FOOD & DRINK PROCESSING & PACKAGING

CONVEYORS

BS Handling Systems delivers automated palletisation cells for Mindful Chef

Automatically stacking 12,000 boxes a day on pallets

BS Handling Systems delivers automated palletisation cells for Mindful Chef

Automatically stacking 12,000 boxes a day on pallets

Schmersal’s innovative DHS door handle system combines the functions of a robust door handle with the signalling of machine status via illuminated handle or push-button.

The door handle system is designed for use with the AZM40 solenoid interlock or with safety sensors from the RSS36 and RSS260 series or as a stand-alone solution. The illuminating handle signals various machine conditions over its area using seven different colours, enabling the user to control the colours individually to signal the machine status.

In addition, a push button is available, which can be individually adapted to customer requirements using the coloured push button caps. The pushbutton can be used for tasks such as a reset function or a request to open the guard door.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

Editor Amanda Buckingham editor@fdpp.co.uk

Business Manager Josh Holmes josh@mhmagazine.co.uk

Publishing

Digital Sales Manager

Jessica Bennett T: 01227 936971

Sales Manager Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971

Martin Holmes martin@fdpp.co.uk Studio Designer Leila Schmitz leila@mhmagazine.co.uk

M H Media Global Ltd. 18/20 Newington Road, Ramsgate Kent, CT12 6EE Tel 01304 806039 www.fdpp.co.uk

We were first to publish in 1991-2001 on mechanisms of PL sterilization/purification and as proven experts offer to develop your IPL applications with ready to ship systems as below:

IPL effectiveness increases proportionally its pulse power w/cm² & its UV content to the point where bacteria & spores are fully disintegrated.

now are discounted & spare UV flash lamps. info@wek-tec.de < automatic & analogue >

Our PL bench-top systems were used at many R&D labs and cited in various industrial and peer-reviewed publications.

IPL fully sterilises clear liquids in transparent packs as it was proven on our IPL system by Baxter Corp. (USA) with UV resistant spores of B. Pumilos.

Dual PEF Pilot to sanitize juices or to extract juices or colours from hard vegetative cells of grass, roots, etc.

The PEF pilot on the left provides a high-indemand dual capability by 3 sets of processing chambers

• coaxial PEF chamber for liquids with changeable gaps,

• colinear PEF chamber to form volume discharges in juices.

• 12L batch volume with controlled juice heating/cooling,

• flat PEF chamber with 14cm round ground and HV electrodes and a variable gap between both of 0.5-3cm.

and broad fixed & gradually changed pulsing:

• positive rectangular pulses 2,5-50µs at 4Hz to 500Hz;

• el. fields 5-65kV/cm by our 25kV 2kW pulser;

• pulsing time 1s-1h,

• convenient LED lighted control panel.

Please click on its photo to get its pdf brochure.

The brochure of its small table-top version is here.

PEF sterilizes juices by 1 of 2 different processes: 1: by electrical stretching bacteria only up to its ruptures or 2: by creating volume el. discharges in a co-liner chamber where free electrons destroy both bacteria and spores.

Details:

wek-tec systems have benefits of the German manufacturing

In today’s fast-paced landscape, packaging automation has become a cornerstone of efficiency and sustainability. Companies are increasingly adopting automated systems to streamline operations, reduce costs, and minimize environmental impact. Among the leaders in this field, NPP stands out with its comprehensive range of case handling and pallet wrapping solutions.

NPP are a proud Sales Partner for Lantech in the UK and Ireland. Partnering with leading suppliers like Lantech allows NPP to provide a range of packaging systems that can help businesses boost efficiency, improve load security, and achieve long-term cost savings.

Packing lines can be a bottleneck, but with Lantech’s advanced case handling solutions, businesses can automate their process for faster, more reliable results. NPP supplies a full range of Lantech case erectors and sealers, designed to handle various box sizes with precision and speed. By reducing manual labour and minimizing errors, these machines enhance productivity while maintaining flexibility to adapt to changing packaging needs.

NPP offers a range of stretch wrappers, from semi-automatic to fully automatic models, catering to the diverse needs of different industries. These machines ensure that pallets are wrapped securely, protecting goods during transit and reducing the risk of damage. Lantech’s patented features, such as the Load Guardian and LeanWrap technology, provide enhanced load containment and reduce film usage. This not only improves operational efficiency but also contributes to sustainability by minimizing waste. While the XT Cut and Clamp can save about two minutes of labour

per load by keeping drivers on their forklifts, thus enhancing productivity as well as safety.

A crucial aspect of NPP’s value proposition is their comprehensive service and parts support. Understanding that downtime can be costly, NPP offers a robust after-sales service to ensure their machines operate smoothly and efficiently. Their team of engineers in the UK are available to provide prompt assistance, minimizing disruptions to production.

With over 40 years of industry experience, NPP is a trusted packaging partner for businesses across food & beverage, agriculture, industrial, and pharmaceutical sectors. From advanced case handling equipment to innovative stretch wrappers and pallet wraps, NPP provides the complete package for businesses looking to optimize their packaging operations.

For further information visit www.nppgroup.co.uk or email sales@nppgroup.co.uk

Liverpool is a city that’s world famous for many things. Its music for a start (it’s the birthplace of The Beatles, of course, and many other great bands and artists), as well as its world-class football team, Liverpool FC.

But travel a few miles north of the city to Aintree, not far from the home of the Grand National, which attracts more attention globally than any other horse race, and you’ll find Food Test Lab, a truly world-class Liverpool business.

“Food Test Lab is an independent, UKASaccredited microbiological testing and chemical analysis laboratory,” explains Laboratory Manager, Cameron Finlay.

“Working for a wide range of customers, we provide ISO 17025-accredited microbiological, chemistry and nutritional testing and food analysis of a diverse list of foodstuffs and feeds.”

World-class laboratory

Food Test Lab’s accredited food testing and food analysis services enable its customers to meet safety regulations, achieve best practice and satisfy consumer needs. Microbiological Manager Jennifer Smith says: “Our highly qualified and experienced team of microbiologists uses the latest technologies and methods to provide accredited microbiological testing of foods, beverages, animal feeds and environmental samples.”

Food Test Lab’s purpose-built testing laboratory in Aintree, which opened in 2016, was designed to process a large volume of microbiological samples every day and results are delivered on time according to customer needs, no matter how demanding.

“We’ll always try to tailor our services to meet specific customer needs” Cameron smiles.

Chemical and nutritional analysis

“In addition to UKAS-accredited microbiological analysis, our food testing laboratories can provide detailed chemical analysis and nutritional analysis for food labelling,” Cameron adds. “Our nutritional analysis and chemical analysis services include moisture, fats and oils, proteins, sugars, sodium, fibre, ash, salt, carbohydrates, fatty acid profile, dietary fibre, energy value and Group I and II nutritional analysis.”

Cameron and his colleagues can provide fast turnaround times for groceries, cooked and raw meats, dairy products, processed foods and exports such as meat, fish, honey, milk, coffee, cocoa and beverages. “Our other food lab testing services include heavy

further information telephone Cameron Finlay or Jennifer Smith on +44 (0)151 525 1488 or email laboratory@alexstewartagriculture.com

metals – mercury, lead, cadmium and arsenic – as well as hydroxyproline, peroxide value, pH, Omega 3, 6, 9, trans fatty acids.”

International customer base

Food Test Lab is the trading name of the UKAS-accredited company Huson and Hardwick, which became part of the Alex Stewart Agriculture Group in 2004. Huson and Hardwick has an enviable reputation as a leading provider of ultra-reliable GAFTA and FOSFA-certified laboratory analysis. Almost 180 years since its formation in Liverpool, Huson and Hardwick continues to innovate and provide exceptional analytical and certification services via Food Test Lab.

Food Test lab also offers fully accredited test services to makers of pet food. As Jennifer explains: “Makers of dog and cat food are under pressure to ensure increasingly higher quality, so that they meet stringent safety and pet-owner requirements. We’re fully equipped to analyse a wide range of manufactured pet foods and our great technical expertise enables us to choose the right sample preparation method to ensure reliable results.”

AS FAR AS YOUR EYES CAN SEE: INFINITE OPTIONS FOR PACKAGING FOOD. BROUGHT TO LIFE WITH SCHUBERT.

Being flexible is good, being fast and flexible is even better. Schubert packaging machines are leading the way. Intelligent control and precise robotics can now replace complex mechanics to ensure maximum flexibility in all packaging processes. In fact, 80% of the leading FMCG companies count on us and our flawless packaging combined with the lowest possible consumption. In line with our Mission Blue Sustainability Initiative: A winning proposition – for our planet and for you. www.schubert.group/en/food.html

The best way to keep your forklift fleet in optimal condition and to ensure maximum efficiency and productivity is by maintaining a strict regime of maintenance and repair. This regime must start with you and your operators!

Over and above any planned routine maintenance and thorough examinations you may have in place with a supplier, it is vital that a documented pre-shift check is done daily. It is just as important to have a system of reporting any defects and a process to ensuring the faults are fixed in a timely manner.

This will ensure the safety of your operators and make sure you get the very best out of your truck.

(Provision and Use of Work Equipment Regulations 1998 (PUWER) Regulation 5 applies to all work equipment.)

1. Every employer shall ensure that work equipment is maintained in an efficient state, in efficient working order and in good repair.

2. Every employer shall ensure that where any machinery has a maintenance log, the log is kept up to date.

So, what should you be checking?

Following the manufacturer’s instructions, the following checks should typically be carried out:

1. Wheels and Tyres - Check if there is any damage to the tyres - Nails and other embedded material, cuts and bubbles (pay attention to the side walls)

- Check the tyre pressures on pneumatic tyres and the thread depth, they should not be excessively worn - Check the condition of the wheels, particularly the flanges on rims fitted with pneumatic tyres and the tightness and security of wheel nuts.

2. Brakes - Like all other vehicles it is important to check and test the brakes - parking brake, service brakes and steering gear to ensure they are working efficiently.

3. Internal combustion trucks - check the fluid levels - fuel, water, engine and transmission oils.

4. Electric trucks - check that the battery is adequately charged and leak free, the charger is switched off and the charge lead disconnected and properly stored, and the battery retention device is in place.

5. Forks: Check the forks for cracks particularly on the heels and mounting hooks, check that they aren’t bent or have damaged fork tips and missing or damaged fork positioning locks and that the forks are lifting and tilting properly. Don’t forget to ensure attachments are working properly (if you have any).

6. Forklift Chains & Fixing Bolts play a crucial role in lifting heavy loads, and even minor damage can compromise their strength. Are the chain links in good condition? Any signs of wear, stretching, or cracks could indicate weakness. Is there excessive rust? While some surface rust is normal, deep corrosion can weaken the chain. Are the chains well-lubricated? Proper lubrication reduces friction and extends the lifespan of the chain.

7. Hydraulic cylinders, valves and seals, are vulnerable to the ingress of dirt. This dirt can cause components to deteriorate and fail. It is therefore important to inspect hydraulic systems for

obvious leaks, and make sure hydraulic fluid levels are correct when the forks are in the parked position.

8. Load Backrest ExtensionProtects You and Your Load. The load backrest extension is designed to prevent materials from falling backward onto the driver. However, a damaged or obstructed backrest can create serious hazards. Check for structural integrity: Is it bent, cracked, or lose? Even minor deformities can affect its ability to support loads. Obstructions: Are there foreign objects such as bricks, blocks, or debris caught in the structure? These can interfere with safe lifting and loading.

9. Inspecting the Cabin & Overhead Guard - The cabin is the operator’s workspace, and its condition directly impacts safety and comfort. A thorough check should include: Overhead Guard Stability: Ensure the guard is securely attached with no loose bolts, cracks, or dents. This guard is essential for protecting the driver from falling objects. Seat Condition & Restraints: Look for any damage to the seat, seatbelt, or adjustment mechanisms to ensure proper support and restraint in case of sudden stops. Pedals & Controls: Confirm that pedals, levers, and control buttons move smoothly without excessive wear or obstruction. Flooring & Footwell: Check for loose debris, oil spills, or wornout mats that could lead to

slips or hinder safe operation. Visibility from the Cabin: Ensure the windscreen (if applicable) is clean and free from cracks that could obstruct the operator’s view.

Warning Systems. Warning signals and visibility aids are crucial for alerting pedestrians, co-workers, and other drivers to the forklift’s movements. Make sure to inspect: Horn & Audible Signals: Press the horn to confirm it works clearly and loudly. If the forklift has reversing alarms or other audible alerts, test them too. Lights: Check headlights, brake lights, indicators, and hazard lights to ensure they function properly, especially in lowlight or indoor environments. Mirrors & Visibility Aids: If fitted, inspect all mirrors for cracks or misalignment and make necessary adjustments for maximum visibility. Additional visibility aids, such as cameras, sensors, or warning beacons, should also be tested.

“Remember, regular daily forklift checks help catch minor issues before they become serious hazards, but only a LOLER inspection can certify that your equipment meets legal safety standards. For expert advice on daily checks or to book your LOLER inspection, contact Impact Handling today at www.impacthandling.com.”

Ensuring the production process meets all the current hygienic and food safety regulations is one of the main challenges facing any wholesale bakery business, when the budget is simply not there to have a fully automated food production system, handling different products in a safe sanitary manner can prove quite difficult. The North Ridge bespoke food grade pump kits are the solution to this.

A traditional family run bakery established for over 50 years required a fully hygienic, easy to clean mobile pump to transfer Fruit Jams, Toffee Sauce, Fruit curds and Whipped cream. The variety of products posed a real challenge to ensure components did not wear prematurely, that damage could not be easily performed to the pump and that the customer had a low maintenance solution.

Some of the products are directly dispensed from a cooking kettle into the pump at an average temperature of 100 - 110 °C whilst others are incredibly viscous as they are stored in a fridge before being used. The customer needed a bespoke multipurpose solution for their processes, which was sanitary grade, capable of handling all the products in question, suitable for high viscosities and temperatures up to 120 °C. It also had to have a very gentle pumping action due to the shear sensitivity of the whipped cream. High temperature liquids can have a negative impact on seals, NPSH and the overall pump lifespan so careful consideration must be taken during pump selection.

Their current procedure involved manually transferring sauces via totes and buckets, however the customer wanted to improve their process to automate food

transfer, reduce the likelihood of burns or accidents, and eliminate manual lifting and tipping of containers. They needed a custom cost-effective unit that operates similar to a semi-automatic liquid filling machine.

We supplied a completely bespoke pump system consisting of one DX hygienic progressing cavity pump, mounted on a mobile trolley, with an integrated control panel. The pump is 3A sanitary certified, which means it is suitable for CIP (cleaning-inplace) and SIP (sterilization-inplace) furthermore, is specifically designed without dead zones or areas where product can build up ensuring the internal components are fully clean after operation and guaranteeing zero cross contamination when handling different liquids. We also ensured the exterior of the unit was easy to clean by fitting a stainless-

At North Ridge Pumps, we’re not limited to choosing just one pump design.

steel shroud that covers both the motor and the gearbox.

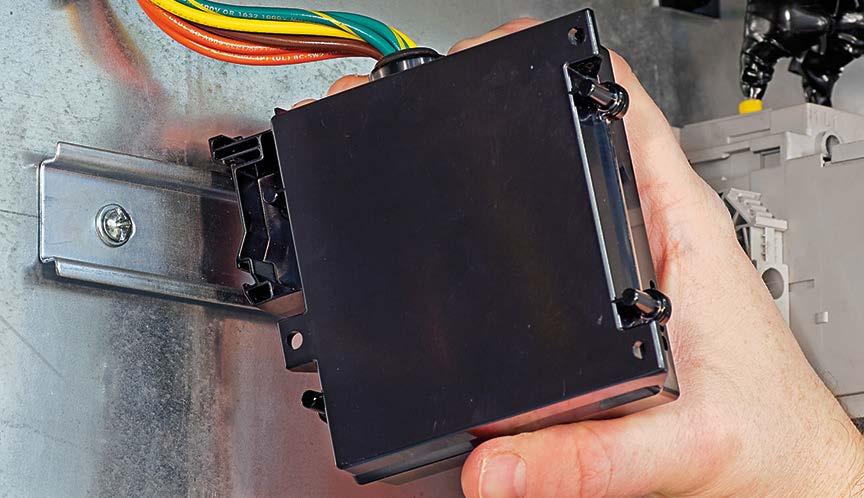

Besides having an integrated inverter, the control panel has several other safety and operation features, such as start/ stop switch, reverse (clockwise/ anti-clockwise) switch, emergency stop, alarm for motor overload protection and temperature control sensor, with alarm to prevent damage (dry running protection).

There is also the added feature of controlling the inverter via the panel or by the use of an App through Bluetooth where operators can also view the status of the pump. This feature is extremely beneficial for the customer as the pump has to operate at a slow speed when handling whipped cream.

We are proud to say that thanks to our pump kit the customer improved their production efficiency dramatically, which in the food industry translates as an increase in profitability. The layout enabled users to operate the unit with very little training due to the simplicity of design but also built-in protection ensures the unit cannot be damaged easily.

If you have an upcoming requirement and are unsure of the correct solution, speak to North Ridge Pumps to see how we can help.

Optimise performance with specialist support

Whether you’re dealing with clogging, separation, downtime, or other issueit’s costly. Time wasted troubleshooting and lower production mean missed targets and less profit. A sanitary pump is the solution but choosing the right one feels like stepping into a minefield. You know what you need it to do but with so many options, it’s difficult to know which is best for your process and parameters.

+ Accelerated stator wear

+ Clogging

+ Changes to fluid consistency

+ Clean-in-place and sterilise-in-place hygiene issues

+ Crushing of sensitive products

+ Inconsistency in finished product

+ Inaccurate transfer of flavourings or ingredients

+ Liquid separation

+ Seal wear or failure

We’ve been engineering sanitary pumps for sectors such as distilling, brewing, food manufacturing/processing, and more, for 20+ years. We understand industry-specific processes and know what it takes to optimise performance through better-suited pump design - giving you complete peace of mind.

Our expert engineers understand your process and guide you through the options, so you can confidently select the most suitable sanitary pump.

EXAMPLE PRODUCTS:

+ Abrasive mixtures

+ Creams, milk & ice cream

+ Edible oils & fats

+ Fish & meat

+ Fruits eg. cooked apples, plums, berries, grapes

+ Grains & seeds

+ Pastes & purees

+ Syrups, juices & alcohols

+ Vegetables & peelings

+ Waste eg. trimmings, packaging & offcuts

+ Sheer sensitive liquids

+ Solid laden or viscous mixtures

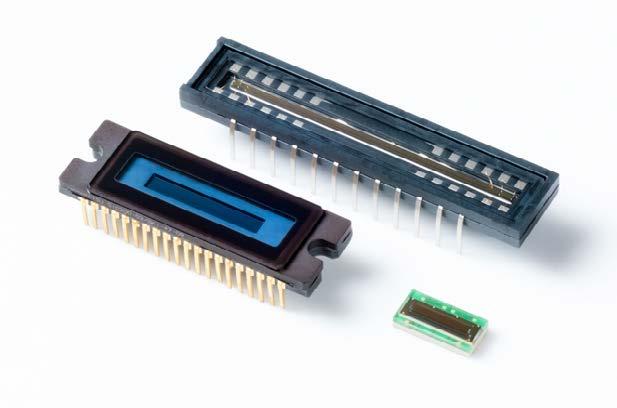

In environments where cleanliness and precision are crucial, it’s essential to follow strict hygiene requirements. Luckly, there are devices that make meeting those requirements much easier, like the new DataMan 290 from Cognex.

The DataMan 290 barcode reader sets a new standard for the food, pharmaceutical, and medical industries. This AI-powered device supports a wide range of applications, providing reliable, accurate, and efficient code reading in environments where purity and precision are key.

The DataMan 290 is designed for easy use, setup, and maintenance, ensuring it meets the most demanding production requirements with advanced technologies.

In the food and beverage industry, tracking is key to ensuring product safety and quality. DataMan 290’s advanced decoding capabilities enable manufacturers to track products throughout the production process, from raw materials to

finished products. This level of tracking supports hazard analysis and critical control point (HACCP) systems, helping to identify and minimise potential hazards.

The pharmaceutical and medical industries also benefit from the precision and reliability of the DataMan 290. The ability to read direct part markings (DPM) on small, complex components ensures traceability, so every part is accurately tracked and documented. This is essential for compliance with regulatory standards and maintaining supply chain integrity.

The DataMan 290 uses advanced technologies to meet the most demanding production requirements. Its AI decoding algorithms and powerful illumination ensure high read rates even in harsh environments. The DataMan 290 also supports CleanIn-Place (CIP) and Sterilise-In-Place (SIP) processes, which are essential to prevent contamination.

Designed for hygienic production environments like clean rooms, the DataMan 290 is made from materials resistant to contamination and easy to clean. Its compact size and flexible mounting options suit confined spaces where cleanliness is key. The barcode reader ensures accurate readings even in challenging conditions, reducing errors and increasing efficiency.

The DataMan 290 barcode reader from Cognex is a breakthrough solution for the food, pharmaceutical, and medical industries. Its advanced technology, robust design, and seamless integration with automation solutions make it an invaluable tool for maintaining high standards of cleanliness and precision. Supporting hygienic production practices, HACCP systems and CIP/ SIP processes, the DataMan 290 ensures that manufacturers can meet the stringent requirements of these key industries while optimising their operations for efficiency and accuracy.

www.cognex.com

Unmatched reliability, ease of use, and end-to-end support

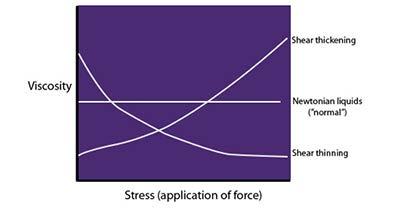

Are you handling or transferring a shear sensitive fluid? Does your manufacturing process involve a liquid that alters when heavy force like stirring is applied? This article from Castle Pumps Ltd will give you more of an insight into exactly what a shear sensitive product is and how this impacts pump selection. So, let’s start with a deeper look at the characteristics of a shear sensitive liquid…

Shear sensitive liquids are those that become altered or even damaged when force is applied. In the most simplistic of terms, they are delicate fluids that change viscosity when “messed with” like shampoo turning into foam, or that contains solids that can be crushed but for the purpose of their use should not be, like fruit pieces in a yoghurt.

In more scientific of explanations, all liquids can be categorised into either Newtonian or nonNewtonian. Newtonian fluids are those that remain at a constant viscosity no matter the amount of shear applied (providing temperature remains the same). These include water, alcohol and mineral oil.

With non-Newtonian fluids, how thick or thin the liquid is can alter depending on the composition of the product and how it reacts to shear being applied. The way the liquid reacts can be identified in four ways - Dilatant (Shear Thickening), Pseudoplastic (Shear Thinning), Rheopectic and Thixotropic.

• Dilant - become much thicker when force is applied - think of a cornflour and water mixture or pancake batter.

• Pseudoplastic - are the exact opposite, with them become less viscous with increased stressjust like tomato sauce!

• Rheopectric – become more viscous as more stress is applied over time – if you whip cream for long enough, it becomes much thicker.

• Thixotropic – becomes less viscous as more stress is applied over time – if you stir honey over a period of time it becomes much more fluid.

But why does this impact pump selection and what exactly is a shear sensitive pump?

Whilst certain pumping technologies such as centrifugal pumps apply high shear in operation, shear sensitive pump designs are able to keep such fluids intact due to their low internal velocity, gentle pumping mechanism and the wider tolerances between their pump casing and internal components. Failing to select a low shear pump when handling a shear sensitive liquid can result in product inconsistencies, damaged solids that need to be intact and costly waste.

Typical low shear pump types are typically positive displacement pumps and include peristaltic pumps, progressive cavity pumps, flexible impeller pumps and AODD pumps.

Does your process involve the handling of a shear sensitive fluid that you cannot risk altering or damaging? Contact the pump experts at Castle Pumps Ltd for help specifying the right pumping solution. www.castlepumps.com

Pump smarter, not harder. Use our 15 years’ experience to save excessive wear, process failures, product waste & operator time.

✓ FDA & 3A hygienic solutions for food and drink

✓ Highly accurate dosing of ingredients & additives

✓ Delicate fluids sensitive to consistency changes

✓ Solid-laden products without crushing or clogging

✓ 99.98% barrel emptying to prevent product waste

✓ Models for the safe handling of cleaning chemicals

Contact our technical sales engineers now!

Today’s global food production system faces significant challenges that must be addressed to sustain our planet’s growing population. It is estimated that food production needs to increase by up to 70% to meet the rising demand. Sustainable farming practices are also more critical than ever, as agriculture contributes to approximately 24% of global greenhouse gas emissions and plays a significant role in water usage and habitat loss.

These environmental implications conflict with the European Union’s sustainability goals for a climateneutral continent by 2050. Climate change exacerbates the challenges in the agri-food sector, increasing crops’ vulnerability to pests, diseases, and extreme weather events. Additionally, around onethird of all food produced for human consumption is lost or wasted, necessitating innovative approaches to balance increased food production sustainably.

Photonics and imaging technology are vital in overcoming these challenges by transforming the agrifood tech sector. Photonics-based instruments emit light that interacts with materials according to their composition and structure. The light may be absorbed, reflected, transmitted, or cause fluorescence. Advanced sensors capture these interactions, yielding detailed information about the target’s chemical, physical, and biological characteristics.

The primary benefits of photonic solutions include their noncontact, quick, and primarily non-destructive testing nature. This non-invasive approach facilitates real-time monitoring and inspection of agricultural products, enabling the detection of diseases, nutritional content, moisture levels, and other critical parameters without compromising sample integrity.

By leveraging light-matter interactions, photonic technologies support precise, efficient, and sustainable management practices in the agri-food sector, promoting higher yields, reduced waste, and enhanced food safety.

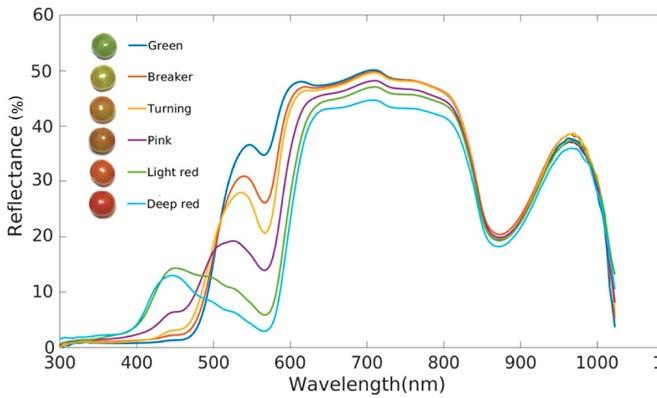

1. Colorimetry & Visible

Colorimetry and visible imaging provide non-destructive means of assessing food quality and characteristics by measuring the intensity of light reflected from an object in the visible spectrum (400-700 nm). Advances in sensor technology have allowed a shift from human evaluation to precise measurements in the CIELAB color space, offering consistent results. RGB sensors that measure colors in a 2-D area have made colorimetry more straightforward and cost-effective. In applications like fruit and vegetable sorting,

these techniques enable automated classification based on ripeness and defects. For instance, colorimetry helps identify the optimal harvest time in apple orchards, enhancing quality while reducing waste through accurate maturity assessment.

2. Visible & Near-Infrared (VNIR) Spectroscopy:

VNIR spectroscopy offers deeper analytical capabilities by assessing the near-infrared range (400-2500 nm) and how materials interact with light. This technique exploits molecular vibrations and overtones, which absorb NIR light, allowing comprehensive insights into the chemical composition of agricultural products. This method enhances the rapid detection of parameters such as moisture content, sugar levels, nitrogen levels, and overall quality used in real-time monitoring for crop optimization and quality control.

In food quality assessment, VNIR spectroscopy is used to quantify the sweetness of fruits by measuring sugar content directly through their skin, allowing for sorting into quality grading without damaging the produce.

3. Fluorescence Imaging:

Fluorescence imaging is a powerful technique used to identify specific biological compounds and pathogens in agricultural products. By illuminating samples with specific wavelengths, substances that fluoresce can be detected, providing insights into the health and quality of crops. This method is valuable for monitoring stress in plants and assessing the presence of contaminants or toxins.

4. Hyperspectral Imaging:

With modern sensors, it is now possible to combine the aforementioned techniques and collect a complete continuous spectrum for each pixel. Hyperspectral imaging captures this spectral data of light, providing comprehensive chemical and physical assessments and improving quality control processes. Hyperspectral imaging is particularly useful in detecting

progressive change of reflectance spectra at different ripening stages of tomato

Hyperspectral imaging assessment of different coffee bean types

diseases, assessing ripeness, and identifying contaminants with high precision.

Multispectral imaging’s balance between spectral detail and operational simplicity makes it an invaluable tool in agri-food technology. Its focused, rapid analysis capabilities facilitate sustainable farming practices and enhance food quality.

Imaging tools are critical for a sustainable agri-food tech sector

As global demand for food intensifies, precision photonicbased techniques and imaging

tools are essential for advancing sustainability in the agri-food sector. By enabling real-time monitoring and non-destructive testing, these technologies support efficient management and contribute to meeting the growing food demand without compromising environmental goals. Adopting such imaging solutions can drive the agri-food industry toward a more sustainable future, ensuring food quality and safety while paving the way for future advancements.

References

For detailed references, please view the full article.

Silverson high shear mixers are engineered to deliver exceptional mixing performance, combining advanced rotor/stator technology with robust construction and scalable designs. In this article, we’ll explore the laboratory and benchtop mixers available in the Silverson product range. Silverson laboratoryscale mixers are engineered to the same fine tolerances as productionscale machines, making scale-up an easier process, ideal for those working in R&D and small-scale manufacturing.

Silverson Laboratory in-tank mixer

The L5 Series Laboratory Mixer is suitable for the widest range of applications – mixing, emulsifying, homogenising, disintegrating and dissolving – with an efficiency and flexibility unmatched by other machines. It has a capacity from 1ml up to 12 litres and the ability to mix in-line with flow rates up to 20 litres/ minute. The model is compatible with over 40 interchangeable mixing assemblies, making it even more versatile.

Silverson Verso – benchtop In-Line mixer

The Silverson Verso is a bench top In-Line mixer ideal for laboratory or pilot scale applications. The unit offers excellent reproducibility when scaling up and provides an accurate and easy means of forecasting the performance of larger In-Line mixers under full-scale working conditions.

The Verso is equipped with a digital tachometer, ammeter and programmable timer, invaluable for applications where process validation and reproducibility are required. It is also compatible with the Silverson “DataLogger” program.

In addition to the standard model, the Verso range includes two additional models:

Verso UHS: An Ultra-Hygienic version of the standard model, the Verso UHS is designed for stringent

applications in the Pharmaceutical and Biotechnology industries as well as Food, Cosmetics and other clean industries.

Verso-UHS-HV: The Verso-UHSHV is designed for mixing high viscosity products. It incorporates the same unique and innovative ‘pumping rotor’ design as the production scale UHS-HV In-Line mixers. This substantially increases its self-pumping capacity, allowing it to process products such as gels, creams, sauces and gum solutions on a laboratory scale.

The FMX5 provides a simple, effective and hygienic means of powder/liquid mixing at laboratoryscale. The unit is suitable for small scale manufacturing and R&D work with a typical batch size of up to 10 litres, depending on viscosity. The mixer can rapidly and effectively disperse powders into liquids, creating uniform mixtures and streamlining formulation development.

If you’d be interested in trialling a laboratory mixer for your application, or you’d like more information, get in touch with Silverson today.

When it comes to process control equipment, accuracy, reliability and a long service life are all key attributes. Food and drink production lines rely on precision manufacturing processes to deliver uniform, high-quality products while maintaining a hygienic environment. Bürkert’s Element control valve system offers 99.9% accuracy and a service life beyond seven million cycles - three times that of conventional designs.

The key to delivering all these benefits is expert design that incorporates features that promote efficiency, reliability and durability. Compressed air is conserved thanks to the intelligent internal design that ensures consumption is up to 40% lower in comparison with conventional process valve systems. Moreover, the Element system is sealed and prevents ingress of moist, contaminated air, stopping corrosion of the actuator spring and removing humidity build-up inside the actuator.

The use of high-quality stainless steel offers long-term advantages in resistance to chemicals and heat, which means the control valve can easily withstand regular washdown processes. The internal components are sealed against dirt and water ingress, with an integrated, contactless stroke position feedback transducer that never wears out or blocks, retaining accuracy over extended periods.

The compact design of the Element range also helps to reduce air consumption. Across a manufacturing plant, this benefit multiplies – on average, using 50 valves per site will result in a saving of £2,500 per year. Furthermore, the lightweight design makes for easier maintenance and the pipework does not need any reinforcement either for new or retrofit installations.

Element valves are easy to install and include a modern operator concept that is both intuitive and user-friendly. The seamless configuration process for

positioners and process controllers is easy to follow. The range is designed for communication with all common protocols including Profibus DPV1, ASI and Device NET. In operation, the valve’s status is conveyed at a glance by a high-performance, clearly visible multicoloured LED display, helping site operators to quickly identify any issues.

Bürkert is leading the field in advances in fluid process control, transforming the food and beverage industry, driving improvements in precision, automation, safety, quality, and sustainability. The Element range of process controllers is just one example. Bürkert’s experienced designers and industry experts can support manufacturing plants with detailed plans for optimised performance that will deliver process reliability, precision control and an extended service life.

For more information, visit our website.

Completely hygienic process control valves for food and beverage applications

• Up to 3 times longer life-span than competitors

• Smart use of stainless steel – reduced weight, robust and strong

• Up to 7 million cycles

• Easy to install and can be fully automated

We make ideas flow.

www.burkert.co.uk/en/type/8802 sales.uk@burkert.com +44 1285 648720

Over the past two decades, plant-based protein ingredients used in the food and beverage industry have evolved and grown significantly.

While soya protein initially dominated the market, consumer demand for clean-label, allergenfriendly, and sustainable alternatives has ushered in a new era for protein alternatives. Today, in addition to pea protein, wheat protein and plant-based protein concentrates (a combination of ingredients such as fava bean and yellow pea) are popular.

With continuous advancements in extraction methods, formulation

techniques, and new recipes, plant proteins will continue their steady upswing, offering more functionality for food manufacturers, and a better taste and sensory experience for consumers – significantly impacting innovations for plantbased product solutions in the food industry.

Driving the shift in plant-based innovation

The rise in plant-based products high in protein is driven by the consumer’s desire to be healthier, take care of the environment, and critically, behave ethically towards domestic animals reared for eating.

These requirements led to a burst of new product development including dairy alternatives, high-protein plant-based snacks, meat substitutes such as nuggets, burgers, and sausages, and readyto-drink beverages and functional shakes in the sports nutrition category.

To meet demand, brands are constantly investigating fresh solutions in high-protein plantbased ingredients that not only offer optimal nutrition, but solutions to common product development challenges.

Historically, high protein plantbased products struggled to meet

the stringent taste demands of consumers, particularly around organoleptic and sensory attributes such as texture and mouthfeel, in combination with formulation challenges such as shelf life and stability.

While a small segment of consumers might compromise taste and texture for health benefits, the majority will not. This makes the development of high-protein plant-based products that can overcome these barriers a challenging and exciting area of discovery and innovation for the industry.

An important source of nutritional components and rich in protein, starch, and fibre, pea protein is considered a high-quality protein and functional ingredient due to its low allergenicity, availability, affordability, ease of use, and sustainability credentials.

Pea protein is also widely considered as one of the lowest carbon proteins. According to an article on BBC Future, producing 100g of protein from peas emits just 0.4kg of CO2e. This is almost 90 times less than getting the same amount of protein from beef. In addition, pea protein offers excellent functional properties that make it a promising ingredient in processing, offering great solubility, water and oil holding capacity, emulsion ability, gelation, and viscosity.

Although traditionally used as a substitute for cereal flour, fats, and animal proteins, the functional properties of pea protein and its fractions offer exciting potential in the development of a wide range of products.

In meat alternatives, pea protein can provide structure and texture in meat analogues, mimicking the fibrous structure of meat, and assisting with binding and water retention while improving juiciness. It can also contribute a creamy mouthfeel to dairy alternatives such as yoghurt, cheese, and high-protein dairy drinks.

In terms of the growing sports nutrition category, pea protein with its high branched-chain amino acid content makes it an appealing ingredient for products targeting muscle recovery, while assisting with moisture retention and the replacement of binding agents in snacks.

However, formulating with pea protein is not without its challenges, particularly regarding taste and flavour, mouthfeel and texture, and functionality in highmoisture foods. These are not insurmountable.

By adapting formulation strategies, it is possible to enhance performance across a wide range of food and beverage products. Blending with other plant proteins, for instance, can improve smoothness while adopting high processing methods, including high moisture extrusion and shear cell technology can assist in improving the texture of meat products. When it comes to weighing up the benefits of using pea protein in new product formulations, the positives far outweigh the negatives!

Wheat protein for select applications

But pea protein is not the only high protein plant-based ingredient that offers excellent functionality. The use of wheat protein in the food industry, primarily as wheat gluten or textured wheat protein has been a key component in plant-based product development for years. Wheat protein is highly regarded for its unique elasticity and binding properties and for its ability to create meat-like textures. This makes it a staple ingredient in numerous food applications.

In plant-based meat substitutes, wheat protein can contribute a chewy, fibrous, and meat-like texture without the need for extensive processing. It also pairs well with other plant proteins and is frequently blended with pea or soy protein to enhance the nutritional value and mouthfeel.

In baked goods and snacks, wheat protein can contribute to dough

elasticity, structure, and moisture retention, while improving rise and crumb texture.5 Wheat protein is often blended with oil, pea protein, and other starches to create a more holistic mouthfeel with great functionality as a binding and texturising agent in bars and extruded snacks.

The primary challenge around wheat protein is that it is not suitable for gluten-free or celiacfriendly products. Processing with wheat protein can also throw up challenges around the texture of products, but processes such as high moisture extrusion, particularly in premium meat alternatives can limit these challenges.

Wheat protein remains a versatile, functional, and cost-effective ingredient in plant-based product development. While it offers excellent texture and binding properties, further innovations in blending, processing, and formulation will optimise its role as a next-generation ingredient for the food and beverage industry.

Unpacking the benefits of soy protein

Soy proteins have a long history of use in the food and beverage industry, with innovations driving improvements in taste, by offering blander profiles, and less viscosity that enable formulators to up the soy content of a product without impacting its texture. It is a brilliantly functional ingredient too, with great dispersibility, flowability, and solubility. These are significant benefits when formulating highprotein nutritional beverages, nutrition bars, and meat and dairy alternatives.

What sets soy protein apart from other plant-based products is its ability to form a gel after heating. Heat gelation can positively impact the texture and shape of a product, bind or immobilise fat and water, and improve sensory and organoleptic properties. In addition, it can also extend shelf life and regulate viscosity while modifying the gel structure of a product.

With continued improvements in taste, texture, and functionality, more consumers will opt for products containing soy protein, and the opportunities for its use across many food categories will expand and grow. Soy proteins will continue to be a popular choice in new formulations - offering stellar protein quality and impactful functional properties. it is also a nutritional powerhouse, providing all nine essential amino acids required by the human body.

The future of plant-based protein innovation

The food and beverage industry is witnessing a remarkable shift as plant-based proteins continue to drive new product development. Pea, soy, and wheat proteins, in addition to new and innovative blends in plant-based concentrates, are revolutionising formulationsenhancing texture, nutritional value, and functionality across a wide range of applications.

While challenges such as taste, texture, and processing complexities remain, advancements in ingredient science and processing technologies mean that the industry is slowly overcoming these hurdles.

The increasing demand for sustainable, allergen-friendly, and high-performance plant proteins will continue to propel the industry forward, opening the door to even more sophisticated, consumercentric innovations.

By leveraging cutting-edge formulation techniques and strategic ingredient combinations, manufacturers can create nextgeneration plant-based products that meet evolving consumer tastes, nutrition, and sustainability expectations.

For information on the ACI Group’s range of alternative proteins, please visit www.acigroup.com for more insights.

Jack Helm, Account Manager - Food, ACI Group

The rise in plant-based products high in protein is driven by the consumer’s desire to be healthier, take care of the environment, and critically, behave ethically towards domestic animals reared for eating. These requirements led to a burst of new product development including dairy alternatives, high-protein plant-based snacks, meat substitutes such as nuggets, burgers, and sausages, and ready-to-drink beverages and functional shakes in the sports nutrition category.

In today’s competitive market, companies in the food and drink industry are under constant pressure to reduce costs while maintaining high standards of quality and sustainability. One area where significant savings can be achieved is in energy consumption, particularly in the charging of batteries for electric forklifts and other material handling equipment. This is where Fronius comes into play with its innovative battery charging solutions.

Fronius Perfect Charging has established itself as a leader in the field of battery charging technology, offering solutions that are not only efficient but also sustainable. Their advanced Selectiva 4.0 chargers are designed to optimise the charging process, ensuring that batteries are charged quickly and efficiently while minimising energy consumption by up to 30%. This is particularly

important for companies in the food and drink industry, where energy costs can be a significant portion of operational expenses.

One of the key features of Fronius battery charging solutions is their ability to reduce total cost of ownership (TCO). By using their patented Ri intelligent charging technology, these systems can extend the lifespan of batteries, reducing the need for frequent replacements. This not only saves money but also reduces waste, contributing to a more sustainable operation. Additionally, Fronius chargers are equipped with advanced monitoring and control systems that provide real-time data on energy usage and battery status. This allows companies to optimise their charging processes and identify inefficiencies or potential issues before they become costly problems.

When maintaining a consistent and reliable supply chain is crucial, the reliability of Fronius charging solutions is a major advantage. The chargers are designed to operate in demanding environments, such as cold stores, ensuring that MHE is always ready for use. This reliability helps to prevent costly downtime and ensures that operations run smoothly.

Fronius are committed to green logistics and offer a comprehensive energy consultation service to help companies achieve maximum efficiency. Their experts work closely with customers to analyse energy usage and develop tailored solutions that meet specific needs. This holistic approach ensures that companies can achieve their sustainability goals while reducing energy costs.

Fronius is revolutionising the way companies manage their energy consumption and reduce the environmental impact of intralogistics processes. By providing innovative, efficient, and sustainable battery charging solutions, Fronius helps companies reduce their operational costs whilst also contributing to a greener future. With their commitment to excellence and customer support, Fronius is undoubtedly a valuable partner for any company looking to improve its energy efficiency and sustainability.

For your free consultation, contact the Fronius UK team on +44(0)1908 512 300, email charger-sales-uk@fronius.com or visit www.fronius.co.uk/perfectcharging

Increase your efficiency and reduce your energy costs and CO 2 emissions with a full portfolio of hardware and software solutions for a holistic approach to MHE battery charging. Full

through the analysis, planning and realisation stages with ongoing support from our UK based team.

on +44 (0)1908 512 300 to find out more.

Offer consistent product quality at the point of use for a wide range of applications, guide rails position the IBC and the mixer is raise and lowered into the IBC with a push button operated electrical actuator.

Fixed or mobile mixing stations are supplied complete with a control panel and safety interlocks.

Standard IBC mixing stations can be adapted to integrate with systems on site including pumps, valves, weighing and measuring instrumentation and controls to meet specific site requirements.

Instrument Hire

We offer a wide range of the latest test equipment complete with certification. Competitive prices and discount structure with full technical support included.

Calibration

Providing a calibration and repair service with traceable certification for electric, electronic and pneumatic equipment. This is backed up by an annual re- calibration reminder via email.

01928 589600

info@aughton.co.uk www.aughtonhire.co.uk

Calibration

Providing a calibration repair service with certification for electric, and pneumatic equipment. is backed up by an calibration reminder

MENZEL was asked to manufacture a custom 6600V electric motor to drive a multistage condensate water pump in a thermal power station. The existing motor needed to be replaced quickly. In just four weeks MENZEL planned, built and delivered a three-phase squirrel cage motor with IC 616 cooling and IP 55 protection.

The Requirements: Precision and Speed

The customer not only wanted a motor that could be seamlessly integrated into the existing system via plug-and-play, but also one that could be implemented quickly. MENZEL was able to complete the motor in just four weeks.

One of our stock motors in the required size formed the basis. However, the following adjustments still had to be made:

• Precision work on the rotor shaft: conversion to shaft nuts with lefthand thread and laser welding of the keyway

• Changing the cooling system: Conversion from IC81W to the IC616 system

• Adaptation of the direction of rotation: including different inner fan wheel Accompanying tests: Extensive tests in the load test field to ensure the highest standards

• Adapterplate and different mechanical modification: for a plug and play type fixing between the motor and the pump

The Implementation: Precision meets Efficiency

During the planning phase, we went through several changes and special requirements. Thanks to the close cooperation between the customer, our project engineers and our production department, we were able to develop and agree

the technical solution quickly. Our ability to meet technical requirements and commercial details in record time was particularly praised. In addition, the motor was extensively tested in our load test field. Where MENZEL successfully met all customer requirements.

Type: MEBKSLF 500-04-011 AC-Motor

• Motor application: Condensate water pump in a thermal power station

• Rated power: 970 kW

• Rated voltage: 6600 V

• Rated speed: 1487 min-1

• Type of construction: IM V1

• Protection class: IP 55

• Cooling type: IC 616

• Weight: 7160 kg

The Delivery: Precisely to the Destination

The finished squirrel cage motor was transported to Japan by plane in order to meet the critical deadline. Installation and commissioning took place at the thermal power plant, where the motor now reliably drives the multistage condensate water pump.

This project is a prime example of our strengths:

• Custom solutions in the shortest possible time

• Efficient communication and close coordination

Highest technical precision, made in Germany

www.menzel-motors.com

....

to a fresh and innovative approach to turnkey solutions

In 2022, BS Handling Systems completed the design, manufacture and installation of pick-to-light conveyor lines at Mindful Chef’s distribution hub in Redditch. The success of the project led Mindful Chef to commission BS Handling Systems to deliver phase two of its development plans, an automated palletisation solution at the end of the pick-to-light lines.

“Phase one was designed to increase throughput performance and reduce error rates in the picking process,” explains Matthew Maxwell, head of operations at Mindful Chef. He continues, “With phase two, the key objectives were to reduce or remove manual handling operations at the end of the lines and further increase throughput speeds.”

Minimising manual handling

Before phase one was completed, Mindful Chef had already started thinking about adding more

automation to the end of the pickto-light lines. With phase one the company achieved a throughput increase of around 30 percent. To cope with this increase it required two operators at the end of each line to manually lift the boxes off and palletise them prior to loading into a trailer for despatch.

Removing these manual handling elements at the end of each line would have several benefits:

i. Reduce the number of operators required to meet increased throughput

ii. Eliminate the health and safety risks to operators

iii. Run continuously and accurately without the need for breaks

iv. Improve the mental health of operators by giving them less repetitive tasks

Matthew Maxwell again, “As part of our due diligence we visited other sites within the Nestlé group to evaluate their palletising operations. The benefits of automating the palletisation became obvious and so we pushed ahead with phase two of the project.”

“BS Handling Systems are really good to work with, they’re extremely knowledgeable and accommodating. They’ve worked with many companies developing warehouse and distribution facilities, so they have a wealth of experience. This is a huge benefit when it comes to designing a system and finding the best way of configuring it.

“Initially, we looked at two possible solutions; one loading pallets directly into the lorry trailers themselves, the other automating the palletisation. After careful consideration, we decided that loading directly into the trailers wouldn’t give us the flexibility we needed, so we opted for palletisation automation.

“The first design concepts had just one palletising cell. This had two robots inside the cell with both pick-to-light lines feeding the cell. After the order was placed for the conveyors to feed the cell, we had second thoughts. The space where we were going to locate the cell was very tight and the design had the potential to cause issues for our operators. So, at the eleventh hour, we decided to look at a different approach.

“A major advantage of working with BS Handing Systems is their flexibility. Even though

we’d already committed to the order, they were open to change throughout the process. Following further analysis we decided to have two automated palletisation cells, one for each pick-to-light line.

“To fit them into the available space Phil Taylor and the team designed the feed conveyors to run from the exit of the box closing machine via a 180 degree bend to come back up parallel to the line before taking a 90 degree turn into the palletisation cell.

“We have three box sizes in the operation, small, large, and extralarge. The conveyor indexes boxes which are presented to the robot in pairs if they are small or large, or one extra-large box. The robot picks up two boxes at a time unless they are extra-large (these are picked up one at a time). The robot continues picking up the boxes and stacking them on the pallet using a preprogrammed pallet configuration with eight boxes on each layer.

“It continues back and forth stacking the boxes until the pallet is full. It is very quick, extremely accurate and consistent. There are two pallet positions in each cell for the robot to load. The idea being that once a pallet is full, that pallet can make its way out of the palletiser via a powered pallet conveyor and the robot doesn’t have to stop, as it moves immediately onto loading the second pallet position.”

20 percent improvement in throughput

“In terms throughput we’ve seen around a 20 percent improvement with the automated palletisation. On the weekends; we’ve gone from 400 boxes an hour to nearly 500 an hour. Not only this, but we’ve also reduced operators at the end of the line from two on the weekend down to zero and midweek from one to zero. The removal of this manual handling element has boosted the team’s moral, they are happier and healthier thanks to the change.

“The peak period for Mindful Chef is in the January window. During this period, when many people

start New Year’s resolutions regarding improving their health, healthy eating is an important element. So when gyms are busy, we’re typically busy. The automated palletisation copes with these peak demand periods effortlessly, removing the stress of manual handling from our team.”

Fully operational from the outset

“The installation of these automated palletisation cells was probably one of my most nervous times. We were expecting to have a period of at least two or three weeks of teething issues which could impact our throughput performance. In reality, however, everything ran smoothly. During peak the cells worked like a dream, stacking up to 12,000 boxes a day on pallets.

“The pick-to-light system in phase one and the automated palletiser in phase two have not only allowed us to become more efficient, but also enabled us to gather more tracking data on customer orders around the site.

“We can now track a customer’s box from the point of order through its journey on our production floor; we know who packed the items in the box and when that box was shipped. Soon we’ll be installing a camera system that will take a photograph of each box prior to it being sealed. This will give us the evidence that what we’ve sent is what was ordered by the customer.”

“The work BS Handling Systems has done for Mindful Chef has delivered savings in the region of hundreds of thousands of pounds. As a consequence, we expect the automation project payback period to be within three years.

“Rob, Phil and the BS Handling team have been superb partners over the last four years. They’re thoroughly professional, flexible and yet fun to work with. They listen to our ideas and are quick to react with solutions. The projects they have worked on have generally been completed in under

nine months which is testament to their proactive, friendly approach.

“The last two or three years have seen a huge change in the way we process orders. This transition could have been an incredibly stressful time. The way BS Handling Systems has managed the process, however, has removed a great deal of this pressure giving us peace of mind and total confidence in their abilities to get the job done.

“Now, it’s hard for our team to imagine the way we used to process orders. The pick-to-light and automated palletisation have been game changers for the business. With all the data that we’re getting from these improvements the future for Mindful Chef is looking extremely rosy,” concludes Maxwell.

2025 looks to be an exciting year for BS Handling, as they begin work on a series of large projects with Oakland International. They also recently partnered with EAE Solutions to become the exclusive UK agent for the “new-to-UK market” E-Cross Belt Sorter.

www.bshandlngsystems.co.uk

The Food Processing Industry is one of the most demanding sectors when it comes to equipment reliability, hygiene and efficiency. Every component plays a crucial role in maintaining production flow, and chain is no exception.

With the need for maximum working life and reduced maintenance downtime, food processors are turning to Donghua Limited for their chain requirements.

Donghua Limited is the UK arm of one of the world’s largest chain manufacturers. The company has established itself as the go-to supplier for the Food and Drink Processing Industry offering an extensive range of high quality chains compatible with leading food equipment manufacturers. Operating from its headquarters in the West Midlands, it boasts a 25,000 sq ft warehouse, chain workshop, and a laboratory.

Hygiene and safety are paramount in food processing environments, which is why Donghua’s chains are available with H1 food grade lubrication. This specialist lubrication is essential in areas where incidental food contact is possible. Unlike standard lubrication methods, Donghua’s

chains undergo a hot-dip process, ensuring the lubricant penetrates deep into bearing areas that conventional lubricants might not reach. As the chain cools, any surplus lubricant drains away, leaving an internal oil deposit that significantly extends wear life.

In addition, Donghua’s special alloy coating provides superior protection against corrosion caused by frequent washdowns, ensuring longevity and reliability in harsh processing conditions.

Donghua’s commitment to durability is evident in its preloading and matching processes. Chain that lacks proper preloading experiences significant elongation during initial use, leading to premature wear and replacement. By applying precise pre-load forces, Donghua ensures reduced fatigue and an extended working life.

Chain matching is another critical aspect, particularly when two chains are used in parallel. Donghua’s manufacturing precision allows for close tolerance matching, maintaining high length accuracy along the entire chain. With production tolerances averaging within 1/3rd of DIN standards, Donghua’s in-house chain length measuring machine further enhances a perfect fit for food processing applications.

Donghua offers a range of chain solutions specifically designed for Food and Drink Processing, including:

Polymer Chain – a plastic conveyor chain engineered to prevent foreign matter ingress while minimising maintenance costs and downtime. With fewer moving parts and no rollers to wear down, this chain significantly reduces maintenance.

Maintenance-free Stainless

Chain (including Drytec Chain) –designed with engineering plastic sleeves (improved mechanical and thermal properties compared to standard plastic), Drytec chain offers increased wear life and exceptional corrosion resistance, making it suitable for use in temperatures of -40° to +60°.

Bespoke Chain – custom-designed attachment chains tailored to meet specific customer requirements for specialised applications.

– a ‘one chain fits all’ solution that replaces 99% of other manufacturers’ attachment chains. Available in standard, nickelplated, zinc-coated, self-lubricating and stainless steel finishes.

Donghua’s Food Processing chain solutions are available through its expanding network of Product Partners, Stockists and Distributors, ensuring food and drink manufacturers have access to the highest quality chain when they need it most.

For more information on how Donghua can enhance your food processing operations, visit: www.donghua.co.uk/food-industry

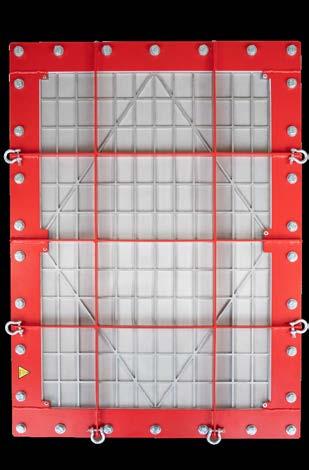

This rapid roll door is robust, requires low maintenance and delivers exceptional wind resistance in exposed areas

Hart Door Systems, the original British manufacturer of the highspeed door concept, is confident that there are considerable prospects for another successful year for its Speedor and Typhoon brands.

“Despite global uncertainties on the political front and the ever present debate on climate change I believe our leading Speedor and Typhoon brands will continue to be in demand,” says Doug Hart, Hart’s chairman.

“We have had many successes at home and abroad during 2024 not just through our Speedor range of high-speed doors but through our range of high quality shutters too. Both these leading brands offer industry a choice of solutions for industry and commerce. The fundamentals delivered by Hart are quality throughout manufacture to installation as well as service back-up to comply with changing national and international safety standards.

“We are cognisant of Climate Change issues and the need to keep both Hart’s and our clients’ carbon footprints to a minimum by using the latest manufacturing technology to streamline the manufacturing process. Where possible we would use recyclable materials.”

“Looking more closely at the Speedor brand, as Britain’s original manufacturer of the automatic high speed door, Hart has always led the way with developments in commercial door technology by being aware of issues facing industry. The Speedor high speed door is a good example of a robustly engineered door system for frequent use in high-traffic situations.

“This rapid roll door is robust, requires low maintenance and delivers exceptional wind resistance in exposed areas. While its high-speed opening and closing action improve efficiency, the energy-saving potential of this rapid roll door is high, controlling internal temperatures, escaping dirt, odours and noise.

“Special features include; moisturecontrolled electrics, mechanical components shielded from dust and dirt, and a unique guide system offering exceptional wind resistance up to class 5 as defined by DIN EN 12424. There are several options with the Speedor brand namely ECO, Storm, Mini, Conveyor and Cleanroom which together strengthen Hart’s overall high-speed door offer.

“Speedor Storm is our bestselling door, ideal for challenging

applications where reliability is essential. Its increasing success is based on its improved, rugged, design predominately for external use up to 8m x 6m/6m x 8m) often in robust operating conditions with high wind loads.

“We have always had quality as our prime driver and our success with new variants, not just in high-speed doors but shutters such as our new Typhoon range, the fundamentals are quality throughout manufacture to installation and service to comply with changing national and international safety standards.”

“Hart Door Systems is now in its 75th year. It is a global business supplying a range of door and shutter systems to sectors such as automotive, agriculture, communications, consumer foods, energy, environment, exports, food, logistics, manufacturing, power, sport, transport and utilities. To underline our global success Hart’s doors can found in nearly 40 international airports, from Newcastle upon Tyne to the Falklands, from Aruba to Vladivostok. This is a remarkable achievement.”

www.hartdoors.com

Food and beverage packaging has been the subject of scrutiny for several years now. Recycling and sustainability are high on the agenda of end-consumers - and various organisations, such as big retail players, are increasingly looking for packaging solutions that

fulfil those preferences. At a global level, this has resulted in a tangible change in the way food and beverage packaging is presented and marketed. For example, with data on the level of recycled materials now being included on labels.

One material which has been under the spotlight as part of these conversations is polyethylene terephthalate, a form of polyester better known as PET. Used across the industry in the form of trays, films, and bottles, PET is the most recyclable plastic in the world and is used widely in global plastic bottle manufacturing.

Industrial Physics’ 2024 research of packaging professionals in the food and beverage industry shows that almost half (49%) of those working with plastic packaging agreed their company’s top goal

is to meet consumer preferences. Reactions to brand choices are loud and prominent in 2025, particularly with the dominance of social media platforms. Therefore, packaging professionals are evolving their products to address these requests and maintain relationships with their own audience - the brands and retailers.

This has led to innovation across food and beverage packaging, with manufacturers seeking to balance sustainability with quality by utilising a variety of techniques and materials.

Sustainability in structure

Brands that have pushed to innovate off the back of consumer feedback are already seeing positive results. 59% of plastic packaging professionals agree that innovations within their

organisation have been well received by customers.

Even the more radical design changes are accepted if they have a sustainable purpose: tethered caps on plastic bottles, for instance, are broadly or strongly supported by 53% of the UK despite the initial debate.

Another design change that has proven popular with PET bottle manufacturers is lightweighting, which involves reducing the material used for each bottle whilst retaining its strength and durability. This technique is playing a critical role in achieving sustainability goals. Bottles made with less material have lower carbon footprints from the point of production, with fewer resources required for manufacture.

The challenge of lightweighting is retaining the integrity of bottled products, which are filled at rapid rates on production lines and must retain enough structural resilience so they do not “fail while filling” (as this causes lengthy downtime).

Appropriate testing procedures are vital for lightweighting to determine whether thinner bottles are durable enough for filling and distribution. Burst testing, for instance,

informs packagers whether a bottle is capable of withstanding pressure (particularly in the case of carbonated drinks) and if this lighter material has the required resilience.

Testing is also used to analyse the material thickness distribution around the entire geometry of a bottle. Measurement data from equipment like a semi-automatic thickness gauge offers essential feedback to fine-tune the blow moulding process and ensure that product integrity is maintained while aligning with lightweighting objectives.

Packaging manufacturers are increasingly meeting consumer demand for sustainability by incorporating recycled PET, or rPET, into their products. While virgin plastic is made from natural gas or crude oil, blending a targeted percentage of rPET into packaging helps lower the carbon footprint. Using measurement data, manufacturers can adjust the amount of rPET based on the required quality and strength of the final product.

Inspecting key dimensional features of the bottle, such as thread design, is essential for producing ecofriendly packaging. This ensures proper interaction with the bottle cap, maintains seal integrity, and improves the overall customer experience.

Testing new innovations in plastic

Producing PET bottles allows for a lower carbon footprint than some alternative packaging methods. However, constantly evolving sustainability goals, consumer expectations, and the increasing link between packaging design and brand identity mean that companies must keep innovating. And for innovation to thrive, this must be supported by advanced test and measurement solutions.

The most effective testing technology empowers plastic packaging manufacturers to implement the upgrades consumers demand while ensuring high-quality standards are consistently met.

Learn more about how packaging professionals are navigating external factors in Industrial Physics’ latest research here.

Panduit’s VeriSafe 2.0 AVT (absence of voltage test) system eliminates the risk of arc flash by confirming any electrical cabinet is de-energized before allowing access. The surface mounted module indicates when it is safe to access a panel, a green indicator is shown, and when it is unsafe to access a panel, by a red light indicator appears, prior to accessing the panel, eliminating risk to plant operators, machine builders and onsite engineers and electricians. The VeriSafe AVT system can be combined with a door interlock system so that the panel doors cannot be opened unless the test has been carried out and “green light status” achieved.

The traditional method for testing for presence of voltage is to, dress in correct PPE, turn off the panel, open the panel, verify the portable tester is operational, test the panel for voltage, re-verify the tester, then, if safe, perform necessary work within the cabinet. This process has two major setbacks. Firstly, this entire process can take around 10 minutes to perform and secondly, a number

of the steps take place after the panel is opened.

VeriSafe AVT ensures the absence of voltage by using the following process:

• Turn off the panel

• Push the button on the VeriSafe Indicator Module, located on the outside of the panel

• When the green light indicates, open the panel, it is now safe.

This method has two of major benefits, the panel is not opened until after it is confirmed that the panel is de-energized, which eliminates risk and improves safety. The entire process takes approximately 10 seconds, compared to the traditional 10 minutes, and so increases productivity.

Moreover, the Verisafe AVT performs a number of complex tasks, which include, confirms power is available to perform the test, checks health of key circuit elements, verifies

threshold circuits in tolerance, checks on known voltage source, verifies connectivity and verifies voltage is under 3V threshold.

As well as eliminating risk and improving productivity Panduit’s AVT meets various standards, its safety functions meet SIL 3 (IEC 61508-1), as well as redundant channels for measurement and detection. The system also satisfies the criteria in NFPA 70E 120.5(7) Exception 1 & CSA Z462 4.2.5 (g) Exception 2, and UL 1436 listing.

VeriSafe 2.0, automatically ensures that the entire test process is followed for every single test. With a push of a button, users can achieve tested safety in both 3-phase and single-phase applications in the extended voltage range up to 1000V for AC and DC applications.

www.panduit.com

Our gas burner systems offer users reliable, high efficiency, process heating solutions.

From design, manufacturing and supply to installation, commissioning and ongoing support, we fulfill process liquid, oven and air heating needs for both new-build and conversion projects.

GPS-NTP Server

Expandable I/O ARINC429

Third-party logistics provider Kammac has reported a significant surge in wellness-related business this January, driven by health-conscious consumer trends such as Dry January and Veganuary.

The company has seen notable increases in orders across key categories, including alcohol-free beverages, wellness drinks, plant-based snacks, and even weighing scales, underscoring a strong shift toward healthier lifestyles in the New Year.

As Kammac continues to grow its network of wellness clients, the company is set to expand its capabilities further to meet the rising demand for high-quality, health-conscious products. With more clients expected to join the ranks of Kammac’s trusted partners, the surge in wellness-related orders demonstrates the impact of consumer health trends on supply chain needs. streamlined and professional logistics solutions oduct basis, which was crucial for ensuring we stayed within our budget.” www.kammac.com

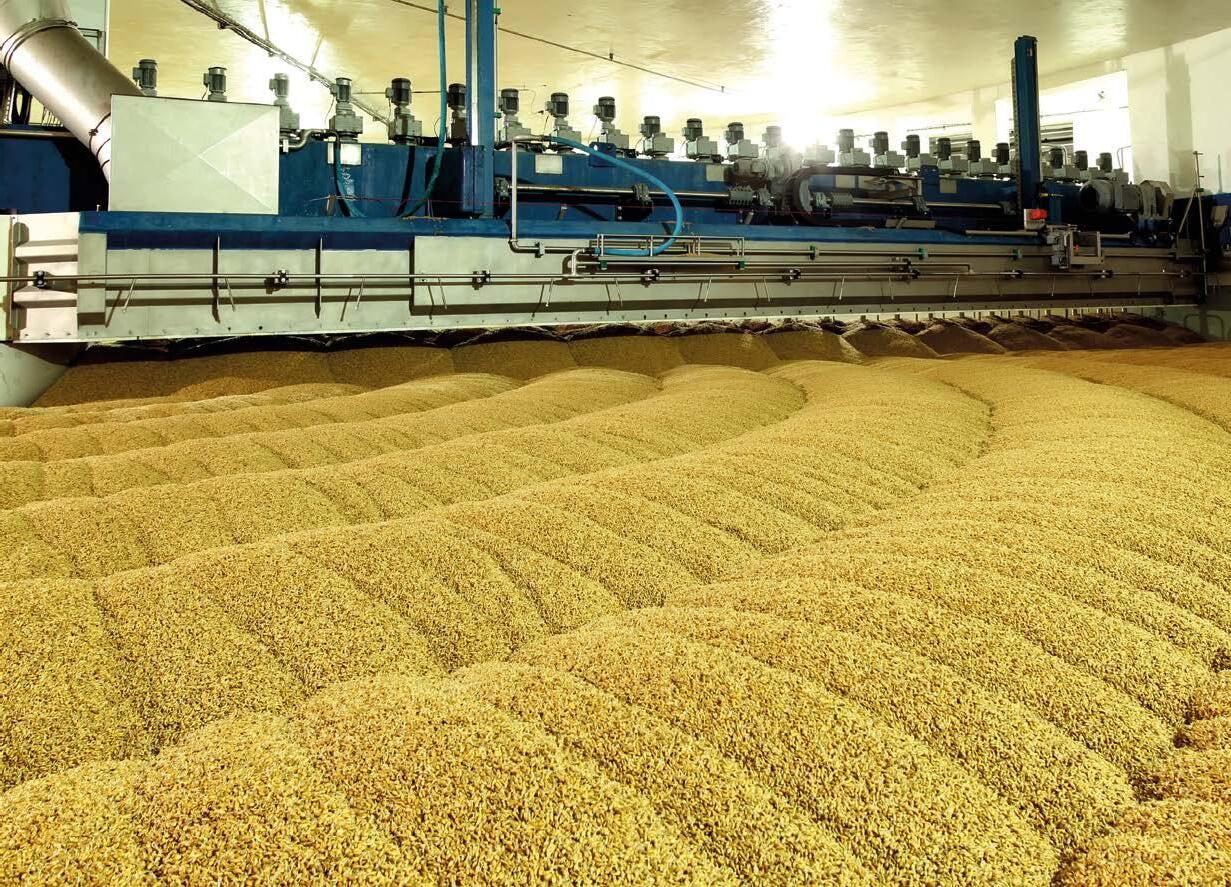

Processes that involve grinding, drying, conveying and storing grain pose some of the biggest risks for combustible dust explosions.

While we’re not so far advanced to ignore combustible dust altogether, innovative technology has made grain milling much safer than it was a century ago. With the right equipment and engineering controls in place, facilities can reduce the risk of devastating explosions.

Explosion venting panels and flameless vents