Ian Walsh, Partner, Argon & Co NZ

Of course, many of the traditional levers had already been pulled, so many businesses did not have a lot of fat to start with, so cost reduction did not offer a lot of opportunity.

The need to avoid borrowing (due to interest rates), precluded a lot of capital options either new kit, or technology meaning many have relooked at productivity.

The reality is many don’t know where to start, because they are unable to see how you could get more from the current team, given everybody is already working so hard.

However, this is exactly what must happen, the reality is NZ has been lagging the world in the adoption of best practices, improvement techniques, workforce development for over 40 years. We now have a burning platform!

So, my hope for 2025 is

1. We see an increased adoption of lean techniques and tools and a genuine interest to properly adopt these tools across all sectors of industry. These are proven globally for over 60 years; the key is the right sponsorship and the right sherpa.

2. As business starts to recover, we see adoption of AI/automation tools to support item 1 above. The tools are not a solution in themselves but help build capability and can supercharge the productivity journey. The SIRI assessments supported by government have been helpful in getting business started on this journey, let’s hope this continues next year.

3. A unified approach to leadership and team capability development, with Te Pukenga,

NZQA and other parties becoming aligned in the need to develop alongside business real capability to address our gaps. With the rate of acceleration of enabled productivity and Industry 5.0 on the horizon, the need to change and change rapidly if we want to stay competitive is greater than ever. If you have been thinking about this journey, now is the time to start your climb to world class. I wish you all the very best of the season and for 2025!

Secure supply of energy and data to moving industrial equipment.

• Large size range

• Vertical travels

• Energy tubes

• Hygienic chains

• Solutions for long travel

• Guide troughs

• Readychain

• Robotic, 3D

• Circular movement

HUGE range of high quality flexible cables

• Control cables

• Single cores

• Data cables

• Sensor/Actuator

• Intrinsically Safe

• VSD/EMC cables

• Halogen Free cables

• High temperature

• Harsh Conditions

• Crane cables

• Profibus cables

• Bus/DeviceNet

• Solar cables

• Instrumentation

• Flat cables

• Curly cords

Largest range of flexible conduits for cable protection

• Conduits

• Conduit fittings

• Divisible systems

• Jumbo systems

• Conduit Accessories

• Braided cable protection

• Fire barrier solutions

• Food and beverage

• EMC systems

• Ex, ATEX, IEC EX

Industrial connectors for many industries

• Rectangular multipole connectors from ILME

• Single pole Powerline connectors from TEN47

• EPIC connectors from Lapp Group

• M23 circular connectors from Hummel

• Circular connectors specifically for the entertainment/stage lighting industry from Socapex

Safety engineering solutions from EUCHNER

• Multifunctional Gate Box MGB

• Transponder-coded safety switches

• Electromechanical safety switches

• Magnetically coded safety switches

Sensor technologies for automation

• High-Precision Laser Distance Sensors

• Ultrasonic Sensors

• Inductive Sensors

• Fluid Sensors

What will 2025 bring?

BUSINESS NEWS

Manufacturing technology and innovation success at Hutt Valley Chamber Awards 2024. We need to support the wool industry.

SMART MANUFACTURING

Unlock the full potential of AI with IRIS. Zenno Astronautics secures investment.

NZ Manufacturing: A year of resilience and transformation in 2024.

Elevating NZ Manufacturing: A vision for 2025 and beyond.

2024 : We are experiencing the bust, are we prepared for the boom?

Innovation in adversity: Transformative approaches to outsourcing.

A year to reflect and renew.

INNOVATIONS 2024

WORKSHOP TOOLS

Esmo introduces world’s first automated final test manipulator.

ThinkTop V55 sensing and control unit for diaphragm valves.

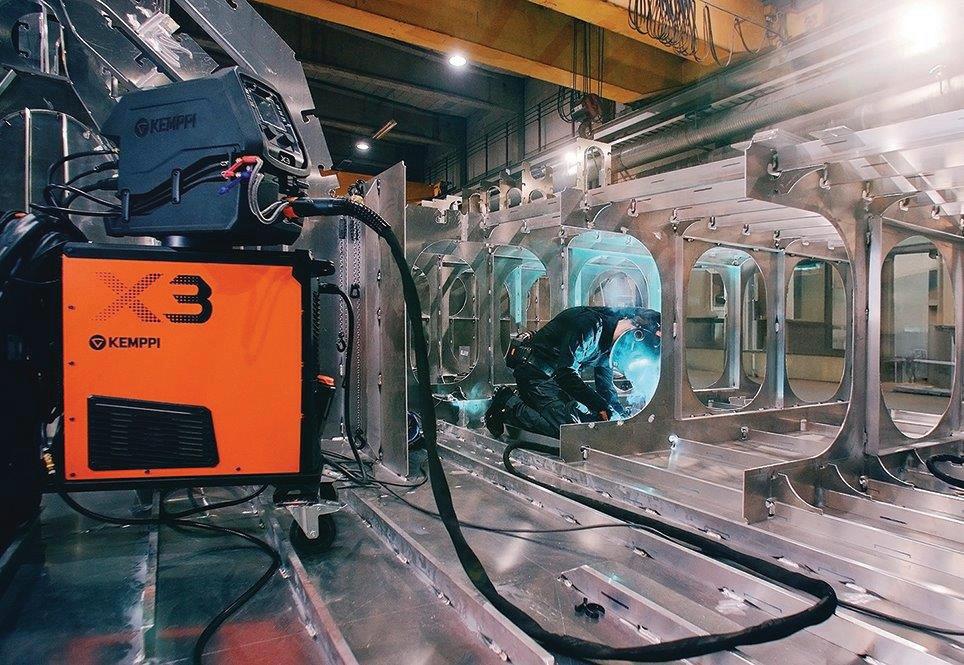

Kemppi releases powerful welding machine.

SUSTAINABILITY

Why human rights matter for manufacturers.

DEVELOPMENTS

Opal boosts manufacturing in Christchurch. Government’s plans for infrastructure are promising.

Boosting employment of disabled Kiwis.

Ian Walsh Ian is a Partner, Argon & Co. NZ, a master black belt improvement specialist and global lean practitioner. He is passionate about improving productivity and helping to create world class New Zealand businesses.

Dr Barbara Nebel CEO thinkstep-anz

Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

oodward

Is Managing Director of Connection Technologies Ltd, Wellington and is passionate about industry supporting NZ based companies, which in turn builds local expertise and knowledge, and provides education and employment for future generations.

Mark Devlin

Having owned food manufacturing and distribution businesses for a decade, Mark Devlin now runs Auckland public relations agency Impact PR. Mark consults to several New Zealand manufacturing firms including wool carpet brand Bremworth, aircraft exporter NZAero and cereal maker Sanitarium.

Insa Errey

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

Jane Finlayson is Head of Advanced Manufacturing at the EMA, and has 25-years’ experience in business and economic development. She is passionate about empowering businesses to grow, innovate and embrace Te Ao Māori.

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: +64 6 870 9029

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, EMA,

Business East Tamaki, Ian Walsh, Adam Sharman, David O’Connor, Mark Devlin, Nicholas Russell, Jane Finlayson, Sean Doherty

ADVERTISING

T: + 64 6 870 9029

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz

Free of Charge.

MEDIA HAWKES BAY LTD

T: +64 6 870 9029

E: publisher@xtra.co.nz

121 Russell Street North, Hastings

NZ Manufacturer ISSN 1179-4992

Vol.16 No.11 December 2024

Copyright: NZ Manufacturer is copyright and may not be reproduced in whole or in part without the written permission of the publisher. Neither editorial opinions expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or publisher of NZ Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the publication.

In a year that has brought its challenges, there are success stories of businesses striving and finding new opportunities and markets.

And we also have a balancing act, one where we retain staff or see them leave for overseas in their quest to try something different.

It has been a year of central government keeping the treasure chest closed and seeing restraint as the best way forward (for now). Let us hope that the Minister for Manufacturing, Andrew Bayly, can, at some stage, soon, be allocated some funding to benefit our manufacturing industries.

In this issue we include our annual Year in Review and Innovations 2024 to reflect on where we have been and where we are going to.

On Page 1, Ian Walsh from Argon and Co, describes this year as “The year to survive”, with businesses focused on managing costs, avoiding unnecessary spending and looking to how they can improve their productivity to improve returns. In 2025, Ian wants to see an increased adoption of lean techniques and tools, AI and automation tools and a unified approach to leadership and team capability.

Adam Sharman, LMAC, (Page 14) believes the New Zealand manufacturing sector has navigated a complex landscape this year, a flat-lining of productivity rather than a significant decline. The industry experienced 2.3% modest growth in 2023-24 which indicates a gradual recovery and renewed resilience.

David O’Connor of The Learning Wave, (Page 15) believes there is a sense of optimism and energy for our manufacturing businesses.

Dr Troy Coyle, CEO, HERA (Page 15) would like to see a bilaterally supported pipeline of national infrastructure projects, with a secured budget allocation, consciously timed to ensure stability of construction.

On Page 16, Director of Auckland public relations agency Impact PR, Mark Devlin, discusses how selective outsourcing can be leveraged to expand capacity and access lucrative export markets.

On Page 17, Jane Finlayson, EMA’ s Head of Advanced Manufacturing says the resilience, adaptability, and determination of our manufacturing community have shone through. However, the year also showed how much work remains to be done to turn the sector around and get productivity back on track.

On Pages 18-21 you can read, in brief, highlights of the year from some of our innovative companies.

Best wishes for the holiday season and 2025.

Doug Green Publisher

Manufacturing, technology and Innovation were again at the centre of the Hutt Valley Chamber of Commerce’s annual business excellence awards

The gala dinner and awards ceremony for the 2degrees Wellington Regional Business Excellence Awards were held in the Hutt Valley on Friday 15th November and manufacturing, technology and innovation organisations were among the finalists and winners.

‘Our local manufacturing, technology and innovation organisations make up so much of our business sector and do so much for our community’ said Patrick McKibbin, CEO of the Hutt Valley Chamber of Commerce. ‘We had so much talent at the Gala Dinner tonight, and it was so good to see so many of our great businesses being recognised.’

The manufacturing, technology and innovation winners and finalists included:

Excellence in Sustainable and Environmental Practices sponsored by CentrePort Ltd: Winner Pact Group Holdings Ltd ��- a lea ding Hut Va lley ma nufa ct urer lea ding t he recycle revolut ion a nd crea t ing sust a ina ble pa ck a g ing solut ions.

Best Small Business sponsored by Gallagher: Winner Prologic Skin Care - a Welling t on ba sed ma nufa ct uring a unique corneot hera peut ic ra ng e of skin ca re product s a nd supplying t o ma rket s in New

Winner - MJH Engineering Ltd – one of New Zealand’s leading structural steel fabricators and based in the Hutt valley

Finalist – Whakatiki Engineering (1984) Ltd – an Upper Hutt Based structural steel fabrication company. Finalist – Sharesies – innovating to help people invest, save, insure and grow their future wealth with Kiwisaver.

Excellence in Manufacturing sponsored by Woburn International:

Winner - Whakatiki Engineering (1984) Ltd - an Upper Hutt Based structural steel fabrication company

Finalist – Contemporary Korowai Designs – from Wainuiomata they hand manufacturer contemporary modern korowai / kakahu

Finalist – Heliner Ltd – Lower Hutt based specialist in industrial CNC machines and robots for manufacture automation

Finalist – Omega Hutt Valley – a Wainuiomata based family business manufacturing windows and doors

Finalist – Steel E.D. & Patton – A lower Hutt based manufacturer of all things aluminium, stainless steel, light structural steel, mild steel, copper brass and many other things.

Excellence in Construction, Trades, and Infrastructure sponsored by Morden: Finalist – James Henry Ltd – Lower Hutt

Excellence in Technology and Innovation sponsored by Pertronic Industries Limited

Winner - Sharesies Ltd – technology creating financial empowerment for everyone

Finalist – Arotec Diagnostics – based in Lower Hutt they manufacturer the highest quality critical components for the autoimmune diagnostics industries

Finalist – JT Group – Lower Hutt based manufacturer of exterior building wash technologies

Finalist – Lab Restraints – manufacturer of seismic restraints for laboratories

Finalist – OpenStar Technologies – innovating to harness the power of the sun to make a difference in the fight against climate crisis.

Three business with over 150 years of combined contribution to the Hutt valley were also recognised

The deliberate exclusion of wool carpet from state homes in favour of synthetic materials by Kainga Ora sets a damaging precedent, according to wool sector advocates.

Under a new Request for Proposal for the national supply of carpet and underlay materials to support Kainga Ora Homes and Communities’ maintenance and construction work, the tender document states the government agency “are not looking to procure wool carpet”.

However, the exclusion appears in conflict with a government directive in November last year to “prefer the use of woollen fibres over synthetic ones” in its buildings, where practical.

Greg Smith, CEO of wool carpet manufacturer Bremworth, says Kainga Ora is New Zealand’s largest landlord, owning or managing over 75,000 homes and a contract to supply this many homes would equate to over a million lineal metres of carpet and would be ‘transformative’ to the wool sector.

“In July 2023 Kainga Ora stated that it was pursuing a more sustainable path for its housing. That meant looking at the fibre being used in their homes after over 600,000 meters of synthetic carpet had been laid over the previous six years.

“This volume of synthetic carpet requires importing around 1.7 million kilos of plastic for its production.

“Ironically many of the Kainga Ora homes would date from a time when wool was the only option for carpet in New Zealand. To suggest that for some reason decades later wool is no longer a viable

option for the same purpose makes no sense.

“Ultimately this means Kainga Ora has chosen to specify a carpet that is made with imported fibre that is essentially plastic. Given we have a large surplus of a high-performing alternative in locally grown strong wool, this decision seems to lack macroeconomic insight and an awareness of the plight of our rural sector and the communities they support in recent years.

“If there is some inherent bias against wool that persists within Government departments, it is important for the industry to have the opportunity to correct any lingering misconceptions.

“For the wool sector to be completely left out of the conversation will be soul-destroying for many farmers.

“We believe the Government and its department heads should be the wool sector’s first customer and most vocal champion.

“The removal of wool carpet from the Kainga Ora contract is a lost opportunity to send a message of support for the sector and to set a precedent for residential developers,” he says.

“Wool carpet is uniquely suited to help provide healthier and safer homes for some of our most vulnerable.

“In contrast with synthetic textiles used in construction, wool is a natural product that requires less chemicals and is naturally fire retardant. Woollen carpets are also naturally stain resistant, hypoallergenic and regulate humidity by absorbing

moisture when the air is moist and releasing it when the air is dry - ensuring a drier home.

“As a nation, we import around $5.6bn worth of building materials annually of which carpet and flooring are part of a $333m subcategory and insulation products make up a further $73m.

“The use of New Zealand-manufactured wool products would help reduce this volume of imports and support regional economic development,” he says.

Smith says they have appreciated the support NZ First Minister, Mark Patterson has provided since his appointment and will continue to work closely with the minister to promote wool and look forward to the coalition’s promise coming to fruition.

Looking for a marketing edge?

70% of licence holders say signing on has positively affected sales.

By Hubertus Breier, Board Member for Technology and Innovation LAPP

Products, processes, and services need to constantly become faster and better, to keep up with the growing needs of industry. As part of this rapid growth, connectivity solutions are being put to the test.

Technology experts at LAPP see six key trends that will shape the industry.

Will make an important contribution to the success of the energy transition and to greater sustainability. This is because experts have established that the use of DC grids significantly reduces energy consumption in existing systems by avoiding conversion stages.

The need for copper for the three/four-core DC cables and AC-DC converter devices is also reduced. DC grids in factories also contribute to a lower peak power at the supply connection to the grid and reduce the load here.

LAPP is setting a good example and showing what the first steps could look like. The cooperation between LAPP and Fraunhofer IPA led to the development of a scalable DC network concept for a production site expansion in France, for example.

This increases efficiency and

enables the integration of PV systems for sustainable grid concepts. This pioneering conceptual work supports the transformation of the factory power supply towards direct current and promotes efficiency and sustainability.

There is huge opportunity for industry to capitalise on solar – on factory roofs, for example – to enhance their sustainability credentials.

181 zettabytes (that’s the number 181 followed by 21 zeros) is the forecast for the amount of digital data generated worldwide in 2025. How can this gigantic amount of data be transmitted quickly and stably?

Copper cables alone cannot cope with this. The solution: light, or more precisely fibre optic cables. A futureproof communication infrastructure in the factory with fibre optic cables is therefore essential.

Today, there are already implementations such as fibre-to-the-curb, where the fibre optic connection is laid to the distribution box in front of the house or factory.

Fibre-to-the-machine is the next logical step in order to connect the highly networked machines in the factory with sufficient data transmission capacity. LAPP already has a wide range of fibre optic cables and connectors for almost every industry and application.

Of course, copper-based data transmission is still the dominant solution in the industry. Since 2019, LAPP has been a member of the SPE Industrial Partner Network e.V.

The association of well-known companies is a central information and exchange platform for SPE and helps the technology to achieve a breakthrough together. In simple terms, the aim is to connect the field level (e.g. sensors or actuators) to the cloud via the Ethernet protocol.

The aim is to replace

previous fieldbus systems with the more modern protocol and pave the way for the Industrial Internet of Things (IIoT).

LAPP is expanding its portfolio to include innovative SPE solutions in order to meet market requirements at an early stage.

The Etherline T1 FD is suitable for continuous-motion use in the drag chain – successfully tested for over 3 million bending cycles.

Ethernet Advanced Physical Layer (Ethernet-APL), which is partly based on SPE, was developed especially for demanding applications in the process industry. The technology enables safe data transmission up to field level in potentially explosive environments. This is ensured by the “intrinsic safety” type of protection. Ethernet-APL also bridges large distances of up to 1000 metres.

The trend towards miniaturisation is continuing in many areas of industry. Applications are becoming more compact, installation spaces smaller, and more and more data and power connections have to be plugged into the smallest of spaces.

With the EPIC Power M12 connectors, these market

requirements have been addressed and consistently realised. The areas of application for the new EPIC® POWER M12L and M12K connectors are diverse.

For example, they are suitable for collaborative human-robot solutions, so-called “cobots”, which work together with humans in production or in the warehouse. The technical properties of the connectors were simulated during development using virtual models.

The two series M12K for power transmission up to 630V/12A and M12L up to 60V/16A were put through their paces virtually even before the first 3D printed model was created.

The issue of electromagnetic compatibility (EMC) is becoming increasingly important. Particularly in industrial systems in which frequency converter-controlled motors are used, unwanted currents can increasingly occur on the potential equalisation cables (PA) or protective earth cables (PE).

These unwanted currents can affect neighbouring data lines and their data quality during transmission, trigger fault circuit breakers incorrectly or even lead to increased corrosion effects in building structures.

A new, innovative cable design from LAPP reliably reduces leakage currents and makes a decisive contribution to improved EMC in machines and systems.

The Ölflex FD Servo zeroCM motor cable has been optimised for leakage currents using a special stranding process and makes an important contribution to the EMC optimisation of frequency-controlled drive systems.

Users are also increasingly looking for environmentally friendly and energy-efficient connection solutions for cables. With Etherline FD bioP Cat.5e, LAPP already has a cable with a sheath made from a partially bio-based TPU sheath material in its range.

This is now followed by the Ölflex Classic FD 810, the prototype of a cable with a sustainable PVC sheath. LAPP is also investigating initial approaches to the use of recycled material, both in the production cycle and the use of “cable scrap”.

In addition to the product-related sustainability approaches, transparency and documentation of the product carbon footprint are important.

New Zealand venture capital (VC) firm Global From Day One (GD1) leads a seed expansion investment round for Zenno. Japan’s Global Brain, ANA Holdings and Mitsubishi Electric join in, marking the VC’s first investment in Australasia

New Zealand-headquartered Zenno Astronautics (Zenno), the space superconductor company, has announced the first close of a seed expansion funding round.

New Zealand’s Global From Day One (GD1) led the round with significant investment from Shasta Ventures and support from other existing investors, including Nuance, K1W1, UniServices, NZVC and New Zealand Growth Capital Partners (NZGCP)’s Aspire Seed Fund.

In a significant new development, Global Brain, one of the largest venture capital firms in Japan with over USD 2 billion under management and extensive expertise in the space sector, joined the round. Contributing investment on behalf of ANA HOLDINGS and Mitsubishi Electric, two of Japan’s most prominent corporations, demonstrates strong

international confidence in Zenno’s superconducting technology for space applications.

Zenno is at the forefront of superconducting technologies for various space applications, first focusing on high-precision, fuel-free satellite positioning. Zenno’s product (Z01) scales to address demanding positioning requirements for satellites from 50kg and up to space station sized.

The product addresses the ongoing need for satellites to reposition in orbit to maximise commercial value. The company’s patented superconducting electromagnet technology is engineered for reliability, scalability, and fully electric space functionality.

Zenno co-founder and CEO Max Arshavsky says, “Zenno builds for life in space. Our mission is to create enabling and highly scalable technologies that will allow humanity to prosper in space without dependence on Earth’s resources, such as the need for fuel, radiation shielding, and frequent resupply of spacecraft in orbit.

“We are very pleased to partner with Global Brain

and their lead, a space evangelist and pioneer, Mr Hidetaka Aoki, who will join Zenno’s board as an observer. This injection of expertise and capital will accelerate Zenno’s ability to deliver the benefits of our technology to global space sector customers. “Partnerships with ANA Holdings and Mitsubishi Electric will ensure that Zenno’s technology is available and deployed in the Japanese market.

IRIS are the specialists within Argon & Co that have deep expertise in data and AI for operations.

With services spanning data and AI advisory, advanced operations analytics and AI applications, underpinned by our innovation lab, we work together with clients to generate real change.

Harnessing the power of AI is no longer just an advantage, it’s a necessity for businesses looking to stay ahead. At IRIS by Argon & Co, we are transforming how businesses deploy and manage AI with our AI Enterprise Platform, Magi – a fully secure, global platform designed to meet the unique demands of enterprise AI solutions.

Our platform enables organisations to adopt cutting-edge AI solutions seamlessly, without the disruption and high costs traditionally associated with advanced technology. The platform ensures that your AI solutions remain efficient, scalable, and aligned with your business objectives by offering managed services such as model monitoring and tuning, financial operations, metering, reporting, and MLOps.

Whether hosted in your secure environment or delivered as a SaaS-like service, our AI Enterprise Platform supports regional data security and management requirements, making it an ideal solution for organisations with complex, global operations.

With a growing suite of AI-based solutions available on the platform, businesses can unlock new opportunities to reduce costs, generate additional revenue, and achieve their business goals faster.

Learn how our AI Enterprise Platform, Magi, can simplify your AI journey and accelerate your success: https://www.argonandco.com/en/news-insights/articles/ video-demo-unlock-the-full-potential-of-ai-with-our-ai-enterprise-platformmagi/?utm_source=news&utm_medium=newsletter&utm_campaign=Magi_ video&utm_id=MHDDigital&utm_content=Magi

Sandra Lukey

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business.

Mike Shatford

is an expert in the field of technology development and commercialisation. His company Design Energy Limited has completed over 100 significant projects in this vein by consulting for and partnering with some of New Zealand’s leading producers.

Among Mike and his team’s strengths are industrial robotics and automated production where the company puts much of its focus.

Sean O’Sullivan

Has a B Com (Hons) Otago University. In 20002001 introduced PCs on the workshop floor and job and staff tracking and a productivity software App to Fletcher Aluminium Group and 100 manufacturers NZ nationwide. Founding Director Empower Workshop Productivity & Scheduling Software App.

Iain Hosie

Iain is a Director and Founder of Nanolayr Ltd, Director for the NZ Institute for Minerals and Materials Research, Commercial Director for Fabribotics Ltd, and Executive Council of BiotechNZ.

Catherine Lye

Is the first Chief Executive Officer of the newly formed cross-sector incorporated society, Advanced Manufacturing Aotearoa (AMA). Catherine has been Head of Manufacturing and Export Communities at the 7,100-member Employers and Manufacturers Association for the past two years. As part of that she has guided the Advanced Manufacturing and Industry 4.0 initiatives.

Adam Sharman

Is a Senior Partner at Dsifer. With a background in technology implementation, manufacturing and strategy, Adam and the team at Dsifer are on a mission to support New Zealand’s manufacturing sector transform using technology, data and analytics to outcompete on the world stage. Combining expertise in data engineering, data science & analytics and visualisation.

Patrick McKibbin

CEO – Hutt Valley Chamber of Commerce Patrick joined the Hutt Valley Chamber of Commerce in September 2021. His passion is identifying and connecting with manufacturing & technology businesses, other businesses, local government, central government and industry associations.

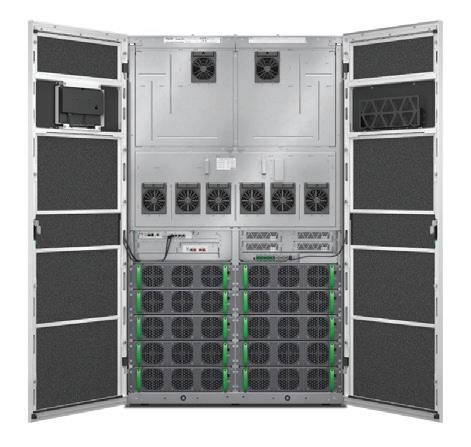

Schneider Electric has accelerated its end-to-end AI-ready data centre solutions with new announcements that address the urgent energy and sustainability challenges driven by high demand for AI systems.

The first part of the announcement is a new data centre reference design, co-developed with NVIDIA, which will support liquid-cooled, high-density AI clusters of up to 132 kW per rack.

Optimised for NVIDIA’s GB200 NVL72 and Blackwell chips, the design streamlines planning and deployment with proven, validated architectures, addressing the unique challenges of utilising liquid cooling at-scale.

Additionally, Schneider Electric has introduced its new Galaxy VXL uninterruptible power supply (UPS), the industry’s most compact, high-density UPS designed for AI, data centre, and large-scale electrical workloads.

Galaxy VXL UPS offers 52% space savings compared with the industry average, and with a power density of up to 1042 kW/m², this scalable, 1.25 MW modular UPS is designed to deliver more efficient power in a smaller, high-density footprint.

Both innovations form part of Schneider Electric’s end-to-end, AI-ready data centre solutions, which focus on three key areas including developing an energy strategy for the AI era; deploying advanced infrastructure; and sustainability consulting.

They seek to benefit data centre owners and operators as they deploy energy efficient, high-density infrastructure to support AI workloads as sustainably as possible.

A recent survey suggests that Kiwi SMEs need more support navigating the complexities of expanding their businesses overseas.

Nearly a third (30%) of NZ SMEs are already operating overseas, or have plans to do so.

Those taking steps to expand internationally are held back by the cost of international payments (42%), regulatory compliance complexities (41%) and New Zealand’s geographical location relative to overseas markets (40%).

59% of NZ SMEs are currently using a traditional bank provider when it comes to their international payments - with over half (54%) citing they believe it’s the most convenient option, and just under half (49%) believing it’s the most trustworthy option. Concerningly 17% are using a traditional bank because they believe it’s the most cost effective option.

Despite the majority of SMEs still being reliant on traditional banks, an almost universal view among business leaders - 91% - is that it should be illegal for banks to hide their exchange rate markups. Yet, hidden FX fees remain a common practice amongst New Zealand’s major banks, often leading to higher costs that are out of businesses’ control.

These higher costs are reflected in the cost of doing business. 41% of businesses agree that they have increased the price of what they sell; 23% agree that they’ve reduced the amount they can pay staff and 36% agree that they’ve reduced the amount they can invest in the business — all as a direct result of the high costs of international banking services in New Zealand.

SMEs spend big on fees - but aren’t clear on what for

The majority of Kiwi business leaders know they’re spending a lot on international payment fees, but out of those who have plans to expand globally, 52% of them don’t fully understand what they’re paying for. A further

8% are completely unaware of the fees.

A third (33%) of SMEs already operating overseas estimate spending up to $5,000 NZD a year on international payment fees alone, with 39% spending above $5,000. Interestingly, 28% of businesses believe they don’t spend anything or don’t know what they pay on international payment fees.

Wise says that the source of confusion comes down to a lack of transparency by the banks, the majority of which aren’t transparent about the exchange rate mark-up on international transactions, and are not legally required to use the mid-market rate, or any specific rate, when exchanging or sending across different currencies.

Traditional banks are charging Kiwis a fee of anywhere from 3-5% of the total transaction amount when sending money overseas. Those fees consist of a currency exchange transfer fee and an exchange rate mark-up, which isn’t made clear to the sender, and is reflected in this research.

Wise says in addition to decoding fee structures for international payments, more can be done to educate business owners on alternative (and cheaper options) available to them, recognising SMEs often don’t have the resources to do this themselves.

SMEs need more support to go global There are a number of independent and government support agencies in New Zealand which provide resources and guidance to help SMEs catapult themselves onto the global stage.

Results from the survey revealed that more than half of SMEs considering expanding overseas would use independent or government support agencies for support and advice when deciding whether or not to expand overseas. However, those numbers drop exponentially for businesses who have already expanded, citing they relied on other SME leaders (30%) or no one at all (36%).

Adam Sharman CEO LMAC-Group APAC

The New Zealand manufacturing sector has navigated a complex landscape in 2024, with significant headwinds such as persistent inflation and increased operational costs, local and global supply chain complexities and global economic uncertainty; factors which led many to adopt the mantra of ‘survive to ‘25’ in order to navigate sales uncertainty and low market and consumer confidence.

Whilst these realities are pervasive in the industry, economic indicators suggest a flat-lining of productivity rather than a significant decline and this year’s performance and the macro level is perhaps best understood through a detailed lens of economic indicators and sector-specific metrics.

According to Statistics New Zealand’s latest manufacturing sector survey [1], the industry’s overall output experienced a modest growth of 2.3% in the 2023-2024 financial year, following a challenging period of contraction in previous years.

This growth, while incremental, signals a gradual recovery and renewed resilience in the sector.

Key economic indicators revealed:

- Manufacturing sector contribution to GDP: 11.5% (up from 10.9% in 2023)

- Total manufacturing sector revenue: NZ$55.3 billion

- Productivity growth: 1.8% year-on-year

- Labor productivity improved by 2.1%, demonstrating increased efficiency through technological adoption

Export data from the Ministry of Foreign Affairs and Trade [2] painted a nuanced picture of New Zealand’s manufacturing capabilities:

- Total manufacturing exports: NZ$29.6 billion

- Top export sectors:

- Food and beverage manufacturing: NZ$12.4 billion (42% of manufacturing exports)

- Machinery and equipment: NZ$5.7 billion

- Chemical and associated products: NZ$3.9 billion

Notably, the food and beverage sector continued to be the main breadwinner for GDP, with dairy-related manufactured products accounting for approximately 25% of total manufacturing exports. The sector saw a 3.5% increase in export value, driven by high-quality processing and global demand for New Zealand’s premium agricultural products.

Whilst there is potentially some cause for optimism in these numbers, despite ongoing advancements in digital tools and processes, productivity remained an ongoing struggle for many New Zealand manufacturers in 2024, and as a result, risks further inertia if investment in these areas is not addressed.

This issue is particularly significant in industries with complex, multi-layered product portfolios, where tracking everything from raw materials to finished goods in real time can be a logistical nightmare. As global supply chains become more fragmented

and the demand for personalised products increases, Kiwi manufacturers are increasingly looking for ways to gain better insights into their product lines, both internally and externally.

In 2024, manufacturers confronted persistent and complex workforce challenges that significantly impacted their operational capabilities.

Skills shortages emerged as a critical bottleneck, particularly in advanced manufacturing domains requiring expertise in emerging technologies like artificial intelligence, advanced robotics, and complex automation systems.

The technological evolution of manufacturing outpaced traditional workforce development strategies, creating a substantial skills gap that hindered productivity and innovation.

Many companies struggled to find workers with the technical proficiency needed to operate sophisticated manufacturing equipment and integrate cutting-edge technological solutions, leading to increased recruitment difficulties and higher training costs.

Workforce efficiency became a key focus for manufacturers seeking to address these challenges. This represents a shift from 12 months ago where staffing numbers was the main issue. Organisations are no longer struggling for applicants, rather the struggle is to find a productive workforce.

To mitigate this, companies are increasingly investing in comprehensive training and development programs, leveraging digital learning platforms, to rapidly upskill their workforce.

Many manufacturers also explored hybrid workforce models that combined human expertise with advanced automation technologies, aiming to maximise productivity while mitigating the impact of skills shortages.

The struggle is rooted in several factors. For one, many manufacturers still rely on disparate systems, disconnected databases, making it difficult to access real-time product data across various departments. Secondly, the growing complexity of product offerings—think customisation, configuration, and bundling—has only increased the need for greater visibility into how products are designed, produced, and delivered.

In 2024, many New Zealand manufacturers are embracing technology such as digital twins, IoT connectivity, and advanced analytics to improve visibility.

These technologies allow manufacturers to create

a digital replica of their physical products and processes, enabling them to monitor everything from the production line to the end customer.

While these technologies are still in the early stages of widespread adoption, they are already proving valuable in providing greater transparency and improving decision-making.

Despite these advancements, the road to achieving full production visibility is still long and fraught with challenges.

Data silos, inconsistent reporting practices, and the inherent complexity of global supply chains all continue to impede progress.

Manufacturers will likely continue to invest in new technologies and strategies to address this issue in the coming years. In fact, the New Zealand Productivity Commission’s report [3] highlighted 2024 as a significant turning point in technological investment.

Manufacturers invested approximately NZ$780 million in digital transformation and advanced manufacturing technologies, representing a 15.6% increase from the previous year.

With this investment and a more favourable interest rate outlook, many organisations are now reporting an uptick in confidence with ‘green shoot’s appearing as the new year beckons.

However, whilst these factors may provide some relief in the short term, New Zealand’s manufacturers will need to maintain vigilance on productivity, innovation and agility as the themes of ongoing market and political uncertainty show no sign of diminishing in 2025.

References

[1] Statistics New Zealand. (2024). Annual Manufacturing Sector Survey 2023-2024.

[2] Ministry of Foreign Affairs and Trade. (2024). New Zealand Merchandise Trade Report 2024.

[3] New Zealand Productivity Commission. (2024). Digital Transformation in Manufacturing Sector Report.

-David O’Connor, Head of Emerging Markets, The Learning wAVE

As we bid farewell to the challenging winds of 2024 and step into a fresh new year, there’s a sense of optimism and energy for what lies ahead for Kiwi manufacturing businesses.

The opportunity to drive growth while scaling operations presents an exciting challenge - one that calls for agility, adaptability, and steadfast commitment to a skills-first approach in talent development.

With over 230,000 workers, New Zealand’s manufacturing sector is a cornerstone of the national workforce. This scale brings a unique opportunity to lead the way in creating long-term skills pathways and building a highly capable workforce. As we look at 2025, focusing on two key priorities will be pivotal:

1. Cultivating highly capable leaders that can lead safe, productive and thriving workplaces - evidence shows that this has never been more critical or urgent.

2. Creating a highly functioning and well funded pathway from school to work that ensures our young people can see their future and career pathway in the sector.

3. By equipping today’s leaders and tomorrow’s workers with the transferable skills to lead the sector into the future, we believe that this is key to transforming the new green shoots of potential into lasting prosperity for NZ Inc.

As we step into 2025, the sector has a prime opportunity to elevate itself to become world class, driven by a blend of advanced technology and empowered and skilled people.

Success lies not in smart technology alone but in

harnessing three key pillars: workforce development, innovation, and collaboration.

To fully harness the benefits of advanced technologies, manufacturers must invest in a skilled, adaptable workforce. With over half of New Zealand’s workforce lacking basic digital confidence, bridging the skills gap is critical.

Businesses and training providers should co-design accessible, dynamic learning programs to evolve with industry needs. Prioritising digital literacy and continuous learning will enhance safety, improve retention, and position New Zealand manufacturing as globally competitive.

“Technology integration demands more than cutting-edge tools, it requires skilled hands and confident minds.”

While integrating technology, businesses must ensure their people are prepared for digital workflows. With 55% of New Zealand’s workforce lacking basic digital confidence, strong partnerships between technology suppliers and training providers are essential to ensure timely and targeted training that builds work-ready digital skills.

In a year that has seen much dialogue on what a future Vocational Education system might be - we end the year with no clarity about what a VET system might or might not be in the future. Therefore, businesses must not sit and wait, by addressing the digital skills gap proactively, manufacturers can empower their teams to thrive in a tech driven environment, rather than leaving success to chance.

The sector holds a unique advantage: the power of collaboration. By pooling resources, sharing insights, and fostering cross-industry partnerships, manufacturers of all sizes can accelerate growth. Technology providers and training partners play a pivotal role in aligning skills, processes, and innovation to create maximum impact. Imagine a ripple effect that uplifts the entire sector where everyone has a highly skilled, engaged and capable workforce that is leading innovation, driving productivity, and shaping a prosperous future. Now that is exciting! From the team at The Learning Wave, we wish you a safe and restful summer break with your whanau. As we step into 2025, we’re excited to continue supporting the sector’s capability uplift in the new year.

2024 was a difficult year for construction and therefore manufacturing supply chains supporting it.

Our levy, which is legislated under the Heavy Engineering Research Levy Act, 1968, is a reliable indicator of sector activity (at least in the segments that use structural steel, such as multi-storey residential, commercial and bridges). In June this year, we experienced the lowest levy level of any month in more than ten years.

Boom and bust cycles are a pattern that is pretty consistent, and which we are not really learning how to avoid (e.g. through planned, transparent and sustainable infrastructure investments).

The consequence is that in the bust, which we are certainly in, there is a significant reduction in the employment of our skilled workforce. Then, in the boom, we no longer have the available skilled workforce available to meet demand. They have mostly gone offshore.

It would certainly help the sector if there was a bilaterally supported pipeline of national infrastructure projects, with a secured budget allocation, that were consciously timed to ensure stability of construction.

Combine a construction bust with an inexplicable proposed “reform” of the Vocational Education System introduced by the Hon Penny Simmonds,

Minister for Tertiary Education ans Skills in 2024, and things are not looking good for the future of our sector.

The link between boom and bust cycles and instability in our vocational education system means that looking ahead (possibly in 2026), construction-related manufacturing could experience an unprecedented skilled labour shortage when the market recovers.

Our industry is reliant upon skilled apprentices and concerningly, at the moment, there doesn’t seem to be a lot of Government support for work-based learning appearing within the planned “reform”.

For steel, there are also potential concerns with the proposed Building (Overseas Building Products, Standards, and Certification Schemes) Amendment Bill. The proposed bill will empower MBIE to recognise overseas standards.

This recognition is expected to be implemented by including these standards in Building Code Appendix B1.

Hopefully, MBIE will work with experts to determine the appropriateness of these standards for building products as they must be fit for purpose in our local UV, corrosive, seismic and geothermal environments, which are not commonly experienced in jurisdictions, such as Europe.

On the positive, we have found the Minister for

Manufacturing, Hon Andrew Bayly, to be highly engaged with the sector.

We were able to host the Minister for a Ministerial visit to some of HERA’s manufacturing-related research collaborators in Australia, including the Australian Composites Manufacturing Cooperative Research Centre (ACM-CRC) and the Facility for Intelligent Fabrication at the University of Wollongong.

Through our relationship with the ACM-CRC, HERA is involved in some world leading research related to AI in manufacturing.

We are also developing significant local capability, through our $10.6 million Endeavour research project related to Construction 4.0, in the area of circular design.

I envisage that 2025 will see an expansion of our research focus in both AI and circular design. Perhaps the former will be a key way for the manufacturing sector to develop more resilience to the boom and bust cycles of construction.

The latter will enable our sector to become a leader in the circular economy.

As the year winds down, businesses across New Zealand reflect on lessons learned and strategise for growth. For some, this year has been transformative, driven by innovative approaches to overcoming industry challenges. Director of Auckland public relations agency Impact PR Mark Devlin, discusses how selective outsourcing can be leveraged to expand capacity and access lucrative export markets.

For many SME manufacturers, this is a frenetic time of year. Trying to pack in two months of production and administration along with plans for time with the family in the three weeks before Christmas can be exhausting.

The public relations sector is no different. Media continue to churn out content, client crises and issues still arise (frequently when the CEO is at the beach for some reason) and we work with journalists looking for stories they can hold to publish over the summer season when the news cycle tends to quieten.

That said, the end of the year is often the only time many of us will get to reflect back on lessons learned and look ahead to better more efficient ways of achieving business growth.

Over the past 12 months, I have worked with two businesses in very different sectors that stood out in this regard. Both of these have developed new ways of overcoming the challenges associated with outsourcing to dramatically expand their capacity and develop new export markets.

Wool carpet manufacturer Bremworth is a great example of how unanticipated adversity can be turned into an opportunity for growth.

In the months following the extensive damage to their Napier facility caused by Cyclone Gabrielle, the company moved to develop a hybrid manufacturing model under which New Zealand wool is sent offshore to be spun into yarn and dyed - before being sent back here to be made into premium wool carpets.

This new approach has removed bottlenecks and constraints on production volumes. Without these restrictions, the door is now opened to much larger offshore markets that would have previously been

out of reach.

In an unrelated industry, the financial services sector, another business we have been working with called Orb 360, has successfully refined an approach to outsourcing that has insights applicable in the manufacturing sector.

According to Orb 360 managing director Jay Changlani, outsourcing is about dissecting processes to identify tasks that could be done by someone when clear instructions are provided.

He has developed a new outsourcing model that allows professional service firms to expand their businesses. This model involves segmenting each accountant’s role into three categories; client-facing interactions, creative and intellectual property work and tasks that can be delegated.

Changlani explains that the tasks in the third category are the most time-consuming and present the greatest barrier to expansion.

To address this, Orb360 pairs each New Zealand-based accountant with a counterpart in India who takes over at night to complete the work.

This transnational service model allows businesses to spread fixed costs across a larger client base, enable faster turnaround times, and increase efficiency. For Orb360, this has resulted in an efficiency increase of up to 20%.

This approach has enabled Orb360 to grow to 20 staff in New Zealand and 10-15 staff in India, serving approximately 2,000 clients.

Changlani believes this model will allow Orb360 to become one of the top 10 accounting firms in New Zealand within five years and will create the capacity to expand into markets like Australia. He suggests that this model could be adopted by other New

Zealand professional services providers, especially in a market where many accounting firms are at capacity and turning away new clients.

Changlani points out that this model is not limited to the accounting sector and could be suited for a wide range of businesses where the work is structured and process-driven. He lists mortgage brokers, immigration advisors and lawyers as examples. Manufacturers could potentially look at the cumbersome, repetitive or administrative tasks within their firms and consider how their NZ staff could be freed up using an offshore outsourcing model. With the right training, instructions and quality measurement it may be possible to free up your staff for more productive work - which ultimately could drive greater efficiency and growth in 2025 and beyond.

This year has been transformative, driven by innovative approaches to overcoming industry challenges.

By EMA Head of Advanced Manufacturing Jane Finlayson

There’s no doubt that 2024 has been another challenging year

Global uncertainties, local economic pressures, and significant supply chain disruptions have tested manufacturers across the country.

Yet, despite these obstacles, the resilience, adaptability, and determination of our manufacturing community have shone through. However, the year also showed how much work remains to be done to turn the sector around and get productivity back on track.

The latest BNZ-BusinessNZ Performance of Manufacturing Index (PMI) for November 2024 showed the 21st consecutive month of contraction for the sector, underscoring the ongoing pressures faced by many manufacturers.

While some encouraging signs were visible midway through the year, with what looked like a gradual return towards the neutral 50.0 mark, October and November decreases highlighted the fragility of the recovery.

The key sub-indices, such as production, employment and deliveries all registered below the neutral mark, with production activity in particular falling to its lowest point since July 2024.

The general economic slowdown continues to weigh heavily on the sector, with many manufacturers grappling with high costs, reduced domestic demand, and external pressures such as the ongoing fallout from global inflationary trends and trade disruptions.

These numbers don’t tell the full story. Beneath the surface, there’s a lot of good work happening. Many of you have been upskilling your teams, adopting new technologies, and finding smarter ways to operate.

These efforts are setting the groundwork for a sector that’s not only resilient but ready to thrive when markets ease and new free trade agreements start to deliver better trading opportunities for some of our goods.

One area that stood out this year is the investment being made in people and their ability to drive productivity, create a culture of safety and lead change.

The EMA has seen strong numbers of teams coming through to upskill in leadership, project management, and health and safety. Whether it’s improving machine guarding or ensuring health and safety representatives are well-equipped to maintain a safe working environment, these efforts are keeping workplaces safer and teams more confident. Such investments help to keep operations running

smoothly and safely and enhance the reputation of businesses as a positive place to work. This will be important to retain and attract skilled workers in individual manufacturing businesses and the sector as whole.

Another bright spot this year has been maintaining the focus on helping manufacturers understand the benefits of Industry 4.0 technologies. The opportunity for improving productivity, safety, and sustainability is being adopted rapidly around the world and more and more manufacturers are understanding that they need to take action now to stay competitive and viable into the future.

If you are still unsure about how your business can benefit and what other businesses are doing, we’d encourage to you come to our ‘ASB Manufacturers Workshop: The Impact of Industry 4.0 on Your Business’ series, running from February to June 2025. Like us, ASB Bank is committed to improving productivity in New Zealand businesses, and its support underscores its dedication to helping manufacturers stay one step ahead with the use of technology and process improvements.

In addition to the EMA and ASB, this programme is due to the collaboration of delivery partners including LMAC Group, whose experts have considerable experience in helping manufacturers transform from manual to digital/automated processes.

We’re also grateful to Nautech Electronics for sharing its real-world experience with automation and its journey to adopt new ways of working.

The workshop wouldn’t be possible without Beca’s Beyon digital twin that takes you ‘inside’ the factory to demonstrate the benefits, and we also appreciate the support of Aspect, local providers of manufacturing execution systems.

If you can’t afford to be left behind, then grab other decision-makers from your business and join us for one of the 20 workshops, co-hosted by local business associations. Check out the details and register here.

With energy costs rising and new regulations around industrial processes – especially boilers – looming, the EMA teamed up with the Energy Efficiency & Conservation Authority (EECA) to run webinars that offered practical solutions.

Our ‘Greening the Furnace’ webinar explained what it all means and introduced EECA’s pathway towards decarbonising industrial heat.

We also ran a webinar on the best options for manufacturers to replace ageing equipment in their factories and warehouses, highlighting sustainable options that will save money and better position them for the changing regulatory environment.

Keep an eye out for more of these energy-related topics next year and remember to take advantage of the tailored tools and resources on the EECA website, to help lower emissions and unlock business benefits.

New Zealand signing the Agreement on Climate Change, Trade and Sustainability (ACCTS) with Costa Rica, Iceland and Switzerland this year is evidence that sustainability and a reduced environmental footprint is the way of the future, and a prerequisite for trade, in an increasing number of markets.

As we’ve outlined recently in NZ Manufacturer, health and safety has also been a major focus for this year. Project Whakahaumaru has kicked off the collaborative effort to reduce harm in manufacturing.

A big thanks to ACC, manufacturers, workers, and business associations who got behind us during the discovery phase. Together, we’ve developed a high-level strategic plan aimed at reducing harm and its economic and social costs.

We’re just getting started, and we trust this collaboration will keep rolling. Our goal is to provide practical tools and targeted programmes for the areas where harm is most common and where workers are most at risk.

We’ve also worked closely with WorkSafe and other manufacturing groups, using what we’ve learned to align priorities and drive change.

The willingness to work together and the collective desire to support a productive, safe and sustainable manufacturing sector have been standout features this year – all indicators that it can thrive in 2025.

New York’s Architizer Inc has awarded Kaynemaile’s RE/8 architectural mesh an A+ Jury Award for ‘Building Envelopes, Cladding, and Roofing’ in its 12th annual awards honouring the world’s best architecture and spaces. Kaynemaile was also the A+ Popular Choice Winner for ‘Sustainable Design.’

The design-led Petone company is on an awards roll following its naming in the U.S. Architectural Record Products of the Year Awards saluting the best building and design products introduced to the US market within the last year.

In 2023 Kaynemaile won ‘Global Gold’ for exporting at Wellington’s Gold Awards and has featured in multiple New Zealand architectural awards won for the Invercargill Central which has transformed the city centre into a vibrant community hub with a beautiful indoor shopping complex.

The U.S. awards are for Kaynemaile’s new RE/8 product launched in San Francisco a year ago. RE/8 is made from 88% bio-circular content from Covestro, the world-leading provider of high-tech polymers. Kaynemaile’s mesh is extremely lightweight, uses 20% of the energy needed to produce steel, and is 100% recyclable.

SmartSat Cooperative Research Centre (SmartSat CRC) has announced the first four new jointly funded space research projects and opened further funding opportunities in partnership with New Zealand’s Ministry of Business, Innovation and Employment (MBIE).

The four initial research projects include research into monitoring methane emissions, enhancing real-time monitoring of greenhouse gases, managing free space optical communication nodes across Australia and New Zealand, improving the tracking of space objects, and developing a joint AUS-NZ concept for maritime domain awareness.

Professor Andy Koronios, CEO of SmartSat CRC, emphasised the importance of this collaboration and stated, “In a significant advancement for Trans-Tasman space collaboration, this partnership between Australia and New Zealand in the space sector demonstrates our commitment to leveraging our combined strengths and resources.

“These projects are a testament to our shared vision of driving innovation and developing capabilities that will not only benefit our respective countries but also contribute to global advancements in space technology.”

Two innovative startups show how AI can enable ingenious Kiwis to develop new products for global markets, says Callaghan Innovation Chief Executive, Stefan Korn.

Prosaic and Script Sense showcased very different use-cases at the AI Activator launch. Script Sense is an award-winning AI platform that helps pharmacists to overcome workforce challenges, enhance efficiency, and improve patient care.

Prosaic is an AI-powered app that uses AI and open banking to help small businesses, sole traders and their accountants to automate the process of finding deductible expenses and income tax credits.

Designed to boost economic growth and exports via the rapid adoption of AI, the AI Activator is a Callaghan Innovation collaboration with partners NZTE and NIWA.

Witnessing the human cost of the Canterbury earthquakes inspired Ben Exton to become an earthquake engineer and find solutions to make New Zealand homes more resilient against future seismic events.

Exton received the Ivan Skinner Award at the New Zealand Society of Earthquake Engineering (NZSEE) annual conference to recognise his innovative work as a practitioner and to support his quest to develop and commercialise cost-effective engineering solutions.

(NZ$3.1m)for hazy

life-sciences

Deep-tech spectroscopy startup Marama Labs closed oversubscribed seed-plus round, led by European agritech investor The Yield Lab, with participation from global investors

The investment was led by The Yield Lab, a European agritech venture capital firm with participation from existing investors, including New Zealand Growth Capital Partners, Icehouse Ventures, Quidnet Ventures and angel groups from New Zealand.

New investors DeepIE, Radar Ventures, NZVC and angel and high-net-worth investors from New Zealand, Ireland and Germany also participated in the round.

The new funding allows Marama Labs to scale up hardware manufacturing capacity in New Zealand for its patented CloudSpec spectroscopy instrumentation and cloud software data analytics tools.

The platform enables opaque liquid samples, like fermenting wines and nanomedicines, to be analysed in a fraction of the time it takes with existing instrumentation, giving customers chemical data to optimise and improve production processes.

Workplace safety statistics often paint a sobering picture. In New Zealand, Ma-ori workers experience 31% more serious non-fatal work-related injuries compared to their non-Ma-ori counterparts.

ACC’s claim rate data, coupled with Stats NZ’s Household Labour Force Survey from 2019 to 2021, underscores a troubling reality: Ma-ori injury rates stand significantly higher, ranging from 25% to 33% above those of non-Ma-ori.

With the New Zealand Manufacturing sector employing over 650,000 people, and Ma-orimaking up approximately 14% of the workforce, it is clear that a transformative shift is required to address these statistics and help build safer work, safer workplaces, and safer workers.

Recognising the need for change, Nik Jessop and Katrina Tahi Tahi from Te Pou Ora - Northern Region Equity, Partnerships & Intervention Design at Worksafe New Zealand and The Learning Wave have developed Maruiti Safe Haven - a Ma-oriSafety Leadership training programme that develops improved safety outcomes by integrating a Te Ao Ma-ori cultural lens into safety leadership practices

Prospr is a robust, autonomous, hybrid, multi-use modular vehicle platform for agriculture. Prospr automates a variety of tree crop and vineyard tasks, including precision automated spraying - to improve efficiency and sustainability and alleviate labour challenges.

Steve Saunders, Co-founder and Chief Executive of Robotics Plus says, “Thinking big and looking to solve global, scalable problems is what drives us at Robotics Plus.

“Agriculture is time-critical, and with Prospr, we’ve combined deep domain expertise to benefit growers. The result is an automated solution that has the smarts to do the job and keep doing it better, helping create a more sustainable and successful agricultural sector.”

What do the Waterview Tunnel, City Rail Link, Auckland Harbour Bridge and the Christchurch Convention Centre all have in common? Their building service supports are constructed and seismically braced using the world’s most flexible, all-purpose metal framing system.

The manufacturer, Atkore Unistrut, has opened a new state-of-the-art factory and distribution centre in Hamilton which will increase production capability and enable the design and manufacture of bespoke engineered solutions.

The opening coincided with the company’s 100-year anniversary.

The 2024 Apprentice of the Year Winner is Reegan Glass, Foster Engineering.

Reegan joined Te Rapa-based Foster Engineering straight from school and rapidly became a valued member of the team, known for his positive attitude, reliability and collaborative nature. He further impressed with his attention to quality and safety, and his contributions to problem-solving.

Among his achievements, Glass recently completed a challenging supply-and-install staircase project. Despite the job’s technical difficulties, such as building off site to match existing steelwork and handling complex panel balustrades, he executed the project largely unaided.

This project stands out as a milestone in Reegan’s transformation from apprentice to tradesman.

Young Achiever of the Year Winner: Aki Liyanage, Beca

Aki Liyanage’s attainment of Chartered Status with Engineering New Zealand Te Ao Rangahau is a testament to his dedication to engineering and his efforts to develop sought-after solutions for Beca’s clients and the built environment.

Liyanage has displayed resilience in facing design challenges, such as navigating consultations with clients on critical decisions like removing existing structures to streamline project designs.

His ability to collaborate effectively under pressure reflects his maturity and a capacity to overcome obstacles. Liyanage’s calm manner has helped to balance competing priorities and arrive at solutions that are ‘best for project’ rather than just a narrow discipline-specific focus.

Judges were impressed with Liyanage’s resilience, communication skills and ability to solve challenging problems.

Liyanage’s sound technical skills in structural steel design, combined with his determination and genuine enthusiasm for achieving project outcomes, make him an asset to Beca.

Particularly notable is Liyanage’s skill in fostering connections and empowering others; through his infectious enthusiasm for engineering, he aspires to inspire those around him.

Global renewable energy infrastructure developer, Harmony Energy Limited has entered a joint venture with First Renewables Limited, part of New Zealand energy group Clarus (formerly Firstgas Group), to develop and own Tauhei Solar Farm.

At the time of commissioning in 2026, it is expected to be New Zealand’s largest solar farm at 150 MWac, constructed on 182 hectares near Te Aroha in the North Island.

Subject to obtaining all necessary consents and approvals, the solar farm’s approximately 330,000 solar panels will generate over 270 GWh per year, enough renewable electricity to supply the equivalent of approximately 35,000 New Zealand homes.

Did you know this? Neither did we. Contributing to only 0.6% of the capital city’s GDP, manufacturing is a very small sector for the city. However, with 18.8% of the nation’s tech firms based in Wellington, the thriving tech sector creates a real strength for manufacturers to lean into.

Industry 4.0 is on the horizon – the utilisation of advanced technologies to create more efficient manufacturing processes – and Wellington manufacturers appear to be in the lead with harnessing this power.

A 3D printed ‘metamaterial’ boasting levels of strength for weight not normally seen in nature or manufacturing could change how we make everything from medical implants to aircraft or rocket parts.

RMIT University researchers created the new metamaterial – a term used to describe an artificial material with unique properties not observed in nature – from common titanium alloy.

But it’s the material’s unique lattice structure design, recently revealed in the journal Advanced Materials, that makes it anything but common: tests show it’s 50% stronger than the next strongest alloy of similar density used in aerospace applications.

New Zealand’s largest and only national stone benchtop fabricator, AGB, is continuing its fight against silicosis with the announcement that it will be the first in the country to supply zero-silica engineered stone. AGB, a family-run business, has been a persistent and staunch advocate for safer products, and a safer working environment for their staff and customers.

AGB was the first New Zealand business to ban high-silica engineered stone – shifting from up to 95 percent silica 12 months ago, to market-leading low-silica engineered stone with less than 40 percent silica.

Now AGB is again a driving force in the industry, becoming the first supplier in New Zealand to offer zero-silica engineered stone, with slabs expected to land in the country in September.

“If low-silica was the revolution, zero is the evolution. It’s actually not that big of a step to make. This is the next advancement of us being at the forefront of health and safety of workers – and our customers,” Cam Paranthoiene, co-owner of AGB Stone, says.

AGB owners Cam and Christine Paranthoiene have for many years led the way stone fabricators should operate – including creating proprietary processes, investing millions of dollars in state-of-the-art machinery and being early adopters of wet-cutting and air monitoring as a safeguard against the potentially-fatal lung disease silicosis.

As part of phasing out high-silica slabs they stopped working with suppliers who chose not to meet the company’s standards of less than 40 percent silica. AGB has now taken a bold step of saying they will work with only those suppliers who commit to transition to zero-silica in its engineered stone range. The Australian government has imposed a total ban on engineered stone following a 2021 report that claimed one in four stonemasons or joiners working with fabricated stone before 2018 had been diagnosed with silicosis.

An industry-leading trades training facility will create exciting new opportunities for aspiring electrical and plumbing trades in the region.

The first of its kind in New Zealand, the Skills Group Skills Hub incorporates a three-trades model, housing the Group’s three specialist trades brands—Etco for apprentice and electrical training, Industry Connection for Excellence (ICE) for plumbing, gasfitting, and drain laying apprentice training, and E-tec for advanced electrical training.

The Bradford-based hub is located in the former Tamahine Knitwear factory that initially opened in 1970, and utilising the same building footprint, the education institution is designed to accommodate up to 140 apprentices at once.

The newly modernised campus will supercharge trades training in the area – and, as the only Level 4 apprenticeship training facility in Dunedin, will eliminate the need for apprentices to travel to Invercargill or Christchurch for Level 4 training.

Skills Group Director of Specialist Trades, Ben Stevens, says the Group is delighted to support Dunedin and the Central Otago area by giving South Island-based apprentices and their employers more training choices with less travel.

New Zealand company Fabrum, a world leader in zero-emission transition technologies to enable a lower-carbon economy, is to supply Toyota with its proprietary liquid hydrogen storage technology. Fabrum has established a reputation globally as a leader in end-to-end hydrogen production and refuelling systems. The green hydrogen project adds to a number of others under construction internationally, with global players in aviation, heavy transport, and industry.

Their work with Toyota represents Fabrum’s second Japan-New Zealand hydrogen project. They are also working with Obayashi Corporation, one of the world’s leading construction companies, to deliver unique dual-pressure hydrogen refuelling technology for an Auckland-based refuelling station project.

For 20 years, Fabrum’s patented cryogenic technology has enabled the global movement towards clean energy transition.

Fabrum’s composite technology has also been adopted into heavy industry mobility, on-board aviation fuel tanks, and superconductivity. Fabrum has built an impressive list of global IP and solution success, applying its sustainable solutions to enable humanity to tread lightly.

The ThinkTop V55 offers unmatched peace of mind to users. Its durable, maintenance-free design ensures reliable performance even in the most demanding environments. Tamperproof construction and built-in self-diagnostics maximize uptime, making it a dependable choice for critical operations. With its advanced features and compact design, the ThinkTop V55 sets a new standard for diaphragm valve monitoring and control, optimising performance and efficiency.

The ThinkTop V55 supports fast, reliable installation and quick commissioning. Onsite auto setup takes less than a minute, while live setup – enabling quick remote valve configuration – requires only a minute or two.

Exchanging or hot-swapping control units can take place without disrupting production, ensuring operational and product safety.

The slim profile of the ThinkTop V55 optimises space utilisation, making integration into new or existing installations effortless. It is easy to mount in any position on the valve actuator to ensure ideal connection.

Moreover, the ThinkTop provides 360° LED visual status indication, making the valve position clearly visible from the factory floor. It delivers highly reliable performance in demanding environments thanks to its self-diagnostic features that boost uptime and productivity.

The ThinkTop V55 provides real-time diaphragm valve monitoring through digital, ASI 3.0, or IO-Link interfaces, ensuring accurate valve position readings. Its point-to-point IO-Link communication protocol integrates sensors and actuators into any automation system, regardless of fieldbus.

esmo group a leading global full-service systems integrator, developer, and supplier of innovative and advanced automation solutions, has launched ares auto setup, the world’s first final test manipulator capable of automated test head finding and positioning.

Final test manipulators play a pivotal role in semiconductor manufacturing. They are responsible for the precise positioning of test heads and boards to prepare the final testing phase.

ares auto setup brings a paradigm shift to the semiconductor industry. Unlike other final test manipulators, ares auto setup allows for the automated manipulation of movement in x, y, z, and more rotational axes, enabling seamless and precise positioning of boards and test heads.

This advancement simplifies the testing process, and eliminates the need for manual operation, saving time, resources, and costs. Additionally, the ares auto setup offers a range of linear and rotational motions to meet individual setup requirements.

The ares’ vision control and absolute value encoders ensure that each movement is precise and controlled, preventing any deviations or errors that might impact the integrity of the semiconductor

This integration makes it easier to capture, store, analyse, and act upon meaningful real-time data thereby supporting Industry 4.0 initiatives, streamlining configurability and process control.

The ThinkTop V55 is designed for Alfa Laval diaphragm valves, offering a true one-size-fits-all solution. It shares the same robust and reliable features as the ThinkTop V series, trusted by hygienic industries worldwide. Moreover, it simplifies purchasing, setup, operation and maintenance.

components under test.

The automated setup feature reduces the time required for positioning and testing by eliminating the need for manual intervention.

With a simple “push of a button”, ares auto setup swiftly and accurately repositions the components for the next phase of testing, allowing semiconductor manufacturers to stay ahead of the curve and meet tight production deadlines. ares auto setup’s automation also minimises the need for manual labor, reducing the chances of human error and improving the overall quality and reliability of semiconductor products.