MATERIALS AUSTRALIA

WA Branch Technical Meeting - 9 November 2020

Corrosion Management: Towards Effective Corrosion Mitigation Strategies Source: Dr Kateřina Lepková. Senior Research Fellow, Curtin Corrosion Centre

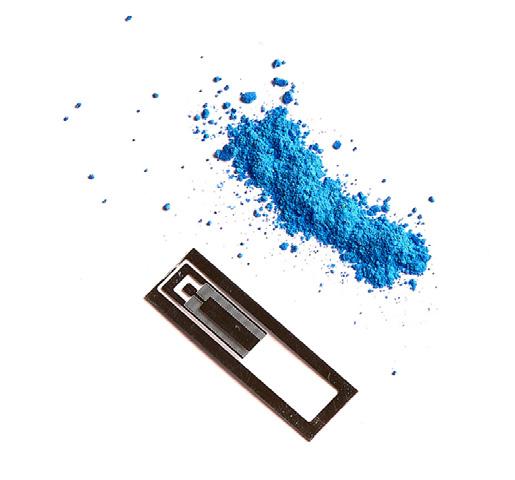

Kateřina Lepková is a corrosion and materials scientist with 15 years of experience in Europe and Australia. Kateřina holds a MSc in Chemical Engineering and a PhD in Physical Chemistry and is a Senior Research Fellow at the Curtin Corrosion Centre (CCC). Kateřina noted that CCC has now been in operation for 32 years, pursuing industrydriven research, and offering a Masters degree in corrosion engineering. Most of CCC’s research has been in partnership with the oil & gas industry; there are many benefits available from technology transfer to other industries, but this is hampered by an evident ‘disconnect’. This is most unfortunate as corrosion costs around 3.4% of Australian GDP annually, and saving of 15-30% can be expected simply by applying current best technologies. Kateřina’s presentation focussed on two well established approaches to corrosion protection: chemical corrosion inhibition and coatings. She described work at the CCC in optimising protection and spoke about leading edge research into understanding protection mechanisms. Chemical inhibition is used against corrosion under insulation, microbially induced corrosion and tribocorrosion. It is used as routine maintenance in closed systems, such as O&G pipelines, and also in open systems, such as ships’ bilges and in washing of aircraft and mining equipment. Inhibitors are surfactants having a hydrocarbon chain with a polar head-group which adheres to steel, and are usually a mixture of inhibiting chemicals working synergistically; the precise mechanism is not clear. Development is aimed at specifying a formulation that is efficient, persistent, environmentally friendly, and low-cost. Test methods include electrochemical testing, partitioning between oil and water, stability under temperature and pressure, and resistance to shear. Evaluation of formulations for specific applications involves simulation of conditions for corrosion at welds and corrosion under deposits, in which ability to penetrate deposits can be evaluated. Avoidance of pitting is an important consideration. 8 | APRIL 2021

L to R: Dr Katerina Lepková; Dr Steve Algie

Advanced research techniques include the use of atomic force microscopy for imaging the morphology of adsorbed micelle structures; these can vary with iron grain orientation, and across weld structures. This technique can also measure the lateral force to remove the adsorbed inhibitors. Kateřina then turned to coatings, noting that early failure is often due to errors in preparation and application or mechanical damage. The standard tests are instrumented long-term outdoor exposure racks and 22-week exposure in salt spray and environmental chambers. Impedance measurement offers a quick (20 day) result but must be correlated against the established longer tests. Artificial intelligence methods are being used to train an assessment system to recognise different defect types (e.g. uniform, pitting or passive surfaces) and correlate the different measurements. As an example of technology transfer, she referred to the corrosivity of bulk cargoes (coal, iron or and mineral concentrates), BACK TO CONTENTS

which can be likened to under-deposit corrosion. Modified under-deposit corrosion measurement techniques are being used to assesses cargo corrosivity. Kateřina concluded her talk with an account of state-of-the-art research the CCC has conducted using the ANSTO facilities and the Australian Synchrotron. Small-angle neutron scattering (ANSTO) is used to resolve micelle structure. High energy, high resolution X-ray diffraction has allowed simultaneous electrochemical and surface analysis. Scanning the beam allows study of the interface layer, and synchrotron tomography has been applied to welds without the need to cut the metal. Access to a timeslot on the Australian Synchrotron is only available through a competitive grant application process, and the time window is strictly limited. Kateřina painted a vivid picture of the state of high excitement involved in making the most of a hard-earned session on the beam line; everything has to be set up precisely well in advance, leaving little time for sleep! WWW.MATERIALSAUSTRALIA.COM.AU