Stepping forward with Industry 4.0

Wayne Carson, Managing Director, D&H Steel Construction

Wayne Carson, Managing Director, D&H Steel Construction

The company has achieved a lot through determination, dedication and focus… What do you put the on-going success down to?

Guiding the company on its path is something we call the ‘D&H Way.’ It is an attitude that sets our company apart and continues to develop from our experience.

It comprises our team’s holistic ‘best for project’ approach, focus on client relationships, goal to exceed expectations, and drive for ‘performance when performance counts.’

The D&H Way has matured with the company ever since it was established in 1972, but it was during the time of the Christchurch rebuild when we finally gave it a title. We were procuring and delivering projects in such a way that it benefitted all parties – ourselves and our clients.

We had developed a reputation for doing what we said we would. This, combined with our can-do, collaborative and no-surprises approach, was a compelling proposition.

D&H’s success is due, in large part, to the strength of our culture. The true essence of the D&H Way lies with our people and our ‘team of teams.’

This ethos manifests itself across the business, with each team adding its own value – from the leadership, estimating, quantity surveying and project management teams, to detailing, workshop and site teams, to the admin, accounts and procurement support teams. It is the secret sauce that will ensure D&H continues to thrive for another 50 years.

Tell readers a bit about your early days

When Bob Haddon and his brother-in-law Barry and sister Judy Dixon established Dixon & Haddon in 1972, they didn’t have a vision, and there wasn’t a series of goals or a business plan, per se.

What they did have was a drive to satisfy their clients, and a focus on ‘performance, performance, performance, and quality.’ The client was – and still is – king.

They priced even the smallest of jobs, and they didn’t turn work away, they just found a way to do it. It all came down to the teamwork and planning. Relationships, too, have always been important to success.

The company’s relationship with Downer led to Dixon & Haddon’s first million-dollar job, which was in support of the expansion of the

ANALYSIS Major international collaboration at the forefront of construction 4.0. MANUFACTURING IN NZ The state of play. THE CIRCULAR ECONOMY Comvita’s Harmony Plan. www.nzmanufacturer.co.nz October 2022 Sales and training—Aust/NZ Region enquiries@baycad.biz - www.baycad.biz 0274847464 Don’t delay, contact us now. 15 day free trial available Alibre Design Version 24 Pro From NZ$1595.0 Exp From NZ$3067.0 Atom3D NZ$414.00 Prices ex GST New features Improved performance Easy to learn and use Designed for businesses of all sizes needing CAD producvity. Free on-line training Buy it—own it Does not use cloud Oponal annual maintenance 7 17 19

continued on Page 22

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz2

DEPARTMENTS

LEAD

Stepping forward with Industry 4.0.

EDITORIAL

Focus on Manufacturing -where we are at, right now.

BUSINESS NEWS

International E-Commerce: When do I need to pay US Sales Tax?

Te Pukenga – a new era of learning for industry.

ANALYSIS

Major international collaboration at the forefront of construction 4.0.

SMART MANUFACTURING

Network Monitoring: The competitive differentiator in manufacturing.

COMPANY PROFILE

Aofrio has a powerful recipe for innovation and growth.

SMART MANUFACTURING

2022 KiwiNet Awards winners announced.

MANUFACTURING IN NEW ZEALAND Investment in innovation propels manufacturers performance.

CYBER SECURITY

Pfizer’s journey to improve cyber security levels mid-pandemic.

THE CIRCULAR ECONOMY

Comvita’s Harmony Plan. Computer Recycling to the fore.

WORKSHOP TOOLS

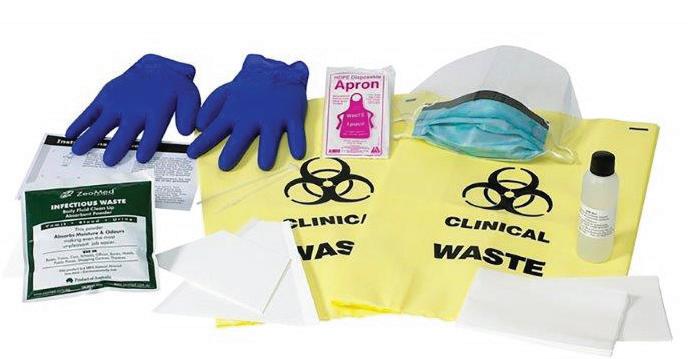

Igumania online game makes motion plastics even more tangible. Spill kits combat potential virus. Flexibility meets safety.

DEVELOPMENTS

Getting the best of everything. RS PRO & Engineers without Borders launch student competition.

THE LAST WORD

Operational technology security in smart manufacturing.

Brett actually grew up with manufacturing, in the family business, Biggins & Co.

3www.nzmanufacturer.co.nz / NZ Manufacturer October 2022 Contents ADVISORS

Kirk Hope

Is Chief Executive of BusinessNZ, New Zealand’s largest business advocacy body He has held a range of senior positions at Westpac and is a barrister and solicitor

Brett O’Riley

EMA chief executive Brett O’Riley has a background in technology and economic development.

He currently holds board roles with Wine Grenade and Dotterel Technologies and is also on the NZ Film Commission board.

Ian Walsh

Ian is Managing Director of Intent Group, a master black belt improvement specialist and global lean practitioner. He is passionate about improving productivity and helping to create world class New Zealand businesses.

Lewis Woodward

Is Managing Director of Connection Technologies Ltd, Wellington and is passionate about industry supporting NZ based companies, which in turn builds local expertise and knowledge, and provides education and employment for future generations.

Dr Barbara Nebel CEO thinkstep-anz Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

1 4 6 7 8 10 11 16 18 19 23 25 27

7 10 19 26 11 20

PUBLISHER

4122.

MANAGING EDITOR

T:

CONTRIBUTORS

ADVERTISING

T:

DESIGN & PRODUCTION

WEB MASTER

PUBLISHING SERVICES

On-Line

DIGITAL SUBSCRIPTIONS

E:

MEDIA HAWKES BAY LTD

Focus on manufacturing - where we are at, right now

AoFrio trades in thirty-one countries and has invented the world’s first Internet of Things (IoT) platform for commercial refrigeration.

The combination of hardware and smart IoT-enabled refrigeration controllers and sensors help customers sell more products, save costs, track assets, gain insights to do business better and save on energy and carbon emissions.

The company, formerly known as Wellington Drive Technologies, founded in 1986

Look them up sometime. Their article can be read on Page 10.

Amongst other ‘must read’ articles in this issue is the announcement of the 2022 KiwiNet Award winners (Page 11), a focus on Manufacturing in New Zealand (Pages 16- 17), a snapshot of manufacturing businesses and thinkstep-nz’s report on Comvita (Page 19) and their plan to ‘leave the world a better place.’

SouthMACH returns to Christchurch in May 2023. So interested exhibitors need to start planning. It’s not that far away.

A reminder: December issue will include The Year I Review, a look at developments and inspirational stories from the land of manufacturing and technology.

Success Through Innovation

Copyright:

in whole or in part

not be

the

of

expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or

of

Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the

If you have a story from your company you consider to be relevant email me publisher@xtra. co.nz and let me know.

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz4

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand

Doug Green

+64 6 870 9029 E: publisher@xtra.co.nz

Holly Green, Barbara Nebel, HERA, EMA Sean O’Sullivan, Scott Fuller Business East Tamaki Cynthia Dearin, Dr. Troy Coyle Sebastian Krueger, Greg Balla Martin Thunman, Alex Mosher

+ 64 6 870 9029 E: publisher@xtra.co.nz

:kim-jean: E: kim.alves@xtra.co.nz

Julian Goodbehere E: julian@isystems.co.nz

Publisher Media Hawke’s Bay Ltd

publisher@xtra.co.nz Free of Charge.

T: +64 6 870 9029 E: publisher@xtra.co.nz 121 Russell Street North, Hastings NZ Manufacturer ISSN 1179-4992 Vol.13 No.9 October 2022

NZ Manufacturer is copyright and may

reproduced

without

written permission

the publisher. Neither editorial opinions

publisher

NZ

publication.

Doug Green

International E-Commerce: When do I need to pay US Sales Tax?

-Cynthia Dearin

US sales tax is levied in almost all 50 states, but at different rates and under different rules. Your business could be liable for sales tax in the US, irrespective of where in the world you’re located. It doesn’t help that the US has one of the most complex tax systems in the world.

Sales tax in the US is levied at the state level and 45 states and the District of Columbia (Washington D.C.) have a sales tax. Five states Alaska, Delaware, Montana, New Hampshire and Oregon – do not have a sales tax. To complicate matters further, 38 states have some form of local tax, collected in part or all of the state.

When must e-commerce sellers collect tax?

Whether or not you have to collect sales tax in a particular jurisdiction depends on whether you have “sales tax nexus” in that location and also on what you sell. In this case we’re talking about physical retail products - the rules that apply to taxation of SaaS products, digital products and online course are different.

What is “sales tax nexus”?

Sales tax nexus means that you have a ‘significant connection’ to a particular state or district and it applies regardless of whether you are based in the U.S. overseas. If you have a sales tax nexus in a U.S.

state, then the state requires you to collect sales tax from customers in that state.

Certain activities are considered to create a nexus. These include:

• Economic nexus – Exceeding the online sales or transactions thresholds set by the state. These differ from state to state.

• A location – an office, warehouse, fulfillment center, store, or other physical place of business

• Inventory – Most states consider storing inventory in the state to cause nexus even if you have no other place of business or personnel

• A drop shipping relationship – If you have a 3rd party ship to your buyers, you may create nexus

• Team - a person providing services for your business including an employee, contractor, salesperson, or installer

• Affiliates – Someone who advertises your products in exchange for a cut of the profits creates nexus in many states

• Selling products at a tradeshow or other event – Some states consider you to have nexus even if you only sell there temporarily

As an international e-commerce merchant, your first step is to work out whether your business has a sales

tax nexus in each of the states you’re selling to.

If you think you may have sales tax nexus in a state, it’s a good idea to check with state’s the taxing authority to determine whether or not you do if you are required to pay sales tax in that state.

This awesome interactive map shows you taxes rates by state and lets you click through for comprehensive information.

What comes next?

If you establish that nexus exists, it’s time to get compliant. Your next step is to register for sales tax, and then collect and remit the taxes. You’ll typically be liable initially for sales tax in the state where your business is registered, unless it’s one of the states that do not levy sales tax. If your ‘home’ state charges sales tax, then you will probably have “nexus” in the state.

Cynthia Dearin is an international business strategist, advisor, keynote speaker and author of Business Beyond Borders: Take Your Company Global and Camels, Sheikhs Billionaires: Your Guide to Business Culture in the Middle East and North Africa. With 23 years of international experience, as an Australian diplomat and management consultant, she is the Founder and Managing Director of Dearin & Associates and the International Business Accelerator.

Providing the tools and support to drive business forward.

is here to make it easier to do business; working alongside business leaders and property owners in the region on security, advocacy, development and growth.

Business News

businessET.org.nz

Like strands of harakeke being woven together, our work-based training organisations, institutes of technology and polytechnics are joining together to become Te Pukenga.

Te Pukenga will be Aotearoa New Zealand’s largest tertiary education provider. It will create better ways of learning for industry, focused on where our workforce needs to be, now and in the future.

As one, national network, Te Pukenga will provide flexible, career-focused learning that fits around the learner’s life – on-the-job, on campus and online vocational training.

Working for everyone

Te Pukenga will be the cornerstone of a cohesive, sustainable vocational education system that helps improve wellbeing for all New Zealanders,

and supports a growing economy that works for everyone.

It will help New Zealand move to a vocational education system that puts learners in the centre.

Closer to industry

Te Pukenga will work closely with industry and business to understand their needs. Directly aligning the training we provide with the needs of employers and their staff.

It’s about helping our communities and workplaces grow and thrive together, and providing businesses with knowledge and skills that are relevant to their changing industries.

Fit for purpose

Te Pukenga is supporting a modern, future-fit

workforce for Aotearoa. Learners are encouraged to stay connected with their whanau, culture and communities as they work and learn.

The same, only better

Local campuses, courses, support and training teams will remain in place, but are now part of Te Pukenga. This will create access to a wide diversity of subjects and locations, and flexible ways of learning –on-the-job, on campus and online. Helping our people, our communities and our workforces grow and thrive together.

Te Pukenga. Learn with purpose.

Find out more at tepukenga.ac.nz

You have TWO options for tracking Staff time on your Jobs and productivity, actual to budgeted time:

Option 1 is using the manual time sheet system, which has been used by NZ manufacturers for over 100 years without change and without improvement.

Manual time sheet reporting provides production information “too little, too late, too inaccurate and too expensive”.

For example, a manufacturer with 10 workshop staff using manual time sheets has lost production

time and administration time cost of $800 per week therefore $40,000 per year.

Option 2 is using the technology of touchscreens on the workshop floor and a Labour Tracking and Productivity Software App, subscription cost is substantially less than the cost of manual time sheets, actually such Apps are as little as 15% of the weekly cost of manual time sheets.

Such Apps have 200+ screens and reports in real time and accurate production information, accurate individual staff times and job times,presented continuously throughout the day on 50 inch TV

monitors in office and on the workshop floor.

One good Labour Tracking and Productivity App option is www.empowersoftware. co.nz – you will see a 20 year and 240 manufacturing clients’ track record of securing: 20% to 40%+ reduction in labour times on Jobs and 20% to 40%+ reduction of labour cost on Jobs.

This on a 10 workshop staff manufacturing site is 80 additional production hours per week and $6,400 additional revenue per week. www. empowersoftware.co.nz

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz6 Business News

Te Pu-kenga – a new era of learning for industry Are you still NOT tracking Staff times on your Jobs? DEUTSCH HD30 & HDP20 CONNECTOR SERIES Designed specifically for the truck, bus, and off-highway industry, heavy duty, environmentally sealed, multipin circular connectors. contact sizes 4 through 20. Tel: 04 566 5345 Email: sales@connectors.co.nz Web: www.connectors.co.nz

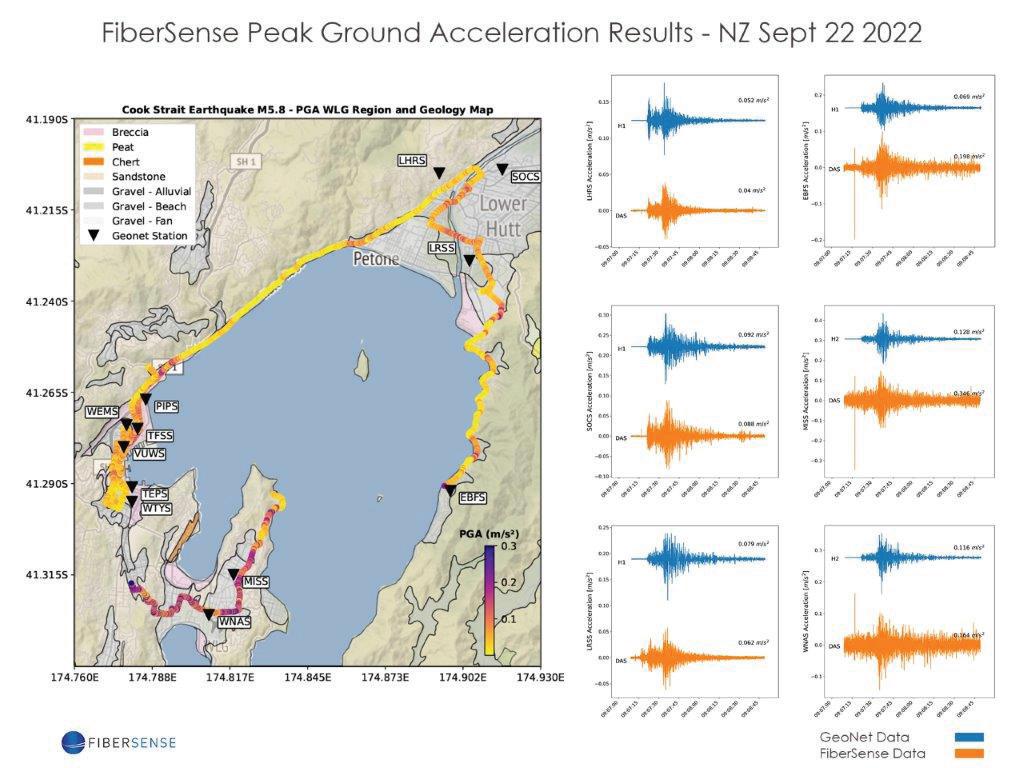

Major international collaboration at the forefront of construction 4.0

-Dr Troy Coyle, HERA CEO

I was on leave in the middle of the Australian bush, koala spotting, when we got the great news that after years of work in the background, our Endeavour Funding bid for $10.3 million had been successful.

The need for this project had been brought to my attention during my member visits in my first 90 days as CEO of HERA, initially by Wayne Carson, Managing Director of D&H Steel Construction. I asked other members for their views in subsequent meetings, and heard the industry reflect that this was a big issue.

How it was told to me (in summary) that there was a nexus between design, construction and beyond, leading to inefficiencies. There was a lot of data and knowledge floating around but it wasn’t connected, optimised or in an easily used form.

Having established that it was a broader problem for the sector, I knew HERA had to do something to assist in solving that problem, including how decisions were optimised for sustainability. I also knew this was going to be a technically challenging (and huge) project requiring an Industry 4.0 approach.

That member feedback, along with HERA’s commitment to its vision “of securing tomorrow’s future by innovating today” is what led us on a four-year long journey to get this project running.

Why is this project important for the sector?

Currently, there is a profound limitation in the way construction is performed in Aotearoa New Zealand. The challenge is that complex decisions are being made based on simple data inputs. Decision points in the process are in linear silos with little inter-connection or data-derived decision support.

The process is entrenched and far from optimised. For example, designers do not have adequate tools to optimise designs for ease of manufacture/ fabrication, let alone the ability to resolve the conjoint considerations required to deliver design for sustainability, constructability, Te Ao Māori, resilience and affordability simultaneously. Such decisions require collection, connection and analysis of complex data sets.

Construction is a system that is greater than the sum of its parts

To overcome these issues, new technologies of the 4th industrial age are required to transform construction from a linear to a circular system known as Construction 4.0. Construction 4.0 provides the construction industry with a decentralised connection between the physical space and the

cyberspace via ubiquitous connectivity. Therefore, the science problem is one of complex big data managing and connectivity.

This will be world leading research

The research will be world-leading in an emerging area of international interest and create data-driven decision-making for the future of construction.

There are several major advances expected in this project to make the work globally unique:

• Complex system data management science stretch –this project will take a complexity science approach to construction optimisation using customer input. It will consider complex interactions between cost, sustainability performance, structural performance, constructability, and people’s subjective preferences using fuzzy logic based on stakeholder interaction/feedback.

• Technical science stretch – new approaches will be developed, to cover the broad range of practical construction options to be considered in the big data optimisations.

• Matauranga Maori interfaces – this will be the first time globally that indigenous world views are incorporated into decision support tools using Construction 4.0. This presents a significant challenge due to inherent differences, in viewpoint and the practical challenges with codifying this data and resolving incompatibilities with prevailing approaches. This in itself will transform the sector and make it more holistic. [Note: MBIE has requirements around Vision Matauranga, which we want to honour meaningfully versus

It requires a global effort: researchers and industry leaders working together

The application of complexity science and Industry 4.0 in construction is an immature discipline globally with very few identified experts in Construction 4.0 research.

We have brought a team of global experts (experience and skills mix) together to ensure linkages internationally, within industry and existing research programs, enable outcomes to meet international best practice and avoid redundancy.

Experts in Matauranga Maori and its interface with engineering, as well as sustainability and resilience in the built environment are also key team members.

We have also incorporated expertise in technology transfer in traditional industries, and public policy development to ensure the project outcomes are both ready for adoption and readily adoptable.

To increase productivity and quality, the Construction 4.0 framework and guidelines developed in this project will manage complexity, reduce uncertainty and enhance information exchange and communication between stakeholders. It will create a step-change in construction sector transformation, create jobs and upskill the workforce through innovation and/or digital literacy.

We know this is a big project and we are only just coming to terms with the fact that it has been successful in gaining funding. Stay tuned for more updates along the journey.

7www.nzmanufacturer.co.nz / NZ Manufacturer October 2022 Analysis

ticking a box to merely get the funding].

ADVISORS

is an expert in the field of technology development and commercialisation. His company Design Energy Limited has completed over 100 significant projects in this vein by consulting for and partnering with some of New Zealand’s leading producers.

Among Mike and his team’s strengths are industrial robotics and automated production where the company puts much of its focus.

Sandra Lukey

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business. She has over 20 years’ experience working with companies to boost profile and build influential connections.

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz8

Mike Shatford

Sean O’Sullivan Has a B Com (Hons) Otago University. In 2000 - 2001 introduced PCs on the workshop floor and job and staff tracking and a productivity software App to Fletcher Aluminium Group and 100 manufacturers NZ nationwide.

In 2001 – 2022 Founding Director Empower Workshop Productivity & Scheduling Software App. 236 manufacturing and engineering clients mainly throughout NZ and Australia, also UK and US.

Network Monitoring - The competitive differentiator in manufacturing

By Sebastian Krueger, Vice President APAC, Paessler

Every industrial revolution brings along a learning revolution. Digitisation is transforming the world in ways people a few decades ago would have hardly imagined.

You hail a taxi ride to take you to the best restaurant in town using your smartphone and get items you ordered just yesterday delivered to your home. The list is endless.

At the core of it lie technologies that have enabled these changes, which are also disrupting areas like manufacturing, automation, and energy. All these technologies have one thing in common: data.

Data takes centre stage in the converged IT/OT era

Today, data has become a critical component to optimize your business to be more competitive, or to develop new business models based on analytical insights.

One well-known term in this regard is Industry 4.0, which caters to the ultimate goal of optimising the entire value chain of a product including development, manufacturing, usage, maintenance, and even recycling.

This is enabled through modern technologies and the intelligent connection between humans, machines, factories, and the end product.

Digital infrastructure like cloud-hosted systems, its local production network, or simply a web shop comprises the key technology stack for a company that decides to move into the future.

The convergence of Information and Operational Technology (IT/OT), Industry 4.0 and increased digitisation have all reshaped the way the production floor connects and interacts with IT.

This interconnectivity makes it pertinent to have a unified overview of your entire infrastructure.

These include programmable logic controllers, industrial PCs, smart industrial gateways, sensor technologies, as well as traditional IT infrastructure components like network switches, routers, and wireless devices. Monitoring it all requires an integrated solution that can coalesce OT and IT together into a single view.

Why do you need holistic monitoring for your industrial IT?

In today’s modern shop floor, network connectivity is king, so all affected systems can react to real-time and dynamic product orderings. IT monitoring empowers users to monitor every aspect, from the web shop through to the state of a single PLC (Programmable Logic Controller) on the shop floor.

Streamlining the flow of data brings it into a single view to collect, analyse and generate insights. Performing root cause analysis allows you to understand the cause of a problem in order to prevent it from happening again.

Monitoring the various touch points between OT and IT also ensures that critical data is flowing to upstream systems.

By providing the right data to the right teams, different views of the infrastructure can be generated based on the same core data.

Teams that traditionally worked in silos, now rely on each other. For example, IT teams are responsible for ensuring data generated by machines on the factory floor makes its way to the cloud, while industrial engineers or managers might need access to that data to make decisions regarding the production line.

Because this data travels across OT and IT networks, it is essential to monitor that it is flowing correctly at various interfaces and touchpoints in the infrastructure.

Minimising downtime and reducing energy consumption have proven to be key parameters to increasing productivity, efficiency, industrial output and revenues.

Having a transparent view of what systems or equipment are currently down is the most pressing goal when it comes to managing downtime.

Monitoring can help prevent downtime even before it happens and provides you with an understanding of what typically fails by identifying patterns and using them to take predictive measures.

It not only shows you what is down in your infrastructure right now, but lets you analyse data over a period of time to help you forecast these

patterns.

Knowing how much energy your machines and devices are using also plays a key role in reducing consumption.

By monitoring sources consumption data either directly from machines with built-in consumption measurements, or through power meters, It facilitates the gathering of energy consumption data from various sources in one tool to analyse and identify areas where you can reduce energy usage.

The make or break componentSecurity

Security of critical infrastructure including manufacturing plants is gaining paramount importance, as cyber threats continue to evolve in scale and complexity. Networks must continuously be monitored for potential breaches, traffic spikes or suspicious and unusual activity.

Monitoring leverages various techniques such as Intrusion Prevention and Intrusion Defense systems, to keep track of what is generating the traffic in the network, and for what purposes.

In conclusion, as the manufacturing sector navigates through a disruptive era powered by technology, it becomes imminent for organisations and countries to keep a close eye on their bottom line, network monitoring can become a game changer in helping the sector iron out the gaps in the connected shopfloor and propel your organisation towards becoming future ready.

9www.nzmanufacturer.co.nz / NZ Manufacturer October 2022

Profile

Adding software to hardware – A Powerful Recipe for Innovation & Growth

AoFrio is a New Zealand technology leader that few local people know about. With deep manufacturing and hardware roots, the company has decades of experience supporting food and beverage companies around the world with their refrigeration.

Now, the business has innovated beyond hardware and invented the world’s first Internet of Things (IoT) platform for commercial refrigeration.

The combinations of hardware, like motors and fans, and smart IoT-enabled refrigeration controllers and sensors help customers sell more products, save costs, track assets, gain insights to do business better and save on energy and carbon emissions.

AoFrio is growing into a hardware-enabled, software as a service (SaaS) provider.

It’s their pathway to lifting recurring revenue (because they sell their solution ongoing to customers), to expanding in existing markets and exploring new regions around the world.

But the path to getting there has been long and not without its challenges.

In the words of Greg Balla, CEO of AoFrio:

From where I sit now, it’s easy to see a future where hundreds of millions of refrigerators around the world are connected to AoFrio’s platforms, giving us data to drive powerful, purposeful outcomes for customers.

But there are many moments in AoFrio’s history that plotted the way to becoming the company we are today. We’re now in the position where we can couple our hardware abilities with software and data-driven insights to give clear customer insights and actions that are impactful to their bottom line.

One of the turning points for us is around 2012. The company was tired of purely competing on price. Deciding instead to design the best refrigeration motor in the world. We set a goal that our electronically controlled motor would be better than the competition in every single respect.

Most of our competitors looked at what we were doing and laughed. They thought nobody would buy it. The industry had been trudging along for years, producing what they thought customers wanted. The team dug deep into our customers’ needs and produced what they actually wanted.

With electronics’ costs decreasing and microprocessors becoming cheaper, we took a lot of the techniques that had only been applied to large motors and applied them to small ones. While everyone in our industry was jumping to the right, we took a massive leap to the left.

The conscious decision to innovate began to drive a culture of continually pushing boundaries. We now have 30 people in our R&D team, with a worldwide head count of around 100 people. Their job is to develop new products and innovate existing products.

But all the team, at some point in their day, are involved in innovating. We use a proven stage-gate process to move products and solutions from ideation to launch.

We are ensuring that we do not shift out of this culture as we grow. Now, 15-20% of everyone’s roles is focused on learning and innovating, across the whole organisation. We provide them with the space and time to do that.

Greg Balla, CEO, Aofrio.

IoT is relatively new in commercial refrigeration.

Nearly two years ago, we began employing Customer Success Managers. With deep knowledge of technology and commercial refrigeration, the Managers help drive maximum performance gains for customers which accelerates further adoption and drives data acquisition, providing us with deeper insights.

Managers feed new feature ideas and customer issues into a platform called JIRA, an agile, project management tool, linking directly to the R&D and engineering team. This system drives further innovation.

Today, we’re well and truly becoming a hardware-enabled SaaS company that sells our software as a service to customers ongoing. We still make the best electronically controlled motor, but we do much more.

It gives us diversified revenue streams. It means we can connect our customers to their data, helping them drive meaningful differences to their businesses – and we’re doing it from New Zealand.

We’re proudly headquartered and listed in New Zealand, but we trade in 31 countries and our team are located across 10 offices around the world.

From here, we’re taking the best of our hardware skills and coupling that with software to lift the game on a global scale.

So far, we’ve installed more than three million motors, resulting in an energy savings equivalent to what New Zealand’s largest thermal power station takes four and a half years to produce – but we’re only just getting started.

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz10 / www.nzmanufacturer.co.nz

Company

TechRentals® is an IANZ endorsed Calibration Laboratory We offer both IANZ Endorsed and Traceable Calibrations of test and measurement equipment inluding: 0800 832 473 www.techrentals.co.nz

2022 KiwiNet Awards winners

The winners, selected from a record number of finalists, include a new test for gastric function, a breakthrough innovator responsible for a disruptive zinc recycling process, a university student set to launch a cauliflower-based ice cream and tech for measuring the chemical structure of molecules. Research entrepreneurs and commercialisation professionals were also honoured for their work, and renowned deep-tech leader Professor Cather Simpson was named KiwiNet’s Commercialisation Icon.

The KiwiNet Awards celebrate the scientific discoveries being successfully developed and launched into the market from New Zealand’s universities, Crown Research Institutes and other research organisations and their impact on Aotearoa and beyond.

The 2022 KiwiNet Research Commercialisation Awards winners are:

Momentum Student Entrepreneur

Researcher Entrepreneur Award

Judges special mention/highly-commended: RespirAq, AUT Ventures: Waterless, active, heated respiratory humidification

Commercialisation Impact Award

Mrinali Kumar, Massey University: Is it ice cream? Yeah, Kinda Breakthrough Innovator Award

Commercialisation Professional Award

Magritek: Massey Ventures and Wellington UniVentures - Beautiful science to business

Commercialisation Icon Award

Jonathan Ring - Zincovery / University of Canterbury: Zincovery - Decarbonising zinc recycling

Gastric Alimetry, UniServices: Gastric Alimetry - The new test of gastric function

Professor Cather Simpson: University of Auckland –An inspirational commercialisation leader, advocate, and entrepreneur, driving returns for Aotearoa and empowering the next generation

In addition to the six prestigious category awards, the Commercialisation Icon is awarded as KiwiNet’s highest honour to a champion of New Zealand’s research commercialisation community who has made an outstanding impact in the ecosystem and advanced the commercialisation of publicly funded research within New Zealand.

11www.nzmanufacturer.co.nz / NZ Manufacturer October 2022

Professor Justin Hodgkiss, Te Herenga Waka— Victoria University of Wellington: A leader in deep-tech research commercialisation

Evelyn Body, UniServices: Unique combination of expertise delivering exceptional outcomes Breakthrough Project Award

text title NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz12 HEADING SMART FACTORY SHOWCASE Featuring Questions or feedback? Please contact - manufacturing@ema.co.nz The Smart Factory Showcase Understand how Industry 4.0 can transform a business and see first-hand what a high level of maturity in Industry 4.0 technologies looks like, based on a real ‘smart factory’ in New Zealand. Your chance to experience the future of advanced manufacturing by immersing yourself in the Smart Factory Showcase. Our aim is that you will leave the showcase feeling inspired by the solutions offered and armed with the knowledge needed to kick-start your own Industry 4.0 journey Feature a digital twin of Nautech Electronics’ Auckland facility which enables us to deliver real content and stories directly to you. The interactive session examines how Nautech integrated smart technology to enhance efficiency, connectivity, and processes. They also highlight how you can engage and improve employee experiences and enhance manufacturing agility. Transform your business The sessions Get started www.industry4.govt.nz/UpcomingEvents DELIVERY PARTNERPROGRAMME PARTNERSPOWERED BY Register here

NETWORK SITE VISITS

The Network Site Visits is a programme to encourage sharing of Industry 4.0 knowledge across the sector. Whether you are well into your Industry 4.0 journey or just starting out, the programme provides a range of opportunities to expand your understanding of Industry 4.0 technologies and learn from others who have already embarked on their Industry 4.0 journey. Join us for events, undertake an assessment or expand your knowledge through resources and case studies.

eadiness Assessment

Companies can apply for a fully funded Smart Industry Readiness Index (SIRI) Assessment process to help accelerate their own journey towards Industry 4.0, the result of which will be a benchmark against other companies in their sector and a high level prioritisation roadmap.

Apply for the assessment

Factory Tour Webinars

The tours provide an opportunity to see first-hand what businesses have implemented as a result of the SIRI Assessment. They will showcase developments, specific technologies and learnings on their Industry 4.0 journey. Targeted at local manufacturers, these events are delivered across New Zealand and are a great way to network and connect with others in the region.

Upcoming events

The webinar series is an opportunity to hear stories from all stages of the Industry 4.0 journey, focusing on the benefits of implementing these technologies, what challenges you may need to overcome along the journey and specific examples of Industry 4.0 technologies, all based on the experience of New Zealand companies.

Upcoming events

Case Studies

Documented as part of the SIRI Assessment, the case studies provide an opportunity to understand a specific example of how Industry 4.0 technology has been implemented in a manufacturing environment. They will provide you with key learnings to take away and inform your own journey.

Resources

text title 13www.nzmanufacturer.co.nz / NZ Manufacturer October 2022 HEADING

DELIVERY PARTNER

PROGRAMME PARTNERSPOWERED BY

How to successfully deliver your CRM project with Clarity, Simplicity and Certainty.

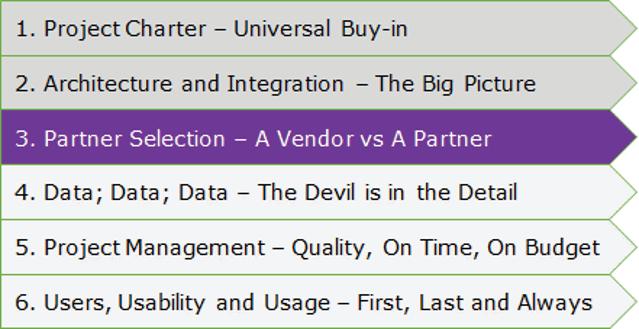

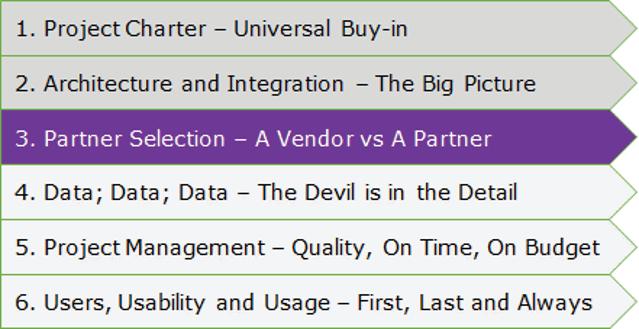

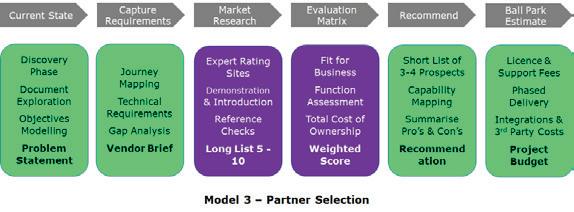

This is the 3rd in a series of 6 articles looking at how to successfully deliver your CRM project. The full series contains:

Taking the time to look past the functional capability offered by a company will determine if you want

So before starting your search for the right CRM, start by deciding the characteristics of your Partner, or Vendor.

• Will you deal directly with Vendor or via an implementation Partner?

• Either way, how do want to engage, what involvement do you expect, what services will you require to compliment your in-house resources?

• Is it more cost effective to pay an external partner than divert internal teams?

/ will get a Partner or a Vendor. There are very good reasons to purchase your CRM solution from a Vendor, implement it asap and then just pay the Licence Fees for the term of the Agreement. Full Stop!!

There are however more and far better reasons to look ahead to see how your full CRM ecosystem (Refer to Article 2 in this series) will support the evolution and growth of your business in the long term and how valuable a Partner can be. The behaviours of your Partner, vs a Vendor, are highlighted in Table 1 below.

In short, a Vendor will give you exactly what you asked for and how you can leverage the generic capability and services. A Partner will take the time to understand your business, as well as technology, requirements and use them to drive out the right solutions.

Project Factors Partner Vendor

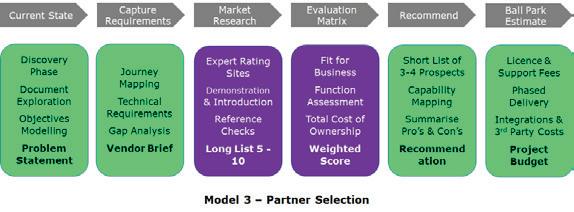

The answer to all these questions will direct you to the type of relationship that will best suit you in successfully delivering your CRM Project. Model 3, which is not a Project Plan, illustrates the Pre- and Post-Evaluation activities as part of the full selection process.

c. Reference Checks – Reference sites provided by the vendor will be positively biased but tough questions will still elicit honest responses. This should be complemented by identifying from your own networks other similar businesses who have deployed the same solution.

d. Long List – The Long List will be as long as needs to be to include the best options

2. Evaluation Matrix

a. The Matrix – It is worth taking time to design and build a robust Matrix, normally in Excel and can be built to produce results at a Requirement, Requirement Group, Focus Area, Urgency level. These results can then roll up into the Functional Assessment

b. Fit for Business – Does the solution fit the size of our business? Does the Licence Type and Technology used fit with our IT Strategy?

c. Functional Assessment – The detailed Requirements assessment is rolled up as either Requirement Category or Focus Area

d. Total Cost of Ownership – Hard Costs (Licencing, Hosting and Delivery) and Soft Costs (Internal Support for development and version releases) will collectively give the Total CoO.

The two middle panels are the activities to be undertaken when you take the identified requirements to market:

1. Market Research

a. Expert Rating Sites – Sites such as Gartner and Forrester will give you detailed independent analysis of multiple options. Others will give you their opinion of the best 3, 5, 10 solutions in respect to Quality of Product and Price. It is uncommon to get any indication of the Quality of Service

b. Demonstration & Introduction – Although the purpose of the demonstration is for the Vendor to show they have the required capability, the additional value is did they listen to what you specifically wanted to see and were they flexible enough to follow the conversation. These are key indicators of how the relationship will develop

e. Weighted Score – All the above along with a Priority Coefficient(s) will give each Potential Vendor a Weighted Score in order to Short List and ultimately Recommend the selected solution

3 x Critical Success Factors

These are CSFs for the Selection Process, not the Project:

1. Focus on Cost of Ownership not Price

The Evaluation Matrix pulls together all aspects of the decision as to what is the best solution and who is best to partner with to deliver it. The Quality of the Product (Does it do what we need) is paramount but the Quality of Service (How well will they do it) can have a dramatic effect on the Total Cost of

the right people and facilitate the right process for your business from discovery to deployment.

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz14

Shared Vision Drives the program Fits it to the tool Detailed Requirements Designs solutions Presents capability Functional Fit Customises for purpose Allows configuration Acceptance Testing Fully involved Facilitates how-to Training & Support Personalised / Periodic Modular / Static ResourcesTime & $$$ Quoted / Evolves Fixed / Inflexible Table 1 – Partner vs Vendor

Discuss your business needs Scott Fuller 027 596 9053 scott@xception.co.nz We understand the key drivers and specialist requirements of manufacturing businesses. We engage

DISCOVERY & SCOPE > SYSTEM ARCHITECTURE BUSINESS CASE > VENDOR SELECTION > PROJECT MANAGEMENT BUSINESS REQUIREMENTS > TRAINING & DEPLOYMENT CRM solutions designed and built for manufacturers CLARITY SIMPLICITY CERTAINTYIntegrated technology solutions built to work to your business processes. Business focused, user driven, fit for purpose and future proofed. continued on Page 25

Change your bearing now Moving energy made easy

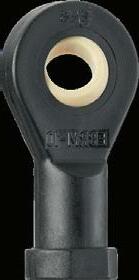

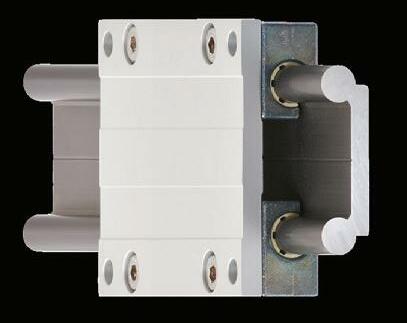

additional lubrication, light weight. This is what makes our high-performance plastics special. They replace metal in plain, spherical and ball bearings, in slewing ring bearings and in linear technology. Less cost and higher service life for moving applications, proven in the igus test lab; get a competitive edge with our dry-tech® range. All motion plastics can be configured and calculated online. igus.co.nz/dry-tech

15www.nzmanufacturer.co.nz / NZ Manufacturer October 2022

No corrosion, no

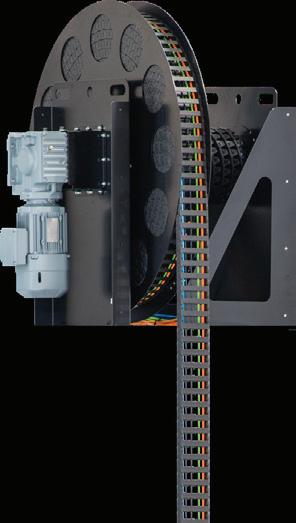

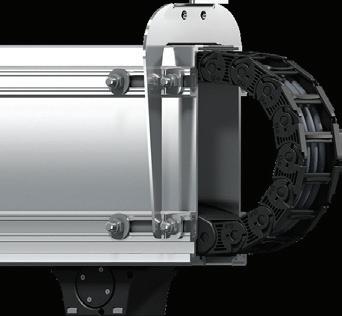

Our comprehensive range matches energy chains and cables to the movement on your machine. For vertical, horizontal or rotary motion, as standard or as special solutions, with smart technology for predictive maintenance. From individual components with no minimum order quantity to harnesed, readyto-intstall systems. All motion plastics® can be configured and calculated online. igus.co.nz/the-chain Auckland & Hamilton | 0800 847 200 | www.treotham.co.nz | info@treotham.co.nz

The leading supplier of high quality components and products to industrial markets

Manufacturing in New Zealand

Investment in innovation propelling performance for mid-sized manufacturers

• Majority of local manufacturers polled predicting revenue increases for year ahead

• More than half surveyed seeing increased work in pipeline for upcoming quarter

• Nearly two thirds have invested in innovation over the past 12 months Off the back of a challenging year to date, a new snapshot looking at the performance and priorities of some of New Zealand’s mid-market manufacturers shows a brighter business outlook and increased economic optimism for the months ahead.

Commissioned by MYOB, the latest Mid-market Snapshot reporting on a sample of mid-sized manufacturing businesses, revealed that while 44% of the New Zealand manufacturers surveyed reporting a drop in revenue on a year ago, more than a third (39%) say they’ve seen an increase – and further insights indicate that this upward trajectory is expected to continue.

Nearly 7-in-10 local manufacturers polled predict that their revenue will be up in the next 12 months, and more than half (55%) surveyed say they have more work in the pipeline for the next three months than they would usually expect at this time.

Jo Tozer, MYOB Head of Go-to-Market says the increase in positive sentiment around both business performance and economic outlook is encouraging as we head toward a new year.

“While we know mid-market businesses tend have continued to have a slightly more positive economic and business outlook compared to their SME counterparts, the past few years haven’t been without their challenges.

“The ongoing repercussions of the pandemic, the increased cost of goods, disruptions to supply chain and increases in the cost of their business overheads are all issues manufacturers we surveyed said are impacting their business at the moment and ones they expect to continue to effect things over the

Views: GTech

next six months,” she adds.

“However, with our insights showing many are investing in future-proofing their business, an increase in adaptability, productivity and resilience that comes from doing so will be helping to bolster their confidence as they look to capitalise on increased sales volumes in the months ahead.”

Innovation driving growth

In terms of what’s propelling these businesses forward, many manufacturers surveyed have seized the opportunity to do things differently.

Almost two thirds (64%) of the New Zealand manufacturing businesses surveyed said they have invested in innovation for their business over the past 12 months, with key areas for investment by this group including: new software solutions to manage their business (52%), more automation of manual processes (51%), improving production lines (41%) and tightening or improving supply chain (39%).

Building on this momentum, innovation also remains firmly on the radar for the year ahead with more than 7-in-10 surveyed saying that innovation is a key priority for their business.

For these businesses looking to innovate their operations in the next year, the majority (51%) plan to tighten or improve their supply chain, while almost half (49%) want to improve their production lines, and 44% want to expand their services to customers and clients.

“For businesses that want to thrive in any environment, innovation is absolutely key and the manufacturers we surveyed clearly recognise the meaningful impact changing their business approach and investing in innovation can have on their performance moving forward,” explains Jo Tozer.

“Almost three quarters of those we polled who plan to innovate in their business over the next year said they’re doing so to improve bottom line, while nearly two-thirds believe their changes will streamline operations and almost half of this group acknowledged it will help their teams get time back

to focus on other things.

“All of these potential outcomes are absolutely critical to a business’s success and manufacturers taking steps to achieve these ambitions will have a real edge,” Jo says.

Looking ahead

In addition to driving their own changes through innovation in their businesses, many local manufacturers appear to be gearing up for changes in the industry more broadly. More than half (59%) of New Zealand manufacturers polled for the Snapshot believe the industry will rapidly change over the next five years.

Amongst the biggest changes likely to shape the industry over the next five years, the most common responses from this group included: More competition (85%), more automation (62%), more customisation (62%) and the prospect of bigger businesses buying up smaller businesses (45%).

However, change is already upon the sector, with three quarters of mid-sized manufacturers surveyed stating they’ve seen a rise in the need for customisation – a trend which is likely to influence business approaches moving forward.

“As both the business environment and the customer needs continue to change, it’s likely we’ll see manufacturers continue to evolve their approach to their production workflows and their business operations systems to meet this demand.

“Digitisation of their business management systems is certainly a consideration here, with 60% of those we surveyed saying they’d like more than half their business to run using digital technology in future,” says Jo.

“With one-in-five mid-sized manufacturers we surveyed saying they had turned down customers because their current systems don’t enable them to deliver to their requirements, it’s clear there’s an opportunity to grow their pipeline even further –one which they can’t afford to be missing out on.”

Will Colenso is General Manager of GTech, a specialist manufacturer of industrial grade equipment and technology solutions for international markets to support the circular economy.

First established in New Zealand, the business has offices in the United States, Australia and Christchurch, New Zealand. GTech’s range of products, including the industry-leading 3 phase separation machines, help businesses recover valuable materials, reduce waste and treat water.

GTech General Manager Will Colenso says the business is forecasting an improving revenue trend for 2023.

“This is obvious in our short-term pipeline,” says Will Colenso. “Until recently, we only had visibility for two or three months ahead. Currently we have

orders out until April next year – a position we haven’t been in since 2018.

“Our supply chain is definitely the most critical business issue we face at present, and I don’t think there’s any chance of an improvement in the near term. Along with significant delays, we are still seeing rising costs in freight and components.”

Mr Colenso says, in terms of managing demand, time to market is absolutely key, with the business looking at a range of strategies to manage the impact of disrupted supply chains and strong international demand.

“Automation is also a major focus for us – both in terms of demand from our customers to increase automation in the machines we manufacture for them, and in how we automate processes in our own business. A lot of that demand is driven not only by improved efficiency but as a response to ongoing skills shortages.

“As we look forward, our focus is on our key markets, including the US, and how we reach the customers and maximise the demand we know is there.”

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz16

Manufacturing in New Zealand

Views: RML Engineering

For more than 40 years, RML has been a leading multi-disciplinary engineering company specialising in production line automation. Daryl Joyce, CEO of manufacturing business is feeling optimistic about the year ahead.

“Over the past 12 months the business has been steady and improving, with our pipeline for the next six months at full capacity, to a point where we have never been this busy before.”

While Daryl is feeling very positive about the next six months, he said there are several big challenges that lay ahead and it’s still difficult to predict where the economy will be this time next year.

“Although we are seeing supply and material starting to free up, the rise in costs is one of the biggest challenges and this is partly due to the exchange rate fluctuation. As we import materials, when the dollar drops, our costs skyrocket, so it’s difficult to make accurate predictions when the economy is going through so many bumps.

“At RML we are helping our clients solve some of the major challenges they are facing and maximising human potential. In this environment of staff volatility and labour shortages, that’s proving to be very motivational for many existing and new RML customers.”

RML has spent the last three years making innovation a core focus - investing in their systems, support and their people.

“The implementation of new technology and systems has helped increase productivity and made a huge impact on the overall business. We have forged strong links with key robotics partners like ABB which can handle complex integrations of these machines and the increasingly sophisticated control systems that drive the solutions.

“The business is operating 24/7 and because of the new technology and systems we have in place, we have been able to keep up production while being short-staffed. This would never have been possible before we invested in new equipment. While technology and systems are an upfront cost, it has moved the business from being static, to getting genuine results,” he said.

Daryl is working towards a growth business strategy and investing in systems now to ensure RML can reach its ambitious target of growing by a third in the next 3-5 years.

Customers have included: GoodmanFielder, Mars, Fonterra, PepsiCo, Nestle, Kraft

Employees: Approx 54 employees across two sites –1x NZ (Te Rapa, Hamilton), 1 x AU (Victoria).

CLIMATE CHANGE

Booking Deadline – 11 November 2022

Advertising Copy Deadline – 11 November 2022

Editorial Copy Deadline – 11 November 2022

Advertising – For bookings and further information contact: Doug Green, P O Box 1109, Hastings 4156, Hawke’s Bay Email:

Editorial material to be sent to : Doug Green, P O Box 1109, Hastings 4156, Hawke’s Bay Email: publisher@xtra.co.nz Tel: 06 870 9029

NZ

our aim is to keep our

up to date with the latest industry

and manufacturing advances in a tasty morsel, ensuring they do not get left behind in the highly competitive and rapidly evolving manufacturing world.

17www.nzmanufacturer.co.nz / NZ Manufacturer October 2022

Opinion Manufacturing Profiles Letters to the Editor Politics of Manufacturing Trade Fair World Diary of Events World Market Report Q/A Export News Machine Tools Business Opportunities Commentary As I See It Business News Appointments Around New Zealand Australian Report New to the Market Lean Manufacturing Equipment for Sale Recruitment Environmental Technology Manufacturing Processes NZ MANUFACTURER FEATURES NOVEMBER 2022 Issue Advertising

At

MANUFACTURER

readers

news

www.nzmanufacturer.co.nz INDUSTRY 4.0 SMART MANUFACTURING PRODUCTIVITY

Security

Pfizer’s journey to improve cybersecurity levels mid-pandemic

Article by cybersecurity firm Claroty

In any discussion around cybersecurity in manufacturing facilities, a set of common themes emerge. Firstly, operational technology (OT) that was once isolated from the internet and therefore inaccessible to hackers, is becoming increasingly connected with organisations’ wider IT systems, which is exposing it to a host of new dangers.

Secondly, OT networks rely on a large number of proprietary and often legacy devices that can be difficult to identify and secure.

Finally, these problems are often exacerbated by a lack of communication and collaboration between the people responsible for OT and those for IT.

Board recognition

What can organisations do to overcome these challenges? They must recognise the unique requirements of OT security and prioritise this at a board-level. This is what multinational pharmaceutical company Pfizer did, paving the way for other manufacturers to follow suit.

In 2017, one of Pfizer’s major competitors, Merck MSD, was hit by the NotPetya ransomware attack, resulting in severe consequences and operational downtime.

Identifying partners

Following this, Pfizer initiated a program to determine a series of cybersecurity

objectives, and the best strategy to achieve this.

They also identified the particular partners and cybersecurity consultants that would be required to help them on the journey.

The company developed a new security strategy for its manufacturing facilities based on the US Government’s NIST Cybersecurity Framework, a voluntary set of standards, guidelines and best practices to manage cybersecurity risk.

To find the most appropriate solution, Pfizer initiated a series of pilot programs and tested out various technologies. After an extensive analysis period, the company selected Claroty’s leading industrial cybersecurity platform to provide visibility into its OT environment.

Pfizer needed a tool that would give them full visibility into their production environment. After all, it’s impossible to protect all your devices if you don’t actually know what’s out there.

Accurate inventory essential

Unless manufacturers can confidently identify all the assets on their network, they can’t protect them all. Therefore, it’s absolutely critical to have a complete OT inventory, which gives manufacturers visibility over all communication paths between assets, and any access points into the network.

While Pfizer needed to bridge the gap between IT and OT, it also needed to secure that bridge with OT-IT segmentation.

In recent years, attackers have been highly successful in their use of phishing as a conduit for delivering malware to the OT environments in networks that lack proper segmentation.

Pfizer recognised that segmentation was a safe way to connect the production floor with IT systems, without opening the door to increased cyber risk.

As a result, the company strictly limited which assets are able to communicate between the production floor and IT, limiting this to only the critical business functions.

Firewalls for OT/IT segmentation

Pfizer had been using industrial firewalls at some production facilities since 2014 with good results, so it moved to achieve segmentation with a wide-scale rollout, and followed this with the deployment of Claroty’s security platform.

Production is king in manufacturing, and operational downtime is simply not an option for companies like Pfizer. They required a solution that was able to monitor network traffic in the production environments without impacting production in any way, shape, or form.

Tackling the human factor

Pfizer has also paid special attention to the human aspect of OT-IT convergence, by ensuring its IT and OT teams are able to collaborate effectively.

In any large manufacturer, it can be difficult to facilitate strong collaboration and communication between teams. This journey does not take place overnight, and cultural differences need to be melded and blended over time.

The takeaway

Securing a global manufacturing supply chain is an inherently complex endeavor with far-reaching implications — and few examples illustrate this reality better than the lifesaving Pfizer vaccine and medicines being used to combat COVID-19.

In today’s era of digital transformation, all manufacturers must be aware of growing cyber risk and the emerging technologies that can help defend against this.

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz18

Cyber

The Circular Economy

Comvita’s Harmony Plan: sustainability strategy built on purpose and values

Comvita’s ambitious sustainability strategy, its Harmony Plan, is guiding the Bay of Plenty-based manufacturer to ‘leave the world in a better place’.

The global market leader in Mānuka honey and bee consumer goods set out, almost 50 years ago, to work in harmony with bees and nature in New Zealand, to heal and protect the world. From the beginning, the company’s aim has been to help people feel better and live well.

The Harmony Plan – an interconnected ecosystem

Comvita has identified where it can have the most impact and has built its sustainability plan around four cornerstones.

The company aspires to be a leader in climate action, act as kaitiaki (guardians) for bees, restore balance in nature, and invest in its people and communities.

‘The Harmony Plan reflects the commitment we hold ourselves to. To be successful, we have to deliver positive outcomes for all our stakeholders,’ says Heather Johnston, Comvita’s Head of Safety and Sustainability.

Comvita’s tips for making progress on sustainability

Heather is keen to share Comvita’s experience to help other manufacturers make progress. She offers this advice.

1. Understand your ‘why’

Start by identifying your purpose. Why are you in business? Link this purpose to everything you do: how you produce, package and market your products, how you train your team and build your culture, how you manage your supply chain.

For the team at Comvita, the ‘why’ was simple. They want to heal and protect the world by working in harmony with bees and nature.

2. Focus on what matters – from the start

Making progress on sustainability is about tackling the right things at the right time.

“Don’t go for the ‘shiny’ things,”says Heather. “Keep purpose at the core, prioritise what matters most and where you can have an enduring, positive impact – in your business and beyond. Our Harmony Plan reflects the type of business we want to be and our purpose – which is why it was natural for our team to get behind it.”

To prioritise its efforts, Comvita engaged with important stakeholders, including customers, suppliers, business partners, investors and employees, to understand the economic, social and environmental topics that were most material to them. What topics matter most in your relationship with Comvita?

Comvita’s leadership team then added the ‘business lens’. What do these topics mean for our long-term profitability? Our urgent business priorities? The regulations that govern us?

Bringing these discussions together showed Comvita

the ‘sweet spot’: 11 topics that created the biggest impact and were most important to everyone.

They include product quality, sustainable performance, climate action, health, safety and wellbeing, and circular economy.

Together, they give Comvita the focus it needs to match its effort to its impact.

3. Measure. Measure. Measure.

Know your numbers, says Heather, including your baseline (where you’re starting from). What environmental impact does your business have?

For Comvita, understanding the starting point meant measuring its carbon footprint across all its global operations and entities and publishing its first Greenhouse Gas Inventory Report in August 2022.

From these benchmark figures, Comvita will reduce its footprint to meet its goals. It wants to be carbon neutral globally by 2025 and net carbon positive by 2030.

Climate action projects underway in the Harmony Plan

Comvita has prioritised these activities.

Measuring the environmental impacts of its products

The manufacturer has commissioned a Life Cycle Assessment (LCA) to understand the environmental impacts of ‘honey in a pot’ at every stage of the product’s life cycle.

These stages include supporting and transporting the hives and colonies so the bees make honey, harvesting the honey, packaging it, transporting it to market, and disposing of the packaging when consumers have used the honey.

The LCA will help the Comvita team understand where, and how, to make changes to reduce the honey’s carbon footprint across all stages of its value chain.

Measuring the environmental impacts of its packaging

Comvita wants to understand how well its existing packaging meets the standards of a circular economy.

A circular economy designs out waste and pollution, keeps products and materials in use and regenerates natural systems.

The manufacturer is using the Material Circularity Indicator (MCI) from the Ellen MacArthur Foundation to understand how to reuse resources to prevent waste.

This work resulted in a bespoke tool to make its packaging more circular. The tool will help Comvita design out ‘hotspots’ (areas it needs to focus on) and make informed decisions when it designs its product and packaging and buys goods and services.

Creating business value through the Harmony Plan

The Harmony Plan is creating business value. It is helping Comvita:

• Confirm its sustainability strategy. Comvita’s strategy is clear, aspirational and founded on its core purpose.

• Inspire investors’ confidence. The business is building resilience. With the Harmony Plan, it can report on non-financial performance as well as financial.

• Reduce risks. The carbon inventory makes it possible for Comvita to set targets with confidence, measure performance, and reduce its environmental risks and emissions.

• Build its brand. Comvita has a strong story to tell, built on sustainability, science and its founding values. This story is connecting its customers, employees, communities, and other stakeholders.

• Attract, engage and retain employees Employees want to work for a company like Comvita which shows purpose and intent. thinkstep-anz.com

19www.nzmanufacturer.co.nz / NZ Manufacturer October 2022

The Circular Economy

Computer Recycling

If we want to create business solutions that better serve the environment, we need to shift our manufacturing mindset from take, make, waste – to reduce, return, reuse.

This circular economy mindset, whereby products can be endlessly used through continuous business systems, is what gave birth to Computer Recycling.

Computer Recycling is Aotearoa’s leading electronic waste recycler, recycling more that 4.8 million kilograms of waste since it was bought by Managing Director, Patrick Moynahan in 2018. Patrick took out a loan and used his personal savings to purchase and consolidate Computer Recycling into what it is today.

The company’s goal is to eliminate electronic waste from the country’s landfills by actively engaging in sustainable recycling and reuse practices – a mission focused on driving Aotearoa’s circular economy.

The average Kiwi produces 20kg of e-waste per year, which is one of the highest amounts per capita on Earth. That’s around 80,000 tonnes of e-waste per year – estimates suggest that a mere 2% of it is recycled.

A lot of people don’t consider what happens to electronics, or waste in general, once it’s in the bin. It’s trickier for e-waste given it contains toxic plastics and metals which can harm our environment. That’s why it’s important e-waste is properly disposed of, and where applicable, recycled.

For businesses, it’s one thing to manufacture and sell a product, but there needs to be equal consideration for what happens to that product at the end of its life.

Businesses need to be responsible for a product’s entire lifecycle. It’s their responsibility to ensure products are disposed of / recycled properly, and they need to educate customers on appropriate disposal habits as part of that.

At Computer Recycling, e-waste is both refurbished and recycled. Once the e-waste is gathered, it’s then brought back to Computer Recycling’s site in Penrose, and is sorted, graded, and split into two categories – reuse or recycling.

Electronics have a lot of valuable material in them such as gold, silver, cadmium and iron. They also have fire-retardant plastics, nickel, lithium, cobalt, and other materials with no further value.

Anything that can no longer be used is stripped for their most valuable components and exported under Environmental Protection Authority permits to facilities in Asia and Europe. From there, they are returned to base elements and used again.

Items that may have a second life are cleared of data, refurbished, and retailed through Computer Recycling’s retail, outlet CR Tech.

These recycling and refurbishing processes reduce the amount of e-waste being dumped into landfill, preventing further harm to the environment.

Aotearoa is the only country in the OECD that doesn’t have a national e-waste scheme or bans e-waste from being dumped in landfills.

New Zealand prides itself on its clean and green reputation. However, we are one of the worst offenders when it comes to waste, we’re one of the most wasteful countries in the developed world.

To combat the problem and ensure electronic waste isn’t going to waste, all stakeholders need to eliminate e-waste to landfill.

It’s about Kiwis disposing of their household e-waste appropriately. It’s about businesses building e-waste into their sustainability strategy to ensure no business e-waste ends up in landfill. It’s also about product manufacture and creating a lifecycle that doesn’t end with a product on a shelf but through to its end-of-life too.

And it’s especially about encouraging policy and regulation preventing e-waste from going to landfill, and for business to better consider their product’s environmental impact.

Recycling e-waste and provoking change and regulation in the industry are the first steps towards unleashing the power of Aotearoa’s circular economy.

Looking for a marketing edge?

NZ Manufacturer October 2022 / www.nzmanufacturer.co.nz20

70% of licence holders say signing on has positively affected sales.

INDUSTRY 4.0: REVOLUTION OR EVOLUTION?

When tackling i4.0, food manufacturing and processing industries are all on a journey of discovery.

Industry supplier NZ Controls includes itself in this bracket, describing the company as a service provider rather than a manufacturer.

“We are also working out how it all fits together so that we can help our customers. We want to add value. It’s our responsibility to be informed and ready to help guide our customers into the world of Industry 4. We work hard to battle the hype and drill down into real and practical applications with measurable returns,” says Nikk King, director business development, NZ Controls.

NZ controls believes that the best approach is to consider the i4.0 technologies as a set of tools and concepts to enhance what it is already doing. Thus, i4.0 is more an evolution than a

Drive productivity with data

revolution. Nikk says that while the results can be revolutionary, “We don’t need to ditch everything and start again or even make significant physical changes”.

Perhaps the best way to take advantage of the i4.0 tools and techniques is to change or broaden the mindset to one of iterative and continuous improvement. While there’s nothing revolutionary there, says Nikk, NZ Control’s ability to apply emerging technologies leads to newly discovered opportunities for improvement. In some other cases, i4.0 tools may just provide the data needed to prove what you may already suspect, finally giving the justification to get those projects moving.

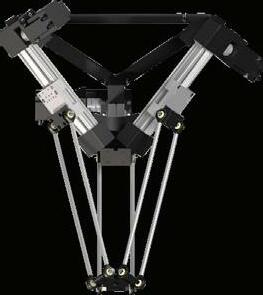

Another key application for the i4.0 toolkit is to allow more flexibility and potentially ‘revolutionise’ some aspects of production. For example,

evolving from a very linear and inflexible workflow to a more adaptive cell or modular approach, perhaps using collaborative robots and automated guided vehicles to move components instead of traditional conveyors filling up the floor.

“From NZ Controls perspective we must provide measurable value. We seek to collaborate on developing a measurable business case, delivering i4.0 technology solutions and help our customers realise their return on investment. In doing so, we maintain our customers’ trust and in some small way help to evolve the local manufacturing sector into one which is incrementally more productive.”

“You can’t manage what you don’t measure”

Measure to gain control

text 21www.nzmanufacturer.co.nz / NZ Manufacturer October 2022

FTR502

Peter Drucker

• Repeatable production • Traceability • Track costs and outcomes • Manage efficiency • Drive continuous improvement

2 MARCH 2020 INDUSTRY 4.0

continued from Page 1 Stepping forward with Industry 4.0

New Zealand Steel plant at Glenbrook.

The ownership of Dixon & Haddon went through changes in the mid 1980s; Bob and Judy sold their interest and Bob became business partners with Mike Sullivan, who also owned Clearwater Construction.

Mike and Bob each brought different yet complementary skills to the partnership – there was Bob’s acumen around structural steel, and Mike’s business acumen and strengths as a main contractor.

Mike proceeded to introduce changes that had a significant impact on Dixon & Haddon’s direction, including investing in machinery, cranes and technology. In the mid ’90s, the company started to embrace technology and that focus continued to grow, as did the size and complexity of the structural steel jobs the company was tackling.

When Bob retired in the mid 2000s, Dixon & Haddon became D&H Steel Construction. It was always Mike’s vision to set up a state-of-the-art facility.

For more than 30 years, the company had operated out of a modest workshop in Span Farm, West Auckland, but it was no longer fit for purpose.

In 2010, D&H officially opened its brand new high-tech plant in Henderson.

What challenges has the company faced?

The first 50 years of business have seen D&H Steel face significant challenges only to emerge stronger than before – from the early union days and share market crash to the GFC and a global pandemic.

All the while the company has kept pace with the ever-changing construction industry – often enough it has been at the forefront of those changes.

Another challenge was educating the market about the value of structural steel so we could grow its market share. In the early 1990s, structural steel had less than five percent of the construction market.

Engineers were content to continue designing familiar concrete structures; they were not in a rush to move out of their comfort zone to explore steel alternatives.

So, D&H Steel joined the Heavy Engineering Research Association and Steel Construction New Zealand to support the work that these industry organisations were doing to educate designers and procurers, and to raise the bar across the entire industry. Today, structural steel enjoys more than a 50 percent share of the construction market nationwide.

The steel construction industry is the busiest it has ever been.

How are you finding current business conditions?

The steel construction industry is the busiest it has ever been. We are currently facing a perfect storm: an overstimulated market; labour and skills shortages; and inflation and the cost of living pushing resources out of Auckland.

There needs to be a focus on smoothing demand to avoid overcapacity resource constraints – government procurement agencies need to be mindful of this when planning their pipeline activity.

Staffing challenges.

Finding staff remains a challenge. Our industry cannot train apprentices fast enough to satisfy demand for skilled staff.

Exacerbating this are employees departing the business to move to the regions or offshore.

Apprenticeship training schemes are still broken; the pace of change to restructure is frustratingly complicated and slow, and we are having to bring staff in from offshore to catch up. We would like to see Te Pukenga lift its game.

Our industry is doing its part: almost 11 percent of the total workforce employed by local structural steel contractors are in a training programme, and 70 percent of structural steel contractors employ an average of five apprentices.

The future direction?

The steel fabrication industry is changing with advances in technology and D&H Steel is aware it needs to keep pace with the times. As a business, we have been focused on keeping ahead of the market and have been early adopters of technology and systems.

New technology is very much on our radar, including the use of robotics and advances in manufacturing techniques.

We are embracing the Industry 4.0 pathway, which is about making smarter decisions in real time based on available data. It is advancing quickly.

Most of our work is still human powered, so it’s more about trying to give people tools to make their days a bit easier or give them better information.