Skills shortage survey confirms worst fears.

The Advanced Manufacturing Industry Transformation Plan (ITP) recognises the essential role manufacturing plays in the New Zealand economy, for jobs and communities.

The draft plan, released for public consultation in June 2022, attracted hundreds of participants to workshops and 60 written submissions that helped identify some key priorities for the ratified plan.

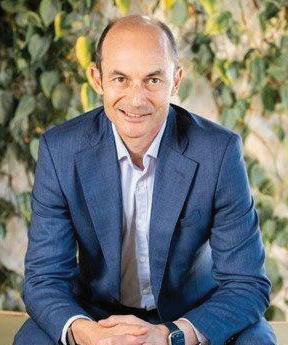

“Increasing investment in advanced technologies and processes to lift productivity and wages, and improving the understanding and perceptions of advanced manufacturing to attract more people into the sector will be the initial focus based on the feedback received,” says Brett O’Riley, EMA Chief Executive and Co-Chair of the Advanced Manufacturing ITP Steering Group. Manufacturing plays an important role in creating jobs and is the second largest employer of Māori and Pacific peoples in the country.

The plan identifies ways to help manufacturers acquire

more skills and embrace the low-carbon, sustainable economic growth it offers.

“One of the keys to accelerating growth will be the investment in new plant, new technology, and new skills, something the EMA will continue to work with the Government on,” Mr O’Riley says.

Rachel Mackintosh, fellow Co-Chair of the Advanced Manufacturing ITP Steering Group and Vice-President of the New Zealand Council of Trade Unions Te Kauae Kaimahi and Assistant National Secretary of E T , agrees.

“We want to transform the industry so that people will choose to work in advanced manufacturing for generations to come. We have the opportunity to harness the creativity of the diverse manufacturing workforce to develop a sustainable industry, where people can build their skills and enjoy decent work and decent wages. To do that we need cooperation across workers, employers, communities, and the government,” she says.

continued on Page19

Aad van der Poel: Aad@xpo.co.nz | 021 314 199 southmach.co.nz

SMART MANUFACTURING

SMART MANUFACTURING State of

WOMEN IN ENGINEERING Ankeeta Karmakar. www.nzmanufacturer.co.nz April 2023 Sales and training—Aust/NZ Region enquiries@baycad.biz www.baycad.biz NZ 0274847464 AU 64274847464 Don’t delay, contact us now. Free trial available 30 Days, No Restricons NEW VERSION E P P CAD S B I O O I F PROUDLY SUPPORTED BY 24-25 MAY 2023

Smart Manufacturing Report.

Enquire about exhibiting at the South Island’s largest engineering, manufacturing and technology trade show.

Christchurch Arena

9 12 13

Increasing investment in advanced technologies a priority for manufacturing

2023 Media Kit www.nzmanufacturer.co.nz For a copy of the NZ Manufacturer Media Kit 2023 email publisher@xtra.co.nz All articles are published at no charge, unless promoted (advertorial) content is required. Success Through Innovation asiamanufacturingnewstoday.com ASIA M ANUFACTURING N EWS 2023 Asia’s manufacturing future. MEDIA KIT Media Kit 2023 Innovation + Dedication = Success www.australianmanufacturingnews.com TechRentals® is an IANZ endorsed Calibration Laboratory We offer both IANZ Endorsed and Traceable Calibrations of test and measurement equipment inluding: 0800 832 473 www.techrentals.co.nz

DEPARTMENTS

LEAD

Increasing investment in advanced technologies a priority for manufacturing.

BUSINESS NEWS

Glen Cornelius to lead Engineering New Zealand.

UKG Talk to engage and connect teams. How is your learning organisation?

SMART MANUFACTURING

Composites Technician Apprentice of the Year.

State of Smart Manufacturing Report. Skills shortage confirms worst fears.

WOMEN IN ENGINEERING

Ankeeta Karmakar

CIRCULAR ECONOMY

Ten tips to get Kiwi manufacturers started on circular economy.

Tyres first off the regulated stewardship start line.

DEVELOPMENTS

Pasteurisation plays crucial role in New Zealand AD plant.

SOUTHMACH 2023

Exhibitors and floor plan.

THE INTERVIEW

Timoti Harris, Managing Director, Empowering Change.

COMPANY PROFILE

Clean Planet.

WORKSHOP TOOLS

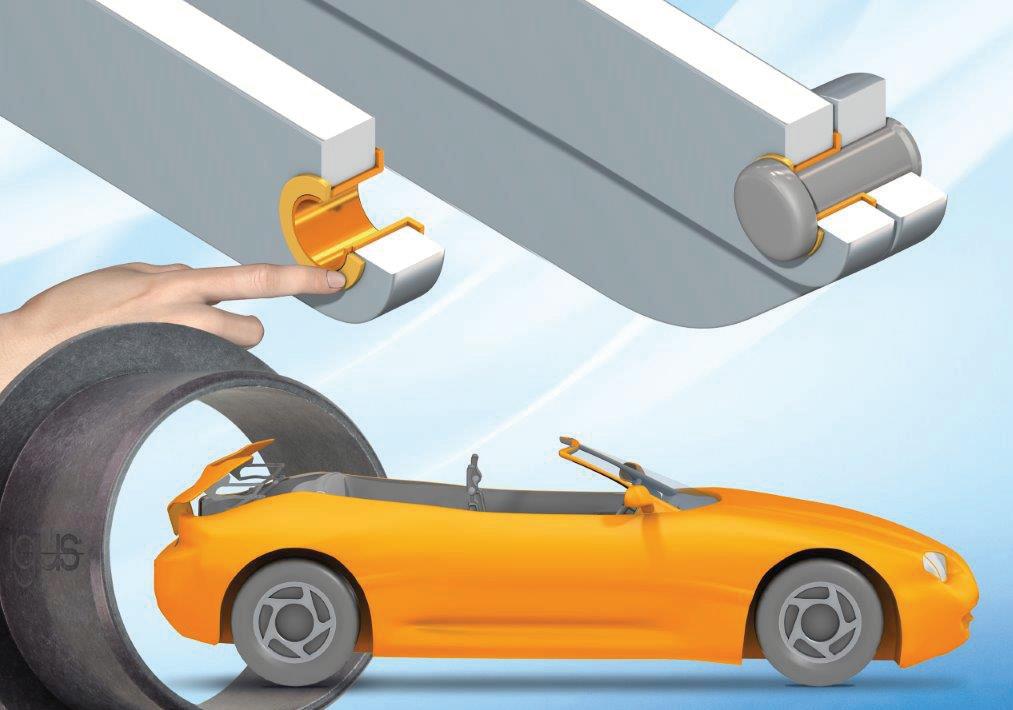

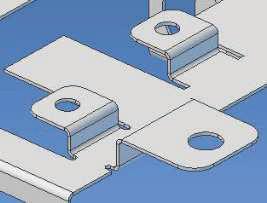

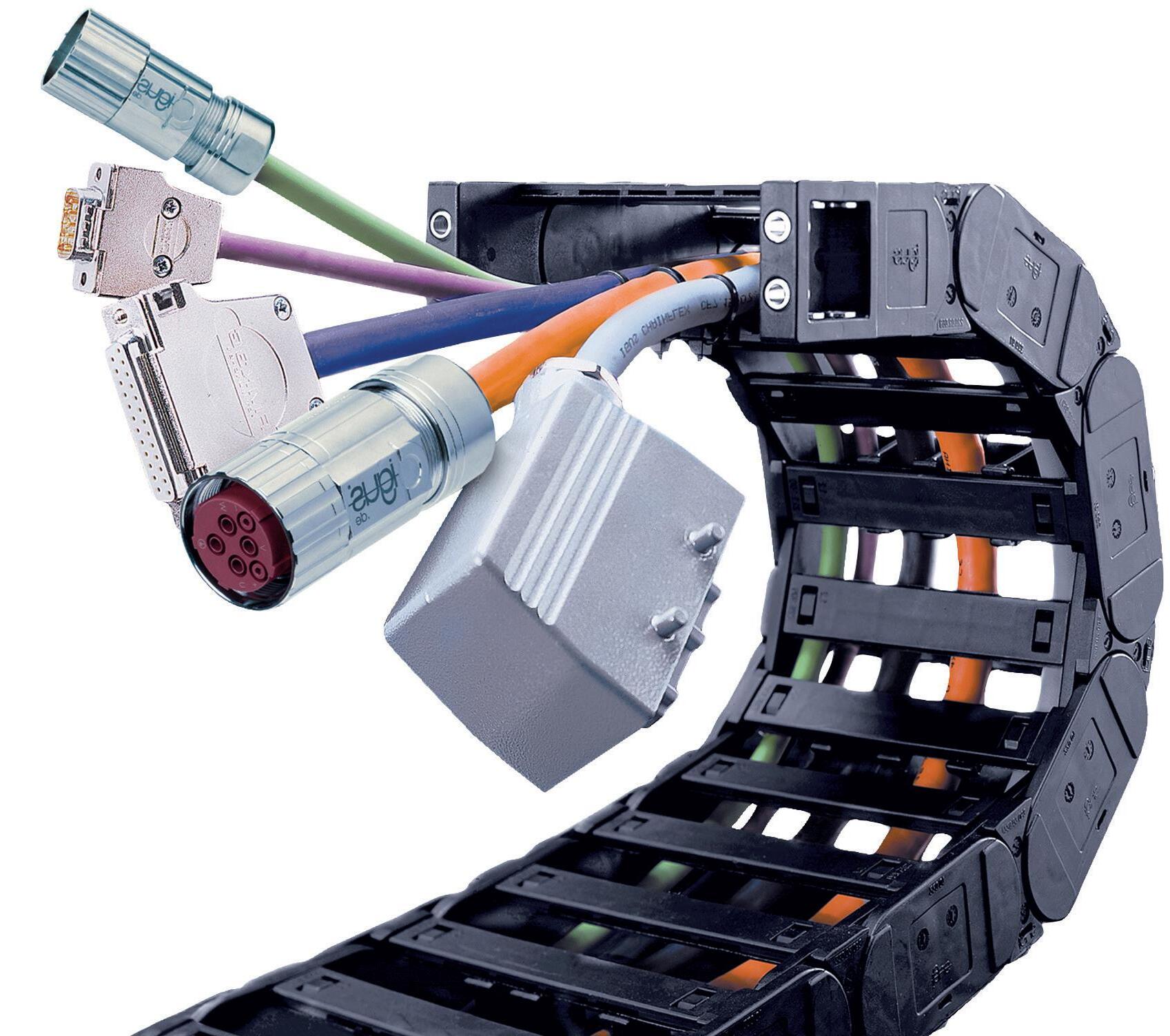

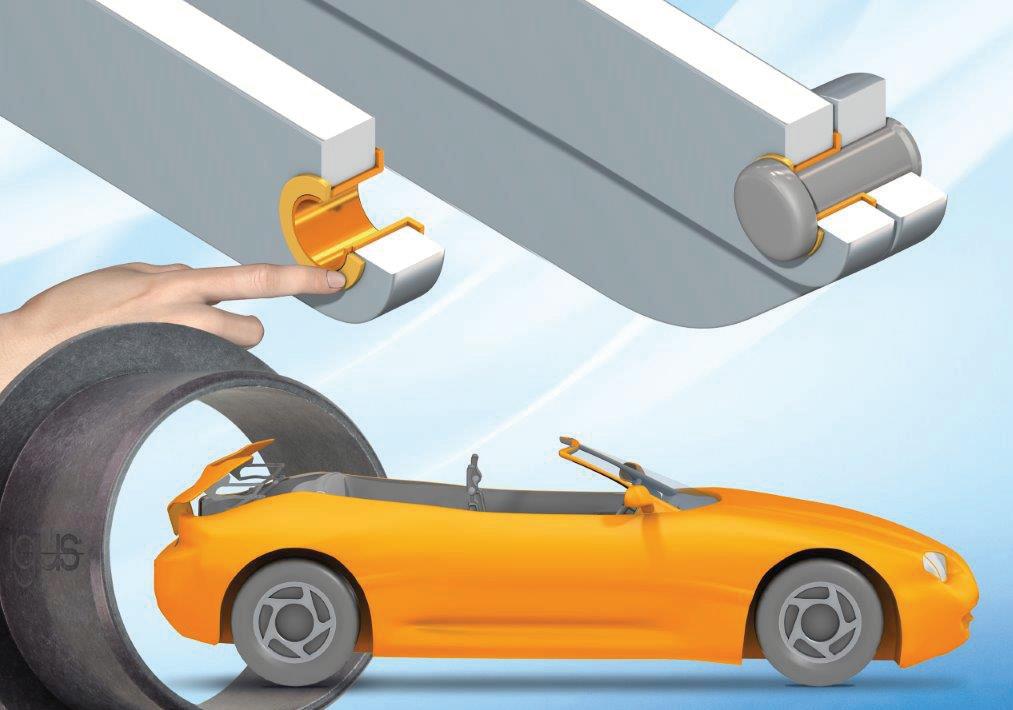

How igus energy chains become power-saving champions.

Injection systems support transition to new fuels.

Clearance-free multi-link hinges for automotive applications.

SUPPLY CHAIN

Jaybro enters new age of freight forwarding with eSchenker.

How Gallagher circumvented global supply chain disruption.

DEVELOPMENTS

Erica Lloyd joins Zenno. $215k excess inventory could spell cash windfall for NZ firms.

THE LAST WORD

The case for best-in-class regulatory controls

Is Chief Executive of BusinessNZ, New Zealand’s largest business advocacy body He has held a range of senior positions at Westpac and is a barrister and solicitor

Ian is a Partner, Argon & Co. NZ, a master black belt improvement specialist and global lean practitioner. He is passionate about improving productivity and helping to create world class New Zealand businesses.

CEO thinkstep-anz

Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

Is Managing Director of Connection Technologies Ltd, Wellington and is passionate about industry supporting NZ based companies, which in turn builds local expertise and knowledge, and provides education and employment for future generations.

EMA chief executive Brett O’Riley has a background in technology and economic development.

Brett actually grew up with manufacturing, in the family business, Biggins & Co. He currently holds board roles with Wine Grenade and Dotterel Technologies and is also on the NZ Film Commission board.

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 4 Contents

ADVISORS

Kirk Hope

Brett O’Riley

Ian Walsh

Lewis oodward

Insa Errey

Dr Barbara Nebel

1 6 8 13 14

17 20 22 23 24 26 27 28

6 8 9 13 17 22 27

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: +64 6 870 9029

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, HERA, EMA

Business East Tamaki

Ian Walsh, Dr. Barbara Nebel, Rebecca Reed, Ankeeta Karmakar Trevor Tutt, Rocky Lu

ADVERTISING

T: + 64 6 870 9029

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher

Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz

Free of Charge.

MEDIA HAWKES BAY LTD

T: +64 6 870 9029

E: publisher@xtra.co.nz

121 Russell Street North, Hastings

NZ Manufacturer ISSN 1179-4992

Vol.14 No.3 April 2023

The role of advanced technologies in the years ahead

The Advanced Manufacturing Industry Transformation Plan (ITP) (Page 1) recognises the essential role manufacturing plays in the New Zealand economy.

To step-up the effort, greater investment needs to be made in advanced technology and staff training to improve levels of productivity and job satisfaction in the years ahead. A highly skilled and creative workforce will bring benefits and satisfaction and transform our industry bases.

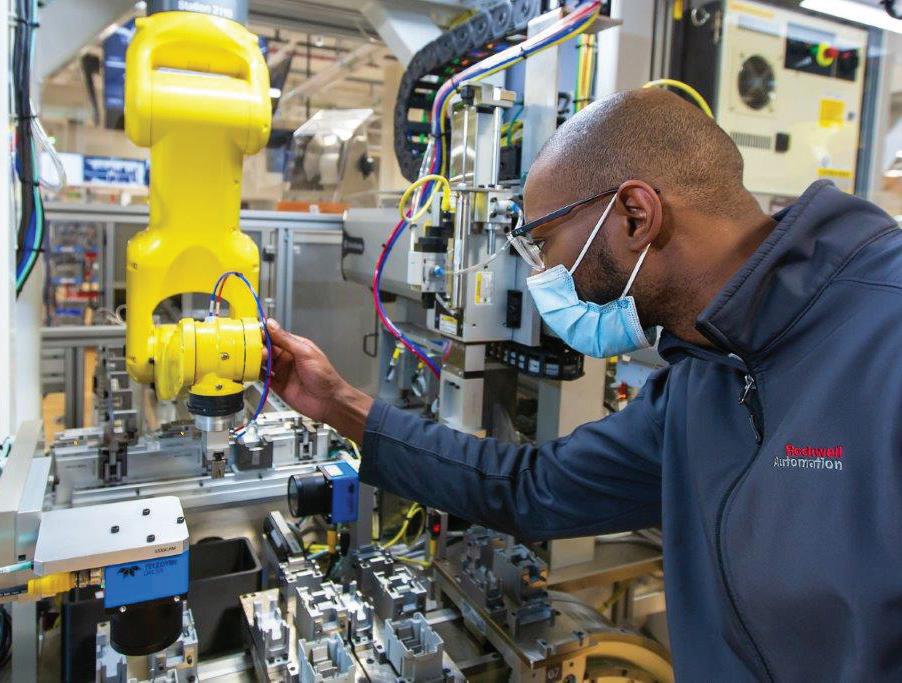

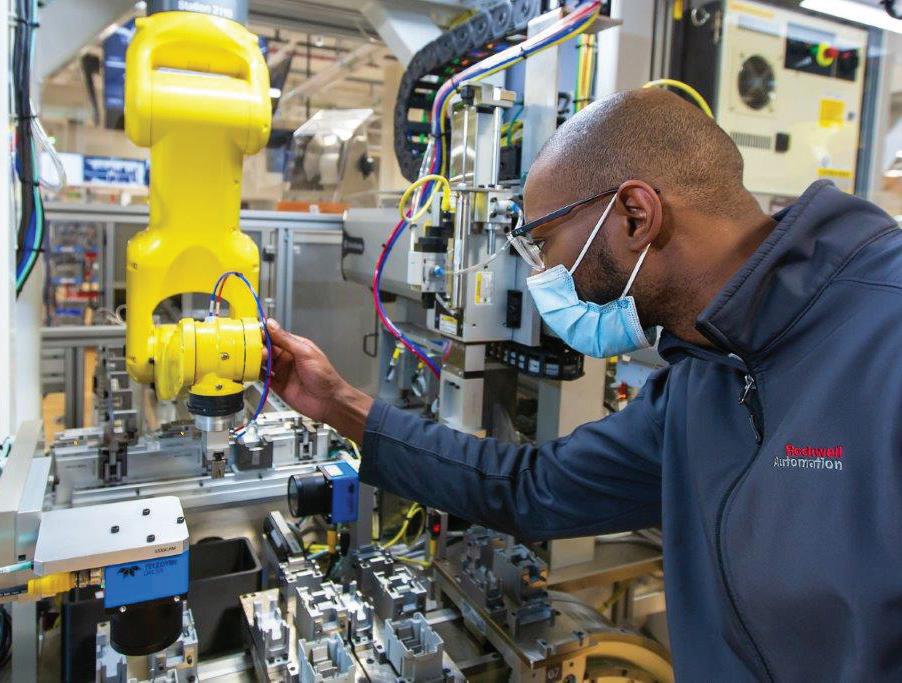

Rockwell Automation’s 8th annual “State of Smart Manufacturing Report” focusses on delivering profitable growth without sacrificing quality and increasing adoption of technology to build resilience, enable agility, increase sustainability, and address workforce challenges.

The report is focussed on Asia-Pacific and can be read in full here:

www.rockwellautomation.com/en-us/capabilities/digital-transformation/state-of-smart-manufacturing.html

Key findings include:

Balancing quality and growth. Tracking or quantifying sustainable practices. Manufacturers believe their organisation lacks the technology needed to outpace the competition.

Four out of five manufacturers still lack an end-to-end supply chain planning solution.

Close to half of APAC manufacturers (44%) plan to adopt smart manufacturing within the next year.

Copyright: NZ Manufacturer is copyright and may not be reproduced in whole or in part without the written permission of the publisher. Neither editorial opinions expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or publisher of NZ Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the publication.

The biggest barriers to adopting smart manufacturing are employee resistance to technology adoption and change. Lack of skills and the value of smart manufacturing are also factors. And of course, cyber security and quality management are other factors.

In this highly competitive business world, it may well be that the level of your company’s investment in technology determines your future.

5 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023

Success Through Innovation Editorial

Glen Cornelius to lead Engineering New Zealand

Glen Cornelius FEngNZ CPEng has been elected the new president of Engineering New Zealand Te Ao Rangahau.

“As President, I will ensure the Engineering New Zealand Board and members benefit from my proven leadership and extensive governance skills,” he says.

“I will uphold Engineering New Zealand’s commitments of promoting the Te Tiriti o Waitangi principles by forming partnerships, being responsive

and ensuring there are equal opportunities.”

A civil engineer by training, Glen has been Chief Executive of engineering and consulting firm Harrison Grierson for the last 12 years. He will be stepping down from this role on 31 March providing more space for other pursuits, including as President of Engineering New Zealand.

Prof. Jan Evans-Freeman DistFEngNZ has been elected Deputy President, and Kennie Tsui FEngNZ,

UKG Talk to engage and connect teams

UKG Talk is a modern technology platform purpose-built to support connected workforces, to the Australia and New Zealand (ANZ) market.

As many organisations shift to a long-term hybrid workforce model, and with 71 per cent of Australian employees feeling disengaged with their jobs (1), helping frontline workers and teams to seamlessly collaborate and communicate is more important than ever.

UKG Talk fits seamlessly into workflows and empowers employees to effortlessly communicate and collaborate while fostering a sense of belonging no matter where people physically do their work. UKG Talk lets leadership easily reach all employees at once, which promotes increased engagement, boosts workforce productivity, and creates a more inclusive sense of community for all. This ensures that not only are employees more connected, but management is too.

The mobile-first solution provides a familiar communication experience, similar to today’s popular social media platforms, that lets all employees be heard. Built with the user in mind, UKG Talk has four primary components:

• Messaging: provides timely communications to all employees or specific individuals or groups, streamlines intra- and inter-departmental communications via 1:1 communication and group chats, and helps easily find teammates in the employee directory or chat within an existing thread.

• Groups: supports a vibrant and inclusive culture by giving employees a space to engage in discussions about work or outside interests and foster peer-to-peer and team collaboration, public recognition, and a sense of community.

• Engagement: the employee recognition app lets businesses recognise people at key moments

CPEng Vice President, for the same term.

Aidan Cooper CMEngNZ CPEng and Sarah Sinclair FEngNZ join Engineering New Zealand’s Governing Board as newly-elected Directors for a three-year term.

or after significant achievements and listen and gather feedback and opinions through pulse-check surveys. Additionally, the Ideabox app lets users simulate brainstorms or collaborations where employees can suggest their best ideas for a particular topic.

• Insights: measures and evaluates in real time if communications are engaging and resonating with people and teams through key user behaviour metrics like engagement, trending content, or top contributors.

UKG Talk is an engine room for modern organisations to foster exceptional and transformative employee experiences. The mobile-first solution puts employees at the centre of communications, empowers an environment where people can feel heard and valued, and provides real-time insights that let managers continually health check the business to continue driving a better culture.

6 Business News Creating opportunities for networking, learning, and engaging. Business East Tāmaki (formerly the Greater East T

Business Association) is here to make it easier to do business; working alongside business leaders and property owners in the region on security, advocacy, development and growth. businessET.org.nz

Glen Cornelius FEngNZ CPEng (Photo supplied by Engineering New Zealand)

āmaki

Glen Cornelius FEngNZ CPEng has been elected the new president of Engineering New Zealand Te Ao Rangahau.

How is your learning organisation?

and ensuring there are equal opportunities.”

-Ian Walsh, Argon &

2010

“As President, I will ensure the Engineering New Zealand Board and members benefit from my proven leadership and extensive governance skills,” he says. “I will uphold Engineering New Zealand’s commitments of promoting the Te Tiriti o Waitangi principles by forming partnerships, being responsive

Fifth Discipline”

Clearly, any business that survives and grows, must be delivering value to customers and performing at least near enough to its competition in that market. However, if one competitor starts to develop better products or service offerings than the rest of the market, then over time that competitor will capture more market share and will ultimately become more successful.

This is what we see in highly competitive markets like the USA and Europe.

I recently asked a number of business owners how much time they allowed each week for team development, learning or group problem solving. Out of 30 individual owners, only three set aside time, with many admitting they had not done any formal training and development or set aside time for this activity in over 2 years!

Of the three, they allowed between 0.5hour to 1 hour – less than 2.5% of the working week.

The people working in your business are the only people who can improve it. If we don’t empower, train, develop and motivate them to do so, then we are accepting or hoping that our current performance will be good enough to sustain and grow the business in the future and outpace any local or international competitor. Does this approach seem wrong? Well, it is. This is the slow road to ruin and one of the reasons NZ is in the bottom of the OECD in terms of productivity.

The skills and competencies, especially around leadership, are lagging and it is imperative that we recognise that the future businesses in NZ will need capabilities around building and sustaining teams, strategic and team leadership, competitive systems and practices, and problem solving to list just a few.

I get requests almost weekly from businesses as to whether I know a good shift leader, production manager, operations leader and so on. These requests are a symptom of a marketplace that does not have enough talent. Unfortunately, this is not a new phenomenon. It has been exacerbated by Covid, but this has been the case for the last 20 years and the root cause is that not enough NZ businesses are investing in or developing talent.

They recognise they need better leaders

A civil engineer by training, Glen has been Chief Executive of engineering and consulting firm Harrison Grierson for the last 12 years. He will be stepping down from this role on 31 March providing more space for other pursuits, including as President of Engineering

and suchlike, but are not willing to invest in developing their people.

So, can you envision a workplace where the team are trained, they have developed the right data capture and information systems to highlight any problems with product or service, and the teams work in a structured way to solve those problems relentlessly?

To realise this vison we need:

1. Leaders who are willing to empower their teams and people and make some short-term sacrifices

2. Team members who are willing to learn and apply themselves

3. Appropriate training and learning experiences

4. Mentors to help you establish the system and processes to enable the teams and the business to succeed.

Items 1 and 2 are up to the business leadership, commitment and having a clear purpose and vision. Items 3 and 4 are about providing the right support to help them develop, and measuring and managing the outcomes.

If you, as a leader within your business, are up for items 1 and 2 then items 3 and 4 can be addressed through qualifications such as the Diploma in Competitive Systems and Practices.

This year this qualification is fee-free funded, so if you can invest peoples time to build capability then the cost could be zero! And you could benefit from a highly productive and trained workforce. If you want to be part of this initiative then drop me a line ian.walsh@argonandco.com

7

Co

In his

book “The

Peter Senge said “in the long run the only sustainable competitive advantage is your organisation’s ability to learn faster than the competition.”

ADVISORS

Composites Technician Apprentice of the Year -Tyler Williams

Sandra Lukey

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business. She has over 20 years’ experience working with companies to boost profile and build influential connections.

Tyler Williams has been a part of the SailGP Technologies team for the past three years.

Throughout his time in the composites industry he has made quite an impact with members both inside SailGP Technologies, NZ Composites Association and at MAST Academy where he recently completed his 2 year Composite Technician Apprenticeship and is only one year off completing his Composite Boat Building Apprenticeship.

Mike Shatford is an expert in the field of technology development and commercialisation. His company Design Energy Limited has completed over 100 significant projects in this vein by consulting for and partnering with some of New Zealand’s leading producers. Among Mike and his team’s strengths are industrial robotics and automated production where the company puts much of its focus.

Williams dedication and drive to succeed in the industry has led him to be awarded New Zealand Composites Technician Apprentice of the Year, presented in 2023 by NZ Composite Association and NZ Marine, recognising excellence within its field.

Graeme Allen, an established boat builder and one of the central mentors for Williams at SailGP Technologies commented, “It is no surprise to me that Tyler made the top guy because he stands out across the board.

“Everything we’d work on from bookwork to boat building, he was enthusiastic and got it done. Did it well. His skill level is very high, amazing.”

Williams did not come from a background in boating, but over time he began paving a way for himself in the marine industry.

“Tyler always has a consistent, positive approach to his work. And if he sees someone who is good at their job, he’s right in there wanting to learn from them. That’s what makes him stand out,” adds Allen. His journey started at the age of 17 when he was introduced to key industry figures such as Sean Regan from Emirates Team New Zealand and NZ Marine field officer Mike Birdsall who took the time to show Williams all the exciting opportunities the industry has to offer from America’s Cup boats to TP52s and later on the SailGP F50’s.

spent the last 3 years at SailGP Technologies.

“I didn’t even know what the F50 boats were until my friend who used to work at SailGP Technologies said come through the facility, you know, you can work on these amazing boats and go all over the world on the regattas.

“And I thought, well that sounds amazing. I told the foreman, I’m not really a sailor but I appreciate all the work that goes into these boats,” says Williams.

From the day Williams started at SailGP Technologies he was brought in to work on some pretty amazing projects. “I started my apprenticeship building the daggerboards for Mike Pollard in the Top Shop. From there I worked on all the 52s that came through, so both TP52 Sled and IRC 52 Caro. Most of my apprentice work was from working on the 52s. But I’ve also built the F50s, I built the hulls, decks, pods and so on.”

Has a B Com (Hons) Otago University. In 2000 - 2001 introduced PCs on the workshop floor and job and staff tracking and a productivity software App to Fletcher Aluminium Group and 100 manufacturers NZ nationwide.

In 2001 – 2022 Founding Director Empower Workshop Productivity & Scheduling Software App. 236 manufacturing and engineering clients mainly throughout NZ and Australia, also UK and US.

He was drawn in immediately and began both his Boat Building and Composite Technician Apprenticeships.

“I could see all high performance sports starting to utilise composites, all the Formula One teams, all the high performance yachts, everything. I thought, this is the industry I need to be in.” explains Williams.

Williams began his career at Cooksons Boats building 52’s, then moved to Yachting Developments and has

Tyler with the Tech Team in Lyttelton for the ITM Christchurch Sail Grand Prix event. PhotographerSailGP

Over the last two weeks Williams was picked to be part of the build team in Lyttelton, New Zealand working in the SailGP Tech Team to get all nine SailGP F50 boats race ready for the ITM Christchurch Sail Grand Prix.

Williams has many opportunities to weigh up at the end of his boat building apprenticeship but first he’d like to expand his horizons traveling.

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 8

Sean O’Sullivan

Tyler Williams standing with the New Zealand SailGP F50 boat ‘Amokura’. Photographer - Brett Phibbs

State of Smart Manufacturing Report

Finds over 45% of Asia-Pacific manufacturers struggle to outpace competitors, due to lack of innovation, skilled workforce and technology.

Rockwell Automation has announced the results of the 8th annual “State of Smart Manufacturing Report.” The global study surveyed more than 1,350 manufacturers across 13 of the leading manufacturing countries including Australia, China, India, Japan and the Republic of Korea.

This year’s report reveals a focus on delivering profitable growth without sacrificing quality, an emphasis on accessing data’s true potential, and increasing adoption of technology to build resilience, enable agility, increase sustainability, and address workforce challenges.

Key findings include:

• “Balancing quality and growth,” and “tracking or quantifying sustainable practices” are the biggest internal obstacles inhibiting progress for Asia-Pacific (APAC) manufacturers this year, compared to deploying and integrating new technology in 2022.

• Globally, twice as many manufacturers believe their organization lacks the technology needed to outpace the competition, as compared to 2022.

• Four out of five manufacturers still lack an end-to-end supply chain planning solution.

• Close to half (44%) of APAC manufacturers plan to adopt smart manufacturing within the next year; out of this, China (80%), Australia (60%) and India (59%) are already using some components of smart manufacturing.

• The biggest barriers to adopting smart manufacturing for APAC manufacturers are employee resistance to technology adoption and change, lack of skill set to manage smart manufacturing implementation, and lack of clear definition of the value/ROI of smart manufacturing.

• Quality management system (QMS) is the smart manufacturing system that APAC respondents have seen the largest ROI, followed by manufacturing execution system (MES) and enterprise resource planning (ERP).

• Cybersecurity risks rank highest as the obstacle all respondents are looking to mitigate with smart manufacturing initiatives.

• 88% of APAC manufacturers plan to maintain or grow employment due to technology adoption. Additionally, 39% of respondents believe they will be able to repurpose existing workers due to their increasing use of technology.

• Of the 94% of APAC manufacturers who have formal or informal environmental, social and governance (ESG) policies in place, close to half (48%) cite “a competitive differentiator” as the top driving factor for pursuing ESG initiatives. “Manufacturers are continuing to seek opportunities for profitable growth but are realizing that uncertainty in workforce availability is impacting quality, along with their ability to meet evolving customer needs,” said Veena Lakkundi, senior vice president, Strategy and Corporate Development, Rockwell Automation.

“The survey found that smart manufacturing technology is enabling manufacturers of all sizes to optimise more resilient, agile, and sustainable solutions that accelerate transformation. If we’ve learned anything from history, it’s that organisations that invest in innovation, with a bias for action, during times of uncertainty can outpace competitors.”

Based on the survey findings, technology is crucial to mitigating risk and delivering growth. However, for one-third of manufacturers globally, the range of available systems and platforms is leading to “technology paralysis” – an inability to decide between solutions.

Manufacturers can overcome this indecision by choosing a partner with relevant industry expertise and experience who can advise and guide them in implementing a fit-for-purpose solution to achieve desired outcomes.

9 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023

SMART FACTORY SHOWCASE

Featuring

The Smart Factory Showcase

Your chance to experience the future of advanced manufacturing by immersing yourself in the Smart Factory Showcase.

Transform your business

Understand how Industry 4.0 can transform a business and see first-hand what a high level of maturity in Industry 4.0 technologies looks like, based on a real ‘smart factory’ in New Zealand.

The sessions

Feature a digital twin of Nautech Electronics’ Auckland facility which enables us to deliver real content and stories directly to you. The interactive session examines how Nautech integrated smart technology to enhance efficiency, connectivity, and processes. They also highlight how you can engage and improve employee experiences and enhance manufacturing agility.

Get started

Our aim is that you will leave the showcase feeling inspired by the solutions offered and armed with the knowledge needed to kick-start your own Industry 4.0 journey

Questions or feedback? Please contact - manufacturing@ema.co.nz

text title NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 10 HEADING

DELIVERY PARTNER PROGRAMME PARTNERS POWERED BY Register here

www.industry4.govt.nz/UpcomingEvents

NETWORK SITE VISITS

The Network Site Visits is a programme to encourage sharing of Industry 4.0 knowledge across the sector. Whether you are well into your Industry 4.0 journey or just starting out, the programme provides a range of opportunities to expand your understanding of Industry 4.0 technologies and learn from others who have already embarked on their Industry 4.0 journey. Join us for events, undertake an assessment or expand your knowledge through resources and case studies.

eadiness Assessment

Companies can apply for a fully funded Smart Industry Readiness Index (SIRI) Assessment process to help accelerate their own journey towards Industry 4.0, the result of which will be a benchmark against other companies in their sector and a high level prioritisation roadmap.

Apply for the assessment

Factory Tour

The tours provide an opportunity to see first-hand what businesses have implemented as a result of the SIRI Assessment. They will showcase developments, specific technologies and learnings on their Industry 4.0 journey. Targeted at local manufacturers, these events are delivered across New Zealand and are a great way to network and connect with others in the region.

Upcoming events

Webinars

The webinar series is an opportunity to hear stories from all stages of the Industry 4.0 journey, focusing on the benefits of implementing these technologies, what challenges you may need to overcome along the journey and specific examples of Industry 4.0 technologies, all based on the experience of New Zealand companies.

Upcoming events

Case Studies

Documented as part of the SIRI Assessment, the case studies provide an opportunity to understand a specific example of how Industry 4.0 technology has been implemented in a manufacturing environment. They will provide you with key learnings to take away and inform your own journey.

Resources

text title 11 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023 HEADING

DELIVERY PARTNER PROGRAMME PARTNERS POWERED BY

Ninety per cent of businesses are struggling to fill vacancies, and nearly a third have had roles in the market for more than six months, according to the latest EMA Skills Shortage Survey.

The EMA Skills Shortage Survey 2023, received 543 responses from across the country, representing 17 different sectors and a broad range of business sizes.

“We’re aware of the skill shortage and have been pushing hard to increase the number of skilled

migrants allowed into New Zealand, in combination with initiatives to get local people into permanent work,” said Brett O’Riley, Chief Executive of the EMA. “The survey results confirm just how bad things really are for business trying to find staff.”

Restrictions around the number of work visa have been compounded by an increase in the lack of literacy and numeracy skills in domestic job applicants. The 2022 survey showed this issue was at 19-22 per cent. It has now doubled to 43-44 per cent.

“When you can’t fill roles through immigration, you look to the domestic market, or to upskill existing staff, but they need a level of proficiency. Poor literacy and numeracy skills will continue to hold people back and disrupt business growth.”

Upskilling and training staff may be the easiest solution for the 71 per cent of businesses unable to fill technical roles, with 54 per cent already engaged in apprenticeships, and another 24 per cent planning to take on an apprentice in the next twelve months. “We know education is part of the solution and it is encouraging to see that 84 per cent of businesses surveyed plan to maintain or increase their training budget, said Mr O’Riley.

“But that’s a long-term solution and almost half the people we surveyed said the skill shortage situation was getting worse, so immigration has to step in to provide some assistance, and also bring in the skilled workers who can help upskill colleagues.”

Forty-seven per cent of businesses are looking to hire skilled migrants, and while the majority were open to any nationality, others are specifically targeting the Philippines, South Asia (India), Southern Africa, and the UK.

While most businesses found they could navigate the migrant visa process, many have found it difficult.

“When you’re looking for staff and facing a complex visa process for overseas talent, education issues with local talent, and a tight labour market, what do you do? That’s the question we’ve continued to put to the Government, and we are working with them to find an answer that balances the various factors.”

The full results of the EMA Skills Shortage Survey 2023, a collaboration between the EMA and Immigration partners Malcolm Pacific Immigration, are available on the EMA website https://emalive. co.nz/documents/advocacy/Skills-Shortage-Survey-Results-2023.pdf

World first responsible AI Network to uplift industry

The Responsible Artificial Intelligence (AI) Network, is a world-first, cross-ecosystem program to support companies using and creating AI ethically and safely.

AI is expected to be worth $22.17 trillion to the global economy by 2030, but poorly developed AI solutions can have serious consequences, from data and privacy breaches to ethical issues.

The network will be the gateway for Australia’s industries to uplift its practice of responsible AI. Bringing together a national community of practice, guided by world leading expert partners, and enabling Australian businesses with best practice

guidance, tools and learning modules, the network is centred around six core pillars: Law, Standards, Principles, Governance, Leadership and Technology. Established by the National AI Centre, initial Knowledge Partners of the Responsible AI Network include the Australian Industry Group, Australian Information Industry Association (AIIA), CEDA, CSIRO’s Data61, Standards Australia, The Ethics Centre, The Gradient Institute, The Human

title Skills shortage survey confirms worst fears NE Tech

Technology Institute, and the Tech Council of Australia.

The announcement comes at a time when the world is racing to build guardrails for AI development and deployment to ensure responsible AI practices are developed in parallel with a rapidly accelerating AI landscape.

It’s no secret NZ’s agricultural and mariculture industry is flagrant with waste - the National Food Waste Prevention Project has estimated that New Zealand’s food waste could feed 262,917 people a year, while food and organic waste contributes 9 percent of New Zealand’s biogenic methane emissions and 4% of our total greenhouse gas emissions.

NZ’s growing fish-oil industry headlines a menagerie of nutraceutical products tainted by unsustainable manufacturing processes. Until recently, coaxing the desirable oils from fish & shellfish has required highly expensive, wasteful, and energy-intensive processes; either through ethanol or supercritical fluid extraction. All methods which require drying the raw material before separating the valuable oils.

NE Tech has designed a process to alter the actual composition of the raw product, changing its melting point, and allowing the value to be extracted without needing to dry the base material. As a result, NE Tech drastically reduces the total energy

required, and is able to double the yield when compared with traditional extraction methods.

The startup is on a mission to capture waste and reduce energy in the extraction of agricultural products like mussels, using its technology to eliminate waste in the manufacturing stream and improve yield. The system is being licensed by other major players through the global mariculture industry, with eyes to expand into additional industries before the year’s end.

NE Tech is an offshoot of sibling duo Ron & Sam Park’s popular green-lip mussel venture, K rure, where the Parks recognised the shortcomings of the existing manufacturing processes.

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 12 / www.nzmanufacturer.co.nz

text

Ankeeta Karmakar

Why did you come to New Zealand?

When I was considering different universities across the world to study as an international student, I was looking for a Master’s programme that would focus on earthquake engineering.

Most of the programmes that I found were master of civil and/or structural engineering, so when I found out about the University of Auckland’s Master of Earthquake Engineering programme, I just couldn’t think of any other schools.

I belong to a region, Assam (North-eastern part of India), where earthquakes are frequent. I wanted to pursue this path so I can apply my learnings both here in New Zealand and back in my native India to build an earthquake-resilient society.

So, here I am, pursuing my PhD in Civil Engineering, specialising in Earthquake Engineering. I successfully completed my Master of Earthquake Engineering last year in November and started my PhD in December 2022.

Earthquake research is big for you?

It is indeed. I fear earthquakes a lot and recognise that pursuing a career in this space will help me to overcome this fear, while also contributing knowledge and insight to how governments can improve their response when crisis does strike.

This is particularly relevant to New Zealand, where GNS records more than 20,000 earthquakes in the country per year, of which about 100 are felt.

Women in Engineering

The research that comes out of the University of Auckland is world-renowned, and I have gathered a huge amount of knowledge during my Masters programme that will help in developing an earthquake-resilient society in New Zealand, as well as in India.

How can NZ make residential properties more earthquake resilient?

With mindful research and use of available resources. Does your research suggest that NZ must be more mindful as to where building is done?

It is hugely important to be mindful of building, especially in cities where density is increasing. In growing cities with limited access to space, it will be difficult to relocate people to a safer place temporarily while a building is repaired following an earthquake.

Through my PhD research I want to make a building earthquake resilient using available resources. This would be helpful to mitigate post-earthquake costs and social disruptions.

Who are your role models?

I got a taste of civil engineering from my father, who is a retired civil engineer. When I was a kid, I always saw him doing calculations, drawing sketch after sketch of the bending moment, shear forces, and building design details.

Back then, I couldn’t fathom what those were but

after high school, I knew I had to pursue the field that my father pursued. Without him, I wouldn’t have succeeded in whatever I was doing. In the future, I see myself as following the footsteps of my supervisor at the University of Auckland, Prof Charles Clifton in 10-15 years. In my academic journey, he has been a constant support.

Greatest inspiration?

My father’s words are my greatest inspiration. I talk with him 2-3 times a day. I tell him how my day goes and if there are any problems, it’s him I discuss them with.

Each time he has a solution, or even if he doesn’t, he just calms me down. Father, I love you.

Favourite book?

Abundance Now by Lisa Nichols.

8. How do you relax?

Well, I sketch different types of mandala (dot art, free hand, graphic) to soothe my mind. It is also a fun way for me to pass my time. I have made hundreds of mandala and the biggest I could go to is A1.

13 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023

DEUTSCH HD30 & HDP20 CONNECTOR SERIES Designed specifically for the truck, bus, and off-highway industry, heavy duty, environmentally sealed, multipin circular connectors. contact sizes 4 through 20. Tel: 04 566 5345 Email: sales@connectors.co.nz Web: www.connectors.co.nz

SOUTHMACH 2023 PREVIEW

WOMEN IN ENGINEERING

SMART MANUFACTURING

CIRCULAR ECONOMY RENEWABLE ENERGY WORKSHOP TOOLS

Advertising Booking Deadline – 8 May 2023

Advertising Copy Deadline – 8 May 2023

Editorial Copy Deadline – 8 May 2023

Advertising – For bookings and further information contact:

Doug Green, P O Box 1109, Hastings 4156, Hawke’s Bay

Email:

Editorial material to be sent to :

Doug Green, P O Box 1109, Hastings 4156, Hawke’s Bay

Email: publisher@xtra.co.nz

Tel: 06 870 9029

At NZ MANUFACTURER our aim is to keep our readers up to date with the latest industry news and manufacturing advances in a tasty morsel, ensuring they do not get left behind in the highly competitive and rapidly evolving manufacturing world.

The Circular Economy

Article: Part two Ten tips to get Kiwi manufacturers started on circular economy

In last month’s article www.nzmanufacturer.co.nz, we looked at circular economy (CE): what it is (and isn’t), how it works, and how ‘going circular’ will benefit your manufacturing business, the environment, and people.

This month we help you get started with circular economy, with ten tips to gain the benefits. (The word ‘economy’ appears for a reason!) Learn how to reduce your risks and costs, make your business more resilient, build your brand, and identify new income streams.

Tip 1: understand circular concepts

CE is much more than recycling. Here it is in a nutshell.

• CE is an economic system. It recognises that the ‘linear’ economic system we use to produce and consume goods and services – ‘take-makedispose’ – cannot go on forever.

• CE is based on three principles. Firstly, it keeps products and materials in use. For example, if a product can be repaired, it retains the value created during manufacturing. Plus, there’s no need to extract new materials. Secondly, circular economy designs out waste and pollution. It preserves finite resources and avoids attendant problems like volatile prices and ecological damage.

Thirdly, circular economy regenerates natural systems. It supports natural processes which result in healthy soil and flourishing biodiversity.

• There are many circular manufacturing processes. They include sharing, reusing, repairing, and remanufacturing products and building them ‘to last’. Some are more circular than others.

Tip 2: understand circular tools

• The Material Circularity Indicator (MCI). Do you want to know how circular your product, materials and business are? The Ellen MacArthur Foundation’s MCI compares different options for your product from the start to the end of its life. How well do these options reuse or recycle materials? How durable is your product? How easily can consumers repair it?

The MCI identifies ‘hotspots’ in your production process. These are the areas to focus on to make your product or business more circular. It rates circularity on a scale of 0 to 1. Single-use packaging, produced in a linear (‘take-make-dispose’) process,

scores 0.1. A refillable milk bottle, produced in a fully circular process, rates a 1.

• Circulytics. Do you want to know how circular your business is and how well-equipped you are to continue to make it more circular? The Ellen MacArthur Foundation’s Circulytics calculates this. It includes quantitative and qualitative measures. An independent party confirms the results.

• Circular Transition Indicators (CTI). Do you want to turn your data into an action plan that will make your products and business more circular? To identify risks and opportunities? Confirm your priorities and set targets? The CTIs, developed by businesses and the World Business Council for Sustainable Development, help you do this.

Tip 3: get your data in order

You’ll need good data from the start – but it doesn’t need to be perfect. Data will help you understand your starting point, map where to head, and measure your progress.

Tip 4: identify the risks your manufacturing business faces

What problem are you trying to solve? Are you struggling to secure raw materials? To access international markets as regulations tighten? To retain market share because consumers are concerned about the waste you create? Your circular economy strategy should address these risks.

Tip 5: identity the circular opportunities available to your business

Could you redesign your product to reuse materials? Build market share by becoming known as the manufacturer whose products last? Add services based on your product?

Talk with your customers. Can you design your product so they can use it again? Can you change your business model to a ‘pay for service’? (This has been common in photocopying for decades.) Your suppliers will have ideas too. Are there opportunities to create circularity in your supply chain?

Tip 6: find the best way in for your manufacturing business

Revamping your packaging may be easier than redesigning your product – fewer suppliers, less financial outlay. Minimise or eliminate your packaging. Make what’s left reusable, compostable or recyclable. Use what you learn to make your product circular too. Consider running a pilot before you make big changes.

Tip 7: collaborate

CE economy is about systems and partnerships. Collaborate with suppliers, customers and, at a general level, your competitors too.

Tip 8: educate and listen

CE economy is still new in New Zealand. Get alongside your customers, suppliers, industry association, and team. Talk about your vision. Show

www.nzmanufacturer.co.nz

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 14

Opinion Manufacturing

Diary

World Market

Export News Machine Tools Business Opportunities Commentary As I See It Business News Appointments Around New Zealand Australian Report New to the Market Lean Manufacturing Equipment for Sale Recruitment Environmental Technology Manufacturing Processes NZ MANUFACTURER FEATURES MAY 2023 Issue

Profiles Letters to the Editor Politics of Manufacturing Trade Fair World

of Events

Report Q/A

them the benefits. Understand their concerns. Will your product last? Does it meet legal requirements? How do encourage customers to look after it? Are there regulations that prevent your sector from being more circular?

Tip 9: break your circular project into stages Don’t try to do everything at once. Approach CE in stages.

• Stage one (get started): understand the concepts and tools. Benchmark your existing circularity. Set realistic targets and metrics.

• Stage two (make progress): (re) design your product or service. Build circularity into your supply chain. Measure your impact and tell your story.

• Stage three (lead the way): benchmark your product against competitors’ products and

continue to improve it. Consider Cradle to Cradle certification. It’s one of the world’s most advanced standards for products that are circular, safe and responsibly made.

Tip 10: bring this information together in a plan Develop a CE strategy, business case and roadmap. (Circularity involves continuous improvement.) Then get started!

Tyres are first off the regulated stewardship start line

By Trevor Tutt – GM Innovation, 3R Group (Tyrewise implementation scheme managers)

A new waste strategy for Aotearoa New Zealand was unveiled at the end of last month. Front and centre is the drive to create a circular economy and see producers take responsibility for the environmental impact of their products.

But what does that mean in the real world?

Tyres give us an example of how a ‘waste’ product can become a valued resource from which to create new and innovative products. And how product stewardship, the mechanism through which producers take responsibility, can accelerate the process.

The value of tyres

Waste reduction, reducing pollution and protecting the environment are all strong reasons for taking action on end-of-life tyres. But local manufacturers are proving there’s also an economic case for recovering the resources within a tyre and creating circular economy solutions for them.

While these markets for waste tyres currently use around 40% of the tyres that reach their end of life each year in Aotearoa, nearly 4 million still end up in landfill, illegally dumped, or stockpiled. They represent a vast resource pool of materials like rubber and steel which could be used in high-value processes and products. The missing piece has been an effective nationwide system to manage them.

Tyrewise™, New Zealand’s first regulated product stewardship scheme to achieve government accreditation, will also be the first to ‘go live’. It will provide the system required to ensure end-of-life tyres are collected and tracked through to processing. The scheme will also incentivise innovation and research for new end markets for processed tyres and ensure a consistent supply of tyres to manufacturers.

Current solutions

Currently the biggest outflow for waste tyres is as fuel and an ingredient in the Golden Bay cement kiln. The company’s specially designed kiln uses tyres as 15% of its fuel source. This can be increased to 30% once greater surety of supply is created under Tyrewise.

The company, which supplies 60% of the country’s cement, has a target for reducing their carbon footprint by 30% by 2030. According to Golden Bay they produce New Zealand’s lowest carbon GP cement (EcoSure®) and have made solid progress on their carbon reduction through co-processing end-of-life tyres alongside wood waste as an alternative fuel.

The high temperature in the kiln means there is no smoke, odour or visible emissions from the process, the company says. A further benefit of using tyres is the steel is incorporated into the final product, reducing the amount of iron sand needed to make cement.

There are other companies making use of end-of-life tyres too. Cambridge-based Treadlite produces granulated rubber for use in various applications like artificial sports turf and equestrian arenas to playground matting. New Zealand company Matta™ uses crumbed truck tyre rubber, alongside other waste materials, to make the shock pad component of their playground and safety matting. Research by the University of Canterbury and Institute of Environmental Science and Research shows crumbed tyre rubber can be used in residential building foundations to make them more resilient to earthquakes. This process has the added benefits of reducing the need for gravel as aggregate. According to the research, the optimal mixture of 40% rubber would use 9,000 passenger tyres in the foundation of a 200m2 residential building.

Turning point

In 2012, the industry-led Tyrewise project was set up to develop a product stewardship programme to manage the tyre problem in Aotearoa. At that time, effective end markets for old tyres were few and far between. The requirement for the industry to move forward with a scheme was that Government declare tyres a priority product, effectively making stewardship mandatory. This would create a level playing field and prevent free riders – those who choose not to be part of a stewardship scheme but whose product would be stewarded anyway – and help develop those critical end markets.

Eight years passed before the priority product declaration was made. End markets developed but not at the scale required.

Then, in 2022, Auto Stewardship New Zealand (ASNZ) – the product stewardship organisation for Tyrewise – was awarded $1.2 million from the Waste Minimisation Fund – Te P tea Whakamauru Para to begin the Tyrewise implementation project. This allows the practical building blocks to be put in place to get the scheme ready to launch.

As part of this, a four-month operational trial to test systems and processes was held in the North Island in late 2022. The Tyrewise team is also engaging with all stakeholders and, critically, encouraging everyone involved in the import, sale, collection and processing of tyres in New Zealand to register with the scheme.

Once the scheme is live, consumers and businesses will see an advanced stewardship fee (ASF) charged when they buy tyres. On the flip side, at the end of a tyre’s life, disposal will be free.

The new fee, which is paid firstly by the importer of the tyre and required to be transparently passed on to the consumer, will replace the inconsistent disposal fees for old tyres that are currently in place.

The significance of Tyrewise

3R Group has been involved in Tyrewise from the beginning, facilitating the scheme co-design and ensuring continuity for the project. We are firm believers in the key role product stewardship plays in helping to create a circular economy. It’s also testament to the commitment of the industry to find better outcomes for end-of-life tyres that they have been willing to work with us to keep the project alive over the last decade.

The accreditation of Tyrewise not only means end-of-life tyres will finally be stewarded through a regulated stewardship scheme, but Tyrewise will lead the way for the other priority products to follow. It represents a step change in the way New Zealand deals with waste and is crucial to the development of a circular economy where recovered resources play a key role in reducing extraction of new materials. 3R accelerate the circular economy through the design, implementation and management of product stewardship schemes and other sustainability services. 3R have been involved with Tyrewise since its inception and are currently the implementation project managers. Find out more at www.3r.co.nz or www.tyrewise.co.nz

15 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023

The Circular Economy

www.thinkstep-anz.com

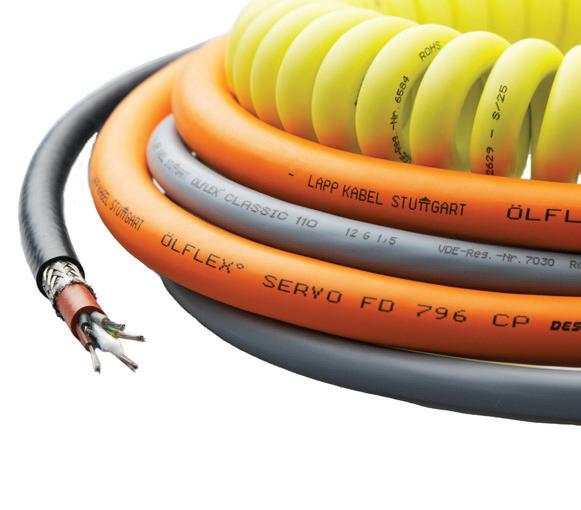

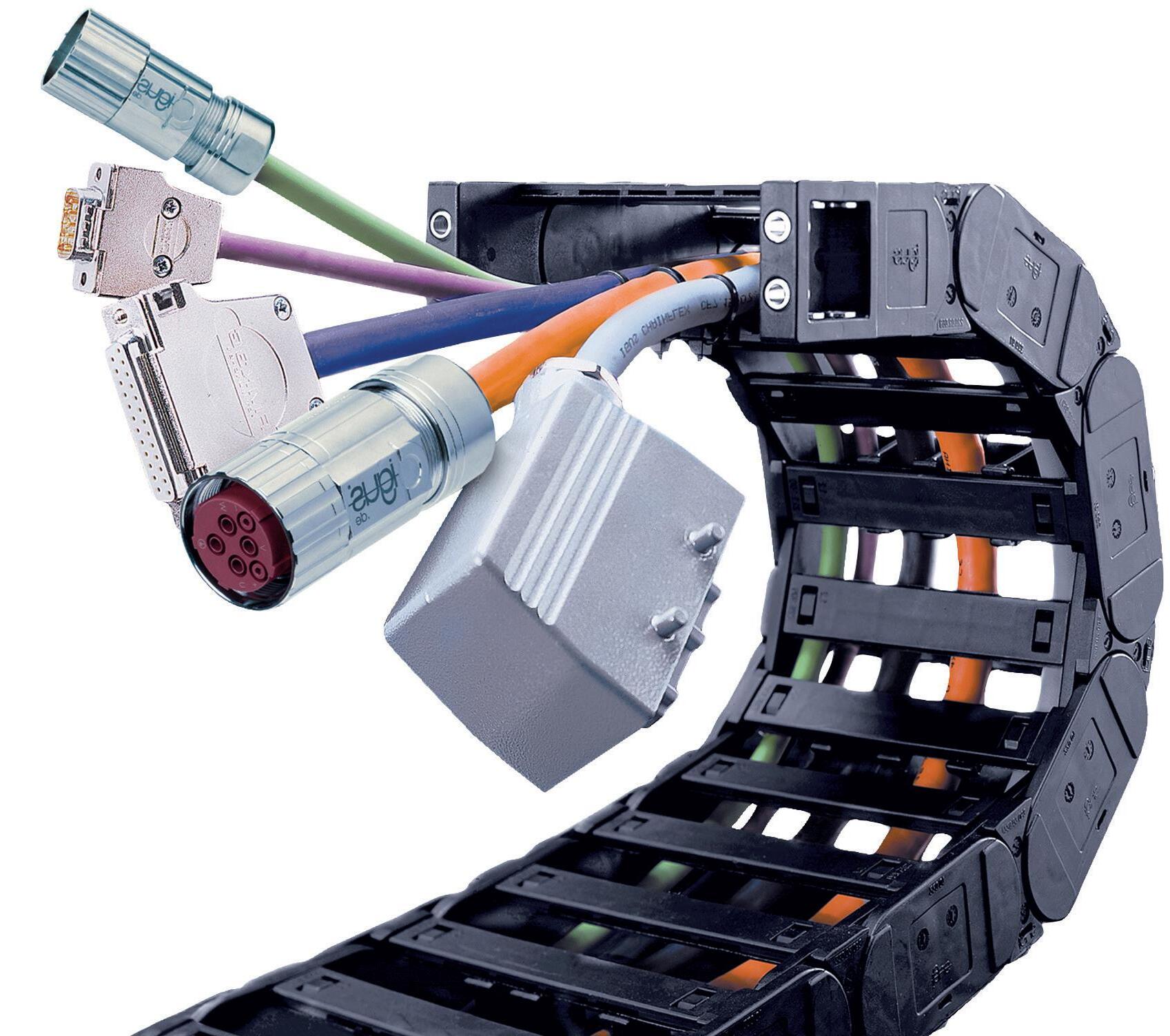

The leading supplier of high quality components and products to industrial markets

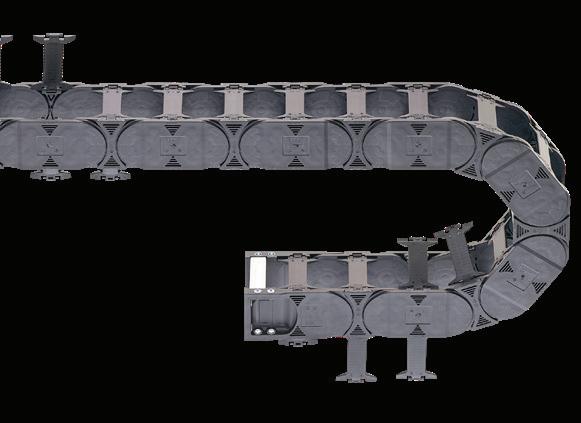

Treotham Automation is the exclusive distributor for many world class international product lines. As a leader in automation control, Treotham have a broad capacity to provide systems and custom-built solutions using a diverse range of products and components. Contact our technical engineers for more information.

text title NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 16

Auckland & Hamilton | 0800 847 200 | www.treotham.co.nz | info@treotham.co.nz CHECK OUT OUR NEW WEBSITE www.treotham.co.nz Flexible Cables Measuring Systems Flexible Conduits Chainflex Cables Energy Chains Cable Accessories

boxes Bearings

Units Sensors Connectors Safety Products

Gear

Linear

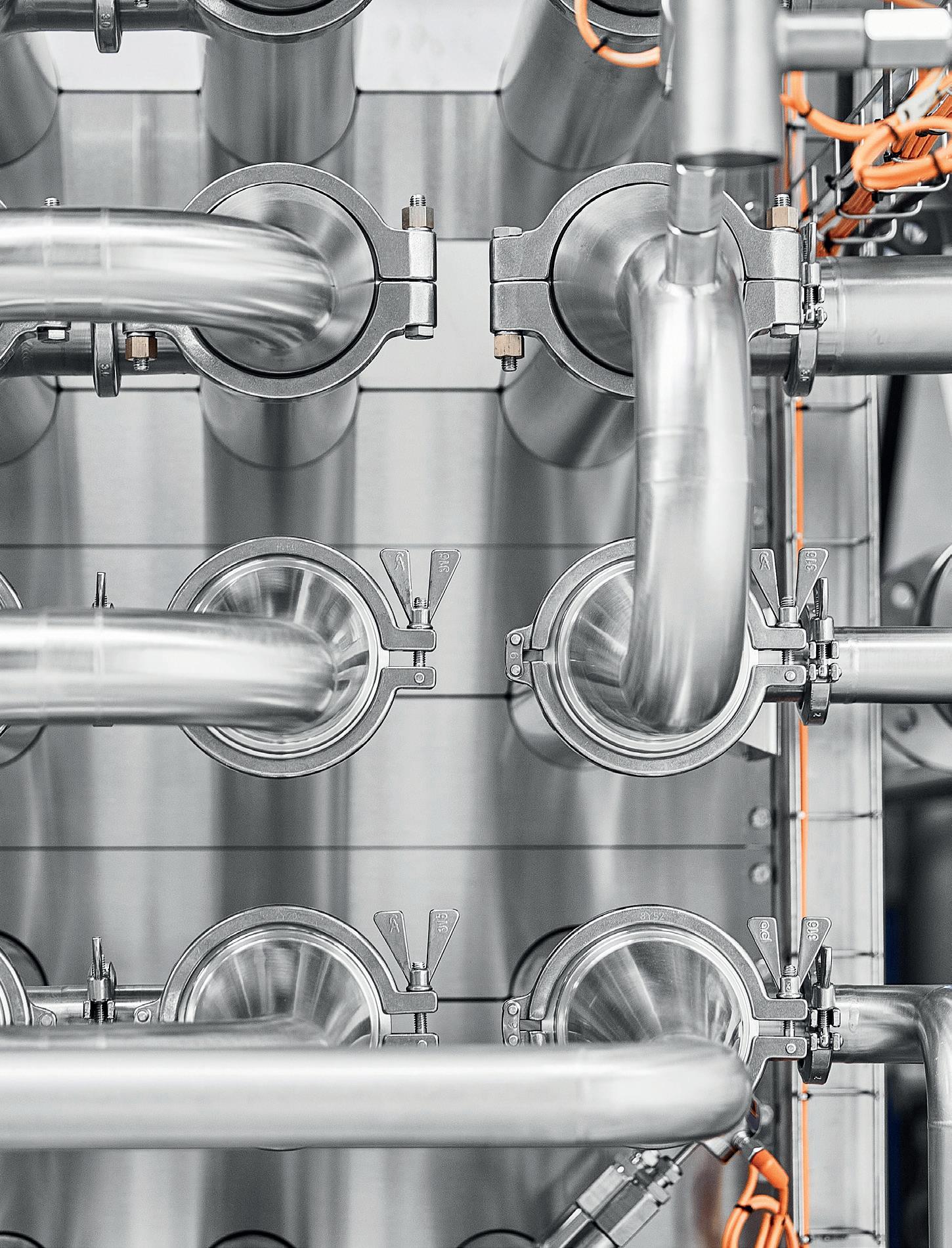

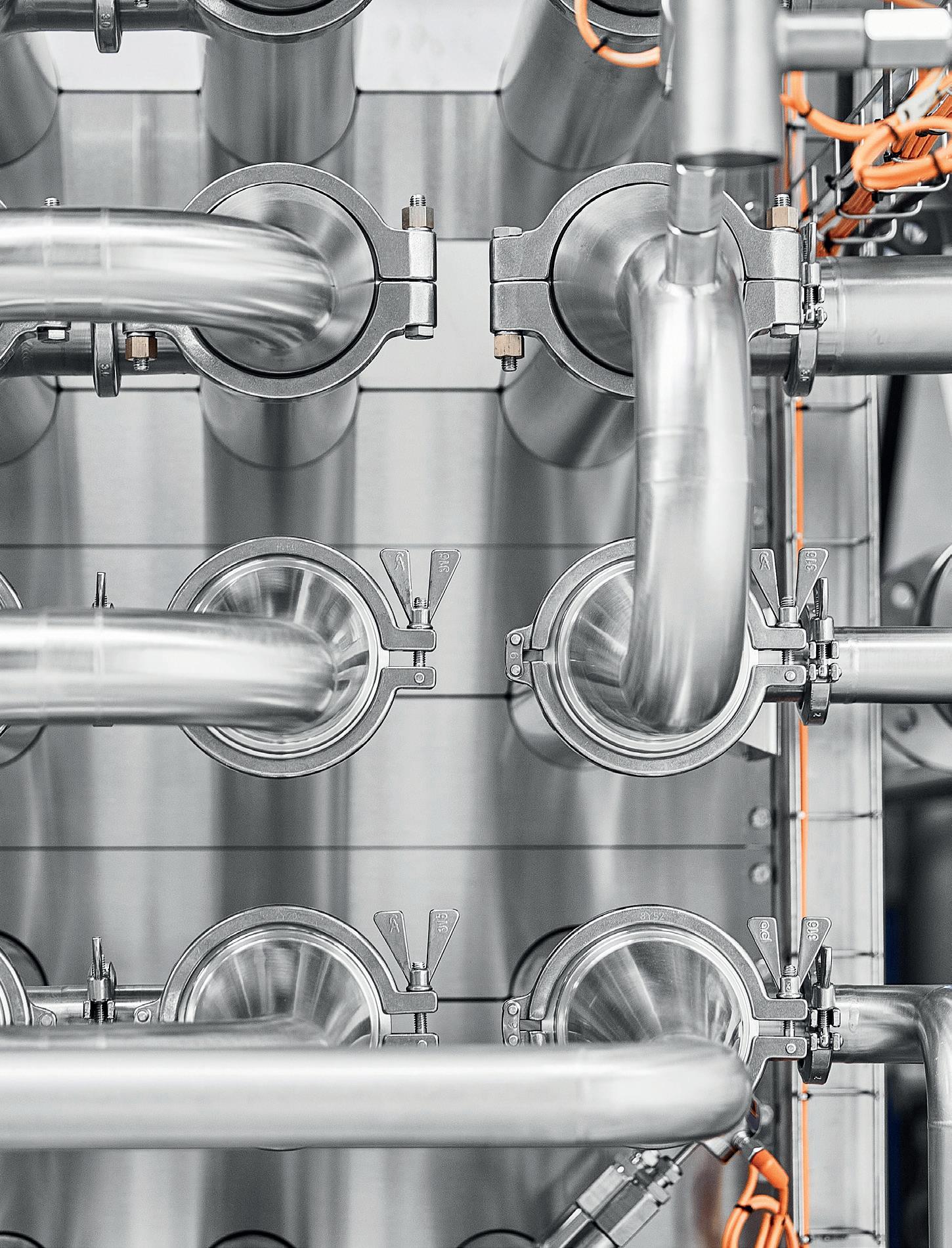

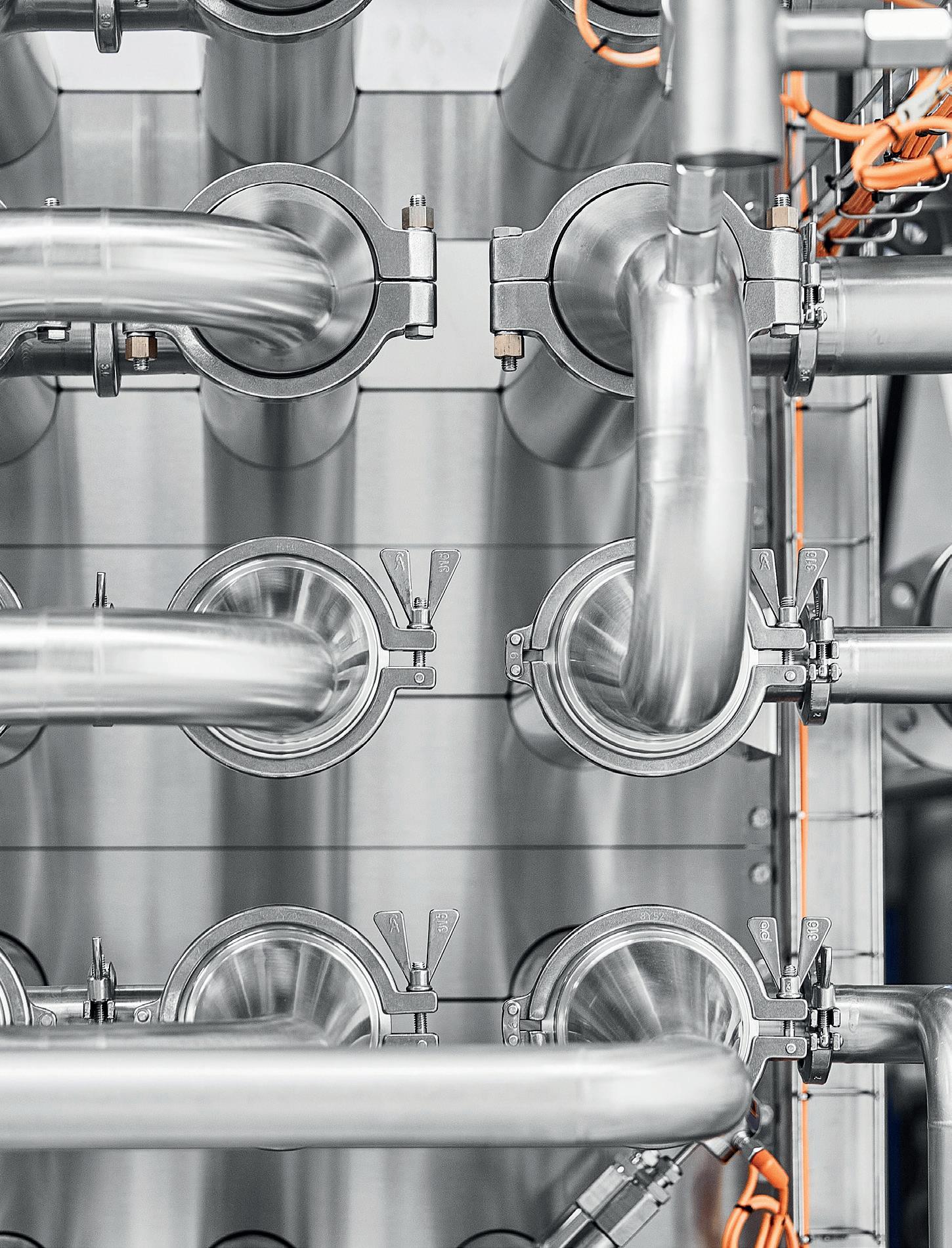

Pasteurisation plays crucial role in New Zealand AD plant

HRS Heat Exchangers recently supplied a Digestate Pasteurisation System (DPS) to New Zealand’s first and largest dedicated food waste anaerobic digestion (AD) treatment plant. The DPS plays a crucial role in ensuring that the valuable digestate produced by the process is safe for farmers and growers to use as a sustainable biofertiliser.

Ecogas has built New Zealand’s first full scale energy plant powered by food waste at Reporoa, in the middle of the North Island. The plant will process around 75,000 tonnes of organic waste each year from council kerbside collections, commercial and industrial food producers – eliminating more than 11,000 tonnes of CO2 a year and helping towards New Zealand’s target of being net carbon zero by 2050.

The plant, which was officially opened in October 2022, produces biogas and digestate biofertiliser. From October 2023, the biogas will be upgraded into biomethane, which will then be injected into New Zealand’s gas grid, and the carbon dioxide will be supplied to a nearby tomato greenhouse where it will help crop growth.

The co-mingled food waste used as feedstock at Reporoa has the potential to contain organisms which have the potential to impact human, animal, or plant health. The HRS DPS pasteurises the digestate produced at the plant prior to use to render such pathogens inert, along with other undesirable elements such as weed seeds. This means that the valuable and sustainable biofertiliser can be safely used by farmers and growers.

Traditional pasteurisation systems heat the digestate in a tank using a heating jacket – a bit like waiting for a giant kettle to boil – and then dump the heat after it has served its original purpose. The HRS system, however, employs energy recovery and is typically two to three times more efficient. By transferring energy from the hotter (pasteurised) sludge to the colder (unpasteurised) sludge, energy consumption is reduced, and the need for additional heat sources is removed.

The HRS DPS utilises ‘waste heat’ from the site based Combined Heat and Power Plants (CHP) to heat digestate to >70 °C and hold it for one hour at this temperature, before cooling. This is done with the HRS DTI Series heat exchangers, which are designed in such a way to recover up to 70% of the heat energy required for the process. The tube which carries the digestate through the system’s heat exchanger features a unique corrugated design; unlike the smooth or dimpled tubes used in alternative exchangers. This boosts heat transfer by creating extra turbulence and helps reduce fouling, resulting in less downtime and maintenance, and increasing the system’s lifespan.

The fully automated system provides an auditable kill-step for efficient and effective reduction of pathogens such as Salmonella, Staphylococcus, E. coli etc.

Once treated in this way, the digestate produced is safe biofertiliser product, turning what would otherwise be a waste stream into a value-added organic substitute to mineral fertilisers. Not only does the DPS heat-treat the digestate, but it also helps to remove odours while maintaining the quality of the resulting biofertiliser.

The DPS was delivered to site and installed in February 2022. The heat exchanger section of the HRS DPS is split into two frame modules, which are stacked and inter-connected for reduced footprint on site.

Alzbeta Bouskova, General Manager at Ecogas explains why the company chose to use the HRS DPS system. “Ecogas adopted UK-based PAS110 digestate standards as our primary design and operation principle to ensure that the biofertiliser produced from the Reporoa facility is of the highest quality, safety and value for the potential users. Pasteurisation is a key step in the PAS110 standard for source-separate food waste for destroying pathogens and viruses potentially present in this type of waste.

“The Reporoa plant is the first of its kind in New Zealand, and with that comes the process of introducing our new biofertiliser product, Fertify™, to the farming and horticulture sector. We know that brand trust is hard to earn but easy to lose with

the community and we have no room for mistakes. “We chose HRS based on their reputation and strong track record in digestate pasteurisation. This was further supported by the highly engaged local HRS team, who worked hard to meet their timelines and quality of the equipment and installation.”

HRS Managing Director for Oceania Chris Little comments, “It is fantastic to have extended our global footprint for HRS Digestate Pasteurisation Solutions to New Zealand, particularly as Ecogas Reporoa is such a significant project in the development of NZ’s Bioenergy Sector.

“We firmly believe that if renewable energy from Biogas and Anaerobic Digestion is to reach its full potential globally, then it needs to be as efficient as possible, and that includes extracting the most benefit from digestate in terms of its use as a renewable organic fertiliser.

“We foresee a step-change in the value of this abundant and nutrient-rich by-product, which, with the ever-increasing cost of chemical fertilisers, may very well end up being a key commercial driver for AD Projects in future.

“The HRS DPS ensures that digestate can be put to good use with the full confidence of the client and the consumer, returning nutrients to the land from where they originated.”

17 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023

Developments

The new Ecogas food waste anaerobic digestion facility at Reporoa.

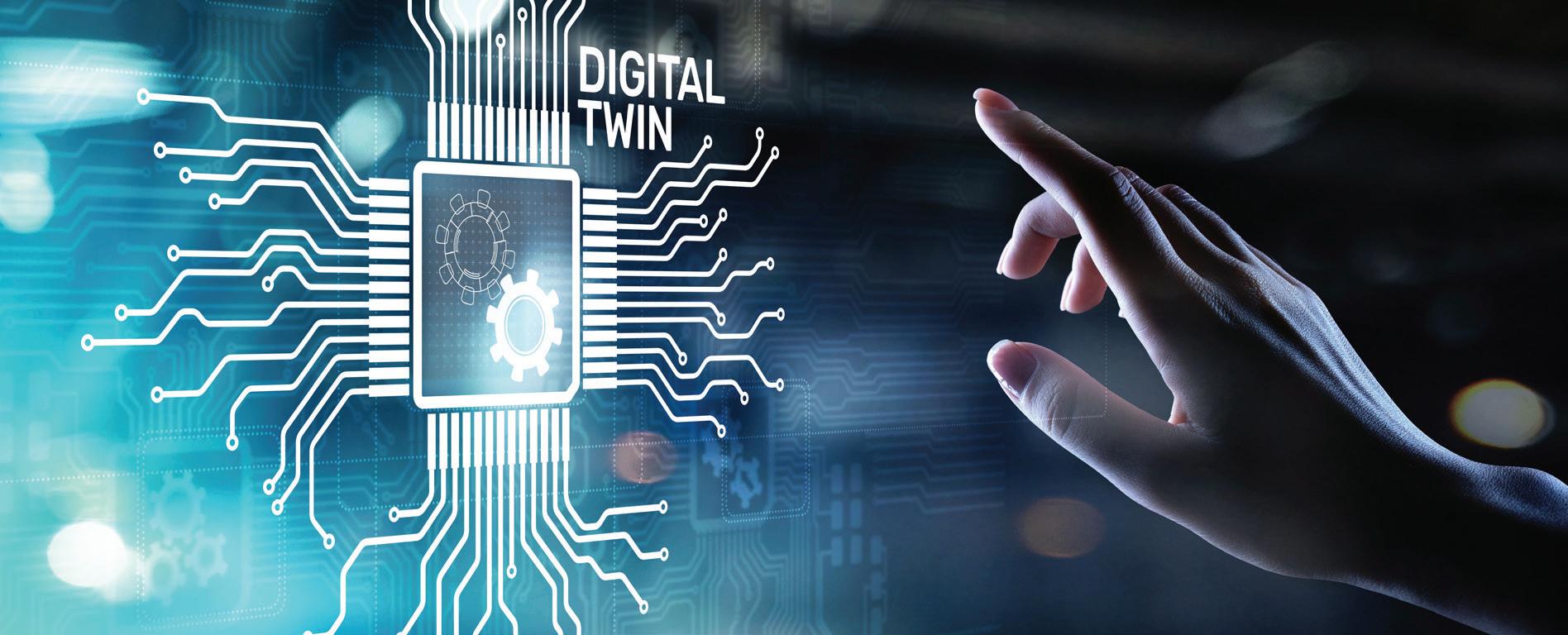

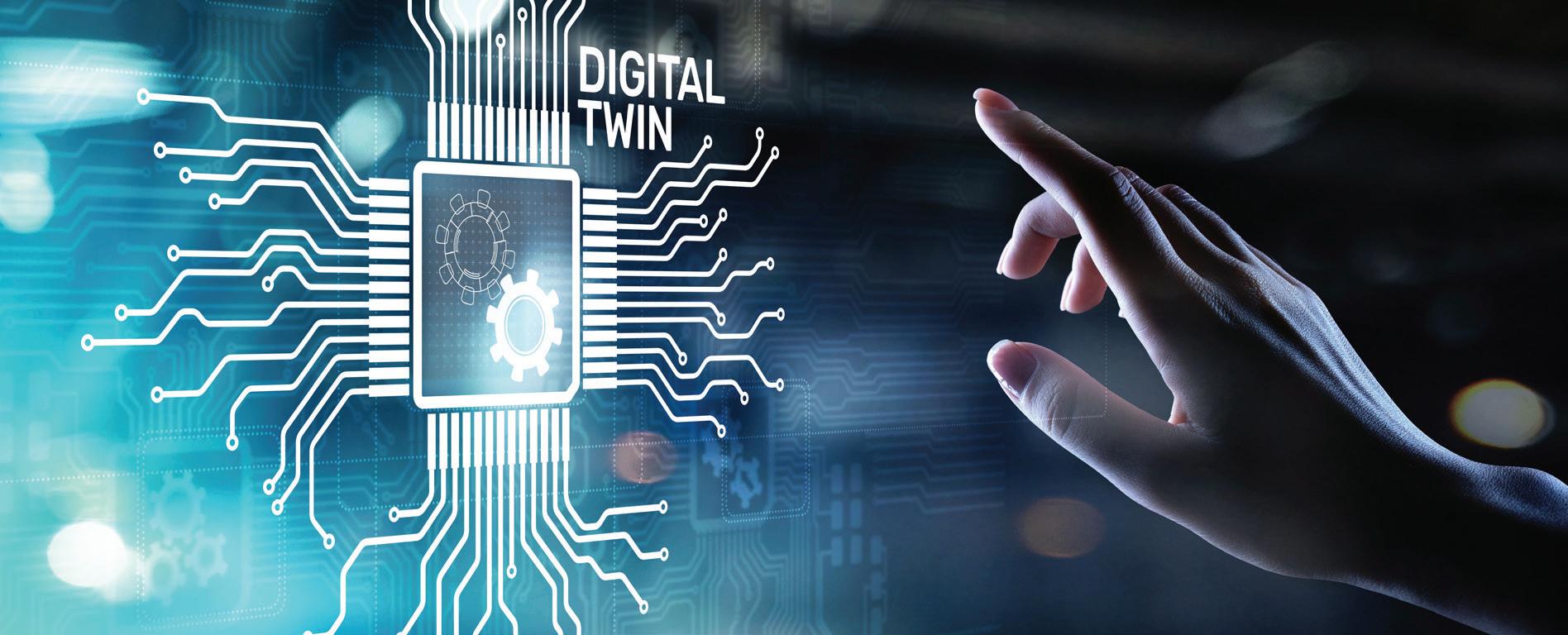

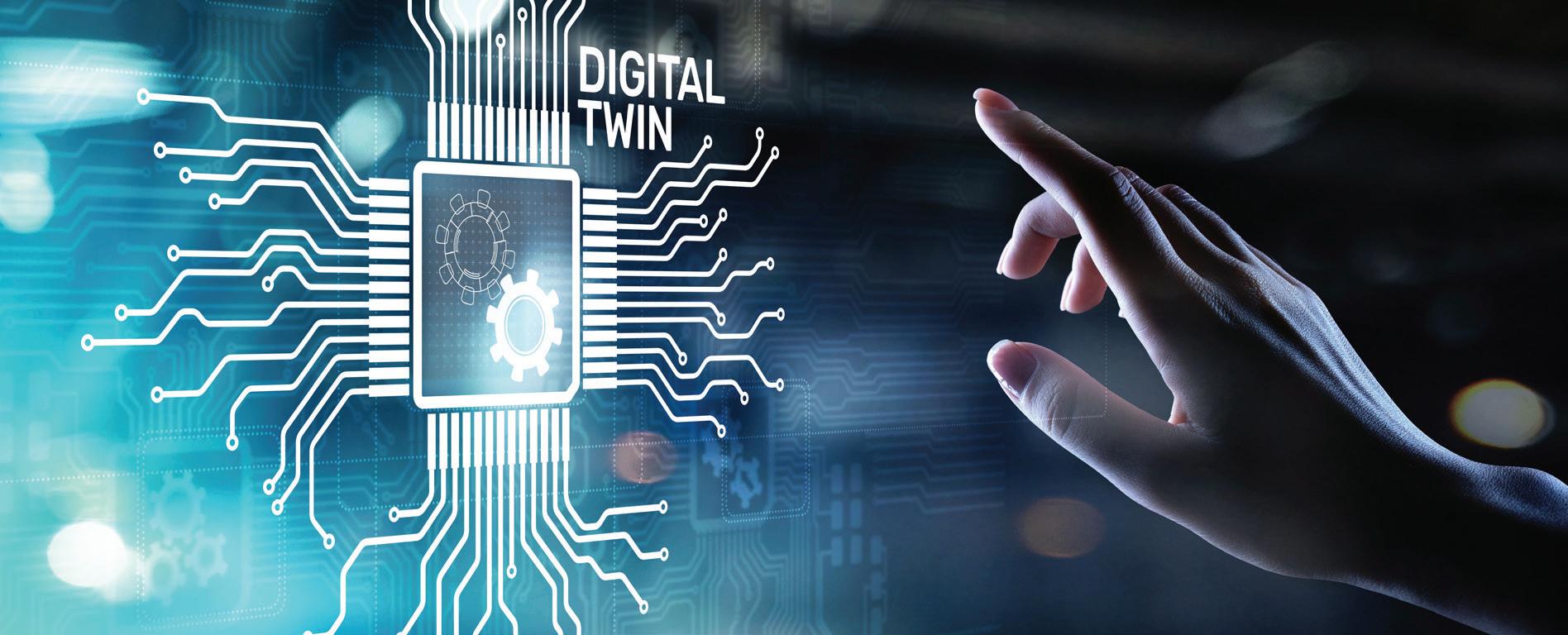

DO YOU HAVE A DIGITAL TWIN?

There is no doubt that the manufacturing industry is seeing the biggest change in how goods are produced in decades, and it is all driven by data, or the access, storage, and analysis capabilities we now have to make use of this data, coupled with the ability to interconnect everything in the manufacturing process.

Enabling technologies of Industry 4, such as IIoT edge gateways, advanced analytical software, or scalable control platforms, are all contributing to this change and to the creation of what has been coined the Digital Twin of a physical process or asset. This enables visibility into all stages of

production, quickly contextualize process and quality data, improve batch consistency and identify deviations, collaborate to create and share process knowledge. Does your manufacturing process have a Digital Twin yet?

NZ controls, a leading industrial automation solution provider believes that the best approach is to consider the industry 4 technologies as a set of tools and concepts to enable faster insights that drive asset availability, consistent product quality, higher yields, increased water and energy efficiency, and cost containment.

“We want to add value. It’s our responsibility to be informed and

ready to help guide our customers into the world of Industry 4. We work hard to battle the hype and drill down into real and practical applications with measurable returns,” says NZ Controls director, Nikk King. NZ Controls operations manager, Dave Lee says: “Controlling and monitoring of processes and operation is key to a secure and sustainable manufacturing business. Automation of processes is vital and can result in significant direct cost reductions but also importantly ensure repeatable and high-quality products are produced.”

These automation solutions rely on

the data that can now be utilized from industry 4 technology.

Before you create a digital twin for assets or processes, first you need a digital twin automation partner for your business.

King says: “From NZ Controls perspective we must provide measurable value. We seek to collaborate on developing a measurable business case, delivering industry 4 technology solutions, and becoming the digital twin automation partner to our customers on their journey to a digitalised future. Return on investment is key and can be achieved quicker than ever before.”

- Peter Drucker

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 18 FTR845 Drive productivity with data

• Repeatable production • Traceability • Track costs and outcomes • Manage efficiency • Drive continuous improvement

Measure to gain control

“You can’t manage what you don’t

measure”

PROCESSING

Buy NZ Made signs on with TradeWindow Assure+

The iconic ‘Buy New Zealand Made’ (BNZM) Kiwi trademark is partnering with TradeWindow to verify and deliver enhanced supply-chain visibility for their 1400-strong pool of licencees.

The trusted trademark is recognised by close to 90 per cent of New Zealanders[1] and is currently relied upon by over 1400 New Zealand manufacturers to differentiate their products and services domestically and internationally across key trading partners such as the US, UK, China, Australia and India.

TradeWindow CEO AJ Smith welcomes the partnership with BNZM and highlights the enhancements the new partnership will deliver to

continued from Page1

BNZM and their licensees.

The partnership sees BNZM integrate TradeWindow’s award-winning Assure+ solution to their own business model. The solution is designed to enhance transparency and provide full visibility on product provenance, and traceability all the way back to the points of cultivation and production.

The new partnership is welcomed by Dane Ambler, Executive Director of Buy New Zealand Made.

“The Buy New Zealand Made is widely trusted as a mark that stands for the quality and integrity of products that originate in New Zealand and we need to keep it that way. TradeWindow Assure+ will help

us effectively manage our licencees and help their end customers unpack what proof is in behind our brandmark on the product,” Mr Ambler says. Assure+ will help BNZM issue, manage and monitor licence certifications, and protect BNZM’s intellectual property from counterfeit use of propriety marks. The software is secure, and accessible, with a mobile-friendly interface that allows for the easy tracking of data and records.

For BNZM, this partnership will give their licensees the option to integrate the TradeWindow Assure+ solution into their business model alongside the BNZM trademark.

Increasing investment in advanced technologies a priority for manufacturing

The ITP brings together a raft of elements - skills, sustainability, carbon neutrality and competitiveness - to plot a path to the future of advanced manufacturing.

“There is an ongoing commitment from business to realising the vision for the ITP and we will be forming a new group, Advanced Manufacturing Aotearoa, to continue to bring together the key parties and leaders to drive the ITP, along with regional groups to ensure there is localised commitment and action,” says Mr O’Riley.

“Developing this plan has been a joint project. By continuing to work together, we can build world class advanced manufacturing capability in our New Zealand businesses, increasing productivity and lifting both incomes and profits.”

The Hon Stuart Nash, Minister for Economic Development, officially released the Advanced Manufacturing Industry Transformation Plan at Temperzone, an air conditioning manufacturer based in South Auckland.

It identifies six specific priorities to drive transformation along with measurable implementation actions over one to three years.

The aim of the ITP is to create a thriving Aotearoa New Zealand advanced manufacturing sector of world-class creators, innovators and makers delivering quality products, sustainable solutions and intergenerational wellbeing.

Mr O’Riley says: “We know through COVID there was a fresh appreciation of the contribution that advanced manufacturing made to the NZ economy

and people’s livelihoods.

“We need to build on that, and the ITP sets a clear path to achieving the growth and productivity gains our country needs to compete on a global scale.”

The latest GDP figures have further highlighted the need for increased investment in manufacturing, and the accelerated depreciation scheme is the logical next step.

The ITP to help manufacturers develop advanced capability addresses falling GDP in the sector. Specifically, more investment in software, hardware and skills, stimulated through an accelerated depreciation scheme, would help generate low-carbon, sustainable economic growth.

HRS Heat Exchangers operates at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide, focusing on managing energy efficiently

19 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023

Developments

Food Environmental Industrial Pharmaceutical Heating Cooling Evaporation Crystallisation HRS Heat Exchangers info@anz.hrs-he.com | AU +61 3 9489 1866 | NZ +64 9 889 6045 www.hrs-heatexchangers.com/anz MANAGING ENERGY EFFICIENTLY

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 20

SouthMach Floorplan

21 www.nzmanufacturer.co.nz / NZ Manufacturer April 2023 Company Stand # 3D Printing Systems 85 Agen 178 Amada 40 Aspex ........................................................................... 8 ATNZ 132 Autobend 190 Autoline Automation 60 Barcode Products 173 Baskiville .................................................................. 155 BDL 3D Copiers 179 Beckhoff 98 Caliber Design 135 Callaghan Innovation - Smart Factory 39 Callaghan Innovation (contra) ................................. 150 Camfil 170 Cebelio Ltd 157 Central Innovation 134 Chemz 4 Competenz ............................................................... 145 Control Devices 1 CSE-WAF 158 Design Energy 66 DMO Solutions 94 Duroweld ................................................................. 130 EasyKleen 139 EIS 51 Epicor 138 Eurotec 90 Fabribotics................................................................ 149 fi Additive - Complete 3D 95 Formtech 157 Haas CNC 89 Industry 4.0 Mobile Showcase 25 Invenio ....................................................................... 61 IP Enclosures 2 Jonel Hydraulics / Enerpac 7 Kiwibots 143 Konica Minolta 96 Leap Australia ............................................................ 24 Linak 87 MACH3 195 Machinery House 88 Make NZ 185 MESNZ ..................................................................... 186 Milwaukee Tools 115 Motion Design 97 Motion Solutions 156 National Springs & Wires 112 Nautech Electronics ................................................. 159 NVMS Solutions 167 NZ Engineering News 194 PB Tech 131 Phoenix Contact 67 Photoetch Industries ................................................ 144 Pilz Pomona Group 3 Professional CAD Systems 182 Ram 3D 186 Read Industrial ......................................................... 188 RF Test Solutions 116 Rivtec 177 Roadrunner 191 Rugged Tabs 181 Saint Gobain ............................................................ 187 Scott Machinery 70 Sprockets NZ 10 Taylors Manufacturing 45 Trotec Laser 50 UoC - Mechanical Engineering ................................. 169 Visiscope 148 Vortex Engineering 45

The Interview

Timoti Harris

Managing Director at Empowering Change

Te Tiriti in the workplace

While the broad strokes of Te Tiriti o Waitangi are now widely acknowledged, many people do not know its contents and intent. Much of HERA’s forward programme of research involves achieving industry focused solutions – but a much-needed change is that it now needs to be reviewed through the lens of te ao Māori.

This is part of HERA’s commitment to acknowledge Te Tiriti o Waitangi and interfaces between Mātauranga Māori (Māori knowledge) and industry to expand knowledge and practice more generally.

An example of this is HERA’s Endeavour Fund four-year research project focused on transforming the construction sector in Aotearoa New Zealand using Construction 4.0 approaches.

The Mātauranga Māori research theme within it, aims to address the gap of knowledge that exists and build a uniquely Māori framework to address the challenges of Construction 4.0. This will create new knowledge domestically and will sit internationally as an example of indigenous knowledge being incorporated into sectoral transformation.

HERA acknowledges that for industry, this will be confronting for some. Challenging the status quo of ‘doing’ business requires courage, even more so when the way to do it means looking through a cultural lens that may be unfamiliar.

However, there are significant changes occurring in New Zealand that indicate HERA needs to focus on this, as does business. This includes from a government perspective, the development of the Vision Mātauranga strategy of MBIE; development of the Te Ara Paerangi Future Pathways White Paper on the future of the research, science and innovation system imbedding Te Tiriti as one of four key focus areas; the revisions to the Education Act that now require honouring of Te Tiriti; and changes to government procurement rules that call for business to consider how to create opportunities for Māori.

As industry faces skills gaps and labour shortages, attracting the Māori workforce will be significant for them – particularly in attracting current rangatahi (youth), given by 2038 the Māori population aged 15-64 is expected to increase by 36% (around 136,000 people).

HERA’s work is heavily informed by the insights and guidance of experts, and we recently spoke to Timoti Harris, Managing Director at Empowering Change, about the importance of honouring Te Tiriti.

Timoti is on a mission to bring about the transformation of people and organisations by unpacking the ins and outs of Te Tiriti o Waitangi and its implications in the workplace. Here we share an interview excerpt from the latest Stirring The Pot podcast.

Timoti Harris: “Te Tiriti o Waitangi has always fascinated me because throughout all my different jobs, I’ve realised that few of us know much about the Treaty. We call it Te Tiriti o Waitangi as

opposed to the Treaty of Waitangi because that reminds us that they’re two documents written in two languages that say some different things.

“When we are talking with people, I often find they have quite strong attitudes around the Treaty, including its worth and relevance to our country. I worry because when I ask people what the words of the Treaty said or about the Treaty, my experience normally is that most of us simply don’t know.

“As an educator, I wonder why that is. Perhaps the reason is because we’ve never been taught our history. For 182 years, except for a very small group of senior students who might do New Zealand history, few in our country have learned about it. There’s a danger in that for a lot of us. We hold opinions about something, yet we don’t know what it said.

“As a personal opinion, we are all citizens of Aotearoa New Zealand, therefore we all are connected through the Treaty. As a recently retired Secondary School principal I like going to places in our country, particularly buildings, and just sitting there.

“Taking time to listen and I ask myself, can I hear anything in this building – or this room, or this meeting – that is from a Māori world? I look around the building. What do I see on the walls here which tells me I’m in Aotearoa New Zealand?

I’ve always asked that about all our spaces for learning. As a Tumuaki (Principal), I would often visit a classroom, sit and close my eyes and listen for five minutes, then ask, could I guarantee I’m in a learning space in Aotearoa? If I’m hearing kupu Māori (Māori words) being used – greetings, correct pronunciations, anything like that – I go, this is definitely not Sydney, this is in Aotearoa New Zealand. I would also take a look at what’s on the walls and ask the same thing. Is this a learning space, appropriate and inclusive, honouring Matauranga Māori in this country?

“It’s the same for me in industry. People often share their feelings they had when they first arrive at Auckland International Airport in Mangere, walking down those corridors, hearing the tui, seeing the whakairo (carvings), and hearing waiata play.

“For many of us, these are familiar of our land. This is Aotearoa, we’re home, we’re back in our unique place.

“For workplaces and spaces, I ask what, what do we do every day in a workplace that shows that we are active Treaty partners? What is our pronunciation like? How do we use greetings? What is on our walls? What sort of art? What greetings and in what languages do we record on the letters we write? Do we include some of the Māori world, Te Ao Māori, in whatever we are doing? The Māori world is a significant world of Aotearoa.

“Many of us have experienced that warm feeling when we are walking down a street in some far-off country and see objects like pounamu being worn round a person’s neck, see a design from

the Māori world on a garment being worn or even hear a waiata, we immediately think, “Hey, that’s from home.” It’s distinctive, uniquely of Aotearoa New Zealand. The Treaty said that all such taonga would be nurtured and looked after, would not be destroyed.

“It is a patai (question) for every company, school or organisation – where is the Māori world visible here and if it is, who did I ask about using it and have I got all the information I need to use it appropriately?

“It’s not saying a Māori world is better, but equally so, it is saying that it’s not less and must never be seen as being less which historically may have been the case in many facets on New Zealand life. “We’ve got supermarkets and shopping centres now that have big signs on their walls in Te Reo Māori – how exciting and awesome. It’s just normalising the use of Te Reo Māori. It’s a bit ironic, to be in a process of normalising our nation’s first language, indeed our nation’s first official language at that.

“The bottom line is the Māori world was here first. If the Māori language and tikanga, Taahuhu Kōrero (histories), along with the essence and knowledge from and of the Māori world disappeared from Aotearoa, there’s not one other place on Earth where it exists, then it would be gone forever.

“Every other culture including all other languages represented within Aotearoa New Zealand today, remain alive and strong in practice somewhere else on this planet, it has another home. My commitment is simple, both as a citizen and educator, allow Te Tiriti/The Treaty, through its principles to live and be lived; let its full intent be realised for us all.”

To hear the full interview, visit https://www.hera. org.nz/podcast/. If you are interested in attending Te Tiriti o Waitangi workshops facilitated by Timoti in partnership with HERA get in touch with HERA’s Mātauranga Māori Project Lead, Kim Nugent via email kim.nugent@hera.org.nz. This is a great opportunity to understand how Te Tiriti relates to industry and workplaces and how it can help improve credentials as a strong cultural partner in business.

NZ Manufacturer April 2023 / www.nzmanufacturer.co.nz 22

Company Profile

Clean Planet manufacturing healthier and safer cleaning solutions

Clean Planet is a nationwide health and sustainability focused cleaning and life services franchisor, established in 2008 by a passionate bunch of New Zealanders who recognised the need for healthier, greener cleaning solutions.

It is also the first cleaning company to come up with their own locally formulated and manufactured range of sustainably sourced, health-focused products.