INDUSTRY NEWS

Local Research Collaboration Cuts the Wear And Tear on Mineral Processing Equipment Source: Sally Wood

A new $2.4 million research partnership between the University of South Australia (UniSA), LaserBond, and the Innovative Manufacturing Cooperative Research Centre (IMCRC), will develop some of the world’s most resilient minerals processing equipment. Minerals processing machinery – often worth hundreds of thousands of dollars – endures some of the harshest possible conditions, including erosion, corrosion and wear and tear induced by repetitive impact. A key competitive advantage for the industry and for manufacturers alike, would be to increase the longevity of mineral processing equipment through composite coatings, also known as cladding. When the improved cladding matches facility maintenance shutdown schedules, unforeseen shutdowns can be avoided or minimised. Shutdowns for repairs and maintenance of the equipment can cost over $100,000 for every hour of downtime. Lead researcher at UniSA, Professor Peter Murphy, said he welcomed the chance to grow the advanced manufacturing sector within Australia. “This comes at a time where we need to nurture our manufacturing capability and this project has the capacity to grow, employ and lead Australia through the challenging economic times,” Professor Murphy said.

“What we hope to do through this partnership is work with LaserBond to refine the technology, specifically focussing on key areas within mineral processing machinery prone to wear in different circumstances, to provide tailor-made coatings that resist that degradation,” Associate Professor Hall said. He explained how UniSA’s extensive range of technology can help strengthen testing, and also accelerate further relationships between academia and industry. “UniSA’s extensive tribology laboratories can be used to perform accelerated wear testing in erosion, corrosion and impact abrasion, and we want to combine these results to predict wear rates in the real world and then inform material and process optimisation carried out by LaserBond.” FII builds knowledge and capacity in core future industries and develops an internationally competitive research capacity. It is focused on four key areas: minerals and resources engineering; energy and advanced manufacturing; environmental science and engineering, and biomaterials engineering and nanomedicine. It ranked number one in Australia for research impact and engagement as part an assessment from the Australian Research Council in 2018. It also boasts

100 per cent of its research is either at, or above world-class standards. The Chief Executive Officer and Managing Director of IMCRC David Chuter explained how the research collaboration builds on a long-standing and consultative partnership between LaserBond and UniSA. “Together, wear and corrosion, continues to be a costly and disruptive challenge across many industries and developing advanced materials and technologies for wear and corrosion protection will help both Australian and global manufacturers combat these challenges,” Chuter said. IMCRC assists Australian companies to increase their global relevance through new innovations in manufacturing. It is informed by research, and operates on an end-user basis. The team at IMCRC work with a range of Australia research partners, including universities, CSIRO, and hospitals with a research capacity. Chuter said the new partnership between LaserBond and UniSA could open new opportunities for Australian research on the international stage. “It is great to see, that through engagement with the University of South Australia’s researchers, LaserBond, in collaboration with local manufacturers can develop its solution locally and then take it globally,” he said.

LaserBond are a pioneering Australian surface engineering company, who will work with UniSA’s Specialist Coatings Research Group at the Future Industries Institute (FII) to continue their collaboration on this new challenge. UniSA’s Industry Associate Professor Colin Hall is a key researcher on the project, who said industry experts in surface engineering, like LaserBond, have long recognised the challenge and have specialised in the development of hard, wear-resistant coatings using laser cladding. 18 | APRIL 2021

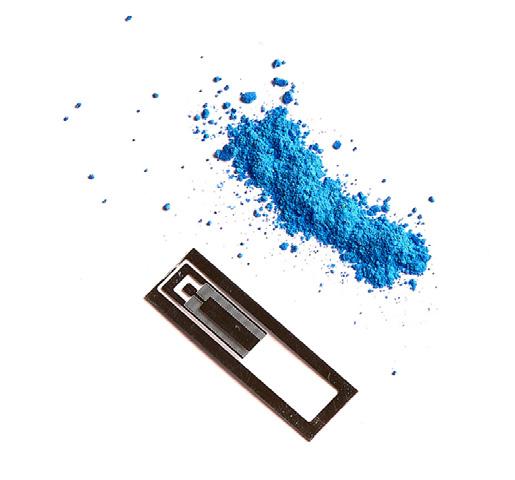

UniSA, LaserBond, and the IMCRC will develop some of the world’s most resilient minerals processing equipment. Image credit: University of South Australia.

BACK TO CONTENTS

WWW.MATERIALSAUSTRALIA.COM.AU