AMA gets business-led ITP actions underway

Advanced Manufacturing Aotearoa (AMA)* is a new cross-sector incorporated society representing manufacturing businesses across the country. It will be industry-driven and work alongside all stakeholders to coordinate business-led initiatives that help deliver Advanced Manufacturing Industry Transformation Plan (ITP) outcomes.

Business-led ITP initiatives

• Initiative 15: Strengthening Advanced Manufacturing networks

• Initiative 6: Individual development plans

• Initiative 8: Attraction strategy to increase workers and diversity

• Initiative 13: Improving understanding and perceptions of manufacturing.

Initiative 15. Strengthening advanced manufacturing networks is one of four priorities that AMA is responsible for leading. The process for proposals for programmes to meet Initiative 15.

Strengthening advanced manufacturing networks is open until 5pm, Sunday, September 24, 2023.

What is Initiative 15?

Initiative 15 is designed to strengthen advanced manufacturing networks to ensure healthy, inclusive advanced manufacturing networks that collaborate to deliver on ITP priorities. The AMA is developing a preferred model to strengthen networks and collaboration. It is piloting a regional approach to ITP outcomes through leveraging what is already working, while enhancing connection with unions, research institutions, and organisations representing Māori and Pasifika manufacturers.

There is $2m in the first year in seed funding allocated equally for national initiatives and across 10 Regional Manufacturing Working Groups to support those regions to develop, pilot and evaluate a preferred model.

The proposal will outline the approach, programme, and activities to best deliver the outcomes.

Ideas are also being sought for national initiatives to deliver Initiative 15 outcomes. Please contact the AMA interim Executive Director for more details.

How will proposals be considered?

AMA will seek proposals for, assess, and make recommendations to the ITP Steering Group, for each of the initiatives above. This will be done in conjunction with the AMA Council, which will co-ordinate 10 Regional Manufacturing Working Groups, participating industry associations, and the AMA Board, made up of six independent directors and a chairperson.

It will review progress against KPIs for particular initiatives as well as management of funding.

Who can put in a proposal?

For Initiative 15 proposals will come from regional manufacturing entities, which must have the people, networks and systems immediately available to enable efficient, timely and sustainable delivery. For an application form, proposal documentation and template, please contact the AMA interim Executive Director.

*Advanced Manufacturing Aotearoa (AMA) is the umbrella organisation leveraging business networks to implement ITP priorities. It takes an industry-led, collaborative approach to helping deliver initiatives that make a difference.

COMMENT NZ needs a Minister of Manufacturing. SMART MANUFACTURING KiwiNet Awards 2023 finalists announced. www.nzmanufacturer.co.nz September 2023 Don’t delay, contact us now. enquiries@baycad.biz NZ 0274847464 AU 64274847464 Aust/NZ Region Free trial available 30 Days, No Restricons Alibre Design New release Version 27 Solid Parts Sheetmetal Parts Assemblies BOM Drawings Buy It and Own It Professional CAD Soware Powerful, yet easy-to-use

Phone: 0800 655 465 Email: sales@acelink.co.nz Website: https://www.acelink.co.nz/mid-year-sale/ 8 9 16 COMPANY PROFILE Wellington company showing the way for low carbon

2023 Media Kit www.nzmanufacturer.co.nz For a copy of the NZ Manufacturer Media Kit 2023 email publisher@xtra.co.nz All articles are published at no charge, unless promoted (advertorial) content is required. Success Through Innovation asiamanufacturingnewstoday.com ASIA M ANUFACTURING N EWS 2023 Asia’s manufacturing future. MEDIA KIT Media Kit 2023 Innovation + Dedication = Success www.australianmanufacturingnews.com TechRentals® is an IANZ endorsed Calibration Laboratory We offer both IANZ Endorsed and Traceable Calibrations of test and measurement equipment inluding: 0800 832 473 www.techrentals.co.nz

DEPARTMENTS

LEAD

AMA gets business-led ITP actions underway.

BUSINESS NEWS

Robert Scott joins PDV team. OpenStar raises $10m seed round.

COMMENT

Why NZ needs a Minister of Manufacturing.

SMART MANUFACTURING

KiwiNet Awards 2023 finalists announced.

The importance of operational technology cybersecurity.

Enable smarter production lines with the right connectivity.

COMPANY PROFILE

Wellington company showing the way for low carbon.

ANALYSIS

NZ lagging with health and safety.

SUSTAINABILITY

Serious about reducing your carbon footprint? Read on!

PROMPT ENGINEERING

Feeling the Heat.

START UPS

Callaghan Innovation launches counselling service for startup founders.

WORKSHOP TOOLS

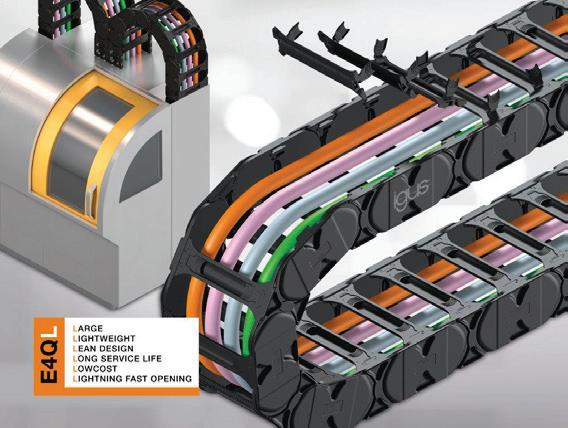

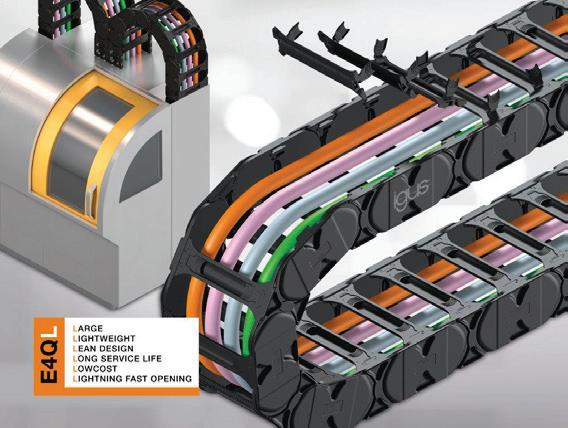

New low-cost igus energy chain for unsupported applications.

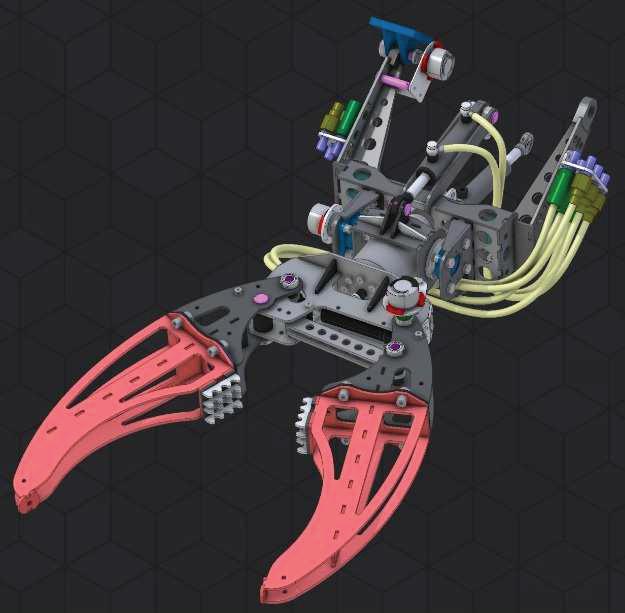

Miller Vortex HDV provides next level of protection.

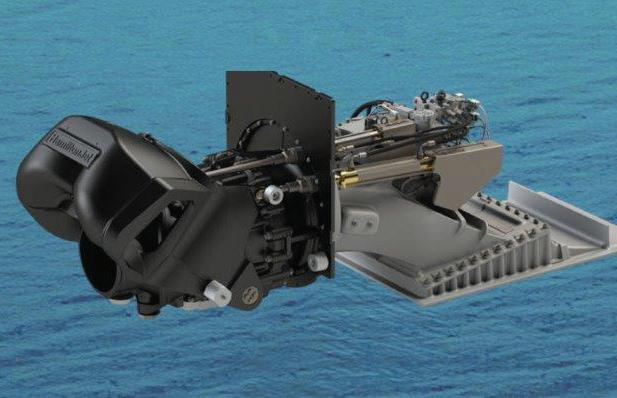

HamiltonJet reimagines the waterjet with the LTX36.

DEVELOPMENTS

Frucor Suntory boosts productivity.

Demystifying the entrepreneurial mindset. Is being an AI ‘whisperer’ a short-lived fad?

THE LAST WORD

Slow train coming.

ADVISORS

Kirk Hope

Is Chief Executive of BusinessNZ, New Zealand’s largest business advocacy body He has held a range of senior positions at Westpac and is a barrister and solicitor

Ian is a Partner, Argon & Co. NZ, a master black belt improvement specialist and global lean practitioner. He is passionate about improving productivity and helping to create world class New Zealand businesses.

Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

Is Managing Director of Connection Technologies Ltd, Wellington and is passionate about industry supporting NZ based companies, which in turn builds local expertise and knowledge, and provides education and employment for future generations.

EMA chief executive Brett O’Riley has a background in technology and economic development.

Brett actually grew up with manufacturing, in the family business, Biggins & Co. He currently holds board roles with Wine Grenade and Dotterel Technologies and is also on the NZ Film Commission board.

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

NZ Manufacturer September 2023 / www.nzmanufacturer.co.nz 4 C0NTENTS 1 6 8 9 16 17 19 20 21 22 25 27

8 9 12 16 19 27

Brett O’Riley

Ian Walsh

Lewis oodward

Insa Errey

Dr Barbara Nebel CEO thinkstep-anz

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: +64 6 870 9029

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, EMA, Business East Tamaki, Ian Walsh, Dr. Barbara Nebel, Adam Sharman, Andrew Bayly, Philip Laird

ADVERTISING

T: + 64 6 870 9029

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher

Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz Free of Charge.

MEDIA HAWKES BAY LTD

T: +64 6 870 9029

E: publisher@xtra.co.nz

121 Russell Street North, Hastings

NZ Manufacturer ISSN 1179-4992

Vol.14 No.8 September 2023

Copyright: NZ Manufacturer is copyright and may not be reproduced in whole or in part without the written permission of the publisher. Neither editorial opinions expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or publisher of NZ Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the publication.

Delivering advanced manufacturing outcomes

Chances are that by the time you read the next issue, October, the election will be over and we will all be moving forward (or continuing to move) to meet the ongoing challenges the country needs to bring us back into the black. A difficult, but noble ambition.

In September issue (on Page 8) we have included the article, ‘NZ needs a Minister of Manufacturing’. If this request was met, was successful, and that person only achieved to have our productivity raised in their term in office, then that person would be time remembered. Would be a hero.

Imagine, putting in place the tools and incentives to take away the pressures on businesses and staff, to enable an enduring quality of life?

News (on Page 1) of Advanced Manufacturing Aotearoa (AMA) tells us that a new incorporated society, representing manufacturing businesses across the country, will be industry-driven to help deliver Advanced Manufacturing Industry Transformation Plan (ITP) outcomes.

Through ITP Initiative 15 to strengthen advanced manufacturing networks to ensure healthy, inclusive advanced manufacturing networks that collaborate to deliver on ITP priorities.

There is $2m in seed funding in the first year allocated equally for national initiatives and across 10 Regional Manufacturing Working Groups to support those regions to develop, pilot and evaluate a preferred model.

On Page 9 you can read the bios of some of the KiwiNet Awards 2023 finalists. Fascinating, creative people involved in hydrogen production through to deep tech.

The Company Profile (Page 16) is Wellington’s Niche Modular Construction, the first company to use HERA’s Zero Carbon Steel program.

Enjoy the read…and vote wisely!

5 www.nzmanufacturer.co.nz / NZ Manufacturer September 2023

EDITORIAL

Success Through Innovation

Real Steel acquires Precision Cutting & Processing — expanding South Island PDV Consultants expands team with electrical and control systems expertise

Real Steel has bought Precision Cutting & Processing. Real Steel is one of the leading steel plate processors in New Zealand, supplying customers all over the country from its 8500m2 factory in Upper Hutt.

This acquisition will see Real Steel take over Precision Cutting & Processing’s modern factory and plant based centrally in the South Island in Ashburton. Luke Mathieson, Managing Director of Real Steel says, “By combining the strengths of Real Steel and Precision Cutting & Processing, we aim to deliver unparalleled value and experience to all customers. We’re pleased to announce Josh O’Malley, Managing Director of Precision Cutting & Processing will continue to lead the Ashburton factory and will join the Real Steel leadership team.”

Key benefits for customers include: raw material, access to SSAB steel, a wider range of plate processing capabilities, geographic proximity and state-of-the-art software.

Over the past few years, Real Steel has made large investments to build customised machinery, software, and systems for part marking and part

Hamilton-based global engineering consultancy PDV Consultants (PDV) is pleased to announce that Robert Scott will be joining the PDV Team as Principal Electrical Engineer. Robert brings with him 25 years of international electrical engineering and control systems experience.

PDV provides process engineering design and solutions for food and biosciences industries around the globe, including some of the world’s largest dairy, manufacturing, and food companies.

Robert joins PDV after running his own electrical engineering company, where he worked on the design and delivery of large scale electrical and control systems in New Zealand and internationally.

PDV’s attention to detail along with their professional expertise in delivering

BUSINESS NEWS

is here to make it easier to do business; working alongside business leaders and property owners in the region on security, advocacy, development and growth. businessET.org.nz

Providing the tools and support to drive business forward.

OpenStar, “NZ’s most ambitious startup” raises $10m seed round

Fusion startup OpenStar Technologies has closed a $10m seed round led by deep tech investor Outset Ventures, and supported by Icehouse Ventures, Blackbird, Radar, Ngāi Tahu Holdings, K1W1, and Aspire.

OpenStar is on the bold mission to repeat the feats of Maui and seize the power of the sun by mastering fusion, the same process that powers the stars.

Fusion, a field of science that has captured the world’s imagination for decades, involves the merging of light atomic nuclei to produce energy.

The field’s promise as the cure to our most pressing energy issues has seen it attract many billions of dollars in investment, and, should it succeed, would give rise to the next industrial revolution.

In the global quest for fusion energy, Māori-led Wellington startup OpenStar has taken a different path, opting to revisit the mostly forgotten ‘Levitated Dipole Experiment’ (LDX) originally pioneered by MIT and Columbia University in the early 2000’s.

Dr Ratu Mataira, co-founder and Chief Executive of OpenStar, says that the LDX poses the best possible path to achieving limitless energy.

“If not for a chance conversation with a friend in 2020, the Levitated Dipole Experiment may have easily been lost to history. I looked at the development of technologies such as the High Temperature Superconductors (HTS) and realised that these solved a number of the key issues that dogged the original approach,” said Mataira.

The levitated dipole reactor (LDR) is essentially the “geometric inverse” of a tokamak, the mainstream approach to controlled fusion in which magnets confine a donut shaped plasma in their centre. The levitated dipole reactor instead positions its superconducting magnets in a donut shape, which confines plasma around the magnets. The LDR geometry gives it a host of benefits from a plasma physics perspective, which presents an enormous competitive advantage over the mainstream approach taken by other private fusion companies.

A year ago OpenStar quietly opened the

doors at its Ngauranga facility, recruiting 28 hyper-specialised staff to build one of the boldest engineering prototypes New Zealand has seen.

Angus Blair, Partner at Outset Ventures, says OpenStar’s vision, technical expertise, and aggressive execution has all of the hallmarks of one of the great NZ startups.

“New Zealand’s legacy of bringing generational technology and talent to the world is in safe hands with Ratu and the Open Star team. They are undoubtedly the most ambitious startup to come out of New Zealand”

For Robbie Paul, CEO of Icehouse Ventures, the investment speaks to the role of venture capital in Fusion technology, a space that had largely been the investment domain of nation states for many years.

“Not long ago space exploration was an activity limited to governments – and only a dozen of them before Peter Beck took New Zealand to space. Similar transitions have occurred in finance, communications, and education on the back of extraordinary entrepreneurs. We are excited to support Ratu and the Open Star team to lead an energy revolution,” said Paul.

Before the end of the year OpenStar aims to use its prototype Junior to spark its first plasma around a levitated dipole in a large vacuum chamber. If successful, the startup will have surpassed the technical feats of the LDX, with half the money, in a fifth of the time, and with the addition of OpenStar’s key enabling technological approach.

OpenStar has its roots at Robinson Research Institute, Victoria University of Wellington, which has pioneered many of the necessary technologies, not just for OpenStar, but for many fusion efforts relying on High Temperature Superconductors (HTS).

CEO Dr Ratu Mataira, himself an alumni of the Robinson research programme, credits his rich whakapapa with his single-minded quest for OpenStar.

title BUSINESS NEWS

7

Why NZ needs a Minister of Manufacturing

-Andrew Bayly, National Spokesperson for Manufacturing and MP for Port Waikato

National wants to not only support existing manufacturers, but to attract more people into the sector and more manufacturing to New Zealand. We need all parts of our economy firing on all cylinders if New Zealand is going to recover from the current economic crisis quickly.

To do so, we must reduce costs for our manufacturers, encourage investment, reduce taxes and make it easier for firms to hire and train new staff.

Why manufacturing matters

Manufacturing is critical to the New Zealand economy. It represents about 10 per cent of GDP and underpins over half of our exports.

The sector employs about 250,000 people, accounting for nearly 11 per cent of all jobs in the economy. Its contribution to R&D is also significant, accounting for 24 per cent of business spending on R&D ($649 million in 2020). This has been achieved against a backdrop of a government that has added costs and strangled businesses with red tape.

From the numerous roundtable discussions and workshops up and down the country, some key themes have been voiced by manufacturers where improvements can be made to drive the sector forward.

Making our manufacturers globally competitive

Improving the global competitiveness of New Zealand’s manufacturers means improving their productivity and accelerating the development of new products and services.

Encouraging and adopting Industry 4.0 is essential. We need to strengthen collaboration with research organisations in Australia and beyond, and ensure our own Callaghan Innovation remains focused on supporting the introduction of Industry 4.0 technologies on a broad front.

But to encourage manufacturers to make capital

investments in new technologies, we need to ensure that skill development happens in tandem. One without the other won’t work. The lack of the requisite digital skills among their workforce, and in the wider labour market, prevents manufacturers from pursuing the introduction of digital technologies before capital investment decisions can even be considered.

Making manufacturing an attractive career choice

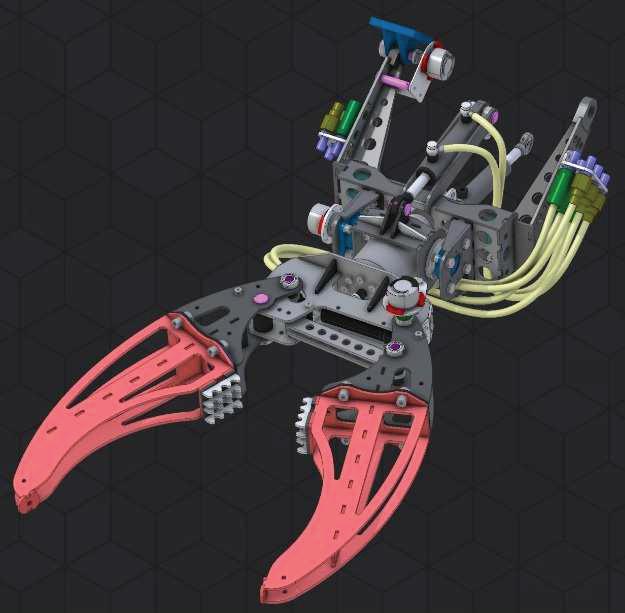

At many of the meetings around the country, manufacturers spoke about the difficulty of attracting people into the sector due to their preconceived perceptions of the industry. This is especially so amongst school leavers and people retraining after time away from the workforce or coming in from other industries, particularly women. However, manufacturing is now predominantly a high-tech high-value sector, with businesses that utilise high levels of automated machinery, sometimes in a lights-out environment. Not a grease gun in sight!

How do we attract young people and how do we train them up to an adequate state where they can work proficiently in one of these high-tech manufacturing businesses?

One of the barriers identified is getting teachers on board who want to encourage young people to go into manufacturing, especially where the academic system leans more towards encouraging young people to go to university. A second obstacle is winning over parents so that they see manufacturing as a viable career path for their children.

Developing a pathway into manufacturing for school leavers

In the Hutt Valley, there are a large number of manufacturers who coincidentally are all located in close proximity, with the benefit of there also

being secondary schools and a vocational education provider located nearby.

As a result of discussions at various meetings in the Hutt with manufacturers and the Hutt Valley Chamber of Commerce, we agreed that it would be useful to work on a programme that would firstly give students exposure to manufacturers, and then ultimately provide training so they will become work ready.

The programme will build on the Chamber’s Work Integrated Learning activity with engineering businesses in the Hutt Valley – work that is based on the successful Hastings Boys High School / Patton Engineering model.

Chamber CEO Patrick McKibbin says Work Integrated Learning is having a positive impact, helping school leavers transition to further education and employment, reducing risky behaviour and offending, and improving outcomes educationally and socially.

I invited a number of representatives of these organisations to Parliament to discuss this (see photo), as the first step to developing a programme for manufacturers that, ultimately, we hope to roll out across the country.

Recognising the value of manufacturing

Government cannot develop sound policies for a sector it doesn’t understand and of which it has no internal institutional knowledge. Therefore, as a prerequisite for the development of policies to better support the sector, we would give manufacturers a better voice within Government through the appointment of a Minister for Manufacturing and the creation of a dedicated resource (within MBIE) to support that Minister.

This would also serve as a signal to the wider public that the Government recognises the value of manufacturing to the NZ economy.

NZ Manufacturer September 2023 / www.nzmanufacturer.co.nz 8

COMMENT

Over the last year, I have met with manufacturers from Whangarei in the north to Dunedin in the south. I have asked them what the Government could do to better support them.

In July, representatives from the Hutt Valley Chamber of Commerce, local high schools and manufacturers met in Parliament with MP Andrew Bayly (seated, far right). Local MP Chris Bishop is also very supportive of the initiative.

KiwiNet Awards 2023 finalists announced

Finalists for the 2023 KiwiNet Research Commercialisation Awards have been announced. Winners will be presented on 28 September. The finalists include:

Award Category Sprout Breakthrough

Innovator

Dr Jerome Leveneur -BSPKL/GNS

Award Category BNZ Researcher Entrepreneur

Professor Rod Badcock, Robinson Research Institute, Te Herenga Waka, Victoria University of Wellington Professor Rod Badcock is the Deputy Director and a founding member of Paihau – Robinson Research Institute at Victoria University of Wellington.

He is recognised as a pioneer in the field of applied superconductivity, focusing on accelerating this technology into new applications such as generators, motors, power transformers, medical imaging systems, electric space propulsion and high field magnets.

Rod is currently leading New Zealand’s contribution to an international effort to decarbonise transport.

have raised over $13M of investment to date. His impact also extends to the wider deep tech sector. Kevin has established several valuable forums for entrepreneurs and commercialisation professionals across NZ; he is a mentor to others in the space; and in 2022 he helped organise a New Zealand delegation of 14 companies to attend the ‘Cleantech Forum Asia’ in Singapore which led directly to at least two international partnerships.

Significantly, Kevin has recently been involved in highlighting the need to enhance support for scale-up of NZ deep tech companies, drawing many stakeholders together into constructive discussions and presenting the findings to the government.

Kevin is a tireless champion for the wider ecosystem, adept at identifying the people and projects with potential, and building relationships between entrepreneurs, TTOs (the transfer offices), investors and others.

Bspkl co-founders Dr. Jérôme Leveneur CTO and Christina Houlihan CEO of the company which is a finalist in the Pwc Breakthrough Project Award category.

Jerome is Science Co-Founder and CTO of Bspkl, New Zealand’s first deep technology hydrogen start-up. This new manufacturing technology, targeting the electrolyser and fuel cell market, supports the world’s transition to a more sustainable future.

He was an Ion Beam Materials Scientist at GNS Science when he developed a new manufacturing technology that could drastically reduce the amount of precious metals used in the production of catalyst-coated membranes (CCM), used in technologies for hydrogen production, while also increasing the speed of the CCM manufacturing process.

This led to the invention of Bspkl - a revolutionary approach to ion beam modification with a wide range of potential industrial applications, and which no one else in the market can currently produce.

Bspkl was spun-out in April 2023 with a $2.8 million seed investment round led by WNT Ventures. As the first start-up to be formed with IP from GNS Science, it represents the culmination of many years of innovation and championing of commercialisation. Jérôme is deeply passionate about creating real-world impact, and he continues to work on collaborative new IP with other public research institutions, helping to generate other new IP that can move Aotearoa closer to a zero-carbon future. At a time when the world is increasingly interested in investing in green hydrogen, Jérôme has helped put New Zealand on the map as having the capability to accelerate a green hydrogen economy.

His team is developing cutting-edge work on electrifying aviation and other heavy transport, which has attracted interest from the industry’s top global players and promises to put New Zealand at the forefront of an emerging global electric aircraft motor market, estimated to be worth more than $200 billion USD by 2050.

As a champion of New Zealand’s innovation system, Rod fosters an entrepreneurial environment at the Robinson Research Institute, urging students to design innovations that address problems in the real world beyond the lab.

This has resulted in the spin-out of exciting new companies like OpenStar Technologies and the international success of domestic start-ups like HTS 110.

Award Category: Simpson Grierson Commercialisation

Professional

Kevin Sheehy, MacDiarmid Institute Kevin is a highly accomplished commercialisation professional whose work has a deep and wide-ranging impact nationally.

In Kevin’s core role supporting deep tech and cleantech researchers within the MacDiarmid Institute, he oversees a pipeline producing 2-3 affiliated start-ups per year. Since Kevin joined the Institute, it has spun out nine deep tech innovations.

He tangibly contributes to success- at all points along that pipeline – from supporting new PhD students through to guiding founding professors. The MacDiarmid Institute affiliated startups he supports

Award Category: Simpson Grierson

Commercialisation Professional

Dr Sean Mackay, Massey University Dr Sean Mackay represents a new generation of commercialisa tion professional, blending his roles as a scientist, inventor, commercialisation vmanager, and founder.

Starting out as an inventor of several deep-tech opportunities, Sean now works for Massey Ventures in a tailor-made Senior Commercialisation Manager role that unleashes his unique skillsets.

He is responsible for a pipeline of commercial opportunities at Massey University, including many where he acts as a principal investigator, inventor, and/or founder. In under three years, Sean has helped raise around $3M and supported four spinouts (one where he was a founding inventor) and two licenses (one with Sean as a named inventor).

These include: Ampersand Technologies, Retrabac Therapeutics, Nanophage Technologies, Captivate Technology and Strawberry Birthmarks.

He is also responsible for facilitating the University’s first Iwi investment, generating a healthy pipeline of commercial opportunities, and supporting the introduction of a flexible benefit-share model for founders and a new Student IP policy.

Sean has actively sought new opportunities to advance his skills, such as participating in KiwiNet’s Emerging Innovator Programme, and moulding his career to suit his strengths, creating the best outcomes for his organisation and team.

9 www.nzmanufacturer.co.nz / NZ Manufacturer September 2023 SMART MANUFACTURING

What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution taking place right now. This revolution is driven by the convergence of digital technologies such as the Internet of Things (IoT), robotics, artificial intelligence (AI), augmented and virtual reality, 3D printing and more. Adopting these technologies is enabling manufacturers to enhance their performance, output, monitoring, quality and control on a global scale.

The Industry 4.0 Demonstration Network

The challenge for New Zealand businesses starting out on their Industry 4.0 journey is knowing when, how and what technologies to adopt to improve efficiency, quality, documentation, business intelligence and sustainability.

Where do I start?

This Government initiative enables Kiwi manufacturers to experience Industry 4.0 technologies first-hand via nationwide showcase events, manufacturing site visits, interacting with and learning from industry leaders.

THE FUTURE OF MANUFACTURING IS HERE

THE SMART FACTORY SHOWCASE

The Smart Factory Showcase is a free, interactive session designed to demystify and break down Industry 4.0 with a world leading NZ example. The session will highlight how incorporating smart technologies improves efficiencies, productivity, connectivity, solves common manufacturing issues and streamlines systems and processes. The Showcase provides an ideal introduction to kick-start or progress your own Industry 4.0 journey.

Who should attend

This event is designed for CEO’s, Digital Technology Managers, Operations Managers, Design Engineers and Managers seeking an in-depth understanding of the latest available technologies for businesses. It is a valuable forum to get buy-in from stakeholders and the events are relevant across all sectors. Teams are encouraged to attend together.

What to expect

The Smart Factory Showcase highlights Nautech Electronics’ Auckland facility and what the future of advanced manufacturing looks like – You will be inspired, gain powerful insights to enhance your manufacturing agility and be armed with the knowledge to join the Industry 4.0 revolution.

View all Showcases

It can really help by providing concrete examples of how you can actually apply this stuff and get value from it, and network with others to find out what they’re doing to implement Industry 4.0

Mitchell Sanson, Engineering Manager, Hansa Products

Featuring

“

“

The importance of operational technology cybersecurity ADVISORS

Sandra Lukey

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business. She has over 20 years’ experience working with companies to boost profile and build influential connections.

Mike Shatford is an expert in the field of technology development and commercialisation. His company Design Energy Limited has completed over 100 significant projects in this vein by consulting for and partnering with some of New Zealand’s leading producers.

Among Mike and his team’s strengths are industrial robotics and automated production where the company puts much of its focus.

Sean O’Sullivan

Has a B Com (Hons) Otago University. In 2000 - 2001 introduced PCs on the workshop floor and job and staff tracking and a productivity software App to Fletcher Aluminium Group and 100 manufacturers NZ nationwide.

In 2001 – 2022 Founding Director Empower Workshop Productivity & Scheduling Software App. 236 manufacturing and engineering clients mainly throughout NZ and Australia, also UK and US.

Iain Hosie

Iain Hosie is a respected figure in the NZ Advanced Manufacturing and Materials sectors, with extensive experience in product development, research projects and commercializing tech products. Iain is a Director and Founder of Nanolayr Ltd, Director for the NZ Institute for Minerals and Materials Research, Commercial Director for Fabribotics Ltd, and Executive Council of BiotechNZ.

Rockwell Automation has partnered with cyber-physical systems protection company, Claroty, to release a white paper on safeguarding Australia and New Zealand’s industrial systems.

In the face of an ever-growing climate of cybersecurity attacks, operational technology (OT) security specialists bear the weight of safeguarding Australia and New Zealand’s most critical infrastructure. Ensuring uninterrupted essential services such as energy, food and beverage, healthcare, data processing, and mining industries demands utmost vigilance. However, the recent Rockwell Automation and Claroty survey of 42 C-suite executives and heads of security exposes a concerning truth – many OT systems remain exposed and vulnerable.

“A lot of the challenges organisations face today can be traced back to the fact that OT has traditionally been operated and managed as a separate entity from conventional information technology (IT) environments,” says Anthony Wong, regional director, South Pacific, for Rockwell Automation. The survey bears this out with 26% of respondents admitting that there is a low or medium level of collaboration between OT and IT, and the two units could do better.

“Increasingly, cybercriminals are exploiting sometimes lax OT security as springboards to launch a wider attack across an organisation,” says Wong. For example, a recent cyber-attack on a major Australian meat packing company, forced the temporary shutdown of 47 sites across Australia and a ransom demand of $14.2 million.

Key Findings: A Wake-Up Call

• 65% of respondents detected at least one OT-related cybersecurity incident in the last 12 months.

• 60% of cybersecurity leaders believe their budget is not enough to protect their operations

• 29% of respondents were concerned that an OT security incident could disrupt their production.

• 26% of respondents admitted having low or medium levels of visibility into the operations of their network.

• 26% of respondents worry that attacks could compromise the safety of their employees or others

• Just 14% of respondents feel well equipped to identify an OT cybersecurity incident.

The new white paper includes insights such as “With 30.9% of survey respondents citing compliance goals as a main driver for improving cybersecurity visibility – particularly in the energy and food service industries – it’s clear that the increased scrutiny of OT environments is spurring many businesses to action.”

A Disconnect Threatening Resilience

The survey reveals a significant challenge faced by companies – the ongoing disconnect between teams managing OT and IT systems. A quarter of respondents admit that their IT and OT business units are not collaborating as effectively as they should be. This lack of cohesion poses risks to the integrity, availability, and business continuity of critical infrastructures.

“Segregating OT and IT responsibilities used to be manageable because disconnected OT systems were seen as being functionally separate from mainstream systems. But with casual connectivity now built into nearly every device installed into corporate networks, these assumptions no longer hold true,” said Wong.

OT and IT systems can no longer be treated separately, and a greater collaboration between departments is required to meet cybersecurity standards, according to the new Rockwell Automation and Claroty white paper.

Securing the Future

To confront these pressing issues, it is imperative to bridge the gap between OT and IT teams and secure the infrastructure against relentless exploitation. Implementing full-spectrum IT/OT/Internet of Things (IoT) visibility and detection capabilities becomes essential to combat threats that transcend the IT/OT boundary.

Download the full white paper for more insights.

NZ Manufacturer September 2023 / www.nzmanufacturer.co.nz 12 SMART MANUFACTURING

Enable smarter production lines with the right connectivity

Thanks to technological advancements that realise the potential of Industry 4.0, factory operators are investing more resources into the development of smart factories for enhanced operational efficiency.

A recent study showed that the smart factory market is expected to grow 9.33% from 2021 to 2026. But before businesses can reap the benefits of smart factories, operators need to gain visibility of the production floor.

This means they need to deploy more sensors and systems at production lines so that engineers can collect sufficient information, develop analytics, and ultimately take appropriate actions and improve efficiency.

Developing a holistic view for your production lines requires different types of information. For instance, the production status of each production line informs you of how the line is performing and whether any potential or existing backlogs exist.

By monitoring the real-time production process, you can improve your chances of eliminating potential downtime and enhancing productivity. In addition, tracking the operating condition of machines can help you arrange maintenance tasks without unwanted surprises. Furthermore, additional sensors can be deployed in production lines to collect temperature and humidity information to help minimize the likelihood of interruptions due to environmental factors.

designed to serve production purposes reliably in your factories for decades, but they often come without network interfaces, or they only come with legacy communication interfaces such as serial.

Use sensors to capture production information for devices that do not have any communication capability or consider a serial-to-Ethernet solution to retrieve data from legacy devices.

• Monitor your production status from the control centre. Your production lines are usually controlled by engineers through a PLC and HMI located at the field site. When the central system also needs to control and monitor your production lines, they must be able to understand and communicate with the field PLC and HMI. However, machine vendors often adopt communication protocols that might not be compatible with SCADA systems. Such scenarios require a protocol conversion solution to enable communication between the SCADA system and the PLC and HMI in the field.

• Minimise impact from environmental factors. There are various kinds of sensors that can be used to measure environmental conditions, such as the temperature, humidity, and air pressure. These sensors come with multiple I/O interfaces and you need a remote I/O solution that can easily collect information. In addition, pay attention to the supported protocols for your remote I/O solution and choose the one that fits your SCADA system.

production control systems or have time-critical processes in your production lines, you can consider developing your networks based on time-sensitive networking (TSN), the standard Ethernet unified infrastructure, to deliver your commands to the right place at the right time.

Finally, deploying numerous network devices leads to tremendous installation and maintenance effort. This is something you should take into consideration because it is important that you should find an efficient solution that simplifies your networking management.

Don’t overlook cyberthreats

The growing number of cyberattacks targeting industrial applications in recent years has also made cybersecurity more important than ever. A recent survey showed that 4 in 10 manufacturers indicated that their operations were affected by a cybersecurity incident in the past 12 months.

No matter what kind of information you are planning to collect to achieve the goals of your ideal smart factory application, enabling smooth communication between production lines and the control centre can present major challenges for engineers.

Without a reliable connection and a solid network implemented between remote sites and the control centre, operators cannot receive complete and accurate data for comprehensive planning and optimising operational efficiency.

Here are some suggestions you can consider when enabling connectivity for your production lines:

Evaluate Your Connectivity Requirements Thoroughly

When enabling connectivity for your production lines, you need to know what communication interfaces and protocols your field devices use, as well as what systems these devices need to communicate with. The following three scenarios are commonly seen when getting started.

• Retrieve operating information from legacy devices. Your legacy machines are specifically

No matter what kind of scenario you encounter, the bottom line is there will be a variety of connectivity requirements that need to be fulfilled before you can receive data to improve your operational efficiency. You should carefully evaluate the connectivity options you have and choose the one that not only gets your devices and systems connected, but also enables smooth communication with minimal maintenance effort.

Deploy a reliable and flexible network for real-time monitoring

Enabling a smarter production line requires stronger network capacity and better visibility. When planning your network communication, carefully assess your demands on transmission bandwidth, network control capability, and manageability for each network node.

First, calculate your network bandwidth requirements. Connected production lines generally deploy more sensors and systems that generate substantially more data. Huge amounts of data not only require sufficient transmission bandwidth, but also need redundancy to avoid packet loss due to unexpected network downtime.

Second, your networking devices require support for communication protocols at both the field site and the control centre in order for engineers to monitor and take actions in real time.

In addition, if you are developing adaptive

Threats are everywhere, including unauthorised access, unwarranted programs, and denial-of-service attacks that could lead to disruption of a production line.

To mitigate security concerns, the first thing is to verify the security level of your networking devices. Use a checklist to verify if you are choosing a product that is secure-by-design in the first place.

In addition, network segmentation is essential to slowing down threat propagation in the event of an actual cyberattack. Ultimately, it is crucial to remember that security is a journey, not an one-time event.

Constantly monitoring your devices and security status and performing vulnerability scans on a regular basis can give you more control over your security posture before mitigation is required.

As a leading expert in industrial networking, Moxa has helped customers around the world develop smooth and secure communication to control and monitor their production lines. Download our case studies and see how other companies develop communication systems for their production lines with Moxa’s solutions.

Need help selecting connectivity or networking products for your project? Download our E-book and learn about the key criteria for choosing the right products for your needs.

Moxa Inc.

www.moxo.com

Acelink www.acelink.co.nz is the representative for Moxa in New Zealand

13 www.nzmanufacturer.co.nz / NZ Manufacturer September 2023 SMART MANUFACTURING

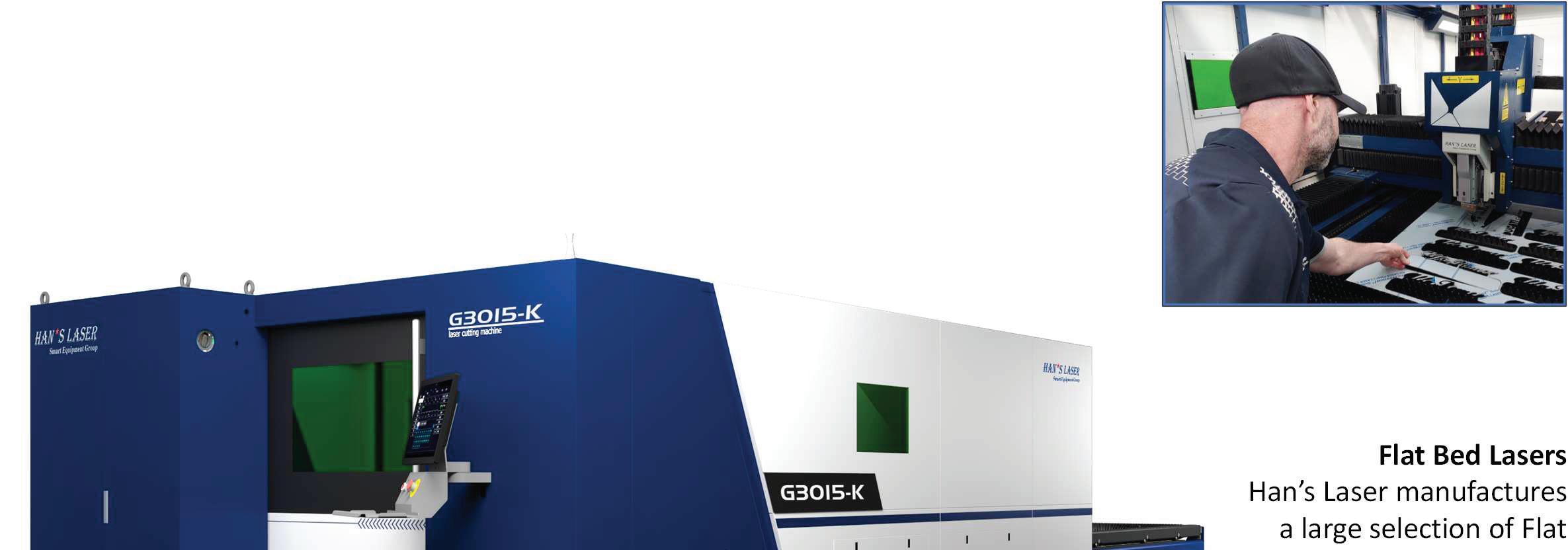

LEABOURN & ROSE & HANS LASER

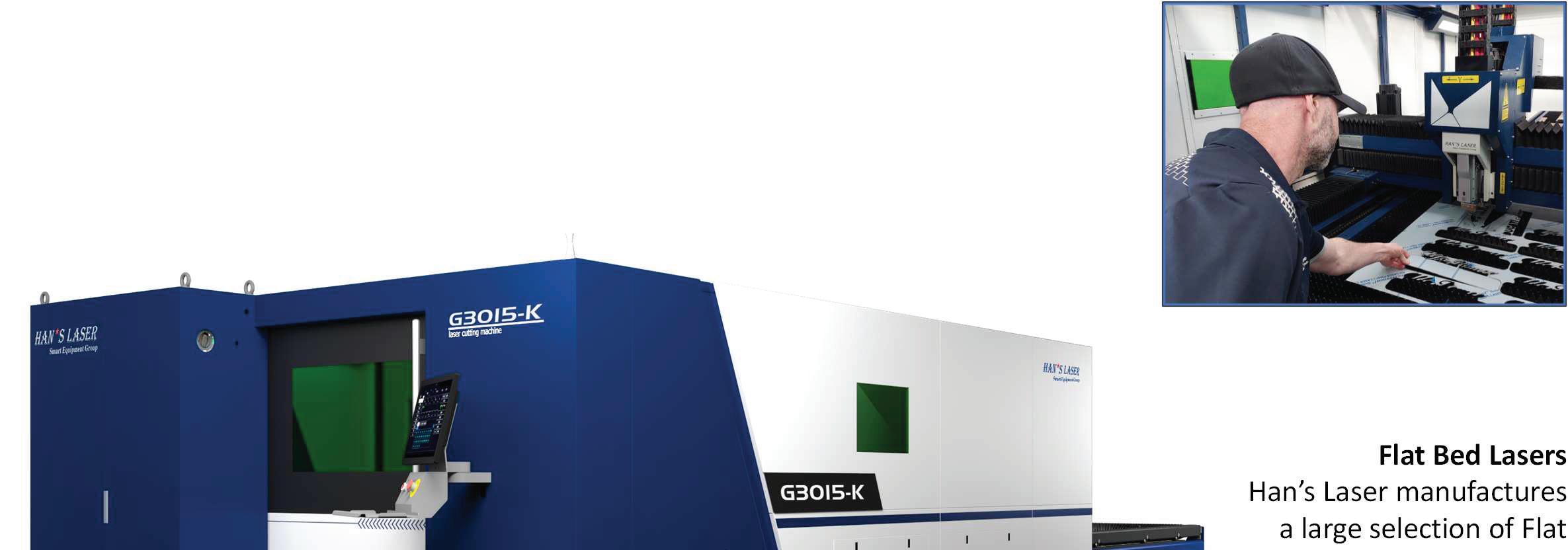

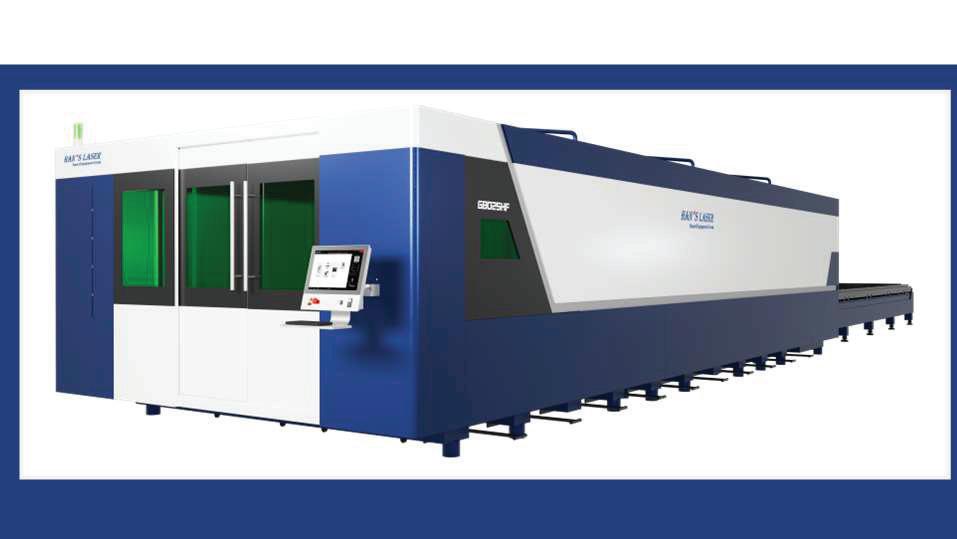

Han’s Laser has a solid 27 years of laser manufacturing experience. Established in 1996, Han’s Laser is now described as the world's largest laser equipment manufacturer. Han's Lasers success is its fully vertical integrated manufacturing process. Producing and testing all core components internally, starting with the integral welded frame that is stress relieved. The laser head is machined inhouse and assembled in dust free medical grade rooms; the CNC controller is self-developed; and in 2016 they purchased 100% of the Canadian laser pinnacle, CORACTIVE.

Leabourn & Rose is a company that backs up what it sells. It is supported by 45 years of machine tool knowledge, technical expertise, and quality brands –and that makes a big difference. We don’t just sell you a piece of equipment, we will assist you in implementing a solution that will help you to increase efficiencies, reduce costs and increase productivity. We will help you get the right machine, and ourexceptional team will support you every step of the way.

Han’s Laser manufactures a large selection of Flat Bed laser cutting machines options with models ranging from 3kW to 50kW. They offer an exceptional balance of high cutting quality, fast cutting speed, high production efficiency, and low production costs.

O f f e r i n g yo u f u l l t u r n key l a s e r c u t t i n g s o l u t i o n s

With Han’s precision laser cutting technology and Leabourn & Rose’s technical expertise you can be assured you will receive the best innovative solution for your present & future requirements

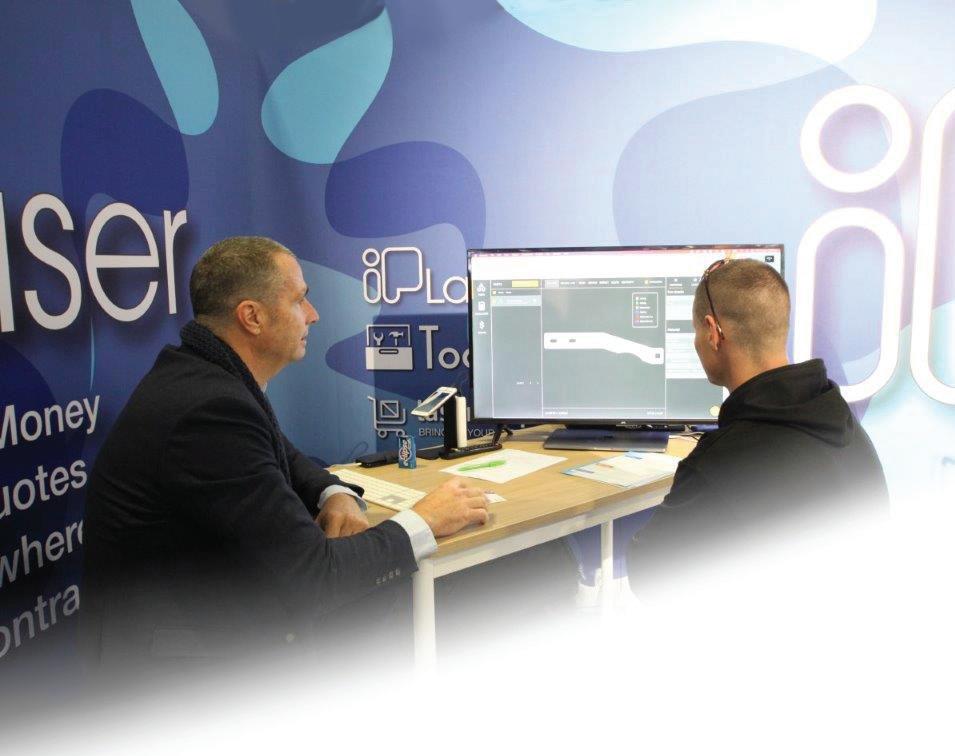

Technical engineer Lance Abernethy inspecting the laser cut quality performed on the Han’s Laser G3015F-3kW flat bed laser.

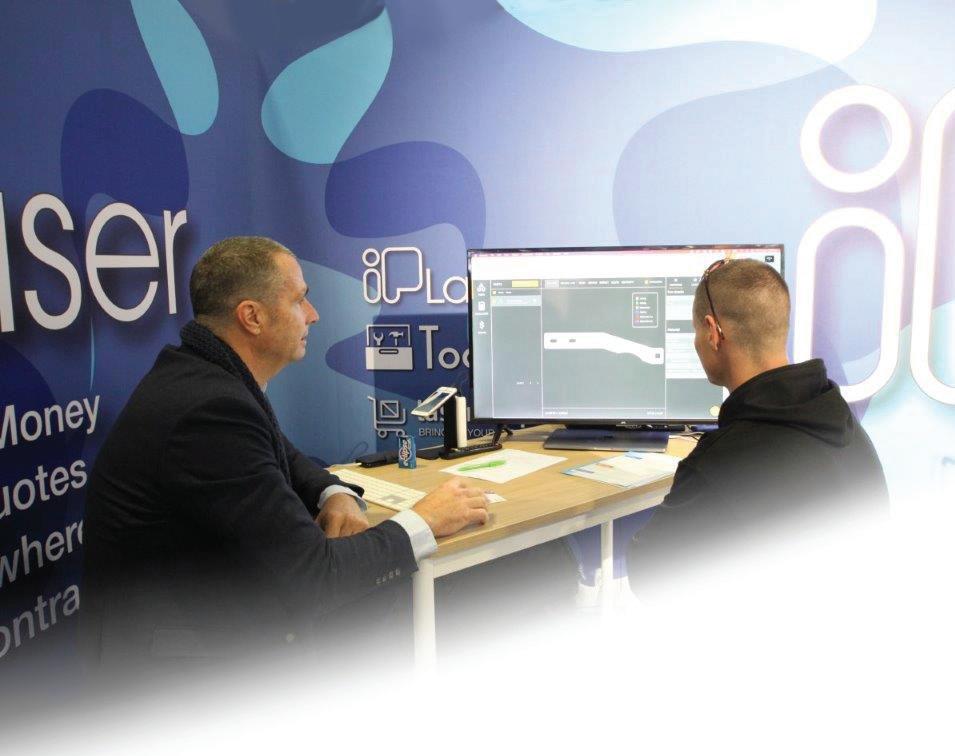

Technical manager Wei Shi and technical director Andrew Leabourn reviewing the Han’s Laser software programme.

Automation production line, seamlessly connecting multiple laser cutting machines and Implementing a comprehensive automatic loading and unloading system.

Automation Production Line

Han’s Laser cutting automatic production line signifies a significant advancement in the sheet metal processing industry. By seamlessly connecting multiple laser cutting machines and implementing a comprehensive automatic loading and unloading system, this innovative solution has revolutionized productivity, precision, and cost effectiveness.

Tube Lasers

Han’s Laser tube cutting series stands out as a cutting-edge high-tech product. Han’s offers models for cutting pipes, RHS, angle iron and “H” profile from Ø20mm to Ø500mm in carbon steel, stainless steel, or aluminiumalloys. Compared to traditional methods of cutting and drilling pipes, the Han’s Laser tube cutter can save an impressive 50% to 90% of processing time.

Han’s Laser Controller & Nesting Software

The self-developed Han’s Laser CNC controller is intuitive and powerful, it utilisesa digital EtherCAT(Ethernet for Control Automation Technology) system to allow real-time control of the servo motors. The speed of this communication link is essential to maintain accuracy and repeatability at the high acceleration and high traverse speeds the Han’s Laser moves at.

CORACTIVE Laser Source

100% owned by Han’s Laser Group but still manufactured in Canada with CE certification. The CORACTIVE laser source boasts world leading wall power efficiency of 36.5% and beam stability < ±1% on full load working conditions. CORACTIVE self-developed back-reflection isolator absorbs 99% of back-reflection, delivering unmatched capability on highly reflective material cutting. The CORACTIVE laser source exceeds the quality, reliability, and performance of other brands.

Safety Requirements Met

The Han's Laser machine covers off safety concerns, they include enclosed cutting zone, power stabiliser, light curtain protection around the change table, and a Donaldson fume filter.

G8025HF-50kW Flat Bed Laser

w w w. l e a b o u r n - ro s e .c o. n z P h : ( 0 9 ) 2 74 6 1 8 6 8 7 S p r i n g s R d , E a s t T a m a k i , A u c k l a n d

Tube Laser with Semi Automatic Loading

Wellington company showing the way for low carbon

The drive for low carbon has rapidly become a focal point for Aotearoa’s construction sector, where the most forward-thinking and innovative operators are partnering with other experts to decarbonise in ways that also deliver biological, ecological, and social co-benefits.

One company showing the way is Wellington-based volumetric offsite manufacturing company Niche Modular Construction, whose technical manager Nico Patchay spoke to HERA’s CEO Troy Coyle on the Stirring the Pot podcast about the business’ adoption of HERA’s Zero Carbon Steel program, H taka Whakakore Puhanga Waro, which launched last year in a global first for the construction sector.

The offsetting program means there is now a zero-carbon steel option for most steel products used in Aotearoa, noting that the sector has a number of other decarbonisation initiatives in play, including the recently announced plans to construct an Electric Arc Furnace at New Zealand Steel.

The program is supported by the work of thinkstep-anz, which HERA commissioned to develop robust program rules to determine the underlying requirements for calculating the emissions for offsetting. HERA’s partnership with Ekos, a leader in carbon management and environmental financing, underpins the administration of the offsetting process, and offsets are sourced from native forest projects in the Pacific Islands.

Niche Modular Construction was the first company to use HERA’s Zero Carbon Steel program, and is utilising the carbon offsets to reduce the net emissions of its steel modular building projects, which are primarily classroom buildings. Niche operates in both the public and private sectors and is also exploring the potential application of offsets in modular apartments. Niche currently utilises around 15 tonnes of steel in its builds and has its own engineering department that handles all aspects of the structural steel components.

Niche Modular reports the additional costs of using Zero Carbon Steel have been manageable; it bears the expense of offsetting rather than transferring this to the customer.

Nico Patchay happened upon the zero-carbon program on the HERA website while doing research for a tender process. “We were looking for a solid

way to prove our carbon reduction processes, and the program was perfectly timed for us. We’ve adopted it as another process that we can add to our tool belt along with the other sustainability initiatives we have.

“We are using the program as part of our front-end process as a volumetric modular company. Because the modular system doesn’t change often, it’s fairly straightforward for us to adopt a process or program such as this to apply to various projects and use repeatedly.

“How it works is that each volumetric module has its own data that we input into the program – we set it up like a spreadsheet and continuously input the data into the program based on the build-up of that particular project and its total modules.”

Based on Niche’s experience, Nico advises that HERA’s associated instructional resources are helpful. “The process has very useful instructional videos on what to do, and we watched them and broke down into parts what we needed to do and how we would achieve each step. My advice would be to treat it as a project – establish a timeline, establish your resources, and start to build a method of how you’re going to, first, generate the data and then input the data.”

Overall, Nico says, the program has allowed Niche to achieve and demonstrate its environmental responsibility to clients. “This tool forms part of our wider carbon reduction strategy. And it’s also given us the ability to get buy-in from other stakeholders, such as our architects, engineers, and suppliers. We can say, ‘We use steel, and this is what we’re doing to mitigate the embodied carbon’.”

Regarding the resources or roles that businesses interested in the Zero Carbon Steel program might need to dedicate,Troy Coyle says, “From an organisational point of view, it is important that a business considers the benefit of creating roles that are specifically focused on achieving sustainability-focused outcomes in their mahi.

“Alternatively, as a competitive advantage or point of difference offering, they can look to upskill existing roles that overlay with procurement and costing of projects to understand the potential of including sustainability metrics in the works they are bidding on.”

Other options for businesses are to become Sustainable Steel Certified via the Sustainable Steel Council, and to start thinking about calculating their operational carbon footprint as a first step towards achieving carbon neutrality.

Nico expects there are wider benefits still to come, and notes that offsite manufacturing is already ahead of the low-carbon curve in the sector. “It inherently has low-carbon qualities just through the construction process, but we also have internal processes such as high recyclability and robust processes for recycling where we build in the factory – that comes with very low waste, and very low water consumption.

“Looking at the innovation horizon, we want to continuously improve our system. As a volumetric modular solution, I think we’ve got a great product, but there are always new technologies to help us. At the moment I’m actively working on coming up with a standardised approach to lifecycle assessments and environmental product declarations. We’re also looking at overall circular economic opportunities with certain material suppliers.

“I’m looking into digitisation and using more building information modelling methodologies, which will really help if we can input them into some of our carbon reduction strategies – not just with our data recording but also forecasting where we’re going and continuously benchmarking and reducing.”

Dr Coyle expects more organisations to start to follow Niche’s example not only because pursuing carbon neutrality is the right thing, but because it illustrates the applicability of solutions at every stage of a company’s lifecycle.

“Some of the decision-making is still coming down to cost, but increasingly we will see it as standard, rather than an option. At the minimum, Niche’s progress demonstrates steel as a zero-carbon option through offsetting and helps to dispel misconceptions and misinformation around steel’s sustainability credentials. The education piece is critical in getting our industry to that tipping point, and when organisations are ready, they will find the support and tools are there.”

For more information on Hotaka Whakakore Puhanga Waro and to access the Zero Carbon Steel program, visit https://www.hera.org.nz/ sustainability/zero-carbon-steel/.

text title NZ Manufacturer September 2023 / www.nzmanufacturer.co.nz 16 COMPANY PROFILE

Nico Patchay

NZ lagging with health and safety

By Adam Sharman, Senior Partner, dsifer

A recent report by the Business Leaders’ Health and Safety Forum shows that New Zealand continues to lag behind the rest of the world when it comes to health and safety in the workplace. Of course, the $ value impact is just one impact resulting from workplace fatalities, injuries and poor health.

In our work with organisations and industry bodies, we see that the top performing organisations consider workplace health and safety across an ecosystem of considered, human centric job design, environment design and culture & leadership dimensions. This is not something that can be fixed through a policy document of lines in an annual report.

As a starting point, our analysis with organisations we work with identifies 1. Insufficient training, 2. Fatigue or burnout induced by poor work design and high levels of overtime, and 3. Cultural complacency as being the most significant contributors to poor health & safety performance.

Of course, it is not as simple as just saying, let’s just fix these priority factors; for sustainable change, a data-driven approach to identifying and addressing their underlying drivers as an ecosystem should be applied. For example, organisations, especially manufacturers, are struggling to attract the number and calibre of talent they need to run their operations, leading to high levels of overtime as the current workforce picks up the slack. A data-driven approach to the analysis.

For the highest impact, organisations should apply data analytics to three key dimensions of health & safety:

1. Complete, accurate and timely data capture. The accurate and timely capture of H&S data forms the baseline of understanding the true picture of an organisation’s H&S performance. Whilst this may seem obvious, it is surprising how many organisations do not accurately capture data on their H&S incidents, beyond those that result in injury. Complete H&S data should capture all relevant data required using a methodology (whether online or offline) that reduces data quality risk through non-compliance error.

2. Combine data sources for deeper insights. With a baseline of complete, accurate and timely data, analysis can be conducted through combination of data sets to provide deeper insights in to underlying drivers of H&S incidents and trends. Combining H&S data with workforce planning data, for example can identify relationships between job design dimensions, such as shift patterns, and H&S trends. These insights can support targeted prioritisation of intervention activities and resources for maximum impact.

3. Communicate the impact. The insights gathered through combining quality data sources support the analysis of the organisational impact resulting from poor H&S trends. Identifying the commercial

and/or productivity impact of negative H&S performance, can support sponsorship and change management activities that drive support for H&S interventions and catalyse sustainable behaviour change.

Of course, the rationale for supporting improvement in H&S performance for the purposes of improving individual health, safety and wellb eing is worthy enough in isolation of any organisation performance impact. However, it can’t be ignored that customers and investors are increasingly prioritising Environmental, Social and Governance (ESG) factors in the purchasing and investment decision analysis, including evidence that an organisation is taking care of its employees. As such, the imperative to focus on H&S performance is not just a zero-harm initiative, it is a strategic imperative.

A holistic approach using evidence-based decision making to understand the true root cause drivers of negative health and safety performance, combined with leadership that is genuinely committed to improvement in this area is the only sustainable approach to turning these statistics around.

17 www.nzmanufacturer.co.nz / NZ Manufacturer September 2023

ANALYSIS

Adam Sharman

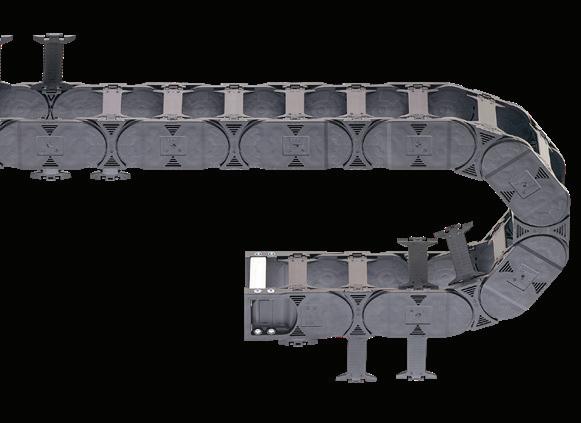

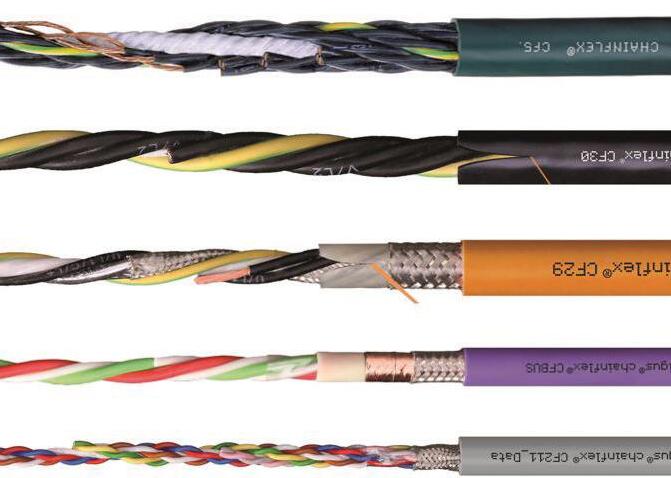

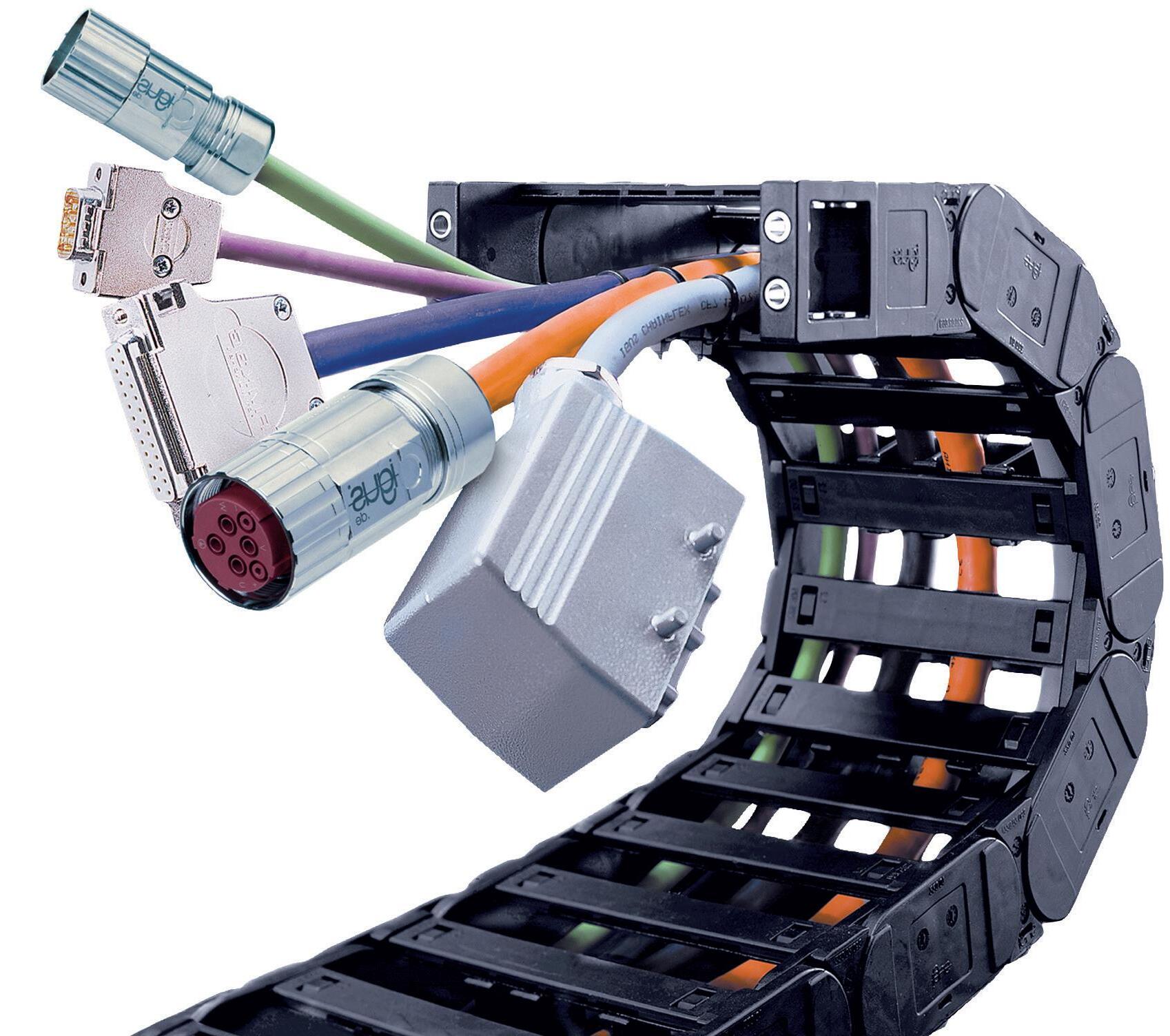

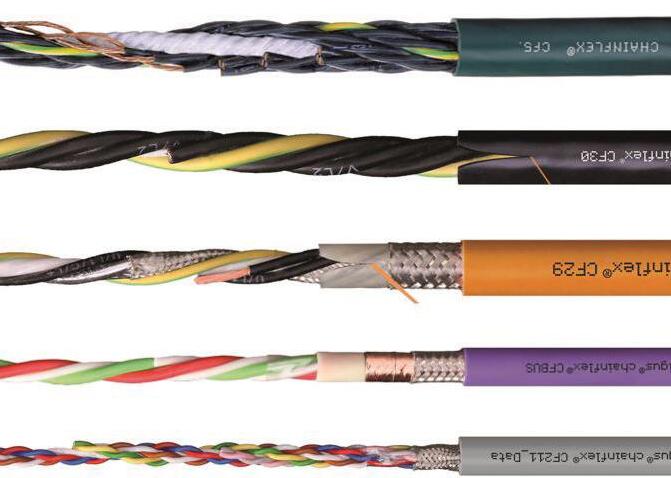

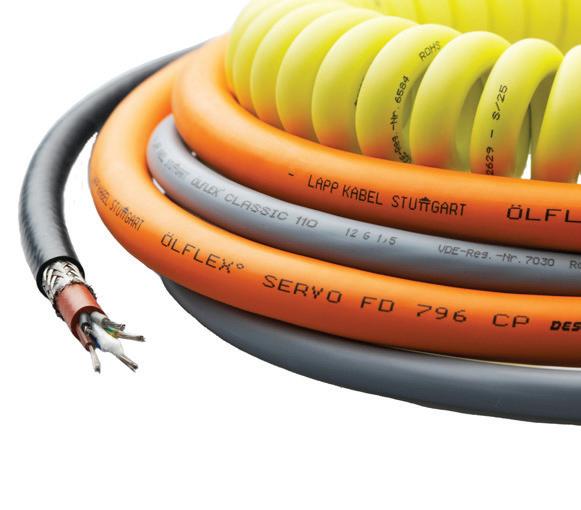

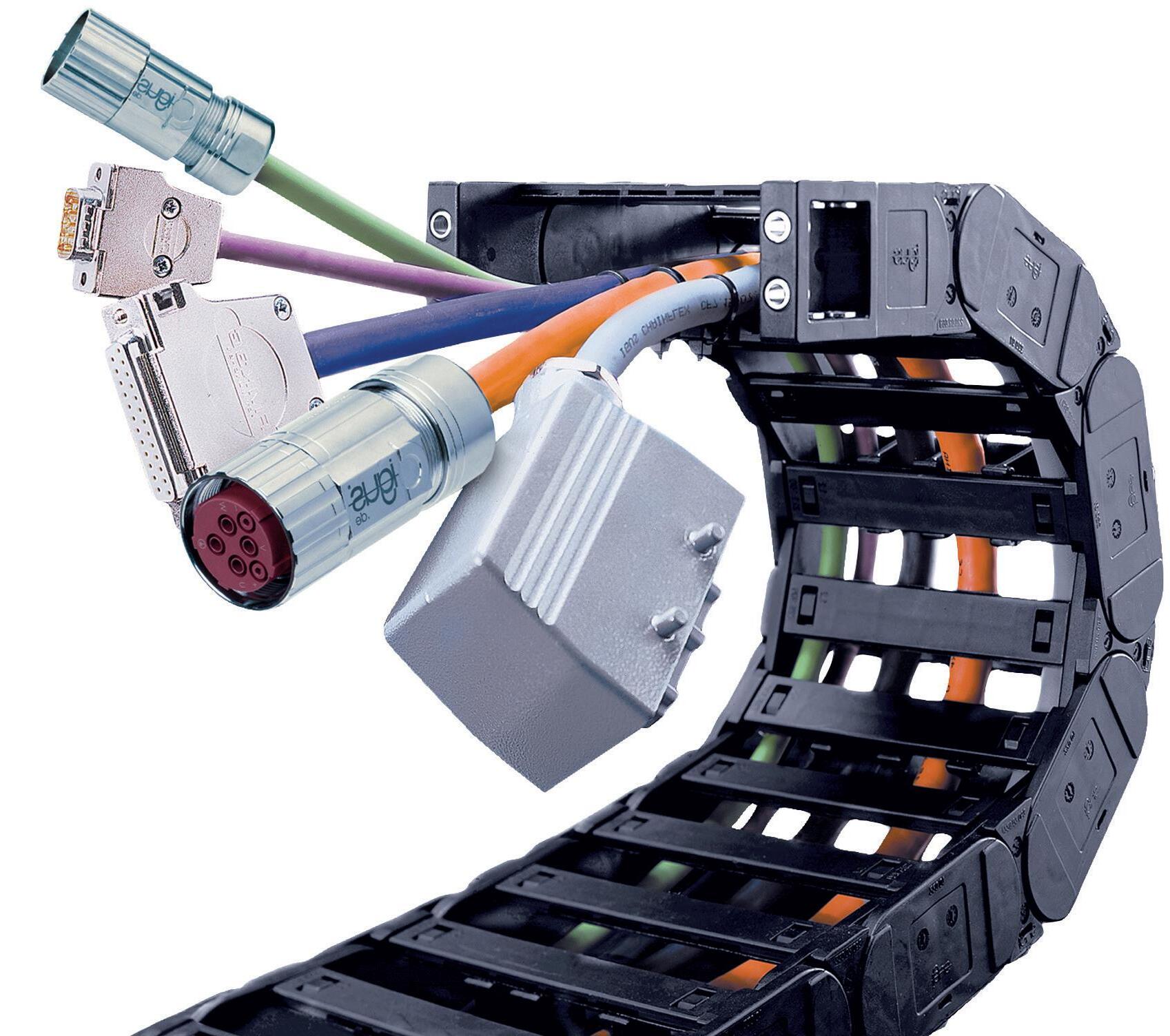

The leading supplier of high quality components and products to industrial markets

Treotham Automation is the exclusive distributor for many world class international product lines. As a leader in automation control, Treotham have a broad capacity to provide systems and custom-built solutions using a diverse range of products and components. Contact our technical engineers for more information.

NZ Manufacturer September 2023 / www.nzmanufacturer.co.nz 18

Auckland & Hamilton | 0800 847 200 | www.treotham.co.nz | info@treotham.co.nz CHECK OUT OUR NEW WEBSITE www.treotham.co.nz

Conduits Chainflex Cables Energy Chains

Accessories

boxes

Units

Connectors Safety Products

Flexible Cables Measuring Systems Flexible

Cable

Gear

Bearings Linear

Sensors

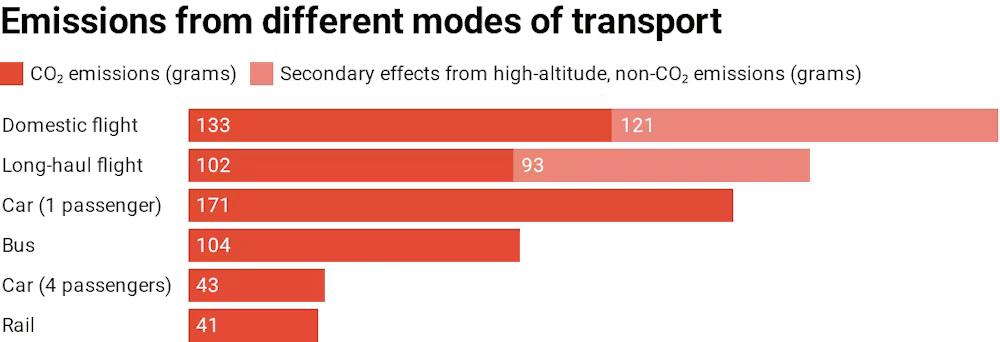

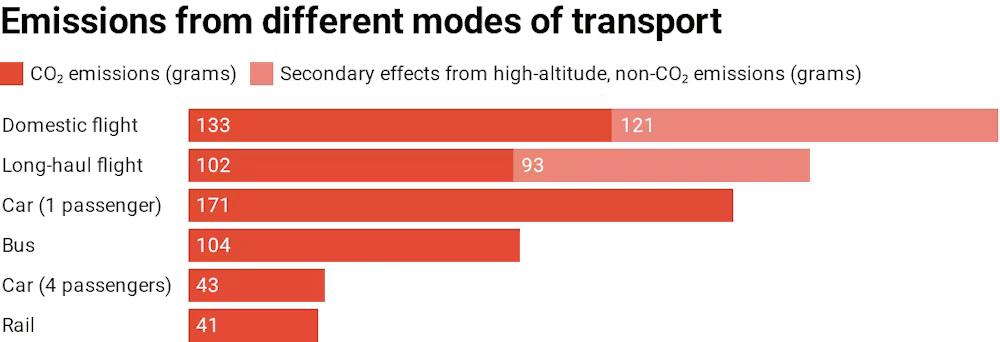

Serious about reducing your carbon footprint? Read on!

Chances are you’re already talking about carbon – and climate change too. If not, you need to start!

But when you’re a busy manufacturer, getting to grips with carbon can be daunting, we know. So in this first of two articles, Head of Carbon at thinkstep-anz Nicky Andrews explains how to get started and keep making progress.

for a business that takes climate action seriously. Finally, because winkling out carbon involves delving into everything you do, you’ll spot opportunities to reduce your costs.

What are the three Scopes (types) of emissions?

The international Greenhouse Gas Protocol is one of the standards that govern how organisations measure and reduce their carbon emissions. The Protocol splits carbon into three groups (Scopes).

Diagram of the Scopes: thinkstep-anz, based on

Step one: identify your main sources of emissions

Scopes 1 and 2

Look at the main activities that generate these emissions. Your Scope 1 GHGs may come from fuelling your vehicles with petrol and diesel, powering your factory with natural gas, and cooling your operations with refrigerants. Your Scope 2 emissions are likely to come from running your operations on electricity.

Scope 3

Nicky Andrews, thinkstep-anz Head of Carbon

Understanding carbon emissions

What are carbon emissions?

‘Carbon emissions’ is shorthand for ‘greenhouse gas emissions’ (GHGs) – the gases that are trapping heat in Earth’s atmosphere and warming our planet.

There are many types of GHGs. Common ones include carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O).

Why do manufacturers need to reduce carbon emissions?

You’ll be helping to keep global warming to below 1.5°C and meeting the goals of the Paris Agreement. There are many good business reasons, too, for manufacturers to tackle carbon.

How does my business benefit from reducing emissions?

First up, you’ll reduce your risks. For example, if the government introduces a carbon tax, you’ll be prepared.

You’ll strengthen your brand. Customers may already be asking what you’re doing to reduce your emissions. That’s because they (and their customers) are increasingly seeking lower-carbon products.

You’ll strengthen relationships. For example, you’ll keep your investors happy if you manage your emissions (and their money) carefully. Your team will value your efforts too. Many people want to work

International Greenhouse Gas Protocol.

Scope 1 emissions are direct emissions. They come from day-to-day activities like fuelling your vehicle fleet with diesel.

Scope 2 emissions are indirect emissions. They come from the electricity you purchase to run your factory and the heat, steam and cooling you buy.

Scope 3 emissions are also indirect emissions. They may be your biggest group of emissions but they’re ‘hidden’ in your value chain. (These are the processes that add value to your business, like funding your operations and designing, producing, transporting, and marketing your product.) There are 15 categories of Scope 3 emissions.

How do we measure carbon emitted?

Some gases warm the earth’s atmosphere more than others. To keep things simple, we measure the impact of different GHGs as equivalents of carbon dioxide (CO2e). For example, methane is 28 times more powerful than carbon dioxide at warming the atmosphere so 1kg of methane equates to 28kg CO2e.

Reduce your carbon emissions in three steps

There are three steps involved: identify your main sources of emissions; measure your emissions; reduce them. This article explains the first step.

Start by ‘screening’ your emissions to find the sources of carbon that are most relevant to your business and most material in size. Use the free thinkstep-anz Scope 3 Explorer. These sources are relevant to most manufacturers. Category 1 (purchased goods and services) covers the carbon in your raw materials. Category 4 (upstream transport) and Category 9 (downstream transport) account, respectively, for the carbon involved in transporting raw materials to your factory and delivering products to your customers.

Category 12 (end-of-life of sold products) measures the carbon your product emits at the end of its life. While every product has an ‘end of life’, this category is more important for some products than others. For example, paper, wood and food emit carbon in landfill. Plastic is relatively inert.

Some categories are relevant for some manufacturers only. Category 10 (processing sold products) is important if you manufacture an intermediary product like plastic resin. Your customers generate carbon when they make their own products from the resin.

Category 11 (using sold products) comes into play if your customers draw energy to use your product. For example, if you manufacture toasters, your customers use electricity to brown their morning toast. The design of your product influences how much electricity they use.

The nature of your product determines which categories matter most to your business. To gauge the size of your GHGs, you’ll need to consider (among other things) what your product is, what it is made of and how customers use and dispose of it. That’s the theory lesson done. Next month we look at the practice: how to measure your carbon emissions and how to reduce them.

www.thinkstep-anz.com

19 www.nzmanufacturer.co.nz / NZ Manufacturer September 2023

SUSTAINABILITY

Feeling the heat

~ The importance of temperature regulation in heat transfer ~

The temperature of the office is an ongoing debate. Employers often search for the optimal temperature to ensure employees are comfortable and productive, but did you know there’s also an optimal air temperature for industrial facilities?

Here Dave Dyer, technical sales engineer at thermal fluid specialist Global Heat Transfer, explores the importance of air temperature when operating heat transfer systems and how to regulate it effectively.

Temperature control is essential for any manufacturing environment — changing temperatures can have a significant impact on processes, products and people. Some applications, such as food, chemicals, plastics or pharmaceuticals manufacturing, require heating for production. Manufacturers in these industries must consider not only how the temperature of circulating fluid will impact product quality, but how it will impact the entire facility.

Health and safety teams should monitor air temperature to ensure it does not negatively impact employee productivity or safety. Working in higher temperatures for longer periods of time can lead to fatigue, increasing the risk of illness while reducing personal productivity.

Working around hot, uncovered equipment, also increases the likelihood of injuries such as burns. In order to remain compliant with health and safety legislation, companies must find ways to reduce the health and safety risks of working in facilities with heat transfer fluids.

Hot equipment

While employee safety is paramount, engineering managers should also monitor air temperature to ensure that equipment remains operational — as equipment overheats energy consumption increases and equipment efficiency decreases. While a thermal fluid system is built for indirect heat transfer, exceeding the intended operating temperature can negatively impact productivity. One area that can be particularly affected is the expansion tank, a critical component that allows hot thermal fluid with the space it needs to expand, which when heated can be up to 20 per cent of system volume.

To allow for this as well as provide a sufficient safety factor, the expansion tank should always be approximately a third full when the system is cold. When the system is at full working temperature, the level in the expansion tank where oil hits the atmosphere should not exceed 60 degrees Celsius. If the tank exceeds 60 degrees, the oil inside will oxidise, leading to a build-up of acid and carbon (as seen in figure 1). Over time this will reduce the heat transfer efficiency of the equipment and could lead to costly downtime.

Keep it covered

Investing in correct, and properly installed insulation is the best way to regulate air temperature in the facility, control the temperature of equipment and better protect employees.

Insulation ensures that heat created in the manufacturing process does not heat up the facility elsewhere, enabling manufacturers to ensure the air temperature is consistent. Insulating parts of the system also means that manufacturers can better regulate the

temperature of equipment that must operate at specific temperatures, such as the expansion tank. When choosing insulation for a heat transfer system, manufacturers should consider what material best suits the application. During its lifespan, a heat transfer fluid will degrade. The degradation process introduces by-products into the fluid, such as carbon that forms inside (as seen in figure 2) and acid corrodes unseen parts of a thermal fluid system. If this continues without intervention, small holes can appear in the coil (as seen in figure 3), allowing fluid to leak, posing a fire hazard. Thermal oil would soak into porous insulation, increasing the risk of fire and other hazards, so using a non-porous insulation, such as blown glass, works best in areas of the system where fluid could leak, including flanges.

Further benefits

While insulation is key to improving conditions for employees and equipment, there are added benefits. Insulation prevents heat from escaping, improving heat transfer efficiency. Over time, manufacturers will find that less energy wasted from heat escaping will reduce energy usage in the facility while also reducing the carbon footprint of the process. Finding the correct temperature for a work environment is not easy. For example, in a 2018 survey by CareerBuilder, 46 per cent of workers said their office is either too hot or cold. While offices continue to argue over the thermostat for employee comfort, it is clear that manufacturing facilities must take better action to regulate temperature. Regulating air temperature can prevent health and safety risks, reduce the risk of downtime and improve equipment efficiency.

For more advice on insulating thermal fluid systems and other factors relating to regulatory compliance, speak to the experts at Global Heat Transfer by visiting www.globalhtf.com/heat-transfer-management/.

Visualisation for Visionaries

NZ Manufacturer September 2023 / www.nzmanufacturer.co.nz 20

PROMPT ENGINEERING

Design, test, and deploy applications directly from a web browser

Callaghan Innovation launches counselling service for startup founders

Plans for the service were announced at the Electrify Aotearoa conference in August at the same time as the organisation launched a guidance and resolution service for any startup founder who has experienced inappropriate behaviour within the startup ecosystem.

The findings of an online survey of 258 startup founders in New Zealand conducted by Horizon Research was commissioned by Callaghan Innovation to gain insight into the types of issues impacting the mental wellbeing of founders and to better understand what kind of support could help them.

“We have looked at global trends and anecdotal evidence on founder wellbeing but there is limited local data available,” says Callaghan Innovation Chief Executive Stefan Korn. “The work done by Horizon Research gives us some further insights into the state of founder wellbeing in Aotearoa.”

Creating a startup is inherently difficult, and the Horizon Research report indicates that startup founders in New Zealand are indeed feeling the pressure, with 87% of respondents reporting that being a startup founder can have a negative impact on their mental health.

Seventy per cent said that they have had anxiety, 55% have experienced burnout and 31% indicated that they had depression.

To provide some international comparison, research published earlier this year by founder advisory Startup Snapshot revealed that 72% of overseas founders felt that running a startup had a negative impact on their mental health. Thirty-seven per cent reported feelings of anxiety, 36% had experienced burnout and 13% had depression.

While the results suggest that New Zealand founders are doing it tough compared to their peers overseas, 32% of respondents said that being a startup founder has had a positive impact on their mental health.

The Horizon Research respondents in New Zealand were asked if they would like to utilise an anonymous, free and confidential counselling service for startup founders whose mental wellbeing had been impacted by the pressures of operating a startup business. Fifty-three per cent of respondents said they would ‘likely’ or ‘very likely’ use this service. Callaghan Innovation will pay for startup founders who are struggling with the daily pressures of startup life to access three counselling sessions delivered by

leading employment assistance programme provider Benestar.

The service is for New Zealand-based startup founders who would like professional support for their mental health and wellbeing, and is being run on a trial basis until the end of 2023, at which time the service will be reviewed. It is available to all startup founders, regardless of whether they are a Callaghan Innovation customer or not.

The free counselling service complements Callaghan Innovation’s recently-announced guidance and informal resolution service, which is delivered through Aspen Restorative Consulting. That service is available to startup founders who have experienced inappropriate behaviour within the startup ecosystem. They do not need to be a Callaghan Innovation customer to take advantage of the service.

The launch of the service through Aspen Restorative Consulting is timely, as nearly half (49%) of respondents to the Horizon Research survey said they have experienced or witnessed inappropriate behaviour in the startup ecosystem. In the four weeks since its inception, 22 people have booked appointments.

21 www.nzmanufacturer.co.nz / NZ Manufacturer September 2023 STARTUPS

Callaghan Innovation has launched a counselling service to support founders whose mental health is suffering due to the significant pressures associated with establishing and growing a startup.

Looking for a marketing edge?

70% of licence holders say signing on has positively affected sales.

Miller Vortex HDV provides next level of welding respiratory protection

Protecting the respiratory health of welders during grinding and welding operations is crucial to ensuring a safe and healthy work environment.

In recent years, there has been a growing demand for respiratory protection that not only offers increased protection, but also enhances comfort and visibility while welding.

These advantages are particularly important within industries that use stainless steel, steel/manganese alloys, aluminium, galvanised steel in their production.

Depending on the process and filler metal used, some welding operations can create more hazardous welding fumes and contaminants than others across industries including mining and mineral processing, oil and gas reticulation sites, plus pipelines and vessels in industries such as water and wastewater and chemical processing, manufacturing, food and beverage processing, and metal fabrication, as well as tanks and vessels involved in bulk materials handling, primary industry, and process engineering.

Weldwell New Zealand has addressed this need with its latest innovation, the Miller Vortex HDV powered air purifying respirator (PAPR) System.

Designed to take respiratory protection to the next level, the Miller Vortex HDV PAPR System offers a range of features and exclusive technologies that set it apart from other systems, says Product Manager Aleksandr Koshelyev, who consults extensively with users of welding equipment concerning their industries’ particular and evolving needs.

Exclusive Miller technology

The Vortex HDV PAPR system standout is its HDV technology which provides a sharp, detailed view

at any angle with minimal distortion. This feature makes it easier for welders to see their work with increased visibility.

Other technologies include:

• ClearLight™ 2.0 which offers a second-generation view through the lens, providing advanced high-definition optics for a clearer, brighter, and more realistic weld view.

• “X-Mode is another benefit to welding operators. Designed for outdoor usage, it eliminates sunlight interference, as the lens only darkens when the welding operator strikes an arc. Described as game changing it’s also ideal for low amp TIG and out-of-position welding.”

• InfoTrack™ 2.0 technology is also exclusive to Miller, allowing users to track arc time and arc counts, as well as store and switch between two custom preset memory settings.

Stand out features

With comfort and visibility in mind, Miller’s Vortex PAPR system includes a lightweight blower unit. Only1362 grams, it provides long-term comfort so that welders can wear it for extended periods without causing strain.

While the large 174 x 126 mm integrated grind shield offers a larger, clear viewing area for grinding and other tasks.

From a productivity perspective, Miller have integrated a quick release one-piece HDV cover lens to simplify lens changes and reduce downtime, and a brighter 2.5 Light State so welders can keep their

hood down for improved safety and productivity. The system provides protection against solid particles, welding fumes and mists, making it an ideal choice to improve safety and reduce health risks associated with grinding and welding operations.

Six air distribution points ensure that the air is evenly distributed, providing maximum cooling and comfort, while the three air speeds allow the operator to control the volume of air to meet their work conditions.

The audible and vibrating alarm increases safety by notifying the user in noisy environments of low battery.