Unleashing robotic potential with real-time operating

The role of nature's greenest metal in the energy transition

ABB ROBOTICS - 52

ABB Robotics teams with innovative tech start-up to deliver sustainable and affordable housing

CWIEME BERLIN - 24

CWIEME BERLIN - 24

MANUFACTURING Engineering Process Control & PECM Global Success Through Innovation Issue 68 2024 £4.95 www.pecm.co.uk

BLACKBERRY QNX - 6

jasic.co.uk

Sections

Editor’s Choice

MANUFACTURING

Engineering Process Control &

CLPA

Advancing industrial printing with TSN

FERRARI

The electrochemical research laboratory promoted by Ferrari in Collaboration with the university of Bologna and NXP

SUMITOMO

Polymer Succession Planning … without the drama

SUBCON 2024

Discover your next manufacturing partner at Subcon - The Manufacturing Solutions Show

SM&E WEEK 2024

Smart Manufacturing & Engineering Week 2024: A Hub for Education and Innovation

EXEL COMPOSITES

Small-diameter composite tubes and robotics

CPA LTD

What to consider when choosing a power quality meter

FLEX

How AI and ML are Revolutionizing Electronics Manufacturing

NTEC

Your future in the Nuclear Industry

SULZER

Sulzer introduces rental test equipment for agile and cost-effective process development

PRIMEVISIONS

Consistently meeting fluctuating demand in logistics

Issue 68 PECM 3

Inside...

Subcon Show Preview Coatings Connectors & Fittings Control & Automation Electrical & Electronics Gears, Drives & Motors Health & Safety Machining & Machinery Measurement & Monitoring Packaging Process Technologies Pumps Storage, Handling & Distribution Tools, Plant & Equipment Valves & Flow Control 4 32 36 40 46 55 61 66 78 88 92 94 102 106 107 110 Inside

68

Issue

Cover photo: CLPA

• Continuous diagnostic: Full coverage of your critical assets at all times.

• Early diagnostics: Monitoring of imbalance, wear and overall vibration.

• Maximum efficiency: Permanent diagnostics helps keep your assets running efficiently.

• Easy integration: ifm provides individual solutions suited to different types of machines. Reducing costs, avoiding unplanned downtime and optimising processes: The ifm application solutions. ifm – close to you!

Vibration monitoring 24/7 Monitoring

Based

and Condition

Maintenance of rotating machinery. This complete solution makes your machines fit for Industry 4.0

Protect your critical assets from spinning out of control! ifm.com / uk ifm.com / uk Go ifmonline Go ifmonline years WARRANTY on ifm products

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 140,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

Hardcopy Edition

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

Digital Edition

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices. All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

MANUFACTURING Engineering Process

The Team

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Jake Page jake@pecm.co.uk Tel: 01227 937174

SALES MANAGER

Martin Richardson martin@pecm.co.uk Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971

Please

&

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk Tel: 01304 806039

DIGITAL ASSISTANT

Stacey Goodwood Tel: 01227 936971

MH Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk

Issue 68 PECM 5

Every effort is made to ensure the accuracy and reliability of material published in Process Engineering, Control & Manufacturing however, the publishers accept no responsibility for the claims or opinions made by the contributors, manufacturers or advertisers. No part of the publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including printing), recording or stored in any information retrieval system without the prior written consent of the publisher.

Control

Subscribe

mention Process Engineering Control & Manufacturing when responding to items in this issue.

PRECISION IN PRODUCTION

Unleashing Robotic Potential with Real-Time Operating

By Winston Leung, Senior Product Marketing Manager at BlackBerry QNX

In manufacturing — where precision is paramount — the role of robotics in shaping efficient assembly lines, welding processes, and material handling cannot be overstated. The demand for precise synchronization in these operations is key; any deviation can lead to misalignments, defective products, and decreased overall throughput.

Particularly critical in automotive assembly, even the slightest jitter or latency issues can disrupt the seamless integration of components, resulting in quality control complications and increased production costs.

Embedded software addresses these challenges as highperformance, hard real-time operating systems emerge. They are designed for a spectrum of applications from robotic arms to autonomous mobile robots (AMRs) to drones. These systems must address present needs and align with Industry 5.0’s trajectory, which is built upon an even greater collaboration between humans and robots than we see today.

Manufacturing Challenge: The High-Stakes Precision Struggle

The critical demand for precision in production creates formidable challenges, particularly when it comes to high-speed robotic movements. Systems and devices requiring microprocessors with memory management units, such as robot manipulators, land and aerial drones, and automated guided vehicles (AGVs) require

hard real-time operating systems to facilitate seamless kernel execution across multiple cores. This provides the performance needed for safety-critical systems, particularly in advanced robotics and industrial controls.

The issue of jitter, defined by unpredictable timing variations, looms as a substantial threat to the meticulous accuracy required in these operations. This concern is amplified in scenarios where milliseconds wield immense significance, as observed in the intricacies of automotive assembly lines.

The repercussions of heightened jitter extend beyond mere inconveniences: They manifest as misaligned components and the creation of defective products, both of which contribute to a palpable decline in overall operational efficiency.

As industries strive for heightened productivity, the precise calibration of robotic movements emerges as a keystone that necessitates a strategic approach to address the intricacies of timing variations and safeguard the delicate orchestration of highspeed operations.

Manufacturing Solution: RealTime Operating Systems as a Precision Compass

Maximizing the performance of robotic systems, particularly in the face of high-speed movements, requires a strategic ally in the form of real-time operating systems (RTOS). Precision becomes a guiding compass for unparalleled efficiency.

Enhanced System Throughput

RTOS optimizes the overall performance of robotic systems by finely tuning task scheduling and execution. This meticulous orchestration ensures that critical operations take precedence, resulting in increased throughput and heightened production rates.

Optimized Processor Utilization

At the core of RTOS lies the ability to minimize processor utilization. By efficiently managing tasks and system resources, RTOS guarantees judicious use of processing power to prevent unnecessary delays and bottlenecks. This not only boosts overall robotic system efficiency but also yields significant cost savings by maximizing available processing power.

Power-Safe Recovery

Introducing resilient power-safe recovery mechanisms, RTOS enables robotic systems to gracefully handle unexpected events or faults. In case of a failure, the system can recover seamlessly without compromising precision. This minimizes downtime and helps ensure uninterrupted operation. This resilience is crucial to maintain a consistent level of precision in production processes.

Fast Boot Capabilities

The fast boot capabilities of RTOS significantly reduce the start-up time of robotic systems. This is particularly beneficial in scenarios where rapid deployment and initiation of operations are critical. With minimized start-up times, manufacturers can enhance the agility of their production processes to respond promptly to market demands while maintaining the desired level of precision.

6 PECM Issue 68

EDITOR’S CHOICE

BLACKBERRY QNX

Energy Consumption Optimization

RTOS contributes to energy efficiency by managing power consumption intelligently. Through optimized task scheduling and resource allocation, RTOS helps ensure that energy is utilized efficiently, reducing overall power consumption. This both aids in achieving sustainability goals and contributes to cost savings.

Conclusion

In the pursuit of precision in production, the choice of a realtime operating system emerges as an imperative. Its ability to elevate system throughput, minimize processor utilization, deploy power-safe recovery, reduce startup time, and optimize energy consumption aligns seamlessly with the demands of high-speed robotic movements. As industries strive for enhanced efficiency,

Introducing resilient power-safe recovery mechanisms, RTOS enables robotic systems to gracefully handle unexpected events or faults.

reduced costs, and impeccable precision, integrating an RTOS into robotic systems becomes a requisite step.

In the intricate balance of precision and efficiency within robotic systems, QNX® Software Development Platform (SDP) 8.0 emerges as the orchestrator of unparalleled solutions. It delivers

enhanced efficiency, costeffectiveness, and unwavering precision.

Its future-ready architecture, perfectly suited for the nuances of high-speed robotic movements, positions it as a key to unlocking the full potential of manufacturing processes.

BlackBerry® QNX® software solutions — including the SDP, RTOS, and Hypervisor — accommodate higher-compute applications. As Industry 5.0 unfolds, the integration of robotics and the human workforce becomes vital. BlackBerry QNX’s robust OS helps provide fault tolerance, failsafe deployment, and the hard real-time performance crucial for manufacturing applications where safety and reliability are paramount.

For further information, please visit www.blackberry.qnx.com/en

Issue 68 PECM 7

Good Practice Guidance for Electrical Instrumentation, Control and Cyber Security in Industrial Engineering –Improving efficiency and safety

• ‘By Industry, For Industry’, practical guidance for everyday and irregular situations and tasks

• Readily accessible for all in the industry –wherever they are, whatever time they have

• FREE task and procedure checklists

• professional development

• Webinars and seminars for knowledge sharing

• This selection of specialist publications and many

Also... EEMUA Seminar – Engineering Energy Transition – London, UK – 6 June 2024

To make EEMUA’s guidance, training, events and other practical resources work best for you and your team

ask@eemua.org or visit www.eemua.org

Training to prevent loss of hazardous substances…

From day one, Learners on the EEMUA MIPC® training build a unique workbook of mechanical integrity know how tailored to each Learner, site and company. Combining live online classes, e-learning, and one-to-one sessions with expert Tutors, enhanced by Mentor support and guidance throughout, EEMUA's Mechanical Integrity Practitioner Certificate course gives professionals the flexibility to learn on-site or on-call.

Registration open now. Learning starts 21October 2024. .

Developed and verified by industry to satisfy industrial engineering’s requirements for primary containment in old and new equipment – including pressure systems.

Keeps practitioner-level engineers on top of industry developments and good practice – so that valuable practitioners are most effective wherever they’re needed on-site. Enterprise-class, blended, live online system for productive learning – on-site or on-call.

Adapts to the engineering needs of each Learner and their company via an Induction of 2 hours prior to the course – to fit work schedules from September 2024

In-depth training to fit work schedules – 4 hours per week for 27 weeks.

CPD-approved with i industry recognised 5-year certification via robust exam.

For more information please contact online-learning@eemua.org +44 (0)20 7488 0801 www.eemua.org

MIPC® shortlisted for the Best E-learning/ Online Education Initiative memcom membership excellence awards 2020 and 2022

8 PECM Issue 68

Publication 227 Edition 1 Management of ageing electrical assets Publication 186 Edition 7 A Practitionerʼs Handbook for potentially explosive atmospheres Publication 227 Edition 1 Management of ageing electrical assets Publication 191 Edition 3 Alarm systems: Guide to design, management, and procurement Publication Edition Control rooms: Guide to specification, design, commissioning and operation

–

.

. . .

.

EDITOR’S CHOICE

ECO-MODE

Dirty Parts Cleaning at the Lowest Cost

Rozone’s bioremediating ROwasher range outperforms every parts washer on the market and beats our previous machine’s running costs by 54.5% and uses 30%-37% less consumables.* The ROwasher is the first innovation in parts washing for decades. It is UK-designed and manufactured, together with the bioremediating filter mat and the ROwash degreaser.

Contaminants such as oils and grease are always present in engineering and workshop environments. Current legislation makes us improve our sustainability, environmentally friendly, and health and safety credentials.

The ROwasher reduces toxic solvent use, cuts any toxic waste, and improves the technicians’ working environment, whilst reducing operating costs.

Discover more about bioremediation at www.rozone.co.uk/ bioremediation

For more information on the ROwasher, visit www.rozone.co.uk/ rowasher

Call Rozone’s ROwasher experts on 0121 514 0607, or email info@rozone.co.uk.

*Based on data from controlled laboratory trials in 2022

The GEMÜ 1441 cPos-X with ATEX / IECEx certification

An intelligent, digital electro-pneumatic positioner in two-wire technology used to control pneumatically operated process valves.

• ATEX / IECEx certified explosion protection for gas environments.

• Two-wire connection technology.

• Bluetooth communication for remote app access and configuration.

• Fast commissioning using well-balanced reconfiguration.

• Economical, almost no air consumption when idle.

• Low maintenance replaceable solenoid / filter cartridge.

www.gemu.co.uk

Issue 68 PECM 9

EDITOR’S CHOICE

REDUCES

THIS

*VERSES LEADING COMPETITOR BASED ON INTERNALLY CONDUCTED CONTROLLED LABORATORY TESTS IN 2022 WWW.ROZONE.CO.UK 01215 140 607

ENERGY CONSUMPTION BY 54%*

EQUATES TO A SAVING OF UP TO £300 PER YEAR IN ENERGY COSTS

INVESTMENT CASTING

The key benefits of manufacturing components using this versatile process

Investment casting allows us to create highly intricate and complex components with virtually any alloy. It produces excellent dimensional accuracy, high integrity, and a fine surface finish, capable of meeting the demanding specifications of a wide range of industry sectors.

What is investment casting?

Investment casting derives its name from the process used to form the moulds. A series of wax patterns is assembled together and dipped (‘invested’) in tanks of liquid slurry alternated with ceramic stucco. This builds up layers that dry to form a ceramic mould.

The wax is melted away, then molten metal is carefully poured into the mould. After cooling under controlled conditions, the ceramic shell can be removed, and the cast metal parts finished to requirements.

The key benefits of investment casting

• Versatility of design

Investment casting offers exceptional design flexibility. Complex components can be cast to near net shape, including internal shaping, undercuts and slots, and complex passageways. Thinner walls may be cast than is possible in other processes such as sand casting, leading to lower overall weight and improved efficiency.

• Versatility of materials

Most alloy bases, such as ferrous, aluminium, nickel, copper and cobalt, are well-suited to investment casting. At Investacast, we are expert in air investment casting nickel-base

superalloys. These alloys can be difficult to machine from solid, or to machine post-casting, and expensive to forge. Investment casting is the more economical manufacturing process of choice for components in these materials.

• Range of sizes and applications

At Investacast we have cast components weighing from 10g to 30Kg, for applications from turbine blades to camera housings, for a wide range of industries.

Tight tolerances

Investment castings can be held to much tighter tolerances than sand castings or forgings: close dimensional tolerances down to +/ - 0.15mm/25mm can be achieved.

• Exceptional surface finish

Investment casting gives a very smooth finish thanks to the ceramic mould, typically offering 1.6 Ra to 3.2 Ra surface finish as cast. This can significantly reduce the amount of secondary machining, and therefore time, required compared to other manufacturing processes.

• Rapid prototyping

Investacast’s rapid prototyping service allows companies to turn ideas

into products quickly and efficiently. We offer casting simulation and rapid production of prototypes to mitigate any risks when transitioning to production tooling.

• Low tooling costs

The investment casting process has much lower tooling set-up costs than gravity die or high pressure die casting, which require permanent casts to be manufactured. This makes it suitable for pre-production runs for high-volume pressure die cast products.

• Repeatability

The quality of investment castings is maintained, providing a very reliable product and low-cost repeat runs.

• Sustainability

Investment castings are created to near net shape, and we recycle our wax, so production waste is minimal. Advice from the investment casting experts

Our expert team can advise on DfM and whether investment casting is the right manufacturing method for your components. Call+44 (0) 1271 866200 or email info@investacast.com

10 PECM Issue 68

EDITOR’S CHOICE

INVESTACAST Find out more from the experts at www.investacast.com

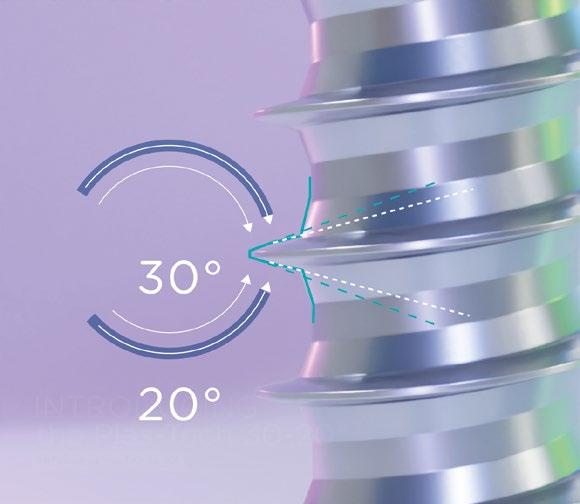

CUTTING-EDGE MOTION CONTROL

Advancing industrial printing with TSN

Developers of printing machines are facing particularly fast-paced and dynamic market conditions.

Harnessing the true potential of smart, automated industrial operations is crucial to meeting ever more ambitious customers’ needs and staying ahead of the competition. As fractions of a second can make a significant difference within advanced printing machines, cutting-edge motion control becomes paramount.

Tom Burke, Global Strategic Advisor at the CC-Link Partner Association (CLPA), looks at how Time-Sensitive Networking (TSN) can help achieve seamless synchronization, accuracy, and precision within complex, autonomous printing systems.

In many sectors, from publishing to pharmaceutical manufacturing, printing and stamping operations rely on machines that can quickly and reliably add high-quality designs and text with excellent resolution. To this end, the equipment must effectively offer precise positioning capabilities, correctly handle products and have all its axes moving in sync.

State-of-the-art motion control is therefore at the core of such units and their activities. Even more, as printing applications demand higher speed, greater resolutions and accuracies as well as lower tolerances, the need for next-level motion control solutions is evident.

Besides, as Industry 4.0 frameworks become a must to remain competitive, printing machine users are asking for solutions that can communicate with other machines

on the shop floor as well as higher enterprise-level systems to support smarter operations. Ultimately, to meet these demands, OEMs need to create highly interoperable setups that are equipped to offer this level of convergence. In this

regard, the selected industrial automation components must be able to leverage a high-performance network technology.

Addressing the needs of competitive industrial printing

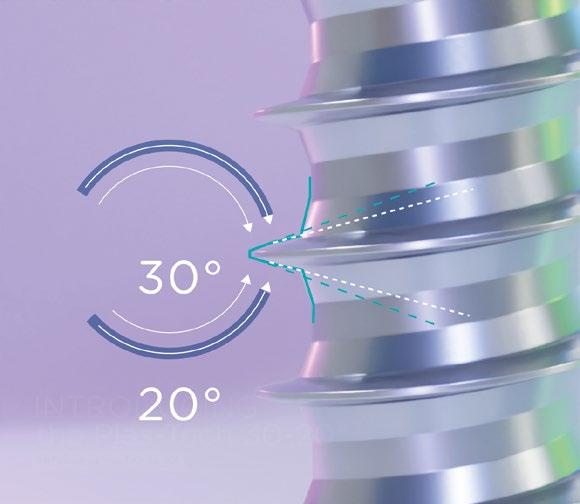

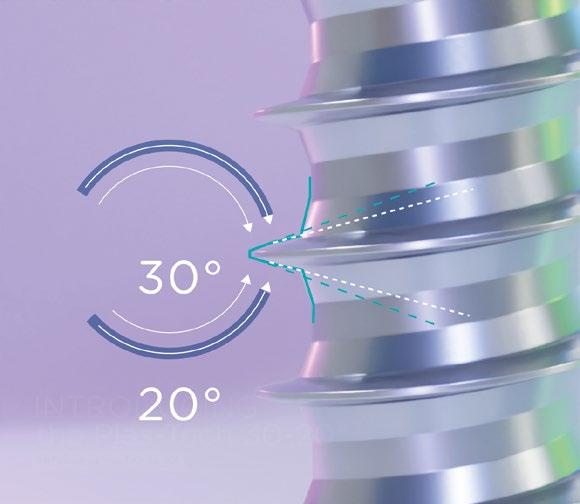

Traditionally, standard Ethernet has had limitations in meeting the stringent requirements of motion control, necessitating the setup of isolated networks to reduce latency, avoiding jitter and delay. The advent of Time Sensitive Networking (TSN) is providing a breakthrough solution. This technology, defined by IEEE 802.1 standards, is capable of establishing accurate, distributed time synchronization across multiple axes and network nodes.

TSN also enables the prioritization of urgent, time-sensitive traffic, while reserving cycle time for regular control data packets. This ensures deterministic performance even with large volumes of non-transient traffic, eliminating the need for specialized communication infrastructures for motion control. As a result, TSN can support the seamless integration of various message types from both the information technology (IT) and operational technology (OT) domains, in line with smart manufacturing strategies.

A leading network solution that embraces this technology is CC-Link

IE TSN, the first open industrial Ethernet with TSN functions and gigabit bandwidth. It offers a cycle time of 31.25μs and can synchronize up to 256 axes with accuracies in the order of ±1μs, therefore helping machine builders and end users with ambitious motion control systems for printing applications.

Case study: TSN advances industrial printing operations

A leading OEM of industrial printing and stamping machines wanted to develop an innovative, highly competitive solution to address its customers’ needs for increased speed, accuracy and repeatable quality. To deliver a such machine, the company invested in industrial automation technologies compatible with CCLink IE TSN, namely PLCs and servo drives.

In particular, the resulting machine could combine high-precision screen printing and hot stamping operations by being able to accommodate 90 axes. Through CC-Link IE TSN, these could all be synchronized with limited tolerances to deliver the high level of accuracy that customers would require. As a result, the setup offers a highly integrated and versatile solution that maximizes productivity, cost-effectiveness, flexibility, print quality as well as scalability.

Extremely happy with the capabilities of CC-Link IE TSN compatible devices, the OEM is now using them to upgrade its printing machine portfolio, driving its customers as well as its own competitiveness.

For further information, please visit www.cc-link.org/en/clpa/members/index.html

12 PECM Issue 68

CLPA

EDITOR’S CHOICE

RMIG is the world’s largest manufacturer and supplier of perforated metal and its related products.

We know our customers’ requirements for price and quality and meet their demands with uncompromising service.

Not only do we offer standard and bespoke perforated metal sheets, we are able to offer you a range of secondary operations as detailed below.

Complete solutions

Cutting

We can cut and shape perforated sheet to meet the needs of your nal application.

Levelling

For some applications a high degree of atness is required, we have processes in place to ensure our perforated coils and sheets meet with your most demanding requirements.

Rolling and forming

We can roll, bend and form perforated sheets to match your design.

Specialist Training for the Storage Tank Industry Live online

,

• Gain or renew your 5-year Certificates of Competence*

• Courses based on EEMUA 159

• English, Dutch, German and French language options

• Select from courses throughout year, including: TankInspector courses*

20-23 May 2024 – in English –classroom – London, UK

16-18 September 2024 – in French – classroom – Paris, FR

27-30 May 2024 – in English –live online – for MEA – GMT+3

10-13 June 2024 – in French –classroom – Paris, FR

14-17 October 2024 – in Dutch –classroom – Rotterdam, NL

4-7 November 2024 – in German –live online

TankBasics courses 16 September - 25 October 2024

–in English – blended learning (live online, e-learning, and more)

Also...

16-18 September 2024 – in English – live online – Houston time

23-25 September 2024 – in Dutch – classroom – Rotterdam, NL

28-30 October 2024 – in English – classroom – London, UK Storage Tanks e-learning

On-demand – in E English or D Dutch In-house courses

By arrangement for your choice of: time, language, location

EEMUA Seminar – Engineering the Energy Transition 6 June 2024 – London, UK

Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Publication 159 Edition5 TankAssessor courses*

More choices, information and registration at www.eemua.org and events@eemua.org

we make ideas come to life

EDITOR’S CHOICE

e-learning

in-house

classroom, blended,

or

YOUR SAFETY, OUR PRIORITY

A safe and secure working environment for your personnel, plant and property

As the industrial filtration, bulk handling and process industries face the constant challenge of explosion hazards, MacClancy and Sons Ltd emerges as a reliable partner in workplace safety. Their range of integrated Fire and Explosion Mitigation solutions includes top-ofthe-line fire & explosion protection systems.

In this article, we explore the critical role of these systems in mitigating risks and maintaining a safe and secure working environment for your personnel, plant and property.

The Importance of Effective Explosion Protection Systems

Explosions in industrial settings can, sadly, have catastrophic consequences, posing threats to human life, property, and operations. Investing in reliable explosion protection systems is a simple proactive approach to safeguarding your facility against potential disasters and it could cost less than you think.

Cutting-Edge Explosion Protection Systems

Early Detection: Raptor Spark detection systems feature advanced

A safe work environment fosters trust which is known to increase productivity.

infra-red sensors capable of detecting even the slightest presence of sparks, embers or even glowing dust particles. Early detection enables swift responses to potential ignition sources in multiple protected zones which can prevent a full deluge scenario across your plant.

Rapid Isolation & Venting: In the event of an explosion, VigilEX products simultaneously close isolation valves and release overpressure via sacrificial explosion vents in milliseconds, preventing any escalation beyond your filter, minimizing collateral damage and maximising safe working areas.

Customization and Flexibility

MacClancy and Sons understand that each industrial facility has unique explosion risks. Therefore, systems

are customizable and adaptable to specific needs, whilst providing optimal protection.

Long-Term Impact on Safety

By integrating VigilEX explosion protection & Raptor Spark detection systems into your workplace, you are demonstrating your strong commitment to the safety and well-being of your employees. A safe work environment fosters trust which is known to increase productivity. A well protected and safe workplace also reduces downtime due to better housekeeping, reduced safety related incidents or accidents and helps enhance your company’s reputation as an employer who leads the way in safety and safe working practices.

These explosion protection & detection systems are a crucial part of a comprehensive safety strategy for industrial filtration, bulk handling and process industries. With their cutting-edge technology, customization options, and expert guidance, they can empower your facility to stay ahead of any potential explosion risks and protect your assets.

14 PECM Issue 68

EDITOR’S CHOICE

MACCLANCY

LTD For further information, please visit www.macclancyandsons.com

AND SONS

CORROSION RESISTANCE

STAR FASTENERS

A Superior Corrosion Resistant Huck® Blind Structural Fastener

The Huck® 316 (A4) Stainless Steel Magna-Lok® Structural Blind Fastener

Engineered for superior corrosion resistance and retaining all the features of the standard (steel, aluminium and A2 stainless steel) version of the Huck® Magna-Lok®, the 316 A4 stainless steel MagnaLok® offers corrosion resistance beyond anything else in the Huck® blind fastener range.

The Huck® structural blind MagnaLok® retains the pin in the rivet body (sleeve) post-installation for extra tensile and shear strength. This 360° internal locking technology enables the pin to be mechanically locked to the sleeve as it expands during installation, giving excellent joint tightness and high-quality resistance to liquid penetration. The Huck® 316 (A4) stainless steel MagnaLok® is available in 6.4mm (1/4’’) diameter, with a wide grip range to accommodate variations in joint thickness (2.03mm -15.88mm).

Key Advantages of 316 Marine Grade, Non-Magnetic Huck® Fasteners:

metals and composites, expanding their applicability across industries.

Non-magnetic properties: Non-magnetic fasteners are essential in environments where magnetic fields can disrupt sensitive electronic components or equipment

Strength and durability: Huck® fasteners provide strong and reliable joints, often with loadcarrying capabilities comparable to or even exceeding traditional fasteners. 316 stainless steel offers high tensile strength and durability, allowing fasteners to withstand significant loads and stresses.

Ease of installation: Huck® MagnaLok® structural blind fasteners are relatively easy to install, requiring minimal access to only one side of the of the joint.

Vibration resistance: Huck® fasteners offer excellent resistance to vibration, making them suitable for applications where the joint might experience movement or mechanical stress.

Corrosion resistance: The primary advantage of using 316 stainless steel fasteners is their exceptional resistance to corrosion.

Aesthetic appeal: The smooth and polished appearance of stainless steel 316 gives a visually appealing finish to the fasteners, making them suitable for applications where aesthetics matter.

Low maintenance: Thanks to their corrosion resistance, Huck® fasteners generally require minimal maintenance over their lifespan.

Versatility: They can be used to join different materials, including

Replaces welding: In some cases, 316 Magna-Lok’s can replace the need for welding. 316 stainless steel is susceptible to weld decay; the welded area can be more vulnerable to corrosion, weakening the bond of the weld. Weld decay primarily affects the microstructure of the material around the weld joint. When 316 stainless steel is heated to certain temperatures (typically in the range of 800 to 1600°F or 425 to 870°C) during welding, carbon in the steel combines with chromium to form chromium carbides. This process depletes the chromium content in the immediate vicinity of the weld joint, leading to a reduced ability to form a protective chromium oxide layer that provides the stainless steel’s corrosion resistance.

Mechanical advantages: these include, excellent gap closure capability, a flush pin break and outstanding hole filling on the blind side and is capable of filling irregular, slotted, oversized, or misaligned holes, whilst providing strong, vibration resistant joints.

Where is the Huck® A4 MagnaLok® Fastener Used

The A4 stainless steel Magna-Lok® is widely used in industries and applications where a combination of corrosion resistance, strength, durability, and aesthetic appeal is required. It finds applications in construction, architecture, automotive, aerospace, food processing, medical devices, household appliances, and many other areas where resistance to corrosion and staining is essential.

16 PECM Issue 68

EDITOR’S CHOICE

Huck Range Force Battery Installation Tool

Stainless Steel: A2 vs A4

– a simple guide

Chemical Composition

A2: Often referred to as 304 or 18/8 stainless.

18/8 refers to the amount of chromium and nickel in the alloy – 18% chromium and 8% nickel, the chromium provides a corrosion and oxidation resistance, however it can be prone to tarnishing.

A4: often referred to as 316, 18/10 and marine grade stainless.

18/10 refers to the chromium and nickel content- 18% chromium and 10% nickel, and 2-3% molybdenum. The molybdenum increases the corrosion resistance to withstand attack from many solvents, for example, sulfuric acid, chlorides, de-icing salts and industrial chemicals. It is considerably more resistant to solutions of bromides, iodides and fatty acids at high temperature.

Corrosion Resistance

A2 (304): Offers good corrosion resistance in most environments, but not as resistant as A4 in corrosive environments like marine or chloride-rich settings.

A4 (316): Provides excellent corrosion resistance, particularly in chloride environments like marine settings or industrial areas with exposure to chemicals.

Strength and Durability

A2 (304): Offers good strength and toughness suitable for many general-purpose applications.

A4 (316): offers the same strength characteristics as A2 but it is more corrosion resistant in demanding environments.

Both A2 and A4 grades are classed as Austenitic stainless steel (sometimes called the 300 series). This means that they have high chemical resistance but cannot be hardened by heat treatment. They can be hardened by cold working.

Molybdenum Content

A2 (304): Does not contain molybdenum.

Huck Magna-Lok Cross SectionUninstalled and Installed

A4 (316): Contains molybdenum which enhances its corrosion resistance.

Stainless steel may also contain other alloying elements such as nickel, titanium, copper and manganese, among others, to enhance specific properties like strength, corrosion resistance, and durability. Non-metal additions are also made, the main ones being Carbon and Nitrogen. The exact composition and properties of stainless steel can vary depending on the specific grade or type.

Common Properties of A2 and A4 Stainless Steel

While A2 (304) and A4 (316) stainless steels share common properties, their differences in composition, particularly the addition of molybdenum in A4 (316), result in variations in corrosion resistance and mechanical properties. As a result, the selection between A2 and A4 stainless steel depends on the specific application requirements, particularly the level of corrosion resistance needed.

In summary, while both A2 (304) and A4 (316) stainless steels offer corrosion resistance and are widely used, the choice between them depends on the specific application requirements. A4 (316) is generally preferred for applications where superior corrosion resistance, particularly in harsh environments is essential.

Star Fasteners have been a Huck® fastener distributor for over thirty years and are the UK’s largest stockists - we have a wealth of knowledge and experience gained from working in a wide variety of industries. An extensive stock ensures that customers never have a break in supply; this together with a hire tool fleet, an in-house tool maintenance repair department, and in-house powder coating facility, ensures an allencompassing service can be relied upon.

A key strength of Star Fasteners is our ability to work with customers on projects and to find solutions that will help optimise the application whilst also improving the overall efficiency. We work globally with a diverse range of end users and distributors from across a number of industries, offering technical application knowledge and customer support. Huck® fasteners guarantee performance and help maximise your return on investment; get the right fastener for your project and achieve your business goals.

Issue 68 PECM 17

For more information call us on +44(0)115 932 4939 or email sales@starfasteners.co.uk

ADAPT OR PERISH

AXAIR FANS UK LIMITED

A new approach in an antiquated industry

By Andrew Jones – Technical Director, Axair Fans UK Limited

Based on data 90% of large, and more than two thirds of smallmedium enterprises are facing skills shortages in engineering. In our industry the problem is far more specific; it’s an in-depth knowledge and application of physics to understand pressure development, air movement behaviour, the infinity fan laws around power, pressure and volume, and a basic awareness of chemical properties, these are the common things that our customers in particular struggle with. In education, this type of knowledge is typically taught only in theory, yet the application of that theory used to problem solve and apply, is a skill that is more difficult to ascertain. As a child I was born with what the industry calls “the knack”, a natural ability to understand and apply concepts quickly and easily, but my formal education was in no way suited to the skill set I had.

This brings me on to qualifications and skills being different. These transferable skills are so specific that companies simply cannot get that experience from looking at employee’s formal qualifications, or by making hires based on statements on paper. Especially, as with my experience, people sometimes don’t find their feet until later due to a lack of direction. As the technical director of a fan business, I’m pleased that we have a forward-thinking approach, removing the barriers that can obstruct people from entering the profession, allowing them to reach their potential and rise to the top.

We hire on ability, through having conversations and interpreting their understanding and approach to problem solving, we quickly determine if the knack is there. Out in the field there are striking gender differences, especially on more technical roles, I’m proud that we have an equal balance of male and female employees. Comparably, our team are getting younger, going against the grain on the issue of an aging workforce in the field. Today’s industry employment reports show that 19.5% of engineers working in the UK will retire by 2026, exacerbating the skills shortage.

The continued challenge for manufacturers is evident, with 98% of companies expressing concerns that their business will suffer if they can’t hire the right engineers or technical biased employees. New graduates often struggle with the ability to apply their theory to actual problems as their education has not been geared towards problem solving. This leaves that seismic shift when experienced engineers at the top are replaced with new engineers.

That’s where collaboration with suppliers and manufacturers is key, the new approach in an antiquated industry. It’s ignorant to think that companies should have an inhouse team that make technical calculations, designing in isolation with the desired outcome of delivering the best system that performs at the optimal level for the customer project. Minimising disruption by working with external experts in niche areas is one way to make an instant positive impact to your business, with no training or recruitment required. Incredibly valuable if those businesses are working on time-sensitive projects or need to avoid any impact on production delays.

It’s a matter of adapting or perishing for businesses that rely on their technical product selection teams. Adapt by working collaboratively and utilising the skill sets of other businesses, businesses such as Axair that can understand the industry needs and anticipate solutions, suggesting potentially creative business enhancing fan components that could create opportunities for greater market share and customer satisfaction, or perish by losing competitive advantage through falling behind on technological advancements and relying on inhouse teams that lack the application knowledge without giving them the support from these experts. At the end of the day, no one ever beat a competitor by staying the same, speed and adaptability is the new key performance indicator in today’s economy. The antiquated approach of we’ve always done it this way simply doesn’t hold weight.

18 PECM Issue 68

EDITOR’S CHOICE

For further information, please visit www.axair-fans.co.uk

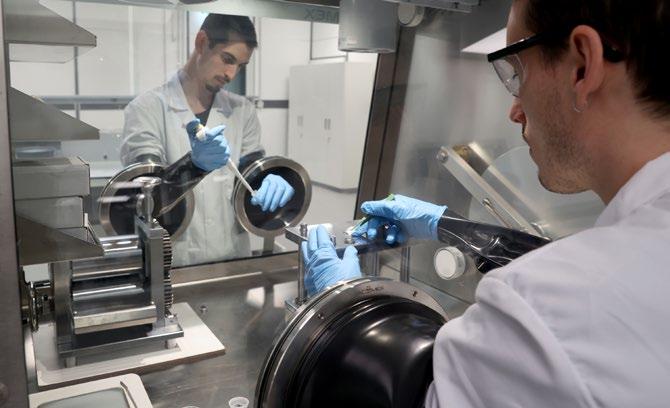

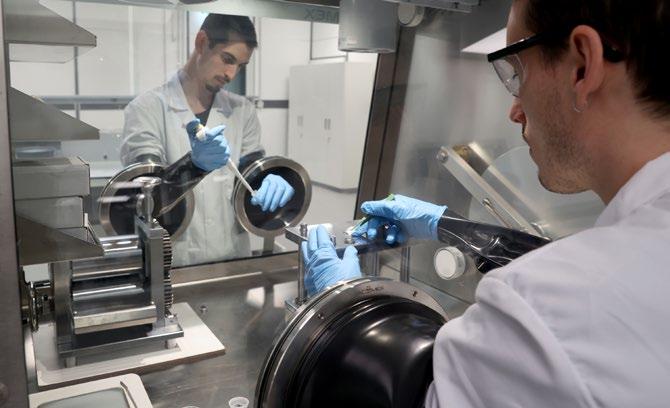

INAUGURATION OF E-CELLS LAB

The electrochemical research laboratory promoted by Ferrari in Collaboration with the university of Bologna and NXP

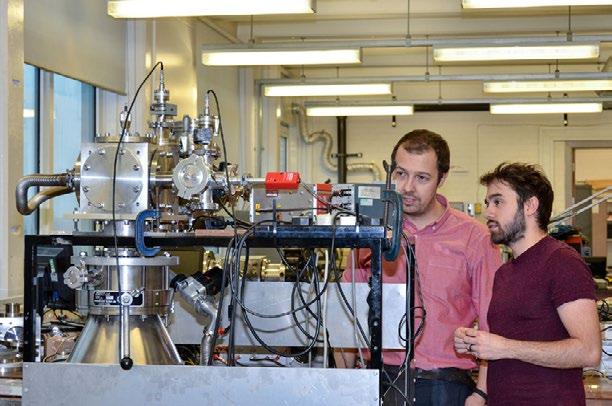

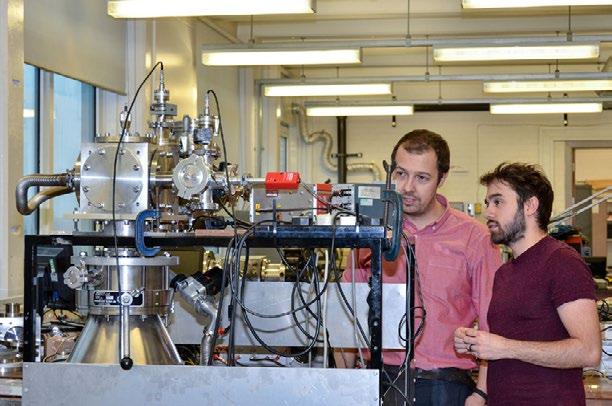

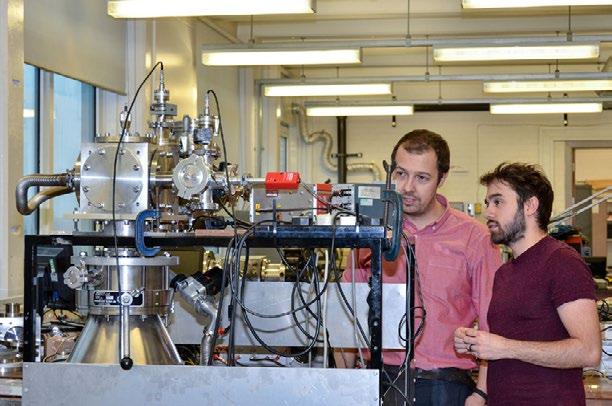

The inauguration of E-Cells Lab, a research centre for electrochemistry within the University of Bologna, was held today. The laboratory, which was set up under the university’s scientific direction, aims to build knowledge of the materials, and the chemical and physical properties, of lithium cells.

It marks an important contribution to the electrochemical research, thanks to the collaboration with the University of Bologna with whom a dedicated space with cutting-edge equipment to conduct advanced analyses. Ferrari has FERRARI

also promoted and supported the laboratory through the exchange of expertise with the university and its partner; it strongly believes in the great value the project holds for the local area, and for the automotive segment in particular.

The applications developed in E-Cells Lab will be shared with leading electronics company NXP, technology partner and supporter of the project. This collaboration between different organisations, which in future may extend to new companies, will be of vital importance in extending the scope and value of the research activity.

The laboratory consists of two areas: the first is dedicated to preparing electrochemical materials, the second to analysis, tests and determining the characteristics of the materials themselves. There will be a particular focus on solid states, fast charging, thermal charging, cell safety and performance. The results will help Ferrari to develop a shared language with its cell suppliers, with the aim of optimising the performance of the batteries that will be assembled in the Maranello plants.

“E-Cells Lab represents an exciting beginning and demonstrates our

20 PECM Issue 68

EDITOR’S CHOICE

E-Cells Lab represents an exciting beginning and demonstrates our commitment to education and research.

commitment to education and research. The project also reflects the importance that the confluence between the academic and business worlds has always had for us,” said Benedetto Vigna, CEO of Ferrari. “Today, from this confluence comes a laboratory that will make an important contribution to studies in the field of electrochemistry, generating innovation in our local area and building the skills of the future.”

The Chancellor of the University of Bologna, Giovanni Molari, commented: “I am pleased that Ferrari has chosen the Alma Mater for this important project

in scientific and educational innovation. I’m sure that this collaboration will be fruitful and herald significant results. This agreement encapsulates many characteristic facets of the Alma Mater: the will to remain at the cutting edge of both teaching and research; dialogue with the Italy’s most important public and private institutions; the desire to promote new synergies that can act as a model and a driver for key areas in our collective development.”

“Close collaboration across industry and academia allows us to accelerate the research on safe, efficient and sustainable battery innovations significantly,” said Jens Hinrichsen, EVP and GM of Advanced Analog at NXP. “Through the combined efforts of NXP, Ferrari and University of Bologna, we expect to set new benchmarks for performance and sustainability to reach our common goal of a greener, brighter future.”

Issue 68 PECM 21

For further information, please visit www.ferrari.com

ADDITIVE MANUFACTURING

MARKFORGED

“In the year ahead, we’ll see more additive technology at work on factory floors around the world…”

In 2023, global events coupled with the cost of living crisis have motivated manufacturers across a range of industries to re-think their centralised production models. We’ve seen more companies integrate technologies like additive manufacturing (AM) into their factory floor operations to work alongside traditional processes, enabling more immediate and costeffective manufacturing on-demand – helping to meet the challenges head on.

Advances in technology are helping to drive this shift away from shortterm solutions-led thinking toward a more strategic approach – using AM for the sustainable production of certified end-use parts, which we’ll see more of in the year ahead.

This article explores trends in manufacturing practices, along with Markforged’s Senior Product Marketing Manager Daniel Leong’s predictions for the role of AM in 2024.

The continuing trend of personalised and on-demand manufacturing

On-shore production and localised manufacturing practices are already providing businesses with greater flexibility, responsiveness, and resilience in the production process, which I believe is set to continue in the coming year.

I predict we will see more designers, engineers and manufacturers across a variety of industries adopting AM to design, test, create and customise the parts, tools and products they need, when and where they need them.

This AM-fuelled drive toward ondemand manufacturing will also help businesses to reduce their transportation and shipping costs, environmental impact, and product lead time, increasing efficiency.

Smart(er) AM

Additive technology is getting smarter. This is due in large part to advances in connected AM platforms that allow machines to collect – and learn from –information with each build. In essence, AI is helping to solve hardware problems with a software solution, creating new opportunities and challenges for AM.

In the year ahead, we will see further integration of data-driven technologies such as sensors, feedback, analytics, artificial intelligence, and the Internet of Things (IoT) continuing to enhance the quality, reliability, and efficiency of the AM process and products.

These data-empowered, Smart AM platforms will add another layer of insurance against supply chain challenges, untimely holdups and failures, helping to perfect designs that allow manufacturers to get the best performance and business returns from every part they print.

Faster printing speeds

Smarter AM also means faster AM. In-built calibration and inspection technologies not only optimise part design and accuracy, but help to speed up the 3D printing process. In addition, increased material capacities and automated material changeover capabilities found in the latest machines like Markforged’s

FX10 reduce human intervention and bottlenecks, keeping things running smoothly.

Faster, more accurate prints reduce the time and cost of AM and increase its ROI, making it even more competitive than traditional manufacturing methods. This acceleration also helps new adopters of the technology to learn, test and iterate through faster prototyping, enhancing the innovation and learning potential of AM.

Overcoming challenges, together

With advancements come new challenges, and two which I believe will have an impact on the adoption rate of AM in the year ahead are regulatory issues and tighter budgets.

Collaboration is essential to help address and overcome these obstacles.

While standards bodies like ASTM have developed a range of AMspecific global standards, there is still work to be done. A lack of clear and consistent guidelines, certifications, and quality assurance can pose risks and barriers to widespread adoption of the technology in industries like aerospace. I’m hoping we’ll see all parties sit around tables in the coming year to address these issues and challenges and work together to establish workable standards. We will no doubt see more restricted budgets across industries in the new year, making it even more essential for any technology to prove ROI. AM providers and their customers can help to advance adoption rates by highlighting the benefits at

22 PECM Issue 68

EDITOR’S CHOICE

board level by documenting their successes, sharing proof of concept wins and developing case studies illustrating increased efficiencies and innovation.

Sustainability and ESG

With the global temperature in 2024 set to be the warmest year on record, it will be harder for governments and business to ignore the growing social, and governance (ESG) agenda. While these are complex issues, especially when it comes to manufacturing industries, I believe investors and consumers alike will continue to encourage the development of a circular economy and the reduction of carbon emissions. AM’s role in local and

While standards bodies like ASTM have developed a range of AM-specific global standards, there is still work to be done.

on-demand manufacturing can help to reduce the monetary and environmental costs of waste, energy consumption, and shipping, but there is more to be done.

The industry is already asking questions and exploring issues

like: how plastic from processes like 3D printing can be reused, how production waste can be recycled and how we can develop strong, robust filament from recycled materials. I think we will see a move in the AM community toward research and advances in more sustainable materials and processes not just in 2024, but in the years ahead.

As it continues to become smarter, faster, more accurate, efficient, and – undoubtedly – more sustainable, AM will become a more integral part of production lines and manufacturing processes. I believe that in 2024, we will see more additive technology at work on factory floors around the world.

For further information, please visit https://markforged.com/

Issue 68 PECM 23

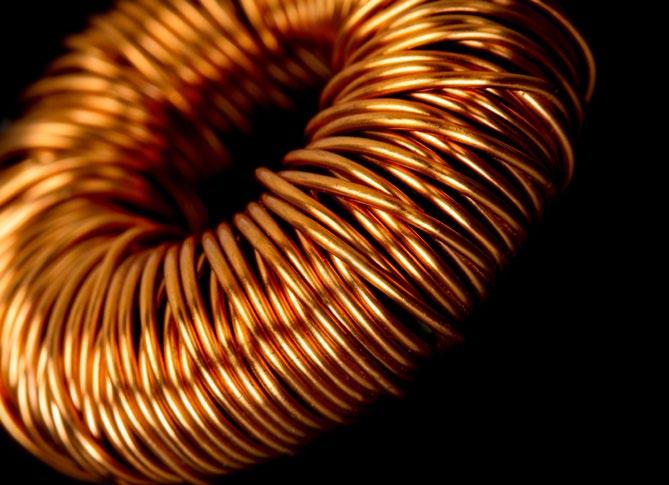

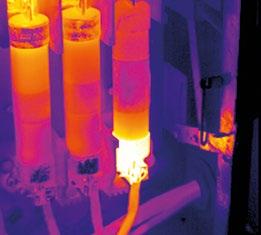

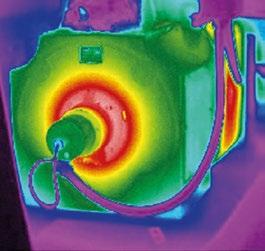

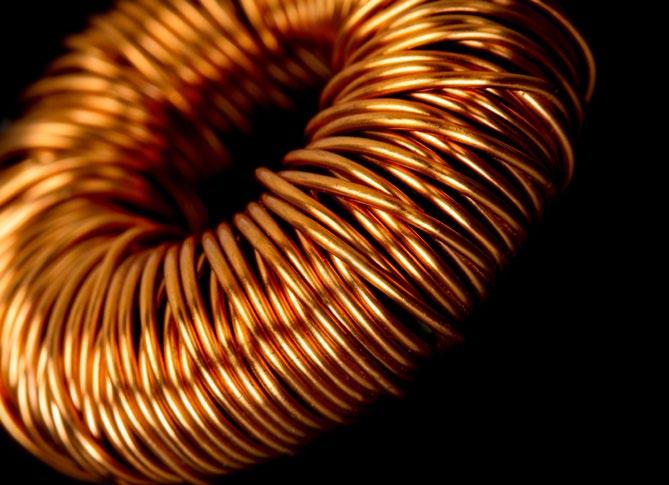

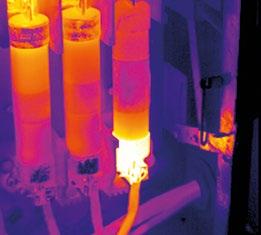

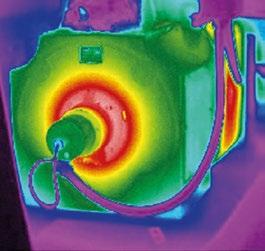

NO COPPER, NO NET ZERO

CWIEME BERLIN

The role of nature’s greenest metal in the energy transition

Achieving Net Zero by 2050 essentially means completely phasing out fossil fuels in under 30 years. We can’t do that without copper, say Bruno De Wachter and Fernando Nuño, representatives of the International Copper Association and members of the advisory board of international electrical engineering trade show, CWIEME Berlin. Here they discuss the challenges facing our relationship with this ancient metal.

Humanity’s history with copper goes back around 10,000 years. Neolithic peoples first used native copper in tools, weapons and decorative items, and smelting of copper kicked off the Bronze Age about 5,000 years ago. The Romans mainly sourced it from Cyprus, calling it aes cyprium, ‘metal

of Cyprus’. This subsequently became cuprum, the origin of the English word copper.

In Roman times, copper was predominately used in the empire’s coins and to make brass for specialised uses like ornaments and some aspects of plumbing and architecture. Today however, more than two thirds (70 per cent) of modern copper production is earmarked for electrical applications. Copper is involved at every stage of the electricity system: generating it, transferring it, and using it.

Why copper?

On the journey to Net Zero, electricity is our main tool, and the backbone of our electrical system is copper.

Copper is the second most conductive known metal after silver, and more conductive than gold, but the scarcity and price of these two precious metals make them unsuitable for the millions of tonnes required for a global energy network. Copper’s physical properties, such as its ductility and resistance to corrosion make it ideal for countless components like cables, connectors, and coils. Finally, it’s the 25th most abundant element in Earth’s crust and it can be recycled without any significant loss of quality.

Copper’s unique properties solidify its position as the essential material for electrification, the energy transfer system that underpins humanity’s path to Net Zero.

24 PECM Issue 68

EDITOR’S CHOICE

More power, faster

As electrical infrastructure develops and standards of living improve around the world, we’ll naturally need more megawatts of power to meet demand. But a side effect of the green energy transition is that each megawatt of electricity end use will be more copper intensive than fossil fuel alternatives.

The main reason is that renewable electricity generation is much more dispersed than conventional thermal generation from fossil fuels, making it more material intensive. For example, each wind turbine of 1 to 5 MW has its own generator, while a coal fired thermal power plant has one generator of typically 400 MW. A more dispersed generation also means that the grid for transferring electricity from where it’s made to where it’s needed must expand.

In addition, generating electricity from sustainable sources is often weather-dependent. While coal can burn nearly 24/7, wind power needs a consistent breeze and solar power only works during the daytime. To compensate for natural low-output periods, we’ll need extra production capability and storage to keep up with demand, meaning more copper for more renewable energy systems. This is another reason why we need a stronger grid: the better all sites of generation and consumption are interconnected, the easier it becomes to tap the electricity from where it is available at that moment.

Clean electricity will be the largest consumer of copper by 2040, but copper is also used for some of the non-electrical systems that aid the transition to Net Zero.

Generation is one thing, but Net Zero means decarbonising energy at the other end of the chain too: the end user. Carbon-free end-use energy on the roads, for instance, means more electric vehicles, but each requires 2-3 times more copper than an internal combustion engine powered vehicle.

Clean electricity will be the largest consumer of copper by 2040, but copper is also used for some of the non-electrical systems that aid the transition to Net Zero. For example, as an excellent thermal conductor, copper is often used in heating and cooling systems, such as those found in heat pumps, which are playing a major role in reducing fossil fuel use for heating.

Finally, the quest for energy efficiency itself is copper intensive. According to Joule’s law, energy lost as heat in an electrical wire

is proportional to resistance and resistance is inversely proportional to wire diameter — so the thicker a copper cable is, the less energy is wasted as heat and therefore the more efficient the system is. This includes the windings of transformers and electric motors. Essentially, the more copper we use in each application, the more energy we save.

Is there enough?

The International Energy Agency has published two scenarios for future copper demand. The Stated Policies Scenario (STEPS) is based on what governments have already pledged to do, and the more aggressive Sustainable Development Scenario (SDS) is based on reaching Net Zero by 2050. Both scenarios see annual copper demand increasing to 40 Mt by mid-century (from around 26 Mt nowadays), either in 2050 for STEPS or 2040 for SDS.

Considering these lofty figures, it is natural to wonder whether Earth has enough copper to meet our requirements. The short answer is yes. Enough resources exist to support the energy transition and meet society’s needs. The question is whether we can extract that copper quickly enough to align with STEPS or SDS.

Primary copper production currently sits at 22 million tonnes (Mt) annually. Together with 4 Mt of recycled copper, this meets current demand of 26 Mt. Demand has grown by about 3.3 per cent per year for over a century, doubling about every 30 years. In the past, the drivers for copper demand were population growth, electrification deployment and electricity usage. Today, it is the green energy transition and improving global standards of living. At present, we have about 41 years’ worth of copper reserves — copper in the ground at operational mines — and up to 250 years’ worth of predicted, but currently unexploited resources.

Surprisingly, the number of years’ worth of copper reserves has been roughly the same for decades. Just like with oil, the scarcer it becomes, the more effort goes into finding more.

Issue 68 PECM 25

It may be possible to reduce our reliance on copper by developing alternatives such as aluminium. Aluminium is about three times lighter than copper, so might be advantageous for use in electricity overhead lines, for example. On the other hand, in space and weight constrained applications, the increased volume of aluminium and surrounding structure required to provide the same functionality as copper makes it unsuitable.

Another area of research is graphene, which is also three times lighter than copper but more than twice as conductive and made from carbon, which is ten times more abundant. It’s promising, but the uses of graphene in the electrical industry is a field currently dominated by research and it will likely be decades before graphene becomes a mainstream alternative to copper.

If growth continues at historical rates and copper production increases in line, as it has done for over 100 years, there’s nothing to be concerned about. Meanwhile, changes in the way we produce copper are being introduced.

Low impact production

It’s essential that we maximise copper recycling to keep secondary copper in circulation. Electrical copper’s properties, such as purity,

favour recycling and doing so is much less impactful than mining. However, current recycling of pre- and postconsumer scrap (10 Mt) provides just a third of today’s demand and a fifth of 2040’s SDS. Furthermore, post-consumer scrap only becomes available after the lifespan of the equipment has passed, around 30 years for a transformer, for instance.

Green copper

For now, at least, mining existing resources for primary copper is essential. In fact, without mining there can be no Net Zero. While zero impact mining is impossible, mining must be responsible — a careful balance of economic, environmental, political and social challenges.

In some cases, that balance is hard to strike, as evidenced by the closure of one of the world’s largest openpit copper mines in late 2023. In response to nationwide protests ranging from environmental concerns to corruption suspicions, Panama’s top court ruled that Canadian miner First Quantum Minerals’ contract at Cobre Panama was unconstitutional and forced it to shut down operations at the mine. The site in Donoso employed 7,000 people, accounted for around five percent of Panama’s gross domestic product and one per cent of global copper output.

International collaboration and sharing of ideas and expertise at events like CWIEME Berlin, help the industry collaborate and do its part to maximise the benefits of copper use and reduce the environmental impact of copper production.

For example, 0.2 per cent of global carbon emissions come from the production cycle of copper, from mining to refining and production. While this is much less than the emissions copper helps prevent, the members of the International Copper Association have committed to the ambition of reaching Net Zero for Scope 1 and 2 emissions by 2050. Or consider The Copper Mark, an industrywide standard to encourage the responsible production, sourcing and recycling of copper and other critical metals. Based on 32 indicators, the certification is designed to cover social and environmental themes, from social engagement and prevention of child labour to responsible use of water and management of resources.

Humans have been using copper to make life better for thousands of years and, with the right approach, we can continue using it for thousands more — perhaps its greatest era is still to come.

26 PECM Issue 68 For further information, please visit www.berlin.cwiemeevents.com/home

® UK's largest distributor AUTHORISED HUCK TOOLING SALES, HIRE & REPAIR RIVETS,THREADED INSERTS MAGNA-LOK® BOBTAIL® PENTALOK HUCKTAINER® C5OL® MAGNA-GRIP® BOM® ·�·Traditionally Innovative

FORWARD PLANNING

Polymer Succession Planning … Without the Drama

If you’ve been gripped by the brutish award-winning series Succession, you’ll be forgiven for picturing every top-level management transition as a dynastic psychodrama. Yet, as technical toolmaker and trade moulder Cybertools can testify, the retention struggle for UK SMEs in the manufacturing space can be eased with some sensible forward planning combined with the support of external industry training.

Succession planning is something that every business needs to face. Whether through retirement or an unexpected shift in personnel, having a plan is strategically crucial. However, it is not an overnight process.

Marking an important phase in the company’s growth and having just secured a 40-percent share in a Chinese-based tooling factory, founder and leader of Cybertools Paul Brown has put in place a robust plan for the Buntingford-based firm’s business continuity. Investing heavily in his workforce, the forward-looking MD is one of the strongest advocates of removing development barriers and nurturing talent internally.

Rather than reacting and filling positions passively, Cybertools is instead developing its workforce to grow into these future gaps. Part of this process includes incrementally adding responsibilities and booking team members onto the IOM3accredited Sumitomo (SHI) Demag Academy courses run by Darren Vater-Hutchison.

Mould Setter Leo, accompanied by Quality Control Production Trainee Jiji, are now on an accelerated progression journey at Cybertools, with a vested interest in carrying forward the company’s legacy.

A rising tide lifts all boats

As the third largest employer in the UK, the plastics industry comprises a high proportion of SMEs. Like Cybertools, most of these are lean, family-run businesses, headed up by owners looking to retire in the next decade or sooner.

With the industry’s technical education and skills system still teetering on a precipice, and conscious that time is ticking, Paul took the proactive steps to invest in his teams’ future, earmarking several colleagues for progression and booking them onto three Academy courses. Leo is three quarters of the way through his development program at the Daventry facility, with just the Advanced Injection Moulding course to complete. Jiji is close behind.

The reciprocal, and equitable benefits of investing in development, are multiple, exclaims Paul. “We

are creating a work environment where everyone can feel they can give their best and that this will lead to a fulfilling career pathway. By extension, it increases their confidence in our business, which increases loyalty. The more skilled team members become, the more I can delegate and step back from the day-to-day management tasks.”

Returning from their respective Sumitomo (SHI) Demag Academy courses at the end of 2023, both Leo and Jiji expressed heightened confidence in operating the injection moulding machines and a more detailed understanding of advanced setter processes.

Although subtle, the productivity benefits are also evident states Paul. “Confidence results in quicker set up times. This probably gives us 2-3 hours more of production capacity each week. However, the most

28 PECM Issue 68

EDITOR’S CHOICE

SUMITOMO

Jigi (L) and Leo (R) with Cybertools founder and leader Paul Brown, a strong advocate of removing development barriers and nurturing talent internally.

We are creating a work environment where everyone can feel they can give their best and that this will lead to a fulfilling career pathway.

noteworthy benefit is the swift return on investment. Knowledge equals expertise; expertise equals value; and valued people feel more seen and appreciated.”

Tapping diverse perspectives

The result is a contagious culture. “Positive and driven colleagues motivate others. When my team return from a course sharing everything they have learned with their production peers, it only reaffirms the importance of investing in skills,” adds Paul.

Examining the wider challenges, Paul encourages leaders who are scouting for talent to look for potential rather than pedigree. “Given the scarcity of academic technical training, utilising well-respected development

frameworks designed by people who understand the ins and outs of our industry can help our future leaders to define and steer their career pathway. Another sideline benefit is we are empowering future mentors.” Industry trainer and one of the masterminds behind the winning 2023 Plastic Industry Awards training & development program, Darren Vater-Hutchison concurs. Having delivered courses to over 700 industry colleagues at Sumitomo (SHI) Demag’s IOM3-accredited Academy, Darren expands: “High quality industry training can help to address the lack of curriculum investment and provides a more direct and immediate solution to local and national skills shortages. Machines make parts. However, knowledge creates value. This value increases markedly as knowledge moves up the scale. Most importantly, this accumulative knowledge is being passed onto to future leaders.”

Earning the certificate in Toolsetting Technology (TSett) and Mould Mounting (MMount), Jiji, who joined Cybertools with no significant engineering knowledge, has reached the halfway point in his professional development program. Jiji comments: “The Academy courses have helped me to gain a better understanding of moulding processes and how

they relate to QC issues. I am more confident in my ability to get good results from the machines with an understanding of cause and effect in the processes. This is giving me the confidence to progress as a tool setter which will hopefully open up even more career possibilities in the future.”

Testament to the progression opportunities, Leo commenced his career with Cybertools as a temporary picker and packer. Now running the UK mould shop, he recently started to provide input into major project quotations. Leo comments: “The Academy training has given me a more advanced machine understanding and guidance on ways to be more precise with process adjustments.” Leo is eager to continue putting this advanced knowledge into practice, and hopes to shortly complete the Advanced Injection Moulding (AIM) course to further his knowledge and career.

Attesting to the importance of training, Paul says that when the right person comes along who clicks with your business and culture, you just know that making the investment is worth it. “Developing staff is a long game. Jiji proved straight away that he was good with detail, which is perfect for QC work. Having tuned his technical abilities, Leo is now running our mould shop.”

Paul cautions that failure to listen and address workforce needs could result in alienating and losing your future talents and company successors. “People need to have a workspace where they can feel they can thrive and progress. Much of this can be underpinned by clear development goals and a good training program.”

The Sumitomo (SHI) Demag Academy offers a mix of structured and bespoke polymer processing and industry-led training and development courses, aimed at all operational levels, from new starters to tool setters, engineers and asset care managers. All course content has been designed to enhance skills knowledge, workforce productivity and Overall Equipment Effectiveness (OEE).

Issue 68 PECM 29

www.sumitomo-shi-demag.uk | www.sumitomo-shi-demag.ie/

Earning the certificate in Toolsetting Technology (TSett) and Mould Mounting (MMount), Quality Control Production Trainee Jigi demonstrates his understanding of moulding processes to colleagues.

Union Industries rises to the challenge with triple Bulldoor installation at Warburtons

Union Industries, the UK’s leading manufacturer of bespoke high-speed doors, has helped Britain’s largest bakery brand overcome adverse weather conditions with the installation of three Bulldoors.

Led by the fifth generation of the Warburton family, the company approached Union to assist in combating strong winds at its Burnley site, which already has a Bulldoor as well as two Matadoors from the range.

It first approached Union Industries in 2004 to install a Bulldoor, which continues to operate effectively and efficiently two decades later.

Union’s Bulldoors, regarded as the ‘reliable workhorse’ of rapid roll doors, are known to perform more than 1.4 million cycles per year, making them a popular choice across multiple sectors. They feature specialist ‘Crash-Out’ and ‘Auto-Reset’ damage protection facilities, and offer control outputs for options such as airlocks, traffic control systems and remote monitoring, whilst aiding temperature control for ambient and chilled environments.

Cybertools Limited

If you are looking for a UK based toolmaker, then you need look no further than Cybertools. Cybertools are specialists in the design and manufacture of plastic injection mould tools. We have a fully equipped Toolmaking facility here in the UK and have over 25 years of toolmaking experience. We have quality standard ISO 9001 and ISO 14001 accreditation.

We are currently working towards ISO 13485 accreditation which is the medical industry’s optimal medical device standard. We have a range of plastic injection moulding machines on site from 35 tonnes to 300 tonnes including two precision all electric machines used for tool

The market-leading, bespoke, high-speed roller doors help to prevent the severe drop of ambient temperature in buildings, especially evident in the winter months, eliminating any potential impact on production environments.

Steve Moultrie, Technical Sales Engineer at Union Industries, said: “This collaboration marks the continuation of a longstanding partnership between Union Industries and Warburtons, dating back 20 years, which is testament to our dedication to durability and quality craftsmanship.

“We are proud to have provided Warburtons with a reliable solution to their operational challenges. Our doors are engineered to perform in demanding environments, ensuring continuous productivity and efficiency.”

Ryan Seddon, Asset Care Lead at Warburtons, said: “The triple Bulldoor installation has significantly improved our warehouse operations, particularly during adverse weather conditions. Union Industries’ doors are incomparable to any other doors we have installed, and their commitment to quality and innovation has made them a valued partner in our supply chain.”

trial and T1 first-off sampling as well as Factory Acceptance Test (FAT) and initial batch runs. We will work with you from initial concept and design through to production and assembly.

All projects are designed, specified and guaranteed by our UK team with manufacturing optimised across our UK and Chinese facility according to your projects technical, budget and delivery requirements. All mould tools are supplied warrantied and production ready. Cybertools provide a fast-response service for urgent repairs, with engineers available to visit your site to endeavour to minimise machine and tool

downtime to protect your manufacturing schedules.

We always work through a thorough Design for Manufacture (DFM) process and mould flow analysis prior to producing a full General Assemble (GA) drawing for customer approval. This is done before we start work on manufacturing your injection mould tool. Once we start work on the tool a T1 date will be set and weekly updates will be supplied in the form of a Gannt timing plan and images of the engineering progression.

www.cybertoolsltd.co.uk

email: training@bpma.org.uk

30 PECM Issue 68

www.unionindustries.co.uk

EDITOR’S CHOICE For more information call 0121 601 6691, scan code for the training guide

Independent Pump Training from 2 day course 20th & 21st June 2024 Classroom & hands on training Held at BPMA Offices West Bromwich B70 6PY

From left, Steve Moultrie, Technical Sales Engineer at Union Industries and Eve Pyrah, engineering apprentice at Warburtons.

or

Pump Repair & Maintenance Course

POSSIBILITIES FOR EVERYONE

Discover your next manufacturing partner at Subcon - The Manufacturing Solutions Show

Subcon 2024, scheduled for June 5-6 at the NEC, Birmingham is the premier event for manufacturing buyers across all sectors. As a cornerstone event for the industry, Subcon provides an unrivaled opportunity to source your next manufacturing solutions from a variety of world-class exhibitors. With over 150 subcontractors and outsourced engineering services, Subcon is packed with possibilities for everyone.

This year’s event promises a refreshed and innovative format, with new developments introduced to adapt and enhance the experience for both visitors and exhibitors. Attendees can look forward to a dynamic programme featuring interactive CPD-accredited workshops, cuttingedge product demonstrations, and insightful keynote presentations. Additionally, you can engage in meaningful discussions through roundtable sessions that are designed to foster collaboration and ideasharing.

Whether you are aiming to benchmark your capabilities, seeking innovative solutions, or simply looking to stay ahead of industry trends, Subcon is your gateway to the future of manufacturing.

World-Class Manufacturing Solutions from Industry Leading Exhibitors

Meet with over 150 leading UK and international suppliers under one roof, showcasing the latest innovations and solutions available from sectors such as CNC machining, metal fabrication, electronics, component parts, and more, all dedicated to advancing the

capabilities of your supply chain.

Thousands of new products and innovations will be on display across the full range of advanced engineering technology, systems and services – from Additive Manufacturing and Metrology solutions to Frictionless bearings, cables and controls, and everything in between. This is a show geared to helping you increase capacity, optimise productivity, improve flexibility and remain competitive.

Revamped Workshop and Sessions Programme: A Hub of Innovation and Learning

New for 2024, Subcon has announced a significant enhancement to its conference and workshop programme, with the introduction of a variety of different session formats that take place within three specialised areas; designed to cater to a diverse range of interests and professional needs within the manufacturing industry: the Innovation Zone, Workshops and Learning Space, and the Manufacturing Insights Theatre.

Additionally, the programme is now officially CPD accredited, ensuring attendees can gain valuable professional development credits while engaging with top industry experts and cutting-edge technologies.

Manufacturing Insights Theatre: Explore insightful keynote presentations and engage in

lively panel discussions at the Manufacturing Insights Theatre. This forum features thought leaders discussing the latest trends and challenges in manufacturing. Each session includes interactive Q&A segments, making it a dynamic platform for learning and engagement.

Workshops & Learning Space:

Dive into hands-on learning with roundtable discussions and sectorfocused peer-to-peer meetings in the Workshops & Learning Space. Tailored to address specific industry challenges, these sessions offer practical insights and networking opportunities, facilitated by industry experts.

Innovation Zone:

This area is dedicated to hands-on demonstrations, showing you how new technologies and products operate in real-time. It’s the perfect place to see the newest innovations in action and discover how they can enhance your manufacturing processes.

That’s not all! More NEW features include:

Motorsport Simulators & Prize

Draw: Compete in professional motorsport simulators operated by FP Zero. Dive into the thrilling world of Formula 1 racing right on the exhibition floor. The fastest lap will not only boast bragging rights but will also win a PalmerSport driving day experience valued at over £600!