con rms a new and strong trend in modern yachting, namely luxury yacht liners. They are a new breed of very exclusive vessels that combine the scale of small and intimate cruise ships with superyachts’ amenities, splendour and level of sophistication”, says TDoS’ Partner and Executive Director Fredrik Johansson. “Our

new project started with a very clear and unique vision from our client. The brief was condensed into a single line: imagine that [legendary yacht built for Aristotle Onassis] Christina O meets James Bond. It would be hard to go wrong there, you may think - but it is also a huge challenge. You must not go wrong - failure is simply not an option. Every part and every detail of the yacht must be perfect.”

Established in 2022, The Viken Group includes Tillberg Design of Sweden, Hot Lab, and Thalia Marine. It provides a full range of design, naval architecture and project management services in the yachting industry. All these pro ciencies will be available to both cruise line and yacht clients, as well as to customers

within hotel, resorts and private island developments. TDoS has long been one of the major players in cruising design and today it specialises in design concepts for cruise ships and yachts, while also providing graphic design and branding for a variety of clientele.

Based in Trieste, Italy, Thalia Marine is a full-service project management rm providing technical design expertise ranging from design consultancy, quantity surveys, on-site inspections and much more for the cruise ship and yacht building industries.

Hot Lab from Milan, Italy is The Viken Group’s most recent acquisition. The studio embraces the sophisticated ‘Architecture for Voyagers’ concept that helps nd the perfect balance between style and luxury. It has received some of >>

The METSTRADE Show is the world’s largest marine equipment trade show and the only truly international B2B exhibition. With excellent networking opportunities, a broad range of showcased innovations and located in one of the most beautiful cities in the world, the METSTRADE Show is an unmissable event for every professional in the marine industry.

the most prestigious international design awards in the yachting industry, including many World Superyacht Awards and ShowBoats Design, and it works with interior and exterior designs on both custom and series produced yachts.

For the Four Seasons yacht, the TDoS team has created a truly timeless elegance, with a curvaceous and elegant architecture. The harmonious lines and proportions of Christina O, which also featured a very generous and beautifully furnished a pool deck, inspired the designers to add a 20m long pool with a surrounding deck in the very a of the 14-deck Four Seasons, and its layout caters perfectly for both privacy and socialising. The pool bottom will double up as a stage for catwalks, live music, et cetera.

“At the inception of this project, Tillberg Design of Sweden worked very closely with the Marc-Henry team and Four Seasons, in analysing extensive market research, and creating a very clear and solid brand manifesto. As we are building a

“The iconic, timeless and beautiful exterior is also the work of TDoS, and they have since master planned the whole vessel, designed all the guest suites, and some of the prime public areas onboard.”

whole new guest experience from scratch, this document has been instrumental as a guidance for the development of our entire yacht, which has turned out distinctly unique,” says Larry Pimentel, CEO of MarcHenry Cruise Holdings. “The iconic, timeless and beautiful exterior is also the work of TDoS, and they have since master planned the whole vessel, designed all the guest suites, and some of the prime public areas onboard. Our collaboration with TDoS has been incredibly inspiring and fruitful. As our lead architects, they have once again demonstrated their passion and deep knowledge of high-end design, from the broad strokes down to the nest details.”

The silhouette of Christina O is largely shaped by its large and iconic funnel. The Four Seasons Yacht however, will be designed and equipped to minimise emissions. The Tillberg Design of Sweden

TDoS has long been one of the major players in cruising design, since founder Robert Tillberg made the ocean liner and cruiser Kungsholm a showcase of bespoke Scandinavian style in 1964. Today TDoS specialises in design concepts for cruise ships and yachts, while also providing graphic design and branding for a variety of clientele. Lightness and luminosity of spaces is a trademark of TDoS, all in all with a purposeful Scandinavian design that is rmly grounded in history, and with a future-proof timelessness.

team therefore thought hard and long of a way to give the funnel of the Four Seasons yacht a completely new and innovative context – and the concept of the sublime ‘Funnel Suite’ was born. Guests will have a total of 892m2 of combined indoor and outdoor space, distributed over four levels, meaning that they really are on top of the world here. It’s also accessible, directly and privately, from a tender platform at water level, allowing one to invite friends onboard at complete discretion. This is as close as one will come to a true James Bond moment on any yacht.

“Much inspiration was taken from the private and sophisticated atmosphere of Surf Club, Miami Beach - and of course from the golden era of classic yachting. Already at the outset, we concluded that the master planning must be made to welcome every single guest as if it was to the yacht of a close friend, instilling an instant sense of relaxation and belonging”, adds Mr Johansson.

Yet another spectacular design feature onboard is the port-to-starboard transversal marina. Not only is this dual marina a unique engineering masterpiece, but its

terraced design also allows the guests to enjoy the sea rst hand, with immediate access to water activities, and to sea limousine transfers to shore. It can also be transformed into an exclusive dining experience.

As for the interior, the TDoS’ design team will create suites and social spaces that re ect a truly e ortless Dolce Vita and worldly sophistication, o ering everything that is essential for a truly epic yachting experience.

The vessel’s 95 spacious accommodations will feature an extensive network of joining suite combinations creating adaptable, villa-like residences. Each suite will o er oor-to-ceiling windows providing unobstructed natural light and access to expansive terrace decks. The combination of generous indoor and outdoor private guest space and ceiling heights of more than 2.4m will achieve a new level of guest comfort. The Four Seasons Yacht will also feature a number of high-class restaurants, lounges, bars, spas and other high-class amenities.

The Viken Group includes Tillberg Design of Sweden, Hot Lab and Thalia Marine. It has been established to gather leading and passionate companies, with similar ideas and business ethics, under one umbrella. This enables it to provide a full range of completely aligned and comprehensive design, naval architecture and project management services. All these pro ciencies will be available to both cruise line and yacht clients, as well as to customers within hotel, resorts and private island developments.

Tillberg Design of Sweden has a strong experience in the relatively new yacht liner eld. The studio is the lead architect for master planning and interior concepts for 222m Somnio dubbed the world’s largest private residence superyacht and The Ritz-Carlton Yacht Collection.

i. tillbergdesign.com

In this Holland-themed edition of SuperYacht Industry, we cannot leave out Feadship. Every Feadship is an innovation in itself, as the Dutch company constantly strives to rede ne the perception of perfection and makes every Feadship better than the last in terms of construction and technology.

The company uses space-age technologies and materials, hyper-modern design tools, and the very latest insights into construction and systems. Feadships are products of an evolutionary R&D and overall quality enhancement philosophy that results in inimitable yachts. Let’s take a look at their latest projects.

The 67.4m Project 823 has recently been seen in the bold light of day for the rst time. This impressive new Feadship has been moved outside of the construction hall at the Kaag yard for nal out tting in advance of her sea trials later this year. Project 823 has been fully designed in-house by Feadship. The hull engineering is by Azure Naval Architects, while the exterior and interior design are by Studio De Voogt. The exterior pro le is bold with a muscular reverse sheer to the bow. Chiselled contours and dark horizontal strip windows lend the yacht a poise and grace. “The main theme of the yacht is strength”, says Jan Scha ers, Senior Designer at Studio De Voogt. “The radii throughout are larger than usual to emphasise this. At the same time we aimed to focus on the length of the yacht by creating uninterrupted lines, for instance in the widebody windows and the superstructure. Together this creates a very unique character.” Designed and built for an experienced owner, the interior layout was tailored to his family’s speci c needs and provides ensuite accommodation for ten guests in three lower deck cabins, one VIP suite on the bridge deck, and a master stateroom on the main deck forward. >>

The interior design by Studio De Voogt is simple yet sophisticated and based on natural tones, light wood veneers and organic forms for an ambience that is soberly tasteful but also informal and welcoming. An elevator can whisk guests from the lower deck all the way to the large sundeck – a highlight of the design and a focal point for family life on board. The central lounging / conversation zone is protected from the wind by a glass windbreak and from the sun by the hardtop, but wide side windows and nine skylights in the roof ensure uninterrupted views and en plein air appeal. The ventilation casings can be regarded as powerful legs, clad with grilles that repeat the horizontal lines to create a more elegant volume, but without losing its power. The radar mast was engineered to span these glass skylights, supported by at panel satellite hardware for broadband internet. In order to free up space for a large wellness area and gym on the lower deck in the stern, the tenders are stowed behind the high bulwarks on the foredeck. Careful attention has been paid also to the crew quarters and service areas

with additional fridge-freezer storage, a large laundry room and extra dry storage on the tank deck.

Also very recently, one of the most technically advanced and dynamically designed Feadships of recent years has slipped out of her construction hall at the Feadship yard in Aalsmeer for nal out tting in advance of sea trials. Project 710, as she is known at the yard, extends to 84m. According to the design team, the brief called for every yacht design norm to be questioned and challenged, both in terms of architecture and engineering, to create a next generation project. Her length is optically stretched by a low pro le, horizontal styling features, and very clean shapes owing a from a strong bow showcasing strength and seaworthiness. For the rst time in years, Feadship has launched a yacht with a single level engine room, a ording considerably more room for creativity with accommodation, in a layout as bold and modern as the exterior pro le suggests. Both the exterior design

and interior architecture and design are by the British rm RWD in collaboration with MONK design. There are surprising destination spaces, such as an asymmetrical atrium staircase leading to a lower deck dining saloon, where an entire wall opens to reveal a terrace view just above sea level. Near the stern is an Aqua Lounge with massive windows below water level. In place of a mooring deck forward there is a revelatory bow observation lounge with double-curved glass oor-to-ceiling windows. Terraced a decks oat without pillars, while glass balustrades allow unobstructed views from both a deck and fully glazed a interior spaces, creating a vital connection to the natural environment.

Striving for innovation and rst-class engineering, Project 710 is the perfect next step on Feadship’s path toward building zero-emission superyachts by 2030. It is the rst of the new generation of large yachts furthering carbon reduction through hulls optimised at cruising speed instead of top

speed, weight control, advancements in electric propulsion, and the ability to run her generators on HVO, a secondgeneration biodiesel, a so-called net zero CO2 fuel. Sea trials and delivery ll will be HVO, reducing total CO2 emissions by about 90%.

Using Feadship’s Advanced Electrical Drive (FAED) program for diesel-electric hybrid power, Project 710 has 4.5 times more electrical storage capacity than the rst hybrid yacht, Savannah. She has no drive sha s, and no rudders. Electric drive and steering are through a pair of electric Veth contra-rotating thrusters. Feadship and

Veth collaborated on computational uid dynamics (CFD) analysis of the drive legs and propellors’ shapes to maximise e ciency and minimise vibration.

Providing energy for the luxury hotel load accounts for much of a yacht’s fuel consumption. For Project 710, the engineering team took a deep dive into capturing waste heat from the custom variable speed generators and air conditioner chiller to supply heat to the AC system, pool water, domestic water, engine preheating, and more. An innovative heat pump system allows the yacht to draw heat from seawater. All these

features (and more) were developed to connect to the surrounding environment within a next gen yachting platform that leaves minimal trace within that environment.

Feadship is already busy organising for this year’s Monaco Yacht Show and can’t wait to meet everyone this autumn at the Côte d’Azur. At their stand (JS3), people will be able to discover their all-new Future Concept as well as get a copy of the newest Pilot Magazine.

i. feadship.nl

When sailing the ocean, feeling the greatness of the earth, there is a longing for nature on board. We want to stay connected with nature and you can see that re ected in the latest interior designs.

There is a calling for natural materials and in recent boat shows we have seen some exquisite examples of environmentally friendly and sustainable materials.

Styled ower bouquets are o en not the only natural element on board. True gardens with living plants make their way to the decks. Some yachts even house a horizontal garden, stretching over two decks. With harsh conditions sailing the ocean, such as salty, sunny weather, it is

challenging to provide living plants with ideal conditions, not to mention the required maintenance.

The designer, who recognised the desire for nature coming up years ago, is Liesbeth Bulk from the Dutch studio Crush on Nature. She happens to be an expert on designing with plants and owers with a Master’s degree in ne arts from the Rietveld Academy.

Teaming up with glass companies from the superyacht industry, she worked for a variety of clients in private residences and business locations, Crush on Nature developed many techniques to implement plants in interiors.

For superyacht interiors, as they are literally ‘on the move’, the studio o ers bespoke glass panels with true fern leaves inside. The so green foliage, melted in glass, creates a beautiful natural

atmosphere. Perfect for a vanity room or wellness area. The patterns of true leaves make a calm place for relaxation. Application is not limited to a wall panel or tabletop. Also, a shower wall with elegant strategic masking with the true fern leaves is possible. So backlighting, layering multiple panels, and a combination with mirror glass, create depth and the experience of endless natural space.

The studio has created large Floating Flora dividing walls. A large collage, of at-dried plants, is placed between two planes of glass. The ligree of the plants creates a light and spatial interior. The Rotterdambased studio translated delicate plant collages into high-resolution digital images. Crush on Nature’s ower and plant collection is one of Europe’s biggest

The studio has created large Floating Flora dividing walls. A large collage, of at-dried plants, is placed between two planes of glass. The ligree of the plants creates a light and spatial interior.

digitalised, creative herbaria. With this amazing collection Crush on Nature can not only create glass panels with collages of owers, leaves, twigs, and tendrils but also provide images to be transferred to paneling, textile, tiles, Corian, etc.

Does your project require a natural touch?

Crush on Nature o ers a full scope of brainstorm meetings to explore how they can translate your ideas into Crush on Nature techniques. Or do you have a

speci c request for a digital collage? They know exactly how to bring the perfect natural atmosphere and balance into an interior using real and digital ora.

Crush on Nature is looking forward to hearing from you!

i. crush-on-nature.com

Another not to miss player within the Dutch superyacht sector is, of course, Heesen. Let’s have a look at what is currently cooking in the Heesen kitchen.

Just recently, Heesen con rmed with great delight that, following a rigorous programme of computational uid dynamics simulations and two days of model tests in the new tank at the Wolfson Unit in Southampton, the hull design of Project Setteesettanta has passed with ying colours.

“The fast displacement hull of this 57m yacht was tested in many di erent sea states, including those representing very harsh conditions”, comments Perry van Oossanen of renowned Dutch hydrodynamicists van Oossanen Naval architects. “We had paid particular attention in the design to achieving low accelerations, in both pitch and roll –which are the measure of comfort onboard – and to ensuring a dry vessel in spite of her reversed-bow design.”

Calm water tests proved equally

satisfactory, Mr Van Oossanen con rms, “They demonstrated yet again the topnotch performance of the Fast Displacement Hull Form.”

Project Setteesettanta is a full-custom motor yacht for repeat Heesen clients, who requested a yacht tailored to their lifestyle. Setteesettanta incorporates the nest details to satisfy every family member and deliver the best experience possible, whether on passage or at anchor, with a particular emphasis on maximum comfort in all sea conditions. A conventional propulsion system and two compact MTU 16V2000M72 (1,440kW) diesel engines will give the yacht a top speed of 18kn with a remarkable range of 3,900nm at 12kn. >>

Heesen excels in building lightweight, all-aluminium yachts engineered and built to the nest tolerances. Meticulous weight control ensures outstanding performance in both speed and e ciency.

“Project Setteesettanta sports a fourth deck, a large pool, and a low stern, which allowed us to ex our mental muscles to ensure the vessel’s stability”, says Sjoerd van Herk, Heesen Senior Naval Architect. “We are currently nalising the preliminary design, and next month, we will begin the engineering phase. We look forward to the keel laying in September.”

Another exciting project which is currently in build at the Heesen shipyard is Project Akira, the rst in Heesen’s new 57m

all-aluminium series of fast yachts, with an enclosed volume of approximately 780GT and a lightweight, ultra-e cient Fast Displacement Hull Form. Heesen is one of the few shipyards in the world with the in-house capability to weld such highperformance structures to the required tolerances. In April of this year, Heesen announced the sale of project Akira. Mark Cavendish, CCO at Heesen states, “It is a very exciting time for our shipyard as YN 20457 Project Akira is the rst in a new class of yachts, which we have carefully studied and engineered to deliver optimum luxury on water. We look forward to working with the owners and their family to build a yacht that will provide many days of happy sailing and create long-lasting memories.”

Heesen presented the 57m series design at the Monaco Yacht Show in 2019, and construction of YN 20457 began in February 2022 as a speculative venture. The o cial keel-laying was witnessed by the American Bureau of Shipping surveyor. To mark the occasion, four Heesen employees celebrating their 25th work anniversary carried out the rst welds. Another milestone took place on 18November of 2022, when Akira’s two IMO Tier III-compliant MTU 16V 4000 M65L engines were installed. This propulsion package, in concert with the super-e cient hull design, will give the yacht a maximum speed of 22kn, which is quite remarkable for a superyacht displacing approximately 490t at half load and with no lack of luxury.

Joining the hull and the superstructure was another landmark occasion in Akira’s construction and took place in December of 2022. The project remains on schedule and is set to be delivered to her new owners in time to enjoy the 2024 summer season. Frank Laupman of Omega Architects penned a distinctive pro le that, as well as making Akira stand out at sea with her assertive attitude, sweeping lines and a near-vertical bow, will also turn heads in harbour, thanks to a unique scooped stern that gives her a compelling quayside presence.

Harrison Eidsgaard worked closely with Frank Laupman and Heesen’s in-house engineers to create an e cient and purposeful layout. The owners and their team are working with Harrison Eidsgaard

and Heesen’s interior engineer to personalise the yacht and meet their tastes and lifestyle. Akira will o er plenty of outdoor space to enjoy life at sea, and generous indoor areas in which to socialise and relax.

Twelve guests are accommodated in six staterooms, with the 63m2 owner’s apartment located forward on the main deck. There is a VIP suite on the bridge deck above, while the remaining guest cabins are on the lower deck. A glass and stainless-steel elevator serves all three decks. Heesen Yachts Interiors, Heesen’s ne cabinetry workshop in Winterswijk, is responsible for handcra ing the re ned bespoke furniture for Project Akira.

Europort has two official publications that will be released during this year’s show; the EXHIBITION GUIDE and the

. Now is your chance to secure

The EXHIBITION GUIDE is a compact, pocket-sized booklet with clear and brief directions to easily find every exhibitor.

• 20,000 distributed copies

• Alphabetical list of exhibitors per hall with respective booth number

• Programme schedule

• General floor-plan and detailed floor-plan of each individual hall

• Ads starting at € 600,-

Turkish yacht builder VisionF Yachts has strengthened its team by appointing Ali Tanir as General Manager, a significant step towards implementing the company’s longterm strategy. Founded just four years ago, the Istanbul-based shipyard specialises in producing composite and aluminium motor catamarans and is now poised to capitalise on Mr Tanir’s vast experience. From 2012 to 2023, he held various executive positions at Numarine starting as Communication and Brand Manager, and then moving into the role of Sales and Marketing Manager and Head of International Sales.

On 1 April, Bert Beckers will stop as Head of Production at Damen Yachting. Fortunately, after exactly 21 years in this position, he will not be leaving the Damen family just yet. As HSSEQ manager, Mr Beckers will be responsible for leading the HSSEQ team and sustainability. In addition, effective 1 April, Willem Bierens, who has been with the organisation for 20 years and most recently served as Manager Production, will take over as the new Head of Production.

French water treatment specialist BIO-UV Group has appointed Laurent-Emmanuel Migeon as its new Chairman and Chief Executive Officer, succeeding company founder Benoît Gillmann. Mr Gillmann, who founded the company in 2000, says, “After more than 22 years of service dedicated to the development of BIO-UV Group, I have decided to sell my BIO-UV Group shares to focus on other projects and my family. I am proud of what we have achieved over the last two decades and thank all those past and present members of the BIO-UV Group family who have been key to that success. I am leaving the company in very capable hands.”

On 1 April, Norbert Leifeld will join Bavaria Yachts as the new Chief Operating Officer (COO). As COO, he will be responsible for product development and operations and form, as the second managing director, the Management Board together with Marc Diening, the Chairman of the Management Board and CEO of Bavaria Yachts. Mr Leifeld has worked as a management consultant for leading OEMs in the automotive, yacht and RV industries for the past 15 years. In addition to his operational responsibilities, he has achieved particular success in project management, product development and organisational development.

The Viken Group – a conglomerate of businesses and preferred partners operating at the highest levels of the cruise and yacht industries – has announced appointments to two new roles.

First, Anna Silvesjö – CFO of Tillberg Design of Sweden – joins as Viken’s CFO to work alongside Viken CEO Stefan R. Nilsson.

Second, Antonio Romano – Co-founder and Business Director at Italian design studio Hot Lab – has been appointed Commercial Director at Viken.

The Viken Group was established in 2022 to bring together leading design and project management companies in the marine sector who share similar beliefs and passions both for the development of design and the evolution of the sector toward more sustainable propositions.

YSA Design has appointed Fabiana Vale Dornelas and Trond Sigurdsen as Head of Sustainability & Implementation and Head of Sustainability & Technology, respectively. In the newly created roles, Ms Dornelas, Senior Interior Architect, and Mr Sigurdsen, Senior Architect & Partner, will jointly coordinate YSA’s efforts to advance sustainability throughout its own organisation and across every aspect of its cruise ship interior design work.

As a design studio that counts environmental responsibility among its core values, YSA Design already takes a painstaking approach to materials selection that places as much emphasis on sustainability as it does on style and function. In addition, the company only uses wood from managed forests and, where possible, sources materials locally to minimise transport emissions.

AEGEAN YACHT

Main Of ce

Akdeniz Caddesi 4, Yokusbasi, Bodrum 48400, Turkey

T +90 252 313 26 55

F +90 252 313 84 68

Boatyard

Turkevleri No: 192, Oren, Milas, Mugla / Turkey

T +90 252 532 30 40

F +90 252 532 30 20

E ege@egeyat.com.tr

I www.aegeanyacht.com

Aegean Yacht has been building, chartering, and refitting yachts since 1976. The company is based in Bodrum Turkey and so far has built and sold yachts up to 66 meters LOA to all around the World. Apart from yacht building & brokerage Aegean Yacht also provides drydocking, refit & repair services at their full service 20,000m2 seaside boatyard located in Oren –Bodrum Turkey. The boatyard can to haul out vessels up to 400 tons of displacement. We provide;

–New building & refit steel, aluminum & composite

–Machine & Hydraulic works

–Propulsion & power systems

–Electrics

–Pipeworks

–paint works

–interior and exterior joinery

–Fiberglass and epoxy

–Rigging

to the unique craft of building luxury superyachts, focusing on semi-custom steel aluminium builds, between 30 and 50 metres. This means we intrinsically know our craft and how to enhance your onboard experience at every stage.

The passion of our team and clients will always be the driving force behind our yachts’ unsurpassed quality and beauty. This is our passion and we are excited to be on this journey with you.

extensive network ensures a strong international presence in 59 countries. Besenzoni has established the widest product range available on the market: external hydraulic and retracting gangways, cranes for flybridge and stern, pilot seats, electric side doors, hydraulic bathing ladders and side ladders, hard tops, electric opening windows, hydraulic tender lifts and much more.

F +31 (0)33 299 25 99

E pr@heinenhopman.com

I www.heinenhopman.com

Contact: J.W.E. Hopman

Heinen & Hopman Engineering is a world leader in air conditioning, mechanical ventilation,central heating, refrigeration, sanitary systems, fire protection, environmental systems and air duct cleaning. Founded in 1965, the company is renowned for being an innovator in the design, engineering and installation of customised solutions. We work in four specialist areas: –Superyachts.

OCEANCO

Marineweg 1, 2952 BX Alblasserdam

P.O. Box 20, 2950 AA Alblasserdam

The Netherlands

T +31 (0)78 699 5399

F +31 (0)78 699 5398

E info@oceanco.nl

I www.oceancoyacht.nl

Contact: Marcel Onkenhout (CEO)

Oceanco designs and builds large, luxury, custom superyachts, employing the very highest standards of engineering, planning and craftsmanship allied with the most modern facilities. Oceanco is credited with producing some of the most sophisticated and innovative luxury superyachts in the world. The numerous awards won signify and underscore Oceanco’s commitment to designing and building acclaimed superyachts of exceptional craftsmanship, style and innovation. Oceanco currently has various 85m+ superyachts under various stages of construction.

MOONEN YACHTS

Graaf van Solmsweg 52F

5222 BP ‘s-Hertogenbosch

The Netherlands

T +31 (0)73 621 00 94

E info@moonen.com

I www.moonen.com

Contact: Marianne Hendriks

The name Moonen Yachts has become synonymous with exceptional quality and craftsmanship that is second to none. For more than 40 years we have been dedicated

BESENZONI SPA

Via Molere, 2

24067 Sarnico (BG), Italy

T +39 (0)35 910 456

E info@besenzoni.it

dario.tosto@besenzoni.it

I www.besenzoni.it

For 50 years Besenzoni has been constantly serving and assisting its clients in 90 countries qualifying itself in the world as one of the flagship companies of the Made in Italy. The

EMIGREEN B.V.

Noordeinde 19

3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317

F +31 (0)184 415 582

E info@emigreen.eu

I www.emigreen.eu

Contact: Niko J. Dalpis

Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector. Emigreen also provides services including design, specification, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, flow dynamics, thermodynamics and noise and vibration control. Emigreen develops and tests components including catalytic converters, particulate filters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot filter system has set the standard for others to beat. All Emigreen solutions are highly efficient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht. Emigreen links science and the market

–Commercial shipping. –Offshore industry. –Navy vessels.

Our mission is to ensure that the climate ‘indoors’ will perfectly meet the needs of people and products alike, whatever the weather outside. Heinen & Hopman offers a worldwide, 24/7 service via a network of subsidiaries and sales centres.

HEINEN & HOPMAN

Produktieweg 12

3751 LN Spakenburg

The Netherlands

T +31 (0)33 299 25 00

MTU FRIEDRICHSHAFEN GMBH

88040 Friedrichshafen, Germany

T +49 7541 90 7003

F +49 7541 90 7081

E marineregion1@mtu-online.com

I www.mtu-online.com

MTU diesel engines and drive systems are used in commercial, military and governmental vessels, as well as in yachts. Its product portfolio for yachts comprises engines and propulsion systems delivering power outputs of 466 to 10,000 kilowatts. They power series-built and displacement yachts as well as mega-yachts. They are complemented by standardized automation systems for monitoring and control of the propulsion plant. Completing the product portfolio is MTU ValueCare service support at over 1,200 locations around the world. Service includes engine maintenance, spare parts supply, and remanufacturing of engine components and complete drive systems.

Algerastraat 20

3125 BS Schiedam, The Netherlands

T +31 (0)10 238 0999

F +31 (0)10 238 0988

E info@nicoverken.nl

I www.nicoverken.nl

Contact: Jacco Vermunt

Distributor, 24/7 service & spare parts agent of marine equipment.

In our programme there are stainless steel marine pipes and drains, filtration, anti-fouling & cathodic protection, reverse osmosis desalinators (water makers), wastewater treatment, vacuum sanitary systems for yachts, deck equipment (doors & hatches) and watertight sliding door systems.

Our Ship Repair department is specialised in the overhaul of all types of main and auxiliary engines, including attachments i.e. governors, turbochargers, fuel equipment and the sales of spare parts and engines. We are capable of crankshaft grinding. Our service is 24/7 worldwide!

operation of a yacht´s propulsion system.

Piening Propeller fulfils its briefs in: Consideration of all hydrodynamic aspects during the design and an accurate manufacturing of propellers and shafts according to highest ISO classes.The company is approved by all common classification societies.

Repairs and adjustments of propellers are done with the same care as new buildings. Piening Propellers scope of supply includes:

PropellersFPP > 800mm Ø

CPP > 1.100mm Ø

Shaftsup to a several length of 16,000mm

Sterntubeswith sealings and bearings

Shaft brackets complete

GearboxesBrand ZF ®

SCHAFFRAN PROPELLER + SERVICE

GMBH

Bei der Gasanstalt 6-8

D-23560 Lübeck, Germany

T +49 (0) 451 58323-0

F +49 (0) 45158323-23

E info@schaffran-propeller.de

I www.schaffran-propeller.de

Contact: Matthias Eckert

WINEL B.V.

P.O. Box 70, 9400 AB Assen

The Netherlands

T +31 (0)592 366 060

F +31 (0)592 312 392

E sales@winel.nl

I www.winel.nl

Contact: Bert Knijp

Winel is a major supplier to the large yachts market, offering a wide range of unique premium quality shell doors, platforms, pantographic doors, transom doors, bulwark doors, hatches and watertight doors. For these custom made masterpieces we use proven concepts as the basis, coupled with smart technical solutions to optimize our products. Wishes of our customers can be incorporated without compromise.

Marine Aftermarket

Distributieweg 7

2645 EG Delfgauw

The Netherlands

T +31 15 27 02 350

E marine.benelux@zf.com

I www.zfmarinebenelux.nl

ZF Marine supplies propulsion systems and components for e.g. motor yachts, fast crafts, fast ferries, commercial vessels and sail boats for the marine market. ZF Services in Benelux is the aftermarket partner that supports you with services during the entire life cycle of the ZF products in your vessel.

Original ZF parts, new constructions, replacement, maintenance, repair and exchange are bundled in our ‘next generation service’.

The best high-quality ZF Service for your vessel.

OPACMARE S.R.L.

via Luigi Einaudi, 150/154

10040 Rivalta (Torino), Italy

T +39 (0)11 904 5411

F +39 (0)11 909 3022

E info@opacmare.it

I www.opacmare.com

Contact: Mauro Gardois

Opacmare designs and produces accessories for the nautical market with a high level of quality and innovation.

We are developing products (standard or customized) and services able to meet the needs and the requirements of our customers, the most important shipyards in the World.

Designing and manufacturing of custom made propellers, complete shaft installations as well as hydraulically operated controllable pitch propellers for conventional as well as for LNG and Hybrid propulsion systems.

Particular emphasis is being put on high efficiency with low fuel consumption as well as the minimisation of noise and vibration for all ship propulsion systems.

Schaffran is approved by all common classification societies.

Range of products:

–Fixed pitch propellers

–Controllable pitch propellers

–Propeller- and intermediate shafts up to a length of 16m

–Stern tubes with sealings & bearings

–Shaft brackets, Nozzles, Gearboxes

Quarantaineweg 5, 3089 KP Rotterdam

P.O. Box 5003, 3008 AA Rotterdam

Harbournr: 2637

The Netherlands

T +31 (0)10 429 2222

F +31 (0)10 429 6459

E info@wortelboer.nl

I www.wortelboer.nl

HELIOS LUBEOIL

Louis-Krages-St. 32

D-28237 Bremen, Germany

T +49 421 2233681

E mail@superyachtlube.con

E info@helios-lubeoil.de

I www.oilanalysis.eu

I www.superyachtlube.eu

PIENING PROPELLER

Am Altendeich 83

D-25348 Glueckstadt

Germany

T +49 4124 9168-0

F +49 4124 3716

E pein@piening-propeller.de

I piening-propeller.de

Contact: Mathias Pein

Noise reduction relies upon the quiet

–Repair-, assembly- and spare part service

Yachts are always a real treat to look at and the anchors and the chain cables should look fantastic as well. Wortelboer supplies chain cables and anchors to yacht builders all over the world. Our super mirror-polished stainless-steel anchors, as well as our hot-dip galvanized anchors and chain cables (both short link and stud link) can be found on countless yachts. All our materials are approved by any of the well-known class societies such as LRS, BV, RINA, DNV/GL, ABS and RMRS.Should you wish to hide the anchor from view, we are also able to deliver stainless-steel pockets and bottom plates. Come to Wortelboer and you can be certain that the anchors and chains will be the perfect finishing touch for your yacht.

I www.helios-lubeoil.de

Lubricant supplier, lubeoil surveys for new build and refit. Owners, shipyards, management and crew assistance. Oil sampling monitoring and a lot brand lubricants available in Europe, e.g. South France, Spain, Germany and US. MTU named approvals as well as other manufacutrer specification. In Germany AGO and MGO physical supplier, duty free possible.

Bulk supply by RTW and packed lubes will be delivered on individual request. Own large storage will make shipping easy. Save costs, fuel and resources with latest lubricant technology. Extent DPF and oil change interval. helios lubeoil is in the position to provide you with most kinds of lubricants. Start today and be prepared for tomorrow.

We have already started preparing our upcoming issues of SuperYacht Industry. Below you will nd some of the main topics we are planning to cover. Please feel free to provide our editorial staff with any relevant information, so they can take your input into consideration for publication. Our commercial department will be happy to assist you with your marketing needs.

Monaco Yacht Show 2023

Deck equipment & machinery

Superyacht marinas

Focus on Turkey

Naval architecture & design interior/exterior

Copy deadline | 5 July 2023

Advertisement deadline | 26 July 2023

Release date | 29 August 2023

METS Amsterdam 2023

Focus on Germany

Masts, spars, sails & rigging

Paint & coating systems

Copy deadline | 13 September 2023

Advertisement deadline | 04 October 2023

Release date | 07 November 2023

COLOPHON

COMMERCIAL DEPARTMENT

MARCO GEELS | Director marco@ynfpublishers.com

ROB DE KERF | Account Manager rob@ynfpublishers.com